Page 1

®

VISUAL MERCHANDISERS

COR7VM, COR12VM, COR17VM, COR23VM,

COR35VMSD, COR45VMSD, COR49VMD, COR67VMST

Service Manual

Release Date: May 24, 2005

Publication Number: 630460243SER

Revision Date: NA

Revision: A

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus, and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2005, All Rights Reserved, IMI Cornelius, Inc.

Page 3

Visual Merchandiser Service Manual

TABLE OF CONTENTS

Features of the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Cleaning and Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fluorescent Lamp and Ballast Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

To remove the motor cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Ballast Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

To remove the ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

To replace the fluorescent lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Temperature Control Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Required tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

To remove the temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Evaporator Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

To disconnect the evaporator fan motor electrical terminals . . . . . . . . . . . . . . . 10

To remove the evaporator fan motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Condensing Unit Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

To remove the motor cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

To pull out the condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

To replace the condensing unit fan motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Starting Relay, Overload Protector, and Start Capacitor Replacement . . . . . . . . . 17

Required tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

To remove the motor cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

To pull out the condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

To remove the electrical box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

To replace the relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

To replace the overload protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

To replace the starting capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

To install the electrical box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Door and Spring Hinge System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To remove the motor cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

To remove the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

To install the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

To assemble spring hinge components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Glass Door Pane Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To remove the motor cover and door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To remove the glass door pane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

To install the door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Starter relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

© 2005, IMI Cornelius Inc. - i - Publication Number: 630460243SER

Page 4

Visual Merchandiser Service Manual

Thermal protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Condenser fan motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Evaporator fan motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Capillary tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Drier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Temperature control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Cooling cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

The Refrigeration Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Wiring Diagram 115 V/60 Hz/1 Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Possible causes and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Publication Number: 630460243SER - ii - © 2005, IMI Cornelius Inc.

Page 5

FEATURES OF THE UNIT

Fluorescent interior light

Visual Merchandiser Service Manual

Heavy duty hinges

Strong body with 1 3/4”

thick walls, injected with

CFC-free polyurethane

foam

Forced-air evaporator

for quick temperature

pull down

NSF compliant

interior cabinet

Heavy duty R-134a

condensing unit with zero

maintenance condenser

Double-pane low-e glass

door for high ambient

conditions

Durable PVC frame

Exterior cabinet made of

galvanized, pre-painted

steel, with baked polyester

paint

Reinforced heavy-duty

shelves

Reinforced, 16-gauge,

galvanized steel base

FIGURE 1

CLEANING AND PREVENTIVE MAINTENANCE

Weekly or sooner, as required:

1. Disconnect the power source before cleaning. Remove all products and place in a proper cooler.

2. Clean the interior and exterior with a mild soap or detergent solution and then rinse with a warm

baking soda solution (one cup of baking soda to one gallon of warm water). Dry the interior

completely before replacing products.

3. Clean the condenser unit periodically by vacuuming the unit compartment, especially the

condenser unit coil (it looks like a small auto radiator). If the condenser coil has accumulated dirt

and grease (possible in heavy traffic areas or a kitchen), use a strong cleaning solution. If you find

any oil in the condensing unit compartment, call a qualified service person immediately.

4. Empty out and clean the drain pan located next to the condensing unit as required. Check regularly

for excessive water accumulation.

5. Plug in the cabinet and wait until the proper temperature is achieved before reloading the cabinet

with product.

© 2005, IMI Cornelius Inc. - 1 - Publication Number: 630460243SER

Page 6

Visual Merchandiser Service Manual

FLUORESCENT LAMP AND BALLAST REPLACEMENT

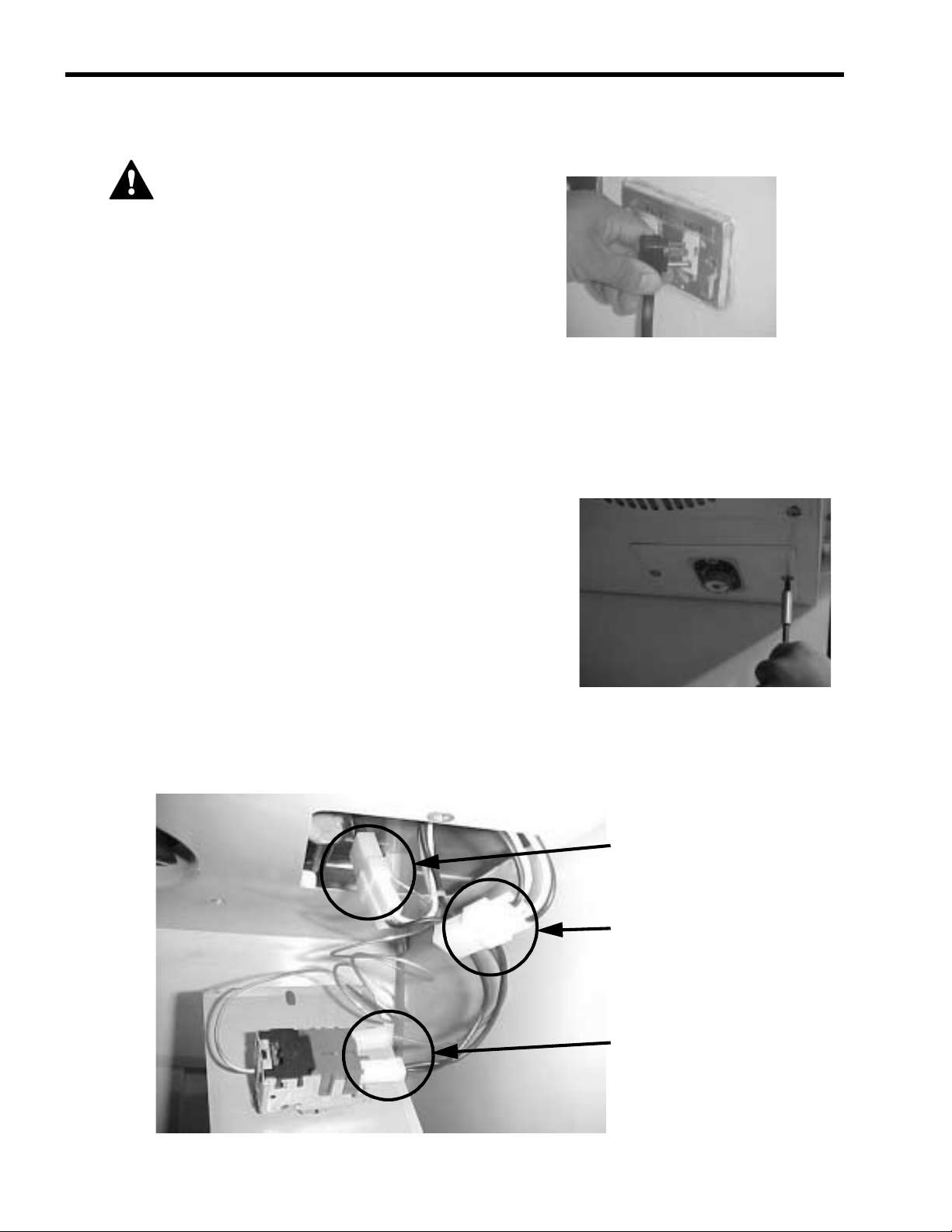

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

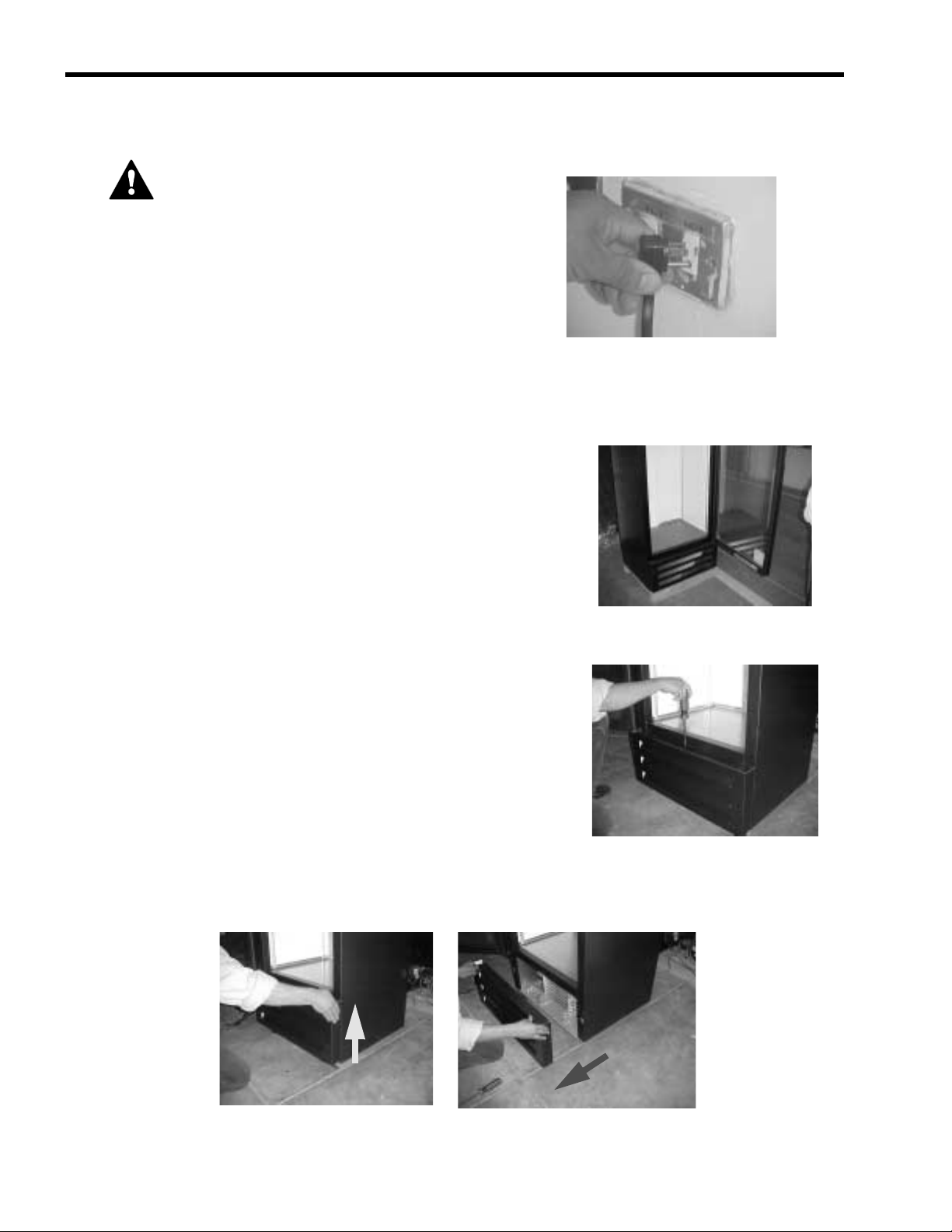

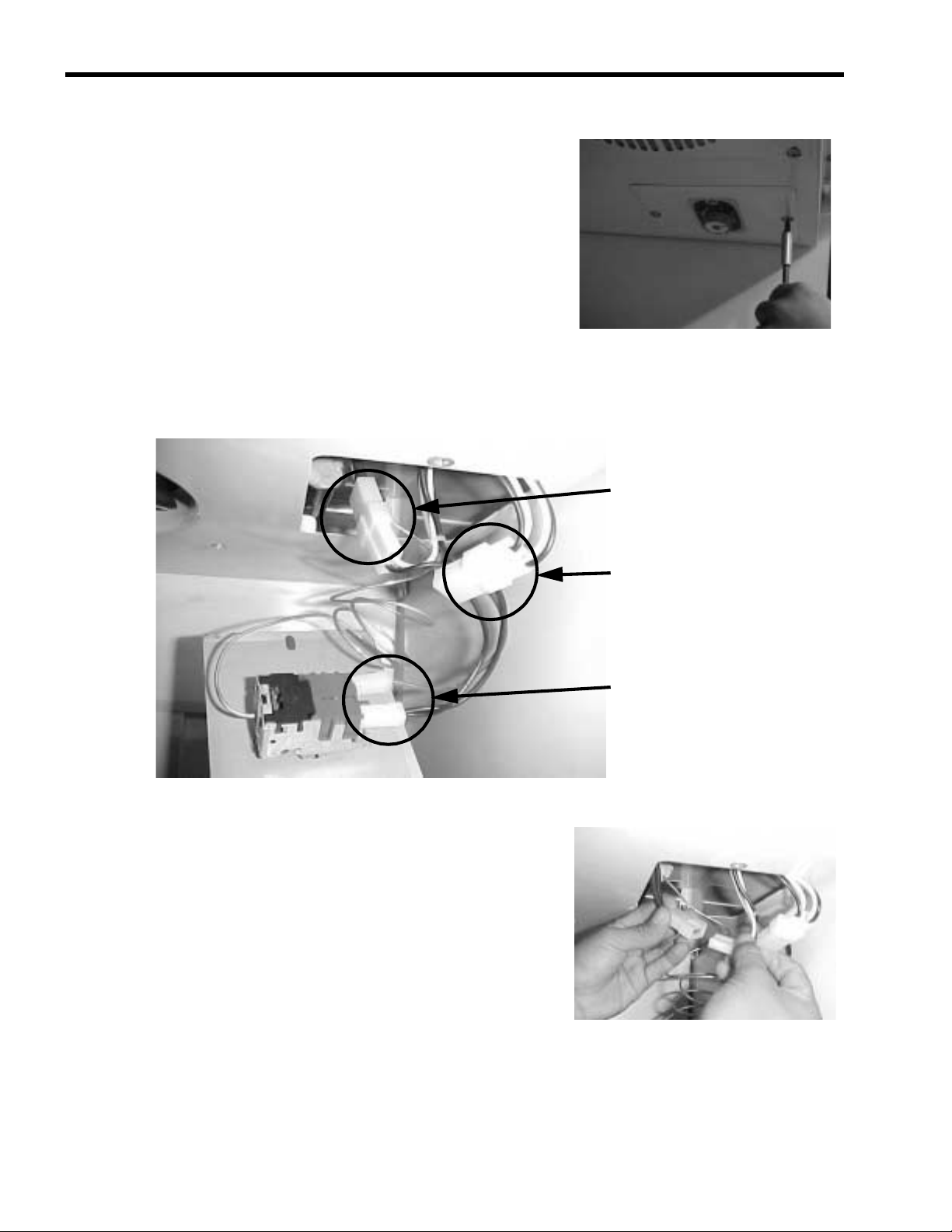

To remove the motor cover

1. Open the door.

2. Use a #2 Phillips screwdriver to remove the flat-head screw

holding condensing the unit motor cover.

3. Remove the condensing unit motor cover by pulling it up and out.

FIGURE 2

FIGURE 3

FIGURE 4

Publication Number: 630460243SER - 2 - © 2005, IMI Cornelius Inc.

Page 7

BALLAST REPLACEMENT

Required tool

• one #2 Phillips screwdriver with a 4” long blade

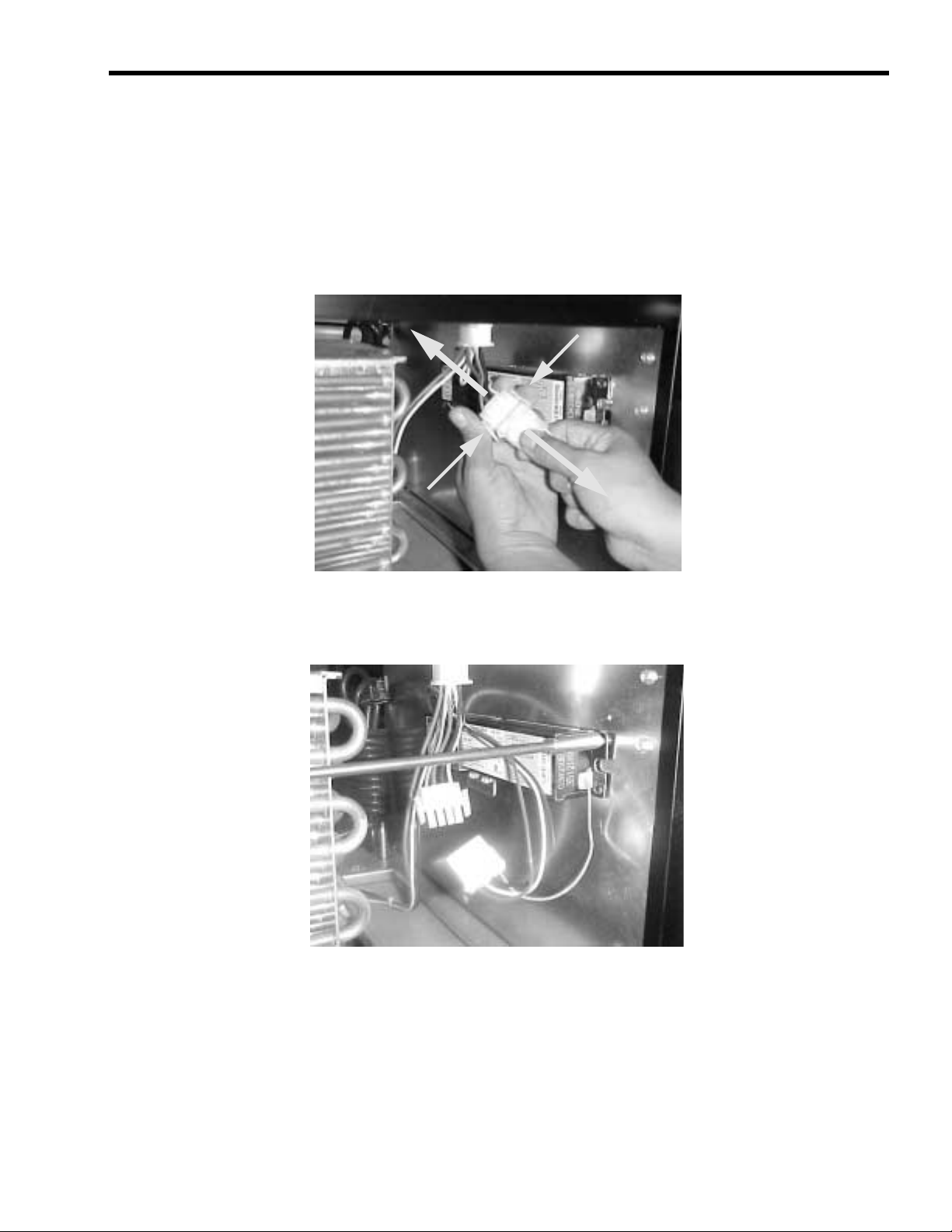

To remove the ballast

1. Push down with your fingers on the plastic tabs that hold the male and female connectors in

position. Then pull out the male connector (connected to the ballast).

Visual Merchandiser Service Manual

FIGURE 5

2. Use a Phillips screwdriver to remove the single screw holding the ballast to the metal bracket. The

ballast sits on a metal bracket to make replacement easier.

FIGURE 6

© 2005, IMI Cornelius Inc. - 3 - Publication Number: 630460243SER

Page 8

Visual Merchandiser Service Manual

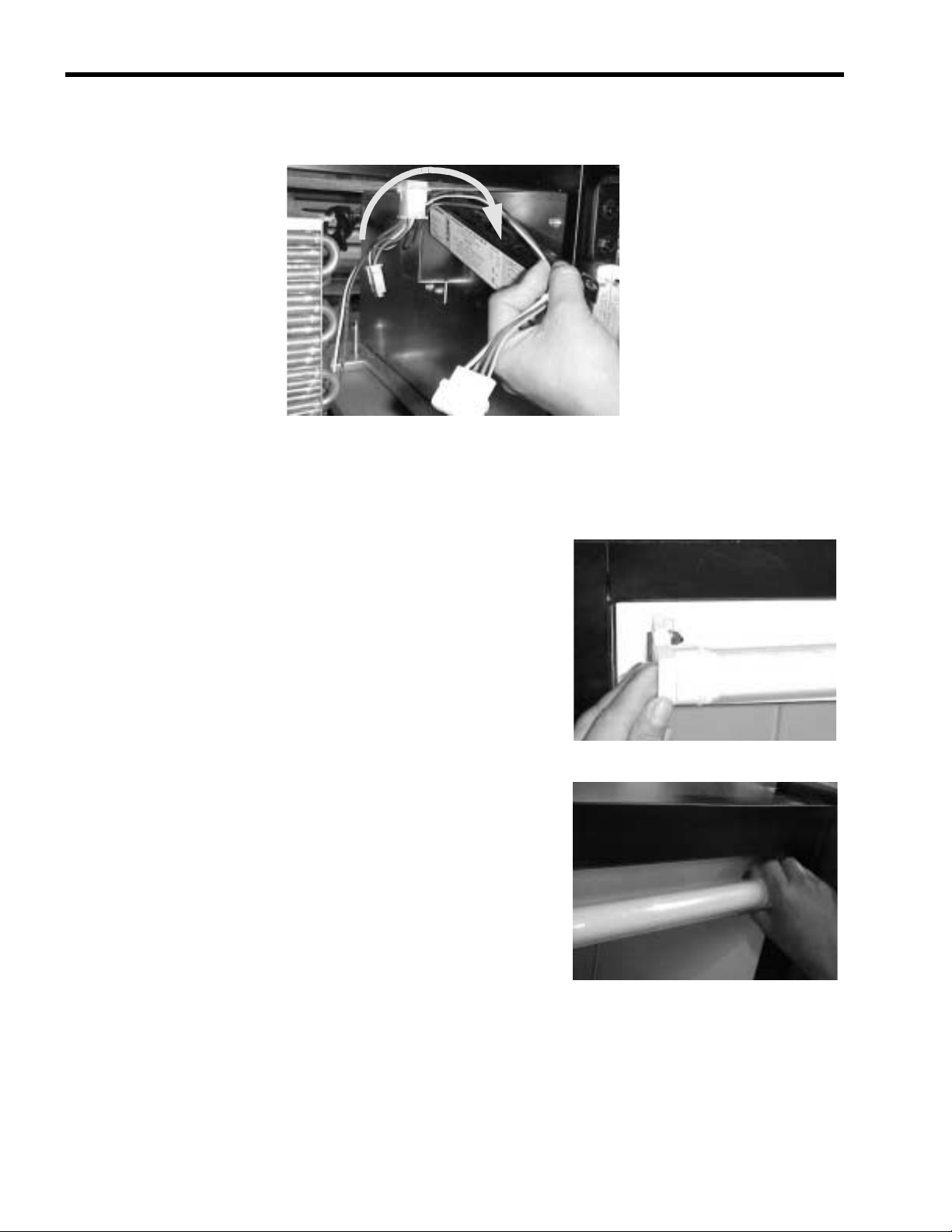

3. To remove the ballast, lift the ballast wires over the metal bracket which holds the back end of the

ballast.

4. To reinstall a new ballast reverse steps 1 through 3.

FIGURE 7

To replace the fluorescent lamp

1. Pull one end of the lamp holder base half way out.

2. Pull the other end of the lamp holder base half way out.

FIGURE 8

FIGURE 9

Publication Number: 630460243SER - 4 - © 2005, IMI Cornelius Inc.

Page 9

3. Once the two bases have been pulled half way out, use both

hands to pull out the entire lamp assembly

4. Remove the lamp holder bases from each end of the lamp.

Visual Merchandiser Service Manual

FIGURE 10

FIGURE 11

5. Remove the plastic cover from the lamp. Now you can

replace the lamp.

6. To install a new lamp, reverse steps 1 through 5.

FIGURE 12

© 2005, IMI Cornelius Inc. - 5 - Publication Number: 630460243SER

Page 10

Visual Merchandiser Service Manual

TEMPERATURE CONTROL REPLACEMENT

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

Required tool

• one #2 Phillips screwdriver with a 4” long blade

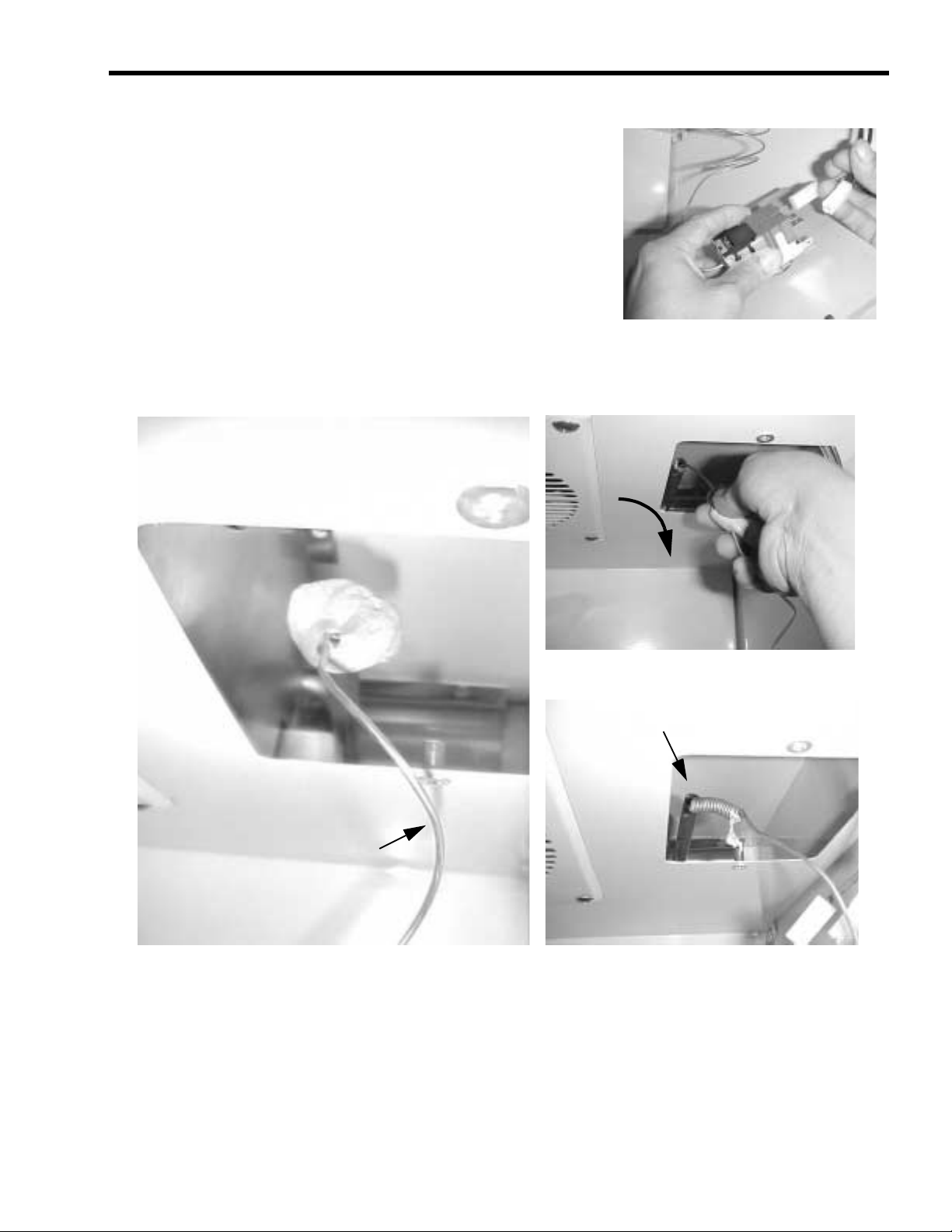

To remove the temperature control

1. Remove the two Phillips head screws that hold the

temperature control mounting plate (located on the baffle).

FIGURE 13

With the temperature control mounting plate removed from the baffle, you can see the thermostat,

light, and fan motor connectors.

Evaporator fan motor connections

Fluorescent lamp connections

Temperature control connections

FIGURE 14

Publication Number: 630460243SER - 6 - © 2005, IMI Cornelius Inc.

Page 11

Visual Merchandiser Service Manual

2. Disconnect the electrical connections from the temperature

control.

FIGURE 15

3. Carefully pull the bulb sensor out of the temperature control well. There is a patch of permagum at

the opening of the well which seals the bulb sensor from humidity.

Temperature control sensing bulb

Temperature control well

FIGURE 16

© 2005, IMI Cornelius Inc. - 7 - Publication Number: 630460243SER

Page 12

Visual Merchandiser Service Manual

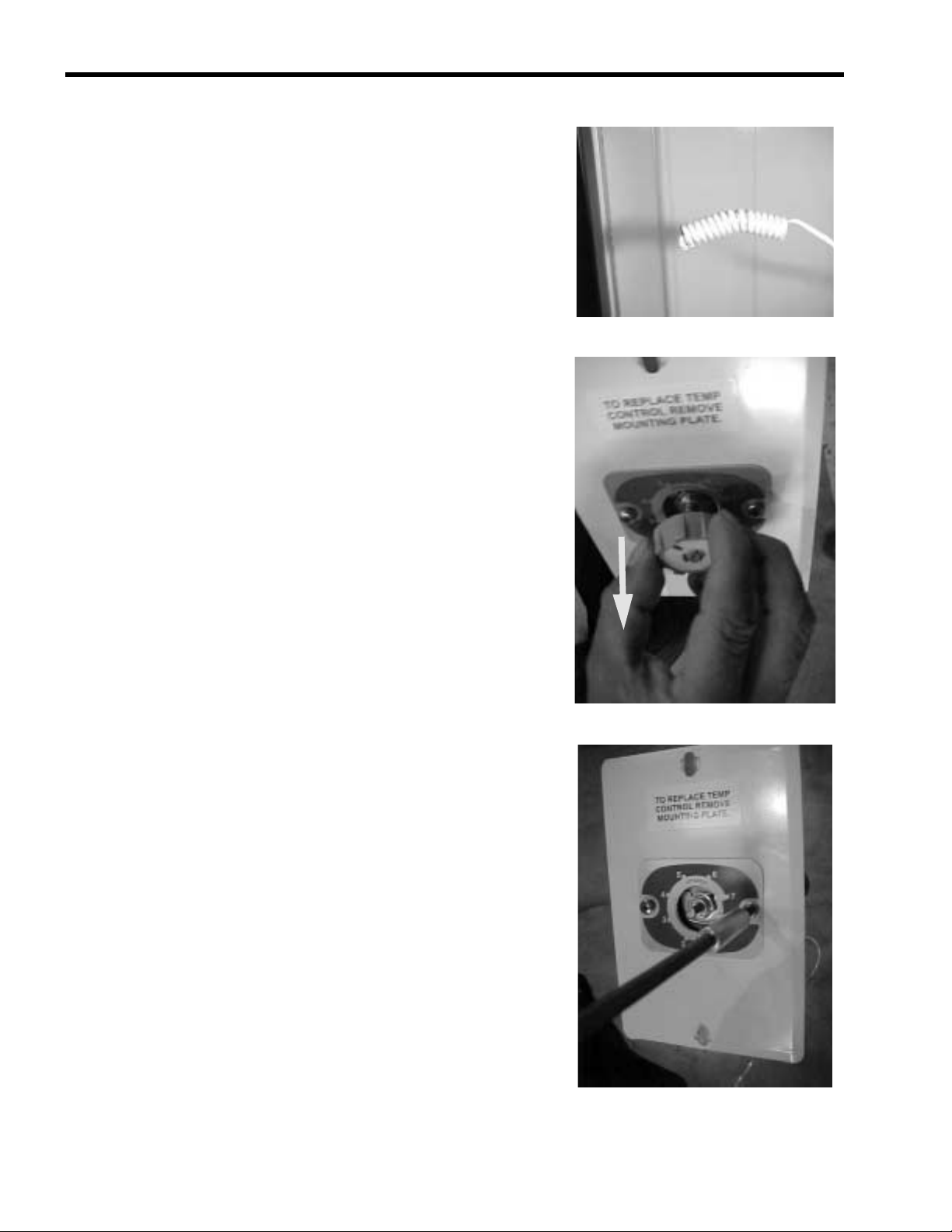

The bulb sensor has a slight curve to make a tight fit inside

the temperature control well.

4. Remove the temperature control knob by pulling it outward.

FIGURE 17

5. Use a Phillips screwdriver to remove the two Phillips head

screws the hold the temperature control to its mounting

plate.

FIGURE 18

FIGURE 19

Publication Number: 630460243SER - 8 - © 2005, IMI Cornelius Inc.

Page 13

6. With the two Phillips head screws removed, you can now

install a new temperature control by reversing steps 1

through 5.

Visual Merchandiser Service Manual

FIGURE 20

EVAPORATOR FAN MOTOR REPLACEMENT

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

Required tools

To replace the evaporator fan motor, you need:

• one #2 Phillips screwdriver with 4” blade

• one side-cutting pliers

• one 1/4” socket screwdriver

© 2005, IMI Cornelius Inc. - 9 - Publication Number: 630460243SER

Page 14

Visual Merchandiser Service Manual

To disconnect the evaporator fan motor electrical terminals

1. Remove the two Phillips head screws that hold the

temperature control mounting plate (located on the baffle).

With the temperature control mounting plate removed from the baffle, you can see the thermostat, light,

and fan motor connectors.

Evaporator fan motor connections

FIGURE 21

FIGURE 22

2. Disconnect the fan motor electrical connector.

Fluorescent lamp connections

Temperature control connections

FIGURE 23

Publication Number: 630460243SER - 10 - © 2005, IMI Cornelius Inc.

Page 15

3. Remove the rubber grommet, located in the plastic bushing near at the right air diffuser.

To remove the evaporator fan motor

1. Use a Phillips screwdriver to remove the four screws holding

the evaporator fan grill at the baffle.

Visual Merchandiser Service Manual

FIGURE 24

2. Remove the fan blade. Use the side-cutting pliers to

unscrew the nut-type washer that holds the fan motor in

place.

FIGURE 25

FIGURE 26

© 2005, IMI Cornelius Inc. - 11 - Publication Number: 630460243SER

Page 16

Visual Merchandiser Service Manual

3. Pass the electrical wire of the motor through the plastic bushing on the air diffuser.

4. Use a Phillips screwdriver to remove the four screws holding the base of the fan motor to the top of

the internal cabinet.

Plastic bushing on the air diffuser

FIGURE 27

Four Phillips head screws

FIGURE 28

5. Use a 1/4” socket screwdriver to remove the three socket head screws holding the fan motor to its

base.

Three socket head screws

FIGURE 29

6. Replace the fan motor with another of the same model. Reinstall the fan motor by reversing steps 1

through 5.

Publication Number: 630460243SER - 12 - © 2005, IMI Cornelius Inc.

Page 17

CONDENSING UNIT FAN MOTOR REPLACEMENT

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

Required tools

The following tools are required to repair the spring hinge system or assemble a new door:

• one Phillips #2 screwdriver with 4” blade

• one 3/8” open end or box end wrench

Visual Merchandiser Service Manual

• one 7/16” open end or box end wrench

• one adjustable wrench, 4” or 6”

• one measuring tape

To remove the motor cover

1. Open the door.

2. Use a #2 Phillips screwdriver to remove the flat-head screw

holding condensing the unit motor cover.

FIGURE 30

FIGURE 31

© 2005, IMI Cornelius Inc. - 13 - Publication Number: 630460243SER

Page 18

Visual Merchandiser Service Manual

3. Remove the condensing unit motor cover by pulling it up and out.

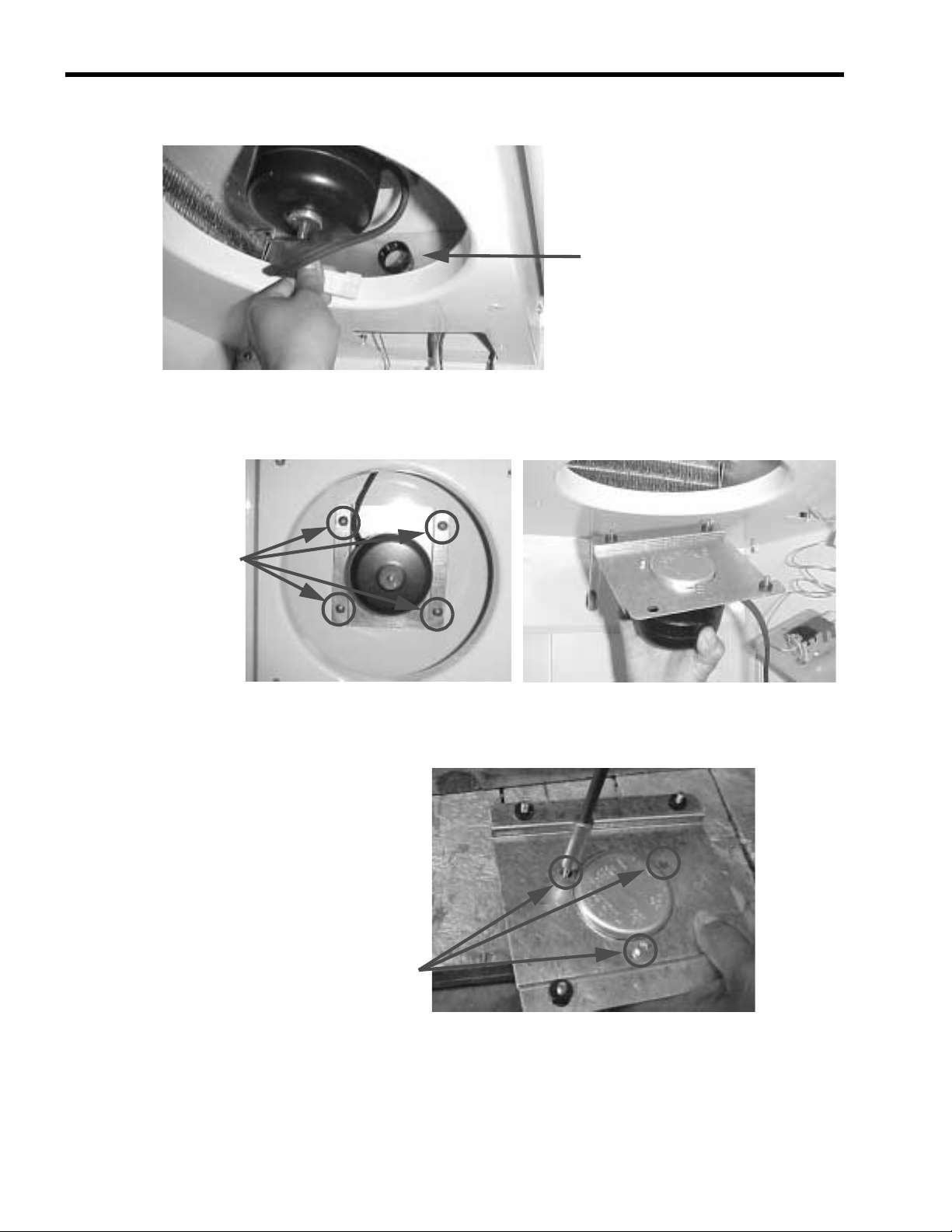

To pull out the condensing unit

1. Use a 1/2” open or box end wrench to remove the bolts that hold the rails that support the

condensing unit.

FIGURE 32

FIGURE 33

2. Slowly push the condensing unit from the rear of the cabinet. Be sure the suction line and the

capillary tubing do not break.

FIGURE 34

Publication Number: 630460243SER - 14 - © 2005, IMI Cornelius Inc.

Page 19

3. Pull the condensing unit about 13 inches from the base of the cabinet to provide access to the

condensing unit fan motor, relay, overload protector, and capacitor.

FIGURE 35

To replace the condensing unit fan motor

1. Untie the fan motor electrical wire.

Visual Merchandiser Service Manual

2. Disconnect the fan motor electrical connectors.

FIGURE 37

FIGURE 36

© 2005, IMI Cornelius Inc. - 15 - Publication Number: 630460243SER

Page 20

Visual Merchandiser Service Manual

3. Use a 7/16” open end or box end wrench to remove the four

nuts and bolts that hold the base of the fan motor to the rails

of the condensing unit.

4. Tilt the fan motor from one corner in the direction of the

arrow to remove the fan motor from the condenser shroud.

FIGURE 38

5. Pull the fan motor out in the direction of the arrow.

6. Use the side cutting pliers to remove the fan blade.

FIGURE 39

FIGURE 40

FIGURE 41

Publication Number: 630460243SER - 16 - © 2005, IMI Cornelius Inc.

Page 21

Visual Merchandiser Service Manual

7. Use a 1/4” socket screwdriver to loosen the four screws that hold the fan motor chassis to its

bracket. Replace the fan motor.

FIGURE 42

8. To reinstall the fan motor, reverse steps 1 through 7.

STARTING RELAY, OVERLOAD PROTECTOR, AND START CAPACITOR

R

EPLACEMENT

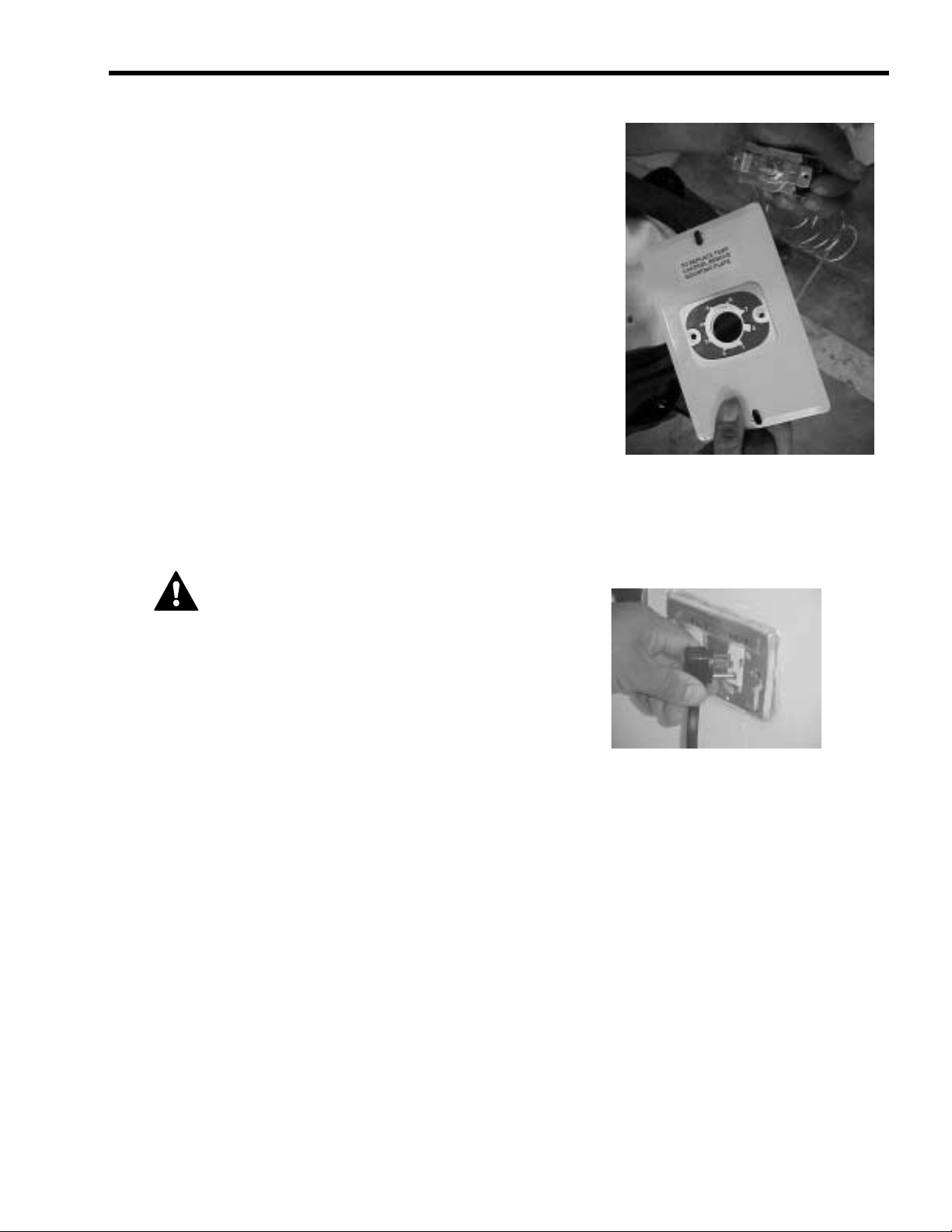

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

If any electrical problems arise, a wiring diagram is included with each cabinet to aid in tracing the source

of trouble and making the necessary repairs.

Required tool

You will need one Phillips #2 screwdriver with 4” blade and one flat blade screwdriver.

To remove the motor cover

1. Open the door.

FIGURE 43

© 2005, IMI Cornelius Inc. - 17 - Publication Number: 630460243SER

Page 22

Visual Merchandiser Service Manual

2. Use a #2 Phillips screwdriver to remove the flat-head screw

holding condensing the unit motor cover.

3. Remove the condensing unit motor cover by pulling it up and out.

FIGURE 44

To pull out the condensing unit

1. Use a 1/2” open or box end wrench to remove the bolts that hold the rails that support the

condensing unit.

FIGURE 45

FIGURE 46

Publication Number: 630460243SER - 18 - © 2005, IMI Cornelius Inc.

Page 23

Visual Merchandiser Service Manual

2. Slowly push the condensing unit from the rear of the cabinet. Be sure the suction line and the

capillary tubing do not break.

FIGURE 47

3. Pull the condensing unit about 13 inches from the base of the cabinet to provide access to the

condensing unit fan motor, relay, overload protector, and capacitor.

FIGURE 48

© 2005, IMI Cornelius Inc. - 19 - Publication Number: 630460243SER

Page 24

Visual Merchandiser Service Manual

To remove the electrical box

1. Insert a flat blade screwdriver into the slot on the top of the plastic electrical box (attached to one

side of the compressor), push the screwdriver downward, and remove the box.

Slot on top of the electrical box

FIGURE 49

2. While pushing down on the slot, hold box with your other

hand and pull it out.

FIGURE 50

Publication Number: 630460243SER - 20 - © 2005, IMI Cornelius Inc.

Page 25

Visual Merchandiser Service Manual

3. Once the electrical box is removed from the compressor shell, the following components and wires

are visible:

• relay

• overload protector

• two black wires that connect to the starting capacitor

• ground wire (green)

• common wire (black)

• start winding (blue)

Starting relay

Two black wires

connected to the starting

capacitor

Ground wire

Overload protector

To replace the relay

1. Disconnect the two black starting capacitor wires and the blue start winding wire.

2. Use a slotted screwdriver as a pry bar to pull the relay from the compressor shell.

Blue start winding wire

Common wire

FIGURE 51

FIGURE 52

3. To reinstall the relay, reverse these steps.

© 2005, IMI Cornelius Inc. - 21 - Publication Number: 630460243SER

Page 26

Visual Merchandiser Service Manual

To replace the overload protector

1. Pull the overload protector from the compressor shell.

2. To reinstall the overload protector, reverse the above steps.

To replace the starting capacitor

1. Use a slotted screwdriver as a pry bar to remove the

starting capacitor from its base (attached to the top of the

plastic electrical box).

FIGURE 53

2. Remove the top of the starting capacitor to completely

detach it from its base.

3. To reinstall the starting capacitor, reverse these steps.

FIGURE 54

FIGURE 55

Publication Number: 630460243SER - 22 - © 2005, IMI Cornelius Inc.

Page 27

To install the electrical box

1. Be sure all wires are properly connected. The starting capacitor wires must pass through the slotted

channel on the box to ensure correct connection between the electrical box and the compressor

shell.

Visual Merchandiser Service Manual

Two wires from the starting

capacitor pass through the slotted

channel on the box.

FIGURE 56

2. Insert the top of the box into the compressor shell.

3. Use your hand to push the whole box until you hear a click.

FIGURE 57

FIGURE 58

© 2005, IMI Cornelius Inc. - 23 - Publication Number: 630460243SER

Page 28

Visual Merchandiser Service Manual

4. Slowly push the condensing unit back to its original position. Avoid breaking the suction line and

capillary tubing.

5. Re-tie all the wires.

FIGURE 59

FIGURE 60

6. Return the suction line and the capillary tubing to their

original positions.

Re-tie all the wires

FIGURE 61

Publication Number: 630460243SER - 24 - © 2005, IMI Cornelius Inc.

Page 29

DOOR AND SPRING HINGE SYSTEM

CAUTION - Make sure the power supply is

turned off before making any electrical

repairs.

Required tools

The following tools are required to repair the spring hinge system or assemble a new door:

• one Phillips #2 screwdriver with 4” blade

• one 3/8” open end or box end wrench

• one 7/16” open end or box end wrench

• one adjustable wrench, 4” or 6”

Visual Merchandiser Service Manual

• one measuring tape

To remove the motor cover

1. Open the door.

2. Use a #2 Phillips screwdriver to remove the flat-head screw

holding condensing the unit motor cover.

FIGURE 62

FIGURE 63

© 2005, IMI Cornelius Inc. - 25 - Publication Number: 630460243SER

Page 30

Visual Merchandiser Service Manual

3. Remove the condensing unit motor cover by pulling it up and out.

To remove the door

NOTE: Reinstall the door support bracket before removing

the door. The door support bracket allows door removal to be

performed by just one person.

FIGURE 64

FIGURE 65

1. Use a Phillips screwdriver to remove the door support bracket from the condensing unit

compartment, held in place by two Phillips screws. This bracket has been placed on the interior left

side wall of the condensing unit compartment for storage purposes only.

FIGURE 66

Publication Number: 630460243SER - 26 - © 2005, IMI Cornelius Inc.

Page 31

Visual Merchandiser Service Manual

2. Using the same two Phillips screws, reinstall the door support bracket in the two holes located on

the bottom of the door frame.

FIGURE 67

3. This photo shows the door support bracket installed and

holding the door.

4. Relieve the tension in the spring hinge, located at the

bottom hinge of the door, before beginning work on the

spring hinge system.

5. The securing nut is right-hand threaded. Use a 7/16”

wrench to turn the nut clockwise one and one half turns to

loosen it.

FIGURE 68

FIGURE 69

FIGURE 70

© 2005, IMI Cornelius Inc. - 27 - Publication Number: 630460243SER

Page 32

Visual Merchandiser Service Manual

6. One end of the main rod has a square head which is used to adjust the spring tension using an

adjustable wrench. One of the faces of the square head has an indentation and is painted red. This

red indentation should face the right-hand side of the cabinet when the spring has tension.

Securing nut

Square end of main rod

Position of the main rod when

the spring has tension

FIGURE 71

7. Use the red indentation as a point of reference to turn the main rod 3/4 of a turn counterclockwise

to relieve the spring tension. The red mark should face away from the cabinet front when the spring

tension has been relieved.

Red mark faces away

from the cabinet after

the spring tension has

been relieved.

FIGURE 72

Decrease the spring tension by turning the main rod counterclockwise.

8. Use a 3/8” wrench to remove the two screws that hold the

bottom hinge in place.

FIGURE 73

Publication Number: 630460243SER - 28 - © 2005, IMI Cornelius Inc.

Page 33

Visual Merchandiser Service Manual

IMPORTANT: The door support bracket must be installed for a single person to remove the door.

9. Pull the door downward to separate the door from the top hinge.

FIGURE 74

To install the door

NOTE: Reinstall the door support bracket before installing

the door. The door support bracket allows door installation to be

performed by just one person.

FIGURE 75

© 2005, IMI Cornelius Inc. - 29 - Publication Number: 630460243SER

Page 34

Visual Merchandiser Service Manual

The springe hinge system consists of a securing nut, a pressure washer, the main rod, the bottom hinge,

an axial ball bearing, a plastic bushing, and the spring torsion.

Axial ball bearing

Plastic bushing

Main rod

Pressure washer

Bottom hinge

Spring hinge

Securing nut

FIGURE 76

1. Slowly insert the spring hinge system. Make sure the spring arm goes through the slot on the

plastic profile.

Slot on the plastic profile

Slot

FIGURE 77

Spring arm

Publication Number: 630460243SER - 30 - © 2005, IMI Cornelius Inc.

Page 35

Visual Merchandiser Service Manual

2. After the spring hinge system has been inserted into the door frame, use a piece of masking tape to

hold it in place so it will not fall out when putting the door back into the cabinet.

FIGURE 78

NOTE: Make sure the door support bracket is in place before reinstalling the door. Refer to the

instructions at the beginning of the section “To remove the door.”

3. Insert the door onto the pin of the top hinge by pushing the door upward.

FIGURE 79

4. Insert the two screws that hold the bottom hinge in place and tighten them with a 3/8” wrench.

FIGURE 80

© 2005, IMI Cornelius Inc. - 31 - Publication Number: 630460243SER

Page 36

Visual Merchandiser Service Manual

5. The securing nut is right-hand threaded. Use a 7/16” wrench to turn the nut clockwise one and onehalf turns to loosen it. The red indentation should face away from the cabinet front before tensioning

the spring.

6. Turn the main rod clockwise 3/4 turn with the adjustable wrench using the red indentation as

reference. Tighten the nut on the hinge with the 7/16” wrench by turning it counterclockwise so the

spring hinge tension is not lost. Tighten the nut by turning the wrench counterclockwise.

Red indentation

faces away from the

cabinet before

tensioning the

spring

FIGURE 81

FIGURE 82

Increase spring tension by turning the main rod clockwise.

7. The red indentation should face the right side of the cabinet when the spring has tension.

Red indentation

faces the right side

Securing nut

Square end of main rod

FIGURE 83

Publication Number: 630460243SER - 32 - © 2005, IMI Cornelius Inc.

of the cabinet when

the spring has

tension

Page 37

Visual Merchandiser Service Manual

8. Test the tension of the door by opening it and letting it close by itself.

FIGURE 84

9. Remove the door support bracket and reattach it to the interior left side wall of the condensing unit

compartment for storage.

10. Replace the condensing unit motor cover by reversing the procedure to remove the motor cover.

© 2005, IMI Cornelius Inc. - 33 - Publication Number: 630460243SER

Page 38

Visual Merchandiser Service Manual

To assemble spring hinge components

The springe hinge system consists of a securing nut, a pressure washer, the main rod, the bottom hinge,

an axial ball bearing, a plastic bushing, and the spring torsion.

Axial ball bearing

Plastic bushing

Main rod

Pressure washer

Bottom hinge

Spring hinge

FIGURE 85

Securing nut

1. Insert the square end of the main rod into the spring-curved

arm.

2. Hook the end of the main rod that goes inside the door to

the spring as shown in the photo to ensure proper main rod

and spring hinge assembly.

FIGURE 86

FIGURE 87

Publication Number: 630460243SER - 34 - © 2005, IMI Cornelius Inc.

Page 39

3. Insert the plastic bushing as shown in the photo.

4. Then insert the axial ball bearing. The bearing consists of

two flat washers with the bearing between them.

Visual Merchandiser Service Manual

FIGURE 88

5. The hinge has a 1/4:-28 right-hand threaded hole. Screw

the main rod to the bottom hinge by turning the bottom

hinge clockwise.

6. Make sure the main rod extends 1/2” beyond the hinge.

FIGURE 89

FIGURE 90

FIGURE 91

© 2005, IMI Cornelius Inc. - 35 - Publication Number: 630460243SER

Page 40

Visual Merchandiser Service Manual

7. Insert the pressure washer before inserting the securing

nut.

8. Then insert the securing nut.

FIGURE 92

9. Use high temperature bearing grease before inserting the

spring hinge system into the door frame.

FIGURE 93

FIGURE 94

Publication Number: 630460243SER - 36 - © 2005, IMI Cornelius Inc.

Page 41

Visual Merchandiser Service Manual

10. Add grease between the plastic bushing and the spring arm and to the axial ball bearing.

FIGURE 95

The complete spring hinge system looks like this:

Axial ball bearing

Plastic bushing

Main rod

Pressure washer

Spring hinge

Bottom hinge

Securing nut

FIGURE 96

© 2005, IMI Cornelius Inc. - 37 - Publication Number: 630460243SER

Page 42

Visual Merchandiser Service Manual

11. Finish the spring hinge assembly by using a 7/16” wrench to

tighten the securing nut before installing the spring hinge

system to the door.

12. Refer to the photo at right to be sure you have the rod ends

correctly aligned with the bottom hinge before inserting it

into the door frame.

FIGURE 97

FIGURE 98

Publication Number: 630460243SER - 38 - © 2005, IMI Cornelius Inc.

Page 43

GLASS DOOR PANE REPLACEMENT

To remove the motor cover and door

Refer to the previous section for removal of the motor cover and door.

Required tools

• one scraper

• one rubber mallet

To remove the glass door pane

1. Place the door, with the gasket facing up, on two 2” X 2”

pieces of wood on a table.

Visual Merchandiser Service Manual

FIGURE 99

2. The glass pane is held in place by four pieces of plastic trip, inserted around the door frame. Use a

scraper to remove the two long plastic trims first and then the two short ones.

Removable plastic trim

FIGURE 100

IMPORTANT: First, remove the long trims, then remove the short ones. It is not necessary to

remove the gasket seal to replace the glass pane.

© 2005, IMI Cornelius Inc. - 39 - Publication Number: 630460243SER

Page 44

Visual Merchandiser Service Manual

3. Insert the scraper into the groove of the trim at the middle of one of the long pieces. Push the trim

up and towards the center of the glass as shown.

Scraper

Door gasket seal

4. Remove the trim by hand.

Removable plastic trim

Door frame

FIGURE 101

Glass pane

5. Remove the other three trims in the same way.

FIGURE 102

FIGURE 103

Publication Number: 630460243SER - 40 - © 2005, IMI Cornelius Inc.

Page 45

Visual Merchandiser Service Manual

G

G

Pl

6. Place one hand underneath the glass pane and push it up to separate it from the door frame.

lass pane

Door frame

FIGURE 104

7. Carefully place the new glass pane inside the plastic door

frame.

lass pane

Door frame

FIGURE 105

8. Beginning at the corners, insert one of the short plastic trims into the groove in the door frame.

astic trim inserted at left corner

Plastic trim inserted at right corner

FIGURE 106

© 2005, IMI Cornelius Inc. - 41 - Publication Number: 630460243SER

Page 46

Visual Merchandiser Service Manual

9. Push the trim in the middle by hand and finish inserting it using a rubber mallet as shown in the

photo.

10. Follow steps 8 and 9 to insert the remaining trims.

To install the door

Follow the instructions in the previous section to re-install the door.

FIGURE 107

REFRIGERATION SYSTEM

Compressor

The compressor is a factory-sealed unit located underneath (outside) the cooling cabinet. This pump is

activated by a motor which draws low-pressure vapor (refrigerant) from the evaporator. It then

compresses the gas and forces it into the condenser at a high pressure.

Starter relay

The starter relay is attached on one side of the compressor box. The compressor motor has two

windings: one for starting and another for running. In order to provide the necessary additional torque

when the motor is first started, the starter relay connects the additional start-up windings. After the motor

reaches its correct operating speed, the relay opens the ignition windings and the motor continues with

the operation windings.

Thermal protector

This protector is a thermo-sensible device attached to one side of the compressor’s box. In any given

situation, if the compressor overheats or if the voltage source varies drastically, the thermal protector

opens, turning off the compressor. After the compressor cools down to a normal and safe working

temperature, the thermal protector turns on the compressor.

Condenser

The condenser is located underneath (outside) the cooling cabinet in front of the compressor. It receives

hot, high-pressure refrigerant gas from the compressor and cools it down until it returns to a liquid state.

Publication Number: 630460243SER - 42 - © 2005, IMI Cornelius Inc.

Page 47

Condenser fan motor

The condenser fan motor is located underneath the cooling cabinet. It is a ventilation device which forces

the ambient air to flow over the condenser to cool down the refrigerant flowing inside it. The fan motor

works only if the compressor is on.

Visual Merchandiser Service Manual

Evaporator

The evaporator is located inside the cooling cabinet. As the gas flows at a low pressure through the

evaporator, it absorbs heat through the copper coil from inside the cabinet.

EVAPORATOR

FAN M OTOR

EVAPORATOR

ACCUMULATOR

CAPILLARY

SUCTION

COMPRESSOR

FIGURE 108

DRIER

DISCHARGE

CONDENSER

CONDENSER

FAN MOTOR

LEGEND

R-134A

FLOW

Evaporator fan motor

This device provides the required circulation of air through the cooling cabinet as well as over the surface

of the evaporator’s serpentine thermal exchange area. This fan motor runs continuously.

The evaporator and condenser serpentines have aluminum fins that help increase the surfaces for the

thermal exchange in an efficient way.

Capillary tube

It consists of several feet of tubing having a small inside diameter. It is a device used to control the

amount of refrigerant that flows into the evaporator.

Drier

The drier is located in between the condenser and the evaporator. It traps and removes moisture in the

refrigeration system while allowing oil and refrigerant to flow freely.

Accumulator

The accumulator is located in between the evaporator and the compressor. It is a storage tank which

receives refrigerant liquid from the evaporator and prevents it from flowing into the compressor.

Temperature control

The adjustable temperature control is responsible for detecting temperature changes inside the cooling

cabinet. It also starts the compressor motor whenever the cabinet rises above the desired temperature.

© 2005, IMI Cornelius Inc. - 43 - Publication Number: 630460243SER

Page 48

Visual Merchandiser Service Manual

The temperature control consists of a switch which is mechanically activated by a diaphragm. This

diaphragm is connected to a thermo-sensible bulb (located inside the cabinet) through a small diameter

tube. All three components (the diaphragm, the thermo-sensible bulb, and the small diameter tube) are

filled with refrigerant gas which reacts to temperature changes.

When the cabinet temperature rises, the refrigerant in the bulb heats up and expands, expanding the

diaphragm. The diaphragm’s expanding closes the temperature control’s interrupting device and then

starts the compressor and condenser motors.

The drop in temperature inside the cooling compartment is caused by the refrigerant’s continuous

circulation through the system. When the temperature drops, the refrigerant inside the temperature

control’s bulb contracts, allowing the diaphragm to open the interrupting device, which consequently

shuts down the compressor and condenser motors.

Cooling cabinet

This is the area where the goods are stored. It has been designed to allow for constant cold air circulation

to flow through the goods.

THE REFRIGERATION CYCLE

1. Depending on the increase in temperature inside the cooling compartment, the refrigerant gas

inside the temperature control's bulb heats up and expands, expanding the diaphragm. The

diaphragm's expansion closes the temperature control's interrupting device.

2. The temperature control's interrupting device turns on the compressor and condenser motors.

3. The compressor recirculates the refrigerant throughout the system by drawing the refrigerant gas

as low vapor pressure from the evaporator. Then it compresses the refrigerant and forces it into the

condenser.

4. The condenser, with the help of its fan motor, removes the refrigerant's heat as it flows through the

condenser. The heat is then released to the outside environment. Consequently, the decrease in

temperature will change the refrigerant from a gaseous to a liquid state.

5. The capillary tube regulates the amount of refrigerant that is discharged into the evaporator.

6. The evaporator's serpentine allows the refrigerant to absorb and remove heat from the cooling

compartment.

7. The drop in temperature inside the cooling compartment is caused by the refrigerant's continuous

circulation through the system. This gas continuously absorbs the heat that exists inside the cooling

compartment and expels it to the outside environment. When the temperature drops, the refrigerant

inside the temperature control's bulb contracts, allowing the diaphragm to open the interrupting

device, which consequently shuts down the compressor and condenser motors.

Publication Number: 630460243SER - 44 - © 2005, IMI Cornelius Inc.

Page 49

WIRING DIAGRAM 115 V/60 HZ/1 PHASE

Visual Merchandiser Service Manual

FIGURE 109

© 2005, IMI Cornelius Inc. - 45 - Publication Number: 630460243SER

Page 50

Visual Merchandiser Service Manual

TROUBLESHOOTING

Possible causes and solutions

PROBLEM POSSIBLE CAUSE SOLUTION

COMPRESSOR WILL NOT

START

No voltage in the electrical

socket.

The electrical conductor or

wires may be cut.

Defective electrical

components such as:

thermostat, relay, thermal

protector, etc.

Thermostat in “off” position. Turn the thermostat’s knob to

Compressor motor has a

winding open or shorted.

Dirty condenser; lack of air

flow.

Low voltage. Use a voltage regulator if the

Compressor is stuck. Change the compressor.

Use a voltmeter to check the

voltage.

Use an ohmmeter to check for

continuity.

Replace defective components.

its maximum position and wait

to see if the compressor starts.

Measure the ohmic resistance

of the main and auxiliary

windings using an ohmmeter.

Compare them with the correct

values.

Clean condenser and allow for

air circulation.

voltage is lower than 103 volts.

THE TEMPERATURE IS TOO

COLD

THE TEMPERATURE IS NOT

COLD ENOUGH

Thermostat knob is set at a

very cold position.

Thermostat does not

disconnect the condensing unit.

Thermostat capillary bulb is

loose or installed improperly.

Thermostat knob is set at a

very warm position.

Condenser is dirty; lack of air

flow.

The refrigerator has been

placed at an inadequate

location.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

Check the insulation of the

thermostat. If the problem

persists, change the

thermostat.

Correctly fasten the thermostat

capillary bulb.

Set the thermostat knob to a

colder position.

Clean the condenser and allow

for air circulation.

The unit must not be near

stoves, walls that are exposed

to the sun, or places that lack

sufficient air flow.

Publication Number: 630460243SER - 46 - © 2005, IMI Cornelius Inc.

Page 51

Visual Merchandiser Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

THE TEMPERATURE IS NOT

COLD ENOUGH

The refrigerator has been used

improperly.

The refrigerator has been

overcharged with the

refrigerant gas.

The refrigerant gas is leaking. Find the location where the gas

The evaporator and/or

condenser fans aren’t working.

Low voltage. Use a voltage regulator if the

ELECTRICAL SHOCKS Wires or electrical components

are in direct contact with

metallic parts.

The shelves must never be

covered with any type of plastic

or other material that will block

the circulation of cold air within

the refrigerator.

Check to see if condensation or

ice crystals have formed on the

suction line. If so, charge with

the correct amount of gas.

is leaking in order to seal it or

replace the defective

component. Change the drier.

Perform a good vacuum and

recharge the unit.

Check the electrical

connections and make sure

that the fan blade isn’t stuck.

Replace the fan motor if it

doesn’t work.

voltage is lower than 103 volts.

Check for appropriate

insulation on the connections of

each electrical component.

NOISE The refrigerator is not properly

leveled.

The condenser is not fastened

correctly. Copper tubings are in

contact with metal.

The evaporator and/or

condenser fans are loose.

Compressor has an internal

noise.

EXTREME CONDENSATION

INSIDE THE REFRIGERATOR

Thermostat knob is set at a

very cold position.

The outside environment’s

relative humidity is very high

(over 75%).

Check if the noise goes away

after you level the refrigerator.

While the compressor is

working, check to see if metal

parts are in contact with one

another and/or if the screws

that fasten the condenser are

tightened.

Check if the fans are securely

fastened. Also, check if the fan

blades are loose, broken or

crooked. If so, change the

faulty blade.

If the noise persists after all

other measures have been

taken, it may be originating

from the compressor.

Set the thermostat knob to a

warmer position and check if

the compressor stops

according to the thermostat’s

operating range.

This type of occurrence is

caused by local climatic

conditions and not by the

refrigerated unit.

© 2005, IMI Cornelius Inc. - 47 - Publication Number: 630460243SER

Page 52

Visual Merchandiser Service Manual

PROBLEM POSSIBLE CAUSE SOLUTION

EXTREME CONDENSATION

INSIDE THE REFRIGERATOR

The refrigerator door won’t shut

completely.

The refrigerator has been

placed at an inadequate

location.

NO ILLUMINATION The light switch is in “off”

position.

False contact on the light

switch, the fluorescent tube, or

the ballast.

Light switch, ballast and/or

fluorescent tube are damaged.

Check the door and/or the

magnetic gasket. Adjust the

door hinges if needed; replace

the gasket if broken.

The unit must not be near

sources that produce too much

heat.

Press the light switch to the

“on” position.

Inspect all connections.

Replace the damaged

component.

Publication Number: 630460243SER - 48 - © 2005, IMI Cornelius Inc.

Loading...

Loading...