Craftsman 119224000 Owner’s Manual

Owner's Manual

12-ino BANDSAW

3/4 HP MOTOR

Model 119.224000

CAUTION: Before using this

product, read this manual and

follow a!l its Safety Rules

and Operating instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

www.craftsman,com

OM-22400-MI

o Table of Contents

® Full One Year Warranty

® Safety instructions

®Assembly

® Getting to Know Your Bandsaw

®Adjustment

® Operation

o Maintenance

® Electricam Schematic

® Troubleshooting

o Parts List "

Table of contents ................................................................................................................................................................................................. 2

Futlone year warranty. ............................................................................................................................................................................................. 2

Safety instructions .................................................................................................................................................................................................... 2

Assembly .................................................................................................................................................................................................................... 4

Getting to knowyour bandsaw ...................................................................................................................................................................................... 7

Adjustment ................................................................................................................................................................................................................... 7

Operation ................................................................................................................................................................................................................... 11

Maintenance .............................................................................................................................................................................................................. 11

Electrical schematic ................................................................................................................................................................................................ 11

Troubleshooting ...................................................................................................................................................................................................... 12

Parts list............................................................................................................................................................................................................. ! 3

If this Craftsman tool fails due to a defect in material or workmanship within one

year from the date of purchase, CALL 1-800-4-MY-HOME® TO ARRANGE FOR

FREE REPAIR.

If this tool is used for commercial or rentaI purposes, this warranty will apply for

only ninety days from the date of purchase.

This warranty applies only whiIe this tool is in the United States.

This warranty gives you specific legal rights, and you may also have other rights,

which vary, from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffmarl Estates, IL 60179

GENERAL SAFETY WARNINGS

KNOW YOUR POWER TOOL. Read the owner's manual carefuIly. Learn the tool's applications, work capabilities, and its specific

potential hazards.

Always Ground All "fools.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacIe. If you use

an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a known ground. Never

remove the third prong of the plug.

Always Avoid Dangerous Environments.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

Always Remove the Adjusting Keys and Wrenches from Tools after Use,

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning it on,

Always Keep Your Work Area Clean. Cluttered areas and benches invite accidents.

_ Always Keep Visitors Away from Running Machines,

All visitors should be kept a safe distance from the work area,

Always make the Workshop Childproof,

Childproof with padlocks, master switches, or by removingstarter keys,

Never operate a tool while under the influence of drugs, medication, or alcohol.

2

Always Wear Proper Apparel.

Never wear loose c!othtr_g or jewelry that might get caught in moving parts, Rubber-soled footwear is

recommended for the best footing.

Always Use Safety Glasses and Wear Hearing Protection.

Also use a face or dust mask if the cutting operation is dusty.

Never Overreach.

Keep your proper footing and balance at all times.

Never Stand on Tools.

Serious injury could occur ifthe tool is tipped or ifthe cutting tool is accidentally contacted,

Always Disconnect Tools.

Disconnect tools before servicing and when changing accessoriessuch as blades, bits, and cutters.

Always Avoid Accidental Staring.

Make sure switchis in "OFF" positionbefore plugging in cord.

Never Leave Tools Running Unattended.

Always Check for Damaged Parts,

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to assure that

will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other

damaged parts should immediately be properly repaired or replaced,

SPECIAL SAFETY RULES FOR BANDSAWS

1. Always stop the Bandsaw before removing scrap pieces from table.

2. Always keep hands and fingers away from the blade.

3. Never attempt to saw stock that does not have a flat surface, unless a suitable support is used,

4. Always hold material firmly and feed it into the blade at a moderate speed.

5. Always turn off the machine if the material is to be backed out of an uncompleted cat.

6. Check for proper blade size and type for thickness and type of material being cut.

7. Make sure that the blade tension and blade tracking are properly adjusted,

8. Make "relief' cuts before cutting long curves.

9. Release blade tension when the saw will not be used for a long period of time.

10. Note and follow the safety warnings and instructions that appear on the lower door.

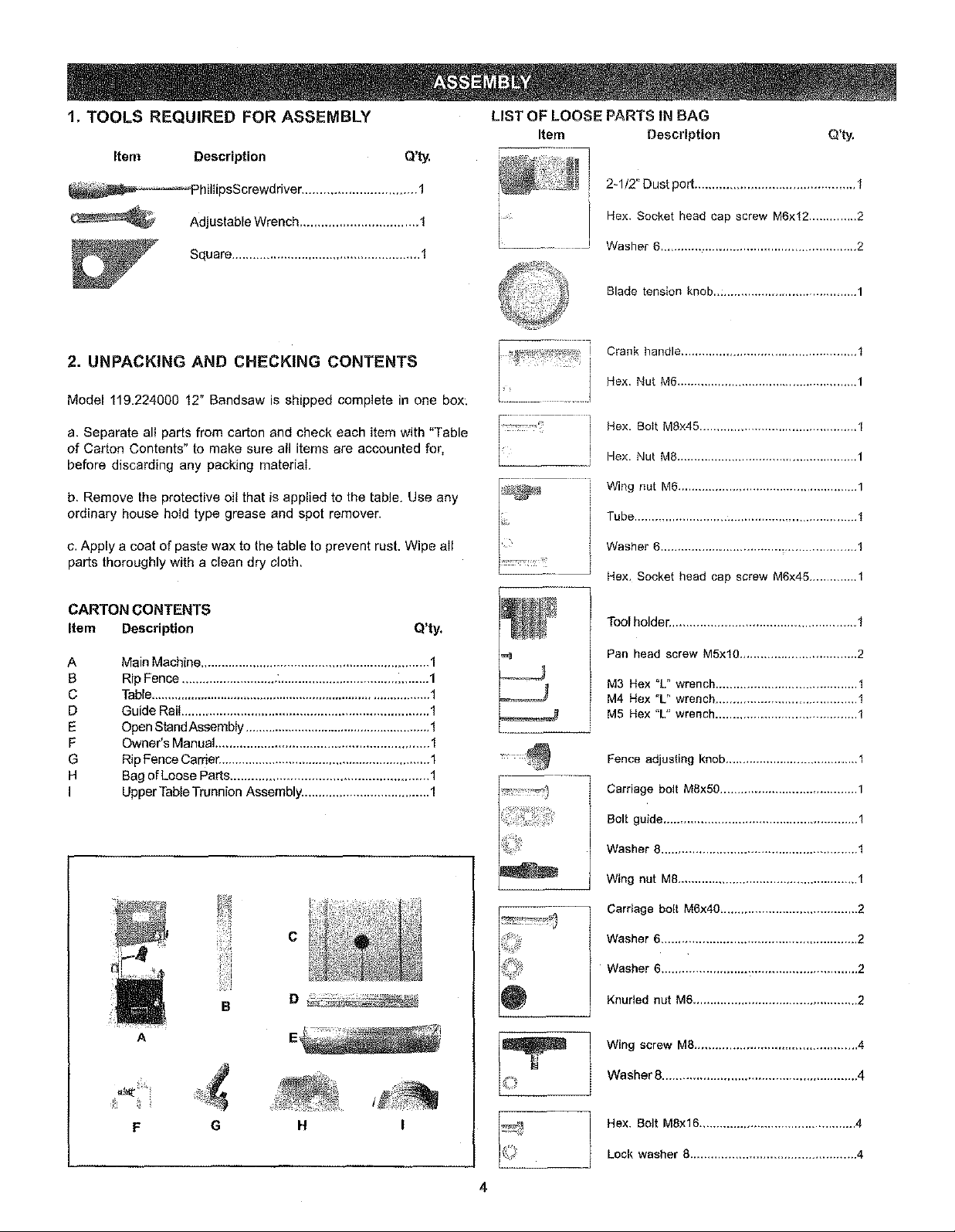

1. TOOLS REQUIRED FOR ASSEMBLY

Item Description Q'ty.

LIST OF LOOSE PARTS IN BAG

Item Description Q'ty.

_o--_hiUipsScrewdriver ............................... 1

Adjustable Wrench ................................. 1

Square...................................................... 1

2. UNPACKING AND CHECKING CONTENTS

Model 119.224000 12" Bandsaw is shipped complete in one box:

a. Separate all parts from carton and check each item with "Table

of Carton Contents" to make sure all items are accounted for,

before discarding any packing material.

b. Remove the protective oil that is applied to the table, Use any

ordinary house hold type grease and spot remover.

c. Apply a coat of paste wax to the table to prevent rust. Wipe all

parts thoroughly with a clean dry cloth,

CARTON CONTENTS

Item Description Q'ty.

A

B

C

D

E

F

G

H

I

Main Machine.................................................................. 1

RipFence ..............................................................i........1

Table....................................................................................1

Guide Rai!....................................................................... !

Open StandAssembly ........................................................1

Owner's Manual ............................................................. 1

RipFence Carder...............................................................1

Bag of Loose Parts ........................................................ 1

UpperTable Trunnion Assembly..................................... 1

2-1/2" Dust port .............................................. 1

Hex. Socket head cap screw M6x12 .............. 2

Washer 6......................................................... 2

Blade tension knob..: ....................................... 1

Crank handle .................................................. 1

Hex, Nut M6.....................................................

Hex. Bolt MBx45 ..............................................

Hex. Nut M8.....................................................

Wing nut M6....................................................1

i

I Washer 6.........................................................1

l,uho.................................................................1

!

J Hex, Socket head cap screw M6x45..............1

Toolholder...................................................... !

Pan head screw M5xlO .................................. 2

M3 Hex "L _ wrench ......................................... 1

M4 Hex "L" wrench ........................................ I

M5 Hex "L" wrench ......................................... !

Fence adjusting knob ....................................... 1

Carriage bolt M8x5O........................................ 1

Bolt guide ......................................................... 1

Washer 8......................................................... 1

Wing nut M8 ..................................................... 1

Carriage bolt M6x40 ........................................ 2

Washer 6......................................................... 2

Washer 6......................................................... 2

B

A

F

G

0

Knurled nut M6 ................................................ 2

Wing screw M8...............................................4

Washer8 .........................................................4

Hex, Bolt M8x16 .............................................. 4

Lock washer 8................................................ 4

4

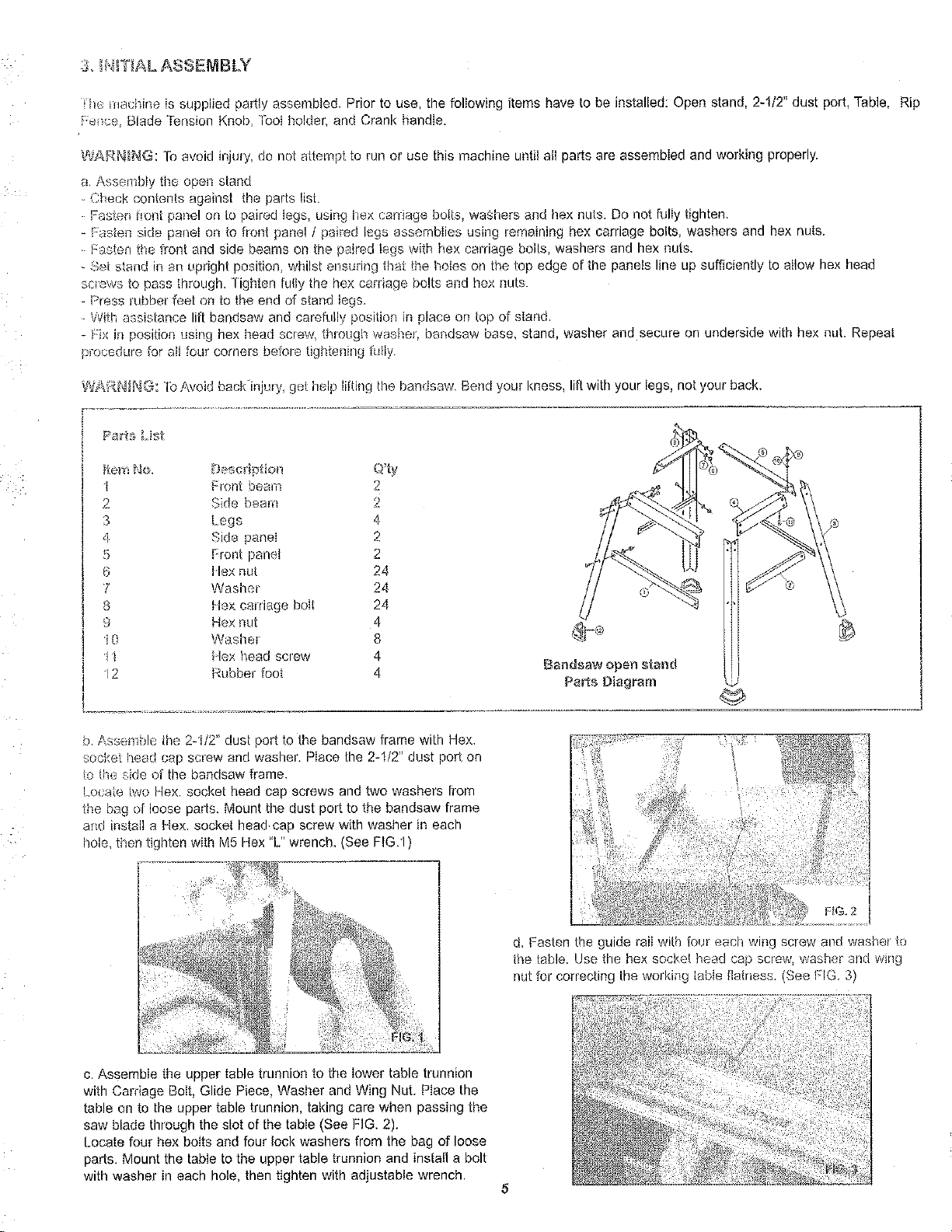

:_ !t4_T_AL ASSEMBLY

H_{::machine is supplied partly assembled. Prior to use, the following items have to be installed: Open stand, 2-1/2" dust port, Table, Rip

Fa_co, Blade Tension Knob, Foot I;older, and Crank handle.

W.#.RN_NG: To avoid injury, do not attempt to run or use this machine until all parts are assembled and working properly.

a, A;:;sernbly the opea stand

- CI,eck contents against the parts list.

- Fasten fient panel on to paired legs, using hax carriage bolts, washers and hex nuts. Do not fully tighten.

Fasten side panel on to front panel / paired legs assemblies using remaining hex carriage bolts, washers and hex nuts.

•- Fasten the front and side beams on the paked legs with hex carriage bolls, washers and hex nuts.

- Set stand in an upright position, whilst ensuring that the holes on the top edge of the panels line up sufficiently to al!ow hex head

screws to pass through, lighten fuity the hex carriage bolts and hex nuts.

Press lubber feet on to the end of stand legs.

With assistance lift bandsaw and carefully position in place on top of stand.

- :qx iu position using hex head screw, through washer, bandsaw base, stand, washer and secure on underside with hex nut. Repeat

procedure for all four corners before tightening flJily

%t&iXNING: tb/',void back'injuw, get help lifting the bandsaw Bend your kness, lift with your legs, not your back.

Pa_rts_ist

_te[_iNo. Descriptie_l Q'ty

I Front beam. 2

2 Side beam 2

3 Legs 4

4 Side panel 2

5 Front panel 2 "1'1

6 Ilex nut 24

7 Washer 24

8 H,excarriage bolt 24

9 Hex nut 4

i 0 Washer 8

/1 'lex head screw 4

12 Rubber foot 4 Bandsaw open stand

Parts Diagram

ji

@

b, Assemble the 2-1/2" dust port to the bandsaw frame with Hex,

socket head cap screw and washer. Place the 2-1/2" dust port on

to the side or the bandsaw frame.

Locate two Hex. socket head cap screws and two washers [rein

the bag of loose parts. Mount the dust port to the bandsaw frame

and install a Hex. socket head cap screw with washer in each

hole then tighten with M5 Hex "L" wrench. (See FIG,l)

c. Assemble the upper table trunnion to the lower table trunnion

with Carriage Bolt, Glide Piece, Washer and Wing Nut. Place the

table on to the upper table trunnion, taking care when passing the

saw blade through the slot of the table (See FIG. 2).

Locate four hex bolts and four lock washers from the bag of loose

pads. Mount the table to the upper table trunnion and install a bolt

with washer in each hole, then tighten with adjustable wrench.

d. Fasten the guide rail with four aach wing screw and washer to

the table. Use the hex socket head cap screw, weans'n"ana wtg

r_utfor correcting the working table tla/ness. (See FIG 3

Loading...

Loading...