Page 1

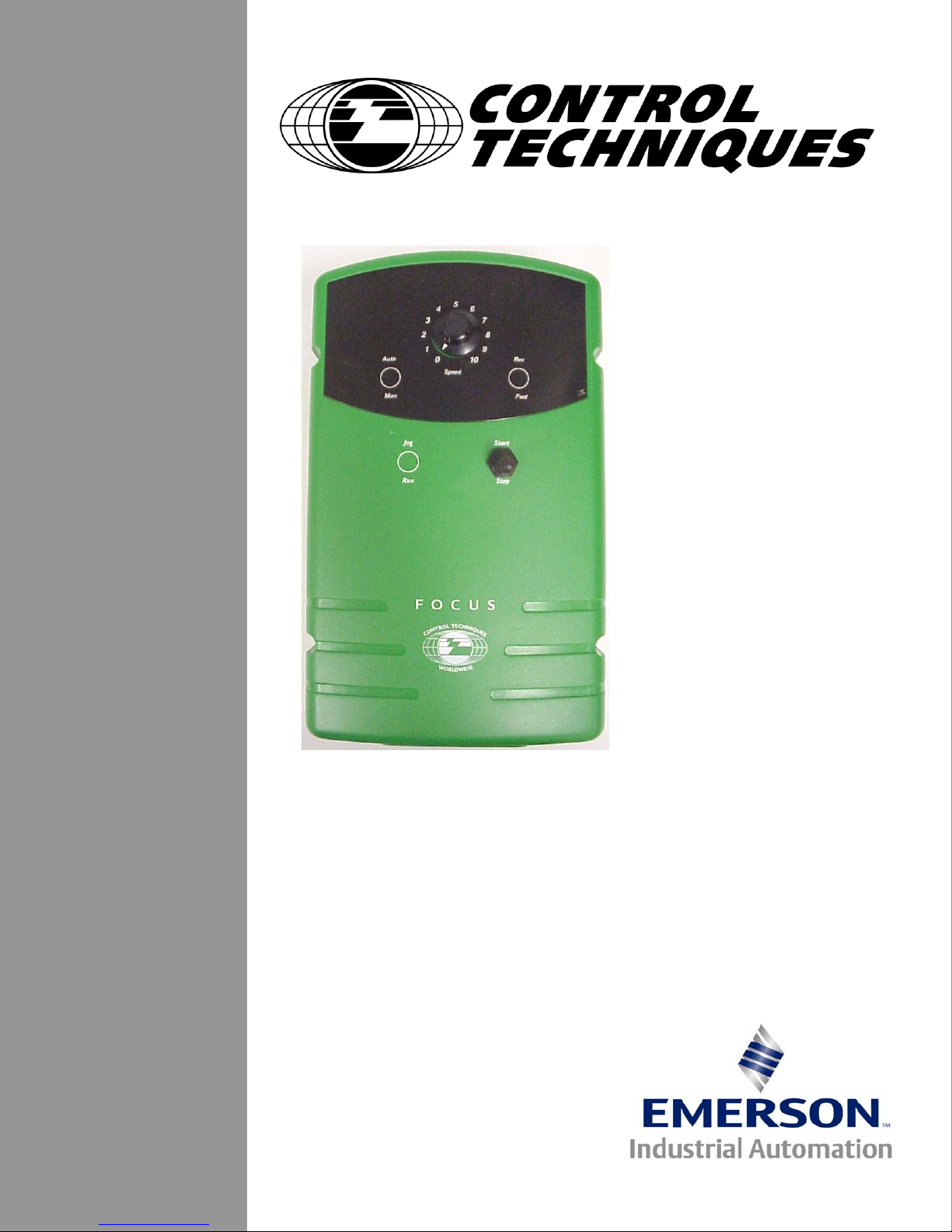

Focus 3R

¼ to 5HP Single Phase

Bi-Directional

Regenerative DC Drive

Page i

Page 2

General Information

The manufacturer accepts no liability for, negligent or incorrect installation or adjustment

of the optional operating parameters of the equipment or from mismatching the variable

speed drive with the motor.

The contents of this User Guide are believed to be correct at the time of printing. In the

interests of a commitment to a policy of continuous development and improvement, the

manufacturer reserves the right to change the specifications of the product or its

performance, or the contents of the User Guide, without notice.

All rights reserved. No parts of this User Guide may be reproduced or transmitted in any

form or by any means, electrical or mechanical, without permission in writing from

Control Techniques.

Page ii

Page 3

Customer Support

Control Techniques

359 Lang Boulevard, Building B

Grand Island, New York 14072

U.S.A. Telephone: (716) 774-1193

It is Control Techniques’ goal to ensure your greatest possible satisfaction with the

operation of our products. We are dedicated to providing fast, friendly, and accurate

assistance. That is why we offer you so many ways to get the support you need.

Whether it’s by phone, fax or modem, you can access Control Techniques support

information 24 hours a day, seven days a week. Our wide range of services include:

Fax (716) 774-8327

You can FAX questions and comments to Control Techniques Just send a FAX to the

number listed above.

Website and Email www.emersonct.com

Website: www.emersonct.com

Email: info@emersonct.com

If you have Internet capabilities, you also have access to technical support using our

website. The website includes technical notes, frequently asked questions, release

notes and other technical documentation. This direct technical support connection lets

you request assistance and exchange software files electronically.

Technical Support (716) 774-1193 or (800) 893-2321

Email: pdtechsupport@emersonct.com

Control Techniques’ products are backed by a team of professionals who will service

your installation. Our technical support center in Grand Island New York is ready to help

you solve those occasional problems over the telephone. Our technical support center

is available 24 hours a day for emergency service to help speed any problem solving.

Also, all hardware replacement parts, if needed, are available through our customer

service organization.

When you call, please be prepared to provide the following information:

The type of controller or product you are using

What you were doing when the problem occurred

How you tried to solve the problem

Need on-site help? Control Techniques provides service, in most cases, the next day.

Just call Control Techniques’ technical support center when on-site service or

maintenance is required.

Customer Service (716) 774-1193 or (800) 367-8067

Email: customer.service@emersonct.com

Authorized Control Techniques distributors may place orders directly with our Customer

Service department. Contact the Customer Service department at this number for the

distributor nearest you.

Page iii

Page 4

“Warning” indicates a potentially hazardous situation that, if

not avoided, could result in death or serious injury.

“Caution” indicates a potentially hazardous situation that, if

not avoided, may result in minor or moderate injury.

“Caution” used without the safety alert symbol indicates a

potentially hazardous situation that, if not avoided, may result in property

damage.

Page iv

Page 5

Safety Considerations

Safety Precautions

This product is intended for professional incorporation into a complete system. If

you install the product incorrectly, it may present a safety hazard. The product

and system may use high voltages and currents, carry a high level of stored

electrical energy, or are used to control mechanical equipment that can cause

injury.

You should give close attention to the electrical installation and system design to

avoid hazards either in normal operation or in the event of equipment

malfunction. System design, installation, commissioning and maintenance must

be carried out by personnel who have the necessary training and experience.

Read and follow this safety information and instruction manual carefully.

Enclosure

This product is intended to be mounted in an enclosure that prevents access

except by trained and authorized personnel and prevents the ingress of

contamination. This product is designed for use in an environment classified as

pollution degree 2 in accordance with IEC664-1. This means that only dry, nonconducting contamination is acceptable.

Setup, Commissioning and Maintenance

It is essential that you give careful consideration to changes to drive settings.

Depending on the application, a change could have an impact on safety. You

must take appropriate precautions against inadvertent changes or tampering.

Restoring default parameters in certain applications may cause unpredictable or

hazardous operation.

Safety of Machinery

Within the European Union all machinery in which this product is used must

comply with Directive 89/392/EEC, Safety of Machinery.

The product has been designed and tested to a high standard, and failures are

very unlikely. However the level of integrity offered by the product’s control

function – for example stop/ start, forward/reverse and maximum speed – is not

sufficient for use in safety-critical applications without additional independent

channels of protection. All applications where malfunction could cause injury or

loss of life must be subject to a risk assessment, and further protection must be

provided where needed.

Page v

Page 6

General warning

Failure to follow safe installation guidelines can cause death or serious injury. The

voltages used in this unit can cause severe electric shock and/or burns, and could be

lethal. Extreme care is necessary at all times when working with or adjacent to this

equipment. The installation must comply with all relevant safety legislation in the country

of use.

AC supply isolation device

The AC supply must be removed from the drive using an approved isolation device or

disconnect before any servicing work is performed, other than adjustments to the

settings or parameters specified in the manual. The drive contains capacitors, which

remain charged to a potentially lethal voltage after the supply has been removed.

Grounding (Earthing, equipotential bonding)

The drive must be grounded by a conductor sufficient to carry all possible fault current

in the event of a fault. The ground connections shown in the manual must be followed.

Fuses

Fuses or over-current protection must be provided at the input in accordance with the

instructions in the manual.

Isolation of control circuits

The installer must ensure that the external control circuits are isolated from human

contact by at least one layer of insulation rated for use at the applied AC supply voltage.

Page vi

Page 7

Page 8

Table of Contents

Topic Page

Introduction 4

Motor Compatibility 5

Basic Control Modes/Feedback 6

Armature Voltage Feedback 6

Speed or Tach Feedback 6

Quick Stops 6

Receiving, Inspection, Storing 7

Performance Features 8

Nameplate Information 9

Nameplate Location 9

Catalog Number Definition 9

Specifications

Ratings Table 10

Performance Specifications 11

Operating Conditions 11

Internal Adjustments (Potentiometer) 11

Customer Selections (Jumpers) 11

Operator Functions 12

Control Circuit Specifications 12

Options 12

Dimensions 13-14

Option Kits & Descriptions 15-19

Customer Connections & Start-Up

Start-Up Guidelines 20

Incoming Power Requirements 21

Grounding 21

Motor Wiring 21-22

When viewing this document electronically, the Table of Content items

are active and will direct you to that topic by clicking on that item.

Page 2

Page 9

Table of Contents

Topic Page

Power Wiring 23-24

Control Wiring 25-32

Speed Pot Wiring 33

Customer Selections

Jumper Programming 34-38

Current Ranges 35

Current/Torque Control 35

LED Status Indicators 39

Potentiometer Adjustments 40-46

Basic Adjustments 41-42

Tuning Adjustments 43-44

Interconnect Drawings

Functional Block Diagram 48

Non-Regen Circuit Overview 49

Start-up Guide Worksheet 50-52

Initial Start-Up & Basic Test Setups 53

Installation of Option Kits 53

Motor Test 54-56

Trouble Shooting Guide 56-59

Light Bulb Test 61-62

Retrofitting Focus 3 to Focus 2 Applications 63-65

Application Notes 66

Tachometer Follower Application 67-68

Spare Parts 70

When viewing this document electronically, the Table of Content items

are active and will direct you to that topic by clicking on that item.

Page 3

Page 10

Introduction

This is the User’s Guide for Focus 3R (Regenerative) series of DC Drives. The Focus 3 is

a 3rd generation product of the long-standing Focus series. The Focus 1 was introduced back

in 1980 and the Focus 2 later in 1982. The Focus 2 was retired when the Focus 3 was

introduced as it took advantage of many technological advances in power electronics. The

Focus 3 Regen is a single-phase, bi-directional analog drive for DC motors with power ranges

from ¼ to 5HP.

Your Focus 3R is a general purpose regenerative DC motor speed controller that is

powered from either 115Vac or 230Vac single phase power. A regenerative (four quadrant)

drive is one that can provide motoring and regenerating torque for acceleration and deceleration

to overcome rated loads. There are a great many applications where regenerative drives

provide the most economical solution. A regenerative drive can slow down a motor faster than

the motors normal coasting rate and can stop overhauling load situations.

Both drives incorporate many features that are standard on high performance system

drives, such as dynamic stability and built-in signal follower adjustments. Focus 3 drives come

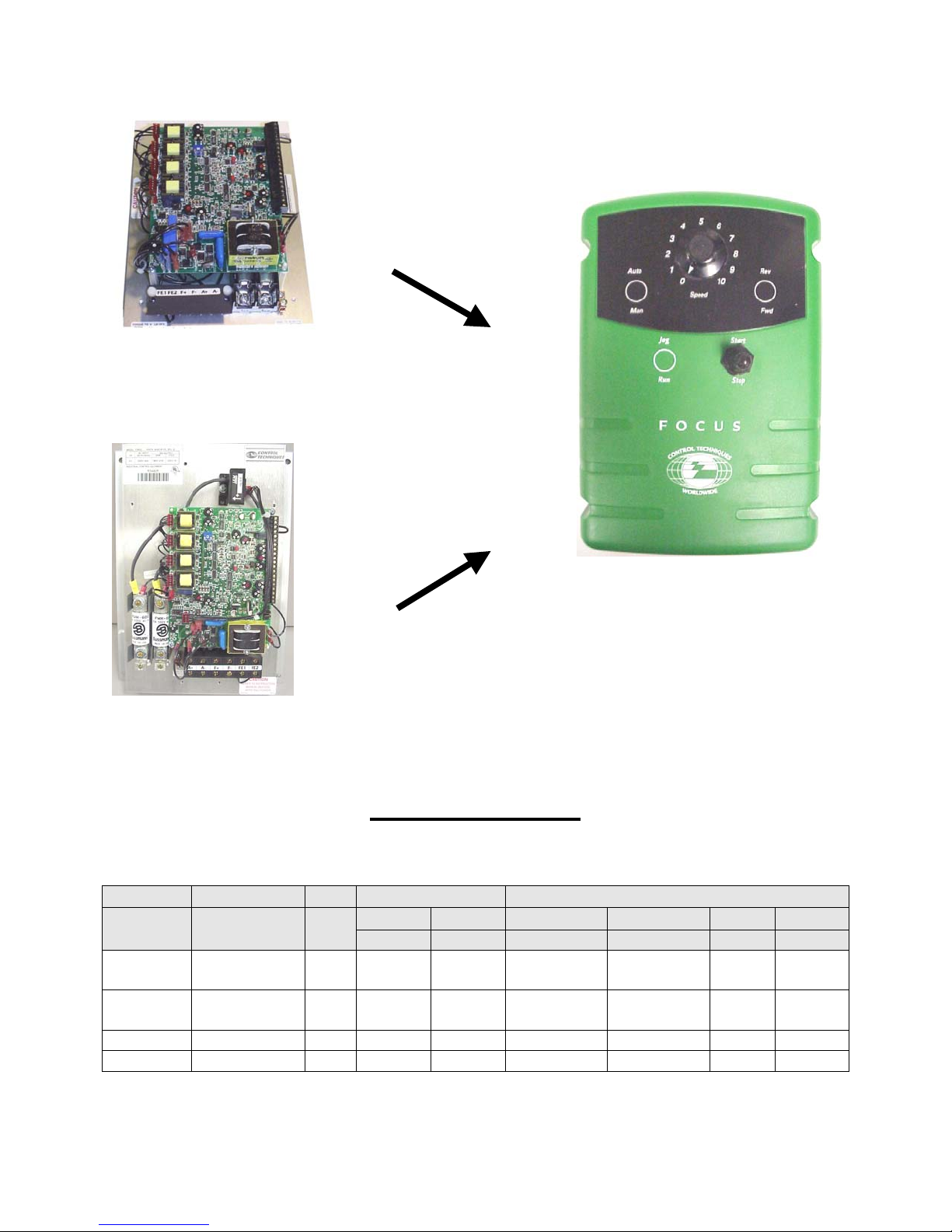

in two basic model variations- with and without enclosure

Chassis Model

.

The model without an enclosure is denoted as a chassis model.

The chassis model is intended for mounting within a User

supplied cabinet and where the User intends to provide remote

Start/Stop and Speed control signals.

(5 Hp model shown)

Enclosed Model

The Enclosed version comes to you already in a NEMA 4/12

enclosure that would allow the User to mount the Focus on a wall

or machine surface. The Enclosed version has Start/Stop and the

Speed Control adjustment on the front cover for convenient

operation.

For a complete overview of the Focus 3 product

line and available options, visit our website at:

www.emersonct.com or click the link below:

Focus 3 Catalog Section

Page 4

Page 11

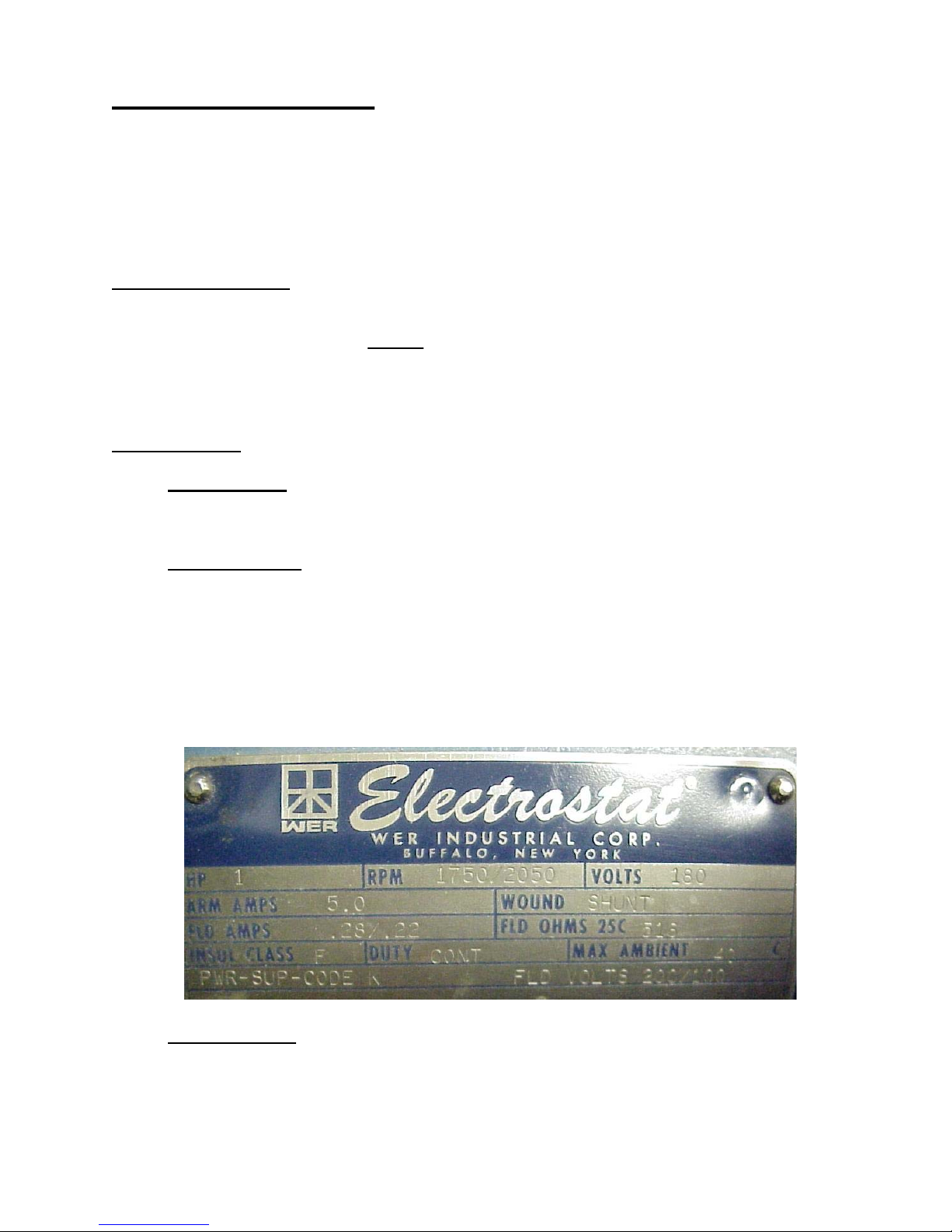

Motor Compatibility

The Focus 3 was designed to run standard 90 Vdc or 180 Vdc Shunt Wound or Permanent

Magnet DC motors in both directions. The Focus 3 can run motors with other characteristics

(such as Universal motors) but one must review those requirements to insure compatibility.

Universal motors have commutator brushes but typically plug into the AC power line. Universal

motors are often used in tools such as Drills, Saws, Shop VAC’s, Routers, etc and typically

cannot be run in reverse.

Shunt Wound Motors that are controlled by single phase DC drives typically have 4 power

wires. Two of these are the Armature leads typically designated A1 & A2 or A+ & A-. The

other two power wires are the shunt field leads and typically designated F1 & F2 or F+ & F-.

The Focus 3 can supply up to 1 Amp for shunt field excitation (field current requirements

beyond 1A may damage field rectifier diodes). If your motor does not have Field Current

information on the nameplate, you can determine compatibility by measuring your motors Field

resistance using a calibrated ohmmeter.

Motors with:

90v Armatures typically require 100 Vdc for field excitation. In these cases, the Focus

3 requires 120vac input power and must be internally set for this input level. The motor

Field resistance should not be less than 100 ohms when cold.

180v Armatures typically require 200 Vdc for field excitation. In these cases, the Focus

3 requires 240vac input power and must be internally set for this input level. The motor

Field resistance should not be less than 200ohms when cold.

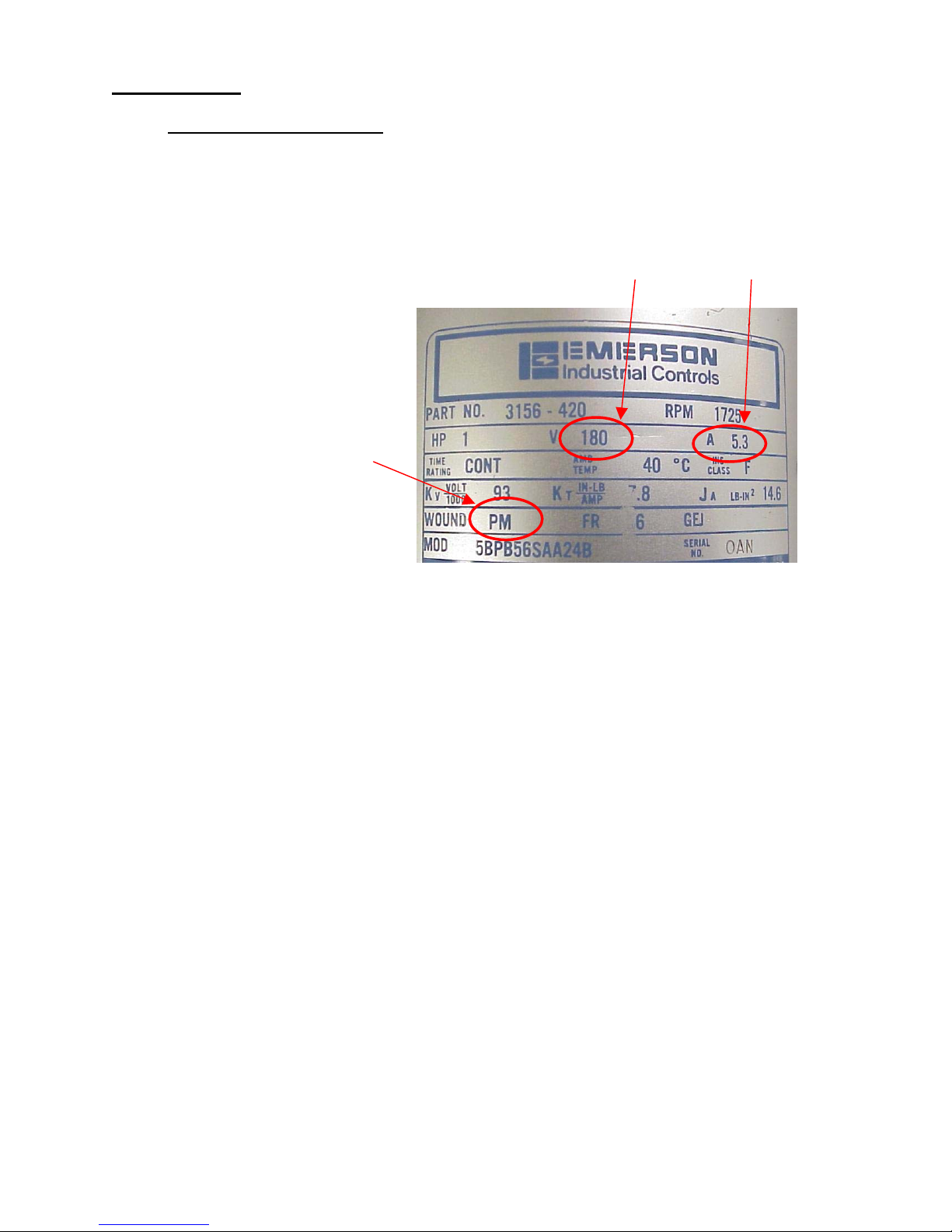

The motor nameplate information is key to determining compatibility. As seen below,

the motor below easily falls in the range of the Focus 1 operated from a 240vac supply.

The drive will supply 180v for the armature and 200v for the field ( this motor indicates

there are 2 field windings and for 200vdc they must be wired in series ). The field

current requirement is 0.28A which is well under the 1A maximum.

1 1750 / 2050 180

5.0 SHUNT

0.28/.22 518

FLD VOLTS 200/100

240v Armatures typically require 150 Vdc for field excitation. In these cases, the Focus

3 requires 240vac input power and must be internally set for this input level. The motor

field resistance should not be less than 150 ohms when cold and will require a series

resistor to drop the additional field supply voltage. Consult Control Techniques Technical

Support for additional information.

Page 5

Page 12

Motors with:

Permanent Magnet Motors typically have only 2 power wires. These are the Armature

leads and typically designated A1 and A2 or A+ and A-.

Armature

Voltage

Armature

Current

Page 6

Page 13

Speed Control

Armature Voltage Feedback

The Focus 3 can vary the speed of the motors mentioned above as a function of the

Speed potentiometer setting (or external speed command signal) by simply varying the

output Armature voltage (field excitation if used typically remains constant). A great

many motor applications do not require ultra precise speed control. Because of this, the

Focus 3 is factory set for Armature Voltage Feedback. Armature Voltage Feedback (or

simply Armature Feedback) does not require any special motor mounted speed

feedback device and is therefore inherently quite reliable and is capable of providing up

to 1% speed regulation.

Speed Feedback- Tachometer

Should more precise speed control be required, the Focus 3 can accommodate those

motors equipped with DC Tachometers (AC tachometers require an option kit). DC

tachometers output a linear voltage proportional to their RPM and can provide the Focus

3 with accurate motor speed feedback information. With good DC tachometers up to

0.5% speed accuracy can be achieved.

Tach failure will typically result in motor speed runaway. One who designs

systems with Speed Feedback devices such as DC tachometers should be

cognizant of this fault condition and must take machine design precautions

should this event occur.

We would recommend that all DC Drives be initially run using Armature Voltage

Feedback to verify operation even if Tach Feedback is the ultimate goal.

Quick Stops

The DB option provides a rather quick stopping action and provides motor turning

resistance when the drive is not in the RUN condition. The Focus 3R can be outfitted

with a Dynamic Braking resistor should this requirement be desired.

Regenerative drives are capable of stopping the motor more quickly than dynamic

braking by rapidly reducing the speed command to zero and then disabling the drive.

This requires the drive to be active and some external means of disabling the drive after

the motor reaches zero speed.

Power Outages

Shunt Wound Motors

Should a power outage occur, the drive would turn off and the motor would coast to rest.

If a Dynamic Braking resistor were employed there would typically be enough decaying

field strength to enable some faster stopping action.

Permanent Magnet Motors

Should a power outage occur, the drive would turn off and the motor would coast to rest.

If a Dynamic Braking resistor were employed, full Dynamic Braking force would be

exerted because the field is maintained by the motors internal permanent magnets.

Therefore, there would be motor turning resistance during power outages as well.

Note: DB Resistors require Contactor Option - See Options

Page 7

Page 14

General Information

r

Introduction

The purpose of this manual is to provide the user with the information needed to

install, start-up, and maintain the Focus 3 drive. This instruction manual should be read

in its entirety, paying special attention to the warning and caution notices, before

installation and before performing any start-up or drive maintenance.

Receiving

The user is responsible for inspecting the equipment thoroughly before accepting

the shipment from the freight company. Check the items received against the purchase

order. If any items are obviously damaged, do not accept delivery until the damage has

been noted on the freight paperwork.

Inspection

Before installation and start-up of the drive, inspect the unit for mechanical integrity

(i.e. loose parts, wires, etc). If physical damage was sustained during shipment, leave

the shipping container intact and notify the freight agent. After unpacking, check the

drive nameplate catalog number against the purchase order.

Storing

Store the drive in its shipping container prior to installation. If the drive isn’t used

for a period of time, store according to the following instructions in order to maintain

warranty coverage:

Clean, dry location

Ambient Temperature Range: -400C to 700C

: -400F to 1600F

Humidity: 95%, Non-condensing

Improper procedures can result in personal injury or equipment damage. Only

qualified electrical maintenance technicians familiar with electronic drives and thei

standard safety precautions should be permitted to install, start-up, or maintain this

apparatus.

Page 8

Page 15

PERFORMANCE FEATURES

• Solid State Full Wave Power Bridge -Uses generously rated power semiconductors for

Maximum reliability and long life.

• Four Quadrant Operation – The drive is capable of running in both the directions and

providing full braking torque in both directions.

• Control Circuit Isolation – The control circuitry is isolated from the drives power section

allowing signal common to be connected to earth ground or process signals referenced to

earth ground.

• Inner Current Loop Regulator - Inherent high bandwidth capability for fast response.

• Semiconductor Fusing - Both AC lines fused for maximum protection in case of short

circuit.

• AC Line Filter and Transient Voltage Suppressor Network - Eliminates interaction

between other drives or AC equipment.

• Current Limit Ranges - Selectable current limit ranges to match the drive to the motor

being used. Provides smooth acceleration of high inertia loads.

• Speed Regulator - 1 % accuracy armature voltage feedback with IR compensation or 0.5 %

accuracy with DC tachometer feedback. Regulation accuracy may be affected by the

tachometer selected.

• Current (Torque) Regulator -

2% accuracy armature current regulator allows the user to control motor torque instead of

speed.

• Circuit Board Indicators - Light emitting diodes (LEDs) on the control board indicate when

the drive is in Run Mode or the Current Limit is enabled.

• Remote Current Limit - Available by the simple addition of a potentiometer.

• Current Signal Follower lnput** - Allows the motor speed to be controlled by a current

signal from a commercially available transducer. The signal may be one of the following:

0 -5mA or 0-20mA

• Voltage Signal Follower lnput - Allows the motor speed to be controlled by a voltage

signal from a DC tachometer generator or a process voltage signal. It accepts an input with

a range of 0-200 Vdc.

• Auto/Manual Operation - Standard circuitry allows the drive to be controlled by the

operator speed potentiometer or by the current/voltage signal inputs.

• UL/cUL - All Focus 3 Drives are UL/cUL listed.

** Note: The Current Signal Follower Input on the Focus 3 Regenerative Drives is designed for 0

to 5 or 0 to 20 ma, not 1 to 5 or 4 to 20 ma. The circuitry can be adjusted to bias out the 1 or 4

milliamp current levels and the drive will follow the signals correctly. The difference is that if the

current input drops below the 1 or 5 ma level, the drive will rotate in the reverse direction ( as

much as 25% speed if the signal goes to zero). If a 1 to 5 or 4 to 20 ma signal is required on a

Focus 3 Regenerative Drives, it is recommended that the Focus 3 Signal Isolator board (F3NSBD)

be used since it has circuitry built in to block the reverse speed signal.

Page 9

Page 16

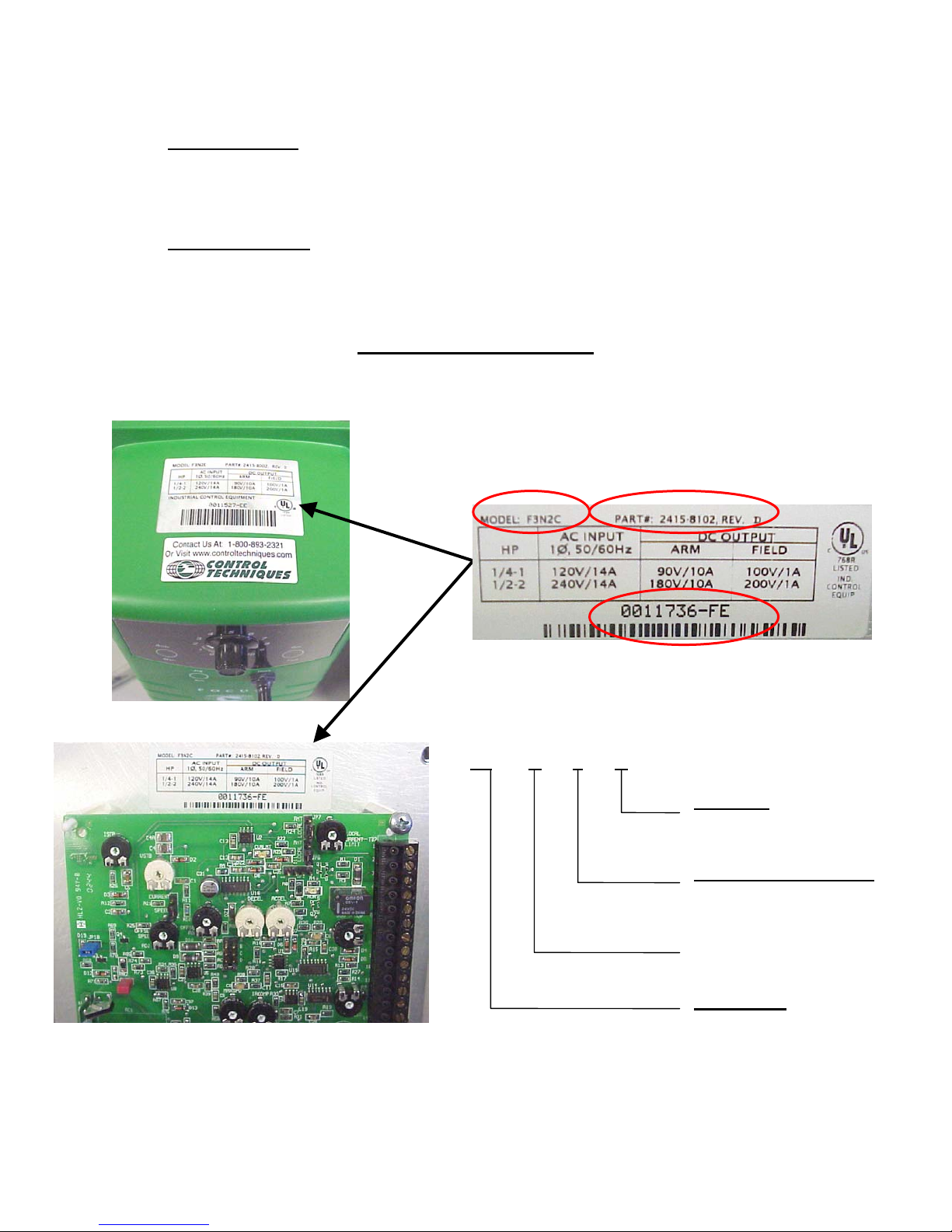

The Focus 3 comes in two basic model variations- with and without enclosure.

Chassis Model

The model without an enclosure is denoted as a chassis model. The chassis model is

intended for mounting within a User supplied cabinet and where the User intends to

provide remote Start/Stop and Speed control signals.

Enclosed Model

The Enclosed version comes to you already in a NEMA 4/12 enclosure that would allow

the User to mount the Focus on a wall or machine surface. The Enclosed version has

Start/Stop and the Speed Control adjustment on the front cover for convenient operation.

Nameplate Information

Enclosed Unit

Model #

Model Number Definition

F3 N 2 C

Part #

Serial #

Enclosure

Chassis (C)

Enclosed (E)

Max HP Rating @240vac

2 HP (2)

5 HP (5)

Always record the drive Model Number, Part Number and Serial Number for future

warranty situations and spare parts. A good location to record these is on the Start-up

Guide Worksheet on page #49.

Page 10

Non-Regen (N)

Regen (R)

Drive Family

Focus 3 (F3)

Page 17

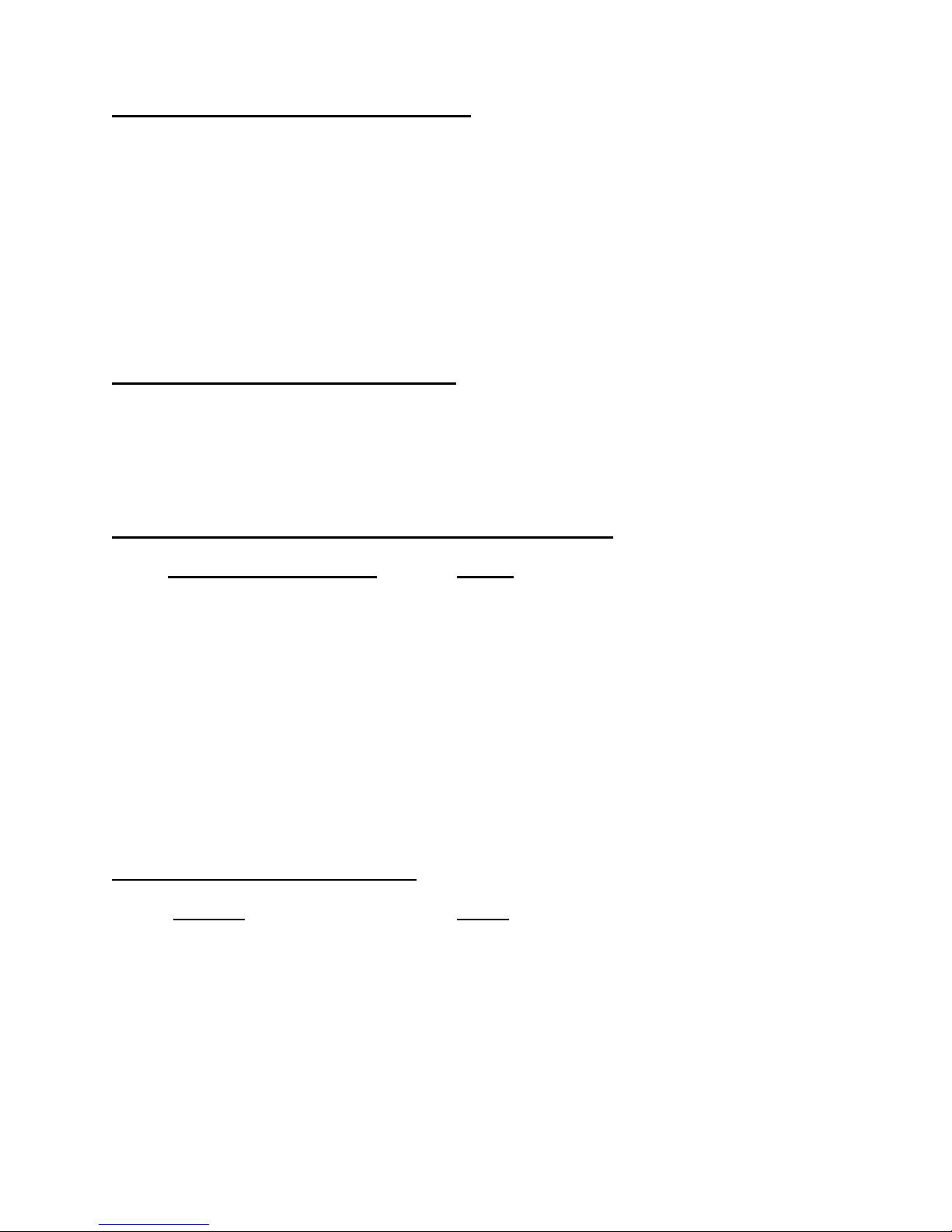

Chassis Models

Enclosed Models

F3R2C

F3R2E

F3R5E

F3R5C

Specifications

Ratings

Input

AC

Catalog Enclosure HP 1Ø Max

Part #

F3R2C Chassis ¼ -1

½-2

F3R2E NEMA 4/12 ¼ -1

½-2

F3R5C Chassis 3-5 240 35 180 25 200 1

F3R5E NEMA 4/12 3-5 240 35 180 25 200 1

Volts Amps Volts Amps Volts Amps

120

240

120

240

14

14

14

14

Armature

DC Output

90

180

90

180

Armature Field Field

10

10

10

10

100

200

100

200

1

1

1

1

Page 11

Page 18

Page 12

Page 19

PERFORMANCE SPECIFICATIONS

Service Factor 1.0

Speed Regulation (95% Load Change):

Armature Voltage 1% of Max. Speed with IR Compensation

All other variables

(voltage regulated) 15% of Base Speed

Tachometer Feedback (DC) 0. 5% of Base Speed

Speed Range: 30:1

Efficiency:

Control Only 98%

Drive System (motor and control) 86% typically

DRIVE OPERATING CONDITIONS

Altitude (without derating) 3300Ft ( 1000meters )

Ambient Temperature:

Chassis Models 0-550C ( 32-130° F )

Enclosed (NEMA 4/12) 0-400C ( 32-104° F )

INTERNAL ADJUSTMENTS (POTENTIOMETERS)

Potentiometer Function Range

Maximum Speed 80-120% of Rated Speed

Minimum Speed 0-30% of Maximum Speed

IR Compensation 0-20% of Rated Voltage

Current Limit 0-150% of Selected Range

Acceleration Time 0.3-20 seconds (linear)

Deceleration Time 0.3-20 seconds (linear)

Jog Speed 0-30% of Full Speed command

Speed Loop Offset Adjustable

Velocity Loop Stability Adjustable

Current Loop Stability Adjustable

Current Signal Follower Gain Adjustable

Velocity Signal Follower Gain Adjustable

Signal Follower Zero Bias Adjustable

CUSTOMER SELECTIONS (JUMPERS)

Function Range

Input Voltage 120/240Vac

Control Mode Speed / Torque

Current Feedback range High / Medium / Low / Xlow

Current Limit Pot Selector Local / Remote

Armature Voltage level 90 Vdc/180 Vdc

Optional “M” Contactor Yes/No

Tachometer Feedback High/Low

Speed Feedback Selector Armature / Tachometer

Line Frequency 50/ 60Hz

Page 13

Page 20

OPERATOR FUNCTIONS

Chassis Enclosed

Speed Adjustment (Speed Pot) Standard Standard

Start/Stop Customer Supplied Standard

Auto/Manual Optional Optional

Run/Jog Optional Optional

Fwd/Rev Optional Optional

CONTROL CIRCUIT SPECIFICATIONS

Logic Control Power 24 Vdc

Speed Potentiometer 5000 ohms

Input Signal Requirement 10 Vdc @ 0.5mA

Control Circuit Isolation Standard with regen F3R models

Current Signal Follower (see note, page 8) 0-5mA or 0 - 20mA

Voltage Signal Follower 10 – 200 Vdc (at Maximum Speed)

FOCUS 3 OPTIONS

CATALOG

NUMBER DESCRIPTION

F3SE Enclosure Small (2HP), NEMA 4/12

F3LE Kits Large (5HP), NEMA 4/12

F3M112 “M” ¼ - 1HP @ 120V

F3M224 Contactor ½ - 2HP @ 240V

F3M524 Kits 3 - 5HP @ 240V

F3DB224 ½ HP @ 120V, 2HP @ 240V

F3DB1524 ¼ - 1/3 HP @ 120V, I .5HP @ 240V

F3DB124 Dynamic ¾ -1HP @ 240V

F3DB0524 Braking ½ HP @ 240V

F3DB112 Kits ¾ -1HP @ 120V

F3DB324 3HP @ 240V

F3DB524 5HP @ 240V

F3TS Toggle Switch, NEMA 4 /12

F3NSBD Signal Isolation Board

2450-9024 Remote Percent Speed Meter Kit

2450-9021 Remote RPM Speed Meter Kit

2950-9066 Remote Operator Station ( 3 Function )

2950-9068 Remote Operator Station ( 5 Function )

6160-9001 Ten-Turn Precision Potentiometer

Page 14

Page 21

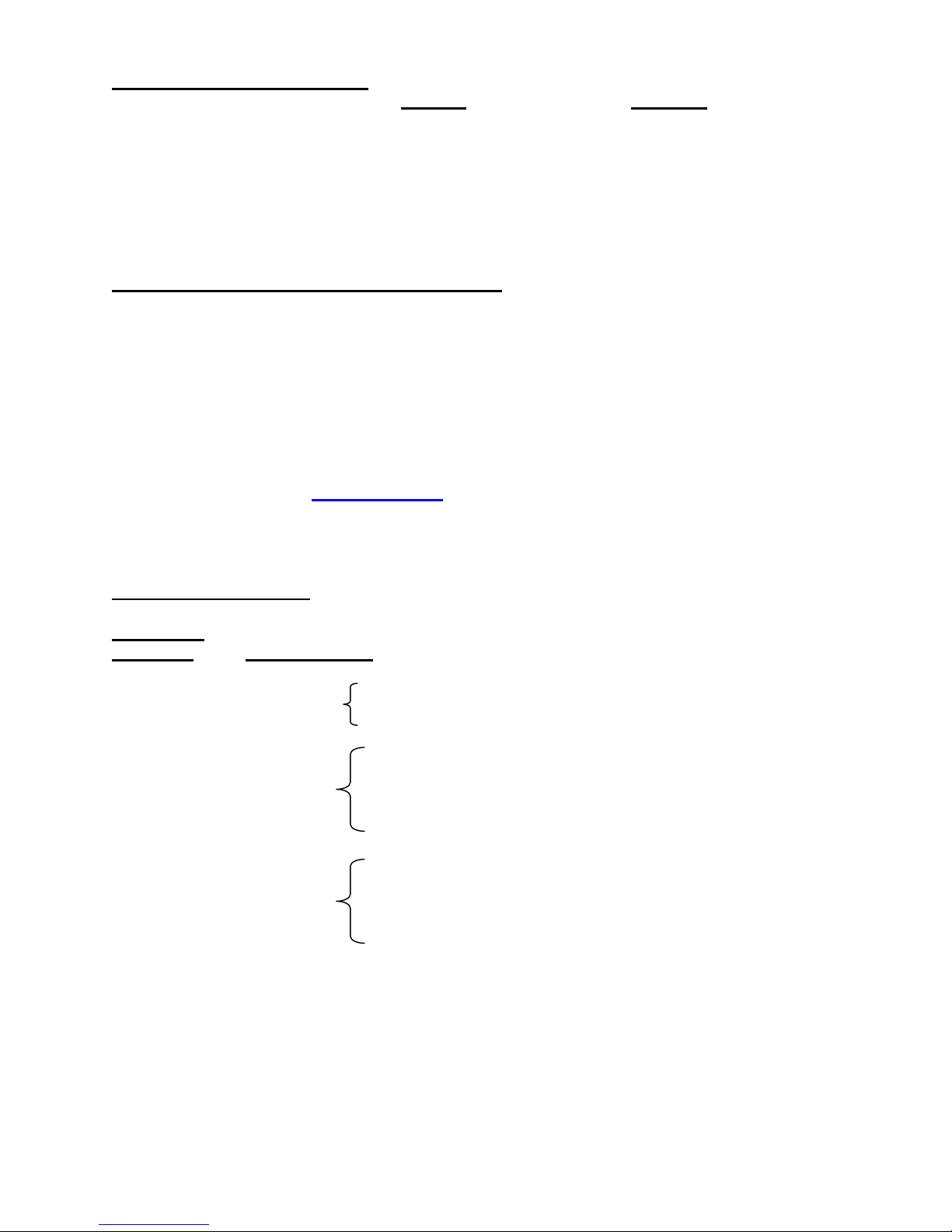

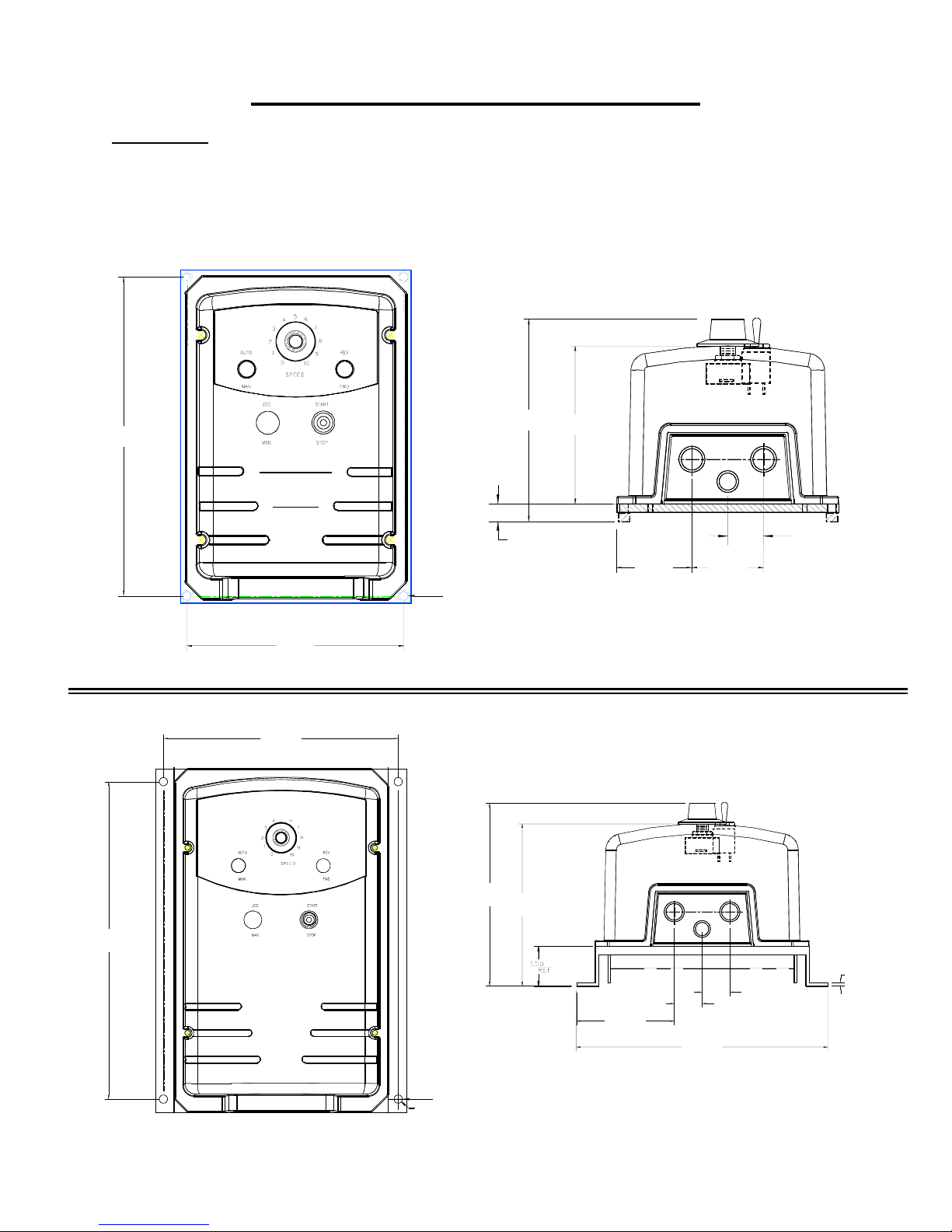

Focus 3 Chassis Dimensions

Chassis

Suitable for mounting in a user’s enclosure where internal temperatures will not exceed

550C or 1300F.

TB2

2

3

4

5

6

SMALL

REGEN

&

NON-REGEN

MOUNTING

9.75" 9.35"

7

8

9

10

11

12

13

14

15

16

17

18

19

20

B

D

B

C

C

A

A

E

JP11

8

1

T1

3.30"

AC1 AC2

0.25"

13.00"

12.00"

B B

1

LAL

0.168" (4 PLACES)

F3R2C

6.36"

6.75"

TB2

2

3

4

LARGE

REGEN

&

NON-REGEN

MOUNTING

A

TB1

2

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

B

D

B

C

C

A

A

E

JP11

8

1

4.50"

AC2 G2

0.13"

8.88"

9.50"

0.312" (4 PLACES)

F3R5C

Page 15

Page 22

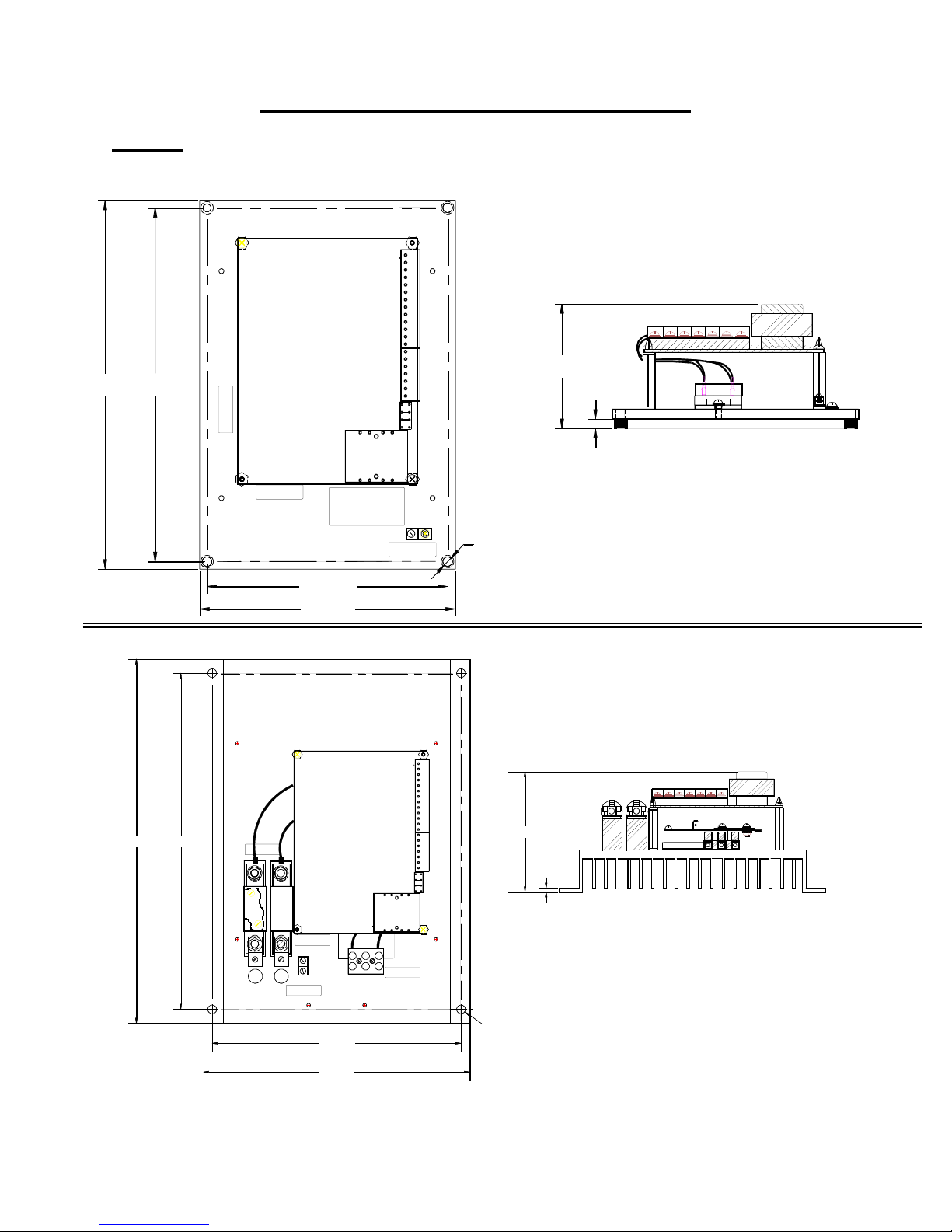

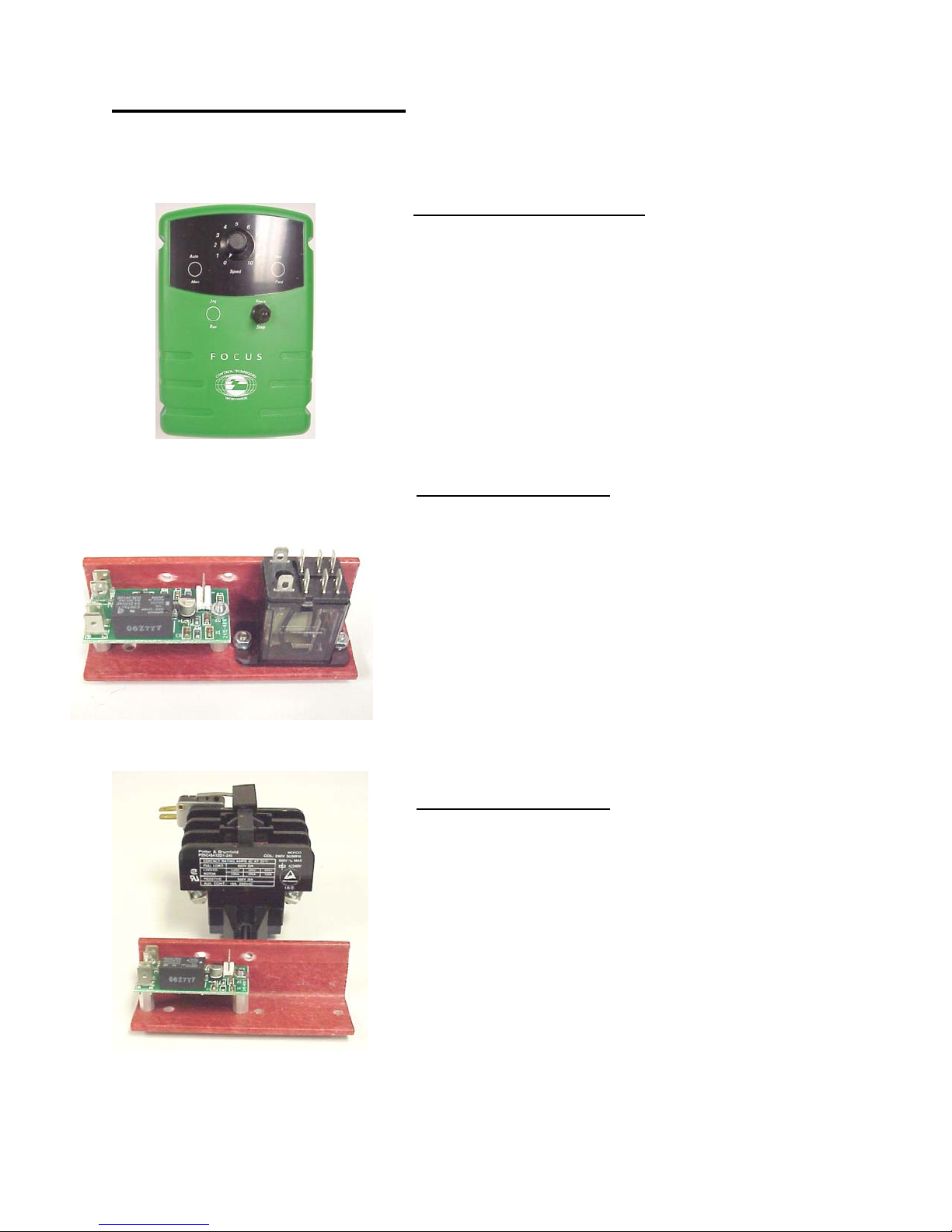

Focus 3 Enclosed Dimensions

NEMA 4/12

Suitable for most well ventilated factory areas where industrial equipment is installed.

Locations subject to steam vapors, oil vapors, flammable or combustible vapors,

chemical fumes, and corrosive gases or liquids should be avoided unless an

appropriate enclosure has been supplied. Ambient temperature is not to exceed 400C.

5.93

9.35

4.63

12.00

6.36

8.88

0.168 Dia

(4 Places)

6.91

0.51

6.13

F3R2E

3.70

9.50

2.102.22

1.05

1.05

0.13

1.05

Page 16

Ø0.31

F3R5E

Page 23

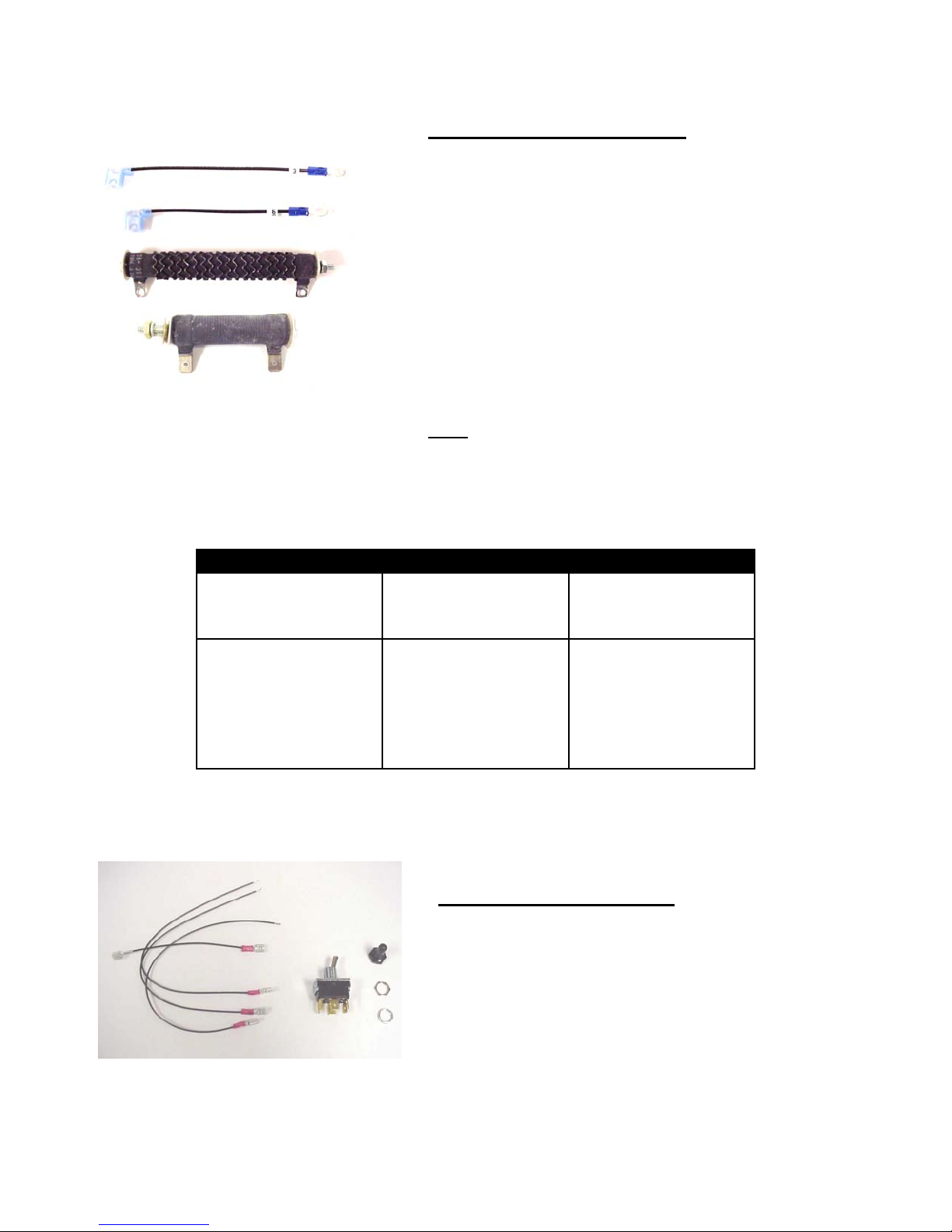

Focus 3 Option Kits

r

f

f

Focus 3 Enclosure Option – F3SE (small) up to 2HP

F3LE (large) 3-5HP

This kit provides the flexibility of stocking only Chassis

drives and adding the enclosure when required. It

reduces the number of stocked items to 6 (four chassis

drives and two covers) as opposed to eight (fou

enclosed drives and four chassis drives). It includes the

speed adjustment potentiometer and the start/stop

switch pre-wired to a plug-on terminal strip and all seals

to provide a NEMA 4/12-enclosure rating.

Focus 3 Contactor Kit – P/N F3M112 (1 HP,120vac)

P/N F3M224 (2 HP, 240vac)

This Kit includes a magnetic contactor that can be

mounted either in the Focus 3 enclosed unit or on the

chassis mount unit. It provides a positive disconnect o

the motor armature when the controller is stopped,

preventing motor rotation in the event of SCR mis-fire

due to line noise. This kit may also be required by local

and/or National Electrical Codes. This kit also includes

the DB (dynamic braking) poles, an auxiliary normally

open contact and all connection wires.

Focus 3 Contactor Kit– P/N F3M524 (3-5 HP, 240vac)

This Kit includes a magnetic contactor that can be

mounted either in the Focus 3 enclosed unit or on the

chassis mount unit. It provides a positive disconnect o

the motor armature when the controller is stopped,

preventing motor rotation in the event of SCR mis-fire

due to line noise. This kit may also be required by local

and/or National Electrical Codes. This kit also includes

the DB (dynamic braking) poles, an auxiliary normally

open contact and all connection wires.

Page 17

Page 24

Focus 3 Option Kits

r

r

f

AC Input HP (Typical) Part Number

120 Vac

240 Vac

Focus 3 Dynamic Braking Kit

PN– See Table Below

For use with Focus 3 Contactor Kits. Dynamic

braking provides rapid motor stopping by quickly

dissipating the stored energy in the rotating moto

and load. These resistors have been sized in

accordance with Nema specifications for dynamic

braking.

“Providing 3 stops in rapid succession with the

load inertia equal to the motor inertia, then

cooling forever.”

Note: Large and small dynamic braking resistors

shown, ¼-2 HP use small and the 3-5 HP use the

large resistor.

1/4-1/3

1/2

3/4-1

1/2

3/4-1

1.5

2

3

5

F3DB1524

F3DB224

F3DB112

F3DB0524

F3DB224

F3DB1524

F3DB224

F3DB324

F3DB524

Page 18

Focus 3 Toggle Switch – P/N F3TS

This kit can be mounted in the drive enclosure cove

or remote mounted when used with chassis drives.

The kit includes the switch, NEMA 4/12 switch boot

and the connection wires for enclosure use. It is

used to provide one of the following functions:

Fwd/Rev, Run/Jog, or Auto/Manual. Up to 3 o

these kits may be used with the Drive cover.

Page 25

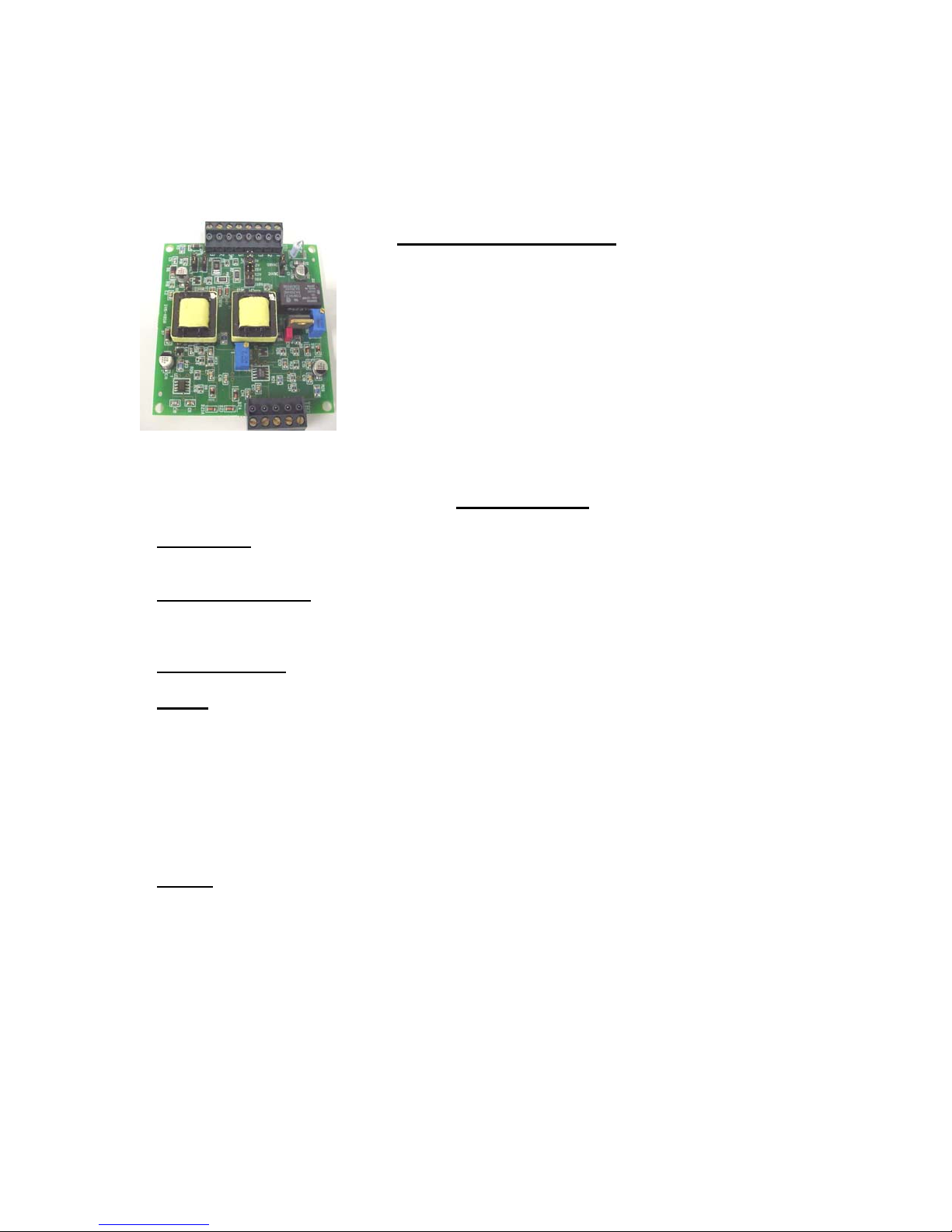

Focus 3 Option Kits

Signal Isolator Board – P/N F3NSBD

This option is used in applications where isolation is

required between an external control signal and the

motor controller (which may or may not be at earth

ground potential). It can be utilized to isolate a variety

of voltage or current signals (see specifications below).

It may also be used simply to isolate the speed

adjustment pot, and the pot power supply is included.

This option can be mounted in the enclosure or in a

piece of plastic track (included with kit).

Specifications:

Input Power: 17- 30 Vdc @ 50mA Max. (for control circuitry)

Control Relay (CRR): 24 Vdc @ 12.1 mA (JP5 = 24 Vdc)

120 Vac @ 20 mA (JP5 = 120 Vac)

Contact Type/Rating – 2 Form A / 1A @ 250 Vac

Isolation Voltage: 240 Vac Power Systems

2000 Vac Hi-Pot for 1 Minute

Inputs:

Voltage Ranges: 5,12,26,52,98 & 208 Vdc, 180 Ohms/volt

Current Ranges: 0-5 mA, 1-5 mA, 910 Ohms input impedance

0-20 mA, 4-20 mA, 250 Ohms input impedance

Speed Pot: 5Kohms, 2W (Includes +10 Vdc power supply for potentiometer)

Output: 0 to +10 Vdc (Uni-polar)

Application Note:

Although the Focus 3 Regenerative drives are isolated, this board is useful in

applications requiring control with a 4-20 milliamp speed reference since the drive was

designed for a 0-20 milliamp signal. It also adds an additional layer or isolation. In

addition, the adjustments on this board are multi-turn adjustment potentiometers

providing much finer adjustments than the ones on the drive.

Page 19

Page 26

Focus Family Options

r

Speed

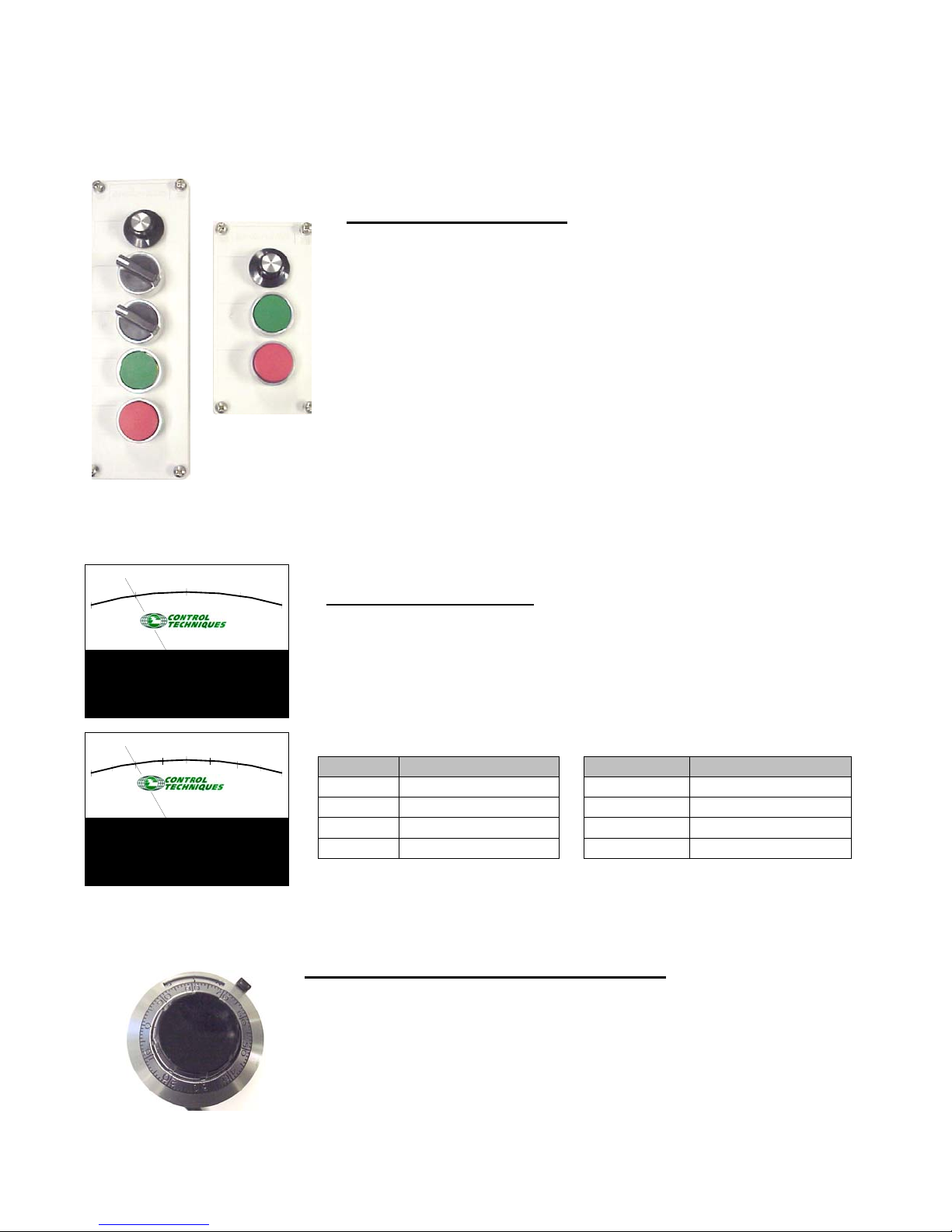

Remote Operator Station – P/N 2950-9068 /2950-9066

Speed

Run

Jog

Auto

Man

Start

Stop

25

0

25

50

75

100 100

Start

Stop

-

50

0

75

100

25

50

75

These NEMA 1 operator stations can be used to remotely

control Focus 1 and Focus 3 Motor Controllers. Two models

are available as shown. Both units include a Speed

Potentiometer, a green normally open start button and a red

normally closed stop button. The 2450-9068 also includes

two two- position switches with two contacts, 1 normally

open, 1 normally closed.

Remote Percent Meters – P/N See Accessories Catalog

This meter may be used to remotely display the motor speed in

percent of maximum speed. Included is a calibration board. It is

available in left zero (unidirectional applications) or 0-center (bidirectional applications) Meters supplied loose for customer

mounting.

P/N Meter P/N Calibration board

M1 Meter 0 - 100 C1 Cal+/-10vdc

M2 Meter 0 - 150 C2 Cal-90vdc

M3 Meter 100 –0 -100 C3 Cal-180vdc

M4 Meter 150 –0 -150

Ten-Turn Precision Speed Potentiometer – P/N 6160-9001

This is a multi-turn speed potentiometer. It provides a vernie

scale for precise and repeatable speed setting. A locking tab is

provided to prevent in advertent speed changes. It may be

mounted in either of the Focus 1 and Focus 3 enclosures or the

Remote Operator Station described above.

Page 20

Page 27

r

r

These options are

used with the

chassis mount

controls and

include Din rail for

panel mounting in

the customer’s

enclosure.

Speed Potentiometer – P/N SpdPot

This potentiometer can be used for either a remote speed

command potentiometer or a remote current limit

potentiometer.

120Vac Interface – P/N ACIF-2R-Focus – Run/Stop & Jog

This kit is available for the Focus series of drives. It is designed

to provide a 120-Vac interface for applications requiring

remotely mounted industrial operator devices (i.e. Operato

Stations shown on previous page).

120Vac Interface – P/N ACIF-6R-Focus – Run/Stop

Forward/Reverse, Jog and Auto/Manual

This kit is available for the Focus series of drives. It is designed

to provide a 120-Vac interface for applications requiring

remotely mounted Industrial operator devices (i.e. Operato

Stations shown on previous page).

Page 21

Page 28

Customer Connections & Start-Up

r

r

NOTE

Read this manual in its entirety, paying particular attention to the Warnings and Cautions

in each section before installing, starting, or maintaining this drive.

Improper procedures can result in personal injury or equipment damage. Only qualified

electrical maintenance technicians familiar with electronic drives and their standard safety

precautions should be permitted to install, start-up, or maintain this apparatus.

Start-up Guidelines

STEP 1: Receiving & Inspection Page 7

STEP 2: Drive Installation . . . Page 21

STEP 3: Power Wiring Pages 22-24

STEP 4: Control Wiring Pages 25-32

STEP 5: Jumper Programming Pages 33-37

STEP 6: Potentiometer Adjustments Pages 39-45

STEP 7: Start-up of Drive Page 48-54

Installation of this equipment must be done in accordance with the National Electrical

Code and all other applicable regional or local codes. Proper grounding, conducto

sizing, and short circuit protection must be installed for safe operation. Imprope

installation or operation of this control may cause injury to personnel or damage to

equipment.

Hazardous voltages may be present on external surfaces of ungrounded controls. This

can result in personal injury or equipment damage.

When performing visual inspections and maintenance, the incoming AC power must be

turned off and locked out. Hazardous voltages will be present until the AC power is

turned off. The drive contactor does not remove hazardous voltages when opened.

Page 22

Page 29

Incoming Power Requirements

A remote fused AC line disconnects or circuit breaker installed ahead of the control is required

by the NEC (National Electrical Code). The control is designed to accept single-phase AC line

voltage.

Grounding

The control must be connected to earth ground either via mounting screws provided by an

enclosure or chassis-installed screw or by using the Earth Ground lug provided on the drive

heatsink, for safety of operating personnel. The ground wire should be of the same gauge as

the AC Input wires and must be connected to the panel or enclosure frame for personal safety.

Wiring Guidelines for Focus DC Drives

Check drive nameplate data for conformance with AC power source and motor

AC

Catalog HP Fusing Max

Part # Volts Amps AWG Volts Amps AWG Volts Amps AWG

F3R2C ¼ -1

½-2

F3R2E ¼ -1

½-220Amp

F3R5E

F3R5E

F3R5E

F3R5E

3 60

5 60

20

Amp

250Vac

250Vac

Amp

500Vac

Amp

500Vac

120

240

120

240

240 24 #10 180 15 #10 200 1 #14

240 40 #8 180 25 #8 200 1 #14

Input

16

16

16

16

Wire Armature

#14 90

180

#14 90

180

DC Output Shunt Field

Armature Wire Field Field Wire

10

10

10

10

#14 100

200

#14 100

200

1

1

1

1

#14

#14

Notes:

All wiring based on 75° C copper wire, types FEPW, RH, RHW, THHW,

THW, THWN, XHHW, USE, ZW

Wire gauge size based on 30° C maximum ambient and no more than

three conductors in a raceway or cable and 1.25 service factor.

Please refer to National Electric Code Table 310-16 for additional

information.

Wiring must also meet all Local Codes.

Do not place knife switches, polarity reversing switches, reversing contacts in

the armature or field circuits.

During normal operation, keep all covers in place and cabinet doors shut.

Page 23

Page 30

Motor Thermal Switch

For Motor Thermostat wiring, see the “Control Wiring” section.

Wrong Motor Rotation

If the motor rotates in the wrong direction, one of the following changes will correct it:

Exchange Al and A2 output Motor Armature leads.

Or

Exchange Fl and F2 Motor Shunt field leads.

If DC Tachometer Feedback is being used, Tach wires will also need to be swapped.

Installation of Option Kits

Do not install option kits until you have verified the basic operation as outlined in the

Start-Up section.

Pre-installation of option kits before verification of basic drive operation will make

troubleshooting much more difficult. Option kits are often installed incorrectly and one

cannot determine if the drive was functional before kits were installed.

Page 24

Page 31

Drive Power Wiring

)

¼ - 2 HP Focus 3 Models

F3R2E & F3R2C

F+ F- A+ A-

A+ & A- are the motor

Armature leads

F+ & F- are a shunt wound

motors Field leads

( they will not be present on

Permanent Magnet or

Universal Motors

AC Line

Input

Earth

Connection

Page 25

Page 32

Drive Power Wiring

)

3 - 5 HP Focus 3 Models

F3N5E & F3N5C

AC Line

Input

Earth

Connection

A+ & A- are the motor

Armature leads

F+ & F- are a shunt wound

motors Field leads

( they will not be present on

Permanent Magnet or

Universal Motors

A+ A- F+ F-

Page 26

Page 33

Control Wiring

TERMINAL CONNECTIONS (TB2) & DESCRIPTIONS

Pin Number

1 +24 Vdc Supply: Powers the logic inputs to the drive. It is not intended

for it to be used to power external circuits. External use will void warranty.

2 Tie Point: It has no internal connections and is used as a tie point for

the Motor Thermal or Stop button connection. see Application Safety

3 Run Input: When +24 Vdc is applied to this terminal, the Run relay picks

up, the Speed loop and the Current loop are enabled, and the clamp on

the SCR firing circuits is released.

4 Run Relay Contact Output: Normally Open connection. Rated:

0.5amps @ 120VAC for non-inductive loads. It can be used as the seal-in

contact in a three-wire run circuit or as the run contact feedback in a twowire system.

5 Run Relay Contact: Relay common connection.

6 Run Relay Contact: Normally Closed connection. Rated: 0.5amps. @

120VAC for non-inductive loads.

7 Jog Input: When +24 Vdc is applied to this input, the output of the

accel / decel circuit is electronically disconnected from the speed loop and

the jog speed command (from the jog speed pot) is electronically switched

in. This jog speed command can be configured as a Thread speed

(maintained jog speed) by jumpering terminals TB2-3 & 4 in addition to the

Run/Jog connections already shown on page 30.

8 Jog Potentiometer Supply voltage input: This terminal is typically

connected to the +10 Vdc (TB2-9) speed pot supply when jog is required.

9 +10 Vdc Speed pot / Jog supply voltage: Maximum load is 5ma

therefore the recommended Jog Pot value would be 5K ohms

10 Standard Speed command input: Typically this input is connected to

the wiper of the speed pot wiper. Input impedance: 20Kohm.

11 -10 Vdc Speed pot / Jog supply voltage: Maximum load is 5ma

therefore the recommended Jog Pot value would be 5K ohms

Page 27

Page 34

TERMINAL CONNECTIONS (TB2) & DESCRIPTIONS

12 Drive Signal Common Connection: Drive circuit common connection.

13 Minimum Speed Potentiometer Connection: This terminal is used in

conjunction with the speed pot to provide a minimum speed setting. It is

compatible with the Forward/Reverse switch option.

14 Remote Current Limit Potentiometer: Wiper connection. Jumpers JP6

& JP7 must be set to RMT position. Shielded cable should be used for

wiring purposes if the pot is not mounted on the drive front cover. A

standard pot (5Kohm) may be used – see Accessories/Options

15 Remote Current Limit Potentiometer: Clockwise connection. Jumpers

JP6 & JP7 must be set to RMT position. Shielded cable should be used

for wiring purposes if the pot is not mounted on the drive front cover. A

5Kohm potentiometer should be used, see Accessories/Options

Note: Counter clockwise connection and shield should be connected to

terminal TB2 pin 12.

16 Auto/Manual Input: When +24 Vdc is applied to this terminal, the speed

command input to the accel/decel circuit is switched from the standard

speed pot input to the follower (current or voltage) speed command

derived from terminal TB2- pins 17 or 18. If the current/voltage follower is

the only signal used, terminals TB2- pins 2 & 16 must be jumpered.

17 Current Signal Follower Input: positive input for external mA current

source. Input impedance: 100 ohms. Range: 0-5mA or 0-20 mA

** Note: The Current Signal Follower Input on the Focus 3 Regenerative Drives is designed for 0

to 5 or 0 to 20 ma, not 1 to 5 or 4 to 20 ma. The circuitry can be adjusted to bias out the 1 or 4

milliamp current levels and the drive will follow the signals correctly. The difference is that if the

current input drops below the 1 or 5 ma level, the drive will rotate in the reverse direction ( as

much as 25% speed if the signal goes to zero). If a 1 to 5 or 4 to 20 ma signal is required on a

Focus 3 Regenerative Drives, it is recommended that the Focus 3 Signal Isolator board (F3NSBD)

be used since it has circuitry built in to block the reverse speed signal.

For more detailed information click on the “blue” F3NSBD above.

18 Voltage Signal Follower Input: positive input for external voltage

source. Input impedance: 1 Kohm/volt. Range: 0-200 Vdc.

19 DC Tachometer Input: negative input from motor mounted DC

tachometer. Input impedance: 120 Kohm in the high position and 13.5K

ohm in the low position. Range at maximum speed: 6.5 to 17.4 Vdc in the

low position and 60 –160 Vdc in the high position. Note: virtually any

tachometer voltage can be used with the addition of an external resistor in

series with the tach lead (consult factory it required).

20 DC Tachometer Input: positive input from motor mounted DC

tachometer. Note: Cable shield should also be connected to this terminal.

Page 28

Page 35

Terminal Block (TB2)

t

t

r

j

Installation

On chassis drives, the terminal block

(TB2) is installed so that control wires are

inserted into the terminal point from the

right side of the block. For enclosed drives,

the terminal block must be installed so

wires extend up (900 angle) from the drive

PC board. lf the control wires extend ou

to the side, there is not sufficien

clearance space for the enclosure

cover.

If the customer supplied moto

thermal is not used, pins 1 & 2 must be

umpered or the drive will not start.

NOTE:

Enclosed

Units

Wire Entry

Chassis

Units

Wire Entry

Shielded wire (2 or 3 conductor) is

recommended for speed command and

other signal wire connections. Shields

should be taped off at the remote end. At

the drive, connect shields to the circuit

common, route wire away from high

current lines (i.e. AC lines and armature

wiring).

Recommended Cables and pots are

available from :

Control Techniques Service Center

@ 1-800-367-8067

Signal &

Control Wiring

Entry

Page 29

Page 36

Terminal Strip Connections

r

p

A

y

Enclosed Model

Standard Start / Stop & Speed Potentiometer Connections

Motor Thermal or Jumper

1

2

(customer supplied)

Sto

3

4

5

9

10

13

12

*

CW

Chassis Model

Start

Drive will not start without this. This

is intended for system interlock- see

pplication Safet

The Start/Stop Switch

And the Speed

Potentiometer are

supplied as shown on

the drive cove

The Chassis Model has no

operator devices connected to

the drive control terminal strip.

The only connections made

are connections from terminal

#3 to #4 which is required for

three wire Start/Stop controls.

The next four pages show various configurations of operator control devices and speed

(or current) adjustment potentiometers. These can be used on Chassis models, which is

typically the case, or the Enclosed models, which would require possible enclosure and

internal wiring changes. The two wire configuration (top of next page) is commonly used

for remote contol of the drive (i.e. PLC control).

Page 30

The Speed Potentiometer is

supplied “loose” with the drive.

Page 37

Optional Terminal Strip Connections

y

y

p

p

A

y

A

y

Note: It is strongly recommended that all remote control connections to the drive (i.e. speed pot,

start / stop etc.) are wired with shielded cable for noise immumity

1

2

3

4

10

12

* Jumper installed at factor

*

+

-

Two Wire ON / OFF

with remote 0 to +10Vdc Speed

command

1

2

3

4

5

9

10

13

12

1

2

3

4

5

Sto

Start

*

CW

* Jumper installed at factor

Motor Thermal or Jumper

(customer supplied)

Motor Thermal or Jumper

(customer supplied)

Sto

Start

Run/Jog

Drive will not start without this. This

is intended for system interlock- see

pplication Safet

Three Wire Start / Stop

With Uni-polar Speed Potentiometer

Drive will not start without this. This

is intended for system interlock- see

pplication Safet

Three Wire Start / Stop

with Run / Jog Selector Switch

7

8

*

9

10

13

12

CW

-

* When using Jog function, remove factory installed

jumper from terms 3 & 4

and add to terms #8 & 9

Page 31

Page 38

Typical Terminal Strip Connections

p

V

A

y

Note: It is strongly recommended that all remote control connections to the drive (i.e. speed pot,

start / stop etc.) are wired with shielded cable for noise immumity.

Drive will not start without this. This

Motor Thermal or Jumper

1

2

3

4

5

7

(customer supplied)

Sto

Start

Run/Jog

(Switch shown in

run position)

is intended for system interlock- see

pplication Safet

Three Wire Start / Stop

with Run / Jog Selector Switch

8

9

10

13

12

14

15

16

17

18

19

20

CW

With Uni-polar Speed Potentiometer

To Pin #1

With

Manual / Auto Speed command Selector

Switch

(Manual – Speed Pot)

+

+

-

I

-

-

DC Tachometer Input

+

Current Signal Input

Voltage Signal Input

(Auto – Either Current Signal

or

Voltage Signal)

With

DC Tachometer Feedback

Shielded cable should be 3 conductor with overall shield w/pot end tied off and dressed.

Cable and pots are available from Control Techniques Service Center @ 1-800-367-8067

Cable P/N 3CONCBL-XXX (XXX in feet)

Page 32

Page 39

Typical Terminal Strip Connections

p

A

y

Note: It is strongly recommended that all remote control connections to the drive (i.e. speed pot,

start / stop etc.) are wired with shielded cable for noise immumity. These are all low voltage

signals.

Drive will not start without this. This

is intended for system interlock- see

Motor Thermal or Jumper

1

2

3

4

5

7

(customer supplied)

Sto

Start

Run/Jog

(Switch shown in

run position)

pplication Safet

Three Wire Start / Stop

With Run / Jog Selector Switch

8

9

10

13

12

14

15

16

17

18

19

20

CW

Speed

Potentiometer

Current Limit

Potentiometer

CW

-

DC Tachometer Input

+

With

Uni-polar Speed Potentiometer

With

Remote Current Limit Potentiometer

With

DC Tachometer Feedback

The Current Limit potentiometer is

available from Control Techniques;

see accessories section, page 20

Shielded cable should be 3 conductor with overall shield w/pot end tied off and dressed.

Cable and pots are available from:

Control Techniques Service Center @ 1-800-367-8067

Cable P/N 3CONCBL-XXX (XXX in feet)

Page 33

Page 40

Typical Terminal Strip Connections

p

Note: It is strongly recommended that all remote control connections to the drive (i.e. speed pot,

start / stop etc.) are wired with shielded cable for noise immumity. These are all low voltage

signals.

Drive will not start without this. This

is intended for system interlock- see

Application Safety

Three Wire Start / Stop

With Run / Jog Selector Switch

With Forward / Reverse Switch

1

2

3

4

5

7

8

9

10

11

13

Motor Thermal or Jumper

(customer supplied)

Sto

Start

Run/Jog

(Switch shown in

run position)

Forward /

Reverse

(shown in

Forward)

CW

12

15

16

17

18

19

20

-

DC Tachometer Input

+

Speed

Potentiometer

Speed Potentiometer

With

DC Tachometer Feedback

The Current Limit potentiometer is

available from Control Techniques;

see accessories section, page 20

Shielded cable should be 3 conductor with overall shield w/pot end tied off and dressed.

Cable and pots are available from:

Control Techniques Service Center @ 1-800-367-8067

Cable P/N 3CONCBL-XXX (XXX in feet)

Page 34

Page 41

Standard Unipolar Speed Potentiometer Wiring

+10vdc

Ref.

Min Spd

Common

9

10

13

12

Cable should be 3 conductor with overall shield w/pot end

tied off and dressed. Cable and pots are available from:

Control Techniques Service Center @ 1-800-367-8067

Cable P/N 3CONCBL-XXX (XXX in feet)

Wiper

CWCCW

Speed Pot

Rear View

CCW=counter

clockwise

Speed Potentiometer P/N SpdPot

Page 35

Page 42

Customer Jumper Selections

Jumper Programming

Equipment damage and/or personal injury may result if jumper programming is

attempted while control is operational. Always lock out power at the remote

disconnect before changing jumper positions.

See page 36 for jumper locations

JUMPER DESCRIPTION RANGE FACTORY SETTING

JP1 Optional “M” Contactor Yes or No No Contactor

Sequencing Module (NO JUMPER)

JP2* Speed or Current Control Speed or Current Speed

Mode (see next page) (SPD) (CUR)

JP3 Tachometer Feedback Low (6.5-17.4 Vdc) or HI

Range (at max. speed) HI (60-160 Vdc)

JP4 Speed Feedback Selector Tachometer (TACH) or Armature

Armature (ARM)

JP6 Local or Remote Current Local or Remote (RMT) Local

Limit Pot Selector

JP7 Local or Remote Current Local or Remote (RMT) Local

Limit Pot

JP8 Armature Voltage LOW (90 Vdc) or HI (180 Vdc)

Level Selector HI (180 Vdc)

JP9 Current Feedback A thru D C

Range (see next page)

JP10 Line Frequency Selector 50 or 60Hz (w/ jumper) 60Hz

JP11 Input Voltage 120 or 240Vac 240Vac

Selector (see Table below)

Input Line Voltage JP11 Jumper Positions

120Vac A to E and B to D

240Vac

Items in BOLD RED are factory set positions

Page 36

A to C and B to C

Page 43

Current Feedback Range (JP9)

FOCUS Catalog DC Output Current JP9

Number (Amps) Jumper Position

2.6 No Jumper

(1/4 – 2 HP) 5.5 A

F3R2C 7.5 B

F3R2E 10 C

5.2 No Jumper

(3 – 5 HP) 11 A

F3R5E 15 B

F3N5E 20 C

25 D

Current Control Mode

Focus 3 Drives can be configured to operate in the Current Control Mode which is often

referred to as making the drive a “Current Regulator”. Since motor torque is directly

proportional to the armature current, a drive configured as a Current Regulator is often

referred to as a “Torque Regulator”.

*If using the Focus drive as Torque Regulator, make the following

adjustments:

JP2: Select current (CUR) control

JP4: Select tachometer (TACH) feedback, but do not use a tachometer.

JP9: Select the appropriate current feedback range.

ACCEL and DECEL pots: Set to full counterclockwise position.

LOCAL CURRENT LIMIT pot: Set to full clockwise position.

In torque control mode, the motor speed is determined by how much load there is on the

motor and the torque level set on the drive. If torque in the motor (as set by the Drive) is

set to a level higher than what is required to move the load, the motor will accelerate in

speed until either the load from the motor increases to the level set by the drive or the

drive reaches its maximum output voltage (as set by the line voltage).

In the case of a lightly loaded motor,

the motor could accelerate to almost twice-base speed under these conditions.

In this mode the user be aware of this and MUST PROVIDE OVERSPEED PROTECTION.

Page 37

Page 44

JP5

IR Comp

Positive

Or

Negative

JP2

Regulation

Mode

Speed /

Current

JP10

50 / 60 Hz

Operation

(in = 60Hz)

Programming Jumper Locations

Optional

Motor

Contactor

Control

Connection

JP6 / JP7

Current

Limit Pot

Selection

Local or

Remote

JP4

Armature/

Tachometer

JP8

Armature

Voltage

Range

JP9

Maximum

Output

Current

Selection

JP3

Tachometer

Feedback

Range

Selector

JP11

AC Input

Range

Selection

Page 38

Page 45

Jumper Programming

j

r

JP3-Tach Feedback Range

Lo - 6.5 to 17.4 Vdc

Hi - 60 to 160 Vdc

JP4 -------- Feedback Selector

Tachometer (Tach)

Armature (Arm)

JP8 --------- Armature Voltage

90 Vdc

180 Vdc

Bold Fonts indicate Factory Settings

JP11 ---- Input Voltage

120 Vac A to E

&

B to D

240 Vac A to C

Photo shown

umpered fo

240 Vac input

B to C

&

Page 39

Page 46

JP9 -- Max Output Current

y

(100%)

Removed - 2.7 A and less

A – 5.5 A

B – 6.4 A

C – 7.5 A

D – 10A

Select based on Armature

requirements

JP6 & JP7 --- Remote

Current Limit

Pot Select

Local – Uses Current

Limit pot on

Control Board

Bold Fonts indicate

Factor

Page 40

Settings

Remote – Uses remote

Current limit

Potentiometer

Page 47

LED Status Indicators

Run

Current

Run LED – This red led will illuminate any time the run relay is energised

Curr Lmt (Current Limit) LED – This yellow led will illuminate any time one

of the three conditions are met:

1. The drive is at the maximum output

current as set by the current limit

potentiometer and the selected position

of JP9

2. The motor is at the maximum output

voltage as possible based on the supply

voltage.

3. The motor armature is open circuit

( no motor connected )

Page 41

Page 48

Internal Adjustments I Potentiometers

Deceleration

Acceleration

Velocity

Stability

Maximum

Speed

Jog

Speed

Adjust

Local

Current

Limit

Minimum

Speed

Current

Follower

Voltage

Follower

Speed

Rate

Page 42

Current

Stability

Follower Zero

Bias Adjust

Page 49

Basic Customer Adjustments

A

r

A

f

j

Maximum Speed (MAX SPD)

The MAX SPD pot sets the maximum motor speed (80-120% of motor base

speed) allowed. It is factory preset to the midway position. Note: Do not exceed

motor nameplate maximum speed rating. With the motor running, turn the speed

pot on the drive enclosure cover/operator control panel fully clockwise while

monitoring actual motor RPM or by measuring the Armature Voltage on A+ & A-.

Then, adjust the MAX SPD pot on the control board to set the desired maximum

motor speed. Do not exceed the motors Armature Voltage nameplate rating.

Minimum Speed (MIN SPD)

The MIN SPD pot sets the minimum speed (0-30% of maximum speed

setting) at which the motor will run. It is factory preset at its full counterclockwise

position. With the motor running, turn the speed pot on the drive enclosure

cover/operator control panel fully counterclockwise. Adjust the MIN SPD pot

clockwise until the desired lowest motor speed is reached.

Acceleration and Deceleration Times (ACCEL / DECEL)

djust the ACCEL and DECEL pots clockwise to increase the linea

acceleration and deceleration times (0.3-30 seconds). These adjustments are

independent from each other. Note: Controlled deceleration time occurs when the

speed pot is turned down, but not when the start/stop switch is placed in the STOP

position. Note: When the drive is used in torque (current) control mode, the

CCEL/DECEL pots adjust how quickly the motor torque level changes as the

main torque pot is varied.

Local Current Limit (LOC ILMT)

Set the LOC ILMT pot to limit the motor armature current to 150% or less o

the motor nameplate rating. It should represent the lowest level consistent with

satisfactory operation. The pot is factory preset at 150% of the range selected by

umper JP9 (A-D).

The yellow Current Limit LED indicator light on the drive control board

illuminates when the armature current reaches 95-100% of the current limit setting.

Jog Speed (JOG SPD)

Adjust the JOG SPD pot clockwise to increase the speed (0-30% of full speed

reference) at which the motor will run when in jog mode. It is factory preset to its

full counterclockwise position.

Page 43

Page 50

Acceleration and Deceleration Times (ACCEL / DECEL)

v

A

v

v

The Focus 3 Regenerative DC Drive is a bi-directional drive, meaning that the drive can

follow speed reference ranging from (+)10vdc (full speed forward) to 0 to (-)10vdc (full

speed reverse). The acceleration and deceleration times are set by two potentiometers

on the control board. Since there are only two, one sets the time to change from

(+)10vdc to (–)10vdc while the other sets the time to change from (-)10vdc to (+)10vdc.

In essence, what this means is that the acceleration potentiometer sets the acceleration

time in the forward direction and the deceleration time in the reverse direction and vice

versa. The diagram below shows this graphically.

Time set by Acceleration potentiometer

Time set by Deceleration potentiometer

+10vdc

Forward

1

-10vdc

Reverse

Fwd

Accel

Fwd

Decel

Re

ccel

Time

Re

Speed

Re

Decel

Page 44

Page 51

Basic Customer Adjustments

Acceleration

and

Deceleration

Time adjustments

JOG

SPEED

Sets Jog

Speed

MAX SPD

Adjust for maximum Motor speed

MIN SPD

Adjust for

minimum

Motor speed

Local Current Limit

Limits maximum Output Current

Page 45

Page 52

Additional Tuning Adjustments

Internal Resistance Compensation ( IR COMP )

Compensation pot is used to overcome the motor’s natural tendency to slow

down as the load increases. If the motor slows down excessively as it is loaded, adjust

the IR COMP pot clockwise to recover speed lost during the loaded condition. The

motor will oscillate in speed or “hunt” if the IR COMP pot is adjusted too far clockwise.

If this pulsing of speed occurs, adjust the IR COMP pot counter clockwise until the

motor speed stabilizes.

If JP4 is set in the TACH position indicated tachometer feedback is being used,

turn the IR COMP pot fully counter clockwise otherwise instability will occur.

Note: If the drive is using the voltage or current signal follower, perform these

adjustments with the Auto/Manual switch in the Manual position.

Velocity Stability (VEL STAB)

The VEL STAB pot helps match the dynamic characteristics of the drive to the

dynamic characteristics of the DC motor and its load. The drive’s outer velocity loop

includes an electrical “lead” circuit to compensate for the mechanical “lags” that exist in

both the DC motor and its driven mechanical system. The VEL STAB pot adjusts the

time constant of this lead circuit.

Clockwise rotation causes the drive to respond more quickly to speed

command/speed feedback changes but increases the overshoot experienced by the

drive. Counterclockwise adjustment of this pot dampens the drive response. It is factory

preset at the midway position.

Current Stability (ISTAB)

The ISTAB pot matches the dynamic characteristics of the drive to the dynamic

characteristics of the DC motor armature. The drive’s inner current loop includes an

electrical “lead” circuit to compensate for the electrical “lag” that exists in the DC motor

armature current. The ISTAB pot adjusts the time constant of this lead circuit.

In torque (current) control applications, the velocity loop is bypassed and the

current loop is used. For speed (velocity) control applications, the current loop is fed

from the output of the velocity loop.

The current loop responds to current changes quickly. Therefore, the ISTAB pot

is very sensitive and harder to adjust properly. Clockwise rotation causes the drive to

respond more quickly to current changes, but the factory shipped setting is usually

adequate for most applications.

Speed Loop Offset (SPD OFFSET)

This pot is used to zero out any offsets in the speed loop amplifier. With the

speed pot set to zero (as well as the Min Spd pot, if used), adjust the SPD OFFSET so

any “creep” in the motor speed is eliminated with zero speed command. It is factory

preset to its midway position.

Page 46

Page 53

Additional Tuning Adjustments

Velocity Stability

(VSTB)

Adjust for speed loop

stability

IR Comp

Adjust for motor speed

droop due to load

Current Stability

(ISTB)

Adjust for current

loop stability

Speed Loop Offset

Adjust for zero creep

speed

Page 47

Page 54

Optional Tuning Adjustments

Speed Rate Feedback (Spd Rate Fdb)

Used with the VEL STAB pot, the SPD RATE FDB pot controls the relative magnitude of

the “lead” circuit in the velocity loop. Clockwise rotation reduces the drive’s velocity rate

of change and decreases the overshoot experienced by the drive. Normally used in

tachometer feedback applications, this pot is factory set to its full counterclockwise

position.

The following adjustments are only required when either the current follower input (i.e.

4-20 mA input) or the voltage follower input (i.e. tachometer follower) is used. Only one

of these inputs may be used. Terminal #16 must be tied to +24 Vdc (terminal #1) to

activate the follower input speed command; typically this selection is made by the

Auto/Manual selector switch (see page 31) .

Signal Follower Zero Bias (BIAS) used with Voltage Input (TB2-18)

The BIAS pot prevents “creep” in the motor speed by eliminating any unwanted

offset voltage levels in the voltage source. It may also be used to add a slight offset to

the voltage signal.

Signal Follower Zero Bias (BIAS) used with Current Input (TB2-17)

Adjust the BIAS pot so the drive is at zero speed when the minimum current

signal follower speed command (0-20 or 0 –5 mA) is applied.

If a 4-20mA (or 1-5mA) speed command is required, use the optional signal

isolation board (F3NSBD). SEE Note on page 8

Voltage / Speed Signal Follower Gain (SP REF GAIN)

The SP REF GAIN pot calibrates the User supplied Voltage Signal Follower

speed command (0 - 200 Vdc) so the motor reaches its rated voltage/speed when the

input voltage signal is set to its maximum value. It is factory preset to its full

counterclockwise position.

Current Signal Follower Gain (IREF GAIN)

The IREF GAIN pot calibrates the User supplied Current Signal Follower speed

command ( 0-5mA or 0-20mA ) so the motor reaches its rated voltage/speed when the

current signal is set to its maximum value. It is factory preset to its full clockwise

position. SEE Note on page 8

Page 48

Page 55

Optional Tuning Adjustments

Speed Rate

Zero Bias

Speed

Reference Gain

Current

Reference

Gain

Page 49

Page 56

Page 50

Page 57

Page 51

Page 58

Start-up Guide Worksheet

Improper procedures can result in personal injury or equipment damage. Only qualified electrical

maintenance technicians familiar with electronic drives and their standard safety precautions

should be permitted to install, start-up, or maintain this apparatus.

At this point all INPUT POWER must be OFF !

Obtain the following information:

Focus Drive Model

F3R2C or F3R2E Drive Serial Number

F3R5E or F3R5E Drive Part Number _____________

a) AC Input Line Voltage 240 Vac

120 Vac

b) Motor Nameplate Information: Armature Voltage _________Vdc

Armature Current _________A

Field Voltage _________Vdc

Field Current _________A

Rated RPM _________ rpm

c) Type of Speed Feedback Armature Voltage ( most common case )

DC Tachometer

Focus drives come to you factory set for Armature Voltage feedback. Even if your

motor is equipped with Tachometer for Speed feedback, we would strongly suggest

that you first run your motor using Armature Voltage initially. After you have set the

motors maximum speed in Armature Voltage feedback, you can check your

tachometers output to verify that it producing the correct output before actually using it.

d) Regulation Mode Speed ( most common case )

Torque ( read first ! )

Focus drives come to you factory set for Speed Regulation mode which is the most

common case. Even if your application requires Torque control, we would strongly

suggest that you first run your motor Speed Control initially. After you have verified

Page 52

Page 59

proper operation in the Speed mode, you could then switch over to Torque mode.

Page 53

Page 60

Focus 3 Jumper Setup Worksheet

Refer to the data recorded on the previous page for this worksheet

Refer to your motor nameplate data.

STEP 1 Does your motor have a shunt field winding?

If No go to STEP 5 otherwise go on.

STEP 2 Is your motor field current greater than 1.1A?

If No, go to STEP 3

If Yes STOP The Focus 3 Field Supply rectifier will be damaged!!!

Call Tech Support for a solution.

STEP 3 If your motor field voltage is 100 Vdc,

then you must use 120 Vac for Input Power ----- Set JP11 as shown

and Set JP8 to Low

then go to STEP 7

If you must use 240 Vac ----- Call Tech Support for a solution

otherwise go to STEP 4

: :

STEP 4 If your motor field voltage is 200 Vdc,

then you must use 230 Vac for Input Power ---- Set JP11 as shown

and Set JP8 to Hi

then go to STEP 7

otherwise STOP ---- Call Tech Support for a solution

STEP 5 If your motor armature voltage is greater than 110 Vdc,

then you should use 230 Vac for Input Power ---- Set JP11 as shown

and Set JP8 to Hi

then go to STEP 7

If you must use 120 Vac ---- Call Tech Support for a solution

otherwise go to STEP 7

STEP 6 If your motor armature voltage is less than 110 Vdc,

then you must use 115 Vac for Input Power ----- Set JP11 as shown

and Set JP8 to Lo

then go to STEP 7

: :

Page 54

Page 61

Armature Current Programming - (JP9) Current Feedback Range

STEP 7

Are you applying a Focus Model F3R2C or F3R2E ? If yes, then set jumper JP9 to the

letter that matches up most closely with your motors Armature Amp rating from the table below:

otherwise go to STEP 7a

FOCUS Catalog DC Output Current JP9

Number (A) Jumper Position

2.6 No Jumper

(1/4 – 2 HP) 5.5 A

F3R2C 7.5 B

F3R2E 10 C

then go to STEP 8

STEP 7a

Are you applying a Focus Model F3R5C or F3R5E? If yes, then set jumper JP9 to the

letter that matches up most closely with your motors Armature Amp rating from the table below:

otherwise go to STEP 7

FOCUS Catalog DC Output Current JP9

Number (A) Jumper Position

5.2 No Jumper

(3 – 5 HP) 11 A

F3R5C 15 B

F3R5E 20 C

25 D

Page 55

Page 62

Application Safety

When applying a motor drive in a manufacturing process, one must understand that the

motor drive merely provides the energy for a motor to turn and it will do so without

regard upon activation and command. There could be failure modes in any external

interface equipment and/or the Focus drive itself that could cause the motor to turn

suddenly at any speed or cause it to fail to stop on command without warning. When

considering Operator safety the Installer must include and employ additional

equipment to provide safeguards to insure Operator safety.

Consult all NEC and OSHA machine safety recommendations and guidelines.

These safeguards are the sole responsibility of the Installer. For these reasons, the

Installer must envision all, implement all and test or simulate all failure methods. The

Installer is responsible for his/her resulting implementation to insure safe and reliable

operation of the installation.

In addition, the Installer should provide the End User of his Installed system with a

System User’s Manual and instruct the User/Operator on correct/safe operation.

Instruction should include the demonstration and purpose of safety features that you the

Installer has included and the importance of periodic testing to insure they do indeed

operate as designed. The Installer should instruct, inform and warn his End User

customer against bypassing the safety permissives the Installer has provided.

NOTE: Without the use of the Contactor option, P/N 2400-9001 (or the Reversing

Contactor option, P/N 2400-9002, if reverse is required) potential motor movement in the

event of a power line disturbance (causing an SCR (power device) to misfire) can occur

since the motor is connected directly to the power circuit even when the drive is

disabled. It is highly recommended that one of these contactor kits be used to guard

against such occurrences.

Page 56

Page 63

Initial Start-Up

The following procedure is to verify proper operation of the drive in its simplest form as

a basic speed regulator with no option kits installed. It is assumed that the drive is in its

“out of box” condition with respect to jumper programming with the exception of what

was just changed in the previous pages, jumper setup worksheet.

Installation of Option Kits

Do not install option kits until you have verified the basic operation as outlined in the

Start-Up section.

Pre-installation of option kits before verification of basic drive operation will make

troubleshooting much more difficult. Option kits are often installed incorrectly and one

cannot determine if the drive was functional before kits were installed.

Page 57

Page 64

Initial Start-Up con’t

d

A minimal number of connections are made to the terminal strip (see diagrams

below). If the drive is an enclosed unit with operator devices (start/stop and

speed pot) only the jumper from terminal block TB2-1 to TB2-2 needs to be