Page 1

®

INTELLICARB

ICE COOLED DISPENSER

CB1522 (75lbs), CB2323 (80 & 100lbs), and CB3023

(130lbs) with 8X4 carbonator (80lbs) and 12X4

carbonator (75, 100, & 130lbs), with Flexible manifolding.

Installation Manual

Release Date: January 29, 2003

Publication Number: 630460204INS

Revision Date: July 1, 2005

Revision: D

Visit the IMI Cornelius web site at www.cornelius.com

for all your Literature needs.

Page 2

INTELLICARB DRINK DISPENSERS

INSTALLATION GUIDE

The products, technical information, and instructions contained in this manual are subject

to change without notice. These instructions are not intended to cover all details or variations of the equipment, nor to provide for every possible contingency in the installation,

operation or maintenance of this equipment. This manual assumes that the person(s)

working on the equipment have been trained and are skilled in working with electrical,

plumbing, pneumatic, and mechanical equipment. It is assumed that appropriate safety

precautions are taken and that all local safety and construction requirements are being

met, in addition to the information contained in this manual.

To inquire about current revisions of this and other documentation or for assistance with

any Cornelius product contact:

www.cornelius.com

800-238-3600

Trademarks and copyrights:

Aurora, Cornelius, FlavorFusion, Hydro Boost, Optifill, Pinnacle, and Vanguard are registered trademarks of IMI Cornelius Inc.

This document contains proprietary information and it may not be

reproduced in any way without permission from Cornelius.

Printed in U.S.A.

Copyright © 2005, All Rights Reserved, IMI Cornelius, Inc.

Page 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TABLE OF CONTENTS

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Read and follow all safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Recognize safety alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Different types of alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Qualified Service Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CO2 (Carbon Dioxide) Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Shipping And Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drop-In Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drop-In Dimensions (CB1522) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Drop-In Dimensions (CB2323) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drop-In Accessories — Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Custom Compact Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drop-in Dimensions (CB3023) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Requirements Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Delivery Inspection and Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Back Room Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1522-2323-3023 Drop-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conversion Instructions for Valves Connected into Manifold . . . . . . . . . . . . . . 10

Conversion Instructions for 1522 Valve #1 from Carb to Non/Carb . . . . . . . . . 11

Drop-In Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Adjust Water-To-Syrup Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cold Plate Plumbing & Wiring Diagram for CB2323 & CB3023 8 Valve . . . . . . 17

Cold Plate Plumbing & Wiring Diagram for CB2323 6 valve . . . . . . . . . . . . . . . 18

Cold Plate Plumbing & Wiring Diagram for CB1522 6 Valve . . . . . . . . . . . . . . 19

IntelliCarb Back Room Plumbing and Settings . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removal and Installation of Carbonator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Carbonator Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Carbonator Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manifold Parts Breakdown (1522, 2323, 3023) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CB 1522 IntelliCarb Stainless Tower 75lb with 12 x 4 Carbonator . . . . . . . . . . . . . 24

CB 2323 IntelliCarb Stainless Tower 100lb with 12 x 4 Carbonator . . . . . . . . . . . . 25

CB 2323 IntelliCarb Stainless Tower 80lb with 8 x 4 Carbonator . . . . . . . . . . . . . . 26

CB 3023 IntelliCarb Stainless Tower 130lb with 12 x 4 Carbonator . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Page 4

Page 5

SAFETY

SAFETY INSTRUCTIONS

Read and follow all safety instructions

Read and follow all safety instructions in this guide and on the machine (decals, labels, and laminated

cards).

Read and understand all applicable OSHA (Occupation Safety and Health Administration) safety regulations before operating the machine.

Recognize safety alerts

This is the safety alert symbol. When you see it in this guide or on the machine be

alert to the potential of personal injury, or damage to the machine.

Different types of alerts

There are three types of safety alerts:

IntelliCarb Drop-In Ice Cooled Installation Guide

DANGER — Indicates an immediate hazardous situation which if not avoided WILL result in seri-

ous injury, death, or equipment damage.

WARNING — Indicates a potentially hazardous situation which, if not avoided, COULD result in

serious injury, death, or equipment damage.

CAUTION — Indicates a potentially hazardous situation which, if not avoided, MAY result in

minor or moderate injury or equipment damage.

SAFETY TIPS

• Carefully read all safety messages in this guide and safety signs on the machine.

• Keep safety signs in good condition and replace missing or damaged safety signs.

• Learn how to operate the machine and how to use the controls properly.

• Do not let anyone operate the machine without proper training.

• Keep your machine in proper working condition and do not allow unauthorized modifications to the

machine.

QUALIFIED SERVICE PERSONNEL

CAUTION — Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES.

CO2 (CARBON DIOXIDE) WARNING

WARNING — CO

CO

gas leaks in the entire CO2 and soft drink system. If a CO2 gas leak is suspected, particularly

2

in a small area, immediately ventilate the contaminated area before attempting to repair the leak.

Personnel exposed to high concentration of CO

rapidly by loss of consciousness.

© 2003-2005, IMI Cornelius Inc. - 1 - Publication Number: 630460204INS

Displaces Oxygen. Strict Attention must be observed in the prevention of

2

gas will experience tremors which are followed

2

Page 6

IntelliCarb Drop-In Ice Cooled Installation Guide

SHIPPING AND STORAGE

CAUTION

and all sanitizing solution must be purged from the syrup systems. All liquids, after sanitizing, must

be purged from the unit. A freezing ambient environment will cause residual sanitizing solution or

water remaining inside the Unit to freeze resulting in damage to the internal components.

— Before shipping, storing, or relocating the Unit, syrup systems must be sanitized

Publication Number: 630460204INS - 2 - © 2003-2005, IMI Cornelius Inc.

Page 7

SYSTEM OVERVIEW

DROP-IN PRODUCT OVERVIEW

The Drop-In IntelliCarb consists of the following:

• Front inlet fittings

• 75 lbs., 80 lbs., 100 lbs., and 130 lbs. capacity ice bin

• Foamed polyurethane insulation

• Key lock switch

• 9 3/4 inch cup clearance

• Extended drip-tray for cup staging, removable for cleaning

• High capacity 11/18 cold plate, 5-2-1 configuration

• All fittings are 3/8 inch

• Supports UF-1 fast flow (3.0 oz./sec.), UF-1 Ultra flow (4.5 oz./sec.), and UFB 2.0 - 4.0 valves

• Improved ability to clean outlet line area

• Lighted and non-lighted merchandiser options

IntelliCarb Drop-In Ice Cooled Installation Guide

• Optional cabinet stand for free standing installations.

SPECIFICATIONS

Drop-in Unit

Drop-In Dimensions (CB1522)

Counter Top Cutout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 1/4 x 23 1/4 inches

Height above counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 inches

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 inches

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 inches

Shipping weight (approx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235 pounds

© 2003-2005, IMI Cornelius Inc. - 3 - Publication Number: 630460204INS

Page 8

IntelliCarb Drop-In Ice Cooled Installation Guide

Drop-In Dimensions (CB2323)

Counter Top Cutout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 1/4 x 23 1/4 inches

Height above counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 inches

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 inches

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 inches

Shipping weight (approx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235 pounds

Drop-In Accessories — Optional

Lighted marquee merchandiser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166208004

Cabinet stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165492000

Custom Compact Dimensions

Counter Top Cutout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 1/4 x 23 1/4 inches

Height above counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 inches

Height of Merchandiser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 inches

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 inches

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 inches

Shipping weight (approx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235 pounds

Drop-in Dimensions (CB3023)

Counter Top Cutout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 1/4 x 23 1/4 inches

Height above counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 inches

Width. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 inches

Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 inches

Shipping weight (approx) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285 pounds

Publication Number: 630460204INS - 4 - © 2003-2005, IMI Cornelius Inc.

Page 9

INSTALLATION

CAUTION — Only trained and certified electrical, plumbing and refrigeration technicians should

service this unit. ALL WIRING AND PLUMBING MUST CONFORM TO NATIONAL AND LOCAL

CODES.

INSTALLATION REQUIREMENTS

Requirements Summary

Weight:...................................................counter must be level and able to support 450 lbs.

Environment:..................................................................................... indoor installation only

Temperature:................................................................... 40 to 100° F ambient temperature

CO

:................................................................................................................. 75 psi at unit

2

Syrup: ....................................................................... 60 psi. min,.70 – .75 ounces per sec.,

...............................not to exceed 3.75 oz/sec Finished Product Flow Rate (.6 gpm) at unit

Water pressure: ....................................................................................60 psi max. at pump

Electrical: ..................................................................................................... see name plate

Water volume...........................................................................................................125 gph

Product supply beverage tubing ............................................................................ .375 min.

IntelliCarb Drop-In Ice Cooled Installation Guide

© 2003-2005, IMI Cornelius Inc. - 5 - Publication Number: 630460204INS

Page 10

IntelliCarb Drop-In Ice Cooled Installation Guide

DELIVERY INSPECTION AND UNPACKING

Inspection

Upon delivery inspect the unit for damage or irregularities and immediately report problems to the delivering carrier and file a claim with that carrier.

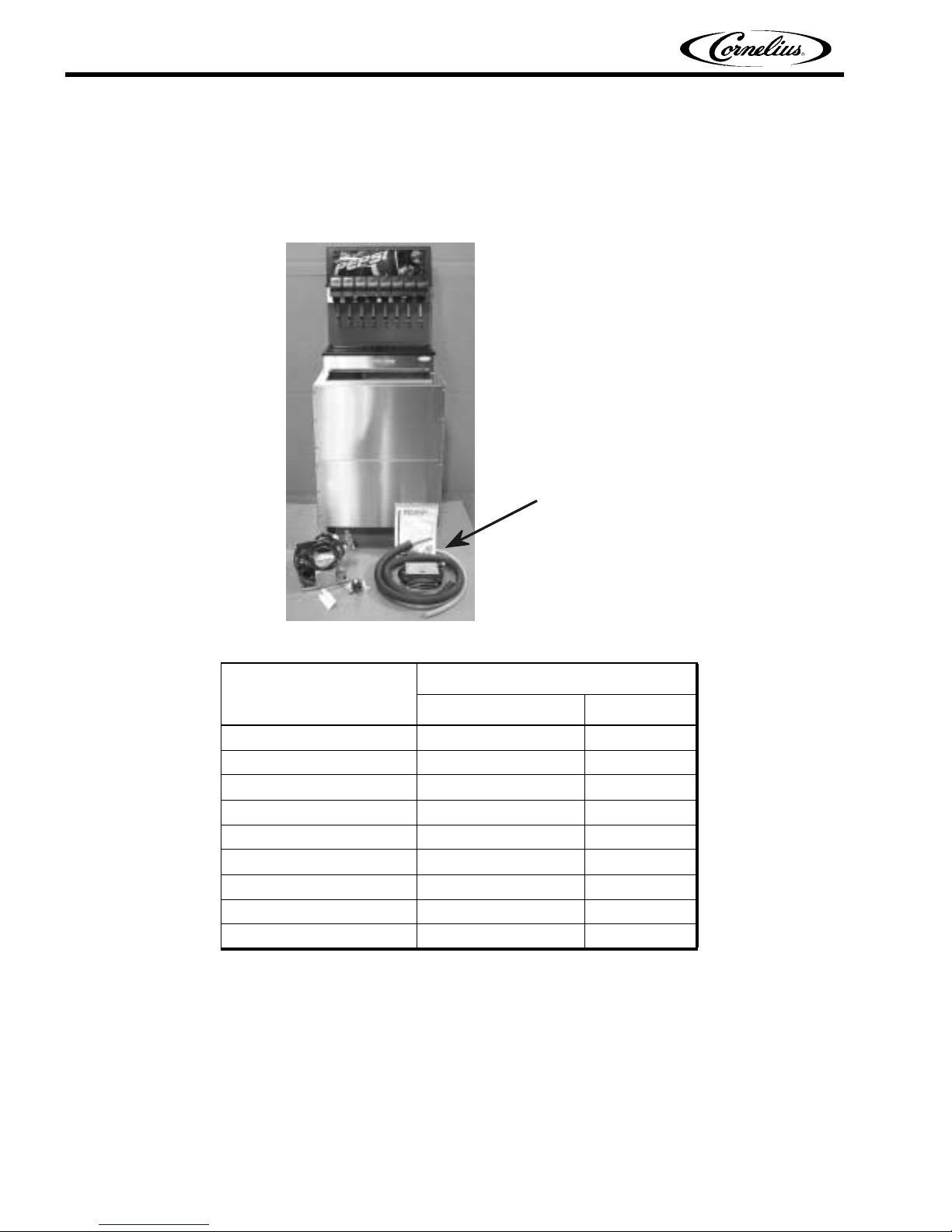

1. Open loose parts packages and inspect parts.

Loose

parts

Make sure all items are present.

Part Name

Pump &motor assy. 629087457 1

4" legs n/a n/a

Clamps Oetiker n/a

Drain pan drain line 167090002 1

Cold plate drain line 167467072 1

Merchandiser assy. 166167010 1

Transformer 630000601 1

Ftg-3/4 Soc x 3/4 fpt n/a n/a

Ftg-3/4 mptx1" barb n/a n/a

Drop-In

P/N Qty.

Publication Number: 630460204INS - 6 - © 2003-2005, IMI Cornelius Inc.

Page 11

INSTALLATION PROCEDURE

Back Room Package

TUBING

NOTE: Tubing, hoses, and cabling can come from underneath or in back of the unit.

1. Run bundled tubing from back room to dispenser location.

WATER

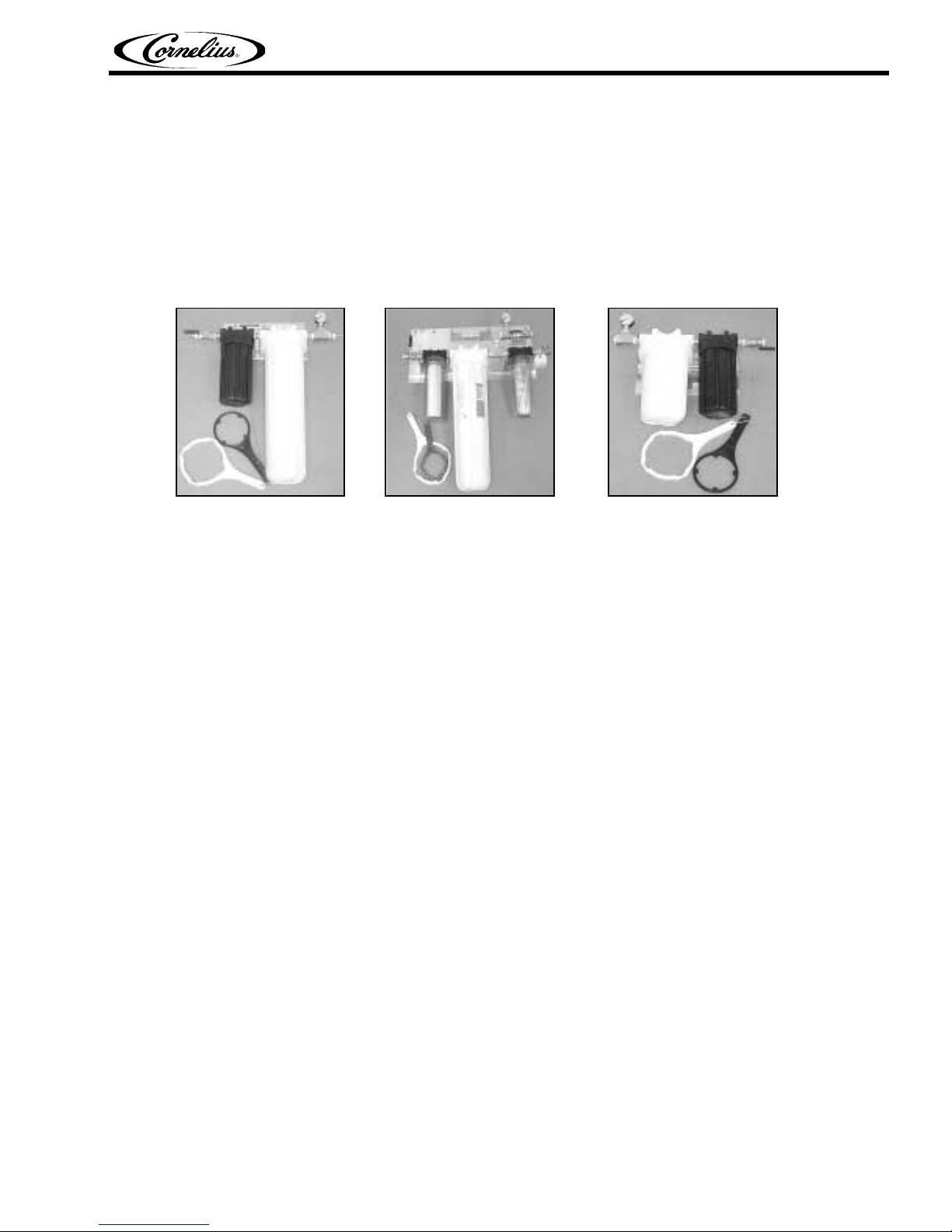

1. Install water filter system between booster pump and water pressure regulator.

IntelliCarb Drop-In Ice Cooled Installation Guide

p/n 605620

Pre filter

p/n 605625ST

Main filter

p/n 605600

Polyphosphate feeder (Ice

Maker water)

NOTE: Recommended shut off valve be installed on outlet side of filter system.

2. Run water line from source to inlet connection on booster pump.

3. Connect water line from booster pump outlet to water filter system inlet.

© 2003-2005, IMI Cornelius Inc. - 7 - Publication Number: 630460204INS

Page 12

IntelliCarb Drop-In Ice Cooled Installation Guide

NOTE: Do not route beverage make up water through polyphosphate feeder.

Publication Number: 630460204INS - 8 - © 2003-2005, IMI Cornelius Inc.

Page 13

4. Connect from water filter system outlet to

water regulator assembly and tee to surge

tank.

5. Connect water lines from manifold outlet to

water line going to each dispenser.

IntelliCarb Drop-In Ice Cooled Installation Guide

2-wide BIB

shelf assembly

P/N 561300067

shelf assembly

P/N 561300066

SYRUP

6. Connect syrup lines from bundled tubing to BIB

pump outlet fitting.

HIGH PRESSURE CYLINDER CO

2

1. Connect primary regulator manifold to high pres-

sure cylinder CO

source and connect tubing to

2

the secondary regulator mounted on the side of

BIB rack.

2. Connect one CO

line from the bundled tubing to the primary regulator manifold on CO2 source to

2

supply each dispenser.

BULK CO

1. Connect bulk CO

TA NK

2

tank to the secondary regulator mounted on the side of BIB rack. DO NOT USE

2

PRIMARY REGULATOR WITH BULK CO

TANKS.

2

connection

from filters

3-wide BIB

Secondary

regulator

BIB

pumps

Water

Water

connection

to unit(s)

© 2003-2005, IMI Cornelius Inc. - 9 - Publication Number: 630460204INS

Page 14

IntelliCarb Drop-In Ice Cooled Installation Guide

1522-2323-3023 DROP-IN

Conversion Instructions for Valves Connected into Manifold

1. Remove the cup rest, front panel, and drip tray.

2. Remove insulation pad, 2 screws, and bracket (as shown below).

3. Pull out the plug fitting and tubing with barb fitting of the desired valve for conversion.

4. Place tubing with barb fitting into desired outlet on the manifold.

5. Replace plug fitting in open outlet.

6. Reassemble bracket, 2 screws, and insulation pad.

7. Reassemble drip tray, front panel, and cup rest.

BRACKET

PLUG FITTING

FRONT CONNECTION

CARBONATED WATER

OPTION

TUBING WITH

BARB FITTING

SCREW

OETIKER CLAMP

MANIFOLD

REAR CONNECTION

NON-CARB WATER

OPTION

Publication Number: 630460204INS - 10 - © 2003-2005, IMI Cornelius Inc.

Page 15

IntelliCarb Drop-In Ice Cooled Installation Guide

Conversion Instructions for 1522 Valve #1 from Carb to Non/Carb

1. Remove the cup rest, front panel, and drip tray.

2. Remove insulation pad, 2 screws, and bracket (as shown above on page 10).

3. Pull out a plug fitting from the rear connection of the manifold.

4. Disconnect soda line from valve #1.

5. Assemble straight fitting and oetiker clamp to soda line from valve #1 (as shown on page 10).

6. Assemble soda line from valve #1 to manifold.

7. Assemble hose plug and clamp oetiker to soda line valve #1 (as shown on page 10).

8. Reassemble bracket, 2 screws, and insulation pad.

9. Reassemble drip tray, front panel, and cup rest.

Drop-In Installation

1. Install dispenser in counter following standard procedures.

2. Use the Template supplied to mark the location of the hole to be cut into the counter top. Cut the

hole as marked and remove the material.

3. Apply the double stick tape (if supplied with the loose shipped parts).

NOTE: To comply with the National Sanitation Foundation (NSF) requirements, the unit must be

sealed to the counter top.

4. Liberally apply a sealant, such as Dow Corning RTV 731 or equivalent, to the unit flange bottom sur-

face.

5. Lower the unit into position to complete the seal of the rim to the counter top. Apply additional seal-

ant around the rim to ensure a complete seal.

NOTE: Do not move the unit after positioning or the seal will be broken.

6. Remove any excess sealant.

NOTE: For non-electrical valves, skip the next step.

7. Mount the Transformer power supply under the counter, in a position to allow access to the electrical

outlet and to allow the 24V power cord to reach the dispenser.

8. Install the drain hose to the ice bin drain fitting and route the drain hose to a permanent drain.

9. Mount secondary CO

regulator, carbonator pump with motor, and valve transformer in a conve-

2

nient location, no more than 7 feet from the unit.

Secondary

regulator

Carbonator

motor and

pump

assembly

Valve

transformer

10. Connect carbonator motor 3 wire plug to the tower 3 wire harness.

Connect the tower 2 wire harness to the transformer.

© 2003-2005, IMI Cornelius Inc. - 11 - Publication Number: 630460204INS

Page 16

IntelliCarb Drop-In Ice Cooled Installation Guide

11. Connect CO2 line from bundled tubing to fixed secondary regulator inlet fitting.

Connect tubing from secondary regulator outlet to

carbonator tank CO

Route CO

line down center channel raceway with

2

inlet.

2

wire harness.

12. For 2323 Drop-In install a tee in water line (must be

before pump). Run one line to carbonator pump inlet.

Connect carbonator pump outlet to “S”.

13. Connect syrup lines.

14. Connect fittings and drain hoses to ice bin and drip tray drains.

Run separate hoses all the way to the drain. Allow a 3” air gap

between the drain and the end of the hose. All connections

must comply with local plumbing and health codes.

CO2 line

2323 Drop-In

W1

15. Turn water supply on.

Plug in water booster pump (on BIB rack).

After the booster pump cycles off, check that water pressure

regulator is set at 60 psi.

16. Turn CO

source on. Set secondary regulator for BIB pumps

2

(located on side of rack) at 60 psi min. Bleed carbonator.

17. Fill bin with ice.

18. Plug in Pump Motor and valve transformer.

The carbonator tank should fill in 7 to 12 seconds.

Water

manifold

assembly

Water

pressure

regulator

Open each valve until carbonated water comes out.

19. Connect syrup lines to bag-in-boxes.

Bleed syrup from each valve.

Free-Standing Dispenser

1. Install the 6” legs to the dispenser cabinet if they are to be used.

2. Place the dispenser in the location selected. Be sure the dispenser is level. This is important to

ensure that the bin drains properly.

3. Mount the Transformer power supply in a convenient location to allow access to the electrical outlet

and to allow the 24V power cord to reach the dispenser.

4. Install the drain hose to the ice bin drain fitting and route the drain hose to a permanent drain.

Publication Number: 630460204INS - 12 - © 2003-2005, IMI Cornelius Inc.

Page 17

IntelliCarb Drop-In Ice Cooled Installation Guide

SANITIZING PRODUCT COLD PLATE TUBING

Preparing the Cleaning Solution: Using a clean tank (tank system) or a five-gallon container (bag-inbox system), prepare a full tank or container of liquid dishwasher detergent by using 70°F (21°C) to

100°F (38°C) potable water and 0.5 oz. (15 ml) of liquid dishwasher detergent (such as Joy, Ivory, ect.) to

one gallon of potable water. Shake detergent solution to thoroughly mix the solution.

Preparing the Sanitizing Solution: Using a clean tank (tank system) or a five-gallon container (bag-inbox system), prepare sanitizing solution using 70°F (21°C) to 100°F (38°C) potable water and 0.5 oz. (15

ml) of household liquid bleach such as non-scented Hi-Lex or Chlorox that contains a 5.25% sodium

hypochlorite concentration to one gallon of potable water. This mixture

must not

exceed 200 PPM of

chlorine. Shake sanitizing solution to thoroughly mix.

STEP 1. WASH PRODUCT/SYRUP SYSTEMS

1. Using a clean tank (tank system) or a five-gallon container (bag-in-box system), prepare a full tank

or container of liquid dishwasher detergent by using 70°F (21°C) to 100°F (38°C) potable water and

0.5 oz. (15 ml) of liquid dishwasher detergent (such as Joy, Ivory, ect.) to one gallon of potable

water. Shake detergent solution to thoroughly mix the solution.

Tank Systems.

• Observe and note CO

pressure settings on the tanks CO2 regulator, then re-adjust CO2 regula-

2

tor to 60 to 80-psi. Pressurize the tank containing detergent solution to 60 to 80-psi.

• Connect detergent solution tank, pressurized at 60 to 80-psi, into one of the tubing systems.

Bag-in Box Systems.

• Install bag valves (cut empty bag-in-box syrup containers) on ends of syrup containers syrup outlet tubes connectors.

• Place all syrup outlet tubes, with bag valves on their ends, in container containing detergent

solution.

2. Flush the syrup system and dispensing valve as follows:

• Place waste container under applicable dispensing valve.

• Activate the dispensing valve for one minute to purge all syrup and flush out the syrup system.

• Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

3. Connect detergent solution to remaining syrup systems and flush syrup out of syrup systems as

instructed in step 2 preceding.

4. Remove detergent solution source from the syrup system.

STEP 2. FLUSH COOLING SYSTEMS

Tank Systems.

1. Connect tank containing potable water, pressurized at 60 to 80-psi, into one of the tubing systems.

Bag-in-Box Syrup System

2. Fill five-gallon container with potable water, then place all bag-in-box syrup containers syrup outlet

tubes in container containing potable water.

• Flush detergent solution out of syrup system and dispensing valve as follows:

• Place waste container under applicable dispensing valve.

• Activate the dispensing valve for one minute to purge all detergent solution and flush out of the

syrup system.

• Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds).

3. Connect potable water source to remaining syrup systems and flush detergent solution out of syrup

systems as instructed in step A preceding.

4. Remove potable water source from the syrup system.

© 2003-2005, IMI Cornelius Inc. - 13 - Publication Number: 630460204INS

Page 18

IntelliCarb Drop-In Ice Cooled Installation Guide

STEP 3. SANITIZE COOLING SYSTEMS

1. Using a clean tank (tank system) or a five-gallon container (bag-in-box system), prepare a full tank

or container of liquid dishwasher detergent by using 70°F (21°C) to 100°F (38°C) potable water and

0.5 oz. (15 ml) of liquid dishwasher detergent (such as Joy, Ivory, ect.) to one gallon of potable

water. Shake detergent solution to thoroughly mix the solution

Tank Systems.

• Connect sanitizing solution tank, pressurized at 60 to 80-psi, into one of the tubing systems.

Bag-in-Box Syrup System.

• Place all bag-in-box syrup containers syrup outlet tubes in container containing sanitizing solution.

2. Sanitize the syrup system and dispensing valve as follows:

• Place waste container under applicable dispensing valve.

• Activate the dispensing valve for one minute to purge all water from and install sanitizing solution

in the syrup system and dispensing valve.

• Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

3. Repeat steps to flush water out of and install sanitizing solution in the remaining syrup systems and

dispensing valves.

4. Remove sanitizing solution source from the syrup system.

5. Allow sanitizing solution to remain in the syrup systems for not less than 10 or no more than 15-minutes (max.) contact time.

STEP 4. WATER FLUSH SYSTEMS

WARNING: Flush sanitizing solution from the systems as instructed. Residual sanitizing solution

left in the systems could create a health hazard.

1. Fill tank (tank system) or a five-gallon container (bag-in-box system) with potable water.

Tank Systems.

• Connect tank containing potable water, pressurized at 60 to 80-psi, into one of the systems.

Bag-in-Box Syrup Systems.

• Place all bag-in-box syrup containers syrup outlet tubes in container containing potable water.

2. Flush sanitizing solution from the syrup system and the dispensing valve as follows:

• Place waste container under applicable dispensing valve.

• Activate the dispensing valve for one minute to purge all sanitizing solution out of the syrup sys-

tem and the dispensing valve.

• Continue to activate the dispensing valve in cycles (“ON” for 15-seconds, “OFF”, then “ON” for

15-seconds). Repeat “ON” and “OFF” cycles for 15-cycles.

3. Repeat preceding steps to purge sanitizing solution out of the remaining syrup systems and dispensing valves.

4. Remove potable water source from the syrup system.

STEP 5. PURGE WATER (RESTORE OPERATION)

Tank Systems.

1. Noting tanks CO

regulator pressure setting observed in step 4 preceding, readjust CO2 regulator to

2

the observed pressure setting.

• Connect tanks containing the product into the system.

Publication Number: 630460204INS - 14 - © 2003-2005, IMI Cornelius Inc.

Page 19

IntelliCarb Drop-In Ice Cooled Installation Guide

Bag-in-Box Syrup Systems.

• Remove all bag valves from bag-in-box syrup containers outlet tubes connectors.

• Connect bag-in-box containers into the syrup system.

2. Place waste container under dispensing valves. Dispense from all dispensing valves to permit

syrup to purge all potable water from the syrup systems and the dispensing valves. Continue to dispense from the dispensing valves until only syrup is dispensed from the syrup systems and valves.

WARNING: To avoid possible personal injury or property damage, do not attempt to remove the

syrup tank cover until CO

pressure has been released from the tank.

2

3. Dispose of waste sanitizing solution in sanitary sewer, not in storm drain, then thoroughly rinse

inside and outside of the container that was used for sanitizing solution to remove all sanitizing solution residue.

CLEANING THE ICE BIN

1. Prepare a mild detergent soap solution in 100°F potable water.

2. Using a nylon (not wire) bristle brush, clean the cold plate and the interior of the ice bin with the

soap solution.

3. Rinse the cold plate and interior bin surfaces with clean potable water.

4. Using a mechanical spray bottle, prepare a sanitizing solution according to the manufacture’s directions and spray the entire interior bin surfaces. Allow to air dry.

CONNECTING PRODUCT TO THE DISPENSER

NOTE: All inlet connections are clearly marked with a label adjacent to the inlet connections.

NOTE: Always leak check all connections.

Post-Mix units must have syrup, carbonated water and plain water connected. The number of syrups will

depend on the number of valves on the dispenser. Refer to the plumbing diagram for details of the

hookup.

Pre-Mix units must have a pre-mix supply connected to each inlet for each valve supplied. Refer to

plumbing diagram for details of the hook-up.

NOTE: A plumbing diagram when supplied with the unit, can be found in the dispensing tower.

PREPARING FOR OPERATION

On units Without Electrically Operated Valves, Skip Steps 1 and 2 Below

1. Plug transformer into electrical outlet. The 24V supply must be connected in the dispensing tower.

2. Turn the key-switch to the ON position. The ice-bin lid must be closed to allow the valves to operate.

3. Adjust the CO

regulators as indicated in the following chart:

2

Post-Mix

Regulator Pressure Setting

Primary (Carbonator) feed line to Carb secondary regulator 90-120 PSI

Secondary, Sugared Syrup Tank 55 PSI min.

Secondary, Diet Syrup Tank 8-12 PSI

Secondary, B-I-B 60 PSI min

4. Operate each valve until product is flowing.

5. Fill the bin with 32°F ice. DO NOT use ice taken directly from the freezer.

6. Adjust the brix (water-to-syrup ratio) for post-mix valves.

© 2003-2005, IMI Cornelius Inc. - 15 - Publication Number: 630460204INS

Page 20

IntelliCarb Drop-In Ice Cooled Installation Guide

Adjust Water-To-Syrup Ratio

Water-To-Syrup

ratio cup

1. Remove valve cover and install syrup separator over the diffuser and through the nozzle.

2. Hold cup under valve and dispense beverage for a specific time (i.e. 2 seconds).

3. NOTE: Water and syrup must be cold before checking ratios.

4. Adjust carbonated water flow to the desired rate (such as 90 to 110 ml (3 to 3.75 oz.) per second).

Turn the flow adjuster 1/4 of a turn at a time and recheck the flow.

To increase reading turn clockwise.

5. Set syrup flow adjuster to get the desired ratio.

6. Test the valve and adjust until a consistent ratio is delivered three consecutive times.

7. Repeat procedure for other valves.

Separator

Valve Type

Manufacturer

Maximum Operating

Portion Control

Cornelius 130 psi

Flowmatic 100 psi

Pushbutton

Cornelius 130 psi

Flowmatic 100 psi

Lever Type

Cornelius 130 psi

Flowmatic 100 psi

Autofill Lever

Cornelius 130 psi

Flowmatic 100 psi

Non-Electric

Cornelius 130 psi

Pressure

Publication Number: 630460204INS - 16 - © 2003-2005, IMI Cornelius Inc.

Page 21

IntelliCarb Drop-In Ice Cooled Installation Guide

© 2003-2005, IMI Cornelius Inc. - 17 - Publication Number: 630460204INS

Cold Plate Plumbing & Wiring Diagram for CB2323 & CB3023 8 Valve

CONTINUOUSLY

BK

REMOTE TRANSFORMER BOX

WH

WH

BK

VALVE WIRE HARNESS

PLUG

24 VAC

LOCKOUT

1

2

3

MERCHANDISER

CONNECTION TO

HAVE MERCHANDISER

SWITCH

OPTIONAL

LIGHTED

BY KEYSWITCH

CONTROLLED

KEY

OUTLET

BK

BK

WH

2

3

1

24 VAC

BK

BK

COM

24 VAC MERCH.

OPTIONAL

CONNECTION

(SOME UNITS)

TO HAVE

WIRE HARNESS

SWITCH

BK

WH

BK

WH

BK

VALVES

24 VAC

VALVE

NO

REMOTE MOTOR/PUMP BOX

GRND

GRND

SUPPLY

115 VAC

POWER

WH

BK

BK

125 GPHB

PUMP

WH

WATER OUT - S

WATER IN

POWER

SUPPLY

115 VAC

WIRE

GROUND

GRND

WH

WH

CIRCUIT BOARD

BK

GRND

WH

WH

BK

BK

CARBONATOR

MANIFOLD LEFT

PLAIN WATER

FROM MOTOR/PUMP

CARBONATOR

8 VALVE UNIT

(FRONT VIEW)

PLUMBING DIAGRAM

DISPENSING VALVES

COLDPLATE INLETS

S

W1

12

M4

W4

M1

W1

M2

W2

M3

W3

SL SR

POST-CHILL

PRE-CHILL

12

M1 1W1M2 2

SODA OUT

WATER IN

GAS

VALVE

CO-2

345678

WIRING DIAGRAM

M5

W5

S5

S4

S1

S2

S3

MANIFOLD RIGHT

S8

W8

M8

S7

S6

W7

M7

W6

M6

435

SL

M3 3 M4 4 M5 5

WATER

678

M7SR6M6

W1

7M88

PROBE

SODA

Page 22

IntelliCarb Drop-In Ice Cooled Installation Guide

Publication Number: 630460204INS - 18 - © 2003-2005, IMI Cornelius Inc.

Cold Plate Plumbing & Wiring Diagram for CB2323 6 valve

CONTINUOUSLY

REMOTE TRANSFORMER BOX

PLUG

24 VAC

VALVE WIRE HARNESS

GRND

LOCKOUT

3

2

1

MERCHANDISER

HAVE MERCHANDISER

CONNECTION TO

SWITCH

OPTIONAL

LIGHTED

CONTROLLED

BY KEYSWITCH

KEY

OUTLET

2

3

1

24 VAC

BK

BK

COM

24 VAC MERCH.

(SOME UNITS)

CONNECTION

TO HAVE

OPTIONAL

SWITCH

WIRE HARNESS

BK

WH

BK

WH

BK

VALVE

NO

24 VAC

VALVES

REMOTE MOTOR/PUMP BOX

GRND

SUPPLY

115 VAC

POWER

WH

BK

BK

PUMP

125 GPHB

WH

WATER OUT - S

WATER IN

115 VAC

POWER

SUPPLY

WIRE

GROUND

GRND

WH

WH

CIRCUIT BOARD

BK

GRND

WH

BK

CARBONATOR

MANIFOLD LEFT

PLAIN WATER

FROM MOTOR/PUMP

CARBONATOR

6 VALVE UNIT

(FRONT VIEW)

PLUMBING DIAGRAM

DISPENSING VALVES

2

COLDPLATE INLETS

S

W1

1

M3

S3

W3

W2

M2

S2

M1

W1

S1

SL SR

POST-CHILL

PRE-CHILL

1

W1

SL

M1 1 M2

SODA OUT

WATER IN

GAS

VALVE

CO-2

23 456

WIRING DIAGRAM

M4

W4

S4

M5

W5

MANIFOLD RIGHT

S6

W6

M6

S5

M5

34

M3234M4

WATER

56

SR

5M66

W1

PROBE

SODA

Page 23

IntelliCarb Drop-In Ice Cooled Installation Guide

© 2003-2005, IMI Cornelius Inc. - 19 - Publication Number: 630460204INS

Cold Plate Plumbing & Wiring Diagram for CB1522 6 Valve

W

S

4

COLDPLATE INLETS

12 3

213

45

M6656

DISPENSING VALVES

PLUMBING DIAGRAM

(FRONT VIEW)

6 VALVE UNIT

WIRING DIAGRAM

SODA OUT

WATER IN

CARBONATOR

PROBE

CO-2

VALVE

POST-CHILL

FROM MOTOR/PUMP

PLAIN WATER

PRE-CHILL

SR S1

GAS

WATER

SODA

6

HAVE MERCHANDISER

REMOTE TRANSFORMER BOX

CONTINUOUSLY

LIGHTED

GRND

GRND

VALVE WIRE HARNESS

BK

WH

1

PLUG

24 VAC

CONNECTION

SWITCH

CONNECTION TO

OPTIONAL

KEY

BY KEYSWITCH

MERCHANDISER

CONTROLLED

TO HAVE

OUTLET

24 VAC

3

1

2

BK

BK

2

3

24 VAC MERCH.

WIRE HARNESS

OPTIONAL

(SOME UNITS)

BK

BK

WH

VALVES

24 VAC

BK

GRND

125 GPHB

REMOTE MOTOR/PUMP BOX

SUPPLY

POWER

115 VAC

PUMP

WH

BK

WH

BK

CIRCUIT BOARD

WATER OUT - S2

WATER IN

WIRE

GROUND

POWER

SUPPLY

115 VAC

WH

WH

BK

CARBONATOR

GRND

WH

FLEXIBLE MANIFOLD

M2

W2

S2

SR

W1

S3 S6

M3

W3

M6

W6

S1 1 M2 M323 M54M4 5

W5

S5

S4

W4

M5M4

Page 24

IntelliCarb Drop-In Ice Cooled Installation Guide

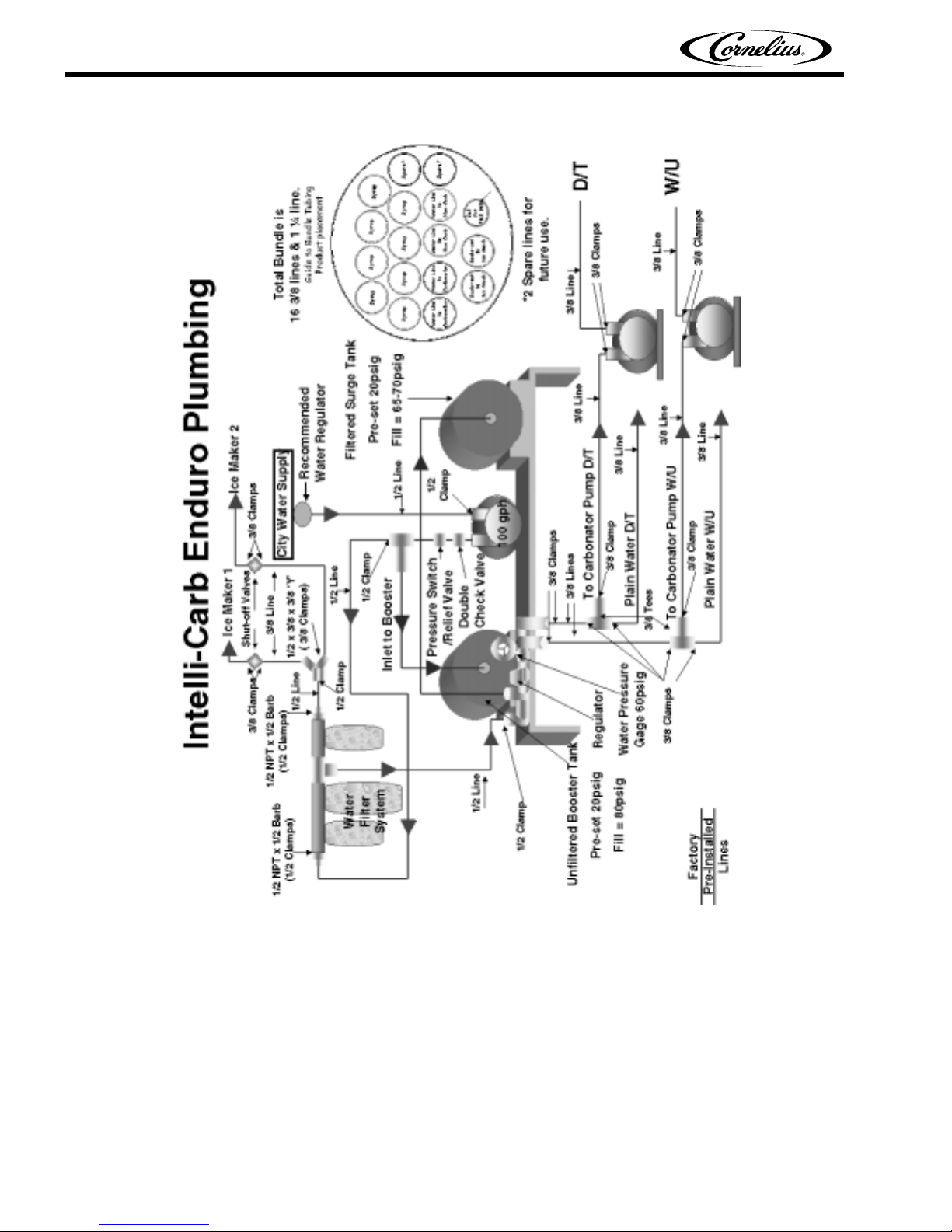

IntelliCarb Back Room Plumbing and Settings

Publication Number: 630460204INS - 20 - © 2003-2005, IMI Cornelius Inc.

Page 25

Removal and Installation of Carbonator

IntelliCarb Drop-In Ice Cooled Installation Guide

Carbonator Removal

1. Remove ice from bin.

2. Disconnect the power to the unit and to the pump and motor.

3. Shut off the CO

4. Shut off the water supply that is connected to the pump and motor.

5. Remove Cup Rest, Splash Panel, Drip Tray, Sliding Lid and Sanitary Plate.

6. Relieve pressure in the system by flipping the pressure relief valve to the up position on the Carbonator.

7. Remove front cover, back cover and valve body of No. 8 (left side).

8. Remove the plug button on the left side of tower and cover hole with tape (safety).

9. Disconnect the barb fitting for the CO

10. Disconnect the barb fitting on the Carbonator lines to the coldplate tubes.

11. Disconnect probe wire from pump and motor harness.

12. Cut the silicone seal with putty knife around Carbonator a minimum of 1.5” deep and remove.

Relief

Val ve

supply that is connected to the Carbonator.

2

line on Carbonator.

2

© 2003-2005, IMI Cornelius Inc. - 21 - Publication Number: 630460204INS

Page 26

IntelliCarb Drop-In Ice Cooled Installation Guide

Carbonator Installation

1. Clean around Carbonator tank opening removing all silicone, and make sure cavity is clean and dry.

2. Place new Carbonator in place of the old one.

3. Reconnect probe wire harness to pump and motor.

4. Seal top of Carbonator with silicone.

5. Connect the CO

replace white gasket).

6. Reconnect the Carbonator lines to the Carbonator.

7. Reinstall valve body, back cover and front cover of the valve No. 8 to unit.

8. Turn on the CO

9. Turn on the water supply that is connected to the pump and motor.

10. Reconnect the power to the unit and to the pump and motor.

11. Test system and pump and motor for leaks.

12. Apply insulation tape as needed to cover tubes on Carbonator.

13. Remove and clean all foreign substance from bin and replace ice.

14. Replace Sanitary Plate, Sliding Lid, Drip Tray, Splash Panel and Cup Rest.

line from the barbed fitting Carbonator and tighten to 80+/- 10 in pounds (Note:

2

supply that is connected to the Carbonator.

2

Publication Number: 630460204INS - 22 - © 2003-2005, IMI Cornelius Inc.

Page 27

IntelliCarb Drop-In Ice Cooled Installation Guide

MANIFOLD PARTS BREAKDOWN (1522, 2323, 3023)

1

2

3

4

5

7

8

6

Item No. Part No. Name Qty.

1 620407728 MANIFOLD FLEX 5 POS 2

2 164126000 SCREW SM 08 TA TRPH 16 SS 10

3 620519005 PLUG MANIFOLD 12

4 630201533 BRKT MANIFOLD BLOCK 2

5 77051500 FITG-VAL DOLE ELB 102 DEGREE 8

6 309854000 CLAMP OETR 413 OPEN STPLS #10.5 8

7 630201532 BRKT RETAINER MANIFOLD 2

8 630600024 HOSE .375 B 5.00” C-PLT TO MANIFOLD BLOCK 4

© 2003-2005, IMI Cornelius Inc. - 23 - Publication Number: 630460204INS

Page 28

IntelliCarb Drop-In Ice Cooled Installation Guide

CB 1522 INTELLICARB STAINLESS TOWER 75LB WITH 12 X 4 CARBONATOR

Item No. Part No. Name Item No. Part No. Name

1 630201449 Frame Dec CB1522 14 630300373 Harn Wire Jumper (Opti-

TM

only)

Fill

2 630000601 Transfrmr 115/24 RMT

75VA

3 630001125 Tank Carb Foam Asy

4X12

4 167491001 Splashguard Panl SBR

TWR GE

15 318308000 Screw TR 10-32 PAPH

32 SS HRD

16 630200858 Cup-Rest CB1522 Opti

TM

(Opti-Fill

only)

167787000 Cup-Rest 1522SST

STND

5 163545001 Switch Key-Lock Termi 17 630900910 Drip-Tray 18” 1522 Intel-

liCarb

6 161168014 Screw Ma 1032 012TR

SS PH

7 630000794 Tower W/A 18” SS BLT

DN 1522

8 167244008 Cover TWR 18.5 x 3.5

SS

18 630001101 Plate Sanitary 75# Intelli-

Carb

19 630001100 Lid Sliding 1522 Intelli-

Carb

20 162865010 Strainer Corner Drain W/

A

9 162968004 Hose 0.265F 16” 21 168745001 Bolt MA 1/4-20 HX 16

STZI

10 630201568 Panel 6VLV 18” SS TWR 22 630300341 Harn Wire TWR 96” 2

CR 25R

11 630300344 Harn Wire 6VLV 2CR

23 629087457 Pump Asy MTR

3.50SPC

12 163518000 Conn Elec Mate-N-Lok

2CR

13 168462002 Plug-Butn 1/2 Hole STNI

SWC

24 630000952 Hose Asy Carb to C-PLT

S-Tube 1522

25 630201516 Lid Top 1522 Sliding (not

shown)

Publication Number: 630460204INS - 24 - © 2003-2005, IMI Cornelius Inc.

Page 29

IntelliCarb Drop-In Ice Cooled Installation Guide

CB 2323 INTELLICARB STAINLESS TOWER 100LB WITH 12 X 4 CARBONATOR

78

2

20

1

31

16

17

18

30

19

13

3

4

15

10

14

9

12

11

25

24

23

22

6

5

21

Item No. Part No. Name Item No. Part No. Name

1 630201423 Decorative Frame 16 630900042

2 630000601 Transformer Ass’y, 115/

167787002 Cup Rest (Standard)

Cup Rest, Grille (Opti-Fill

24V RMT 75V

3 630001125 Carbonator (12 X 4) 17 630150005 Drip Tray

4 167491003 Panel, Splash 18 630001129 Plate, Sanitary

5 163545001 Switch, Key Lock 19 630200832 Lid, Sliding

6 161168014 Machine Screw, Phil

20 162865010 Strainer

Truss Hd., No. 10-32 By

3/8-In. Long

7 630000631 Tower 21 630300357 Lead Wire, Black)

8 167244007 Cap, Tower 22 167570001 Switch, Valve Lockout

9 162968004 Hose, .265 I.D. 23 21633 Hex Nut, No. 4-40

10 630201561 Panel Valve, 6-Flavor 24 21632 Machine Screw, Rd Hd, No.

4-40 By 3/4-In. Long

630201551 Panel Valve, 8-Flavor 25 168745001 Machine Screw, 1/4-20 By

1/2-In. Long

11 630300344 Wire Harness, 6-Flavor 26 630300341 Wire Harness, Power Sup-

ply to Tower

630300345 Wire Harness, 8-Flavor 27 41710 Fitting, 3/4-MPT By 3/4-Barb

12 163518000 Connector, 2 Circuit 28 161508006 Fitting, 3/4-FPT By 3/4-Barb

13 168462000 Button Plug 29 629087457 Pump and Motor with Dou-

ble Check Valve

14 630300373 Wire Harness (Opti-Fil

Valves only)

15 318308000 Thread Rolling Screw,

Phil Pan Hd., No. 10-32

30 630000951 Hose Ass’y, Carb to Cold

Plate

31 630000952 Hose Ass’y, Carb to Cold

Plate S-Tube

By 1-In. Long

TM

)

© 2003-2005, IMI Cornelius Inc. - 25 - Publication Number: 630460204INS

Page 30

IntelliCarb Drop-In Ice Cooled Installation Guide

CB 2323 INTELLICARB STAINLESS TOWER 80LB WITH 8 X 4 CARBONATOR

31

30

Item No. Part No. Name Item No. Part No. Name

1 630201423 Decorative Frame 16 630900042 Cup Rest, Grille (Opti-Fil)

2 630000601 Transformer Ass’y, 115/

167787002 Cup Rest (Standard)

24V RMT 75V

3 630001124 Carbonator (8 X 4) 17 630150005 Drip Tray

4 167491003 Panel, Splash 18 630001129 Plate, Sanitary

5 163545001 Switch, Key Lock 19 630200832 Lid, Sliding

6 161168014 Machine Screw, Phil

20 162865010 Strainer

Truss Hd., No. 10-32

By 3/8-In. Long

7 630000631 Tower 21 630300357 Lead Wire, Black)

8 167244007 Cap, Tower 22 167570001 Switch, Valve Lockout

9 162968004 Hose, .265 I.D. 23 21633 Hex Nut, No. 4-40

10 630201561 Panel Valve, 6-Flavor 24 21632 Machine Screw, Rd Hd, No.

4-40 By 3/4-In. Long

630201551 Panel Valve, 8-Flavor 25 168745001 Machine Screw, 1/4-20 By

1/2-In. Long

11 630300344 Wire Harness, 6-Flavor 26 630300341 Wire Harness, Power Sup-

ply to Tower

630300345 Wire Harness, 8-Flavor 27 41710 Fitting, 3/4-MPT By 3/4-Barb

12 163518000 Connector, 2 Circuit 28 161508006 Fitting, 3/4-FPT By 3/4-Barb

13 168462000 Button Plug 29 629087457 Pump and Motor with Dou-

ble Check Valve

14 630300373 Wire Harness (Opti-Fil

Valves only)

15 318308000 Thread Rolling Screw,

Phil Pan Hd., No. 10-32

30 630000952 Hose Ass’y, Carb to Cold

Plate

31 630000951 Hose Ass’y, Carb to Cold

Plate

By 1-In. Long

Publication Number: 630460204INS - 26 - © 2003-2005, IMI Cornelius Inc.

Page 31

IntelliCarb Drop-In Ice Cooled Installation Guide

CB 3023 INTELLICARB STAINLESS TOWER 130LB WITH 12 X 4 CARBONATOR

29

Item No. Part No. Name Item No. Part No. Name

1 630201420 Frame Dec CB3023 16 167787013 Cup-Rest CB3023 Opti

TM

only)

2 630000601 Transfrmr 115/24 RMT

75VA

(Opti-Fill

167787007 Cup-Rest 3023SST

STND

3 630001125 Carbonator Tank Assy 17 167481019 Drip-Tray 30” TWR BLK

4 167491009 Splashguard Panl 30”

SST

18 630000658 Plate Sanitary W/A 30”

IntelliCarb

5 163545001 Switch Key-Lock Termi 19 630200933 Lid SLI 3023 IntelliCarb

6 161168014 Screw Ma 1032 012TR

SS PH

20 162865010 Strainer Corner Drain W/

A

7 630000847 Tower W/A 30” SS 21 630300357 Lead Wire 22” BK 20G2

187-250

8 167244011 Cover TWR 30” SS TWR 22 167570001 Switch Val Lock-Out

9 162968004 Hose 0.265F 16” 23 21633 Nut Hex 04-40 STZI

10 630001123 Panel Val CB3023 W/A 24 21632 Screw MA 04-40 RD 24

STZI

11 630300345 Harn Wire 8VLV 2CR

2.56SPC

12 163518000 Conn Elec Mate-N-Lok

2CR

13 168462002 Plug-Butn 1/2 Hole STNI

25 168745001 Bolt MA 1/4-20 HX 16

STZI

26 630300341 Harn Wire TWR 96” 2CR

25R

27 629087457 Pump Asy Mtr

SWC

14 630300373 Harn Wire Jumper (Opti-

TM

only)

Fill

15 318308000 Screw TR 10-32 PAPH

28 630001001 Hose Asy Carb to C-Plt

S-Tube

29 630001006

32 SS HRD

© 2003-2005, IMI Cornelius Inc. - 27 - Publication Number: 630460204INS

Page 32

IntelliCarb Drop-In Ice Cooled Installation Guide

TROUBLESHOOTING

Trouble Probable Cause Remedy

ADJUSTMENT OF DISPENSING VALVE SYRUP

FLOW REGULATOR

DOES NOT INCREASE

TO DESIRED WATERTO-SYRUP “RATIO”

ADJUSTMENT OF DISPENSING VALVE SYRUP

FLOW REGULATOR

DOES NOT DECREASE

TO DESIRED WATERTO-SYRUP “RATIO”

DISPENSED PRODUCT

CARBONATION TOO

LOW

A. Dispensing Valve syrup flow regu-

lator, syrup tank quick disconnect,

or syrup line restricted.

B. Syrup tank quick disconnects not

secure.

C. Syrup tanks secondary CO

regu-

2

lator out of adjustment.

D. No syrup supply.

E. Improper syrup Baume.

F. Dirty or inoperative piston or

spring in dispensing valve syrup

flow regulator.

G. Tapered nylon washer inside tube

swivel nut connector distorted

from being overtightened.

A. Dirty or inoperative piston or spring

in dispensing valve syrup flow regu-

lator.

A. Air in carbonator tank.

B. Water, oil or dirt in CO

supply

2

A. Sanitize syrup system as

instructed.

B. Secure quick disconnects.

C. Adjust syrup tanks secondary

CO

regulator as instructed.

2

D. Replenish syrup supply.

E. Replace syrup supply.

F. Disassemble and clean dispens-

ing valve syrup flow regulator.

G. Replace nylon washer and make

sure it seats properly.

A. Disassemble and clean dispensing

valve syrup flow regulator.

A. Vent air out of carbonator tank

through relief valve. Actuate dispensing valve carbonated water

lever to make carbonator pump

cycle on.

B. Remove contaminated CO

Clean CO

system (lines, regula-

2

tors, ect.) using a clean CO

2

.

2

sup-

ply.

DISPENSED PRODUCT

A. Oil film or soap scum in cup or

COMES OUT OF DISPENSING VALVE CLEAR

BUT FOAMS IN CUP OR

B. Ice used for finished drink is sub-

GLASS.

NOTE: Crushed ice in the glass also causes dispensing problems. When finished drink hits

sharp edges of ice, carbonation is released from dispensed drink.

C. Syrup over-carbonated with CO

D. Warm product-No ice in bin,

Publication Number: 630460204INS - 28 - © 2003-2005, IMI Cornelius Inc.

glass.

cooled.

as indicated by bubbles in inlet

syrup lines leading to unit.

bridged ice on cold plate or

plugged drain.

A. Use clean cup or glass.

B. Do not use ice directly from

freezer. Allow ice to become

“wet” before using. (Refer to following NOTE).

C. Remove syrup tanks quick dis-

2

connects. Relieve tank CO

sure, shake tank vigorously, then

relieve tank CO

pressure as

2

many times as necessary to

remove over-carbonation.

D. Replenish ice, break ice up to

eliminate bridging, unplug the

drain.

2

pres-

Page 33

IntelliCarb Drop-In Ice Cooled Installation Guide

Trouble Probable Cause Remedy

NOTE: If water supply is dirty, be sure to flush lines and carbonator completely. It may be necessary to remove lines to carbonator tank. Flush tank and all inlet lines to remove any foreign particles or dirt.

NO PRODUCT DISPENSED FROM ONE

DISPENSING VALVE

ONLY CARBONATED

WATER DISPENSED.

ONLY SYRUP DISPENSED

A. Broken or disconnected wiring.

B. Inoperative dispensing valve sole-

noid coil.

C. Inoperative dispensing valve

micro switch.

A. Quick disconnects not secure on

syrup tanks.

B. Out of syrup.

C. B-I-B connectors not properly

connected.

D. Syrup secondary CO

regulator

2

not properly adjusted.

E. Inoperable dispensing valve.

F. Dispensing valve syrup flow regu-

lator not properly adjusted.

G. Dispensing valve syrup flow regu-

lator, syrup tank quick disconnect,

or syrup lines restricted.

A. Plain water inlet supply line shut-

off valve closed.

B. Carbonator power cord

unplugged from electrical outlet.

A. Repair or connect wiring.

B. Replace solenoid coil as

instructed.

C. Replace micro switch as

instructed.

A. Secure quick disconnects on

syrup tanks.

B. Replenish syrup supply as

instructed.

C. Properly attach the connectors.

D. Adjust syrup tanks secondary

CO

regulator as instructed.

2

E. Repair dispensing valve.

F. Adjust dispensing valve syrup

flow regulator (Water-to Syrup

“Ratio”) as instructed.

G. Sanitize syrup system as

instructed.

A. Open plain water inlet supply line

shutoff valve.

B. Plug carbonator power cord into

electrical outlet.

Trouble Probable Cause Remedy

PUMP MOTOR WILL

NOT RUN

© 2003-2005, IMI Cornelius Inc. - 29 - Publication Number: 630460204INS

TROUBLESHOOTING for Carbonator

A. Locked pump rotor-dirt or pipe

compound in pump; pump seized.

B. Carbonator flooded.

C. No power.

A. Remove and check for free rota-

tion or replace. Also check CO

2

supply, faulty single check valve,

liquid level control or probe.

B. Main water supply pressure

higher than CO

pressure within

2

the carbonator. If maximum water

supply pressure is within 20 PSI

of CO

pressure, install water

2

pressure regulator.

C. Check source of electrical supply

and for loose connections.

Page 34

IntelliCarb Drop-In Ice Cooled Installation Guide

TROUBLESHOOTING for Carbonator

Trouble Probable Cause Remedy

PUMP RUNS CONTINUOUSLY

A. Pump water supply restricted.

B. Pump discharge line restricted.

C. Inefficient or worn pump.

D. Overdrawing.

A. Check water filter and pump inlet

strainer and clean. NOTE: Noisy

pump operation usually indicates

restricted water supply. Also

check for faulty double check

valve, water leak or low pump

bypass.

B. Water inlet check valve may be

plugged. Remove, clean, or

replace rubber O-Rings.

C. To test for efficiency, disconnect

discharge line from pump. Connect a 300 pound gauge and

hand shut off valve to pump discharge. Start pump. Bleed off any

air, close hand valve then observe

pressure. If it is approximately

180 PSI, pump is O.K. If it is significantly below 180 PSI, it may

be increased by adjusting the

pump by-pass. Increasing the bypass is accomplished by removing sealing acorn cap and turning

the adjusting screw in. If pressure

rises to 180 PSI, pump is O.K. If it

is still below 150 PSI, and the

screw is turned all the way in, the

pump is worn. Replace. NOTE:

Abadly worn pump and/or premature failure usually indicates foreign material in the supply water.

Install a water filter in supply line.

Also check for faulty liquid level

control, corroded electrode, or

broken pump shaft.

D. Check capacity of pump. The

combined rate of flow from dispensing valves should not exceed

the stated GPH for pump, or

pump will run continuously.

NOISY PUMP A. Bad motor bearings or worn pump

B. Failure of Triac on liquid level

C. Insufficient water supply.

Publication Number: 630460204INS - 30 - © 2003-2005, IMI Cornelius Inc.

shaft.

control.

A. Repair or replace motor.

B. Repair or replace liquid level con-

trol.

C. Check that water supply is on.

Also check for clogged water filter, ruptured tank or bad double

check valve.

Page 35

IntelliCarb Drop-In Ice Cooled Installation Guide

TROUBLESHOOTING for Carbonator

Trouble Probable Cause Remedy

VALVE DELIVERS CO

2

A. Pump motor will not run.

GAS CONTINUOUSLY

B. Pump water supply restricted.

C. Relief valve venting.

D. Worn pump.

VALVE DELIVERS SODA

WATER AND CO

GAS

2

A. Pump water supply restricted.

INTERMITTENLY

B. Relief valve venting.

C. Inefficient or worn pump.

POOR CARBONATION A. Flooded carbonator.

B. Water temperature too high

(warm).

C. Oil in water supply.

D. Supply water containing too much

air in solution.

E. Poor quality paper cups.

F. Dirty or greasy glassware.

G. Excessive foam.

H. Flat drinks.

A. See

PUMP MOTOR WILL NOT

RUN.

B. Clean strainer. Check for faulty

double check valve.

C. Repair or replace.

D. See

PUMP MOTOR WILL NOT

STOP

.

A. Clean strainer. Check for faulty

single check valve, clogged water

filter, water supply off or blocked,

ruptured tank, faulty liquid level

control or double check valve.

B. Replace or repair.

C. See

A. See

PUMP MOTOR WILL NOT

STOP

.

PUMP MOTOR WILL NOT

RUN.

B. Check water inlet temperature.

Lower temperature provides bet-

ter carbonation.

C. Check pipe thread compound.

Remove and clean and replace

with teflon pipe thread tape.

D. To remove air before it enters

pump, it will be necessary to

install an open tank with float to

control water level.

E. Purchase quality cups made for

this application.

F. Wash all glassware.

G. CO

BIB pump pressure too high,

2

contamination within the bever-

age system, poor quality paper

cups or dirty glassware.

H. Draw drinks against side of glass

or cup. Check for insufficient CO

contamination, bad check valve,

ruptured CO

2

line

2

© 2003-2005, IMI Cornelius Inc. - 31 - Publication Number: 630460204INS

Page 36

IntelliCarb Drop-In Ice Cooled Installation Guide

TROUBLESHOOTING

Trouble Probable Cause Remedy

DRINK HAS OFF-TASTE

OR ODOR (WATER CONTA MI NAT IO N )

A. Leaking check valves.

B. Too much plumbers pipe com-

pound on pipe joints.

C. Soda water and beverage lines

made of brass or copper.

D. High chlorine level.

E. Tank corrosion.

F. Contaminated CO

2

WARRANTY

A. Replace O-Rings in double check

valve or replace double check

valve. See check valve installation instruction section.

B. Remove pipe compound and

clean joints. Use Teflon pipe

thread tape.

C. Carbonated water reacts with

brass or copper and should not

dispensed through lines of this

material. Replace lines with stainless steel or beverage grade plastic.

D. Install water filter to eliminate

chlorine in excess of 1.5 ppm.

Use type that do not remove all

chlorine.

E. Replace tank.

F. Check that CO

grade.

is beverage

2

be

IMI Cornelius Inc. warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your Cornelius product, in

your country, please write, fax, or telephone the IMI Cornelius office nearest you. Please provide the

equipment model number and the date of purchase.

Publication Number: 630460204INS - 32 - © 2003-2005, IMI Cornelius Inc.

Page 37

Page 38

IMI Cornelius Inc.

www.cornelius.com

Loading...

Loading...