Page 1

®

COLD SHOT

Operator’s Manual with

Installation and Service

Release Date: June 1, 2006

Publication Number: 621058201OPR

Revision Date: July 24, 2006

Revision: C

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

SERVICE MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

1-800-468-4231

Trademarks and copyrights:

Aurora, Cornelius, FlavorFusion, Hydro Boost, Optifill, Pinnacle, and Vanguard are regis-

tered trademarks of IMI Cornelius Inc.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2006, All Rights Reserved, IMI Cornelius, Inc.

Page 3

TABLE OF CONTENTS

Start up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Daily (or as required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Monthly (or as required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Brand Changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dispenser Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cleaning Exterior Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cleaning Tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts Changeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Side Panel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Thermostat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Lever Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Valve Change Over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Servicing Top Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 4

Page 5

Cold Shot Owner’s Manual

DRINK RESPONSIBLY

If you do choose to drink, please do so responsibly. Alcohol use by persons under the age of 21 is illegal

and is not condoned by IMI Cornelius.

START UP INSTRUCTIONS

1. Place unit on a sturdy countertop near a safe GFCI electrical outlet. Ensure all four feet on bottom

of unit are firmly sitting on a level surface.

IMPORTANT: Allow 4 inches of clearance on each side and rear of the unit for proper ventilation

of the refrigeration system. If proper clearance is not maintained the compressor will not be able

to keep the product cold.

CAUTION: To avoid damage to the compressor it must be in an upright position at lease 4 hours

before plugging the unit in.

2. Clean tank with soap solution. Then flush out the tank with warm tap water.

Whenever emptying the tanks completely the unit needs to be tilted forward at a 45-degree angle to

ensure all liquid is removed.

3. Pour product into the unit reservoir tanks. It will take about 1.5 liter of product to fill each tank for the

first time. Invert the last bottle vertically and let it sit upside down on the tank inlet.

4. Plug unit into GFCI outlet for use. Let the unit’s refrigeration system cool down the reservoirs for

approximately 2-3 hours. After the appropriate cool down time has lapsed, the compressor will

continue to cycle on and off to keep product cool. The product will then dispense between 5°F and

15°F.

OPERATING INSTRUCTIONS

To operate depress lever of respective brand beverage and continuous dispense will occur. As the level

in the tank decreases, the internal tank is automatically filled by evacuation of the bottle on top. When a

bottle on top of the unit is completely empty, it must be replaced immediately with a full bottle of the same

product, or performance will degrade. To maintain proper cooling, capacity, and prevent freezing it is

recommended to replace empty bottles immediately with full bottles. Use the visual slots in bottle holders

as a guide to determine volume remaining inside the top bottle.

The unit is supplied with single-handed operation faucets. This allows the bar-staff serving the cold shots

the capability of using one hand to hold the glass while simultaneously activating the lever to allow

beverage to flow. If the valve lever is raised forward and vertical it then allows free-flow of the product

from the respective faucet. This mode is used for filling large glasses, pitchers, cleaning or emptying the

tanks.

Do not tighten down on nut on valve, as this will affect the tank to valve seal.

If the dispenser fails to dispense product see troubleshooting guide.

© 2006, IMI Cornelius Inc. - 1 - Publication Number: 621058201OPR

Page 6

Cold Shot Owner’s Manual

DAILY (OR AS REQUIRED)

Clean faucets externally with clean wet towel.

Wipe down unit with damp cloth and rinse out drip tray with soap solution.

MONTHLY (OR AS REQUIRED)

Make sure when cleaning the tanks that unit is unplugged.

Clean tank with soap solution.

Vacuum condenser coils in back of unit.

BRAND CHANGEOVER

Clean and sanitize tank with proper cleaning procedure.

Follow the “Cleaning Tanks” procedure and step 2 of the “Start up” procedure for each flavor being

changed.

CLEANING INSTRUCTIONS

Soap solution – Use a mixture of mild detergent and warm (100 F) potable water.

MAINTENANCE

Sanitizing solution

sanitizing solution to this ratio will create a solution of 200 PPM.

– Use ½ ounce of household bleach in 1 gallon of potable water. Preparing the

DISPENSER MAINTENANCE

Cleaning Exterior Surfaces

IMPORTANT: Perform the following daily.

1. Remove cup rest from drip tray.

2. Wash the drip tray with soap solution. Then rinse with clean water.

3. Wash cup rest with soap solution and rinse in clean water. Install the cup rest into the drip tray.

4. Clean all exterior surfaces with soap solution and rinse in clean water.

5. Vacuum dust from grill on back of unit.

Cleaning Tanks

1. Unplug unit.

2. Remove product from tanks.

3. Rinse out tanks with soap solution.

4. Rinse out tanks with potable water.

5. Open the faucet and tilt entire unit forward at a 45-degree angle to completely drain each tank;

otherwise the residual water and soap solution will remain inside the tanks.

Publication Number: 621058201OPR - 2 - © 2006, IMI Cornelius Inc.

Page 7

Cold Shot Owner’s Manual

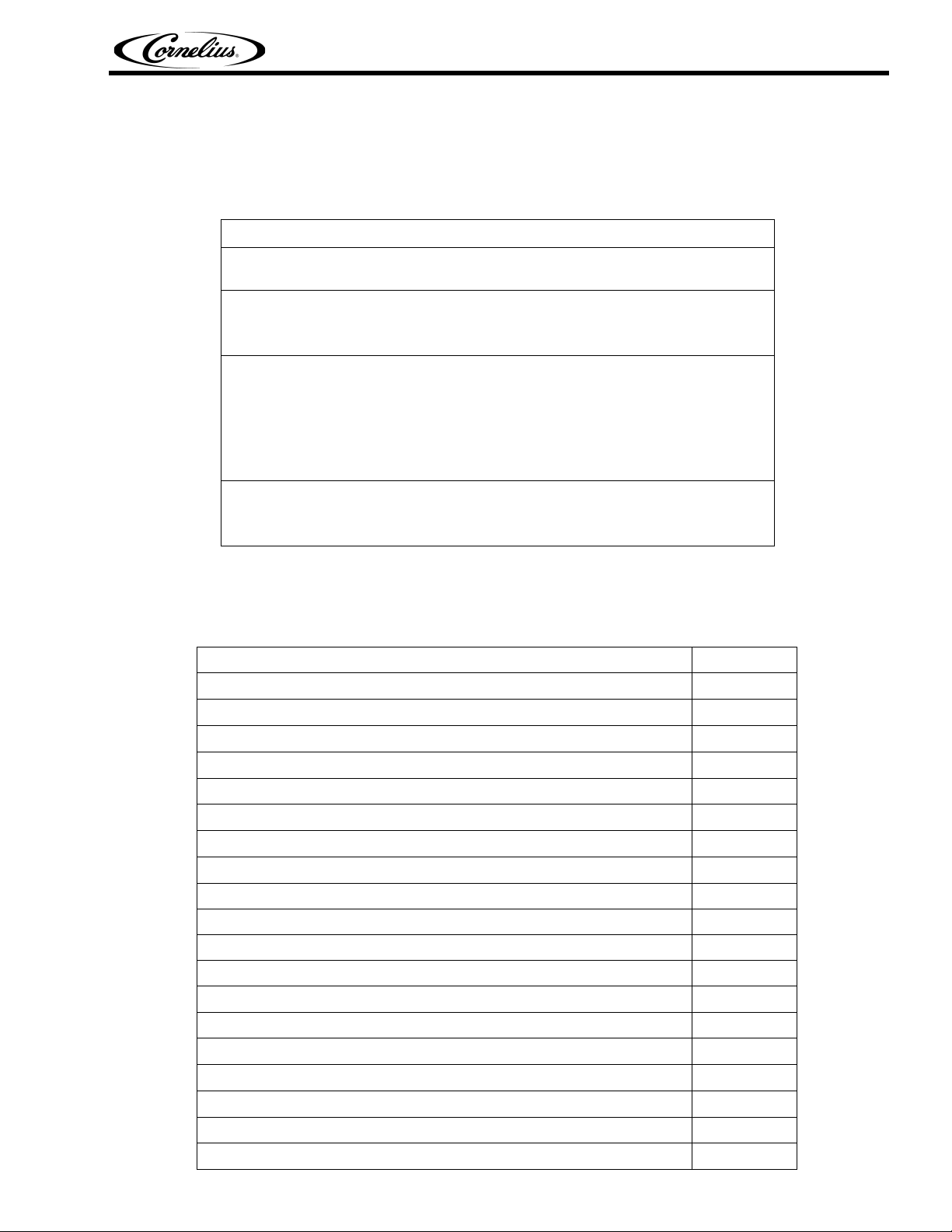

TROUBLESHOOTING

IMPORTANT: Only qualified personnel should service internal components or electrical wiring.

Should your unit fail to operate properly, check that there is power to the unit. If the unit does not

dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

Trouble Probable Cause

TRIPPED CIRCUIT BREAKER. A. Short circuit in wiring.

B. Circuit breaker overloaded.

PRODUCT DOES NOT DISPENSE. A. Out of product.

B. Clog in valve body.

C. Lever not attached.

PRODUCT WARM. A. Thermostat setting

incorrect.

B. Unit not plugged in.

C. Circuit breaker tripped.

D. Defective refrigerator deck.

E. Unit capacity exceeded.

LIGHTS DO NOT TURN ON A. No power

B. Switch turned off.

C. Lights burnt out.

SERVICE PARTS

To order service parts contact IMI BEVCORe at 1-866-275-6392 between the hours of 7:30 am and 5:00

pm (Central time) Monday - Friday (excluding holidays).

Cladding Panel RH Side 620052965

Cladding Panel LH Side 620052966

Drip Tray 620046271

Cup Rest sheet metal 620708546

Thermostat 620314421

Plug Silicone Thermowell 620519024

Valve Assembly (includes Lever) 620608787

Lever 620709345

O-Ring 310784000

Window Clear Side 620052944

Guard Top Light (qty.2 per unit) 620047511

Screw long 10-32 x 7/8 Phillips (functional) 620720802

Screw short TF 8-16 x 1/4 Phillips (decorative) 620720596

Decal pack of two large side (rectangular shape) 620920157

Decal pack of six small front brands (wedge shape) 620920156

Label “COLD SHOT” side (qty. 2 per unit) 620921118

Label caution front (triangular shape) 620921119

Label “Drink Responsibly” front drip tray 620921120

Lens clear Top Light 620518226

Lens red Top Light 620518227

© 2006, IMI Cornelius Inc. - 3 - Publication Number: 621058201OPR

Page 8

Cold Shot Owner’s Manual

BLK

WHT

RED

TOP LIGHT

BLK

WHT

RED LED

LOW VOLTAGE

BLK

BLK

WHT

WHT

YELLOW LED

WHT

BLK

RED

BLK

WHT

CONTROLLER

BLK

WHT

BLK

WHT

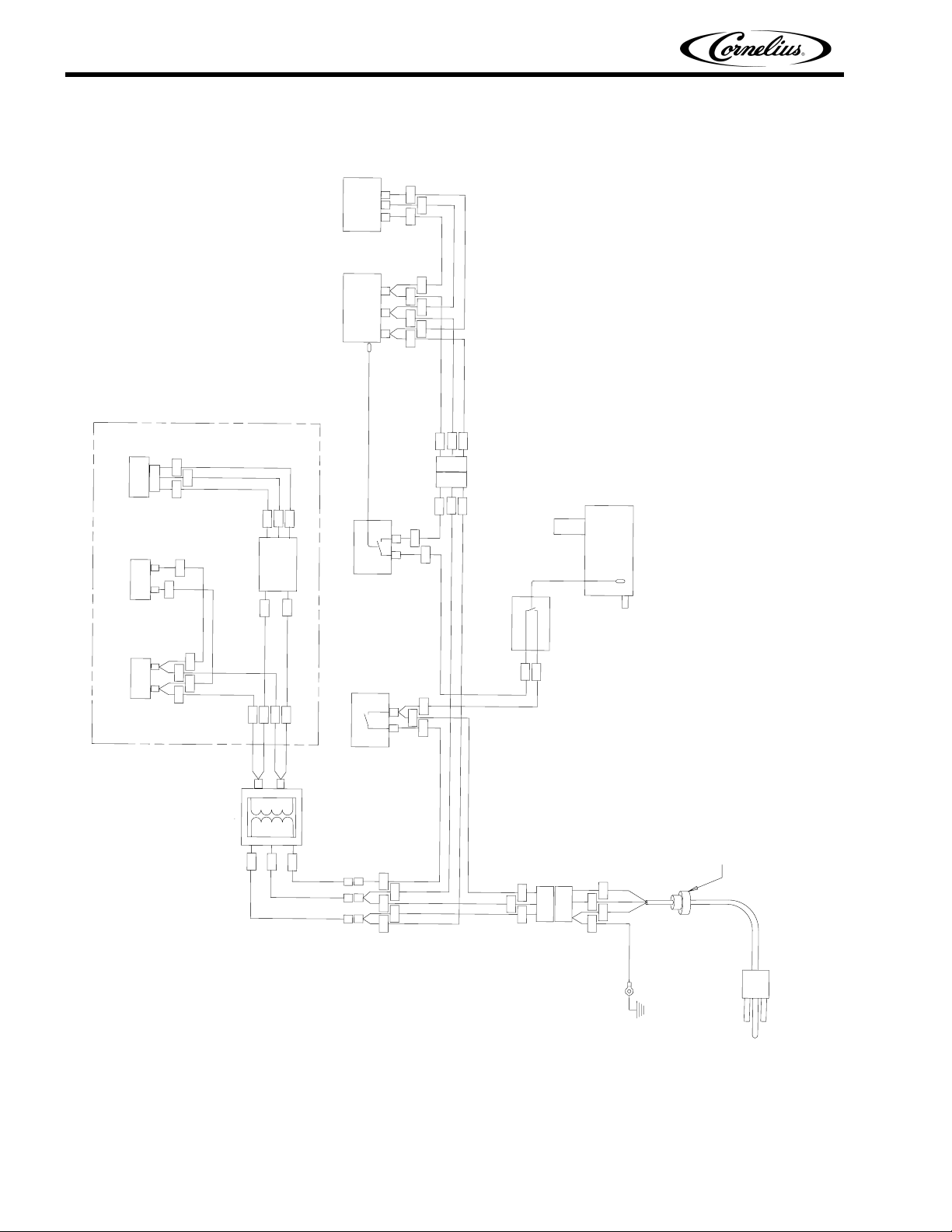

WIRING DIAGRAM

GRN

FAN

CONDENSER

COMPRESSOR

SHRINK WRAPPED

PRESSURE SWITCH

BLK

YEL

WHT

GRN

YEL

BLK

WHT

BLK

WHT

GRN

YEL

BLK

BLK/WHT

WHT

GRN

YEL

WHT

GRN

YEL

THERMOSTAT

YEL

BLK

PRODUCT

RESERVOIR

LIGHT SWITCH

120 VOLTS IN

GRN

BLK

TRANSFORMER

BLK

10 VOLTS OUT

BLK/WHT

WHT

WHT

GRN

GRN

WHT

BLK

GRN

WHT

GRN

BLK

GRN

CHASSY

GROUND

RELEIF

STRAIN

PLUG

POWER IN

120 VOLT 60 HZ

STANDARD GROUNDED

Publication Number: 621058201OPR - 4 - © 2006, IMI Cornelius Inc.

Page 9

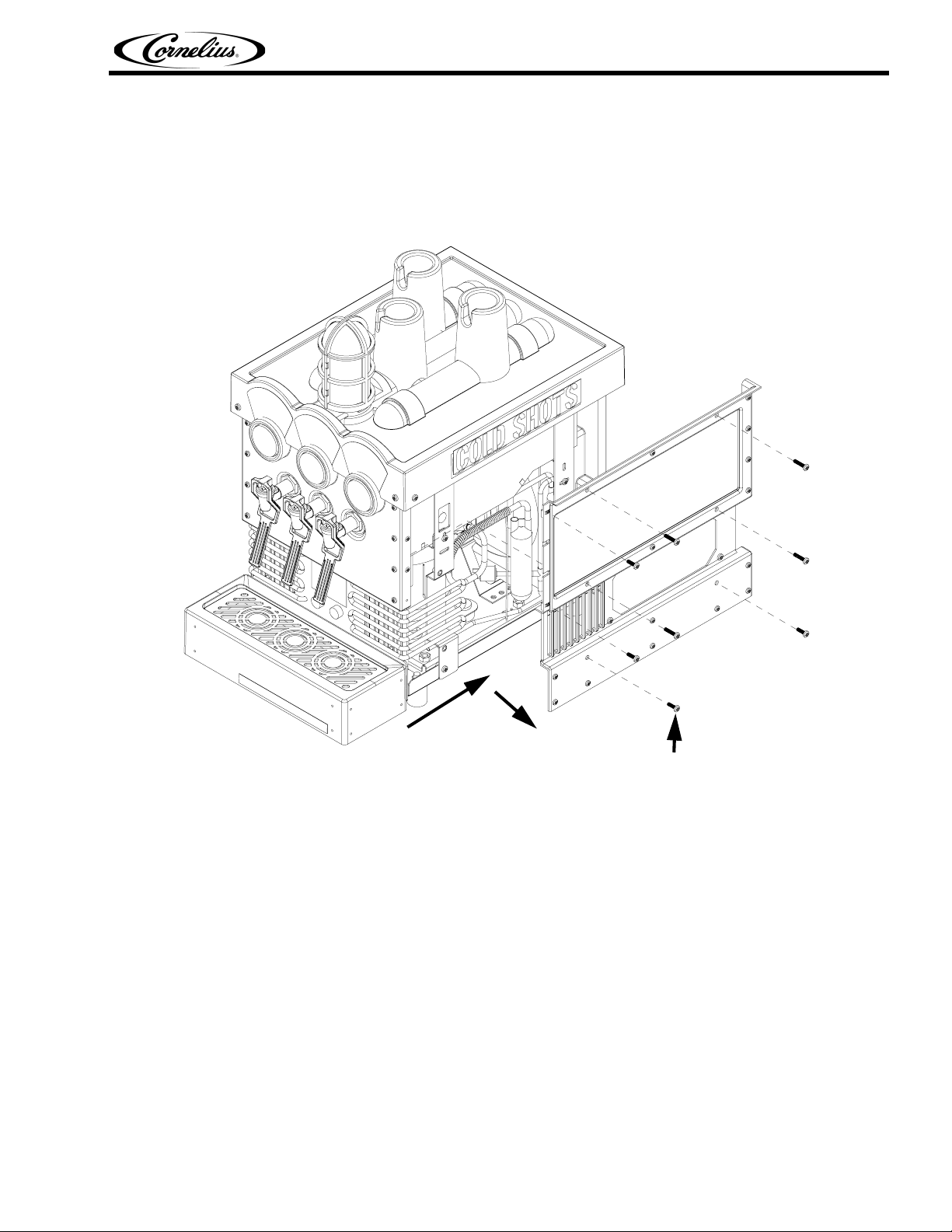

SIDE PANEL REMOVAL

1. Remove the screws on the side panel.

2. Slide the panel back and then pull it out to remove.

Cold Shot Owner’s Manual

PARTS CHANGEOUT

Remove Screws

© 2006, IMI Cornelius Inc. - 5 - Publication Number: 621058201OPR

Page 10

Cold Shot Owner’s Manual

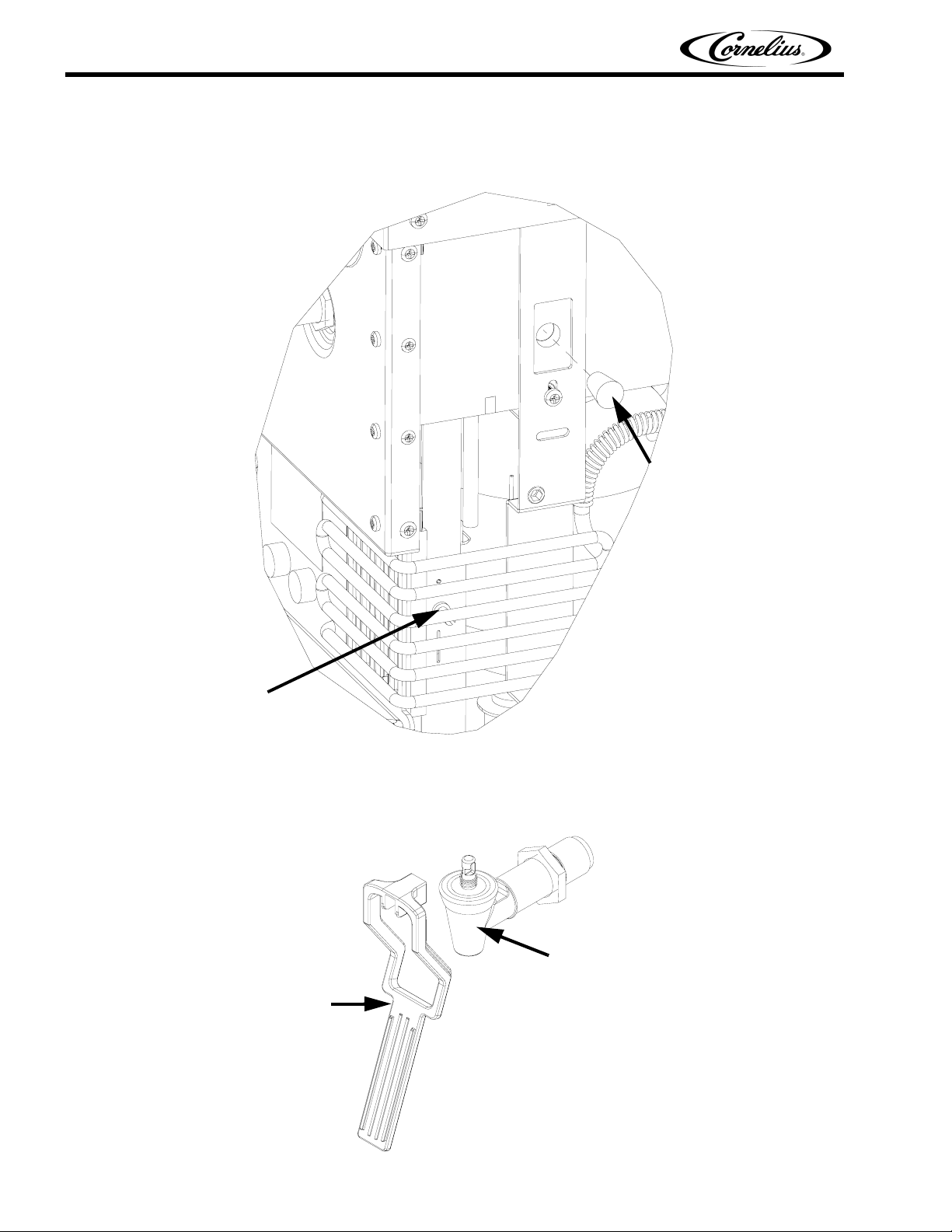

THERMOSTAT REPLACEMENT

1. Remove silicone plug.

2. Remove nut and then remove the thermostat.

Silicone Plug

Nut and Thermostat

LEVER REPLACEMENT

1. Push a blunt object up into the faucet opening.

2. Pull the lever forward to remove.

Faucet

Lever

Publication Number: 621058201OPR - 6 - © 2006, IMI Cornelius Inc.

Page 11

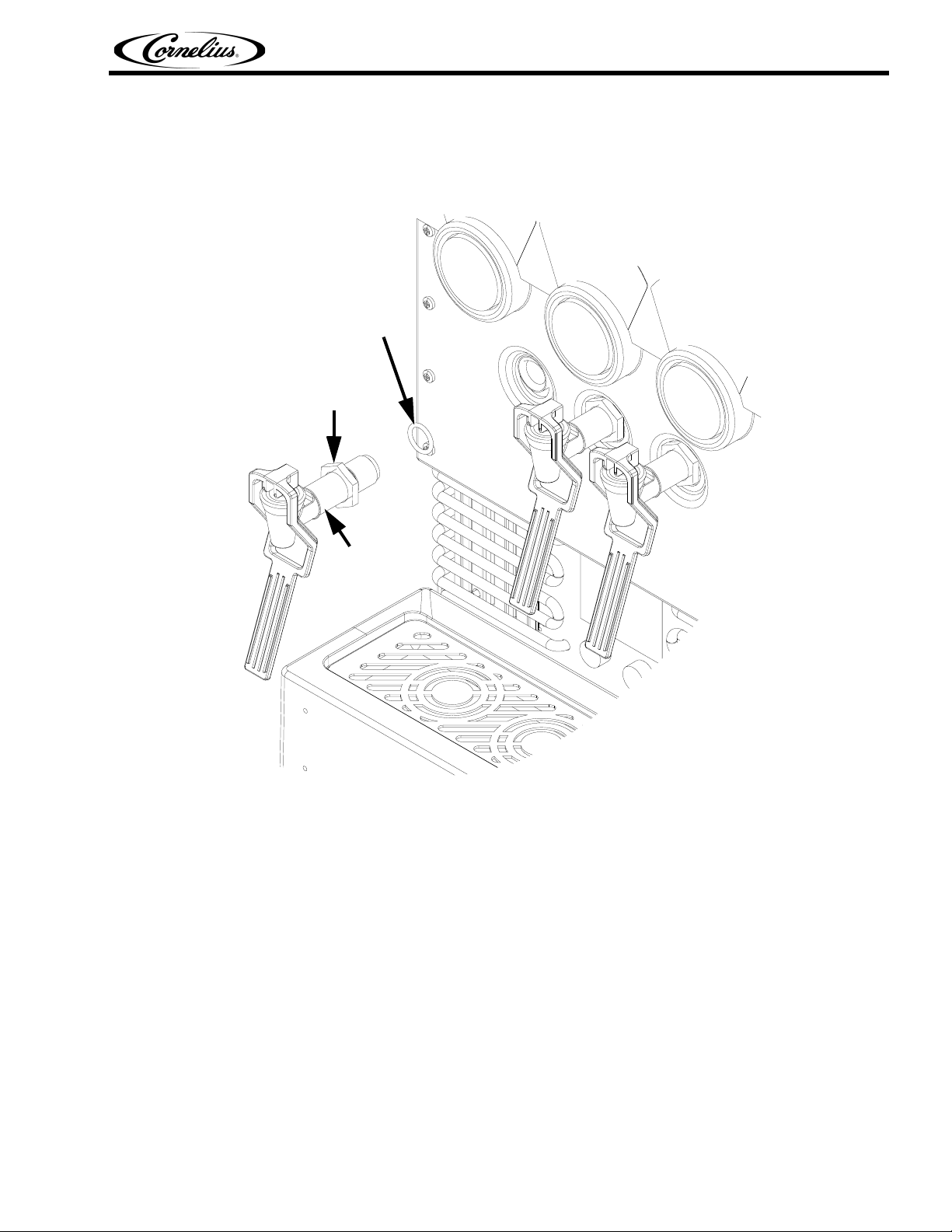

VALVE CHANGE OVER

1. Unscrew the entire valve body.

2. Replace the o-ring and screw the valve back in place.

3. Tighten the nut onto the o-ring.

Nut

Cold Shot Owner’s Manual

O-Ring

Valve Body

© 2006, IMI Cornelius Inc. - 7 - Publication Number: 621058201OPR

Page 12

Cold Shot Owner’s Manual

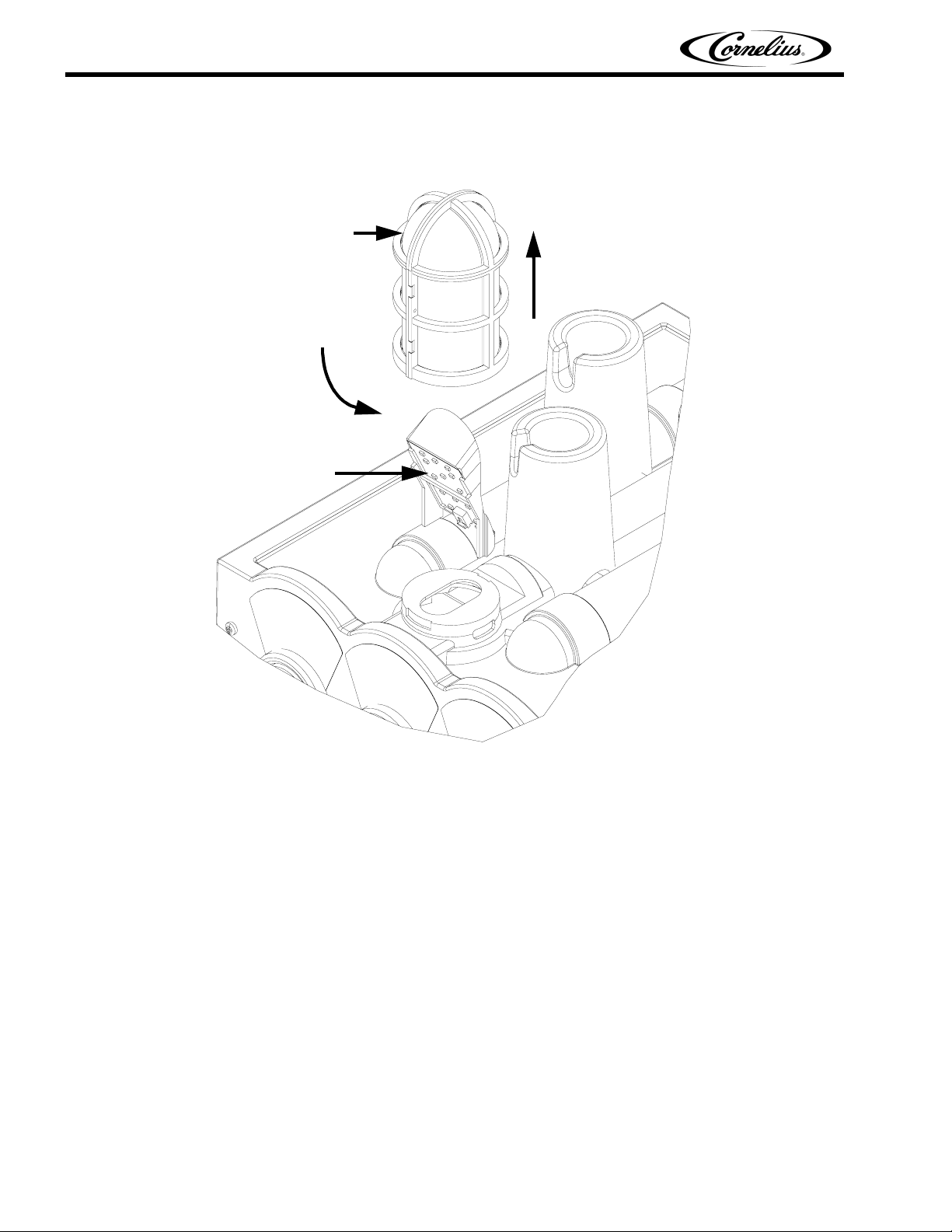

SERVICING TOP LIGHT

1. Slightly twist and pull up on the top light.

2. Unplug the harness and replace the LED board.

LED Board

Top Light

Publication Number: 621058201OPR - 8 - © 2006, IMI Cornelius Inc.

Page 13

Page 14

IMI Cornelius Inc.

www.cornelius.com

Page 15

®

DISPENSADOR DE TRAGOS FRÍOS

COLD SHOT

Manual del Operador con Instrucciones

de Instalación y Servicio

Fecha de edición: 1 de junio de 2006

Número de publicación: 621058201OPR

Fecha de revisión: 24 de julio de 2006

Revisión: C

Para encontrar las publicaciones que necesite, visite el sitio web de IMI Cornelius,

www.cornelius.com

Page 16

MANUAL DE SERVICIO

Los productos, la información técnica y las instrucciones que contiene este manual están

sujetos a modificación sin previo aviso. La finalidad de estas instrucciones no es tratar

todos los detalles o variantes del equipo, como tampoco abarcar todas las contingencias

posibles que pueden surgir en la instalación, operación o mantenimiento del mismo. Este

manual supone que las personas que trabajan en el equipo han recibido capacitación y

poseen las destrezas necesarias para trabajar con equipos eléctricos, neumáticos,

mecánicos y de plomería. También se supone que se toman las precauciones de

seguridad apropiadas y que se cumplen todos los requisitos de seguridad y construcción

locales, además de lo indicado en este manual.

Para averiguar acerca de las revisiones actualizadas de ésta y otra documentación, así

como para solicitar asistencia relacionada con cualquier producto de Cornelius, póngase

en contacto con:

www.cornelius.com

1-800-468-4231

Marcas comerciales y derechos de copyright:

Aurora, Cornelius, FlavorFusion, Hydro Boost, Optifill, Pinnacle y Vanguard son marcas

registradas de IMI Cornelius Inc.

Este documento contiene información amparada por derechos de propiedad intelectual

y no se puede reproducir de ninguna manera sin autorización de Cornelius.

Impreso en EE.UU.

Copyright © 2006, Todos los derechos reservados, IMI Cornelius, Inc.

Page 17

ÍNDICE

Instrucciones de puesta en funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Instrucciones de operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Diario (o según se requiera) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mensual (o según se requiera) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Cambio de marcas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instrucciones de limpieza . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mantenimiento del dispensador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Limpieza de las superficies exteriores . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Limpieza de los tanques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Solución de problemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Piezas de repuesto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Diagrama de cableado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cambio de piezas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Desmontaje del panel lateral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Reemplazo del termostato . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Reemplazo de la palanca . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cambio del retén anular de la válvula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Servicio de la luz superior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 18

Page 19

Manual del Propietario de Cold Shot

BEBA RESPONSABLEMENTE

Si le gusta beber, hágalo responsablemente. El consumo de alcohol por menores de 21 años es ilegal e

IMI Cornelius no lo consiente.

INSTRUCCIONES DE PUESTA

EN FUNCIONAMIENTO

1. Coloque la unidad sobre una mesa sólida, cerca de un tomacorriente seguro provisto de un

disyuntor diferencial por falla de tierra (GFCI). Asegúrese de que las cuatro patas de la parte

inferior de la unidad estén firmemente apoyadas sobre una superficie nivelada.

IMPORTANTE: Deje 10 cm (4 pulg.) de espacio libre de cada lado y en la parte trasera de

la unidad, para la correcta ventilación del sistema de refrigeración. Si no se mantiene una

separación apropiada, el compresor no puede mantener frío el producto.

PRECAUCIÓN: Para evitar daños al compresor, debe estar en posición vertical al menos 4 horas

antes de enchufar la unidad.

2. Limpie el tanque con agua jabonosa. Luego, enjuague el tanque con agua corriente tibia.

Cada vez que se vacíen completamente los tanques, es necesario inclinar la unidad 45 grados

hacia adelante, para asegurarse de que salga todo el líquido.

3. Vierta el producto en los tanques de depósito de la unidad. Se necesita alrededor de 1,5 litros

del producto para llenar cada tanque por primera vez. Invierta verticalmente la última botella

y apóyela boca abajo sobre la entrada del tanque.

4. Enchufe la unidad en el tomacorriente con disyuntor para usarla. Permita que el sistema de

refrigeración de la unidad enfríe los depósitos durante 2 ó 3 horas aproximadamente. Después

de transcurrir el tiempo de enfriamiento apropiado, el compresor arranca y para cíclicamente para

mantener fresco el producto. La temperatura a la que se sirve el producto es entre -15 y 0°C

(5 y 15°F).

INSTRUCCIONES DE OPERACIÓN

Para operar la unidad, oprima la palanca de la bebida de la marca pertinente y el líquido se dispensará

continuamente. Cuando disminuye el nivel del tanque, el tanque interno se rellena automáticamente

desde la botella colocada en la parte superior. Cuando dicha botella esté completamente vacía,

se debe reemplazar inmediatamente por una llena del mismo producto. En caso contrario, se perjudicará

el funcionamiento. Para mantener un enfriamiento y una capacidad adecuados, así como para prevenir

el congelamiento, se recomienda reemplazar inmediatamente las botellas vacías por botellas llenas. Use

las ranuras visuales de los soportes de botellas como guía para determinar el volumen remanente en la

botella de la parte superior.

La unidad cuenta con grifos para operación con una mano. Esto permite al personal de la barra que sirve

los tragos fríos usar una mano para sostener el vaso mientras activa simultáneamente la palanca para

permitir la salida de la bebida. Si la palanca de la válvula se levanta hacia adelante y verticalmente,

permite el libre flujo del producto que sale por el grifo respectivo. Este modo se usa para llenar vasos

grandes y jarras, así como para limpiar o vaciar los tanques.

No apriete hacia abajo la tuerca de la válvula porque se afectará el sello entre el tanque y la válvula.

Si el dispensador no entrega el producto, consulte la guía de solución de problemas.

© 2006, IMI Cornelius Inc. - 1 - Número de publicación: 621058201OPR

Page 20

Manual del Propietario de Cold Shot

MANTENIMIENTO

DIARIO (O SEGÚN SE REQUIERA)

Limpie externamente los grifos con una toalla mojada limpia.

Friegue la unidad con un paño húmedo y enjuague la bandeja de goteo con agua jabonosa.

MENSUAL (O SEGÚN SE REQUIERA)

Cuando limpie los tanques, asegúrese de que la unidad esté desenchufada.

Limpie el tanque con agua jabonosa.

Aspire los serpentines del condensador de la parte trasera de la unidad.

CAMBIO DE MARCAS

Limpie y desinfecte el tanque siguiendo el procedimiento de limpieza correcto.

Cumpla el procedimiento “Limpieza de los tanques" y el paso 2 del procedimiento "Puesta en

funcionamiento" para cada sabor que cambie.

INSTRUCCIONES DE LIMPIEZA

Agua jabonosa – Use una mezcla de detergente suave y agua potable tibia (a 38°C [100F°]).

Solución desinfectante

de agua potable. Si se utiliza esta proporción, la concentración de la solución desinfectante resultante

es 200 PPM.

– Use 15 ml (½ onza) de lejía de uso doméstico en 3,800 litros (1 galón)

MANTENIMIENTO DEL DISPENSADOR

Limpieza de las superficies exteriores

IMPORTANTE: Realice las siguientes tareas diariamente.

1. Retire el apoyavasos de la bandeja de goteo.

2. Lave la bandeja de goteo con agua jabonosa. Enjuague con agua limpia y deje que las soluciones

corran por el drenaje.

3. Lave el apoyavasos con agua jabonosa y enjuáguelo con agua limpia. Instale el apoyavasos

en la bandeja de goteo.

4. Limpie todas las superficies exteriores con agua jabonosa y enjuáguelas con agua limpia.

5. Aspire el polvo de la rejilla de la parte trasera de la unidad.

Limpieza de los tanques

1. Desenchufe la unidad.

2. Retire el producto de los tanques.

3. Enjuague los tanques con agua jabonosa.

4. Enjuáguelos con agua potable.

5. Abra el grifo e incline la unidad completa 45 grados hacia adelante para drenar completamente

cada tanque. De lo contrario, quedarán en los tanques residuos de agua jabonosa.

Número de publicación: 621058201OPR - 2 - © 2006, IMI Cornelius Inc.

Page 21

Manual del Propietario de Cold Shot

SOLUCIÓN DE PROBLEMAS

IMPORTANTE: El servicio de los componentes internos o del cableado eléctrico sólo puede

ser realizado por personal calificado.

En caso de que su unidad no funcione correctamente, verifique que esté alimentada. Si la unidad

no dispensa el producto, verifique la tabla siguiente según los síntomas apropiados, como ayuda para

la localización del defecto.

Problema Causa probable

SE DISPARÓ EL DISYUNTOR. A. Cortocircuito en el cableado.

B. Disyuntor sobrecargado.

EL DISPENSADOR NO ENTREGA EL PRODUCTO. A. Falta de producto.

B. Obstrucción en el cuerpo de válvula.

C. Palanca sin acoplar.

EL PRODUCTO ESTÁ TIBIO. A. Ajuste incorrecto del termostato.

B. Unidad sin enchufar.

C. Disyuntor disparado.

D. Bandeja refrigeradora defectuosa.

E. Capacidad de la unidad excedida.

LAS LUCES NO SE ENCIENDEN. A. Falta alimentación.

B. Interruptor en posición de apagado.

C. Luces quemadas.

PIEZAS DE REPUESTO

Para solicitar repuestos, comuníquese con IMI BEVCORe al 1-866-275-6392 de lunes a viernes

(excluidos feriados) de 7:30 a.m. a 5:00 p.m. (hora del Centro de EE.UU.)

Panel de revestimiento derecho 620052965

Panel de revestimiento izquierdo 620052966

Bandeja de goteo 620046271

Apoyavasos de chapa metálica 620708546

Termostato 620314421

Tapón de silicona de termopozo 620519024

Conjunto de válvula (incluye palanca) 620608787

Palanca 620709345

Retén anular 310784000

Ventana lateral transparente 620052944

Luz de la defensa superior (cant.2 por unidad) 620047511

Tornillo, largo 10-32 x 7/8 Phillips (funcional) 620720802

Tornillo corto TF 8-16 x 1/4 Phillips (decorativo) 620720596

Paquete de dos calcomanías laterales grandes (rectangulares) 620920157

Paquete de seis calcomanías delanteras pequeñas con marcas (forma de cuña) 620920156

Etiqueta “COLD SHOT” lateral (cant. 2 por unidad) 620921118

Etiqueta de precaución delantera (triangular) 620921119

Etiqueta “Drink Responsibly” (Beba responsablemente) delantera para la bandeja de goteo 620921120

Cristal transparente para la luz superior 620518226

Cristal rojo para la luz superior 620518227

.

© 2006, IMI Cornelius Inc. - 3 - Número de publicación: 621058201OPR

Page 22

Manual del Propietario de Cold Shot

DIAGRAMA DE CABLEADO

NGO

BCO

RJO

LUZ SUPERIOR

LED ROJO

BAJA TENSIÓN

LED AMARILLO

BCO

NGO

NGO

BCO

NGO

BCO

BCO

NGO

RJO

NGO

BCO

CONTROLADOR

NGO

BCO

NGO

BCO

CONDENSADOR

VENTILADOR DEL

COMPRESOR

TERMOCONTRAÍBLE

INTERRUPTOR DE PRESIÓN

VDE

NGO

AMA

BCO

VDE

AMA

NGO

BCO

NGO

BCO

VDE

AMA

NGO

NGO/BCO

AMA

AMA

BCO

BCO

VDE

VDE

TERMOSTATO

AMA

NGO

PRODUCTO

DEPÓSITO DE

INTERRUPTOR DE LUZ

SAL 10 V

ENT 120 V

VDE

NGO

TRANSFORMADOR

NGO

NGO/BCO

BCO

BCO

VDE

VDE

BCO

NGO

VDE

BCO

VDE

NGO

VDE

CONTRA

TIRONES

PROTECTOR

120V60HZ

TIERRA DEL

CHASIS

ENCHUFE DE ENTRADA DE

ALIMENTACIÓN CON CONEXIÓN

A TIERRA ESTÁNDAR

Número de publicación: 621058201OPR - 4 - © 2006, IMI Cornelius Inc.

Page 23

CAMBIO DE PIEZAS

DESMONTAJE DEL PANEL LATERAL

1. Desmonte los tornillos del panel lateral.

2. Deslice el panel hacia atrás y luego extráigalo para desmontarlo.

Manual del Propietario de Cold Shot

Desmonte los tornillos

© 2006, IMI Cornelius Inc. - 5 - Número de publicación: 621058201OPR

Page 24

Manual del Propietario de Cold Shot

REEMPLAZO DEL TERMOSTATO

1. Retire el tapón de silicona.

2. Desmonte la tuerca y luego retire el termostato.

Tapón de

silicona

Tuerca y termostato

REEMPLAZO DE LA PALANCA

1. Coloque un objeto romo dentro de la abertura del grifo.

2. Tire de la palanca hacia adelante para desmontarla.

Palanca

Grifo

Número de publicación: 621058201OPR - 6 - © 2006, IMI Cornelius Inc.

Page 25

Manual del Propietario de Cold Shot

CAMBIO DE RETÉN ANULAR DE LA VÁLVULA

1. Desenrosque el cuerpo de válvula completo.

2. Reemplace el retén anular y enrosque la válvula nuevamente en su sitio.

3. Apriete la tuerca en el retén anular.

Retén anular

Tuerca

Cuerpo de

válvula

© 2006, IMI Cornelius Inc. - 7 - Número de publicación: 621058201OPR

Page 26

Manual del Propietario de Cold Shot

SERVICIO DE LA LUZ SUPERIOR

1. Gire ligeramente y tire de la luz superior hacia arriba.

2. Desenchufe el arnés y reemplace la tarjeta de LED.

Luz superior

Tarjeta de LED

Número de publicación: 621058201OPR - 8 - © 2006, IMI Cornelius Inc.

Page 27

Page 28

IMI Cornelius Inc.

www.cornelius.com

Page 29

®

COLD SHOT

Mode d’emploi,

installation et entretien

Date de parution : 1 juin 2006

Numéro de publication : 621058201OPR

Date de révision : 24 juillet 2006

Révision : C.

Pour de la documentation supplémentaire, veuillez consulter le site Internet

de IMI Cornelius sur www.cornelius.com

.

Page 30

MANUEL D’ENTRETIEN

Les produits, les informations techniques et les instructions contenus dans ce manuel

peuvent être modifiés sans préavis. Ces instructions ne concernent pas les détails ou les

variations pouvant apparaître sur les équipements. Elles ne traitent pas non plus de tous

les imprévus pouvant survenir lors de l'installation, du fonctionnement ou de la

maintenance de cet équipement. Ce manuel suppose que les personnes qui travaillent sur

cet équipement ont été formées et présentent les compétences requises pour la

manipulation d'équipement mécanique, pneumatique, électrique et la plomberie. Outre les

informations contenues dans ce manuel, il est présumé que les précautions appropriées

en matière de sécurité ont été prises et que toutes les exigences locales de construction

et de sécurité sont satisfaites.

Pour se renseigner sur les nouvelles versions de ce même document ou pour obtenir une

autre documentation ou de l'aide concernant un produit Cornelius, veuillez contacter :

www.cornelius.com

1-800-468-4231

Marques de commerce et copyright :

Aurora, Cornelius, FlavorFusion, Hydro Boost, Optifill, Pinnacle et Vanguard sont des

marques déposées de IMI Cornelius Inc.

Ce document contient des informations confidentielles et ne doit pas

être reproduit sans l’autorisation de Cornelius.

Imprimé aux États-Unis.

© 2006, tous droits réservés, IMI Cornelius, Inc.

Page 31

TABLES DES MATIÈRES

Instructions de démarrage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Mode d’emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Quotidienne (ou lorsque cela est nécessaire) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Mensuelle (ou lorsque cela est nécessaire) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Changement de marque de boisson . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instructions de nettoyage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Maintenance du distributeur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nettoyage des surfaces extérieures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nettoyage des réservoirs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Schéma de câblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Remplacement des pièces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Enlèvement des panneaux latéraux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Remplacement du thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Remplacement du levier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changement de la valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Remplacement du voyant supérieur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 32

Page 33

Mode d’emploi du Cold Shot

BUVEZ AVEC MODÉRATION

Vous avez choisi de boire, faites-le de façon responsable. Il est illégal de servir de l’alcool aux personnes de moins

de 18 ans et IMI Cornelius cautionne cette loi.

INSTRUCTIONS DE DÉMARRAGE

1. Placez l’unité sur un plan de travail solide, à proximité d’une prise électrique munie d’un disjoncteur de fuite à

la terre. Assurez-vous que les quatre pieds de l’unité touchent uniformément la surface.

IMPORTANT : laissez 4 pouces (10 cm) d’espace libre de chaque côté et à l'arrière de l'unité pour

assurer la ventilation du circuit de refroidissement. Si cet espace libre n’est pas assuré, le

compresseur ne pourra pas maintenir la température fraîche du produit.

ATTENTION : pour ne pas endommager le compresseur, il doit être en position verticale et à

l'endroit pendant au moins 4 heures avant de mettre l'unité sous tension.

2. Nettoyez l’unité à l'eau savonneuse. Rincez le réservoir à l'eau chaude du robinet.

Pour vider complètement les réservoirs et s’assurer d’enlever tout le liquide, l’unité doit être inclinée à 45°.

3. Versez le produit dans les réservoirs de l’unité. La première fois, il vous faudra environ 1,5 litres de produit pour

remplir entièrement chaque réservoir. Placez et laissez la dernière bouteille à l’envers sur l’orifice de

remplissage du réservoir.

4. Branchez l’unité sur une prise munie d’un disjoncteur de fuite à la terre. Laissez le circuit de refroidissement de

l’unité refroidir les réservoirs pendant environ 2 à 3 heures. Une fois cette période de refroidissement passée,

le compresseur est programmé cycliquement pour maintenir

le produit frais. Le produit sera ensuite servi à une température comprise entre 5°F et 15°F.

(-15 et -9 °C).

MODE D’EMPLOI

Pour faire fonctionner l’unité et distribuer de façon continue la boisson, appuyez sur le levier correspondant à la

boisson. Lorsque le niveau de liquide dans le réservoir baisse, le réservoir interne se remplit automatiquement en

vidant la bouteille placée sur le réservoir. Une fois la bouteille sur l’unité complètement vide, elle doit être

immédiatement remplacée par une bouteille pleine du même produit.. L'appareil risque sinon de ne pas offrir les

mêmes performances. Pour assurer un refroidissement et une capacité optimale, ainsi que pour éviter le gel, il est

recommandé de remplacer immédiatement les bouteilles vides par des nouvelles. Utilisez les fentes dans les

supports à bouteille pour déterminer visuellement le volume restant dans la bouteille.

L’unité est fournie avec des robinets à fonctionnement à une main. Cela permet au personnel du bar utilisant le Cold

Shot de tenir le verre d’une main tout en activant le levier de l'autre pour verser la boisson. Si le levier est soulevé

vers l’avant et à la verticale, le produit coule alors librement du robinet correspondant. Ce mode est utilisé pour

remplir les grands verres, les carafes ou pour nettoyer et vider les réservoirs.

Ne pas serrer l'écrou sur la valve, cela affecte le joint entre le réservoir et la valve.

Si le distributeur ne laisse pas couler de produit, reportez-vous à la section Dépannage.

© 2006, IMI Cornelius Inc. - 1 - Publication Numéro : 621058201OPR

Page 34

Mode d’emploi du Cold Shot

MAINTENANCE

QUOTIDIENNE (OU LORSQUE CELA EST NÉCESSAIRE)

Nettoyez l’extérieur des robinets avec une serviette propre humide.

Essuyez l’unité avec un chiffon humide et rincez le plateau d’égouttage avec une solution savonneuse.

MENSUELLE (OU LORSQUE CELA EST NÉCESSAIRE)

Assurez-vous d’avoir débranché l’unité lorsque vous nettoyez les réservoirs.

Nettoyez l’unité à l'eau savonneuse.

Dépoussiérez le serpentin réfrigérant à l’arrière de l’unité.

CHANGEMENT DE MARQUE DE BOISSON

Nettoyez et désinfectez le réservoir en suivant la procédure de nettoyage appropriée.

Suivez les procédures « Nettoyage des réservoirs » et l’étape 2 de la procédure de « Démarrage »,

à chaque changement de saveur.

INSTRUCTIONS DE NETTOYAGE

Solution savonneuse – Utilisez un mélange de détergent doux et d’eau potable chaude (100 °F

soit 38 °C).

Solution de désinfection

d’une solution de désinfection à ce taux correspond à une solution de 200 PPM.

– Utilisez ½ once (environ 14 ml) de javel dans 1 gallon (4 l) d’eau potable. La préparation

MAINTENANCE DU DISTRIBUTEUR

Nettoyage des surfaces extérieures

IMPORTANT : effectuez cette procédure tous les jours :

1. Déposez le support du plateau d’égouttage

2. Lavez le plateau d’égouttage avec une solution savonneuse. Placez le support dans le plateau d’égouttage.

3. Lavez toutes les surfaces extérieures avec une solution savonneuse et rincez à l’eau claire. Dépoussiérez

la grille à l’arrière de l’unité.

4. Lavez toutes les surfaces extérieures avec une solution savonneuse et rincez à l’eau claire.

5. Dépoussiérez la grille à l’arrière de l’unité.

Nettoyage des réservoirs.

1. Débranchez l’unité

2. Enlevez les produits des réservoirs.

3. Rincez les réservoirs avec une solution savonneuse.

4. Rincez les réservoirs avec de l’eau potable.

5. Ouvrez le robinet et inclinez l’unité à 45 degrés pour vidanger complètement chaque réservoir et éviter qu’il ne

reste de l’eau et de la solution savonneuse dans les réservoirs.

Publication Numéro : 621058201OPR - 2 - © 2006, IMI Cornelius Inc.

Page 35

Mode d’emploi du Cold Shot

DÉPANNAGE

IMPORTANT : Seul un personnel qualifié est autorisé à intervenir sur les composants internes ou

le câblage électrique.

Si votre unité ne fonctionne pas correctement, commencez par vérifier qu’elle est sous tension. Si l’unité ne distribue

pas de boisson, consultez le tableau suivant pour trouver les symptômes correspondants et localiser le défaut.

Panne Cause probable

LE DISJONCTEUR A SAUTÉ A. Court-circuit dans le câblage

B. Disjoncteur surchargé

LE PRODUIT N’EST PAS DISTRIBUÉ A. Il n’y a plus de produit.

B. La valve est obturée.

C. Le levier est mal fixé.

LE PRODUIT EST CHAUD A. Mauvais réglage du thermostat.

B. L’unité n’est pas sous tension.

C. Le disjoncteur a sauté.

D. Le plateau refroidissant est

E. Capacité de l’unité dépassée

LES VOYANTS NE S'ALLUMENT PAS A. Pas d’alimentation électrique

B. Interrupteur en position Arrêt

C. Les ampoules ont grillé.

défectueux.

PIÈCES DE RECHANGE

Pour commander des pièces de rechange, veuillez téléphoner à IMI BEVCORe au 1-866-275-6392 entre

7h30 et 17h00 (heure des États du centre des États-unis) du lundi au vendredi (hors vacances).

Panneau de gainage, côté droit, 620052965

Panneau de gainage, côté gauche, 620052966

Plateau d’égouttage 620046271

Support métallique 620708546

Thermostat 620314421

Puit thermométrique, bouchon en silicone 620519024

Ensemble valve (avec levier) 620608787

Levier 620709345

Joint torique 310784000

Paroi latérale transparente 620052944

Voyant supérieur de guidage (2 par unité) 620047511

Vis longue 10-32 x 7/8 Phillips (fonctionnelle) 620720802

Vis courte TF 8-16 x 1/4 Phillips (décorative) 620720596

Ensemble de 2 grandes décalques pour les côtés (rectangulaires) 620920157

Ensemble de 6 petites décalques pour l’avant avec les marques (en biseau) 620920156

Étiquette « COLD SHOT » pour le côté (2 par unité) 620921118

Étiquette Attention pour l’avant (en forme de triangle) 620921119

Étiquette « Buvez avec modération », à l’avant du plateau d’égouttage 620921120

Lentille claire Voyant supérieur 620518226

Lentille rouge Voyant supérieur 620518227

© 2006, IMI Cornelius Inc. - 3 - Publication Numéro : 621058201OPR

Page 36

Mode d’emploi du Cold Shot

NOIR

BLANC

ROUGE

VOYANT

SUPÉRIEUR

NOIR

DEL ROUGE

BASSE TENSION

DEL JAUNE

BLANC

NOIR

BLANC

CONTRÔLEUR

NOIR

BLANC

SCHÉMA DE CÂBLAGE

VERT

BLANC

NOIR

CONDENSATEUR

VENTILATEUR DU

NOIR

JAUNE

BLANC

BLANC

VERT

VERT

COMPRESSEUR

VERT

BLANC

JAUNE

VERT

BLANC

JAUNE

JAUNE

NOIR

NOIR

NOIR/BLANC

JAUNE

THERMOSTAT

YEL

NOIR

BLANC

ROUGE

BLANC

BLANC

NOIR

BLANC

NOIR

NOIR

NOIR

INTERRUPTEUR PRESSION

EMBALLÉ SOUS FILM PLASTIQUE RÉTRACTABLE

PRODUIT

RÉSERVOIR

INTERRUPTEUR VOYANT

SORTIE 10 VOLTS

VERT

ENTREE 120 VOLTS

NOIR

TRANSFORMATEUR

NOIR

NOIR/BLANC

BLANC

BLANC

VERT

VERT

BLANC

NOIR

VERT

BLANC

VERT

NOIR

VERT

TERRE

TENSION

RÉDUCTEUR DE

120 VOLTS 60 HZ

MISE À LA TERRE

STANDARD PRISE

ALIMENTATION ÉLECTRIQUE

Publication Numéro : 621058201OPR - 4 - © 2006, IMI Cornelius Inc.

Page 37

REMPLACEMENT DES PIÈCES

ENLÈVEMENT DU PANNEAU LATÉRAL

1. Enlevez les vis du panneau latéral.

2. Faites glisser le panneau vers l’arrière puis tirez le hors de l’unité.

Mode d’emploi du Cold Shot

Enlevez les vis.

© 2006, IMI Cornelius Inc. - 5 - Publication Numéro : 621058201OPR

Page 38

Mode d’emploi du Cold Shot

REMPLACEMENT DU THERMOSTAT

1. Enlevez le bouchon en silicone.

2. Enlevez l’écrou puis enlevez le thermostat.

Bouchon en

silicone

Écrou et thermostat

REMPLACEMENT DU LEVIER

1. Insérez un objet au bout arrondi dans l'ouverture du robinet.

2. Tirez le levier vers l’avant pour le dégager.

Levier

Robinet

Publication Numéro : 621058201OPR - 6 - © 2006, IMI Cornelius Inc.

Page 39

CHANGEMENT DE LA VALVE

1. Dévissez entièrement le corps de la valve.

2. Remplacez le joint torique et revissez la valve en place.

3. Serrez l’écrou sur le joint torique.

Joint torique

Écrou

Mode d’emploi du Cold Shot

Corps de la valve

© 2006, IMI Cornelius Inc. - 7 - Publication Numéro : 621058201OPR

Page 40

Mode d’emploi du Cold Shot

REMPLACEMENT DU VOYANT SUPÉRIEUR

1. Tournez légèrement puis tirez sur le voyant supérieur.

2. Débranchez le faisceau de fils puis replacez le panneau de voyants DEL.

Voyant supérieur

Panneau de voyants DEL

Publication Numéro : 621058201OPR - 8 - © 2006, IMI Cornelius Inc.

Page 41

Page 42

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...