Page 1

INTELLICARB

Training Manual

®

Release Date: April 29, 2004

Publication Number: TP01071

Revision Date: NA

Revision: A

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

INTELLICARB TRAINING MANUAL

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, Decade, Hydro Boost, Sitco, Spirit, UF-1, Vanguard, Venture, Olympus,

and Vista are registered trademarks of IMI Cornelius Inc.

Optifill trademark is pending.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2004, All Rights Reserved, IMI Cornelius Inc.

Page 3

InelliCarb Training Manual

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Delivery Inspection and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Drains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Cornelius IntelliCarb Carbonator Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Carbonator Time Out Reset Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Carbonator Relief Valve Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Mechanical Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Gate Restrictor Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Ice Diverter Kit 02394 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Removal and Replacement of Agitators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

To Remove Agitators For Cleaning (300 shown) . . . . . . . . . . . . . . . . . . . . . . . .10

Post-Mix Valve Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Set-up Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Dimensions & Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

System Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Water Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Adjusting Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Calculating Flow Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Syrup/Concentrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Setting Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Shurflo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Shurflow Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Shurflow Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Plumbing Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

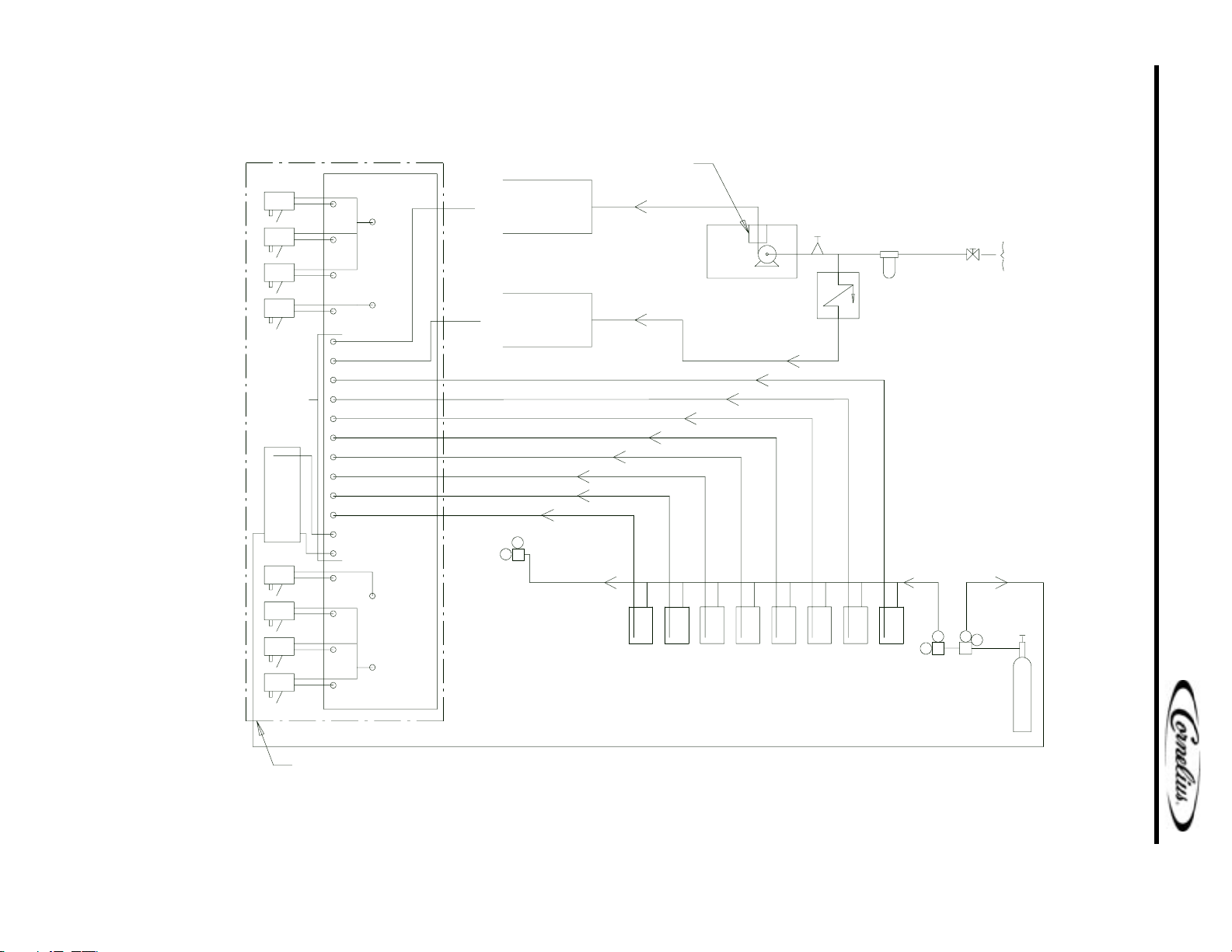

Flow Diagram 1xx (Six Flavor Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Flow Diagram 1XX (Eight Flavor Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Flow Diagram 2xx (Eight Flavor Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Flow Diagram 2xx (Ten Flavor Models)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Flow Diagram 300 (Twelve Flavor Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

© 2004, IMI Cornelius Inc. - i - Publication Number: TP01071

Page 4

IntelliCarb Training Manual

Electrical Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Carbonator Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

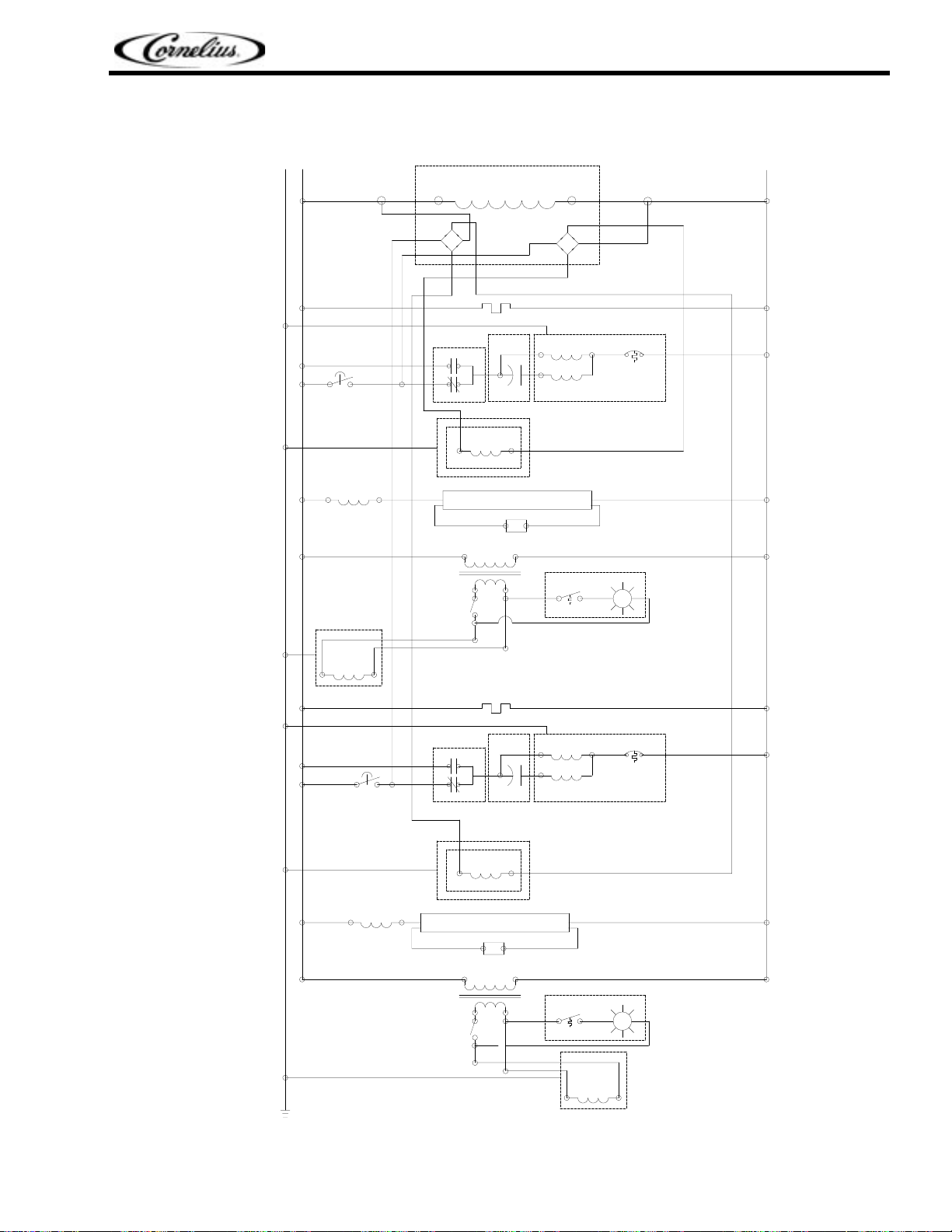

Wiring Diagram 1xx (120V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Schematic 1xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Diagram 2xx (120V Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring Diagram 2xx (220/240V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Wiring Diagram 2xx (220/240V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Wiring Diagram 300 (220/240V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring Diagram 300 (220/240V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Schematic 300 (120V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Schematic 300 (220/240V Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SHURflow Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Pumping Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pumps in Series for Long Distances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pump Sanitizing / Winterizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pump Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

DOES NOT OPERATE / GAS APPLIED / DISPENSER VALVE OPEN . . . 37

OPERATES BUT WILL NOT PRIME / DISPENSER VALVE OPEN . . . . . .37

DOES NOT ACHIEVE SOLD-OUT WITH EMPTY B-I-B . . . . . . . . . . . . . . . 37

AIR IN INLET AND/OR OUTLET TUBING . . . . . . . . . . . . . . . . . . . . . . . . . .37

STROKES WITH DISPENSER VALVE CLOSED . . . . . . . . . . . . . . . . . . . . 37

FLUID FROM EXHAUST OR VISIBLE WITHIN GAS INLET TUBING . . . . . 37

GAS BLOWING FROM EXHAUST CONTINUOUSLY . . . . . . . . . . . . . . . . . 37

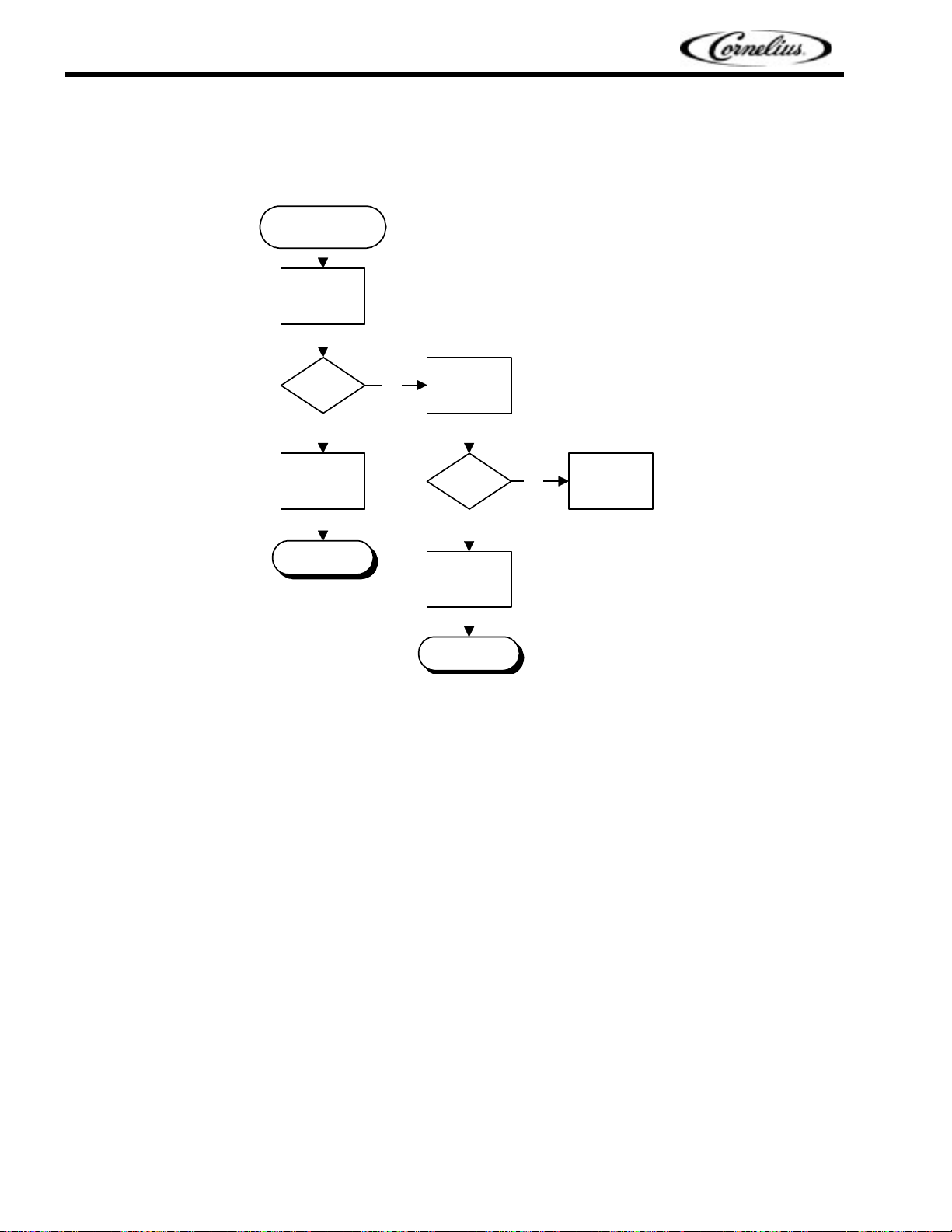

Dispenser Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

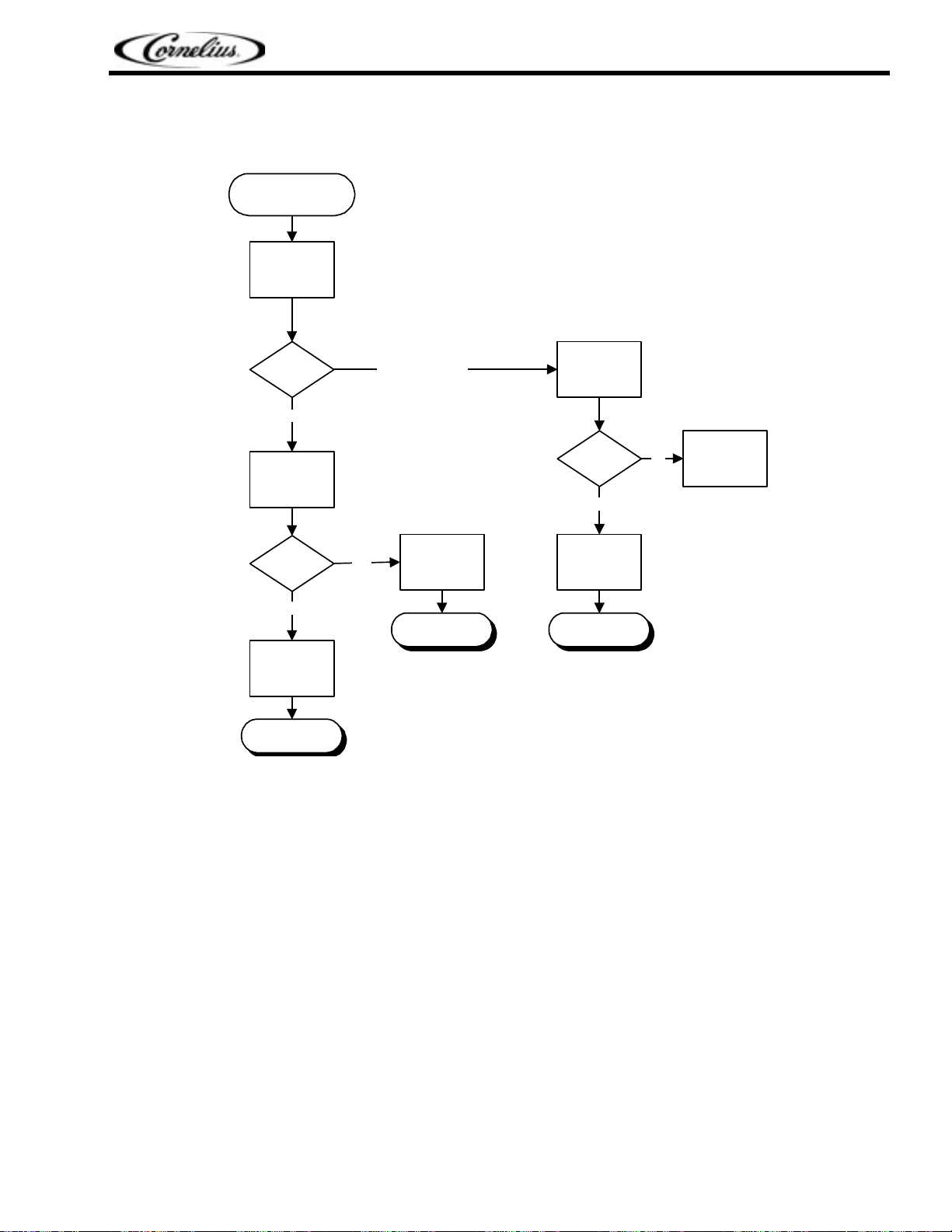

Valve Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Excess Foam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Off Taste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Valve Stuck Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

No Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Carbonator Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Solid State Carbonator Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Test Solid State Level Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Publication Number: TP01071 - ii - © 2004, IMI Cornelius Inc.

Page 5

UNIT DESCRIPTION

• Built-in cold carbonator produces bottle-quality drinks every time

InelliCarb Training Manual

INTRODUCTION

• No seasonal CO

• A complete system for simplified installation

• Reduces service frequency and lowers equipment life cost

• Generates increased beverage sales and greater consumer satisfaction

• Illuminated merchandiser delivers unique, high impact marketing message

• Ice used to cool cold plate kept separate from ice dispensed into cups

• One piece ABS thermoformed plastic ice storage hopper. Durabide™ design provides durability and

ensures all ice in the hopper is dispensable

• Unit readily accepts top mount cubers with manual ice fill capability

adjustments required for changes in water temperature

2

THEORY OF OPERATION

The rate of CO2 solubility increases with cold water. IntelliCarb System provides pre–chilled cold water

from the cold plate and mix with CO

high volume 125gph Procon pump and high torque motor.

The amount of carbonated water reserve is controlled by a probe mounted in the tank. The probe is

called a “liquid level probe”. The liquid level probe senses the water level in the tank. Probe controls the

pump “ON” and “OFF” cycle through the electronic board called “liquid level board”.

NOTE: The probe works on a 5 M.V. D.C. current that continually reverses direction to prevent

probe corrosion.

in the carbonator tank. The water is introduced into the tank with a

2

DESCRIPTION

The “Enduro IntelliCarb” series of ice dispensers solves your ice and beverage service needs in a

sanitary, space saving, economical way. Designed to be automatically filled with ice from a top mounted

ice machine or manually filled with ice from any remote ice-making source, these dispensers will

dispense cubes (up to 1-1/4 inch in size), cubelets, and hard-chipped or cracked ice. In addition, the units

include beverage faucets, a cold plate, an internal carbonator tank and an external pump for the

carbonator, and are designed to be supplied direct from syrup tanks with no additional cooling required.

IMPORTANT: For dispensing compressed or extruded style ice, an Ice Diverter Kit must be installed on

the dispenser, see FIGURE 13 on page 9.

© 2004, IMI Cornelius Inc. - 1 - Publication Number: TP01071

Page 6

IntelliCarb Training Manual

SPECIFICATIONS

ED150 ED175 ED200 ED250 ED300

B=(Beverage)

Model

Descriptions:

Ice Storage:

Maximum

Number of

Faucets

Available:

Built-in Cold

Plate:

Electrical:

Dimensions:

CO

2 Operating

Pressure

C=(Coldplate)

H=(Internal

Carb)

Z=(No DripTray)

150 Pounds 175 Pounds 200 Pounds 250 Pounds 300 Pounds

Yes Yes Yes Yes Yes

$PSV7RWDO8QLW'UDZ 120/1/60, 3.5 Amps Total Unit Draw

Width 22”

Deep 30--11/16”

High 35--5/8”

Z--Models

Width 22”

Deep 23--1/16”

High 35--5/8”

75--psig (max) 75--psig (max) 75–psig (max) 75–psig (max) 75–psig (max)

B=(Beverage)

C=(Coldplate)

H=(Internal

Carb)

Z=(No DripTray)

6 8 10 10 12

Outlet should be within 6 feet of dispenser.

Width 24.5”

Deep 30--11/16”

High 35--5/8”

Width 24--1/2”

Deep 23--1/16”

High 35--5/8”

B=(Beverage)

C=(Coldplate)

H=(Internal

Carb)

Z=(No DripTray)

230/1/50, 2.0 Amps Total Unit Draw

Width 22”

Deep 30–11/16”

High 35–5/8”

Z–Models

Width 22”

Deep 23–1/16”

High 35–5/8”

B=(Beverage)

C=(Coldplate)

H=(Internal

Carb)

Z=(No DripTray)

Width 24.5”

Deep 30–11/16”

High 39–5/8”

Width 24–1/2”

Deep 23–1/16”

High 39–5/8”

B=(Beverage)

C=(Coldplate)

H=(Internal

Carb)

Z=(No DripTray)

120/1/60, 4.0

Amps Total Unit

Draw

230/1/50, 3.0

Amps Total Unit

Draw

Width 44–3/8”

Deep 31–1/2”

High 37”

Z–Models

Width 44–3/8”

Deep 23–1/16”

High 37”

REQUIREMENTS

• Weight: counter must be level and able to support 450 lbs.

• Environment: Indoor installation only

• Temp eratu re: 40 to 100

• CO2: 75 psi at unit

• Syrup: 60 psi., 0.70 -- 0.75 ounces per sec. (0.6 gpm) at unit

• Water: 60 psi at pump

• Electrical: See name plate

o

F

DELIVERY INSPECTION AND UNPACKING

Upon delivery inspect the unit for damage or irregularities and immediately report problems to the

delivering carrier and file a claim with that carrier.

• Open loose parts packages and inspect parts.

Part No. Description Qty.

710000030 Pump and Motor Assy 1

70970 4”Legs 4

70750 Clamps 2

620702201 Brush 1

51774 Drain Pan Drain Line 1

50335 Drain Line Insulation 1

)LWWLQJ6RF[)SW 1

)LWWLQJ0SW[µ%DUE 1

Publication Number: TP01071 - 2 - © 2004, IMI Cornelius Inc.

Page 7

INSTALLATION

1. Locate the dispenser indoors on a level counter top.

A. LEG OPTION

Unpack the four (4) legs and install them into the threaded holes provided in the bottom of the

unit. The installer must provide flexibility in the product and utility supply to permit shifting the

position of the dispenser sufficiently to clean the area beneath it.

B. COUNTER MOUNTING

If counter mounted the ice drink dispenser must be sealed to the counter. The template drawing

indicates where openings can be cut in the counter. Locate the desired position for the dispenser,

then mark the outline dimensions on the counter using the template drawings. Cut openings in

counter.

Apply a continuous bead of NSF International (NSF) silastic sealant (Dow 732 or equal) approximately 1/4--inch inside of the unit outline dimensions and around all openings. Then, position the

unit on the counter within the outline dimensions. All excess sealant must be wiped away immediately.

2. The beverage tubes, drain tube and power cord are routed through the large opening in the bottom

of the unit. See the mounting template for locating the required clearance opening in the counter for

these utility lines.

3. Drip tray assembly: Route the drain tube to an open drain with the end of the tube above the “flood”

level of the drain. Use the tubing, fittings, clamps, and insulation provided with the Dispenser to

assemble the drain. The completed drain line must pitch continuously downward and contain no

“traps” or improper drainage will result. Must have a 4 inch air gap between drain line and drain.

NOTE: This equipment must be installed with adequate backflow protection to comply with federal, state, and local codes.

InelliCarb Training Manual

NOTE: IMI Cornelius Inc. recommends that a water shutoff valve and water filter be installed in

the plain water inlet supply line. A Cornelius Water Filter (P/N 313860000) and QUICK DISCONNECT SET (P/N 313867000) are recommended.

CAUTION: Check the minimum flow rate and the maximum pressure of the plain water inlet supply line.

MINUMUM FLOW RATE MUST BE AT LEAST 125--GALLONS PER HOUR. If flow rate is less than 125-

-gallons per hour, starving of the carbonator water pump will occur. Starving will damage the water pump

and could cause the carbonator to time out. INCOMING PLAIN WATER INLET SUPPLY LINE WATER

TO PUMP PRESSURE MUST REMAIN A MINIMUM OF 10--PSI BELOW THE CARBONATOR C

O2

OPERATING PRESSURE. (Example: Carbonator CO2 operating pressure is 75--PSI and the maximum

water pressure can be no more than 65--psi, etc.). Water over pressure (higher than C

O2 operating pres-

sure) can cause carbonator flooding, malfunction, and leakage through the carbonator relief valve. If

water is exceeding maximum pressure specifications, a Water Pressure Regulator Kit (P/N 310150000)

or equivalent must be installed in the plain water inlet supply line. If fitting connector is not available,

water line must be 1/2” or 3/4” diameter with a shut off valve within 6 feet of the dispenser.

4. Locate the carbonator pump assembly and connect probe wires from Ice/Drink Unit and pump. Con-

nect inlet water to pump and pump outlet to Ice/Drink Unit using 3/8--inch food--grade tubing.

NOTE: Locate carbonator assembly within 6 feet of the dispenser. Do not lengthen the control

board harness.

5. Connect the beverage system product tubes as indicated in applicable Plumbing Flow Diagram, see

page 19. This work should be done by a qualified service person.

NOTE: Water pressure for non carbonated beverages must be 60 P.S.I. minimum.

NOTE: See applicable Flow Diagram or Decal on the lower front of the unit for the location of

syrup and water connections.

6. Clean the hopper interior.

7. Connect the two power cords to a 120 volt, 60 cycle, 3-wire grounded receptacle. For 220--240 Volt

International Units, a 3--wire power cord is provided. An adapter plug for the particular country will

need to be provided by the Installer.

© 2004, IMI Cornelius Inc. - 3 - Publication Number: TP01071

Page 8

IntelliCarb Training Manual

Drains

Use a 1 - 1/2” rigid pipe (e.g. ABS on P.V.C.) this is to prevent kinking or collapsing. Make sure to leave a

4 inch air gap between the drain line and the floor drain.

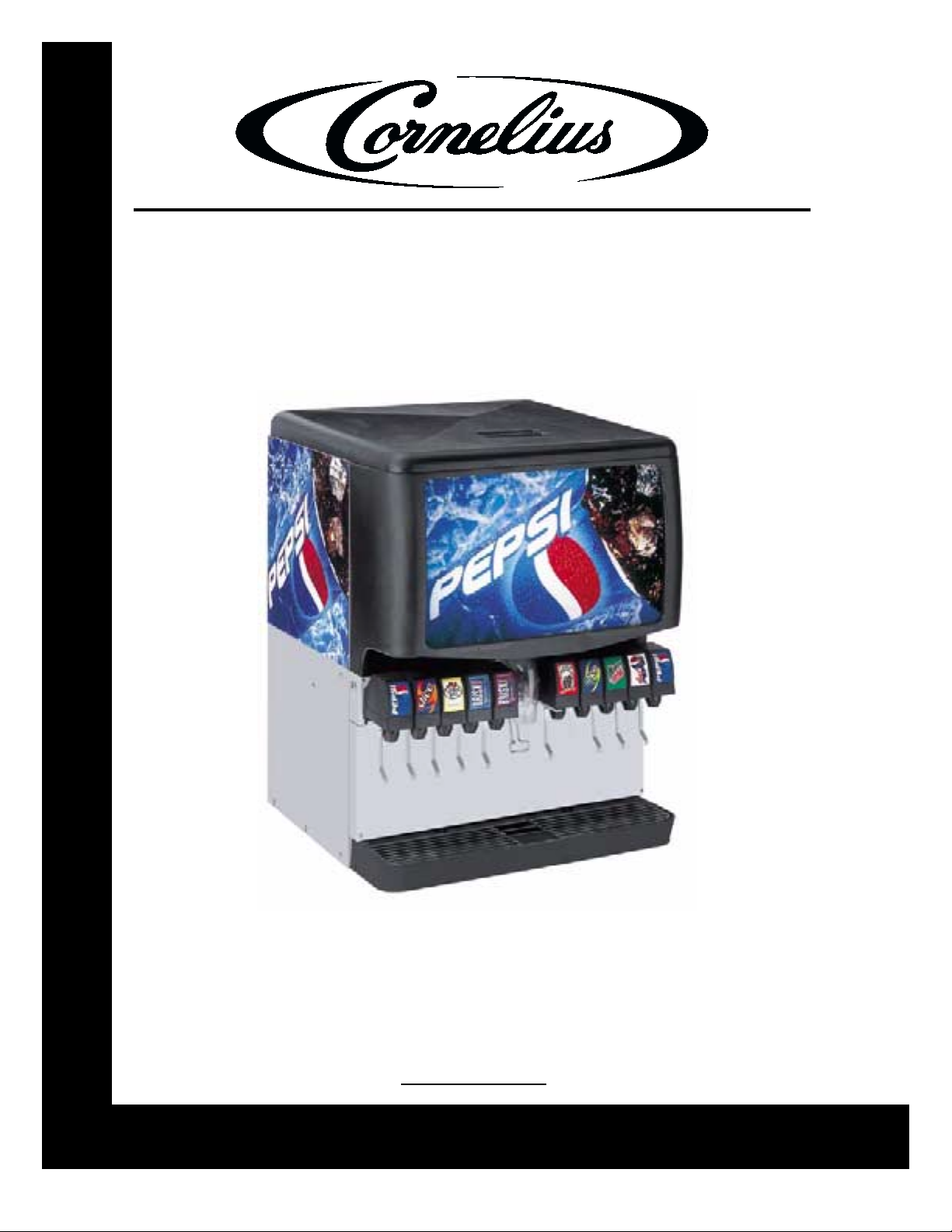

CORNELIUS INTELLICARB CARBONATOR ASSEMBLY

1. Ice Drink / Drop-In Carbonator Pump & Motor Unit

Vent to Atmosphere Check Valve

Liquid Level Control Box

Preset CO2 Regulator (75P.S.I.)

Carbonator Time Out Reset Switch

The board can be set to turn the carbonator off after three or seven minutes of continuos time. The feature can also be disabled. See the carbonator instruction in this manual.

FIGURE 2 FIGURE 3

1. Locate carbonator assembly below dispenser no more than 6 feet away. Important: Make

sure there is clearance for the liquid level control reset switch on the side of the control box

to avoid accidentally tripping the switch. The control board has an internal timer to prevent the

pump motor from running continuously. In the event of a water supply interruption or malfunction of

the water level probe and/or motor relay circuit. If there is a time-out event, make necessary repairs

to what caused the time out, then depress and release the reset switch to put the control board

back in service. By moving a jumper on the control you can select either a 7 minute or 3 minute time

out or this feature can also be disabled.

A. Hook-up a 3/8 ID water supply line 125 G.P.H. minimum (60 psig. max.) to pump inlet. Minimum

flowing pressure is 30 psig. Important: Tap for non-carb water supply must be upstream of

pump inlet. Do not tap in the pump outlet.

B. Hook-up a 3/8 (.375 ID) CO

psig.) on the Pump & Motor base. Note: If using a bulk CO

regulator must be set to 100-105 psig. The regulator on the bulk tank should be a secondary.

supply line (100 psig.) to the inlet of the pre-set CO2 regulator (75

2

FIGURE 1

Carbonator

Time Out Reset

Switch

Time Out

Selector Pins

Liquid Level

Control Board

125 G.P.H. ProCon Water Pump

High Torque Pump Motor

tank as supply, tank pressure

2

Publication Number: TP01071 - 4 - © 2004, IMI Cornelius Inc.

Page 9

C. Initial start-up procedure for carbonated water system: Turn on the CO2 supply to the car-

bonator tank, vent air from carbonator tank by pulling the tank relief valve. Turn on water supply to

the pump. Connect electrical power to the pump and motor unit. Bleed the air out of the system

by energizing a beverage valve until carbonated water is flowing from the valve.

NOTE:If the carbonator Pump and Motor does not cycle (turn on and off) properly, check that the

probe harness connector and ground lead are secured to the carbonator tank connection points.

D. If service is required on Ice Drink units, it will be necessary to lower the beverage valve panel to

gain access to the probe and ground connection. Remove the lower front panel (2 screws) from

the cabinet and the ice chute cover (“snap” fit). Remove the 6 screws that secure the beverage

panel to the cabinet. The panel can now be moved downward due to the flexibility of the beverage

tubing to expose the carbonator tank connections.

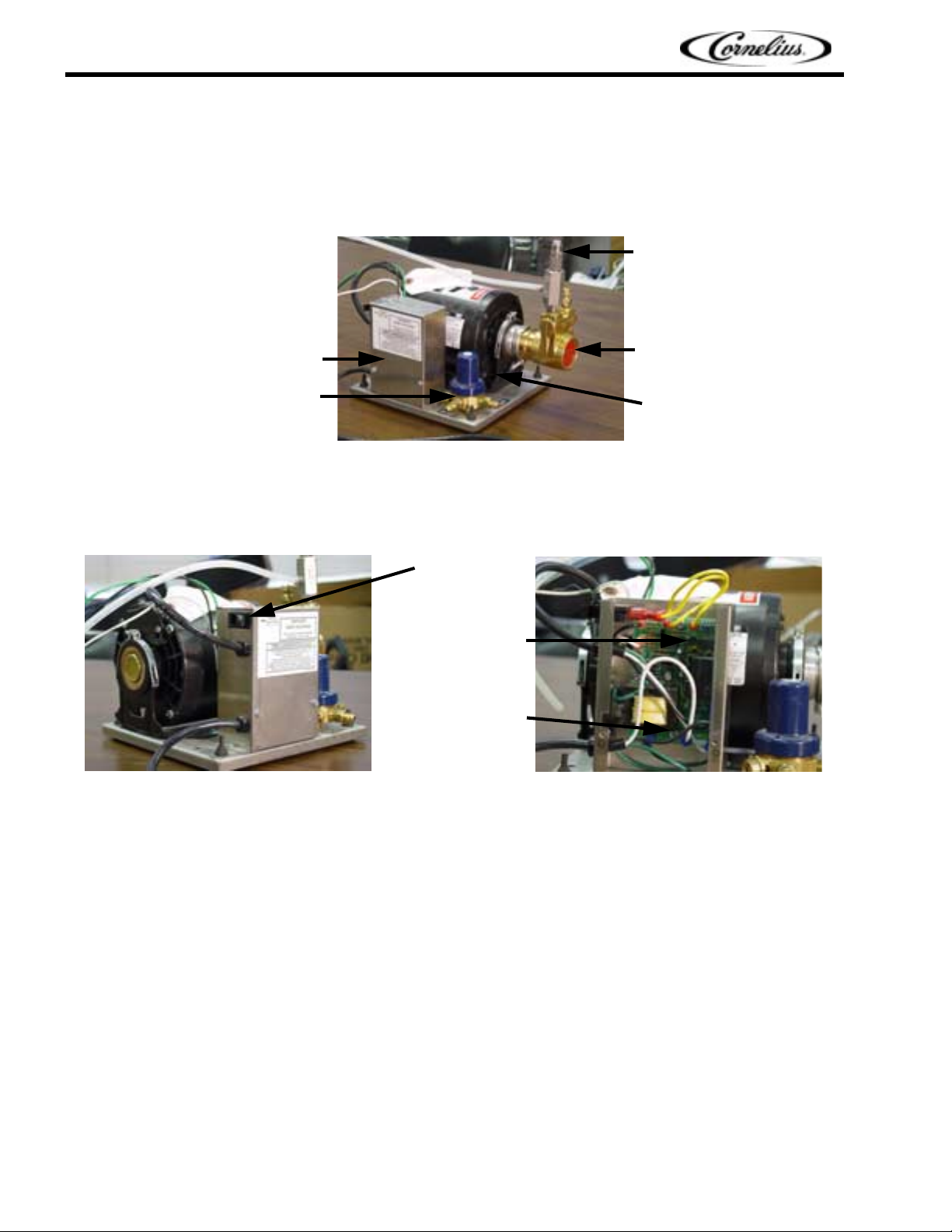

Carbonator Relief Valve Locations

The carbonator tank is located behind the splash panel, on the right side of the dispenser. You will need

to pull the relief valves to purge air from the system after the CO

do this will cause low carbonation volume and popping of the relief valves.

Relief

Valve Ring

Agitator

Motor

Carbonator

Tan k

Carbonator

Tank Relief

Valve

InelliCarb Training Manual

supply has been hooked up. Failure to

2

2. Dispenser

Total Flex Manifold

(with insulation)

Cold Plate Inlets

(3/8 Barb)

Carb. Tank Liquid

Level Probe Harness

FIGURE 6

FIGURE 7

Ice Drink Model ED175BCH (Lower Front Panel Removed)

FIGURE 8

Insulated Cold Plate

Cover & Carbonator

Tank Assembly

Total Flex Manifold

(insulation removed)

Carb Tank CO2

Supply Line

© 2004, IMI Cornelius Inc. - 5 - Publication Number: TP01071

Page 10

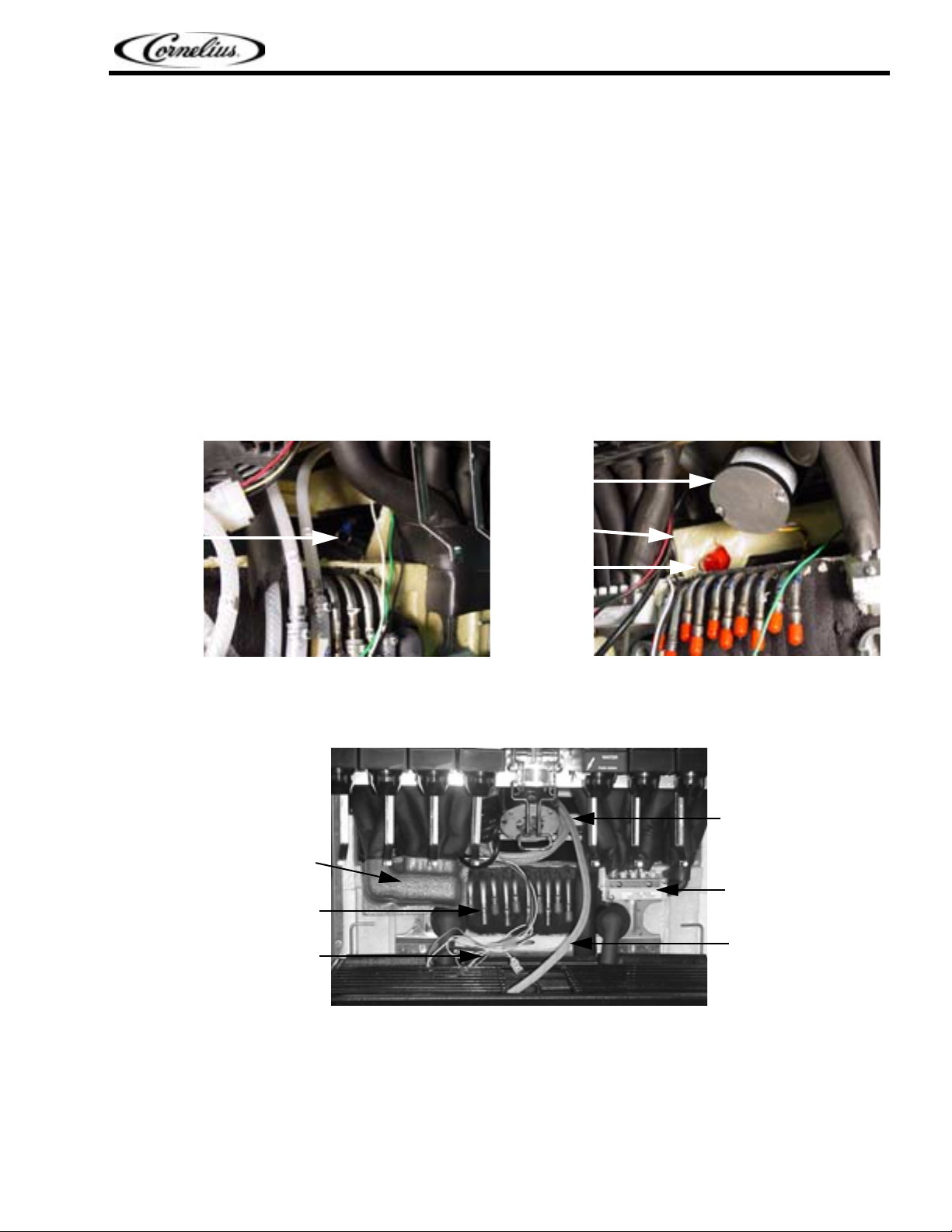

IntelliCarb Training Manual

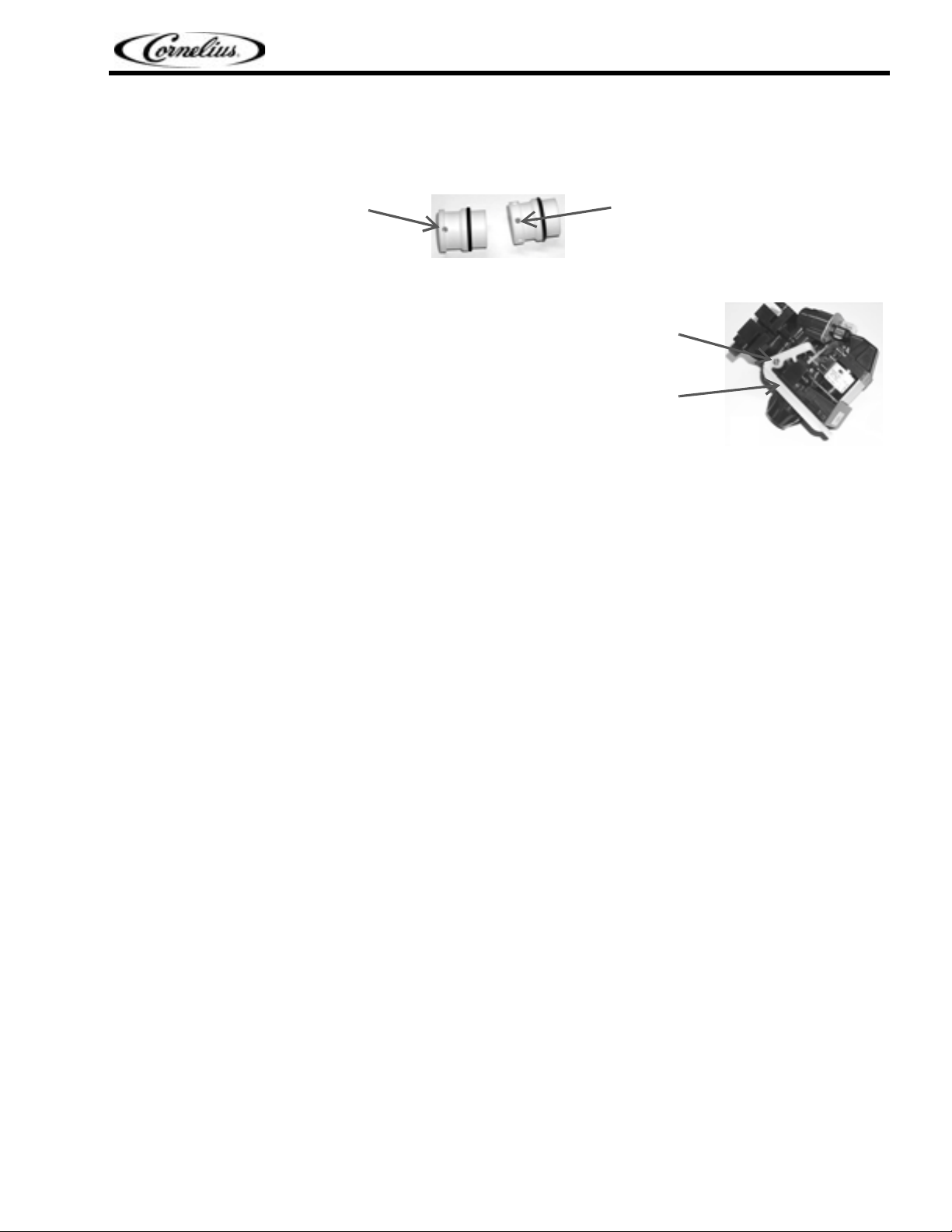

Ice Drink Model ED150/175/300 Coldplate Cover

Liquid Level Probe

CO2 Check Valve with Ground Stud

FIGURE 9

Ice Drink Model ED200/250 Coldplate Cover

In-line CO2 Check Valve

3. Total Flex System for Ice Drink Models ED150/175/200/250/300

Total Flex Manifold (Insulation Removed)

Water Line

Retainer Clip

Probe

FIGURE 10

Ground Plate/Stud

Plugs

Manifold Block

FIGURE 11

Total Flex is a system of water manifold blocks located at the front of the cold plate, adjacent to the cold

plate inlets, for easy switch over of carbonated / non-carbonated beverage drinks. The right hand manifold block is for the beverage valves located to the right side of the ice chute, and the left block is for the

left bank of valves. Each beverage valve on the dispenser can be set up for either carbonated or non-carbonated drinks. Refer to the unit’s plumbing diagram for the factory carbonated / non-carbonated valve

locations. The procedure for switching carbonated / non-carbonated water lines on a beverage valve is

as follows:

A. Shut off the water supply to the dispenser. Depressurize and drain both the carbonated and non-

carbonated water circuits.

B. Remove the retainer clip (2 screws) from the manifold block. Switch the plug and water line fitting

to their respective carbonated / non-carbonated outlet locations on the block.

C. Replace the retainer clip. Turn on the water supply and energize the “switched” valve(s). Check

for water leaks.

4. Important: Route the dispenser’s drain line to an open drain with the end of the tube above the flood

level of the drain. The drain line must pitch downward and contain no “traps”.

5. Connect both the carbonator pump and motor unit and the dispenser to a grounded

electrical sup-

ply outlet.

Publication Number: TP01071 - 6 - © 2004, IMI Cornelius Inc.

Page 11

IntelliCarb Training Manual

6. Check list for proper “finished” drink carbonation:

A. Fill ice storage hopper with ice.

B. Water supply must be from a continuous source (no tank supply).

C. Use only filtered water.

D. Supply water line to the carbonator pump must be a minimum of .375 ID.

E. Syrup supply lines must be a minimum of .265 ID.

F. Water inlet pressure range: 45-60 max. static psig. with a minimum flowing pressure of 30 psig.

G. Syrup CO

H. CO

2

secondary regulator pressure set to 60 psig.

2

supply must be high quality, food grade.

I. Purge all water, carb-water, and product lines of air before brixing valves.

J. Important: Brix valves with cold product. Allow at least 15-20 minutes for ice to cool down the

coldplate on initial start-up before brixing the valves.

K. Dispense at least (2) 12 oz. drinks before taking a carbonation level reading.

L. Carbonation tester thermometer must read 32-33

o

F. for accurate carb-level reading. Store tester

in ice water bath during use.

M. Hold cup at valve nozzle for drink to be tested. Pour drink slowly down the side wall into the carb-

tester to avoid agitation during pouring. Press vent valve once on carb-tester after tightening lid.

N. Shake carb-tester in vertical motion until peak pressure reading is obtained. Use Pepsi chart for

carbonation level reading.

NOTE: Carbonator troubleshooting procedure located on page 43.

© 2004, IMI Cornelius Inc. - 7 - Publication Number: TP01071

Page 12

IntelliCarb Training Manual

MECHANICAL SECTION

GATE RESTRICTOR PLATE

NOTE: Disconnect power to dispenser before installing, removing, or adjusting restrictor.

ADJUSTMENT

Adjustment

This plate may be adjusted as shown to reduce or increase the dispensing rate of ice, especially

desirable when using glasses or other containers with small openings. Adjustment can be made by

sliding up or down with nuts loosened, to obtain the desired amount of restriction.

INSTALL PLATE

ON STUDS AS

SHOWN

FIGURE 12

Publication Number: TP01071 - 8 - © 2004, IMI Cornelius Inc.

Page 13

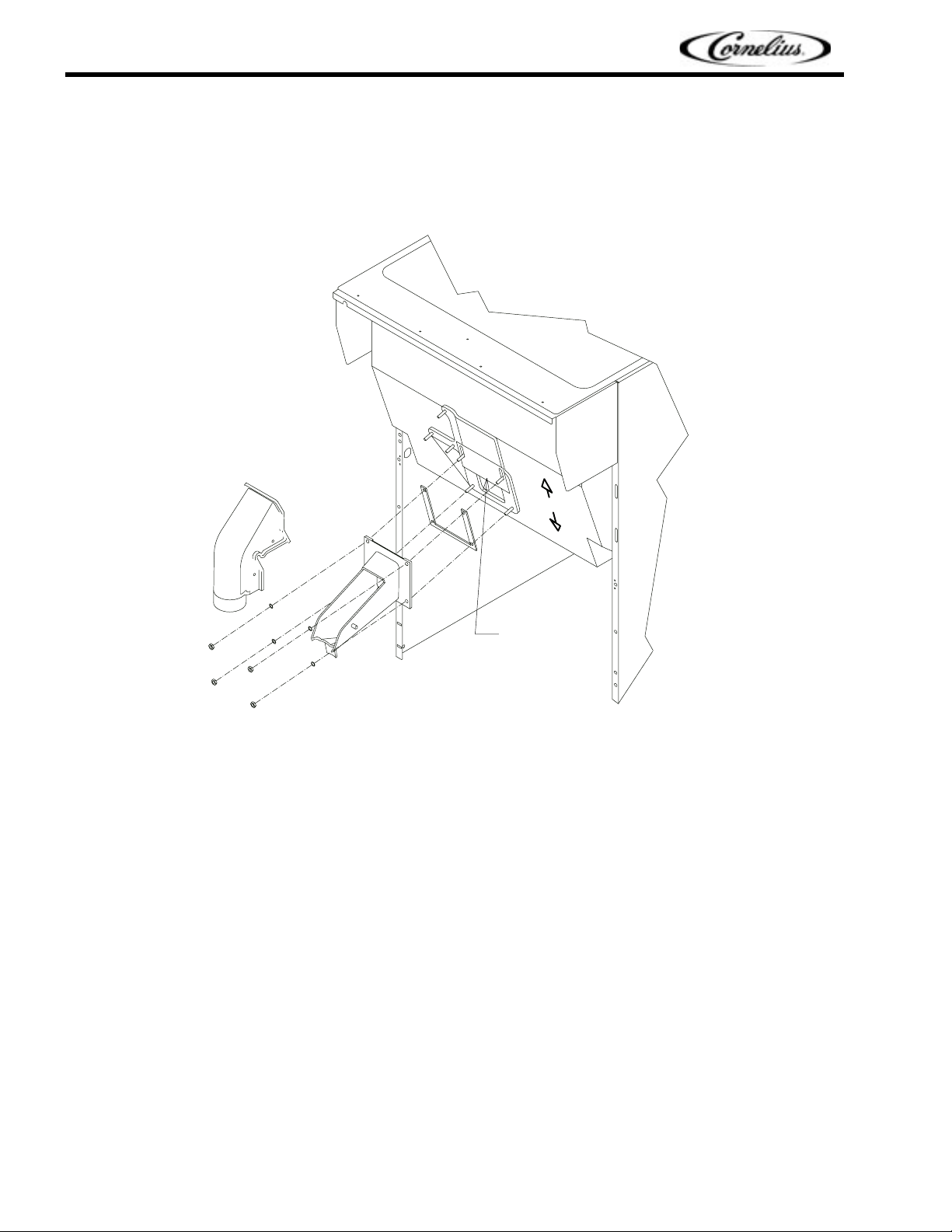

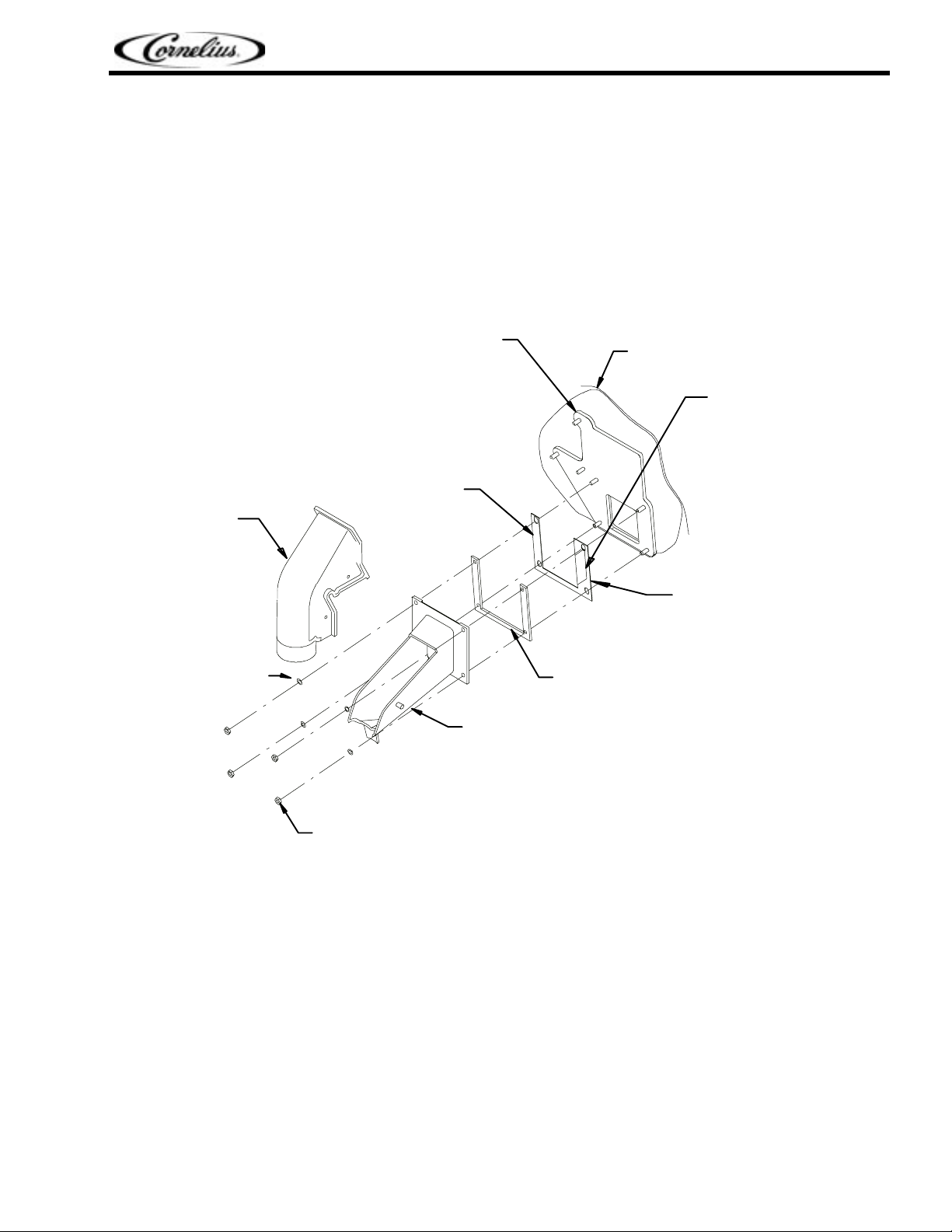

ICE DIVERTER KIT 02394

NOTE: For dispensing Scotsman, Wilshire, and Hoshizaki compressed ice cubes:

1. Disconnect power to dispenser.

2. Remove Merchandiser from dispenser.

3. Remove ice chute and discard gate restrictor.

4. Install ice diverter on gate mounting plate as shown below.

5. Apply RTV to back surface of ice diverter, to seal to gate mounting plate.

6. Reinstall gasket and ice chute.

7. Reinstall merchandiser and energize unit.

IntelliCarb Training Manual

IC E C H UT E

COVE R

10--32 WA S HE R

GATE MOUNTING P LATE

IC E DIV E R T E R

IC E C H UT E

GASKET

STORAGE HOPPER

FLANGE E XTENDS

INTO S TORA GE HOP-

PER THROUGH GATE

OPE NING

APPLY RTV TO

THIS SUR FACE TO

SEAL TO HOPPER

GATE MOUNTING

PLATE

10--32 NU T

FIGURE 13

© 2004, IMI Cornelius Inc. - 9 - Publication Number: TP01071

Page 14

IntelliCarb Training Manual

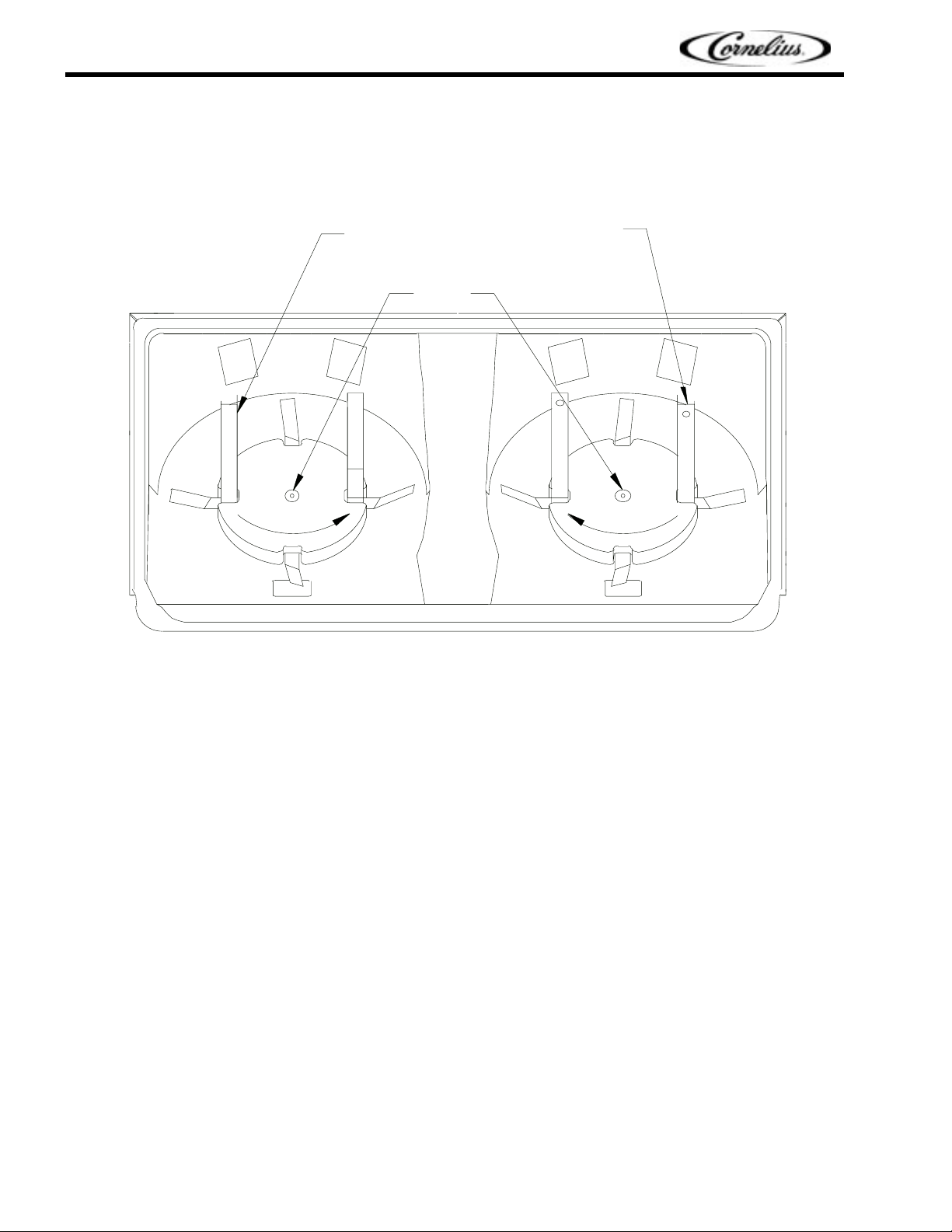

REMOVAL AND REPLACEMENT OF AGITATORS

To Remove Agitators For Cleaning (300 shown)

NOTE: All other models have only one agitation Assembly.

COUNTERCLOCKWISE

ROTATION

LEFT HAND

AGITATOR

O–RING

FRONT (VALVE SIDE) VIEW FROM TOP OF DISPENSER

RIGHT HAND AGITATOR

WITH HOLE IN UPRIGHT

CLOCKWISE

ROTATION

FIGURE 14

1. Lift agitator and disc from unit.

2. Remove O-Ring starting at notch. Warm the O-Ring with water to ease removal.

3. Lift the plastic agitator disc off of the stainless-steel agitator.

4. Replace by reversing steps.

NOTE: Refer to Sanitize Procedure in the Owners Instruction for complete cleaning and sanitiz-

instructions.

ing

Publication Number: TP01071 - 10 - © 2004, IMI Cornelius Inc.

Page 15

POST-MIX VALVE SECTION

SET-UP INSTRUCTIONS

IntelliCarb Training Manual

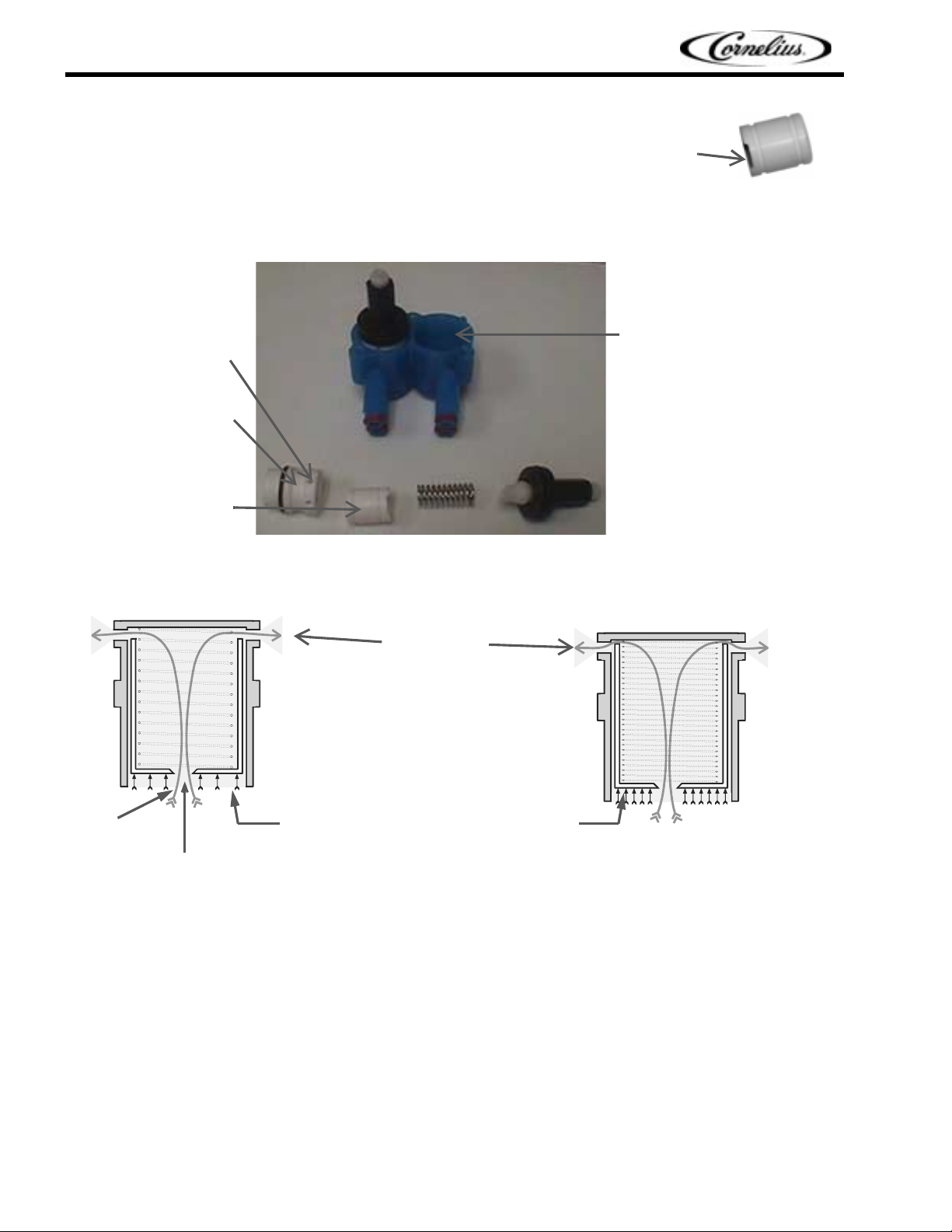

Concentrate valve sleeve

has only one hole

A side water lever kit can be added to a valve allowing for

dispensing of water without syrup or concentrate. The side

water lever can be added to either a carbonated drink valve

or a noncarbonated drink valve.

Post-mix valves control:

• the ON–OFF of syrup and water,

• the flow rates of syrup and water,

• the mixing of the two ingredients as they pour into the

cup, and

• in some instances - dispensed portion.

Dimensions & Capacities

Fast Flow ............................................................................................................... 1 ½ to 3 oz./sec.

UFB-1 ......................................................................................................................... 2 to 4 oz./sec.

Ultra Flow .............................................................................................................. 3 to 4 ½ oz./sec.

Operational temperature range: ......................................................... 10°C (50°F) to 43°C (110° F)

Voltage requirements:................................................................................ 22 to 27 VAC (50/60 Hz)

Syrup valve sleeve

has six holes

FIGURE 15

Mounting

screw

Water

lever

FIGURE 16

Transformer (electronic valves) ........................................................................................80 VA min.

Operating Pressure (flowing)...............................................................................syrup = 20 psi min.

.............................................................................................................................water = 35 psi min.

Concentrates and juices that contain particulates must be dispensed from a juice valve.

A slanted drip tray is necessary when using an Optifill valve.

SYSTEM DETAILS

Water

Water Quality

Water quality issues have an affect on dispensing valves. Chloramine, a combination of chlorine and

ammonia is responsible for some degradation of rubber components. Chloramine is used in many U. S.

water supplies. Its affects can be minimized by installing and maintaining a water filtration system.

Ultra pure water affects the sensitivity of the Optifill™ valve. Because ultra pure water has less mineral

content, it reduces the conductivity of the water keeping the circuit open and overfilling the beverage

container.

Water Flow

The size of the orifice in the piston varies depending on whether the piston is used for syrup or water, and

whether it is high flow or ultra flow valve.

© 2004, IMI Cornelius Inc. - 11 - Publication Number: TP01071

Page 16

IntelliCarb Training Manual

NOTE: The notched water piston on the Ultra Flow and UFB-1 valve.

results in at least one orifice in the sleeve always open. This eliminates pulsating and smooths water flow at higher flow rates.

In operation the liquid flows through the knife–edged orifice in the bottom

of the piston and then out the orifices in the sleeve. The outlet orifice size

in the sleeve is regulated by the position of the piston. In the illustration,

the piston is restricting approximately 1/2 of the outlet orifices.

Orifice

Sleeve

Piston

Notch in

piston

FIGURE 17

UFB-1 Flow Module

FIGURE 18

Lower Fluid Pressure BUT

Larger Orifice Openings

Knife

edge

Syrup/Water Flow

Lower Fluid

Pressure Pushing Against Piston & Spring

Same Volume Of

Syrup/Water Flows

From Orifices

Higher Fluid

Pressure Pushing

Against Piston &

Spring

Higher Fluid Pressure BUT

Smaller Orifice Openings

FIGURE 19

The position of the piston inside the sleeve is determined by the upward pressure of the liquid against the

base of the piston and the downward pressure of the spring inside the piston (not shown here). The

pressure of the spring is regulated by the adjusting screw.

If the pressure of the liquid increases, the flow rate through the knife–edged orifice will increase. The

piston is moved upward closing off more of the outlet orifices. The same flow rate is thereby maintained.

Publication Number: TP01071 - 12 - © 2004, IMI Cornelius Inc.

Page 17

IntelliCarb Training Manual

Adjusting Flow Rates

Flow rates of the water and syrup are adjusted based on the desired ratio. For example: if the desired

ratio is 5:1, then the flow rate of the water is 5 times that of the syrup.

If the desired finished drink total flow rate is 3.0 ounces per second, then the water flow rate is 2.5 oz./

sec and the syrup flow rate is 0.5 oz./sec. (The water at 2.5 oz./sec is five times the 0.5 oz./sec syrup flow

rate.)

NOTE: Always adjust water within its range.

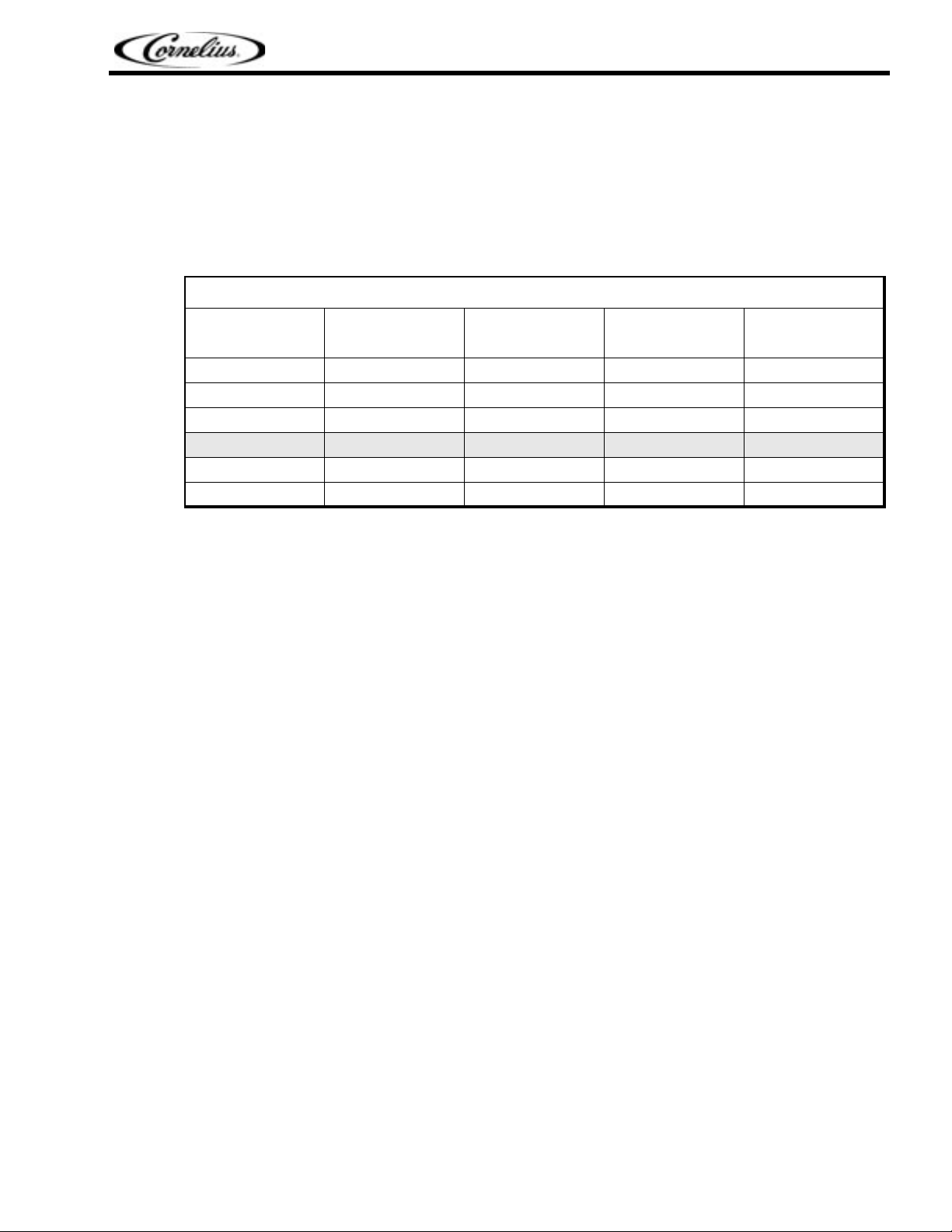

Water Flow Rates At Selected Ratios

Water To Syrup

Ratio

2 to 1 1.00 oz./sec. 2.00 oz./sec. 2.50 oz./sec. 3.00 oz./sec.

3 to 1 1.13 oz./sec. 2.25 oz./sec. 2.81 oz./sec. 3.38 oz./sec.

4 to 1 1.20 oz./sec. 2.40 oz./sec. 3.00 oz./sec. 3.60 oz./sec.

5 to 1 1.25 oz./sec. 2.50 oz./sec. 3.13 oz./sec. 3.75 oz./sec.

6 to 1 1.29 oz./sec. 2.57 oz./sec. 3.21 oz./sec. 3.86 oz./sec.

7 to 1 1.31 oz./sec. 2.63 oz./sec. 3.28 oz./sec. 3.94 oz./sec.

Calculating Flow Rates

The most frequent ratio is 5:1. The charts above list the breakdown for many ratios and flow rates. It is

useful to be able to calculate flow rates when a chart is not available.

An example of calculating the water and syrup flow rates given the finished drink flow rate and the water

to syrup ratio:

Given:

1. Finished Drink Flow Rate = 3.0 oz./sec.

2. Water to Syrup Ratio = 5 to 1

To calculate Water Flow Rate:

1. Calculate the Total Portions = Water Portion + Syrup Portion

(example 5 + 1 = 6)

2. Calculate Syrup Flow Rate = Finished Drink Flow Rate ÷ Total Portions

(example 3.0 oz./sec ÷ 6 = .5 oz./sec)

3. Calculate Water Flow Rate = Finished Drink Flow Rate – Syrup Flow Rate

(example 3.0 oz./sec - .5 oz./sec = 2.5 oz./sec)

Prove the calculation is correct by adding water flow rate of 2.5 oz./sec + syrup flow rate of .5 oz./sec =

finished drink flow rate of 3.0 oz./sec.

Water flowing at 2.5 oz./sec and syrup flowing at .5 oz./sec achieves a ratio of 5:1 and 3.0 oz./sec. flow

rate.

Water at 1.5 oz./

sec. Total Flow

Water at 3.0 oz./

sec. Total Flow

Water at 3.75 oz./

sec. Total Flow

Water at 4.5 oz./

sec. Total Flow

Syrup/Concentrate

Syrup should always be precooled before setting the ratio. Syrup takes a path through the valve

parallel to the water path. It is introduced in the block, travels through a syrup flow control, banjo, valve

head and out the nozzle. Note, concentrate is not cooled.

High sugar syrups are more viscous (thicker) than diet syrups and consequently have more

pressure drop within a system. This pressure drop results in less flow at the valve and therefore a slower

fill time. Increasing the pump pressure will help overcome the pressure drop caused by high sugar

syrups.

© 2004, IMI Cornelius Inc. - 13 - Publication Number: TP01071

Page 18

IntelliCarb Training Manual

Setting Ratios

If the ratio varies and must be adjusted often, it is probably the result of a restricted syrup

system. It is then time to clean and sanitize the syrup tubing and cooling coils and check for other

problems such as syrup pumps, etc.

NOTE: Try raising the pressure on the pump before cleaning.

Set the water flow rate first, then adjust the syrup to the desired ratio. This gives the most accurate

valve flow setting possible. Measure the ratio and adjust the syrup flow, if necessary. This will result in

uniform flow, better carbonation retention, and improved drink quality.

When using a ratio cup always take these precautions to ensure accuracy:

• After installing the separator tube, open the valve to fill the syrup tube before starting the ratio test.

• Clean the cup thoroughly between tests so there is no carry–over from one test to the next.

• Fill the cup to approximately 3/4 full and use approximately the same quantity for each test to ensure

accurate settings.

• Take another sample to verify the settings.

Ratio Cup and Syrup Separator

FIGURE 20

NOTE: Valve troubleshooting information is available on page 39.

Publication Number: TP01071 - 14 - © 2004, IMI Cornelius Inc.

Page 19

SHURFLOW OVERVIEW

SHURflo’s Beverage Gas Pump supplies syrup under pressure to a post-mix dispenser, which mixes the

syrup with water to an exact ratio (brix). The pump is used in conjunction with non-pressurized Bag-InBox (B-I-B) containers and a bag connector (Q.D.) fitting.

IntelliCarb Training Manual

SHURFLO

The pump can be operated on regulated C

drives the pump and is not in contact with the syrup. Separate syrup and gas chambers prevent

contamination, foaming, and purging of the tubing when the B-I-B has emptied.

The pump retains pressure in the outlet line, operating only when syrup is needed. When the dispenser

valve is opened, the pump reacts to the pressure drop by operating to maintain pressure in the line.

When the dispenser is closed, the incoming gas and output syrup pressures equalize and the pump

stops. Actual dynamic line pressure is dependant upon system losses as outlined in the section

"Pumping Capability".

The automatic "sold-out" feature within the pump ensures consistent syrup delivery right up to the

moment the B-I-B is empty. Vacuum produced by the pump evacuates the syrup within the bag. Once the

preset vacuum point is achieved and held, incoming gas pressure to the pump is shutoff causing the

outlet syrup pressure to drop to zero. When a new B-I-B is installed, the vacuum drops, the pump

automatically restarts and pressurizes the system. The SHURflo Beverage Gas Pump ensures quality

from the first drink to the last.

Beverage Gas Pumps are intended for soda syrups and low viscosity concentrates that do not contain

solids.

The use of a SHURflo Juice Pump (-09) is recommended for concentrates containing soft solids, classed

as round, up to 0.025 in. [0.6 mm] or that are of higher viscosity than soda syrups.

When concentrates contain pulp classed as long/stringy, seed particles or are exceptionally viscous, the

Particulate Juice Pump (-10) should be used as it can handle soft solids up to

Standard gas pump models are for installations where geographic elevation is less than 5000 ft.[1523M].

For elevations above 5000 ft. specific high altitude models with a reduced sold-out spring rate must be

used to compensate for the loss in atmosheric pressure.

O2, nitrogen or compressed filtered air. The compressed gas

1 /4" [6 mm] cubed.

For further application and model information please contact SHURflo.

NOTE: Shurflow Troubleshooting information available on page 35.

© 2004, IMI Cornelius Inc. - 15 - Publication Number: TP01071

Page 20

IntelliCarb Training Manual

SHURFLOW INSTALLATION

• As indicated on the pump, the outlet port is to be mounted up.

• Pumps are to be mounted at the same level or higher than the B-I-B. The best choice is to have the

pump above the B-I-B.

• INLET

[3mm])

tubing from the B-I-B to the pump use; 3/8" I.D. [10mm] minimum, heavy wall (1/8"

clear, NSF listed vacuum tubing. Inlet tubing should not have excessive length. Tubing that is allowed to drape down can trap air in the B-I-B creating a potential for pump "soldout" problems.

not exceed 5 ft [1.5 M

• If plumbing multiple B-I-B’s to a pump, B-I-B's should be "Teed" side-by-side horizontally,

rather than one on top of the other

• OUTLET tubing from the pump to the dispenser should be high pressure rated and NSF

listed. Consult "Pumping Capability"

• Always cut CO2 and outlet tubing at least 2 ft. [.6 M] longer to provide a "service loop" so the

The maximum vertical distance from the bottom of the B-I-B to the pump must

]. Maximum inlet tubing length is 10 ft. [3 M ].

(vertically).

(see page 2) for appropiate tubing I.D.

B-I-B rack can be moved for cleaning or service.

• Use new (clean), 1/4" I.D. [6 mm], flexible, high pressure, braided tubing from the CO2 / air

regulator to the pump.

NEVER connect a transfer tank "system" in series with a B-I-B system. Syrup contaminants in

old components may work their way through the air supply causing premature failure of the gas

pump. Gas used to operate pumps

water, etc

tanks should be drained regularly. Pumps subjected to contaminated air are not covered by warranty.

). Air compressors may be used with proper particle filters and moisture separators. Air storage

MUST be clean and contain no contaminants (syrup, oil, rust,

High concentrations of CO2 can be fatal as it will displace the air from non-ventilated areas.

Pumps operated by CO

2 must be in ventilated areas.

If placed in a confined area

the room air on a continuous basis should be used.

• All tubing connections must be secured with stainless steel, stepless Oetiker ® clamps.

• Cable-tie all tubing securely to prevent kinks or sags that inhibit performance or cause damage to the

pump fittings.

START-UP PROCEDURE

1. Confirm that all tubing connections are properly clamped, fittings are tight, and tubing is not kinked.

Install bag connector to the B-I-B.

2.

Adjust gas regulator to about 20 psi. [1.4 bar] allowing the pump to stroke slowly.

3. Operate the valve until all air trapped within the tubing has been purged.

4.

Once the air has been purged, adjust the CO2 regulator to the pressure necessary to main-

tain the desired brix. The most efficient gas usage occurs at 40 psi.

static gas pressure to the pump is 85 psi. [5.8 bar], minimum 20 psi. [1.4 bar].

Flowrates that result in a stroke-rate of more than two strokes per second will decrease pump

(Consult factory) Pump failure due to "overrunning" is not covered by the limited warranty.

life.

To prevent air from entering the system always leave the bag connector attached to the empty

B-I-B until a new B-I-B can be installed. Air entered into the system, via air in the bags or

vacuum leaks, may cause brix fluctuation, foaming, spitting, non-operation of the vacuum soldout or pump "run-on" with the valve closed.

pump.

(basement, closet, cooler box, etc.), exhaust fans capable of changing

[2.8 bar]. MAXIMUM

Symptoms of this kind can lead to a misdiagnosis of the

Publication Number: TP01071 - 16 - © 2004, IMI Cornelius Inc.

Page 21

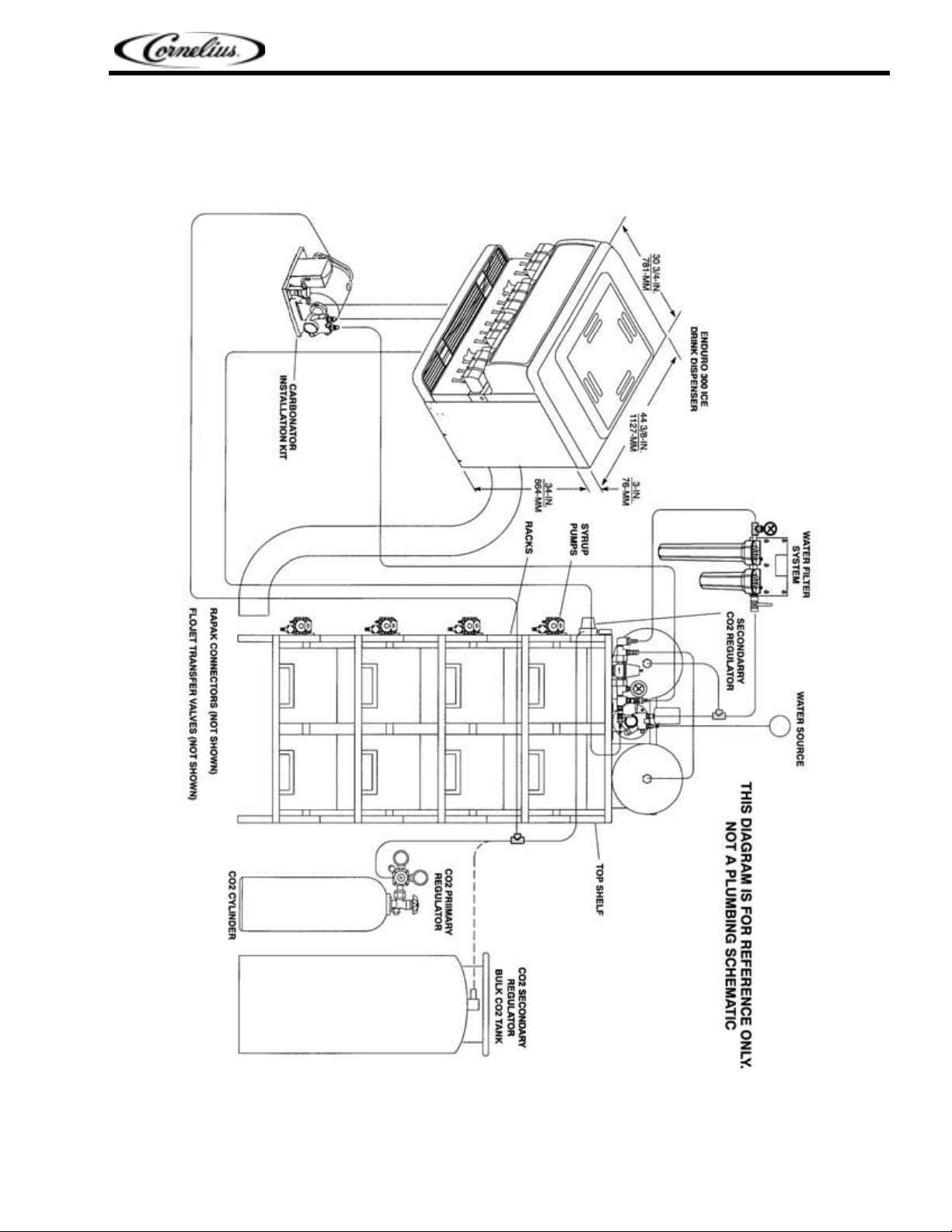

TYPICAL INSTALLATION

IntelliCarb Training Manual

PLUMBING

FIGURE 21. Typical Installation

© 2004, IMI Cornelius Inc. - 17 - Publication Number: TP01071

Page 22

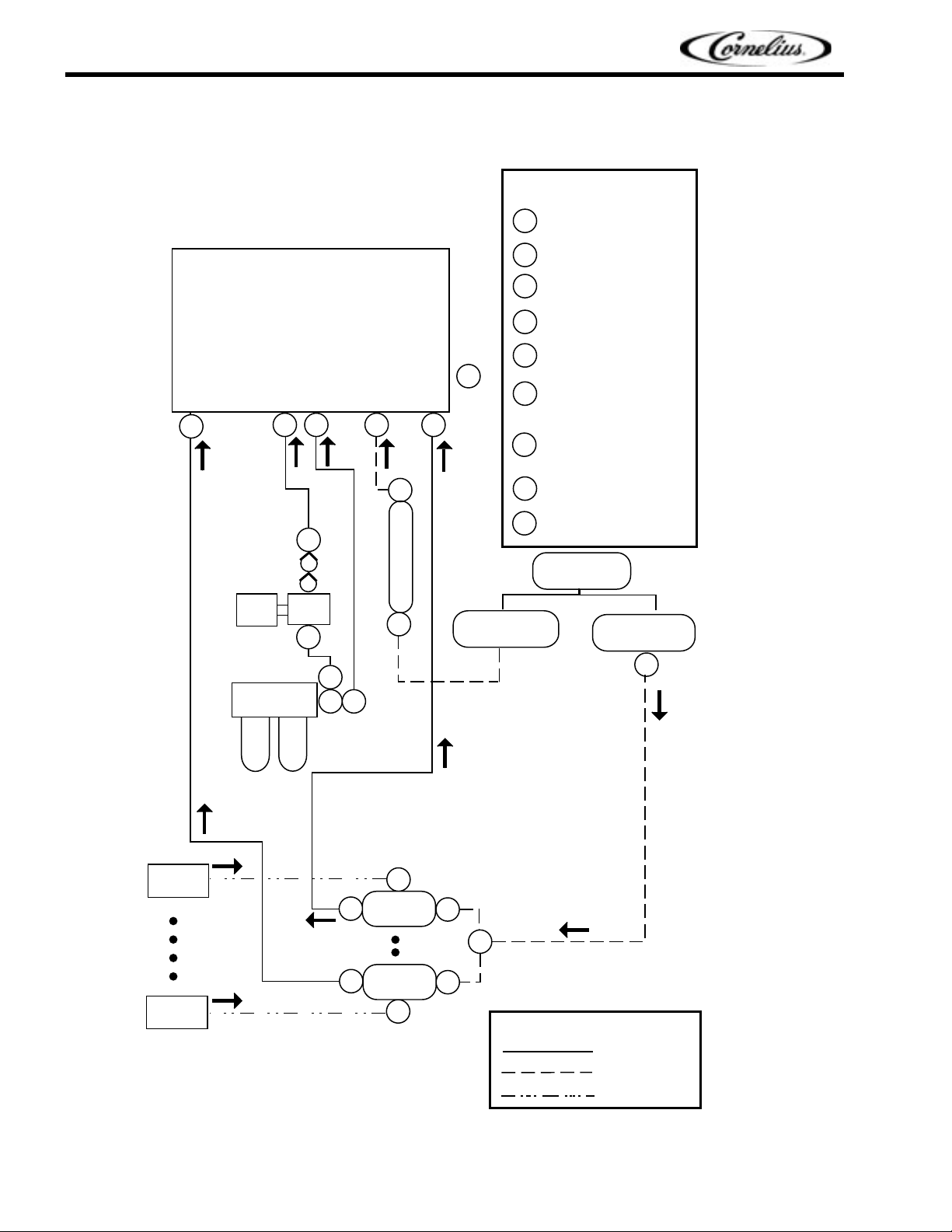

IntelliCarb Training Manual

PLUMBING LAYOUT

3-5 Per Side

Brand Syrup Inlets

B

Plain Water In

Carb Water In

BB

C

Brand Syrup Inlets

Carbonator Tank CO2 Inlet

C

3-5 Per Side

B

E

Connection Legend

3/8" Female Fir Nut

A

3/8" Barb Conn

B

C

1/4" Barb Conn

3/8" Hose Barb - 3/4" NP

D

1/4" Female Flr Nut

E

Direct Conn to SUR

F

Outlet on BIB Pmp

Direct Conn to CO2

G

Inlet on BIB Pmp

Syr Inlet BIB Pmp

H

BIB Syrup

6-10 Brand

Flavors

Carb

Pump

Water Filter

I

A

75 psi Fixed Reg

Regulator

100 psi

G

G

BIB Pump

BIB Pump

F

E

H

A

D

I D

F

3/4" NPT TEE

CO2 Supply

Regulator

55-60 psi

E

BIB Syrup

Publication Number: TP01071 - 18 - © 2004, IMI Cornelius Inc.

H

Tubing Legend

3/8" Bev Tubing

1/4" Bev Tubing

3/8" Tycon Tubing

FIGURE 22. Plumbing Layout

Page 23

© 2004, IMI Cornelius Inc. - 19 - Publication Number: TP01071

FIGURE 23. Flow Diagram 1xx (Six Flavor Model)

FAUCETS VIEWED FROM THIS SIDE

FA UC E TS

6

5

4

FLOW DIAGRAM 1XX (SIX FLAVOR MODEL)

DOUBLE CHECK

VA LV E

W1,

W1

S6

S5

W2

S4

VALVES 1,2,

3,6

W2,

VALVES 4,5

CARB ONATOR

PUMP

NON--CARB

WAT ER

OPTIONAL

PRESSURE

REGULATOR

CHECK

VA LV E

FILTER

INSTALL FOR

NON--CARB A S

REQUIRED

POTABL E

WAT ER

SUPPLY

COLDPLATE

INLET

CONNECTIONS

CARBONATOR

TAN K

3

2

1

W2

S3

S2

S1

ITEMS INSIDE BROK EN LINE

INCLUDED WITH UNIT

W1

COLD PLATE

S5

S6

S7

S1

S2

S3

OPTIONAL FOR

DIET DRINKS

OR ROOT B EER

5--15

PSIG

PLUGGED

S1

S2

S3

SYRUP TANKS

15--50 PSIG

S6S7

S5

PRESSURE

REGULATORS

75 PSI

IntelliCarb Training Manual

CO2

CYLINDER

Page 24

Publication Number: TP01071 - 20 - © 2004, IMI Cornelius Inc.

FLOW DIAGRAM 1XX (EIGHT FLAVOR MODELS)

IntelliCarb Training Manual

FAUCETS

8

7

FAUCETS VIEWED FROM THIS SIDE

COLDPLATE

CONNECTIONS

6

5

INLET

TAN K

4

3

2

1

FIGURE 24. Flow Diagram 1XX (Eight Flavor Models)

S8

S7

S6

S5

CARBONATOR

S4

S3

S2

S1

W1

W2

S5

S6

S7

S8

S1

S2

S3

S4

W2

W1

COLD PLATE

W1,

VALVES 1,2,

3,7,8

W2,

VALVES 4,

5,6

5--15

PSIG

OPTIONAL FOR

DIET DRINKS

OR ROOT B EER

DOUBLE CHECK

VA LV E

OPTIONAL

PRESSURE

REGULATOR

CARB ONATOR

PUMP

NON-- CARB

WAT ER

S4 S5

S2

S3

SYRUP TANKS

15--50 PSIG

S1

CHECK

VA LV E

S8

FILTER

INSTALL FOR

NON-- CARB A S

REQUIRED

S6S7

PRESSURE

REGULATORS

CYLINDER

POTABL E

WAT ER

SUPPLY

75 PSI

CO2

ITEMS INSIDE BROK EN LINE

INCLUDED WITH UNIT

Page 25

© 2004, IMI Cornelius Inc. - 21 - Publication Number: TP01071

FIGURE 25. Flow Diagram 2xx (Eight Flavor Models)

FAUCETS

8

7

6

5

W1

W2

W1

VALVES 1,2

3,6,7,8

W2

VALVES 4,5

DOUBLE CHECK

VALV E

CARBONATOR

OPTIONAL

PRESSURE

REGULATOR

CHECK

VALV E

FILTER

INSTALL FOR

NON–CARB AS

REQUIRED

FLOW DIAGRAM 2XX (EIGHT FLAVOR MODELS)

POTABLE

WATER

SUPPLY

COLDPLATE

INLET

CONNECTIONS

CARBONATOR

TANK

4

3

2

1

S8

S7

S6

S5

W2

W1

S4

S3

S2

S1

COLD PLATE

W2

W1

5–15

PSIG

OPTIONAL FOR

DIET DRINKS

OR ROOT BEER

Non–Carb Water

75 PSI

IntelliCarb Training Manual

S1

S2 S3

S4 S5

SYRUP TANKS

15–50 PSIG

S6

S8S7

PRESSURE

REGULATORS

ITEMS INSIDE BROKEN LINE

INCLUDED WITH UNIT

CO2

Cylinder

Page 26

IntelliCarb Training Manual

FLOW DIAGRAM 2XX (TEN FLAVOR MODELS))

POTABLE

WATER

SUPPLY

FILTER

PRESSURE

OPTIONAL

REGULATOR

VALV E

DOUBLE CHECK

W1

VALVES 1,2,3

4,7,8,9,10

W2

VALVES 5,6

INSTALL FOR

NON–CARB AS

CHECK

VALV E

CARBONATOR

PUMP

REQUIRED

NON CARB WATER

75 PSI

S10S9

S8S1 S2

S6 S7

S3 S4 S5

5–15

PSIG

DIET DRINKS

OPTIONAL FOR

OR ROOT BEER

15–50 PSIG

SYRUP TANKS

PRESSURE

REGULATORS

CO2

CYLINDER

S4S3S2

S5

INLET

COLDPLATE

CONNECTIONS

S1

CARBONATOR

TANK

W2

S4

S5

4

5

W1

COLD PLATE

S2

S3

3

2

S1

1

INCLUDED WITH UNIT

ITEMS INSIDE BROKEN LINE

10

FAUCETS

S10

W1

S6

S7

S8

S9

S10

W2

S6

S7

S8

S9

9

7

8

6

FAUCETS VIEWED FROM THIS SIDE

FIGURE 26. Flow Diagram 2xx (Ten Flavor Models)

Publication Number: TP01071 - 22 - © 2004, IMI Cornelius Inc.

Page 27

© 2004, IMI Cornelius Inc. - 23 - Publication Number: TP01071

FLOW DIAGRAM 300 (TWELVE FLAVOR MODELS)

FAUCETS

FIGURE 27. Flow Diagram 300 (Twelve Flavor Models)

FAUCETS VIEWED FROM THIS SIDE

12

11

10

COLDPLATE

INLET

CONNECTIONS

9

8

7

FAUCETS

6

5

4

COLDPLATE

INLET

CONNECTIONS

3

2

1

COLD PLATE

S12

S11

S10

W1

W2

S10

S11

S12

S7

S8

S9

S9

S8

S7

COLD PLATE

S6

S5

S4

W1

W2

S4

S5

S6

S1

S2

S3

S3

S2

S1

W2

W2

W2

W2

W1

W1

W1

W1

TO COLDPLATE

SYRUP INLETS

OPTIONAL FOR

DIET DRINKS

OR ROOT BEER

5–15

PSIG

DOUBLE CHECK

VALV E

NON–CARB WATER

S1 S6 S5

CARBONATOR

PUMP

SYRUP TANKS

15–50 PSIG

CHECK

VALV E

S4 S9

S8S3 S2

OPTIONAL

PRESSURE

REGULATOR

INSTALL FOR

NON–CARB AS

REQUIRED

S12S7

FILTER

S10S11

PRESSURE

REGULATORS

POTABLE

WATER

SUPPLY

CO2

CYLINDER

CO2

75 PSI

IntelliCarb Training Manual

CARBONATOR TANK

ITEM INSIDE BROKEN LINE

INCLUDED WITH UNIT

Page 28

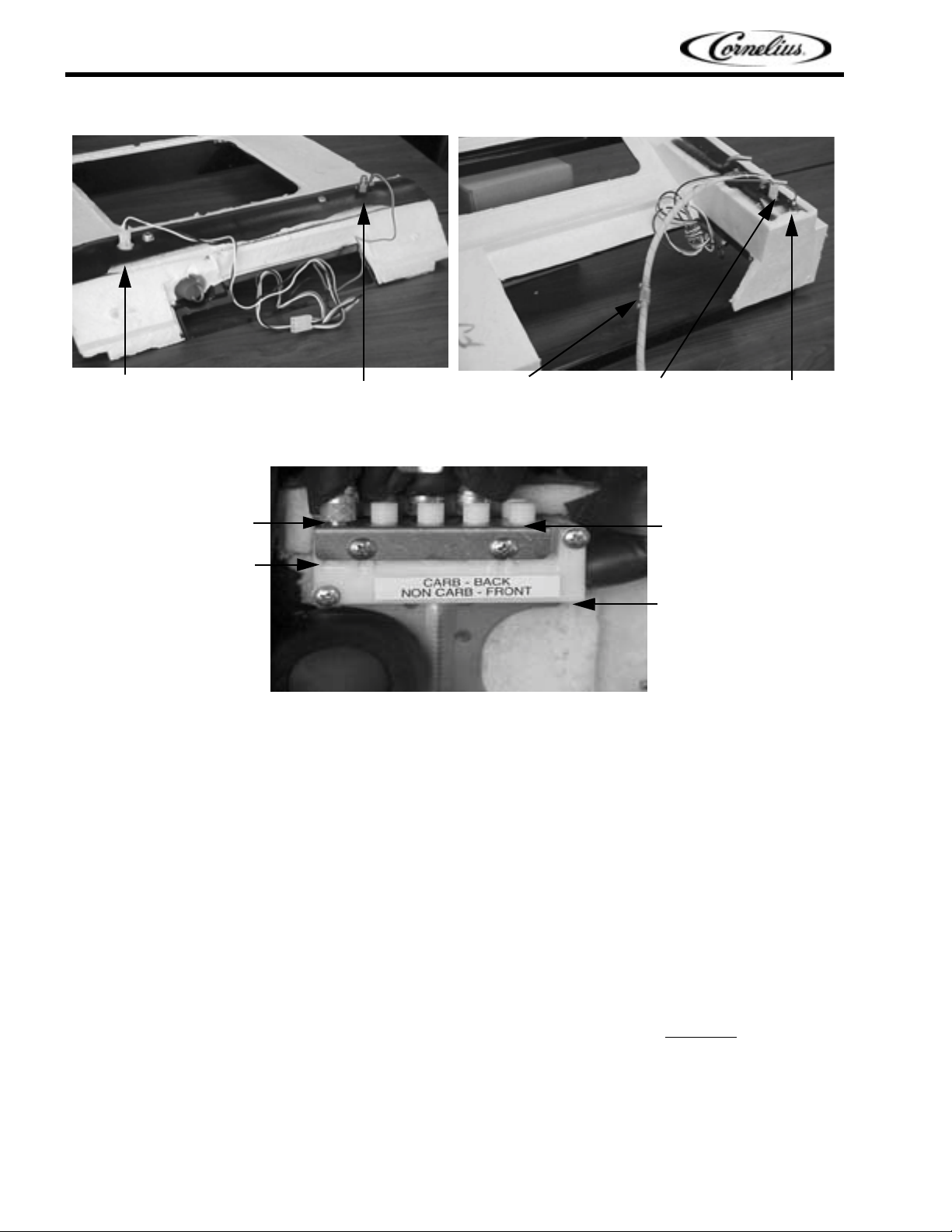

IntelliCarb Training Manual

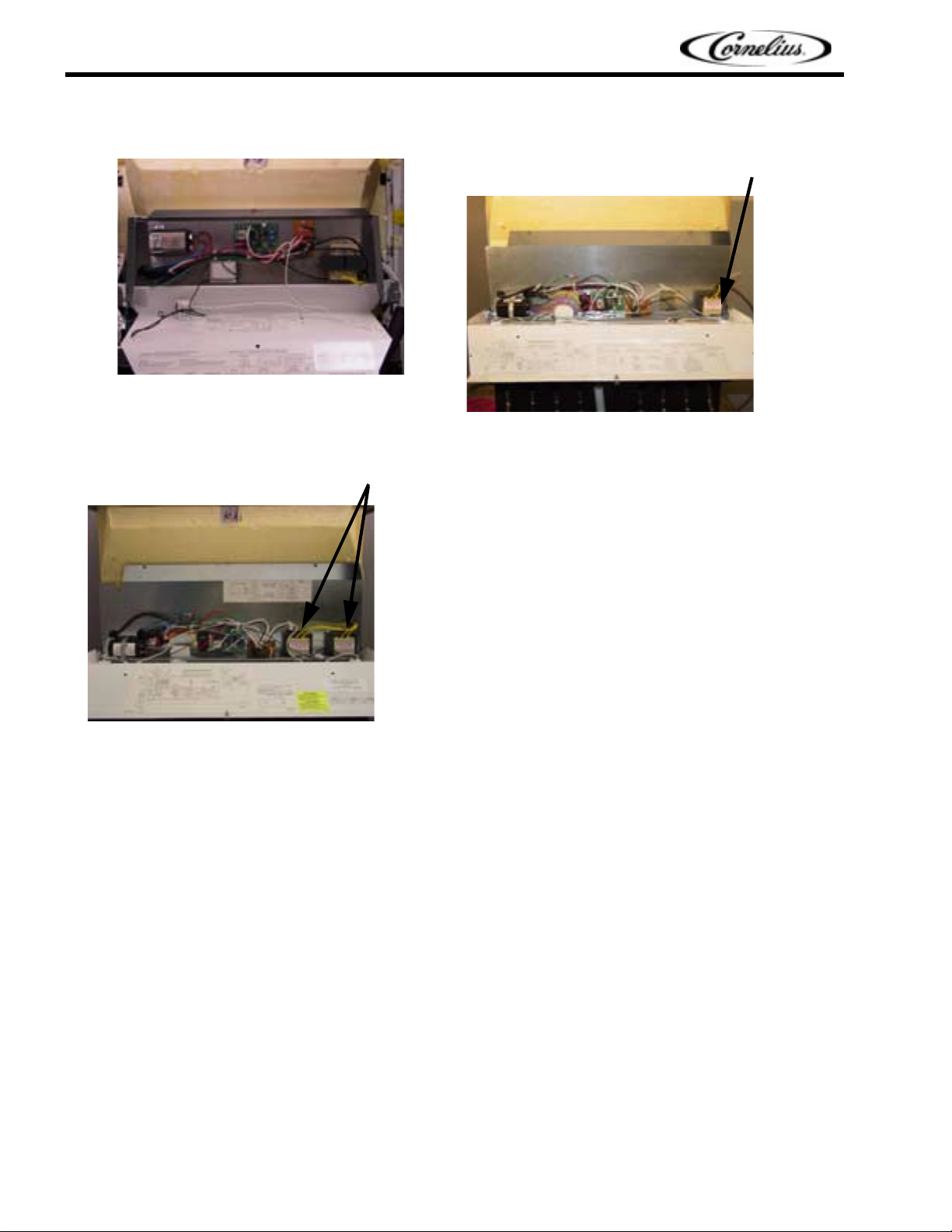

One Transformer Powers the Left Bank

and the Other Powers the Right Bank.

Will Power All Valves Simultaneously.

Transformers

ELECTRICAL SECTION

FIGURE 28. Electrical Box 1xx Single Transformer

Control Box Single Transformer Will Power

up to Three Valves Simultaneously.

FIGURE 29. Electrical Box 2xx Single Transformer

Transformer

FIGURE 30. Electrical Box 2XX Dual Transformer

Publication Number: TP01071 - 24 - © 2004, IMI Cornelius Inc.

Page 29

CARBONATOR WIRING DIAGRAM

Time Out Selection Pins.

7min/3 min/Disabled

(Move Jumper to Select)

IntelliCarb Training Manual

RESET CONNECTIONS

© 2004, IMI Cornelius Inc. - 25 - Publication Number: TP01071

Page 30

Publication Number: TP01071 - 26 - © 2004, IMI Cornelius Inc.

WIRING DIAGRAM 1XX (120V)

IntelliCarb Training Manual

SERVICE INFORMATION

FIGURE 31. Wiring Diagram 1xx (120V)

CCW

AGITATOR

MOTOR

Q.C.

CONNECTOR

GRD

115 V

SUPPLY

TO HINGE

MOTOR

HEATER

GRN

DISPENSE

SWITCH

N

L

+

--

O

W

B

B

B

R

H

L

A

I

U

N

T

E

G

E

E

G

W

B

R

H

L

E

I

A

C

E

T

N

E

K

G

R

E

E

N

BLACK

BLACK

OPTIONAL

B

B

B

B

R

R

L

L

L

L

L

L

E

E

A

A

A

U

A

U

D

D

C

C

C

E

C

K

K

BLACK

E

K

K

BLUE

WHITE

BLACK

RED

WHITE

PINK

RED

BLUE

GATE

SOLENOID

(106VDC)

OPTIONAL

PINK

DANG ER!

BLACK

BLACK

NC

NCNOCOM

L2

COMNO

L1

WHITE

ELECTRIC SHOCK HA ZA RD. DISCONNECT

POWER B EFORE SERVICING UNIT.

YELLOW

YELLOW

W

B

H

L

I

A

T

C

E

K

WHITE

G

BLACK

RED

R

E

E

N

WHITE

WHITE

WHITE

W

H

I

T

E

BLACK

R

E

D

B

R

L

E

A

D

C

K

BLACK

BLACK

BLACK

WHITE

TO BEVERAGE FAUCET

KEY SWITCH

T’STAT

1

ICE LEVEL

OPTIONAL

2

WHT

OPTION

LIGHT

Page 31

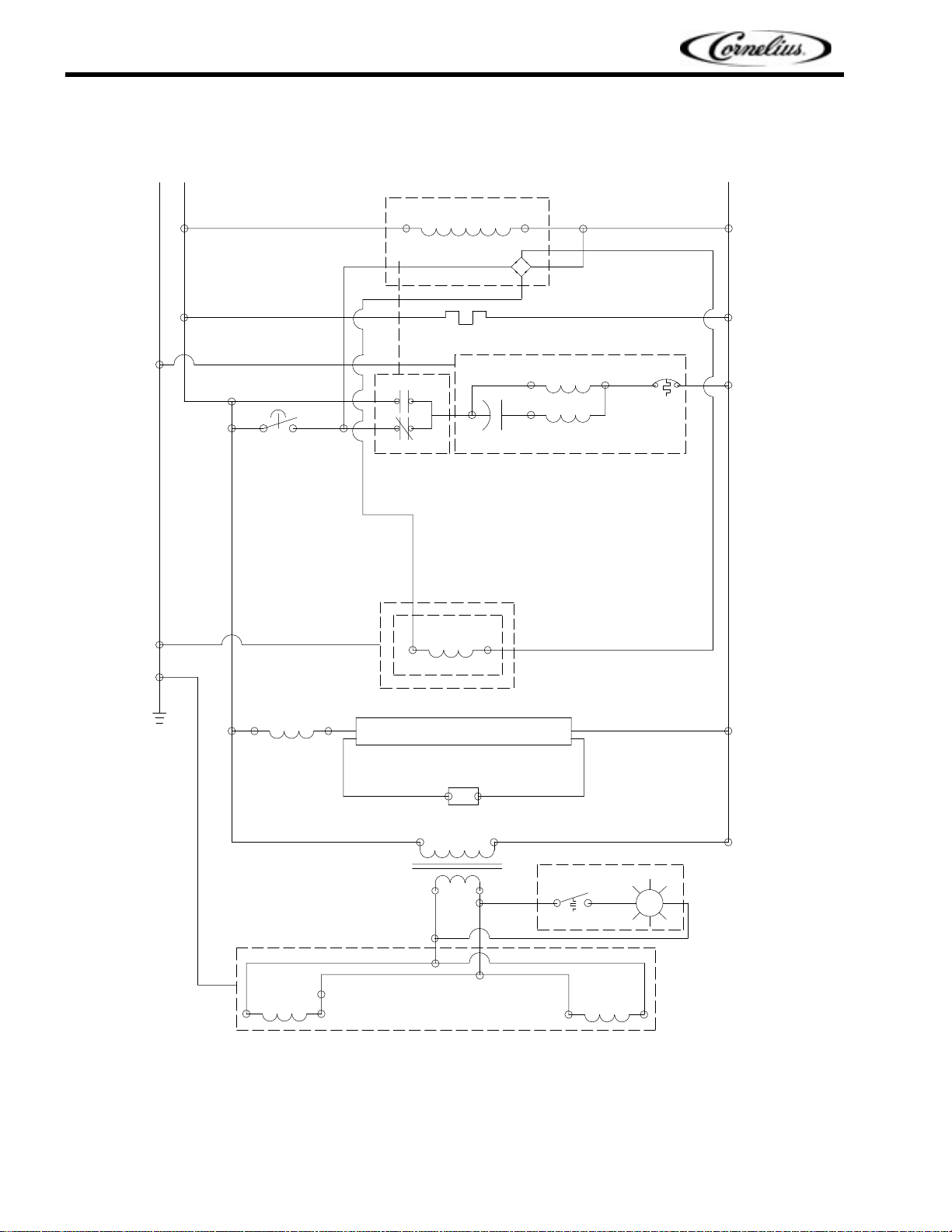

SCHEMATIC 1XX

IntelliCarb Training Manual

L

G

TIMER

VEND SWITCH

L2

MOTOR HEATER

N.O.

C

N.C.

CAPACITOR

RECTIFIER

L1

AGITATOR MOTOR

N

OPTIONAL

BALLAST

BEVERAGE

VALVES

GATE

SOLENO ID

OPTIONAL LIGHT

OPTIONAL

STARTER

BEVERA GE TRA NSFOR MER

OPTIONAL LOW ICE LEVEL

BEVERA GE PANEL

T’STAT

BEVERAGE

VALVES

LIGHT

FIGURE 32. Schematic 1xx

© 2004, IMI Cornelius Inc. - 27 - Publication Number: TP01071

Page 32

Publication Number: TP01071 - 28 - © 2004, IMI Cornelius Inc.

MOTOR

AGITATOR

MOTOR

FIGURE 33. Wiring Diagram 2xx (120V Model)

Q.C. CONNECTOR

GATE

SOLENOID

(106VDC)

Y

B

E

L

L

K

TO HINGE

HEATER

BLK

GRN

N

L

DISPENSE

SWITCH

DANGER!

SERVICE INFORMATION

ELECTRIC SHOCK HAZA RD. DISCONNECT

POWER BEFORE SERVICING UNIT.

LIGHTT’STAT

2

1

BLUE

I CE LEVEL SI GNAL

OPTI ON

TO 24V

TRANSFORMER

BLUE

TO BEVERAGE VALVES

KEY SWITCH

YELLOW

WIRING DIAGRAM 2XX (120V MODEL)

IntelliCarb Training Manual

MOTOR START

CAPACITOR

B

W

B

B

L

H

L

L

A

I

U

U

C

T

E

E

K

E

BLACK

WHITE

OPTIONAL

LIGHT SOC KET

RECTIFIER

W

B

H

L

I

U

T

E

E

R

Y

B

W

G

B

B

BLACK

RED

+

--

R

E

D

B

L

U

E

B

B

L

L

U

U

E

E

B

L

A

OPTIONAL

C

K

STARTER

E

L

L

A

L

C

O

K

W

LIGHT

B

B

R

G

E

H

R

L

L

L

L

E

R

D

I

E

A

A

A

A

D

E

T

E

C

C

C

E

C

E

K

N

K

K

K

N

W

H

I

T

E

WHITE

BLACK

Y

E

MOTOR

L

START

R

L

RELAY

O

W

3

R

E

D

4

2

W

H

I

T

E

NC

E

D

NO

NC

G

R

E

E

N

BLACK

COM

AGITATION

TIMER

NOCOM

G

R

E

E

N

BLACK

L2

L1

WHITE

BLACK

WHITE

BLACK

OPTI ONAL

LIGHT BALLAST

WHITE

WHITE

BLACK

BLACK

BLACK

WHITE

TRANSFORMER

W

H

I

T

E

WHITE

BEVERAGE

(O PTIONAL )

BEVERAGE

TRANSFORMER

(O PTIONAL )

W

H

B

L

A

C

K

I

T

E

OPTIONAL

LIGHT SOCKET

BLACK

WHITE

B

L

A

C

K

Page 33

WIRING DIAGRAM 2XX (220/240V MODELS)

BLACK

POWER

SWITCH

BROWN

TO BEVERAGE VALVES

BROWN

BEVERAGE

(OPTIONAL)

TRANSFORMER

WHITE

IntelliCarb Training Manual

WHITE

BLACK

LIGHT

SOCKET

OPTIONAL

LIGHT

T’S TAT

KEY SWITCH

YELLOW

BEVERAGE

(OPTIONAL)

OPTION

BLUE

ICE LEVEL SIGNAL

TO 24V

TRANSFORMER

.

BLUE

2

1

POWER BEFORE SERVICING UNIT

ELECTRIC SHOCK HAZARD. DISCONNECT

SER VICE INFORMATION

TRANSFORMER

LIGHT

BALLAST

OPTIONAL

LINE

LAMP

LT BLUE

LOA

FILTER

N

POWER LINE

GRN

WHITE

LT BLUE

D

L

WHITE

BLACK

WHITE

BROWN

BROWN

WHITE

BLACK

WHITE

BLACK

FIL TER

WHITE

ASY

L2

NC

LT BLUE

J10

COM

NO

N

AGITATION

J9

TIMER

COM

NO

BROWN

L

L1

NC

BLACK

BLACK

RED

RED

BLACK

BROWN

BROWN

BLU

E

BLACK

LT B LU E

BROWN

GRN/YEL

GRN/YEL

MOTOR

HEATER

TO

BLU

BLK

MOTOR

AGITATOR

BLK

N

E

PANEL

BEVERAGE

E

Q.C. CONNECTOR

DANGER!

L

GUSSET

TO HINGE

SWITCH

DISPENSE

GATE

SOLENOID

GRN/YEL

GRN/YEL

GRN/YEL

GRN/YEL

RED

BLACK

BLACK

BLACK

GRN/YEL

GRN/YEL

LTBLU

BROWN

GRN/YEL

RED

YELLO

GRN/YEL

BLACK

BLU

E

GRN/YEL

BLU

E

BLACK

CAPACITOR

MOTOR START

BLACK

START

RELAY

MOTOR

E

W

RED

3

4

2

WHITE

LIGHT

OPTIONAL

BLACK

WHITE

STARTER

BLACK

OPTIONAL

WHITE

LIGHT

SOCKET

FIGURE 34. Wiring Diagram 2xx (220/240V Models)

© 2004, IMI Cornelius Inc. - 29 - Publication Number: TP01071

Page 34

IntelliCarb Training Manual

WIRING DIAGRAM 2XX (220/240V MODELS)

G

L

N

VEND SWITCH

TIMER

L1

RECTIFIER

MOTOR HEATER

N.O.

C

N.C.

GATE

SOLENOID

L2

AGITATOR MOTOR

OPTIONAL

BALLAST

OPTIONAL

BEVERAGE

VALVES

OPTIONAL LIGHT

OPTIONAL

STARTER

OPTIONAL

BEVERAGE TRANSFORMER

BEVERAGE PANEL

OPTIONAL ICE LEVEL

FIGURE 35. Wiring Diagram 2xx (220/240V Models)

OPTIONAL

BEVERAGE

VALVES

Publication Number: TP01071 - 30 - © 2004, IMI Cornelius Inc.

Page 35

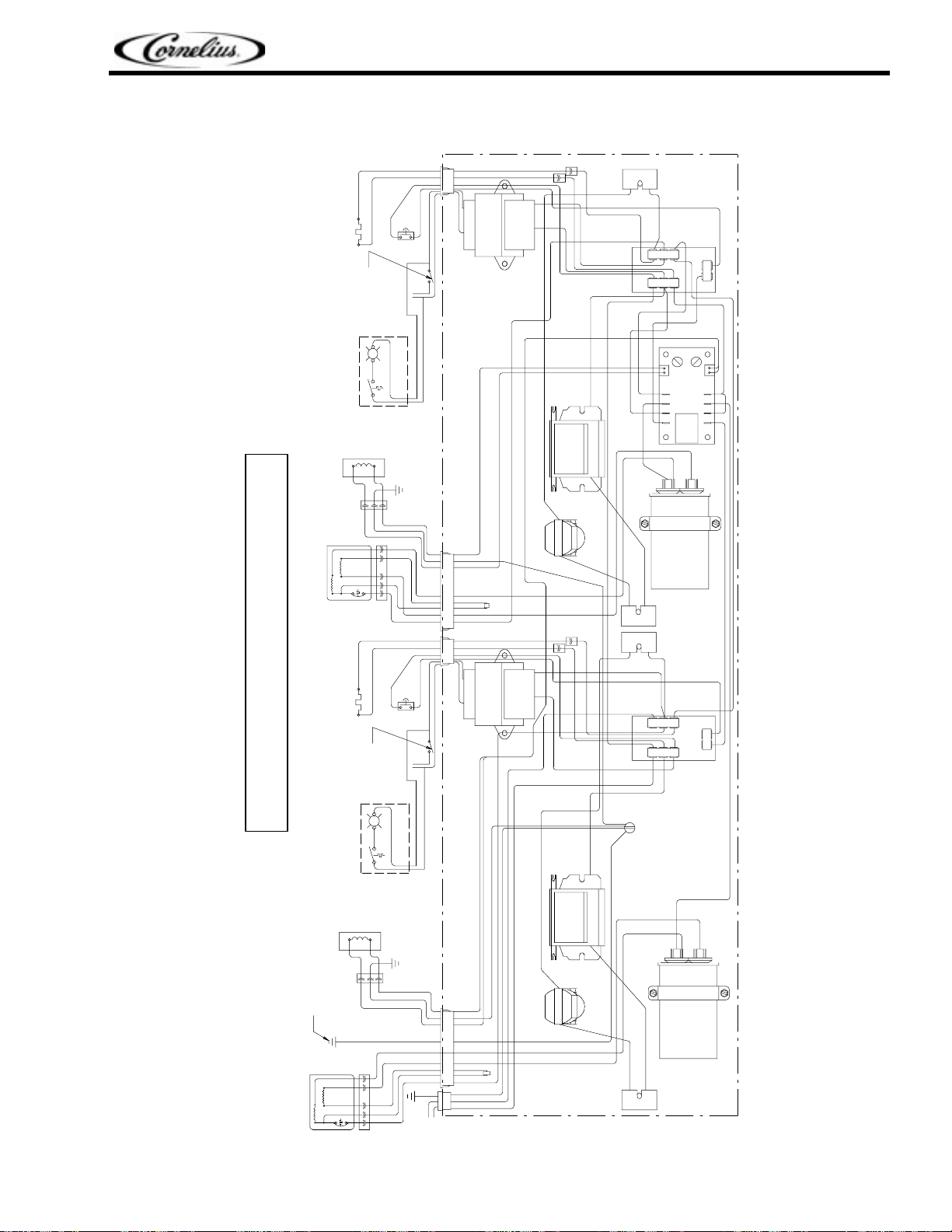

WIRING DIAGRAM 300 (220/240V MODELS)

BLACK

BLACK

BLACK

RED

YELLOW

YELLOW

YELLOW

BEVERAGE

(OPTIONAL)

TRANSFORMER

MOTOR

HEATER

KEY

SWITCH

SWITCH

DISPENSE

(OPTIONAL)

TO BEVERAGE

FAUCET

BLACK

BLACK

WHITE

WHITE

WHITE

BLACK

WHITE

WHITE

BLACK

IntelliCarb Training Manual

LIGHT

SOCKET

OPTIONAL

RED

WHITE

RED

WHITE

LIGHTT’STAT

BLUE

2

ICE LEVEL

1

SIGNAL OPTION

BLU

E

FAUCET

TO BEVERAGE

TO 24V TRANSFORMER

BLU

GRN/YEL

BLU

RED

BLU

ORN

BLACK

WHITE

YELLOW

YELLOW

YELLOW

GATE

SOLENOID

(DC COIL)

(CW)

RIGHT

MOTOR

AGITATOR

SWITCH

MOTOR

HEATER

POWER BEFORE SERVICING UNIT.

ELECTRIC SHOCK HAZARD. DISCONNECT

SERVICE INFORMATION

DISPENSE

KEY

SWITCH

(OPTIONAL)

BLUE

E

E

E

BLACK

BEVERAGE

TRANSFORMER

BLUE

WHITE

BLUE

BLACK

(OPTIONAL)

BLUE

BLACK

RED

WHITE

OPTIONAL

LIGHT STARTER

BLUE

WHITE

BLUE

LIGHT

BALLAST

OPTIONAL

BLACK

BLACK

BLACK

WHITE

BLACK

BLACK

BLACK

WHITE

BLACK

BLACK

WHITE

PINK

BLACK

L2

LIGHT

OPTIONAL

WHITE

WHITE

BLACK

J10

COM

NC NO

RED

MOTOR

SOCKET

TIMER

AGITATION

CAPACITOR

RED

WHITE

J9

BLACK

L1

COMNO

NC

RED

DANGER!

LEFT

MOTOR

(CCW)

AGITATOR

TO HINGE BRACKET

LIGHTT’STAT

BLUE

2

ICE LEVEL

1

SIGNAL OPTION

BLU

E

TO 24V TRANSFORMER

GATE

SOLENOID

(DC COIL)

GRN

GRN

L

N

BLU

BLU

RED

BLU

BLACK

ORN

WHITE

GREEN

WHITE

BLACK

GREEN/YELLOW

E

E

E

BLACK

GREEN

WHITE

OPTIONAL

LIGHT STARTER

GREEN

LIGHT

OPTIONAL

BALLAST

BLACK

BLACK

BLACK

LIGHT

SOCKET

OPTIONAL

RED

MOTOR

CAPACITOR

PINK

BLUE

FIGURE 36. Wiring Diagram 300 (220/240V Models)

© 2004, IMI Cornelius Inc. - 31 - Publication Number: TP01071

Page 36

IntelliCarb Training Manual

WIRING DIAGRAM 300 (220/240V MODELS)

BRN

BRN

YELLOW

YELLOW

TO 24V TRANSFORMER

BLU

BLU

RED

BLU

ORN

BLACK

WHITE

YELLOW

YELLOW

BLACK

BEVERAGE

(OPTIONAL)

TRANSFORMER

E

E

E

BLACK

BEVERAGE

(OPTIONAL)

TRANSFORMER

BLACK

BLACK

WHITE

WHITE

BLACK

OPTIONAL

BLACK

RED

LIGHT STARTER

SERVICE INFORMATION

ON/OFF

SWITCH

RIGHT

MOTOR

AGITATOR

MOTOR

HEATER

(CW)

MOTOR

HEATER

T’STAT LIGHT

KEY

SWITCH

SWITCH

DISPENSE

(OPTIONAL)

BLUE

2

1

GATE

SWITCH

DISPENSE

YELLOW

FAUCET

TO BEVERAGE

ICE LEVEL

SIGNAL OPTION

BLU

E

SOLENOID

(DC COIL)

RED

POWER BEFORE SERVICING UNIT.

YELLOW

KEY

FAUCET

SWITCH

TO BEVERAGE

T’STAT LIGHT

(OPTIONAL)

BLUE

2

1

ICE LEVEL

SIGNAL OPTION

BLU

E

TO 24V TRANSFORMER

BLUE

WHITE

DANGER ELECTRIC SHOCK HAZARD. DISCONNECT

LIGHT

BALLAST

OPTIONAL

BLACK

BLACK

GREEN

OPTIONAL

BLACK

LIGHT

BALLAST

WHITE

WHITE

WHITE

WHITE

WHITE

WHITE

BLACK

BLACK

BLUE

BLACK

BLACK

WHITE

PINK

BLACK

BLACK

LIGHT

OPTIONAL

WHITE

L2

LIGHT

OPTIONAL

WHITE

WHITE

SOCKET

J10

COMNO

NC

RED

MOTOR

CAPACITOR

SOCKET

TIMER

AGITATION

BLACK

D

E

R

RED

WHITE

RED

BLUE

BLACK

J9

L1

NOCOM

NC

RED

BRN

PINK

BLUE

LEFT

AGITATOR

MOTOR

(CCW)

TO HINGE

GATE

SOLENOID

(DC COIL)

BLU

E

BLU

GRN

GRN

E

RED

BLU

E

BLACK

ORN

WHITE

GREEN

BLU

BRN

L

N

OPTIONAL

GREEN

LIGHT STARTER

BLACK

MOTOR

BLACK

CAPACITOR

BLACK

LIGHT

SOCKET

OPTIONAL

BRN

FIGURE 37. Wiring Diagram 300 (220/240V Models)

Publication Number: TP01071 - 32 - © 2004, IMI Cornelius Inc.

Page 37

SCHEMATIC 300 (120V MODELS)

G

L

L1

TIMER

RECTIFIER

MOTOR HEATER

IntelliCarb Training Manual

N

L2

VEND SWITCH

BALLAST

OPTIONAL

BEVERAGE

VALVES

BEVERAGE PANEL

VEND SWITCH

N.O.1

C

N.C.1

CAPACITOR

GATE

SOLENOID

OPTIONAL LIGHT

STARTER

OPTIONAL

BEVERAGE TRANSFORMER

MOTOR HEATER

N.O.2

C

N.C.2

CAPACITOR

AGITATOR MOTOR

OPTIONAL ICE LEVEL

AGITATOR MOTOR

GATE

SOLENOID

BALLAST

OPTIONAL LIGHT

STARTER

OPTIONAL

BEVERAGE TRANSFORMER

BEVERAGE PANEL

OPTIONAL ICE LEVEL

OPTIONAL

BEVERAGE

VALVES

FIGURE 38. Schematic 300 (120V Models)

© 2004, IMI Cornelius Inc. - 33 - Publication Number: TP01071

Page 38

IntelliCarb Training Manual

SCHEMATIC 300 (220/240V MODELS)

G

E–BOX GD.

POWER

PUSH BUTTON

SWITCH

L

VEND SWITCH

OPTIONAL

BALLAST

L1

N.C1

N.O1

EMC

LINE

FILTER

MOTOR HEATER

MOTOR HEATER

TIMER

RECTIFIER

C

OPTIONAL LIGHT

OPTIONAL STARTER

L2

GATE

SOLENOID

AGITATOR MOTOR

N

VEND SWITCH

OPTIONAL BALLAST

BEVERAGE

KEYLOCK SWITCH

OPTIONAL BEV. TRANSFORMER

24V

BEV. FAUCETS

GATE

SOLENOID

N.C2

C

N.O2

OPTIONAL LIGHT

OPTIONAL STARTER

24V

BEV. FAUCETS

OPTIONAL

BEV. TRANSFORMER

EMC

AGITATOR MOTOR

FIGURE 39. Schematic 300 (220/240V Models)

Publication Number: TP01071 - 34 - © 2004, IMI Cornelius Inc.

Page 39

TROUBLESHOOTING

SHURFLOW TROUBLESHOOTING

Pumping Capability

The distance syrup can be delivered is

limited by inherent factors

the inlet

& outlet sides of the beverage

dispensing system. Due to variances in

system configuration and equipment, an

accurate determination of pressure drop is

difficult. Before deciding on a system’s

tubing size, SHURflo recommends

estimating system losses by considering the

following:

• Syrup viscosity and temperature (coldplate,

re-circ., etc.).

Total syrup flow rate of valve(s) connected

•

to a pump.

• Inside diameter of the inlet/outlet tubing,

fittings, bag connector, etc.

• Horizontal & vertical distance of the outlet

tubing.

Vertical tubing runs will reduce total achievable

tubing run length. To estimate the losses within

the vertical distance, use the chart to the

. Take 1% of the distance in feet [3% if

right

meters

]. The resulting number is multiplied by

the vertical distance. This product is then

subtracted from the maximum horizontal

distance. The resulting length is the total

horizontal/vertical (horz./vert.)

obtainable for that flow rate, tubing I.D. and

viscosity.

For example:

(restrictions) within

tubing run that is

IntelliCarb Training Manual

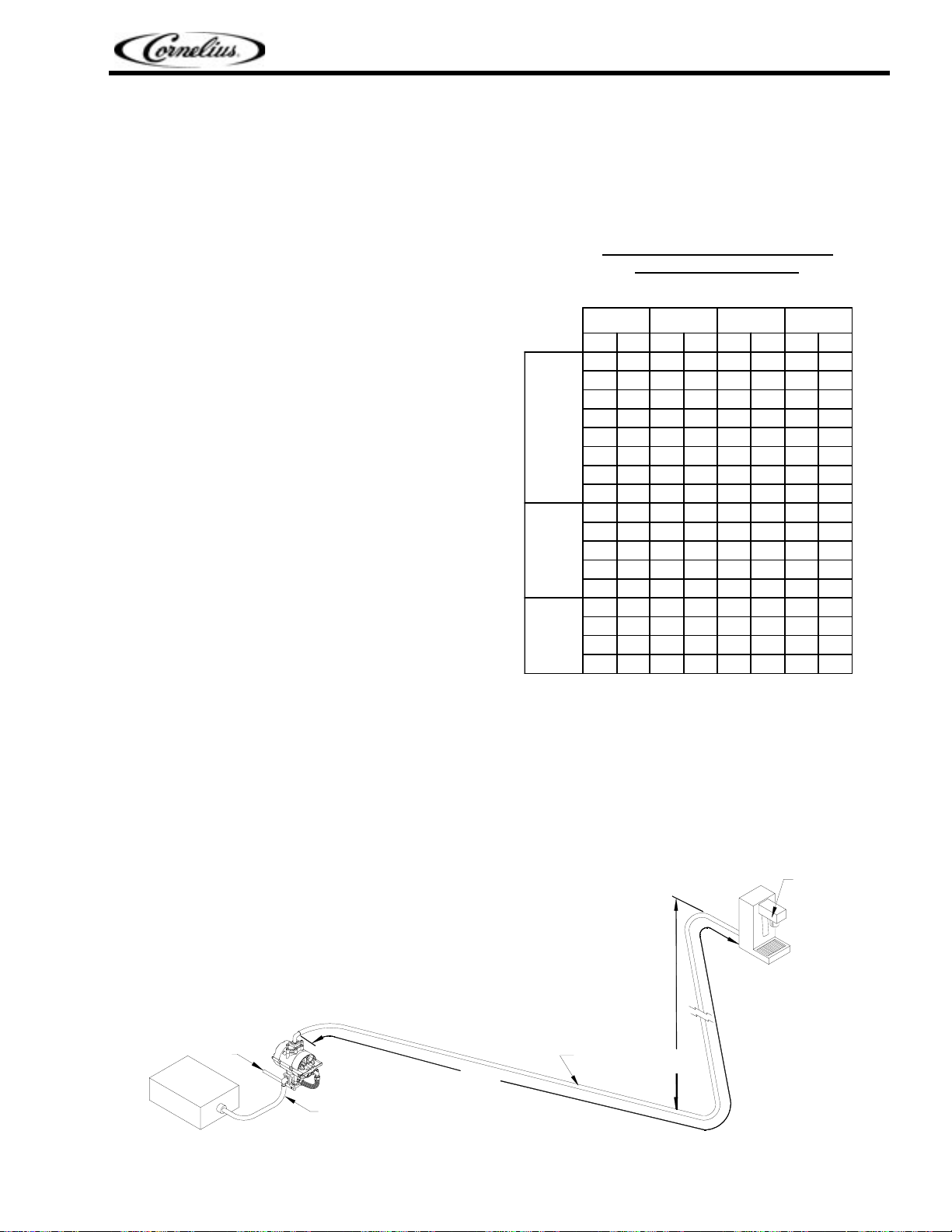

MAXIMUM HORIZONTAL TUBING

BY

Meter

152+

152

138

65

31

19

9

--

152

40

24

9

3

39

23

16

8

VISCOSITY

3

/8" I.D.

[10mm]

Feet

Meter

500+

500+

500+

500+

500

398

297

212

500

500

388

193

127

500

345

239

127

152+

152+

152+

152+

152

121

90

65

152

152

118

59

39

152

105

73

39

500+

500+

500+

500+

500+

500+

500+

500+

500+

1

/2" I.D.

[13mm]

Feet

500

500

500

500

500

366

500

425

Meter

152+

152+

152+

152+

152+

152

152

152

152+

152+

152

152

112

152+

152+

152

129

LENGTHS

Distances shown are intended as a guidline only.

(cPs.=Centipose)

mL

15

22.5

30

45

60

75

90

105

15

22.5

30

45

60

15

22.5

30

45

1

Feet

500+

500

453

212

102

64

32

--

500

133

79

32

10

129

75

53

26

/4" I.D.

[6 m m ]

FLO W RATE

SEC.

/

OZ.

.5

.7 5

Diet

Soda

Syrup

(5 cPs.±3)

Standard

Soda

Syrup

(20 cP s.±3)

Heavy

Soda

Syrup

(35 cP s.±3)

1.0

1.5

2.0

2.5

3.0

3.5

.5

.7 5

1.0

1.5

2.0

.5

.7 5

1.0

1.5

Distances shown are the results of tests conducted at 70°F

[21°C] ambient with a static pressure of 85 psi. [5.8 bar] to the

pump. All distances assume a dynamic pressure of 35 psi. [2.38

bar] at the dispenser to maintain brix.

FAST FLOW VALVE

1

/2 oz./sec. [15 mL]

(syrup flow only)

GAS IN

HEAVY SODA

SYRUP

3

/8" I.D. [10mm]

TUBING (min.)

TOTAL TUBING RUN

[113M]

370 ft.

3

/8" I.D. [10mm]

TUBING

22 ft.

VERTICAL

[6.7M]

© 2004, IMI Cornelius Inc. - 35 - Publication Number: TP01071

Page 40

IntelliCarb Training Manual

The chart indicates that heavy syrup with 1/2 oz./sec [15mL] flow-rate (per the illustration) can be

sustained over a horizontal distance of 500 ft.

[152M] when 3/8" I.D. [10mm] tubing is used.

Feet: Take

1% of 500 ft. (500 x 1%) = 5. Which then is multiplied by the 22 ft. vertical, (22 x 5) =

110 ft.

Subtract this product from the 500 ft.

(horz./vert.) is possible, while the example only requires a distance of 370 ft.

Meters: Take

= 30.5M.

6.7)

Subtract this product from the 152

3% of 152M (152 x 3%) = 4.56. Which then is multiplied by the 6.7M vertical, (4.56 x

M (152-30.5)=121.5. The results indicate a 121.5M tubing run

(horz./vert.) is possible, while the example only requires a distance of 113M.

NOTE: Had the example above resulted in a value that was equal to, or less than the nec-

essary total tubing run, consider a larger I.D. tubing or installation of a pum

using a SHURflo Vacuum Regulator.

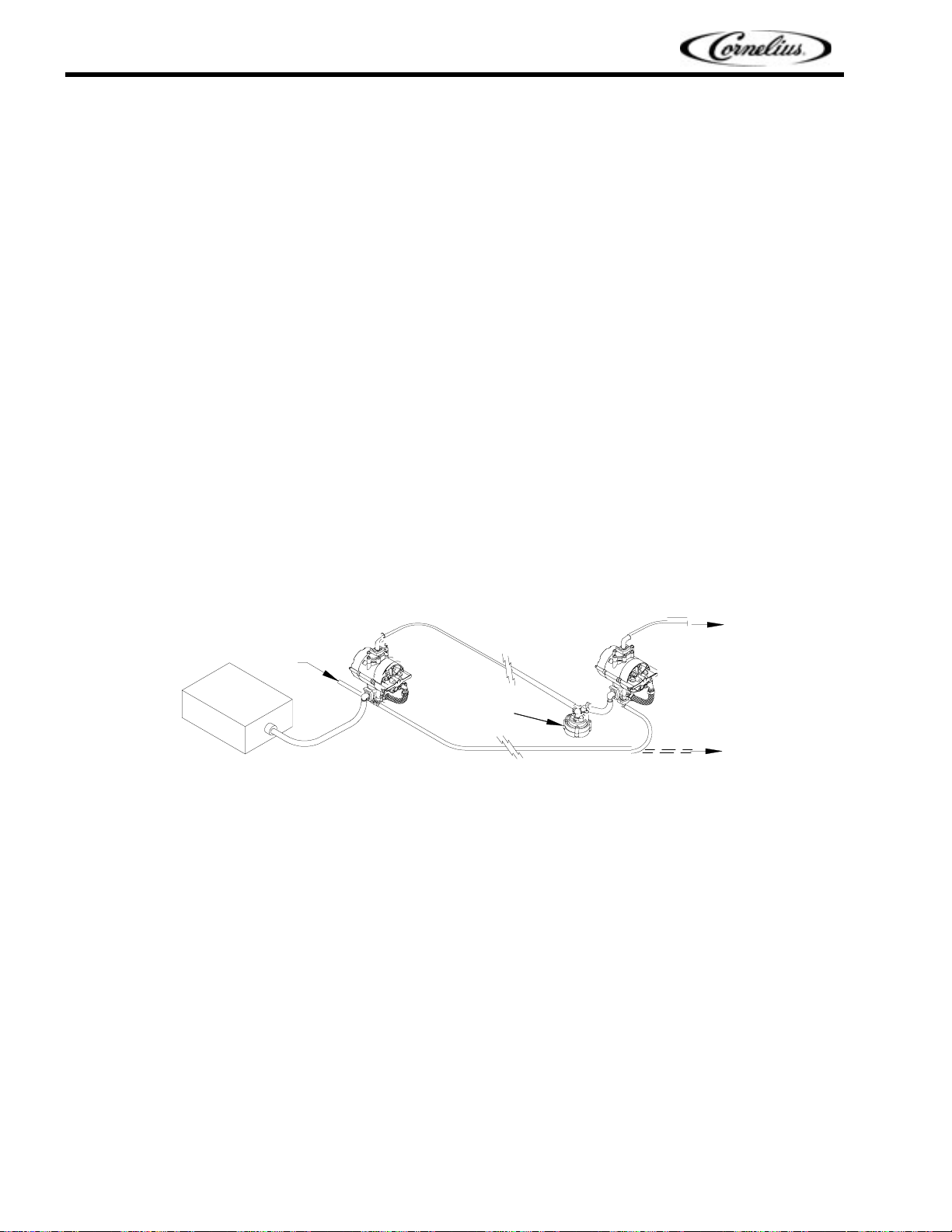

Pumps in Series for Long Distances

Long tubing runs or high vertical lift can be achieved by installing pumps in series. Standard

SHURflo Beverage pumps are not designed to have positive pressure on the inlet side. The

SHURflo Vacuum Regulating Valve

source. By positioning a VRV at the inlet of the secondary pump, incoming pressure is

to zero, permitting syrup to be drawn in under vacuum.

SHURflo can recommend several other methods to meet the requirements for a particular installation,

including Pressurized Inlet Pumps or Accumulators. Contact SHURflo for more information.

(VRV) allows the pump to receive liquid from a pressurized

(500 - 110) =390. The results indicate a 390 ft. tubing run

p(s) in series

reduced

FIRST

GAS IN

B-I-B

PUMP

Pump Sanitizing / Winterizing

Sanitization of the SHURflo Beverage Gas Pump is required. The frequency of Sanitization is

dependant on the concentrate type and its manufacturer’s requirements.

affect the frequency of this procedure are: temperature, concentrate volatility, facility conditions,

installation and equipment. The sanitizing procedure fulfills a required 10 minute contact time

with a 200 ppm Sodium Hypochlorite solution. Refer to SHURflo Service Bulletin #1025 for the

N.S.F. listed sanitizing procedure for the SHURflo pump

freezing

Service Bulletin #1025 for complete winterizing procedure. Refer to the equipment

manufacturer’s instructions for sanitizing and winterizing procedure for carbonators, dispensers

and tubing.

Pumps that have been winterized and/or out of service for a period of time should be sanitized prior to

being placed back in service.

Never apply pressure to the pump’s liquid inlet. Pressurized tanks may damage internal

components if used to sanitize or purge fluid from the pump

(below 32° F [0°C]) must be purged of fluid to prevent damage. Refer to SHURflo

VRV

SECOND

PUMP

TO NEXT

VRV/PUMP

OR

DISPENSER

GAS TO NEXT

PUMP

Factors which also

(only). Pumps that are subjected to

(operating or not).

Publication Number: TP01071 - 36 - © 2004, IMI Cornelius Inc.

Page 41

Pump Troubleshooting

DOES NOT OPERATE / GAS APPLIED / DISPENSER VALVE OPEN

• B-I-B empty or inlet tubing pinched off activating vacuum "sold-out".

Gas regulator over-pressurizing. (Pump stalled)

•

• Outlet tube kinked or restricted.

Operated without fluid for excessive period. (Dry run)

•

•

Transfer tube and gas lines contaminated (syrup, rust, oil, etc.) [ensure clean gas supply, change

out all contaminated pumps]

• Internal damage of control cover.

OPERATES BUT WILL NOT PRIME / DISPENSER VALVE OPEN

[consult Start-up Procedure for proper priming]

• Pump valves have no moisture/dry (add water/syrup to the inlet port with pump stroking slowly).

• Vacuum leaks at Q.D., barb fitting clamps, or inlet fitting o-ring.

• Debris in valve seats or warped/swollen valves.

DOES NOT ACHIEVE SOLD-OUT WITH EMPTY B-I-B

• Vacuum leaks at Q.D., barb fitting clamps, or inlet fitting o-ring.