Page 1

CHILLERS

MODELS: CH250 AND CH251

Operator’s & Installation Manual

Release Date: April 19, 2004

Publication Number: 620914801

Revision Date: April 29, 2010

Revision: D

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

CH SERIES CHILLER

OPERATOR’S & INSTALLATION MANUAL

The products, technical information and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

1-800-551-4423

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 1999-2010, All Rights Reserved, IMI Cornelius Inc.

Page 3

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Design Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Data Plate Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chiller Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Location of Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Process Water Flow, Units and Pump and Tank (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Standard Thermostat Eliwell IC902 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chiller Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pump Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Circulation System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fluid Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 4

Page 5

CH Series Chiller Operator’s & Installation Manual

GENERAL INFORMATION

INTRODUCTION

The Cornelius “CH” Series Recirculating Water Chiller is designed to provide an accurate, reliable and user-friendly system for cooling a continuous flow of water and keep it at a constant tempe rature in various closed loop

or tank cooling applications.

The “CH” Series Chiller consists of an air--cooled refrigeration system housed in a sturdy sheet metal frame and

cabinet. A standard pump and insulated water reservoir package provides a complete liquid cooling and

circulating system.

The “CH” Series Chiller is designed to operate in a clean laboratory or industrial environment where ambient

temperatures range from 40 to100° F (5 to 38° C). With prope r in stallation, operation and maintenance , th e “ CH”

Series Chiller will provide years of trouble free service.

UNPACKING AND INSPECTION

This unit was thoroughly inspected before leaving the factory and the carrier has accepted and signed for it. Any

damage or irregularities should be noted at the time of delivery and immediately reported to the carrier. Request

a written inspection report from the Claims Inspector to substantiate any necessary claims. In the event that an

immediate replacement is necessary, please contact Cornelius Chiller Sales at 1-800-551-4423.

DESIGN DATA

The voltage and the frequency are indicated on the serial number plate, located behind the drip tray and on the

right hand side near the controls.

CH250 CH251

Cooling Capacity:

BTU/hr (W) at 80° F (27° C) and 70°

F (21° C) Liquid Temperature

Compressor Horsepower .25 (.2 kW) .25 (.2 kW)

Electrical Data:

Voltage/Phase/Hertz/Amperage

Refrigerant Type R134a R134a

Physical Dimensions, Width X Depth

X Height

Fittings:

Process Connections 1/2” FPT (S/S) 1/2” FPT (S/S)

Optimum Process Liquid Flow GPM

(Liters/Min)

Condenser Air Flow (CFM) 225 225

3,000 (879) 3,000 (879)

115/1/60

7.5 Amps

17.125” X 14.125” X 13.375”

(43.5 cm X 35.9 cm X 34 cm)

0.6 (2.72) 0.6 (2.72)

230/1/60

3.8 Amps

17.125” X 14.125” X 13.375”

(43.5 cm X 35.9 cm X 34 cm)

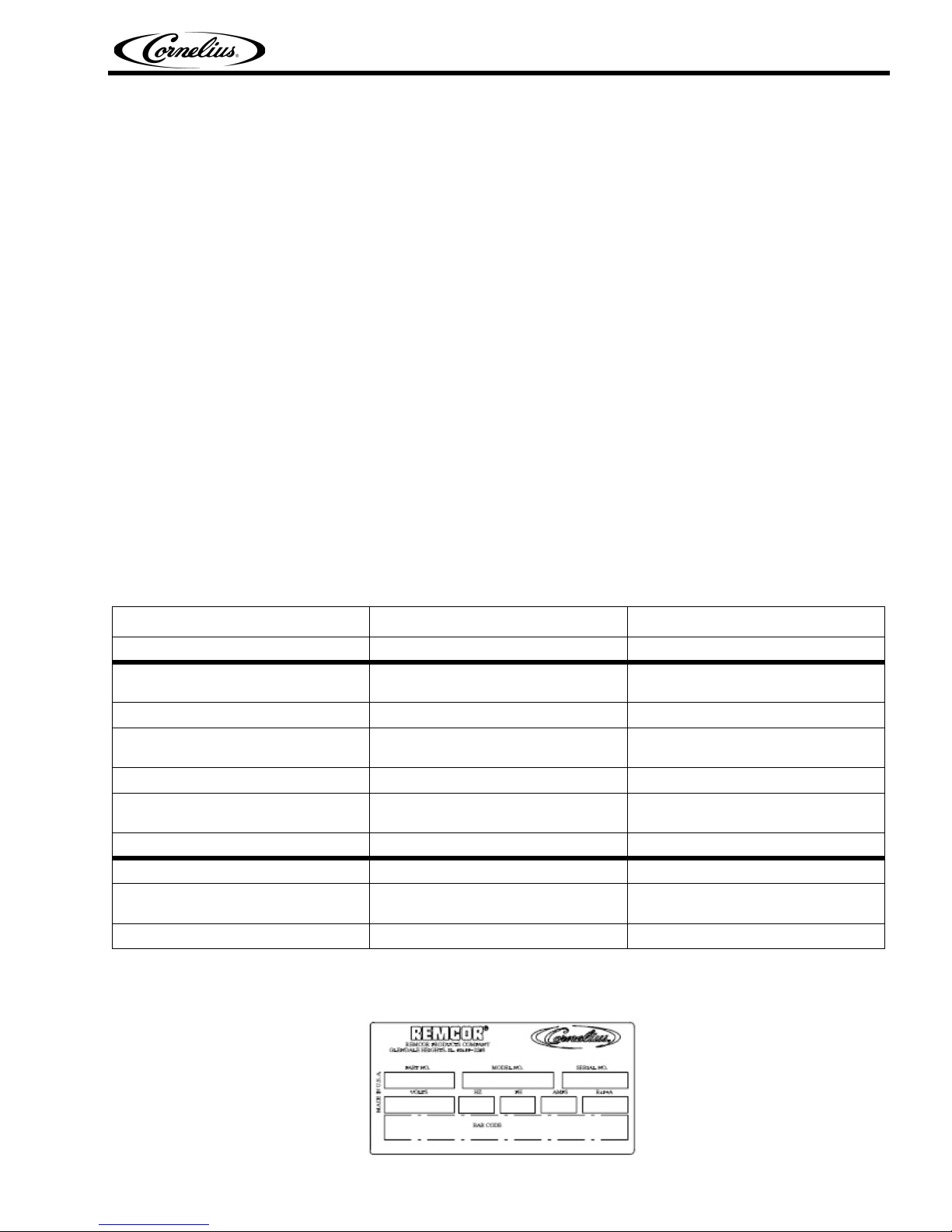

DATA PLATE INFORMATION

© 1999-2010, IMI Cornelius Inc. - 1 - Publication Number: 620914801

Page 6

CH Series Chiller Operator’s & Installation Manual

Figure 1. Sample Data Plate

When servicing a Cornelius Chiller, it is important to note the information contained on the data plate located in

the upper rear of the Unit.

If technical assistance is needed, the phone technician will need the Serial Number of your chiller. That information

is found on the Data Plate along with the model number, voltage requirement and refrigerant information.

The serial Number is also needed when replacement parts are being ordered or for warranty claims. See CHILLER

WARRANTY PAGE.

NOTE: Be sure to include the serial number on any documentation or billing information.

CHILLER INSTALLATION

Location of Chiller

THE CHILLER MUST BE LOCATED NEAR A PROPERLY GROUNDED ELECTRICAL OUTLET. THE CIRCUIT

SHOULD BE FUSED AND NO OTHER ELECTRICAL APPLIANCE SHOULD BE CONNECTED TO THE

CIRCUIT. ALL ELECTRICAL WIRING MUST CONFORM TO NATIONAL AND LOCAL ELECTRICAL CODES.

The chiller must be located in a well ventilated, indoor area where ambient temperatures will remain above 40° F

(5° C) and will never increase above 100° F (38° C). To obtain optimum cooling capacity, the ambient

temperature should be at or below 80° F (27° C).

It is very important that the air intake and discharge sides of the chiller are not obstructed by other free standing

objects. A minimum of two feet of space on all four sides of the chiller will be sufficient to prevent air flow obstructions.

It is also important to direct any hot air discharge from other equipment away from the air intake side of the chiller .

Condenser air entering the “CH” unit should be below 100° F (38° C).Condenser air temperatures above 100° F

(38° C) can cause the high pressure safety control to shut down the un it.

Electrical Connections

All wiring must conform to the National Electric Code and any applicable local codes. The chiller must be

permanently wired by means of electrical conduit to a properly fused disconnect of prope r amperage or wir ed to a

properly rated power cord and plugged into an outlet with the appropriate disconnect and amperage rating. The

electrical junction box, located on the back panel of the chiller, includes a four terminal strip for power supply

connection. Refer to Figure 2 for the CH250 model and Figure 3 for the CH251 model.

Publication Number: 620914801 - 2 - © 1999-2010, IMI Cornelius Inc.

Figure 2. Wiring Diagram (115V)

Page 7

CH Series Chiller Operator’s & Installation Manual

Figure 3. Wiring Diagram (230V)

The data plate, located next to the junction box, includes the actual voltage, phase and amperage of the chiller.

START UP

WARNING: Never operate the chiller with it’s panels removed.

Always use the power switch to turn off the chiller when it is not being used.

Always ensure that all air inlets and outlets are free from obstruction.

Be sure that the reservoir is filled with fluid prior to powering up the unit (see Fluid Recommendations

page).

Process Water Flow, Units and Pump and Tank (Standard)

Follow standard plumbing practices and local codes in making water connections. The chiller inlet and outlet

connections are 1/2”. Flexible hose and fittings are recommended for plumbing the system. A No. 20 mesh strainer

should be installed on the chiller inlet to prevent foreign particles from entering the system and should be cleaned

monthly . Lines should be routed with as few bends as possible. Prevent lines from running near radiators, hot water

pipes, etc. Any lengths of tubing that are exposed to high ambient temperatures should be insulated to prevent

condensation and/or significant liquid heat loss.

After ensuring that the system is free from the obstruction, that all valves are open and the reservoir when

available is full, push the CONTROL POWER switch to the “ON” position. The pump should now be operating.

STANDARD THERMOSTAT ELIWELL IC902

The following procedure should be followed to adjust the Eliwell IC902 thermostat temperature setting:

1. To set the SET POINT, press and release the SET button. SET displays.

2. Press the SET button again, the current SET POINT is displayed. Press the UP or DOWN button to

change the SET POINT to the desired temperature.

3. Press the fnc button twice to exit the program. The current liquid temperature is displayed.

The thermostat has a range that is pre-set at the factory. The range is 40° F (5° C) to 100° F (38° C). If o per ation

outside of this range is required, please contact the Cornelius Technical Service Department.

© 1999-2010, IMI Cornelius Inc. - 3 - Publication Number: 620914801

Page 8

CH Series Chiller Operator’s & Installation Manual

Figure 4. Control Panel

CHILLER MAINTENANCE

WARNING: Disconnect electrical power to the chiller to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service the internal

components or electrical wiring.

out1

o

F

fnc

set

Condenser

On air-cooled chillers, the CONDENSER FINS should be cleaned by blowing compressed air through the

condenser from the fan side. Dirt and debris accumulate on the condenser fins over time and this build up can

severely reduce the performance of the chiller. Cleaning of the CONDENSER COIL FINS should be done

approximately every three months, depending upon cleanliness of your application.

Pump Motor

The PUMP MOTOR should be lubricated with thirty drops of SAE 20 oil once a year.

Circulation System

The CIRCULATION SYSTEM should be drained and flushed periodically to avoid build up an d a possible flow

restriction caused by contaminants.

Publication Number: 620914801 - 4 - © 1999-2010, IMI Cornelius Inc.

Page 9

CH Series Chiller Operator’s & Installation Manual

FLUID RECOMMENDATIONS

Cornelius chillers are designed to operate with water to provide maximum performance for temperatures of 40° F

(4.4° C) to 100° F (37.8° C).

Distilled Water Acceptable

De-Ionized Water

(1-5 Meg

De-Ionized Water

(5+ Meg

Propylene Glycol

(Lab & Industrial Grade)

Lab & Industrial Grade Ethylene Glycol

Mineral/Hydraulic Oils

(Commercial/Automotive Antifreeze)

Acidic/Basic Solutions

(Above 8 or below 6 PH)

Mineral/Hydraulic Oils

(Viscosity > 50 Centistrokes)

ohms)

ohms)

Acceptable

Acceptable with S tainless S t eel & PVC only (No Copper

or Brass)

Acceptable - 30% Glycol/70% Water

(For Applications with Temperatures below 40° F)

Acceptable - 30% Glycol/70% Water

(For Applications with Temperatures below 40° F)

NOT Acceptable

(Silicate Rust Inhibitors in Automotive/Commercial antifreeze damages pump seals and housing which lead to

failure.)

Not Acceptable

Not Acceptable

For questions regarding special or other fluids contact IMI Cornelius at 800-551-4423.

To purchase Lab or Industrial Glycol contact:

IMI Cornelius, 1-800-551-4423 - Part No. 111521000, 5 Gal.

© 1999-2010, IMI Cornelius Inc. - 5 - Publication Number: 620914801

Page 10

CH Series Chiller Operator’s & Installation Manual

TROUBLESHOOTING

WARNING: Disconnect electrical power to the chiller to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service the internal

components or electrical wiring.

If repairs to the chiller must be made, disconnect electrical power to the unit, then shut off

the water source.

Trouble Problem Cause Remedy

A. No Power to unit

Chiller does not operate, Power

Light “OFF”

Pump does not Operate but Power

Light is “ON”

Unit runs continuously, but is not

cooling process water enough.

NOTE: When servicing a Cornelius chiller, it is important to note all information provided on the

DATA PLATE located on the upper rear of the unit. If technical assistance is needed, the Cornelius

Service Technician will need this information along with any description of the problem(s) you are

encountering. The serial no. and other information will also be required when ordering replacement

parts and any other Warranty Claims.

B. Defective Control Power Switch

C. Defective Contr ol Transformer

D. Wrong Voltage supplied to Unit

A. Line to or from chiller is

restricted.

B. Internal or external filter is

blocked with debris.

C. Pump contactor is defective

D. Damaged pump motor or impel-

ler.

A. Condenser is restricted.

B. Unit low on refrigerant.

C. Inefficient compressor.

D. Unit is undersized for applica-

tion.

A. Check main disconnect fuses,

wiring and power lead to unit.

B. Replace Switch

C. Replace Transformer

D. Supplied Voltage MUST be

within +/- 10% of nameplate rat-

ing

A. Inspect lines and remove any

obstructions.

B. Remove and clean strainer,

then replace.

C. Replace contactor

D. Replace pump motor or impel-

ler.

A. Clean condenser.

B. Call Service.

C. Call Service.

D. Call Cornelius Chiller Sales

Rep.

Publication Number: 620914801 - 6 - © 1999-2010, IMI Cornelius Inc.

Page 11

CH Series Chiller Operator’s & Installation Manual

Table 1. 115V Chiller

Item

No.

Part No. Description

1 32386 Temperature Controller

2 31934 Power Switch

3 61014 Evaporator

4 620023502 Wrapper Panel

5 51882 Priming Reservoir Assy

6 24388 Panel, Left Side

7 60992 Compressor

8 31955 Pump

9 24390R Base Assy

© 1999-2010, IMI Cornelius Inc. - 7 - Publication Number: 620914801

Figure 5. Cabinet Section Exploded View

Page 12

Ice Frost Operator’s Manual

Table 1.

Item

No.

10 31962 Fan Motor

11 31488 Fan Blade

12 620023503 Panel, Right Side

13 60576 Condenser

14 33082 Relay

15 32378 Transformer

16 32588 Temperature Probe

17 620023504 Panel, Front

18 24389 Shroud, Condenser

Item

No.

1 32386 Temperature Controller

2 31935 Power Switch

3 61014 Evaporator

4 620023502 Wrapper Panel

5 51882 Priming Reservoir Assy

6 24388 Panel, Left Side

7 18361 Compressor

8 30730 Pump

9 24390R Base Assy

10 31487 Fan Motor

11 31488 Fan Blade

12 620023503 Panel, Right Side

13 60576 Condenser

14 33082 Relay

15 32378 Transformer

16 32588 Temperature Probe

17 620023504 Panel, Front

18 24389 Shroud, Condenser

Part No. Description

Table 2. 230V Chiller

Part No. Description

115V Chiller

IMI Cornelius Inc. warrants that all equipment and p art s ar e free from defe cts in material and workmanship under

normal use and service. For a copy of the warranty applicable to your Cornelius or Wilshire product, in your

country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide th e equ ipment mo de l

number, serial number and the date of purchase.

Publication Number: M620919596OPR - 8 - © 2004-2007, IMI Cornelius Inc.

WARRANTY

Page 13

Page 14

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...