Page 1

Frame 3 to 4

Power Installation Guide

Unidrive M600 to

M702 and HS70 to

HS72

Part Number: 0478-0254-03

Issue: 3

Page 2

Original Instructions

General Information

For the purposes of compliance with the EU Machinery Directive 2006/42/EC.

This guide covers the basic information that is required to install the drive, in applications where a drive malfunction

does not result in a mechanical hazard. When the drive is used in a safety related application, i.e. where a

malfunction might result in a hazard, it is essential to refer to this guide and the Control User Guide. The Control User

Guide is available for download from:

http://www.emersonindustrial.com/en-EN/controltechniques/downloads/userguidesandsoftware/Pages/downloads.aspx

or

www.emersonindustrial.com/en-EN/leroy-somer-motors-drives/downloads/Pages/manuals.aspx

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional operating parameters of the equipment or from mismatching the variable

speed drive with the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of a commitment to a

policy of continuous development and improvement, the manufacturer reserves the right to change the specification

of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical

or mechanical including photocopying, recording or by an information storage or retrieval system, without permission

in writing from the publisher.

Drive firmware version

This product is supplied with the latest firmware version. If this drive is to be connected to an existing system or

machine, all drive firmware versions should be verified to confirm the same functionality as drives of the same model

already present. This may also apply to drives returned from an Emerson Industrial Automation Service Centre or

Repair Centre. If there is any doubt please contact the supplier of the product.

The firmware version of the drive can be checked by looking at Pr 11.029

Environmental statement

Emerson Industrial Automation is committed to minimising the environmental impacts of its manufacturing operations

and of its products throughout their life cycle. To this end, we operate an Environmental Management System (EMS)

which is certified to the International Standard ISO 14001. Further information on the EMS, our Environmental Policy

and other relevant information is available on request, or can be found at:

http://www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/Pages/environment.aspx.

The electronic variable-speed drives manufactured by Emerson Industrial Automation have the potential to save

energy and (through increased machine/process efficiency) reduce raw material consumption and scrap throughout

their long working lifetime. In typical applications, these positive environmental effects far outweigh the negative

impacts of product manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they must not be discarded but should

instead be recycled by a specialist recycler of electronic equipment. Recyclers will find the products easy to

dismantle into their major component parts for efficient recycling. Many parts snap together and can be separated

without the use of tools, while other parts are secured with conventional fasteners. Virtually all parts of the product

are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller

products come in strong cardboard cartons which themselves have a high recycled fibre content. If not re-used, these

containers can be recycled. Polythene, used on the protective film and bags for wrapping product, can be recycled

in the same way. Emerson Industrial Automation’s packaging strategy prefers easily-recyclable materials of low

environmental impact, and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH)

requires the supplier of an article to inform the recipient if it contains more than a specified proportion of any

substance which is considered by the European Chemicals Agency (ECHA) to be a Substance of Very High Concern

(SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

For current information on how this requirement applies in relation to specific Emerson Industrial Automation’s

products, please approach your usual contact in the first instance. Emerson Industrial Automation’s position

statement can be viewed at:

www.emersonindustrial.com/en-EN/controltechniques/aboutus/environment/reachregulation/Pages/reachregulation.aspx.

Copyright © February 2016 Emerson Industrial Automation.

The information contained in this guide is for guidance only and does not form part of any contract. The accuracy

cannot be guaranteed as Emerson have an ongoing process of development and reserve the right to change the

specification of their products without notice.

Control Techniques Limited. Registered Office: The Gro, Newtown, Powys SY16 3BE. Registered in England and

Wales. Company Reg. No. 01236886.

Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9, France.

Share Capital: 65 800 512 €, RCS Angoulême 338 567 258.

Issue Number: 3

Drive Firmware: 01.14.00.00

Page 3

Contents

1 Safety information ....................................................................................... 8

1.1 Warnings, Cautions and Notes ................................................................................ 8

1.2 Electrical safety - general warning ........................................................................... 8

1.3 System design and safety of personnel ................................................................... 8

1.4 Environmental limits ................................................................................................ 8

1.5 Access ..................................................................................................................... 9

1.6 Fire protection .......................................................................................................... 9

1.7 Compliance with regulations .................................................................................... 9

1.8 Motor ....................................................................................................................... 9

1.9 Mechanical brake control ......................................................................................... 9

1.10 Adjusting parameters ............................................................................................... 9

1.11 Electrical installation .............................................................................................. 10

2 Product information ..................................................................................11

2.1 Introduction ............................................................................................................ 11

2.2 Model number ........................................................................................................ 11

2.3 Nameplate description ........................................................................................... 12

2.4 Ratings .................................................................................................................. 13

2.5 Drive features ........................................................................................................ 15

2.6 Items supplied with the drive ................................................................................. 16

3 Mechanical installation ............................................................................. 17

3.1 Safety information .................................................................................................. 17

3.2 Planning the installation ......................................................................................... 18

3.3 Terminal cover removal ......................................................................................... 20

3.4 Dimensions and mounting methods ...................................................................... 23

3.5 Enclosure for standard drives ................................................................................ 27

3.6 Enclosure design and drive ambient temperature ................................................. 32

3.7 Heatsink fan operation ........................................................................................... 32

3.8 Enclosing standard drive for high environmental protection .................................. 32

3.9 Installation of high IP insert for size 3 and 4 .......................................................... 34

3.10 Size 3 and 4 internal braking resistor .................................................................... 37

3.11 External EMC filter ................................................................................................. 41

3.12 Terminal size and torque settings .......................................................................... 43

3.13 Routine maintenance ............................................................................................. 44

4 Electrical installation .................................................................................45

4.1 Power and ground connections ............................................................................. 46

4.2 AC Supply requirements ........................................................................................ 48

4.3 Supplying the drive with DC .................................................................................. 50

4.4 DC bus paralleling ................................................................................................. 51

4.5 24 Vdc supply ........................................................................................................ 52

4.6 Low voltage operation ........................................................................................... 53

4.7 Fan power supply .................................................................................................. 53

4.8 Ratings .................................................................................................................. 53

4.9 Output circuit and motor protection ....................................................................... 54

4.10 Braking .................................................................................................................. 57

4.11 Ground leakage ..................................................................................................... 62

4.12 EMC (Electromagnetic compatibility) ..................................................................... 63

5 Technical data ............................................................................................76

5.1 Drive technical data ............................................................................................... 76

5.2 Optional external EMC filters ................................................................................. 96

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 4

6 UL listing information ................................................................................98

6.1 General ..................................................................................................................98

6.2 Overload, overcurrent and overspeed protection ...................................................98

6.3 Short-circuit protection for branch circuits ..............................................................99

6.4 Control circuit protection ........................................................................................99

6.5 Wiring terminal markings ......................................................................................100

6.6 Environment .........................................................................................................100

6.7 Mounting ..............................................................................................................100

6.8 Listed accessories ................................................................................................101

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 5

Declaration of Conformity

G Williams

Vice President, Technology

Date: 30th November 2015

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration applies to the Unidrive M/HS product range comprising model numbers listed below:

Model

number

X Application

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the

following European harmonized standards:

EN 61800-5-1:2007

EN 61800-3: 2004

EN 61000-6-2:2005

EN 61000-6-4:2007

EN 61000-3-2:2006

EN 61000-3-3:2008

EN 61000-3-2: 2006 Applicable where input current < 16 A. No limits apply for professional equipment where input

power ≥1 kW.

These products comply with the Restriction of Hazardous Substances Directive - RoHS 2011/65/EU, the Low

Voltage Directive - LVD 2006/95/EC and the Electromagnetic Compatibility Directive - EMC 2004/108/EC.

Interpretation Nomenclature aaaa - bbc ddddde

M = Manufacturing Automation, E = Elevator, F = Flow, H = HVAC, CSD =

Compressor, EVC = Emerson Variable Scroll, HS = High Speed

M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, F300,

H300, E200, E300, CSD1, HS30, HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier +

Inverter (external choke), N = 18P Rectifier + Inverter, T = 12P Rectifier +

Inverter

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 3: EMC requirements and specific

test methods

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial

environments

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission standard for

industrial environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current emissions

(equipment input current ≤16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes, voltage

fluctuations and flicker in public, low voltage supply systems, for equipment with rated

current ≤16 A per phase and not subject to conditional connection

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

These electronic drive products are intended to be used with appropriate motors, controllers, electrical protection

components and other equipment to form complete end products or systems. Compliance with safety and EMC

regulations depends upon installing and configuring drives correctly, including using the specified input filters. The

drives must be installed only by professional installers who are familiar with requirements for safety and EMC. The

assembler is responsible for ensuring that the end product or system complies with all the relevant laws in the

country where it is to be used. Refer to the Product Documentation. An EMC data sheet is also available giving

detailed EMC information.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

5

Page 6

Declaration of Conformity

(including 2006 Machinery Directive)

Control Techniques Ltd

The Gro

Newtown

Powys

UK

SY16 3BE

This declaration applies to the Unidrive M/HS product range comprising model numbers listed below:

Model

number

X Application

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe

Torque Off function may be used for a safety function of a machine. None of the other functions of the drive

may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive 2006/42/EC and the EMC Directive 2014/

108/EC.

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

Notified body identification number: 0035

The harmonized standards used are shown below:

EC type-examination certificate numbers:

01/205/5270.01/14 dated 2014-11-11

01/205/5387.01/15 dated 2015-01-29

01/205/5383.02/15 dated 2015-04-21

EN 61800-5-1:2007

EN 61800-5-2:2007

EN ISO 13849-1:2008

EN ISO 13849-2:2008 Safety of machinery, Safety-related parts of control systems. Validation

EN 61800-3: 2004

EN 62061:2005

Interpretation Nomenclature aaaa - bbc ddddde

M = Manufacturing Automation, E = Elevator, F = Flow, H = HVAC, CSD =

Compressor, EVC = Emerson Variable Scroll, HS = High Speed

M300, M400, M600, M700, M701, M702, F300, H300, E200, E300, CSD1,

HS30, HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier +

Inverter (external choke), N = 18P Rectifier + Inverter, T = 12P Rectifier +

Inverter

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 5-2: Safety requirements Functional

Safety of Machinery, Safety-related parts of control systems, General principles for

design

Adjustable speed electrical power drive systems - Part 3: EMC requirements and

specific test methods

Safety of machinery, Functional safety of safety related electrical, electronic and

programmable electronic control systems

Moteurs Leroy-Somer

Usine des Agriers

Boulevard Marcellin Leroy

CS10015

16915 Angoulême Cedex 9

France

6

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 7

Person authorised to complete the technical file:

G Williams

Vice President, Technology

Date: 30th November 2015

C Hargis

Chief Engineer

Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. It is the

responsibility of the installer to ensure that the design of the complete machine, including its safety-related

control system, is carried out in accordance with the requirements of the Machinery Directive and any

other relevant legislation. The use of a safety-related drive in itself does not ensure the safety of the

machine.

Compliance with safety and EMC regulations depends upon installing and configuring drives correctly,

including using the specified input filters. The drive must be installed only by professional installers who

are familiar with requirements for safety and EMC. The assembler is responsible for ensuring that the end

product or system complies with all relevant laws in the country where it is to be used. For more

information regarding Safe Torque Off, refer to the Control User Guide.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

7

Page 8

1 Safety information

WARNING

CAUTION

NOTE

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for avoiding a safety hazard.

A Caution contains information which is necessary for avoiding a risk of damage to the

product or other equipment.

A Note contains information, which helps to ensure correct operation of the product.

1.2 Electrical safety - general warning

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive. Specific warnings

are given at the relevant places in this guide.

1.3 System design and safety of personnel

The drive is intended as a component for professional incorporation into complete equipment or a

system. If installed incorrectly, the drive may present a safety hazard.

The drive uses high voltages and currents, carries a high level of stored electrical energy, and is used

to control equipment which can cause injury.

Close attention is required to the electrical installation and the system design to avoid hazards either

in normal operation or in the event of equipment malfunction. System design, installation,

commissioning/start-up and maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and this guide carefully.

The STOP and Safe Torque Off functions of the drive do not isolate dangerous voltages from the

output of the drive or from any external option unit. The supply must be disconnected by an approved

electrical isolation device before gaining access to the electrical connections.

With the sole exception of the Safe Torque Off function, none of the drive functions must be

used to ensure safety of personnel, i.e. they must not be used for safety-related functions.

Careful consideration must be given to the functions of the drive which might result in a hazard,

either through their intended behavior or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or allow damage, loss or injury, a

risk analysis must be carried out, and where necessary, further measures taken to reduce the risk for example, an over-speed protection device in case of failure of the speed control, or a fail-safe

mechanical brake in case of loss of motor braking.

The Safe Torque Off function may be used in a safety-related application. The system designer is

responsible for ensuring that the complete system is safe and designed correctly according to the

relevant safety standards.

1.4 Environmental limits

Instructions in this guide regarding transport, storage, installation and use of the drive must be

complied with, including the specified environmental limits. Drives must not be subjected to

excessive physical force.

8

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 9

1.5 Access

Drive access must be restricted to authorized personnel only. Safety regulations which apply at the

place of use must be complied with.

1.6 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must be provided.

For further information, refer to section 3.2.5 Fire protection on page 18.

1.7 Compliance with regulations

The installer is responsible for complying with all relevant regulations, such as national wiring

regulations, accident prevention regulations and electromagnetic compatibility (EMC) regulations.

Particular attention must be given to the cross-sectional areas of conductors, the selection of fuses

or other protection, and protective ground (earth) connections.

This guide contains instruction for achieving compliance with specific EMC standards.

Within the European Union, all machinery in which this product is used must comply with the

following directives:

2006/42/EC: Safety of machinery.

2004/108/EC: Electromagnetic Compatibility.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s recommendations. Ensure the

motor shaft is not exposed.

Standard squirrel cage induction motors are designed for single speed operation. If it is intended to

use the capability of the drive to run a motor at speeds above its designed maximum, it is strongly

recommended that the manufacturer is consulted first.

Low speeds may cause the motor to overheat because the cooling fan becomes less effective. The

motor should be installed with a protection thermistor. If necessary, an electric forced vent fan should

be used.

The values of the motor parameters set in the drive affect the protection of the motor. The default

values in the drive should not be relied upon.

It is essential that the correct value is entered in Pr 00.046 motor rated current. This affects the

thermal protection of the motor.

Safety information

Product information Mechanical installation Electrical installation Technical data UL listing information

1.9 Mechanical brake control

The brake control functions are provided to allow well co-ordinated operation of an external brake

with the drive. While both hardware and software are designed to high standards of quality and

robustness, they are not intended for use as safety functions, i.e. where a fault or failure would result

in a risk of injury. In any application where the incorrect operation of the brake release mechanism

could result in injury, independent protection devices of proven integrity must also be incorporated.

1.10 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

9

Page 10

1.11 Electrical installation

1.11.1 Electric shock risk

The voltages present in the following locations can cause severe electric shock and may be lethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

1.11.2 Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply

has been disconnected. If the drive has been energized, the AC supply must be isolated at least ten

minutes before work may continue.

10

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 11

2 Product information

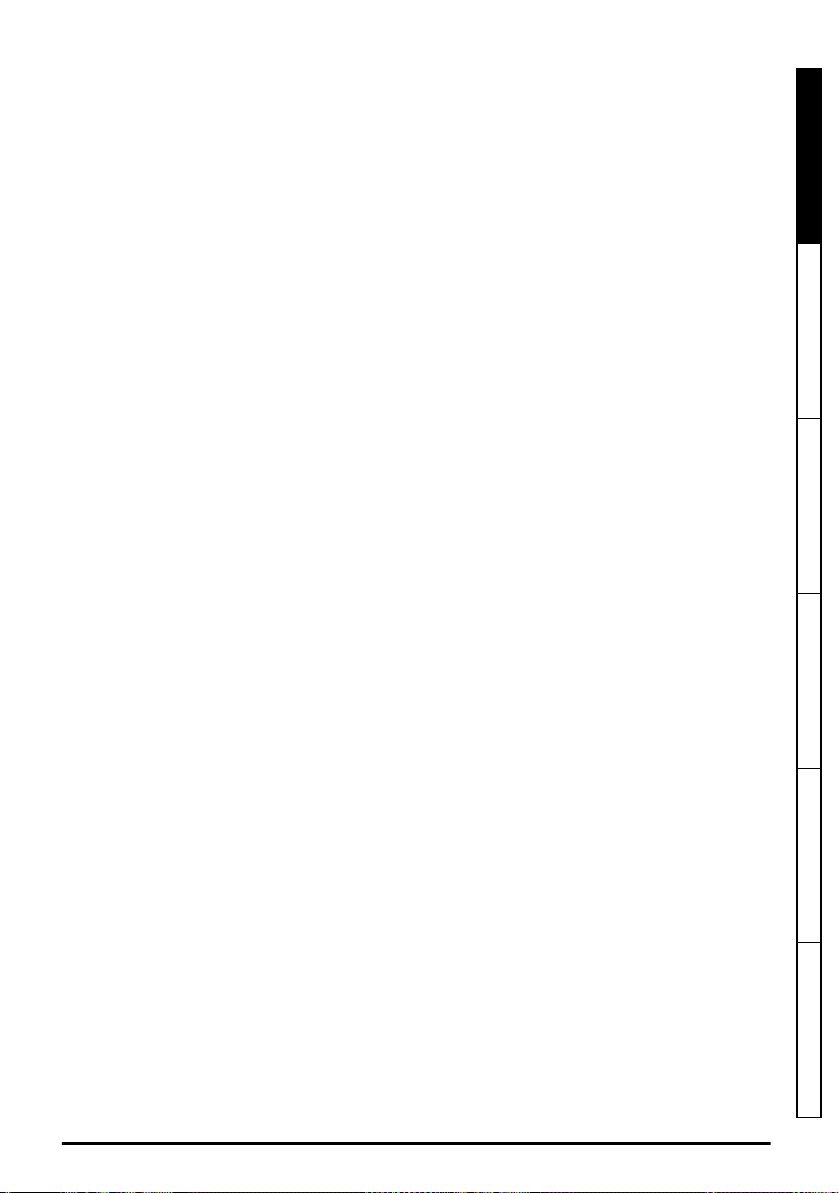

IdentificationLabel

ElectricalSpecifications

Derivative

UnidriveM600

UnidriveM700

UnidriveM701

UnidriveM702

UnidriveHS70

UnidriveHS71

UnidriveHS72

ProductLine

FrameSize

:

VoltageRating:

CurrentRating:

HeavyDutycurrentratingx 10

PowerFormat:

Reserved

0

OptionalBuild

CustomerCode

01

A B 1 00

CustomerCode:

00 = 50 Hz

01 = 60 Hz

Reserved:

ConformalCoating:

0 = Standard

IP / NEMA Rating:

1 = IP20 / NEMA 1

BrakeTransistor:

B = Brake

Cooling:

A = Air

Documentation

1

Documentation:

0-Suppliedseparately

1-English

2-French

3-Italian

4-German

5-Spanish

2-200V(200-240

-400V(380-480

-575V(500-575

-690V(500-690

± 10%)

4 ±

±

±

10%)

5 10%)

6 10%)

Power

Format

M600 - 03 4 00078 A

A - ACinACout(withinternalchoke)

D-DCin ACout(Inverter)

C- ACinDCout(Rectifier)

E- ACin ACout(withoutinternalchoke)

T - ACinACout(12P rectifier plus inverter)

2.1 Introduction

This guide provides the information necessary to install the following drive models:

Unidrive M600 to M702 frame 3 to 4

Unidrive HS70 to HS72 frame 3 to 4

This guide focuses on the drive power section, for example: electrical installation of the supply /

motor cables and mechanical installation of the drive.

For information about the drive control section, for example: parameter set up information, control

and encoder connections please refer to the Control User Guide.

2.2 Model number

The model numbers for the Unidrive M/HS product range are formed as illustrated below:

Figure 2-1 Model number

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

11

Page 12

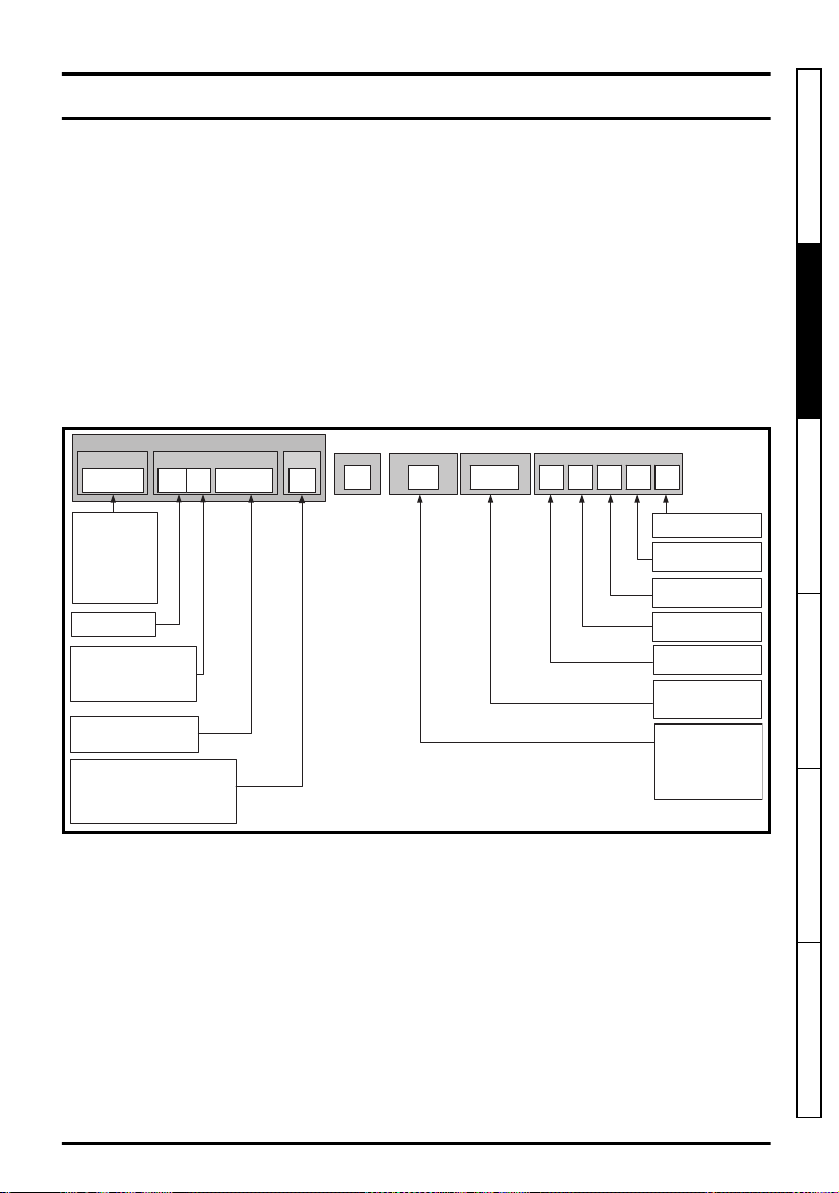

2.3 Nameplate description

Approvals

Inputvoltage

Output

voltage

HeavyDuty/

NormalDuty

powerrating

Customerand

datecode

Serial

number

Input

frequency

No.ofphases&

Typicalinputcurrentfor

NormalDutyrating

HeavyDuty/

NormalDutyrating

outputcurrent

Referto

UserGuide

Model

Frame

size

Voltage

HeavyDuty

currentrating

Driveformat

M600-03200050 A

Key to approvals

CE approval Europe

RCM regulatory

compliance mark

Australia

UL / cUL approval USA & Canada

RoHS compliant Europe

Functional safety USA & Canada

Eurasian conformity Eurasia

R

NOTE

Figure 2-2 Typical drive rating labels

Date code format

The date code is split into two sections: a letter followed by a number. The letter indicates

the year, and the number indicates the week number (within the year) in which the drive

was built. The letters go in alphabetical order, starting with A in 1990 (B in 1991, C in 1992

etc).

Example: A date code of Y28 would correspond to week 28 of year 2015.

12

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 13

2.4 Ratings

WARNING

NOTE

NOTE

Fuses

The AC supply to the drive must be installed with suitable protection against overload and

short-circuits. The following section shows recommended fuse ratings. Failure to observe

this requirement will cause risk of fire.

Nominal cables sizes below are based on the cable installation method B2 (ref: IEC603645-52:2001) unless otherwise specified, and are provided as a guide only. Ensure cables

used suit local wiring regulations.

The continuous output current ratings given below are for maximum 40 °C (104 °F), 1000 m altitude

and 3 kHz switching frequency. Derating is required for higher switching frequencies, ambient

temperature >40 °C (104 °F) and high altitude. For further information, refer to Chapter 5 Technical

data on page 76.

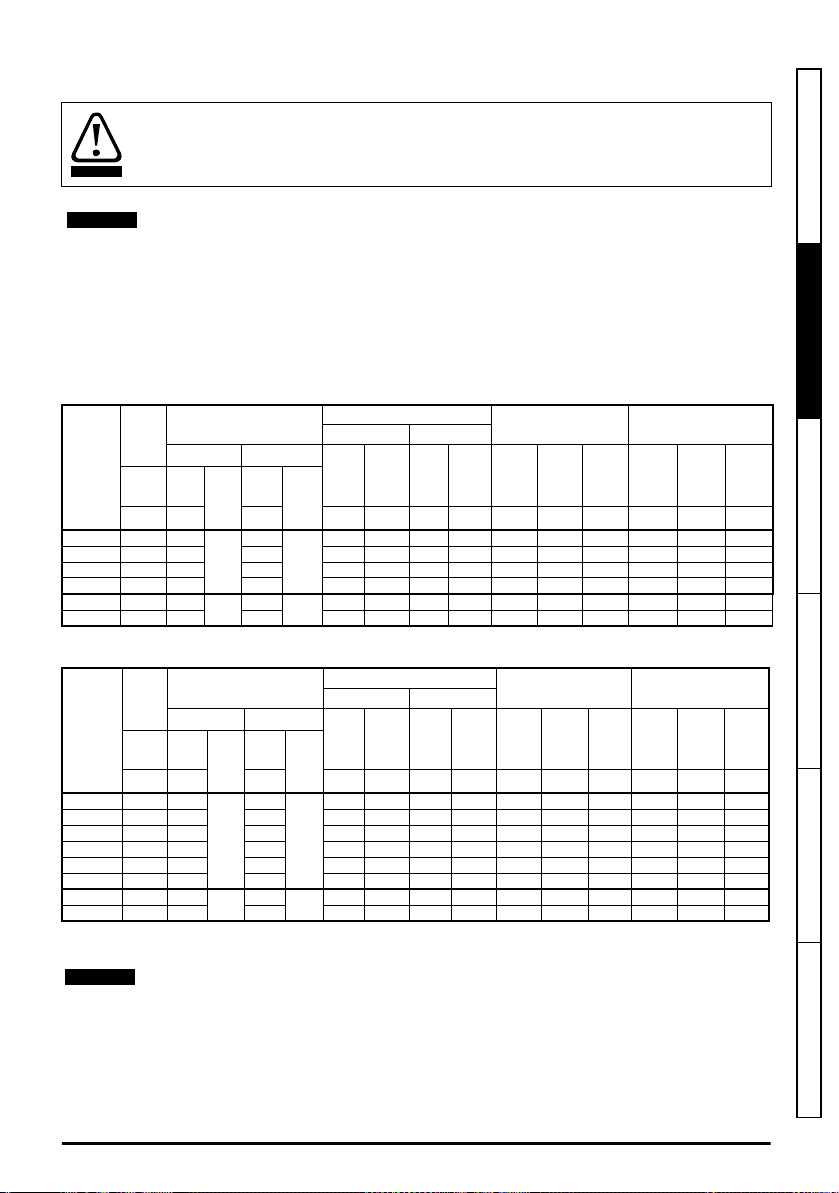

Table 2-1 200 V drive ratings, cable sizes and fuse ratings

Max.

cont.

input

current

Model

3ph Nom

03200050 10.7 16

03200066 13 20 20 1.5 1.5 14 14 8 1.5 2 6.6 1.1 1.5

03200080 17.8 25 25 4 4 12 12 11 2.2 3 8 1.5 2

03200106 20.6 25 25 4 4 12 12 12.7 3 3 10.6 2.2 3

04200137 20.1 25

04200185 26.8 32 30 8 8 8 8 25 5.5 7.5 18.5 4 5

A A A

Fuse

IEC UL

Nom

Class

16

gG

25

gG

Class

CC, J

CC,

J or T*

Nominal cable size

European USA

Input Output Input Output

2

mm2mm

1.5 1.5 14 14 6.6 1.1 1.5 5 0.75 1

or

T*

6 6 10 10 18 4 5 13.7 3 3

AWG AWG A kW hp A kW hp

Normal Duty Heavy Duty

Max.

Nom

Motor

cont.

output

current

power

@

230 V

power

@

230 V

Max.

cont.

output

current

Nom

power

@

230 V

Motor

power

@

230 V

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Table 2-2 400 V drive ratings, cable sizes and fuse ratings

Max.

cont.

input

current

Model

3ph Nom

03400025 5 6

03400031 6.6 10 10 1.5 1.5 16 16 4.5 1.5 2 3.1 1.1 1.5

03400045 9.1 10 10 1.5 1.5 14 14 6.2 2.2 3 4.5 1.5 2.0

03400062 13.1 20 20 2.5 2.5 14 14 7.7 3 5 6.2 2.2 3.0

03400078 13.4 20 20 2.5 2.5 14 14 10.4 4 5 7.8 3 5.0

03400100 15.8 20 20 2.5 2.5 12 12 12.3 5.5 7.5 10 4 5.0

04400150 18.7 25

04400172 24.3 32 30 6 6 8 8 24 11 15 17.2 7.5 10.0

A A A

Fuse

IEC UL

Nom

Class

10

gG

25

gG

Class

CC, J

CC,

J or T*

Nominal cable size

European USA

Input Output Input Output

2

mm2mm

1.5 1.5 18 18 3.4 1.1 1.5 2.5 0.75 1.0

or

T*

4 4 10 10 18.5 7.5 10 15 5.5 10.0

AWG AWG A kW hp A kW hp

Normal Duty Heavy Duty

Max.

Nom

power

@

400 V

Motor

power

@

460 V

cont.

output

current

* These fuses are fast acting.

Refer to Chapter 5 Technical data on page 76 for maximum fuse rating, maximum cable

size and peak currents.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Max.

cont.

output

current

Nom

power

@

400 V

Motor

power

@

460 V

13

Page 14

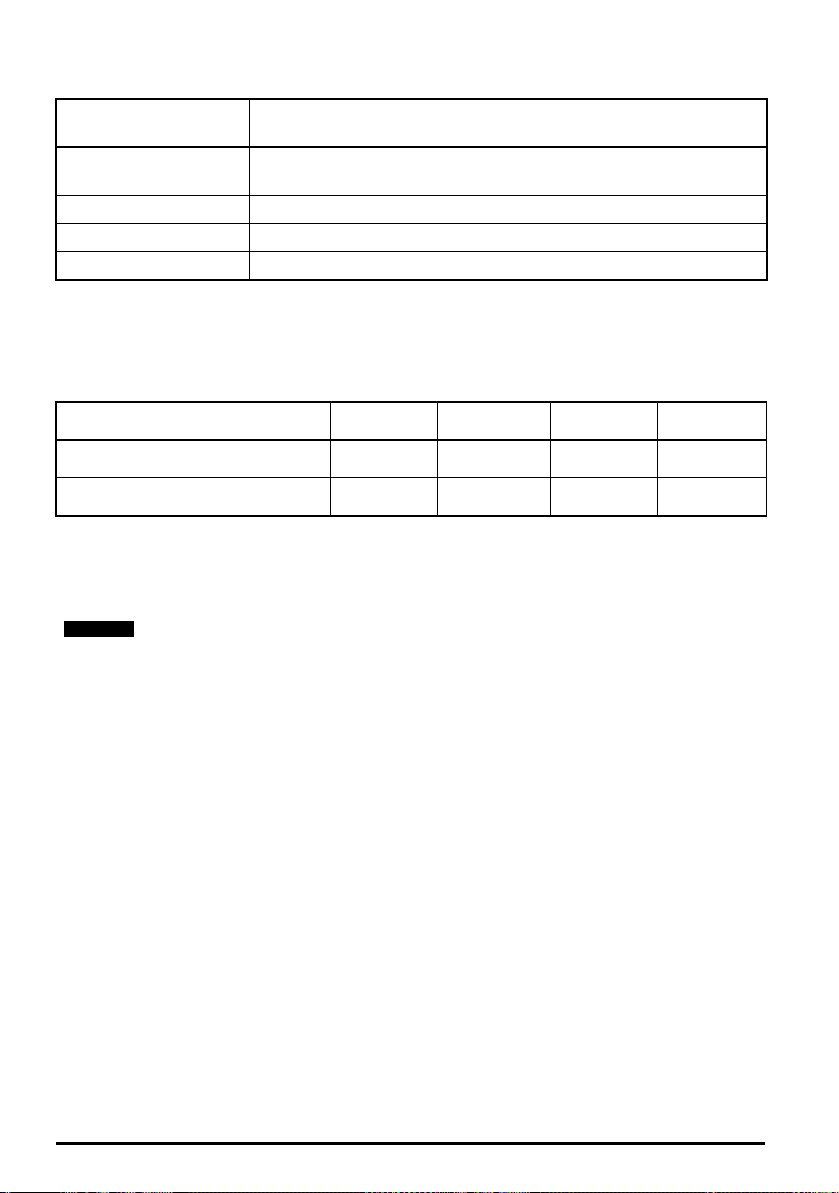

Table 2-3 Protective ground cable ratings

NOTE

Input phase

conductor size

≤ 10 mm

2

> 10 mm2 and ≤ 16 mm

Either 10 mm2 or two conductors of the same cross-sectional area as

the input phase conductor

2

The same cross-sectional area as the input phase conductor

> 16 mm2 and ≤ 35 mm216 mm

> 35 mm

2

Half of the cross-sectional area of the input phase conductor

2

Minimum ground conductor size

Typical short term overload limits

The maximum percentage overload limit changes depending on the selected motor. Variations in

motor rated current, motor power factor and motor leakage inductance all result in changes in the

maximum possible overload. Typical values are shown in the table below:

Table 2-4 Typical overload limits

Operating mode RFC from cold RFC from 100 %

Normal Duty overload with motor rated

current = drive rated current

Heavy Duty overload with motor rated

current = drive rated current

Open loop

from cold

110 % for 165 s 110 % for 9 s 110 % for 165 s 110 % for 9 s

200 % for 28 s 200 % for 3 s 150 % for 60 s 150 % for 7 s

Open loop

from 100 %

Generally the drive rated current is higher than the matching motor rated current allowing a higher

level of overload than the default setting.

The time allowed in the overload region is proportionally reduced at very low output frequency on

some drive ratings.

The maximum overload level which can be attained is independent of the speed.

Output current

The continuous output current ratings given on the rating label are for maximum 40 °C (104 °F), 1000

m altitude and 3 kHz switching frequency. Derating is required for higher switching frequencies,

ambient temperatures >40 °C (104 °F) and higher altitude. For derating information, refer to the

Chapter 5 Technical data on page 76.

Input current

The input current is affected by the supply voltage and impedance. The input current given on the

rating label is the typical input current and is stated for a balanced supply.

14

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 15

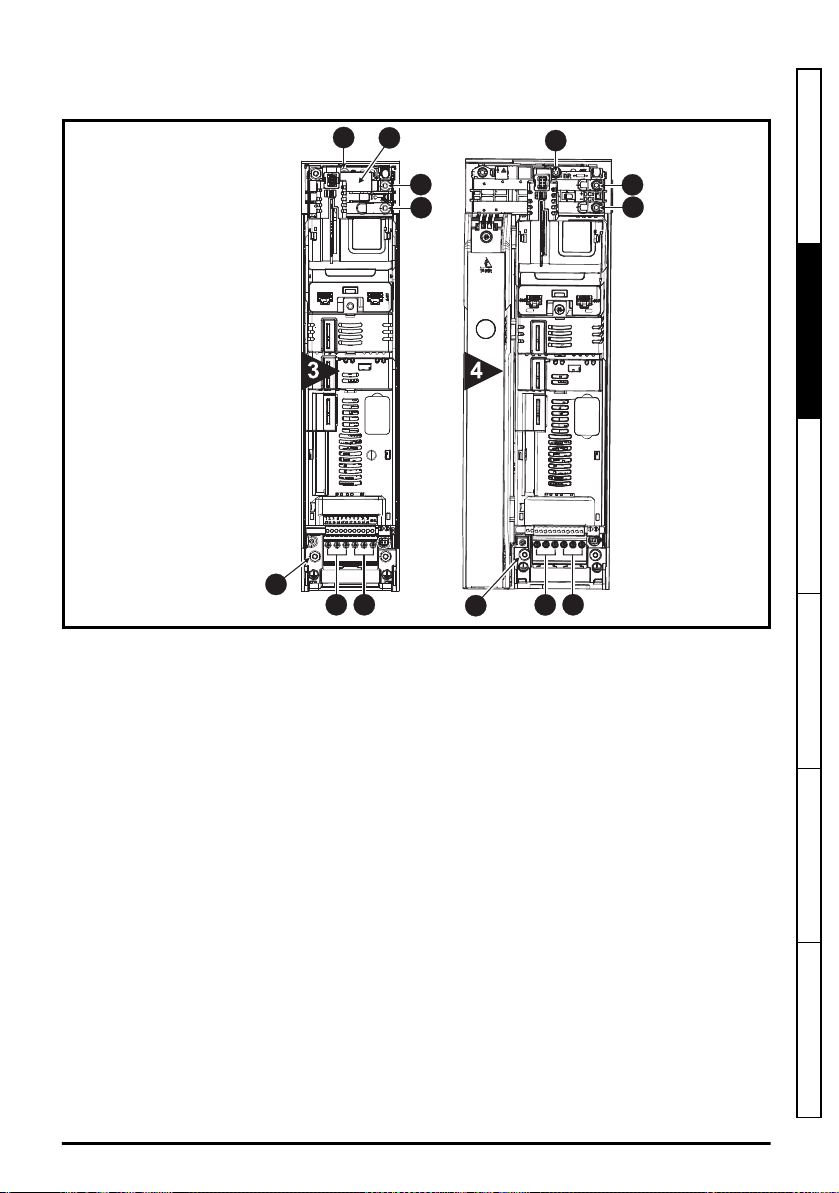

2.5 Drive features

1

2

3

4

6

5

7

1

3

4

6

5

7

Figure 2-3 Features of the drive power section

Key

1. Braking terminal 2. Internal EMC filter 3. DC bus + 4. DC bus -

5. Motor connections 6. AC supply connections 7. Ground connections

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

15

Page 16

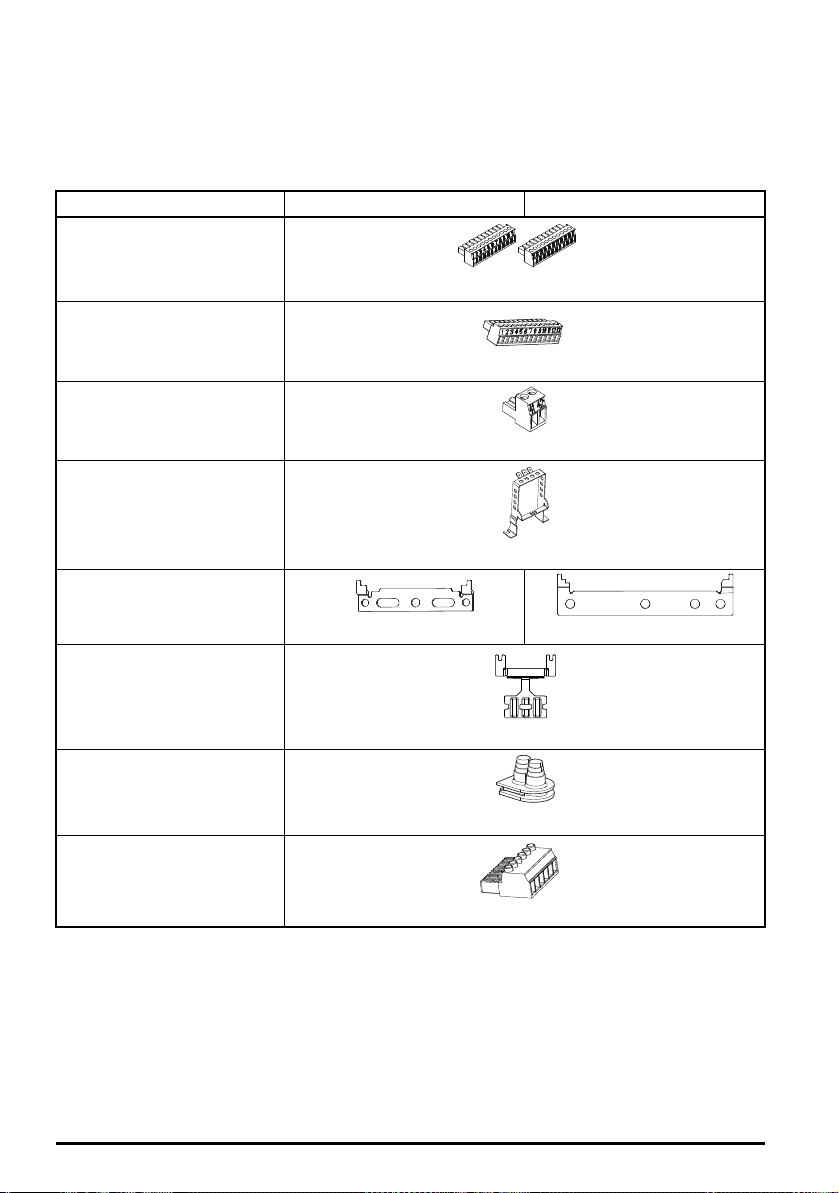

2.6 Items supplied with the drive

The drive is supplied with a copy of the Power Installation Guide and a copy of the Control Getting

Started Guide, a safety information booklet, the Certificate of Quality and an accessory kit box

including the items shown in Table 2-5.

Table 2-5 Parts supplied with the drive

Description Size 3 Size 4

Control connectors

(1 to 11 way and 21 to 31 way)

x 1* x 1*

Control connectors (1 to 13)

x 1**

Relay connector

x 1

Grounding bracket

x 1

Surface mounting brackets

x 2 x 2

Grounding clamp

x 1

DC terminal cover grommets

x 2

Supply and motor connector

x 1

* Supplied with Unidrive M600 / M700 / M701and HS70 / 71 only.

** Supplied with Unidrive M702 and HS72 only.

16

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 17

3 Mechanical installation

WARNING

WARNING

WARNING

WARNING

3.1 Safety information

Follow the instructions

The mechanical and electrical installation instructions must be adhered to. Any questions

or doubt should be referred to the supplier of the equipment. It is the responsibility of the

owner or user to ensure that the installation of the drive and any external option unit, and

the way in which they are operated and maintained, comply with the requirements of the

Health and Safety at Work Act in the United Kingdom or applicable legislation and

regulations and codes of practice in the country in which the equipment is used.

Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the

AC supply has been disconnected. If the drive has been energized, the AC supply must

be isolated at least ten minutes before work may continue.

Normally, the capacitors are discharged by an internal resistor. Under certain, unusual

fault conditions, it is possible that the capacitors may fail to discharge, or be prevented

from being discharged by a voltage applied to the output terminals. If the drive has failed

in a manner that causes the display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Emerson Industrial Automation or their

authorized distributor.

Competence of the installer

The drive must be installed by professional assemblers who are familiar with the

requirements for safety and EMC. The assembler is responsible for ensuring that the end

product or system complies with all the relevant laws in the country where it is to be used.

Enclosure

The drive is intended to be mounted in an enclosure which prevents access except by

trained and authorized personnel, and which prevents the ingress of contamination. It is

designed for use in an environment classified as pollution degree 2 in accordance with IEC

60664-1. This means that only dry, non-conducting contamination is acceptable.

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

17

Page 18

3.2 Planning the installation

NOTE

The following considerations must be made when planning the installation:

3.2.1 Access

Access must be restricted to authorized personnel only. Safety regulations which apply at the place

of use must be complied with.

The IP (Ingress Protection) rating of the drive is installation dependent. For further information, refer

to section 3.8

3.2.2 Environmental protection

The drive must be protected from:

• Moisture, including dripping water or spraying water and condensation. An anti-condensation

heater may be required, which must be switched off when the drive is running.

• Contamination with electrically conductive material

• Contamination with any form of dust which may restrict the fan, or impair airflow over various

components

• Temperature beyond the specified operating and storage ranges

• Corrosive gasses

3.2.3 Cooling

The heat produced by the drive must be removed without its specified operating temperature being

exceeded. Note that a sealed enclosure gives much reduced cooling compared with a ventilated one,

and may need to be larger and/or use internal air circulating fans.

For further information, refer to section 3.5

3.2.4 Electrical safety

The installation must be safe under normal and fault conditions. Electrical installation instructions are

given in Chapter 4

3.2.5 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must be provided.

For installation in the USA, a NEMA 12 enclosure is suitable.

For installation outside the USA, the following (based on IEC 62109-1, standard for PV inverters) is

recommended.

Enclosure can be metal and/or polymeric, polymer must meet requirements which can be

summarized for larger enclosures as using materials meeting at least UL 94 class 5VB at the point of

minimum thickness.

Air filter assemblies to be at least class V-2.

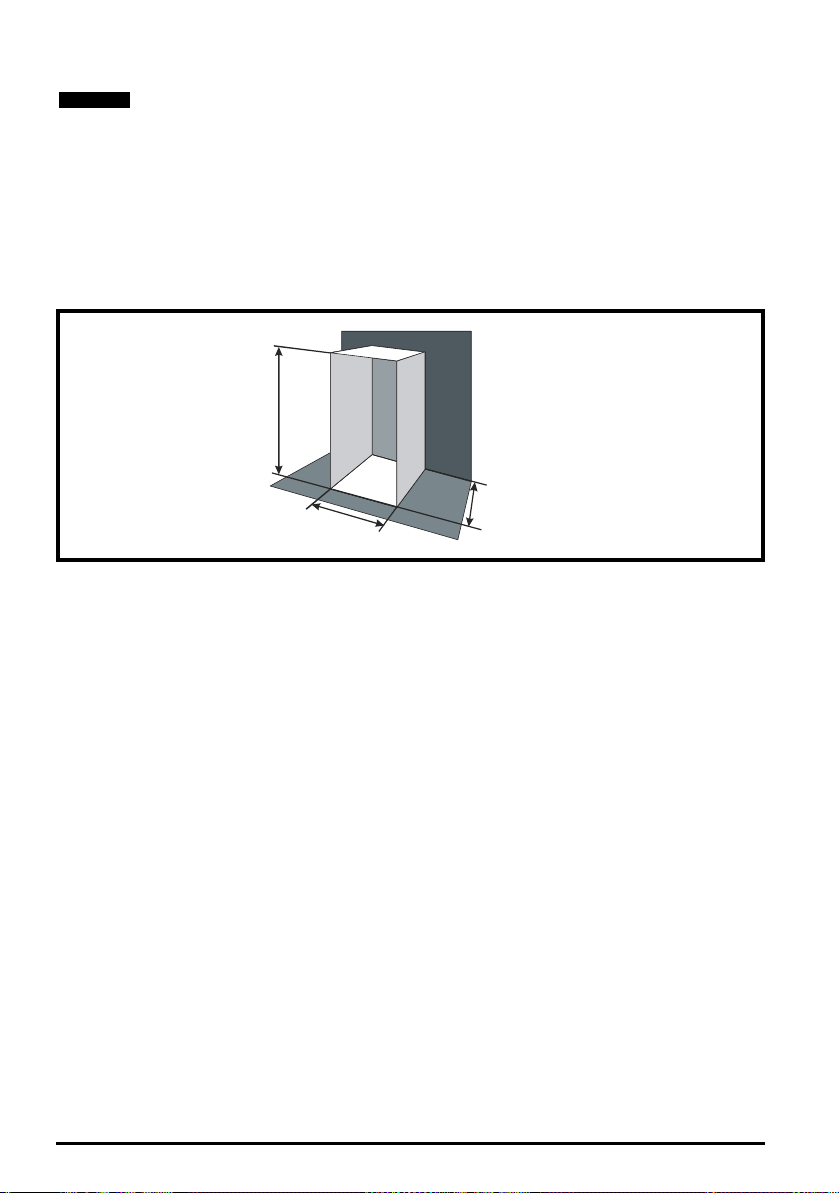

The location and size of the bottom shall cover the area shown in Figure 3-1. Any part of the side

which is within the area traced out by the 5° angle is also considered to be part of the bottom of the

fire enclosure.

Enclosing standard drive for high environmental protection

During installation it is recommended that the vents on the drive are covered to prevent

debris (e.g. wire off-cuts) from entering the drive.

Enclosure for standard drives

Electrical installation on page 45

.

on page 32.

on page 27.

18

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 19

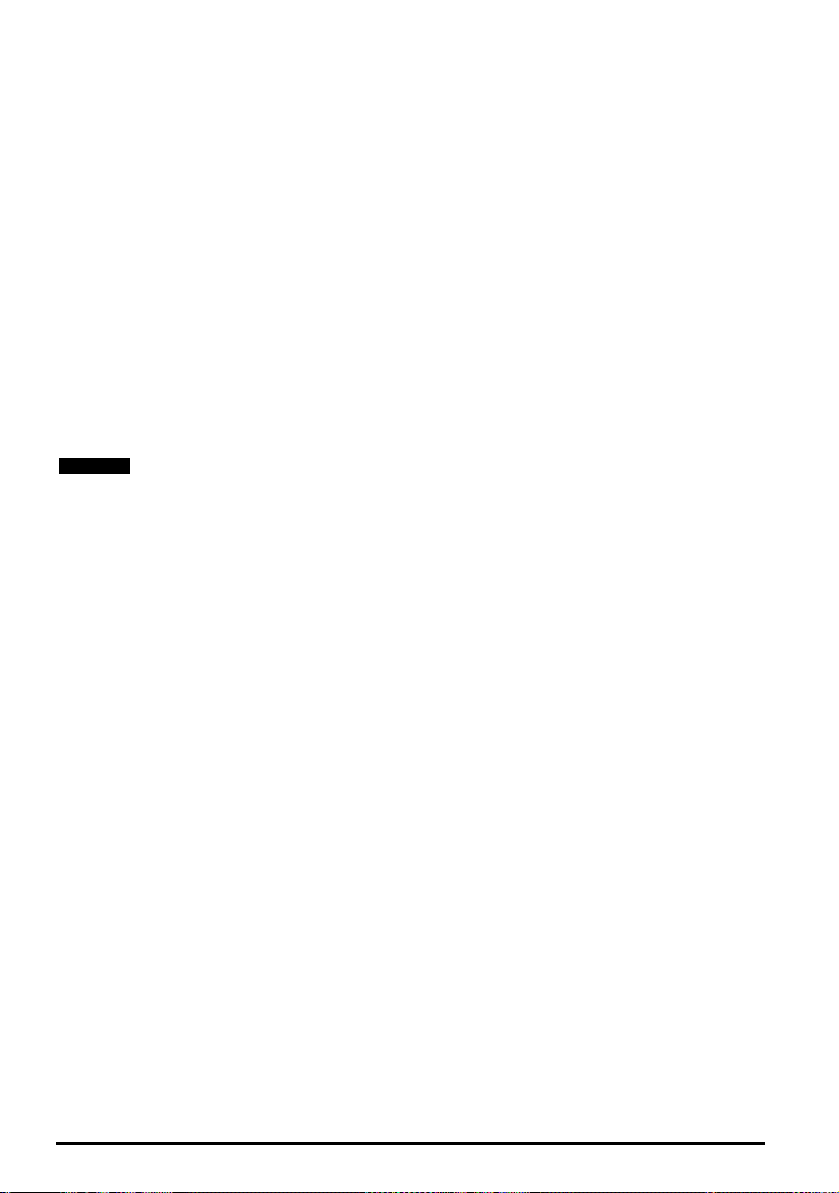

Figure 3-1 Fire enclosure bottom layout

Drive

5

o

5

o

N o t le s s

t ha n 2 X

B a ff le p la te s ( m a y b e

a b ov e o r b e lo w b o tt o m

o f e n cl o su r e)

X

B o tt o m o f f ir e

e n cl os u re

Not less

than 2

times ‘X’

Baffle plates (may be above or

below bottom of enclosure)

Bottom of fire enclosure

X

The bottom, including the part of the side considered to be part of the bottom, must be designed to

prevent escape of burning material - either by having no openings or by having a baffle construction.

This means that openings for cables etc. must be sealed with materials meeting the 5VB

requirement, or else have a baffle above. See Figure 3-2 for acceptable baffle construction. This

does not apply for mounting in an enclosed electrical operating area (restricted access) with concrete

floor.

Figure 3-2 Fire enclosure baffle construction

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

3.2.6 Electromagnetic compatibility

Variable speed drives are powerful electronic circuits which can cause electromagnetic interference if

not installed correctly with careful attention to the layout of the wiring.

Some simple routine precautions can prevent disturbance to typical industrial control equipment.

If it is necessary to meet strict emission limits, or if it is known that electromagnetically sensitive

equipment is located nearby, then full precautions must be observed. In-built into the drive, is an

internal EMC filter, which reduces emissions under certain conditions. If these conditions are

exceeded, then the use of an external EMC filter may be required at the drive inputs, which must be

located very close to the drives. Space must be made available for the filters and allowance made for

carefully segregated wiring. Both levels of precautions are covered in section 4.12

(Electromagnetic compatibility) on page 63

.

EMC

3.2.7 Hazardous areas

The drive must not be located in a classified hazardous area unless it is installed in an approved

enclosure and the installation is certified.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

19

Page 20

3.3 Terminal cover removal

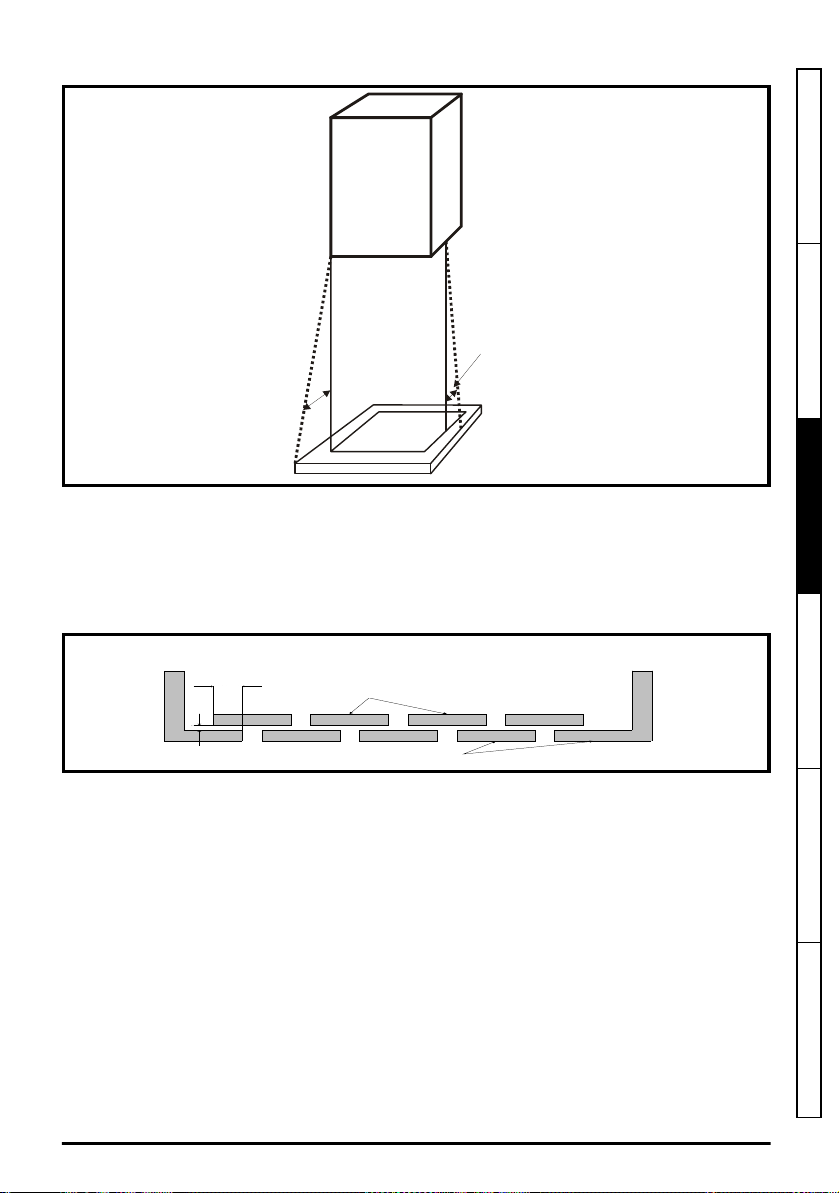

WARNING

WARNING

3

DC/Braking

terminalcover

Control/ AC/

Motorterminalcover

4

Control/ AC/

Motorterminalcover

DC/Braking

terminalcover

Isolation device

The AC and / or DC power supply must be disconnected from the drive using an approved

isolation device before any cover is removed from the drive or before any servicing work

is performed.

Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the

AC and / or DC power supply has been disconnected. If the drive has been energized,

the power supply must be isolated at least ten minutes before work may continue.

Normally, the capacitors are discharged by an internal resistor. Under certain, unusual

fault conditions, it is possible that the capacitors may fail to discharge, or be prevented

from being discharged by a voltage applied to the output terminals. If the drive has failed

in a manner that causes the display to go blank immediately, it is possible the capacitors

will not be discharged. In this case, consult Emerson Industrial Automation or their

authorized distributor.

3.3.1 Removing the terminal covers

Figure 3-3 Location and identification of terminal covers (size 3 to 4)

20

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 21

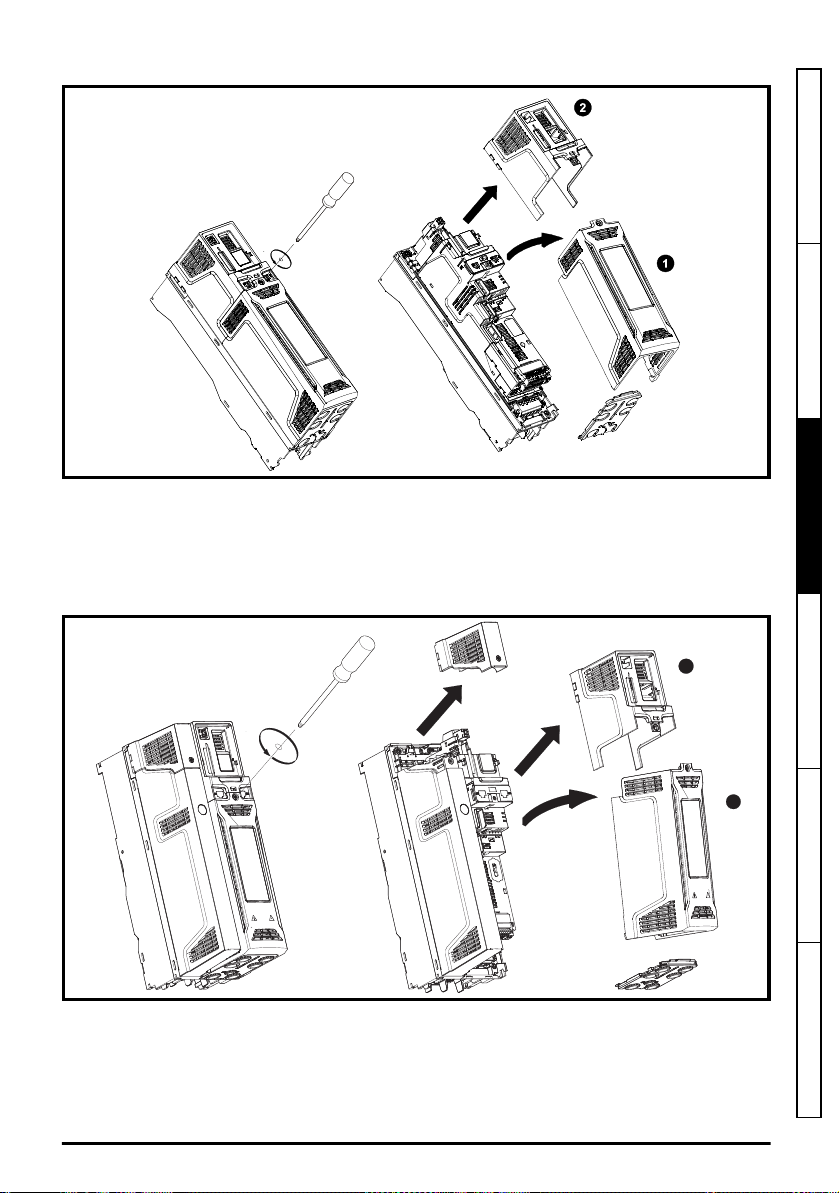

Figure 3-4 Removing the size 3 terminal covers

1

2

1. Control / AC / Motor terminal cover

2. DC / Braking terminal cover

The Control / AC / Motor terminal cover must be removed before removal of the DC / Braking

terminal cover. When replacing the terminal covers, the screws should be tightened to a maximum

torque of 1 N m (0.7 lb ft).

Figure 3-5 Removing the size 4 terminal covers

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

1. Control / AC / Motor terminal cover

2. DC / Braking terminal cover

The Control / AC / Motor terminal cover must be removed before removal of the DC / Braking

terminal cover. When replacing the terminal covers, the screws should be tightened to a maximum

torque of 1 N m (0.7 lb ft).

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

21

Page 22

3.3.2 Removing the finger-guard and DC terminal cover break-outs

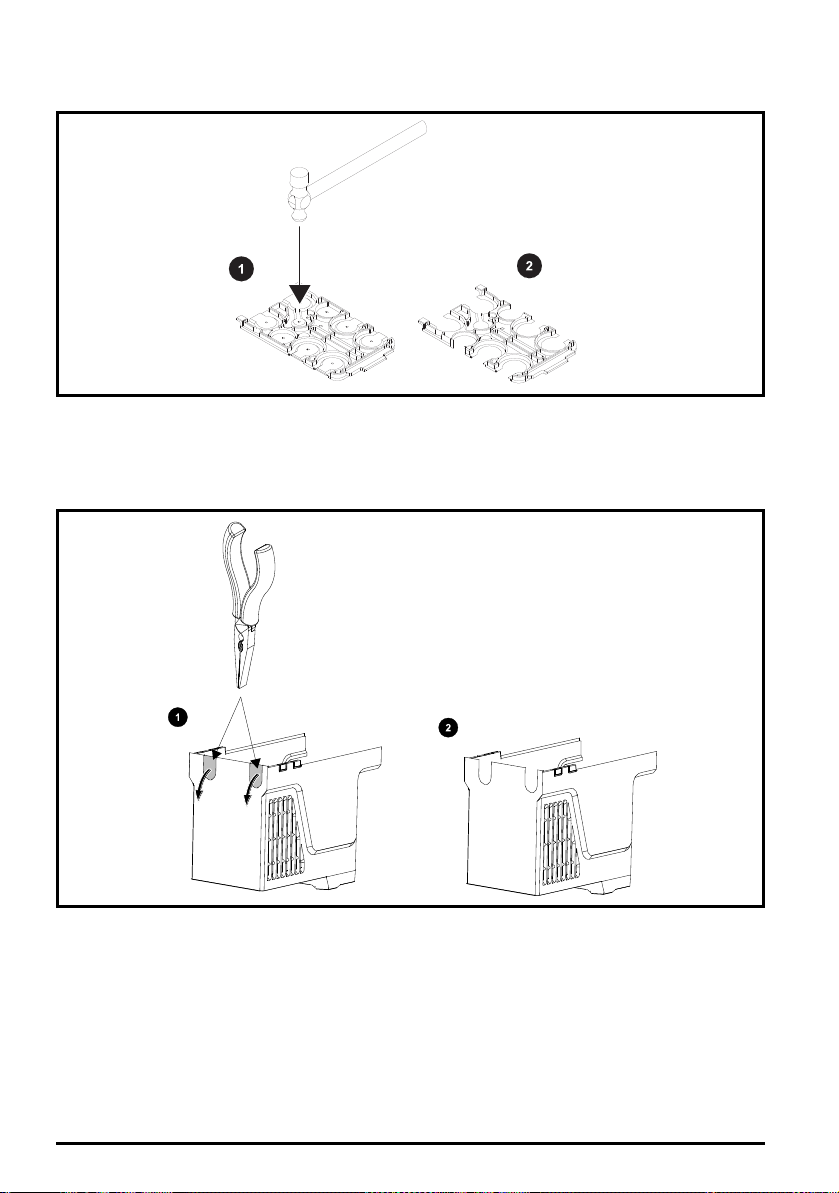

Figure 3-6 Removing the finger-guard break-outs

Place finger-guard on a flat solid surface and hit relevant break-outs with hammer as shown (1).

Continue until all required break-outs are removed (2). Remove any flash / sharp edges once the

break-outs are removed.

Figure 3-7 Removing the size 3 and 4 DC terminal cover break-outs

Grasp the DC terminal cover break-outs with pliers as shown (1) and pull down in the direction shown

to remove. Continue until all required break-outs are removed (2). Remove any flash / sharp edges

once the break-outs are removed. Use the DC terminal cover grommets supplied in the accessory

box (Table 2-5

22

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Parts supplied with the drive

on page 16) to maintain the seal at the top of the drive.

Issue Number: 3

Page 23

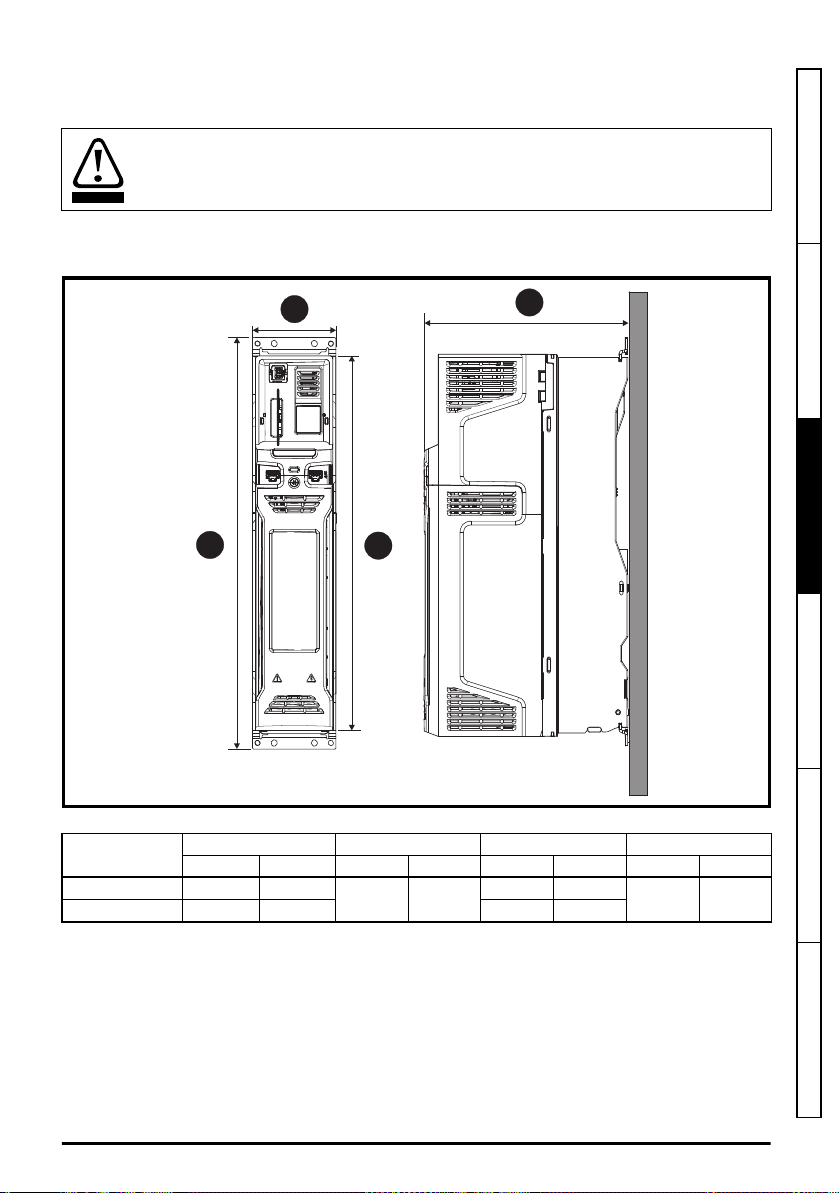

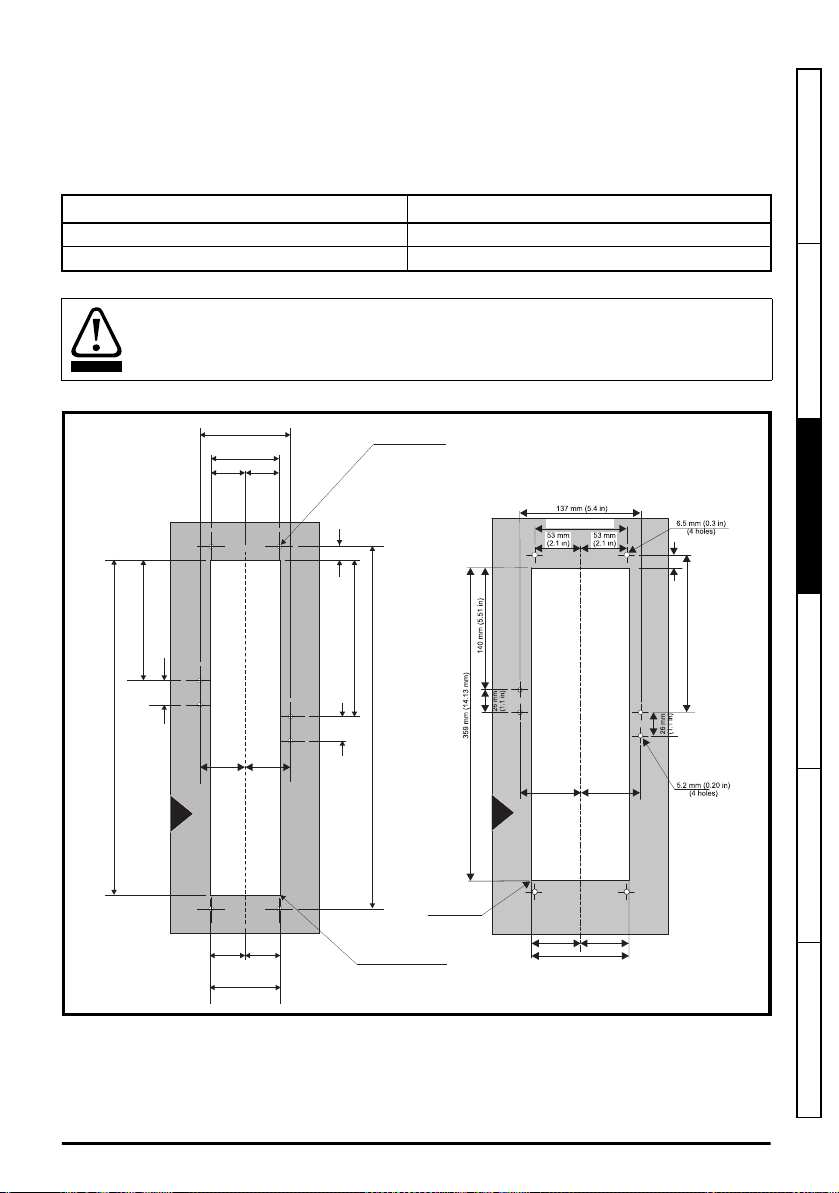

3.4 Dimensions and mounting methods

WARNING

H

H1

H2

W

D

Drive sizes 3 and 4 can be surface, through-panel or tile mounted using the appropriate brackets.

If the drive has been used at high load levels for a period of time, the heatsink can reach

temperatures in excess of 70 °C (158 °F). Human contact with the heatsink should be

prevented.

3.4.1 Drive dimensions

Figure 3-8 Drive dimensions (size 3 illustrated)

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Size

H1 H2 W D

mm in mm in mm in mm in

3 382 15.04

4 391 15.39 124 4.88

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

365 14.37

83 3.27

200 7.87

23

Page 24

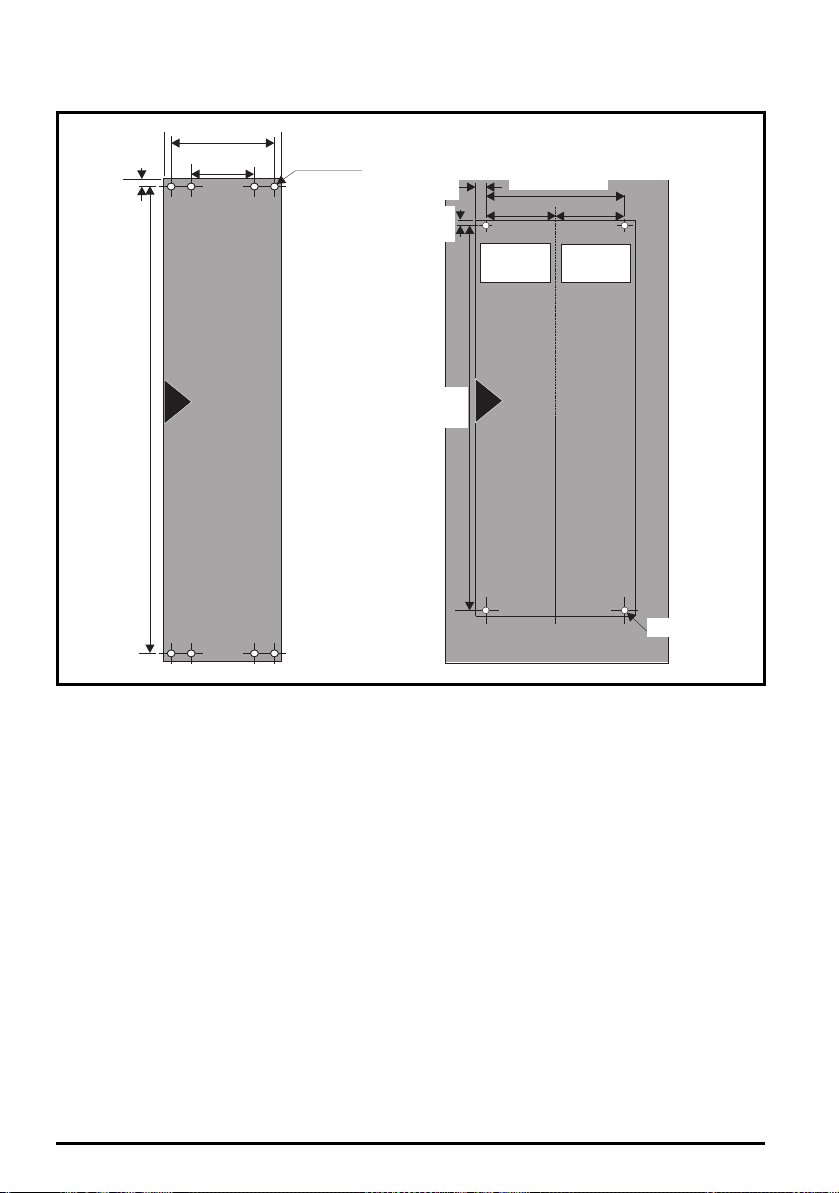

3.4.2 Surface mounting

6.0mm

(0.24in)

73.0mm(2.87in)

Æ

5.5mm

(0.22in)

370mm

(14.57in)

3

375mm

(14.76in)

8mm

(0.32in)

4

Æ

6.5mm

(0.26in)

x4holes

9mm

(0.35in)

53mm

(2.09in)

53mm

(2.09in)

106mm

(4.17in)

40mm

(1.58in)

Figure 3-9 Surface mounting dimensions

Surface mounting size 3

Each mounting bracket contains 5 mounting slots / holes, the outer holes (5.2 mm) x 2 should be

used for mounting the drive to the backplate as this allows the heatsink fan to be replaced without

removing the drive from the backplate. The inner slots / holes (6.2 mm) x 3 are used for Unidrive SP

size 1 retrofit applications.

Surface mounting size 4

The outer holes in the mounting bracket (6.5 mm) x 2 are to be used for surface mounting.

24

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 25

3.4.3 Through-panel mounting

WARNING

4

17mm

(0.67in)

68.5mm

(2.70in)

68.5mm

(2.70in)

117mm(4.61in)

168mm(6.61in)

58.5mm

(2.30in)

58.5mm

(2.30in)

4

106mm(4.17in)

97mm(3.82in)

36.5mm

(1.44in)

Æ5.20mm(0.21in)

x8holes

73mm(2.87in)

36.5mm

(1.44in)

15mm

(0.59in)

129mm(5.08in)

26mm(1.02in)

168mm(6.61in)

360mm(14.17in)

389mm(15.32in)

26mm(1.02in)

Radius1.0mm(0.04in)

38mm

(1.50in)

38mm

(1.50in)

76mm(2.99in)

3

48.5mm

(1.91in)

48.5mm

(1.91in)

Radius1.0mm

(0.04in)

The drive can be through-panel mounted using the appropriate brackets, see section 3.8

standard drive for high environmental protection

on page 32 for further details.

The through-panel mounting kit is not supplied with the drive and can be purchased separately,

below are the relevant part numbers:

Size CT part number

3 3470-0053

4 3470-0056

If the drive has been used at high load levels for a period of time, the heatsink can reach

temperatures in excess of 70 °C (158 °F). Human contact with the heatsink should be

prevented.

Figure 3-10 Through-panel mounting dimensions

Enclosing

Safety information Product information

Mechanical installation

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Electrical installation Technical data UL listing information

25

Page 26

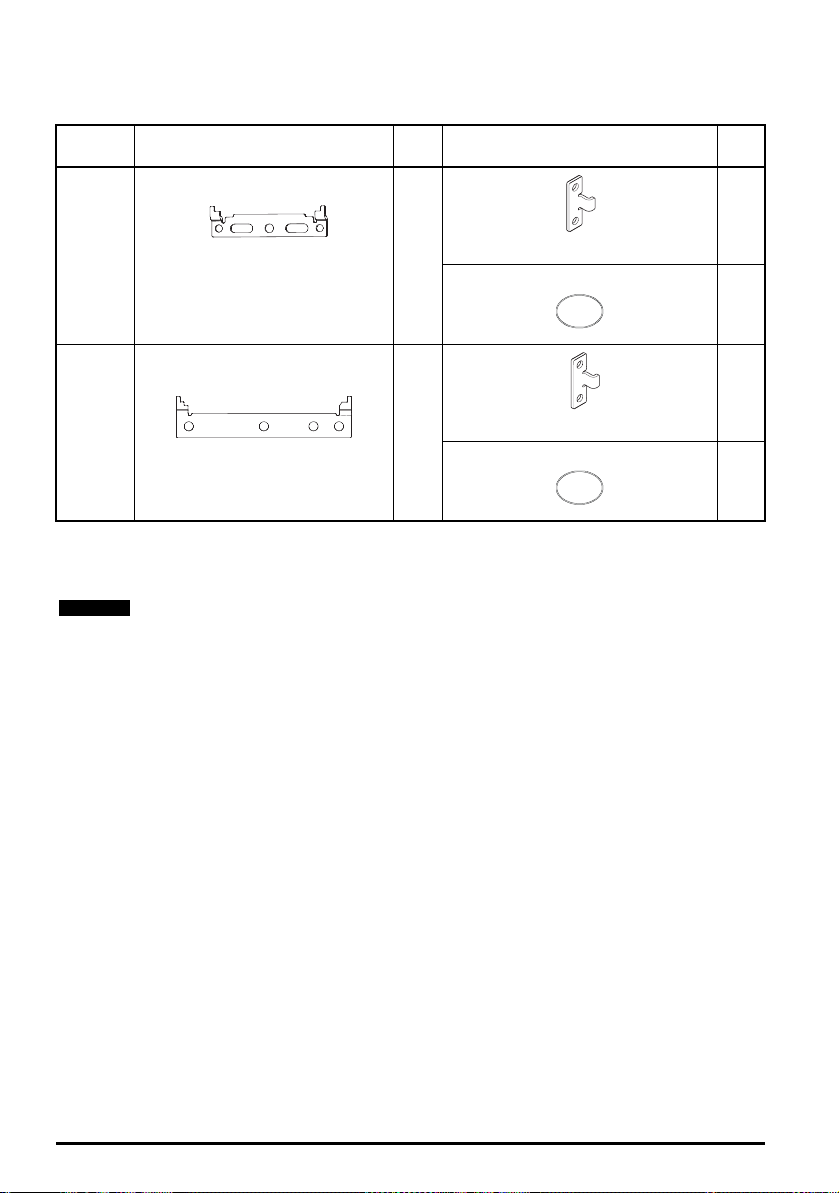

3.4.4 Mounting brackets

NOTE

Table 3-1 Mounting brackets

Frame

size

Surface Qty Through-panel* Qty

x 2

3

Outer hole size: 5.2 mm (0.20 in)

Centre hole / slot size: 6.2 mm (0.24 in)

4

Hole size: 6.5 mm (0.26 in)

x 2

x 2

Hole size: 5.2 mm (0.21 in)

Hole size: 5.2 mm (0.21 in)

* A gasket is supplied in the through-panel mounting kit, see section 3.8

high environmental protection

on page 32 for further details.

A retrofit kit is available for Unidrive M/HS size 4 that allows mounting of the drive in

applications previously using Unidrive SP size 2, the part number of this kit is 3470-0062.

A similar kit is not necessary for Unidrive M/HS size 3 because it has the same mounting

hole positions as Unidrive SP size 1.

x 1

x 2

x 1

Enclosing standard drive for

26

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 27

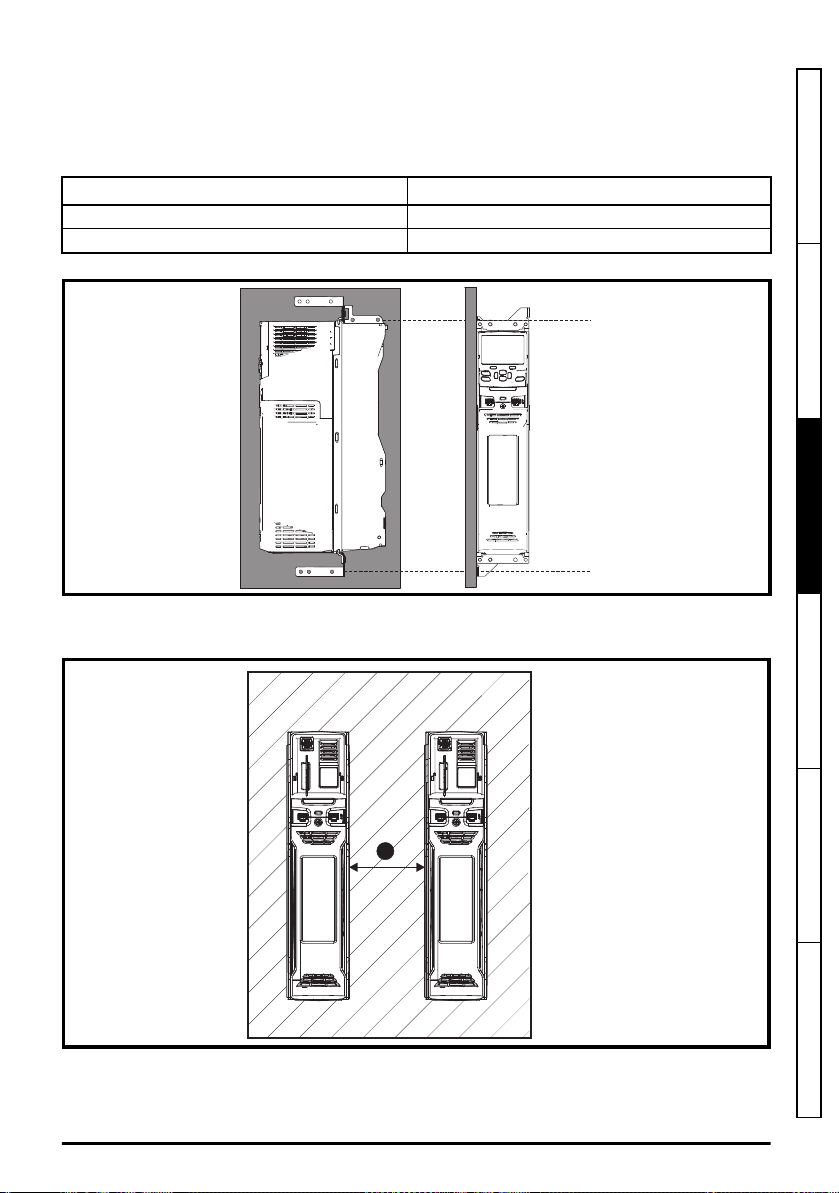

3.4.5 Tile mounting

Enclosure

A

Drive sizes 3 to 4 can be tile mounted where limited mounting space is available. The drive is

mounted sideways with the side panel against the mounting surface as shown in Figure 3-11. The tile

mounting kit is not supplied with the drive, it can be purchased separately using the following part

numbers:

Size CT part number

3 3470-0049

4 3470-0060

Figure 3-11 Tile mounting

Safety information Product information

Mechanical installation

3.5 Enclosure for standard drives

Figure 3-12 Recommended spacing between the drives

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Electrical installation Technical data UL listing information

27

Page 28

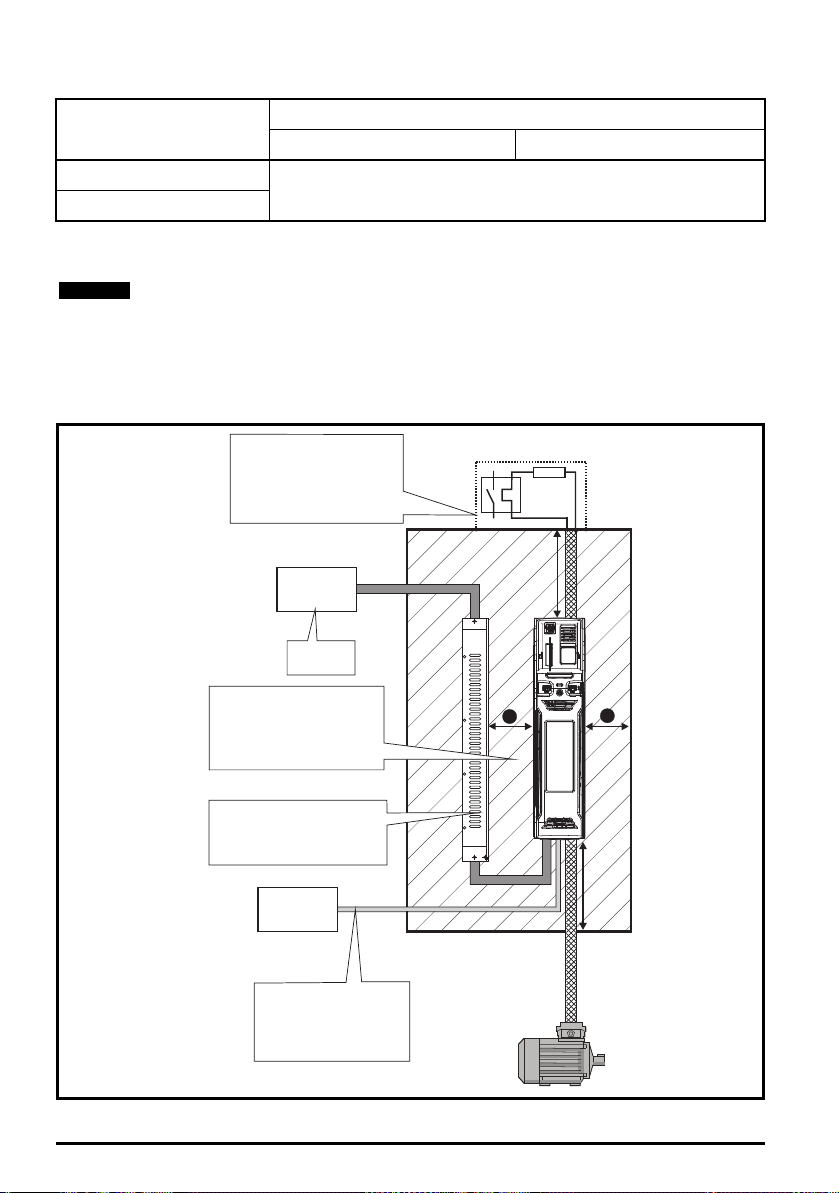

Table 3-2

NOTE

³100mm

(4in)

Enclosure

ACsupply

contactorand

fusesorMCB

Locateas

required

External

controller

Signalcables

Planforallsignalcables

toberoutedatleast

300mm(12in)fromthe

driveandanypowercable

Ensureminimumclearances

aremaintainedforthedrive

andexternalEMCfilter.Forced

orconvectionair-flowmustnot

berestrictedbyanyobjector

cabling

³100mm

(4in)

Optionalbrakingresistorandoverload

Locateas

Locateoptionalbraking

resistorexternalto

cubicle(preferablyneartoor

ontopofthecubicle).

Locatetheoverloadprotection

deviceasrequired

TheexternalEMCfiltercanbe

bookcasemounted(nexttothe

drive)orfootprintmounted(with

thedrivemountedontothefilter).

B

B

* 50 °C derating applies, refer to Table 5-5

(122 °F)

Spacing required between the drives (without high IP insert)

Drive Size

3

4

40°C 50°C*

Spacing (A)

0 mm (0.00 in)

Maximum permissible continuous output current @ 50 °C

on page 79.

When through-panel mounted, ideally drives should be spaced 30 mm (1.18 in) to

maximize panel stiffness.

3.5.1 Enclosure layout

Please observe the clearances in the diagram below taking into account any appropriate notes for

other devices / auxiliary equipment when planning the installation.

Figure 3-13 Enclosure layout

28

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 29

Table 3-3 Spacing required between drive / enclosure and drive / EMC filter

NOTE

A

e

P

k T

in tTex t

–( )

-----------------------------------

=

Drive Size Spacing (B)

3 0 mm (0.00 in)

4 30 mm (1.18 in)

For EMC compliance:

1. When using an external EMC filter, one filter is required for each drive.

2. Power cabling must be at least 100 mm (4 in) from the drive in all directions

3.5.2 Enclosure sizing

1. Add the dissipation figures from section 5.1.3

to be installed in the enclosure.

2. If an external EMC filter is to be used with each drive, add the dissipation figures from section

5.2.1

EMC filter ratings

on page 96 for each external EMC filter that is to be installed in the

enclosure.

3. If the braking resistor is to be mounted inside the enclosure, add the average power figures from

for each braking resistor that is to be installed in the enclosure.

4. Calculate the total heat dissipation (in Watts) of any other equipment to be installed in the

enclosure.

5. Add the heat dissipation figures obtained above. This gives a figure in Watts for the total heat that

will be dissipated inside the enclosure.

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding air by natural convection (or

external forced air flow); the greater the surface area of the enclosure walls, the better is the

dissipation capability. Only the surfaces of the enclosure that are unobstructed (not in contact with a

wall or floor) can dissipate heat.

Calculate the minimum required unobstructed surface area

Power dissipation

Ae for the enclosure from:

on page 80 for each drive that is

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Where:

A

Unobstructed surface area in m2 (1 m2 = 10.9 ft2)

e

T

Maximum expected temperature in

ext

T

Maximum permissible temperature in oC

int

P

Power in Watts dissipated by

k

Heat transmission coefficient of the enclosure material in W/m2/oC

o

C

outside

all

heat sources in the enclosure

the enclosure

inside

the enclosure

Example

To calculate the size of an enclosure for the following:

• Two drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40 °C

• Maximum ambient temperature outside the enclosure: 30 °C

For example, if the power dissipation from each drive is 187 W and the power dissipation from each

external EMC filter is 9.2 W.

Total dissipation: 2 x (187 + 9.2) =392.4 W

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

29

Page 30

Power dissipation for the drives and the external EMC filters can be obtained from

NOTE

W

H

D

A

e

392.4

5.5 40 30–( )

---------------------------------

=

W

Ae2H D–

H D+

--------------------------

=

W

7.135 2 2× 0.6×( )–

2 0.6+

-----------------------------------------------------

=

Chapter 5

Technical data

on page 76.

The enclosure is to be made from painted 2 mm (0.079 in) sheet steel having a heat

transmission coefficient of 5.5 W/m2/oC. Only the top, front, and two sides of the

enclosure are free to dissipate heat.

The value of 5.5 W/m2/ºC can generally be used with a sheet steel enclosure (exact

values can be obtained by the supplier of the material). If in any doubt, allow for a greater

margin in the temperature rise.

Figure 3-14 Enclosure having front, sides and top panels free to dissipate heat

Insert the following values:

T

40 °C

int

T

30 °C

ext

k

5.5

P

392.4 W

The minimum required heat conducting area is then:

= 7.135 m2 (77.8 ft2)

(1 m2 = 10.9 ft2)

Estimate two of the enclosure dimensions - the height (H) and depth (D), for instance. Calculate the

width (W) from:

Inserting H = 2m and D = 0.6 m, obtain the minimum width:

=1.821 m (71.7 in)

If the enclosure is too large for the space available, it can be made smaller only by attending to one

or all of the following:

• Using a lower PWM switching frequency to reduce the dissipation in the drives

• Reducing the ambient temperature outside the enclosure, and/or applying forced-air cooling to

the outside of the enclosure

• Reducing the number of drives in the enclosure

• Removing other heat-generating equipment

30

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 31

Calculating the air-flow in a ventilated enclosure

V

3k P

T

in tTex t

–

---------------------------

=

P

o

P

l

-------

V

3 1.3× 323.7×

40 30–

---------------------------------------

=

The dimensions of the enclosure are required only for accommodating the equipment. The

equipment is cooled by the forced air flow.

Calculate the minimum required volume of ventilating air from:

Where:

V

Air-flow in m3 per hour (1 m3/hr = 0.59 ft3/min)

T

Maximum expected temperature in °C outside

ext

T

Maximum permissible temperature in °C

int

P

Power in Watts dissipated by

k

Ratio of

all

heat sources in the enclosure

the enclosure

inside

the enclosure

Where:

P0 is the air pressure at sea level

PI is the air pressure at the installation

Typically use a factor of 1.2 to 1.3, to allow also for pressure-drops in dirty air-filters.

Example

To calculate the size of an enclosure for the following:

• Three drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40 °C

• Maximum ambient temperature outside the enclosure: 30 °C

For example, dissipation of each drive: 101 W and dissipation of each external EMC filter: 6.9 W

(max).

Total dissipation: 3 x (101 + 6.9) = 323.7 W

Insert the following values:

T

40 °C

int

T

30 °C

ext

k

1.3

P

323.7 W

Then:

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

=

126.2 m3/hr (74.5 ft3 /min)

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

(1 m3/ hr = 0.59 ft3/min)

31

Page 32

3.6 Enclosure design and drive ambient temperature

Drive derating is required for operation in high ambient temperatures

Totally enclosing or through panel mounting the drive in either a sealed cabinet (no airflow) or in a

well ventilated cabinet makes a significant difference on drive cooling.

The chosen method affects the ambient temperature value (T

) which should be used for any

rate

necessary derating to ensure sufficient cooling for the whole of the drive.

The ambient temperature for the four different combinations is defined below:

1. Totally enclosed with no air flow (<2 m/s) over the drive

T

= T

rate

+ 5 °C

int

2. Totally enclosed with air flow (>2 m/s) over the drive

T

= T

rate

int

3. Through panel mounted with no airflow (<2 m/s) over the drive

T

= the greater of T

rate

+5 °C, or T

ext

int

4. Through panel mounted with air flow (>2 m/s) over the drive

T

= the greater of T

rate

ext

or T

int

Where:

T

= Temperature outside the cabinet

ext

T

= Temperature inside the cabinet

int

T

= Temperature used to select current rating from tables in Chapter 5

rate

Technical data

on

page 76.

3.7 Heatsink fan operation

The drive is ventilated by an internal heatsink mounted fan. The fan housing forms a baffle plate,

channelling the air through the heatsink chamber. Thus, regardless of mounting method (surface

mounting or through-panel mounting), the installing of additional baffle plates is not required.

Ensure the minimum clearances around the drive are maintained to allow air to flow freely.

The heatsink fan on all sizes is a variable speed fan. The drive controls the speed at which the fan

runs based on the temperature of the heatsink and the drive's thermal model system. The maximum

speed at which the fan operates can be limited in Pr

derating. Refer to section 3.13.1

Fan removal procedure

06.045

. This could incur an output current

on page 44 for information on fan removal.

3.8 Enclosing standard drive for high environmental protection

An explanation of environmental protection rating is provided in section 5.1.10

page 85.

The standard drive is rated to IP20 pollution degree 2 (dry, non-conductive contamination only)

(NEMA 1). However, it is possible to configure the drive to achieve IP65 rating (sizes 3 to 4) (NEMA

12) at the rear of the heatsink for through-panel mounting (some current derating is required). Refer

to Chapter 5

Technical data

on page 76.

This allows the front of the drive, along with various switchgear, to be housed in a high IP enclosure

with the heatsink protruding through the panel to the external environment. Thus, the majority of the

heat generated by the drive is dissipated outside the enclosure maintaining a reduced temperature

inside the enclosure. This also relies on a good seal being made between the heatsink and the rear

of the enclosure using the gaskets provided.

32

Unidrive M/HS Frame 3 and 4 Power Installation Guide

IP / UL Rating

Issue Number: 3

on

Page 33

Figure 3-15 Example of IP65 (sizes 3 to 4) (NEMA 12) through-panel layout

IP20

(NEMA1)

IP65(sizes3to4)(NEMA 12)enclosure

Drivewith

highIP insert

installed

Gasket

seal

NOTE

Drive

Gasket

Enclosure

rearwall

Safety information Product information

The main gasket should be installed as shown in Figure 3-16.

On drive sizes 3 and 4, in order to achieve the high IP rating at the rear of the heatsink it is necessary

to seal a heatsink vent by installing the high IP insert as shown in Figure 3-18 and Figure 3-19 on

page 36.

The heatsink fans have conformal coated PCBs and have sealant at cable entry points.

This means that the electronics of the fan are rated to IP54. Dripping, splashing or sprayed

water can impede the operation of the fan, therefore if the environment is such that the fan

may be subjected to more than occasional dripping or sprayed water while operational,

then suitable drip protection covers should be employed.

Figure 3-16 Installing the gasket

To seal the space between the drive and the backplate, use two sealing brackets as shown in Figure

3-17.

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

33

Page 34

Figure 3-17 Through panel mounting

Throughpanel

securingbracket

Enclosure

rearwall

Throughpanel

securingbracket

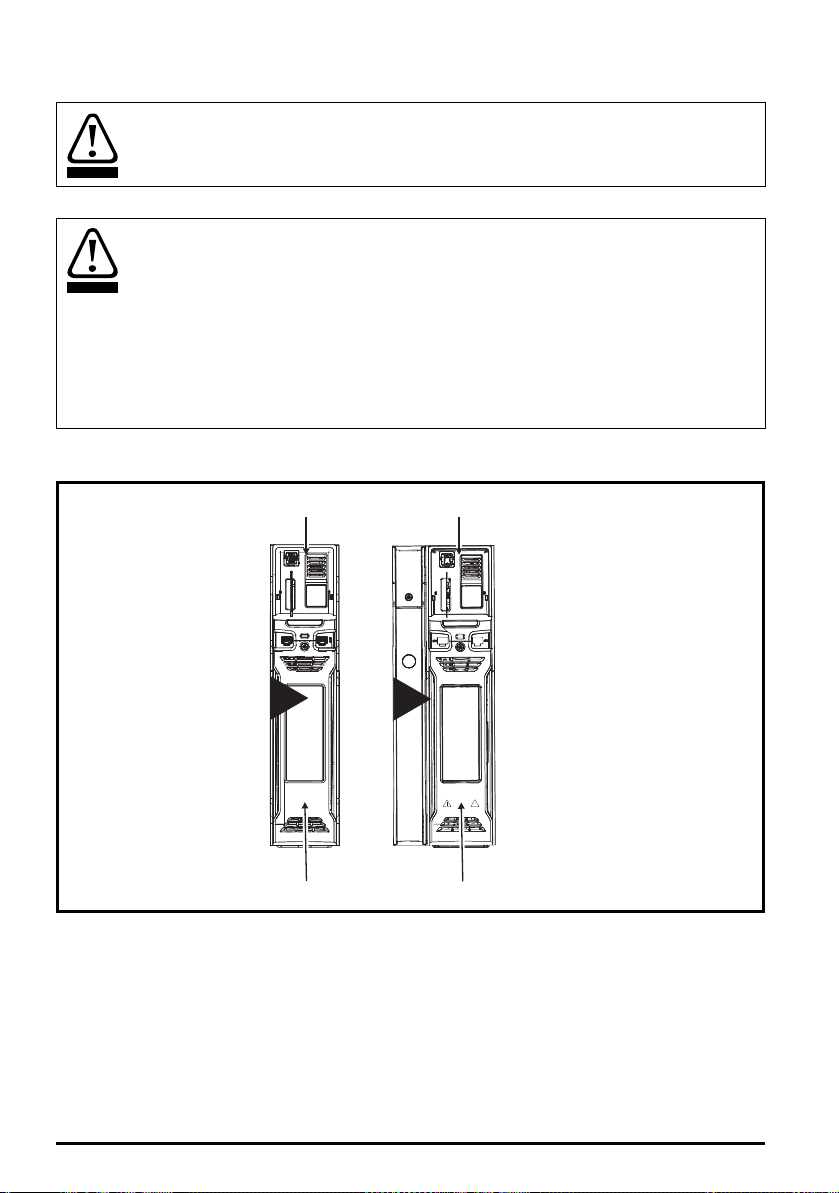

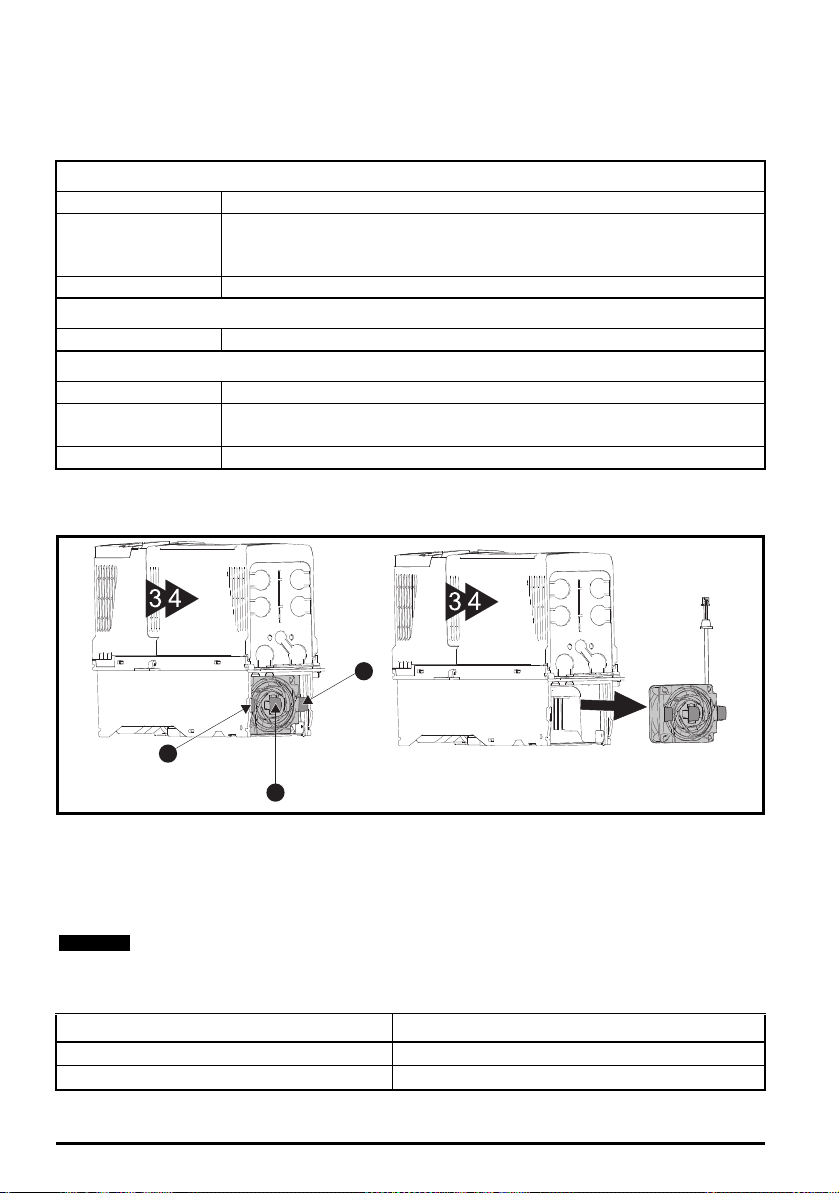

3.9 Installation of high IP insert for size 3 and 4

The standard drive is rated to IP20 pollution degree 2 (dry, non-conductive contamination only)

(NEMA 1). However, it is possible to configure the drive to achieve IP65 rating sizes 3 to 4 (NEMA

12) at the rear of the heatsink for through-panel mounting (some current derating is required).

On drive sizes 3 and 4, in order to achieve the high IP rating at the rear of the heatsink it is necessary

to seal a heatsink vent by installing the high IP insert as shown in Figure 3-18.

34

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 35

Figure 3-18 Installation of high IP insert for size 3

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

1. To install the high IP insert, firstly place a flat head screwdriver into the slots highlighted (1).

2. Pull the hinged baffle down to expose the ventilation hole, install the high IP insert into the

ventilation hole in the heatsink (2).

3. Ensure the high IP insert is securely installed by firmly pressing it into place (3).

4. Close the hinged baffle as shown (1).

5. To remove the high IP insert, reverse the above instructions.

The guidelines in Table 3-4 should be followed.

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

35

Page 36

Figure 3-19 Installation of high IP insert for size 4

1. To install the high IP insert, firstly place a flat head screwdriver into the slots highlighted (1).

2. Pull the hinged baffle up to expose the ventilation hole, install the high IP insert into the

ventilation hole in the heatsink (2).

3. Ensure the high IP insert is securely installed by firmly pressing it into place (3).

4. Close the hinged baffle as shown (1).

5. To remove the high IP insert, reverse the above instructions.

The guidelines in Table 3-4 should be followed.

36

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 37

Table 3-4 Environmental considerations

NOTE

NOTE

WARNING

Environment High IP insert Comments

Clean Not installed

Dry, dusty (non-conductive) Installed

IP65 compliance Installed

A current derating must be applied to the drive if the high IP insert is installed. Derating

information is provided in Chapter 5

Technical data

Failure to do so may result in nuisance tripping.

Safety information Product information

Regular cleaning recommendedDry, dusty (conductive) Installed

on page 76

When designing an IP65 (NEMA 12) enclosure (Figure 3-15

4) (NEMA 12) through-panel layout

on page 33), consideration should be made to the

Example of IP65 (sizes 3 to

dissipation from the front of the drive.

Table 3-5 Power losses from the front of the drive when through-panel mounted

Frame size Power loss

3

4

≤

≤

50 W

75 W

3.10 Size 3 and 4 internal braking resistor

Size 3 and 4 have been designed with an optional space-saving heatsink mounted resistor. The

resistor can be installed within the heatsink fins of the drive. When the heatsink resistor is used, an

external thermal protection device is not required as the resistor is designed such that it will fail safely

under any fault conditions. The in-built software overload protection is set-up at default to protect the

resistor. The resistor is rated to IP54 (NEMA 12).

Table 3-6 Size 3 and 4 internal braking resistor part numbers

Frame size Part number

3 1220-2752

4 1299-0003

The internal / heatsink mounted braking resistors must only be used with the following

drives. Brake resistor 1220-2752 must only be used with size 3 drives. Brake resistor

1299-0003 must only be used with size 4 drives.

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

37

Page 38

3.10.1 Internal braking resistor installation instructions

Brake resistor bung

1

Figure 3-20 Brake resistor installation on size 3

• Remove the terminal covers.

• Remove the internal EMC filter as shown in Figure 4-11

filter

• Remove the brake resistor bung (1) from the hole in the chassis, the closed end of the bung will

• Feed brake resistor bung onto outer insulation of brake resistor cable. The wider end of the bung

• Install the braking resistor to the heatsink using the captive screws. The screws should be tighten

• Route the cables through the provided hole at the rear of the heatsink as shown in Figure 3-20

• Crimp the cable ends and make appropriate connections. The brake terminals must be tightened

• Replace the terminal covers on the drive, tighten to a maximum torque of 1 N m (0.7 lb ft).

on page 66.

need to be pierced so that the cable has access to be routed through.

should be inserted first. The Narrow end should align with end of insulation.

to a maximum torque of 2 N m (1.5 lb ft).

and take the cable out from the front side of the drive. Ensure the cables are routed between the

fins of the heatsink, and the cables are not trapped between the heatsink fins and the resistor.

to a maximum torque of 2 N m (1.5 Ib ft).

Removal of the size 3 internal EMC

38

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 39

Figure 3-21 Brake resistor installation on size 4

Brake resistor bung

1

• Remove the terminal covers.

• Remove the brake resistor bung from the hole (1) in the chassis, the closed end of the bung will

need to be pierced so that the cable has access to be routed through.

• Feed brake resistor bung onto outer insulation of brake resistor cable. The wider end of the bung

should be inserted first. The Narrow end should align with end of insulation.

• Install the braking resistor to the heatsink using the captive screws. The screws should be tighten

to a maximum torque of 2 N m (1.5 lb ft).

• Route the cables through the provided hole at the rear of the heatsink as shown in Figure 3-21

and take the cable out from the front side of the drive. Ensure the cables are routed between the

fins of the heatsink, and the cables are not trapped between the heatsink fins and the resistor.

• Crimp the cable ends and make appropriate connections. The brake terminals must be tightened

to a maximum torque of 2 N m (1.5 Ib ft).

• Replace the terminal covers on the drive, tighten to a maximum torque of 1 N m (0.7 lb ft).

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

39

Page 40

3.10.2 External brake resistor

1

2

118mm(4.65in)

15.5mm

(0.61in)

Æ 4.5mm(0.18in)

x2holes

1.5mm

(0.06in)

30.5mm

(1.20in)

80mm(3.15in)

130mm(5.12in)

Æ 4.5x6mm(0.18in)

x2holes

R=1.5mm

(0.06)

External brake resistors are available from Emerson Industrial Automation for drive sizes 3 to 4. They

can be mounted in the enclosure as per mounting recommendation in Figure 3-13

layout

on page 28 using mounting bracket part number 6541-0187 (shown in Figure 3-23). Figure 322 below shows the brake resistor mounted on the mounting bracket. Two M4 screws and nuts (2)

can be used to fix the brake resistor to the mounting bracket. One M4 nut with washer (1) is provided

to use for the ground connection. The brake resistor is equipped with a thermal switch, the thermal

switch should be integrated in the control circuit by the user.

Figure 3-22 Brake resistor with the mounting bracket

1. Ground connection (1 x M4 nut and washer).

2. Attaching the brake resistor to the mounting bracket (using 2 x M4 screws and nuts).

Figure 3-23 Mounting bracket dimensions

Enclosure

40

Unidrive M/HS Frame 3 and 4 Power Installation Guide

Issue Number: 3

Page 41

Figure 3-24 Brake resistor dimensions

60mm(2.36in)

68mm(2.68in)

118mm(4.65in)

130mm(5.12in)

Æ 4.5mm(0.18in)

x4holes

15mm

(0.59in)

3.11 External EMC filter

The external EMC filter for size 3 and 4 drives can be footprint mounted or bookcase mounted as