Page 1

®

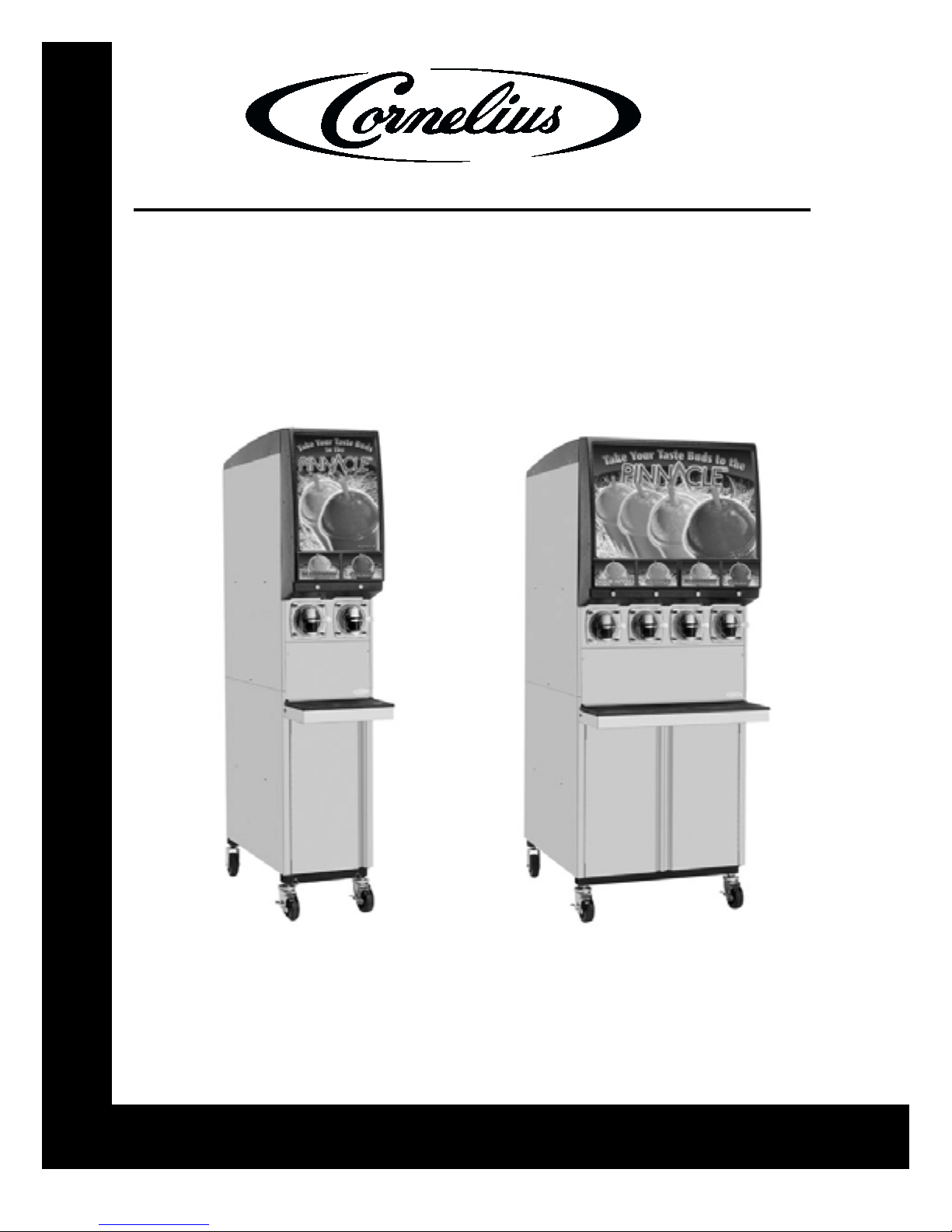

FCB PINNACLE

2 and 4 Flavor

Operator’s Manual

FCB - 2 Flavor FCB - 4 Flavor

Release Date: November 24, 2003

Publication Number: 560006533OPR

Revision Date: September 28, 2004

Revision: C

Page 2

CONTACT INFORMATION

The products, technical information, and instructions contained in this manual are subject to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to

provide for every possible contingency in the installation, operation or maintenance of this equipment.

This manual assumes that the person(s) working on the equipment have been trained and are skilled in

working with electrical, plumbing, pneumatic, and mechanical equipment. Appropriate safety precautions

should be followed and all local safety and construction requirements should be met.

To inquire about current revisions of this and other documentation, or for assistance with any Cornelius

product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permis-

sion from Cornelius.

Printed in U.S.A.

Copyright © 2003-04, All Rights Reserved, IMI Cornelius Inc.

Page 3

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

TABLE OF CONTENTS

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Cylinder Status Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Replenishing Syrup Supply (Syrup Sold Out) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Daily Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Maintaining Product Quality

Cornelius FCB Equipment - Operator Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1. Dispensed Product Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Dispensed product throughput matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. Programmed Defrost Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

3. Viscosity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Control Panel Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Control Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Control Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Control Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Menu 1 — BARREL STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Error & Non-Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

© 2003-04, IMI Cornelius Inc. - i - Publication Number: 560006533OPR

Page 4

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

Publication Number: 560006533OPR - ii - © 2003-04, IMI Cornelius Inc.

Page 5

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

OPERATIONS

CYLINDER STATUS LIGHT

Status Lights

(x4 for 4 Flavor)

(x2 for 2 Flavor)

FIGURE 1

The light above the dispensing valve indicates the status of that dispensing cylinder (see Figure 1). The

different lights and their meanings are:

Light Status Action

No light Unit ready for normal operation. Dispense product.

Solid red Unit is in defrost mode or has not

reached serving viscosity after

defrost.

Blinking green Error condition on that cylinder. Check Control Panel.

Blinking red and green Syrup Sold Out error. Replenish syrup supply.

Do NOT dispense product until

red light is out.

REPLENISHING SYRUP SUPPLY (SYRUP SOLD OUT)

Bag-In-Box System:

1. Replace the empty BIB.

• Wait for the syrup error to automatically clear.

2. If the barrel is not full, fill it by opening the pressure relief valve on the face plate. Keep the valve open

until the liquid reaches the top of the barrel.

3. The display for the barrel that was out of syrup will change from SYRUP to ON.

4. Ready to serve in 5 to 7 minutes.

Tank System (Need to add kit part # 629087516 to accommodate Tank System.):

1. Remove the empty syrup tank by disconnecting the syrup tube first, then the CO

2. Rinse the disconnects in warm water to remove any syrup residue.

3. Move a full Syrup

4. Return to Barrel Status menu, press SYRUP. The cylinder will automatically prime itself.

5. If the barrel is not full, fill it by opening the pressure relief valve on the face plate. Keep the valve open

until the liquid reaches the top of the barrel.

6. The display for the barrel that was out of syrup will change from SYRUP to ON.

NOTE: If the blendonator has not started filling after 15 seconds, press SYRUP again.

tank into position and connect the CO2 tube first, then the syrup tube.

tube.

2

Publication Number: 560006533OPR - 1 - © 2003-04, IMI Cornelius Inc.

Page 6

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

DAILY CLEANING

Wash external surfaces with mild soap solution, rinse with clean water, and wipe dry. Remove the drip

tray (if applicable), wash with mild soap solution, rinse, and dry.

NOTE: Do not use abrasive cleaners on the unit.

MAINTAINING PRODUCT QUALITY

CORNELIUS FCB EQUIPMENT - OPERATOR INSTRUCTIONS

It has been determined that the following factors can affect the rate at which product quality diminishes

(as indicated by a change in product appearance).

1. Dispensed Product Throughput

2. Programmed Defrost Scheduling

3. Viscosity Setting

Cornelius recommends the following instructions be read and followed relative to operating and

establishing settings with the FCB equipment. Cornelius equipment service manuals contain instructions

on how to program settings within the control system. Operators who have not been trained on servicing

Cornelius FCB equipment should not attempt to modify equipment settings but should contact an

accredited service provider.

Cornelius makes the following recommendations to help assure maximum product quality:

1. Dispensed Product Throughput

FCB equipment is designed to provide a high throughput of frozen carbonated dispensed product to

meet peak draw demands. Where low product throughput is experienced, there is the potential for

product quality to diminish. The matrix below outlines the minimum throughput per barrel that must be

dispensed on a 24 hour basis.

Dispensed product throughput matrix

V-Series Viscosity </= 8 Viscosity >8

Volume of dispensed product per barrel

per 24 hours required to maintain product

quality.

Pinnacle Viscosity </= 4 Viscosity >4

Volume of dispensed product per barrel

per 24 hours required to maintain product

quality.

Cornelius recommends that, in conditions where the FCB machine is operational and the

minimum throughput (set forth in the matrix above) is not met on a per barrel basis, product

should be dispensed and discarded to increase throughput and help assure that product quality

is maintained.

1

48 oz 60 oz

48 oz 60 oz

1. 'DWDLQPDWUL[DVVXPHVHTXLSPHQWKDVEHHQFRUUHFWO\LQVWDOOHGFRPPLVVLRQHGDQGFDOLEUDWHGDVSHU

GLUHFWLRQVFRQWDLQHGLQDOOWHFKQLFDOOLWHUDWXUHSXEOLVKHGE\&RUQHOLXVDQGWKHUHFRPPHQGDWLRQVFRQ

WDLQHGLQWKLVGRFXPHQWKDYHEHHQIROORZHG

© 2003-04, IMI Cornelius Inc. - 2 - Publication Number: 560006533OPR

Page 7

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

2. Programmed Defrost Scheduling

The control system in Cornelius FCB equipment includes a function to automatically defrost product in

the barrel at programmed times. Programmed defrosts must be scheduled frequently to ensure that

product quality within the barrel is maintained. Failure to defrost regularly during periods of low

throughput will allow increased ice crystal growth, with a possible decrease in product quality. Regular

throughput of dispensed product will replenish the barrel frequently with liquid and reduce the

requirements of programmed defrosts.

Cornelius recommends that programmed defrosts be scheduled to occur during any 3 hour

window during which time dispensed product throughput is low. Low throughput is defined as

less than 8 x 16oz drinks per barrel during any 3-hour window.

3. Viscosity Setting

The control system in Cornelius FCB equipment includes a function to select the desired product

viscosity. This function is referred to as “Viscosity Setting”. With V-series there is a selectable Viscosity

Setting range from 4–12, and with Pinnacle, the range is 1–9. The higher the number selected the more

viscous the frozen product in the barrel will become. This increased viscosity is achieved by freezing the

product in the barrel to a lower temperature thereby increasing ice crystal size/growth. As the ice crystal

size increases, however, there is potential for product quality to diminish.

Cornelius recommends that the viscosity settings be set at the lowest possible setting to achieve

the desired drink quality. In most typical installations using a sugar-based syrup, acceptable

drink quality can be achieved by programmed Viscosity Settings in the 8-9 range for V-series and

in the range of 4-5 for Pinnacle.

Diet FCB syrups freeze much more readily than sugar based syrups, so the Viscosity Setting

should be selected at the minimum value available, 4 for V-series and 1 for Pinnacle equipment.

CONTROL PANEL

Control Panel Overview

The Pinnacle is controlled by a microprocessor that monitors and controls the major systems and components of the machine. The microprocessor is pre-programmed at the factory to perform the tasks necessary to keep the Pinnacle operating correctly. The microprocessor keeps track of diagnostic information

that is used when adjusting and/or repairing the machine.

Error messages are displayed on the Control Panel located behind the lighted merchandising panel (see

Figure 2). There are two levels of Control Panel access: one used by the operator for normal operations,

and one used by qualified service technicians for installation and service functions.

The Control Panel has many different displays of information called Menus. The first menu (menu 1) that

is displayed is the BARREL STATUS menu. From each menu there is a button to return to the previous

menu and another button to advance to the next menu (if applicable).

Control Panel

Display

FIGURE 2

Publication Number: 560006533OPR - 3 - © 2003-04, IMI Cornelius Inc.

Page 8

Control Panel Description

Control Panel Display

The Control Panel display has two main areas. The first area on the control panel presents information

about the status and settings of the machine (see Figure 3). It also displays menus for actions that are

taken to change the functioning of the machine.

Control Panel Buttons

The second area on the control panel is the button area. There are five buttons that are pressed to activate various functions of the microprocessor. Each button has a label directly above it that describes

what happens if that button is pressed (see Figure 3).

Pressing a button performs the action labeled just above the button.

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

Menu

Title

System

Time

Button #1 Button #2 Button #3 Button #4 Button #5

FIGURE 3 Display Layout

Message Display

Area

Control Panel

Display Area

Control Panel

Action Buttons

Menu 1 — BARREL STATUS

The Barrel Status menu is the main control panel menu. This menu displays the system clock and the

present status of each cylinder (see Figure 4).

Cylinder

Status

Messages

Button

Labels

Barrel Status Menu Button Descriptions:

#1 - MENU . . . bring up the Choose Mode menu (menu 2) service use only

#2 - ON . . . . . . turn all cylinders ON (beater bar turning and refrigeration active)

#3 - OFF . . . . . turn all cylinders OFF (beater bar off and refrigeration inactive)

#4 - Not used . in the Bag-In-Box System

#4 - SYRUP . . pressing the SYRUP button causes the syrup to prime in the Tank System

#5 - ERR. . . . . pressing ERR displays the Error menu which lists all system errors

If there are no Syrup Sold Out conditions the Syrup message is not displayed for button #4 (button #4 is

only used for Tank System), and if there are no errors the ERR message is not displayed for button #5.

From the Barrel Status menu pressing Menu displays the Control Panel menu (menu 2).

© 2003-04, IMI Cornelius Inc. - 4 - Publication Number: 560006533OPR

FIGURE 4 Barrel Status Menu

Page 9

FCB Pinnacle 2 and 4 Flavor Operator’s Manual

Error & Non-Error Messages

The following status messages may be displayed for each cylinder.

Cylinder Status Menu Error Messages:

SYRUP . . . . . . . . . . . . . . . . . . . . . . . . . . syrup sold out - replace syrup

CO2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . sold out - replace CO

2

H2O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . H2O sold out

ERROR . . . . . . . . . . . . . . . . . . . . . . . . . .electronics problem - call service

TIME CLOCK . . . . . . . . . . . . . . . . . . . . .real time clock error - call service

HOT GAS . . . . . . . . . . . . . . . . . . . . . . . .hot gas condition - call service

VOLT. . . . . . . . . . . . . . . . . . . . . . . . . . . .high or low voltage - call service

DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . .motor problem - call service

TORQUE. . . . . . . . . . . . . . . . . . . . . . . . .over torque - call service

REFRIG . . . . . . . . . . . . . . . . . . . . . . . . .freeze cylinder refrigeration or ice bank refrigeration, call ser-

vice

SENSOR. . . . . . . . . . . . . . . . . . . . . . . . .sensor problems - call service

Cylinder Status Menu Non-Error Messages:

ON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .beater bar is turning and refrigeration to this freeze cylinder is

active

OFF. . . . . . . . . . . . . . . . . . . . . . . . . . . . .beater bar is not turning and refrigeration to this freeze cylinder

is inactive

MOTOR. . . . . . . . . . . . . . . . . . . . . . . . . .beater bar is turning and refrigeration to this freeze cylinder is

inactive

DFRST . . . . . . . . . . . . . . . . . . . . . . . . . .freeze cylinder is presently in defrost mode

Solid red LED (just above the display) . .thermostat has tripped, call for service

Publication Number: 560006533OPR - 5 - © 2003-04, IMI Cornelius Inc.

Page 10

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...