Page 1

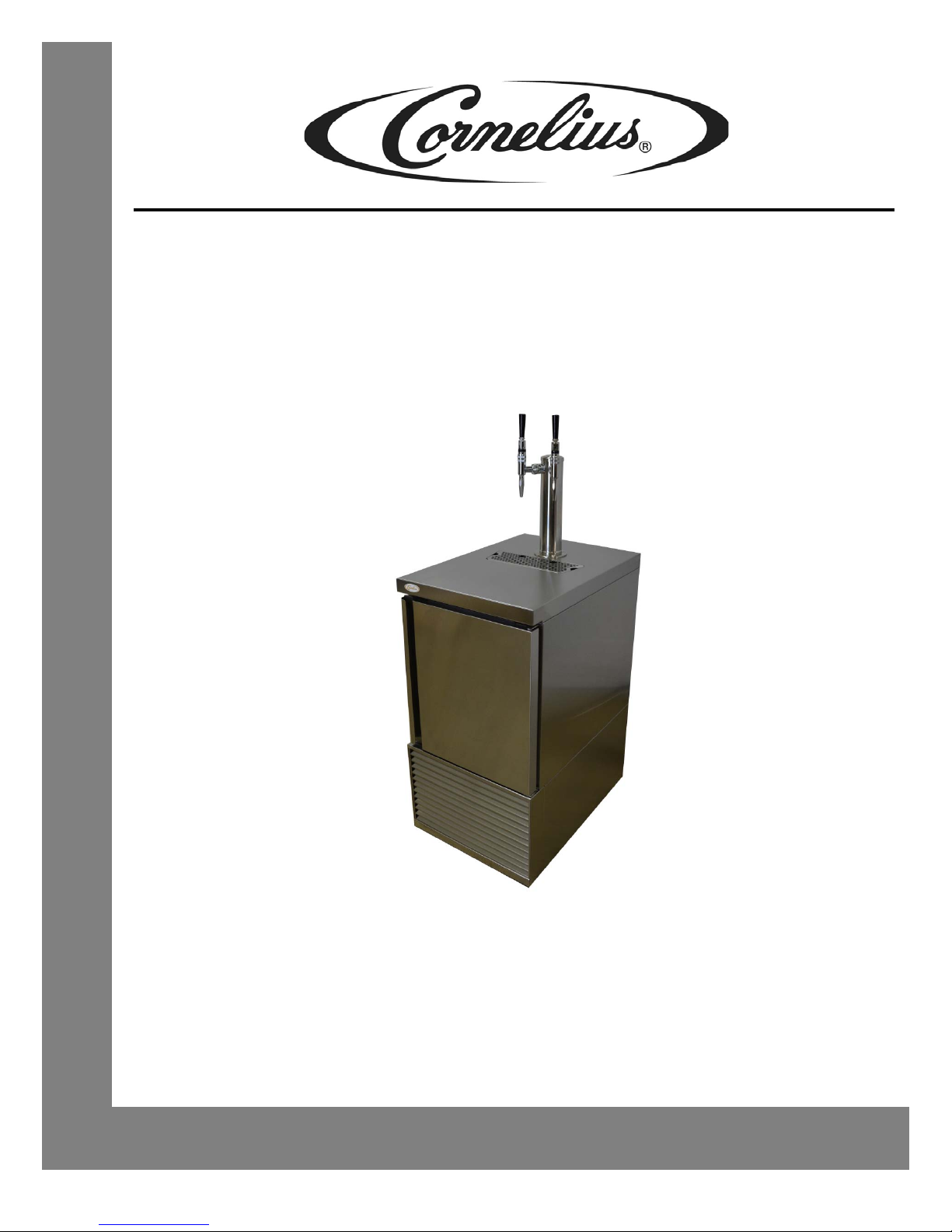

COLD NITRO BREW DISPENSER

Model: CNB BIB

Operator’s Manual

Release Date: 9/26/17

Publication Number: 621058723OPR

Revision Date: 3/14/18

Revision: Rev. A

Visit web site http://cornelius-usa.com and create an account for all your literature needs.

Page 2

The products, technical information, and instructions contained in this manual are subject to change without notice. These

RECYCLE

instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency

in the installation, operation or maintenance of this equipment. This manual assumes that the person(s) working on the equip

ment have been trained and are skilled in working with electrical, plumbing, pneumatic, and mechanical equipment. It is

assumed that appropriate safety precautions are taken and that all local safety and construction requirements are being met,

in addition to the information contained in this manual.

This Product is warranted only as provided in Cornelius’ Commercial Warranty applicable to this Product and is subject to all of

the restrictions and limitations contained in the Commercial Warranty.

Cornelius will not be responsible for any repair, replacement or other service required by or loss or damage resulting from any

of the following occurrences, including but not limited to, (1) other than normal and proper use and normal service conditions

with respect to the Product, (2) improper voltage, (3) inadequate wiring, (4) abuse, (5) accident, (6) alteration, (7) misuse, (8)

neglect, (9) unauthorized repair or the failure to utilize suitably qualified and trained persons to perform service and/or repair

of the Product, (10) improper cleaning, (11) failure to follow installation, operating, cleaning or maintenance instructions, (12)

use of “non‐authorized” parts (i.e., parts that are not 100% compatible with the Product) which use voids the entire warranty,

(13) Product parts in contact with water or the product dispensed which are adversely impacted by changes in liquid scale or

chemical composition.

Contact Information:

To inquire about current revisions of this and other documentation or for assistance with any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and Copyrights:

This document contains proprietary information and it may not be reproduced in any way without permission from Cornelius.

‐

This document contains the original instructions for the unit described.

CORNELIUS INC

101 Regency Drive

Glendale Heights, IL

Tel: + 1 800‐238‐3600

Printed in U.S.A.

Correct Disposal of this Product

This marking indicates that this product should not be disposed with other household wastes throughout the EU. To prevent

possible harm to the environment or human health from uncontrolled waste disposal, recycle it responsibly to promote the

sustainable reuse of material resources. To return your used device, please use the return and collection systems or contact

the retailer where the product was purchased. They can take this product for environmental safe recycling.

Page 3

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and Follow ALL Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different Types of Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Qualified Service Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Sound Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Machine Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Grounding Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

System Overview 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Unit Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting Nitrogen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unit Cleaning and Sanitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Monthly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Changing a BIB Container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Changing Coffee Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unit Foam Head Height Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 4

Cold Nitro Brew BIB Dispenser Operator’s Manual

!

DANGER:

!

WARNING:

CAUTION:

!

!

SAFETY INSTRUCTIONS

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Safety Overview • Read and follow ALL SAFETY INSTRUCTIONS in this manual and any warning/

caution labels on the unit (decals, labels or laminated cards).

• Read and understand ALL applicable OSHA (Occupational Safety and Health

Administration) safety regulations and/or national and local codes before oper‐

ating this unit.

Recognition

Recognize Safety Alerts

Different Types of Alerts

This is the safety alert symbol. When you see it in this manual or on the unit, be alert to

the potential of personal injury or damage to the unit.

Indicates an immediate hazardous situation which, if not avoided, WILL result in seri‐

ous injury, death or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor

or moderate injury or equipment damage.

© 2017, Cornelius Inc. ‐ 1 ‐ Publication Number: 621058723OPR

Page 5

Cold Nitro Brew BIB Dispenser Operator’s Manual

!

WARNING:

!

WARNING:

!

WARNING:

CAUTION:

!

SAFETY TIPS

• Carefully read and follow all safety messages in this manual and safety signs on

the unit.

• Keep safety signs in good condition and replace missing or damaged items.

• Learn how to operate the unit and how to use the controls properly.

• Do not let anyone operate the unit without proper training. This appliance is

not intended for use by very young children or infirm persons without supervi‐

sion. Young children should be supervised to ensure that they do not play with

the appliance.

• Keep your unit in proper working condition and do not allow unauthorized

modifications to the unit.

QUALIFIED SERVICE PERSONNEL

SAFETY PRECAUTIONS

Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND

LOCAL CODES. FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY, DEATH OR

EQUIPMENT DAMAGE.

This unit has been specifically designed to provide protection against personal injury. To

ensure continued protection, observe the following:

Disconnect Power When Servicing ‐ Disconnect power to the unit before servicing follow‐

ing all lock out/tag out procedures established by the user. Verify all of the power is off to

the unit before any work is performed. Failure to disconnect the power could result in seri

ous injury, death or equipment damage.

Avoid Clutter - Always be sure to keep area around the unit clean and free of clutter. Failure

to keep this area clean may result in injury or equipment damage.

‐

Publication Number: 621058723OPR ‐ 2 ‐ © 2017, Cornelius Inc.

Provide Emergency Power Off (EPO) ‐ Connect to a switchable AC outlet (switch

within operator’s reach) or ensure that the AC receptacle is in a readily‐accessible

location allowing quick, emergency shutdown by the operator.

Page 6

SHIPPING AND STORAGE

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

UNIT LOCATION

Cold Nitro Brew BIB Dispenser Operator’s Manual

Before shipping, storing, or relocating the unit, the unit must be sanitized and all

sanitizing solution must be drained from the system. A freezing ambient environ‐

ment will cause residual sanitizing solution or water remaining inside the unit to

freeze resulting in damage to internal components.

The CNB BIB unit is not suitable for installation in an area where a water jet could

be used.

POWER CORD

The CNB BIB unit must be located in a horizontal position.

This CNB BIB unit is not designed for use in outdoor locations.

If the power cord is damaged, it must be replaced by a special cord available from

the manufacturer or its service agent.

SOUND LEVELS

© 2017, Cornelius Inc. ‐ 3 ‐ Publication Number: 621058723OPR

The A‐weighted sound pressure level has been determined to be below 60 dBA.

Page 7

Cold Nitro Brew BIB Dispenser Operator’s Manual

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

CAUTION:

!

!

DANGER:

CAUTION:

!

MACHINE USAGE

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction concerning use of the CNB BIB unit

by a person responsible for their safety.

Children should not be allowed to play with or operate the unit.

This appliance is intended to be used in commercial applications for the dispens‐

ing of only non‐hazardous product.

UNIT CLEANING

GROUNDING INSTRUCTIONS

This CNB BIB unit MUST NOT be cleaned by using a water jet.

This appliance must be grounded. In the event of malfunction or breakdown,

grounding provides a path of least resistance for electric current to reduce the risk of

electric shock. This appliance Is equipped with a cord having an equipment‐ground‐

ing conductor and a grounding plug. The plug must be plugged into an appropriate

outlet that is properly Installed and grounded in accordance with all local codes and

ordinances.

Improper connection of the equipment‐grounding conductor can result In a risk of

electric shock. The conductor with green insulation with or without yellow stripes Is

the equipment grounding conductor. If repair or replacement of the cord or plug Is

necessary, do not connect the equipment grounding conductor to a live terminal. If in

doubt whether the appliance is properly grounded, check with a qualified electrician

or serviceman. Do not modify the plug provided with the appliance ‐ if it will not fit the

outlet, have a proper outlet installed by a qualified electrician.

Publication Number: 621058723OPR ‐ 4 ‐ © 2017, Cornelius Inc.

This appliance is for use on electrical circuits, as shown in Table 1, and has a ground‐

ing plug that looks like the plug illustrated in Figure 1.

Page 8

Cold Nitro Brew BIB Dispenser Operator’s Manual

3‐Prong Plug *

* Example of grounded North American plug.

A qualified electrician should be consulted if there is any doubt about the outlet box being

properly grounded.

Figure 1.

© 2017, Cornelius Inc. ‐ 5 ‐ Publication Number: 621058723OPR

Page 9

Cold Nitro Brew BIB Dispenser Operator’s Manual

SYSTEM OVERVIEW

OVERVIEW

The Cold Nitro Brew (CNB BIB) Dispenser is a self‐contained, on‐demand, in‐line nitrogen infu‐

sion unit. The CNB BIB (Bag‐in‐Box) unit allows for still and nitro product to be poured from the

same post‐mixed source through different dispensers.

The CNB BIB unit provides the highest quality drink appearance and consistency, while keeping

operation and maintenance simple and straightforward.

FEATURES

• Durable, robust design

• Easy to use – double‐dispenser lever interface

• Easy to Clean – dispense area is easily wiped down

• Small Footprint – CNB BIB design allows the unit to be installed remotely and under‐

counter with minimum space requirement.

• OPTIMIZED DESIGN — Efficient front breathing design allows the unit to be installed

under a counter top or stand‐alone.

• SELF‐CONTAINED DESIGN — Water, Nitrogen, and electrical connections are all that

are needed, a drain is optional. The unit automatically chills water for cold bever‐

ages.

• PROPRIETARY INFUSION — Unique infusion process layers the beverage with an

industry leading, long lasting cascade.

• No Mixing, No Shaking, No Filling. Just connect the BIB and go!

• Utilizes concentrated BIB’s of cold brew, 1:3 ‐ 1:5 ratio automatic mixing.

Publication Number: 621058723OPR ‐ 6 ‐ © 2017, Cornelius Inc.

Page 10

SPECIFICATIONS

Cold Nitro Brew BIB Dispenser Operator’s Manual

Table 1.

Food Grade Nitrogen Requirements 80 psi (0.55 MPa) at input

Nitrogen Input Connection 90˚ ¼” BARB

Water Supply Requirements

Water Supply Connection 90˚ 3/8” BARB

Electrical Ratings 120V/60Hz/4.5Amps

Drain Line 3/8” ID Tubing

Cabinet Capacity

Cabinet (Door closed, not including tower)

Cabinet (Door closed, including tower) 30.1" (76.5 cm) D (includes standoffs) x 20” (50.8

Shipping Weight 285 lbs. (129.3 kg)

Cup Clearance 7 1/4” (18.4 cm) drip tray to spout nozzle

Recommended pouring size:

Ambient Operating Temperature 55° F to 100° F (12.8° C to 37.8° C)

Filtered water @ > 0.5 GPM and 90 psi

(0.62 MPa) at store

(2) 3‐gallon BIBs (Approx. box Dimensions:

13 1/2” H x 7 1/2” W x 9 1/2” D)

30.1" (76.5 cm) D (includes standoffs) x 20” (50.8

cm) W x 34” (86.4 cm) H

cm) W x 50.8” (129 cm) H

At 75°F ambient temperature and 75°F input water

temperature, the unit can pour drinks at 16 oz. per

minute with a drink temperature of 41°F or lower.

© 2017, Cornelius Inc. ‐ 7 ‐ Publication Number: 621058723OPR

Page 11

Cold Nitro Brew BIB Dispenser Operator’s Manual

Left Tap

Right Tap

Cup Rest

Drip Tray

INITIAL START UP

UNIT DETAILS

The CNB BIB unit consists of two taps for dispensing two varieties of coffee. The left tap dis‐

penses still cold brew coffee and the right tap dispenses Nitro cold brew coffee.

NOTE: The tap handles need to be pulled all the way down.

OPERATION

Connecting Power

Connecting Water

Figure 2

Make sure the power cord is plugged into the appropriate AC outlet.

Make sure the Water line is properly secured to the back of the unit, as shown in Figure 3

Publication Number: 621058723OPR ‐ 8 ‐ © 2017, Cornelius Inc.

Page 12

Connecting Nitrogen

AC Power

Cord

Socket

Drip‐tray

Water

Inlet Port

Nitrogen

Drain

Inlet Port

3/4” BARB

3/8” BARB

1/4” BARB

Cold Nitro Brew BIB Dispenser Operator’s Manual

Make sure the nitrogen input connector is properly secured to the back of the unit, as shown

in

Figure 3.

Figure 3.

© 2017, Cornelius Inc. ‐ 9 ‐ Publication Number: 621058723OPR

Page 13

Cold Nitro Brew BIB Dispenser Operator’s Manual

CAUTION:

!

UNIT MAINTENANCE

DAILY MAINTENANCE

Use only products approved by Cornelius in the CNB BIB unit. Failure to do so can

result in reduced unit performance or render the unit inoperable.

Perform the items listed in Table 2 on a daily basis.

Step Action

1

2 Wash and rinse the drip tray grate.

3 Check tap nozzles for coffee grains and clean if required.

4 Check the level of the product BIB.

5

Table 2.

Wipe the outside, inside, tower, drip tray and taps of the dispenser with a

clean disposable towel.

If using a nitrogen generator, be sure the generator is operational and the

gauge shows pressure.

If using a nitrogen tank, check the primary nitrogen tank pressures: the pri‐

mary side gauge should be between 500 and 2500 PSI (3.45 MPa and 17.24

MPa) and the secondary gauge should be approximately 80 PSI (0.55 MPa). If

either gauge is not in the proper range, alert the manager on duty of the nitro‐

gen level.

Cleaning Products

KAY-5® Cleaner/Sanitizer

Mix one 1 oz. (29.6 ml) packets of Kay‐5 ® Sanitizer/Cleaner solution (or similar brand) in

0.75 gallons (3 quarts) of tap water to insure 330 PPM of available chlorine.

Urnex Sani-Pure Sanitizer & Cleaner

Mix 3 oz. (88.7 ml) of Urnex Sani‐Pure Sanitizer & Cleaner solution (or similar brand),

in 1 gallons (4 quarts) of tap water to insure 600 PPM of available chlorine.

IMPORTANT: Use tap water at 75‐95°F (23.89‐35°C). Water above this range breaks down

the chlorine count and minimizes sanitation.

Publication Number: 621058723OPR ‐ 10 ‐ © 2017, Cornelius Inc.

Page 14

WEEKLY MAINTENANCE

Unit Cleaning and Sanitation

Cold Nitro Brew BIB Dispenser Operator’s Manual

The following procedures are to be performed on a weekly basis, in addition to the daily main‐

tenance tasks.

Before using the CNB BIB unit for product dispensing and on an ongoing basis, the product

tubing and the tower dispenser must be cleaned and sanitized.

Sanitize the product tubing and tower dispenser thoroughly (internally and exterior surfaces)

by using one of the cleaners listed.

For the cleaning process, have the following ready: Two, 1 gallon buckets, one white cleaning

adapter and approved Sanitizer.

To clean and sanitize the unit, the product tubing and the tower dispenser, perform the proce‐

dure in Table 3.

Step Action

1 Open the cabinet door (front door).

A. Disconnect the product output connector from the BIB

(Bag in Box product) by turning the BLACK threaded

2

connector counterclockwise and lifting on the outside

of the BLACK connector

B. Remove the BIB from the unit

Table 3.

© 2017, Cornelius Inc. ‐ 11 ‐ Publication Number: 621058723OPR

Connect the WHITE screw‐in connector to the BLACK

3

prodct output connector by turning the threaded connec‐

tor clockwise.

Page 15

Cold Nitro Brew BIB Dispenser Operator’s Manual

Step Action

Using a clean and empty food-grade container:

4

Prepare approximately 0.5 gallons (1.9 liters) of warm water.

Place container of water inside the cabinet storage area.

Place the BLACK product output connector with the WHITE

5

cleaning adapter inside the food‐grade container so that

the connector will stay at the bottom.

Table 3.

Turn the Sanitizing Valve to the “Dispense”

6

position and the Nitrogen valve to the “OFF” position.

A. Open LEFT tower dispenser and dispense 0.25 gallons (1

quart) of water or until the dispense looks clear.

B. Close the tap.

C. Open RIGHT tower dispenser and dispense 0.25 gal‐

7

lons (1 quart) of water or until the dispense looks clear.

D. Close the tap.

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME TIME

AS DISPENSING MAY PULSE OR EVEN STOP.

Remove the bucket of water from the machine and dispose

8

of the remaining water.

Publication Number: 621058723OPR ‐ 12 ‐ © 2017, Cornelius Inc.

Page 16

Cold Nitro Brew BIB Dispenser Operator’s Manual

20 Minutes

Table 3.

Step Action

Using a clean and empty food-grade container:

Prepare any of the listed sanitizer/cleaner solutions from the

9

list of cleaning products on

itizer/cleaner solution inside the cabinet storage area.

Place the BLACK product output connector with the WHITE

cleaning adapter inside the food‐grade container so that the

10

connector will stay at the bottom.

page 10. Place the container of san‐

A. Open LEFT tower dispenser and dispense 0.25 gallons (1

quart) of sanitizer/cleaner solution.

B. Close the tap.

C. Open RIGHT tower dispenser and dispense 0.25 gal‐

11

12

13

lons (1 quart) of sanitizer/cleaner solution.

D. Close the tap.

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME

TIME AS DISPENSING MAY PULSE OR EVEN STOP.

Turn the Sanitizing Valve to the “SANITIZE” position.

A. Open LEFT tower dispenser and dispense 0.25 gallons (1

quart) of sanitizer/cleaner solution

B. Close the tap

C. Open RIGHT tower dispenser and dispense 0.25 gal‐

lons (1 quart) of sanitizer/cleaner solution

D. Close the tap

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME

TIME AS DISPENSING MAY PULSE OR EVEN STOP.

© 2017, Cornelius Inc. ‐ 13 ‐ Publication Number: 621058723OPR

With the taps straight up (closed), allow sanitizer/

14

cleaner solution to soak in the lines for 20 minutes.

Page 17

Cold Nitro Brew BIB Dispenser Operator’s Manual

Step Action

A. Open LEFT tower dispenser and dispense 0.25 gallons (1

B. Close the tap

C. Open RIGHT tower dispenser and dispense 0.25 gal‐

15

D. Close the tap

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME TIME

Turn the Sanitizing Valve to the “DISPENSE” position and

16

the Nitrogen valve to the ON position.

A. Open LEFT tower dispenser and dispense 0.25 gallons (1

B. Close the tap

C. Open RIGHT tower dispenser and dispense 0.25 gal‐

17

D. Close the tap

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME TIME

Table 3.

quart) of sanitizer/cleaner solution

lons (1 quart) of sanitizer/cleaner solution

AS DISPENSING MAY PULSE OR EVEN STOP.

quart) of sanitizer/cleaner solution

lons (1 quart) of sanitizer/cleaner solution

AS DISPENSING MAY PULSE OR EVEN STOP.

A. Remove the food‐grade container from the cabinet and

discard any remaining sanitizer.

B. Disconnect the WHITE cleaning adapter from the BLACK

18

product output connector by turning the BLACK con‐

nector counterclockwise and lifting on the outside of

the BLACK connector.

Reusing a clean and empty plastic food‐grade container:

A. Prepare a cleaning solution containing 100PPM avail‐

able chlorine using any of the listed sanitizer/cleaner

19

solutions as described by manufacturer’s instructions.

Prepare at least 1 gallon (4 quarts) of solution.

B. Bring container of solution to the coffee dispense

area.

Publication Number: 621058723OPR ‐ 14 ‐ © 2017, Cornelius Inc.

Page 18

Cold Nitro Brew BIB Dispenser Operator’s Manual

Press

Release

Tab

Upward

15 Minutes

Table 3.

Step Action

A. Remove the two dispenser nozzles by unscrewing

clockwise (as viewed from above). Carefully use a

wrench if needed.

B. Disassemble the nozzle parts by inserting a straw into

20

21

the skinny end of the nozzle and pressing gently. Be

careful to catch the o‐ring, jet disc, and regulation

cone.

C. Place the two nozzles and their internal parts into the

food‐grade container with sanitizer/cleaner solution.

From inside of the cabinet:

A. Disconnect the BIB product output line from the dis‐

penser panel connector by pushing up on the release

tab on the top of the connector and pulling the hose

straight out.

B. Place the hose assembly into the container with sani‐

tizer/cleaner solution.

C. Close the cabinet door.

A. Soak the BIB product line and nozzles for 15 minutes.

B. While the parts are soaking, wipe the outside, inside,

22

tower, drip tray and valves of the dispenser with a

clean, disposable towel. Do not use caustic cleaners

inside the unit, use only a damp towel as needed.

C. Wash and rinse the drip‐tray grate and reinstall.

A. Wash hands and put on single‐use gloves.

23

B. Remove the nozzles and their internal parts from the

container of cleaner/sanitizer solution.

A. Perform a visual inspection on each nozzle., o‐ring, jet

disc, and regulation cone.

B. Assemble the nozzle by placing the regulation cone

24

into the nozzle first, point side down. Insert the jet

disc next and ensure it sits flat. Lastly, insert the o‐ring

against the jet disc as shown to the right.

C. Screw the two dispenser nozzles onto the spout,

tighten only hand tight.

© 2017, Cornelius Inc. ‐ 15 ‐ Publication Number: 621058723OPR

Page 19

Cold Nitro Brew BIB Dispenser Operator’s Manual

Step Action

A. Remove the BIB product line from the sanitizer/cleaner

25

B. Grasp the hose by the metal connector.

C. Push the hose straight into the “BIB OUT” port until it

A. Obtain a product BIB.

B. Place it in the cabinet, outlet port towards the base of

26

C. Close the cabinet door.

A. Open LEFT tower until cleaner is displace and coffee

B. Close the tap

C. Open RIGHT tower until cleaner is displace and coffee

27

D. Close the tap

E. NOTE: DO NOT OPEN BOTH VALVES AT THE SAME

Table 3.

solution.

locks in place.

the cabinet, and connect the BLACK product output

connector by turning the threaded connector ring clock‐

wise. Be sure the connector is screwed on completely.

comes out

comes out

TIME AS DISPENSING MAY PULSE OR EVEN STOP.

28 Open the door and turn on the nitrogen gas valve

29 Open the RIGHT tower until nitro coffee is dispensed

Publication Number: 621058723OPR ‐ 16 ‐ © 2017, Cornelius Inc.

Page 20

MONTHLY MAINTENANCE

Two Screws

Cover

Thumbscrew

Water Fill Tube

Cold Nitro Brew BIB Dispenser Operator’s Manual

Check the water level in the ice bank and replenish it when it is low, as described in Table 4.

Table 4

Access the ice bank for water filling.

A. Lift grill upwards and pull bottom towards the front to

1

disengage the locking tabs in the bottom frame assem‐

bly

B. Unfasten cover (remove 2 screws at top of cover).

C. Slide filter to the left

© 2017, Cornelius Inc. ‐ 17 ‐ Publication Number: 621058723OPR

Open the ice‐bank water‐refill cover.

A. Remove the thumbscrew securing the ice‐bank refill

2

cover.

B. Lift off the cover and set it aside.

Page 21

Cold Nitro Brew BIB Dispenser Operator’s Manual

Pour Water

into Opening

Overflow

Connection

Fill the ice bank with potable water.

A. Use a funnel and pour water into refill opening. Capacity

3

B. Replace the filter, cover, and grille in reverse order

CHANGING A BIB CONTAINER

Table 4

is approximately 3.6 gallons (13.6 liters). The reservoir is

full when water begins trickling through the overflow

tubing at the lower-front, center of the ice bank.

NOTE: The ice bank may also be filled with chilled water

to reduce the time for cool down to 33°F (0°C). (Typical

cooling time using room‐temperature water is 6 hours.)

NOTE: The ice bank typically requires a water refill every

month. Observe the water level shown in the drain tube

(with red cap). Remove cap for accurate reading.

from step 1 above

When changing a product BIB container, orient the BIB with the connector hose upward to

prevent spillage during product hose disconnection. Be sure to clean up any spillage.

Table 5.

Step Action

1 Open the cabinet door.

A. Disconnect the product line connector from the empty

BIB by unscrewing the BLACK threaded ring counter‐

2

clockwise.

B. Remove the empty BIB container and properly discard

it.

Publication Number: 621058723OPR ‐ 18 ‐ © 2017, Cornelius Inc.

Page 22

Step Action

Remove Cap

A. Open the new BIB box to expose the bag outlet

3

connector.

B. Remove the protective white cap from the outlet con‐

nector and discard.

Cold Nitro Brew BIB Dispenser Operator’s Manual

Table 5.

A. Orient the BIB as shown and place it into the cabinet.

B. Connect the dispenser product line to the BIB by

4

5

pressing its BLACK connector into the BIB outlet while

rotating the threaded ring clockwise. Ensure it

is secure and not leaking.

C. Close the cabinet door.

A. Dispense about 8 to 10 oz. of product to remove any trapped air in the lines.

B. Check foam height and adjust if required by referring to the next section, Unit

Foam Head Height Adjustment.

© 2017, Cornelius Inc. ‐ 19 ‐ Publication Number: 621058723OPR

Page 23

Cold Nitro Brew BIB Dispenser Operator’s Manual

CHANGING COFFEE TYPES

In some cases the type of coffee used in the CNB BIB unit may require an adjustment of the

height of the foam head for proper presentation. If this adjustment is required, it should be

performed by a manager or technician who is trained in the operation of the CNB BIB unit.

Unit Foam Head Height Adjustment

NOTE: Follow all previous INSTALLATION and CLEANING/SANITATION section processes

before continuing with this section.

Once the equipment has been installed, cleaned, and sanitized, perform the procedure in

Table 6 to adjust the foam head height on the CNB BIB unit.

Table 6.

Step Action

Make sure the Nitrogen tank is open or the nitrogen gener‐

ator is turned on.

1

The primary side gauge should be between 500 and 2500

PSI and the secondary gauge should between 60 and 80

PSI.

2 Open the cabinet door.

Inside the cabinet, ensure that the Nitrogen inlet valve is

3

turned to the “ON” position.

4

Publication Number: 621058723OPR ‐ 20 ‐ © 2017, Cornelius Inc.

A. Open/remove Nitrogen secondary regulator access

cover.

B. Locate the secondary Nitrogen regulator.

Adjust only the regulator shown.

Page 24

Cold Nitro Brew BIB Dispenser Operator’s Manual

Table 6.

Step Action

REDUCED FOAM HIGHT adjustment:

A. Adjust the regulator control knob slightly (approxi‐

mately 1/8th of a turn) to the LEFT (counter‐clockwise).

Only very fine adjustments are required. This reduces

the amount of Nitrogen injected.

B. Open the RIGHT tower dispenser and dispense about

5

8 oz. of product to drain the line of product at the previ‐

ous foam setting. Then dispense 12 oz. of product and

confirm the foam head height. Repeat and dispense

another 12 oz. to confirm setting.

C. Repeat step A if a further reduction of foam head

height is required.

INCREASED FOAM HIGHT adjustment:

A. Adjust the regulator control knob slightly (approxi‐

mately 1/8th of a turn) to the RIGHT (clockwise). Only

very fine adjustments are required. This increases the

amount of Nitrogen injected.

B. Open the RIGHT tower dispenser and dispense about

6

8 oz. of product to drain the line of product at the previ‐

ous foam setting. Then dispense 12 oz. of product and

confirm the foam head height. Repeat and dispense

another 12 oz. to confirm setting.

C. Repeat step A if a further increase of foam head height

is required.

7 Reinstall the regulator access cover.

© 2017, Cornelius Inc. ‐ 21 ‐ Publication Number: 621058723OPR

Page 25

Cold Nitro Brew BIB Dispenser Operator’s Manual

TROUBLESHOOTING

Table 7 describes some of the possible symptoms and solutions for troubleshooting the CNB

BIB unit.

Symptom Probable Cause Solution

Refrigerator not

working

Dispenser tap is

dripping

Tap l eaks at the

tower coupling.

Tap cannot be

removed from

tower coupling.

Tap is spurting or

no product is

being dispensed.

Table 7.

A. Power cord not plugged into outlet.

B. GFI outlet tripped.

C. Store breaker on dispenser circuit

is tripped.

A. Tap handle not fully in off position.

B. Tap valve seal is worn or damaged.

C. Excessive system pressure.

A. Tap is not connected tightly.

B. Worn/cracked coupling gasket.

A. May not have been removed

recently.

A. BIB is empty or nearly empty.

B. Tap strainer is clogged.

A. Plug into outlet.

B. Press reset on outlet.

C. Check/reset the breaker.

A. Move to off position.

B. Check/replace seal(s).

C. Check/adjust Water and Nitro‐

gen pressure settings.

A. Tighten coupling nut.

B. Replace coupling gasket.

A. Pour hot water on the coupling

ring to loosen it.

A. Replace BIB.

B. Remove the tap nozzle and

clean internal components.

If none of the above solutions fix the unit, call service.

Publication Number: 621058723OPR ‐ 22 ‐ © 2017, Cornelius Inc.

Page 26

Cornelius Inc.

www.cornelius-usa.com

Loading...

Loading...