Convotherm OES, OEB, OGS, OGB Installation Manual

Combi steamer

OES OEB OGS OGB /

OES OEB OGS OGB easyTOUCH=

ENG Installation manual

Translation of the original

Table of Contents

Table of Contents

1

General information 4

► Environmental protection 5

► Identifying your combi steamer 6

► About this installation manual 9

2 Layout and function 11

► Intended use of your combi steamer 12

► Layout and function of the combi steamer (standard controls) 13

► Layout and function of the combi steamer (easyTOUCH controls) 16

3 For your safety 19

► Basic safety code 20

► Hazards and safety precautions 21

► Requirements for safe setup, installation and preparation for first-time use 23

► Requirements to be met by personnel, personal protection equipment and working

positions 24

► Warning signs on the combi steamer 25

► Safety devices 27

4 Moving and setting up the appliance 29

► Requirements for the installation location 30

► Taking to the installation location 35

► Unpacking 36

► Setting up table-top appliances 39

► Setting up floor-standing appliances 42

5 Connecting up the combi steamer 44

► Electrical installation 45

► Energy optimization system 47

► Water supply 48

► Water drain 51

► Making settings in the Service program 54

► Regulations for installing gas appliances 56

► Approvals 57

► Gas installation to a fixed connection on OGS/OGB appliances 58

► Gas installation for liquid gas bottles on OGS/OGB appliances 61

► Flue gas removal system for OGS/OGB appliances 66

6 Preparing for first-time use, taking out of service and

disposal 69

► Safe working 70

► Procedure for preparing the appliance for first-time use 72

► Taking out of service and disposal 74

7 Optional equipment and accessories 75

► CONVOClean automatic interior oven cleaning system 76

► CONVOVent and CONVOVent Plus extractor hood/condensation hoods 79

Installation manual 2

Table of Contents

► Stacking kit 81

► Grill version 82

► Ship model 84

► Communications interface 85

8 Technical data, dimensional drawings and connection

diagrams 86

8.1 Technical data 87

► Technical data for OES 88

► Technical data for OEB 92

► Technical data for OGS 97

► Technical data for OGB 102

► Technical data for accessories 107

8.2 Dimensions, dimensional drawings and connection diagrams 108

► OES/OEB 6.10 109

► OES/OEB 6.20 110

► OES/OEB 10.10 111

► OES/OEB 10.20 112

► OES/OEB 12.20 113

► OES/OEB 20.10 114

► OES/OEB 20.20 115

► OGS 6.10 116

► OGS 6.20 117

► OGS 10.10 118

► OGS 10.20 119

► OGS 12.20 120

► OGS 20.10 121

► OGS 20.20 122

► OGB 6.10 123

► OGB 6.20 124

► OGB 10.10 125

► OGB 10.20 126

► OGB 12.20 127

► OGB 20.10 128

► OGB 20.20 129

9 Checklists and completion of installation 130

► Checklist: Installation 131

► Checklist: Safety devices and warnings 134

► Checklist: Customer guidance and instruction - safety 135

► Checklist: Customer guidance and instruction - operation and maintenance 140

► Completion of the installation 141

Installation manual 3

General information

1 General information

Purpose of this chapter

This chapter shows you how to identify your combi steamer and provides guidance on using this manual.

Contents

This chapter contains the following topics:

Page

Environmental protection 5

Identifying your combi steamer 6

About this installation manual 9

Installation manual 4

General information

► Environmental protection

Statement of principles

Our customers' expectations, the legal regulations and standards and our company's own reputation

set the quality and service for all our products.

We have an environmental management policy that not only ensures compliance with all environmental regulations and laws, but also commits us to continuous improvement of our green credentials.

We have developed a quality and environmental-management system in order to guarantee the continued manufacture of high-quality products, and to be sure of meeting our environmental targets.

This system satisfies the requirements of ISO 9001:2008 and ISO 14001:2004.

Environmental protection procedures

We observe the following procedures:

Use of residue-free compostable wadding materials

Use of RoHS-compliant products

Multiple re-use of cardboard packaging

Recommendation and use of bio-degradable cleaning agents

Recycling of electronic waste

Environmentally friendly disposal of old appliances via the manufacturer

Join us in a commitment to environmental protection.

Installation manual 5

General information

► Identifying your combi steamer

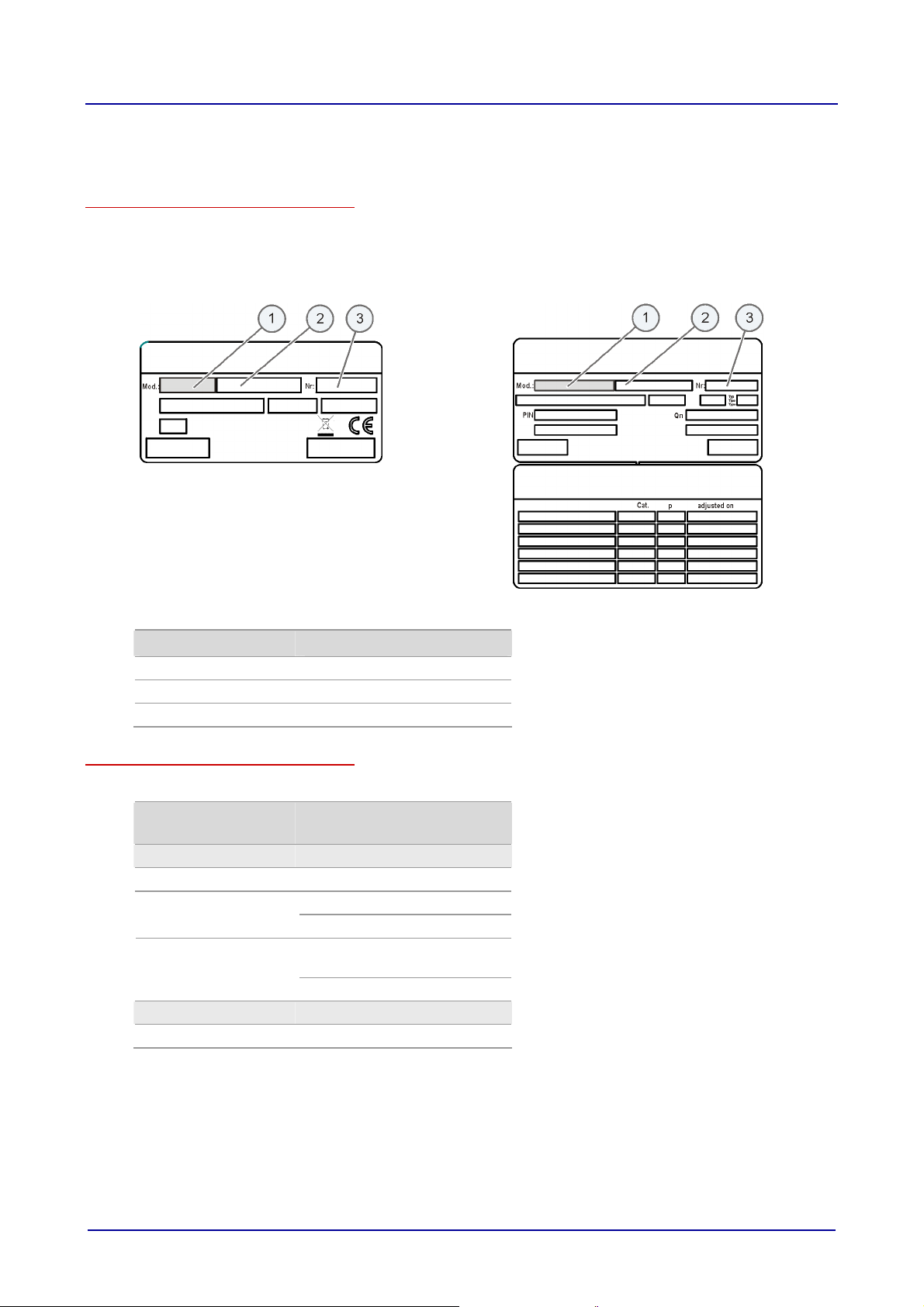

Position and layout of the type plate

You can use the type plate to identify your combi steamer. The type plate is located on the left-hand

side of the combi steamer.

The type plate has the following layout on electric

appliances:

The type plate has the following layout on gas

appliances:

The following table lists the relevant items on the type plate:

Item number Meaning

1 trade name

2 part number

3 serial number

Code making up the trade name

On both type plates, the code making up the trade name (1) identifies your appliance:

Elements of the trade

name

Letters

1. letter O = Eco (always present)

3. letter

Numerical values

xx.yy Appliance size

Meaning

E = Electric appliance 2. letter

G = Gas appliance

B = Appliance with steam gen-

erator

S = Appliance with injection

_

Installation manual 6

General information

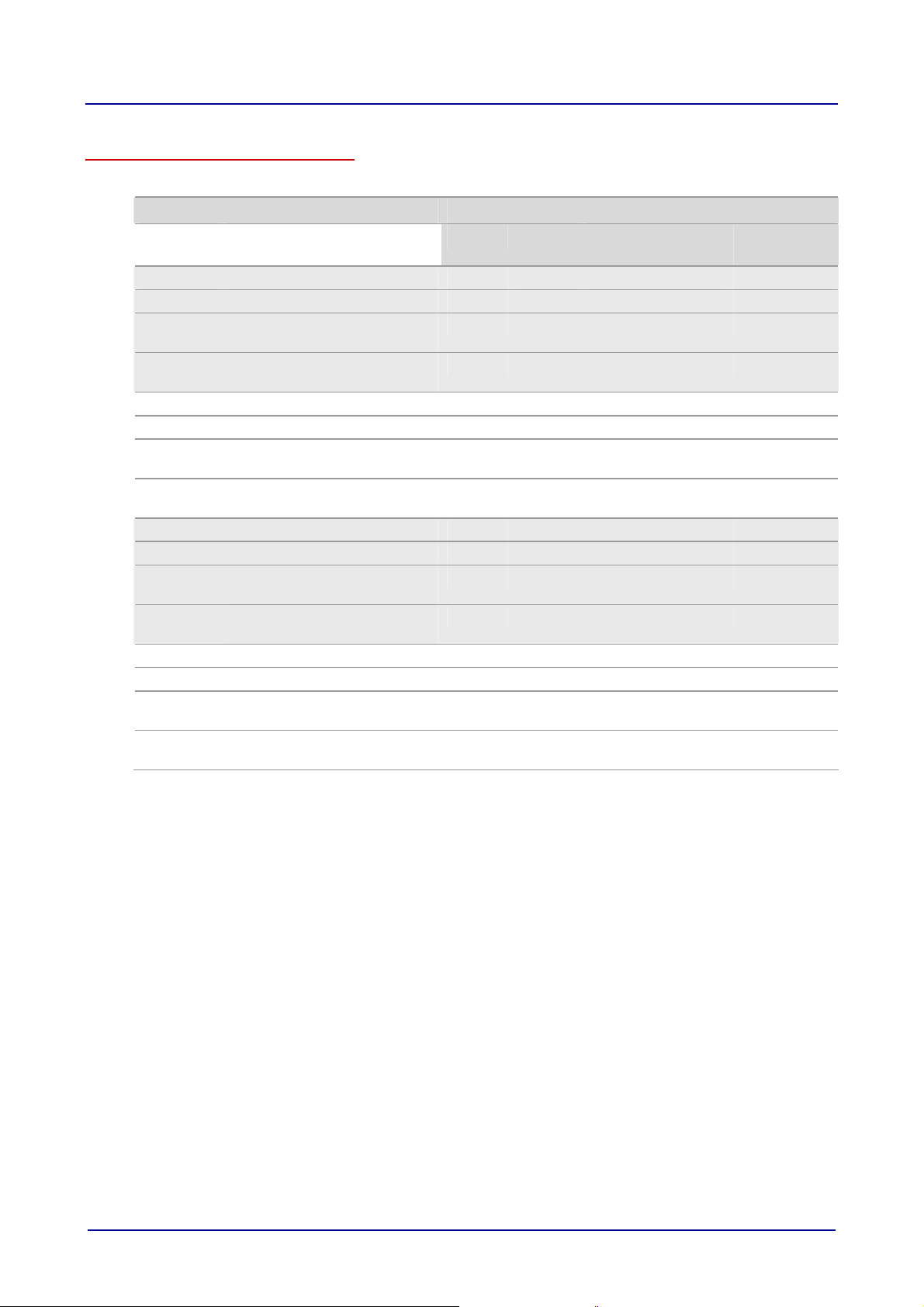

Table-top appliances

Use the table below to identify your table-top appliance from the trade name on the type plate:

Model Typ e Number of shelves Optional shelves

1/1 GN 2/1 GN 600 x 400 baking tray Number of

OES 6.10 Electric appliance with injection 7 - 5 20

OGS 6.10 Gas appliance with injection 7 - 5 20

OEB 6.10

OGB 6.10

OES 6.20 Electric appliance with injection 14 7 12 42

OGS 6.20 Gas appliance with injection 14 7 12 42

OEB 6.20

OGB 6.20

OES 10.10 Electric appliance with injection 11 - 7 32

OGS 10.10 Gas appliance with injection 11 - 7 32

OEB 10.10

OGB 10.10

OES 10.20 Electric appliance with injection 22 11 18 63

OGS 10.20 Gas appliance with injection 22 11 18 63

OEB 10.20

OGB 10.20

Electric appliance with steam

generator

Gas appliance with steam generator

Electric appliance with steam

generator

Gas appliance with steam generator

Electric appliance with steam

generator

Gas appliance with steam generator

Electric appliance with steam

generator

Gas appliance with steam generator

7 - 5 20

7 - 5 20

14 7 12 42

14 7 12 42

11 - 7 32

11 - 7 32

22 11 18 63

22 11 18 63

plates

Installation manual 7

General information

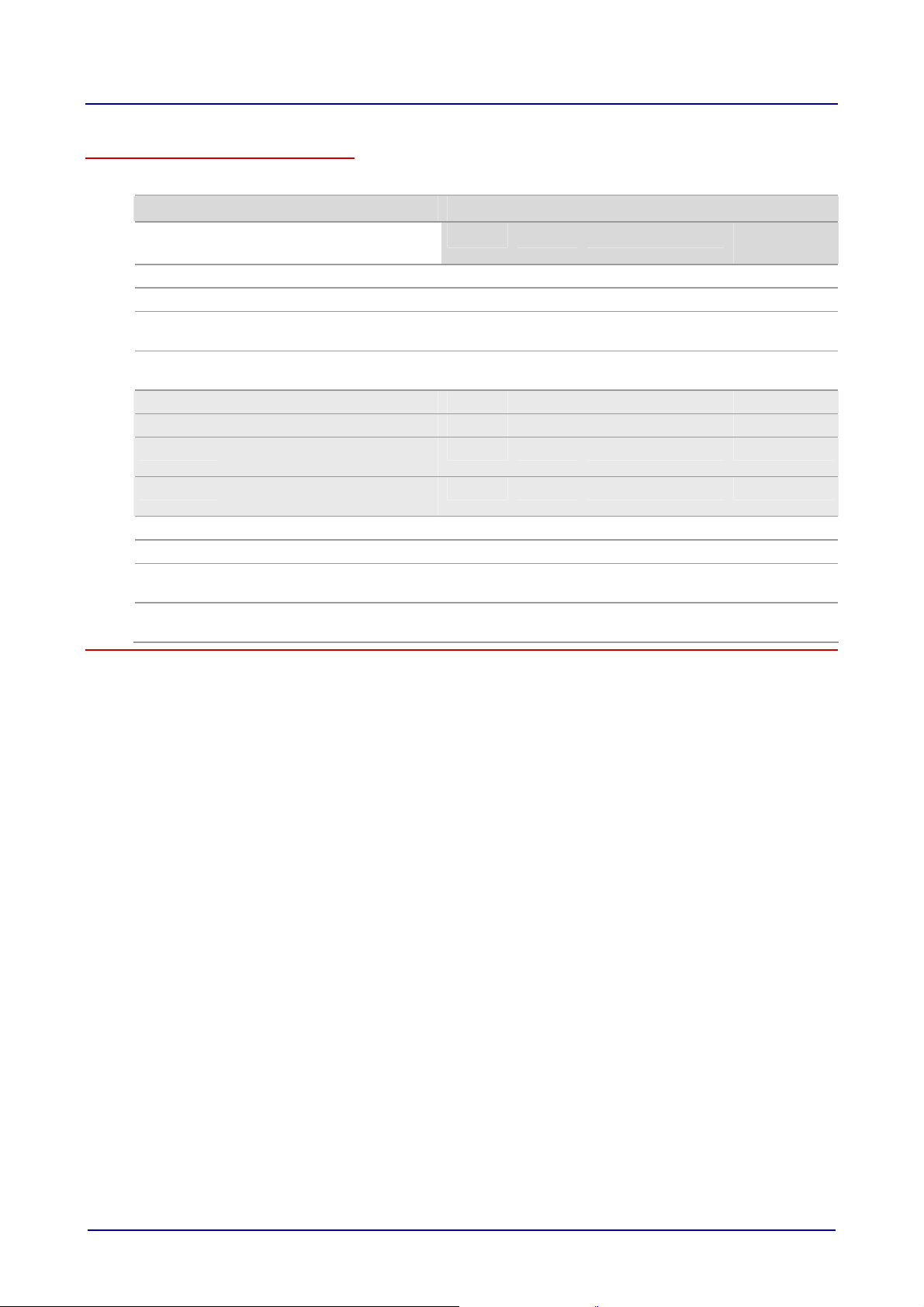

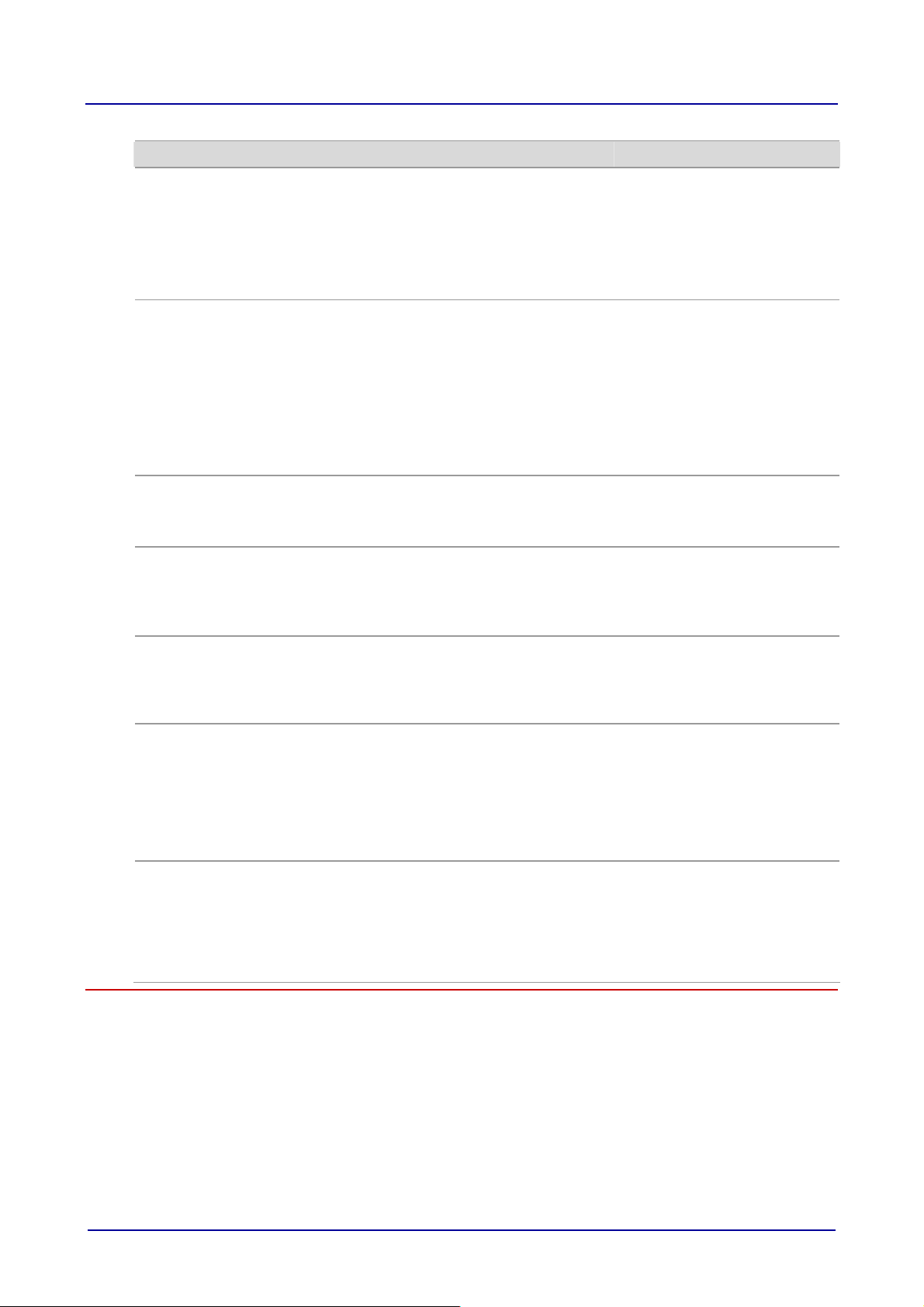

Floor-standing appliances

Use the table below to identify your floor-standing appliance from the trade name on the type plate:

Model Typ e Number of shelves Optional shelves

1/1 GN 2/1 GN 600 x 400 baking tray Number of

OES 12.20 Electric appliance with injection 24 12 10 59 or 74

OGS 12.20 Gas appliance with injection 24 12 10 59 or 74

OEB 12.20

Electric appliance with steam

generator

OGB 12.20

Gas appliance with steam genera-

tor

OES 20.10 Electric appliance with injection 20 - 17 50 or 61

OGS 20.10 Gas appliance with injection 20 - 17 50 or 61

OEB 20.10

Electric appliance with steam

generator

OGB 20.10

Gas appliance with steam genera-

tor

OES 20.20 Electric appliance with injection 40 20 17 98 or 122

OGS 20.20 Gas appliance with injection 40 20 17 98 or 122

OEB 20.20

Electric appliance with steam

generator

OGB 20.20

Gas appliance with steam genera-

tor

24 12 10 59 or 74

24 12 10 59 or 74

20 - 17 50 or 61

20 - 17 50 or 61

40 20 17 98 or 122

40 20 17 98 or 122

plates

Installation manual 8

General information

► About this installation manual

Purpose

This installation manual provides answers to the following questions:

How do I set up the combi steamer?

How do I connect up the combi steamer?

How do I prepare the combi steamer for use?

The aim of this installation manual is to show you how to perform the following tasks:

Setting up the appliance.

Connecting the appliance to the electrical supply.

Connecting the appliance to the water supply.

Connecting the appliance to the gas supply.

Connecting the appliance to the flue gas installation.

Preparing the appliance for use.

Who should read this manual

This installation manual is aimed at the following groups:

Personnel

Equipment mover

Tasks Qualifications Chapter to read before task

Conveying within the

establishment

Trained in the use of a pallet

truck and forklift truck

For your safety on page 19

Moving and setting up the appliance on page 29

Service engineer

Setting up the appliance

Connecting the appliance

Preparing the appliance

for first-time use

Taking the appliance out

of service

Instructing the user

Is an employee of an

approved customer service unit.

Has relevant technical

training.

Is trained in the particular

appliance.

Layout and function on page 11

For your safety on page 19

Moving and setting up the appliance on page 29

Connecting up the combi steamer

on page 44

Preparing for first-time use, taking

out of service and disposal on

page 69

Optional equipment on page 75

Gas fitter Connecting the applian-

ce: gas

Isolating the appliance

from the gas supply

mains

Electrical fitter Connecting the applian-

ce: electric

Isolating the appliance

from the electrical supply

mains

Is a gas fitter authorized

by the gas supply company.

Has relevant professional

training.

Is an employee of an

approved customer service unit.

Has relevant professional

training.

Is a qualified electrician.

Layout and function on page 11

For your safety on page 19

Connecting up the combi steamer

on page 44

Layout and function on page 11

For your safety on page 19

Connecting up the combi steamer

on page 44

Documents included in the Customer documentation

The customer documentation for the combi steamer includes the following documents:

Installation manual (this document)

User manual

Help facility included in the software (extracts from the user manual)

Installation manual 9

General information

Chapters in the installation manual

The table below lists the chapters in this manual and summarizes their content and purpose:

Step Action

General information

Layout and function

For your safety

Moving and setting up the

appliance

Connecting up the combi

steamer

Preparing for first-time use,

taking out of service and

disposal

Optional equipment

Technical data, dimensional

drawings and connection

diagrams

Checklists and completion of

installation

Shows you how to identify your combi steamer.

Provides guidance on using this installation manual.

Specifies the intended use of the combi steamer.

Explains the functions of the combi steamer and shows the position of its

components.

Describes the hazards posed by the combi steamer and appropriate preven-

tive measures.

It is important that you read this chapter carefully.

Specifies the basic appliance dimensions.

Specifies requirements for the installation location.

Provides information on conveying the appliance to the installation location,

unpacking and setting up.

Lists necessary approvals.

Provides information on installing the:

electrical supply

gas

water

flue gas

drain

air vent

Explains the procedure for preparing the appliance for first-time use.

Explains the procedure for taking out of service.

Contains disposal instructions.

Describes features of the various optional equipment.

Contains the technical data and connection diagrams.

Contains the checklists for

Installation

Safety instructions and warnings

Customer guidance and instruction.

Contains information on the warranty and explains the completion procedure

using the checklists.

Symbols used for safety instructions

Safety instructions are categorized according to the following hazard levels:

Hazard level Consequences Likelihood

Caution

Death / serious injury (irreversible) Immediate risk

Death / serious injury (irreversible) Potential risk

Minor injury (reversible) Potential risk

Damage to property Potential risk

Installation manual 10

Layout and function

2 Layout and function

Purpose of this chapter

This chapter specifies the intended use of the combi steamer and explains its functions.

Contents

This chapter contains the following topics:

Page

Intended use of your combi steamer 12

Layout and function of the combi steamer (standard controls) 13

Layout and function of the combi steamer (easyTOUCH controls) 16

Installation manual 11

Layout and function

► Intended use of your combi steamer

Intended use

The combi steamer must only be used for the purposes specified below:

The combi steamer is designed and built solely for cooking different foodstuffs. Steam, convection

and superheated steam are used for this purpose.

The combi steamer is intended solely for professional, commercial use.

The ambient temperature must lie between 4°C and 35°C.

In addition, the combi steamer is only being used as intended when the following conditions are met:

To avoid accidents and damage to the combi steamer, the owner must train staff regularly. The

combi steamer must only be operated by trained staff.

The manufacturer regulations for operation and maintenance of the combi steamer must be ob-

served.

Restrictions on use

The following restrictions on use must be observed:

The combi steamer must not be operated in toxic or potentially explosive atmospheres.

The combi steamer must only be operated at ambient temperatures between +4°C and +35°C.

The combi steamer must only be used by trained personnel.

The combi steamer must be suitably sheltered from the rain and wind if operated outdoors.

The combi steamer must not be loaded over the maximum permissible loading weight for the given

model.

The combi steamer must only be operated when all safety devices are fitted and in working order.

Dry powder or granulated material must not be heated in the combi steamer.

Highly flammable objects with a flash point below 270 °C must not be heated in the combi steamer.

These include items such as highly flammable oils, fats or cloths (kitchen cloths).

Food in sealed tins or jars must not be heated in the combi steamer.

Installation manual 12

Layout and function

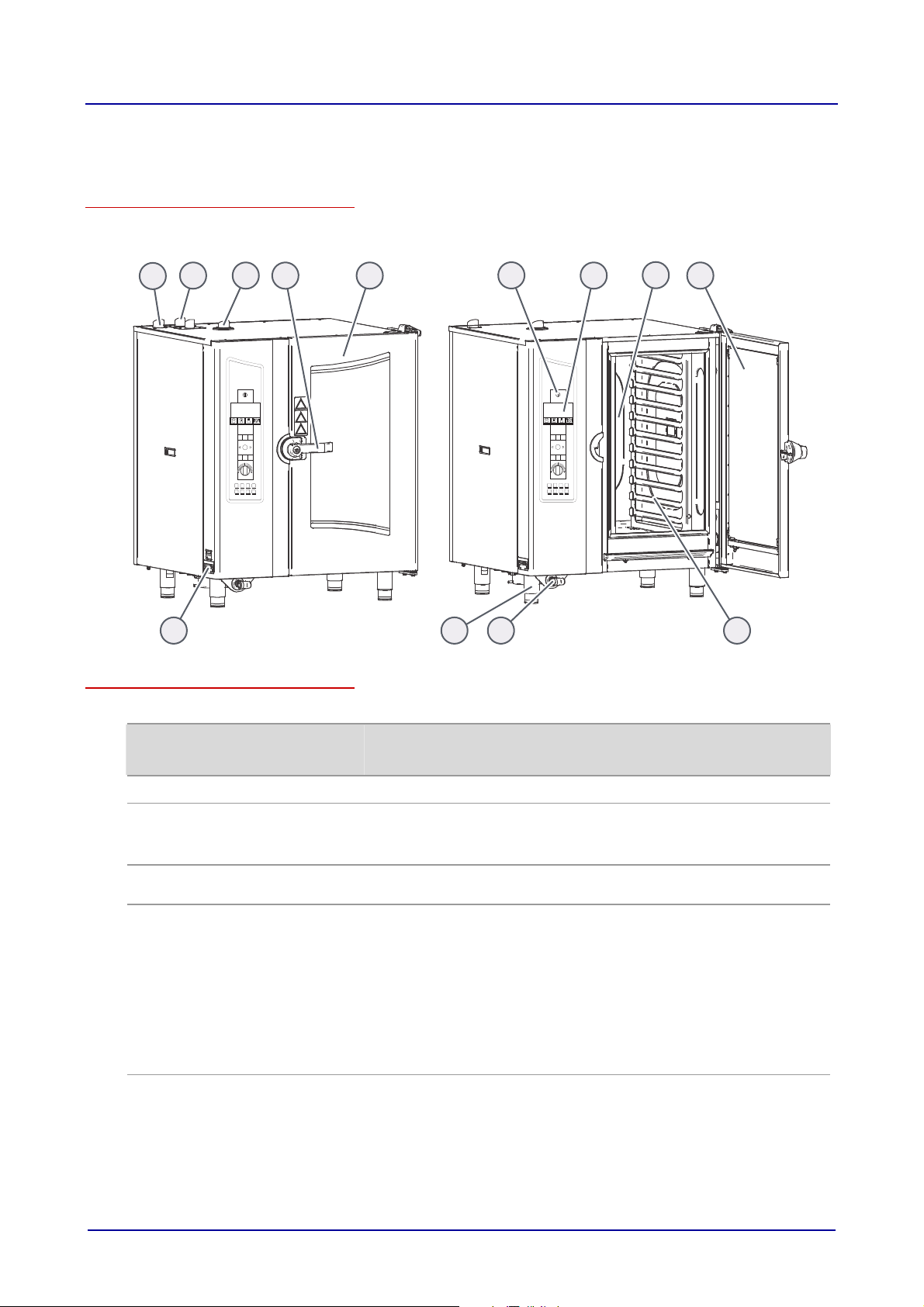

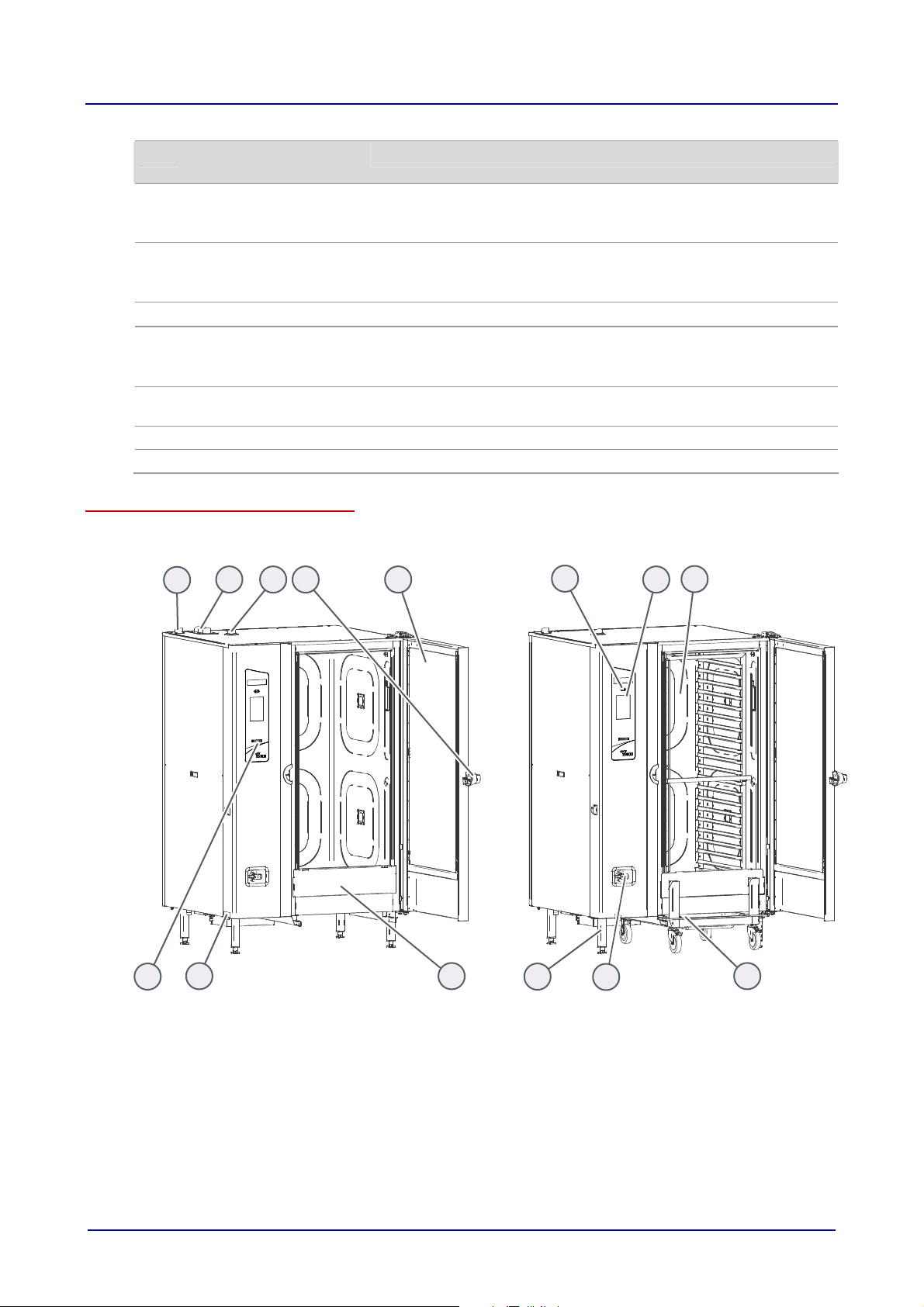

► Layout and function of the combi steamer (standard controls)

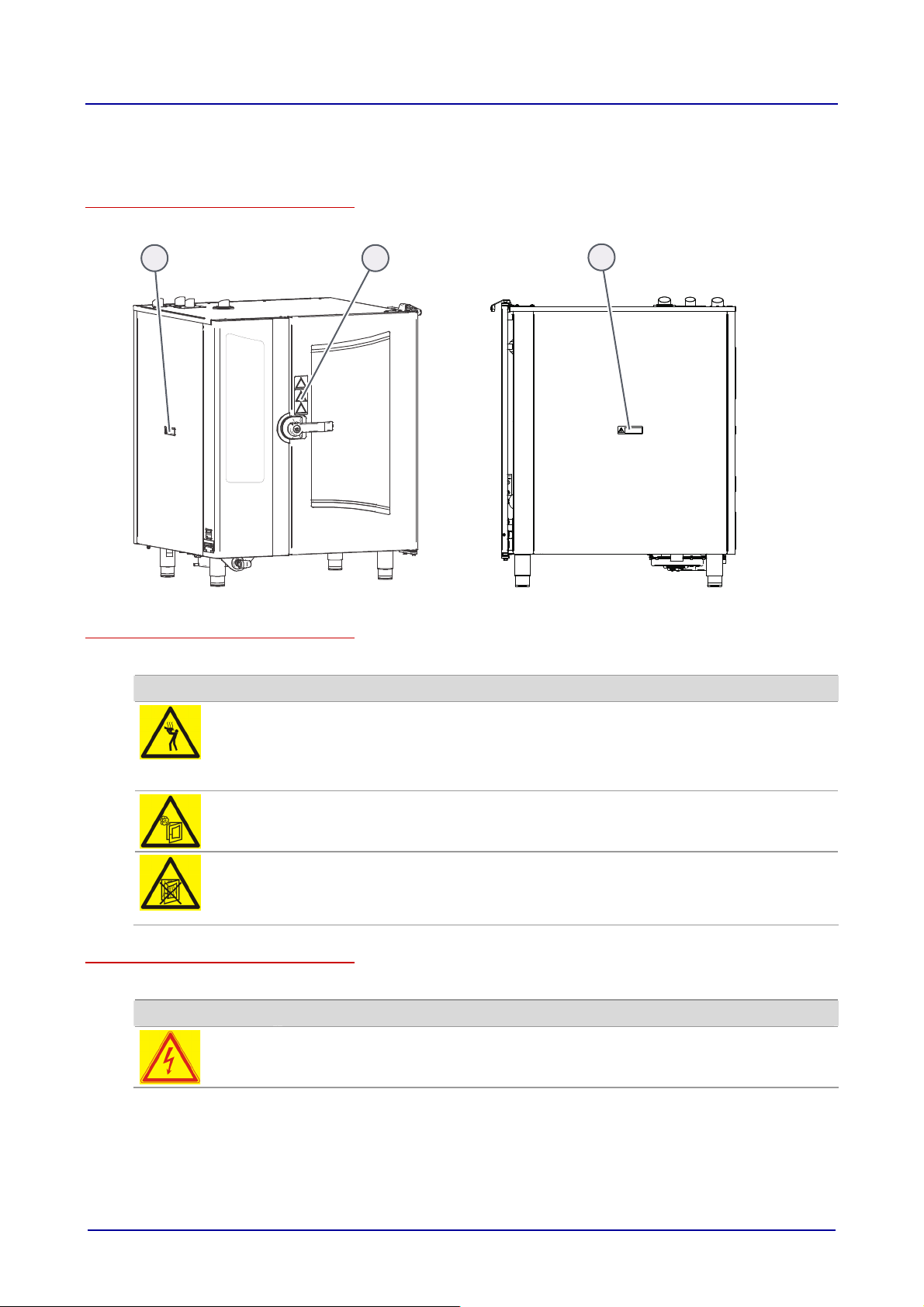

Table-top appliance construction

The following diagram shows a gas appliance and an electric appliance, representing all table-top

appliances:

32

1

4

R

6019050_01

5

6

OGB 10.10 OEB 10.10

12

Components of the table-top appliances and their function

The components of the table-top appliances have the following function

11

10

8

7

R

6019050_01

5

9

No. Name

Picture

1

2

3

Air vent Controls ventilation

Gas flue pipe

Low-pressure failsafe device

4 Multi-function door handle

("Hygienic Handle")

5 Appliance door ("disappea-

ring door")

Function

On gas appliances only (vents flue gases):

1 gas flue pipe on appliances with injection

2 gas flue pipes on appliances with steam generator

Prevents the low pressure in the oven e.g. during fully automatic cleaning

(CONVOClean system)

Has the following functions depending on its position:

Pointing vertically downwards: combi steamer closed, ready for cooking

Horizontal: combi steamer open, in on-latch position

20 degrees above horizontal: Combi steamer can be opened

Also has the following functions:

Additional function as far as on-latch position

In the on-latch position, door can be opened from inside oven in an

emergency

Antibacterial with silver ions

Seals the oven during cooking

Special opening action allows it to slide back against the side of the

combi steamer to save space

Installation manual 13

Layout and function

No. Name

Picture

6

7

8

9

Control panel

Oven

Rack Used to hold GN containers or baking trays

Function

Switches the combi steamer on and off

Central control of the combi steamer:

Controls: membrane keypad and tilt selector switch

Status displays

Contains the food during cooking

Has a different number of shelf levels depending on model

10

11

Hand shower

Appliance feet

Used for rinsing out the oven with water

Continuous flow adjustment

Retracts automatically into the holder after use

Can be adjusted in height to allow the combi steamer to be positioned

horizontally

12

Type plate Used for identifying the combi steamer

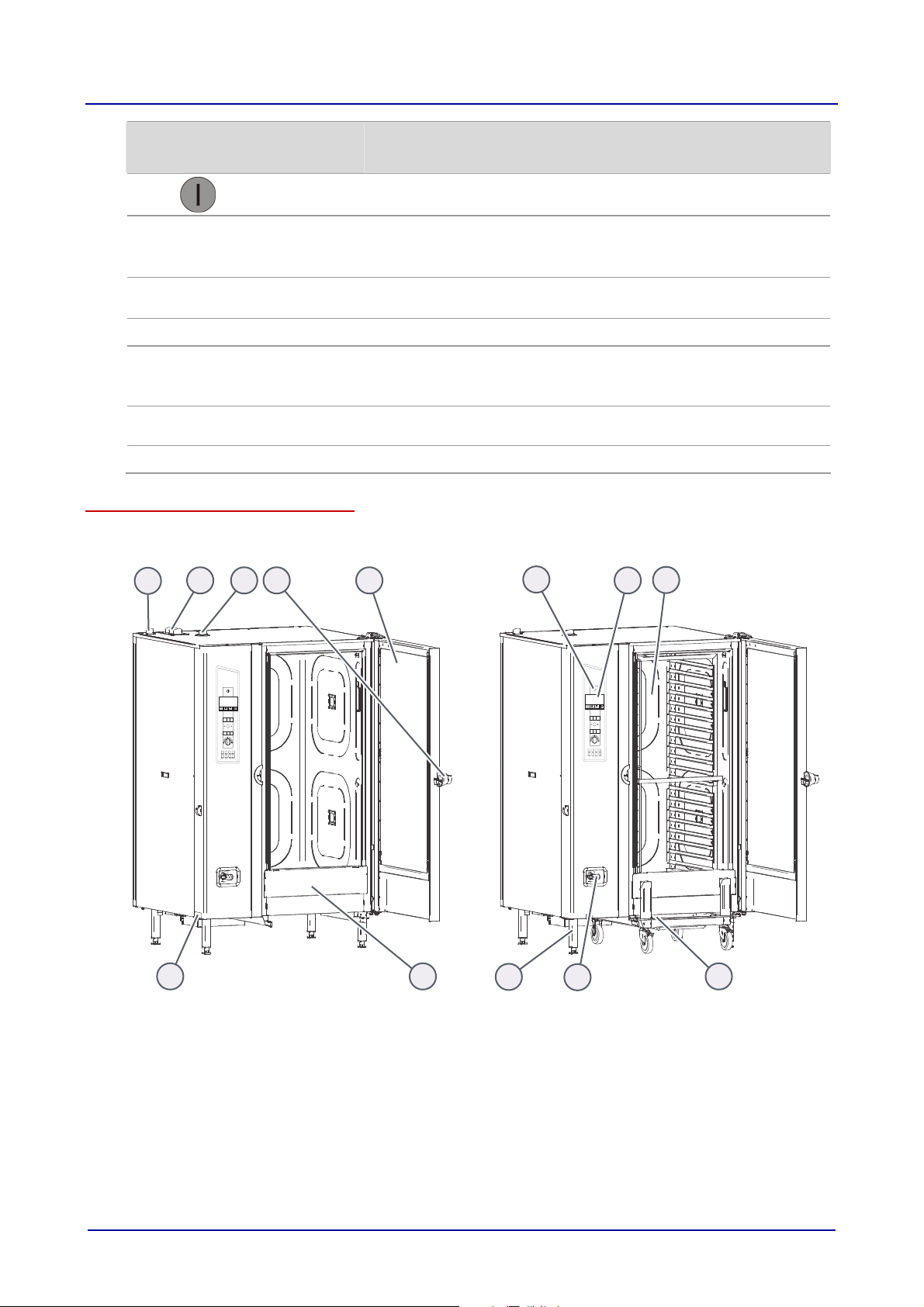

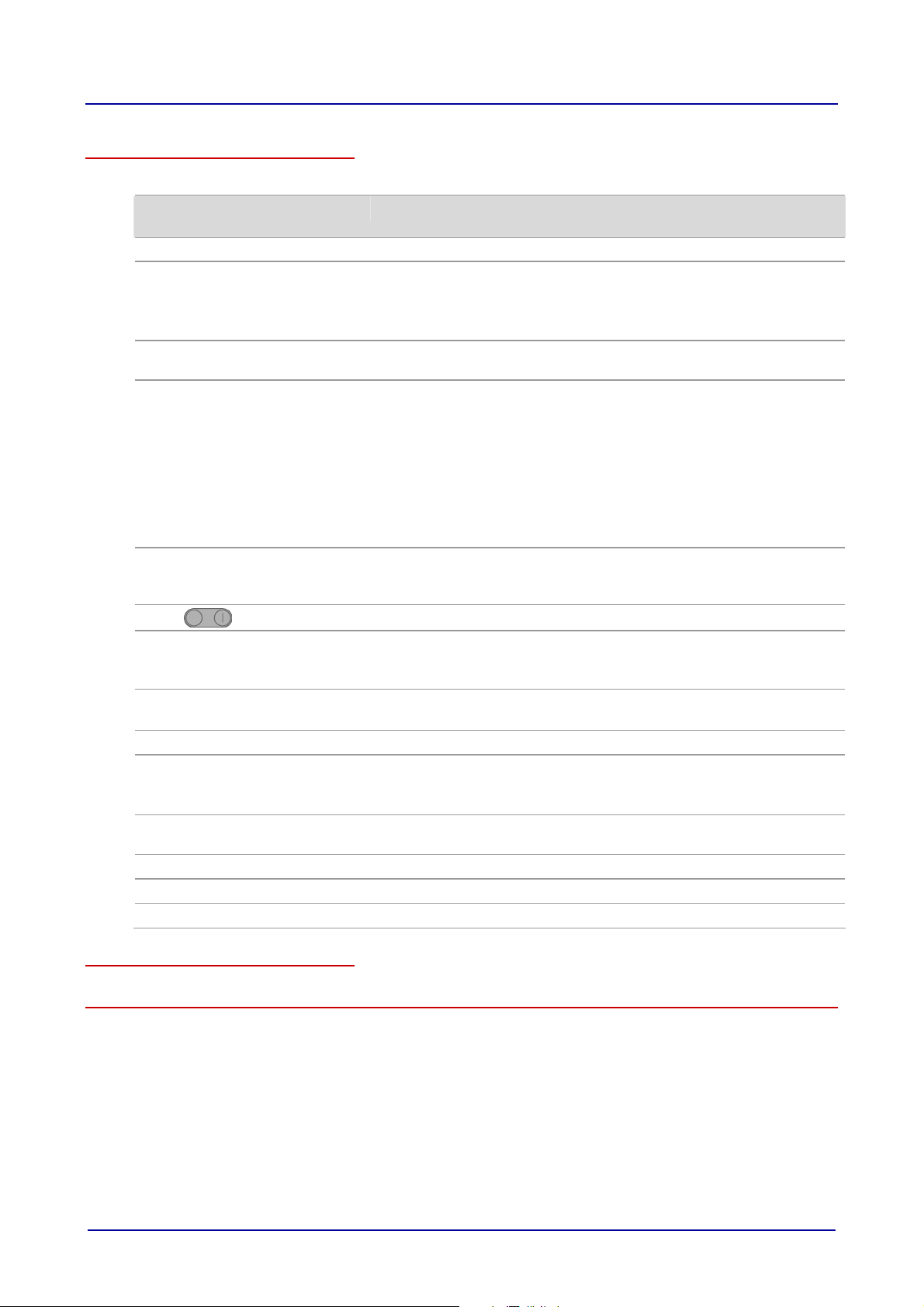

Floor-standing appliance construction

The following diagram shows a gas appliance and an electric appliance, representing all floor-standing

appliances:

3 4 5

1

2

R

6019050_01

6

R

6019050_01

8

7

13

Installation manual 14

OGB 20.20 OEB 20.20

12

11

10

9

Layout and function

Components of the floor-standing appliances and their function

The components of the table-top appliances have the following function:

No. Name

Picture

1

2

3

Air vent Controls ventilation

Gas flue pipe

Low-pressure failsafe device

4 Multi-function door handle

("Hygienic Handle")

5 Appliance door ("disappea-

ring door")

6

7

8

9

Control panel

Oven

Loading trolley Used for loading food

Function

On gas appliances only (vents flue gases):

1 gas flue pipes: OGS 12.20

2 gas flue pipes: OGB 12.20, OGS 20.10, 20.20

3 gas flue pipes: OGB 20.10, 20.20

Prevents the low pressure in the oven e.g. during fully automatic cleaning

(CONVOClean system)

Has the following functions depending on its position:

Pointing vertically downwards: combi steamer closed

Horizontal: combi steamer open, in on-latch position

20 degrees above horizontal: Combi steamer can be opened

Also has the following functions:

Additional function as far as on-latch position

In the on-latch position, door can be opened from inside oven in an

emergency

Antibacterial with silver ions

Seals the oven during cooking

Special opening action allows it to slide back against the side of the

combi steamer to save space

Switches the combi steamer on and off

Central control of the combi steamer:

Controls: membrane keypad and tilt selector switch

Status displays

Contains the food during cooking

Has a different number of shelf levels depending on model

10

11

Hand shower

Appliance feet

Used for rinsing out the oven with water

Continuous flow adjustment

Retracts automatically into the holder after use

Can be adjusted in height to allow the combi steamer to be positioned

horizontally

12

13

Preheat bridge Used for safety purposes during preheating and cleaning

Type plate Used for identifying the combi steamer

Material

The interior and exterior structure of the combi steamer is made of stainless steel.

Installation manual 15

Layout and function

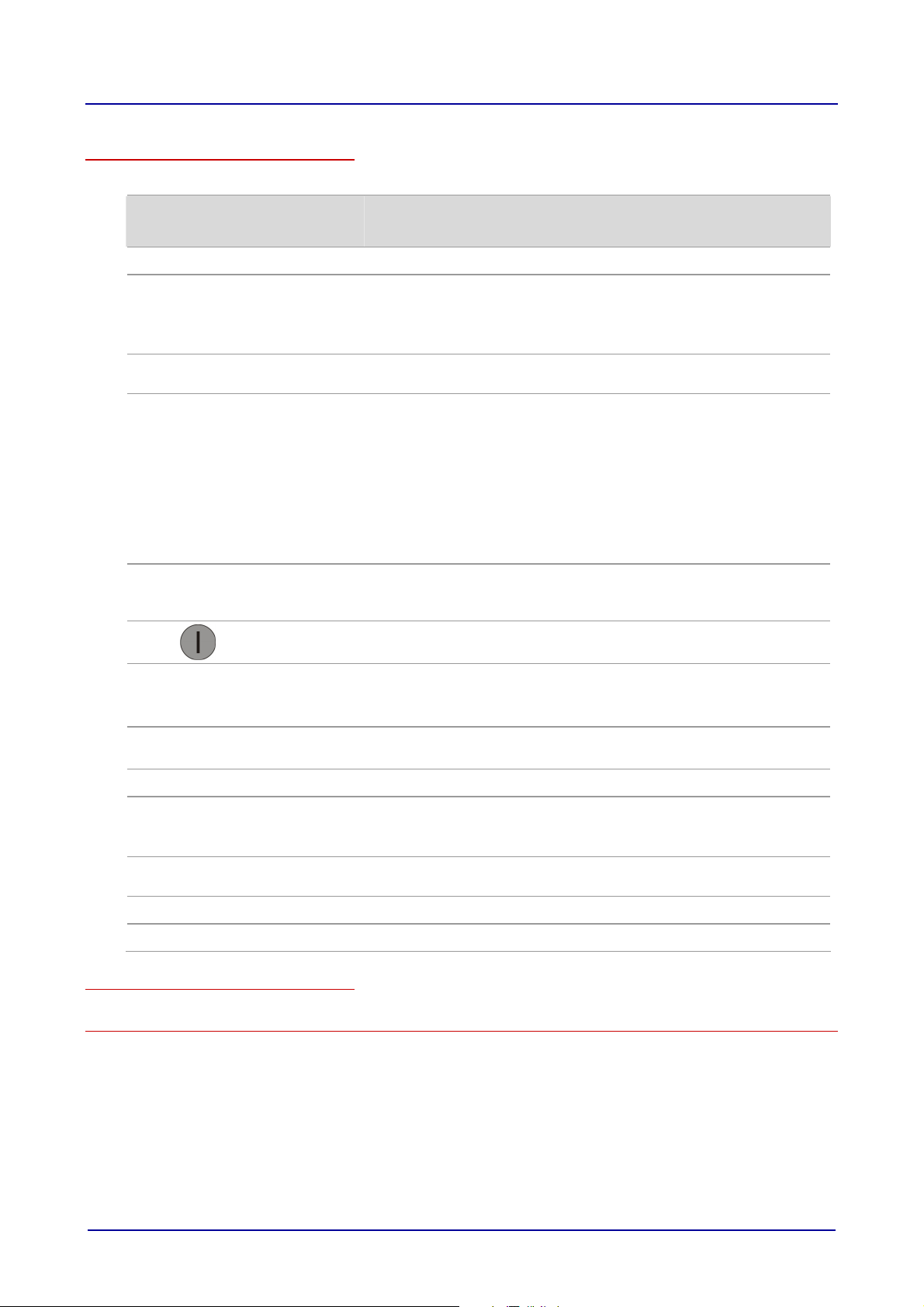

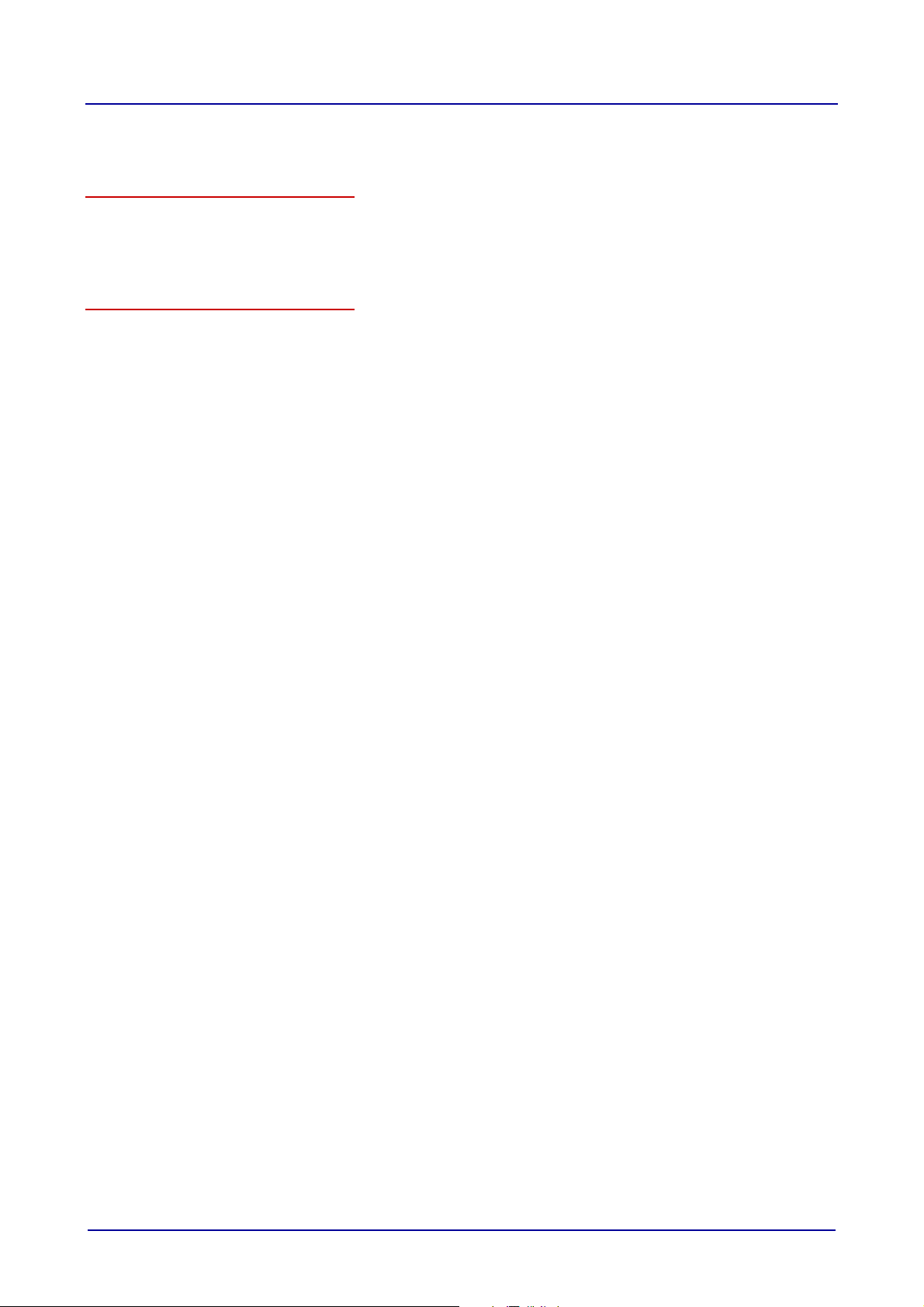

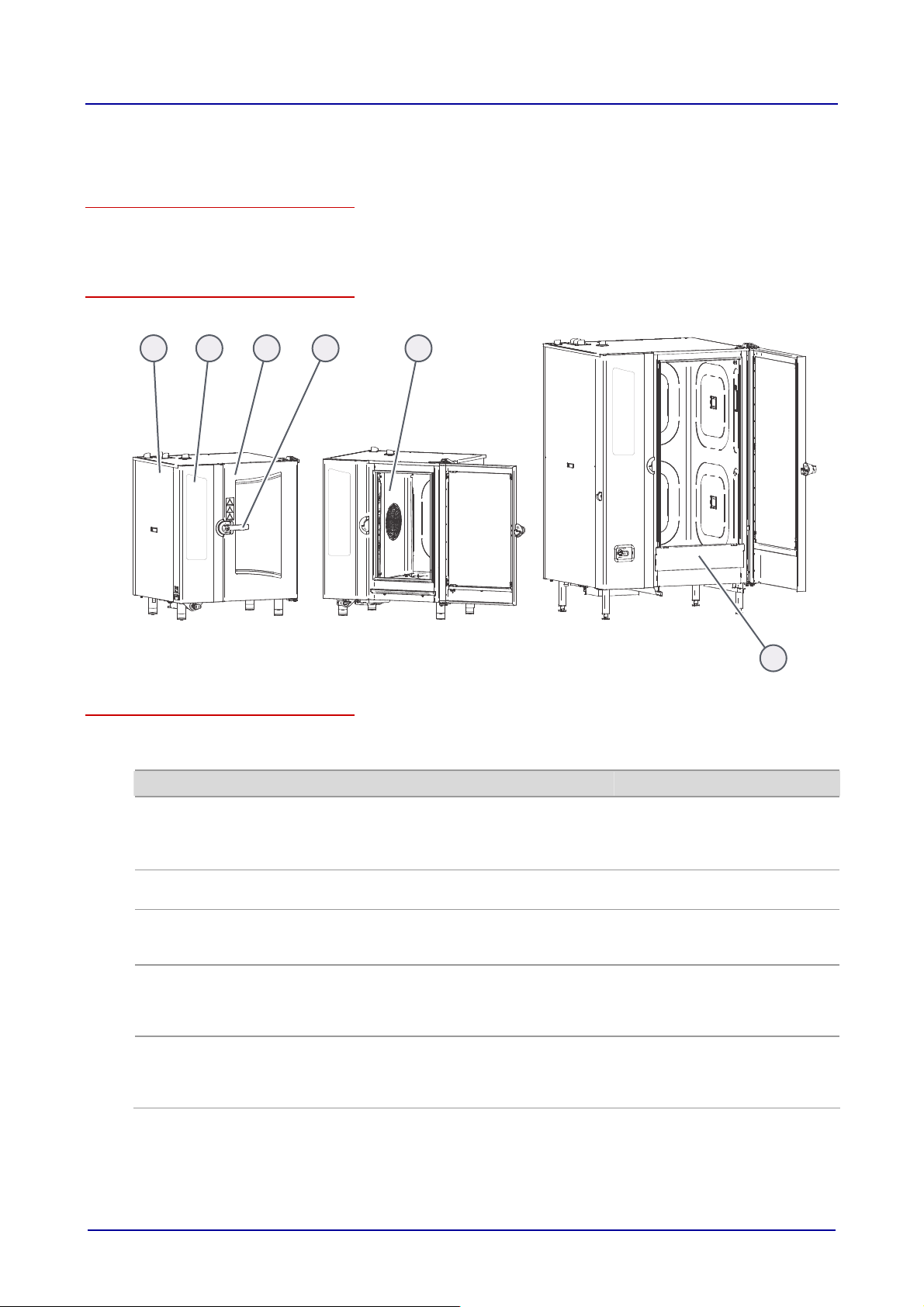

► Layout and function of the combi steamer (easyTOUCH controls)

Table-top appliance construction

The following diagram shows a gas appliance and an electric appliance, representing all table-top

appliances:

32

1

4

5

6

OGB 10.10 OEB 10.10

13

12

Components of the table-top appliances and their function

The components of the table-top appliances have the following function

No. Name

picture

1

2

Air vent Controls ventilation

Gas flue pipe

3 Low-pressure failsafe

device

4 Multi-function door handle

("Hygienic Handle")

5 Appliance door ("disappea-

ring door")

6

Function

On gas appliances only (vents flue gases):

1 gas flue pipe on appliances with injection

2 gas flue pipes on appliances with steam generator

Prevents the low pressure in the oven e.g. during fully automatic cleaning

(CONVOClean system)

Has the following functions depending on its position:

Pointing vertically downwards: combi steamer closed, ready for cooking

Horizontal: combi steamer open, in on-latch position

20 degrees above horizontal: Combi steamer can be opened

Also has the following functions:

Additional function as far as on-latch position

In the on-latch position, door can be opened from inside oven in an

emergency

Antibacterial with silver ions

Seals the oven during cooking

Special opening action allows it to slide back against the side of the combi

steamer to save space

Switches the combi steamer on and off

1011 9

7 5

8

Installation manual 16

Layout and function

No. Name

picture

7

8

Touchscreen

Oven

Function

Central control of the combi steamer:

Combi steamer operated by touching symbols on control-panel pages

Status displays

Contains the food during cooking

Has a different number of shelf levels depending on model

9

10

11

12

13

Rack Used to hold GN containers or baking trays

Hand shower

Appliance feet

Type plate Used for identifying the combi steamer

USB cover Covers the USB connector on the appliance

Used for rinsing out the oven with water

Continuous flow adjustment

Retracts automatically into the holder after use

Can be adjusted in height to allow the combi steamer to be positioned

horizontally

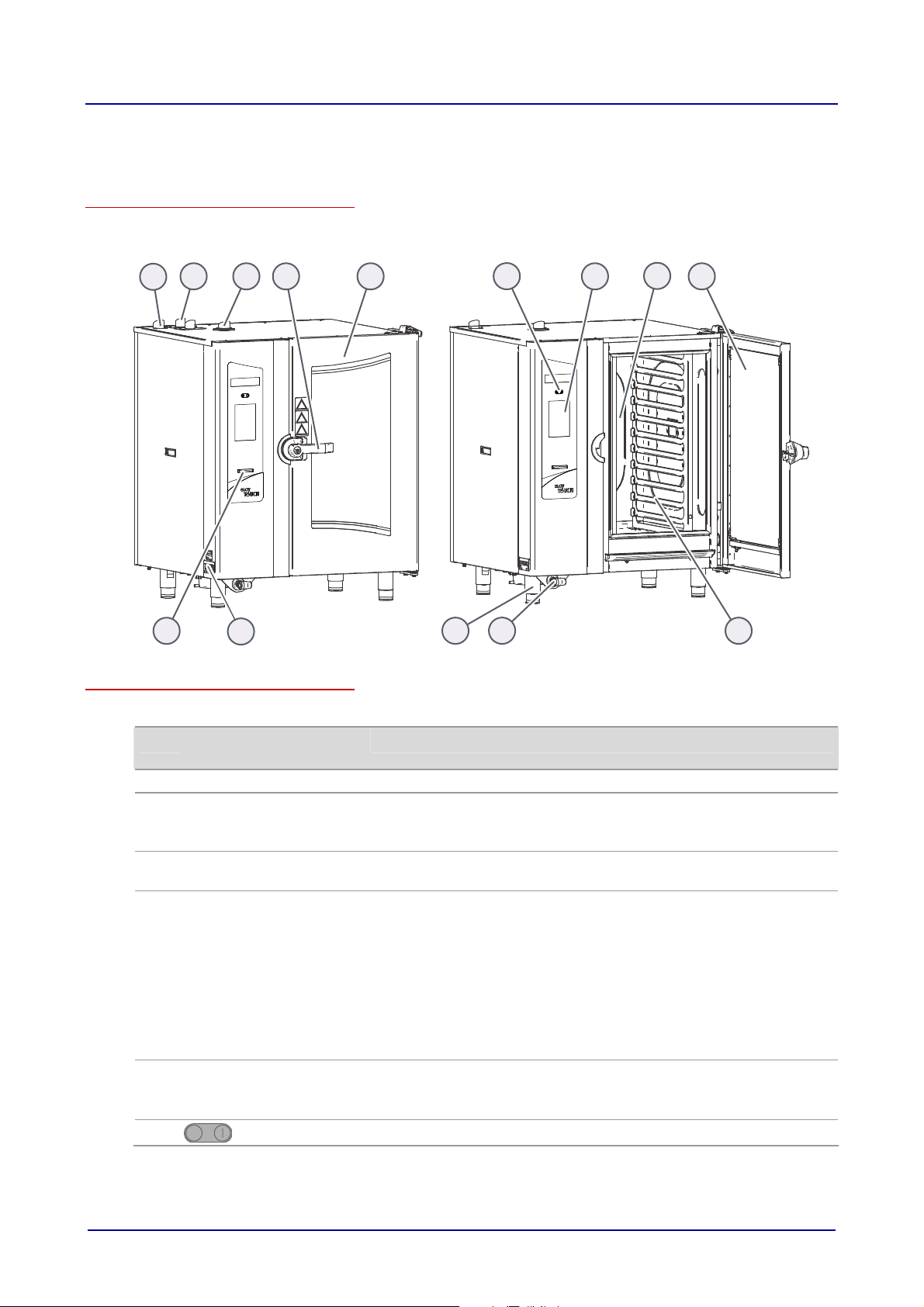

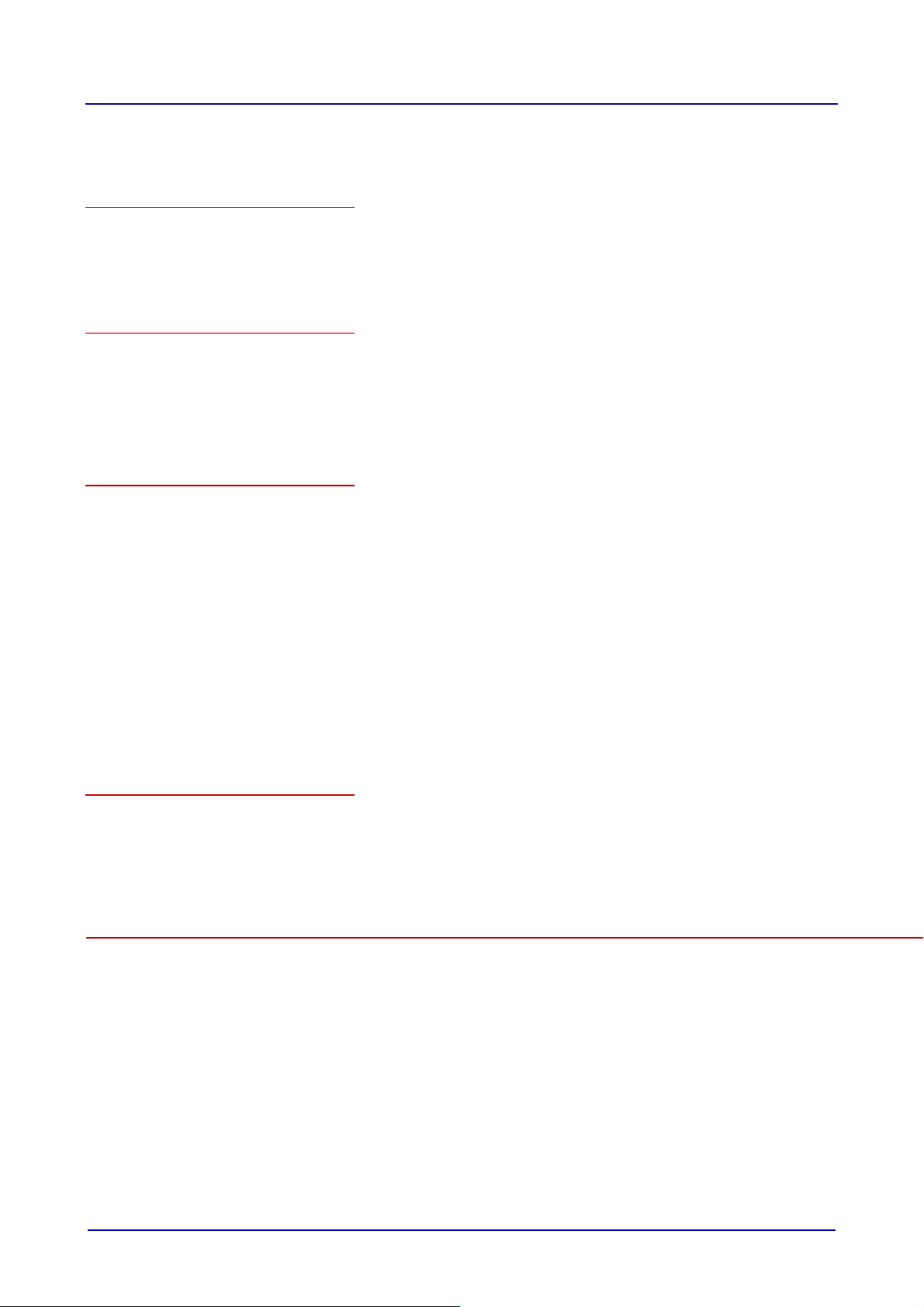

Floor-standing appliance construction

The following diagram shows a gas appliance and an electric appliance, representing all floor-standing

appliances:

3 4

1

2

5

6

8

7

14

Installation manual 17

13

OGB 20.20 OEB 20.20

12

11

10

9

Layout and function

Components of the floor-standing appliances and their function

The components of the table-top appliances have the following function:

No. Name

picture

1

2

Air vent Controls ventilation

Number of gas flue pipes

3 Low-pressure failsafe

device

4

Multipurpose door handle

("Hygienic Handle")

5 Appliance door ("disappea-

ring door")

6

7

8

9

10

11

12

13

14

Touchscreen

Oven

Loading trolley Used for loading food

Hand shower

Appliance feet

Preheat bridge Used for safety purposes during preheating and cleaning

Type plate Used for identifying the combi steamer

USB cover Covers the USB connector on the appliance

Function

On gas appliances only (vents flue gases):

1 gas flue pipes: OGS 12.20

2 gas flue pipes: OGB 12.20, OGS 20.10, 20.20

3 gas flue pipes: OGB 20.10, 20.20

Prevents the low pressure in the oven e.g. during fully automatic cleaning

(CONVOClean system)

Has the following functions depending on its position:

Pointing vertically downwards: combi steamer closed

Horizontal: combi steamer open but in on-latch position

20 degrees above horizontal: Combi steamer can be opened

Also has the following functions:

Additional function as far as on-latch position

In the on-latch position, door can be opened from inside oven in an emer-

gency

Antibacterial with silver ions

Seals the oven during cooking

Special opening action allows it to slide back against the side of the combi

steamer to save space

Switches the combi steamer on and off

Central control of the combi steamer:

Combi steamer operated by touching symbols on control-panel pages

Status displays

Contains the food during cooking

Has a different number of shelf levels depending on model

Used for rinsing out the oven with water

Continuous flow adjustment

Retracts automatically into the holder after use

Can be adjusted in height to allow the combi steamer to be positioned

horizontally

Material

The interior and exterior structure of the combi steamer is made of stainless steel.

Installation manual 18

For your safety

3 For your safety

Purpose of this chapter

This chapter provides you with all the information you need in order to use the combi steamer safely

without putting yourself or others at risk.

This is a particularly important chapter that you should read through carefully.

Contents

This chapter contains the following topics:

Page

Basic safety code 20

Hazards and safety precautions 21

Requirements for safe setup, installation and preparation for first-time use 23

Requirements to be met by personnel, personal protection equipment and

working positions 24

Warning signs on the combi steamer 25

Safety devices 27

Installation manual 19

For your safety

► Basic safety code

Object of this safety code

This safety code aims to ensure that all persons who use the combi steamer have a thorough knowledge of the hazards and safety precautions, and that they follow the safety instructions given in the

user manual and on the combi steamer. If you do not follow this safety code, you risk potentially fatal

injury and property damage.

Referring to the user manuals included in the customer documentation

Follow the instructions below:

Read in full the chapter "For Your Safety" and the chapters that relate to your work.

Always keep to hand the user manuals included in the customer documentation for reference.

Pass on the user manuals included in the customer documentation with the combi steamer if it

changes ownership.

Working with the combi steamer

Follow the instructions below:

Only those persons who satisfy the requirements stipulated in this user manual are permitted to use

the combi steamer.

People (including children) who, because of their physical, sensory or intellectual capabilities, or

because of their lack of experience or knowledge, are incapable of using the appliance safely, must

not use this equipment without the supervision or guidance of a responsible person.

Only use the combi steamer for the specified use. Never, under any circumstances, use the combi

steamer for other purposes that may suggest themselves.

Take all the safety precautions specified in this user manual and on the combi steamer. In particular,

use the prescribed personal protection equipment.

Only stand in the working positions specified.

Do not make any changes to the combi steamer, e.g. removing parts or fitting un-approved parts. In

particular, you must not disable any safety devices.

More on this

Related topics

Intended use of your combi steamer..................................................................................................12

Warning signs on the combi steamer.................................................................................................25

Hazards and safety precautions.........................................................................................................21

Safety devices....................................................................................................................................27

Requirements to be met by personnel, personal protection equipment and working positions ........24

Installation manual 20

For your safety

► Hazards and safety precautions

Meaning

This section describes the potential hazards that authorized personnel may be exposed to when moving and installing the appliance, when preparing the appliance for use and when taking it out of service. It stipulates the measures required to minimize these hazards as far as possible.

Moving the appliance and taking it out of service

When moving the combi steamer and taking it out of service, be aware of the following hazards and

take the specified preventive actions:

Hazard Where or in what situations

does the hazard arise?

Risk of crushing from

heavy items being carried

Overstressing your body

Hazard posed by damaged

gas, water and electrical

connections

When lifting up and setting down

the items being carried

When setting up and moving the

appliance

When moving and dismantling

connected appliances

Preventive action Safety device

Only allow suitably trained

personnel to move the appliance using a pallet truck or

forklift truck

Do not exceed safety limits for

lifting and carrying

Use lifting gear

Disconnect all gas, water and

electrical connections before

moving the appliance and

before taking it out of service.

Work must only be performed

by qualified electricians from

an approved customer service

office and by approved gas

fitters.

None

None

None

Installation manual 21

For your safety

Installation and preparing for first-time use

When installing the combi steamer and preparing it for first-time use, be aware of the following hazards and take the specified preventive actions:

Hazard Where or in what situations

does the hazard arise?

Risk from live parts

Risk of electric shock if the

water supply is leaking or

Under the cover

Under the control panel

On the combi steamer

In the entire working area

cracked.

Preventive action Safety device

Work on the electrical system

must only be performed by

qualified electricians from an

approved customer service

office

Professional working

Disconnect power supply

before removing the cover

Use a permanent connection.

Use only suitable pipes that

comply with DIN EN 61770.

Cover

None

Risk of explosion from gas Where combi steamer is installed

Work on the gas system must

None

only be performed by an

approved gas fitter

Professional working

On smelling gas:

Disconnect gas supply at the

shut-off device

Ventilate room

Do not operate any electrical

equipment

Do not create naked flames

Get help

Risk of suffocation from

faulty combustion

Where combi steamer is installed

Work on the gas system must

only be performed by an

None

approved gas fitter

Risk of suffocation from

Where combi steamer is installed

insufficient supply of air for

combustion

Work on the gas system must

only be performed by an

approved gas fitter

None

Installation manual 22

For your safety

► Requirements for safe setup, installation and preparation for first-

time use

Meaning

Safe operation of the combi steamer is only guaranteed if it has first been set up, installed, connected

and prepared for use in accordance with the basic requirements specified here.

Stability

Observe the following requirements to ensure that the combi steamer is installed in a stable situation:

The standing surface must be flat and sufficiently strong to bear the weight of the appliance.

This must include the maximum permissible loading weight for the appliance model concerned.

The height-adjustable feet on the combi steamer must be adjusted to ensure the appliance is posi-

tioned horizontally on the standing surface.

On vehicles and on-board ships, the combi steamer must be suitably anchored to secure it from

tipping over or sliding about.

Installing the connection to the electrical supply

Observe the following requirements to prevent hazards caused by faulty electrical connections:

Only qualified electricians from an approved customer service office are permitted to perform work

on electrical equipment.

The connection to the electrical supply must be installed in accordance with applicable local regula-

tions of the professional associations and power supply company.

The case of the appliance must be grounded in a suitable manner and connected to an equipoten-

tial bonding system.

All electrical connections must be checked when the appliance is prepared for first-time use to

ensure cables are laid correctly and connections are made properly.

Installing the gas supply

Observe the following requirements to prevent hazards caused by faulty connections to gas appliances:

Only approved gas fitters are permitted to connect the combi steamer to the gas supply.

The connection to the gas supply must be installed in accordance with applicable local regulations

of the professional associations and gas supply company.

All gas supply installations must be checked carefully when the appliance is prepared for first-time

use to ensure the connections are gas-tight and installed correctly.

Environmental conditions at the installation location

To ensure safe operation of the appliance, the environmental conditions at the intended installation

location must meet the following requirements:

It is prohibited to store flammable gases or liquids in an area exposed to heat radiated from the

appliance.

It is prohibited to operate deep-fat fryers or appliances that use hot, uncovered fat, in an area that

can be reached by the water jet from the hand shower.

For the operation of gas appliances, there must be a guaranteed, unrestricted supply of fresh air,

and the ventilation system must be installed in accordance with regulations.

Installation manual 23

For your safety

► Requirements to be met by personnel, personal protection equip-

ment and working positions

Requirements to be met by personnel

Those people using the combi steamer must meet the following requirements:

Personnel

Tasks Qualifications Personal protection equipment

required

Equipment mover

Conveying within the

establishment

Trained in the use of a

pallet truck and forklift

truck

Safety boots

Hard hat (e.g. when heavy loads

are being lifted, working overhead...)

Service engineer

Setting up the appliance

Connecting the appliance

Preparing the appliance

for first-time use

Taking the appliance out of

service

Instructing the user

Gas fitter Connecting the appliance:

gas

Isolating the appliance

from the gas supply mains

Is an employee of an

approved customer

service unit.

Has relevant technical

training.

Is trained in the particu-

lar appliance.

Is a gas fitter author-

ized by the gas supply

company.

Has relevant professi-

Work wear and personal protection

equipment depending on the job

that needs doing as specified in

national regulations.

Work wear and personal protection

equipment depending on the job

that needs doing as specified in

national regulations.

onal training.

Electrical fitter Connecting the appliance:

electric

Isolating the appliance

from the electrical supply

mains

Is an employee of an

approved customer

service unit.

Has relevant professi-

onal training.

Is a qualified electrici-

Work wear and personal protection

equipment depending on the job

that needs doing as specified in

national regulations.

an.

Working positions when installing and preparing the appliance for first-time use

The working position for personnel installing and preparing the appliance for first-time use is the entire

appliance area.

Installation manual 24

For your safety

► Warning signs on the combi steamer

Where are the warning signs fitted?

The warning signs are located in the following positions on the combi steamer:

1

2

1

OGB 10.10 OGB 10.10

Warnings on the appliance door

The following warning signs are fitted on the appliance door above the door handle (2):

Warning sign Description

Warning of hot liquids

Spillage of hot liquid foods can result in scalds if the upper shelves are loaded with liquids

or foods that produce liquid during cooking. Shelves above the level marked by this

warning sign (1.60 m) may not be seen by all users and should not, therefore, be used for

liquids or foods that produce liquid during cooking.

Warning of hot steam and vapor

There is a risk of scalding from hot steam and vapor escaping when the appliance door is

opened.

Warning of corrosive cleaning agents injected into oven

If the appliance door is opened during fully automatic cleaning (CONVOClean system),

there is a risk of chemical skin burns from contact with cleaning agents being injected

during the cleaning program.

Warning signs on the side cover of the combi steamer

The following warning signs are fitted on the side cover (1) of the combi steamer:

Warning sign Description

Warning of electric shock

There is a risk of electric shock from live parts if the appliance cover is opened.

Installation manual 25

For your safety

Warning signs on the loading trolley for floor-standing appliances

The following warning signs are fitted on the loading trolley of floor-standing appliances:

Warning sign Description

Warning of hot liquids

Spillage of hot liquid foods can result in scalds if the upper shelves are loaded with liquids

or foods that produce liquid during cooking. Shelves above the level marked by this

warning sign (1.60 m) may not be seen by all users and should not, therefore, be used for

liquids or foods that produce liquid during cooking.

Installation manual 26

For your safety

► Safety devices

Meaning

The combi steamer has a number of safety devices to protect the user from hazards. It is absolutely

essential that all safety devices are fitted and in working order when operating the combi steamer

Position

The following diagrams show the location of the safety devices:

6261 3 4 5

OGB 10.10 OEB 10.10 OGB 20.20

Functions

The following table enumerates all the safety devices on the combi steamer, explains their function

and describes the check procedure:

No. Safety device Function Check

1 Cover can only be

removed using tool

2 Control panel can only

be removed using a tool

3

4 On-latch position of

5 Suction panel in oven;

Appliance door:

appliance door

can only be removed

using tool

Prevents live parts from being

touched accidentally

Prevents access to the moving

fan from the wiring compartment

Prevents live parts from being

touched accidentally

Protects the operator and outside

environment from hot steam

Prevents scalding of user's face

and hands from escaping steam

Prevents access to the moving fan

and ensures good heat distribution.

Check that the cover is in place

Ensure that the control panel is in

place

Check regularly for scratches,

cracks, indentations etc. and

replace door if any are found

Check door positions at low

temperature as described in

Opening the appliance door safely

in the user manual.

See

Removing and fitting the suction

panel in the user manual for

further details.

10

Installation manual 27

For your safety

No. Safety device Function Check

6

(no picture)

7

(no picture)

8

(no picture)

9

(no picture)

10

11 (installed

by customer)

12 (installed

by customer)

Magnetic door switch:

electrical door sensor in

appliance door

Emergency opening in

appliance door;

Prevents anyone being

locked inside the oven

accidentally

Automatic rinsing after

power failure in case

cleaning agent left in

combi steamer

Spray-guard

Preheat bridge

Disconnection device

Gas shut-off device

Switches off the fan and heater

when the appliance door is opened

Appliance door in the on-latch

position:

Allows the appliance door to be

pushed open from the inside after

shutting the door.

Re-starts fully automatic cleaning

(CONVOClean system) in a defined state after power failure

Stops the cleaning agent being

injected during fully automatic

cleaning (CONVOClean system)

when the appliance door is opened

Prompt to close the appliance door

Prevents scalding from escaping

steam when the loading trolley is

not in the floor-standing appliance

during preheating

Installed by the customer close to

the appliance; easily visible and

accessible, 3-pole action, minimum

contact separation 3 mm.

Used to disconnect the appliance

from the power supply during

cleaning, repair and maintenance

work and in case of danger.

Installed by customer close to

appliance in easily accessible

position and clearly labeled.

Used to disconnect the appliance

from the gas supply during cleaning, repair and maintenance work

and in case of danger.

Check magnetic door switch at low

temperature:

Action

Open the appliance door fully

Press Start

Result

Motor must not start up

Check at low temperature:

put the appliance door in the on-

latch position (see Opening the

appliance door safely in the user

manual)

Action

From the outside, pull forcefully on

the top left of the appliance door

Result

The appliance door must open.

This test is a software function.

There is no need for the operator

to perform a test.

The operability of the magnetic

door switch is checked by the

software at the beginning of each

cleaning program

See

Inserting and removing the preheat bridge (floor-standing appliances only) in the user manual for

further details

Action

Trip the disconnection device.

Check at the X10 terminal strip

on the appliance that there is no

voltage at all three poles.

Action

Close gas shut-off device.

Check that the appliance is

isolated from the gas supply.

Installation manual 28

Moving and setting up the appliance

4 Moving and setting up the appliance

Purpose of this chapter

This chapter specifies all the requirements for the installation location of the combi steamer, and explains the correct on-site procedure for conveying and unpacking the combi steamer, lifting it off the

pallet and setting it up.

Contents

This chapter contains the following topics:

Page

Requirements for the installation location 30

Taking to the installation location 35

Unpacking 36

Setting up table-top appliances 39

Setting up floor-standing appliances 42

Installation manual 29

Loading...

Loading...