Craftsman 113299131 Owner’s Manual

Sears

owners

manual

MODEL NO.

113.299131

CRRFTSMRII

CAUTION:

Read SAFETY

RULES and

INSTRUCTIONS

carefully

Sears, Roebuck and Co., Chicago, III. 60684 U.S.A. and Simpsons-Sears Limited, Toronto

Part No. 62465 Printed in U.S.A.

12-INCH MO TORIZED

FL OOR SAW

assembly

operating

repair parts

general safety instructions for power tools

1. KNOW YOUR POWER TOOL

Read the owner's manual carefully. Learn its

application and limitations as well as the specific

potential hazards peculiar to this tool.

2. GROUND ALL TOOLS

This tool is equipped with an approved 3-conductor

cord and a 3-prong grounding type plug to fit the

proper grounding type receptacle. The green conductor

in the cord is the grounding wire. Never connect the

green wire to a live terminal.

3. KEEP GUARDS IN PLACE

and in working order.

4. REMOVE ADJUSTING KEYS

AND WRENCHES

Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations. Keep

work area well lit. Provide adequate surrounding work

space.

7, KEEP CHILDREN AWAY

All visitors should be kept a safe distance from work

area.

8. MAKE WORKSHOP KID-PROOF

- with padlocks, master switches, or by removing

starter keys.

9. DON'T FORCE TOOL

It will do the job better and safer at the rate for which

it was designed.

10. USE RIGHT TOOL

Don't force tool or attachment to do a job it was not

designed for.

11. WEAR PROPER APPAREL

No loose clothing, gloves, neckties or jewelry to get

caught in moving parts. Rubber-soled footwear is

recommended for best footing.

12. USE SAFETY GOGGLES

Safety gogglesmust comply with ANS Z87.1-1968.

Also useface or dust mask if cutting operation is dusty.

13. SECURE WORK

Use clamps or a vise to hold work when practical. It's

safer than using your hand, frees both handsto operate

tool.

14. DON'T OVERREACH

Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS

before servicing; when changing accessories such as

blades, bits, cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plugging

in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended

accessories. Follow the instructions that accompany

the accessories. The use of improper accessoriesmay

causehazards.

19. NEVER STAND ON TOOL

Serious injury could occur if the tool istipped or if the

cutting tool is accidentally contacted.

Do not store materials above or near the tool such that

it is necessary to stand on the tool to reach them.

CHECK DAMAGED PARTS

20.

A guard or other part that is damaged should be

properly repaired or replaced before further use of the

tool.

Carefully check the repaired or new part to assure that

it will operate properly and perform its intended

function.

If power cord is worn or cut, or damaged in any way,

have it replaced immediately.

The operation of any power tool can result in foreign objects being

thrown into the eyes, which can result in severe eve damage. Always

wear safety goggles complying with ANS Z87.1-1968 before

commencing power tool operation. We recommend Wide Vision

Safety Mask for use over spectacles, or standard safety goggles ...

available at Sears retail or catalog stores.

THIS SAFETY SEAL OF THE

POWER TOOL INSTITUTE ASSURES YOU...

1. That the manufacturer's power tools, including the particular tool

assoc;ated w;th the Seal, are produced in accordance with applicable

,Standards For Safety of Underwriters' Laboratories and American

National Standards (ANSI).

2. That compliance with applicable safety standards is assured by in-

dependent inspection and testing conducted by Underwriters' Labora-

tories (UL).

3. That every motorized tool is inspected under power.

4. That every tool has with it adequate instructions and a llst of safety

rules for the protection of the user.

5. That the tool manufacturer is a member of the Power Tool Institute and

is a sponsor of the Institute's Consumer Safety Education Program.

2 Copyright 1969 by Powe r Tool Institute, Inc. AI_ r_ghts reserved.

SAFETY INSTRUCTIONS TO OPERATOR

WARNING: Do not connect power cord

until the following steps have been

satisfactorily completed:

a. READ CAREFULLY AND UNDERSTAND THE FOL-

LOWING INSTRUCTIONS and the "SAFETY RULES

FOR POWER TOOLS" ON PAGE 2.

b. Examination and operating familiarity with ON-OFF

switch, elevation control, bevel control, miter gauge,

and rip fence.

CAUTION: Always disconnect the power

cord when removing the table insert,

changing the cutting tool, or making

adjustments.

1. The saw should be bolted down if there is any tendency

to tip over or move during normal operations. The

saw table should be approximately 36-inches above

the floor.

2. The saw work area should have adequate overhead,

non-glare light and adequate surrounding work space.

3. The saw should be positioned so neither the operator

nor a casual observer is forced to stand in line with

the saw blade.

4. Kickbacks can cause Serious injury. A "kickback" occurs

when a part of the workplece binds on the saw blade or

binds between the saw blade and the rip fence or other

fixed object, rises from the table, and is thrown toward

the operator. Kickbacks are usually caused by one or

more of the following conditions:

a. Failure to use a spreader when ripping, or failure to

maintain the spreader.in alignment with the saw

blade.

b. Improperly conditioned (dull) saw that permits the

material to pinch on the out-feed edge of the saw

and rise from the table.

c. Failure to determine that the rip fence and the saw

blade are parallel to one another.

d. Ripping wood that has a twisted grain, does not

have a straight edge to guide along the fence, or

wood that is twisted or not flat (which may rock on

the table and pinch the blade).

e. Confining the cut-off piece when ripping or cross-

cutting.

f. Ripping by applying the feed force to the section

of the workplece that will become the cut-off (free)

piece (feed force when ripping should always be

applied between the saw blade and the fence -- use

push stick for narrow or short work).

g. Releasing workplece before operation is complete;

not pushing the workpiece all the way past the saw

blade.

5. Injury from kickbacks can be prevented or minimized

by:

a. Avoiding any of the causes noted above;

b. Making sure by trial before starting the cut that the

anti-kickback pawls will stop the kickback once it

has started (sharpen all points if they do not);

c. Keeping your face and body always out of line of

possible kickbacks, including turning the switch ON

and OFF.

d. Always wearing safety goggles.

e. Never use both the rip fence and miter gauge dur-

ing the same operation.

6. A large proportion of tilting arbor saw accidents is

caused by dull, badly set, improperly filed cutting tools,

by gum or resin adhering to cutting tools and by fence

misallgnment (out of parallel) with the saw blade. Such

conditions cause the material to stick, jam, stall the saw,

or kick-back at the operator. Cracked saw blades should

be discarded immediately. A saw blade can become

cracked if it wobbles or if it is not in balance. NEVER

ATTEMPT TO FREEA STALLED SAW BLADE WITHOUT

TURNING THE SAW OFF. Avoid potential injury by

proper cutting tool and machine maintenance.

7. Gloves should not be worn while operating the saw.

Loose flowing garments, jewelry (rings, wrist watches,

etc.), and neckties should never be worn. Long sleeves

should be rolled to above the elbows.

8. To protect your eyes, always wear safety goggles. In

addition, wear a face shield to protect against flying

particles. Ear protectors (ear plugs or muffs) should be

used during extended periods of operation.

9. Provide proper support for the workpiece, based on its

size and the type of operation to be performed; hold

the work firmly against the gauge or guide. Use a push

stick when ripping short work (under 6-inches long), or

narrow work. A push block or miter gauge hold-down

should be used when dadoing or molding.

10. Never use a length stop (such as the fence when cross-

cutting) on the free end or edge of the workpiece. Never

hang onto or touch the free end of workpiece, or a free

piece that is cut off, while power is "ON" and/or the

sawblade is rotating. In short, to guard against kick-

backs or other potential accidents, the cut-off piece in

any thru-sawing operation must never be confined -- it

must be allowed to move laterally. Never use the rip

fence when cross-cuftlng, or the miter gauge when

ripping.

11. Cross-cutting operations are more conveniently worked

and with greater safety if an auxiliary wood facing is

attached to the miter gauge using the holes provided.

12. Do not leave a long board unsupported so the spring

of the board causes it to shift on the table. A support

should be used to catch the end of the board behind the

blade.

13. Never climb on or near the saw. Serious injury could

occur if the tool is tipped or if the cutting tool is acci-

dently contacted. Never leave the saw with power on,

or before the cutting tool has come to a complete stop.

14. Avoid awkward operations and hand positions, where

a sudden slip could cause a hand to move into a saw

blade or other cutting tool. Never reach in back of the

cutting tool with either hand to hold down the work-

piece.

15. Make sure the top of the arbor or cutting tool rotates

toward you when standing in normal operating position.

Also make sure the cutting tool, arbor collars and arbor

nut are installed properly. Keep the cutting tool as low

as possible for the operation being performed. Keep

all guards in place whenever possible.

16. Do not use any blade or other cutting tool marked for

an operating speed in excess of the design speed of the

saw. Never use a cutting tool larger in diameter than

the diameter for which the saw was designed. For

greatest safety and efficiency when ripping, use the

maximum diameter blade for which thesaw is designed,

since under these conditions the spreader is nearest

the blade.

(Continued on Next Page)

SAFETY INSTRUCTIONS TO OPERATOR

17.

Adjust table inserts flush with, or slightly below, the

table top.

18.

For operations which do not permit the use of a spread-

er, serious consideration should be given to the use of

jigs or fixtures to hold the work so the hands of the op-

erator are removed a safe distance from the point of

operation.

19.

The use of abrasive or cut-off wheels, or wire wheels

can be dangerous and is not recommended. (Abrasive

or cut-off wheels are ,used to saw many different ma-

terials including metals, stone, and glass.)

20.

Objects can be thrown upward toward the operator by

the back of the blade if proper operating procedures

are not followed. ?his usually occurs when a small loose

piece of wood or other object works around to the rear

of the revolving blade. It can usually be avoided by re-

moving all loose pieces from the table immediately

after they are cut off, using a long stick of wood, and

by keeping the guard and spreader in place at all times.

Use extra caution when the guard assembly is removed

for dadoing or molding, and replace the guard as soon

as that operation is completed.

21.

Never perform any operation "freehand." This term

means feeding the stock into the saw blade or other

cutting tool without using the miter gauge, rip fence,

taper jig, or some other device which prevents rotating

or twisting of the workpiece during the operation.

22.

Never turn your saw "ON" before clearing the table

of all objects (tools, scraps of wood, etc.) except the

workpiece and related feed or support devices for the

operation planned.

23.

Safety is a combination of operator common sense and

alertness at all times when the saw is being used.

24.

Do not cycle the motor switch on and off rapidly, as this

may cause the saw blade to loosen. In the event this

should ever occur, allow the saw blade to come to a

complete stop and retighten the arbor nut normally, not

excessively.

WARNING: Do not allow familiarity

(gained from frequent use of your saw) to

become commonplace. Always remember

that a careless fraction of a second is suf-

ficient to inflict severe injury.

CONTENTS

Page

Unpacking and Pre-Assembly Instructions .... 4

Power Supply and Motor Data ........... 5

Assembly and Adjustments ................ 6

Operating Controls ....................... 16

TOOLS NEEDED

_ Square

Screwdriver (medium)

Screwdriver (small) I_ ]J (combination square,

Pencil

Pliers Small steel scale

Page

Maintenance and Lubrication .............. 17

Proper Operating Procedures .............. 18

Trouble Shooting ........................ 22

Repair Parts ............................ 24

3/8-1nch wrench

7/16-inch wrench

_ _ 1/2-inch wrench

NOTE: An arbor wrench and shaft wrench,

for removing or installing the saw arbor nut,

and all necessary hex-"L" wrenches are sup-

plied with the saw. (Refer to the "'Loose

Parts List.")

9/16-1nch wrench

unpacking and pre-assembly

4 S

6

Figure 1

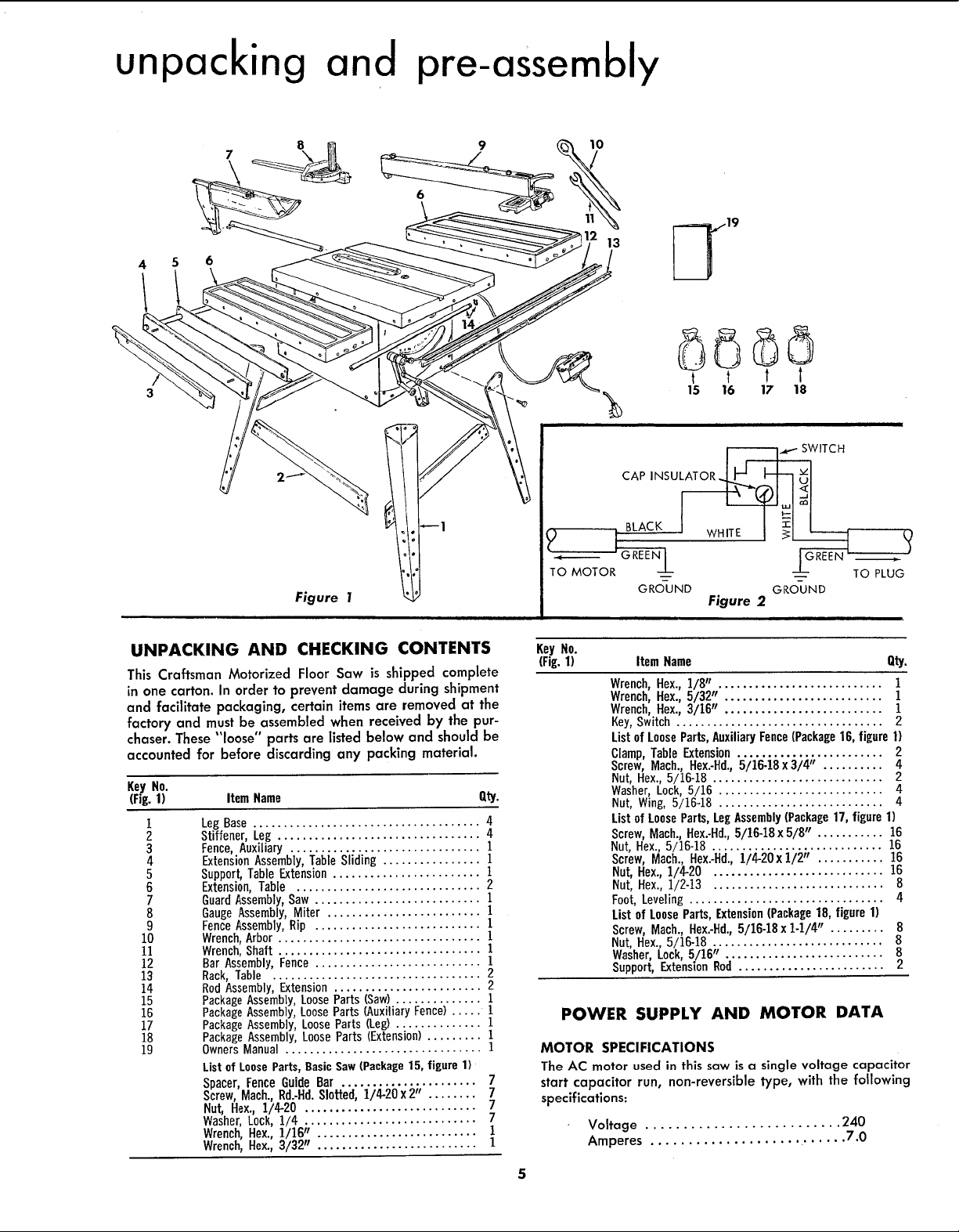

UNPACKING AND CHECKING CONTENTS

This Craftsman Motorized Floor Saw is shipped complete

in one carton. In order to prevent damage during shipment

and facilitate packaging, certain items are removed at the

factory and must be assembled when receiyed by the pur-

chaser. These "loose" parts are listed below and should be

accounted for before discarding any packing material.

KeyNo.

IFig.1) ItemName Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Leg Base ..................................... 4

Stiffener, Leg ................................. 4

Fence, Auxiliary ............................... 1

Extension Assembly, Table Sliding ................ 1

Support, Table Extension ........................ 1

Extension, Table .............................. 2

Guard Assembly, Saw ........................... I

Gauge Assembly, Miter ......................... 1

Fence Assembly, Rip ........................... 1

Wrench, Arbor ................................. 1

Wrench, Shaft ................................. 1

Bar Assembly, Fence ........................... 1

Rack, Table .................................. 2

RodAssembly, Extension ........................ 2

Package Assembly,Loose Parts (Saw).............. 1

Package Assembly,Loose Parts (Auxiliary Fence) ..... 1

Package Assembly, Loose Parts (Leg) .............. 1

Package Assembly, Loose Parts (Extension)......... 1

Owners Manual ................................ 1

List of Loose Parts,BasicSaw (Package15, figure 1)

Spacer, Fence Guide Bar ...................... 7

Screw, Mach.,Rd.-Hd. Slotted, 1/4-20 x 2" ........ 7

Nut, Hex., 1/4-20 ............................ 7

Washer, Lock,1/4 ............................ 7

Wrench,Hex., 1/16" .......................... 1

Wrench,Hex., 3/32" .......................... 1

t t t t

15 16 17 18

ii

Key No.

(Fig. 1) Item Name Qty.

Wrench, Hex., 1/8 ........................... 1

Wrench, Hex., 5/32" .......................... 1

Wrench, Hex., 3/16" .......................... 1

Key, Switch .................................. 2

List of LooseParts,AuxiliaryFence(Package16, figure 1)

Clamp, Table Extension........................ 2

Screw, Mach., Hex.-Hd.,5/16-18 x 3/4" .......... 4

Nut, Hex., 5/16-18 ............................ 2

Washer, Lock,5/16 ........................... 4

Nut, Wing, 5/16-18 ........................... 4

List of LooseParts,LegAssembly(Package17, figure 1)

Screw, Mach., Hex.-Hd.,5/16-18 x 5/8" ........... 16

Nut, Hex., 5/16-18 ............................ !6

Screw, Mach., Hex..Hd., 1/4-20xl/2" ........... 15

Nut, Hex., 1/4-20 ............................ 16

Nut, Hex., 1/2-13 ............................ 8

Foot, Leveling................................ 4

List of LooseParts,Extension(Package18, figure 1)

Screw, Mach., Hex.-Hd.,5/16-18 x 1-1/4" ......... 8

Nut, Hex., 5/16-18 ............................ 8

Washer, Lock,5/16" .......................... 8

Support,ExtensionRod ........................ 2

POWER SUPPLY AND MOTOR DATA

MOTOR SPECIFICATIONS

The AC motor used in this saw is a single voltage capacitor

start capacitor run, non-reversible type, with the following

specifications:

Voltage .......................... 240

Amperes .................... ....... 7.0

II

assembly and adjustments

GROUNDINGBLADE_S I!'y/Z-//' f_ _ I 'EG

" ./'_I / NO ADAPTER IS I _ ! OVERLOAD I

Jfl I AVAILABLEFORI _ J PROTECTORI

" II TH'sTYPE LU°I I

Figure 3 J Figure 4 | Figure 5

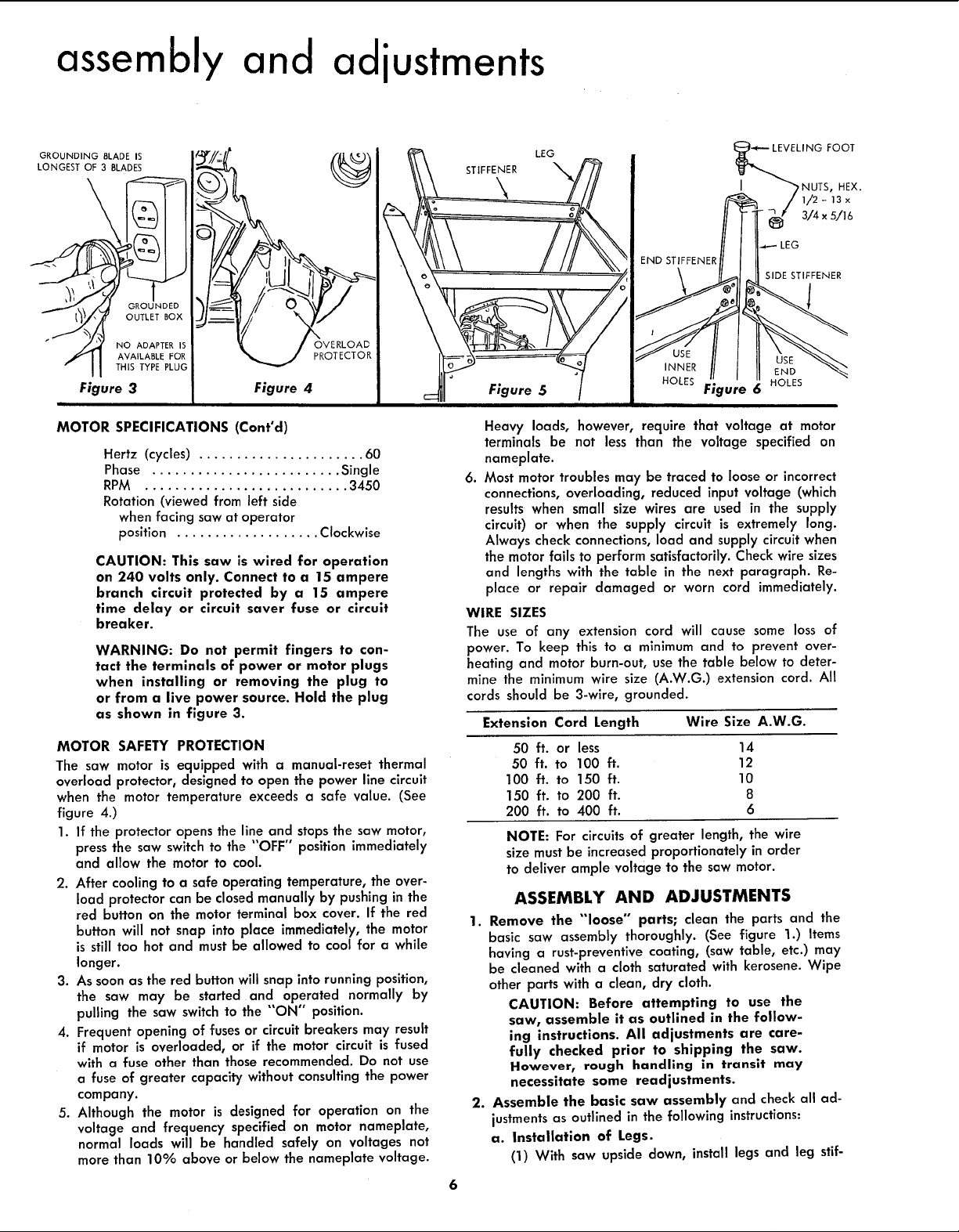

MOTOR SPECIFICATIONS (Cont°d)

Hertz (cycles) ...................... 60

Phase ......................... Single

RPM ........................... 3450

Rotation (viewed from left side

when facing saw at operator

position ................... Clockwise

CAUTION: This saw is wired for operation

on 240 volts only. Connect to a 15 ampere

branch circuit protected by a 15 ampere

time delay or circuit saver fuse or circuit

breaker.

WARNING: Do not permit fingers to con-

tact the terminals of power or motor plugs

when installing or removing the plug to

or from a live power source. Hold the plug

as shown in figure 3.

MOTOR SAFETY PROTECTION

The saw motor is equipped with a manual-reset thermal

overload protector, designed to open the power line circuit

when the motor temperature exceeds a safe value. (See

figure 4.)

1. If the protector opens the line and stopsthe saw motor,

press the saw switch to the "OFF" position immediately

and allow the motor to cool.

2. After cooling to a safe operating temperature, the over-

load protector can be closed manually by pushing in the

red button on the motor terminal box cover. If the red

button will not snap into place immediately, the motor

is still too hot and must be allowed to cool for a while

longer.

3. As soon asthe red button will snap into running position,

the saw may be started and operated normally by

pulling the saw switch to the "'ON" position.

4. Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

with a fuse other than those recommended. Do not use

a fuse of greater capacity without consulting the power

company.

5. Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

I

Heavy loads, however, require that voltage at motor

terminals be not less than the voltage specified on

nameplate.

.

Most motor troubles may be traced to loose or incorrect

connections, overloading, reduced input voltage (which

results when small size wires are used in the supply

circuit) or when the supply circuit is extremely long.

Always check connections, load and supply circuit when

the motor fails to perform satisfactorily. Check wire sizes

and lengths with the table in the next paragraph. Re-

place or repair damaged or worn cord immediately.

WIRE SIZES

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to deter-

mine the minimum wire size (A.W.G.) extension cord. All

cords should be 3-wire, grounded.

Extension Cord Length Wire Size A.W.G.

50 ft. or less 14

50 ft. to 100 ft. 12

100 ft. to 150 ft. 10

150 ft. to 200 ft. 8

200 ft. to 400 ft. 6

NOTE: For circuits of greater length, the wire

size must be increased proportionately in order

to deliver ample voltage to the saw motor.

ASSEMBLY AND ADJUSTMENTS

1. Remove the "'loose" parts; clean the parts and the

basic saw assembly thoroughly. (See figure 1.) Items

having a rust-preventive coating, (saw table, etc.) may

be cleaned with a cloth saturated with kerosene. Wipe

other parts with a clean, dry cloth.

CAUTION: Before attempting to use the

saw, assemble it as outlined in the follow-

ing instructions. All adjustments are care-

fully checked prior to shipping the saw.

However_ rough handling in transit may

necessitate some readjustments.

2. Assemble the basic saw assembly and check all ad-

justmentsas outlined in the following instructions:

a. Installation of Legs.

(1) With saw upside down, install legs and leg stif-

6

END STIFFENER

INNER

HOLES

LING FOOT

/ iI -13x

// I''_ _ 3/4x5/16

I SIDE STIFFENER

Figure

6 HOLES

NUTS, HEX.

J

EXTENSION ROD

SUPPORTS

Figure 7

SMALL STEEL SCALE

Figure 9

feners. (See figure 5.) Using parts from the correct

loose parts bag, assemble the legs to the saw base

with the sixteen 5/16-18x5/8 inch screws and

5/16-18 nuts. (See figure 6.) Leave these screws

loose in order to facilitate mounting the stiffeners.

All four leg stiffeners are identical and since the

distance on the sides is greater than the distance

on the ends, the leg stiffeners used on the sides

should be attached at outer holes while the

stiffeners at the ends should be attached at inner

holes. (See figure 6.)

Assemble the four stiffeners with sixteen 1/4-

(2)

20 x 1/2 inch screws and 1/4-20 inch nuts. After

stiffeners are all in place, tighten all screws

securely. Install leveling feet, each with 2

1/2-13 x 3/4 x 5/16 hex nuts. (See figure 6.)

Place the saw in an upright position on its legs.

(3)

b. Installation of Side Extensions.

(1) Install table extensions on each side of the table

with four 5/16-18x 1-1/4 inch screws, 5/16-18

inch nuts and 5/16 inch Iockwashers in each

extension (See figure 7.) These extensions are

provided with multiple holes on both sides (front

and back) to make them adaptable to various

Figure 8

TABLE EXTENSfON ,_

FENCE GUID_ BAR

SCREW

Figure 10

table mountings. Position the extensions to the

sides of the table so the four holes in the table

and the extensions are aligned when the table

and extensions are correctly mated. An extension

rod support should be located under each end

screw at left-hand side of the saw. (See figures

7 and 8.) Leave screws snug (not tight). Be sure

to position the extension rod supports as shown

in figure 8.

(2) Place a small steel scale across saw table edge

and table extensions edge and, using the rubber

mallet, tap extensions slightly up or down (or

forward and rearward) until the surface of each

table extension is even with surface of table top

and front edge of table. (See figure 9.) Tighten

nuts on all attaching bolts securely and recheck

to make sure tightening nuts did not permit ex-

tension to move.

c. Installation of fence guide bar, rack and switch

box support. (See figure 10.)

(1) Insert a 1/4-20 x 2 inch,slotted round-head screw

through the center hole of guide bar and through

a spacer. The guide bar should be positioned so

the scale faces upward, and is readable from the

front of the saw. (See figure 10.)

SWITCH

BOX

RACK

ii

assembly and adiustments

SIDE VIEW

4 3 2 1

4 /

SAW TABLE SPACER GUIDE BAR

RACK

SCREW

/4 - 20 x 21N._

LOCKW_

SWITCH BOX

Figure 11

(2) Attach this assembly to the center hole in the

table and secure the assembly with a 1/4 inch

Iockwasher and I/4-20 inch hex nut. Do not

tighten the nut until all attaching screws are in

position.

(3) Place each rack in position (as shown in figure

11) and insert a 1/4-20 x 2 inch slotted round

head screw through the outside hole, through the

guide bar, spacer and table extension. Secure

with a 1/4 inch Iockwasher and 1/4-20 inch hex

nut. (See figure 10.)

(4) Place switch box in position (either to right hand

or left hand side of saw table as desired). Attach

with two 1/4-20 x 2 inch slotted round head

screws through switch box mounting flange, rack,

guide bar, spacer and table. Secure with two

1/4 inch Iockwashers and 1/4-20 inch hex nuts.

(See figures 10 and 11.)

(5) Complete attachment of opposlte rack with two

more screws, aligned with table in the same

sequence described above. Tighten all screws

securely.

d. Installation of Auxiliary Fence and Extension.

(See figure 12.)

NOTE: This adjustable, auxiliary fence and ex-

tension was designed for use on the left-hand

side of the saw (when facing the saw at oper-

ator's position).

(1) Attach the table extension support (1, figure 12)

to outside edge of left-hand table extension with

5

4

Figure 12

two 5/16-18 x 3/4 inch screws (5), 5/16-18 inch

nuts and 5/16 inch Iockwashers in position as

shown in figure 12. Do not tighten the screws fully.

(2) Slide the extension slide rod (2) through each

rod support (3) and through the hole in each end

of the support (I). It will be necessary to slide

these rods from under the table because of the

retaining rings.

(3) Attach the sliding extension (9) to each rod (2)

with a 5/16-18 x 3/4 inch screw (5) and 5/16 inch

Iockwasher in the end of each rod. Do not tighten.

This extension should be positioned as shown in

figure 12.

(4) Move the end of sliding extension in. Level the

sliding extension (9) with the table extension.

Tighten 5/16-18 x 3/4 screws (5) in the extension

slide rods (2). Move sliding extension out and

tighten 5/16-18 x 3/4 screws (5) attaching the

support (1) to the extension. If binding is experi-

enced, tap the rod supports (3) in the proper

direction to relieve interference.

(5) Position an extension clamp (7) over each rod

and through the mating hole in support (1). Secure

each extension clamp with a wing nut (8).

(6) Attach the auxiliary fence (6) with the wing nuts

(8), as shown in figure 12.

e. Adjust the Table Insert. (See figures 13 and 14.)

(1) Pressdown on table insertwith fingers to make

sure it is properly secured in the table opening.

(2) Using a small scale or straightedge, check at

FLEVATIOI_ KNOB

CRANK

TILT CRANK-

Figure 13 Figure 14 Figure 15

each of the four set screw positions to determine

if the table insert is even with saw table surface.

(See figure 13.) If uneveness exists, adjust as

follows:

(a) If an adjustment is necessary, rotate each of

the four set screws(or as many as required)

with a 3/32 inch hex-"L'" wrench until table

and insert surfaces are even. (See figure 14.)

(b) Make surethat ends of all four setscrews are

making contact with table recess by pressing

on the insert at each set screw location. If the

insert "rocks" when pressed at any of the

four screw locations, adjust set screws until

the "'rocking" is eliminated.

3. Adjust the 90 ° and 45 ° Stops.

a. Checking and Adjusting the 0 ° Position

(1) Loosen the elevation lock by pulling out the

elevation lock knob and rotate theelevation crank

to raise the saw blade to the deepest cut position.

(See figure 15.) Pushelevation lock in.

(2) Loosen the clamp knob and rotate the tilt crank

counterclockwise until it will rotate no farther.

(3) With the saw blade in position described above,

tighten the clamp knob to secure the tilt mech-

anism.

(4) Place a square on the saw table and against saw

blade. (See figure 16.) The blade should be at 90

degrees (perpendicular) to the table top surface.

(5) If the blade is not square with the table top, loosen

the clamp knob (figure 15) and rotate the tilt

crank to move the mechanism off the 90 ° stop.

This can be accomplished by rotating the tilt crank

until the pointer on tilt scale indicates approxi-

mately 10 degrees. Rotate the 90 ° stop screw

in table top with a 3/16-inch hex-"L" wrench to

produce an approximate correction. (See figure

17.) Rotate the tilt crank until the saw blade is

stopped by the 90 ° stop screw and recheck with

the square for an exact 90 ° position of the saw

blade. Continue these trial settings until the saw

blade stops at exactly 90° with the table top.

-----C.

/

(6) When the saw blade is adjusted squarely with

the table top, check the pointer on the tilt gauge,

which should be positioned at exactly "0" (zero)

degrees. (See figure 15.) If not at zero, loosen

the attaching screw and align pointer with the

"0" mark, then tighten the screw.

-LEVATION

.OCK KNOB

Figure 16

STOPSCREW 45°

STOPSCRE_

Figure 17

assembly and adjustments

ARBOR WRENCH

\

SHAFT

WRENCH

ELEVATION

CRANK

POINTER

q

CLAMP KNOB

aASE OF

COMBINATION SQUARI

Figure 18

sc,_

REAR OF SAW

Figure 21

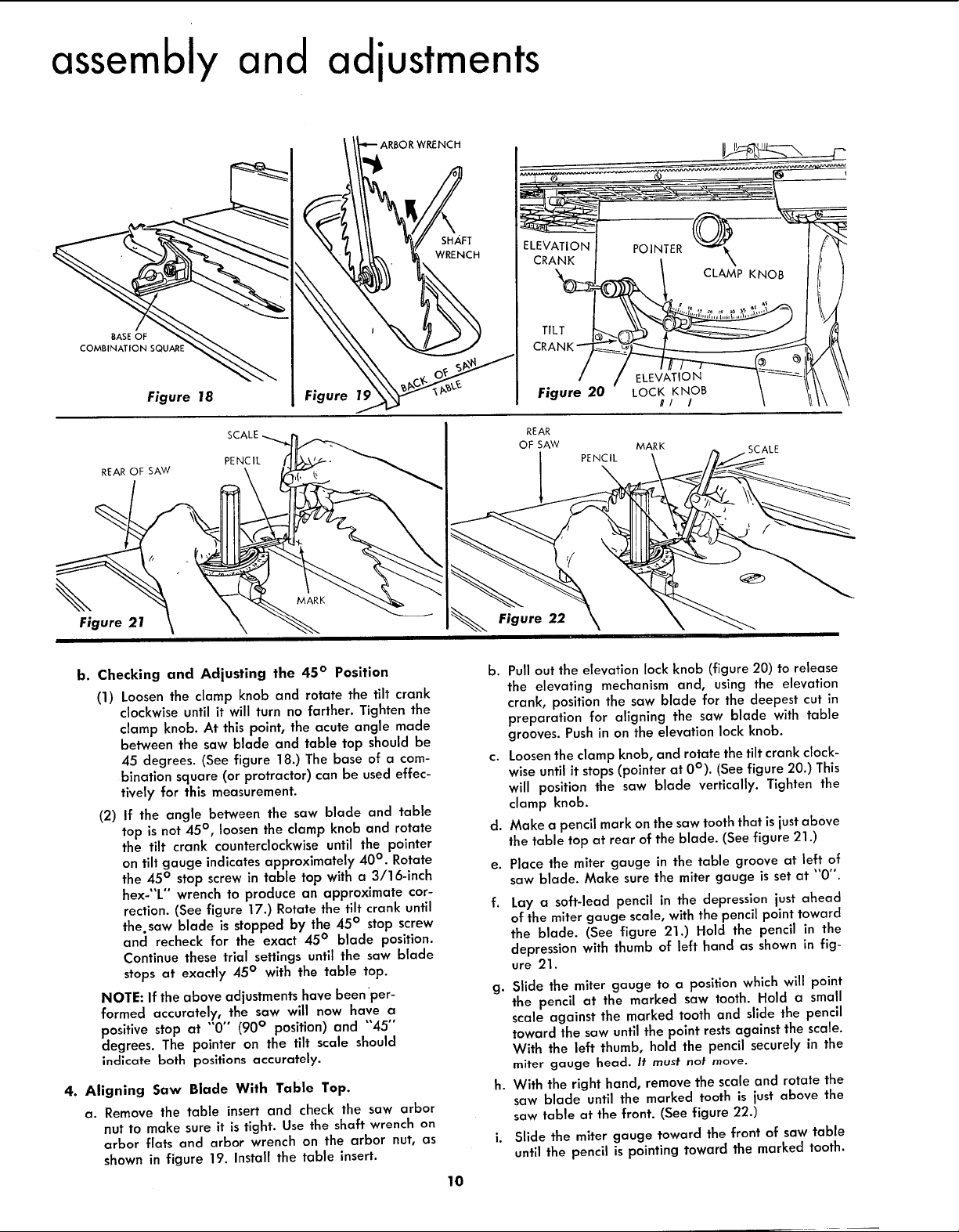

b. Checking and Adjusting the 45 ° Position

(1) Loosen the clamp knob and rotate the tilt crank

clockwise until it will turn no farther. Tighten the

clamp knob. At this point, the acute angle made

between the saw blade and table top should be

45 degrees. (See figure 18.) The base of a com-

bination square (or protractor) can be used effec-

tively for this measurement.

(2) If the angle between the saw blade and table

top is not 45 °, loosen the clamp knob and rotate

the tilt crank counterclockwise until the pointer

on tilt gauge indicates approximately 40 °. Rotate

the 45° stop screw in table top with a 3/16-inch

hex-"L" wrench to produce an approximate cor-

rection. (See figure 17.) Rotate the tilt crank until

the. saw blade is stopped by the 45 ° stop screw

and recheck for the exact 45° blade position.

Continue these trial settings until the saw blade

stops at exactly 45° with the table top.

NOTE: If the above adjustments have been 'per-

formed accurately, the saw will now have a

positive stop at "'0" (90 ° position) and "45"

degrees. The pointer on the tilt scale should

indicate both positions accurately.

4. Aligning Saw Blade With Table Top.

a. Remove the table insert and check the saw arbor

nut to make sure it is tight. Use the shaft wrench on

arbor flats and arbor wrench on the arbor nut, as

shown in figure 19. Install the table insert.

PENCIL

Figure

MARK

TILT

ELEVATION

Figure 20

REAR

OF SAW

Figure 22

b. Pull out the elevation lock knob (figure 20) to release

the elevating mechanism and, using the elevation

crank, position the saw blade for the deepest cut in

preparation for aligning the saw blade with table

grooves. Push in on the elevation lock knob.

c. Loosenthe clamp knob, and rotate the tilt crank clock-

wise until it stops(pointer at 0°). (See figure 20.) This

will position the saw blade vertically. Tighten the

clamp knob.

d. Make a pencil mark onthe saw tooth that is just above

the table top at rear of the blade. (See figure 21.)

e. Place the miter gauge in the table groove at left of

saw blade. Make sure the miter gauge is set at "0".

f.

Lay a soft-lead pencil in the depression just ahead

of the miter gauge scale, with the pencil point toward

the blade. (See figure 21.) Hold the pencil in the

depression with thumb of left hand as shown in fig-

ure 21.

g. Slide the miter gauge to a position which will point

the pencil at the marked saw tooth. Hold a small

scale against the marked tooth and slide the pencil

toward the saw until the point restsagainst the scale.

With the left thumb, hold the pencil securely in the

miter gauge head. It must not move.

h. With the right hand, remove the scale and rotate the

saw blade until the marked tooth is just above the

saw table at the front. (See figure 22.)

i. Slide the miter gauge toward the front of saw table

until the pencil is pointing toward the marked tooth.

10

PENCIL

LOCK KNOB

//! /

MARK

SCALE

Loading...

Loading...