Page 1

®

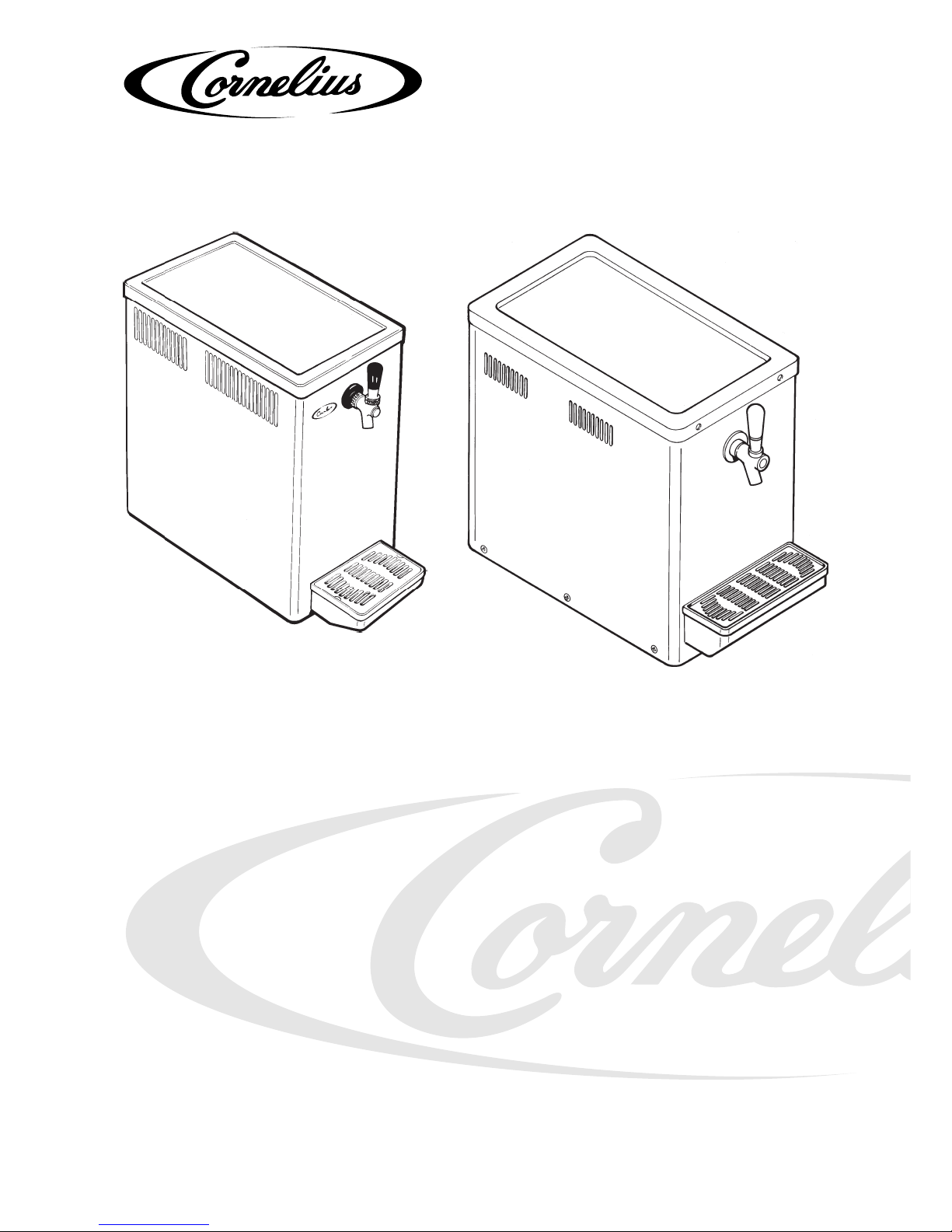

C10/C20

PM R45,R70 Issue 4 3/99

OVERCOUNTER DISPENSE UNITS

PRODUCT MANUAL

Page 2

1

®

C10/C20 Manual

CONTENTS

1. Introduction...................................................................................................................................2

2. User Instructions

2.1 Operation of the Cooler ..........................................................................................................2

2.2 Cleaning Routing ....................................................................................................................2

3. Specification .................................................................................................................................3

4. Installation.....................................................................................................................................3

5. Maintenance.................................................................................................................................. 4

6. Fault Finding................................................................................................................................. 5

7. C10 (48 1180 1XX/48 1180 2XX) Exploded View ......................................................................6

8. C10 (48 1180 1XX/48 1180 2XX) Spare Parts List......................................................................7

9. C10 (48 1180 3XX/48 1180 4XX) Exploded View ......................................................................8

10. C10 (48 1180 3XX/48 1180 4XX) Spare Parts List......................................................................9

11. C20 (06 1 050101/102/201) Exploded View .............................................................................. 10

12. C20 (06 1 050101/102/201) Spare Parts List.............................................................................. 11

13. C20 (06 1 050103) Exploded View............................................................................................. 12

14. C20 (06 1 050103) Spare Parts List............................................................................................ 13

15. C10 (48 1180 1XX/48 1180 2XX) Wiring Diagram ................................................................... 14

16. C10 (48 1180 3XX/48 1180 4XX) Wiring Diagram ................................................................... 14

17. C20 (06 1 0501XX) Wiring Diagram .........................................................................................15

18. C20 (06 1 0502XX) Wiring Diagram .........................................................................................15

Page 3

2

®

C10/C20 Manual

1. INTRODUCTION

The C10 and C20 are a family of over-counter beer coolers designed to be sited on the counter. An

agitator provides constant agitation of the water bath.

These units are available for 230v 50/60Hz or 115v 60Hz supply voltages.

The cooler has been designed with simplicity and reliability in mind.

The C10 cooler will produce a nominal 7kg of ice.

The C20 cooler will produce a nominal 11kg of ice.

A full Product data sheet is available detailing the technical specification and range of cooler models.

2. USER INSTRUCTIONS

2.1 OPERATION OF THE COOLER

To maintain the safe operation and reliability of the cooler during normal use, please observe the

following points:-

The cooler is designed to run continuously. During normal use it should only be switched off when

cooling will not be required for a period longer than 24 hours. The cooler should be re-started at least

5 hours (dependent on model) before it is to be used.

Do not spill or let liquids drip on the cooler – if liquids do spill onto the unit, electrically isolate before

wiping the spillages up.

Do not place items close the the cooler as this can reduce the air flow to and reliability of the cooler.

Do not place items on top of the cooler as this may cause damage to the agitator/pump assemblies.

Do not move the unit once full of water.

Do not block the water tank overflow tube – any condensation generated by the cooler must be allowed

to run away.

Note: In the event of malfunction switch of f and electrically unplug the cooler . Always use a qualified

Service Engineer to repair the unit – there are no user serviceable components.

2.2 CLEANING ROUTINE

Product coils can be internally cleaned as follows:-

1. Purge the product lines with clean, cool water.

2. Add a chlorinated alkaline cleaning solution, diluted with the correct amount of water, to the

system.

3. Allow to stand in the pipes for the time specified by the cleaning solution manufacturer – usually

30 minutes.

4. Flush the system with clean, cool water to remove all traces of the cleaning solution.

5. Refill the system with the product.

The outside of the cooler can be cleaned using a mild non-foaming aerosol cleaner sprayed onto a dry

soft cloth and wiped over the surface of the cooler. Electrically unplug the unit whilst cleaning.

Page 4

3

®

C10/C20 Manual

3. SPECIFICATION

For a full and detailed specification refer to the product data sheet.

DIMENSIONS C10 C20

Height (nominal): 465mm 500mm

Height (inc tap): 500mm

Width: 275mm 375mm

Depth (nominal): 460mm 585mm

Depth (inc drip tray): 580mm 705mm

Weight (operating): 41kg 60kg

Water bath capacity: 14 litres 24 litres

PERFORMANCE

Ice bank weight 7 kg 11kg

Electrical: See rating plate located on the cooler (or product data sheet) for the electrical rating of this

cooler.

4. INSTALLATION

Installation to be carried out by a suitably trained person only. Compliance with local Bylaws and

Codes of Practise must be ensured.

To ensure trouble free operation it is essential that the unit is installed correctly and sanitised prior to use.

1. The cooler should be sited on a firm level surface, in a well ventilated position, and at a maximum

distance of 2 meters from an electrical supply. To ensure efficient and reliable operation of the

refrigeration system allow 75mm clearance around the unit and that there is an un-impeded flow

of air to and from the condenser grilles. Allow for future access to the lid and service panels.

2. If not already fitted, fit the appropriate electrical plug to the service cord. Consult local Electrical

legislation for correct method of Installation.

WARNING - THIS APPLIANCE MUST BE EARTHED

Do not connect the cooler at this point.

3. Remove the lid and filler cap (as appropriate) and fill the bath with cool, clean, water until the

water flows from the overflow into drip tray. Do not use de-ionised w ater or ad d any substance

to the water . Do not leav e hose pipes unattended whilst filling the w ater bath – the overflow will

not remove water quickly enough. Once filled with water do not move the unit.

4. Ensure that all covers and access panels are screwed in place.

5. Ensure that the cooler is electrically safe. The cooler may now be electrically switched on to

allow it to cool whilst the rest of the Installation is completed.

The cooler will displace water through the overflow as it forms its ice.

6. Electrically isolate the cooler . Connect the beer inlet line and check for leaks before completing

the installation.

7. Sanitise the unit – see User instructions.

8. Electrically switch the unit on.

9. The system is now ready for operation but will not give best results until the ice bank is fully formed.

Page 5

4

®

C10/C20 Manual

5. MAINTENANCE

Maintenance to be carried out by a suitably trained person only. Compliance with local Bylaws and

Codes of Practise must be ensured.

The cooler requires occasional checking and cleaning as follows-

1. Check that the water level in the tank is up to the o verflo w . Remo ve the inspection/f ill cov er and

observe the water level.

2. Check that the airflow to the cooler is unimpeded and clean the condenser fins. To clean the fins

– electrically isolate the unit, use a soft bristle brush to clean the condenser fins of dirt, dust etc.

Take care not to damage the fins during cleaning.

At regular intervals to be determined by the user and/or o wner of the cooler, check for electrical safety.

If any maintenance/servicing is required, refer to the fault finding chart, wiring diagram and exploded

drawings contained in this manual and always ensure that the following are observedWhen replacing components always use IMI Cornelius approved spare parts. Failure to do so will

invalidate the coolers warranty.

Always electrically isolate the cooler before removing covers or carrying out any work.

After working on the cooler ensure that the unit is left electrically safe and that all covers and cover

fixings are refitted.

If replacing a condenser fan motor always fit a new fan blade.

The drier must be replaced each time the refrigeration system is opened.

Always replace seals, screws covers etc. after servicing the cooler.

Page 6

5

®

C10/C20 Manual

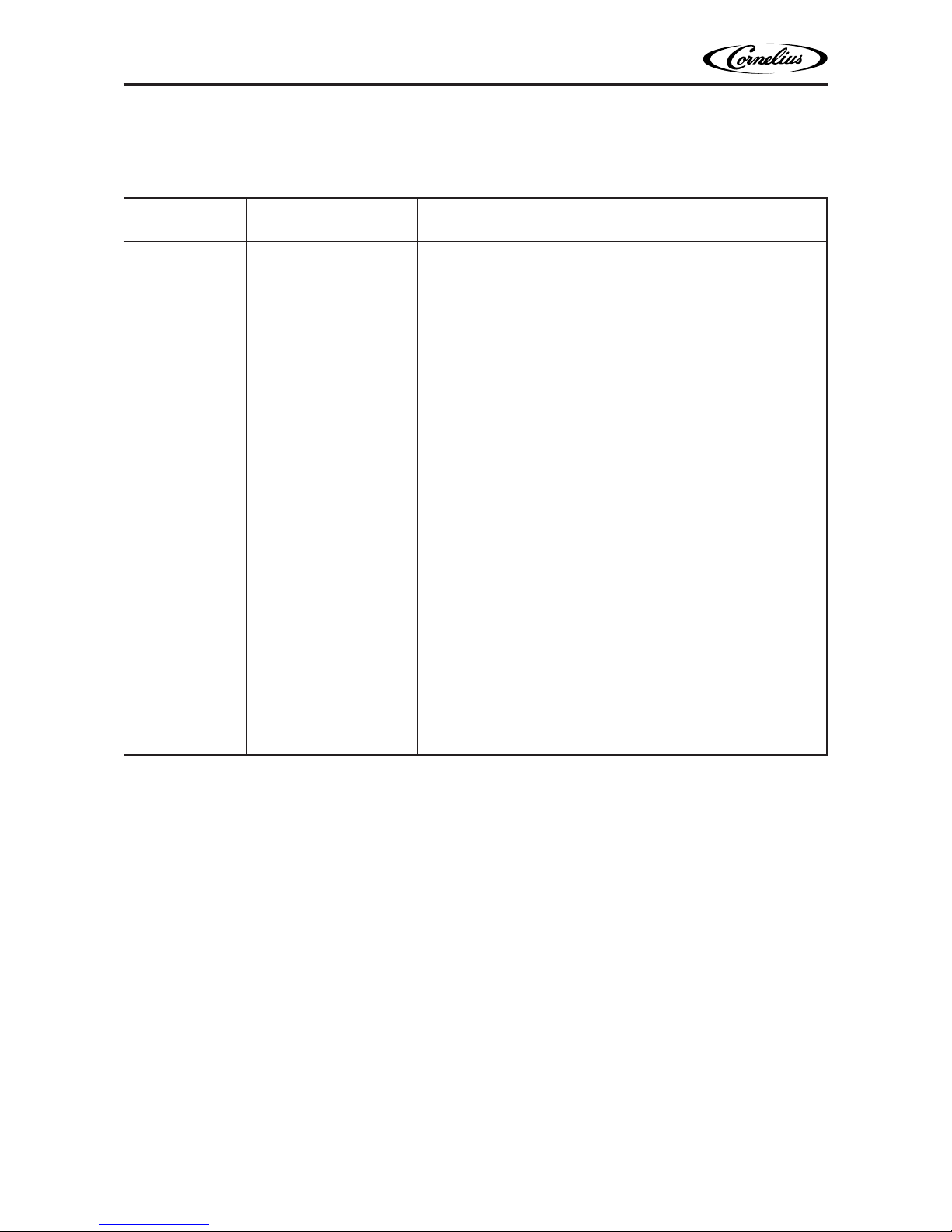

6. FAULT FINDING

PROBLEM POSSIBLE FAULT POSSIBLE CAUSE ACTION

Product frozen in Ice bank too large Faulty thermostat Replace

coil Poorly positioned thermostat phial Reposition

Product warm Reduced ice Faulty thermostat Replace

weight or long Fuse blown Check and replace

time to form ice No electrical supply Check

Refrigeration system failure Replace unit

Poor condenser cooling Check clearance

around cooler and

fan motor operation

Check clearance

around cooler and

fan motor operation.

Check condenser and

and clean if necessary

Insufficient water in tank Top up water level

Product too warm Keg badly positioned Reposition keg

into cooler

Poor agitation of water Motor failure Replace motor

onto coils

Pump impeller failed Replace

Excessive algae growth in bath Clean bath and coil

outer surface

Poor system installation Poor airflow to condenser Re-site cooler

Note: Refrigeration system failure could be - Start device for compressor failed, over temperature device in compressor

tripped, open circuit on compressor motor windings, refrigerant gas leak, capillary tube blockage etc. These

faults are best diagnosed and repaired off site in a workshop environment.

Page 7

6

®

C10/C20 Manual

7. C10 (48 1180 1XX/48 1180 2XX) EXPLODED VIEW

13

14

2

3

9

10

11

12

1

4

5

6

7

8

Page 8

7

®

C10/C20 Manual

ITEM

No.

DESCRIPTIONPART No.

1 58 1185 101 Top Cover

2 58 0345 015 Cooling Fan (6mm Bore)

3 13 6690 000 Impellor for Agitator

4 85 6005 818 Cover - Hole

5 80 0800 710 Peardrop Knob Threaded

6a 58 0483 001 Dispense Tap/Faucet

6b 58 0483 002 Dispense Tap BT50

7 58 1185 111 Cup Rest

8 58 1185 102 Drip Tray

9a 44 0000 205 Comp. Set FR7.5G HST

9b 44 0000 240 Comp. Set FF8.5GX HST 115v

10 58 1180 100 Condenser

11 58 1174 007 Thermostat Superspot

12a 58 0410 176 Motor

3

/4" Stack Fan

12b 58 0410 185 Motor 3/4" Stack 115v Fan

13 58 0431 018 Fan Blade 5" O/D CCWSE

14a 99 1180 110 Agitator Motor Assy.

14b 99 1180 113 Agit Motor Assy 115v

14c 58 1170 051 Pump Assy (No. 2)

Not 99 0420 058 Start Relay (240v)

Shown

Not 99 0420 059 Start Capacitor (240v)

Shown

Not 99 0900 002 Compressor Fixing Assy.

Shown

Not 58 1184 101 Mod to Mains Lead

Shown

8. C10 (48 1180 1XX/48 1180 2XX) SPARE PARTS LIST

Page 9

8

®

C10/C20 Manual

1

2

3

4

5

6

7

9

10

11

12

13

14

9. C10 (48 1180 3XX/48 1180 4XX) EXPLODED VIEW

8

Page 10

9

®

C10/C20 Manual

ITEM

No.

DESCRIPTIONPART No.

1 58 1185 101 Top Cover

2 58 0435 015 Cooling Fan (6mm Bore)

3 13 6690 000 Impellor for Agitator

4 85 6005 818 Cover - Hole

5 80 0800 710 Peardrop Knob Threaded (301/6/7)

6a 58 0483 002 Dispense Tap BT50

6b 14 5225 201 Faucet for C-10 Cooler

6c 84 4206 111 Dalex 200 NFCF DH PN C10

7 58 1185 111 Cup Rest

8 58 1185 102 Drip Tray

9a 44 0000 205 Comp. Set FR7.5G HST

9b 44 0000 240 Comp. Set FF8.5GX HST 115v

10 58 1180 123 Condenser STFT 12218

11a 58 0410 187 Fan Motor 5W 230V M/TEK CCWSE

11b 58 0410 190 Fan Motor 5W 115V M/TEK CCWSE

12 44 0000 052 Fan Blade O/D 165mm 26" CCWSE SUCK

13 58 1174 007 Thermostat Superspot

14a 99 1180 126 Agit Motor Assy.

3

/4" Stack Gain

14b 99 2ZU618A No. 2 Pump Assy. EBM (306 only)

14c 06 0 050114 Agit. Mtr. Assy. 3/4" Stack 115v

Not 99 0420 058 Start Relay (240v)

Shown

Not 99 0420 059 Start Capacitor (240v)

Shown

Not 99 0900 002 Compressor Fixing Assy

Shown

Not 58 1184 101 Mod to Mains Lead

Shown

10. C10 (48 1180 3XX/48 1180 4XX) SPARE PARTS LIST

Page 11

10

®

C10/C20 Manual

1

2

3

4

5

6

7

8

9

10

11

12

13

14

11. C20 (06 1 050101/102/201) EXPLODED VIEW

Page 12

11

®

C10/C20 Manual

ITEM

No.

DESCRIPTIONPART No.

1 06 0 055104 Top Cover

2 58 0435 018 Cooling Fan

3 13 6690 000 Impellor for Agitator

4 85 6005 818 Cover - Hole

5 80 0800 710 Peardrop Knob Threaded

6a 14 5225 201 Faucet

6b 58 0483 002 Dispense Tap BT50

7 58 1185 111 Cup Rest

8 58 1185 102 Drip Tray

9a 58 0900 951 Comp. Set SC10GX HST

9b 14 3627 115 Comp. Set FF10GX HST (115v)

10 14 3297 000 Condenser

11 58 0431 015 Fan Blade 8"x30° CW

12a 58 0410 188 Fan Motor 11W 230V M/TEK CCWSE

12b 58 0410 191 Fan Mtr. 10W 115V60HZ M/TEK CCWSE

13 58 1174 007 Thermostat Superspot

14a 99 1180 126 Agit Motor Assy.

3

/4" Stack Gain

14b 06 0 050114 Agit. Mtr. Assy. 3/4" Stack 115v

Not 99 0900 002 Compressor Fixing Assy

Shown

12. C20 (06 1 050101/102/201) SPARE PARTS LIST

Page 13

12

®

C10/C20 Manual

1

2

3

4

5

6

7

8

9

10

11

12

13

14

13. C20 (06 1 050103) EXPLODED VIEW

Page 14

13

®

C10/C20 Manual

ITEM

No.

DESCRIPTIONPART No.

1 06 0 055104 Top Cover

2 58 0435 018 Cooling Fan

3 03 1BF0 33A No. 62 Propellor 66mm DIA (103)

4 85 6005 818 Cover - Hole

5 80 0800 710 Peardrop Knob Threaded

6 84 4206 111 Dalex 200 NFCF 3/8 DH PN C10

7 58 1185 111 Cup Rest

8 58 1185 102 Drip Tray

9 58 0900 951 Comp. Set SC10GX HST

10 14 3297 000 Condenser

11 58 0431 015 Fan Blade 8"x30° CW

12 58 0410 188 Fan Motor 11W 230V M/TEK CCWSE

13 58 1174 007 Thermostat Superspot

14 58 1180 135 Agit. Motor Assy.

3

/4" Stack Gain (103)

Not 99 0900 002 Compressor Fixing Assy

Shown

14. C20 (06 1 050103) SPARE PARTS LIST

Page 15

14

®

C10/C20 Manual

15. C10 (48 1180 1XX/48 1180 2XX) WIRING DIAGRAM

16. C10 (48 1180 3XX/48 1180 4XX) WIRING DIAGRAM

Page 16

15

®

C10/C20 Manual

17. C20 (06 1 0501XX) WIRING DIAGRAM

18. C20 (06 1 0502XX) WIRING DIAGRAM

Page 17

IMI CORNELIUS

UK LTD

Tything Road

Alcester

W arwickshire B49 6EU

Tel: (44) 1789 763 101

Fax: (44) 1789 763 644

IMI CORNELIUS

BENELUX N.V.

Boskapellei 122

B-2930 Brasschaat, Belgium

Tel: (32) 3 660 1020

Fax: (32) 3 660 1045

IMI CORNELIUS

DEUTSCHLAND GmbH

Carl Leverkus Strasse 15

D-40764 Langenfeld, Germany

Tel: (49) 2173 7930

Fax: (49) 2173 77 438

IMI CORNELIUS

FRANCE

35/37 Avenue du Gros Chene

F-95220 Herblay, France

Tel: (33) 1 3440 1580

Fax: (33) 1 3440 1581

IMI CORNELIUS

OSTERREICH

Ges.m.b.H

am Langen Felde 32

A-1222 Vienna, Austria

Tel: (43) 1 203 35200

Fax: (43) 1 204 4474

IMI CORNELIUS

HELLAS S.A.

55 Theomitoros

Allmos 174 55

Athens, Greece

Tel: (30) 1 985 3800

Fax: (30) 1 985 3801

IMI CORNELIUS

ITALIA

SRL

Via Belvedere 26

I-20043 Arcore, Italy

Tel: (39) 039 627 081

Fax: (39) 039 601 3884

IMI CORNELIUS

BRAZIL LTDA.

Rua Itaocara, 97 - CEP 21381-230

Rio de Janiero, RJ - Brazil

Tel: 55-21-596-9595

Fax: 55-21-593-1759

IMI CORNELIUS INC.

One Cornelius Place

Highway 10 West

Anoka, Minnesota 55303-6234

U.S.A.

Tel: (612) 421 6120

Fax: (612) 422 3255

IMI CORNELIUS INC.

3170 Orlando Drive, Unit 3

Mississauga, Ontario L4V 1R5

Canada

Tel: (905) 673 6653

Fax: (905) 673 2830

IMI CORNELIUS

AUSTRALIA PTY. LTD.

144 Milperra Road

Revesby

NSW 2212, Australia

Tel: (61) 2 9774 4533

Fax: (61) 2 9774 5825

IMI CORNELIUS

NEW ZEALAND LTD.

20 Lansford Crescent

P.O. Box 19 044

Av ondale, Auckland 7

New Zealand

Tel: (64) 9 820 0357

Fax: (64) 9 820 0361

IMI CORNELIUS

(SINGAPORE) PTE LTD.

16 Tuas Street

Singapore 638453, Singapore

Tel: (65) 862 5542

Fax: (65) 862 5604

IMI CORNELIUS

PACIFIC LTD.

15th Floor, Hale Weal Industrial Bldg.

22-28 Tai Chung Road

Tsuen W an, N.T.

Hong Kong

Tel: (852) 2789 9882

Fax: (852) 2391 6222

IMI CORNELIUS

ESPANA S.A.

Poligono Industrial, Riera del Fonollar

Sant Boi de Llobregat

E-08830 Barcelona, Spain

Tel: (34) 93 640 2839

Fax: (34) 93 654 3379

Loading...

Loading...