Page 1

Installation Guidelines

for

Coca-Cola Fountain Equipment for

Free Standing Locations

Initial Issue

10/01/01

Page 2

Table Of Contents

g Key Contact and Critical Install Notes..… Page 3

g Equipment Summary...…………………… Page 4

g Equipment Location Diagram…………… Page 5

g Syrup Line / Pump Assignment…………. Page 6

g Equipment Installation Process…...….… Page 7 - 8

– Coca-Cola service agent requirements

– Chick-fil-A requirements

TS0502S.ppt

g Pictures of Equipment & Locations.....….. Pages 9 - 19

g Installation Check Sheet……………………Page 20

g Post Installation Check Sheet……………. Page 21

2

Page 3

Coca-Cola Key Contact / System Notes

g Cynthia Sheppard - Account Coordinator

– Dispensing Equipment Installations, Replacements, Other Service/Equipment

Issues, and Fountain Distribution

– Phone: 1-800-531-2238 Ext. 3746

– E-mail: cysheppard@na.ko.com

– Fax: 770-998-5772

g System Installation Notes:

– There are two syrup supplies - one for each of two dispenser groups. The

drive thru and the middle counter dispenser are fed from one, and the other

dispensers are fed from the other. Two 12 line groups of 3/8” plastic tubing

are run through the ceiling to the dispenser chases that appear above the

drive thru area. LADDERS ARE REQUIRED FOR INSTALLATION

– One carbonator per dispenser.

TS0502S.ppt

– Line connections are made in the ceiling above the drive thru using “T’s”.

The chases in the ceiling are not to be foamed.

– Bulk CO2 is used…Chase for CO2 line is in ceiling above carb racks.

– Drains for dispensers are unique…see picture on page 19. THESE MUST BE

INSTALLED. Drain kits are in the dispenser ice bins.

– ALL equipment is furnished by Chick-fil-A…the agent furnishes syrup tubing

(estimated 3000’), connectors, etc.

3

Page 4

Equipment Summary

Equipment Summary

Equipment– Chick-fil-A provides all dispensing equipment

g Dispensers

– (4) 6 Valve 23” x 23” Cornelius Drop-In Dispensers w/ 80 # ice bin.

– The dispenser will be configured with a stainless steel tower and a water

spigot on the left (see picture on page 16).

– Drain kits (page 19) are inside the ice bins.

g Backroom Equipment

– (4) Carbonators (see page 9)

– (1) BIB-3 Plus Stacked BIB rack (will be in place)

– (4) 3 BIB Install Pump Kit (wall mounted - page 10)

– (2) Low pressure CO

– (1) Shelf (will be in place) for carbonators

– (2) Bag selectors for Sprite (install on BIB shelf - opposite regulators)

g Tubing Requirements

– (2) groups of (12) 3/8” single lines per system (two systems) through 2

overhead 4” PVC chases, then split in ceiling near drive thru into four 4”

chases (one per dispenser). Total required will approximate 3000’ of 3/8”.

g Standard Flavors

– 2 Classic, Diet, Sprite, Pepper + one other per Dispenser (there may be a

local flavor so check with the Chick-fil-A Operator). See picture on page 18.

Note: Ladders are necessary (due to ceiling height) to run ceiling lines. Do not

foam ceiling chases.

Regulators - page 11)

2

4

TS0502S.ppt

Page 5

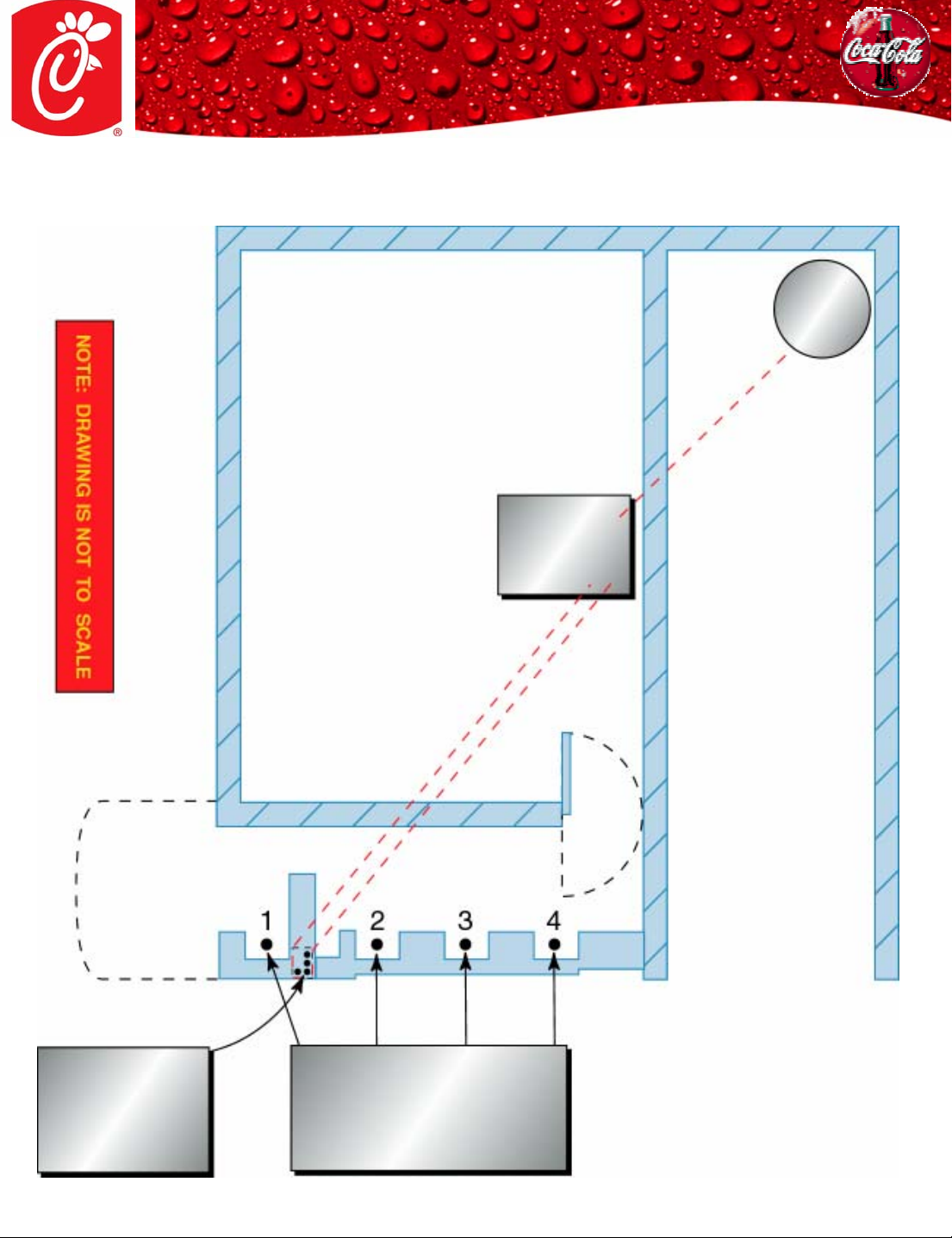

Equipment Location Diagram

STORAGE

OFFICE

KITCHEN

AREA

2 - 4”

CHASES

IN

CEILING

COOLER/

FREEZER

SYRUP

SUPPLY

AREA

E

F

6

5

X

O

R

P

P

A

BULK

CO

2

T

E

4 - 4” CHASES

THAT CARRY

LINES TO

DISPENSERS

TS0502S.ppt

DRIVE

THRU

AREA

SERVING AREA

DROP-IN

DISPENSERS

5

5

Page 6

Syrup Line / Pump

Assignment per System

g Line Dispensers 1 & 3 BIB Pump

g 1 Classic 1

g 2 Sprite 2

g 3 Caffeine Free Diet Coke 3

g 4 Pepper 4

g 5 Hi-C (or other flavor) 5

g 6 Classic 6

g 7 Spare Line

g 8 Carb H2O disp 1 (from carb # 1)

g 9 Carb H2O disp 1 (from carb # 1)

g 10 Carb H2O disp 3 (from carb # 3)

g 11 Carb H2O disp 3 (from carb # 3)

g 12 Filtered H2O shared with both dispensers

TS0502S.ppt

g Note: The second system will be for dispensers 2 & 4. Same line assignment and

pump assignment should apply. Each dispenser gets two carbonated water lines.

Dispenser #1 will be the drive thru unit, dispenser #2 will be next to the drive

thru unit, etc. See picture on page 16.

6

Page 7

Equipment Installation Process

Service Agent Responsibilities:

g Review installation guidelines

– This is a less than a two (2) day effort for two

experienced installers.

g Upon arrival and before starting work, conduct survey

with contractor using pre-installation checklist (page

20) to ensure all activities have been completed.

– If all activities are not finished,

• Complete all work possible

• Call AIC/AC and provide name of contractor, travel

time, time on location, and work not completed.

• Obtain signed work order for trip.

g On site requests to change installation dates or

.

equipment placements must be called into the Area

Installation Coordinator (AIC) or AC (

Cynthia Sheppard).

Only the AIC/AC are approved to authorize changes.

g Before leaving location, conduct the Post Installation

Inspection (page 21) with Construction Manager and

have him sign your work order.

TS0502S.ppt

7

Page 8

Equipment Installation Process

General Contractors

Responsibilities:

g Notify Account Coordinator (AC) (Cynthia Sheppard) 6

weeks prior to expected installation date. Provide the

following information to the AC:

– Full Address

– Contact Phone Numbers

– On-Site Contractor

– Requested Installation Date

– Estimated Turnover Date

– Unit #

g Alert the AC 72 hours prior to installation date if any

Chick-fil-A provided component required for installation is

missing or not complete.

– Reference attached installation check sheet

– Note: Changes to the installation schedule require a 10

business day notice to ensure agent availability.

8

TS0502S.ppt

Page 9

TS0502S.ppt

One carb per dispenser

9

9

W

e

v

l

a

v

f

f

o

t

u

h

s

r

e

t

a

Page 10

Carb Shelf

Bag selectors

TS0502S.ppt

10

10

Page 11

CO2 regulator

TS0502S.ppt

11

11

Page 12

TS0502S.ppt

12

12

Two 4” chases above the carbonators.

Chases are not to be foamed

Ceiling chase above carbonators

Page 13

Chase from bulk CO2. Chase

located above carbonators

TS0502S.ppt

13

13

13

Page 14

Drive thru 4” wall chase in ceiling

above drive thru area

TS0502S.ppt

14

14

14

Page 15

TS0502S.ppt

15

15

1515

4” chases from 3 front counter

dispensers. These are above the

drive thru area

Page 16

TS0502S.ppt

16

16

16

Front counter

disp #2

Drive thru

disp #1

Disp # 3

Water spigot

Disp # 4

Page 17

Drive thru disp (#1)

TS0502S.ppt

17

17

Page 18

TS0502S.ppt

18

18

18

Typical flavor line-up. Notice that Classic is on both end valves. Check with the on-site

customer rep for exact flavor line-ups to ensure correct syrup line use.

Page 19

Drain System

TS0502S.ppt

19

19

Page 20

Chick-fil-A, Inc.

Contractor Installation Check Sheet – Coca-Cola Equipment

Page 1 of 2

Unit #:

Unit Address:

Street # and Name City, State, Zip Code

Date and Sign by Each Item when Completed.

The installation of the Coca-Cola beverage equipment is a two-trip (day) process:

1. Trip (Day) #1: Install syrup lines in the chases; equipment in the counters, etc.

2. Trip (Day) #2: Complete the install and start up system for operation

Trip (Day) #1 - Preparation before Installing Lines and Equipment on trip # 1:

If any of the items below are NOT complete72 hours before the installation date,

call Cynthia Sheppard at 800-531-2238, ext. 3746 to reschedule.

Activity to Complete Date Complete Signature

Counters where equipment is to be installed

must be ready.

Back room for the syrup rack, pumps,

carbonators, and regulator must be clear,

accessible, and finished.

Exact location of equipment placement must be

identified (agent will have pictures; confirm to

avoid confusion).

Other (identify)

Trip (Day) #2 – Preparation for Equipment Start Up for Operations:

If any of the items below are NOT complete72 hours before the start update, call

Cynthia Sheppard at 800-531-2238, ext. 3746 to reschedule.

Activity to Complete Date Complete Signature

Syrup must be available

CO2 must be available

Water must be available

Electricity must be on

Ice must be available (to ratio the flavors)

20

TS0502S.ppt

Page 21

Chick-fil-A, Inc.

Post Installation Inspection – Coca-Cola

Page 2 of 2

Unit #

The General Contractors’ Superintendent is responsible for completing, dating and signing the Post

Installation Inspection before the Coca-Cola technicians leave the site. Additional trips by CocaCola after trip (day) #2 will be charged to the general contractor by Chick-fil-A.

Post Installation Inspection:

Activity to Complete Complete Y/N

If N, Comments

Check the system for leaks – syrup, CO2, and

water.

Check the system for neatness and tidiness –

the installers should leave the work site clean

and neat.

The BIB rack must be attached to the wall for

safety.

Check the beverage taste to ensure that all

appears OK.

Confirm that the Coca-Cola installer has

trained a manager/assistant manager while on

site about the operation and care of the system.

Includes 5 steps to quality/preventative

maintenance and 800# for service.

Check that the installer left the 1/800 service

decal posted in a prominent place.

Check that the drains for the Coca-Cola system

are installed in accordance with the published

guidelines

Sign the Coca-Cola work order - indicating

acceptance of the system.

Other (identify)

Signature

The General Contractor’s Superintendent Must Sign off and Turn in the Completed

Checklist and the Post Installation Inspection to Chick-fil-A’s Construction Manager at

Project Turnover

21

TS0502S.ppt

Loading...

Loading...