Page 1

Angle Grinder

Vinkelslipmaskin

Vinkelslipemaskin

Kulmahiomakone

Important!

Read the entire instruction manual carefully

and make sure that you fully understand

it before you use the equipment. Keep the

manual for future reference.

Viktig information:

Läs hela bruksanvisningen noggrant och

försäkra dig om att du har förstått den innan

du använder utrustningen och spara den för

framtida bruk.

Viktig informasjon:

Les disse anvisningene nøye og forsikre deg

om at du forstår dem før du bruker enheten

og oppbevar dem for senere bruk.

Tärkeätä tietoa:

Lue nämä ohjeet huolellisesti ja varmista

että olet ymmärtänyt ne, ennen kuin alat

käyttää laitetta. Säilytä ohjeet myöhempää

tarvetta varten.

Ver. 001-200604

ENGLISHSVENSKANOR SKSUOMI

Art.no Model

30-9316 CT3234

Ver. 200802

Page 2

2

Page 3

Angle Grinder

Art. no. 30-9316, model CT3234

Please read the entire instruction manual before using the product and save it for

future reference. We apologise for any text or photographic errors and any changes

of technical data. If you have any questions concerning technical problems please

contact our Customer Service Department (see address on reverse.)

Table of Contents

Safety 4

Product Description 11

Assembly 12

Use 13

Changing of grinding wheel 14

Rotating the rear handle 14

Care and Maintenance 15

Troubleshooting Guide 15

Disposal 15

Specications 15

ENGLISH

3

Page 4

1. General safety instructions

Warning! Read all the instructions. Failure to adhere to the following instructions

may lead to electric shocks, res and/or serious injury. The term “electrical hand

ENGLISH

tools” in the warning text below is referring to your mains operated or battery

operated hand tool.

1) The work space

a) Keep the work space clean and well illuminated. Cluttered and poorly lit areas

invite accidents.

b) Do not use electrical hand tools in explosive environments, i.e. nearby

ammable liquids, gas or dust. Electrical hand tools generate sparks that could

easily ignite dust or fumes.

c) Keep away from children and other spectators while using the electrical hand

tool. Distractions can make you lose your concentration and control.

2) Electrical safety

a) The electrical hand tool’s plug must t correctly in the wall socket. Never modify

the plug in any way. Never use an adaptor together with earthed electrical hand

tools. Unmodied plugs and suitable wall sockets decrease the risk of electric

shock.

b) Avoid body contact with earthed objects, such as pipes, radiators, ovens or

refrigerators. There is an increased risk of electrical shock if your body is

earthed.

c) Do not expose the electrical hand tool to rain or other wet conditions. If water

gets inside an electrical hand tool it increases the risk of electrical shock.

d) Do not misuse the lead. Never use the lead to carry, drag or pull the plug out of

the wall socket. Keep the lead away from heat, oil, sharp edges and movable

parts. Damaged or tangled leads increase the risk of electrical shock.

e) When you use an electrical hand tool outdoors; use an extension cord suitable

for this purpose. Use of an extension cord for outdoor use decreases the risk of

electrical shock.

3) Personal safety

a) Pay attention to what you do and use common sense when using electrical hand

tools. Never use an electrical hand tool if you are tired or under the inuence

of drugs, alcohol or medication. One moment of inattention while using an

electrical hand tool may result in serious injury.

b) Use protective equipment. Always use safety glasses. Using protective

equipment such as a face mask, slip resistant protection shoes, a helmet and

ear plugs when needed decreases the risk of injury.

4

Page 5

c) Avoid unexpected starts. Make sure that the switch is set to OFF before you

connect the device to the wall socket. Never carry an electrical hand tool with

one nger on the trigger or never connect the hand tool to a wall socket when

the switch is set to ON, since it may result in injury.

d) Remove all service tools/keys before switching on the hand tool. A forgotten

service tool on a rotating part of the electrical hand tool may result in injury.

e) Do not overreach. Make sure you stand steady and well balanced at all times.

This gives better control in unexpected situations.

f) Wear suitable clothing. Do not wear loose tting clothes or jewellery. Keep hair,

clothes and gloves away from movable parts. Loose tting clothes, jewellery or

long hair could get caught in movable parts.

g) If the equipment for suctioning or dust collecting is available make sure it is

connected and used properly. Using technical aids may reduce dust related

hazards.

4) Use and maintenance of the electrical hand tools

a) Do not overdrive the hand tool. Use a hand tool suitable for the work you are to

perform. At the correct rate of feed, the correct tool will carry out the work better

and more safely.

b) Never use the electrical hand tool if the switch does not work properly to turn

on and shut off the tool. All electrical hand tools that cannot be operated by the

switch are dangerous and must be repaired.

c) Unplug the lead from the wall socket before making any adjustments, changes

of accessories or storing the electrical hand tool away. These precautions

reduce the risk of unexpected starts of the electrical hand tool.

d) Store electrical hand tools that are not being used out of reach from children.

Do not let people unfamiliar with the electrical hand tool or its instructions

use it. Electrical hand tools can be dangerous if they get into the hands of

inexperienced users.

e) Maintenance of electrical hand tools. Check if something is incorrectly set, if

movable parts are getting jammed, or parts are broken or something else that

might cause the electrical hand tool to malfunction. If something is damaged it

must be repaired before use. Many accidents are caused by poorly maintained

electrical hand tools.

f) Keep the tools sharp and clean. Properly maintained cutting tools with sharp

blades are less likely to jam and are easier to control.

g) Use the electrical hand tool, accessories and such according to the instructions

and in a way suitable for the type of electrical hand tool used. Using the

electrical hand tool for work other than that for which it is intended could result in

a dangerous situation.

ENGLISH

5

Page 6

5) Service

a) Let only qualied personel perform service and repairs using original parts.

This guarantees that the safety of the electrical hand tool is maintained.

ENGLISH

2. Safety warnings common for grinding,

sanding, wire brushing, polishing or abrasive

cutting-off operations

a) This power tool is intended to function as a grinder, sander, wire brush or cut-

off tool. Read all safety warnings, instructions, illustrations and specications

provided with this power tool. Failure to follow all instructions listed below may

result in electric shock, re and/or serious injury.

b) Operations such as polishing are not recommended to be performed with this

power tool. Operations for which the power tool was not designed may create a

hazard and cause personal injury.

c) Do not use accessories which are not specically designed and recommended

by the tool manufacturer. Just because the accessory can be attached to your

power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the maximum speed

marked on the power tool. Accessories running faster than their rated speed can

break and y apart.

e) The outside diameter and the thickness of your accessory must be within the

capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

f) The arbour size of wheels, anges, backing pads or any other accessory must

properly t the spindle of the power tool. Accessories with arbour holes that

do not match the mounting hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each use inspect the accessory

such as abrasive wheels for chips and cracks, backing pad for cracks, tear or

excess wear, wire brush for loose or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an undamaged accessory. After

inspecting and installing an accessory, position yourself and bystanders away

from the plane of the rotating accessory and run the power tool at maximum

no-load speed for one minute. Damaged accessories will normally break apart

during this test time.

6

Page 7

h) Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing

protectors, gloves and workshop apron capable of stopping small abrasive or

workpiece fragments. The eye protection must be capable of stopping ying

debris generated by various operations . The dust mask or respirator must be

capable of ltrating particles generated by your operation. Prolonged exposure

to high intensity noise may cause hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone entering the

work area must wear personal protective equipment. Fragments of workpiece or

of a broken accessory may y away and cause injury beyond immediate area of

operation.

j) Hold power tool by insulated gripping surfaces only, when performing an

operation where the cutting accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a “live” wire may make exposed metal parts

of the power tool “live” and shock the operator.

k) Position the cord clear of the spinning accessory. If you lose control, the cord

may be cut or snagged and your hand or arm may be pulled into the spinning

accessory.

l) Never lay the power tool down until the accessory has come to a complete stop.

The spinning accessory may grab the surface and pull the power tool out of your

control.

m) Do not run the power tool while carrying it at your side. Accidental contact with

the spinning accessory could snag your clothing, pulling the accessory into your

body.

n) Regularly clean the power tool’s air vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause

electrical hazards.

o) Do not operate the power tool near ammable materials. Sparks could ignite

these materials.

p) Do not use accessories that require liquid coolants. Using water or other liquid

coolants may result in electrocution or shock.

ENGLISH

7

Page 8

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncontrolled power tool to be forced in

ENGLISH

the direction opposite of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched by the workpiece, the

edge of the wheel that is entering into the pinch point can dig into the surface of

the material causing the wheel to climb out or kick out. The wheel may either jump

toward or away from the operator, depending on direction of the wheel’s movement

at the point of pinching. Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as

given below.

a) Maintain a rm grip on the power tool and position your body and arm to allow

you to resist kickback forces. Always use auxiliary handle, if provided, for

maximum control over kickback or torque reaction during start-up. The operator

can control torque reactions or kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback

over your hand.

c) Do not position your body in the area where power tool will move if kickback

occurs. Kickback will propel the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such

blades create frequent kickback and loss of control.

Safety Warnings specific for grinding and abrasive cutting-off

operations

a) Use only wheel types that are recommended for your power tool and the specic

guard designed for the selected wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are unsafe.

b) The guard must be securely attached to the power tool and positioned for

maximum safety, so the least amount of wheel is exposed towards the operator.

The guard helps to protect operator from broken wheel fragments and accidental

contact with wheel.

8

Page 9

c) Wheels must be used only for recommended applications. For example: do

not grind with the side of cut-off wheel. Abrasive cut-off wheels are intended

for peripheral grinding, side forces applied to these wheels may cause them to

shatter.

d) Always use undamaged wheel anges that are of correct size and shape for

your selected wheel. Proper wheel anges support the wheel thus reducing the

possibility of wheel breakage. Flanges for cut-off wheels may be different from

grinding wheel anges.

e) Do not use worn down wheels from larger power tools. Wheels intended for

larger power tool are not suitable for the higher speed of a smaller tools and

may burst.

Additional Safety Warnings specific for abrasive cutting-off

operations

a) Do not “jam” the cut-off wheel or apply excessive pressure. Do not attempt to

make an excessive depth of cut. Overstressing the wheel increases the loading

and susceptibility to twisting or binding of the wheel in the cut and the possibility

of kickback or wheel breakage.

b) Do not position your body in line with and behind the rotating wheel. When the

wheel, at the point of operation, is moving away from your body, the possible

kickback may propel the spinning wheel and the power tool directly at you.

c) When wheel is binding or when interrupting a cut for any reason, switch off

the power tool and hold the power tool motionless until the wheel comes to a

complete stop. Never attempt to remove the cut-off wheel from the cut while

the wheel is in motion otherwise kickback may occur. Investigate and take

corrective action to eliminate the cause of wheel binding.

d) Do not restart the cutting operation in the workpiece. Let the wheel reach full

speed and carefully re-enter the cut. The wheel may bind, walk up or kickback if

the power tool is restarted in the workpiece.

e) Support panels or any oversized workpiece to minimize the risk of wheel

pinching and kickback. Large workpieces tend to sag under their own weight.

Supports must be placed under the workpiece near the line of cut and near the

edge of the workpiece on both sides of the wheel.

f) Use extra caution when making a “pocket cut” into existing walls or other blind

areas. The protruding wheel may cut gas or water pipes, electrical wiring or

objects that can cause kickback.

ENGLISH

9

Page 10

Safety Warnings specific for sanding operations

a) Do not use excessively oversized sanding disc paper. Follow manufacturers

recommendations, when selecting sanding paper. Larger sanding paper

ENGLISH

extending beyond the sanding pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

Safety Warnings specific for wire brushing operations

a) Be aware that wire bristles are thrown by the brush even during ordinary

operation. Do not overstress the wires by applying excessive load to the brush.

The wire bristles can easily penetrate light clothing and/or skin.

b) If the use of a guard is recommended for wire brushing, do not allow any

interference of the wire wheel or brush with the guard. Wire wheel or brush may

expand in diameter due to work load and centrifugal forces.

Product marking with safety symbols

Read the safety and operating instructions

Always use ear defenders. Always use safety glasses or a visor

and wear a face mask.

10

Page 11

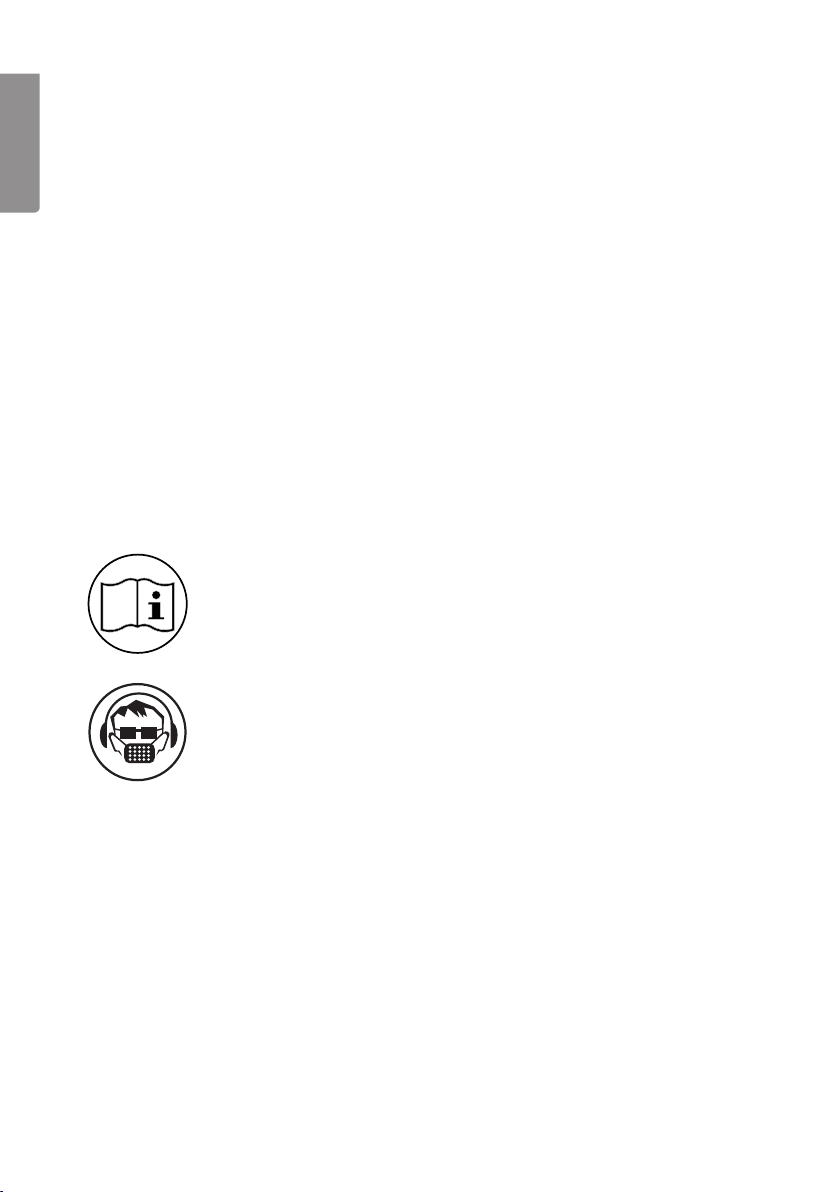

3. Product Description

A

B

C

D

E

F

ENGLISH

I

G

H

a) Handle

b) Shatter guard

c) Inner ange

d) Grinding wheel (not included)

e) Outer ange

f) Spanner

g) Power Switch

h) Machine body

i) Locking button for rotation of handle

11

Page 12

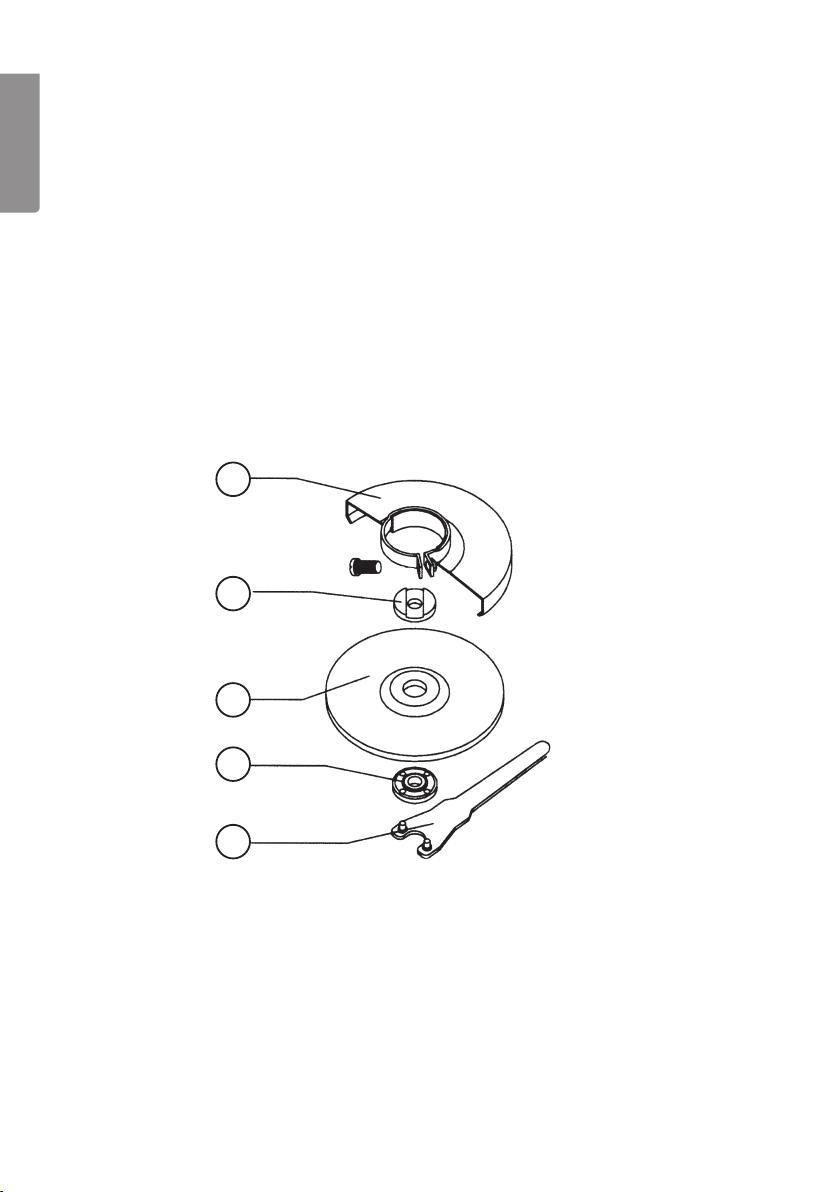

4. Assembly

1. Screw the side handle on the side of the gearbox that ts best. Insert the rubber

ENGLISH

plugs in the holes that are not used. Three different kinds of assembly are

possible.

2. Place the inner unthreaded ange (C) on the spindle and twist it until it locks on

the spindle.

3. Put on a grinding/cutting disc (D) on the spindle so it centres.

4. Put on the outer ange (E) with the concave side towards the disc.

5. Push in the spindle lock and tighten the ange clockwise with the included key.

6. Start the machine and let it run for awhile to make sure the disc is balanced

before grinding.

B

C

D

E

F

12

Page 13

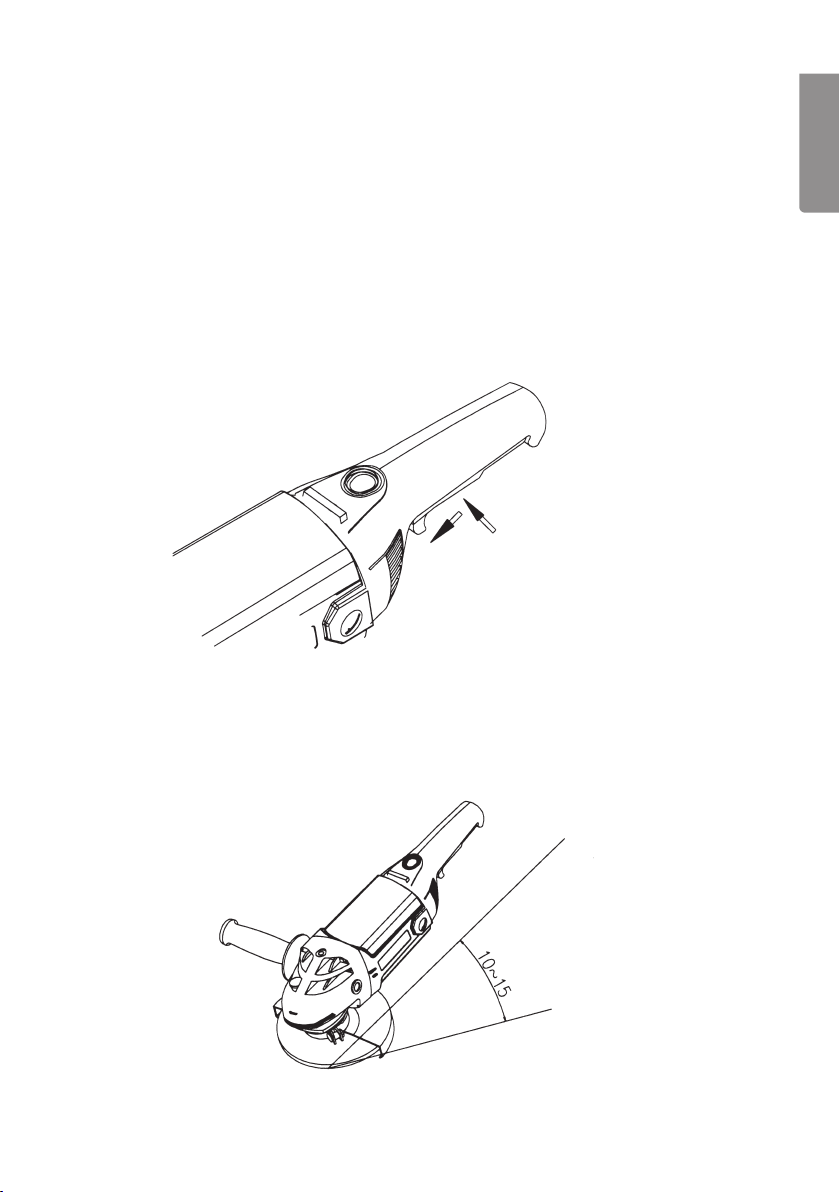

5. Use

• Let the machine come up to speed before grinding.

• Make sure you have good overview when grinding.

• Do not use the side of cutting discs for grinding since they cannot handle

pressure to the face.

• Use a diamond grinding wheel when cutting stone etc.

• Do not angle the machine while cutting. Make straight cuts only with

a cutting disc.

1. Stand steady and hold the machine rmly in both hands.

2. Push the switch forward and then up.

ENGLISH

3. Turn off the machine by releasing the switch.

4. The best method for grinding is to hold the machine in at a 10-15º angle.

13

Page 14

6. Changing of grinding wheel

The grinding wheel must have the correct inner diameter. Never use loose sleeves.

It should be approved for at least 8500 rpm.

ENGLISH

1. Pull out the plug from the outlet before changing the grinding disc.

2. Activate the spindle loc. Loosen the spindle bolt from the outer ange of the

spindle.

3. Remove the old grinding disc and attach a new one.

4. Assemble in reversed order.

5. Start the machine and let it run for awhile to make sure the disc is balanced

before grinding.

Spindle Lock Button

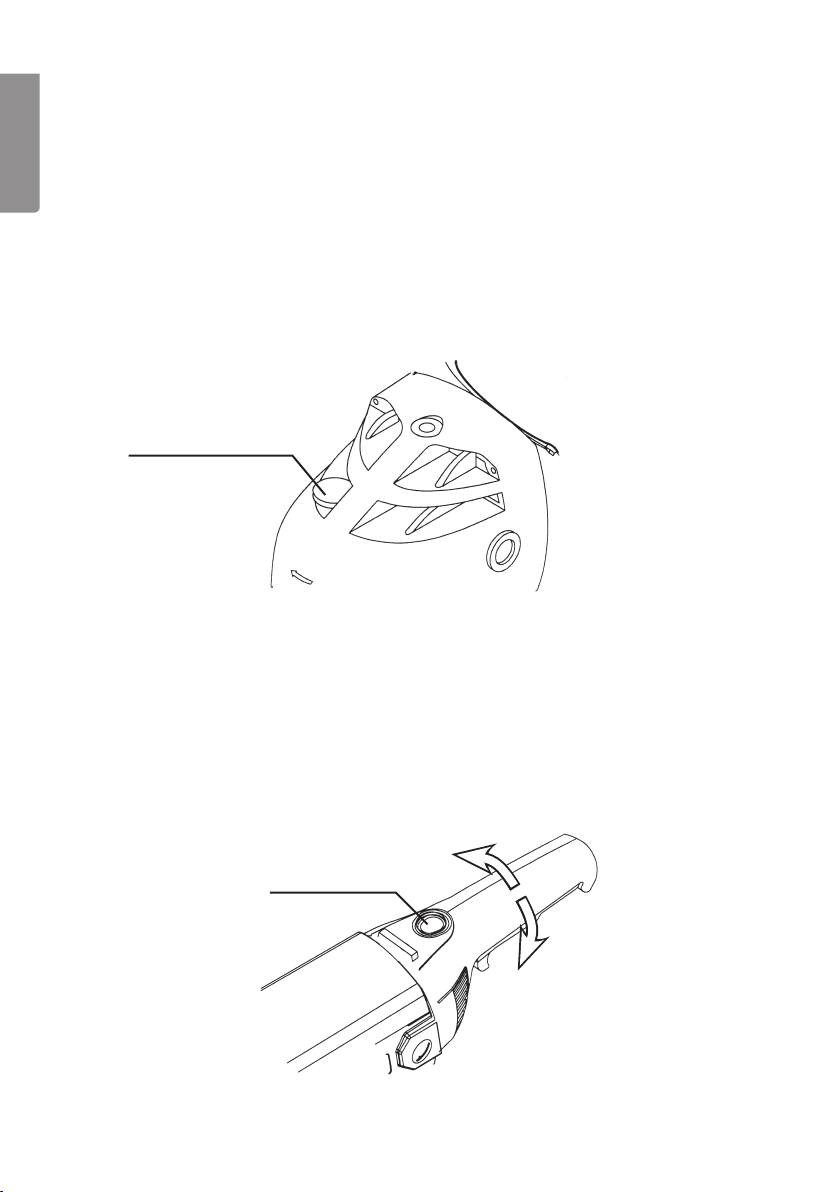

7. Rotating the rear handle

1. Unplug the mains lead before rotating the handle.

2. Push in the locking button to rotate the handle.

3. Rotate the handle to one of the three set positions.

4. Release the locking button and make sure the handle clicks in position.

Locking buttton

14

Page 15

8. Care and Maintenance

Always keep the motor’s ventilation openings free of dust and debris. If needed

dry off the angle grinder with a soft damp cloth. Avoid strong detergents or solvents.

9. Troubleshooting Guide

Problem Possible Cause Remedy

The machine does

not start.

The machine runs

slowly.

Strange noise. Mechanical fault. Contact us in case of motor or

Strong vibrations. Loose cutter/bit. Tighten the tool and make sure

Sparks in the

motor.

No power. Check the power point.

Worn brushes. Contact Customer Service in

Short circuit.

Faulty power switch.

Worn/damaged cutter/bit. Sharpen or change the cutter/bit.

Speed too low. Do not press down too hard.

The motor is overheated.

Faulty windings.

Brushes jammed. Contact Customer Service in

Winding short circuited.

Dirt on collector.

case of motor or electrical faults.

electrical faults.

it is set correctly.

case of motor or electrical faults.

ENGLISH

10. Disposal

Follow local ordinances when disposing this product. If you are unsure

about the disposal of this product contact your municipality.

11. Specifications

Power Supply 230 V ~ 50 Hz

Power 1800 W

No-Load Speed: 8500 rpm

Grinding Wheel Ø 180 mm, hole Ø 22 mm

Weight 4.7 kg (excluding grinding wheel)

Sound Pressure (LpA) 95 dB (A)

Sound Power (Lwa) 108 dB (A)

Vibration Value 4.7 m/s²

15

Page 16

Vinkelslipmaskin

art.nr 30-9316, modell CT3234

Läs igenom hela bruksanvisningen före användning och spara den sedan för

framtida bruk. Vi reserverar oss för ev. text- och bildfel samt ändringar av tekniska

data. Vid tekniska problem eller andra frågor, kontakta vår kundtjänst (se adressuppgifter på baksidan).

SVENSKA

Innehållsförteckning

Säkerhetsinstruktioner 17

Produktbeskrivning 24

Montering 25

Användning 26

Byte av slipskiva 27

Att rotera det bakre handtaget 27

Skötsel och underhåll 28

Felsökningsschema 28

Avfallshantering 28

Specifikationer 28

16

Page 17

1. Generella säkerhetsinstruktioner

Varning! Läs alla instruktioner. Om nedanstående instruktioner inte följs kan detta

leda till elektrisk stöt, brand och/eller allvarlig skada. Termen ”elektriskt handverktyg”

i varningstexten nedan refererar till ditt nätanslutna eller batteridrivna handverktyg.

1) Arbetsutrymmet

a) Håll arbetsutrymmet rent och väl upplyst. Belamrade och mörka utrymmen

inbjuder till olyckor.

b) Använd inte elektriska handverktyg i explosiva miljöer, som i närheten av

lättantändliga vätskor, gaser eller damm. Elektriska handverktyg genererar

gnistor som kan antända damm eller ångor.

c) Håll undan barn och åskådare medan du använder det elektriska

handverktyget. Störningsmoment kan göra att du tappar kontrollen.

2) Elektrisk säkerhet

a) Det elektriska handverktygets stickpropp måste passa i vägguttaget. Modiera

aldrig stickproppen på något vis. Använd aldrig adapter tillsammans med

jordade elektriska handverktyg. Omodierade stickproppar och passande

vägguttag minskar risken för elektrisk stöt.

b) Undvik kroppskontakt med jordade föremål, som rör, element, köksspis eller

kylskåp. Det innebär ökad risk för elektrisk stöt om din kropp är jordad.

c) Utsätt inte det elektriska handverktyget för regn eller våta förhållanden. Om

vatten tränger in i ett elektriskt handverktyg ökar det risken för elektrisk stöt.

d) Misshandla inte nätsladden. Använd aldrig nätsladden för att bära, dra eller

rycka stickproppen ur vägguttaget. Håll nätsladden undan från värme, olja,

vassa kanter och rörliga delar. Skadade eller trassliga nätsladdar ökar risken

för elektrisk stöt.

e) När du använder ett elektriskt handverktyg utomhus, använd en skarvsladd

anpassad för detta ändamål. Användning av en skarvsladd för utomhusbruk

minskar risken för elektrisk stöt.

SVENSKA

3) Personlig säkerhet

a) Var uppmärksam på vad du gör och använd sunt förnuft när du använder

ett elektriskt handverktyg. Använd inte ett elektriskt handverktyg om du är

trött eller påverkad av droger, alkohol eller medicinering. Ett ögonblicks

ouppmärksamhet när du använder ett elektriskt handverktyg kan resultera i

allvarlig personskada.

17

Page 18

b) Använd skyddsutrustning. Bär alltid skyddsglasögon. Användning av

skyddsutrustning som andningsskydd, halksäkra skyddsskor, hjälm och

hörselskydd vid behov minskar risken för personskada.

c) Undvik oavsiktlig start. Se till att strömbrytaren är i läge ”OFF” innan du

ansluter stickproppen till vägguttaget. Att bära ett elektriskt handverktyg

med ett nger på strömbrytaren/avtryckaren eller att ansluta ett elektriskt

handverktyg till elnätet när strömbrytaren är i läge ”ON” inbjuder till olyckor.

d) Tag bort alla serviceverktyg/nycklar innan du slår på det elektriska

handverktyget. Ett kvarglömt serviceverktyg på en roterande del av det

SVENSKA

elektriska handverktyget kan resultera i personskada.

e) Sträck dig inte för långt. Se till att du står stadigt med god balans hela tiden.

Detta möjliggör bättre kontroll i oväntade situationer.

f) Bär lämplig klädsel. Bär inte löst sittande kläder eller smycken. Håll hår, kläder

och handskar undan från rörliga delar. Lösa kläder, smycken eller långt hår

kan fastna i rörliga delar.

g) Om utrustning för utsugning och uppsamling av damm nns tillgängligt, se till

att denna är ansluten och används ordentligt. Användning av dessa hjälpmedel

kan minska dammrelaterade faror.

4) Användning och underhåll av det elektriska handverktyget

a) Pressa inte det elektriska handverktyget. Använd ett elektriskt handverktyg

som är avsett för det arbetsmoment du utför. Korrekt elektriskt handverktyg gör

jobbet bättre och säkrare med avsedd matningshastighet.

b) Använd inte det elektriska handverktyget om strömbrytaren inte slår på och

stänger av verktyget. Alla elektriska handverktyg som inte kan kontrolleras

med strömbrytaren är farliga och måste repareras.

c) Tag stickproppen ur vägguttaget innan du utför några justeringar, byter

tillbehör eller lägger undan det elektriska handverktyget för förvaring. Dessa

åtgärder i förebyggande syfte minskar risken för att starta det elektriska

handverktyget oavsiktligt.

d) Förvara elektriska handverktyg som inte används utom räckhåll för barn och

låt inte personer som inte är förtrogna med det elektriska handverktyget eller

dessa instruktioner använda det. Elektriska handverktyg är farliga om de

kommer i händerna på ovana användare.

e) Underhåll elektriska handverktyg. Kontrollera om något är felinställt, om rörliga

delar kärvar, om delar har gått sönder eller något annat som kan påverka

funktionen av det elektriska handverktyget. Om något är skadat måste

det repareras före användning. Många olyckor beror på dåligt underhållna

elektriska handverktyg.

18

Page 19

f) Håll verktygen vassa och rena. Ordentligt underhållna skärverktyg med vassa

eggar är mindre benägna att kärva och lättare att kontrollera.

g) Använd det elektriska handverktyget, tillbehör och liknande enligt

instruktionerna och på det sätt som är ämnat för just den typen av elektriskt

handverktyg, och ta även hänsyn till arbetsförhållandena och den typ av arbete

som ska utföras. Användning av det elektriska handverktyget för arbeten andra

än vad det är ämnat för kan resultera i en farlig situation.

5) Service

a) Låt behörig personal utföra service och reparationer, och endast med

originalreservdelar. Detta garanterar att säkerheten på det elektriska

handverktyget behålls.

2.

Särskilda säkerhetsvarningar gällande slipning,

putsning, borstning eller kapning

a) Detta elektriska handverktyg är avsett för slipning, putsning, borstning

och kapning. Läs alla säkerhetsvarningar, instruktioner, illustrationer och

specikationer som medföljer detta verktyg. Underlåtelse att följa alla

instruktioner nedan kan resultera i elektrisk chock, brand och/eller allvarlig

skada.

b) Polering rekommenderas ej att utföras med detta elektriska handverktyg.

Utförande av arbeten som detta verktyg inte är avsett för kan orsaka fara och

leda till personlig skada.

c) Använd inte tillbehör som inte är speciellt avsedda och rekommenderade

av verktygstillverkaren. Även om tillbehöret kan monteras på ditt elektriska

handverktyg är det ingen försäkran om säker användning.

d) Märkhastigheten på tillbehöret måste minst motsvara den maximala

hastigheten märkt på det elektriska handverktyget. Tillbehör som roterar

snabbare än märkhastigheten kan gå sönder och falla isär.

e) Ytterdiametern och tjockleken på tillbehöret måste vara inom märkkapaciteten

på ditt elektriska handverktyg. Fel storlek på tillbehören kan inte skyddas eller

kontrolleras ordentligt.

f) Axelstorleken på skivor, änsar och stödrondeller eller något annat tillbehör

måste passa spindeln på ditt elektriska handverktyg ordentligt. Tillbehör vars

fästhål inte passar ihop med det monterade tillbehöret hamnar i obalans,

vibrerar häftigt och kan orsaka att du tappar kontrollen.

SVENSKA

19

Page 20

g) Använd inte ett skadat tillbehör. Inspektera tillbehören och se om det nns

isor eller sprickor på slipskivorna; sprickor, nötningar eller slitage på

stödrondellen, eller lösa eller trasiga borst på stålborstrondellerna. Om du

tappar ditt elektriska handverktyg eller ett tillbehör, kontrollera om det nns

skador eller montera ett oskadat tillbehör. Efter inspektion och montering av ett

tillbehör, placera dig själv och åskådare utanför maskinens riskområde och kör

det elektriska handverktyget på fullt varvtal i en minut. Skadade tillbehör går

normalt sönder under testperioden.

h) Bär personlig skyddsutrustning. Beroende på hur du använder maskinen,

använd ansiktsskydd eller skyddsglasögon. Vid behov, använd ansiktsmask,

SVENSKA

hörselskydd, handskar och arbetsförkläde som skyddar mot små slippartiklar

eller isor från arbetsstycket. Ögonskyddet ska kunna skydda mot

kringygande skräp som bildas vid olika arbetsmoment. Andningsskyddet ska

kunna ltrera partiklar som bildas vid arbetet. Långvarig vistelse i buller kan

orsaka hörselskador.

i) Håll åskådare på behörigt avstånd från arbetsplatsen. Alla som besöker

arbetsplatsen måste bära personlig skyddsutrustning. Flisor från arbetsstycket

eller från ett trasigt tillbehör kan yga iväg och orsaka skada utanför arbetets

omedelbara närområde.

j) Håll det elektriska handverktyget endast i isolerade gripytor när du utför

arbetsmoment där kapskivan kan komma i kontakt med gömda kablar eller den

egna sladden. Kapskivor som kommer i kontakt med en strömförande kabel

kan göra utsatta metalldelar av verktyget strömförande och utsätta användaren

för elektriska stötar.

k) Placera sladden på avstånd från det roterande tillbehöret. Om du förlorar

kontrollen kan sladden kapas eller fastna och din hand eller arm kan dras in i

det roterande tillbehöret.

l) Lägg aldrig ifrån dig det elektriska handverktyget innan tillbehöret har stannat

helt. Det roterande tillbehöret kan fastna i underlaget och dra iväg verktyget

utanför din kontroll.

m) Kör inte det elektriska handverktyget när du bär det med dig. Oavsiktlig kontakt

med det roterande tillbehöret kan göra att det fastnar i dina kläder och dra

verktyget mot kroppen.

n) Rengör regelbundet motorns ventilationsöppningar. Motorns äkt drar åt sig

damm som kommer in under höljet, och överödigt metallspån som ansamlats

kan orsaka elektriska faror.

o) Använd inte det elektriska handverktyget i närheten av lättantändliga material.

Gnistor kan antända dessa material.

p) Använd inte tillbehör som kräver kylvätskor. Användning av vatten eller andra

kylvätskor kan resultera i elektrisk chock eller dödande elektrisk stöt.

20

Page 21

Kast och tillhörande varningar

Kast är en plötslig reaktion på en klämd eller fastkörd rondell, stödrondell, borste

eller någon annat tillbehör. Klämning eller fastkörning orsakar ett snabbt stopp av

det roterande tillbehöret som i sin tur gör att det elektriska handverktyget tvingas i

motsatt riktning mot tillbehörets rotation vid fastkörningspunkten.

Till exempel, om en slipskiva fastnar eller kläms fast i arbetsstycket kan kanten

av slipskivan få grepp i arbetsstycket och orsaka att slipskivan gräver sig ner eller

kastas upp. Slipskivan kastas antingen mot eller bort från användaren, beroende

på rotationsriktningen på slipskivan när den fastnar. Slipskivor kan också gå sönder under dessa omständigheter.

Kast är resultatet av att det elektriska handverktyget används på fel sätt, för fel saker eller under felaktiga förhållanden och kan undvikas genom att nedanstående

försiktighetsåtgärder vidtas.

a) Håll stadigt i det elektriska handverktyget och håll armarna och kroppen så att

du kan parera kast. Använd alltid hjälphandtaget om det nns ett sådant för

maximal kontroll över kast eller reaktioner på vridmomentet vid start. Kast eller

reaktioner på vridmomentet kan kontrolleras av användaren om nödvändiga

försiktighetsåtgärder vidtas.

b) Placera aldrig din hand nära det roterande tillbehöret. Tillbehöret kan få ett

kast över din hand.

c) Ställ dig inte det område dit det elektriska handverktyget kan tänkas hamna

om det inträffar ett kast. Kast driver verktyget i motsatt riktning mot slipskivans

rotation vid fastkörningspunkten.

d) Var extra försiktig när du bearbetar hörn, vassa kanter etc. Undvik att studsa

med och sätta fast tillbehöret. Hörn, vassa kanter och studsning har en

tendens att sätta fast det roterande tillbehöret och orsaka kast eller att du

tappar kontrollen över verktyget.

e) Montera aldrig fast ett sågblad med sågkedja för träbearbetning eller ett tandat

sågblad. Sådana blad orsakar frekventa kast och gör att du tappar kontrollen.

SVENSKA

21

Page 22

Säkerhetsvarningar speciellt för slipning och kapning med kapskiva

a) Använd endast skivtyper som är rekommenderade för det elektriska

handverktyget och ett speciellt sprängskydd avsett för den valda kapskivan.

Skivor som inte är avsedda för det elektriska handverktyget kan inte skyddas

ordentligt och kan vara farliga.

b) Sprängskyddet ska monteras på det elektriska handverktyget på ett säkert sätt

och inställt för maximal säkerhet, så att användaren utsätts för så liten del som

möjligt av skivan. Sprängskyddet hjälper till att skydda användaren från trasiga

skivdelar och oavsiktlig kontakt med skivan.

SVENSKA

c) Skivorna får endast användas för rekommenderade arbetsmoment. Till

exempel: Slipa inte med sidan av en kapskiva. Kapskivor är avsedda för

slipning med kanten, utsätts de för krafter från sidan kan de splittras.

d) Använd alltid oskadade skivänsar av rätt storlek och form för den skiva du

har valt. Passande skivänsar stöder skivan och minskar risken för att den

ska gå sönder. Flänsar för kapskivor kan vara olika mot dem som används för

slipskivor.

e) Använd aldrig nedslitna skivor från ett större elektrisk handverktyg. Skivor

avsedda för större elektriska handverktyg passar inte för det varvtal som

mindre verktyg har och kan spricka.

Ytterligare säkerhetsvarningar speciellt för kapning med kapskiva

a) Pressa inte kapskivan eller lägg på för mycket tryck. Försök inte att kapa för

djupt. Överbelastning av skivan ökar trycket och mottagligheten för att skivan

ska vridas eller fastna i snittet och risken för kast eller att skivan går sönder.

b) Ställ dig aldrig i linje med eller bakom den roterande skivan. När skivan under

användning rör sig bort från dig kan ett kast driva den roterande skivan och det

elektriska handverktyget direkt mot dig.

c) När skivan fastnar eller om du av någon anledning vill avbryta en kapning,

stäng av det elektriska handverktyget och håll still det tills skivan har stannat

helt. Försök aldrig att ta bort kapskivan från kapspåret medan skivan är i

rörelse eftersom det då kan inträffa kast. Undersök och vidta nödvändiga

åtgärder för att minimera riskerna för att kapskivan ska fastna.

d) Efter stopp, återstarta inte kapningen med skivan i arbetsstycket. Låt skivan

nå fullt varvtal först och fortsätt sedan försiktigt i kapspåret. Skivan kan

fastna, vandra upp ur kapspåret eller orsaka kast om kapningen återstartas i

arbetsstycket.

e) Stöd stora skivor eller andra stora arbetsstycken för att minimera risken för

fastkörning eller kast. Stora skivor tenderar att bågna av sin egen vikt. Stöd

måste placeras under skivan nära kapspåret och nära kanten på arbetsstycket

på båda sidor om kapskivan.

22

Page 23

f) Var extra försiktig vid instickskapning i väggar eller andra föremål där du

inte ser var du sågar. Den utskjutande sågklingan kan såga i gas- eller

vattenledningar, elkablar eller andra föremål som kan orsaka kast.

Säkerhetsvarningar speciellt för putsning

a) Använd inte för stora sliprondeller. Följ tillverkarens rekommendationer när du

väljer sliprondeller. Större sliprondeller som sticker ut utanför stödrondellen

innebär risk för sönderslitning och kan orsaka att rondellen fastnar eller går

sönder eller att det inträffar kast.

Säkerhetsvarningar speciellt för stålborstning

a) Tänk på att borst lossnar från stålborstrondellen även vid normal användning.

Pressa inte borstrondellen genom lägga på för mycket tryck. Lösa borst kan

enkelt gå igenom tunna kläder eller huden.

b) Om sprängskydd rekommenderas vid stålborstning, se till att borstrondellen

inte rör vid sprängskyddet. Stålborstrondellen kan expandera av

arbetsbelastningen eller centrifugalkraften.

Produktmärkning med säkerhetssymboler

SVENSKA

Läs igenom hela bruksanvisningen före användning och spar den sedan som referensmaterial.

Använd hörselskydd och andningsskydd.

Använd skyddsglasögon eller visir.

23

Page 24

3. Produktbeskrivning

I

A

SVENSKA

G

B

H

C

D

E

F

A. Handtag

B. Sprängskydd

C. Inre äns

D. Slipskiva (medföljer ej)

E. Yttre äns

F. Nyckel

G. Strömbrytare

H. Maskinkropp

I. Spärrknapp för rotation av handtag

24

Page 25

4. Montering

1. Skruva i sidohandtaget på den sida av växelhuset som känns bäst, sätt i

gummipluggen i dom hålen som inte används. Tre olika monteringar är möjligt.

2. Placera den inre ogängade änsen (C) på spindeln, vrid den så att den låser

på spindeln.

3. Lägg på en slip/kapskiva (D) på spindeln så att den centrerar,

4. Gänga på den yttre änsen (E) så att den konkava sidan är mot skivan.

5. Tryck in spindellåset och dra åt änsen medurs med den bifogade nyckeln.

6. Starta vinkelslipmaskinen och låt den gå i en stund för att kontrollera att

slipskivan är balanserad innan du börjar slipa.

B

C

D

SVENSKA

E

F

25

Page 26

5. Användning

• Låt slipmaskinen gå upp i varv innan slipningen påbörjas.

• Stå så att du har god överblick av slipningen.

• Använd inte sidan på kapskivor till slipning, de tål inte tryck från sidan.

• Använd diamantskiva vid kapning av sten och liknande.

• Vinkla inte vinkelslipen under kapning, gör raka snitt med kapskiva.

• Håll ventilationsöppningarna fria så att inte motorn blir för varm.

SVENSKA

1. Stå stadigt och håll i vinkelslipen med båda händerna.

2. Tryck strömbrytaren framåt och sedan uppåt.

3. Stäng av maskinen genom att släppa strömbrytaren.

4. Bästa metoden för slipning är att hålla vinkelslipen i en vinkel av ca 10 till 15º.

26

Page 27

6. Byte av slipskiva

Slipskivan ska ha rätt innerdiameter, använd aldrig lösa bussningar. Den ska vara

godkänd minst för ett varvtal på 8500 RPM.

1. Dra ut nätsladdens stickpropp ur uttaget innan slipskivebyte.

2. Aktivera spindellåset, lossa yttre änsen från spindeln.

3. Ta bort den gamla slipskivan och sätt dit den nya.

4. Montera i omvänd ordning.

5. Stå bredvid vinkelslipmaskinen och starta den och låt den gå i en stund för att

kontrollera att slipskivan är balanserad innan du börjar slipa.

Spindellås

7. Att rotera det bakre handtaget

1. Dra ut nätsladden innan handtaget roteras.

2. Tryck in spärrknappen för rotering av handtag.

3. Rotera handtaget till ett av dom 3 fasta lägena.

4. Släpp spärrknappen och se till att handtaget klickar fast i läge.

SVENSKA

Spärrknapp

27

Page 28

8. Skötsel och underhåll

Håll motorns ventilationsöppningar fria från spån och skräp. Torka vid behov av

maskinen med en lätt fuktad trasa. Undvik starka eller slipande rengöringsmedel

eller lösningsmedel.

9. Felsökningsschema

Problem Möjlig orsak Åtgärd

SVENSKA

Maskinen går inte. Ingen ström. Kontrollera att uttaget är

strömförande.

Slitna kolborstar. Kontakta oss vid motor- och

Kortslutning.

Fel på strömbrytaren.

Maskinen går sakta. Slött eller skadat verktyg. Slipa om eller byt ut verktyget.

För lågt varvtal. Mata inte så hårt.

Motorn är överhettad.

Ovanliga ljud hörs. Mekaniskt hinder. Kontakta oss vid motor- och

Lindning delvis korsluten.

Starka vibrationer. Verktyget sitter löst. Dra åt verktyget och se till att

Gnistbildning i

motorn.

Kolborstarna sitter fast. Kontakta oss vid motor-

Lindningen kortsluten.

Kollektorn är smutsig.

elfel.

elfel.

det är rätt installerat.

eller elfel.

10. Avfallshantering

När du ska göra dig av med produkten ska detta ske enligt lokala föreskrifter. Är du osäker på hur du ska gå tillväga, kontakta din kommun.

11. Specifikationer

Märkspänning: 230 VAC, 50 Hz

Märkeffekt: 1800 W

Varvtal, obelastad: 8500 v/min

Slipskiva: Ø 180 mm, hål Ø 22mm

Ljud: LPA 95 dB(A)

LWA 108 dB(A)

Vibration: 4,7 m/s

Vikt: 4,7 kg (utan slipskiva)

2

28

Page 29

Vinkelslipemaskin

Art.nr 30-9316, modell CT3234

Les nøye igjennom hele bruksanvisningen og ta vare på den til senere bruk.

Vi reserverer oss mot ev. tekst- og bildefeil, samt forandringer av tekniske data.

Ved tekniske problemer eller andre spørsmål, ta kontakt med vårt kundesenter

(se opplysninger på baksiden).

Innholdsfortegnelse

Sikkerhetsinstruksjoner 30

Produktbeskrivelse 36

Montering 37

Bruk 38

Bytte av slipeskive 39

Hvordan rotere det bakerste håndtaket 39

Vedlikehold og reparasjon 40

Feilsøkningsskjema 40

Avfallshåndtering 40

Spesifikasjoner 40

NOR SK

29

Page 30

1. Generelle sikkerhetsinstruksjoner

Advarsel! Les gjennom hele instruksjonen. Hvis ikke instruksjonen følges, kan

dette føre til elektrisk støt, brann og/eller alvorlige skader. Med ”elektrisk håndverktøy” i teksten nedenfor, menes strømtilkoblet eller batteridrevne håndverktøy.

1) Arbeidsplassen

a) Hold arbeidsplassen ren, ryddig og godt opplyst. Rotete arbeidsplass eller

dårlig opplyste områder kan føre til ulykker.

b) Ikke bruk elektriske håndverktøy i omgivelser med eksplosjonsfare, som for

eksempel i nærheten av lettantennelige væsker, gasser eller støv. Elektrisk

håndverktøy kan danne gnister som kan antenne støv eller trespon.

c) Hold barn og andre tilskuere unna mens du bruker elektriske håndverktøy. Du

kan lett miste kontrollen dersom du blir forstyrret mens du arbeider.

NOR SK

2) Sikkerhet ved bruk av elektrisk strøm

a) Kontakten til det elektriske verktøyet må passe i veggstøpselet. Kontakten må

ikke forandres på. Bruk aldri adapter sammen med elektrisk håndverktøy som

krever jording. Ved bruk av originale kontakter og støpsler minskes faren for

elektrisk støt.

b) Unngå kroppskontakt med jordede gjenstander som rør, ovner, komfyrer og

kjøleskap. Kroppskontakt med disse øker faren for elektrisk støt.

c) Elektrisk håndverktøy bør ikke utsettes for regn eller fuktighet. Hvis det

kommer vann inn i et elektrisk håndverktøy, øker faren for elektrisk støt.

d) Håndter ledningen forsiktig. Den må ikke bli brukt til å bære verktøyet med.

Dra heller ikke i ledningen når du skal ha den ut av stikkontakten. Hold

ledningen unna varme, olje, skarpe kanter og bevegelige deler. Skadede eller

deformerte kontakter kan øke faren for elektrisk støt.

e) Ved bruk av elektrisk håndverktøy utendørs, skal en benytte en skjøteledning

som er beregnet til dette formålet. Når skjøteledning som er beregnet for

utendørs bruk benyttes, minsker faren for elektrisk støt.

3) Personlig sikkerhet

a) Vær våken og bruk sunn fornuft når du bruker et elektrisk verktøy. Ikke bruk

elektriske håndverktøy når du er trøtt eller påvirket av dop, alkohol eller

sterke medisiner. Når du bruker elektrisk håndverktøy kan et lite øyeblikks

uoppmerksomhet resultere i store personskader.

b) Bruk verneutstyr. Benytt alltid vernebriller. Bruk av verneutstyr som støvmaske,

sklisikre såler på skoene, hjelm og hørselvern, ved behov, minsker faren for

personskade.

30

Page 31

c) Unngå uønsket oppstart. Påse at strømbryteren står i posisjon ”OFF” før du

kobler til strømmen. Det å bære et elektrisk håndverktøy med en nger på

avtrekkeren/strømbryteren, eller å koble til strømmen når strømbryteren står i

posisjon ”ON”, kan forårsake ulykker.

d) Fjern alle nøkler/serviceverktøy før du starter det elektriske håndverktøyet. Et

gjenglemt serviceverktøy på en roterende del, kan forårsake personskader.

e) Strekk deg ikke for langt. Påse at du står støtt og har god balanse hele tiden.

Da er du bedre forberedt når uventede situasjoner oppstår.

f) Benytt fornuftige arbeidsklær. Ikke bruk løstsittende klær og smykker. Hold

klær, hansker og smykker unna bevegelige deler. Løse klær, smykker eller

langt hår, kan sette seg fast i bevegelige deler.

g) Hvis det er mulig å koble til en støvsamler/støvsuger, bør dette gjøres. Ved

bruk av sådanne hjelpemidler, kan en minske faren for støvrelaterte skader og

ulykker.

4) Bruk og vedlikehold av elektrisk håndverktøy

a) Ikke press et elektrisk håndverktøy. Bruk elektriske håndverktøy som er

beregnet til den arbeidsoperasjonen du skal utføre. Riktig innmatings-hastighet

er viktig for å utføre bedre og sikrere arbeide.

b) Ikke bruk det elektriske håndverktøyet dersom ikke strømbryteren virker og

verktøyet kan skrues av. Alle elektriske håndverktøy, som ikke kan kontrolleres

med en strømbryter, er farlige og må repareres.

c) Dra ut støpselet før du utfører justeringer, bytter tilbehør eller legger det

elektriske håndverktøyet fra deg. Dette for å unngå at elektrisk håndverktøy får

en ukontrollert start.

e) Vedlikehold av elektrisk håndverktøy. Se til at verktøyet ikke er feilinnstilt, at

bevegelige deler ikke beveger seg usymmetrisk, at ingen deler er skadet eller

at det elektriske håndverktøyet har andre feil, som kan påvirke dets funksjon.

Dersom noe er skadet må dette repareres før verktøyet tas i bruk. Mange

ulykker skyldes dårlig eller manglende vedlikehold.f) Hold verktøyet

rent. Påse også at det elektriske verktøyet holdes skarpt. Godt vedlikeholdt

skjæreverktøy, med skarpe egger, er lettere å kontrollere.

g) Følg instruksjonen, ta hensyn til arbeidsforholdene og den type arbeide som

skal utføres. Bruk av elektrisk håndverktøy til andre arbeidsoperasjoner enn

det det er beregnet til, kan skape farlige situasjoner.

5) Service

a) La profesjonelle fagfolk utføre service og reparasjoner. Benytt kun originale

reservedeler. Dette for å opprettholde sikkerheten ved bruk av det elektriske

håndverktøyet.

NOR SK

31

Page 32

2. Sikkerhetsadvarsler for sliping, pussing, børsting, polering eller

kapping

a) Dette elektriske håndverktøyet er beregnet for sliping, pussing, børsting,

polering og kapping. Les alle sikkerhetsadvarsler, instruksjoner og

spesikasjoner som følger med dette verktøyet. Hvis du unngår å følge alle

instruksjonene nedenfor kan det resultere i elektrisk støt, brann og/eller alvorlig

skade.

b) Polering anbefales ikke med dette elektriske håndverktøy. Hvis maskinen blir

brukt til arbeid den ikke er konstruert for, kan dette forårsake fare og føre til

personlig skade.

c) Bruk ikke tilbehør som ikke er spesielt beregnet for verktøyet og anbefalt

av verktøyprodusenten. Selv om tilbehøret kan monteres på ditt elektriske

håndverktøy er det ingen forsikring om sikker bruk.

d) Merkehastigheten på tilbehøret må minst tilsvare den maksimale hastigheten

det elektriske håndverktøyet er merket med. Tilbehør som roterer raskere enn

NOR SK

merkehastigheten kan gå i stykker.

e) Den utvendige diameteren og tykkelsen på tilbehøret må være innenfor

merkekapasiteten på det elektriske håndverktøyet. Feil størrelse på tilbehøret

kan ikke beskyttes eller kontrolleres ordentlig.

f) Akselstørrelsen på skiver, enser og støtterondeller eller noe annet tilbehør

må passe spindelen på ditt elektriske håndverktøy ordentlig. Tilbehør med

festehull som ikke passer sammen med det monterte tilbehøret havner i

ubalanse, vibrerer kraftig og kan føre til at du mister kontrollen.

g) Bruk ikke tilbehør som er skadet. Kontroller tilbehøret og se om det nnes

iser eller sprekker på slipeskivene; Som sprekker, ujevnheter, slitasje på

støtterondellen, eller løse eller ødelagte bust på stålbørsterondellene. Hvis

du mister ditt elektriske håndverktøy eller et tilbehør, kontroller om det er blitt

skadet. Dersom det er skadet så monter et uskadet tilbehør. Etter inspeksjon

og montering av et tilbehør, plasser deg selv og tilskuere utenfor maskinens

risikoområde, og kjør det elektriske håndverktøyet på fullt turtall i et minutt.

Skadet tilbehør går normalt i stykker under testperioden.

h) Bruk personlig verneutstyr, avhengig av hvordan du bruker maskinen. Bruk

støvmaske og vernebriller. Ved behov, bruk ansiktsmaske, hørselsvern,

hansker og arbeidsforkle, som beskytter mot små slipepartikler eller iser

fra arbeidsstykket. Vernebrillene skal kunne beskytte mot ygende skrap,

som dannes ved forskjellige arbeidsmoment. Støvmasken skal kunne ltrere

partikler, som dannes ved arbeidet. Langvarig opphold i støy kan forårsake

hørselskader.

i) Hold tilskuere på behørig avstand fra arbeidsplassen. Alle som besøker

arbeidsplassen må ha på seg personlig sikkerhetsutstyr. Fliser fra

arbeidsstykket eller fra ødelagte tilbehør, kan bli slynget bort og forårsake

skade utenfor arbeidets umiddelbare nærområde.

32

Page 33

j) Hold det elektriske håndverktøyet kun på isolerte steder når du utfører en

arbeidsoperasjon der kappeskiven kan komme i kontakt med skjulte kabler

eller sin egen ledning.

k) Plasser ledningen på avstand fra det roterende tilbehøret. Hvis du mister

kontrollen kan ledningen kappes eller sette seg fast, og din hånd eller arm kan

dras inn i det roterende tilbehøret.

l) Legg aldri ifra deg det elektriske håndverktøyet før tilbehøret har stoppet helt.

Det roterende tilbehøret kan feste seg i underlaget og kastes bort utenfor din

kontroll.

m) Kjør ikke det elektriske håndverktøyet når du bærer det med deg. Det

roterende verktøyet kan feste seg i klærne og dras mot kroppen.

n) Rengjør regelmessig motorens ventilasjonsåpninger. Motorens vifte trekker til

seg støv, som kommer inn under dekselet. Overødige metallspon samles opp

og kan forårsake elektriske farer.

o) Bruk ikke det elektriske håndverktøyet i nærheten av lettantennelige

materialer. Gnister kan antenne disse materialene.

p) Bruk ikke tilbehør som krever kjølevæsker. Bruken av vann eller andre

kjølevæsker kan resultere i elektrisk sjokk eller dødelig elektrisk støt.

Kast med tilhørende advarsler

Kast er en plutselig reaksjon på en klemt eller fastkjørt rondell, støtterondell, børste eller andre tilbehør. Klemming eller fastkjøring forårsaker en bråstopp av det

roterende tilbehøret som i sin tur tvinger det elektriske håndverktøyet i motsatt

retning av tilbehørets rotasjon ved fastkjøringspunktet.

NOR SK

For eksempel: Hvis en slipeskive setter seg fast i arbeidsstykket, kan kanten av

slipeskiven få tak i arbeidsstykket og forårsake at slipeskiven graver seg ned og

kastes opp. Slipeskiven kastes sannsynligvis mot eller bort fra brukeren, avhengig

av rotasjonsretningen på slipeskiven når det setter seg fast. Slipeskiver kan også

gå i stykker under disse omstendigheter.

Kast er resultatet av at det elektriske håndverktøyet brukes feil, til feil formål eller

under feil forhold. Dette kan unngås ved å ta visse forhåndsregler: Se nedenfor!

a) Hold godt fast i det elektriske håndverktøyet, og hold armene og kroppen slik

at du kan parere kast. Bruk alltid hjelpehåndtaket hvis det nnes, for maksimal

kontroll over kast eller reaksjonene på vrimomentet under oppstart. Kast eller

reaksjoner på vridmomentet kan kontrolleres av brukeren hvis nødvendige

forhåndsregler følges.

b) Plasser aldri hånden nær det roterende tilbehøret. Tilbehøret kan få et kast

over hånden.

33

Page 34

c) Still deg ikke i det området der det elektriske håndverktøyet kan tenkes å

havne hvis det inntreffer et kast. Kast driver verktøyet i motsatt retning av

tilbehørets rotasjon ved fastkjøringspunktet.

d) Vær ekstra forsiktig når du bearbeider hjørner, skarpe kanter etc. Unngå å

stusse med og sette fast tilbehøret. Hjørner, skarpe kanter og stussing har en

tendens til å sette fast det roterende tilbehøret, og å forårsake kast eller at du

mister kontrollen over verktøyet.

e) Monter aldri fast et sagblad med sagkjede for trebearbeiding eller et tannet

sagblad. Slike blad forårsaker frekvente kast, og gjør at du mister kontrollen.

Sikkerhetsadvarsler spesielt for sliping og kapping med kappeskive

a) Bruk kun skivetyper som er anbefalt for det elektriske håndverktøyet, og en

spesiell beskyttelseshette beregnet for den valgte kappeskiven. Skiver, som

ikke er beregnet for det elektriske håndverktøyet kan ikke beskyttes skikkelig,

og det kan være farlig.

NOR SK

b) Beskyttelseshetten skal monteres på det elektriske håndverktøyet på en sikker

måte og innstilt for maksimal sikkerhet, slik at brukeren blir utsatt for så liten

del av skiven som mulig.

c) Skivene må kun brukes til de anbefalte arbeidsmomentene. For eksempel: Slip

ikke med siden av en kappeskive. Kappeskiver er beregnet for sliping med

kanten. Utsettes de for krefter fra siden, kan de splittes.

d) Bruk alltid uskadde skiveenser i riktig størrelse og form, for den skiven du har

valgt. Riktige skiveenser støtter skiven og minsker risikoen for at den skal gå

i stykker. Flenser for kappeskiver, kan være forskjellige fra de som brukes for

slipeskiver.

e) Bruk aldri nedslitte skiver fra et større elektrisk håndverktøy. Skiver beregnet

for større elektriske håndverktøy, passer ikke for det turtall som mindre verktøy

har og det kan sprekke.

Ytterligere sikkerhetsadvarsler spesielt for kapping med kappeskive

a) Press ikke kappeskiven eller legg for mye trykk på den. Prøv ikke å kappe for

dypt. Overbelastning av skiven, øker trykket og sjansene for at skiven kan vris

eller sette seg fast i snittet, og risikoen for kast eller at skiven går i stykker.

b) Still deg aldri i linje med eller bak den roterende skiven. Når skiven ved bruk

beveger seg bort fra deg, kan et kast drive den roterende skiven og det

elektriske håndverktøyet direkte mot deg.

c) Når skiven setter seg fast eller hvis du av en eller annen grunn vil avbryte en

kapping, så skru av det elektriske håndverktøyet, og hold det stille, til skiven

har stoppet helt. Prøv aldri å fjerne kappeskiven fra sporet mens den er i

bevegelse fordi kast da kan inntreffe. Undersøk og gjennomfør nødvendige

tiltak for å minimere risikoen for at kappeskiven kan sette seg fast.

34

Page 35

d) Start ikke kappingen igjen med skiven i arbeidsstykket etter et stopp. La skiven

nå fullt turtall først og før den deretter forsiktig i kappesporet. Skiven kan sette

seg fast, vandre opp fra kappesporet eller forårsake kast hvis kappingen

startes opp igjen i arbeidsstykket.

e) Støtt store skiver eller andre store arbeidsstykker for å minimere risikoen for

fastkjøring eller kast. Store skiver har en tendens til å bue seg av sin egen

vekt. Støtte må plasseres under skiven av kappesporet og nær kanten på

arbeidsstykket på begge sider av kappeskiven.

f) Vær ekstra forsiktig ved innstikkskapping i vegger eller andre gjenstander, der

du ikke ser hvor du sager. Den utstikkende sageklingen kan sage i gass- eller

vannledninger, strømkabler eller andre gjenstander som kan forårsake kast.

Sikkerhetsadvarsler spesielt for pussing

a) Bruk ikke for store sliperondeller. Følg produsentens anbefalinger når

du velger sliperondeller. Større sliperondeller, som stikker ut utenfor

støtterondellen, innebærer risiko for at rondellen slites i stykker, og at det kan

inntreffe kast.

Sikkerhetsadvarsler spesielt for stålbørsting

a) Tenk på at bust løsner fra stålbørsterondellen selv ved normal bruk. Press ikke

børsterondellen ved å legge for mye trykk på. Løs bust kan enkelt gå igjennom

tynne klær eller hud.

b) Om beskyttelseshetten er anbefalt ved stålbørsting, påse at

børsterondellen ikke kommer bort i beskyttelseshetten. Vær oppmerksom

på at stålbørsterondellen kan ekspandere av arbeidsbelastningen eller

sentrifugalkraften.

NOR SK

Produktmerking med sikkerhetssymboler

Les hele bruksanvisningen før du bruker

produktet og spar den for framtidig bruk.

Bruk alltid hørselvern.

Bruk alltid vernebrille og støv-/vernemaske.

35

Page 36

3. Beskrivelse

A

I

G

B

H

NOR SK

C

D

E

F

A. Håndtak

B. Beskyttelsesdeksel

C. Indre ens

D. Slipeskive (følger ikke med)

E. Ytre ens

F. Nøkkel

G. Strømbryter

H. Maskinkropp

I. Sperreknapp for rotasjon av håndtak

36

Page 37

4. Montering

1. Monter håndtaket på den siden av maskinkroppen som er riktig for deg.

Plasser gummipluggen i det hullet som ikke brukes. Det er tre mulige

festepunkter for håndtaket.

2. Plasser den indre ensen (C) på spindelen og vri den slik at den sitter fast på

spindelen.

3. Plasser en slipe-/kappskive (D) på spindelen. Påse at den er sentrert.

4. Skru på den ytre ensen (E) slik at den konkave siden kommer mot skiven.

5. Trykk spindellåsen inn og dra til ensen medurs med nøkkelen (F).

6. Start vinkelslipemaskinen og la den gå en stund, så du får kontrollert at skiven

er balansert, før du begynner å slipe.

B

C

NOR SK

D

E

F

37

Page 38

5. Bruk

• La slipemaskinen komme opp i riktig turtall før du starter slipingen.

• Stå plassert slik at du har god oversikt over slipingen.

• Kappskivens sider tåler ikke trykk fra siden. Du må derfor ikke slipe med

skivens sider.

• Ved kapping av stein og lignende må det benyttes diamantskive.

• Kappskiven er kun beregnet for rette snitt.

• Hold ventilasjonsåpningene rene og åpne slik at motoren får kjøling. Hvis ikke

kan den bli overopphetet og motoren gå i stykker.

1. Hold kroppen i god balanse og hold maskinen med begge hendene, mens du

jobber med den.

2. Trykk først strømbryteren framover, deretter oppover.

NOR SK

3. Maskinen skrus av ved å slippe opp strømbryteren.

4. Best jobber vinkelsliperen når den holdes i en vinkel på ca 10 º til 15º.

38

Page 39

6. Bytte av slipeskive

Slipeskiven skal ha riktig indre diameter. Bruk aldri løse bussinger.

De må være godkjente for et omdreiningstall på 8500 omdreininger/minutt.

1. Dra ut strømledningens støpsel fra uttaket før bytte av slipeskive.

2. Aktiver spindellåsen og skru løs den ytre ensen fra spindelen.

3. Fjern den gamle slipeskiven og sett den nye på plass.

4. Monter i omvendt rekkefølge.

5. Start vinkelslipemaskinen og la den gå en stund for å kontrollere at slipeskiven

er balansert, før du begynner å slipe.

Spindellås

7. Dreie det bakerste håndtaket

1. Dra ut stikket før du dreier håndtaket.

2. Trykk i

3. Drei håndtaket til en av de 3 faste stillingene.

4. Slipp sperreknappen og påse at håndtaket fester seg i den ønskede stillingen.

nn sperreknappen før dreiing av håndtaket.

Du skal da høre et ”klikk”.

Sperreknapp

NOR SK

39

Page 40

8. Vedlikehold og reparasjon

- Hold alltid ventilasjonsåpningene frie for spon og støv.

- Rengjør maskinen regelmessig med en lett fuktet klut. Unngå sterke

rengjøringsmidler og løsemidler.

9. Feilsøkingsskjema

Problem Mulig årsak Tiltak

Maskinen går

ikke.

NOR SK

Maskinen går

sakte.

Maskinen har

ulyd.

Sterke

vibrasjoner.

Gnistdannelse

i motoren.

Ingen strøm. Kontroller at uttaket er strømfø-

rende.

Slitte kullbørster. Kontakt forhandler ved feil på

Kortslutning.

Feil på strømbryteren.

Sløvt eller skadet verktøy. Slip eller skift ut verktøy.

For lavt turtall. Ikke mat så hardt.

Motoren er overopphetet.

Mekanisk hindring. Kontakt forhandler ved feil på

Kabel er delvis kortsluttet.

Verktøyet er ikke skikkelig

festet.

Kullbørstene sitter fast. Kontakt forhandler ved feil på

Kabelen er kortsluttet.

Kollektoren er full av støv.

motor eller det elektriske.

motor eller det elektriske.

Dra til festemutter for verktøy og

påse at verktøy er riktig montert.

motor eller det elektriske.

10. Avfallshåndtering

Når du skal kaste dette produktet, skal det skje i henhold til gjeldende lokale

forskrifter. Dersom du er usikker på reglene, kontakt de lokale myndigheter for

mer informasjon.

11. Spesifikasjoner

Spenning: 230 V AC, 50 Hz

Effekt: 1800 W

Turtall (ubelastet): 8500 o/min

Slipeskive: Ø 180 mm, hull Ø 22 mm

Lyd: LPA 95 dB(A)

LWA 108 dB(A)

Vibrasjon: 4,7 m/s²

Vekt: 4,7 kg (uten slipeskive)

40

Page 41

Kulmahiomakone

tuotenumero 30-9316, malli CT3234

Lue käyttöohjeet ennen tuotteen käyttöönottoa. Säilytä käyttöohjeet tulevaa tarvetta varten. Pidätämme oikeuden teknisten tietojen muutoksiin. Emme vastaa

mahdollisista teksti- tai kuvavirheistä. Jos laitteeseen tulee teknisiä ongelmia, ota

yhteys myymälään tai asiakaspalveluun (yhteystiedot käyttöohjeen lopussa).

Sisällysluettelo

Turvallisuusohjeita 32

Tuotekuvaus 49

Asennus 50

Käyttö 51

Hiomalaikan vaihto 52

Taaemman kädensijan kääntö 52

Huolto ja ylläpito 53

Vianhakutaulukko 53

Kierrätys 53

Tekniset tiedot 53

41

SUOMI

Page 42

1. Yleisiä turvallisuusohjeita

Varoitus! Lue kaikki ohjeet. Seuraavien ohjeiden noudattamatta jättäminen

saattaa johtaa sähköiskuun, tulipaloon ja/tai vakavaan onnettomuuteen. Varoitustekstien termi ”sähkökäyttöinen käsityökalu” tarkoittaa sinun verkkovirralla tai

paristoilla/akulla toimivaa käsityökaluasi.

1) Työtila

a) Pidä työtilat puhtaina ja hyvin valaistuina. Täynnä tavaraa olevat ja pimeät tilat

ovat avoin kutsu onnettomuudelle.

b) Älä käytä sähkökäyttöisiä käsityökaluja räjähdysherkässä ympäristössä,

kuten helposti syttyvien nesteiden, kaasujen tai pölyn lähellä. Sähkökäyttöiset

käsityökalut muodostavat kipinöitä, jotka saattavat sytyttää pölyn tai höyryt.

c) Pidä lapset ja vierailijat loitolla, kun käytät sähkökäyttöisiä käsityökaluja.

Häiriötekijät saattavat johtaa laitteen hallinnan menettämiseen.

2) Sähköturvallisuus

a) Sähkökäyttöisen käsityökalun pistokkeen tulee sopia pistorasiaan. Älä muuta

pistoketta millään tavalla. Älä käytä adapteria maadoitettujen sähkökäyttöisten

sähkötyökalujen kanssa. Pistokkeet, joita ei ole muutettu sekä sopivat

pistorasiat pienentävät sähköiskun vaaraa.

SUOMI

b) Vältä koskettamasta maadoitettuja esineitä, kuten putkia, lämpöpattereita,

hellaa tai jääkaappia. Sähköiskun riski kasvaa, mikäli kehosi on maadoitettu.

c) Älä altista sähkökäyttöistä käsityökalua sateelle, äläkä käytä sitä kosteissa

olosuhteissa. Veden joutuminen sähkökäyttöiseen käsityökaluun lisää

sähköiskun vaaraa.

d) Käsittele sähköjohtoa varoen. Älä käytä sähköjohtoa laitteen kantamiseen,

äläkä irrota pistoketta pistorasiasta johdosta vetämällä. Älä altista virtajohtoa

kuumuudelle, öljyille, teräville reunoille tai liikkuville osille. Vioittuneet tai

sotkeutuneet virtajohdot lisäävät sähköiskun vaaraa.

e) Kun käytät sähkökäyttöistä käsityökalua ulkona, käytä ainoastaan ulkokäyttöön

sopivia jatkojohtoja. Ulkokäyttöön sopivan jatkojohdon käyttäminen pienentää

sähköiskun vaaraa.

3) Oma turvallisuutesi

a) Ole huolellinen ja käytä tervettä järkeä kun työskentelet sähkökäyttöisellä

käsityökalulla. Älä käytä sähkökäyttöistä käsityökalua, mikäli olet väsynyt

tai huumeiden, lääkkeiden tai alkoholin vaikutuksen alaisena. Lyhyenkin

hetken kestävä tarkkaavaisuuden herpaantuminen saattaa johtaa vakavaan

loukkaantumiseen.

42

Page 43

b) Käytä suojavarusteita. Käytä aina suojalaseja. Suojavarusteiden, kuten

hengityssuojaimen, liukuestekenkien, kypärän ja kuulosuojaimien käyttäminen

vähentää loukkaantumisvaaraa.

c) Vältä tahatonta käynnistystä. Varmista, että virtakytkin on asennossa

”OFF” ennen kuin liität pistokkeen seinäpistorasiaan. On äärimmäisen

vaarallista kantaa sähkökäyttöistä käsityökalua sormi liipaisimella tai liittää

sähkökäyttöinen käsityökalu pistorasiaan virtakytkimen ollessa ”ON”asennossa.

d) Poista kaikki huoltotyökalut/avaimet ennen kuin käynnistät sähkökäyttöisen

käsityökalun. Sähkökäyttöisen käsityökalun liikkuvan osan päälle unohdettu

työkalu saattaa johtaa onnettomuuteen.

e) Älä kurota liian kauas. Varmista, että työasentosi on tasapainoinen työn

jokaisessa vaiheessa. Näin olet paremmin varustautunut mahdollisen

onnettomuuden sattuessa.

f) Käytä sopivia vaatteita. Älä käytä löysiä vaatteita tai koruja. Pidä hiukset,

vaatteet ja käsineet loitolla liikkuvista osista. Löysät vaatteet, korut tai pitkät

hiukset saattavat juuttua liikkuviin osiin.

g) Jos käytössäsi on pölynpoistojärjestelmä, käytä sitä. Näiden apuvälineiden

käyttö saattaa vähentää pölyyn liittyviä vaaroja.

4) Sähkökäyttöisten käsityökalujen käyttäminen ja huoltaminen

a) Älä pakota sähkökäyttöistä käsityökalua. Käytä sähkökäyttöistä käsityökalua,

joka soveltuu suunnittelemaasi työtehtävään. Sopiva sähkökäyttöinen

käsityökalu tekee työn paremmin ja turvallisemmin oikealla syöttönopeudella.

b) Älä käytä sähkökäyttöistä käsityökalua, mikäli virtakytkin ei käynnistä ja

sammuta laitetta. Kaikki sähkökäyttöiset käsityökalut, joita ei voida hallita

virtakytkimellä, ovat vaarallisia ja ne tulee korjata.

c) Irrota pistoke pistorasiasta ennen kuin teet sähkökäyttöiseen käsityökaluun

säätöjä tai ennen kuin vaihdat sen varusteita tai ennen kuin asetat

sen säilytykseen. Nämä ennaltaehkäisevät toimenpiteet vähentävät

sähkökäyttöisen käsityökalun tahatonta käynnistymistä.

d) Säilytä sähkökäyttöisiä käsityökaluja lasten ulottumattomissa. Älä luovuta

sähkökäyttöistä käsityökalua henkilöille, jotka eivät tunne sitä tai sen

käyttöohjetta. Sähkökäyttöiset käsityökalut ovat vaarallisia tottumattomien

käyttäjien käsissä.

e) Huolla sähkökäyttöisiä käsityökaluja. Tarkasta, että säädöt ovat kunnossa, että

liikkuvat osat liikkuvat esteettä, että osat ovat ehjiä, ja että sähkökäyttöisessä

käsityökalussa ei ole muita seikkoja, jotka vaikuttavat laitteen toimintaan. Jos

jokin osa on vioittunut, se tulee korjata ennen käyttöä. Monet onnettomuudet

johtuvat väärin hoidetuista sähkökäyttöisistä käsityökaluista.

f) Pidä työkalut puhtaina ja terävinä. Terätyökalun hallinta on helpompaa, kun se

on oikein hoidettu ja sen terät ovat teräviä.

SUOMI

43

Page 44

g) Käytä sähkökäyttöistä käsityökalua, sen varusteita tms. ohjeiden mukaisesti

ja sellaisella tavalla, joka sopii kyseiselle sähkökäyttöiselle käsityökalulle ja

ota myös huomioon työskentelyolosuhteet ja suoritettava työ. Sähkökäyttöisen

käsityökalun käyttäminen muihin kuin sille tarkoitettuihin työtehtäviin saattaa

johtaa vaaratilanteeseen.

5) Huolto

a) Laitteen saa huoltaa ja korjata ainoastaan ammattihenkilö ja huollossa tulee

käyttää ainoastaan alkuperäisosia. Näin taataan sähkökäyttöisen käsityökalun

turvallisuus.

2. Hiontaa, puhdistusta, harjausta ja katkaisua

koskevia turvallisuusohjeita

a) Tämä sähkökäyttöinen käsityökalu on tarkoitettu hiontaan, puhdistukseen,

harjaukseen ja katkaisuun. Lue kaikki laitteen mukana tulevat varoitukset,

ohjeet, kuvitukset ja tekniset tiedot. Ohjeiden noudattamatta jättäminen saattaa

johtaa sähköiskuun, tulipaloon tai vakavaan loukkaantumiseen.

b) Kiillotusta ei suositella tehtäväksi tällä koneella. Työt, joita ei ole tarkoitettu

suoritettavaksi tällä laitteella, saattavat aiheuttaa vaaratilanteen tai käyttäjän

loukkaantumisen.

SUOMI

c) Käytä ainoastaan valmistajan hyväksymiä ja suosittelemia tarvikkeita.

Vaikka varuste voidaan asentaa laitteeseen, sen käyttö ei silti välttämättä ole

turvallista.

d) Varusteen ilmoitetun kierrosnopeuden tulee vastata vähintään sähkökäyttöisen

käsityökalun suurinta kierrosnopeutta. Varusteet, jotka pyörivät niiden suurinta

sallittua kierrosnopeutta nopeammin, saattavat vahingoittua ja hajota pieniin

osiin.

e) Varusteen ulkohalkaisija ja paksuus ei saa ylittää sähkökäyttöisen käsityökalun

ilmoitettu kapasiteettia. Liian ison varusteen käyttäminen tekee laitteen

käsittelystä vaikeaa ja heikentää turvallisuutta.

f) Laikkojen, laippojen, tukilaikkojen tms. akselin tulee sopia laitteen karaan,

jotta laitteen käsittely on turvallista. Varusteet, joiden kiinnitysreiät eivät sovi

asennettuun varusteeseen tärisevät voimakkaasti, käyvät epätasaisesti ja

saattavat johtaa laitteen hallinnan menettämiseen.

g) Älä käytä viallisia varusteita. Tarkasta varusteet: Hiomalaikoissa ei saa olla

irrallisia osasia tai halkeamia, tukilaikoissa ei saa olla halkeamia, koloja tai

kulumaa, teräslankaharjoissa ei saa olla irrallisia tai vioittuneita harjaksia.

Mikäli sähkökäyttöinen laite tai jokin varuste putoaa, varmista etteivät ne

ole vioittuneet. Tarkasta ja asenna varuste, sijoitu koneen vaara-alueen

ulkopuolelle (koskee myös sivullisia) ja käytä laitetta täysillä kierroksilla yhden

minuutin ajan. Vioittunut varuste hajoaa yleensä testin aikana.

44

Page 45

h) Käytä henkilökohtaisia suojavarusteita. Käytä kasvosuojusta tai suojalaseja

koneen käyttötavasta riippuen. Käytä tarvittaessa sellaisia suojavarusteita

(kasvo- ja kuulosuojain, käsineet ja työesiliina), jotka suojaavat työkappaleesta

irtoavilta pieniltä hiontakappaleilta ja paloilta. Silmäsuojuksen tulee suojata

lentäviltä osilta, joita syntyy eri työvaiheissa. Hengityssuojaimen tulee suodattaa työssä syntyvät hiukkaset. Pitkäaikainen oleilu meluisassa ympäristössä

saattaa aiheuttaa kuulovaurioita.

i) Pidä vierailijat riittävän kaukana työpisteestä. Kaikkien työpisteessä oleskele

vien tulee käyttää henkilökohtaisia suojavarusteita. Työkappaleesta tai viallisesta varusteesta lentävät lastut saattavat aiheuttaa vahinkoa myös työpisteen

ulkopuolella.

j) Pidä kiinni ainoastaan laitteen eristetyistä pinnoista, kun työskentelet alueilla,

jossa laikka voi joutua kosketuksiin piilossa olevien kaapeleiden tai laitteen

virtajohdon kanssa. Jos laikka joutuu kosketuksiin virtaa johtavan kaapelin

kanssa, laitteen metalliosat saattavat tulla jännitteisiksi, mikä aiheuttaa käyttäjälle sähköiskun vaaran.

k) Sijoita virtajohto siten, että se ei joudu pyörivän varusteen läheisyyteen. Mikäli

menetät laitteen hallinnan, johto saattaa katketa tai jumittua ja kätesi saattaa

joutua pyörivään varusteeseen.

l) Älä laske sähkökäyttöistä käsityökalua käsistäsi ennen kuin se on lakannut

kokonaan pyörimästä. Pyörivä varuste saattaa tarttua alustaan ja aiheuttaa

laitteen hallitsemattoman liikkumisen.

m) Älä käytä sähkökäyttöistä käsityökalua samanaikaisesti kun kannat sitä. Ta

haton kosketus pyörivään varusteeseen saattaa aiheuttaa laitteen juuttumisen

vaatteisiin ja käyttäjään.

n) Puhdista moottorin ilmastointiaukot säännöllisesti. Moottorin puhallin kerää

pölyä, joka kerääntyy kotelon alle. Laitteeseen kerääntyvä metallijäte saattaa

aiheuttaa turvallisuusriskin.

o) Älä käytä sähkökäyttöistä käsityökalua helposti syttyvien materiaalien läheisyy

dessä. Kipinöinti saattaa aiheuttaa näiden materiaalien syttymisen.

p) Älä käytä varusteita, jotka vaativat jäähdytysnesteitä. Veden tai muiden jääh

dytysnesteiden käyttö saattaa johtaa hengenvaaralliseen sähköiskuun.

-

-

-

SUOMI

-

Takapotku ja sitä koskevat varoitukset

Takapotku on äkillinen ilmiö, joka tapahtuu silloin, kun laikka, tukilaikka, harja tai

jokin muu varuste juuttuu äkillisesti. Puristuminen tai juuttuminen aiheuttaa pyörivän varusteen nopean pysähtymisen, mikä johtaa siihen, että sähkökäyttöinen käsityökalu muuttaa äkillisesti liikesuuntaa varusteen pyörimissuunnan vastaiseksi.

45

Page 46

Esimerkki: hiomalaikka jumittuu tai puristuu työkappaleeseen, mikä saattaa aiheuttaa sen, että hiomalaikan reuna osuu työkappaleeseen ja aiheuttaa sen, että

hiomalaikka kaivautuu työkappaleeseen tai lennähtää ylöspäin. Hiomalaikka lennähtää joko poispäin käyttäjästä tai kohti käyttäjää riippuen hiomalaikan pyörimissuunnasta sen juuttuessa. Hiomalaikka voi myös hajota tietyissä tapauksissa.

Takapotkun riski kasvaa, jos sähkökäyttöistä käsityökalua käytetään väärällä tavalla, väärään tarkoitukseen tai väärissä olosuhteissa, mutta se voidaan välttää

noudattamalla alla olevia turvallisuusohjeita.

a) Pidä tukevasti kiinni sähkökäyttöisestä käsityökalusta ja pidä käsiä ja vartaloa

siten, että pystyt reagoimaan mahdolliseen takapotkuun. Käytä aina laitteen

mahdollista apukahvaa, sillä sen käyttäminen lisää laitteen hallittavuutta

takapotkun tai käynnistyessä tapahtuvan nykäyksen aikana. Takapotku tai

käynnistyksessä tapahtuva vääntömomentin nykäisy voidaan hallita paremmin,

jos käyttäjä noudattaa turvallisuusohjeita.

b) Älä sijoita käsiäsi koskaan pyörivän varusteen läheisyyteen. Laite saattaa

lennähtää kädestäsi.

c) Älä asetu sille paikalle, jonne sähkökäyttöinen käsityökalu todennäköisesti

lentää takapotkun sattuessa. Työkalu lentää takapotkun vaikutuksesta

varusteen pyörimissuuntaan nähden vastakkaiseen suuntaan

juuttumispisteestä.

d) Noudata erityistä varovaisuutta kun työskentelet kulmien, terävien reunojen

SUOMI

tms. kanssa. Varo varusteen kimpoamista ja juuttumista. Kulmat, terävät

reunat ja kimpoaminen saattavat aiheuttaa pyörivän varusteen juuttumisen

sekä takapotkun tai työkalun hallinnan menettämisen.

e) Älä asenna puun työstöön sahanterää, jossa on teräketju tai sahanterää, jossa

on hampaat. Tällaiset terät aiheuttavat usein takapotkun ja laitteen hallinnan

menettämisen.

Katkaisulaikalla tapahtuvaa hiontaa ja katkaisua koskevia

turvallisuusohjeita

a) Käytä ainoastaan sähkökäyttöiseen käsityökaluun sopivia laikkatyyppejä ja

käyttämääsi laikkaan sopivaa laikansuojusta. Laikkoja, joita ei ole tarkoitettu

käsikäyttöisille sähkötyökaluille, ei voida suojata kunnolla, ja niiden käyttö voi

olla vaarallista.

b) Laikan suojus tulee asentaa sähkökäyttöiseen käsityökaluun turvallisella