Craftsman 1243299 Owner’s Manual

Operator's Manual

CRAFTSMH

9-in. BENCH TOP

BAND SAW

1/4 HP MOTOR

Model 124.3299

CAUTION: Before using this

product, read this manual and

follow all its Safety Rules

and Operating Instructions.

Sears Brands Management Corporation,

Hoffman Estates, IL 60179 U.S.A

® Safety Instructions

® Assembly

® Operation

• Maintenance

• Troubleshooting

® Parts List

® Espanol (PG. 26)

Warranty .......................................................................................................................................................................................... 2

Safety Instructions ..................................................................................................................................................................................... 2-3

Specifications ...................................................................................................................................................... 3

Assembly ................................................................................................................................................................................................... 4-6

Getting to Know Your Band Saw.................................................................................................................................................................... 7

Adjustments ............................................................................................................................................................................................. 7-10

Operation ................................................................................................................................................................................................... 11

Maintenance .............................................................................................................................................................................................. 12

Electrical Schematic ................................................................................................................................................................................... 12

Troubleshooting ......................................................................................................................................................................................... 13

Repair Protection Agreements .................................................................................................................................................................... 13

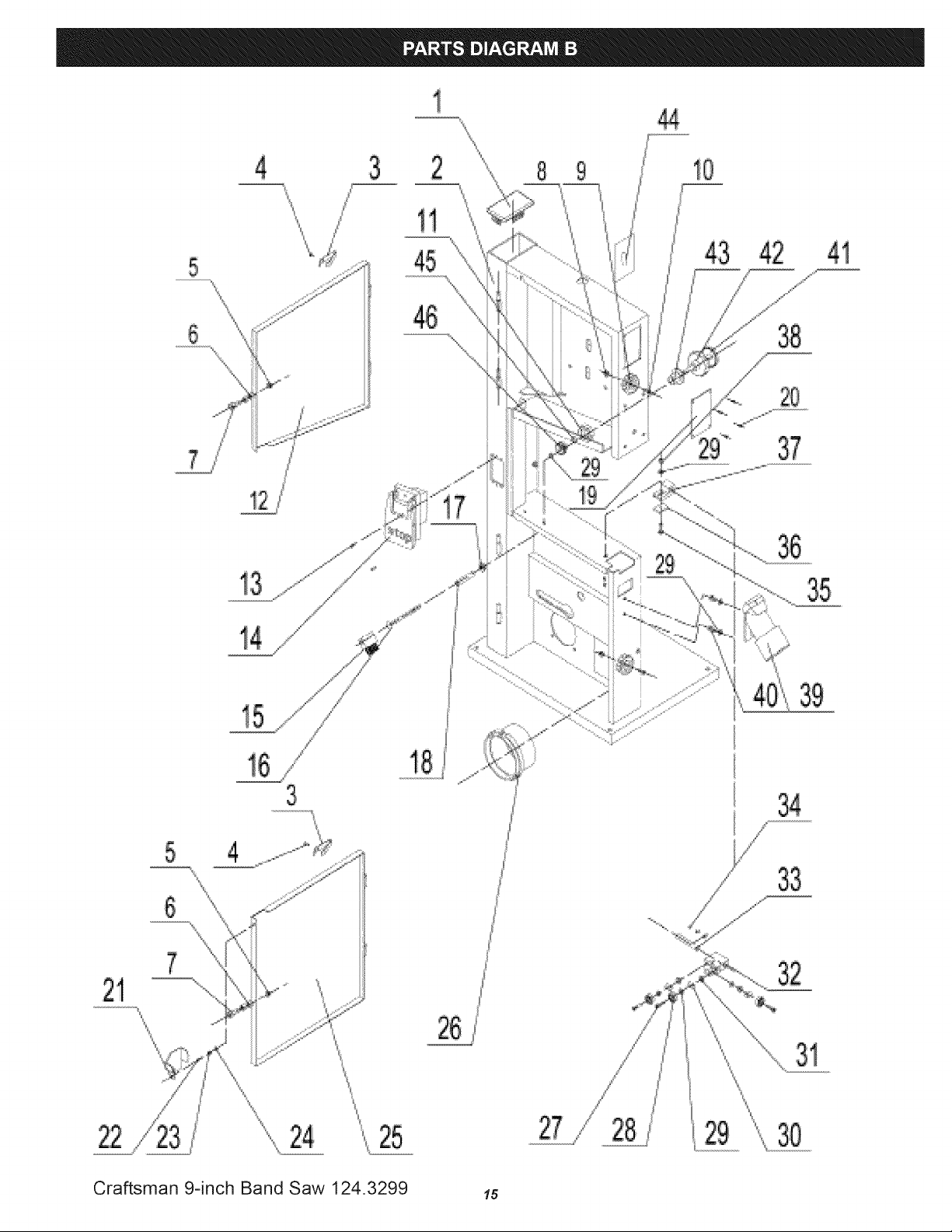

Parts Diagrams .............................................................................................................................................................. 14-24

Notes ..................................................................................................................................................................................................... 25

ONE-YEAR FULL WARRANTY ON CRAFTMAN PROFESSIONAL TOOL

FOR ONE YEAR from the date of purchase, this product is warranted against any defects in material or workmanship. A defective

product will receive free repair or replacement if repair is unavailable.

For warranty coverage details to obtain free repair or replacement, visit the web site: www. craftsman, corn

This warranty does not cover the blade, which is an expendable part that can wear out from normal use within the warranty period.

This warranty is void if this product is ever used while providing commercial services or if rented to another person.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears Brands Management Corporation, Hoffman Estates, IL 60179

GENERAL SAFETY WARNINGS

KNOW YOUR POWER TOOL. Read the owner's manual carefully. Learn the tool's applications, work capabilities, and its specific

potential hazards.

Always Ground All Tools.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle. If you use

an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a known ground. Never

remove the third prong of the plug.

Always Avoid Dangerous Environments.

Never use power tools in damp orwet locations. Keepyour work area well lighted and clear of clutter.

Always Remove the Adjusting Keys and Wrenches from Tools after Use.

Form the habit of checking to see that keys andadjusting wrenches are removedfrom the tool before turning iton.

Always Keep Your Work Area Clean. Cluttered areas and benches invite accidents.

Always Keep Visitors Away from Running Machines.

All visitors should be kept a safe distancefrom the work area.

Always make the Workshop Childproof.

Childproof with padlocks, master switches, or by removing starter keys.

Never operate a tool while under the influence of drugs, medication, or alcohol.

2

Always Wear Proper Apparel.

Never wear loose clothing or jewelry that might get caught in moving parts. Rubber-soled footwear is recommended

for the best footing.

Always Use Safety Glasses and Wear Hearing Protection.

Also use aface or dust mask if the cutting operation is dusty.

Never Overreach.

Keep your proper footing and balance at all times.

Never Stand on Tools.

Serious injurycould occur if the tool is tipped or ifthe cutting tool is accidentally contacted.

Always Disconnect Tools.

Disconnecttools before servicing and when changingaccessories such as blades, bits, and cutters.

Always Avoid Accidental Staring.

Make sure switch is in "OFF"position before plugging in cord.

Never Leave Tools Running Unattended.

Always Check for Damaged Parts.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to assure that it

will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other damaged parts

should immediately be properly repaired or replaced.

SPECIAL SAFETY RULES FOR BAND SAWS

1. Always stop the band saw before removing scrap pieces from table.

2. Always keep hands and fingers away from the blade.

3. Never attempt to saw stock that does not have a flat surface, unless a suitable support is used.

4. Always hold material firmly and feed it into the blade at a moderate speed.

5. Always turn off the machine if the material is to be backed out of an uncompleted cut.

6. Check for proper blade size and type for thickness and type of material being cut.

7. Make sure that the blade tension and blade tracking are properly adjusted.

8. Make "relief" cuts before cutting long curves.

9. Release blade tension when the saw will not be used for a long period of time.

10. Note and follow the safety warnings and instructions that appear on the lower door of this saw.

Blade Length ................................................ 62-1/8"

Blade Width ............................................ 1/4" to 3/8"

Throat Width ................................................... 8-3/4"

Cutting Depth ................................................. 3-1/2"

Blade Speeds ............................................. 1 Speed

Dust Ports ......................................................... 1-2"

SAVE THESE INSTRUCTIONS.

Refer to them often.

Table Size ...................................... 11-1/2" x 11-1/2"

Table Tilt ............................................. 0-45 Degrees

Motor ............................................................. 1/4 HP

Motor Voltage .................................................. 120V

Motor Amperage .............................................. 2.5 A

Net Weight ................................................... 44 LBS

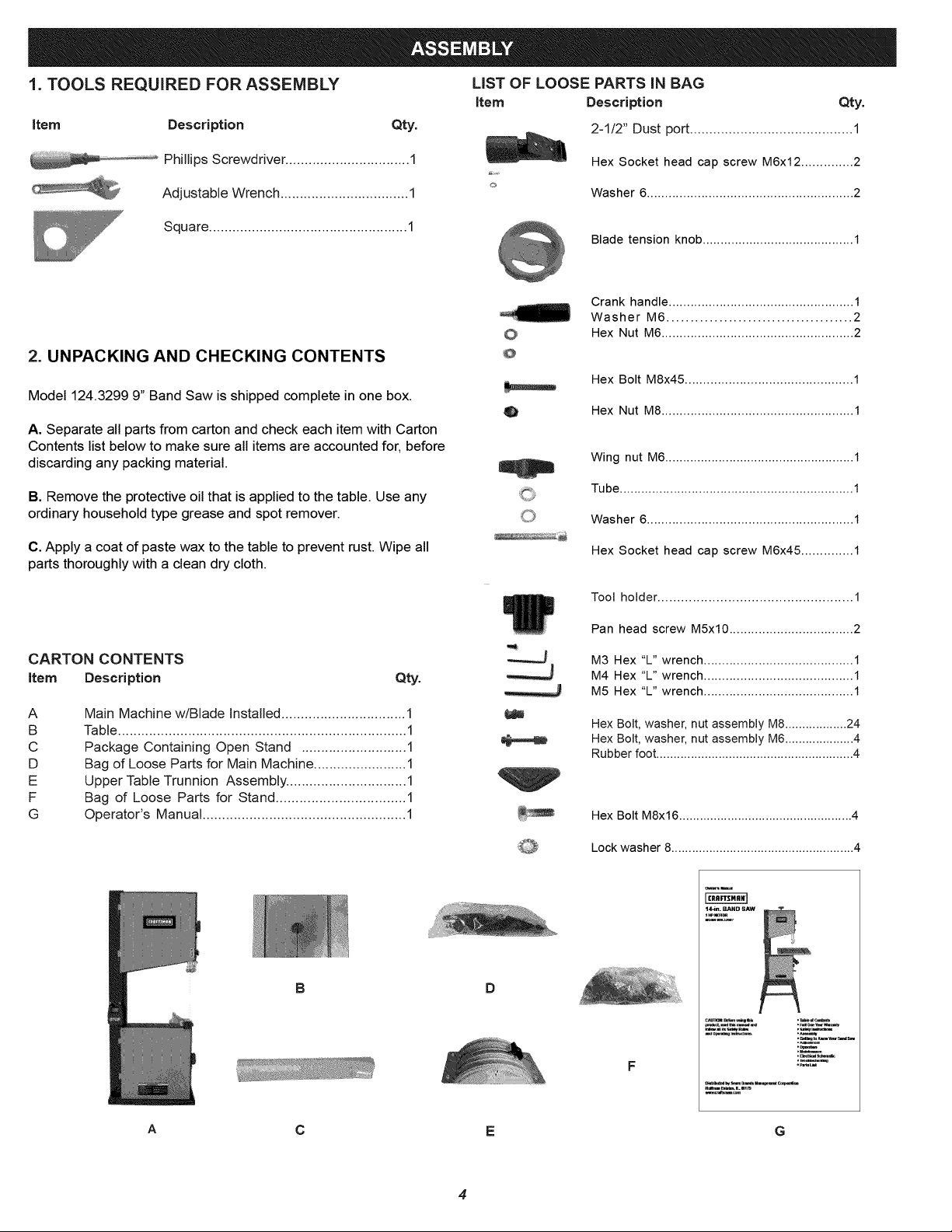

1. TOOLS REQUIRED FOR ASSEMBLY LIST OF LOOSE PARTS iN BAG

Item

Item Description Qty.

Description Qty.

2-1/2" Dust port.......................................... 1

_ Phillips Screwdriver ................................ 1

Adjustable Wrench ................................. 1

Square ................................................... 1

2. UNPACKING AND CHECKING CONTENTS

Model 124.3299 9" Band Saw is shipped complete in one box.

A. Separate all parts from carton and check each item with Carton

Contents list below to make sure all items are accounted for, before

discarding any packing material.

B. Remove the protective oil that is applied to the table. Use any

ordinary household type grease and spot remover.

C. Apply a coat of paste wax to the table to prevent rust. Wipe all

parts thoroughly with a clean dry cloth.

Hex Socket head cap screw M6x12 .............. 2

©

©

Washer 6 ......................................................... 2

Blade tension knob .......................................... 1

Crank handle ................................................... 1

Washer M6 ....................................... 2

Hex Nut M6 ..................................................... 2

@

Hex Bolt M8x45 .............................................. 1

Hex Nut M8 ..................................................... 1

Wing nut M6 ..................................................... 1

Tube ................................................................. 1

Washer 6 ......................................................... 1

Hex Socket head cap screw M6x45 .............. 1

Tool holder .................................................. 1

CARTON CONTENTS

item Description Qty.

A

B

C

D

E

F

G

Main Machine w/Blade Installed ................................ 1

Table .......................................................................... 1

Package Containing Open Stand ........................... 1

Bag of Loose Parts for Main Machine ........................ 1

Upper Table Trunnion Assembly ............................... 1

Bag of Loose Parts for Stand ................................. 1

Operator's Manual .................................................... 1

Pan head screw M5xl0 .................................. 2

M3 Hex "L" wrench ......................................... 1

M4 Hex "L" wrench ......................................... 1

M5 Hex "L" wrench ......................................... 1

Hex Bolt, washer, nut assembly M8 .................. 24

Hex Bolt, washer, nut assembly M6 .................... 4

Rubber foot ......................................................... 4

Hex Bolt M8x16 .................................................. 4

Lock washer 8..................................................... 4

14_n. BAND SAW

D

A

E G

3. iNiTiAL ASSEMBLY

The 124.3299 band saw is supplied partly assembled. Prior to use, the following items have to be assembled: Open Stand, 2" Dust Port,

Table, Blade Tension Knob, Tool Holder, and Crank Handle.

WARNING: To avoid injury, do not attempt to run or use this machine until all parts are assembled and working properly.

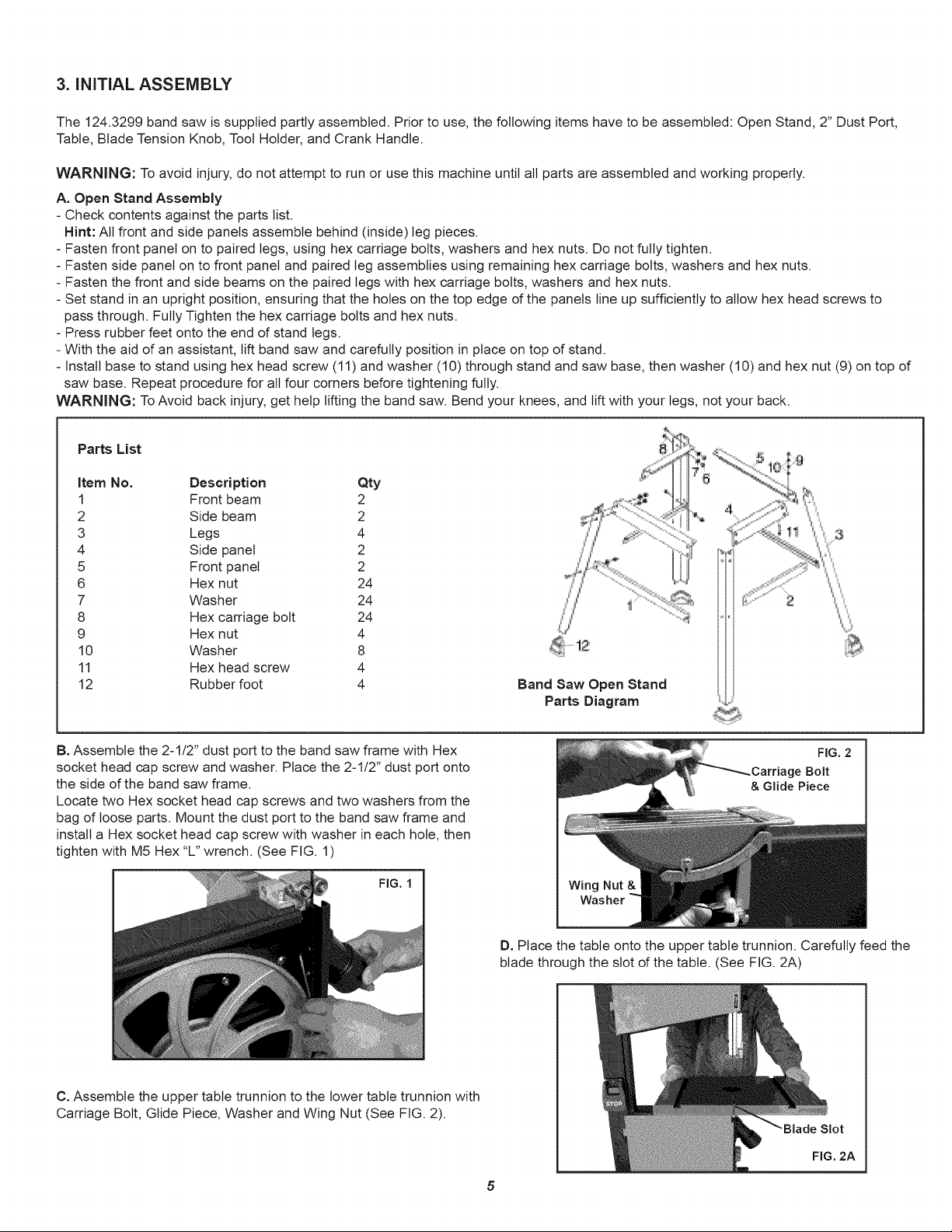

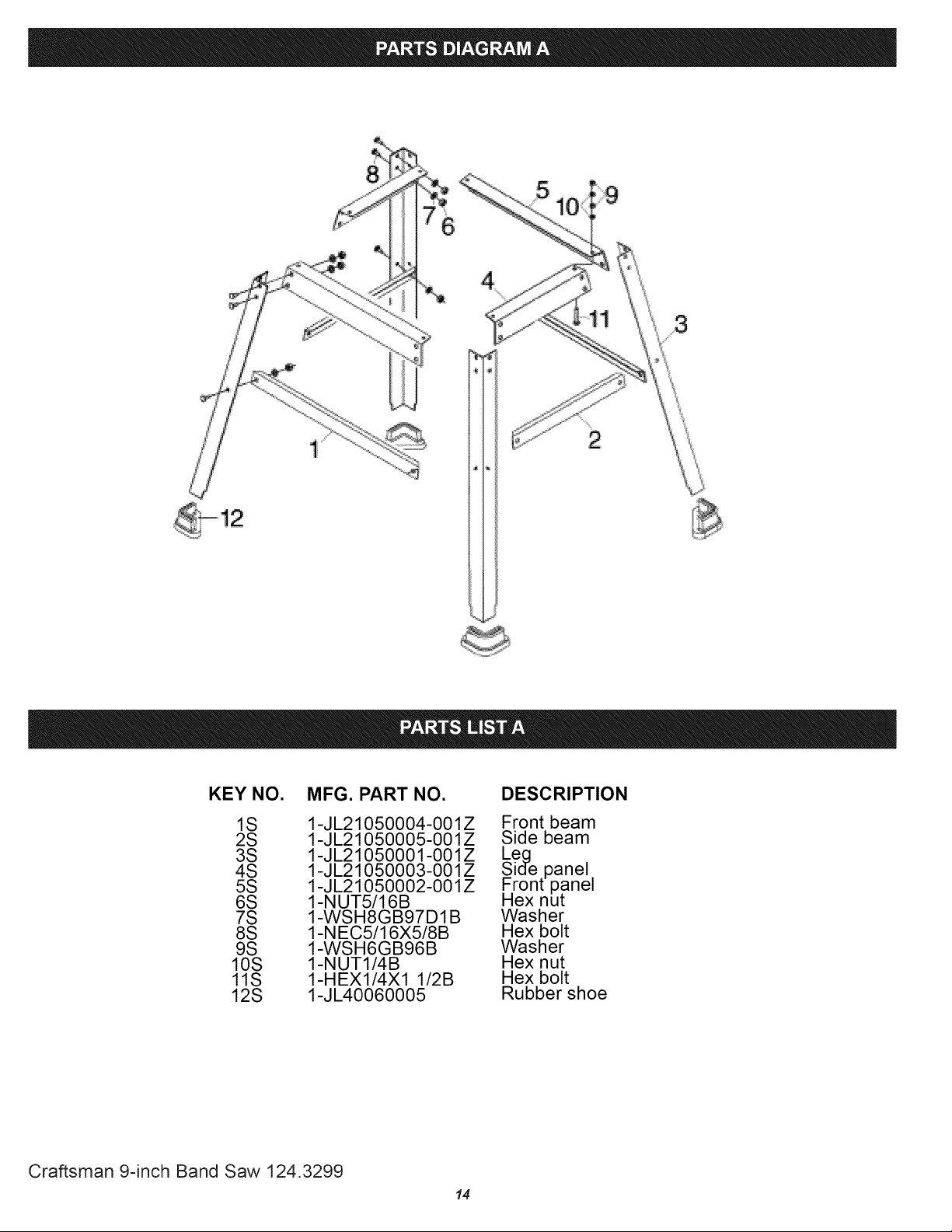

A. Open Stand Assembly

- Check contents against the parts list.

Hint: All front and side panels assemble behind (inside) leg pieces.

- Fasten front panel on to paired legs, using hex carriage bolts, washers and hex nuts. Do not fully tighten.

- Fasten side panel on to front panel and paired leg assemblies using remaining hex carriage bolts, washers and hex nuts.

- Fasten the front and side beams on the paired legs with hex carriage bolts, washers and hex nuts.

- Set stand in an upright position, ensuring that the holes on the top edge of the panels line up sufficiently to allow hex head screws to

pass through. Fully Tighten the hex carriage bolts and hex nuts.

- Press rubber feet onto the end of stand legs.

- With the aid of an assistant, lift band saw and carefully position in place on top of stand.

- Install base to stand using hex head screw (11) and washer (10) through stand and saw base, then washer (10) and hex nut (9) on top of

saw base. Repeat procedure for all four corners before tightening fully.

WARNING: ToAvoid back injury, get help lifting the band saw. Bend your knees, and lift with your legs, not your back.

Parts List

Item No. Description Qty

1 Front beam 2

2 Side beam 2

3 Legs 4

4 Side panel 2

5 Front panel 2

6 Hex nut 24

7 Washer 24

8 Hex carriage bolt 24

9 Hex nut 4

10 Washer 8

11 Hex head screw 4

12 Rubber foot 4

Band Saw Open Stand

Parts Diagram

3

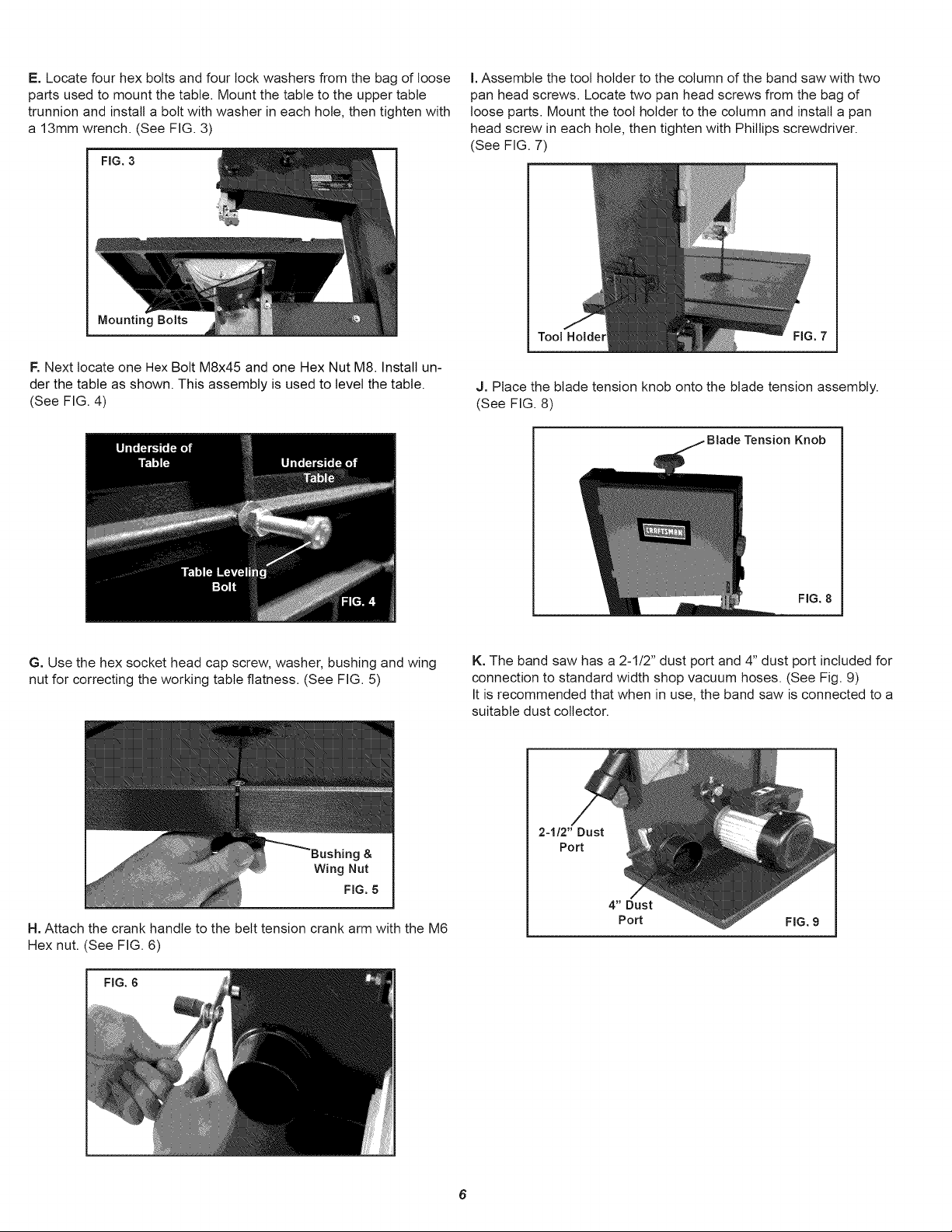

B. Assemble the 2-1/2" dust port to the band saw frame with Hex

socket head cap screw and washer. Place the 2-1/2" dust port onto

the side of the band saw frame.

Locate two Hex socket head cap screws and two washers from the

bag of loose parts. Mount the dust port to the band saw frame and

install a Hex socket head cap screw with washer in each hole, then

tighten with M5 Hex "L" wrench. (See FIG. 1)

FIG. 1

C. Assemble the upper table trunnion to the lower table trunnion with

Carriage Bolt, Glide Piece, Washer and Wing Nut (See FIG. 2).

FIG. 2

_ge Bolt

D. Place the table onto the upper table trunnion. Carefully feed the

blade through the slot of the table. (See FIG. 2A)

FIG, 2A

E. Locate four hex bolts and four lock washers from the bag of loose

parts used to mount the table. Mount the table to the upper table

trunnion and install a bolt with washer in each hole, then tighten with

a 13mm wrench. (See FIG. 3)

FIG, 3

I. Assemble the tool holder to the column of the band saw with two

pan head screws. Locate two pan head screws from the bag of

loose parts. Mount the tool holder to the column and install a pan

head screw in each hole, then tighten with Phillips screwdriver.

(See FIG. 7)

Mounting Bolts

F. Next locate one Hex Bolt M8x45 and one Hex Nut M8. Install un-

der the table as shown. This assembly is used to level the table.

(See FIG. 4)

G. Use the hex socket head cap screw, washer, bushing and wing

nut for correcting the working table flatness. (See FIG. 5)

Tool ,7

J. Place the blade tension knob onto the blade tension assembly.

(See FIG. 8)

Tension Knob

FIG. 8

K. The band saw has a 2-1/2" dust port and 4" dust port included for

connection to standard width shop vacuum hoses. (See Fig. 9)

It is recommended that when in use, the band saw is connected to a

suitable dust collector.

g&

Wing Nut

FIG. 5

H. Attach the crank handle to the belt tension crank arm with the M6

Hex nut. (See FIG. 6)

FIG. 6

2-1/2" Dust

Port

4" Dust

Port FIG. 9

6

Upper Bandwheel

Door Locking Knob

Blade Tension Knob"

Blade Tracking

Blade Tension

Indicator

Blade Guides

Switch

Lower Bandwheel

Table Insert

Table

2-1/2" Dust Port

Drive Belt

Tension

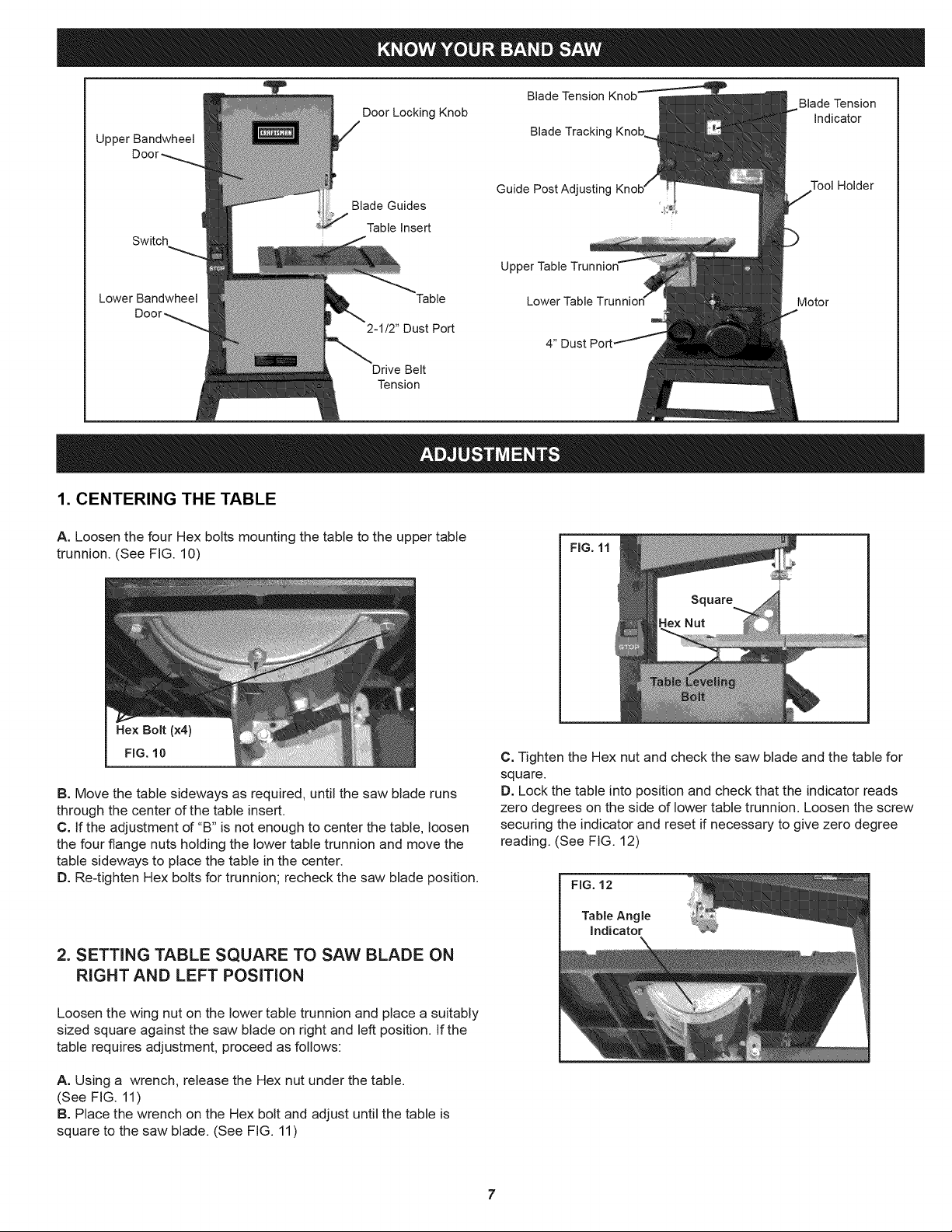

1. CENTERING THE TABLE

A. Loosen the four Hex bolts mounting the table to the upper table

trunnion. (See FIG. 10)

Guide Post Adjusting

Upper Table Trunniori

m

FI6.11

Tool Holder

Motor

Hex Nut

B. Move the table sideways as required, until the saw blade runs

through the center of the table insert.

C. If the adjustment d "B" is not enough to center the table, loosen

the four flange nuts holding the lower table trunnion and move the

table sideways to place the table in the center.

D. Re-tighten Hex bolts for trunnion; recheck the saw blade position.

2. SETTING TABLE SQUARE TO SAW BLADE ON

RIGHT AND LEFT POSITION

Loosen the wing nut on the lower table trunnion and place a suitably

sized square against the saw blade on right and left position. If the

table requires adjustment, proceed as follows:

A. Using a wrench, release the Hex nut under the table.

(See FIG. 11)

B. Place the wrench on the Hex bolt and adjust until the table is

square to the saw blade. (See FIG. 11)

C. Tighten the Hex nut and check the saw blade and the table for

square.

D. Lock the table into position and check that the indicator reads

zero degrees on the side of lower table trunnion. Loosen the screw

securing the indicator and reset if necessary to give zero degree

reading. (See FIG. 12)

FIG. 12

Table Angle

Indicator

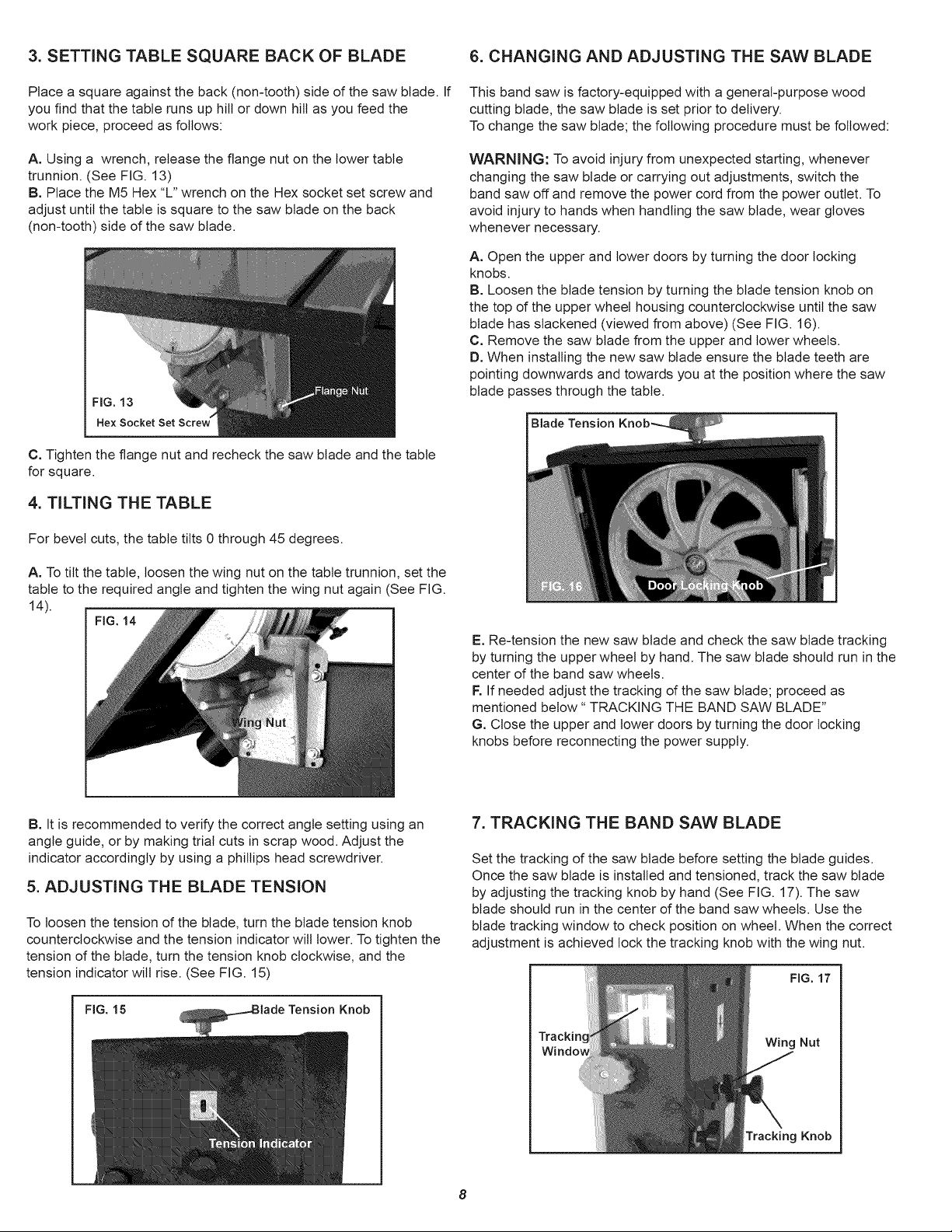

3. SETTING TABLE SQUARE BACK OF BLADE 6. CHANGING AND ADJUSTING THE SAW BLADE

Place a square against the back (non-tooth) side of the saw blade. If

you find that the table runs up hill or down hill as you feed the

work piece, proceed as follows:

A. Using a wrench, release the flange nut on the lower table

trunnion. (See FIG. 13)

B. Place the M5 Hex "L" wrench on the Hex socket set screw and

adjust until the table is square to the saw blade on the back

(non-tooth) side of the saw blade.

FIG. 13

Hex Socket Set Screw

C. Tighten the flange nut and recheck the saw blade and the table

for square.

4. TILTING THE TABLE

For bevel cuts, the table tilts 0 through 45 degrees.

This band saw is factory-equipped with a general-purpose wood

cutting blade, the saw blade is set prior to delivery.

To change the saw blade; the following procedure must be followed:

WARNING: To avoid injury from unexpected starting, whenever

changing the saw blade or carrying out adjustments, switch the

band saw off and remove the power cord from the power outlet. To

avoid injury to hands when handling the saw blade, wear gloves

whenever necessary.

A. Open the upper and lower doors by turning the door locking

knobs.

B. Loosen the blade tension by turning the blade tension knob on

the top of the upper wheel housing counterclockwise until the saw

blade has slackened (viewed from above) (See FIG. 16).

C. Remove the saw blade from the upper and lower wheels.

D. When installing the new saw blade ensure the blade teeth are

pointing downwards and towards you at the position where the saw

blade passes through the table.

IBlade Tension

A. To tilt the table, loosen the wing nut on the table trunnion, set the

table to the required angle and tighten the wing nut again (See FIG.

14).

FIG, 14

B. It is recommended to verify the correct angle setting using an

angle guide, or by making trial cuts in scrap wood. Adjust the

indicator accordingly by using a phillips head screwdriver.

5. ADJUSTING THE BLADE TENSION

To loosen the tension of the blade, turn the blade tension knob

counterclockwise and the tension indicator will lower. To tighten the

tension of the blade, turn the tension knob clockwise, and the

tension indicator wilt rise. (See FIG. 15)

FIG, 15 Knob

E. Re-tension the new saw blade and check the saw blade tracking

by turning the upper wheel by hand. The saw blade should run in the

center of the band saw wheels.

R If needed adjust the tracking d the saw blade; proceed as

mentioned below" TRACKING THE BAND SAW BLADE"

G. Close the upper and lower doors by turning the door locking

knobs before reconnecting the power supply.

7. TRACKING THE BAND SAW BLADE

Set the tracking of the saw blade before setting the blade guides.

Once the saw blade is installed and tensioned, track the saw blade

by adjusting the tracking knob by hand (See FIG. 17). The saw

blade should run in the center of the band saw wheels. Use the

blade tracking window to check position on wheel. When the correct

adjustment is achieved lock the tracking knob with the wing nut.

FIG. 17

Wing Nut

Tracking Knob

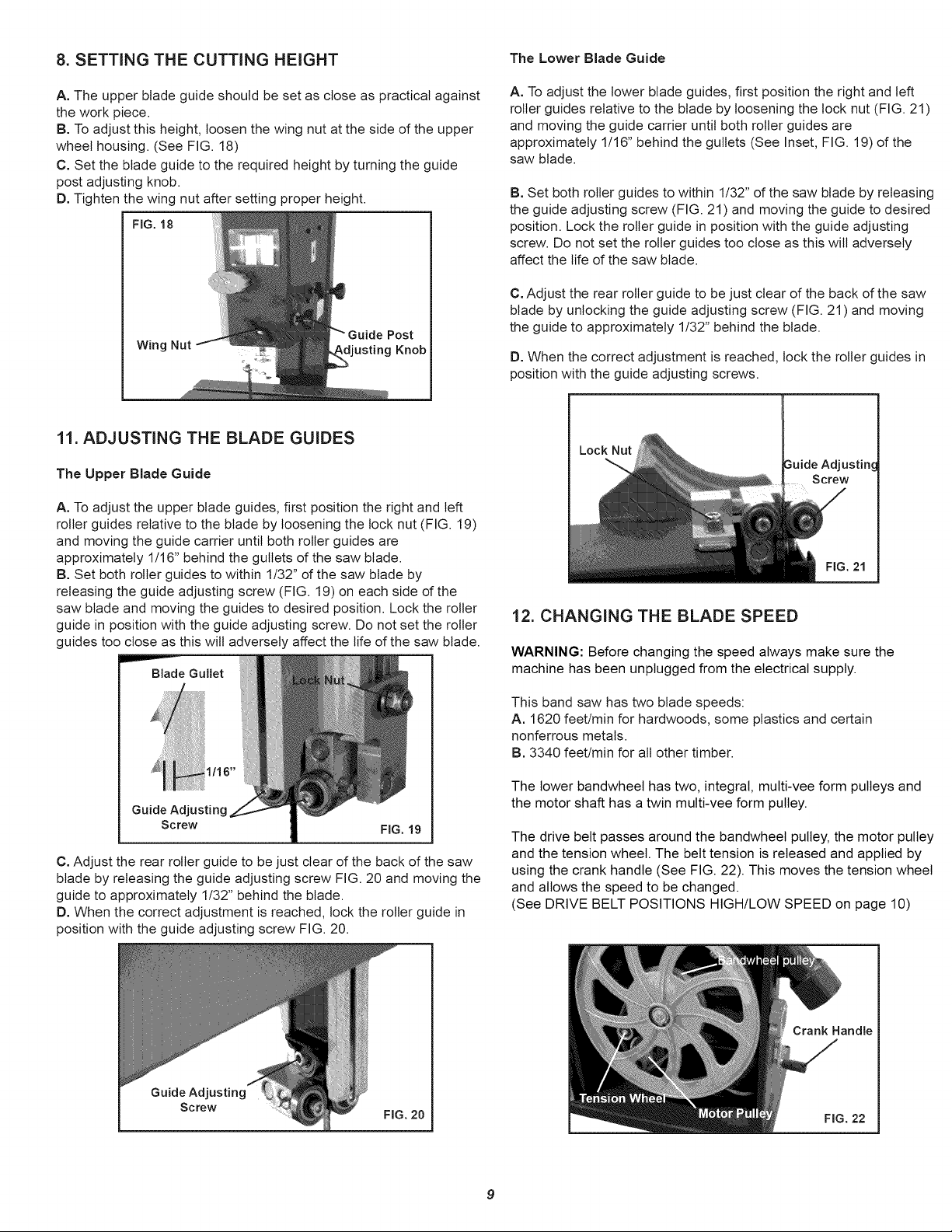

8. SETTING THE CUTTING HEIGHT The Lower Blade Guide

A. The upper blade guide should be set as close as practical against

the work piece.

B. To adjust this height, loosen the wing nut at the side of the upper

wheel housing. (See FIG. 18)

C. Set the blade guide to the required height by turning the guide

post adjusting knob.

D. Tighten the wing nut after setting proper height.

FIG, 18

Post

Wing Nut Knob

11. ADJUSTING THE BLADE GUIDES

The Upper Blade Guide

A. To adjust the upper blade guides, first position the right and left

roller guides relative to the blade by loosening the lock nut (FIG. 19)

and moving the guide carrier until both roller guides are

approximately 1/16" behind the gullets of the saw blade.

B. Set both roller guides to within 1/32" of the saw blade by

releasing the guide adjusting screw (FIG. 19) on each side of the

saw blade and moving the guides to desired position. Lock the roller

guide in position with the guide adjusting screw. Do not set the roller

guides too close as this will adversely affect the life of the saw blade.

Blade Gullet

A. To adjust the lower blade guides, first position the right and left

roller guides relative to the blade by loosening the lock nut (FIG. 21 )

and moving the guide carrier until both roller guides are

approximately 1/16" behind the gullets (See Inset, FIG. 19) of the

saw blade.

B. Set both roller guides to within 1/32" of the saw blade by releasing

the guide adjusting screw (FIG. 21 ) and moving the guide to desired

position. Lock the roller guide in position with the guide adjusting

screw. Do not set the roller guides too close as this will adversely

affect the life of the saw blade.

C. Adjust the rear roller guide to be just clear of the back of the saw

blade by unlocking the guide adjusting screw (FIG. 21 ) and moving

the guide to approximately 1/32" behind the blade.

D. When the correct adjustment is reached, lock the roller guides in

position with the guide adjusting screws.

Lock Nut

Adjustinc

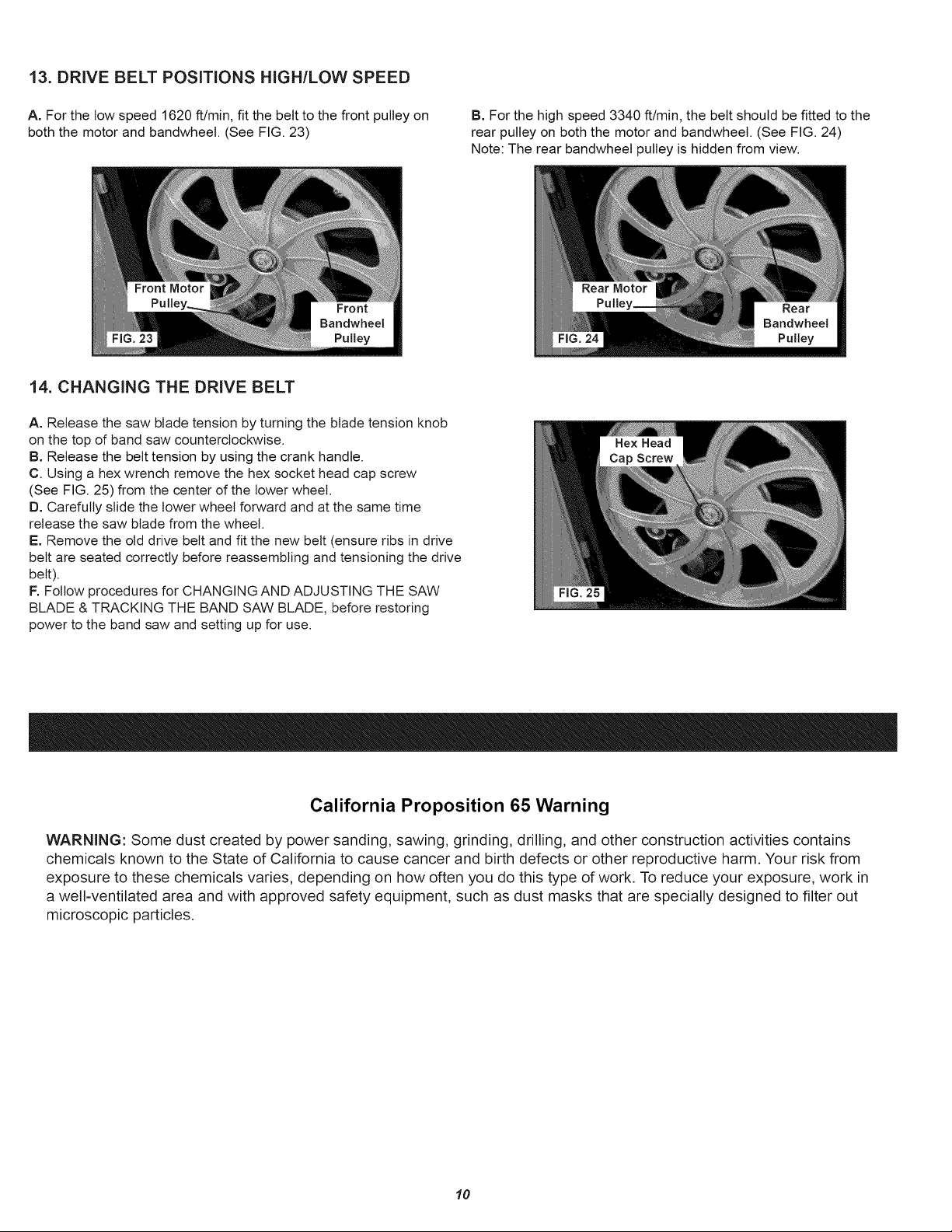

12. CHANGING THE BLADE SPEED

WARNING: Before changing the speed always make sure the

machine has been unplugged from the electrical supply.

Guide Adjusting

Screw

FIG, 19

C. Adjust the rear roller guide to be just clear of the back of the saw

blade by releasing the guide adjusting screw FIG. 20 and moving the

guide to approximately 1/32" behind the blade.

D. When the correct adjustment is reached, lock the roller guide in

position with the guide adjusting screw FIG. 20.

Guide Ad

Screw

FIG. 20

This band saw has two blade speeds:

A. 1620 feet/min for hardwoods, some plastics and certain

nonferrous metals.

B. 3340 feet/min for all other timber.

The lower bandwheel has two, integral, multi-vee form pulleys and

the motor shaft has a twin multi-vee form pulley.

The drive belt passes around the bandwheel pulley, the motor pulley

and the tension wheel. The belt tension is released and applied by

using the crank handle (See FIG. 22). This moves the tension wheel

and allows the speed to be changed.

(See DRIVE BELT POSITIONS HIGH/LOW SPEED on page 10)

13. DRIVE BELT POSiTiONS HIGH/LOW SPEED

A. For the tow speed 1620 ft/min, fit the belt to the front pulley on

both the motor and bandwheel. (See FIG. 23)

14. CHANGING THE DRIVE BELT

A. Release the saw blade tension by turning the blade tension knob

on the top of band saw counterclockwise.

B. Release the belt tension by using the crank handle.

C. Using a hex wrench remove the hex socket head cap screw

(See FIG. 25) from the center of the lower wheel.

D. Carefully slide the lower wheel forward and at the same time

release the saw blade from the wheel.

E. Remove the old drive belt and fit the new belt (ensure ribs in drive

belt are seated correctly before reassembling and tensioning the drive

belt).

F. Follow procedures for CHANGING AND ADJUSTING THE SAW

BLADE & TRACKING THE BAND SAW BLADE, before restoring

power to the band saw and setting up for use.

B. For the high speed 3340 ft/min, the belt should be fitted to the

rear pulley on both the motor and bandwheel. (See FIG. 24)

Note: The rear bandwheel pulley is hidden from view.

Cap Screw

California Proposition 65 Warning

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. Your risk from

exposure to these chemicals varies, depending on how often you do this type of work. To reduce your exposure, work in

a well-ventilated area and with approved safety equipment, such as dust masks that are specially designed to filter out

microscopic particles.

10

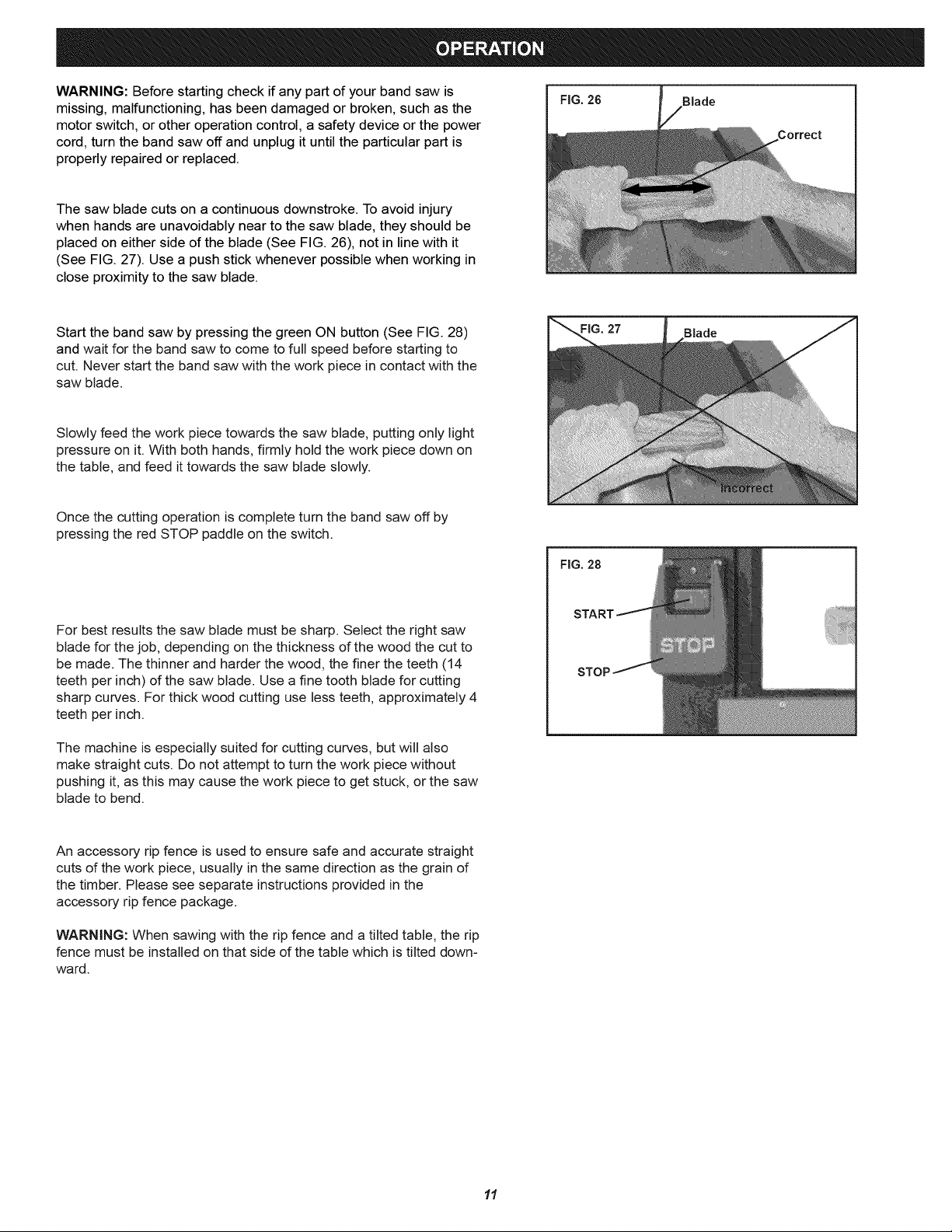

WARNING: Before starting check if any part of your band saw is

missing, malfunctioning, has been damaged or broken, such as the

motor switch, or other operation control, a safety device or the power

cord, turn the band saw off and unplug it until the particular part is

properly repaired or replaced.

The saw blade cuts on a continuous downstroke. To avoid injury

when hands are unavoidably near to the saw blade, they should be

placed on either side of the blade (See FIG. 26), not in line with it

(See FIG. 27). Use a push stick whenever possible when working in

close proximity to the saw blade.

FiG. 26 Blade

Start the band saw by pressing the green ON button (See FIG. 28)

and wait for the band saw to come to full speed before starting to

cut. Never start the band saw with the work piece in contact with the

saw blade.

Slowly feed the work piece towards the saw blade, putting only light

pressure on it. With both hands, firmly hold the work piece down on

the table, and feed it towards the saw blade slowly.

Once the cutting operation is complete turn the band saw off by

pressing the red STOP paddle on the switch.

For best results the saw blade must be sharp. Select the right saw

blade for the job, depending on the thickness of the wood the cut to

be made. The thinner and harder the wood, the finer the teeth (14

teeth per inch) of the saw blade. Use a fine tooth blade for cutting

sharp curves. For thick wood cutting use less teeth, approximately 4

teeth per inch.

The machine is especially suited for cutting curves, but will also

make straight cuts. Do not attempt to turn the work piece without

pushing it, as this may cause the work piece to get stuck, or the saw

blade to bend.

Blade

An accessory rip fence is used to ensure safe and accurate straight

cuts of the work piece, usually in the same direction as the grain of

the timber. Please see separate instructions provided in the

accessory rip fence package.

WARNING: When sawing with the rip fence and a tilted table, the rip

fence must be installed on that side of the table which is tilted down-

ward.

11

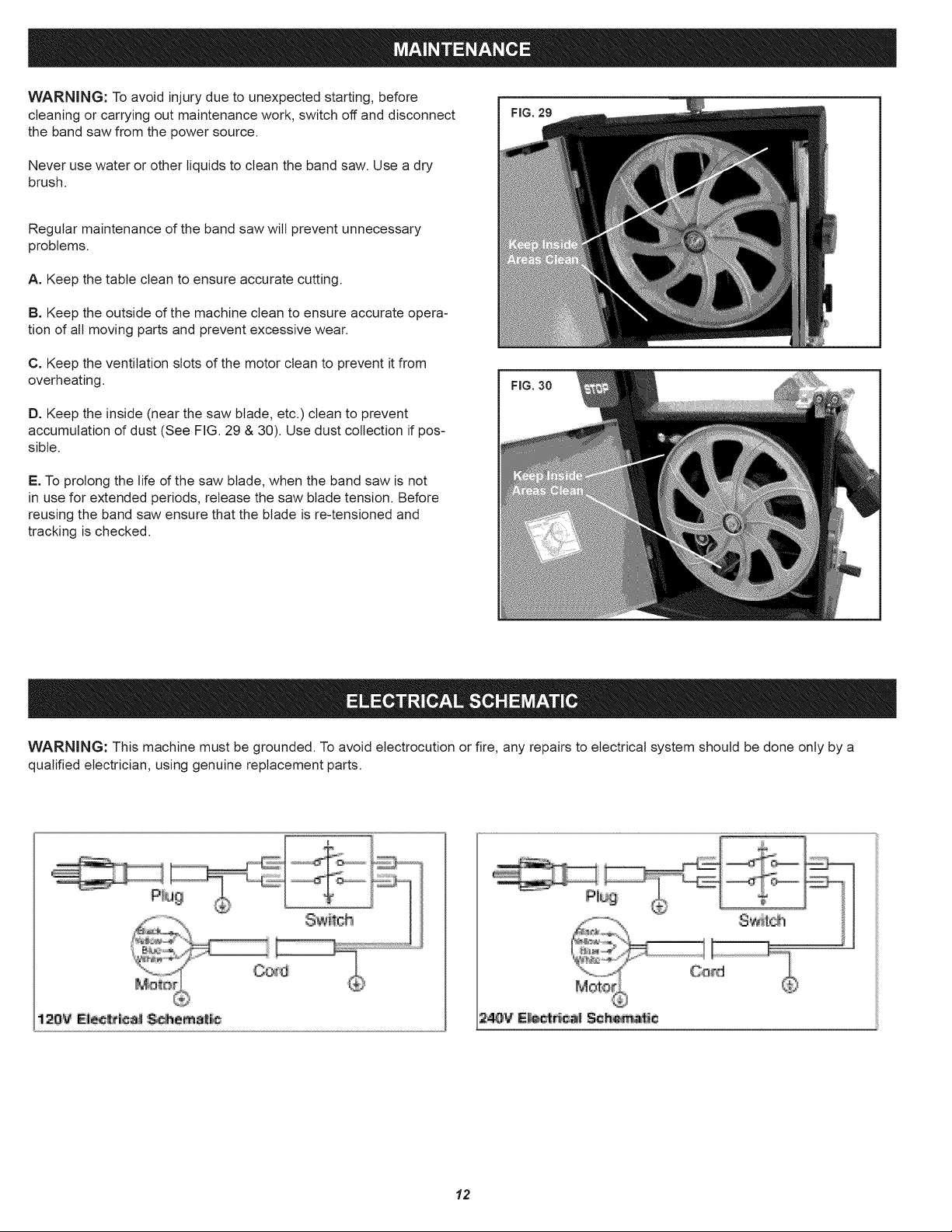

WARNING: To avoid injury due to unexpected starting, before

cleaning or carrying out maintenance work, switch off and disconnect

the band saw from the power source.

Never use water or other liquids to clean the band saw. Use a dry

brush,

Regular maintenance of the band saw wilt prevent unnecessary

problems,

A. Keep the table clean to ensure accurate cutting,

B. Keep the outside of the machine clean to ensure accurate opera-

tion of all moving parts and prevent excessive wear,

C. Keep the ventilation slots of the motor clean to prevent it from

overheating,

D. Keep the inside (near the saw blade, etc.) clean to prevent

accumulation of dust (See FIG. 29 & 30). Use dust collection if pos-

sible,

E. To prolong the life of the saw blade, when the band saw is not

in use for extended periods, release the saw blade tension. Before

reusing the band saw ensure that the blade is re-tensioned and

tracking is checked.

FIG. 29

FIG. 30

WARNING: This machine must be grounded. To avoid electrocution or fire, any repairs to electrical system should be done only by a

qualified electrician, using genuine replacement parts.

120V Ele_i¢_ _emal_

_V E_r_! S_ c

12

ProbJem Diagnosis Remedy

The machine does not work when switched 1. No power supply. 1. Check the cable for breakage.

on. 2. Defective switch. 2. Replace the lock switch.

3 Defective motor. 3. Defective motor.

The saw blade does not move with the

motor running.

The saw blade does not cut in a straight

line.

The saw blade does not cut, or cuts very

slowly.

Sawdust builds up inside the machine.

Sawdust inside the motor housing.

1. The blade tension knob has not been

tightened.

2. The blade has come off one d the

wheels.

3. The saw blade has broken.

4. The drive belt has snapped.

1. Rip fence for cutting not used.

2. Feed rate too fast.

3. The blade teeth are dull or damaged.

4. Blade guides not suitably adjusted.

1. The teeth are dull, caused by cutting

hard material or long use.

2. The saw blade was fitted the wrong way

on the band saw.

This is normal

This is normal

1. Switch off the motor, tighten the blade

tension knob.

2. Open the doors and check.

3. Replace the blade.

4. Replace the belt.

1. Use a rip fence.

2. Put light pressure on the work piece.

Make sure the saw blade does not bend.

3. Try a new saw blade.

4. Adjust the blade guides (see ADJUST-

MENT instructions).

1. Replace the saw blade, use a 6 T.P.I.

(Teeth Per Inch) saw blade for wood and

soft material. Use a 14 T.P.I. saw blade

for harder materials. A 14 T.RI. saw blade

always cuts slower due to the finer teeth

and the slower cutting performance.

2. Fit the saw blade correctly.

Clean the machine regularly. Open the

doors and remove the sawdust with a

vacuum cleaner.

Clean the ventilating slots of the motor with

a vacuum cleaner. From time to time re-

move the sawdust to prevent it from being

drawn into the housing.

The machine does not cut at 45 or 90 de-

grees.

The saw blade can not be properly posi-

tioned on the wheels.

_ _rrnzlkzhg izamerf jmmcheee_Your _

Gmts_u_ ° pudu[:L _ [lle_unnd and _ Tnrynam d

_llnemJ_=_ q_mrJ_rt. I]k.dt likp nil _, it tony umquim u_Mm"

from line kz limp_Thzzlrswhzm _ =iFlz_r _

,#gmeme_ ca. _ ]mu nmnL__1 agil_

_'s ih,zl Ilhe llelpair Pmb_dimz _ incllBdes:

Ezped s,_,,ice by our I(].DOD_ mW_ sWe_alis_

!_1 UnFlll_d _ amdzrm,=1_ rot pml_ im=l Mbmrnn ,,:,q

1. The table is not at right angles to the

blade.

2. The saw blade is dull or too much pres-

sure was put on the work piece.

1. The wheels are not in alignment or de-

fective bearing.

2. The blade tracking knob hasn't been

properly adjusted.

3. Inferior saw blade.

,==,_mmdmmzim

I_ l_mldrEll_Lam_mmlt upb$1_Dl]ifyuLr_m_l l_mluEt

€_r_tluefiJ_d

65 iD_.Gount ulf25n&4[mmm_ulnr puk_ nf _&_ _=1 neJkdml

m Fast henpu_,p_n_ - _ mn _g_u_ _m=_nn-

_ SUl=tnurlhcnm n _ _. l"hink _,-,_

=m_a"tnllnng mimers msmunn"

1. Adjust the table.

2. Replace the saw blade or put less

pressure on the work piece.

1. Replace bearing.

2. Adjust the blade tracking knob (See

ADJUSTMENT instructions).

3. Replace the saw blade.

Once _uu pmdvme the Repeir Pmkeckzn Agmened. e

_imple phmle cd is,d IhaL itkd_ rnrymn "In_le

You cat cell a_lime dey or nigHL,or sdmlule a meek:e

=m:akdm_ online.

]_,=,,==,,=,,ak,r=.,',j,r,m_undu,ir,a the pm_,,=,,=,d_ p_'iud.

tm rail pmq_e n ful mlhurul. Or. a pmrulm9 udurul mqdim_ uflm-

_ inC_Ia vzi_, ® _ ihs_,_IF_ f_l _el_ils

_11 Seam Canada at 1-_1]10-3_1-4_1_.

._n_uS lumtallali_ Smvi_

R_,-_ pu_.lim_ _ aftmme_=_ia'_. n_nne

du=r upusm_. _ub_r hmmdms,and _Jmr maim- hom_ iimms, in _e

U.S.A_ m-Carm_ _dl 14413_-4-IW-140_L__

13

6

KEY NO. MFG. PART NO. DESCRIPTION

1S 1-JL21050004-001Z Front beam

2S 1-JL21050005-001Z Side beam

3S 1-JL21050001-001Z Le;.q

4S 1-JL21050003-001Z Side panel

5S 1-JL21050002-001Z Front panel

6S 1-NUT5/16B Hex nut

7S 1-WSH8GB97 D1B Washer

8S 1-NEC5/16X5/8B Hex bolt

9S 1-WSH6GB96B Washer

10S 1-NUT1/4B Hex nut

11S 1-HEX1/4X1 1/2B Hex bolt

12S 1-JL40060005 Rubber shoe

Craftsman 9=inch Band Saw 124.3299

14

4:3 42 41

\

35

3

6

21

22 "', 24:........25

Craftsman 9-inch Band Saw 124.3299

15

27 '¸

29

33

30

Loading...

Loading...