Page 1

Save This Manual For

Future Reference

SEAMS

owners

manual

MODEL NO.

113.299780

Dust Collection

System

Serial

Number

Model and serial number may be

found on the motor cover.

You should record bottn model and

serial number in a safe place for

future use.

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY.

mms

EiiPfSMii

DUST COLLECTION

SYSTEM

• assembly

• operation

• repair parts

V.

Sold by SEARS, ROEBUCK AND CO., Chicago, !L. 60684 U.S.A.

Part No. SP5373 Printed in Taiwan

J

Page 2

FULL ONE YEAR WARRANTY ON CRAFTSMAN DÖST COLLECTION SYSTEM

If within one year from the date of purchase, this Craftsman Dust Collection System fails due to a defect in

material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/

DEPAffMEI^t THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used In the United States.

This warranty gives you specific legal rights, and you mayalso have otherrights which vary from state to state.

SEARS, ROEBUCK AND CO., D/817 WA HOFFMAN ESTATES, IL 60135

IMPORTANT SAFETY INSTRUCTIONS

When using your Dust Collection System, follow basic

safety precautions including the following.

WARNING a To reduce the risk of

fire, electric shock, or Injury:

• Read and understand this owner’s manual and all

labels on the Dust Collection System before oper

ating, Use only as described In this manual. To

avoid personal injury or damage to Dust Collec

tion System, use only Sears Craftsman recom

mended aCcesSbries.

Sparks inside the etectricai parts, can ignite flammable

vapors or dust. To avoid fire or explosion;

• Do not vacuum, or use this Dust Collection System

near flammable or combustible liquids, gases, gaso

line or other fuels, lighter fluid, cleaners, oil-based

paints, natural gas, hydrogen, or explosive dusts like

coal dust, magnesium dust, grain dust, orgun powder.

• Do not vacuum anything that is burning or smoking,

such as cigarettes, matches, or hot ashes.

• To avoid health hazards from vapors or dusts, do not

vacuum toxic materials.

• To avoid injury from accidental starting, unplug power

cord before changing or cleaning filter/dust bag or chip

bag.

• Do not use without filter/dust bag and/or chip bag in

place.

• Do not unplug by pulling on cord. To unplug, grasp the

plug, not the cord.

• Turn off controls before unplugging.

• Do not use with damaged cord, plug or other parts. If

your Dust Collection System is not working as it

should, has missing parts, has been dropped, dam

aged, left outdoors, or dropped into water, return it to

a Sears Service Center.

• Do not pui! or carry by cord, use cord as handle, close

a door on cord, or puli cord around sharp edges or

corners. Do not run Dust Collection System overcord.

Keep cord away from heated surfaces.

• Do not handle plug of the Dust Collection System with

wet hands.

* Do not use dr store near hazardous materials.

* Do not use outdoors or on wet surfaces,

• Put unit on a stable, level surface.

• Route vacuum hose and electric cord out of traffic

areas.

♦ Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

• Dohbt ieave appliarice plupeci in. Unplug from outlet

when not in use a;nd before servicing.

SAVE THESE !NSTRUCT!ONS

• Do not put any object into ventilation openings. Do not

vacuum with any ventilation openings blocked; keep

tree of dust, lint, hair or anything that may reduce air

flow.

• Keep hair, loose clothing, fingers, and all parts of body

away from openings and moving parts.

• Extension cords in poor condition or that are too small

can pose fire and shock hazards. When using an

extension cord, be sure It is in good condition. See

"Extension Cords" in the "Operation" section torproper

wire sizes.

• Connect to properly grounded outlet only. (See

"Grounding Instructions" on page 14.)

Page 3

Aa CAUTION: if using this Dust Collection System

to help keep airborne wood dust in heavy usage

within acceptable limits, you must regularly monitor

air borne dust and maintain Dust Collection System

to avoid exceeding dust limits. Each application is

unique. Your maintenance schedule must, there

fore, be tailored to your specific use of this Dust Col

lection System.

Safety is a combination of common sense, staying alert

and knowing how your Dust Collection System works.

BEFORE USING THE DUST COLLECTION

SYSTEM:

A

WARN ING: TO AVOID MISTAKES TH AT COU LD

RESULT IN SERIOUS, PERMANENT INJURY, DO

NOT CONNECT POWER CORD UNTIL THE FOL

LOWING STEPS HAVE BEEN SATISFACTORILY

COMPLETED:

1. Assembly, mounting and alignment.

2. Learn the function and proper use of the ON-OFF

switch.

3. Read and understand all safely instructions and

operating procedures throughout the manual.

4. Read the following labels which appear on the top

and bottom of filtration housing and sides of motor.

AWARNING

Metal shavings or dust can set

sawdust on tire.

Collect wood materials only.

Do not collect metal shavings

or dus!.

See manual for délai 1 s.

Risk of electrical shock.

Use indoors in dry area.

Do not use outdoors or on wet

surfaces.

BEFORE EACH USE:

1. Inspect your Dust Collection System. If any parts

are missing, bent, or tail in any way. or any electri

cal components do not work properly, turn off the

Dust Collection System, remove switch key, and

remove power supply cord from power supply.

Replace damaged, missing or failed parts before

using the Dust Collection System again.

2. Plan your work to protect your eyes, hands, face,

ears and body.

A. WEAR SAFETY GOGGLES, FORESIGHT iS

BETTER THAN NO SIGHT. Wear safely

goggles, not glasses, that comply with ANSI

Z87.1 (shown on label). Operating any power

tool can result in foreign objects being ihown

into the eyes which can result in permanent eye

damage. Safety goggles are available at Sears

retail catalog stores, Use of glasses or goggles

not in compliance with ANSI Z87.1 could result

in severe injury from breakage of the eye protec

tion.

B. When cleaning collection bags, wear a dust

mask.

Sparks can ignite vapors from

flammable products.

Do not use around flarnmable

products.

If connected to a circuit protected

by fuses, use time delay (uses

with this appliance.

Electrical: 120 volts, 60 Hz AC only, 7 amps

AWARNING

Hazardous moving parts inside

Unplug before removing inlet guard.

Attach inlet guard before plugging in.

Page 4

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

1. KNOW YOUR TOOL

F^ead and understand owner's manual ard labels

attixed to the tool t eam its application and (imitalicns as welt as its specific potential hazards pec-

2, GROUND THE TOOL

This tobi is equipped with an approved 3-conductor ^

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green coriductor in the cord is the grounding wire Never

O : connect the green wire to a live terminal.

3 KEEP GUARDS IN PLACE

r - in working brdeb and in proper adjustment and

: álignmenLV ;' i

4. REMOVE adju stin g AND WRENCHES

: Form habit of checking:to see that keys and adjust

: ing wrenbhes are rerrioved from tool before turning

. It on; : ; r '

5. KEEP VyORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don’t use power tools in damp or wet locations or

expose them to fain Keep work areá well lighted.

Provide adequate surrounding work space.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

8. MAKE WORKSHOP CHILD-PROOF

-with padlocks, master switches, or by removing

starter keys.

9. USE PROPER SPEED

This tool will do the job better and safer when oper

ated at the proper speed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job tor which

it was not designed

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwalches) to get caught in moving

parts. Non-slip footwear is recommended. W ear

protective hair covering to contain long hair. Roll

long sleeves above the elbow.

12. USE SAFETY GOGGLES (Head Protection)

Wear safety goggles (must comply with ANSI Z87.1)

at all times. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses. Also,

use lace or dust mask if cutting operation is dusty,

and ear protectors (plugs or muffs)during extended

periods or operation

13. DONT OVERREACH

Keep proper footing and balance at all times.

14. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories,

15. DISCONNECT TOOLS

Before servicing, when changing accessories or at

tachments.

16. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plug

ging in.

17. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that accom

pany the accessories. The use of improper accesseries may cause hazards.

18. NEVER STAND ON TOOL

Serious i njury could occur if the tool tips over. Do not

store materials such that it is necessary to stand on

the fool to reach them.

19. CHECK DAMAGED PARTS.

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

ensure that it will operate properly and perform Its

intended function. Check for afignment of moving

parts, binding or rraving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced.

20. NEVER LEAVE MACHINE RUNNING UNAT

TENDED

Turn power "OFF". Don’t leave Dust Collection

System until it comes to a complete stop.

Page 5

Introduction

The Craftsman Dust Collection System is specifically

designed to capture sawdust and wood chips at the

source. The fine dust is filtered by the upper bag while

heavy particles settle in the lower bag for easy removal.

Do not use as a vacuum.

A

CAUTION; The blower housing contains a high

speed fan blade that can amputate fingers, grab

loose clothing and neckties, or propel dust at high

velocities. DO NOT OPERATE WITHOUT ALL PARTS

IN PLACE.

Do not attempt to clean, remove dust bags or service

unit while in operation. Disconnect from power

source.

This Dust Collection System is intended for either com

mercial or household use.

IMPORTANT NOTE

Please Read Carefully

static Shocks Are Common - in dry areas or when the

relative humidity of the air is low. To reduce the fre

quency of slatic shocks in your home, the best remedy

is to add moisture to the air with a console or installed

humidifier.

The safety information in this manual is highlighted by

the following safety alert symbol.

A

The following signal words are used to indicate the level

of risk.

A DANGER: Means that if the safety information

is not followed, someone will be seriously injured or

kilted.

A WARNING: Means that if the safety information

is not followed, someone could be seriously injured or

killed.

A CAUTION: Means that if the safety information

is not followed, someone may be injured.

TABLE OF CONTENTS

ITEM page

WARRANTY INFORMATION .......................................................2

IMPORTANT SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS FOR

POWER TOOLS

INTRODUCTION

Unpacking and Checking Carton Contents

ASSEMBLY........................................................................................7

Mounting Front Pivoting Casters

Mounting Rear Fixed Casters...................................................7

Mounting Inlet Guard

Mounting Support Legs

Mounting Leg Bracket................................................................8

Mounting Inlet Bracket

Mounting Base Plate

Mounting Filler/Dust Bag Holder

Mounting Handle to Filtration Housing.................................10

Chip Bag Assembly...................................................................It

.........................................................................

.............................................................................

................................................................

.............................................................

.............................................................

................................................................

....................................

...........................

.............................................

...........................................

10

ITEM PAGE

Filter/Dust Bag Assembly......................................................11

2

4

5

6

7

7

8

9

9

OPERATION

Attaching Accessories to Inlet Guard

Connecting Dust Collection System to

On/Off Switch............................................................................13

Moving Dust Collection System............................................13

Power Supply............................................................................14

Grounding Instaictions............................................................14

Extension Cords.......................................................................14

MAINTENANCE.............................................................................15

Chip Collecting Bag Removal

Filter/Dust Bag Removal........................................................15

Motor...........................................................................................16

TROUBLESHOOTING

REPAIR PARTS

..................................................................................

..................................

Power Source.....................................................................12

...............................................

.................................................................

...........................................................................

12

12

15

16

18

Page 6

introduction

UNPACKäNG AND CHECKING CARTON CONTENTS

^ WARNING: IF ANY PARTS ARE MISSING OR

BROKEN, GET THE PROPER PARTS FROM SEARS

BEFORE ASSEMBLY OR USING THIS DUST COL

LECTION SYSTEM.

Fiernove entire contents of carton. Check each item

against thé Carton Contents List. Notify your Sears

Store irhmediately if any parts are damaged or missitig.

CARTON contents LISTt

Key

A

B

C Handle

D Filtration Housing

Ë

i/ Inlet Guard ,L.:.......................................

F

G

/■•H'L

1

J

K

L Chip Collecting Bag .

./Mi:

N

0

i/.P://

Q Flexible Hose, 4 Inch . ..

:::?№ //; Adapter

S

Description

Filter/Dust Bag

Fitter/Dust Bag Hanger

Right Side Support Leg

Rear Fixed Casters

Base Plate

Front Pivoting Casters ..... ..... ... 2

Manual

Bracket and inlet Clamp........................

Leg Bracket;...../.....

Left Side Support Leg

Adjustable Band Ctamp

O-Fting......................................................

.....

....

..........::............

.......

.................................................

........

.................

........ . ....

............

...........................

.............................

.....................................................

.

................................

.......

.......................

.

.................

.......

.........

..............

..

...

..........

/:’

...................

....................1

..

...............

......................

.

.

................

i.V.1

....................

...................

.................

.:;///; ;^/;/:i;':/:

CJly.

...A

.....1

.........

1

'■/

1

1

1

1

1

Tools Needed

Adjustable Wrench

t items shown are not actual size

Screwdriver

A

WARNING: PLUGGING THE DUST COLLEC-

TION SYSTEM IN DURING ASSEMBLY CAN RESULT

IN ELECTRICAL SHOCKOR YOUR FINGERS, HAND,

OR ARM BEING CUT OFF FROM FAN BLADE CON

TACT. DO NOT PLUG IN THE COLLECTOR AT ANY

TIME DURINC5 ASSEMBLY. THE DUST COLLEC

TION SYSTEM SHOULD ONLY BE PLUGGED IN

WHEN IT IS to BE USED.

LIST OF PARTS IN LOOSE PARTS BAGt

Key

Description

Qty.

Hex Nut

M6xl,........

3/8-16./

R

Lockwasher

1/4

...................................

5/16

.................................

S Hex Screw

M6x 1 -30

M6x 1 -12

M8x 1.25- 12

....

.................

...............

.

........................

........................

.................

.....................5

.

....................2

....................

................

....................

....................

..................

9

...8

4

6

18/

t Itoms shown are not actual size

Flat Washer

1/4 X 1/2.....................................................7

5/16x11/16x1/16 ..............................................18

3/8 X 3/4.....................................................4

Switch Key....................................................................f

U

Pivoling Caster............................................................2

V

Acorn Nut 3/8-16

w

Fixed Caster................................................................2

X

Hose Clamp.................................................................2

V

........................................................

2

Page 7

assembly

MOUNTING FRONT PIVOTING CASTERS

1. Locale the following items from the loose parts bag:

Description Qty.

A Pivoting Casters

B Hex Nuts* (3/8 - 16)

C Flat Washers’ (3/8 x 3/4)...................................4

D Acorn Nuts*

E Base Plate...........................................................1

2. Screw a hex nut completely on the Caster bolt.

3. Position flat washeron top of previously installed hex

nut and slip the Caster bolt through the hole on front

of Baseplate. Position secondftatwasheron the bolt.

4. Screw the Acorn Nut on the bolt securely with an

adjustable wrench.

5. Tighten the hex nut securely against the base plate,

6. Repeat steps 2 - 5 on opposite side.

.................................................

...........................................

.........................................................

2

2

2

Items are shown actual size

ACORN NUT

FLAT WASHER

FLAT WASHER

HEX NUT

SWIVEL

CASTER

BOLT

SWIVEL CASTER

MOUNTING REAR FIXED CASTERS

1. Locate the following items from the loose parts bag

Description Qty.

A Fixed Casters......................................................2

B Flat Washers’ (1/4 x 1/2)

C Lockwashers* (1/4)............................................4

D Hex Head Screws’ (M6 x 1 -12)

2. Position Fixed Casterur\6er rear of BasePlateso that

holes on Caster bracket and Base Plate line up.

3. Install hex screw, lock washer and flat washer as

shown. Tighten securely using an adjustable wrench

4. Repeat steps 2 and 3 on opposite side.

..............................

.......................

4

4

MOUNTING INLET GUARD

1. Locate the following items from the loose parts bag:

Description Qty

A Flat Washers* (5/16 x 11/16x1/16)

B Hex Screws’(M 8 X 1.25-12)

C Lockwashers* (5/16)......................................4

................

...........................

4

4

(p) (g) gw

A B

Items are shown actual size

BASE PLATE

(REAR)

(o)

A B

HEX SCREW

LOCKWASHER

FLAT WASHER

FIXED CASTER

2. Locate the Filtration Housing ar\ö Inlet Guard.

Items are shown actual size

Page 8

assembly

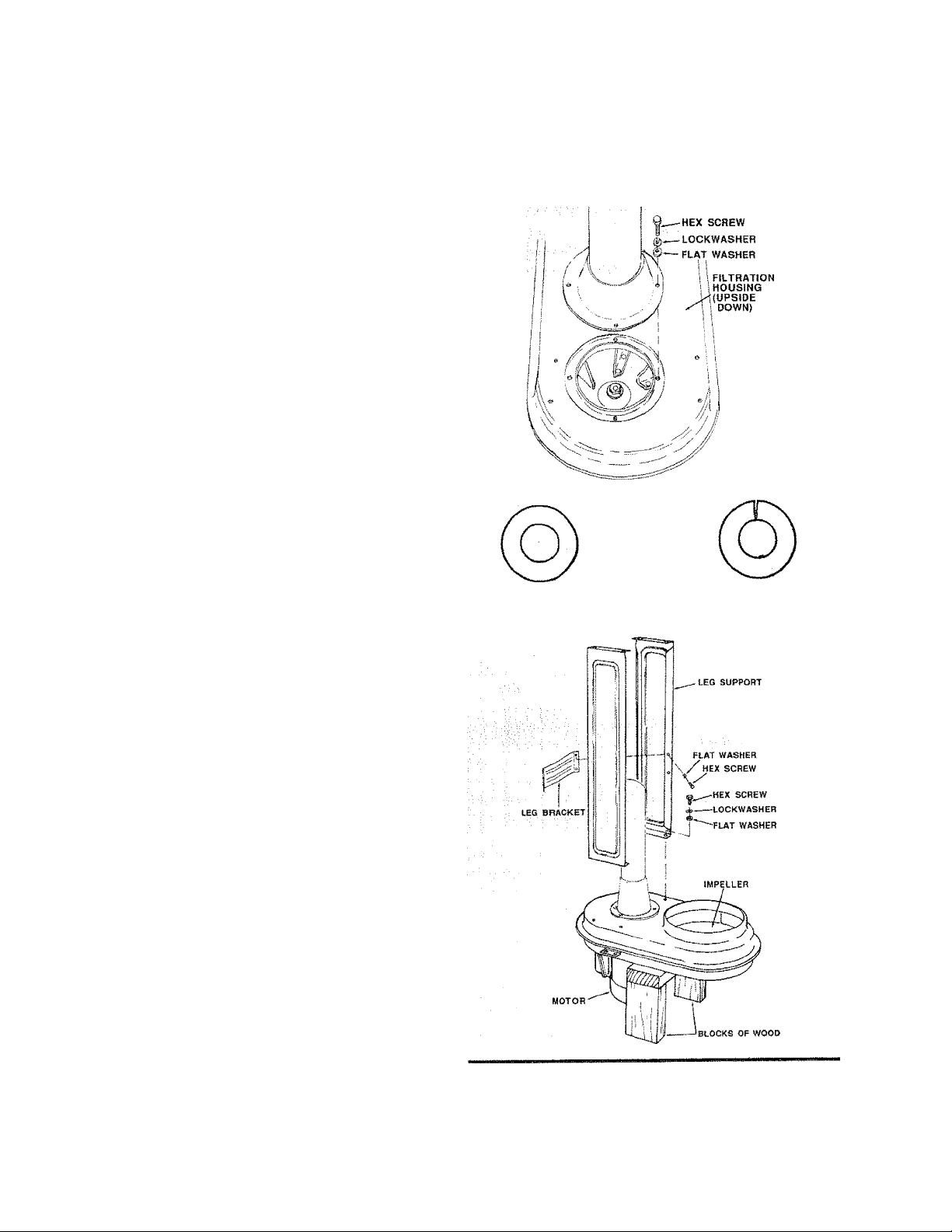

3- Carefully turn the Filtration Housing upside down so

that the Motor endbei! rests against the floor.

■ ( / V u : 7 ' ' V v :

' ^ ; A guard must

y ./ . ' 'Í POINT TO

■■ ■■■, It^REAR OF

. V, . MACHINF.

4. Support the opposite side of Filtration Housing wlh a

block of wood.

A. Place O-Ring in relief of Inlet pipe {See page 18}

5. Position/n/efGuardinlinewiththethreaded holes on

the base of the Filtration Housing.

NOTE: Make surelnlet Guard is pointing to rear of

machine.

6. Place lockwasher and flat washer on hex screw and

insert through the holes of the Inlet Guard into the

threaded holes of the Filtration Housing as shown.

7. Complete the process for the otherthree holes using

same method.

DO NOT SECURE SCREWS AT THIS TIME.

MOUNTING SUPPORT LEGS

1. Locate the following items from the loose parts bag:

Description Qty.

A Flat Washers* {5/16 x 11/16 x 3/32) .....4

B Hex Screws *{M8 x 1.25 - 12)

C Lockwashers* {5/16)

..................

....

..........4

. 4

— INLET GUARD

Items are shown actual size

CAUTION: To avoid injury, keep hands away

from fan blade.

2. Position left Leg Support as shown.

.....

3. Place lockwasher and flat washer on hex screw and

insert through the holes in the Support Leg and

secure to the threaded holes in the Filtration Housing

as shown.

4. Use same method to attach Right Support Leg.

5 . Secure hex screws with the use of adjustable wrench.

MOUNTING LEG BRACKET

1. Locate the following items from the loose parts bag:

Description Qty.

A Flat Washers* (5/16 x 11/16 x 3/32)

B Hex Screws* (M8x 1.25-12)

............

2. Insert Leg Bracket between the Support Legs and

slide against the angled flange of the Leg.

NOTE: Make sure holes in Leg Bracket align with

holes on Leg Support.

3. Place flat washer on hex screw, insert through angled

.....

4

4

flange of Leg Support and attach to threaded hole of

Bracket.

4. Repeat steps 2 and 3 using same process on other

three holes.

Page 9

MOUNTING INLET BRACKET

1. Locate the following items from the loose parts bag:

Description C3ty.

A Flat Washers* (5/16 x 11/16 xi/i6)

B Hex Screws* (M8 x 1.25 -12)

C Flat Washers *{1/4 X 1/2).................................2

D Hex Screws* (M6 x 1 -12)

2. Insert Inlet Bracket between relief flange of Inlet

Guard and against inside edge of angle flange on

Support Leg. Make sure both holes on Bracket align

with similar holes on Leg Support.

3. Place 5/16 flat washer on hex screw, insert through

Leg hole and attach to threaded hole of Bracket.

4. Repeat same process for other hole and secure with

use of adjustable wrench.

5. Attach Fixed Clamp as shown, by placing flat washer

on hex screw, insert hex screw through hole of Fixed

Clamp and attach to threaded hole of inlet Guard

Bracket

6. Repeat step 5 to attach other screw below Inlet

Guard.

...................

..........................

................................

2

2

2

' items are shown actual size

CLAMP AND BRACKET

MOUNT HERE

gli

7. Tighten all screws on Legs. Inlet Guard, and Filtration

Housing securely.

MOUNTING BASE PLATE

1. Locate the following items from the loose parts bag:

Description Qty.

A Flat Washers* (5/16 x 11/16x1/16)

B Hex Screws* (M8 x 1.25 - 12)

2. Attach Base Plate to Leg Supports by flipping base

upside down, aligning holes on both Leg Supports.

3. Place flat washer on hex screw, insert through hole of

Leg and attach to threaded holes in Base Plate as

shown.

4. Repeat same process for other three holes and

secure with adjustable wrench.

5. With the assistance of another person, carefully flip

the Oust Collection System right side up.

......................

...............................

4

4

(o) gni

Items are shown actual size

FIXED CASTERS

SWIVEL CASTERS

Page 10

assembly

MOUNTING FILTER/DUST BAG HOLDER

TO FILTRATION HOUSING

1. Locate the following items from the loose parts bag:

Description

A HexNut* (M6x1)

B Lockwas her* (1/4) ................

C Fiat Washer* {MA x 1/2)

2. Attach hex nut to threaded portion of Filter/Dust Bag

Holder and place lockwasher and flat washer on nut

as shown.

3. Insert Filter/Dust Bag Holder into threaded hole of

Filtration Housing as shwon.

4. Turn Filter/Dust Bag Holder rod clockwise until nut is

secured to Filtration Housing.

5. Secure Filter/Dust Bag Holder in piace with adjust

able wrench.

.................

.........

...............

.............V.1'.'

..................

1

.1

A B

Items are shown actual size

MOUNTING HANDLE TO FILTRATION HOUSING

1. Locate the following items from the loose parts bag:

Description Qty.

A Hex Screws* (M6 x 1 -25)

8 Lockwashers* {1/4" dia.)

C Hex Nuts* (M6x 1)

2. Attach the ends of the Handle to the Relief Flanges on

the side of Filtration Housing as shown.

3 insert hex screw through the Handle and Flange.

4. Attach the lockwasher and the hex nut to the screw

and tighten

5. Repeat process for ali four holes and secure with

adjustable wrench. :

..................

......

............................

4

4

4

to

Page 11

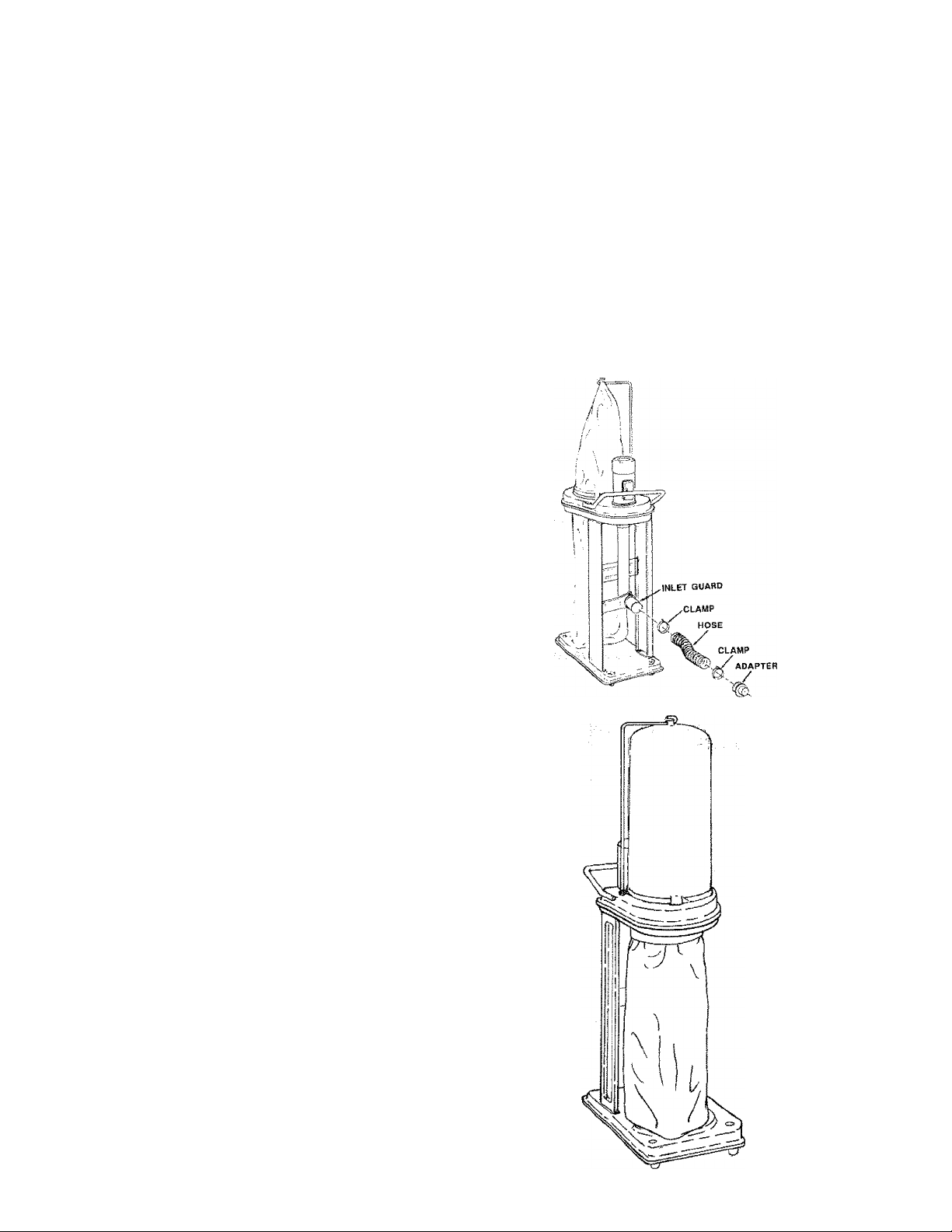

CHIP BAG ASSEMBLY LOWER FiLTRATION HOUSING

1. Insert lower Chip Bag by tilting the Metal Reinforced

Band at an angle and position it through the hole in the

lower Filtration Housing.

2. Tuck one side of the Band under the Sawdust

Chute Extension.

3. Allow the opposite side to rest on the ridge of the

opening.

4. Tug on the Chip Bag to insure proper seating.

UPPER FILTER/DUST BAG ASSEMBLY

FILTBATION HOUSING

SAWOUST CHUTE

extension

1. Disconnect the Adjustable ßandC/ampandinsertthe

end through the loops provided at the opening of the

Fllter/Dust Sag.

2. Invert the Filter/Dust Bag and slip the open end of the

Bag over the 1" Relief on the top opening of the

Filtration Housing.

3. Secure the B^ by adjusting the rectangular barto the

fourth set of hooks.

4. Pull the lever tight until it seats itself.

CAUTION: Make sure the opening of the bag Is

tight against the relief so dust will not escape.

FILTER/

DUST BAG

HOLDER

HANDLE

RELIEF

11

Page 12

operation

This Dust Collection System is designed to be con

nected directly to the woodworking machines. Please,

use only the parts provided for maximum efficiency.

4" Diameter x 60" Hose. PVC Vulcanized rubber

with wire reinforcement and 2 - 4" clamps.

4*72-1/2" Diameter Adapter. This connector allows

direct hookup to many machines including

Bandsaws, Belt and Disk Sanders, and Radial

Saw Sawdust Collector.

WARNING: To avoid fire or explosion caused

by the ignit ing of vapors or dust due to the arcing of

ATTACHING ACCESSORIES TO INLET

GUARD ■ '

4" Diameter Hose/Clamp Assembly and Adapter

1 Open Clamp and insert Hose, by slipping Clamp

;,:iC\6vet Hose. Attach to Inlet Guard and tighten

v CfClampy^ a straight blade screwdriver. Use this

same process to connect Adapter. Tighteh both

Clamps securely to increase air velocity and

The Adapter will permit easy dis-

v; :■ 7 connect. \ ^ i

electricai parts, do not operate this Dust Collection

System In areas with flammable vapors such as

lighter fluid, cleaners, oil-base paints, gasoline,

alcohol or explosive dust such as coal, magnesium,

grain or gun powder in the air. Do not vacuum

explosive dust, flammable or combustible liquids or

hot ashes. To avoid health hazards from vapors or

dusts, do not use near toxic materials. To avoid

electrical shock, do not expose to rain. Store in

doors. Unplug power cord before changing, clean

ing, or emptying the filter/dust bag or chip bag.

CAUTION: To avoid fire, use only the hose and

adaptor designed for this unit. The adapter is de

signed to fit only to the hose. Do not attach it directly

to any other inlet opening.

CONNECTING DUST COLLECTION

SYSTEM TO POWER SOURCE

k CAUTION: If connected to a circuit protected

by fusesi use time delay fuses with this appilance.

1. Prior to connecting your Dust Collection System to

any power source, be sure your bags are installed

properly. Thiswillremoveanypossibilityof dustflying

in your face.

2. The motor on your Dust Collection System is wired for

120 volts, single phase power system. Make sure the

motor rating agrees with the electrical system it is to

be connected to.

3. Too many machines on one circuitwill blow fuses. Be

careful not to overload circuit. •

12

Page 13

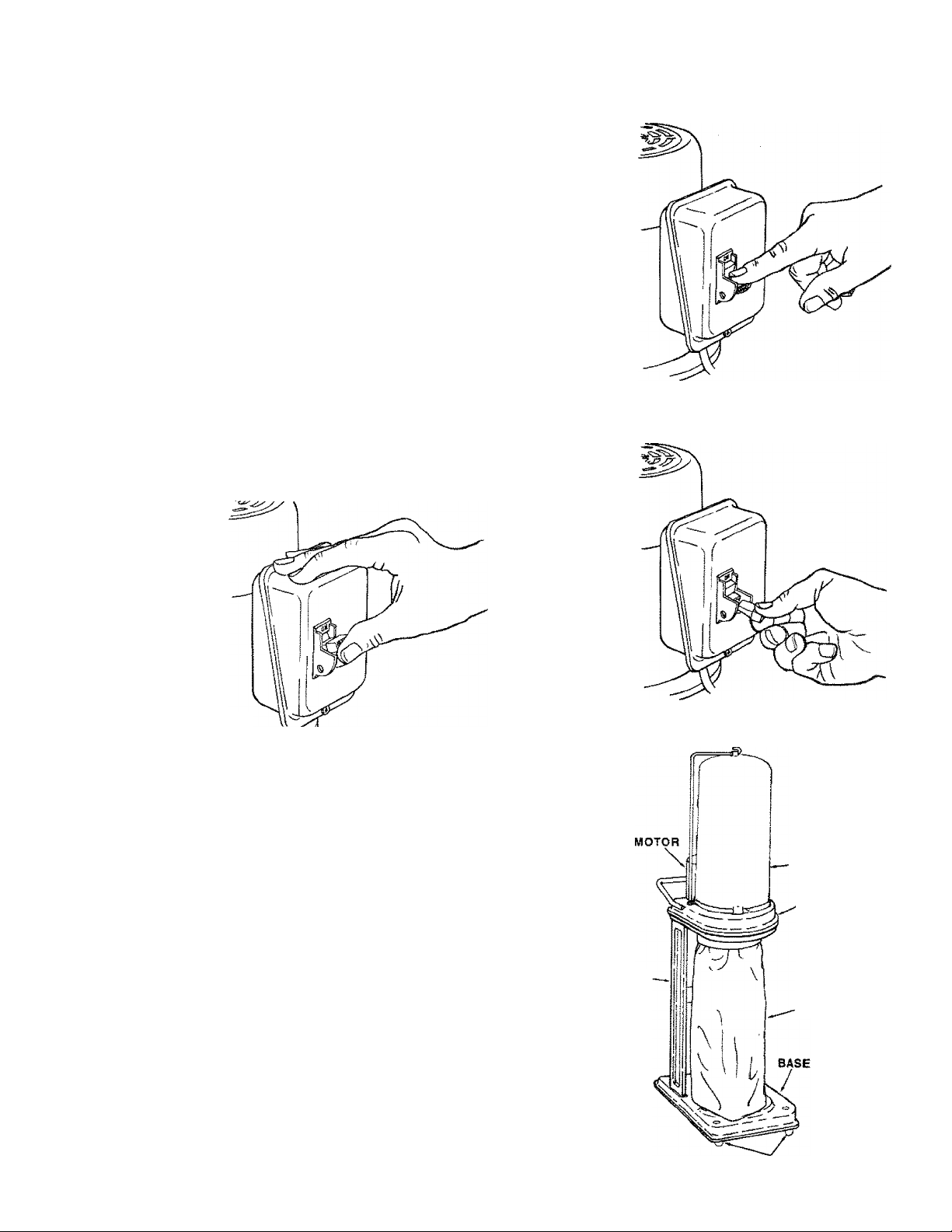

ON/OFF SWITCH

On the rear of the Motor Housing above the Handle, is

the Switch Box. The ON/OFF Switch has the ability to

be turned “ON” v^hen the Red Key is properly

installed. Switch to the “ON" position by moving the

switch upward- Turn the switch “OFF” by moving

downward. Remove the Key from the switch whenev

er the saw is turned “OFF” and keep it out of the reach

of children.

i WARNING: THE DUST COLLECTION SYSTEM

CAN START ACCIDENTALLY OR BE USED BY CHIL

DREN OR OTHERS WHEN THE KEY IS LEFT IN THE

SWITCH. ALWAYS REMOVE KEY WHEN THE DUST

COLLECTION SYSTEM IS 'OFF', AND KEEP IT OUT

OF THE REACH OF CHILDREN.

A WARNING: THE DUST COLLECTION SYSTEM

WILL START IMMEDIATELY WHEN THE POWER

COMES BACK ON AFTER A BLACKOUT IF THE KEY

IS LEFT'ON' IN THE SWITCH. ALWAYS TURN THE

SWITCH 'OFF' AND REMOVE THE KEY.

Turning Switch "ON"

MOVING THE DÜST COLLECTION SYSTEM

This Dust Collection System is able to move easily from

one woodworking machine to another.

CAUTION: To avoid injury from falling unit or

fire from electrical cords, do not cross over large

debris or electric cords when moving unit.

Turning Switch "OFF"

Removing Switch Key

LEG SUPPORT

RLTER/

DUSTBAG

FILTRATION

HOUSING

13

CHIP BAG

CASTERS

Page 14

operation

POWER SUPPLY

WARNING: YOUR DUST COLLECTION SYS-

TION. CONNECT TO A 120V, 15-AfWP, BRANCH

CIRCUIT AND USE A 15-AMP, TIME DELAY FUSE OR

CIRCUIT BREAKER. FAILURE TO CONNECT IN

THIS WAY CAN RESULT IN INJURY FROiW SHOCK

OR FIRE.

Your Dust. Coilection System must be properly

grounded. Not ali.outiets are properly grounded. If you

.are not sure that your outlet is properly grounded,

have it checked by a qualified electrician. , '

A WARNING: IF NOT PROPERLY GROUNDED

THIS DUST COLLECTION SYSTEM CAN CAUSE

ELECTRICAL SHOCK, P ARTICULARLY WHEN USED

IN DAMP LOCATIONS.

WARNING: TO AVOID SHOCK OR FIRE, IF

POWER CORD IS WORN; CUTt OR DAfViAGED IN

ANY WAY. HAVE IT REPLACED IMMEDIATELY.

This appliance is for use on a nominal 120-volt circuit,

and has a grounded plug that looks like the plug iltustratted below. Atemporary adapter may be used to connect

this plug to a 2-pole receptacle, as shown below, if a

properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded

outlet can be installed by a qualified electrican. The

green colored rigid ear, lug, or the like, extending from

the adapter must be connected to a permanent ground

such as a properly grounded outlet box cover. When

ever the adapter is used, it must be held in place by a

metal screw.

WARNING " IMPROPER CONNECTION

OF THE EQUIPMENT GROUNDING CONDUCTOR

CAN RESULT IN A RISK OF ELECTRIC SHOCK.

CHECK WITH A QUALIFIED ELECTRICAN OR SERV

ICE PERSON IF YOU ARE IN DOUBT AS TO

WHETHERTHEOUTLETIS PROPERLY GROUNDED.

DO NOT MODIFY THE PLUG PROVIDED WITH THE

APPLICANCE IF IT WILL NOT FIT THE OUTLET,

HAVE A PROPER OUTLET INSTALLED BY A QUALI

FIED ELECTRICIAN.

3-PRONG PLUG

GROUNDING INSTRUCTIONS

This appliance must be gfetinded. if it should malfunctioh of breakdown; grounding provides a path of least

resistance for electric cùfféht to rèduce the risk of

etectric shock. This appliahce is equipped with a cord

having an equipment-grounding conductor and ground

ing piug. The plug must be plugged into an appropriate

outlet that is properly iristailed and grounded In accor

dance with all local codes and ordinances.

-A WARNING: TO MAINTAIN PROPER DUST

COLLECTION SYSTEM GROUNDING, WHENEVER

THE OUTLET YOU ARE PLANNING TO USE FOR

THIS POWER TOOL IS OF THE TWO PRONG TYPE,

DO NOT REMOVE OR ALTER THE GROUNDING

PRONG IN ANY MANNER.

EXtENSiON CORDS

The use of any extension cord will cause some loss of

power. Use the fotidwing table to determine the mini

mum wire size (A.W.G.) extension cord. Use only 3-wire

extension cords which have 3-prong grounding type

plugs and 3-pole receptacles which accept the tool's

plug-

For circuits that are farther away from electrical circuit

GROUNDING PRONG

PROPERLY

GROUNDED

OUTLET

GROUNDING LUG

i¥1

3-PRONG PLUG

■ t

¥

ADAPTER

1; \ Ii ti

MAKE SURE THIS f

- CONNECTED TO A

KNOWN GROUND

~~~ 2-PRONG

RECEPTACLE

A WARNING: THE ADAPTER ILLUSTRATED IS

FOR USE ONLY IF YOU ALREADY HAVE A PROP

ERLY GROUNDED 2-PRONG RECEPTACLE.

box, the wire size must be increased proportionately

in order to deliver ample voltage to the sawdust collec-

tion system motor.

Length of

gg,oriud.Q.i:

0 - 25 feet

26 - 50 feet

51 -100 feet

Wire Sizes Required

(American Wire Gage

12py lines

No. 16

No. 14

No. 12

14

Page 15

maintenance

A WARNING: FOR YOUR OWN SAFETY, TURN

SWITCH "OFF'’ AND REMOVE PLUG FROM POWER

SOURCE OUTLET BEFORE MAINTAINING YOUR

DUST COLLECTION SYSTEM.

A WARNING; TO AVOID INJURY FROM ELEC

TRIC SHOCK OR SUDDENLY STARTING UNIT, AL

WAYS REMOVE SWITCH KEY AND KEEP UN

PLUGGED WHILE UNIT IS DISASSEMBLED IN ANY

WAY. ALWAYS REASSEMBLE WITH RECOM

MENDED PARTS BEFORE PLUGGING UNIT IN.

CHIP COLLECTING BAG REMOVAL

1. Push Band up and slide opposite edge to the middle

opening.

2. Lower Band carefully through opening as shown.

Deposit chips in appropriate metal container.

A CAUTION: Wear Safety goggles ANSI Z87.1

to protect your eyes prior to commencing opera

tion.

3. Reconnect the Chip Collecting Bag by sliding the

Band through the hpie and slide the opposite side

under Dust Chute Extension. Seat as shown.

FILTER/DUST BAG REMOVAL

A CAUTION: If using this Dust Collection System

to help keep airborne wood dust In heavy usage

within acceptable limits, you must regularly monitor

air borne dust and maintain Dust Collection System

to avoid exceeding dust limits. Each application Is

unique. Your maintenance schedule must, there

fore, be tailored to your specific use of this Dust

Collection System.

1. Shake the Filter/Dust Bag so the fine dust fails into

lower Chip Coltecting Bag.

2. Disconnect the Adjustable Band Clamp by releasir^

the Spring Lever Clamp.

3. Remove the Filter/Dust Bag and deposit all fine dust

in an appropriate metal container.

4. Reconnect the Bag carefully so the Clamp wraps

around the Bag on ail sides. Adjust the lever to the

fourth hook and fasten securely.

5. Slip loop over hook on Filter/Dust Bag Holder.

15

Page 16

maintenance

MOTOR

Excessive dust in motor could cause excessive heaî in

motor.

Every effort should be made to prevent foreign material

from entering the motor. When operated under condi

tions likely to permit accumulations of dust, dirt, or waste

within the motor, a visual inspection should be made at

freguent intervals. Accumulations of dry dust can usu

ally be blown out successfully.

NOTE: Motors used Oft wood-working tools are particu

larly susceptible toithe accumulation of sawdust and

wood chips and should be blown out or "vacuumed"

frequently to prevent interference with normal rnotor

ventilation.

To remove dust, blow off motor with a low pressure air

^hose.: -

MOTOR

___

CAUT50N; To avoid eye Injury or adverse

reaction to dust, high air pressure should not be

used especially In poorly ventilated areas.

The operator performing this cleaning function should

wear safety goggles and filter mask.

Do not use unit if power cord becomes worn or frayed.

If any servicing {other than the above cleaning) be

comes necessary, it should be performed by an author

ized Sears Service Center.

NOTE: The speed of this motor cannot be regulated or

changed.

' i PROBLEM/)'),

Motor vvilf not run.

Excessive sawdust

in air.

Excessive impeller

noise.

PROBABLE CAUSE

1. Defective cord, plug,

switch and/or motor.

2. Blown fuse.

1. Loose connectors

2. Filter/dust bag and/or

chip collection bag

releasing sawdust.

1. Picked up large wood

chips or debris.

2. Loose impeller.

3. Rubbing impeller.

REMEDY SUGGESTED

1. Consult Sears Service. Any attempt to repair this motor

may create a hazard unless repair is done by a qualified

service technician. Repair service is available at your

nearest Sears store.

2. Check for blown fuses and replace with fuse of proper

capacity.

1 Tighten connections.

2. a. Sawdust trapped between clamp bag and housing,

b. Lower bag is hung up on sawdust shoot extension.

Reposition chip bag properly. See “Maintenance - Chip

Bag".

1. Do not pick up metal or ferrous materials. Stop the machine

and the material will.fall to the bottom of inlet tube.

2. Unplug unit prior to disassembly. Hazardous moving

parts inside. Attach inlet guard before plugging in. Use

a piece of wood to free impeller.

3. Consult Sears Service to repair loose or rubbing impeller,

A repair to the housing may create a hazard unless it is

done by a qualified service technician. Repair service is

available at your nearest Sears store.

;i6

Page 17

PROBLEM

PBOBABLE CAUSE

REMEDY SUGGESTED

Excessive noise.

Motor fails to devel

op full power.

NOTE: LOW VOL

TAGE: (Power out

put of motor de

creases rapidly with

decrease in voltage

at motor terminals.

For example, a

reduction of 10% in

voltage causes a

reduction of 19% in

maximum power

output of which the

motor is capable

and a reduction of

20% in voltage

causes a reduction

of 36% in maximum

power output.)

Motor starts slowly

or fails to come up

to full speed.

1. Motor

1 - Circuit overloaded with

lights, appliances and

other rmtors.

2. Undersize extension cord

or extension cord too

long.

3. General overloading of

power company facilities.

1. Low voltage.

2. Windings burned out

or open.

3. Starting switch will not

operate. (Switch contacts

working properly.)

Capacitor is bad.

1. Have motorchecked by qualified s^rvfce technician. Repair

service is avaiable at your nearest Sears store.

1. Do not use other appliances or motors on same circuit

when using the Dust Collection System.

2. Increase the wire sizes on extension cords, or reduce

length of extension cords. See "Motor Specifications and

Electrical Requirements" section.

3. Request a power check from the power company.

1. Request voltage check from the power company.

2. Have motor repaired or replaced by a qualified service,

technician.

3. Have capacitor replaced by a qualified service technician.

Motor overheats

Motor stalls

(resulting in blown

fuses or tripped

circuit breakers).

Frequent opening of

fuses or circuit

breakers.

NOTE; Motors used on wood-workir>g tools are particularly susceptible to the accorrajlation of saw

dust and wood chips and shouW be btown out or "vacuumed" frequently to prevent interference with

fKjrmal motor ventilation and proper operation of the centrifugally-operated starting switch.

1. Motor overloaded.

2. Improper cooling. (Air

circulation restricted

through motor due to

sawdust, accumulating

inside of motor.)

f. Voltage too low to permit

motor to reach operating

speed.

2. Fuses or circuit breakers

do not have sufficient

capacity.

1. Motor overloaded.

2. Fuses or circuit breakers

dk> not have sufficient

capacity.

1. Clean out sawdust to provide normal air circulation through

motor. See "Maintenance" section.

1. Request voltage check from the power company.

2. Install proper size fuses or circuit breakers.

1 .Install proper size fuses or circxiit breakers.

17

Page 18

repair parts

PARTS LIST FOR CRAFTSMAN

DUST COLLECTION SYSTEM

MODEL 113.299780

18

Page 19

repair parts

PARTS LIST FOR CRAFTSMAN DUST COLLECTION SYSTEiyi

Always order by Part Number > not by Key Number.

MODEL 113.299780

Item

No.

1

2 819172

3 819187

4 819302

5

6 819191

7

8

9 819171 Housing, Upper

10 STD551125

11

12

13 STD551025

14

15 819168

16 819198-1

17 124944

18 819184

19

20 819190

21 819195

22 819194

23 STD835010

24

25

26

Part

No.

819166

819189

STD833025

819192

STD840610 * Nut, Hex M6 X 1

819183

STD833012

819182

819202

819201

STD835012

Description

» A Holder, Fiiler/Dust Bag

* Motor, 1 H.P.

A Switch

A Key, Switch

^ Cord with Plug

Handle

* Screw, Hex Hd.M6x 1-25

Plug, Plastic

* Lockwasher, 1/4

Seal, Housing

* Washer, 1/4 X 1/2 X 1/16

* Screw, Hex M6 x 1-12

Impeller

Washer, Flat 5/8 x 1 -1/2 x

1/8

Nut, Hex 5/8 - 18

A Guard. Impeller

Housing, Lower

Sleeve, Housing Edge

O-Ring, 135mm

A Guard, Inlet

* Screw, Hex Hd. M8x 1.25

-8

Clamp, Inlet Support

Bracket, Inlet Support

* Screw, Hex Hd. M8 x i ,25

- 12

Item

No.

27 819198

28

29

30

31

32

33

34

35 819200

36

37

38

39 819165

40

41 819173 Seal, Motor

42

43

44

45 46-57509-3

46

47

48 819269

Part

No.

819196

819207

819199

819203

STD541037

STD551037

STD541837

819186

819170

819169

819185 Screw, Pan Hd. M4x 16

819188

819167

819174

819267

819268

508298

SP5373

Description

Washe r. Flat 5/16 X 11 /16

X, 3/32

Leg

Caster, Fixed

Base

Caster, Pivoting

* Nut,. Hex 3/8 -16

* Washer. Flat 3/8 x 3/4 x

3/32

* Nut, Acorn 3/8-16

Bracket, Leg

Screw, Pan Hd. M4 x 16

- 12 Ty "AB"

* Bag.. Lower Chip

ik Clamp, Fiiter/Dust Bag

ik Bag. Upper Filter/Dust

- 10 Ty "B"

Key

Capacitor

Cover, Capacitor

* Screw. Pan Hd. M4 x

0.7-10

m Hose, Flex 4.0 Inch

^ Clamp, Hose

^ Adapter. 2-1/2’'/4.0”

* Bag of Loose Parts

(Not Shown)

Owner’s Manual (Not

Shown)

* standard Hardware Item - May Be Purchased Locaiiy,

A WARNING: These items Are Important To The Safety Of This Tool. Do Not Substitute

Common Parts.

* Any attempt to repair or replace electricai parts on this unit may create a HAZARD unless repair

is done by a qualified service technician. Repair service is available at your nearest Sears Store.

19

Page 20

smm

'X r

owners

manual

SERVICE

MODEL NO.

113.299780

Dust Collection

System

DUST COLLECTION SYSTEM

Service is available by returning this unit to the

nearest Sears Service Center/Department through

out the United States.

Mode! and serial numbers may be found on the Motor

Cover of your Dust Collection System.

HOW TO ORDER

REPAIR PARTS

J V

WHEN ORDERING REPAIR PARTS. ALWAYS

GIVE THE FOLLOWING INFORMATION;

PART NUMBER

MODEL NUMBER

113.299780

All parts listed may be ordered from any Sears

Service Center and most Sears stores. If the parts

you need are not stocked locally, your order will be

electronically transmitted to a Sears Repair Parts

Distribution Center for handling.

PART DESCRIPTION

NAME OF ITEM

Dust Collection

System

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

Part No. SP5373 Form No. SP5373-1 Printed in Taiwan 10/92

Loading...

Loading...