Page 1

Owner’s Manual

CRRFTSMRN

10-in. BANDSAW

1/3 HP MOTOR

Model 119.214000

CAUTION: Before using this

product, read this manual and

follow all its Safety Rules

and Operating Instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

www.craftsman.com

• Table of Contents

• Full One Year Warranty

• Safety Instructions

• Assembly

• Getting to Know Your Bandsaw

• Adjustment

• Operation

• Maintenance

• Troubleshooting

• Electrical Schematic

• Parts List

• Espanol, p. 12

Page 2

TABLE OF CONTENTS

Table of contents................................................................................................................................................................................... 2

Full one year warranty............................................................................................................................................................................2

Safety instructions..................................................................................................................................................................................2

Assembly..................................................................................................................................................................................................4

Getting to know your bandsaw

Adjustment...............................................................................................................................................................................................6

Operation..................................................................................................................................................................................................8

Maintenance

T roubleshooting..................................................................................................................................................................................... 9

Electrical schematic................................................................................................................................................................................9

Parts list............................................................................................................................................................................................... 10

Español................................................................................................................................................................................................... 12

........................................................................................................................................................................................... 8

........................................................................................

«.r..................................................................5

FULL ONE YEAR WARRANTY

If this Craftsman tool fails due to a defect in material or workmanship within one year from the date of

■purchase, CALL 1-800-4-MY-HOME® TO ARRANGE FOR FREE REPAIR. ^

If this tool is used for commercial or rental purposes, this warranty will apply for only ninety days from the

date of purchase.

This warranty applies only while this tool is in the United States.

This warranty gives you specific legal rights, and you may also have other rights, which vary, from state to

state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

SAFETY INSTRUCTIONS

GENERAL SAFETY WARNINGS

KNOW YOUR POWER TOOL. Read the owner’s manual carefully. Learn the tool’s applications, work capabilities, and its specific

potential hazards.' .

ADANGER

ADANGER

m

ADANGER

Always Ground Ail Tools.

If your tool is equipped with a three-pronged plug, you must plug it into a three-hole electric receptacle. If you use

an adapter to accommodate a two-pronged receptacle, you must attach the adapter plug to a known ground. Never

remove the third prong of the plug.

Always Avoid Dangerous Environments.

Never use power tools in damp or wet locations. Keep your work area well lighted and clear of clutter.

Always Remove the Adjusting Keys and Wrenches from Tools after Use.

Form the habit of checking to see that keys and adjusting wrenches are removed from the tool before turning it on.

Always Keep Your Work Area Clean. Cluttered areas and benches invite accidents.

Always Keep Visitors Away from Running Machines.

All visitors should be kept a safe distance from the work area.

Always make the Workshop Childproof.

Childproof with padlocks, master switches, or by removing starter keys.

ADANGER

Never operate a tool while under the influence of drugs, medication, or alcohol.

Page 3

шашая

ADANGER

ADANGER

ADANGER

Always Wear Proper Apparel.

Never \wear loose clothing or je\welry that might get caught in moving parts. Rubber-soled footwear is

recommended for the best footing.

Always Use Safety Glasses and Wear Hearing Protection.

Aiso use a-face or dust mask if the cutting operation is dusty.

Never Overreach.

Keep your proper footing and balance at all times.

Never Stand on Tools.

Serious injury couid occur if the tooi is tipped or if the cutting tool is accidentally contacted.

ADANGER

Always Disconnect Tools.

Disconnect tools before servicing and when changing accessories such as blades, bits, and cutters.

*w Always Avoid Accidental Staring.

Make sure switch is in “OFP position before plugging in cord.

Never Leave Tools Running Unattended.

ADANGER

Always Check for Damaged Parts.

Before initial or continual use of the tool, a guard or other part that is damaged should be checked to assure that it

will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other

>5

damaged parts should immediately be properly repaired or replaced.

SPECIAL SAFETY RULES FOR BANDSAWS

1. Always stop the Bandsaw before removing scrap pieces from table.

2. Always keep hands and fingers away from the blade. .

3. Never attempt to saw stock that does not have a flat surface, unless a suitable support is used.

4. Always hold material firmly and feed it into the blade at a moderate speed.

5. Always turn off the machine if the material is to be backed out of an uncompleted cut.

6. Check for proper blade size and type for thickness and type of material being cut.

7. Make sure that the blade tension and blade tracking are properly adjusted.

8. Make “relief’ cuts before cutting long curves.

9. 'Release blade tension when the saw will not be used for a long period of time.

10. Note and follow the safety warnings and instructions that appear on the lower door.

FOR YOUR OWN SAFfTY

1 READ AND UNDF RSlAND INSTRUCTION MAN JAl

BEFORE OPERATING DANHSAW

Z Always WC .T' cyr-

3 Do r'ot wt :i- ;rt

iJolNing

4 Ctiur k LI.iOp 'TiT.'iII:>0 onci makp c:cr1din thri! bCi'l:'

lE?i'‘tft f.Oirit ,in A-t;w.itU tGV,Trrf

5 Maintrl I o p’r.ipr'r ,irf j Lislmi'nt ot h Irici t- f ■■ k □ ;in ri

tension, Jjiado nt'C Ljt'nnnrjs

6 Keep hнпa^ out o1 pido rjf hi.irio

‘ii=r >■ J f'Wi*l ry G! iorl^.

’ Si'L i;-vhi'-• y u ,1 г о c V г г bi'forf 'opérai if!t|

Ô Adjust bKidu Çjurird giudr to jubi cJCiir лпгк piece.

9 ЛГГВ fji.-'Li- f'! (Til V .■ig.i!r>s| table and ui'H miter gage

ЛГЧ1 trr’:‘..r I.vhl'f: p C3i О i < ■

'0 Qo riru г..гт’г-vr vi'’'iTidd or cut-otf л'^соа untji hl?clt'

■ 1 Di'-cornei.’ rr’iacTir.i' ft r>m DO■^^Gr source t.fefore making

T.'ii.ti's cif ■id|o'i\rrM:r;ib

^2 0 о *ii-t г» pnSo t о n or l;sc :M damp lnc4t I oris

Page 4

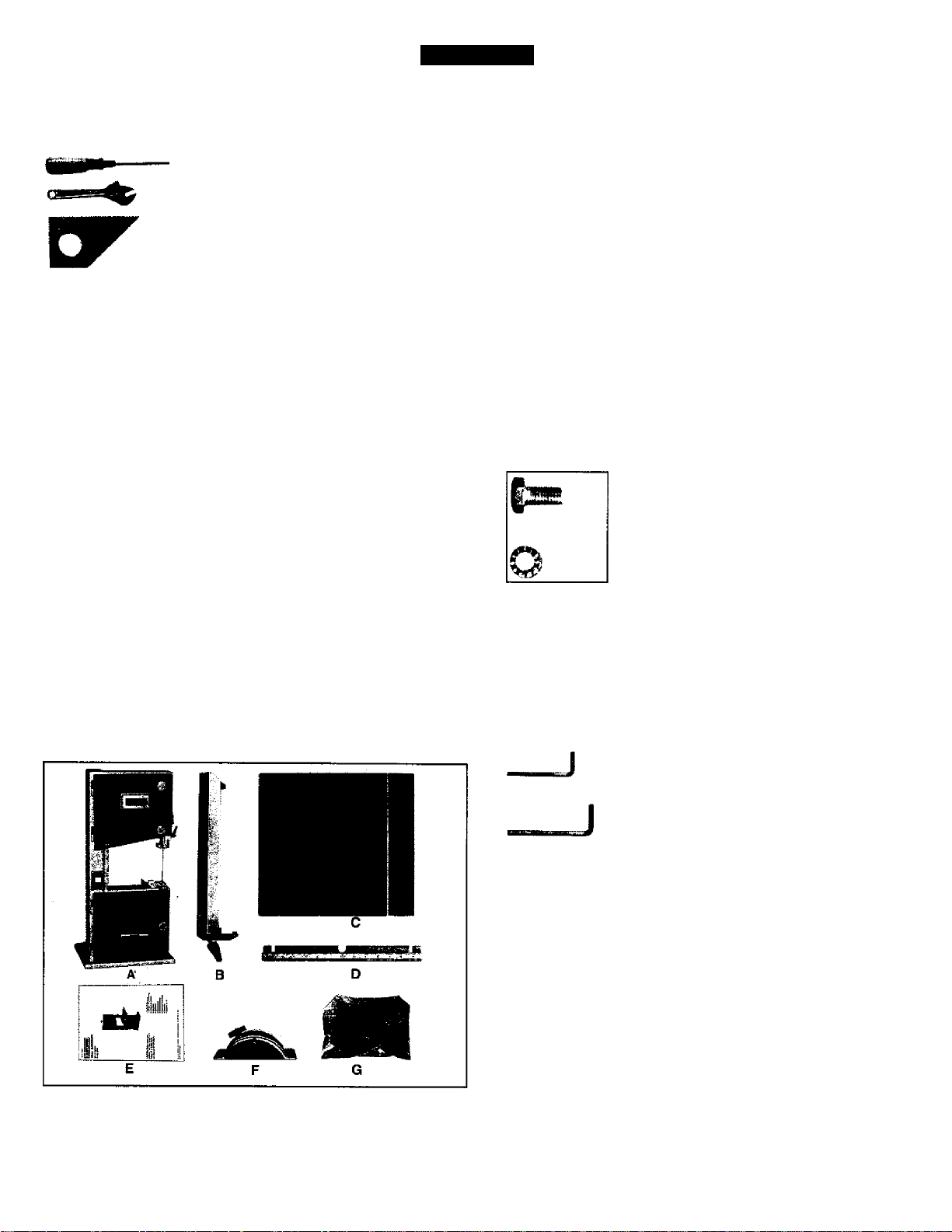

ASSEMBLY

1. TOOLS REQUIRED FOR ASSEMBLY

Item

2. UNPACKING AND CHECKING CONTENTS

Model 119.214000 10” Bandsaw is shipped complete in

one box.

a. Separate all parts from carton and check each item with “Table

of Carton Contents” to make sure all items are accounted for,

before discarding any packing material.

b. Remove the protective oil that is applied to the table. Use any

ordinary house hold type grease and spot remover.

c. Apply a coat of paste wax to the table to prevent rust. Wipe all

parts thoroughly with a clean dry cloth.

Description Q’ty.

’ Medium Screwdriver

Adjustable Wrench..........................1

Square

.............................................

.....................

1

1

LIST OF LOOSE PARTS IN BAG

Item Description

Blade Tension Knob.,

•*

Miter Gauge..

Hex. Socket Head Cap Screw M6x30.......1

O

Washer 6..

Wing Nut M6..

Hex. BoltM6x12..........................................4

Lock Washer 6...........................................4

Q’ty.

CARTON CONTENTS

Item Description Q’ty.

A Main Machine..........................................................1

B Fence Assembly.................................................... 1

C Table........................................................................1

D Guide Rail

E Owner’s Manual.....................................................1

F Upper Table Trunnion Assembly.

G Bag of Loose Parts

...............................................................

........................

...............................................

1

1

1

star Knob Screw..

w-

Washer 6.

o

M3 Hex “L” Wrench..

M5 Hex “L” Wrench..

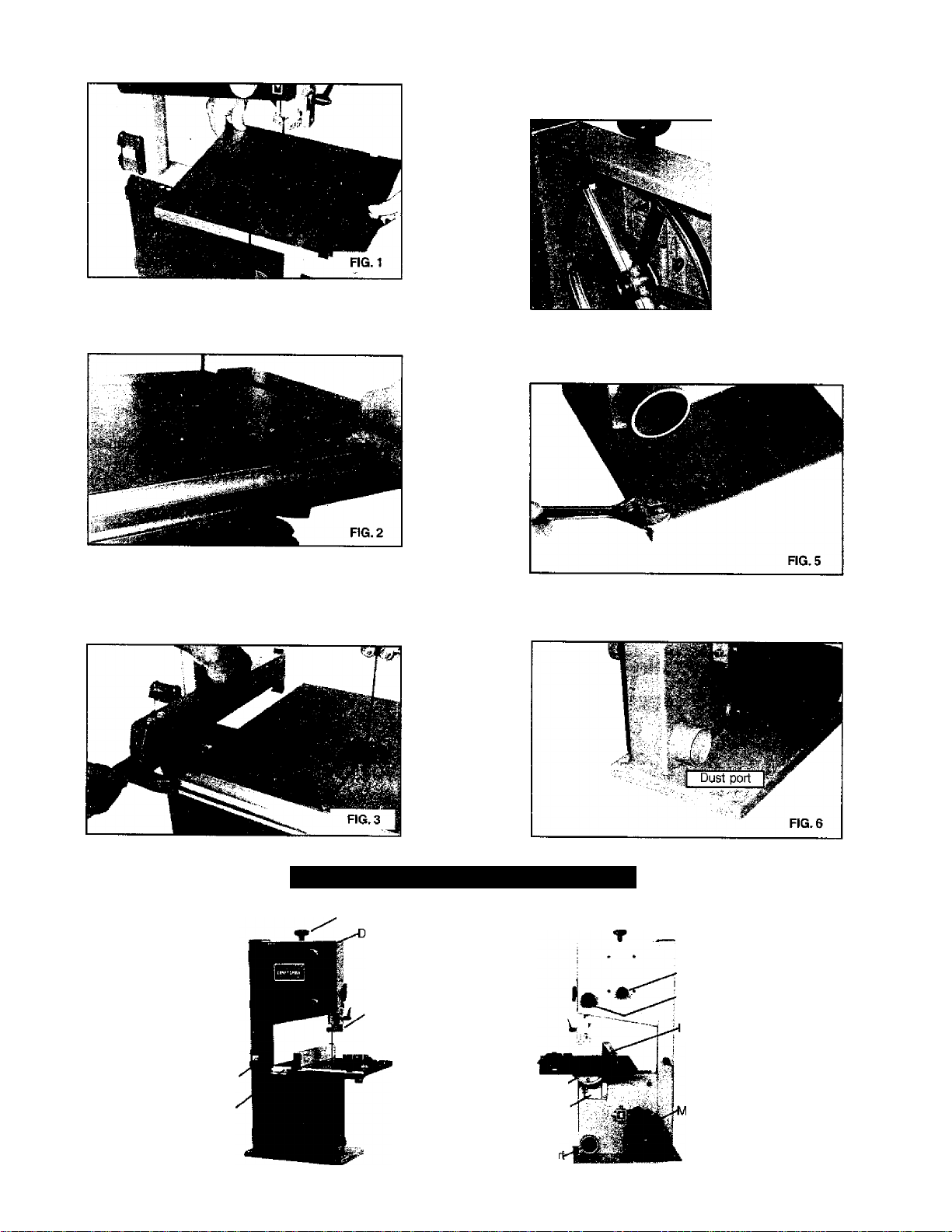

2. INITIAL ASSEMBLY

The machine is supplied partly assembled. Prior to use, the

following items have to be installed: Table, Blade Tension Knob

and Rip Fence.

WARNING: To Avoid injury, do not attempt to run or use this

machine until all parts are assembled and working properly.

a. Assemble the upper table trunnion to the lower table trunion with

Carriage Bolt, Glide Piece, Washer and Wing Nut. Place the table

on to the upper table trunnion, taking care when passing the saw

blade through the slot of the table (See Fig. 1).

Locate four hex bolts and four lock washers from the bag of loose

parts. Mount the table to the upper table trunnion and install a bolt

with washer in each hole, then tighten with adjustable wrench.

Page 5

d. Place the blade tension knob on to the blade tensioner {See

Fig. 4).

b. Fasten the guide rail with two each star knob screw and washer

to the table. Use the hex socket head cap screw, washer and wing

nut for correcting the working table flatness. (See Fig. 2)

c, Lay the rip fence onto the guide rail. Adjust the rip fence parallel

to the saw blade. Tighten rip fence handle by pressing downward.

(See Fig. 3)

FIG. 4

e. To ensure sufficient upright stability of the machine it should be

bolted to floor, bench or worktable. For this purpose 6mm holes

are provided in the machine’s base. (See Fig. 5)

f. The bandsaw has a 2-1/2" dust port included. (See Fig. 5)

It is recommended that when in use, the bandsaw is connected to

a suitable dust collector.

Lock switch

Guide rail

GETTING TO KNOW YOUR BANDSAW

Blade tension knob

oor iocking knob

Blade guide

/Miter gauge

Upper table turnnion-'

Lower table turnnion"

Dust poi

Blade tracking knob

■Guide post adjusting knob

-enee

otor

Page 6

ADJUSTMENT

1. CENTERING THE TABLE

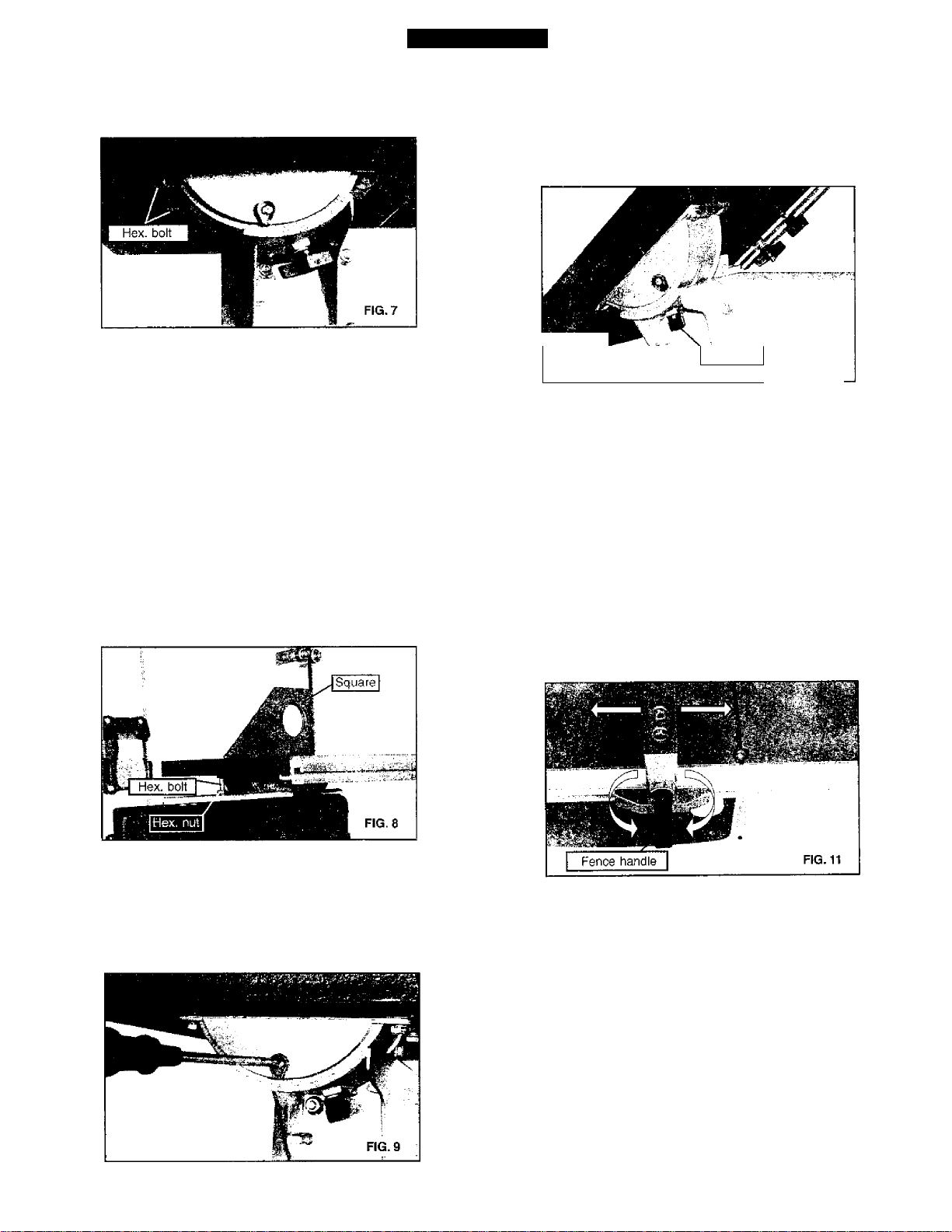

a. Loosen the four hex. bolts mounting the table to the upper table

trunnion. (See Fig. 7)

b. Move the table sideways as required, until the saw blade runs

through the center of the table insert.

c. if the adjustment of “b” is not enough to center the table, loosen

the four flange nuts holding the lower table trunnion and move the

table sideways to place the table in the center.

d. Re-tighten hex. bolts for trunnion, recheck the saw blade

position.

2. SETTING TABLE SQUARE TO SAW BLADE

Loosen the wing nut on the lower table trunnion and place a

suitably sized square against the saw blade. If the table requires

adjustment, proceed as follows:

a. Using a wrench, release the hex. nut on the frame. {See Fig.8)

b. Place the wrench on the hex. bolt and adjust until the table

square to the saw blade.(See Fig.8)

3. TILTING THE TABLE

For bevel cuts, the table tilts 0 through 45 degrees.

a. To tilt the table, loosen the wing nut on the table trunnion, set the

table to the required angle and tighten the wing nut again (See Fig.

10).

Wing nut

b. It is recommended to verify the correct angle setting using an

angle guide, or by making trial cuts in scrap wood. Adjust the

indicator accordingly by using a phillips head screwdriver.

FIG. 10

4. ADJUSTING THE RIP FENCE

The locking pressure of the rip fence has been factory-set, if

adjustment is required proceed as follows:

a. Raise the fence handle to horizontal position.

b. Turn the fence handle clockwise to increase clamping pressure,

counterclockvjise to decrease clamping pressure.(See Fig. 11)

c. After counterclockwise truning the fence handie, sliding the rip

fence to the desired position on the guide rai(.(See Fig. 11)

d. The fence handle has a cam action, press down the handle to

clamp tightly to the table after setting rip fence to desired position.

c. Tighten the hex. nut and recheck the saw blade and the table for

squareness.

d. Lock the table into position and check that the indicator reads

zero degree on the side of lower table trunnion. Loosen the screw

securing the indicator and reset if necessary to give zero degree

reading. (See Fig. 9)

NOTE: Do not adjust the fence handle such that excessive

pressure is exerted during operation - this may lead to deformation

of the end clamp at the rear of the rip fence. Set the fence handle to

apply just enough pressure to enable safe operation during

cutting.

5. CHANGING AND ADJUSTING THE SAW BLADE

This bandsaw is factory-equipped with a general-purpose wood

cutting blade, the saw blade is set prior to delivery.

To change the saw blade, the following procedure must be

followed:

WARNING: To avoid injury from unexpected starting, whenever

changing the saw blade or carrying out adjustments, switch the

bandsaw off and remove the power cord from the main outlet. To

avoid injury to hands when handling the saw blade, wear gloves

whenever necessary. .

Page 7

a. Remove the rip fence, the guide rail, the wing nut and screw

from the table.

b. Open the upper and lower doors by turning the door locking

knobs.

c. Loosen the blade tension by turning the blade tension knob on

the top of the upper wheel housing counterclockwise until the saw

blade has slackened (viewed from above) (See Fig. 12).

c. Set the blade guide to the required height by turning the guide

post adjusting knob.

d. Tighten the wing nut after setting.

8. ADJUSTING THE BLADE GUIDES

d. Remove the saw blade from the upper and lower wheels.

e. When fitting the new saw blade ensure the blade teeth are

pointing downwards and towards you at the position where the

saw blade passes through the table.

f. Re-tension the new saw blade and check the saw blade tracking

by turning the upper wheel by hand. The saw blade should run in

the center of the bandsaw wheels.

g. If need adjust the tracking of the saw blade, proceed as men

tioned below “ TRACKING THE SAW BLADE”

h. Replace the rip fence, the guide rail, the wing nut and screw to

the table.

i. Close the upper and lower doors by turning the door locking

knobs before reconnecting the power supply.

6. TRACKING THE BANDSAW BLADE

Set the tracking of the saw blade before setting the blade guides.

Once the saw blade is installed and tensioned, track the saw

blade by adjusting the tracking knob by hand (See Fig. 13). The

saw blade should run in the center of the bandsaw wheels. When

the correct adjustment is achieved lock the tracking knob with the

wing nut.

The Upper Blade Guide

a. To adjust the upper blade guides, first position the right and left

roller guides relative to the blade by slackening the ratcher handle

Fig. 15 and moving the guide carrier until both roller guides are

approximately 1/16” behind the gullets of the saw blade.

b. Set both roller guides to within 1/32” of the saw blade by

releasing the guide adjusting screw (A) Fig. 15 on each side of the

saw blade. Do not set the roller guides too close as this will

adversely affect the life of the saw blade.

c. Adjust the rear roller guide to be just dear of the back of the saw

blade by unlocking the guide adjusting screw (B) Fig. 15

d. When the correct adjustment is reached, lock the rear roller

guide in position with the guide adjusting screw (B) Fig.15

7. SETTING THE CUTTING HEIGHT

a. The upper blade guide should be set as close as practical

against the workpiece.

b. To adjust this height, loosen the wing nut at the side of the upper

wheel housing. (See Fig. 14)

The Lower Blade Guide

a. To adjust the lower blade guides, first position the right and left

roller guides relative to the blade by slackening the lock nut Fig.16

and moving the guide carrier until both roller guides are approxi

mately 1/16” behind the gullets of the saw blade

b. Set both roller guides to within 1/32" of the saw blade by

releasing the guide adjusting screw (C) Fig. 16 on each side of the

saw blade. Do not set the roller guides too close as this will

adversely affect the life of the saw blade.

c. Adjust the rear roller guide to be just clear of the back of the saw

blade by unlocking the guide adjusting screw (D) Fig, 16

Page 8

d. When the correct adjustment is reached, lock the rear roller

guide in position with the guide adjusting screw (D) Fig.16

9. CHANGING THE DRIVE BELT

a. Release the saw blade tension by turning the blade tension

knob on the top of bandsaw counterclockwise.

b. Using a M6 hex. “L” wrench (not provided) to release the hex.

socket head cap screw on motor mounting flange. (See Fig. 17)

OPERATION

c. Using a clip pliers (not provided) remove the retaining ring from

the center of the iower wheel.

d. Carefully slide the lower wheel forward and at the same time

release the saw blade from this wheel,

e. Remove the old drive belt and fit the new belt, (ensure ribs in

drive belt are seated correctly before reassembling and tensioning

the drive belt)

f. Follow procedures for CHANGING AND ADJUSTING THE SAW

BLADE & TRACKING THE BANDSAW BLADE, before restoring

power to the bandsaw and setting up for use.

WARNING: Before starting check if any part of your bandsaw is

missing, malfuctioning, has been damaged or broken... such as

the motor switch, or other operation control, a safety device or the

power cord, turn the bandsaw off and unplug it until the particular

For best results the saw blade must be sharp. Select the right saw

blade for the job, depending on|the thickness of the wood the cut to

be made. The thinner and harder the wood, the finer the teeth of

the saw blade. Use a fine tooth blade for cutting sharp curves.

part is properly repaired or replaced.

The machine is especially suited for cutting curves, but will also

The saw blade cuts on a continuous downstroke. To avoid injury

when hands are unavoidably near to the saw blade, they should

be placed on either side of the blade, not in line with it. Use a

push stick whenever possible when working in close proximity to

the saw blade.

Start the bandsaw by turning the lock switch on and wait for the

bandsaw to come to full speed before starting to cut. Never start

make straight cuts. Do not attempt to turn the workpiece without

pushing it, as this may cause the workpiece to get stuck, or the

saw blade to bend.

The rip fence is to enable safe and accurate straight cuts of the

workpiece, usually in the same direction as the grain of the timber.

The miter gauge is to enable safe and accurate crosscut of the

workpiece.

the bandsaw with the workpiece in contact with the saw blade.

The tiltable table is used for bevel cuts.

Slowly feed the workpiece towards the saw blade, putting only light

pressure on it. With both hands, firmly hold the workpiece down on

the table, and feed it towards the saw blade slowly.

WARNING: When sawing with the rip fence and a tilted table, the rip

fence must be installed on that side of the table which is tilted

downward.

MAINTENANCE

WARNING: To avoid injury due to unexpected starting, before

cleaning or carrying out maintenance work, switch off and discon

nect the bandsaw from the power source.

Never use water or other liquids to clean the bandsaw. Use a dry

brush.

Regular maintenance of the bandsaw will prevent unnecessary

problems.

a. Keep the table clean to ensure accurate cutting.

b. Keep the outside of the machine clean to ensure accurate

operation of all moving parts and prevent excessive wear.

c. Keep the ventilation slots of the motor clean to prevent it from

overheating.

d. Keep the inside (near the saw blade, etc.) clean to prevent

accumulation of dust. Use dust collection if possible.

e. To prolong the life of the saw blade, when the bandsaw is not in

use for extended periods, release the saw blade tension. Before

reusing the bandsaw ensure that the blade is re-tensioned and

tracking is checked.

Page 9

TROUBLESHOOTING

Problem

The machine does not work when

switched on.

The saw blade does not move with the

motor running.

The saw blade does not cut in a straight

line.

The saw blade does not cut, or cuts very

slowly.

Diagnosis

1. No power supply.

2. Defective switch.

3 Defective motor.

1. The blade tension knob has not been

tightened.

2. The blade has come off one of the

wheels.

3. The saw blade has broken.

4. The drive belt has snapped.

1. Rip fence for cutting not used.

2. Feed rate too fast.

3. The blade teeth are dull or damaged.

4. Blade guides not suitably adjusted.

1. The teeth are dull, caused by cutting

hard material or long use.

2. The saw blade was fitted the wrong

way on the bandsaw.

Remedy

1. Check the cable for breakage.

2. Replace the lock switch.

3. Defective motor.

1. Switch off the motor, tighten the blade

tension knob.

2. Open the doors and check.

3. Replace the blade.

4. Replace the belt.

1. Use a rip fence.

2. Put light pressure on the workpiece.

Make sure the saw blade does not bend.

3. Try a new saw blade.

4. Adjust the biade guides (see ADJUST

MENT instructions).

1. Replace the saw blade, use a 6 T.P.I.

saw blade for wood and soft material.

Use a 14 T.P.I. saw blade for harder

materials. A 14 T.P.I. saw blade always

cuts slower due to the finer teeth and the

slower cutting performance.

2. Fit the saw blade correctly.

Sawdust builds up Inside the machine.

Sawdust inside the motor housing.

The machine does not cut at 45 or 90

degrees.

The saw blade can not be property

positioned on the wheels.

This is normal

This is normal

1. The table is not at right angles to the

blade.

2. The saw blade is dull or too much

pressure was put on the workpiece.

1. The wheels are not in alignment or

defective bearing.

2. The blade tracking knob hasn’t been

properly adjusted.

3. Inferior saw blade.

Clean the machine regularly. Open the

doors and remove the sawdust with a

vacuum cleaner. -

Clean the ventilating slots of the motor

with a vacuum cleaner. From time to time

remove the sawdust to prevent it from

being drawn into the housing.

1. Adjust the table.

2. Replace the saw blade or put less

pressure on the workpiece.

1. Replace bearing.

2. Adjust the blade tracking knob (See

ADJUSTMENT instructions).

3. Replace the saw blade.

ELECTRICAL SCHEMATIC

WAPfNING: This machine must be grounded. To avoid electrocution or fire, any repairs to electrical system should be done only by a

rjuaiified electrician, using genuine replacement parts.

SWITCH

Page 10

isn siavd

Page 11

keV no. DESCRIPTION

1 Door locking knob Cap

2 Hex. Bolt M6x45

3 Door locking knob body

4

5 Slotted Insert

6 Special Spring Washer 10

7 Lock Housing

8

9

10 Leaf Spring

11

12 Tongue Lock

13 Spring Washer 6

14

15

16

17

18 Washer 8

19

20

21

22

23

24

25 Lock Nut M6

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46 .

47

48 T-nut M6

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73.

74

75

76

77

78

79

80

81

82

Hex. Nut M6

Upper Door

Rivet 4x8

Special Nut M22

Lock Nut M6

Blade Tension Knob Cap

Blade Tension Knob Body

Biade Tensioner

Flange Nut M6 .

Carriage Bolt M8x50

Bushing Ring

Top Plug

Frame

Hex. Boit M6x12

Washer 6

Gear

Special Spring Washer 8

Tube

Plastic Nut M20

Adjusting Knob Body

Adjusting Knob Cap

Blade Tracking Knob Cap

Blade Tracking Knob Body

Hex. Boit M6x60

Hex. Nut M6

Wing Nut M6

Washer 6

Tapping Screw ST3.5x13

Rack

Slider

Carriage Bolt M8x20

Bolt Guide

Wing Nut M8

Blade Guide

T-nut M6

Hex. Bolt M6x10

Washer 6

Hex. Socket Set Screw M6x25

Ratchet handle

Guide Adjust Screw

Ball Bearing 6mm

Washer 6

Bearing Mount Cylinder

Hex. Socket Set Screw M6x10

Upper Guide Mount

Upper Guide Shaft

Bearing Mount Cylinder w/Cap

Upper Guide Body

Carriage Boit M6x30

Glide Piece

Upper Table Trunion

Lock Washer 6

Hex. Boit M6x12

Lower Table Trunion

Carriage Boit M6x16

Wing Nut M6 ’

Washer 6

Flange Nut M6

indicator

Tapping Screw ST3.5x9.5

Table

Table Insert

Hex. Socket Head Cap Screw M6x30

Washer 6

Wing Nut M6

Fence Clamper

Threaded Rod

Spring

Rod Guide

Fence

KEY NO. DESCRIPTION

83 Fiat Countersunk Head Screw M6x10

84

85 Guide Rail

86 Fence Carrier

87

88

89 Fence Handle

90 Roll Pin 3x18

91 Star knob screw

92 Washer 6

93 Aluminium Bar

94

95 Indicator

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138 '

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163 Washer 8

Rod Guide

Special Screw

Washer 10

Miter Gauge Base

Pan Head Screw M5x6

Knob

Bearing Mount Cylinder

Hex. Socket Set Screw M6x10

Lower Guide Body

Lower Guide Shaft

Lower Guide Mount

Lock Nut M6

Washer 6

Washer 6

Hex. Bolt M6x20

Guide Adjust Screw

Ball Bearing 6mm

Guide Key

Washer 6

Lock Nut M6

Spring Washer 6

Tongue Lock

Special NutM22

Lower Door

Leaf Spring

Rivet 4X8

Lock Housing

Special Spring Washer 10

Slotted Insert

Hex. Nut M6

Door locking knob Body

Hex. Bolt M6x40

Door locking knob Cap

Hex. Socket Head Cap Screw M8x30

Spring Washer 8

Washer 8

Motor

Hex. Bolt M6x20

Hex. Nut M6

Lower Bearing Bolt

Hex. Nut M14

Motor Pulley

Hex. Socket Set Screw M6x10

Drive Beit

Ball Bearing 12mm

Retaining Ring 28

Lower Wheel

Tire

Retaining Ring 12

Saw Biade

Upper Wheel

Upper Bearing Bolt

Wheel Carrier Bracket

Hex. Nut Ml 4

Star Lock

Mount Shaft

Biade Tensioner

Carriage Bolt M8x65

Brush Strip

Flange Nut M8

'Hex. Bolt M6x35

Hex. Nut M6

Cable w/Plug

Lock Washer 4

Washer 4

Pan Head Screw M4x8

Switch Cover Plate

Lock Switch

Pan Head Screw M4x12

Tension Bracket

Rubber Tube

11

Page 12

TABLE DE CONTENIDOS

Tabla de contenidos................................................................................................................................................................................12

Todo el año con garantía........................................................................................................................................................................12

Instrucciones de seguridad.....................................................................................................................................................................12

Ensamblaje..............................................................................................................................................................................................14

Conocer tu sierra de cinta.......................................................................................................................................................................15

Ajustacion................................................................................................................................................................................................16

Operación................................................................................................................................................................................................18

Mantenimiento.........................................................................................................................................................................................18

Solución de Problemas.......................................................................................................................................................................... 19

Esquema eléctrico...................................................................................................................................................................................19

Lista de partes.........................................................................................................................................................................................10

Español....................................................................................................................................................................................................12

TODO EL ANO CON GARANTIA

En esta herramienta de artesano falla debido ai defecto en material o habilidad dentro de un año desde

la fecha de compra, llamar al 1-800-4-MY-HOME® para ORGANIZAR LA REPARACION GRATUITA.

En esta herramienta es utilizado para los propósitos comerciales o de alquiler, este garantía se aplicará

por solo noventa días desde la fecha de compra.

Este garantía se aplica solo cuando esta herramienta está en Estados Unidos.

Este garantía te da ios derechos legales específicos, y usted también puede tener otros derechos, por el

cual varia, desde un estado al otro estado.

Sears, Roebuck y Co, Dept 817 WA, Hoffman Estates, IL 60179

INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA GENERAL DE SEGURIDAD

SABER TU HERRAMIENTA DE PODER: Leer el manual de usuario cuidadosamente. Aprender las aplicaciones de herramienta, capacidad de

trabajo, y sus riesgos de potencia específico.

APELIGRO

APELIGRO

Siempre Todos los Herramientas en Tierra.

Si tu herramienta está equipada con enchufe de tres-puntas, usted debe enchufarlo dentro de un recipiente eléctrico de trespuntas. Si usted utiliza un adaptador para acomodarlo a un recipiente de dos-puntas, usted debe agarrar el enchufe de

adaptador a tierra. Nunca remover la tercera punta del enchufe.

Siempre evitar los peligros ambientales.

Nunca utilizar los herramientas en sitios húmedos o mojados. Mantener tu area de trabajo bien iluminado y fuera de desorden.

Siempre Remover los botones de ajuste y arranque de los herramientas luego del uso.

Formar el costumbre de chequear que los botones y ajuste de arranque están removidos del herramienta antes de encenderlo.

Siempre guardar tu area de trabajo limpio. Areas y escritorios desordenados puede'causar accidentes.

m

APELIGRO

Siempre mantener los visitados fuera del corrido de las máquinas.

Todos los visitores debe mantener una distancia segura desde el área de trabajo.

Siempre hacer el taller de prueba de los niños

Prueba de los niños con los candados, enchufes de maestro, o por quitanza de las llaves de comienzo.

APELIGRO

Nunca operar los herramientas cuando está bajo de la influencia de las drogas, medicamentos o

alcohol.

12

Page 13

APELIGRO

APELIGRO

APELIGRO

APELIGRO

Siempre poner la ropa apropiada.

Nunca no poner la ropa o joyerías que puede agarrar en partes movidas.

Caucho-exclusivo de calzado está recomendado para un calzado mejor.

Siempre utilizar las gafas de seguridad y poner la proteción de oido.

También utilizar la máscara de cara o de polvo si la operación be corte está empolvado.

Nunca ir demasiado lejos.

Mantener tu calzado apropiado y equilibrar todo los tiempos.

Nunca pararse sobre herramientas.

Puede ocurrir daños severos si el herramienta está emboquillado o si el herramienta de corte está conectada

accidentalmente.

APELIGRO

Siempre desconectar los herramientas.

Desconectar los herramientas antes de servicio y cuando cambia los accesorios tal como filo, broca, y cortantes.

Siempre evitar el comienzo de accidente.

Asegurar que el enchufe está en posición “OFF” antes de enchufarlo dentro del cordon.

Nunca dejar corrido de los herramientas descuidados.

A PELIGRO

Siempre chequear por partes dañados.

Antes de inicial o continuar el uso de los herramientas, la guardia o otras partes está dañado debe estar chequeado para

asegurar que éste operará apropiadamente y realiza sus funciones deseados. Chequear por alineación de partes movidas, atar

las partes movidas, ruptura de partes, montado, y cualquier otros condiciones que puede afectar sus operaciones. La guardia o

otras partes dañados debe ser reparados o reemplazados apropiados inmediatamente.

REGLAS ESPECIALES DE SEGURIDAD PARA SIERRA DE CINTA

1. Siempre parar la sierra de cinta antes de remover los fragmentos de las piezas de la mesa.

2. Siempre mantener los manos y ios dedos fuera del filo.

3. Nunca intenta de sierra el patrón que no tiene superficie plano, a no ser que utiliza un soporte apropiado,

4. Nunca mantener el material firmemente y alimentarlo dentro de filo a la velocidad moderado.

5. Siempre apagar la máquina si et material está retirado fuera de un corte incompleto.

6. Chequear para un tamaño de filo apropiado y tipos de espesor y tipos de material cortado.

7. Asegurar que la tensión de filo y pista de filo están ajustados apropiadamente.

8. Hacer cortes “alivio” antes de cortar curvas largos.

9. Liberar la tensión de filo cuando el sierra no será utilizado por un período largo.

10. Anotar y seguir las advertencias e instrucciones de seguridad que aparece sobre la puerta más bajo.

AwARNJNG

FOR VOÜR OWN SAFETY

'Ì- READ AND UNDERSTAND INSTRUCTION MANUAL

BEFORE OPERATING BANDSAW

2. Always wea? tjye protectiofi

3. Do noi wear glci/trs, ricckirps, jcwDfry or toosn

clothing

4 Check blade rotation arid rrtake cenatn that biado

teeth point downward towartì thi* table

5. Maintain proper adjustment of blade tracKiiìg and

tension, blade quirlDS and back-up bcannris

B Keep hands out of path of saw blade

7 Secure wheel guard covers before operating

8 Adjust upper blade gusrd. guidc to jusl clear workpiece.

9 Hold workpiece firmly agairtst table and use mtter gage

iind fence when possible

10 Do not remove jarTimt'd or cut-off pieces until blade

has stopped

DiHconnoct machtnefrom power source before mskmg

repairs or adjustments

12 Do not ettposc tt» raui or use rn damp iocat+ons.

13

Page 14

ENSAMBLAJE

1. Herramienta requerido para el ensamblaje

Item Descripción Cantidad

Destornillador mediano

Llave ajustable.................................................1

Cuadrado..........................................................1

....................................

1

2. Desemblaje y chequeao de los contenidos

Modelo 119.21400010" Cinta de sierra está embarcado completamente

en una caja

a. Separar todas las partes del cartón y chequear cada Item con “posible

T de los Contenidos Cartón” para asegurar que todos los Items están

contados antes de descargar ninguna material del paquete.

b. Remover el aceite protector que está aplicada para la mesa. Utilizar

algún agarro familiar tipo grasa y removedor.

c. Aplicar una capa de pasta de cera para la mesa por la prevención de

polvo. Limpiar todas las partes directamente con un paño seco y limpio.

LISTA DE PARTES SUELTOS EN EL PAQUETE

Item Descripción Cantidad

Botón de tensión de filo. .1

K-

Medidor..

Enchufe Hex M6x 30..

O

k

Arandela 6..................................................................1

Tuerca dealaMS

Rollo Hex M6x12

........

......

CONTENIDOS DE CARTON

Item Descripción

A Maquina principal

B Perfil de Asamblaje

C Tablero..............................................

D Guia de Carril....................................

E Manual de Usuario

F Asamblaje de Muñón de tablero superior..

Q Paquete de Partes sueltos

............................

.........................

...........................

..............................................

Cantidad

.........

1

.........

1

.........

1

.........

1

.........

1

...........

1

1

Arandela bloqueado 6

Llave Hex “L’’M5

............................................

..........

2. EMSAMBLAJE INICIAL

La máquina está parcialmente emsamblada. Prioridad para el uso, los Ítem

siguientes debe estar instalado: Mesa, Botón de tensión de filo y

desgarrar el protector

ADVERTENCIA: para evitar ef daño, no debe correr o utilizar este

máquina antes de que todas las partes están emsamblado y trabajado

correctamente,

4

a. Emsamblar el tablero de muñón superior con el tablero de muñón

inferior utilizando tornillo, pieza de ligaduradura, Arandela y ala

excéntrico. Ubicar el tablero sobre el tablero de muñón superior cuidando

cuando pasa la cinta de sierra através de ranura de la mesa (Ver Fig. 1)

Localizar cuatro cerrojo hex y cuatro arandela bloqueada del paquete de

partes sueltos. Montar la mesa para la unión de tablero superior e instalar

el cerrojo con arandela en cada agujero, luego ajustarlo con tornillo

ajustable.

14

Page 15

b. Ajustar el guia de carril con dos botones de rosca de comienzo y

arandear al tablero. Utilizar el botón hex puntando el troniilo, arandelar y

balancear para corregir el tablero de trabajo. (Ver Fig. 2)

d. Ubicar botón do tensión de filo sobre el tensión de filo (Ver Fig. 4)

e. Para asegurar la estabilidad vertical suficiente de la máquina éste debe

estar erguido al piso, banco o tabla del trabajo. Para este propósito

agujeros 6mm están siempre en la base de la máquina (Ver Fig 5.)

c. Colocar el rasgón acerca sobre eí guía de carril. Ajustar el rasgón

acerca al pararelo a la cinta de sierra. Apretar el rasgón manejando

presionarlo fiada abajo. (Ver Fig. 3)

CONOCER TU SIERRA DE CINTA

^Soxón de tensión de filo

'Botón de bloqueo de puerta

,Guía de filo

^Medidor

t. Esta cinta de sierra tiene incluido puerta de polvo 2-1/2" (Ver Fig. 6)

Este es recomendado cuando está en uso, ia cinta de sierra está

conectada al colector de polvo.

i ,

] Puerta^e polvo]

FIG. 6

f

____

'Botón de pista de filo

^otón de ajuste post guia

erca

Botón bloqueo

Guía de carri

Tablero de muñón Superior-

Tablero de muñón infe ri or-

Puerta de polvo''"í$'‘-

15

Motor

Page 16

AJUSTACION

1. CENTRALIZAR EL TABLERO

a. Soitar los cuatro botones hex mantadb en el tablero para el muñón de

tablero superior. (Ver Fig 7)

b. Mover el tablero de lugar como requerido, hasta que sierra de cinta

corre através del centro del inserción de tablero.

c. Si el ajustación de "b” no es suficiente al centro de tablero, soltar los

cuatro tuercas bridas reteniendo el muñón de tablero más bajo y mover el

tablero para ubicarlo en el centro.

d. Re-tirar los botones hex. Para munón, rechequear la posición de sierra

de cinta.

2. COLOCAR TABLERO CUADRADO PARA SIERRA DE CINTA

Soltar tuerca balanceado sobre muñón de tablero más bajo y ubiarlo a un

tamaño cuadrado justo contra sierra de cinta.

Si el tablero requiere ajustación, proceder los siguientes:

a. Utilizar una llave, relajar tuerca hex. Sobre el marco. (VER Fig.8)

b. Ubicar la llave sobre botón hex. Y ajustarlo hasta el tablero forma con

sierra de cinta. (Ver Fig.8)

3. INCLINACION DE TABLERO

Para cortes biselado, el tablero inclina 0 grados hasta 45 grados.

a. Para inclinar el tablero, soltar el tuerca balanceado sobre el muñón de

mesa, ubicar el tablero para el ángulo requerido y apretar el tuerca

balanceado nuevamente (Ver Fig. 10)

Aleta de Tuerca

b. Este es recomendado para verificar si el ángulo está correctamente

angulado seleccionado utilizando un guía de ángulo, o por corrido e corte

marcado en fragmento de madera. Ajustar el indicador según por el uso

de tornillo Philips.

FIG. 10

4. AJUSTE DE RASGON PERISCA

La presión de bloqueo del rasgón cerca está seleccionado por la fábrica,

si requiere una ajustación, los procesos es como lo siguiente:

a. Levantar la perisca hacia la posición horizontal.

b. Cambiar la cerca en la dirección del aguja de reloj para incrementar la

presión de abrazadera, contra la dirección del aguja de reloj para

disminuir la presión de abrazadera (Ver Fig.11)

c. Despúes de girar hacia la dirección del aguja de reloj, deslizar rasgón

perisca para la posición deseada sobre el caril (Ver Fig 11)

d. La perisca tiene acción leva, presionar hacia abajo el mango para

abrazadera estirado a la mesa luego de seleccionar rasgón perisca a un

posición deseado.

c. Estirar tuerca hex. Y rechequear el sierra de cinta y el tablero para

cuadrar.

d. Bloquear el tablero dentro de posición y chequear que el indicador lee

cero grado sobre el lado de muñón de tablero más bajo. Soltar el tornillo

asegurando el indicador y resetearlo si es necesario para dar a cero

grado. (Ver Fig. 9)

NOTA:No ajustar la perisca con muchas presiones ejercida durante la

operación. Este puede llegar a deformar al final de abrazadero al levantar

la perisca. Seleccionar perisca para aplicar con presiones suficientes

para estar seguro durante el proceso de corte. ■

5. CAMBIAR Y AJUSTAR EL FILO DE SIERRA

Este sierra de cinta esta equipada por la fábrica con el propósito general

de filo corta madera, el filo de sierra está seleccionado para destríbución.

Para cambiar el filo de sierra, ios porcesos deben ser como lo siguiente:

ADVERTENCIA: Para evitar el daño no esperado, siempre cuando

cambiar el filo de sierra o sacar los ajustes, apagar el sierra de cinta y

sacar el cordón de energía desde la salida principal. Para evitar el daño a

los manos cuando maneja el filo de sierra, poner guantes cuando es

necesario.

16

Page 17

a. Remover la perisca, el caril guiada, el tuerca balanceada y tornillo

desde el tablero.

b. Abrir las puertas superiors e inferiores por botortes de bloqueo de

puertas.

c. Soltar la tensión de filo por giro deí botón de tensión de filo del

ruedecillos superiores con ía direción de aguja de reloj hasta el sierra de

filo está flojo (ver desde arriba) (Ver Fig. 12).

c. Seleccionar el guía de filo por el altura requerido girando el botón de

post ajuste.

d. Apretar aleta de tuerca despuúes de selección.

Botón de guía post ajustación]

8. AJUSTACION DE GUIA DE FILO

d. Remover el sierra de filo desde las ruedecillas superiores e inferiores.

e. Cuando ajusta el nuevo sierra de filo asegurar que el diente de filo está

apuntando hacia abajo y hacia usted a la posición cuando sierra de filo

pasa atraves del tablero.

f. Re-tenslonar el nuevo sierra de filo y chequear sierra de filo girando tas

ruedecillas superiores por mano.Sierra de filo debe recorrer dentro de

centro de las ruedecillas de sierra de filo.

g. Si es necesario de girar sierra de filo, procesarlo como menscionado lo

siguiente “RASTREO DE SIERRA DE FILO” '

h. Reemplazar ia perisca, el carril guiada, el tuerca balanceaba y tornillo al

tablero.

ii. Cerrar las puertas superiores e inferiores girando los botones del

bloqueo de la puerta antes de reconectar el suministro de energía.

6. RASTREO DE SIERRA DE FILO

Seleccionar el rastreo de sierra de filo antes de seleccionar el guía de

sierra. Una vez que el sierra de filo está instalado y tensionado, rastrear

sierra de filo ajustando el botón de rastreo por mano (Ver Fig 13) Sierra

de filo debería correr dentro del centro de las ruedecillas de sierra de filo.

Cuando la ajustación está correctamente está bloqueado el rastreo del

botón con tuerca balanceada.

Guía de filo superior

a. Para ajustar los guías de filo superior. Primero lugar los guias derecho

e izquierdo relativamente para el tilo por aflojar la rueda Fig 15 y mover el

carril guía hasta ambos guías están aproximadamente 1/16" detrás de

garganta de sierra de filo.

b. Seleccionar ambos guías de roller con menos de 1/32" de sierra de filo

aflojando el tornillo de ajuste de guía (A) Fig. 15 sobre cada lado de sierra

de filo. No seleccionar guía de roller demasiado cerca debido que éste

afecta desfavorablemente la vida de sierra de filo.

c. Ajustar guía de roller para estar claro detrás de sierra de filo

desbloqueando los tornillos de ajuste de guía. (B) Fig. 15

d. Cuando la ajustación correcta se encuentra, bloquear el parte posterior

de guía de rueda en posición con el tornillo de guía de ajuste (B) Fig.16

7. SELECCIONAR ALTURA DE CORTE

a. El filo superior debería estar seleccionado contra las piezas de trabajo.

b. Para ajustar este altura, soltar la tuerca balanceada al lado superior del

ruedecilla.(Ver Fig. 14)

Guía de Filo inferior

a. Para ajustar los guías de filo inferior, primer lugar los guías derecho e

izquierdo relativamente para el filo por aflojar la rueda Fig. 16 y mover el

carril guía hasta ambos guías están aproximadamente 1/16" detrás de

garganta de sierra de filo.

b. Seleccionar ambos guías de roller con menos de 1/32" de sierra de filo

aflojando el tornillo de ajuste de guía (C) Fig. 165 sobre cada lado de

sierra de filo. No seleccionar guía de roller demasiado cerca debido que

éste afecta desfavorablemente la vida de sierra de filo.

c. ajustar guía de roller para estar claro detrás de sierra de filo

desbloqueando los tornillos de ajuste de guía. (D) Fig. 16

17

Page 18

9. CAMBIO DE CORREA

a. Aflojar la tensión de sierra de filo presionando el botón de tensión de

sierra sobre el parte superior de sierra de fiio en sentido de aguja de

reloj.

b. Utilizar una llave hex M6. “L” (no suministrado) para aflojar la cabeza

de llave de encaje sobre el reborde de motor. (Ver Fig.17)

c. utilizar el alicate (no suministrado) remover el anillo retenido del centro

del ruedecilla inferior.

d. Sacar cuidadosamente la ruedecilla inferior y al mismo tiempo aflojar

sierra de filo desde este ruedecilla.

e. Remover correa vieja y ajustar una correa nueva, (asegurar la

columna de correa está correctamente seteado antes de reunir y

tensionar la correa) ,

I. Seguir los procesos para CAMBIAR Y AJUSTAR SIERRA DE FILO &

CARRIL SIERRA DE FILO, antes de reiniciar la energía para sierra de filo y

seleccionarlo para el uso.

ADVERTENCIA; Antes de comenzar de chequear si alguna parte de su

sierra de filo está perdido, malfuncionado, están dañado o roto...tal como

varilla de motor, o otro control de operación, un fuente seguro o el cordón

de energía, apagar sierra de cinta y desenchufarlo hasta que las partes

están reparadas o reemplazadas apropiadamente.

Sierra de filo corta carreras continuos. Para evitar el daño cuando los

manos están inevitablemente cerca de sierra de filo, ellos debern estar

ubicado en otro lado del tablero, no en mismo línea con él. Utilizar la vara

emujada cuando es posible durante el trabajo para aproximarse a sierra

de filo.

Comenzar sierra de cinta girando el botón de bloqueo prendido y esperar

que sierra de tilo viene con toda la velocidad antes de comenzar de

cortar. Nunca comenzar sierra de cinta con piezas de trabajo en contacto

con sierra de filo.

Lentamente alimentar los piezas de trabajo hacia sierra de filo, poniendo

solamente poca presión sobre él. Con ambos manos, firmes mantenidos

en piezas de trabajo hacia el tablero, y alimentarlo hacia sierra de filo

lentamente.

MANTENIMIENTO

ADVERTENCIA: Para evitar daño debido a un comienzo inesperado,

antes de limpiar o cargarlo fuera de trabajo, apagarlo y desconectar

sierra de filo desde el fuente de energía.

Nunca utilizar agua o otro líquido para limpiar sierra de filo. Utilizar cepillo

seco.

Para mejores resultados sierra de filo debe estar filoso. Seleccionar

sierra de filo correcto para el trabajo, dependiendo sobre el grosor de la

madera el corte hecho. La madera fino y duro, el diente de sierra de filo.

Utilizar sierra con diente bueno para cortar en forma de curva.

La máquina está especialmente diseñado para cortar curvas, pero

también hace cortes rectos. No pretende de sacar las piezas de trabajo

son empujarlo, como esto puede causar pegado a piezas de trabajo, o

doblar sierra de filo.

La perista da cortes de piezas de trabajo rectos segura y exacto,

generalmente en misma dirección como grano de madera.

El medidor no está seguro y exacto para cortar los piezas de trabajo.

El tablero inclinado se usa para cortes biselado.

ADVERTENCIA: Cuando junta perisca con tablero inclinado, la perisca

debe estar instalado en otro lado del tablero por e! cual está hacia abajo.

Mantenimiento reguiar de sierra de filo podrá prevenir problemas

innecesarios.

a. Mantener limpio el tablero para asegurar el corte correcto.

b. Mantener fuera de máquina limpio para asegurar la operación correcto

de todas las partes moviendo y prevenir cargo excesivo.

c. Mantener ranura de ventilación sobre ei motor, limpiar para prevenirlo

sobrecalentamiento.

d. Mantener el interno limpio (cerca de sierra de filo,etc.) para prevenir

acumulación de polvo. Utilizar colector de polvo si es posible,

e. para prolongar la vida de sierra de filo, cuando sierra de cinta no se

utiliza por un tiempo prolongado, soltar la tensión de sierra de filo. Antes

de reusar sierra de cinta asegurar que sierra está chequeado el re

tensión y rastreo.

18

Page 19

SOLUCIÓN DE PROBLEMAS

Problema

La máquina no trabaja cuando enciende.

Sierra de cinta no será removido cuando el

motor está corriendo.

Sierra de cinta no corta en línea recta.

Sierra de cinta no corta, o corta demasiado

lento.

Diagnostico

1. No hay suministro de energía

2. Enchufe defectuoso.

3. Motor defectuoso

1. Botón de tensión de filo no está bien

ajustado.

2. Sierra sale uno de los ruedecillas.

3. Sierra de cinta está rota.

4. El corrido de cinta está estallido

1. Perisca para cortar no utilizable.

2. Proporción de alimentación demasiado

rápido.

3. Sierra dentado está apagado o dañado.

4. Sierra guiada no está ajustada

apropiadamente.

1. El dentado está apagador, causado por

corte de material pesado o uso prolongado.

: 2. Sierra de cinta está ajustado en forma

incorrecto sobre sierra de cinta.

Remedio

1. Chequear el cable daño

2. Reemplazar el enchufe de bloqueo.

3. Motor defectuoso

1. Apagar el motor, ajustar el botón de tensión

de filo.

2. Abrir las puertas y chequear.

3. Reemplazar la sierra.

4. Reemplazar la cinta.

1. Utilizar perisca.

2. Poner luz de presión sobre pieza de

trabajo. Asegurar que sierra de cinta no está

doblado.

3. Tratar un nuevo sierra de-cinta.

4. Ajustar sierra guiada (ver instrucciones de

AJUSTACION)

1. Reemplazar el sierra de cinta, utilizar el

6T.P.I. sierra de cinta para madera y material

suave. Utilizar el 14 T.P.I. siera de cinta para

material pesado. El 14 T.P.I. sierra de cinta

siempre corta mas despacio debido que el

dentado y forma de corte más lento.

2. Ajustar sierra de cinta correctamente.

Polvo visto dentro de la máquina

Polvo visto dentro del motor de alojamiento. Esto es normal

La máquina no corta a 45 o 90 grados.

Sierra de cinta no puede estar

apropiadamente posioionado sobre las

ruedecillas.

Esto es normal

1.EI tablero no está angulado correctamente al

sierra.

2,Sierra de cinta está apagado o demasiado

presión está puesta sobre piesas de trabajo.

1. Las ruedecillas no están en alineación o

marcación defectuoso.

2. botón de pista de sierra no están ajustada

apropiadamente.

3.Sierra de cinta inferior

Limpiar la máquina regularmente.

Abrir las puertas y remover el polvo visto con

un paño de limpiar. ’

Limpiar la ranura de ventilación del motor con

paño de limpiar. Limpiar de vez en cuando

para remover el polvo visto para prevenirlo

que caiga dentro de alojamiento.

1. Ajustar<el tablero.

2. Reemplazar sierra de cinta o poner menos

presión sobre piesas de trabajo.

1. Reemplazar marcación.

2. Ajustar el botón de pista de sierra (Ver

instrucciones AJUSTACION). .

3. Reemplazar sierra de cinta.

ESQUEMA ELECTRICO

ADVERTENCIA : Este máquina debe estar en tierra. Para evitar eiectrocusión o fuego, todais ias reparaciones eléctricas deber estar hecho

soiamente por eiectricislas caiificados, utilizando los partes reemplazantes auténtico.

19

Page 20

Get it fixed, at your home or ours!

Your Home

For repair-in your home-of all major brand appliances,

lawn and garden equipment, or heating and cooling systems,

no matter who made it, no matter who sold it!

For the replacement parts, accessories and

owner’s manuals that you need to do-it-yourself.

For Sears professional installation of home appliances

and items like garage door openers and water heaters.

1-800-4-MY-HOME® (1 -800-469-4663)

Call anytime, day or night (U.S.A. and Canada)

www.sears.com

www.sears.ca

Our Home

For repair of carry-in items like vacuums, lawn equipment,

and electronics, call or go on-line for the location of your nearest

Sears Parts & Repair Center.

1-800-488-1222

Call anytime, day or night {U.S.A. only)

www.sears.com

To purchase a protection agreement (U.S.A.)

or maintenance agreement (Canada) on a product serviced by Sears;

1-800-827-6655 (U.S A.) 1-800-361-6665 (Canada)

Para pedir servicio de reparación

a domicilio, у para ordenar piezas:

1-888-SU-HOGAR®^

(1-888-784-6427)

Au Canada pour service en français:

1-800-LE-FOYER^^

(1-800-533-6937)

www.sears.ca

® Registered Trademark ! ™ Trademark ! Service Mark of Sears, Roebuck and Co.

® Marca Registrada / Marca de Fábrica / Marca de Servicio de Sears, Roebuck and Co.

Marque de commerce I “° Marque déposée de Sears, Roebuck and Co.

) Sears, Roebuck and Co.

Loading...

Loading...