Craftsman 113298842, 113298843 Owner’s Manual

Save This Manual For

Future Reference

MODEL NO.

113=29884

SAW WITH LEGS

TWO CAST IRON

TABLE EXTENSIONS

MOTOR AND

QUICK RELEASE

RIP FENCE

Sedal

Number

Model and serlQInum_:x_rmay

be fotr_

at 1he rlghf-I'_nd side of the

bose.

You should r_ord both model

and sedal number In a safe

place for future use.

CRRFTSMRH

10" Belt Drive Saw

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY.

_,, J _.

Sold by SEARS, ROEBUCK AND CO., Hoffman Estates, IL. 60179 U.S.A.

Part No SP5624 Printed in U S A

• assembly

= operating

• repair parts

J

BI

if within one year from the data of purchase, this Craftsmen Table Saw fails due to a defect in

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

THIS WARRANTY APPLIES ONLY WHRLE THIS PRODUCTIS USED IN THE UNITED STATES.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to sttata.

SEARS, ROEBUCK AND CO., D/817 WA Hoffman Estates, iL 60179

SAFETY iNSTRUCTiONS FOR TABLE SAW

Safety is acombination of common sense, staying alert

and knowing how your table saw works. Read this

manual to understand this saw.

BEFORE USING THE SAW

WARNING: To avoid mistakes that could cause

serious, permanent Injury, do not plug the saw in

until the following steps have been satisfactorily

completed.

4. GROUND THE SAW- This saw has an approved 3-

conductor cord and a 3-prong grounding type plug.

The plug fitsgrounding type outlets designed for 120

volt 15 amp circuits. The green conductor inthe cord

isthe groundingwire. To avoid electrocution,NEVER

connect the green wire to a live terminal.

5. To avoid injuryfrom electrical shock, make sure your

fingers do not touch the plug's metal prongs when

plugging in or unplugging the saw.

1. Assembly and Alignment (See pages 13 - 34).

2. Learn the use and function of the ON-OFF Switch,

Guard, Spreader, Anti-Kickbackdevice, MiterGauge,

Fence, Table Insert and Blade Elevation and Bevel

Controls. (See page 35)

3. Review and understanding of all safety instructions

and operating procedures inthis manual.

4. Review of the maintenance methods for this saw.

6. To avoid back injury, get help or use recommended

casterswhen you need to movethe saw. Always get

help ifyouneed to il_ the saw. Holdthe saw closeto

yourbody. Bend your knees soyoucan liftwithyour

legs, not your back.

7. NEVER STAND ON TOOL. Serious injury could

occur ifthe tooltips or you accidentally hitthe cutting

tool. Do not store anything above or near the tool

where anyone mightstand on the toolto reach them.

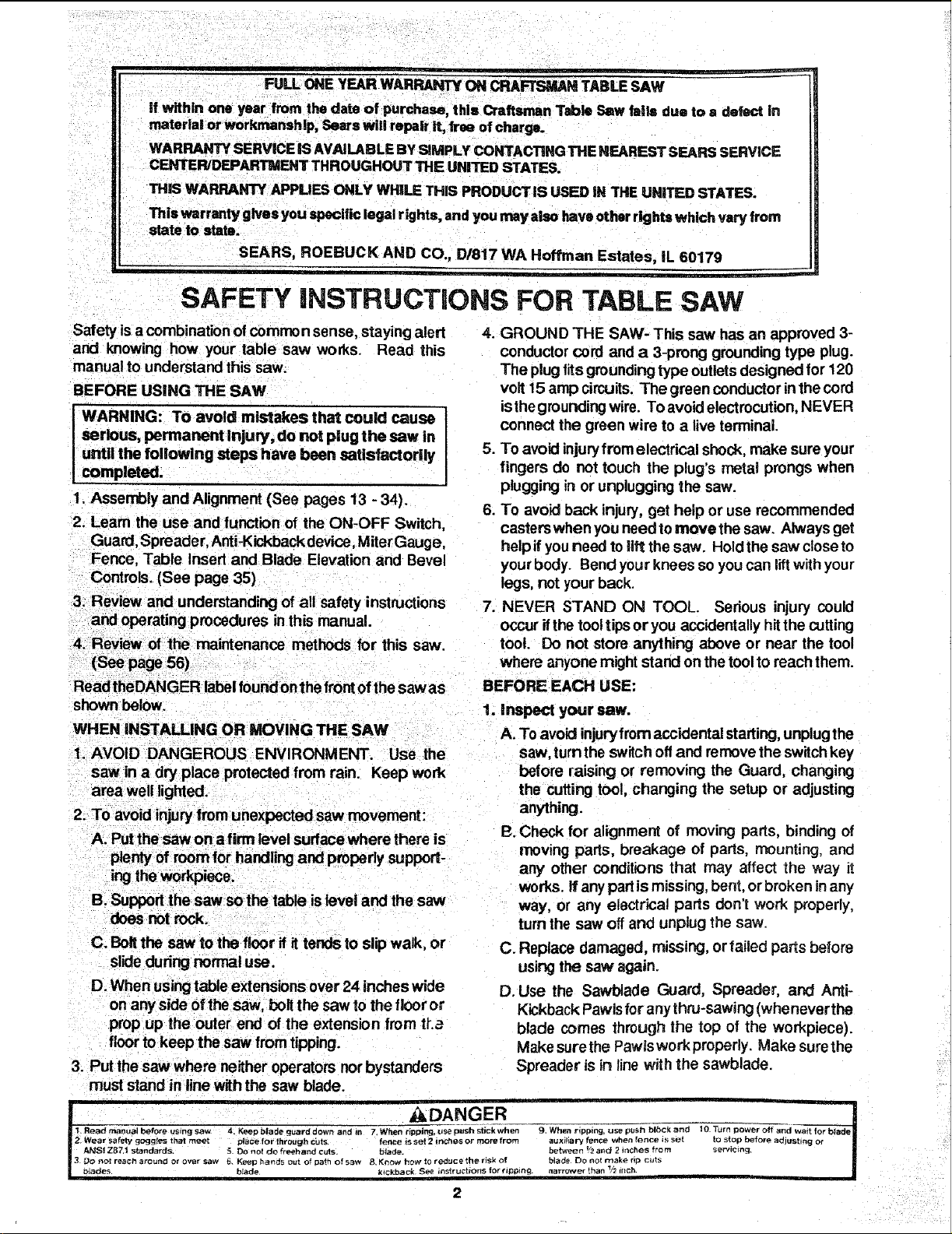

Read theDANGER label found onthefrontofthe saw as BEFORE EACH USE:

shown below.

WHEN INSTALLING OR MOVING THE SAW

1. AVOID DANGEROUS ENVIRONMENT. Use the

saw in a dry place protected from rain. Keep work

area well lighted.

2_To avoid injury from unexpectedsaw movement:

A. Put the saw on a firm level surface where there is

1. Inspect your saw.

A. To avoid injuryfromaccidental starting,unplugthe

saw, turnthe switch off and remove the switchkey

before raising or removing the Guard, changing

the cutting tool, changing the setup or adjusting

anything.

B. Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and

any other condit_ns that may affect the way it

works. If any partis missing, bent, or broken inany

B. Support the saw so the table islevel and the saw

does not rock.

C. Bolt the saw to the floor if it tends to slip walk, or

slideduring normal use.

D. When using table extensions over 24 inches wide

on any side of the saw, boltthe saw to the floor or

prop up the outer end of the extension from tLa

floor to keep the saw from tipping.

3. Put the saw where neither operators norbystanders

way, or any electrical parts don't work properly,

turn the saw off and unplug the saw.

C. Replace damaged, missing, or failed parts before

using the saw again.

D. Use the Sawblade Guard, Spreader, and Anti-

Kickback Pawlsfor anythru-sawing (whenever the

blade comes through the top of the workplace).

Make surethe Pawlswork properly. Make sure the

Spreader is in line with the sawblade.

must stand in line withthe saw blade.

1, Read manual before using saw 4. Keep blade guard down and m 7. When ripping_ use push stickwhen

2. Wear safety goggles that meet pla_e for through cbts. fence is set 2 _nc_es or more from

ANSt ZE_Trl standards, 5 Do not do freehand cuts, blade.

I _DANGER

3 DO not reach around Or over saw 6, Keep h_5 out of path of s3w B. Know how t_ reduce the risk of

b_;_des bJade _c_back See in_ructtons for flppli'Ig

g. When ripping, use push bI_CK ana t0. Turn power Off and wait for blade]_

aux_Fary fence when fence _s set _ stop befor_ _l_jtJStl_lg ot

between 2 and 2 inches from _ervi¢lng

blade Do not make r_ cu_s

narrc_ver tr_an _/_ inch.

!

I

E. REMOVEADJUSTING KEYSANDWRENCHES.

Form habit of checking for and removing keys and

adjusting wrenches from tool before turning it on.

F, To avoid injury from jams, slips or thrown pieces

(kickback and throwback):

1. USE ONLY "RECOMMENDED ACCESSO-

RIES" (See page 58). Follow the instructions

that come with the accessories. The use of

improper accessories maycause riskof injury to

persons.

2. Choose the right blade or cutting accessory for

the material and the type of cutting you plan to

do.

3. Never use grinding wheels, abrasive cut-off

wheels, friction wheels (metal slitting blades)

wire wheels or buffing wheel. Theycan fly apart

explosively.

4. Choose and inspect your cutting tool carefully.

a. To avoidcuttingtoolfailure andthrown shrap-

nel (broken pieces of blade), use only 10" or

smaller blades or other cutting tools marked

for speeds of 3450 rpm or higher.

b. Always use unbroken, balanced blades

designed to fit this saw's 5/8 inch arbor.

c. When thru-sawing (making cuts where the

blade comes through the workpiece top),

always use a 10 inch diameter blade. This

keeps the spreader in closest to the blade.

d. Do not overtighten arbor nut. Use arbor

wrenches to "snug" it securely.

e. Useonlysharpbladeswith properly setteeth.

Consult aprofessional blade sharpenerwhen

in doubt,

f. Keep blades clean of gum and resin.

5. Adjust table inserts flush with the table lop.

NEVER use the saw without the proper insert.

6. Make sure all clamps and locks are tight and no

parts have any excessive play.

2. Keep work area clean

A Cluttered areas and benches invite accidents.

Floor must not be slippery from wax or sawdust.

B. To avoid burns or other fire damage, never use the

saw near flammable liquids, vapors or gases.

C. To avoid injury, don't do layout, assembly, or setup

work on the table while the blade is spinning. It

could cut or throw anything hitting the blade.

Plan ahead to protect your eyes, hands, face,

ears.

3. Plan yourwork

A. USE THE RIGHT TOOL - Don't force tool or

attachment to do a job it was not designed for.

B. Dress for safety:

1. Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches). They can get

caught and draw you into moving parts.

2. Wear nonslip footwear.

3. Tie back long hair.

4. Roll long sleeves above the elbow.

5. Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs when

using saw for long periods of lime.

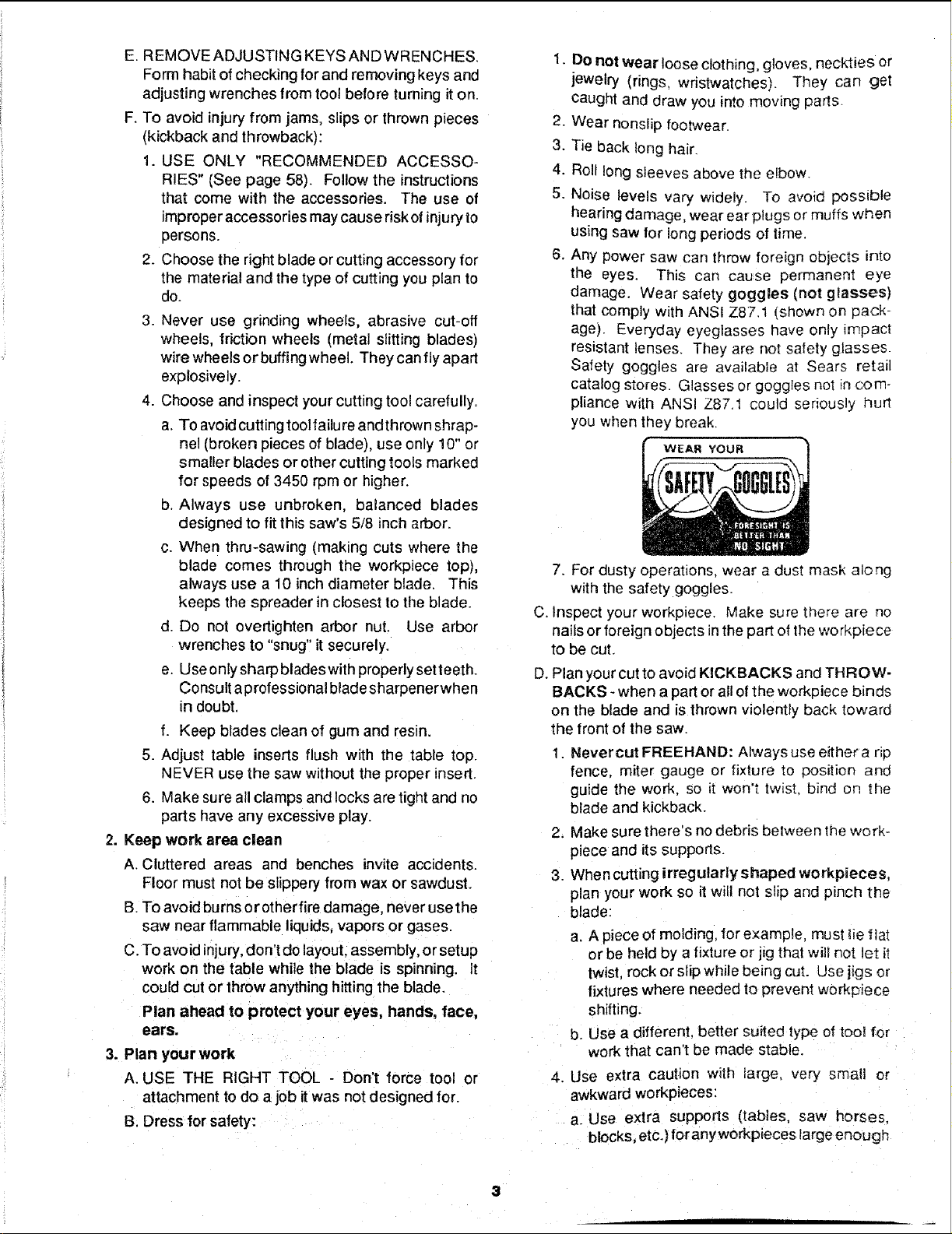

6. Any power saw can throw foreign objects into

the eyes. This can cause permanent eye

damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on pack-

age). Everyday eyeglasses have only impact

resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail

catalog stores. Glasses or goggles not incom-

pliance with ANSI Z87.1 could seriously hurt

you when they break.

WEAR YOUR

7. For dusty operations, wear a dust mask along

with the safety goggles.

C. Inspect your workpiece. Make sure there are no

nails or foreign objects in the part of the workpiece

to be cut.

D. Plan your cut to avoid KICKBACKS and THROW-

BACKS - when apart or all of the workpiece binds

on the blade and is thrown violently back toward

the front of the saw.

1. Nevercut FREEHAND: Always use eithera rip

fence, miter gauge or fixture to position ane

guide the work, so it won't twist bind on the

blade and kickback.

2. Make sure there's no debris between the work-

piece and its supports.

3. When cutting irregularly shaped workpieces,

plan your work so it wilt not slip and pinch the

blade:

a. A piece of molding, for example, must _ieflat

or be held by a fixture or jig that will not let it

twist rock or slip while being cut. Use jigs or

fixtures where needed to prevent workpiece

shifting.

b. Use a different, better suited type of tool for

work that can't be made stable.

4. Use extra caution with large, very small or

awkward workpieces:

a. Use extra supports (tables, saw horses.

blocks, etc.] for anyworkpieces large enough

to tip when not held down to the table top.

NEVER use another person as a substitute

for atable extension, oras additional support

for a workpiece that is longer or wider than

the basic saw table, or to help feed, support

or pull the workpiece.

b. Never confinethe piece being cutoff, that is,

thepieceNOTagainstthe Fence,MiterGauge

or fixture. Never hold it, clamp it, touch it, or

use length stops against it. It mustbe freeto

move. Ifconfined, itcouldgetwedged against

the blade and cause a kickback or throw-

back.

c. Never cut morethan one workpiece at atime.

d. Never turn your table saw "ON"before clear-

ing everything except the workpiece and

related support devices off the table.

4. Plan thewayyou will pushtheworkplecathrough.

A. NEVER pull the workpiece through. Start and

finish thecut from the front of the table saw.

B. NEVER put your fingers or hands in the path of

the sawblade or other cutting tool.

C. NEVER reach Inback ofthe cutUngtoolwitheither

hand to hold clown or support the workpiece,

remove wood scraps, or for any other reason.

D. Avoid hand positions where a sudden slip could

cause fingers or hand to move intoa sawblade or

other cutting tool.

E. DON'T OVERREACH. Always keep good footing

and balance.

F. Push the workpiece against the rotation of the

blade. NEVER feed material intothe cutting tool

from the rear of the saw,

G,Always push the workpiece all the way past the

sawblade.

H.As much as possible, keep your face and body to

one sideofthe sawblade,out of linewith a possible

kickback or throwback.

I. NEVERtumthe saw"ON"before cleadngthetable

of all tools, wood scraps, etc., except the work-

piece and related feed or support devices for the

cut planned.

J. AVOID ACCIDENTAL STARTING - Make sure

switch is "OFF" before plugging saw in.

WHENEVER SAW BLADE IS SPINNING

WARNING: Don't let familiarity (gained from fre-

quent use of your table saw) cause a careless

mistake. Always remember that a careless frac-

tion of a second is enough to cause a severe

injury.

1. Before actually cutting with the saw, watch it while it

runsfor a short while. Ifit makes an unfamiliar noise

or vJ_oratesa lot,stop immediately. Turn the saw off.

Unplug thesaw. Do not restart until finding and fixing

the problem.

2. Make sure the top of the arbor or cutting toot tu ms

toward the front of the saw.

3. Set the cutting tool as low as possible for the cut

you're planning.

4. KEEP CHILDREN AWAY. Ailvisitors shouldbe kept

asale distancefmmwork. Make surebystanders are

clear ofthe saw and workpiece.

5. Let the blade reach full speed before cutting.

6. DON'T FORCE TOOL. It will do the job better and

safer at itsdesigned rate. Feed theworkpiece intothe

blade only fast enough to let it cut without bogging

down or binding.

7. Before freeing any jammed material:

A. -rum switch "OFF".

B. Unplug the saw.

C. Wait for allmovingparts to stop.

D. Check blade, Spreader and Fence for properalign-

ment before starting, again.

8. To avoid throwback of cut off pieces;

A. Use the Guard assembly.

B. To remove loose pieces beneath ortrapped inside

the guard:

1. Turn saw "OFF".

2. Remove switchkey.

3. Wait for blade to stop before liftingthe Guard.

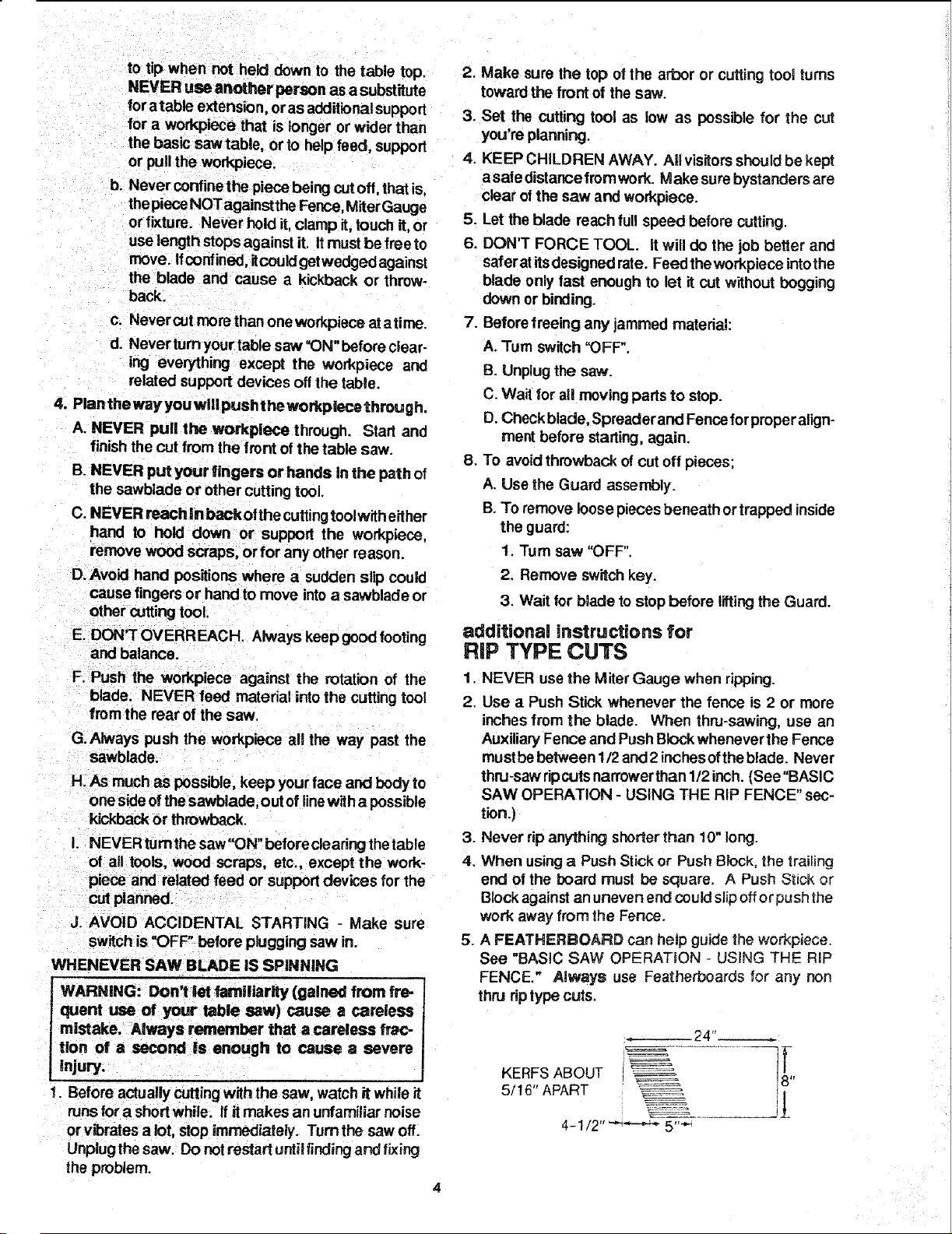

additional instructions for

RiP TYPE CUTS

1. NEVER use the Miter Gauge when ripping.

2. Use a Push Stick whenever the fence is 2 or more

inches from the blade. When thru=sawing, use an

Auxiliary Fence and Push Block whenever the Fence

mustbe between 1/2 and 2 inchesofthe blade. Never

thru-saw ripcutsnarrowerthan 1/2 inch. (See"BASIC

SAW OPERATION - USING THE RiP FENCE" sec-

tion.)

3. Never rip anything shorter than 10" long.

4. When using a Push Stick or Push Block, the trailing

end of the board must be square. A Push Stick or

Block against an uneven end could slip offor push the

work away from the Fence.

5. A FEATHERSOARD can help guide the workpiece.

See "BASIC SAW OPERATION - USING THE RiP

FENCE." Always use Featherboards for any non

thru rip type cuts.

24"

KERFS ABOUT

5/16" APART

4-112 '''-'_--'_ 5'""

BEFORESTARllNG

1. To avoid kickbacks and slips into the blade, make

sure the Rip Fence isparallel to the sawblade.

2. Before thru-sawing, check the Anti-Kickback Pawls.

(See "BASIC SAW OPERATION - USING THE RIP

FENCE.") The Pawls must stop a kickback once it

has started. Replace orsharpen Anti-Kickback Pawls

when points become due

3. Plastic and composition (like hardboard) materials

may be cut on your saw. However, since these are

usually quite hard and slippery, the Anti-Kickback

Pawls may not stop a kickback. Therefore, be espe-

cially careful in your set-up and cutting procedures.

WHILE CUTTING

1. To avoid kickbacks and slips into the blade, always

push forward on the section of theworkpiece between

the saw blade and the Rip Fence. Never pushforward

on the piece being cut off.

3. Use jigsor fixtures to help hold any piece too sina!! to

extend across the full lengthof the Miter Gauge face

during the cut. This lets you propedy hold the Miter

Gauge and workpiece and helps keep your hands

away from the blade. (See page 37.)

WHgLE CUTTING

1. To avoid blade contact, always hold the Miter Gauge

as shown in the "BASIC SAW OPERATIONS - US-

iNG THE MITER GAUGE."

BEFORE LEAVDNG THE SAW

1. Turn the saw off.

2.

Wait for blade to stop spinning,

3.

Makeworkshopchild-proof. Lock the shop. Discon-

nect master switches. Remove the yellow Switch

Key. Store it away from children and others not

qualified to use the tool.

4. Unplug the saw.

additional instructions for

CROSS CUT TYPE CUTS

BEFORE STARTING

1. NEVER use the Rip Fence when crossc:£ting.

2. An auxiliary wood facing attached to the Miter Gauge

can help prevent workpiece twisting andthrowbacks.

Attach it to the holes provided. Make the facing long

enough and big enough to support your work. Make

sure, however, it will not interfere withthe Sawblade

Guard.

SAFETY SIGNAL WORDS

DANGER: means if the safety information is not fol-

lowed, someone wig be seriously injured or killed.

WARNING: means if the safety information is not fol-

lowed, someone could be seriously injured or killed.

CAUTION: means if the safety information is not fo!-

lowed, someone might be injured.

glossary of terms for woodworking

Anti-Kickback Pawts {AKP)

Device which, when properly maintained, isdesigned to

stop the workpiece from being kicked back at the opera-

tor during dpping operation.

Arbor

The shaft on which a cutting tool is mounted.

Crosscut

A cutting or shaping operation made across the width of

the workpiece.

Dado

Anon through cut which produces a square ._;ided notch

or trough inthe workpiece.

Featherboard

A device which can help guide workpieces during rip

type operation.

Freehand

Performing a cut without usinga Fence, Miter Gauge,

fixture, hold down or other proper device to keep the

workpiece from twisting during the cut.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the blade.

Kerr

The amount of material removed by the blade in a

through cut or the slot producedby the blade in a non

through or partial cut.

Kickback

An uncontrolled grabbing and throwing of the workpiece

back toward the front of the saw.

Leading End

The end of the workpiece which, during a rip type

operation, is pushed intothe cutting tool first.

Meldlng

A non through cut which producesa special shape inthe

workpiece used for ioining or decoration.

Push Stick

A device used to feed the workpiece through the saw

during narrow ripping type operations and helps keep

the operator's hands well away from the blade.

Push Block

A device used for rippingtype operations |oo narrow to

allow use of a Push Stick.

Rabbet

A notch inthe edge of a workpiece.

Resin

A sticky, sap base substance that has hardened,

glossary of terms for woodworking

Ripping

A cutting operation along the length of the workpiece.

Revolutions Per Minute (RPM)

Thenumber of turns completed by a spinning object in

one minute.

Sawblade Path

Theareaof theworkpiece ortable topdirectlyin linewith

the part ofthe workplece which willbe or has been, cut

bythe blade.

Set

Thedistancethat theti 3of thesawblade tooth is bent (or

set) outward from the face of the blade.

MOTOR SPECiFiCATiONS AND ELECTRICAL REQUIREMENTS

MOTOR SPECIFICAT|ONS

Thissaw isdesigned to usea 3450 RPM motor only. Do

not use any rnotorthat runsfaster than 3450 RPM. The

A-C motorused inthis saw isacapacitor start, capacitor

run, non-reversible type motor, it is wired at the factory

for operationon 120v AC, 60 Hz., alternating curre_. It

may be converted to operate on 240v AC. Listedbelow

are the motor specifications.

chine or any motor with an automatic reset over-

load protector. They can start up by themselves

t WARNING: Do riot use blower or washing ma-

and you could get Injured.

CONNECTING TO POWER SOURCE

OUTLET

This saw must be grounded while inuse to protect the

operator from electrical shock.

WARNING: Damaged power cords can cause

shock or fires, if the power cord is worn, cut or

damaged in any way, have it replaced immedi-

ately.

WARNING: Electric shockcan kill. Not all ouUets

are properly grounded, if you are not sure that

your outlet is properly grounded, have it checked

by a qualified electrician.

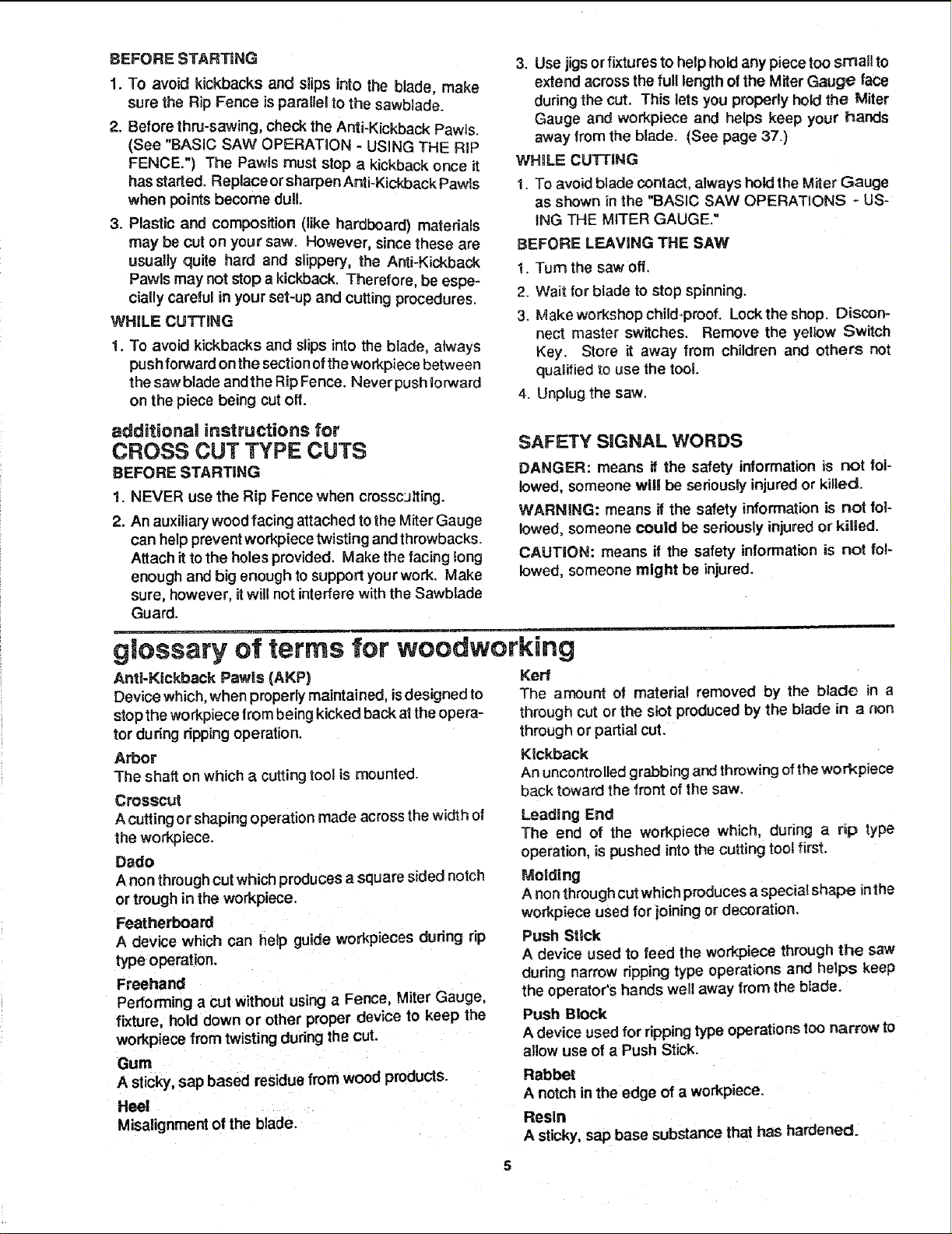

3-PRONG PLUG

GROUNDING PRONG

GROUNDED

3-PRONG OUTLET

ThrOw-Back

Throwing of pieces in a manner similarto a kickback.

Thru-Sawlng

Any cutting operation where the blade extends com-

pletely thoughthe thickness of the workpiece.

Trailing End

The wod_oiece end last cut by the blade in a ripping

operation.

Workpiece

The itemon which the cutting operation is being done,

The sudaces of a workpiece are commonly referred to

as faces, ends, and edges.

WARNING: To avoid electrical shock, do not

permit fingers to touch the terminals o! the plug,

when installing or removing the plug to or from

the outlet.

WARNING: Failure to properly ground this power

tool can cause electrocution or serious shock,

particularly when used in damp locations, or near

metal plumbing, lifshocked, your reaction could

cause your hands to hit the cutting tool.

This saw is equipped with a 3-conductor cord and

grounding type plug which has a grounding prong,

approved by UndePJvriter'sLaboratories and Canadian

Standards Association. The ground conductor has a

green lugand is attached tothe toolhousingat one end

and to the ground prong in the attachment plug at the

other end.

GROUNDING LUG

3-PRONG ¢P;

ADAPTER

This plug requires a mating 3-conductor grounded type

outlet as shown above.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

Atemporary adapter, as shown, isavailable for connect-

ing plug to 2-prong receptacles. The green grounding

lug extending from the adapter must be connected to a

permanent groundsuch aslo a properly grounded outlet

box. This adapter should be used only until a properly

grounded outlet can be installed by a qualified electri-

cian.

[ ,ii

MAKE SURE THIS IS

CONNECTED TO A

KNOWN GROUND

_ 2-PRONG

RECEPTACLE

WARNING: Avoid eJectric shock, if the outlet you

are piannlng to use for this saw Isof the two prong

type, DO NOT REMOVE OR ALTER THE GROUND-

iNG PRONG INANY MANNER. Use an adapter, as

shown, and always connect the grounding lug to

a known ground, such as to a properly grounded

outlet box, Not aJll o_iet boxes are properly

grounded° If you are not sure the outlet box is

properly grounded, have It checked by a quaJified

electrlclan.

CHANGING MOTOR VOLTAGE

WARNING: Eiectric shock can kill.To avold

shock, never connect plug to power source outUet

until a_l assembly slops are completed. Unplug

saw before making or changing any connections.

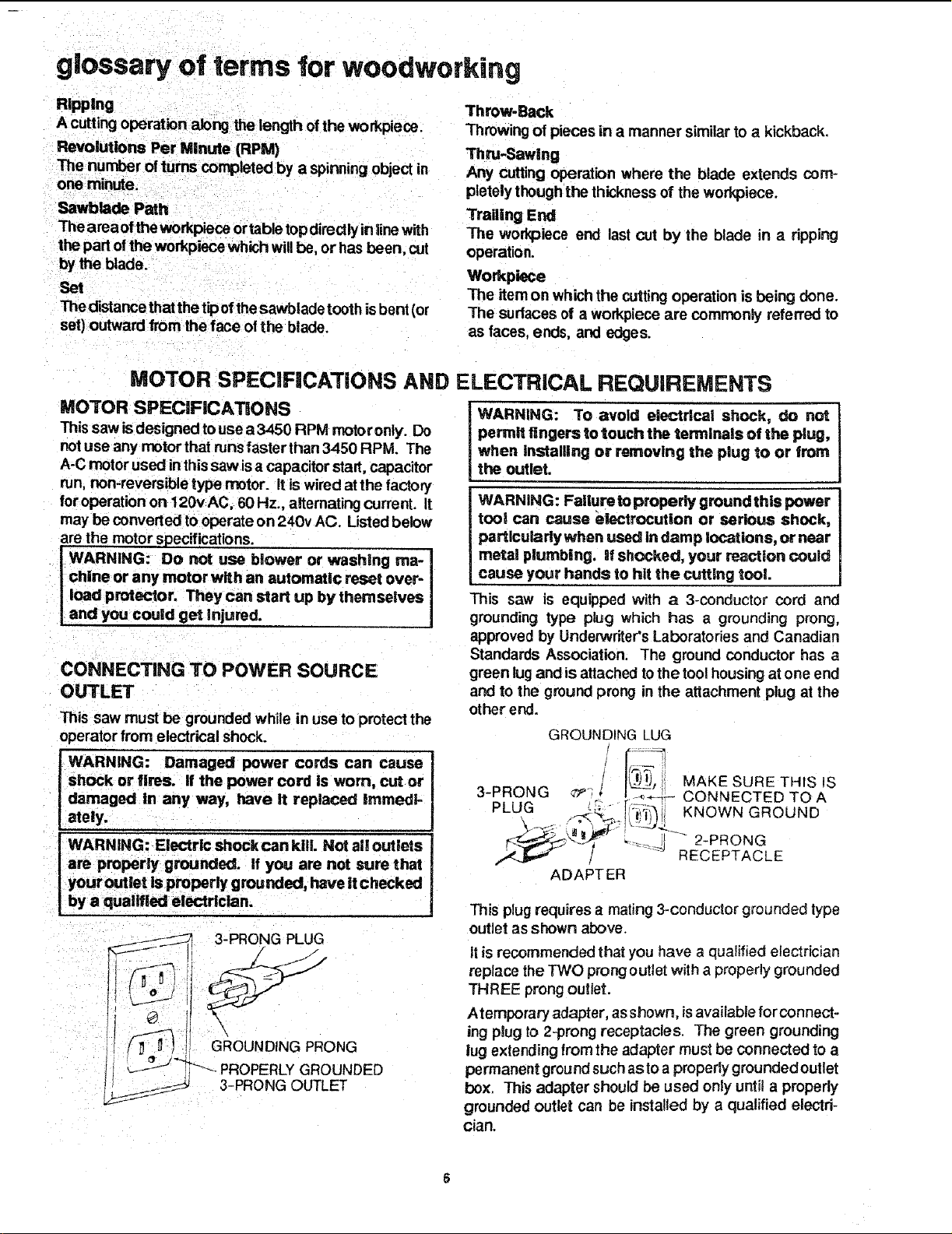

1. Connections for 120v AC Operation

a. Foroperation on 120 volts,the bRackpower lead is

connected to spade terminal beside copper post.

The white power lead is connected to spade termi-

nal beside silver post. Thetwo movable links must

be in position shown in Figure 1, The red motor

lead is connected to terminal "B."

b. The movable links pivotonthe centermost screws.

After linkshave been correctly positioned, be sure

to tighten these screws to insure a good electricaI

connection.

b. The movable links pivot onthe center most screv_,_ -

After links have been correctly positioned, be SL_r_

to tighten these screws to insure agood etectdc _

connection.

240 VOLT CONNECTION

COPPER

BLACK POWE

SPADE TERMINALS,

WHITE POWER

SILVER

GREEN

GROUND SCR E_.W

IN THIS

POSITION

B

FIGURE 2

RED

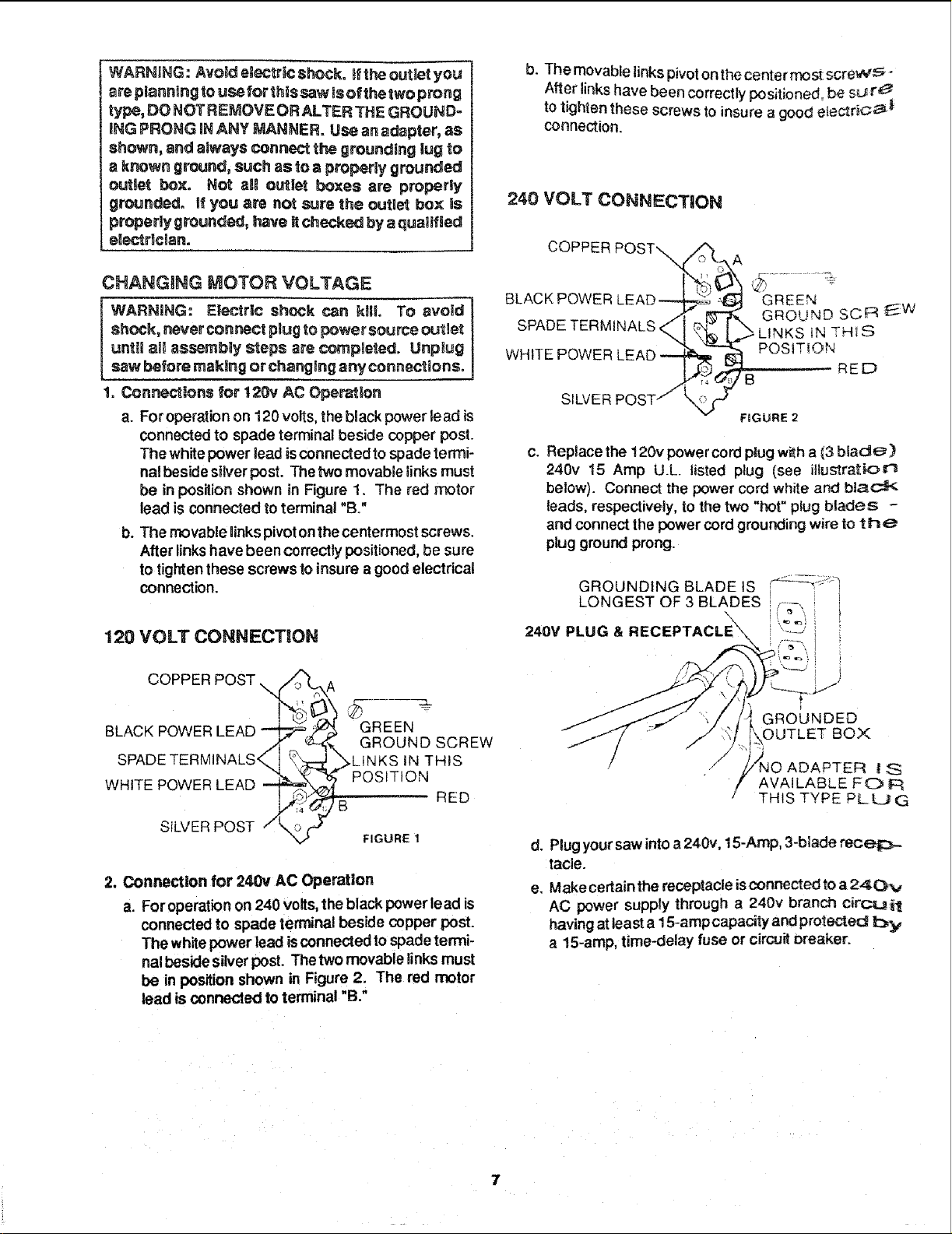

c. Replace the !20v power cord plugwith a (3 blade)

240v 15 Amp U.L listed plug (see illustration

below). Connect the power cord white and black

leads, respectively, to the two "hot" plug blades -

and connect the power cord grounding wire to th_

plug ground prong.

GROUNDING BLADE tS -_..... J

LONGEST OF 3 BLADES ,--

120 VOLT CONNECTION

/r---- ....

BLACK POWER LEAD --n_ GREEN

SPADE TERMINALS_. t _ .LINKS IN THIS

COPPER POST __-J_"4..\_

WHITE :OL_ER LEAD ?_ POSITION

_i ER POST

2. Connection for 240v AC Operation

a. Foroperation on 240 volts, the black power lead is

connected to spade terminal beside copper post.

The white power lead isconnected to spade termi-

nalbeside silverpost. Thetwo movable links must

be in position shown in Figure 2. The red motor

lead is connected toterminal "B."

GROUND SCREW

B RED

FIGURE 1

24ov PLUG&RECEPTACLE i '--_ i

#

GROUNDED

OUTLET BOX

ADAPTEF{ I S

AVAILABLE FO F_

THIS TYPE PLUG

d. Plug yoursaw intoa 240v, 15-Amp, 3-blade receiz_-

tacle.

e, Make cerlain the receptacle isconnected to a 24(3Pv

AC power supply through a 240v branch circ:_ilt

having atleast a 15-ampcapacity and protected by

a 15-amp, time-delay fuse or circuit breaker.

7

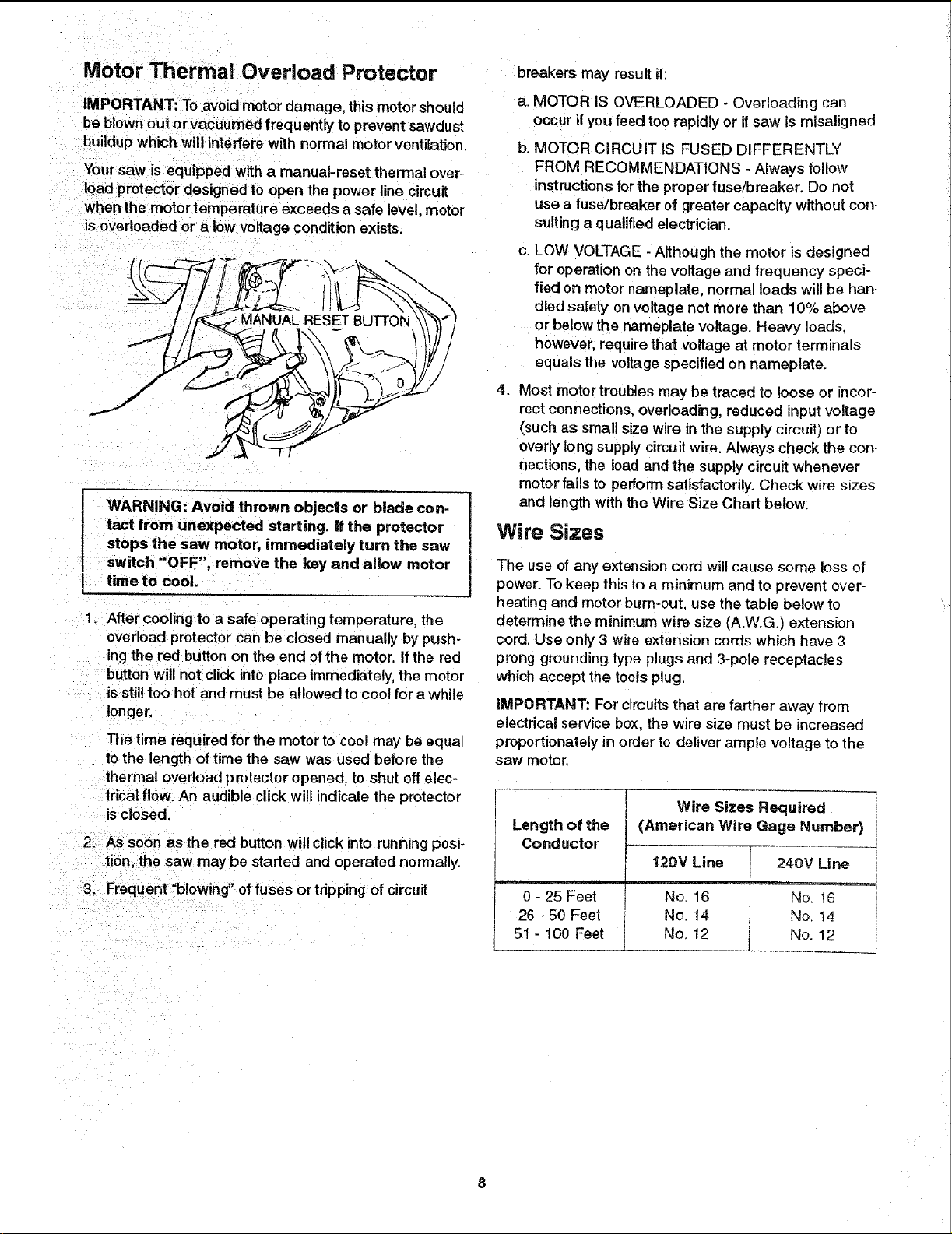

Motor Thermal Overload Protector

breakers may result if:

IMPORTANT: To avoid motor damage, this motorshould

be blown out orvacuumed frequently to prevent sawdust

buildupwhich will interfere with normal motor ventilation.

Your saw is equipped with a manual-reset thermal over-

load protector designed to open the power line circuit

when the motor temperature exceeds a safe level, motor

is overloaded or a low voltage condition exists.

WARNING: Avoid thrown objects or blade con.

tact from unexpected starting, if the protector

stops the saw motor, immediately turn the saw

switch "OFF", remove the key and allow motor

time to cool.

1. After cooling to a safe operating temperature, the

overload protector can be closed manually by push-

ing the red button on the end ofthe motor. If the red

button will not click into place immediately, the motor

is still too hot and must be allowed to cool for a while

longer.

The time required for the motor to cool may be equal

to the length of time the saw was used before the

thermal overload protector opened, to shut of! elec-

trical flow, An audible click will indicate the protector

is closed.

2_ As soon as the red button willclick into running posi-

tion. the saw may be started and operated normally.

a. MOTOR IS OVERLOADED - Overloading can

occur ifyou feed too rapidly or ifsaw is misaligned

b. MOTOR CIRCUIT IS FUSED DIFFERENTLY

FROM RECOMMENDATIONS - Always follow

instructions for the proper fuse/breaker, Do not

use a fuse/breaker of greater capacity without con.

suiting a qualified electrician

c. LOW VOLTAGE - Although the motor is designed

for operation on the voltage and frequency speci-

fied on motor nameplate, normal loads will be han-

died safety on voltage not more than 10% above

or below the nameplate voltage. Heavy loads.

however, require that voltage at motor terminals

equals the voltage specified on nameplate.

4. Most motor troubles may be traced to loose or incor-

rect connections, overloading, reduced input voltage

(such as small size wire inthe supply circuit) or to

overly long supply circuit wire. Always check the con-

nections, the load and the supply circuit whenever

motor fails to perform satisfactorily. Check wire sizes

and length with the Wire Size Chart below.

Wire Sizes

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.] extension

cord. Use only 3 wire extension cords which have 3

prong grounding type plugs and 3-pole receptacles

which accept the toolsplug.

iMPORTANT: For circuits that are farther away from

electrical service box. the wire size must be increased

proportionately in order to deliver ample voltage to the

saw motor.

Wire Sizes Required

Length of the

Conductor

(American Wire Gage Number)

12(}V Line 240V Line

3. Frequent "blowing" offuses or tripping of circuit

0 - 25 Feet No. 16 No. ! 6

26 - 50 Feet No. t4 No 14

51 - 100 Feet _j. No. 12 1 No. 12 __j

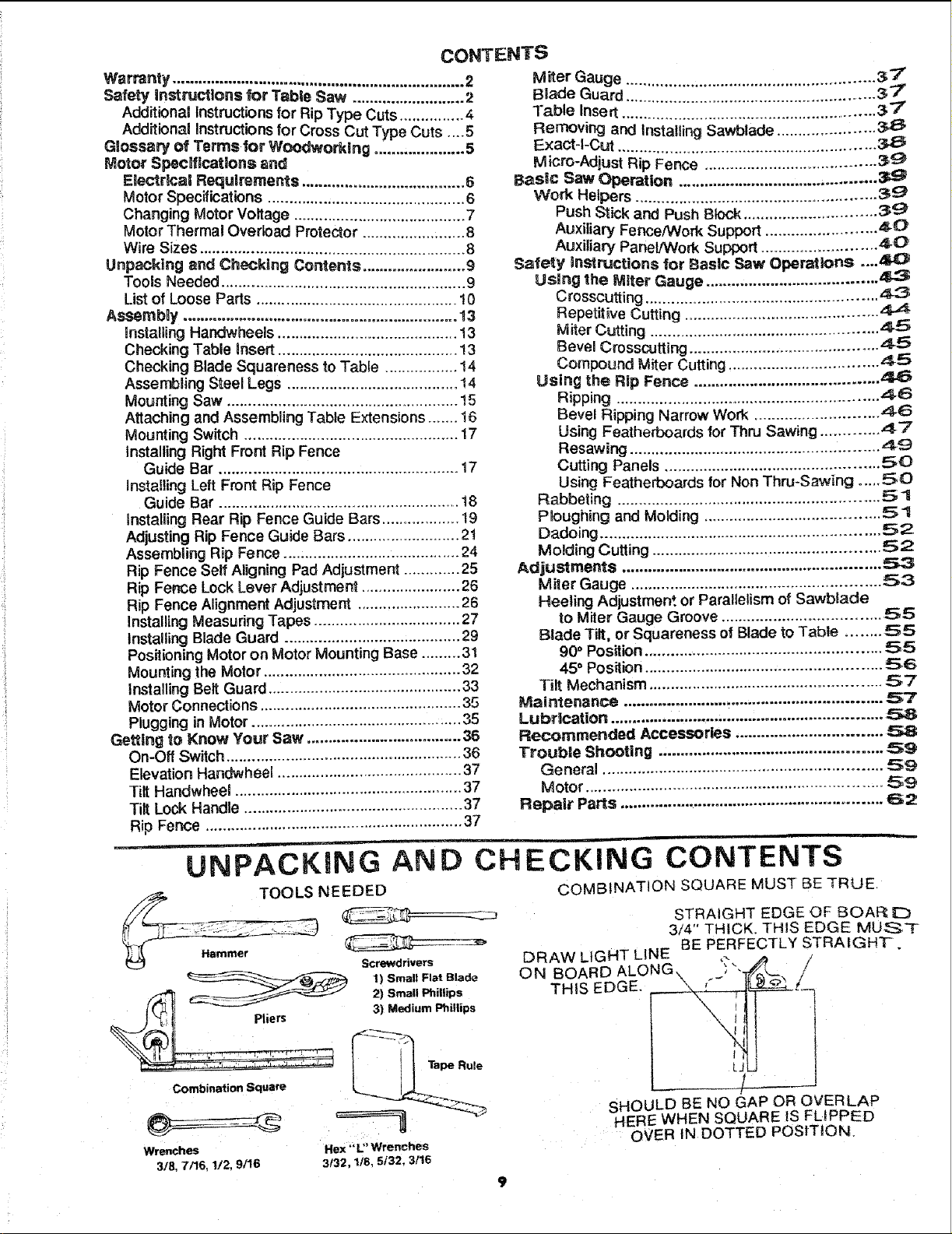

CONTENTS

Warranty .................................................................... 2

Safety instructions for Table Saw .......................... 2

Additional Instructions for Rip Type Cuts ............... 4

Additiona_ Instructions for Cross Cut Type Cuts ...5

Glossary of Terms for Woodworking ..................... 5

Motor Specifications and

Electrical Requirements ...................................... 6

Motor Specifications ............................................. 6

Changing Motor Voltage ........................................ 7

Motor Thermal Overload Protector ........................ 8

Wire Sizes .............................................................. 8

Unpacking and Checking Contents ........................ 9

Tools Needed ......................................................... 9

List of Loose Pads ............................................... 10

AssembSy ................................................................ 13

installing Handwheels .......................................... 13

Checking Table Insed ......................................... 13

Checking Blade Squareness to Table ................. 14

Assembling Steel Legs ........................................ 14

Mounting Saw ...................................................... ! 5

Attaching and Assembling Table Extensions ....... 16

Mounting Switch .................................................. 17

installing Right Front Rip Fence

Guide Bar ........................................................ 17

installingLeft Front Rip Fence

Guide Bar ........................................................ 18

Installing Rear Rip Fence Guide Bars .................. 19

Adjusting Rip Fence Guide Bars .......................... 21

Assembling Rip Fence ......................................... 24

Rip Fence Self Aligning Pad Adjustment ............ 25

Rip Fence Lock Lever Adjustment ....................... 26

Rip Fence Alignment Adjustment ........................ 26

Installing Measuring Tapes .................................. 27

Installing Blade Guard ......................................... 29

Positioning Motor on Motor Mounting Base ......... 31

Mounting the Motor .............................................. 32

Installing Belt Guard ............................................. 33

Motor Connections ............................................... 35

Plugging in Motor................................................. 35

Getting to Know Your Saw .................................... 36

On-Off Switch ....................................................... 36

Elevation Handwheel ........................................... 37

Tilt Handwheel ..................................................... 37

Tilt Lock Handle ................................................... 37

Rip Fence ............................................................. 37

Miter Gauge ......................................................... 3-7

BBade Guard ......................................................... 37"

"]'able Insert ........................................................... 3"7

Removing and Instal{ing Sawblade .....................

Exact-I-Cut ...................................

Micro-Adjust Rip Fence ....................................... 3._;-_

Basic Saw Operation .............................................

Work Helpers ....................................................... 3 g

Push Stick and Push Block .............................. 3_°J

Auxiliary Fence/Work Support ......................... 4.0

Auxiliary Panel/Work Support .......................... z$O

Safety Instructions for Basic Saw Operations ....

Using the Miter Gauge ......................................

Crosscutting .....................................................

Repetitive Cutting ............................................ 4_-_

Miter Cutting ....................................................

Bevel Crosscutting ...........................................

Compound Mfter Cutting .................................. 45

Using the R_p Fence ..........................................

Ripping ............................................................ 46

Bevel Ripping Narrow Work ............................ 4.6

Using Featherboards for Thru Sawing ............. 4-7

Resawing ......................................................... 49

Cutting Panels ................................................. 50

Using Featherboards for Non Thru-Sawing ..... 50

Rabbeting ............................................................ 5 1

P_oughing and Molding ........................................ 53

Dadoing ................................................................ 52

Molding Cutting .................................................... 52

Adjustments ...........................................................

Miter Gauge ......................................................... 53

Heeling Adjustment or Parallelism of Sawbtade

to Miter Gauge Groove .................................... 55

Blade Tilt, or Squareness of Blade to Table ........ 55

90° Position ..................................................... 55

45° Position ...................................................... 56

Tilt Mechanism ..................................................... 5-7

Maintenance ........................................................... 57

Lubrication ..............................................................

Recommended Accessories ................................. 5_

Trouble Shooting ................................................... 59

General ................................................................ 59

Motor .................................................................... 59

Repair Parts ............................................................ 62

UNPACKING AND CHECKING CONTENTS

/_p, TOOLS NEEDED

Screwdrivers

'2', °°

i_;]l Pliers 3) Me_lium Phillips

Combination Square

Wrenches Hex ""L" Wrenches

3/8 7/16, 1/2. 9/16 3132, 1/8, 5132, 3/16

COMBINATION SQUARE MUST BE TRUE

STRAIGHT EDGE OF BOAF_

3/4" THICK. THIS EDGE MUS*T

BE PERFECTLY STRAIGH'F.

[_RAW LIGHT LINE

ON BOARD

THIS EDGE.

LJ

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION.

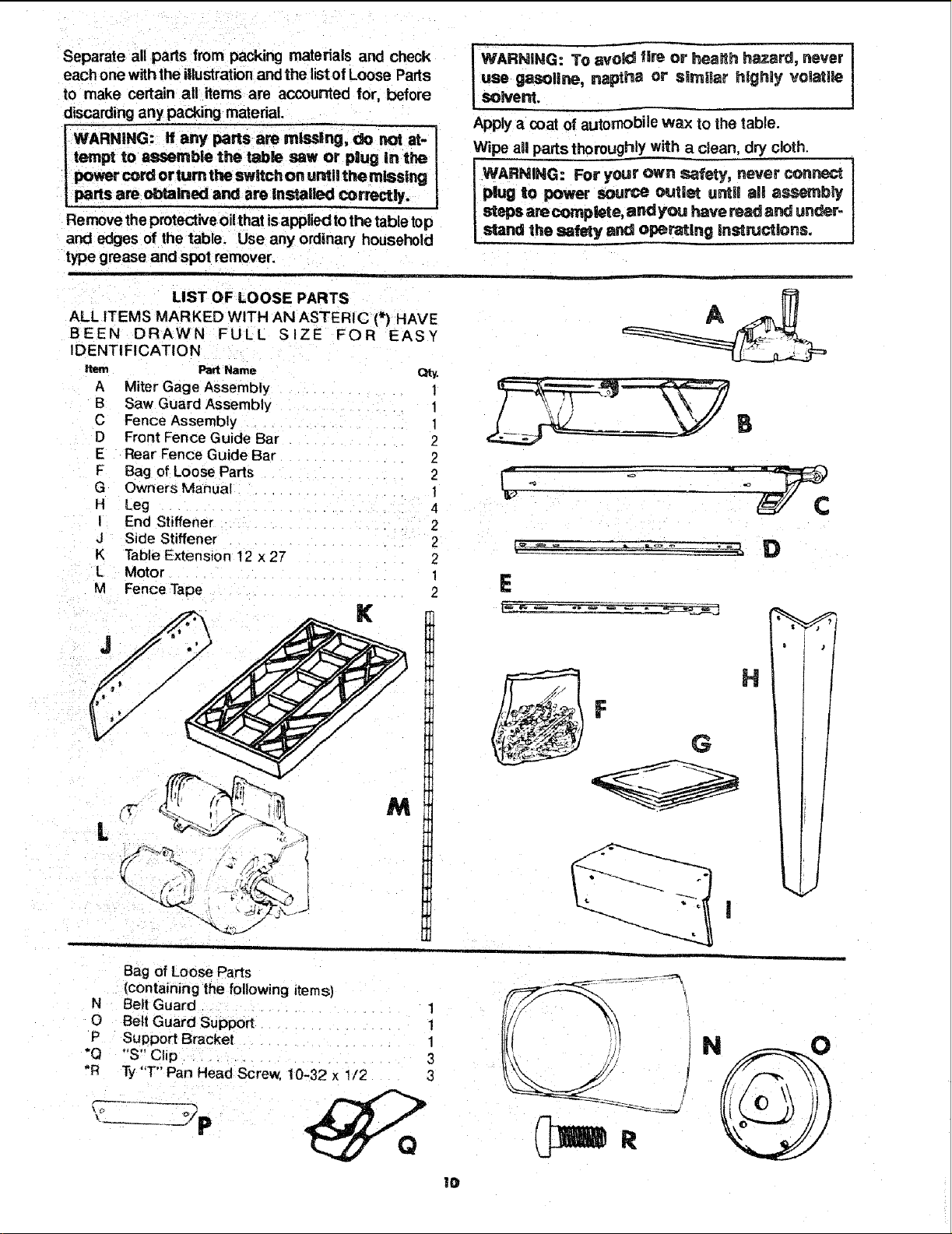

Separate all parts from packing materials and check

each one withthe illustrationand the listof Loose Parts

to make certain all items are accounted for, before

discarding any packing matedaL

tempt to assemble the table saw or plug in the

power cord or turn the switch on ur_l! the missing

j WARNING: If any parts am missing, do not at-

parts are obtained and are Installed correctly.

Remove the protective oilthat is applied tothe table top

and edges of the table. Use any ordinary household

type grease and spot remover.

LIST OF LOOSE PARTS

ALL ITEMS MARKED WITH AN ASTERIC (*) HAVE

BEEN DRAWN FULL SIZE FOR EASY

IDENTIFICATION

item PartName Qtv.

A Miter Gage Assembly 1

B Saw Guard Assembly !

C Fence Assembly

D Front Fence Guide Bar 2

E Rear Fence Guide Bar 2

F Bag of Loose Parts 2

G Owners Manual 1

H Leg 4

I End Stiffener 2

J Side Stiffener 2

K Table Extension 12 x 27 2

L Motor 1

M Fence Tape 2

K

WARNING8voUChes

use gasoline, naptha or smmllar highly volatile

solvent.

Apply a,coat of automobile wax to the table.

Wipe atl parts thoroughly with a clean, dry cJoth.

WARNING: For your own safety, never connect

plug to power source mJtlst u_i! all assembly

steps are complete, and you have read and under-

stand the safety and operating lnstrucUons.

E

: TO _h hazard, never

B

• ._ ?=

L

Bag of Loose Parts

(containing the following items)

N Belt Guard ........... 1

O Belt Guard Support .......... 1

P Support Bracket ......... 1

L,_ip..................... 3

*R Ty"T" Pan Head Screw, 10-32 x 112 3

G H

]0

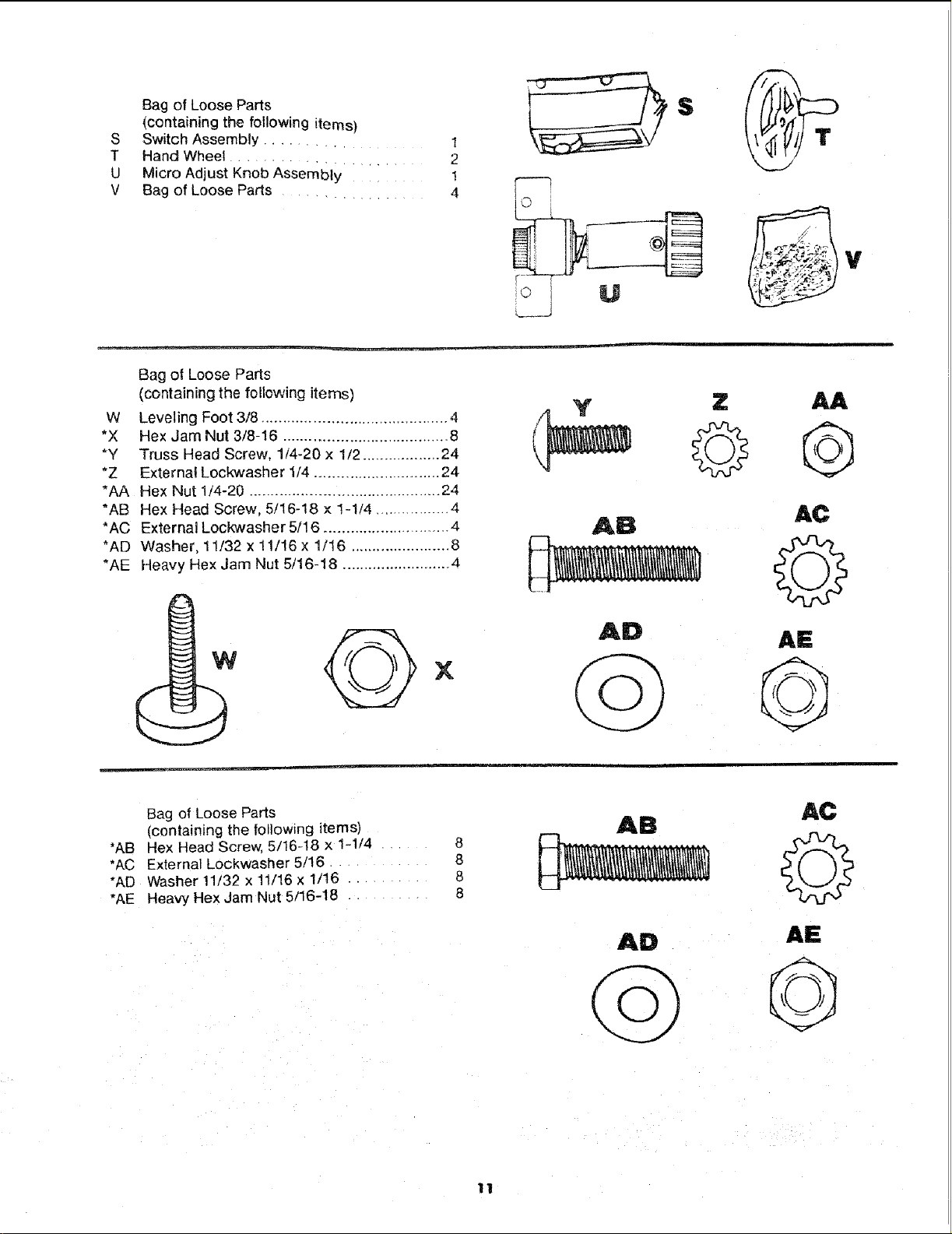

Bag of Loose Parts

(containing the following items)

S Switch Assembly .......... 1

T Hand Wheel .................. 2

U Micro Adjust Knob Assembly ......... 1

V Bag of Loose Parts .............. 4

Bag of Loose Parts

(containing the following items)

W Leveling Foot 3/8 ........................................... 4

*X Hex Jam Nut 3/8-16 ...................................... 8

"Y Truss Head Screw, 1/4-20 x 1/2 .................. 24

*Z External Lockwasher 1/4 .............................. 24

*AA Hex Nut 1/4-20 ............................................ 24

*AB Hex Head Screw, 5/16-18 × 1-t/4 ................. 4

*AC External Lockwasher 5/16 ............................. 4

*AD Washer, 11/32 x 11/16 x 1/16 ....................... 8

*AE Heavy Hex Jam Nut 5/16-18 .......................... 4

V

©

Z JUt

X

Bag of Loose Parts

{containing the following items)

*AB Hex Head Screw, 5/16-18 x 1-1/4 8

*AC External Lockwasher 5/16 . 8

*AD Washer 11/32 x 11/16 x 1/16 ..... 6

*AE Heavy Hex Jam Nut 5/16-18 8

AD

AE

11

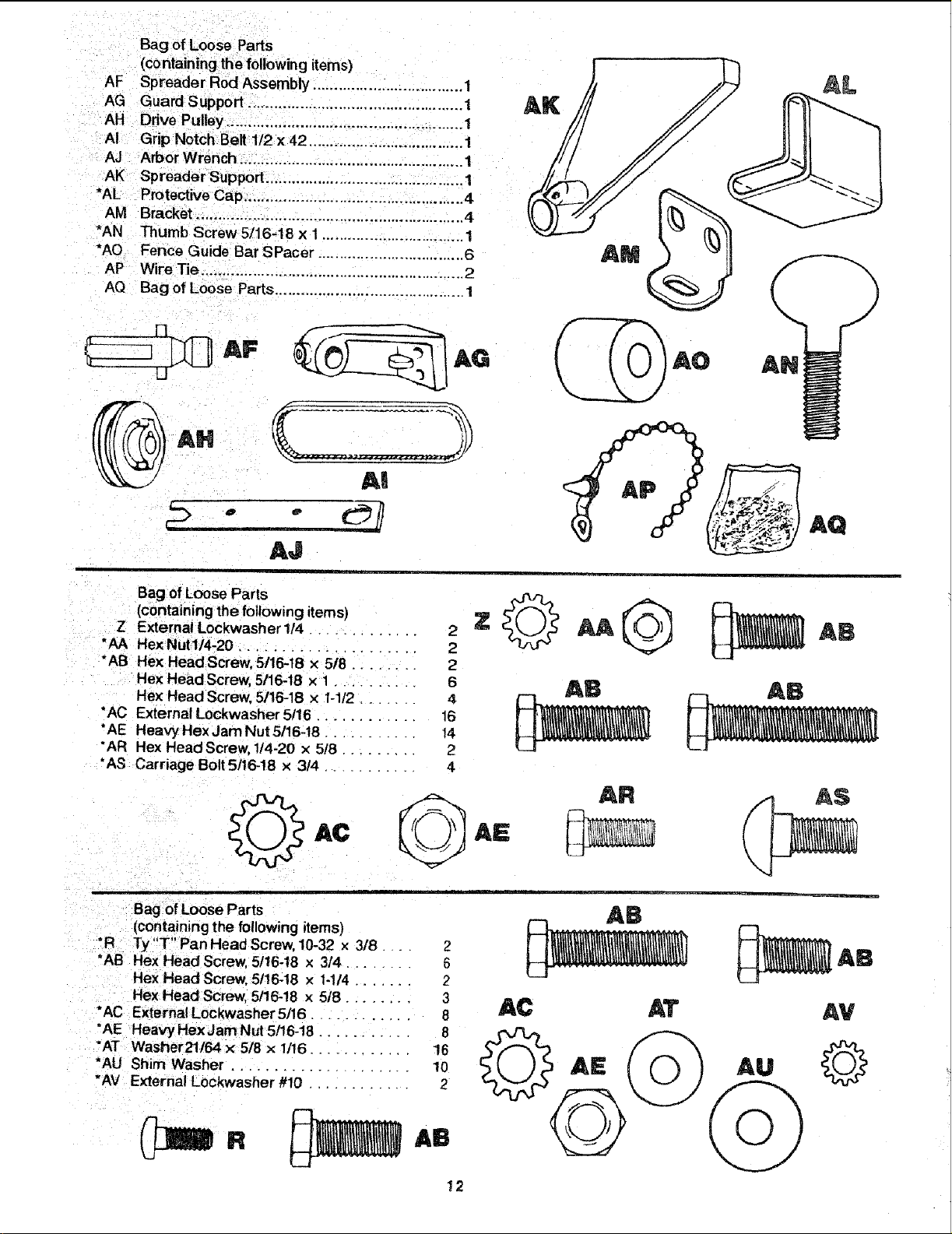

AF

AG Guard Support .................................................. 1

AH Drive Pulley ....................................................... 1

AI Grip Notch Belt 1/2 x 42 .................................... 1

AJ Arbor Wrench. ................................................... 1

AK Spreader Support ............................................. 1

*AL Protective Cap ................................................... 4

AM Bracket .............................................................. 4

*AN Thumb Screw 5/76-18 x 1 ................................. 1

*AO Fence Guide Bar SPacer .................................. 6

AP Wire Tie ........................... 2

AQ Bag of Loose Parts ............................................ 1

i AF

LJ

AI

AJ

Bag of Loose Parts

(containing the following items)

Z External Lockwasher 1/4 ............. 2

"AA Hex Nut1/4-20 ..................... 2

"AB Hex HeadScrew, 5/16-18 x 5/8 ........ 2

Hex Head Screw, 5/16-18 x 1.......... 6

Hex Head Screw, 5/16-18 x 1-1/2 ...... 4

*AC External Lockwasher 5/16 ............ 16

*AE Heavy Hex Jam Nut 5/16-18 ........... 14

"AR Hex Head Screw, 1/4-20 x 518 ......... 2

*AS Carriage BoltS/16-!8 x 3/4 .......... 4

O

Bag of Loose Parts

(containing the following items)

*R Ty "T" Pan Head Screw, 10-32 x 3/8 _. 2

*AB Hex Head Screw, 5/16-!8 x 3/4 ....... 6

Hex Head Screw, 5/16-18 x 1-1/4 ...... 2

Hex Head Screw, 5/16-18 x 5/8 ........ 3

•AC External Lockwasher 5/16 .......... 8

"AE Heavy Hex Jam Nut 5!16-18 ........... 8

*AT Washer21/_4 × 5/8 x 1t16 ............ 16

. A

U Shim Washer ..................... 10

*AV External Lockwasher #10 ............ 2

AB

AC AT

AV

Au

12

ASSEMBLY

Before mounting the saw on legs or a stand or a bench,

the Table Insert and Blade Squareness must be checked

at this time.

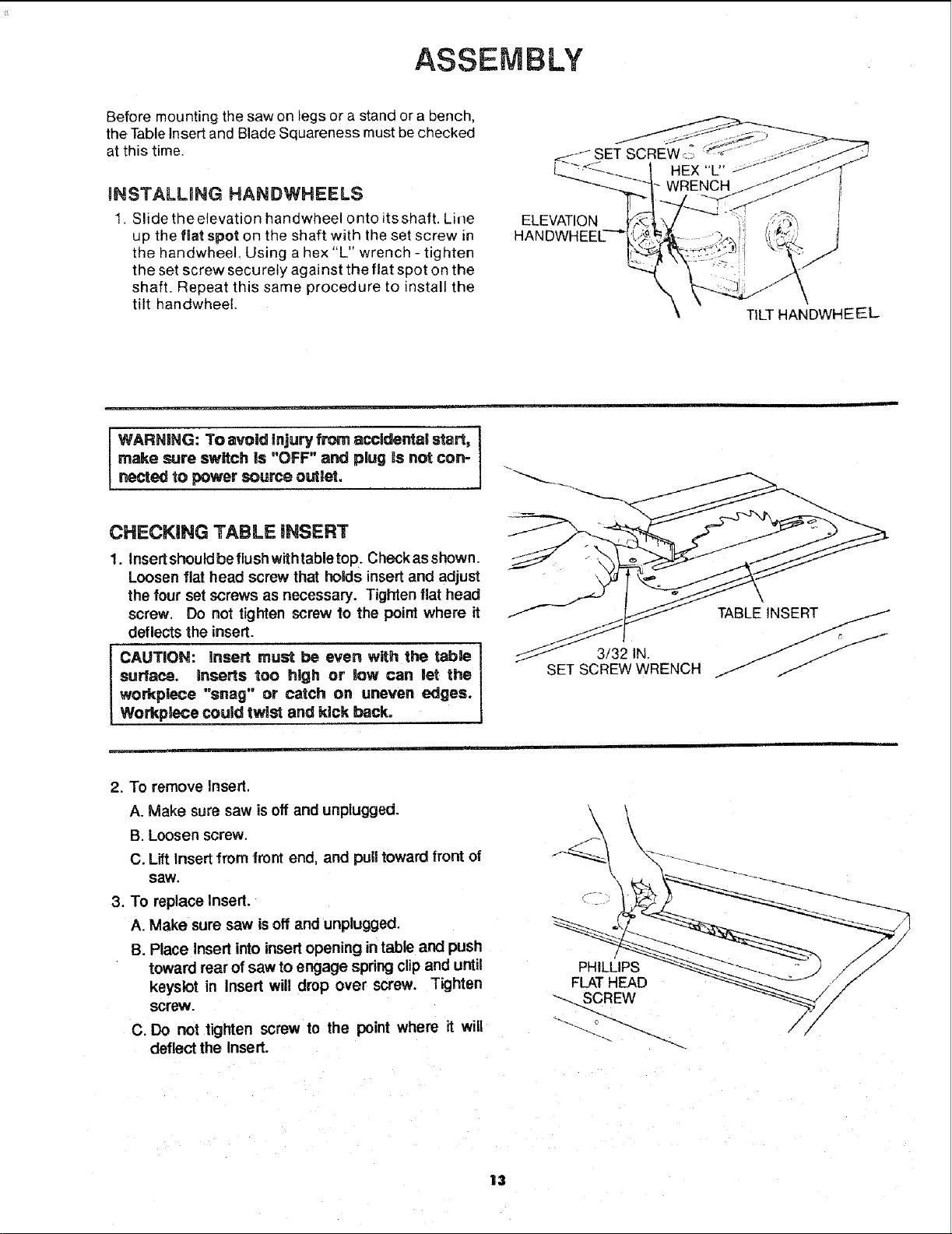

UNSTALLING HANDWHEELS

1. Slide theelevation handwheel onto itsshaft. Line

up the fiat spot on the shaft with the set screw in

the handwheeL Using ahex "L" wrench - tighten

the set screw securely against the flat spot on the

shaft. Repeat this same procedure to install the

tilt handwheel.

make sure switch is "OFF" and plug is not con-

JWARNING: To avoid injury from accideltlai start,

nected to power source ouUet.

ELEVATION

HANDWHEEI

TILT HANDWHEEEL

CHECKING TABLE iNSERT

!. Insert shouldbe flush with table top. Check as shown.

Loosen flat head screw that holds insert and adjust

the four set screws as necessary. Tighten flat head

screw. Do not tighten screw to the point where it

deflects the insert.

CAUTION: Insert must be even with the table I

surface, inserts too high or low can let the I

workplece "snag" or catch on uneven edges. ]

Workplece could twist and kick back°

2. To remove insert.

A. Make sure saw isoff and unplugged.

B. Loosen screw.

C. Lift Insertfrom front end, and pufftoward front of

saw.

3. To replace Insert.

A. Make sure saw is off and unplugged.

B. Place Insert into insert opening intable arid push

toward rear of saw to engage spring clip and urltil

keyslot in Insert will drop over screw. Tighten

screw,

C. Do not tighten screw to the point where it wifl

deflect the Insert.

3/32 IN.

SET SCREW WRENCH

\

PHILLIPS

FLAT HEAD

_-- SCREW

13

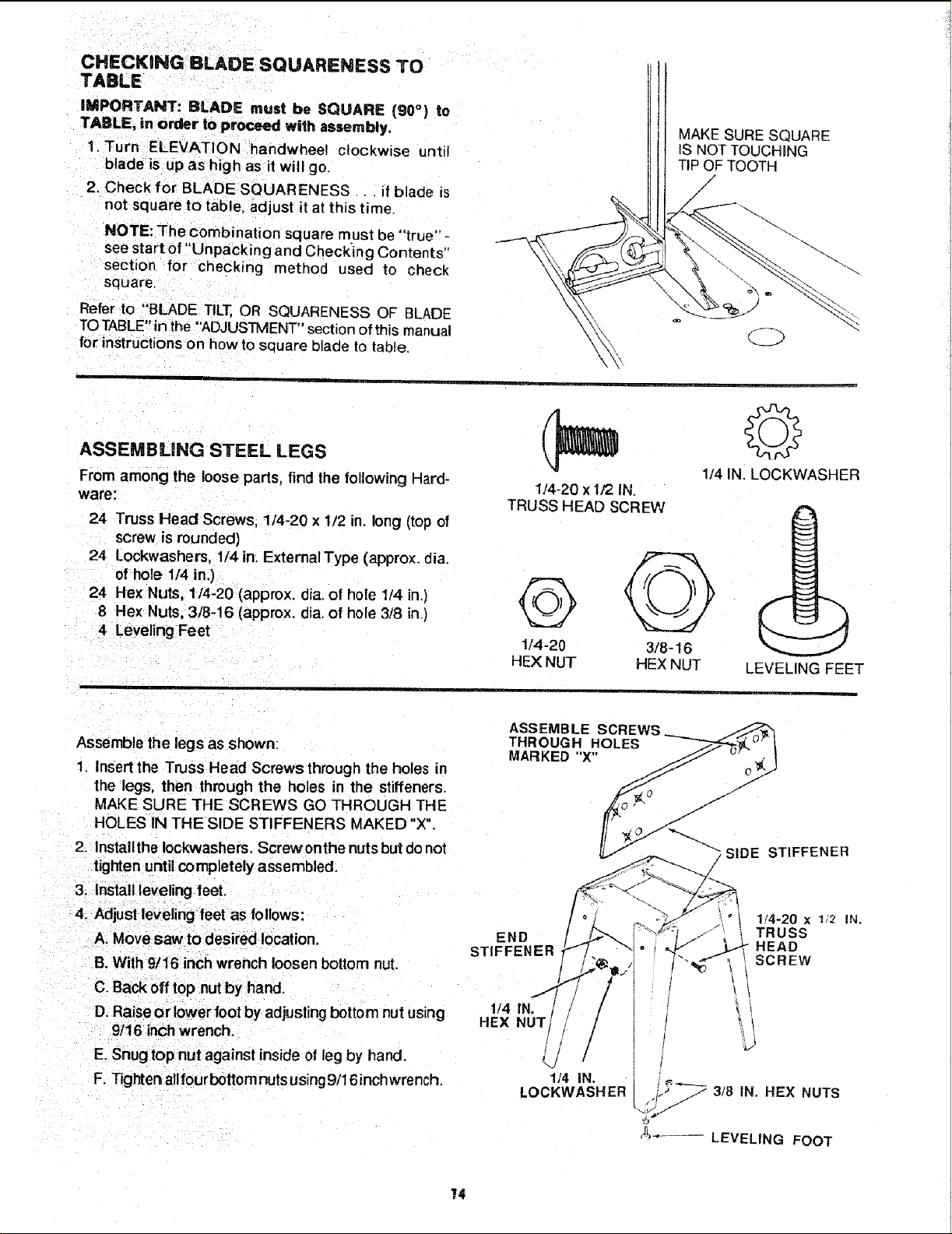

CHECKING BLADE SQUARENESS TO

TABLE

IMPORTANT: BLADE must be SQUARE {90 °) to

TABLE, in order to proceed wilh assembly,

1. Turn ELEVATION handwheel clockwise unti!

blade is up as high as it will go.

2. Check for BLADE SQUARENESS _. if blade is

not square to table, adjust it at this time.

NOTE: The combination square must be "true" -

see start of "Unpacking and Checking Contents"

section for checking method used to check

sq LJare

Refer to "BLADE TET, OR SQUARENESS OF BLADE

TO TABLE" in the "'ADJUSTMENT" section of this manual

for instructions on how to sauare blade to table.

MAKE SURE SQUARE

!S NOT TOUCHING

TIP OF TOOTH

/

ASSEMBLING STEEL LEGS

From among the loose parts, find the following Hard-

ware:

24 Truss Head Screws, 1/4-20 x 1/2 in. long (top of

screw is rounded)

24 Lockwashers, 1/4 in. External Type (approx. dia.

of hole 1/4 in.)

24 Hex Nuts, 1/4-20 (approx. dia. of hole 1/4 in.)

8 Hex Nuts, 3/8-16 (approx. dia. of hole 3/8 in.)

4 Leveling Feet

Assemble the legs as shown:

1 Insert the Truss Head Screws through the holes in

the legs, then through the holes in the stiffeners.

MAKE SURE THE SCREWS GO THROUGH THE

HOLES IN THE SIDE STIFFENERS MAKED "X".

2. Install the Iockwashers. Screw onthe nuts but do not

tighten until completely assembled.

3. Install leveling feet.

4. Adjust leveling feet as follows:

A. Move saw to desired location.

B. With 9/16 inch wrench loosen bottom nut.

C. Back off top nut by hand.

D. Raise or lower foot by adjusting bottom nut using

9!16 inch wrench.

E. Snug top nut against inside of leg by hand.

F. Tighten all fourbottom nuts using 9/16 inchwrench,

1/4-20 x 1/2 IN.

TRUSS HEAD SCREW

Q

1/4-20

HEX NUT

E.o l

STIFFENER F"

1/4 IN.

3/8-16

HEX NUT

©

1/4 IN. LOCKWASHER

LEVELING FEET

1/4-20 x 1/2 IN.

_ TRUSS

HEAD

i SCREW

14

LOCKWASHER, _,,. 3/8 IN. HEX NUTS

_-- LEVELING FOOT

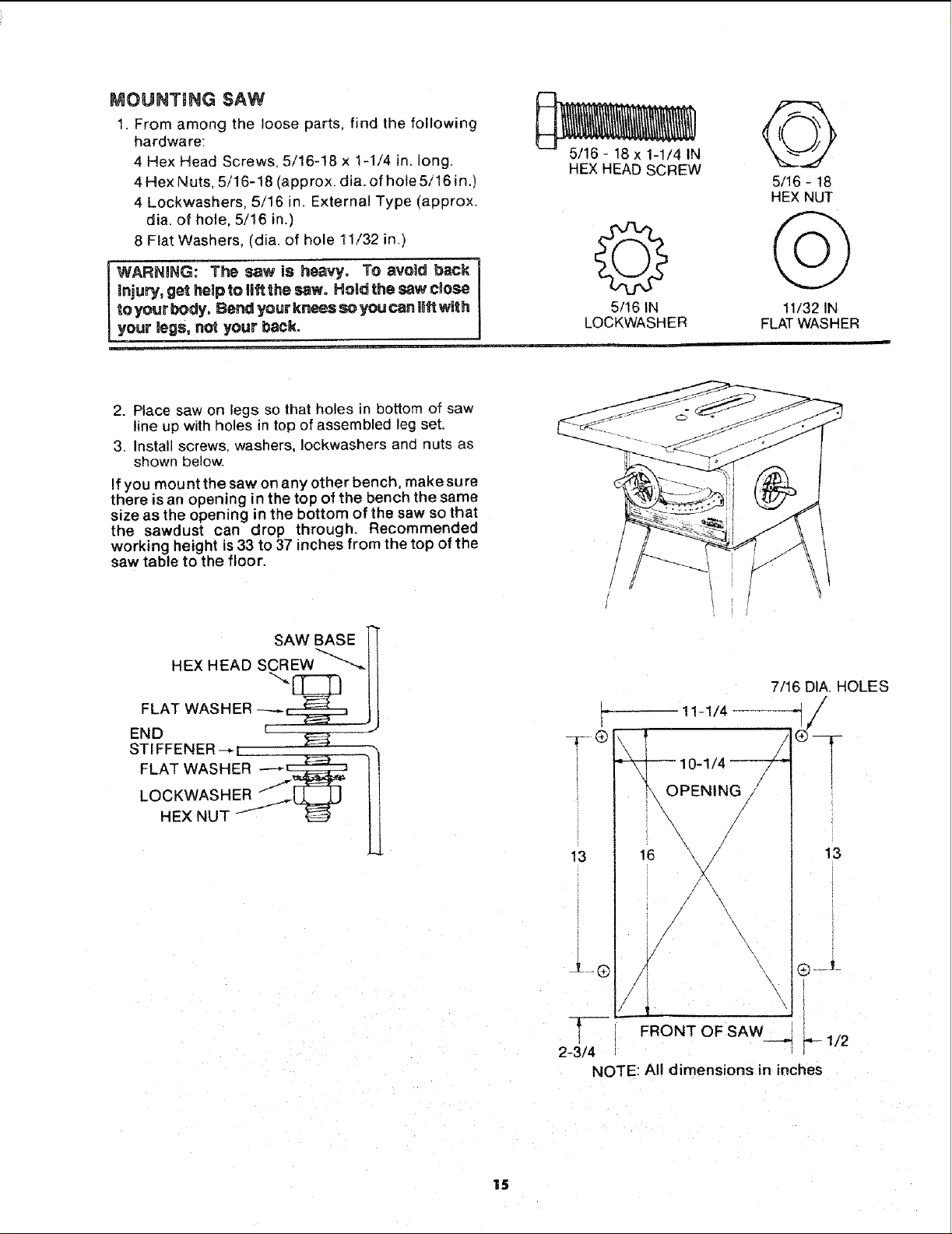

MOUNTING SAW

1. From among the loose parts, find the following

hardware:

4 Hex Head Screws, 5/16-18 x 1-1/4 in. long.

4 Hex Nuts, 5/16-18 (approx. dia. of hole 5/16 in.)

4 Lockwashers, 5/16 in. External Type (approx.

dia. of hole, 5/16 in.)

8 Flat Washers, (dia. of hole !1/32 in.)

WARNING: The saw is heavy. To avoid back

injury, get help to riftthe saw. Hold the saw close

to your body. Bend your knees so you can li_twith

your legs, not your back.

2. Place saw on legs so that holes in bottom of saw

line up with holes in top of assembled leg set.

3. Install screws, washers, Iockwashers and nuts as

shown below.

If you mount the saw on any other bench, make sure

there is an opening in the top of the bench the same

size as the opening in the bottom of the saw so that

the sawdust can drop through. Recommended

working height is 33 to 37 inches from the top of the

saw table to the floor.

_N

HEX HEAD SCREW

5/16 IN

LOCKWASHER

5/16 - 18

HEX NUT

11/32 IN

FLAT WASHER

SAW BASE

FLAT WASHER

END l ...'

STIFFENER--_I _ _

LOCKWASHER /_m==_ l!

HEXNUT

/

11-1/4

'_L_PENIN?/

\

13

16 13

\/

°

/

/

\

/

/

!

i

2-3/4

NOTE: All dimensions in inches

--RONT OF SAW __

7/16 DIA. HOLES

\

Q Y

\

1/2

15

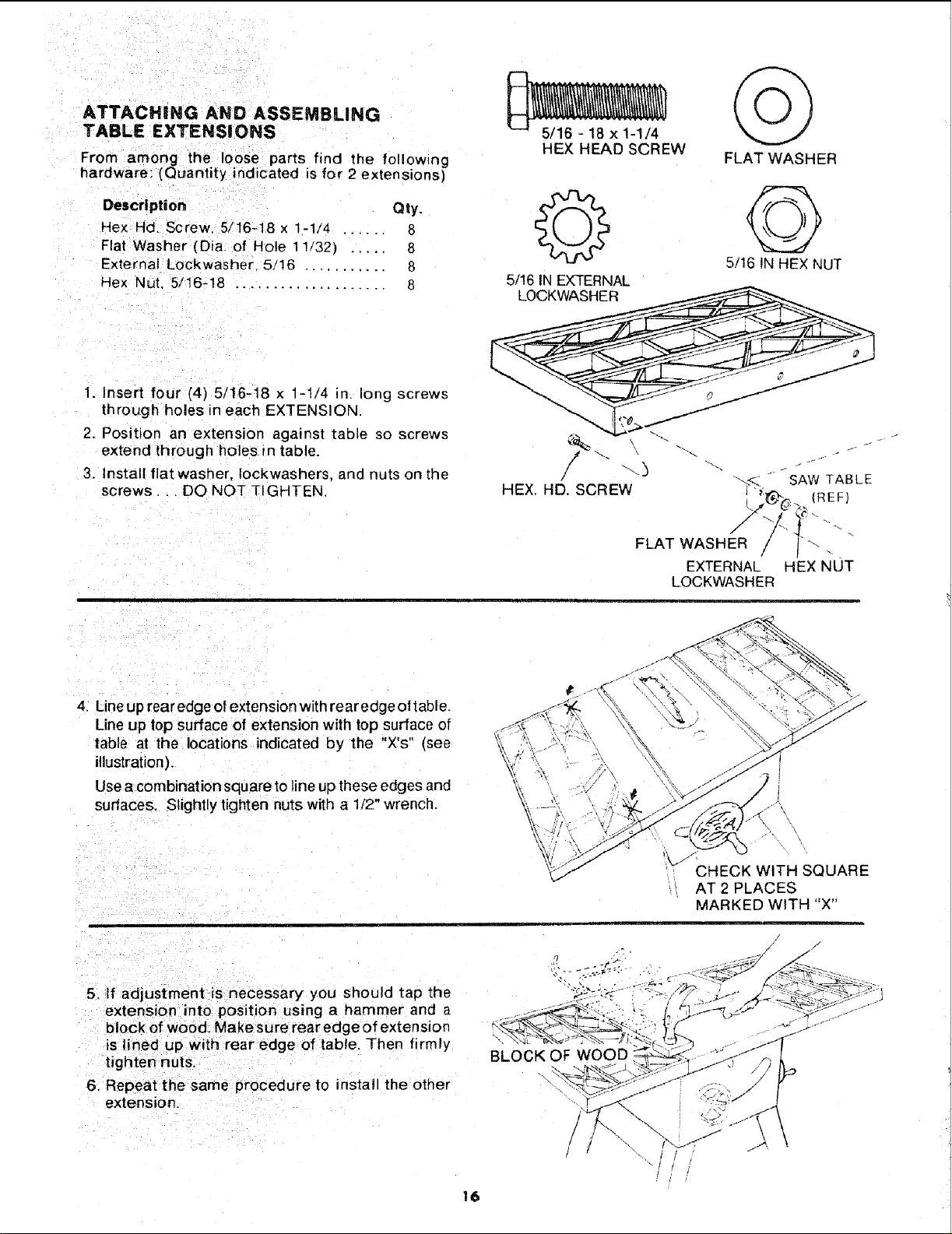

ATTACHING AND ASSEMBLING

TABLE EXTENSIONS

From among the loose parts find the following

hardware: (Quantity indicated is for 2 extensions)

Description Qty.

Hex Hal. Screw 5/16-18 x 1-1/4 ...... 8

Flat Washer (Dia of Hole 11/32) ..... 8

External Lockwasher 5/16 ........... 8

Hex Nut, 5/16-18 .................... 8

1. Insert four (4) 5/16-18 x 1-1/4 in. long screws

through holes in each EXTEN SION.

2. Position an extension against table so screws

extend th rough holes in table.

3. Install flat washer, Iockwashers, and nuts on the

screws, ,. DO NOT TIGHTEN,

HEY, HEAD SCREW

FLAT WASHER

5/16 INHEX NUT

5/16 IN EX-FERNAL

/ \--1 "- -

"_<L -- SAW TABLE

HEX HD. SCREW _G > (REF}

FLAT WASHER // / '"

EXTERNAL HEX NUT

LOCKWASHER

/

4. Une up rearedge of extension with rear edge oftable.

Line up top surface of extension with top surface of

table at the locations indicated by the "X's" (see

illustration).

Use a combination square to line up these edges and

surfaces. Slightly tighten nuts with a 1/2" wrench.

5. If adjustment is necessary you should tap the

extension into position using a hammer and a

block of wood. Make surerear edge of exten sion

is lined up with rear edge of tab{e. Then firmly

tighten nuts

6. Repeat the same procedure to install the other

extension.

CHECK WITH SQUARE

AT 2 PLACES

MARKED WITH "X"

BLOCK OF WOOD

16

MOUNTING SWITCH

1, From among loose parts find the following:

2 Hex Head Screws, 5/16-18 x 5/8 in. long

2 External 5/!6" Lockwashers

2 Hex Nuts, 5/t6-18

2. Select one front fence guide bar.

3. insert two 5/8 inch screws through holes in switch.

4. Insert screws through fourth and fifth holes in front

fence guide bar as illustrated.

5. _nstalltwo Iockwashers and nuts. Tighten nuts.

5/8 IN 5/t6 IN EXTERNAL 5/16 IN

HEX HD SCREW LOCKWASHER HEX NUT

i

JAM NUT

5/16-18

,]

4TH HOLE ! " 5TH HOLE

= = "_=. • .===----,_

FRONT FENCE \_\

GUIDE BAR "_

(UPSIDE DOWN) _ _

,_, _Q/LOCKWASHER

%

HEX HEAD SCREW

5/1 18 x 5/8iN.

iNSTALLiNG RIGHT FRONT RiP FENCE

GUIDE BAR

1. From among the loose parts find the following

hardware:

2 Hex Head Screws, 5/16-18 x 1-1/2 in. long

1 Hex Head Screw, 5/16-18 x 1-1/4 in. long

2 Hex Head Screws, 5/16-18 x 3/4 in. long

5 External Lockwashers, 5/16 in. (approx. dia. of

hole 5/16 in.)

5 Hex Nuts, 5/16-18 (approx. dia. of hole 5/t6 in.)

3 Spacers, 3/4 in. dia. x 1/2 in. long

5 Washers (dia. of hole 21/64 in.)

1 Front Fence Guide Bar (with switch attached)

2 Brackets

1-1/2 IN HEX HD. SCREW

2. Put one of the brackets against the right edge of the

right extension so the bracket is lined up with the

FIRSThole near the front of the extension. Insert a

3/4 inch long screw through a flat washer, through

top hote in the bracket, and through the FIRST hole

in the extension, install a Iockwasher and nut on the

screw. Tighten the nut only slightly.

3. Install the other bracket against the left side of

left extension-using the same procedure explain-

ed above.

1-1/4 IN HEX HD. SCREW

3/4 IN HEX HD.

17

SCREW

5/16 IN EXTERNAL 5/16 IN

LOCK WASHER HEX NUT

1/2 IN SPACER

21/64 iN WASHER

HEX NUT

EXTERNAL

LOCKWASHER HEX HEAD

SCREW

5/16-18 x 3/4 iN

BRACKET

FENCE GUIDE BAR

WITH SWITCH

6TH HOLE SPACER

4. Insert a 1-114 inch long screw through a flat washer _-'_-_, -_._t_--_ _,z

and the SECOND hole IN THE FRONT BAR as illus- _-_ _ "%'---,_:_!'_ _"_"_

trated, insert a 1-I/4 nch ong screw throuah a washer "_,_;_ _ - _';v_"" @_

and through the SIXTH hole inbar. nsert another 1-1I " _ _ ", ; ;itS%,. /,

• ',,y3_'_ _'1 _- - ...... / , ,_ _':

2 Inch long screw through a flat washer and through _ ..... & ,SHE i,_ /

the NINTH hold inbar. / _" .-, [

-" -J _ ,HEX HEAD

Place p ce,sonscrews \

HEX HEAD SCREW "N-_.

5/16-18 X 1-114 y"

6. Turn front bar end for end and insert two screws

through hoaes in righttront edge of table. The third

screw is inserted through the elongated slot in the

bracket you installed earlier. Instafl Iockwashers and

nuts. DON'TSCREW NUTS ON ALL THE WAY, just

get them started on the screws.

iNSTALLiNG LEFT FRONT RiP FENCE

GUIDE BAR

1. From among the loose parts find the following

hardware:

2 Hex Head Screws. 5/16-18 x 1-1/2 in. long

1 Hex Head Screw, 5/16-18 x 1-1/4 in_ long

3 External Lockwashers 5/16 in.

3 Hex Nuts. 5/16-18

3 Flat Washers {dia. of hole 21/64 in.)

3 Spacers, 3/4 in. dia. x 1/2 long

1 Front Fence Guide Bar

2. Lay gu de bar on saw table as illustrated SPACER / ........._" _'-

3. Insert a !-1'2 inch long screw through a flat washer _L_I_ "_" s;--z::.-:__'_"_1-

4. Place spacers over threaded end of screw as illus- 5/16-18 X 1-1/2IN ....

trated. / , _ . .

• 2ND HOLE SPAC_ER ......6TH HOLE

and then through the FIRST hole in the bar as illus- .. _

trated Insert a 1-112 _nch long screw through a flat ,_,-u,-,LE_._ --_._=_,._:_--, <-.... _ _:.,,

washer and then through the SECOND hole in bar. _",_:¢'_.,r_'_ ./". ._'X,

Insert another 1:1t4 ,nch tong screw through a flat WASHER-_i '-_" -- - -

washer and then through the SIXTH hole in bar. HEX HEAD SCREW J- 5/16-18 X 1-1/4 _N

. ,_,L.-:_---.."_-_ .._c-_......- _ \

1-1/2 IN HEX HEAD SCREW

5/16 IN EXTERNAL

WASHER__)

1-1/4 tNHEXHEADSCREW _ _,J ]

FLAT WASHER

L-_--_ ............................ _-_

1/2 IN SPACER

/

FRONT FENCE GUIDE BAR

.... ' HEX HEAD SCREW

5/t6-18

HEXNUT

18

5. Turn front bar end for end and insert two of the

bolts through holes on teftside of front edge on saw

table. The third screw is inserted through the bracket

installed earlier

6. Install lockwashers and nuts on bolts. DO NOT

SCREWNUTS ON ALL THEWAY,just get them started

on the screws.

iNSTALLING REAR FENCE GUIDE BARS

1. From among the loose parts find the following:

2 Brackets

4 Hex Head Screws 5/16-18 x 1in. long

4 Hex Head Screws 5/16-18 x 3/4 in. long

8 Flat Washers (dia. of hole 21/64 in.)

8 External Lockwashers, 5/16 in.

8 Hex Nuts, 5/16-18

2 Rear Fence Guide Bars

4 Protective Caps

SCREWS LOCATED

HERE

5/16-18 x 3/4

HEX HEAD

SCREW

FLAT WASHER

REAR FENCE GUIDE BAR

5/16-18 x 1 IN

HEX HD. SCREW

BRACKET

2. Put one of the brackets against the right rear

edge of the right extension so the bracket is lined

up with the FOURTH hole near the rear of the

extension (see illustration).

3. Insert one of the 3/4 inch long screws through a flat

washer, through the bracket, and through the

FOURTH hole in the extension. Install a Iockwasher

and nut on the screw. Tighten the nut only slightly

4. Install the other bracket against the left side of

the left extension using the same procedure

explained above.

5. Layone rearfenceguidebarontheleft rearsideofthe

saw table as illustrated (as viewed from rear of the

saw). Insert a I inch long screw through a flat washer

and throughthe SECOND hole ofthe rear fence guide

bar. Insert a 1 inch long screw through a flat washer

andthroughthe FOURTH hold. Insert a3t4 inch long

screw through a flat washer and through the

ELEVENTH hole.

5/t 6 IN

EXTERNAL 5/16-18

LOCKWASHER HEX NUT

EXTERNAL

LOCKWASHER

2ND HOLE 4TH HOLE

WASHER

WASHER

HEX HEAD

SCREW

5/15-18 X 1 IN

PROTECTIVE CAP

REAR OF

5/16-18x3/4

HEX HEAD

SCREW

tlTH HOLE

l

HEX HEAD

SCREW

5,'16-18X 3/4 IN

19

BACK OF SAW

EXTERNAL

LOCKWASHER H_x_T

6. Turnthefenceguidebarendforendandinserttwo

ofthe1inchlongscrewsthroughthetwoholesin

HEXNUT\_. _ \__ , - o

theleftrearedgeofthetable.Inserttheother3/4

inchlongscrewthroughthebracket.Installalock-

washerandnutonbolts.DONOTSCREWNUTSON

WASHER .-"-'__' LEFT REAR _' _"

ALLTHEWAY,justgetthemstartedonthescrews.

Pushthefenceguidebarasfartowardtherear

centerofthesawasitwillgo.Itmustremainasclose

totherearcenterofthesawaspossiblethrougt_the

restofthisadjustingprocedure,

7. Lay the other rear fence guide bar on the right rear of 2ND HOLE 9TH HOLE 11TH HOLE

the saw tabel as illustrated (view is shown from rear of _-iI_-_ ....... _T_ :I_

tabe saw " =_ _-F_ - =- _ ::--= _ -_---_

washer and through the SECOND hole. Insert a I inch ..... _;,_,JZ ----_-_ i -_-,:. -_ _ ..::=_'_F-c,_,,

long screw through a flat washer and through the :,_?_'-_----_-3i:_-_ _ ____.Z_ _) WASHER

NINTH hoe nsert a 1 inch long screw thiough a fiat _ WASHL_ _'F'_,) t.,Aeu=_ /

washer and through the ELEVENTH hole _-_

). Insert a 3/4 inch long screw through a flat

• I \ /

HE×HEAD

SCREW _k \ ^ H_u

5/16-18 X 3/4 IN / _ SCREW

_- _ "_ \ .,/WASHER

,f_ GUIDE BAR / %_..._%'

REXHEAD / HE×HEAD

SCREW WASHER SCREW

5/16-18 x 3/4 iN 5/16-18 x 1 iN

VIEWED FROM REAR OF SAW

5/16-18 X 1 IN

VIEWED FROM REAR OF SAW

8 Turn the fence bar end for end and insert two ofthe

1 inch long screws through the two holes in the right

rear edge of the saw table. Insert the other 3/4 inch

long screwthrough the bracket. Install a iockwasher

and nut on the screws. DO NOT SCREW NUTS ON

ALL THE WAY,just get them started on the screw.

9. Push a protective cap overthe exposed end of allfour

(4) fence guide bars as illustrated. You may' want to

secure these to thefence bars using household type

glue,

EXTERNAL

LOCK WASHER

WASHER _" _: .._-:;:-;. ,--_-_J 9

. HEjX_NUT LOCKWASHER_

HEX NUT

T

t o- /

_'/ HEX HEAD

HEX HEAD SCREW CAP

SCREW 5/16-18 x 3/4 IN.

5/16-18 x 1 IN

/ PROTECTIVE

2O

ADJUSTING RIP FENCE GUIDE BARS

WARNING: Mlsadjusted ience guSde bars can

mBsalig n the fence. A misaglgned fence can cause

kickbacks and jams. You could be cut or hit.

Proper_y adjust fence guide bars before using

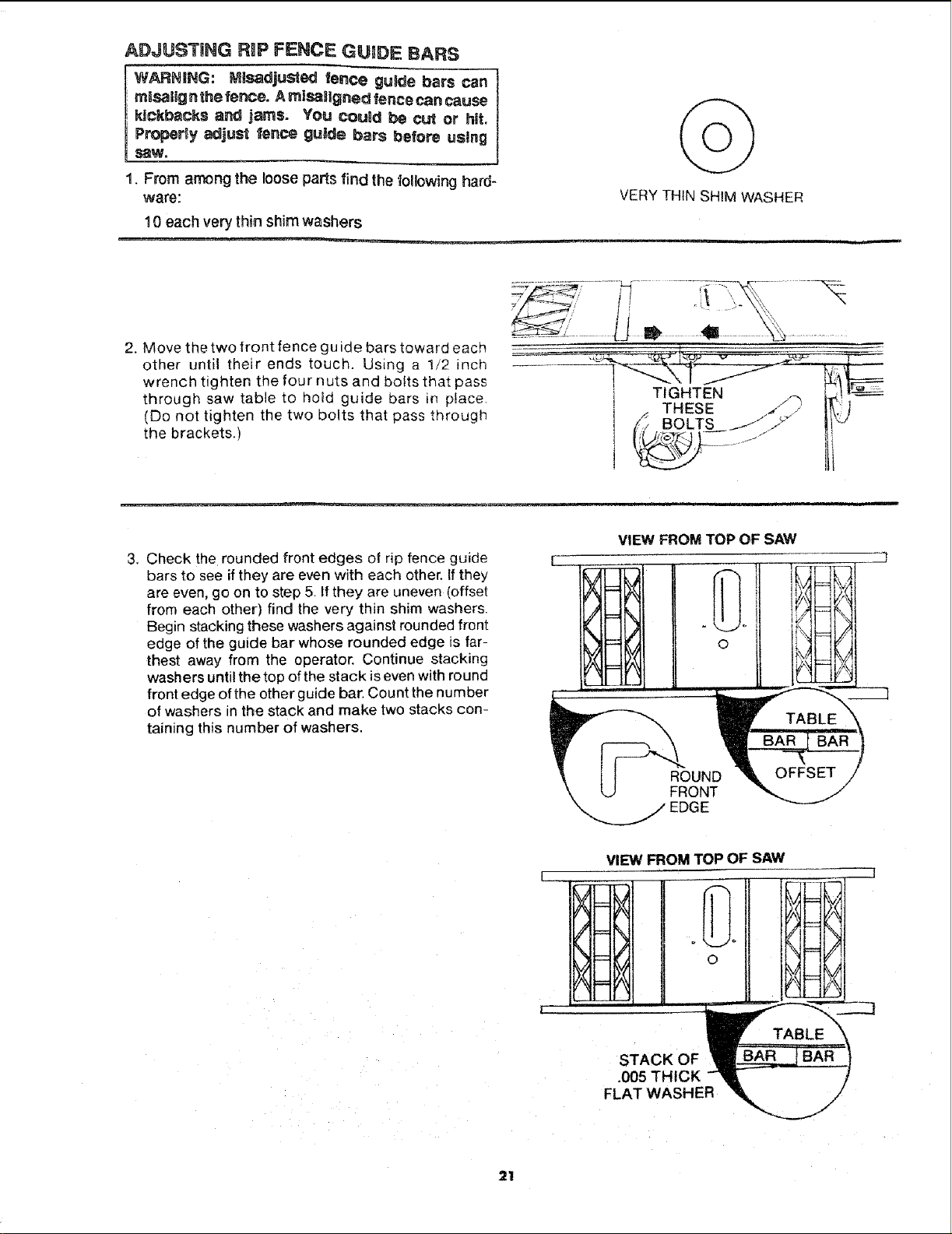

1. From among the loose parts find the following hard-

ware:

10 each very thin shim washers

2. Move the two front fence guide bars toward each

other until their ends touch. Using a 1/2 inch

wrench tighten the four nuts and bolts that pass

through saw table to hotd guide bars in place.

(Do not tighten the two bolts that pass through

the brackets.)

VERY THIN SHIM WASHER

THESE _i!]

BOLTS !! "_'

3. Check the rounded front edges of rip fence guide

bars to see if they are even with each other, tf they

are even, go on to step 5. If they are uneven (offset

from each other) find the very thin shim washers.

Begin stacking these washers against rounded front

edge of the guide bar whose rounded edge is far-

thest away from the operator. Continue stacking

washers until the top of the stack is even with round

front edge of the other guide bar. Count the number

of washers in the stack and make two stacks con-

taining this number of washers.

VIEW FROM TOP OF SAW

VIEW FROM TOP OF SAW

_-_=_

J _

/

\_

X=

o

21

I " '

STACK OF

.005 THICK

FLAT WASHER

!

/

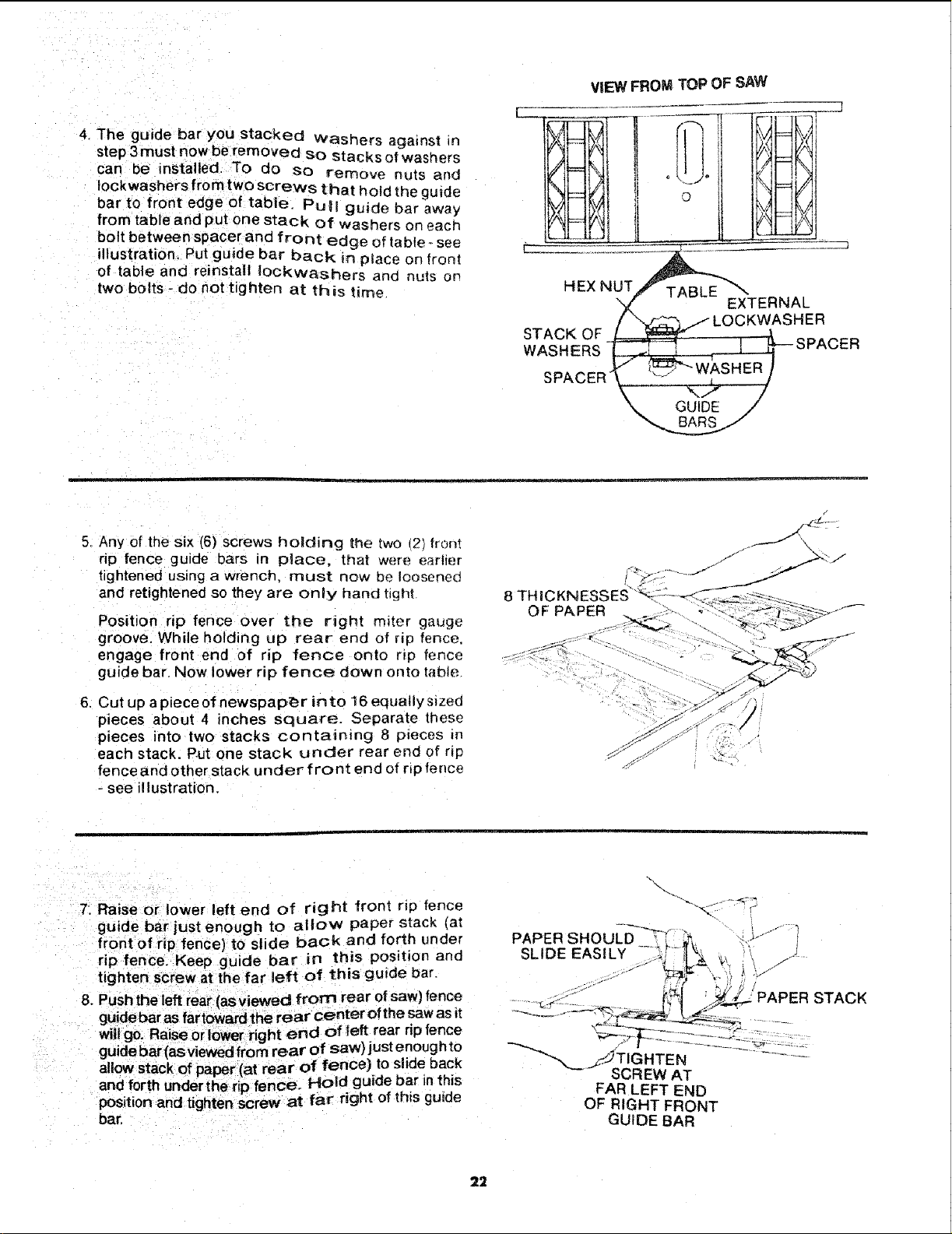

4. The guide bar you stacked washers against n

step 3 must now be removed so stacks of washers

can be installed. To do so remove nuts and

Iockwashers from tWO screws that hold the guide

bar to front edge of table. Pull guide bar away

from table and put one stack of washers on each

bolt between spacerand front edge of table - see

illustration. Put guide bar back in place on front

of table and reinstall [ockwashers and nuts on

two bolts - do not tighten at th is time

VIEW FROM TOP OF SAW

HEX NUT

STACK OF

WASHERS -

SPACER

©

TABLE

EXTERNAL

;HER

5. Any of the six (6) screws holding the two t21 front

rip fence guide bars in place, that were earlier

tightened us=ng a wrench_ must now be loosened

and retightened so they are only hand tight

Position rip fence over the right miter gauge

groove. While holding up rear end of Np fence.

engage front end of rip fence onto r=p fence

guide bar. Now lower rip fence down onto table

6. Cut up a piece of newspaper in to 16 equally s=zed

pieces about 4 inches square. Separate these

pieces into two stacks containing 8 p_eces m

each stack. P.utone stack under rear end of rIp

fence and other stack under front end of rip fence

- see illustration.

7: Raise or lower left end of right front rip fence

guide bar just enough to aliov_ paper stack (at

front of rip fence) to slide back and forth under

rip fence. Keep guide bar in this position and

tighten screw at the far left of this guide bar.

8. Pushthe left rear (as viewed from rear of saw) fence

OF PAPER

t

PAPER SHOI

SLIDE EASILY

PAPER STACK

willgo. Raise or lower right end of left rear rip fence

allow stack of paper(at rear of fence) to slide back

and forth under the rip fence. Hold guide bar inthis

position and tighten screw at far right of this guide

bar.

SCREW AT

FAR LEFT END

OF RIGHT FRONT

GUIDE BAR

22

Loading...

Loading...