Page 1

IMI CORNELIUS REMCOR INC g 500 REGENCY DRIVE g GLENDALE HEIGHTS, IL 60139–2268

Telephone (800) 551–4423 Facsimile (800) 519–4423

Operator’s Manual

CHILLER (“CH” SERIES)

Models: CH 250

CH 251

Part No. 620914801

February 16, 1999

Revised: August 12, 2002

Revision C

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

IMI CORNELIUS INC; 1999–2002

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

GENERAL INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNPACKING AND INSPECTION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESIGN DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DATA PLATE INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHILLER INSTALLATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOCATION OF CHILLER 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CONNECTIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START UP 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROCESS WATER FLOW, UNITS WITH PUMP AND TANK (STANDARD) 2. .

PROCESS WATER FLOW, UNITS WITHOUT RESERVOIR (OPTIONAL) 3. . .

THERMOSTAT ADJUSTMENT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STANDARD THERMOSTAT 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHILLER MAINTENANCE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONDENSER 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FAN MOTOR 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP MOTOR 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCULATION SYSTEM 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FILTERS/STRAINERS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLUID RECOMMENDATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

TROUBLESHOOTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHILLER DOES NOT OPERATE, CONTROL POWER LIGHT “OFF” 6. . . . . . . . .

PUMP DOES NOT OPERATE, BUT POWER LIGHT IS “ON”.6. . . . . . . . . . . . . . .

UNIT RUNS CONTINUOUSLY, BUT IS NOT COOLING PROCESS

WATER ENOUGH. 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF FIGURES

FIGURE 1. SAMPLE DATA PLATE 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. EXTERNAL RESERVOIR WATER LEVEL 3. . . . . . . . . . . . . . . . . . . . . .

FIGURE 3. WIRING DIAGRAM (115V) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. WIRING DIAGRAM (230V) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 4. CABINET SECTION EXPLODED VIEW 8. . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

TABLE 1. DESIGN DATA 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

620914801

Page 3

GENERAL INFORMATION

INTRODUCTION

The REMCOR ”CH” Series Recirculating Water Chiller is designed to provide an accurate, reliable, and user–

friendly system for cooling a continuous flow of water and keep it at a constant temperature in various closed

loop or tank cooling applications.

The ”CH” Series Chiller consists of an air–cooled refrigeration system housed in a sturdy sheet metal frame and

cabinet. A standard pump and insulated water reservoir package provides a complete liquid cooling and circulating system.

The ”CH” Series Chiller is designed to operate in a clean laboratory or industrial environment where ambient

temperatures range from 40 to100° F (5 to 38° C). With proper installation, operation, and maintenance, the

”CH” Series Chiller will provide years of trouble free service.

UNPACKING AND INSPECTION

This unit was thoroughly inspected before leaving the factory and the carrier has accepted and signed for it.

Any damage or irregularities should be noted at the time of delivery and immediately reported to the carrier. Request a written inspection report from the Claims Inspector to substantiate any necessary claims. In the event

that an immediate replacement is necessary, please contact REMCOR Chiller Sales at 1–800–551–4423.

DESIGN DATA

Table 1. Design Data

CH250 CH251

Cooling Capacity:

BTU/hr (W) at 80_ F(27_ C) and

70_ F (21_ C) Liquid Temperature.

3,000 (879) 3,000 (879)

Compressor Horsepower .25 (.2 kW) .25 (.2 kW)

Electrical Data:

Voltage/Phase/Hertz/Amperage

115/1/60

7.5 Amps

230/1/60

3.8 Amps

Refrigerant Type: R134a R134a

Physical Dimensions, Width X Depth

X Height

17.125” X 14.125” X 13.375”

(43.5 cm X 35.9 cm X 34cm)

17.125” X 14.125” X 13.375”

(43.5 cm X 35.9 cm X 34cm

Fittings:

Process Connections 1/2” FPT (S/S)

Optimum Process Liquid Flow GPM

0.6 (2.72) 0.6 (2.72)

1/2I FPT (S/S)

(Liters/Min)

Condenser Air Flow (CFM) 225 225

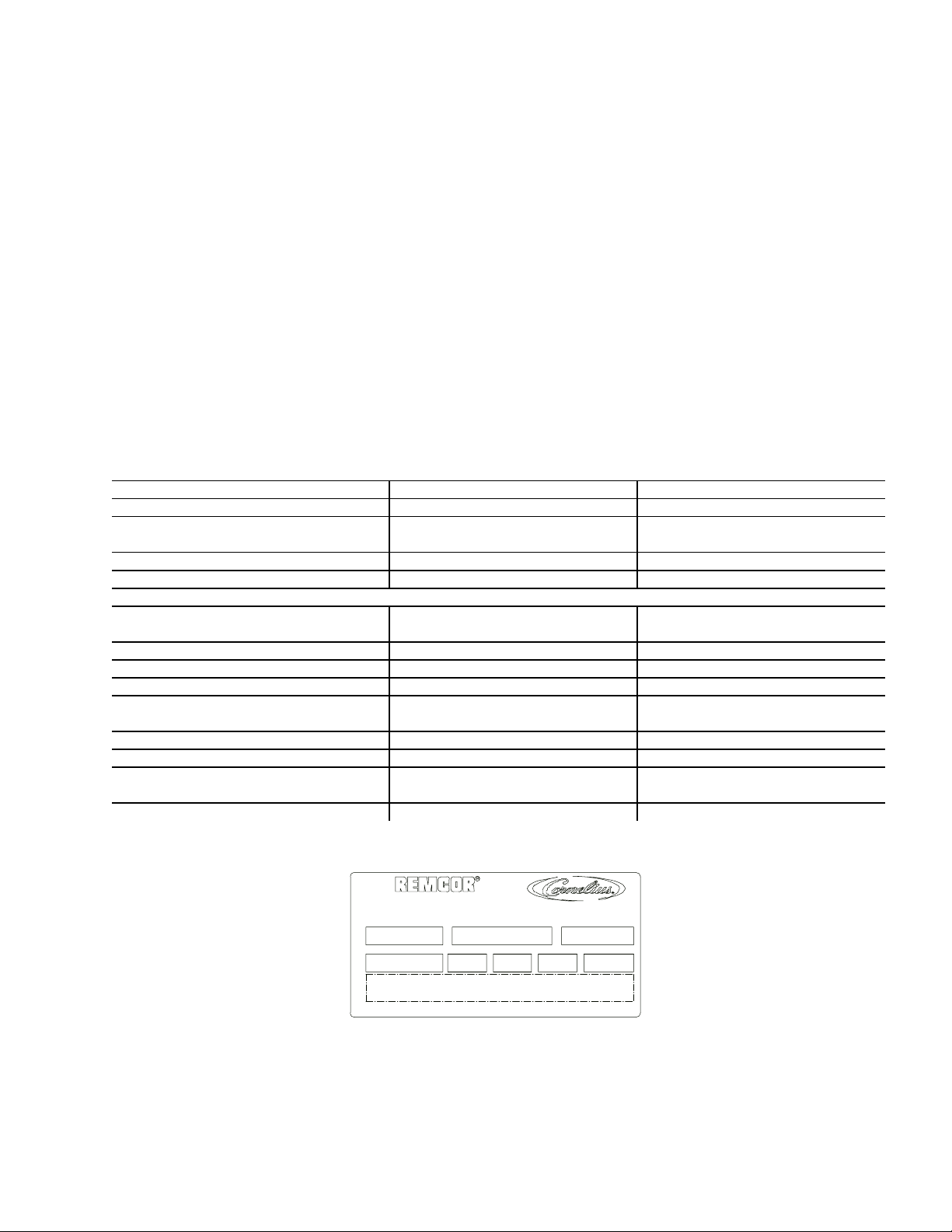

DATA PLATE INFORMATION

REMCOR PRODUCTS COMPANY

GLENDALE HEIGHTS, IL. 60139–2268

MODEL NO. SERIAL NO.PART NO.

VOLTS AMPS

MADE IN U.S.A.

BAR CODE

R134AHZ PH

FIGURE 1. SAMPLE DATA PLATE

1

620914801

Page 4

When servicing a REMCOR Chiller, it is important to note the information contained on the data plate located in

the upper rear of the Unit.

If technical assistance is needed, the phone technician will need the Serial Number of your Chiller. That information is found on the Data Plate along with the model number, voltage requirement, and refrigerant information.

The serial Number is also needed when replacement parts are being ordered or for warranty claims. See

CHILLER WARRANTY PAGE.

Be sure to include the serial number on any documentation or billing information.

CHILLER INSTALLATION

Location of Chiller

THE CHILLER MUST BE LOCATED NEAR A PROPERLY GROUNDED ELECTRICAL OUTLET. THE CIRCUIT SHOULD BE FUSED AND NO OTHER ELECTRICAL APPLIANCE SHOULD BE CONNECTED TO THE

CIRCUIT. ALL ELECTRICAL WIRING MUST CONFORM TO NATIONAL AND LOCAL ELECTRICAL

CODES.

The Chiller must be located in a well ventilated, indoor area where ambient temperatures will remain above

40_ F (5_ C) and will never increase above 100_ F (38_ C). To obtain optimum cooling capacity, the ambient

temperature should be at or below 80_ F (27_ C).

It is very important that the air intake and discharge sides of the chiller are not obstructed by other free standing

objects. A minimum of two feet of space on all four sides of the chiller will be sufficient to prevent air flow obstructions.

It is also important to direct any hot air discharge from other equipment away from the air intake side of the chiller. Condenser air entering the “CH” unit should be below 100_ F (38_ C) .Condenser air temperatures above

100_ F (38_ C) can cause the high pressure safety control to shut down the unit.

Electrical Connections

(see Figure 3)

All wiring must conform to the National Electric Code and any applicable local codes. The Chiller must be

permanently wired by means of electrical conduit to a properly fused disconnect of proper amperage or wired to

a properly rated power cord and plugged into an outlet with the appropriate disconnect and amperage rating.

The electrical junction box, located on the back panel of the Chiller, includes a four terminal strip for power

supply connection.

The data plate, located next to the junction box, includes the actual voltage, phase, and amperage of the Chiller.

START UP

WARNING: Never operate the Chiller with it’s panels removed.

Always use the power switch to turn off the Chiller when it is not being used.

Always ensure that all air inlets and outlets are free from obstruction.

Be sure that the reservoir is filled with fluid prior to powering up the unit (see Fluid

Recommendations page).

Process Water Flow, Units with Pump and Tank (Standard)

Follow standard plumbing practices and local codes in making water connections. The Chiller inlet and outlet

connections are 3/4”. Flexible hose and fittings are recommended for plumbing the system. A No. 20 mesh

strainer should be installed on the Chiller inlet to prevent foreign particles from entering the system and should

be cleaned monthly. Lines should be routed with as few bends as possible. Prevent lines from running near

620914801

2

Page 5

radiators, hot water pipes, etc. Any lengths of tubing that are exposed to high ambient temperatures should be

insulated to prevent condensation and/or significant liquid heat loss.

After ensuring that the system is free from the obstruction, that all valves are open, and the reservoir when available is full, push the CONTROL POWER switch to the “ON” position. The pump should now be operating.

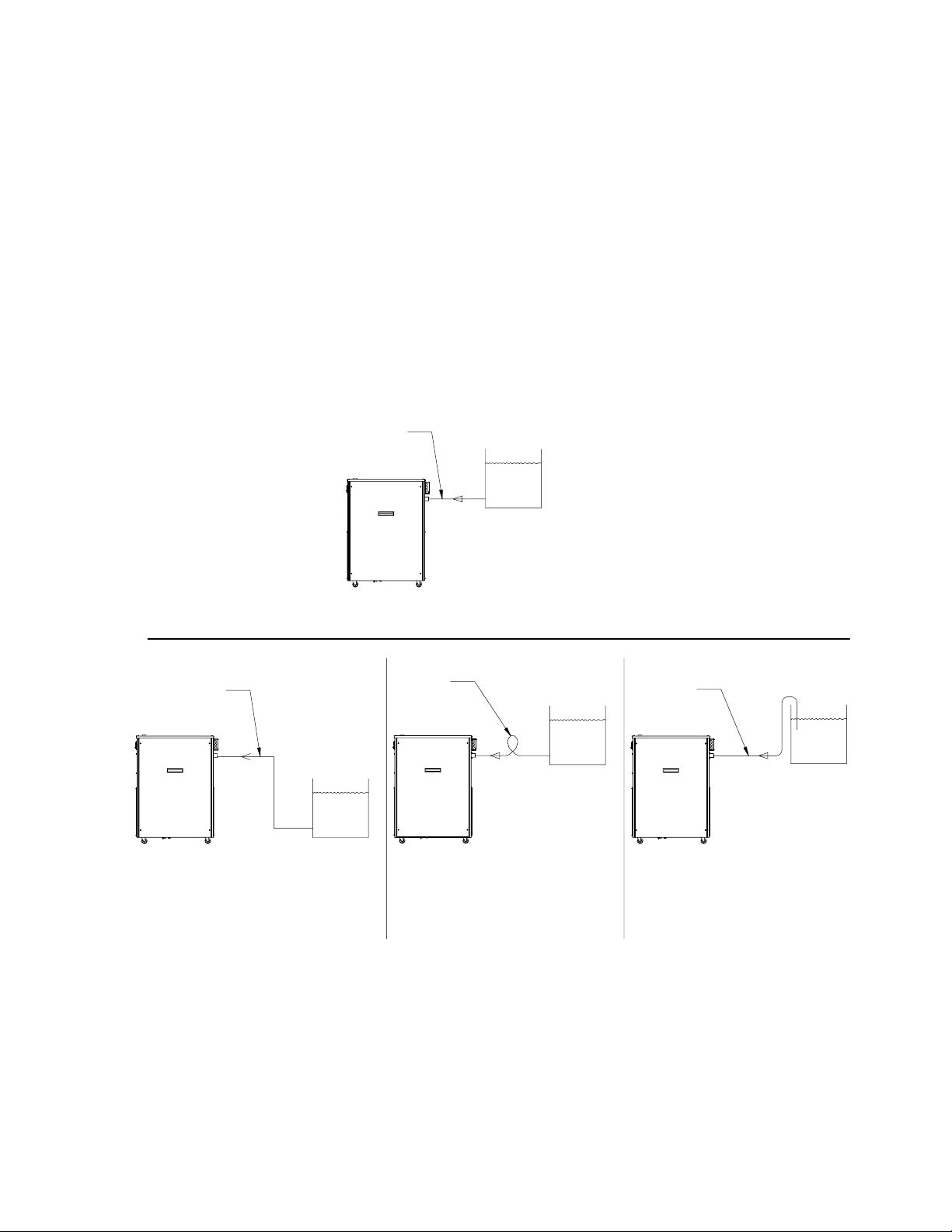

Process Water Flow, Units Without Reservoir (Optional)

Follow standard plumbing practices and local codes in making water connections. The Chiller inlet and outlet

connections are 3/4”. Flexible hose and fittings are recommended for plumbing the system. A No. 20 mesh

strainer should be installed on the Chiller inlet to prevent foreign particles from entering the system and should

be cleaned monthly. Lines should be routed with as few bends as possible. Prevent lines from running near

radiators, hot water pipes, etc. Any lengths of tubing that are exposed to high ambient temperatures should be

insulated to prevent condensation and/or significant water heat loss.

Proper priming of the water lines is essential to prevent pump cavitation. Be certain all air has been purged from

the lines before operating the pump for an extended period of time. Be sure to remove any loops in the lines that

may trap air. The pump must have a supply of water with the level of the water above the inlet of the Chiller.

The supply tank must feed the Chiller from the side of the tank below the water level (see Figure 2).

CHILLER

INLET

LINE

WATER

LEVEL

CHILLER

INLET

LINE

CHILLER

W/O TANK

WATER LEVEL IS

BELOW CHILLER INLET

INCORRECT

CHILLER

W/O TANK

WATER

LEVEL

EXTERNAL

RESERVOIR

EXTERNAL

RESERVOIR

CORRECT

CHILLER

INLET

LINE

CHILLER

W/O TANK

AIR CAN BE TRAPPED IN

CHILLER INLET

INCORRECT

WATER

LEVEL

EXTERNAL

RESERVOIR

CHILLER

INLET

LINE

CHILLER

W/O TANK

WATER FEEDING FROM

TOP OF TANK

INCORRECT

WATER

LEVEL

EXTERNAL

RESERVOIR

FIGURE 2. EXTERNAL RESERVOIR WATER LEVEL

THERMOSTAT ADJUSTMENT

Standard Thermostat

The following procedure should be followed to adjust the standard thermostat:

3

620914801

Page 6

1. Push the “SET” button located to the right of the digital display. The current set-point will be displayed.

2. Push the “UP” or “DOWN” button until the desired set-point is displayed.

3. After approximately 3 seconds, the display will show the system water temperature. The set-point can be

viewed at any time by pressing the “SET” button.

The thermostat has a range that has been pre-set at the factory. The range is 40° F (5° C) to 100° F (38° C). If

operation outside of this range is required, please contact the Remcor Technical Service Department.

UP

5

F

DOWN SET

CHILLER MAINTENANCE

WARNING: Disconnect electrical power to the Chiller to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service the internal

components or electrical wiring.

Condenser

On air–cooled Chillers, the CONDENSER FINS should be cleaned by blowing compressed air through the condenser from the fan side. Dirt and debris accumulate on the condenser fins over time, and this build up can severely reduce the performance of the Chiller. Cleaning of the CONDENSER COIL FINS should be done

approximately every three months, depending upon cleanliness of your application.

Fan Motor

On air–cooled Chillers, the condenser FAN MOTOR should be lubricated every 6 months with a few drops of

SAE 10 oil.

Pump Motor

The PUMP MOTOR should be lubricated with thirty drops of SAE 20 oil once a year.

Circulation System

The CIRCULATION SYSTEM should be drained and flushed periodically to avoid build up and a possible flow

restriction caused by contaminants.

Filters/Strainers

The STRAINER at the Chiller inlet should be removed and cleaned monthly.

The “Y” STRAINER, located inside the unit at the inlet of the pump, should be cleaned periodically depending on

applications. If a reduction in flow or cavitation of the pump occurs, remove the strainer, flush it out with water,

then replace.

620914801

4

Page 7

FLUID RECOMMENDATION

Remcor Chillers are designed to operate with water to provide maximum performance for

temperatures of 40_F–100_F.

Distilled Water Acceptable

De–Ionized Water

(1–5 MEG/OHMS)

De–Ionized Water

(5+MEG/OHMS)

Propylene Glycol

(Lab & Industrial Grade)

Lab & Industrial Grade Ethylene Glycol Acceptable – 30% Glycol/70% Water

Mineral/Hydraulic Oils

(Viscosity<50 Centistrokes)

Ethylene Glycol

(Commercial/Automotive Antifreeze)

Acidic/Basic Solutions

(Above 8/Below 6 PH)

Mineral/Hydraulic Oils

(Viscosity>50 Centistrokes)

Acceptable

Acceptable with Stainless Steel & PVC only

*No Copper or Brass

Acceptable – 30% Glycol/70% Water

*For Applications with Temperatures below 40_F

*For Applications with Temperatures below 40_F

Acceptable

NOT Acceptable

*Silicate Rust Inhibitors in Automotive/Commer-

cial Antifreeze will damage pump seals and

housing which lead to failure.

Not Acceptable

Not Acceptable

For questions regarding special or other fluids contact IMI Cornelius Remcor at

800–551–4423.

To Purchase Lab or Industrial Glycol contact:

Hubbard Hall (800) 648–3412 – Dow Therm SR1 available in 5 gallon

IMI Cornelius (800) 551–4423 – Part# 111521000 5 gallons

5

620914801

Page 8

TROUBLESHOOTING

WARNING: Disconnect electrical power to the Chiller to prevent personal injury before

attempting any internal maintenance. Only qualified personnel should service internal

components or electrical wiring.

If repairs to the Chiller must be made, disconnect electrical power to the unit, then shut off the

water source.

TROUBLE PROBABLE CAUSE REMEDY

CHILLER DOES NOT

OPERATE, CONTROL

POWER LIGHT “OFF”

PUMP DOES NOT OPERATE,

BUT POWER LIGHT IS “ON”.

UNIT RUNS CONTINUOUSLY,

BUT IS NOT COOLING

PROCESS WATER ENOUGH.

A. No Power To Unit. A. Check Main disconnect fuses,

wiring, and power lead to unit.

B. Defective Control Power

Switch.

C. Defective Control Transformer. C. Replace Transformer

D. Wrong Voltage Supplied to

Unit.

A. Line to or from Chiller is

restricted.

B. Internal or external filter is

blocked with debris.

C. Pump Contactor is

defective.

D. Damaged pump motor or

impeller.

A. Condenser is restricted. A. Clean condenser.

B. Unit low on refrigerant. B. Call Service.

B. Replace Switch

D. Supplied Voltage Must be within

± 10% of nameplate rating.

A. Inspect lines and remove any

obstructions.

B. Remove and clean strainer, then

replace.

C. Replace Contactor.

D. Replace pump motor or impeller.

C. Inefficient compressor. C. Call Service.

D. Unit is undersized for

application.

NOTE: When servicing a REMCOR Chiller, it is important to note all information provided on the DATA

PLATE located in the upper rear of the unit. If technical assistance is needed, the REMCOR Service

Technician will need this information along with any description of the problem(s) you are

encountering. The serial number and other information will also be required when ordering

replacement parts and any other Warranty Claims.

620914801

6

D. Call REMCOR Chiller Sales Rep.

Page 9

115/1/60

COMPRESSOR

1

3

PUMP FAN

M

OVERLOAD

15

9

8

24V115V

7

M

6

C

4

M

COMPRESSOR

LIGHT, POWER ON

M

START RELAY

ELECTRICAL WIRING DIAGRAM

S

R

START

CAPACITOR

FIGURE 3. WIRING DIAGRAM (115V)

7

620914801

Page 10

620914801

COMPRESSOR

1

230/1/60

2

FIGURE 4. WIRING DIAGRAM (230V)

8

M

COMPRESSOR

3

PUMP FAN

4

M

OVERLOAD

5

8

24V230V

1

9

M

6

7

M

C

S

R

LIGHT, POWER ON

ELECTRICAL WIRING DIAGRAM

START RELAY

START

CAPACITOR

Page 11

4

16

1

12

18

14

17

10

6

3

7

5

8

11

2

15

13

FIGURE 5. CABINET SECTION EXPLODED VIEW

Item

No. Part No. Name

1 32386 Temperature Controller

2 31934 Power Switch

3 61014 Evaporator

4 620023502 Wrapper Panel

5 51882 Priming Reservoir Ass’y

6 24388 Panel, Left Side

7 60992 Compressor

8 31955 Pump

9 24390R Base Ass’y

9

Item

No. Part No. Name

10 31962 Fan Motor

11 31488 Fan Blade

12 620023503 Panel, Right Side

13 60576 Condenser

14 33082 Relay

15 32378 Transformer

16 32588 Temperature Probe

17 620023504 Panel, Front

18 24389 Shroud, Condenser

9

620914801

Page 12

Page 13

WARRANTY

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius, Remcor or Wilshire product, in your country, please write, fax or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number, serial number and the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

AUSTRIA

D BOSKAPELLEI 122 D B-2930 BRAASCHAAT, BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BELGIUM

D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

BRAZIL

ENGLAND

D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

FRANCE

D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

GERMANY

D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

GREECE

KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

HONG

D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, IT ALY D (39) 39 608 0817 D FAX (39) 39 608 0814

ITALY

ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

NEW

SINGAPORE

SPAIN

USA

D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (763) 421-6120 D FAX (763) 422-3255

LD004

4/21/98

620914801

10

Page 14

IMI CORNELIUS INC.

CORPORATE HEADQUARTERS:

One Cornelius Place

Anoka, Minnesota 55303-6234

(763) 421-6120

(800) 238-3600

9

620914801

Loading...

Loading...