Page 1

Model No. 0220

Sears Item No. 123.24201

User’s Manual and Maintenance Guide

Questions? ..

Please call 1-800-422-3865

DO NOT RETURN TO THE STORE

Call B:00 am to 6:00 p.m Monday ihraughrFriday (Central Standard Time)

J

,i.ji I .

uafe.7 *

.

........ ‘-V-' -' ■- j

. t

• J . ,

...... ..................

11

. I I

'.•-y

\V,y-

Store this manual in the giove compartment of your tow vehicle

A Warning: For safe operation of this trailer, be sure to read all

/JAinstructions and warnings Failure to follow instiiictions and

warnings could result in property damage, serious injury and death

iiistrHCEmi)Ko I02S2U

5/1*1/2007

Page 2

Register your product at www.lifetime.conni.

wwwJifetinie.com

Page 3

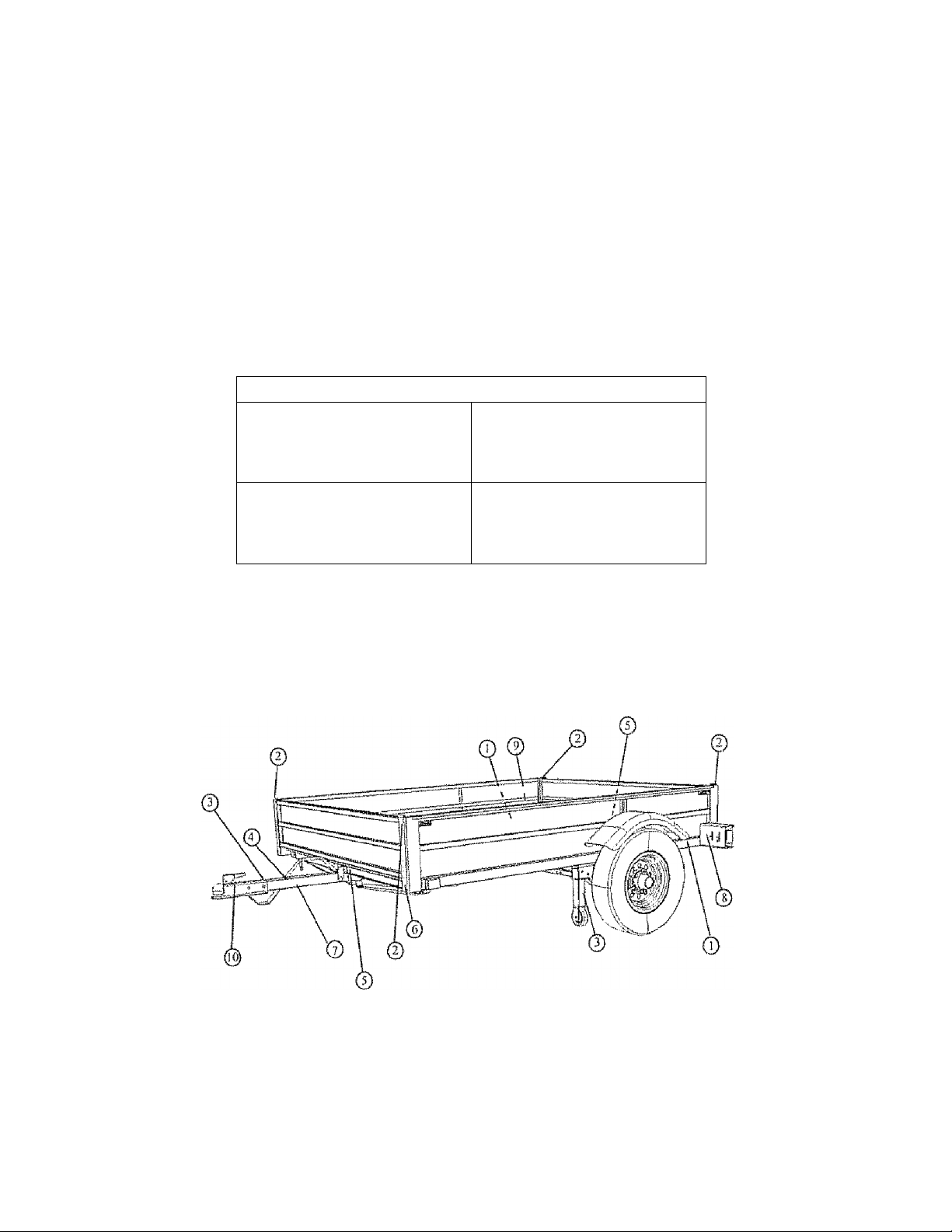

Craftsman Metal Fold-Up Utility Trailer

Model No, 0220

Sears Item No, 123.24201

WARNING

This User’s Manual contains safety information and itisinictions for your trailer. You

must read this manual before loading or towing your trailer. You must follow all

safety precautions and instructions

For parts and service, call our customer service line at: 1-800-422-3865

NHTSA Notification Statement:

If you believe that your vehicle has a defect that couid cause a crash or could cause

injury or death, you should immediately inform the National Highway Tialfic Safety

AdmlnistTation (NHTSA) in addition to notifying Lifetime Products.

If NHTSA receives similar complaints, it may open an investigation, and if it finds

that a safety defect exists in a group of vehicles, it may order a recall and remedy

campaign, However, NHTSA cannot become involved irt individual problems

between you, Sears, or Lifetime Products.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1

888-327-4236 (TTY: 1 -800-424-l>I S3), go to hllp://www,,safecargov; or write to;

Administralor, NHTSA, 400 Seventh Street, SW-, Washington, DC 20590. You can

also obtain other information about motor vehicle safety from

Call 1-800-422-3865 to reach our Customer Service line.

http://www.safecargov.

Page 4

Table of Contents

SECTION 1: SAFETY INFORMATION 7

SECTION 2; TRAILER PARTS & HARDWARE II

^SECTIONS: FIRST-TIME SET-UP REQUIREMENTS 12

SECTION 4: TRAILER SETUP 17

SECTIONS: COUPLING TO THE TOW VEHICLE 19

5.1 Using an Adequate Tow Vehicle and Hitch 19

5.2 Coupling and Uncoupling the Trailer 19

5,2 / Trailer widt Ball-Hitch Coupler 19

5 2 11 Before coupling the trailer to the toM' vehicle 20

5 2 12 Prepare the coupler and hitch 20

5 2 1.3 CoupUng the trailer to the k»v vehicle 20

52 I 4 Rigging the safety chaim 2i

5 2.1.5 Connecting the electrical cables 22

3.2 1.6 Uncoupling the 'frailer 23

SECTION 6: TIRE & SAFETY INFORMATION 24

6.1 Determining Correct Load Limit “Trailer 24¡

6.1.1 Trailers ¡0,000 Fmimh GVÍVR or Less 24\

6.2 Determining Correct Load Limit-Tow Vehicle 24

6.3 Glossary of Tire Terra tiiology 24

6.4 Tire Safety - Everything Rides on It 27

6.4.1 Safety firsi-Basic tire mainteiiance 28

6.4.2 Finding your vehicle's recommended tire pressure and load limits 28

6.4.3 Understanding tire pressure and load iimits 28

6.4.4 Checking tire pressure 29

6.4.5 Steps for maintaining proper fire pressure 29

6.4.6 Tire size 29

6.4.7 Tire tread 30

6.4.8 Tire balance and wheel alignment 30

6.4.9 Tire repair 30

6.4.10 Tire Fundamentáis 30

6 4 JO / Information on Passenger Vehicle Tires 30

6 4 ¡02 VTQGS Information 3.2

6 4 10.3. Additional information on Light Truck Tires 32

6.4.11 Fire Safety Tips 33

6 4 11 1 Preventing Til e Damage 33

6 4 ¡12 Tire Safety Checklist ' 33

6.5 Changing a Flat Tire 33

6.6 Cheeking the Tire Pressure 35

SECTION?: LOADING THE TRAILER 36

7.1. CHECKING THE TONGUE WEIGHT 38

7JJ Checking Tongue Weight — Using a lever and bathroom scale 38

7.2 Securing the Cargo 38

7.2.1 Loading Cargo 38

7.2.!. I Preparing the Trailer for Loading

__

J9

Page 5

7.2 i, 2 Loading ¡he Trailer

SECTION S: CHECK TRAILER BEFORE & DURING TOWING

SECTIONS; BREAKING IN A NEW TRAILER

SECTION 10: MAINTENANCE

10.1 Inspection, Service & Maintenance Summary Charts

10.2 Inspection and Service Instructions

10.2.1 Axle Bolls, Frame, Suspemion, «£ Slructurc

10.2.2 Trailer StriicUire

10.2.2 I Fastener.'; and Frame hdembei;;

10.2.2.1 IVeld'i

10.2.3 Trailer Conmetion to Tow Vehicle

¡0 2.3 i Coupler and Ball

10.2.4 Landing Leg or Jack

10.2.5 Lights and Signals

10.2.6 Tires

10.2.7 Wheel Rims

10.2.8 Wheels, Bearings and Lug Nuts

10 2 8 i Unsealed Bearings (Hubs)

10.2.9 Lug Nuts (Bolts)

10.2.10 Suspemion

SECTION 11: EXPLODED TRAILER VIEWS

SECTION 12: WARRANTY INFORMATION

39

41

43

44

44

45

4.5

46

46\

46

47

■47

47

47

48

48

48

48

49

49

50

56

Page 6

Page 7

SECTIONIT^AFETY

INFORMATION

SAFETY ALERT SYMBOLS AND SIGNAL WORDS

The safety information in this

A

The level of risk is indicated by the following signal words:

SIGNAL WORDS

Warning

Caution

If a label becomes unreadable, you can re-order them fi-oni Customer Service:

1-800-422-3865

manual is denoted by the safety

alert symbol.

Hazards or unsafe practices

which COULD result in severe

personal injury or death if the

warning is ignored.

Hazards or unsafe practices

which could result in minor or

moderate injury if the warning is

ignored,

Warning Labels & Locations

Page 8

Lug Nuts and Tire Pressure

©

AWARNIMG

Tiro, wheel or iugnut failure can cause loss of

control Before towing^ you must CHECK;

1 Tire pressure and tread

2 Tires and wheels for damage

3 Lug nuts far tightness

PoE' new and remoynted wheels,

retighten lug nats at the first

IQ, 25 and SO miles of driving

Ф 2002 NAT>1

Re-ordcr #1025343

The proper tightness (torque) for !vig nuts is 95-120 ft ./lb. Do not exceed 120 li/lb.

Use a torque wrench to tighten the lug nuts, if you do not have a torque wrench, use

a !ug wrench (from youi tow vehicle) and tighten the nuts as much as you can. Then

have a service garage or trailer deafer tighten the lug nuts to the proper torque. See

the section on Tire and Safety Information for more details concerning tire safety

Lug nuts are also prone to loosen after fust being assembled When driving a new

trailer (or after wheels have been remounted), check to make sure they are tight after

the first 10, 25 and 50 miles of driving and before each toiv thereafter

Failure to perform this check can result in a wheel parting flrom the trailer and a crash,

leading to death or serious injury

yy

Tires and Wheels OK?

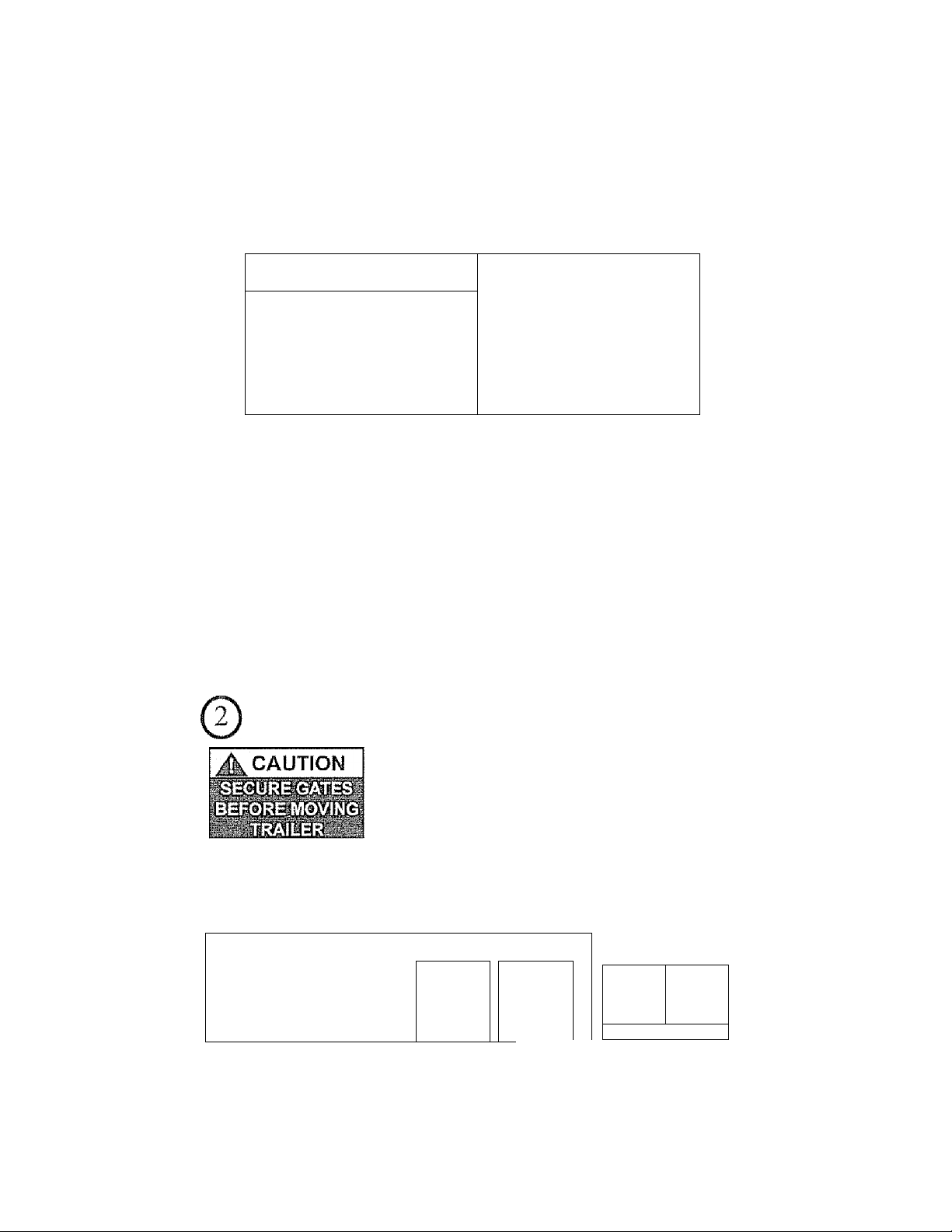

Securely Latching the Trailer Gate

Ensure the trailer gales are secure during towing. Failure

to insert gates securely could result in the load separating

from the trailer causing serious property damage, person

al injury and death,.

Re-order #1012296

Assist Wheel Caution

Always keep the Assist Wheel up when loading, unloading or towing the Trailer.

©

|A CAUTION

always load and tow the Trailer

while tlio Assist Wheel is up Failure

io heed this warning could resuii in

pcrfDMcnt damage to the Assisi Wheel

and void warranty

1

........................................................... ........... r .

vK( :

...

r-iSSSírí*“.’,' i

Part #102*1838

A

AcautionA

ÍQ

n

%

É\'

■c

ns

CL

Pa r t

#1025229

L'

Part#1025229

Page 9

Coupler, Load Weight and Distribution and Electrical

Connections

A WARNING

..

.

Re-order # 1024843

Loads can suddenly move or topple, which can result in death or seiious injitsy.

Overloaded nailers and improper tongue weight can result in loss of coiitiol of the

liailer Ensuie the trailer is coupled cotrectly a?sd the chains are crossed over each other

Ensure the load is tied securely and doesn't exceed the Gross Vehicle Weight (GVW)

Ensure the electricBl connections are lightly filled and fimciioning properly Always

check break Hgiits and turn signals before each tow

Pinch Point Warning

Folded Trailer Warning

A WARNING i

Г'“’™??'" 1

©

.......... mjNG

Watch for pinch

points while

folding or

deploying trailer

as serious injury

could occur

Always use the

Hand Crank

^vhen folding

and deploying

Trailer Ensure

others keep a safe

distance to avoid

any potential

pinch points

¿tyWARNlNGA

NEVER tow

Frailer while in

folded position

Failure to heed this

warning trtay' void

warranty and could

result in property

damage, serious

injury or death.

You can store

the Trailer in

folded position,

but do NOT tow

the Trailer while

rfs folded Tlie

Traiier may tip

ovei resulting in

property damage,

serious injury or

death

Pan ¿11025112

Part #1024837

Page 10

Tire and Loading Inforraatlon

illlllfHlilllil

No rc-ordcrs

Always check tire pressure lo ertsure optimum life and регГогтапсе from your tires

The tires that came with your trailer should have a tire pressure of 80 psi, Sears,

Roebuck and Co,, cannot be held responsible for damages caused by uneven tread

wear and blow outs from an under-in Plated or over-inflated tire

The Trailer and load should never exceed the Gross Vehicle Weight (GVW).,

Whenever loading the trailer, always check to see if you’re within this lirnii,. See the

section on Loading the Trailer for infomratioit regarding how to check

This sticker also displays your Vehicle Identification Numbes (VIN) in the boilom,

left-hand comer.

NATM Compliance

Re-order #]0!4245

Your trailer is in compliance with the

guidelines of the National Association of

Trailer Manufacturers Your trailer has its

own unique number Note: This is not

your Vehicle Identification Number (VIN)

Bail and Hitch Size

Your new trailer comes with a 2-inch coupler. The ball

on the tow vehicle must be 2 inches in diaTTieter, An

incoftect ball size can cause tlie separation of the trailer

ftom the tow vehicle resulting in possible property

' damage, serious injury and death,

10

Patent Advisory

LI F j:ti ts j E p li о i j V CT :

liiiiiiiiipiiiiiiiii

No re-orders

This sticker displays the various patents

applicable to the trailcr-

SL

O20i f

Re-order #1,013499

Page 11

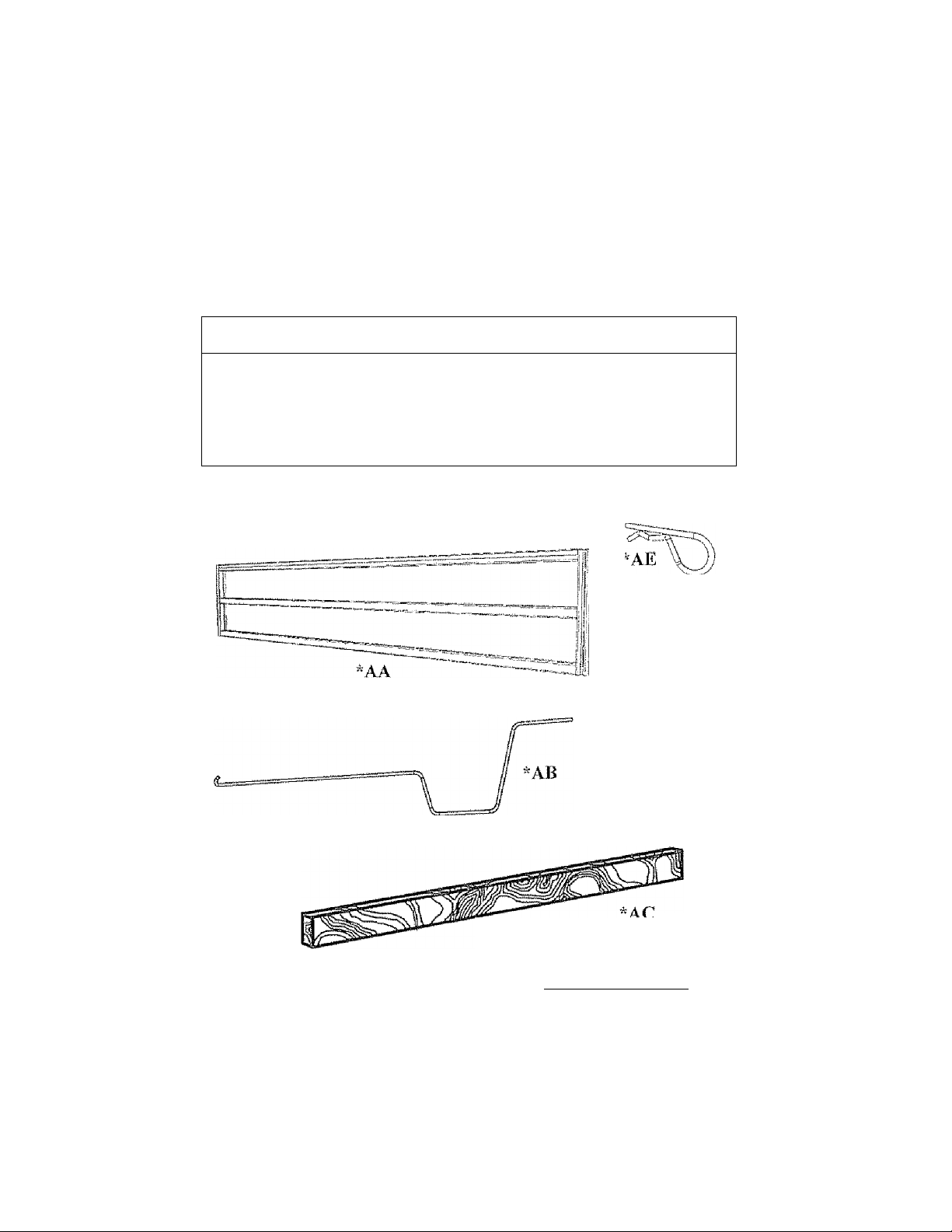

ECTION 2: TRAILER PARm^

HARDWARE

Before beginning assembly, inventory all parts using the Parts List and the Hardwai e Identifier (below) If al! parts are not presenL do NOT assemble the trailer

Cali L800-422-3865,

—

PARTS LIST

ID

ЛЛ

AB Hand Crank 1

ЛС

AD

\AE

Description Qty

Oiitc/R-UTHp -2.

T X 4” Distance Indicator (Do Not Discard) I

L ocking Pin w/ Lanyard (Connected) 1

CoU c г Key (Con ri ec! cd) 1

HARDWARE IDENTIFIER

(*Nol to Scale)

'AD

.....

tJV

V

□

□

□

□

□ 1

Oo Not Discard

TOOLS HEEDED (NOT INCLUDED)

13/16” Lug Wrench or Tire Iron (For changing Tires and periodic lighicning of L ug

, Nuts)

11

Page 12

SECTION 3i

.............

FIRST-TIME SET-UP REQUIREMENTS

Lug Nuts: Tightening Sequence, Torque Requirements

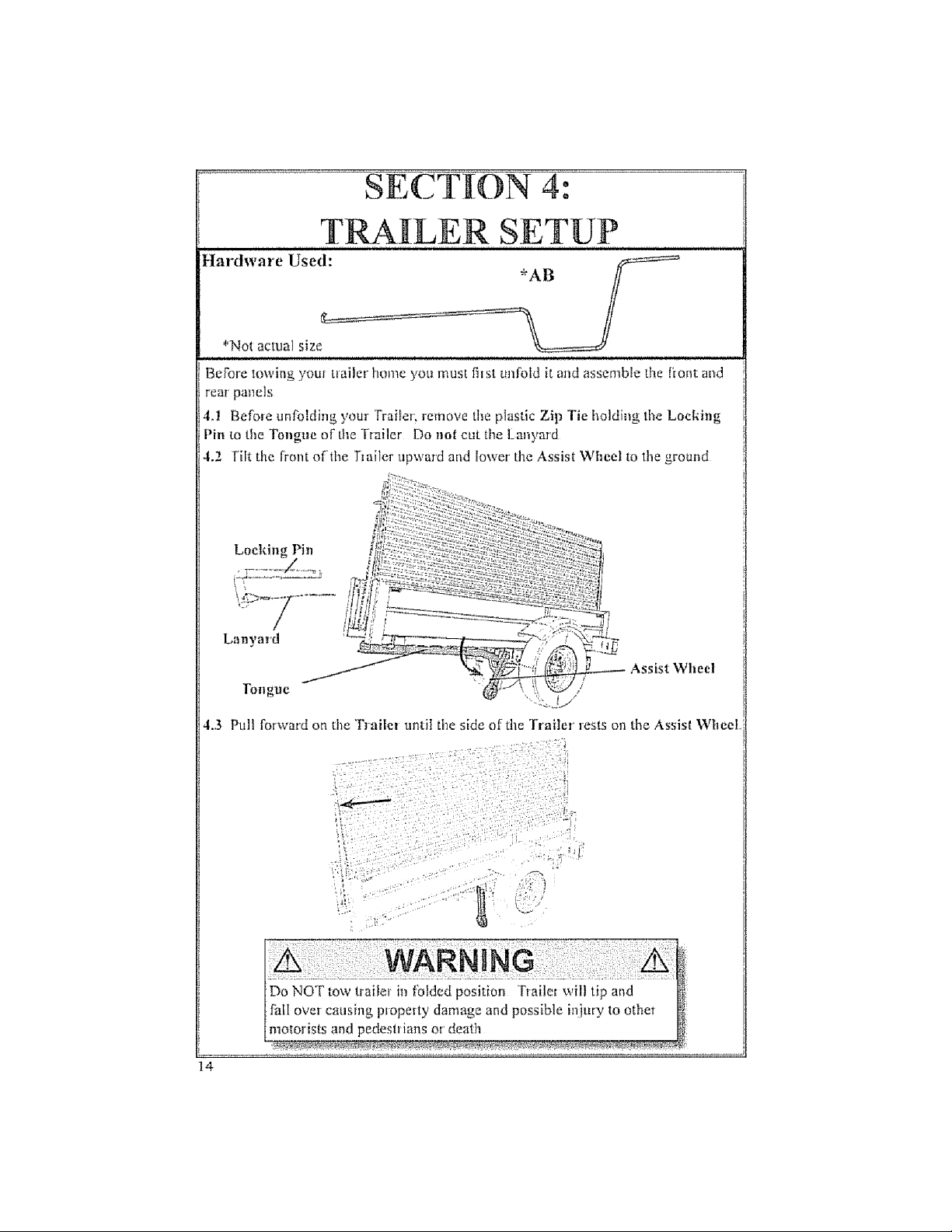

• Before unfbiding your Trisiler. remove the plastic Zip Tic holding the Locking Pin

to the Tongue of the Fraiter Do not cut the Lanyard ,j._

-------------

^Locking Pin

~~———— Lanyard

A

Lag nuts arc prone to [ooseti after initial inslailaiion possibly castsing

ilic wheel So separate iVom the trailer leading to property duniage, death

or serious iitjury

• Check lug nuts for iiglitness on a new trailer or when M'liecifs) have

been remoumed after the (irsi 10, 25 and 5(1 miles of di iving and

after any insptsci

• Lug nuts for the tires must be lighiened by the user betbre each use

• Scars cattnoS be heid responsible for damages caused by loosened

lug nuts

• Before towing the Trailer, you must cnsuie the lug nuts are tightened to the pioper

torque

• The torque requirements for the Lug Nuts are 95 - 120 ft/lb. Do not exceed 120

ft/Ib of torque Tighten the Lug Nuts in the sequence below before you leave the

dealer

Tifiliien lug nuts

in the following

order;

WARNING

^

............

.........................................................................................................

A

.........

r

Verily the proper PSl for your tire

• Tire pressure for the 12” t im & tire should be at 80 psi

Follow posted speed limits but do not exceed 65 mpli.

A

Before loading Trailer, Trailer must be properly connected to

the Tow Vehicle to stabilize the Trailer Failure to follow this

warning could result in property damage, personal itijuty and

death. _

12

WARNING

A

Page 13

Connecting Temporary License Plate

Jf your slate requires a temporary license on your trailer, secure the license to the

license plate holder located on the left blinker before lowing your trailer home

Note; Before leaving the dealet, ensure you have the Manufacture!s Certificate of

Origin (Tiiie) signed over to you

Note: For all inquiries regarding trailer title and registration, please contact your

local Department of Motor Vehicles (DMV) os your local county tax assessor’s

oflice.

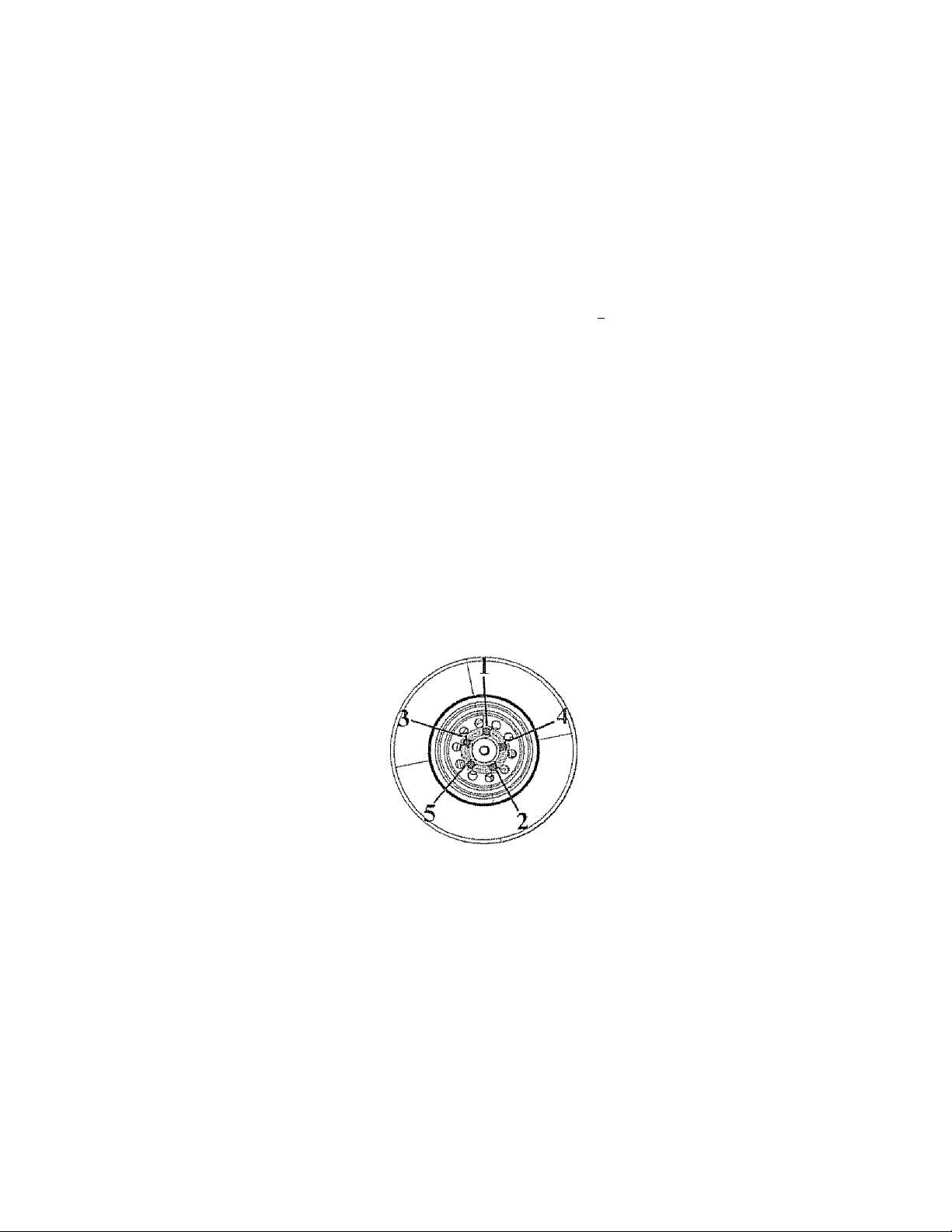

Connecting the Electrical Cables

Connect the bailer lights to the tow vehicle’s electrical system using the

electrical connectors

• Check all lights for proper operation

1 Clearance and Running Lights {Turn on tow vehicle headlights)

2 Brake Lights (Step on tow vehicle brake pedal)

3 Turn Signals (Operate tow vehicle direciionai signal lever)

/L Warning: To ensure your trailer lights function properly, firmly insert the

¿---A Plug (Trailer) into the Receptor (Tovv Vehieic)

Note: Jf your connector does nor look like the one pictuied. you need to purchase

on adapter.

From Trailer From Tow Vehicle From Trailer From Tow Vehicle

Note: Please read Sections 4 and 5 for additional infbmiation on deploying,

coupling and towing your trailer

A

Do'noTlrfi~sporrpeoptTTiT llw’lTalieF'FaF!^^^

rng could result in serious injury such as broken bones, brain

dama'ic, naraivsis oi death

WARNING

A

Page 14

Page 15

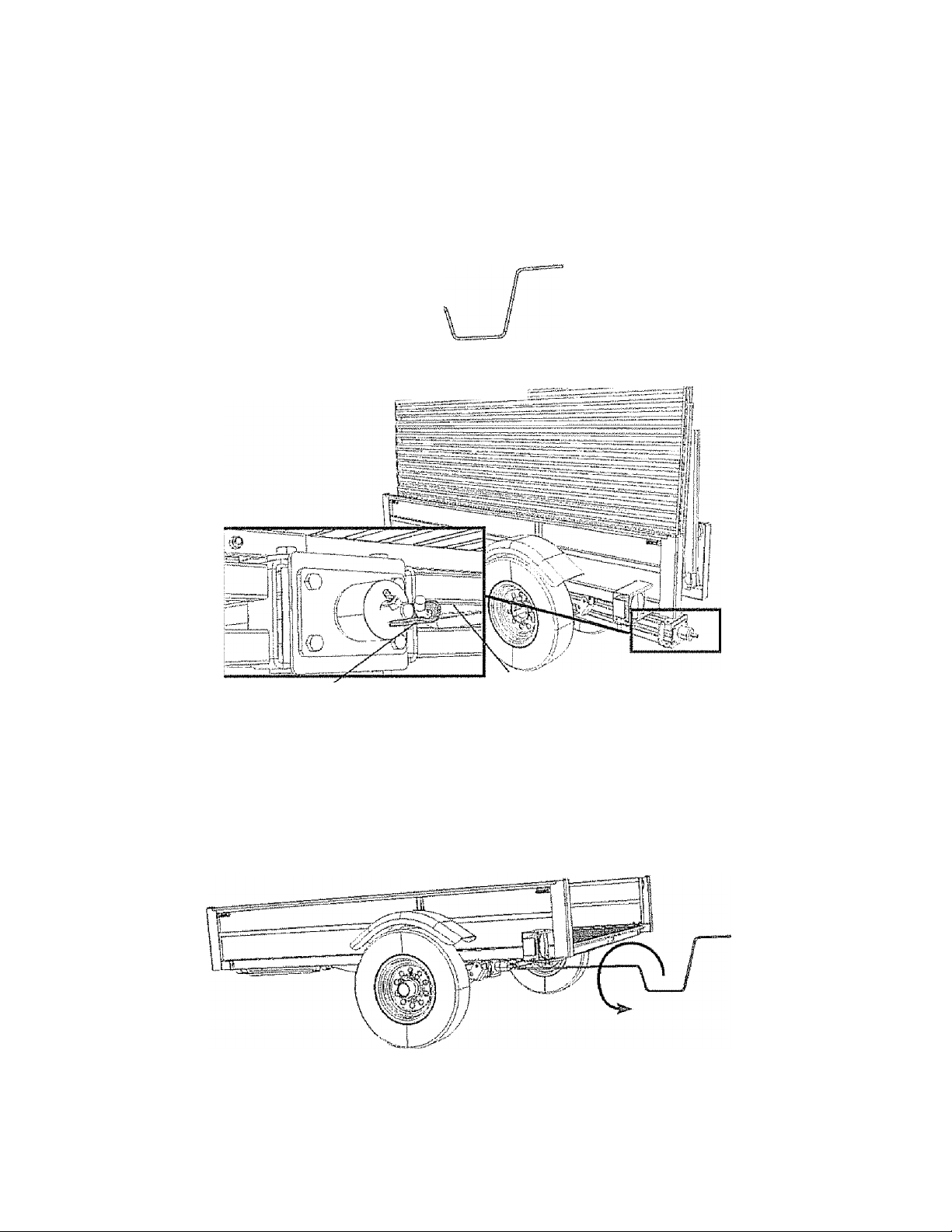

Wilh the right side of the Trailer resting on the Assist Wheel, you can now unfold the

Trailer,

4.4 Remove the Hand Crank (AB) ftom the clips just imside wall of the Trailer,

Note: You may need to remove the Gate/Ramp to access the Hand Crank from the

insde wall of the Trailer

4.5 insert the Hisnd Crank into the jack’s Hand Cr ank Coupler Plate at the rear of

the Trailer (as shown).

Hand Crank Coupler Plate

A

Watch lor pinch points while folding artd deploying trailer as

serious injury could occur.

4.6 Turn the Hand Crank counter-clockwise to unfold the Trailer Continue

turning the Hand Crank until you cannot turn it any fiifther

WARNING

Hand Crank

A

15

Page 16

16

Page 17

43 After unfolding the Ttailer, lift up on the fi'ont of the Trailer and reliact the Assist

Wheel

CAUTION

ALWAYS load and tow the Trailer while the Assist Wheel is up Failure

10 heed this warning could result hi permaneni damage to iltc Assist

Wheel and void warranty.

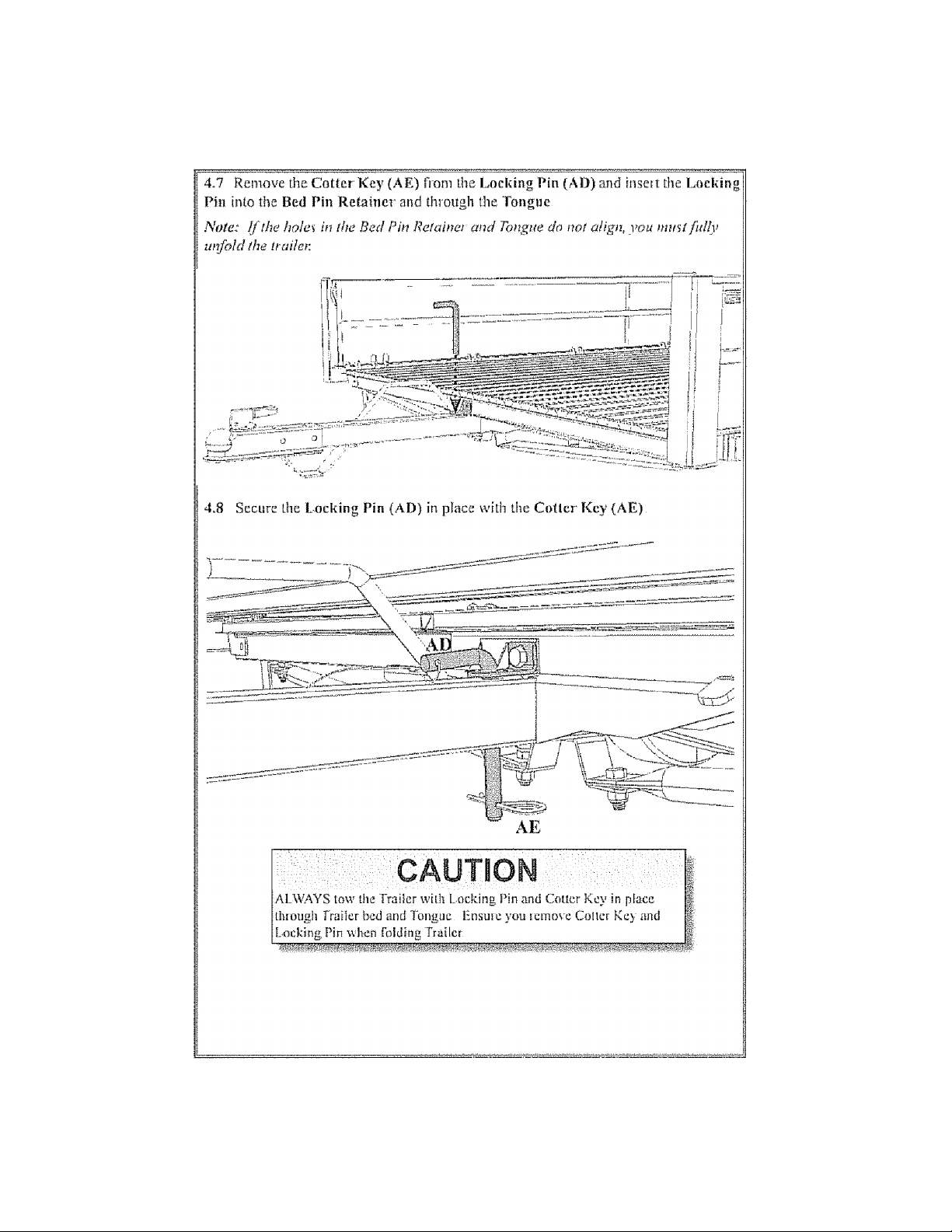

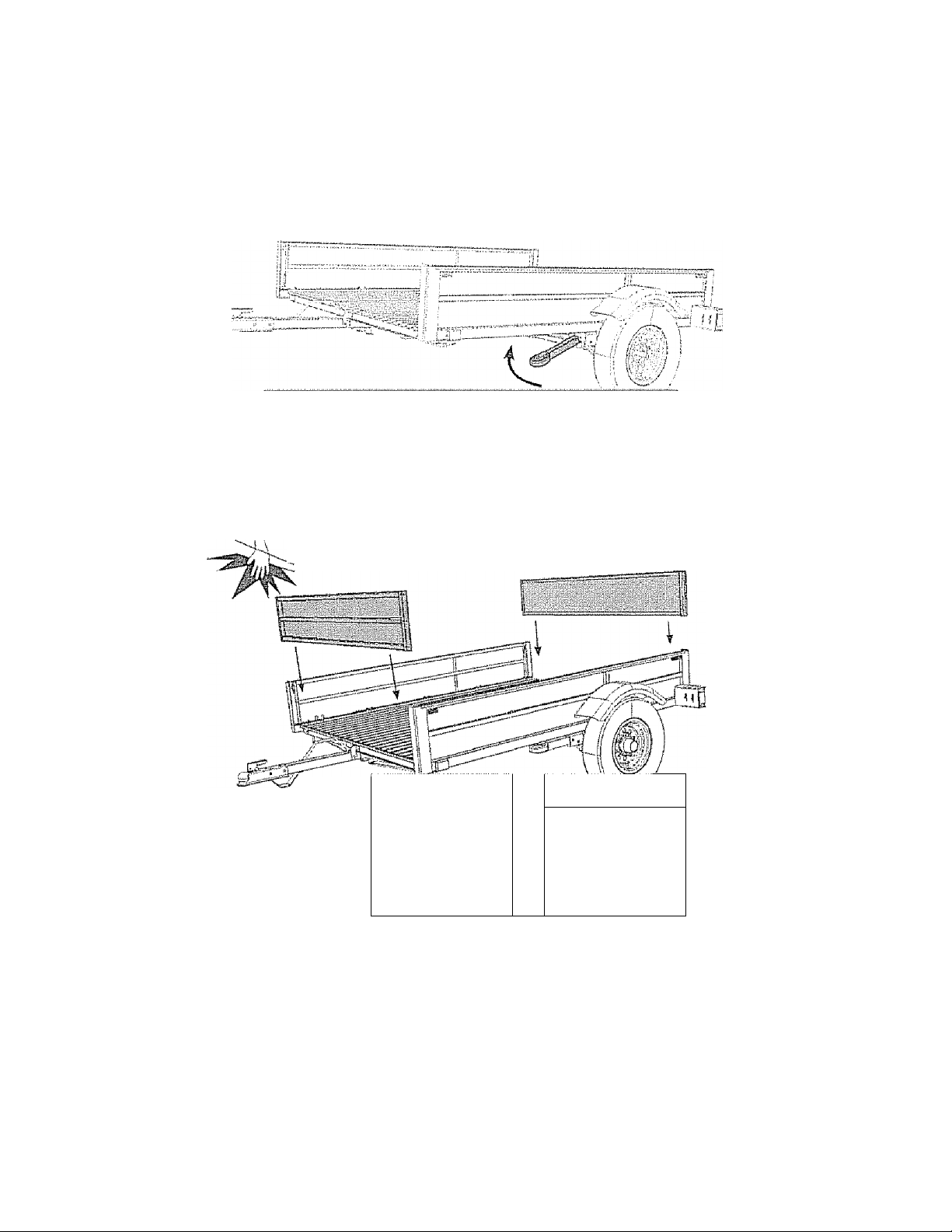

4.10 Insert the Front and Rear Gates (AA) in place Both Gates are the .same; you

can insert each in either the front or tear position

/|\ WARNING: Watch for pinch points as serious injury could

'^^occur;

4,11 Press down firmly

on the Gates until they

lock into place under the

Lip.s of the Side Panels

A WARNING

Do NOT use the Gates for lie-down locations Al! articles being

towed must be tied to the side wails of the Frailer, Gates can

dislodge causing properly damage and possible injuty or death to

other motorists and pedestrians

■'^1

' ' i

—

-- T'

i 1 1 ip " ' ‘

________

A

17

Page 18

4.12 Use the Front and Rear Gates as ramps Simply lemove each Gate and place

the ends into the channel at the rear of the Trailer Bed i

I

A WARNING

Only load Trailer while it is connected to the Tow Vehicle or

Trailer could tip causing property damage, possible injury or

death

4.13 When driving vehicles such as ATVs up the ramps, first place the 2” x 4” x 63”

Distance Indicator in the grooves of the side panels where the front gate should go to 1

help you avoid cliiving too fer |

A

The 2” % 4” Distance Indicator will xjoEprevetU}'ou From driving

off the Fiont of the Trailer It is Used to let you know you’re going

loo Fat Drive slowly and cautiously when driving vehicles up

the ramps.

CAUTION A

2” X 4” X 63” Distance Indicator

' Do Not Discard

A

I

Note: To fold the TraHer, simply i emove the Locking Pin and Gaia and turn the

Htmd Crmik dockwhe Store the Gates and Hand Crank in the Trailer.

A

|Do not transport people in the trailer Failure to heed this warn-

tng could result in serious tujsrry such as broken bones, brain

damage, paralysis or death

18

WARNING A

Page 19

ECTION 5: COUPLING TO

.1 MJLMIj 1 V./ У T V 1 i ж 11V-' KjMb

1?

ATTACHING THE TRAILER TO TOW VEHICLE

Yoti must foJIow ali оГ tlie safety precautions and instructions in this manual lo

ensure safety of persons, cargo, and satisfactory' life of the trailer.

5.1 Warning: Using an Adequate Tow Vehicle and Hitch A

If the vehicle or hitch is not property selected and matched lo the Gross Vehicle

Weight Rating (GVWR) of your trailer; you can cause an accident that could lead to

death or serious injuiy If you already have a tow vehicle, know your velticle tow

rating and make certain tire trailer's rated capacity is less than or equal to the tow

vehicle's rated lowing capacity. If you already have (or plan to buy) a trailer, make

certain that the tow rating of the tow vehicle is equal to or greater than that of the

trailer

5.2 Warning: Coupling and Uncoupling the Trailer A

A secure coupling (or fastening) of the trailer to the tow vehicle is essential, A loss

of coupling may result in death or serious injury. Therefore, you must understand

and follow all of the instructions for coupling your trailer to your tow vehicle.

The following parts are involved in ensuring a secure coupling between the trailer

and tow vehicle:

Coupler: A device on the longue of the trailer that connects to the hitch on the

tow vehicle.

Hitch: A device on the low vehicle that supports the weight of the trailer tongue

and pulls the trailer. The coupler attaches to the hitch,,

Safety chains: If the coupler connection comes loose, the safety chains can keep

the trailer attached to the tow vehicle. With properly rigged safety chains, it is

possible to keep the tongue of the trailer frotn digging into the road pavement,

even if the coupler-to-hitch connection comes apart.

Trailer lighting (and braiung) connector: A device that connects electrical

power from the tow vehicle to the trailer. Electricity is used to turn on brake

lights, running lights, and turn signals as required.

5.2.1 Trailer with Bail-Hilch Coupler

A ball hitch coupler connects to a ball that is located on or under the rear bumper

of the tow vehicle. This system of coupling a trailer to a tow vehicle is sometimes

refeired to as “bumper pull.”

Warning: We have utilized a 2-inch Ball Hitch coupler that is suitable for the

size and weight of the trailer: You must provide a hitch and .2-inch ball for

your tow vehicle, where the load rating of the hitch and ball is equal to or greater

19

Page 20

than that ofyoiir trailer. Also, the ball size must be the same as the coupler size. If

the hitch ball is too small, too large, is underrated, is loose or is worn, the trailer can

come loose from the tow vehicle, and may cause death or serious injury,

THE TOW VEHICLE, HITCH AND BALL MUST HAVE A RATED TOWING

CAPACITY EQUAL TO OR GREATER THAN THE TRAILER GROSS

VEHICLE WEiGHT RATING (GVWR).

IT IS ESSENTIAL THAT THE HITCH BALL. BE OF THE SAME SIZE AS THE

COUPLER (2 INCHES),

The ball size and load rating (capacity) are marked on the ball; hitch capacity is

marked on the hitch

S 2.T. 1 Before coupling the trailer to the tow vehicle

• Ensure the size and rating of hitch ball match the 2-inch coupler on your trailer.

Hitch balls and couplers are marked with their size and rating

■ Wipe the hitch ball clean, inspect it visually and feel fot flat spots, cracks Emd

pits,

• Rock the bail to make .sure it is tight to the bitch, and visually check that the

hitch ball nut is solid against the lock washer and hitch frame

• Wipe the inside and outside of the coupler clean and inspect it visually foi'cracks

and deformations; feel the inside of the coupler for worn spots and pits,

» Be sure the coupler is tight to the tongue of the trailer. All coupler fasteners

must be visibly solid against the trailer ftame.

• Raise the bottom surface of the coupler above the top of the hitch ball Use

wood or concrete blocks to support the trailer longue.

S.2.1.2 Preparing the coupler and hitch

• Lubricate the hitch bail and the inside of the coupler with a thin layer' of

automotive bearing grease.

• Open the coupler locking mechanism, Bali couplers have a locking mechanism

with an internal moving piece and an outside handle

In the open position, the coupler is able to drop fully onto the hitch bail.

See “Uncoupling the Trailer” for details on placing the coupler in the “open”

position,

' Slowly back up the tow vehicle so that the hitch ball is near or aligned under the

coupler,

5,2*13 Coupling the trailer to the tow vehicle

Lift the couplet and place it over the ball

• Lower the trailer until the coupler fully engages the hitch ball.. If the coupler

does not line up with the hitch ball, adjust the position of the tow vehicle,.

' Engage the coupler locking mechanism In the engaged position, the locking

mechanism securely holds the coupler to the hitch ball,

20

Page 21

• Insert a pin or lock through the hole in the locking mechanism

• Ensure tl5e coupler is all the way on the hitch ball and the locking mechanism is

engaged

• Lower the trailer so that its entire tongue weight is held by the hitch Push the

safety latch downward to a horizontal position to lock it in place

• Pull up on the coupler to ensure it is securely fastened to the tow vehicle

if the coupler cannot be secured to the bitch ball, do not fow the traiien

Refer to Section 10.2.3 for information on coupling your trailer.

i ^ ■

A WARNING

Use 3ÖW Motor Oil to lubricate the ball and inside of coupler

Always check ball and coupler before each low for damaged O)

worn edges Damaged baits and couplers should be replaced

immediately Failure to follow this warning could result in

property damage, personal injury and death

5.2.L4 Rigging the safety chains

• Visually inspect the safety chains and hooks for wear or damage Replace worn

or damaged safety chains and hooks before towing

* Rig the safely chains so that they:

1 cross underneath the coupler;

2 loop around a frame member of the tow vehicle or to holes provided in the

hitch system (but, do not attach them to an interchangeable pari of tire hitch

assembly); and

3 have enough slack to permit tight turns, but not be close to the- load surface,

so if the trailer uncouples, the safety' chaiii.s can hold the tongue up above the

road.

A

Page 22

WARNING

improper rigging of the safety chains can result in loss of control

of the trailer and the tow vehicle, leading to death or serious

injtity, if the trailer uncouples from the tow vehicle

■ Fasten chains to frame of tow vehicle Do not fasten chains

to any part of the hitch unless the hitch has holes or loops

specifically for that purpose

' Cross chains underneath hitch and coupler with enough, slack

to permit turning, and to hold tongue up, if the trailer comes

loose

5.2.1.5 Connecting the ciectrical cables

Connect the trailer lights to the tow vehicle's electrical system using the electrical

connectots

• Check all lights for proper operation

1 Clearance and Running Lights {Гшп on tow vehicle headlights)

2, Brake L ights (Step on low vehicle brake pedal)

3 Turn Signals (Operate tow vehicle directional signal lever)

Warming: To ensure your trailer hghls function properly, firmly insert the

A

Ping (Trailer) into the Receptor (Tow Vehicle)

Follow posted speed limits but do not exceed 65 mph

A

22

A WARNING

IDo not transport people in the trailer. Failure to heed this warn- Ч

png could result in serious injury such as broken bones, brain

damage, paialysis or deaiii

A

Í!

i- ,

Page 23

Noie: if your connector doe'; not look /ike the one pictured you need to purchme

an adapter.

From Trailer

From Trailer

A

Check the connection periodicaliy to ensure tail and break lights

ftmetion prooerlv Faiitire lo fbllaw this wanting could result in

property damage, personal itijury and death

5.2,T6 Uncoupling the Trailer

Follow these steps to uncouple your ball hitch trailer from tlie tow vehicle:

1 Remove Uie load fiom the trailet

2 Block trailer tires to prevent the trailer from rolling

.3. Place wood or concrete blocks under the coupler for support.

4, Disconnect the electrical connector

5, Disconnect the safety chains from the low vehicle

6, Unlock the coupler and pull the safety latch upward to a vertical position aiid

lift tlie trailer off the ball

WARNING

From Tow Vehicle

From Tow Vehicle

A

Unlock

23

Page 24

SECTION TIME Si SAFETY

INFORMATION

CHECMNG & CHANGING TIRES

6.1 Defermiiiing Correct Load Limit “Trailer

6.i.l Trailers 10,000 Pounds GVWR or Less

1 Locale the statement, “Hie weight of cargo should never exceed XXX kg or

XXX ibon your vehicle’s placard.

2 This figure equals the available amount of cargo and luggage load capacity.

3 Determine the combined weight of luggage and cargo being loaded on the

vehicle. That weight may not safely exceed the available cargo and luggage load

capacity,

The trailer’s placard refers to the Tire Information Placard attached adjacent to or

near the trailer’s VIN (Certification) label at the left front of the trailer

6.2 Determining Correct Load Limit“ Tow Vehicle

1. Locate the statement, ‘The combined sveight of occupants and cargo should

never exceed XXX lb on your vehicle’s placard

2. Determine the combined weight of the driver and passengers who will be riding

in your vehicle

3. Subtract the combined weight of the driver and passengers from XXX kilograms

or XXX pounds.

4. The resulting figure equals the available amount of cargo and luggage capacity

For example, if the “XXX” amount equals 1400 lb and there will be five 150 !b

: passengers in your vehicle, the amount of available cargo and luggage capacity is

: 650 lb (1400-750 (5 x ISO) - 650 lb.),.

5. Determine the combined weight of luggage and cargo being loaded on the

; vehicle That weight may not safely exceed the available cargo and luggage capacity

calculated in Step # 4,

; 6, If your vehicle will be towing a trailer, load from your trailer will be transferred

: to your vehicle Consult the tow vehicle’s manual to determine how this weight

■ transfer reduces the available cargo and luggage capacity of your vehicle.

6.3 Glossary of Tire Terminology

: Accessory weight: The combined weight (in excess of those standard items which

^ may be replaced) of automatic transmission, power steering, power brakes, power

windows, power seats, radio and heater, to the extent that these items are available

; as factory-installed equipment (whether installed or not).

Bead: The part of the lire that is made of steel wires, wrapped or reinforced by ply

: cords and that is shaped to fit the i sm

Bead separation: This is the breakdown of the bond between components in the

' bead.

: Bias ply tire: A pneumatic lire in which the ply cords that extend to the beads are

^ laid at alternate angles substatilially less than 90 degrees to the center line of the

tread.

24

Page 25

Carcass: The tire structure, except treacTand sidewaii rubber wlticb, when inflated,

bears the load.

Chunking: The breaking away of pieces of the tread or sidewall

Cold itifialion prcs.sure: The pressure in the lire before you drive

Cord; The strands forming the plies in the tire

Cord separation: The parting of cords from adjacent rubber compounds

Cracking: Any parting within the tread, sidewall, or inner liner of the tire

extending to cord material,.

CT: A pneumatic tire witli an inverted flange lire and rim system in which the i im

is designed with rim flanges pointed radially inward and the tire is designed to fit

on die underside of the rim in a manner that encloses the rim flanges inside the air

cavity of the tire,.

Curb weight: The weight of a motor vehicle with standard equipment including

the maximum capacity of fuel, oil, and coolant, and, if so equipped, air conditioning

and additional weight optional engine

Extra load tire: A tire designed to operate at higher toads and at higher inflation

pressures than the corresponding standard tire.

Groove: The space between two adjacent tread ribs.

Inner liner: The layer(s) forming the inside surface of a tubeless tire that contains

the inflating medium within the tire

Inner-liner Separation: The parting of the inner liner from cord material in the

carcass.

Intended outboard sidewall The sidewall that contains a white-wall, bears white

lettering or beats manufacturer, brand, and/or model name molding that is higher or

deeper' than the same molding on the other sidewall of the lire or the outward facing

sidew'all of an asymmetrical tire that has a particular side that must always face

outward when mounted on a vehicle.

Light truck (LT) tire: A tire designated by its manufacturer as primarily intended

for use on lightweight itudes or multipurpose passenger vehicles.

Load rating: The maximum load that a lire is rated to carry for a given inflation

pressure.

Maximum load rating: The load rating for a tire at the maximum peimisstble

inflation pressure for that tire

Maximum permissible inflation pi es.sure: The maximum cold inflaiioii pressure

to which a tire may be inflated

Maxirrtum loaded vehicle weight: The sum of curb weight, accessory weight,

vehicle capacity weight, and production options weight.

Measuring rim: The rim on which a tire is fitted for plwsical dimension

requirements.

Non-pneumatic rim: A mechanical device which, when a non-pneumatic tire

assembly incorporates a wheel, supports the tire, and attaches, either integrally or

separably, to the wheel center member and upon which the tire is attached,.

Non-pneumatic spare tire assembly: A non-pneumatic tire assembly intended

for temporary use in place of one of the pneumatic tires and rims that are fitted to a

passenger car in compliance with the requirements of this standard.

Non-pneumatic tire: A mechanical device which transmits, either directly or

through a wheel or wheel center member, the vertical load and tractive forces from

25

Page 26

the roadway to the vehicle, generates the tractive forces that provide the directional

control of the vehicle and does not rely on the containiTtent of any gas or fluid for

providing those functions.

Non-pneumatic tire assembly: A non-pneumatic tire, alone or in combination with

a wheel or wheel center member, which can be mounted on a vehicle.

Normal occupant weight: This means 68 kilograms (150 lb.) times the number of

occupants specified in tire second column of Table 1 of 49 CFR 57 L. 110

Occupant distribution: The distribution of occupants irs a vehicle as specified in

the third column of Table 1 of 49 CFR 571.110.

Open splice: Any parting at any junction of tread, sidewall, or inner liner that

extends to cord material.

Outer diameter: The overall diameter of an inflated new lire

Overall width: The linear distance between the exteriors of the sidewalls of an

inflated tire, including elevations due to labeling, decorations, or pi elective bands or

ribs.

Ply; A layer of rubber-coated parallel cords..

Ply separation: A parting of rubber compound between adjacent plies

Pneumatic tire: A mechanical device made of rubber, chemicals, fabric and

steel or other materials, that, when mounted on an automotive wheel, provides the

traction and contains the gas or fluid that sustains the load

Production options weight: The combined weight of those installed regular

production options w-eighing over 2.3 Idlogtams (5 Ib) in excess of those standard

items which they replace, not previously considered in curb weight or accessory

weight, including heavy duty brakes, ride levelers, roof rack, heavy duty battery,

and special irini.

Radial ply tire: A pneumatic tire in which the ply cords that extend to the beads

are laid at substantially 90 degrees to the center line of the tread

Recommended inflation pressure; This is the inflation pressure provided by lire

vehicle manufacturer on the fire information label and on the Certification / VIN

tag.

Reinforced tire: A tire designed to Operate at higlier loads and at higher inflation

pressures than the corresponding standard tire

Rim: A metal support for a tire or a tire and tube assembly upon which the tire

beads are seated.

Rim diameter: This means the nominal diameter of the bead seat

Rim size designation: This means the rim diameter and width.

Rim type designation: This means the industry of manufacturer’s designation for

a rim by style Of code

Rim width; This means the nominal distance between rim flanges

Section width: The linear distance between the exteriors of the sidewalls of art

inflated tire, excluding elevations due lo labeling, decoraiiott, or protective bauds.

Sidewall: That portion of a tire betw'cen the tread and bead.

Sidewall separation: The parting of the rubber compound from the cord material

in the sidewall.

Special Trailer (ST) tire: The “ST’ is an indication the tire is for irailer use only,

Test rim: The rim on which a tire is fitted For testing, and may be any rtin listed as

26

Page 27

appropriate for use with that tire.

Tread: That portion of a tire that comes into contact with the road.

Tread rib: Л tread section running circumferentialiy around a tire.

Tread separation: Pulling away of the tread from the tire carcass.

Tread-wear indicators (TWI): The projectiorts within the principal grooves

designed to give a visual indication of the degrees of wear of the tread.

Vehicle capacity weight: The rated cargo and luggage load plus 68 kilograms (150

!b.) times the vehicle’s designated seating capacity'

Vehicle maximum load on the tire; The load on an individual tire that is

determined by distributing to each axle its share of the maximum loaded vehicle

weight and dividing by two

Vehicle norma! load on the tire; The load on an individual tire that is determined

by distributing to each axle its share of the curb weight, accessory weight, and

normal occupant weight (distributed in accordance with Table Í of CRF 49 571,110)

and dividing by .2.

Weather side: The surface area of the rim not. covered by the inflated tire

Wlieei center member: In the case of a non-pneumatic tire assembly incorporating

a wheel, a mechanical device which attaches, either integrally or separably, to the

non-pneumatic rim and provides the connection between the non-pneumatic rim

and the vehicle; or, in the case of a non-pneumatic tire assembly not incorporating

a wheel, a mechanical device which attaches, either mlegrally or separably, to the

non-pneumatic tire and provides the connection between tire and the vehicle

Wheel-hoi ding fixture: fire fixture used to liold the wheel and tire assembly

securely during testing.

6.4 Tire Safety - Everything Rides on It

The National Traffic Safety Administration (NHTSA) has published a brochure (DOT

HS 809 361) that discusses all aspects of Tire Safely, as required by CFR 575,6.

This brochure is reproduced in part below. It can be obtained and downloaded ftora

NHTSA, free of charge, from the following web site:

hrtp;//www.nhtsa.dol.gov/cars/raIes/TireSafety/ridesonil/tires_mdex hlml

Studies of tire safety show that maintaining proper tire pressure, observing tire

and vehicle load limits (not carrying more weight in your vehicle than your tires

or vehicle can safely handle), avoiding road hazards, and inspecting tires for cuts,

slashes, and other irregularities are the most important things you can do to avoid

lire failure, such as tread separation or blowout and flat tires These actions, along

with other care and maintenance activities, can also:

• Improve vehicle handling

• Help protect you and others from avoidable breakdowns and accidents

• Improve fuel economy

• increase the life of your lites.

This booklet presents a comprehensive overview of tire safely, including

infotmation on the following topics:

• Basic tire maintenance

27

Page 28

' Uniform Tire Quality Grading System

' Fundamental characteristics of tires

• Tire safety tips .

Use this information to make tire safety a regular part of your vehicle maintenance

routine. Recognize that the time you spend is minima! compared with the

inconvenience and safety consequences of a flat tire or otlter tire failure

6.4.1 Safetj' firsi“Basic tire maintenance

Properly maintained tires improve the steering, stopping, traction, and loadcariying capability of your vehicle Under-inflated tires and overloaded vehicles

are a major cause of tire failure Therefore, as mentioned above, to avoid flat tires

and other types of tire failure, you should maintain proper tire pressure, observe

tire and vehicle load limits, avoid road hazards, and reguiarly inspect your tires

6.4.2 Finding yorir vehicle’s recommended tire pressure and load limits

Tire information placards and vehicle certification labels contain information on

tire.s and load limits, These labels indicate the vehicle manufacturer’s information

including:

• Recommended tire size

• Recommended tire inflation pressure

• Vehicle capacity weight (VCW-the maximum occupant and cargo weight a

vehicle is designed to cairy)

• Front and rear gross axle weight ratings (GAWR- the maximum weight the

axle systems are designed to cany).

Both placards and certification labels are permanently attached to the trailer near”

the left ftont,

6.4.3 Understanding tire pressure and load limits

Tire inflation pressure is the level of air in the tire that provides it with load

carrying capacity and affects the overall performance of the vehicle. The tire

inflation pressure is a number that indicates the amount of air pressure- measured

in pounds per square inch (psif-a tire requires to be properly inflated (You will

also find this number on the vehicle information placard expressed in kilopascals

(kPa), which is the metric measure used iriternationaliy,)

Manufacturers of passenger vehicles and light trucks determine this number

based on the vehicle’s design load limit, that is, the greatest amount of weight a

vehicle can safely catty and tire vehicle’s tire size T!ie proper tire pressure for

your vehicle is referred to as the “recommended cold inflation pressure ” (As you

will read below, it i.s difficult to obtain the tecommended lire pressure if your dies

are not cold,)

Because tires are designed to be used on more than one type of vehicle, tire

manufacturers list the ‘'maximtim permissible inflation pressure” on the tire

sidewall. This number is the greatest amount of air pressure that should ever be

put in the tire under normal driving conditions.

28

Page 29

6.4.4 Checking tire pres.sure

it is important to dieck your vehicle’s tire pressure at least once a month for the

following reasons:

• Most tires may natutally lose air overtime.

• Tires can lose air suddenly if you drive over a pothole or other object or if you

strike the curb when parking,

• With radial tires, it is usually not possible to determine under-inflation by visucsl

inspection.

For convenience, purchase a tire pressure gauge to keep in your vehicle. Gauges

can be purchased at tire dealerships, auto supply stores, and other retail outiels,.

The recommetided tire inflation pressure that vehicle raariufaciurers provide

reflects the proper psi when a lire is cold The term cold does not relate to tlte

outside temperature. Rather, a cold tire is one that has not been driven on for at

least three hours. When you drive, your tires get warmer, causing the air pressure

within them to increase. Therefore, to get an accurate tire pre.ssure reading, you

must measure tire pressure when the tires are cold or compensate for the extra

pressure in warm tires

6.4.5 Steps for maintaining proper tire pressure

• Step 1: Locate the recommended tire pressure on the vehicle’s tire information

placard, certification label, or in tile owner’s manual

• Step 2: Record the tire pressure of all tires

• Step 3; If the tire pres.sure is too high in any of the tires, slowly release air by

gently pressing on the tire valve stem wdth the edge of your tire gauge until you

get to the correct pressure.,

■ Step 4: If the tire pressure is too low, note the difference between the measured

tire pressure and the correct tire pressure. These “missing” pounds of pressure are

what you will need to add.

• Step 5; At a service station, add the missing pounds of air pressure to each tire

that is under-inflated

• Step 6: Check all the tires to make sure they have the same air pressure (except

in cases in which the front and rear tires are suppo.sed to have differetit amounts of

pressure).

If you have been driving your vehicle and think that a trailer tire is under-ínflated,

fit! it to the recommended cold inflation pressure indicated on your vehicle’s tire

information placard or certification label While your tire may still be .slightly

under-inflated due to the extra pounds of pressure in the warm tire, it is safer

to drive with air pressure that is slightly lower than the vehicle manufacturer’s

recommended cold inflation pressure than to drive with a significantly under

inflated tire Since this is a temporary fix, don’t forget to redieck and adjust the

tire’s pressure svhen you can obtain a cold reading

6.4.6 Tire size

To maintain tire safety, purchase new tires that are the same size as the vehicle’s

oiiginal tires Or another size recommended by the mamifacturer. Look at the

tire information placard, the owner’s manual, or the sidewall of the tire you are

29

Page 30

replacing to find this information If you have any doubt about tlic correct size to

choose, consult with the tire dealer

6.4.7 Tire tread

The tire tread provides the gripping action and traction that prevent your vehicle

from slipping or sliding, especially when the road is wet or icy, In general, tires

are not safe and should be replaced when the tread is worn down to 1/16 of an

inch, Tires have built-in tread-wear indicators that let you know when it is time

to replace your tires. These indicators are raised sections spaced intermittently in

the bottom of the tread grooves. When they appear ‘tovsn” with the outside of the

tread, it is lime to replace your tires.. Another method for checking tread depth is

to place a penny in the tread with Lincoln’s head upside down and facing you. If

you can see the top of Lincoln’s head, you are ready for new tires

6.4.8 Tire balance and wheel alignment

To avoid vibration or shaking of the vehicle when a tire rotates, the tire must be

properly balanced. This balance is achieved by positioning weights on the wheel

to counterbalance heavy spots on the wheel-and-tire assembly. A wheel alignment

adjusts the angles of the wheels so that they are positioned correctly relative

to the vehicle’s frame,. This adjustment maximizes the life of your tires. These

adjustroents require special equipment and should be performed by a qualified

technician,

6.4.9 Tire repair

The proper repair ofb, punctured tire requires a plug for the hole and a patch for

the area inside the tire that surrounds the puncture hole, Punctures through the

tread can be repaired if they are not too large, but punctures to the sidewall should

not be repaired. Tires must be removed from the rim to be properly inspected

before being plugged and patched,

6.4.t0 Tire Fundamentals

Federal law requires tire manufacturers to place standardized information on the

sidewall of all tires This information identifies and describes the frmdamental

characteristics of the lire and also provides a tire identification miniber for safety

standard certification and in case of a геенН

6.4.10.1 Information on Passenger Vehicle Tires

Please refer to the diagram on the next page.

30

Page 31

Raiio of iicighs U> \

H'idlli (aspect ratio)

Nomina! widtli of

¡ire in njidimctcre

Passenger

car lire

Rim tliamcfcr

code

symboJ

IJ,S, DOT tire

itlcniificiiiiim tuimbci

Sever snow

conditions

Mas ^

pcrmissflblc

ihllattun

pressure

Treadwtar, traefnm

and lenipcralurc grades

Max. inad rating

Tire ply

composition

and ma (cria ts

used

P; The “P” indicates the lire is for passenger vehicles.

Next number; This three-digit number gives the width in mtlUmeters of the tire

fi'om sidewall edge to sidewall edge, In general, the larger the number, the wider

the tire..

Next number: This two-digit number, knowm as the aspect ratio, gives the tire’s

ratio of height to width Numbers of 70 or lower radicate a short sidewall for

improved steering response and better overali handling on dry pavement.

R: The “R” stands for radial, Radial ply construction of tires has been the industry

standard for the past 20 years.

Next number: This two-digit number is the wheel or rim diameter in inches If

you change your wheel size, you will have to purchase new tires to match the new

wheel diameter.

Next number: This two- or three-digit number is the the’s load index. It is

a measurement of hoxv much weight each tire can support You may find this

ittfonriation in your owner’s manual If not, contact a local tire dealer: Note: You

mas? not find this infonnation on all liies because it is not required by law,

M+S: The “M+S” or “M/S” indicates that the lire has some mud and snow

capability Most radial tires have these markings; hence, they have some mud and

snow capability

Speed Rating: The speed rating denotes the speed at which a tire is designed to be

driven for extended periods of time. The ratings range from 99 miles per hour

fmph) to 186 mph Note: You may not find this information on all tires because it is

not required by law.

* For tires with a maximum speed capability over 149 mph, lire manufacturers

sometimes use the letters ZR. For those with a maximum speed capability over 186

mph, tire manufacturers always use the letters ZR,

U.S. DOT Tire Identification Number

This begins with the letters “DOT” and indicates that the tire meets all

31

Page 32

federal standards, The next hvo numbers or letters are the plant code where it was

manufactured, and the last four numbers represent the week and year the tire was

built. For example, the numbers 3197 means the 31 st week of 1997- The other

numbers are marketing codes used at the manufacturer’s discretion. This

information is used to contact consumers ifa tire defect requires a recall

Tire Ply Composition and Materials Used

The number of plies indicates the number of layers of rubber-coated fabric in the

tire. In general, the greater the number of pHes, the more weiglit a tire can support

Tire manufacturers also must indicate the materials in the tire, which include steel,

nylon, polyester, and others,

MaxiiiHun Load Rating; This number indicates the maximum load in kilograms

and pounds that can be carried by the tire,

Maxinxusn Permissible Inflation Pressure: This number is the greatest amount

of air pressure iliat should ever be pul in the tire under nonnal driving conditions

6.4J0.2 UTQGS Information

Tread-wear Number: This number indicates the tire’s wear rate. The highet' the

tread-wear number is, the longer it should take for the tread to wear down. For

example, a tire graded 400 should last twice as long as a tire graded ,200

Traction Letter: This fetter indicates a tire’s ability to stop on wet pavement, A

higher graded tire should allow you to stop your car on wet roads in a shorter

distance than a tire with a lower grade Traction is graded from highest to lowest as

“AA’V’A”, “B”, and “C”

Temperature Letter: This tetter indicates a tire’s resistance to heat The

temperature grade is for a tire that is inflated properly and not over loaded

Excessive speed, under inflation or excessive loading, either separately or in

combination, can cause heat build-up and possible tire failure. From highest to

lowest, a tire’s resistance to heat is graded as “A”, “B”, or “C”.

6,4.10.3. Additional Information on Light Truck Tires

Please refer to the following diagram:

Load

l ight truck lire

Maxifflifm load

& hiüalîon when

used a.s a single

32

Load inltiition

limits

Mtiximura iond

iniiaiion when

iiscif iw a dual

Severe .snow

conditions

Page 33

Tires for light tracks have other markings besides tlsose found on the sidewails of

passenger tires

LT; The‘T Г” indicates the tire is For light trucks ш trailers

ST: An “ST" is an indication the lire is for traiicr use only.

Max. Load Dual kg (lb) at kPa (psi) Cold: This inlbi raaiion indicates the

maximum load and tire pressure when the tire is used as a dual, that is, when four

tires are pul on each rear axle (a total of six or more tires on the vehicle)

Max. Load Single kg (Ib) at kPa (psi) Cold: This information indicates the

maximum load and tire pressure when the tire is used as a single

Load Range; This isiromiation identifies the tise’s load-canyiitg capabilities and

its inflation limits.

6.4.11 Tire Safety Tips

6 4.1LI Pteventitig Tire Damage

■ Slow down if you have to go ovei a pothole or other object in the road.

• Do not run over curbs or otiier foreign objects in the roadway, and try not to

strike the curb when parking

6.4Л1..2 Tire Safety Cliecktist

• Check tire pressure regularly (at least once a montli), including the spate.

■ Inspect tires for uneven wear patterns on the tread, cradcs, foreign objects, or

other signs of wear or trauma.

■ Remove bits of gloss and foreign objects wedged in the Head

• Make sure your lite valves have valve caps

• Check tile pressure before going on a long trip

• Do not overload your vehicle

6.5 Changing a Flat Tire

6-5Л If possible, get the Trailer on level ground

6,5.2 Keep the Trailer coupled to the Tow Vehicle and engage the Tow Vehicle’s

emergency brake

lit <!J

A

Tlcver attempt to change the tire while trailer is in folded

position Trailer can tip over.

Failure to heed tiiis warning could result in property damage, seri

ous injury and death

WARNING

A

33

Page 34

6.5,3 Chock the Wheel you aie not changing with bricks or wooden blocks

-

35

A WARNING A

Do not use the Assist Wheel to support the Trailer while

changing your tires Frailer could lip over causing serious injury

or death.

-------------

6.5.4 Place a Tire Jack under the part of the axel near the flat tire

6-5.5 Jack up the axle to lift the wheel a few inches off'the ground

...

----------

SSSPS!””

:

..

■-T-M

I Place a Tire Jack here

-y Ir

6.5,6 Remove the Lug Nuts and Wheel

6.5.7 Place Spare Tire on the axie and lighlen Lug Nuts between 95 - 120 ft /lb

Do not exceed 1.20 ft /lb

6.5.8 'Tighten Lug Nuts in the following sequence:

34

Page 35

633 L ower Tire Jack and remove from under Trailer

A

Never craw! under a trailer on jacks The trailer could slip off

the jack oi' the jack could fail resulting in serious injury' or death

A WARNING

Lug nuts are prone to loosen after initia! insiallalion, which can

ietHl to death or serious injury

Check lug nuts for lightness on a new trailer or when wheel(s)

have been remounted after the first 10. 25 and 50 miles oГdfi^■ing and after any impact.

Lug nuts for the tires must be tightened by the user befor e each

use, Sears cannot be held responsible for damages caused by

loosened lug nuts

6*6 Checking the Tire Piessure

Always check the lire pressure befbie each lotv Use a pressure gauge to ensure

proper tire pressure. The tires provided with your Trailer should be filled to 80 psi

Tire pressure must be checked when the tire is cold !f the ttailer has been towed

for at least one mile, allow at least three hours after a tow for the lire to cool before

checking the pressure

A

To help ensui'e long tread life and your safety. Always check

tire pressure to ensure optimum life and perfoiniance from your

tires The tires that came with your trailer should have a tire

pressure of 80 psi. Scars cannot be held responsible for dam

ages caused by uneven tread w'ear and blmv outs from an under

inflated or over-inflated tire ”

' ' .. . , .

................

WARNING

A

A

WARNING A

' “ "" “ *■* "

........................

—

35

Page 36

SECTION?: 30ADÎ\irrs3F.

TRAILER

LOADING THE CARGO

improper trailer loading causes many accidents and deaths To safely load a trailer,

you must consider:

■ Overall load weight;

• Load weight distr ibution;

• Proper tongue weight; and

• Securing the load properly

To determine that you have loaded the trailer within ils rating, you must consider

the distribution of weight, as well as the total weiglit of tiie trailer and its contents

The trailer axles carry most of the total weight of'tlie trailer' and its contents (Gross

Vehicle Weight, or “GVW”). The remainder oflhe total weight is carried by the tow

vehicle hitcii, For safe towing, it is essentia! that the trailer tongue and tow vehicle

hitch carry the propes amouiu of the loaded trailer weight, otheiwtse the trailer can

suddenly sway wildly at towing speed Read the ‘'Tongue Weight” section below

The load distribution must be such that no componetn pait of the trailer is loaded

beyond its rating. This means that you must consider the rating of the tires, wheels

and axles. For tandem and triple axle trailers, you must make sure that the front-torear load distribution does not result in overloading any axle

Towing stability also depends on keeping the center of gravity as low as possible.

Load heavy items on the floor and over the axles. When loading additional items, be

sure to maintain even side-to-side weight dish ibulion and proper tongue weight The

total weight of the trailer and its contents must never exceed the total weight rating of

the trailer (Gross Vehicle Weight Rating, or “GVWR,”) ”

A WARNING A

An Gverbaded trailer can result in loss of control of the Iraiter,

leading to death or serious injurj'

Do not load a trailer so that the weight on any tire exceeds its

rating

Do not exceed the trailer Gross Vehicle Weight Rating (GVWR)

or an axle Gross Axle Weight Rating (GAWR).

Tongue Weight

It is critical to have a portion of the trailer load carried by the tow vehicle. That is,

the trailer tongue must exert a downward force on the hitch. This is necessary for W'o

reasons First, the proper amount of tongue weight is necessary for the row vehicle

to be able to maintain control of the tow vehicle/trailer system If, for example, the

36

Page 37

tongue exerts an upward pull on the hitch, instead of pushing down on it (because

the trailer is overloaded behind its axle(s)), the rear wheel of the tow vehicle can

lose traction or grip and cause loss of control. Also, even if there is some weight on

the tongue, but not enough weight on the tongue, the trailer can suddenly become

unstable at high speeds.

If, on the other hand, there is too much tongue weight, the front tvheels of the tow

vehicle can be too lightly loaded and cause loss of steering control and ttactioti, as

well, if the front wdieels are driving

In addition to tow vehicle control, tongue weight is necessary to insure that the trailer

axle(s) do not exceed their Gross Axle Weight Rating (GAWR),

The table below has ‘huks of thumb” for proper tongue weight

Irr the table below, the second column notes the rule of Thumb percentage of total

weight of the trailer plus its cargo (Gross Vehicle Weight, or “GVW") that should

appear on the tongue of the trailer For example, a trailer with a bail hitch and a

loaded weight of 1.000 pounds, should have lO-l .5% of 1,000 pounds on tire tongue

That is, the example trailer would have no more than 100 to 150 pounds on its tongue.

37

Page 38

7J. CHECKING THE TONGUE WEIGHT

Fo check the longue weight, the tow vehicle and nailer must be on level ground, as

they will be when the trailer is being towed

If you know the weight on your tow vehicle axles when you are nor towing a tiailer,

trailer tongue weight can be determined with the use of a truck axle scale.

The recommended method of checking tongue weight is to use an accessory called a

“longue weight scale ” If a tongue weight scale is not available, you cart check the

tongue weight using a bathroom scale

Using a bathroom scale to check longue weight: The loaded trailer must be on a

smooth and level surface, and you must block the trailer wheels, front and rear

7.1.1 Checking Tongue Weight— Using a lever and bathroom scale

Cl O O C5

A WARNING

An unrestrained trailer can fall off its support, resulting in seri

ous injuiyf 01“death,

A

i

Before checking tongue rveight, block trailer wheels, front and rear

• Raise the tongue of the trailer with the tongue jack

■ Place a bathroom scale on the ground, directly below the couplet,

• Place a strong block support (such as a cement block) on the scale -- note the

scale reading for the weight of the block support,

• Lovvei the tongue until the coupler rests on the block support and the jack is ‘/2

inch above the ground

• The scale reading, minus the weight of the block support is the tongue weight

7,2 Securing the Cargo

Since the trailer ‘Tide” can be bumpy and rough, you must secure your cargo so that

it does not shift while the trailer is being towed.

A

Shitting cargo can result in loss of control of the trailer, and can

lead to death oj serious injury'

Tie down all loads with proper sized fasteners, ropes, straps, etc.

WARNING

A

Loading Cargo

7,2.1

Couple the trailer to the low vehicle before loading This is essentia! because the

longue can rise during loading, befóte the cargo is properly distributed To

measure the tongue weight, you will have to uncouple the trailer after it is loaded

Do not transport people in the trailer Do not transport comainers of hazardous

substances, cans or containers of flammable substances, such as gasoline.

38

Page 39

kerosene, paint, etc However, f^ud in the tank of an ofF-road vehicle, or a car or

motorcycle, etc, may be carried on your open trailer.

A

Do not transport t1a,mmab[e, explosive, poisonous or other

dangerous materials in your trailer Failure to heed this warning

could resuH in property damage, serious injury and death

Exceptions:

• Fuel in the tanks of Vehicles that are being towed

• Fuel stored in proper containers used in trailer living quar

ters for cooking

• Fuel stored in the lank ofan on-board generator

7.2.i.! Pi eparing the Trailer for Loading

Before loading cargo onto the trailer:

* inspect the deck of the trailer for corrosion or damage; and

* inspect the hold down openings and/or ‘'ff’-tings. Hold down openings must

be sturdy wdth no visible cracks or kinks D-rtngs must be light to the deck and

must not be bent

If the deck or any required hold-down is damaged, do not load the cargo Bring

the trailer to your dealer or a competent repair service before using it to cariy^

cargo

A

Damaged or loose "D’'-rings can break, allowing cargo to become

loose inside the trailer Loose cargo can shift the center of gravity,

and result in loss of control of the trailer

Inspect “D^’-rings, and lest them for looseness before loading

cargo

Do not use a damaged or loose ‘•D"-ring to secure cargo.

Failure to head this warning could result in }3roperty damage,

serious injury' and death.

WARNING

WARNING

_________________________________

A

A

7-2.1.2 Loading flic Trailer'

Before loading the trailer, couple the trailer to the low vehicle and ensure the

deck is level. Do not load or unload the traiiei' when the deck is not level or

when the Trailer is not coupled to the tow vehicle

1 Ensure the lop of the ramp (or ramps) is secure to tire trailer, and the bottom

is resting on firm ground Pockets may be provided to hold the ramp to the

frame of the trailer

2. Load the cargo onto the trailer,

3 Secure ihe Cargo to the trailer using approptiale straps, drains am! tensioning

devices

39

Page 40

Since the tiailer “ride’" can be bumpy and rough, you rausi secure your cargo so

that it does not sltifl while the trailer is being towed

A

Load can suddenly move or Urpple, which can result in death or

serious injury

Do not load or unload your open trailer unless it is prevented

from tipping and is on firm and level ground

4 Return the ramp(s) to tlteir stowed posiiion{s), and secure them so lliat they will

not move during transit

A

Shifting cargo can result in loss of control of the trailer, and can

¡lead to death ot serious injury

Fie down all loads with proper sized fasteners, ropes, straps, etc

A

Before loading Trailer. Trailer must be properly connecied to the

Tow Vehicle This stabilizes the Trailer Faihire to follow this

warning could result in property damage, personal injury and

death.

A

Do NOT use the Gates for tie-down locations All articles being

towed must be tied to the side walls of the frailer. Gates can

dislodge causing property damage and possible injury or death So

other' motorists and pedestrians

..

“Д'Ду-'ГяГТТ’гГ

WARNING

WARNING

.....

,■ -

WARNING A

WARNING A

-----------------------------------

A

A

-

Ж

Do not transport рео|з1е in the trailer Failure to heed t Its war

ing could

damage, p

40

result in serious injury such as broken bones,

analysis or death

WARNING

A.

brain i

1

Page 41

ECTION 8: CHECK TRAILER

BEFORE & DURING TOWING

PRE-TOW CHECKLIST

8-1 Before Towing, Double Ciieck Ali These Items:

■ Tires, wheels and lug nuts (see the section “Breaking in New Ttailer“ and the

section “Tire & Safety Information“

• Couples secured asid locked (see Ihc section “Coupling to the Tow Vehicle’")

• Safety chains properly rigged to tow vehicle, not to hitch or ball (see the section

“Coupling to the Tow Vehicle” of this manual)

• Test of lights: Tail, Stop, Turn and Backup

• Cargo properly loaded, balanced and tied down (see the section “Loading the

Trailer” of this manual)

• Tongue weight

• Doors and gates latched and secured

• Flares and reflectors

A WARNING A

Art improperly coupled trailer can result in death or serious

injuiy

Do not move the trailer until:

* The coupler is secured and locked to hitch;

* The safety drains are secured to the tow veliide; and

* Assist Wheel is fully retracted

* You secure Tongue to Bed using Locking Pin and Cotter Key.

Do not tow the trailer on the road until:

* Tires and wheels are cliecked;

* The load is secured to the trailer; and

* The trailer lights are connected and checked.

' ■ ........

MAKE REGULAR STOPS

8.2 Arter Each 5(! Miles, or One Hour of Towing, Stop and Clieck the Following

Items:

• Coupler secured

• Safety chains are fastened and not dragging

• Cargo secured

• Cargo door latched and secured

41

Page 42

A WARNING

Since roads can be bumpy and rough, lug nuts can loosen over

time and even separate from ihe wheel and possibly causing the

separation of the wheel from the trailer The lug nuts must be

tightened by the user before each use.

The tires must be maintained at the proper tire pressure before

each use Sears cannot be held responsible fot damages caused

by loosened iugnuts, or uneven tread wear and blow outs from

an under inflated orovci inflated tire

Fatlute to heed these warning.s could result in persona! injiny’,

property damage and death

A

A WARNING

Do NOT use the Gates for tie-down locations All artides being

towed must be tied to the side walls of the Trailer Gates can

dislodge causing property damage and possible injury or death to

other motoi ists and pedestr ians

Follow posted speed limits but do not exceed 65 mph

A

fiJo not transpoit people^^i Failure to heed this warn

ing could result ii? serious injury such as brokesr borres, brain

damage, paralysis or death

WARNING

......... .................

A

A

, “W:

42

Page 43

sKi-'nii":, •); liRi-: j'--.

NEW TRAILER

LUG MUTS & TIRE PRESSURE

9.1 Retigbtening Lug Nuts at First 10, 25 & 50 Miles

Wheel lugs can shift and settle quickly after being fiist assembled, and must be

checked after the first 10, 25 and 50 miles of driving and after any impact Failute

to perform this check may result in a wheel coming loose from the trailer, causing a

Clash leading to death oi serious injury.

A

Lug nuts are prone to loosen after initial installation, which can

lead to death or seriou.s injury,

Check lug nuts for tiglitncss on a new trailer or when wheel(s)

have been remounted after die first 10, 25 and 50 miles of driv

ing and after any impact.

A

The kig nuts for the tires must be lightened by the user before

each use The tires must be maintained at the proper tire pressure

before each use. Sears cannot be held tesponsible for damages

caused by loosened lugnuts, or uneven tread wear and blow outs

from an under-inflated or over-inflated tire

Failure to heed this warning could result in property damage,

serious injury and death.

WARNING

.

.............

WARNING

.

A

A

A WARNING A

If low vehicle brakes do not work properly, dcatli or serious

injury can occur.

Road test your tow vehicle’s brakes in a safe area at no more

than 30 mph before each tow.

9.2 Tire Pressure

Check the pressure in each tiie to ensure die is set to the tri e manufacture! s

recommended pressure The tires that came with your trailer should be filled to

SO psi. Use a tire gauge to get an accurate reading. You should clieck the pressure

before each tow

.

43

Page 44

SECTION 10: MAINTENANCE!

INSPECTION, SERVICE & MAINTENANCE

10,1 Inspection, Service & Maintenance Summary Charts

You must inspect, maintain and service youi trader regularly to insure safe and

reliable operation., If you cannot or are unsure how to perform the items listed here,

have your dealer perform them

Note: In addition to this manual, also check the relevant component

manufacturer’s manual.

inspection and Service before Each Use

Item Iiispcetiim/SeEvicc Manual Setlfort Reference

Coupler and Hitch Ball

Safety Ciumi(s) & Hooks

Tires

' Air Pressure

Wheels

* t. ugWuts fBolK) & tilth

Check for cracks, piis, anil

flttU Itcpiacc w/hal! & coupler

having rrailcf GVW Rating

Grease

Check locking device & replace

Check for wear and damage

Check lire pressure when cold

Inilnte lires ui 3(! [ssi

Check for riglitness

Tighten to 95 - 120 iVlh Do

not exceed 120 ft /!b For new

and fcrnountcd wheels, check

torque after firsl 10. 25 & 50

mites of driving and aflcr any

impact

Section 102 3 1

Sections 8.1 & 8.2 i

Sections 6 6, 92 & 102 6

SociiM6 5 7&9 1

Sections 10 2 8, 1028 1 & 10 29 1

Inspection and Service each 3 Months or 3,000 Miles .................................................

Ilc:m InspcciJOH/Scrvjcc |V‘]«iiiU!il Itcfcrcii-Cc

Stmeture

■ Hinges, Doors

Wheels

• Rims

Tires iMpeet for cuts wear ami

Inspect Repair or replace

damaged, worn or broken parts

inspect for dents. (lamagB or out

of round

bulging

Oasie lire maintcnaiicc

Section 102 2 !

10.2 7

Sections 6 4, 6 4 1,6.4 2,64 3,

6 4 4,64 5,6.4 6,64,7,64 8,

6.4,9, 5,4,10, 6.4.n, 6.5 & 10.2.6

Inspection and Service each 6 Months or 6,000 Miles /

lleti! Inspccifon/Scrvtce Manual Section Reference

Tires

Wheels

• UNSEALED Bcittings (Mute)

44

Rotate @ 5,000 mile,<i Section 10.2,6

Ciieek and etmiirm free running

Replace if not

Disassemble / inspect / as

semble and repack Replace

promptly ifirttmersed in xvater

Section 10 2 7 & 10 2 8

Section 10 2 8 1

Page 45

Inspection and Service each 6 Months or 6,000 Miles

Snspension

Inspection and Service Each Year or 12,000 Miles

Item

Slruciure

• Frame members

• Wdds

• Slit!c-t)in

Structure

• Axle Attaclimenl Bolls

10.2 Inspection and Service Instructions

H).2J Axle Bolls, Frame, Suspension, & Structure

Inspect for bending loose faS“

tetters, wear

InspcciiBti/Service Mtmua! Sttlion RcfercncE

htspeci all fratsm members, bolls

& rit'eis Repair or replace ditmaged, wum or broken pans

itispeei alt weWs Repair as

needed

Clean dirt build-tip I ubricaie

slides, shafts ami iiears

CliCflk WITH DEALER

Section 10 2 it!

Section 10 2 2

SettiDW 10 2 2 1

Section (0 2 22

Section 10 2 !

A

Worn or broken suspension pans can cause loss of comrol and

property damage, serious injuty and death may result. Have

trader professionally inspected annually and after any impact

iTo perform many of the inspection and maintenance activities, you must jack up the

I trailer.

When jacking and using jack stands, place them so as to clear wiring and suspension

parts (springs, torsion bars, etc.) Place jacks and Jack stands itisids of die perimeter

strip on the supporting structure to which the axles are attached.

WARNING

WARNING

Never crawl iinderyourtrailer unless it is on firm and level ground

and resting on properly placed and secured jack stands

Never attempt to change the tire while trailer is in folded

position Trailer can tip over

Failure to heed these warnings could result in property damage,

serious injury and death.

A

Do not use the Assist Wheel to support the Trailer while

changing your tires, Frailer could tip over causing serious injury

or death. .

■ . . _

........

■ ■ . ' '

WARNING

A

A

45

Page 46

lft,.2,2 Trailer Structure

Because the tmiler lloor receives the most abuse, it wH! most likely corrode before

any otlter part of the strucwre Using a power washer, wash the floor and tvalls of

the trailer after each use

10,2.2.1 Fasteners and Frame Members

Inspect a!! of the fasteners and stmctural frame members for bending and other

damage, cracks, or failure Repair or replace any damaged fastener and repair the

frame inember Ifyou have atiy questions about the condition or method of repair

of fasteners or frame members, get the recommendation of, or have the repair done

by your dealer

The various fastener types used on your trailer are:

• Bolts, which are used mainly for attaching door and gate hinges to the trailer'

body;

• Buck Rivets, which are used to attach the sides and roof panels of the body to

each other, and to the frame of the trailer; and

• Huck Bolls may be at various locations on the sub-frame Huck bolts are not

user serviceable. Ifyou detect a loose huck bolt fastener, do not tow the trailer.

Call your dealer for insttnetions

A WARNING

Broken or damaged fasteners or welds cats cause serious injury,

damage to trailer and contents and death Inspect for, and repair

all damaged parts at least once a year-

A

10.2.2.2 Welds

All welds can crack or fail when subjected to heavy loads or movement of cargo

that w'as not properly tied to prevent movement Any time you know' or suspect

the trailer has been subjected to heavy loads or movement of cargo, immediately

inspect tite welds and fasteners for damage To prevent severe damage to your

46

Page 47

trailer, inspect all of the welds for cracks or failure at least once a year

A WARNING

Improper weld repair will lead to early failure of the trailer struc