Page 1

Focus 3

Rugged and Robust

OVERVIEW

The Focus 3 is a single-phase analog drive for DC

motors with power ranges from 1/4 to 5 HP. Years of

proven engineering design matched with surface mount

technology make this newest Focus product rugged and

reliable.

Customer feedback guided the development of the

Focus 3. Many features that were typically available only

as options are now standard, expanding its versatility

and simplifying installation.

Control Techniques’ Focus 3 provides flexibility. You can

DC Drives

stock the complete product line with the four chassis

units (two regenerative and two non-regenerative) and

two enclosure kits.

• Analog DC Drive

• 1/4 to 5 HP, 1 phase, 115-230 VAC

• Non-regen and Regen models

• Isolated control circuit (Regen)

• NEMA 4/12 or Chassis

• Tachometer or armature feedback

• Complete Motor Solutions

FOCUS CHASSIS

—Conveyor

—Rugged

4

3

5

2

6

7

1

8

0

9

1

0

FOCUS

186

F3R2C

F3N5C

F3N2C

F3R5C

Page 2

FEATURE PERFORMANCE

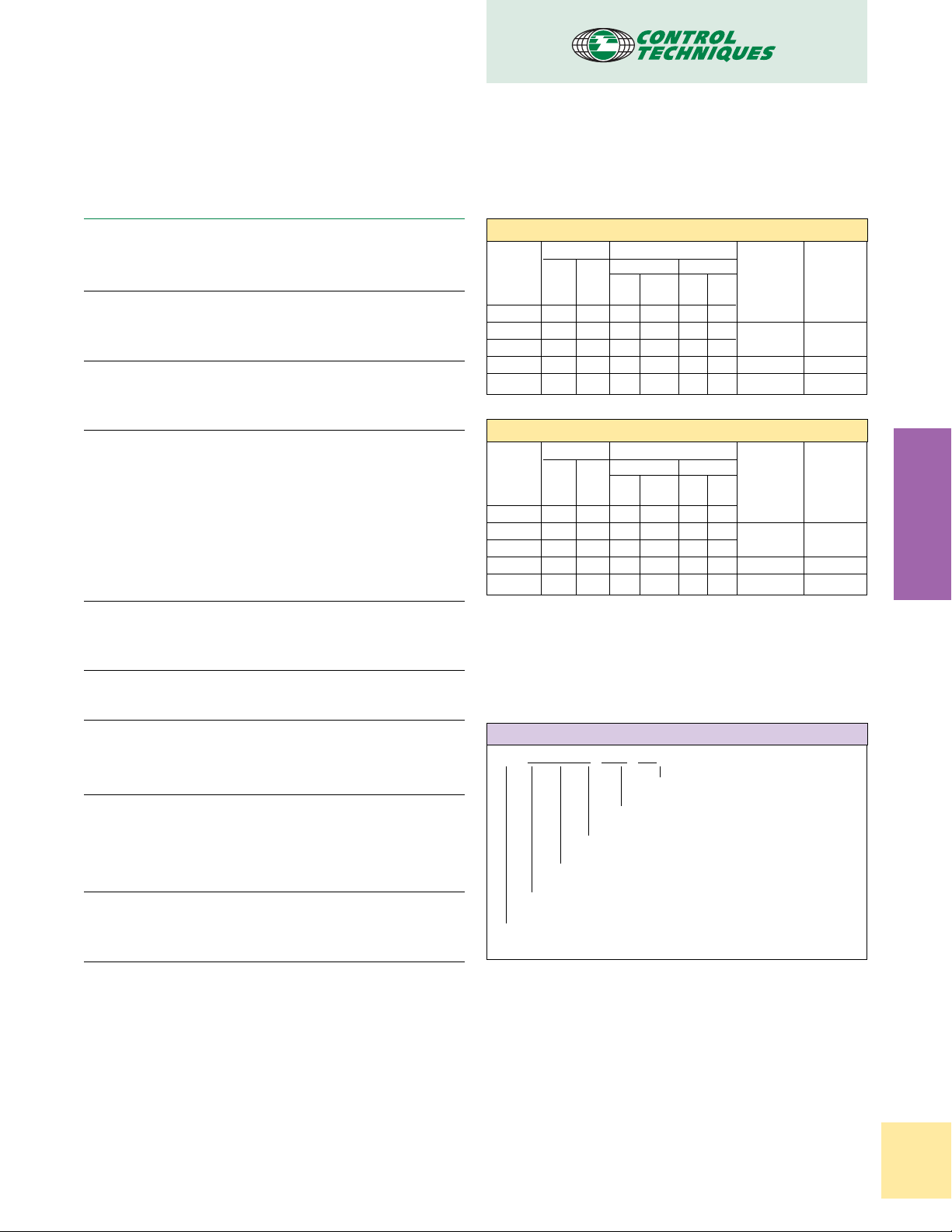

RATINGS: FOCUS 3

SINGLE PHASE INPUT

.25 to 1 HP (115 VAC)

.50 to 5 HP (230 VAC)

Surface mount design

Provides rugged and reliable operation at a cost-

effective price

NEMA 4/12 enclosure as standard

Protects the integrity of the drive in tough,

demanding environments

Regenerative and non-regenerative models available in the

same footprint

Minimizes machine design variations

Jumper programmable for:

Voltage rating (115-230 VAC)

Frequency (50/60 Hz)

Speed or torque control

Tachometer or armature feedback

Inherent flexibility in the drive design meets

numerous customer requirements with a minimal

inventory of drive models and options

Independent acceleration and deceleration rates

Adaptable to many machine and process speed

control requirements

Speed and current loop stability adjustments

Precisely matches the drive to the motor dynamics

Non-regenerative

Motor

HP

.25 to 1 115 14 90 100 10 1

.50 to 2 230 14 180 200 10 1

.25 to 1 115 14 90 100 10 1

.50 to 2 230 14 180 200 10 1

3 to 5 230 35 180 200 25 1 Chassis F3N5C

3 to 5 230 35 180 200 25 1 NEMA 4/12 F3N5E

Regenerative

Motor

HP

.25 to 1 115 16 90 100 10 1

.50 to 2 230 16 180 200 10 1

.25 to 1 115 16 90 100 10 1

.50 to 2 230 16 180 200 10 1

3 to 5 230 40 180 200 25 1 Chassis F3R5C

3 to 5 230 40 180 200 25 1 NEMA 4/12 F3R5E

Input

AC

Volts

Input

AC

Volts

DC Volts Amps

Amps

Arm Field Arm Field

DC Volts Amps

Amps

Arm Field Arm Field

ModelOutput

Chassis F3N2C

NEMA 4/12 F3N2E

ModelOutput

Chassis F3R2C

NEMA 4/12 F3R2E

Order

Code

Order

Code

Focus 3 is available with factory installed modifications.

To order choose the drive required from the table below

and then add modification suffixes to the order code

(separated by hyphens).

DC Drives

Separately adjustable jog speed

Aids the customer in setting up and testing their

machine

Auto (current/voltage signal) or Manual (speed pot)

operation

Provides local or remote speed control without an

option kit

Isolated control circuit (regen)

Signal common can be earth grounded and tied

directly to other drives without additional isolation

Order String

F3 X X X-XX-XX

Modification 2, etc.

Modification 1

C = Chassis, E = Enclosed

Drive Horsepower: 2 = 2 HP, 5 = 5 HP

N = Non-regen, R = Regen

F3 = Focus 3 Product Family

187

Page 3

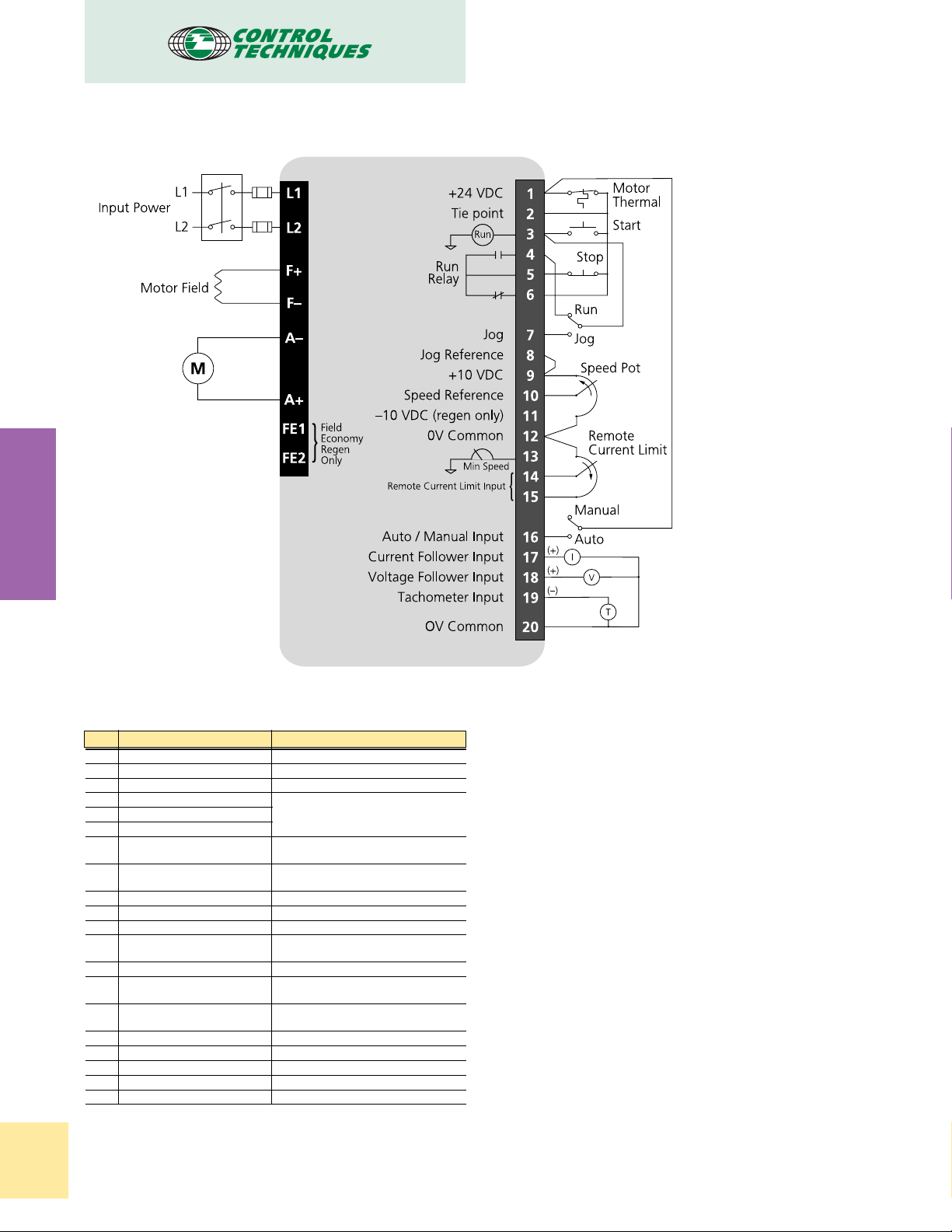

TERMINAL DIAGRAM: FOCUS 3

DC Drives

188

TERMINAL DESCRIPTION

Pin # Type Notes

1 +24 VDC Power Supply For drive use only

2 Tie Point (motor thermal) No internal connection

3 Run Relay +24 VDC @ 10 mA

4 Relay (N.O.) Run relay contact

5 Relay Common 120 VAC, @ 1A resistive

6 Relay (N.C.)

7 Jog Reference Select +24 VDC, 30k Ohms

(Logic Input) (requires run input)

8 Jog Pot Supply Input Analog Input, ±10 VDC

(-10 VDC regen only)

9 +10 VDC Reference Supply, 5 mA max

10 Speed Reference Analog Input, ±10 VDC, 20k Ohms

11 -10 VDC (regen only) Reference Supply, 5 mA max

12 Circuit Common Circuit common hot to earth

ground (non-regen only)

13 Minimum Speed Pot For use with speed pot only

14 Remote Current Limit Pot Wiper input (refer to

Input Jumpers JP6 & JP7)

15 Remote Current Limit Pot CW connection

Input (refer to Jumpers JP6 & JP7)

16 Auto / Manual Input Logic Input, +24 VDC @ 30k Ohms

17 Current follower Input Analog Input, 4-20 or 1-5 mA

18 Voltage follower Input Analog Input, 200 VDC max

19 DC tachometer Input (-) Analog Input, 160 VDC max

20 DC tachometer Input (+) Circuit common

Page 4

SPECIFICATIONS: FOCUS 3

Adjustments

Maximum Speed 80 to 120% of rated speed

Minimum Speed 0 to 30% of maximum speed

IR Compensation 0 to 20% of rated voltage

Current Limit 0 to 150% of selected range

Acceleration 0.3 to 20 seconds

Deceleration 0.3 to 20 seconds

Jog Speed 0 to 30% of rated speed

Operator Functions

Speed Adjustment Standard

Start/Stop Standard (Enclosed)

Customer Supplied (Chassis)

Run/Jog Option Kit

Forward/Reverse (Regen Only) Option Kit

Auto/Manual Option Kit

DIMENSIONS

Rated Input Voltage 115 or 230 VAC

Control Mode Speed or Torque

Output Current Hi / Med / Low / Xlow

Armature Voltage Feedback Hi (180) / Lo (90) VDC

Tachometer Feedback Hi / Lo

Speed Feedback Selector Armature / Tachometer

Line Frequency 50 / 60 Hz

Current Limit Pot Selector Local / Remote

Logic Control Power 24 VDC

Speed Potentiometer 5k Ohms, 2 watts

Speed Regulation

(95% load change):

Armature Voltage Feedback 1% of maximum speed with IR

compensation. (does not include drift

due to field)

Tachometer Feedback (i.e. 5PY) 0.5% of base speed

Customer Selectable

Control

Drive Operating Conditions

NEMA 4/12 Enclosure Standard (Enclosed)

Option Kit (Chassis)

Altitude 1000m (3,300 ft)

Ambient Temperature 0 to 40°C (32 to 104°F) (Enclosed)

0 to 55°C (32 to 131°F) (Chassis)

Rated Input Voltage 115-230 VAC ±10%

Rated Frequency 48 to 62 Hz

Overload Capacity 150% of selected rating

Efficiency:

Controller (min) 98%

Drive (typical) 86%

DC Drives

189

Page 5

Page 6

Focus 3

AC TACHOMETER INPUT

This option kit allows the Focus

3 to accept AC tachometer

feedback. It mounts directly to the

Focus 3 control board and accepts

a range of 45 to 110 VAC at

maximum speed.

Description Order Code

AC Tachometer Input F3ACT

TEN-TURN SPEED POTENTIOMETER

This ten-turn speed

pot provides a vernier

scale for precise and

repeatable speed

setting while a

locking tab prevents

inadvertent speed

changes. It may be

mounted in the Focus

1 or Focus 3 enclosure, or in a remote operator station.

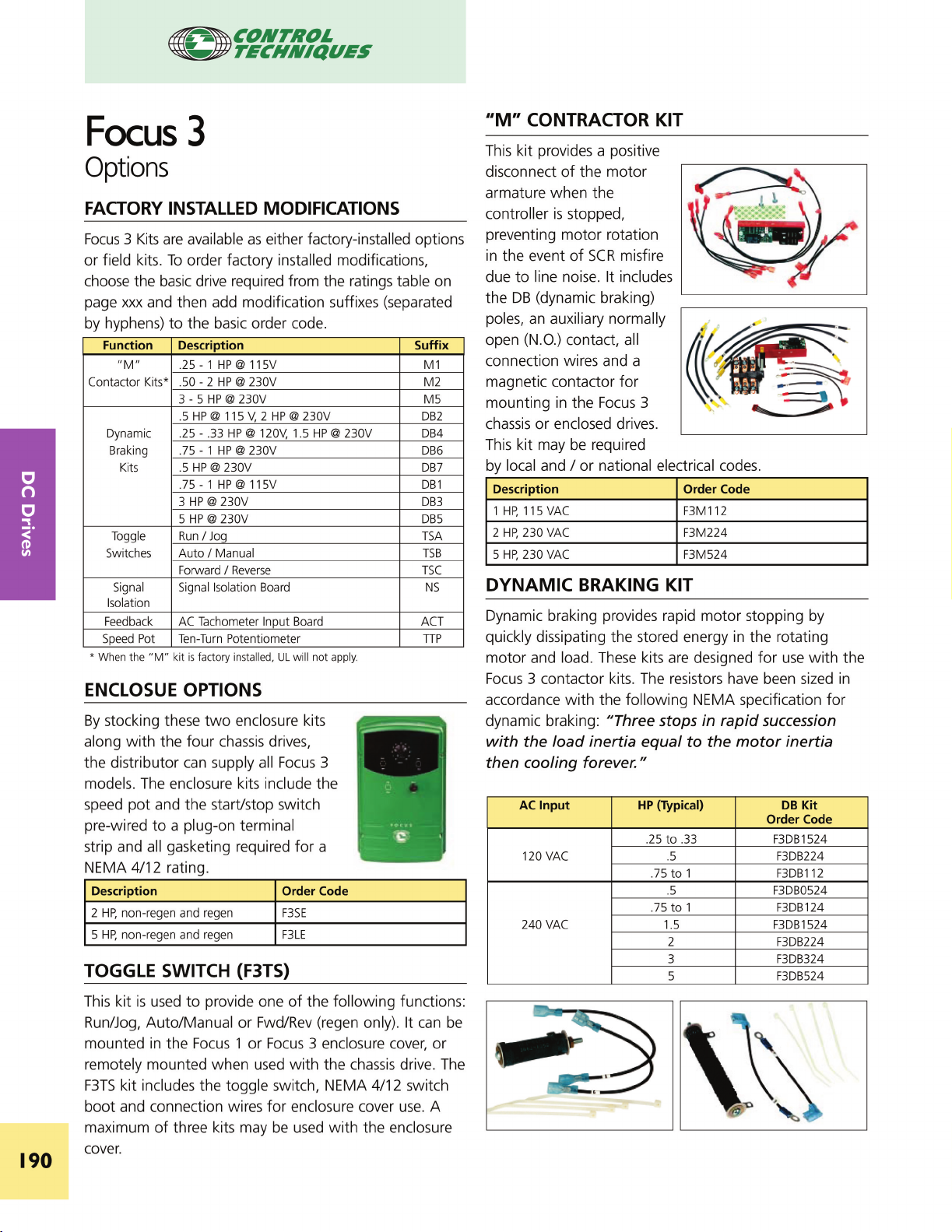

SIGNAL ISOLATOR BOARD

This option is used in

applications where

isolation is required

between an external

control signal and the

motor controller (which

may or may not be at

earth ground potential).

It can be used to isolate a variety of voltage or current

signals (see specifications below) or simply to isolate

the speed potentiometer. The potentiometer power

supply is included. This option can be mounted inside

the Focus 3 cover or panel mounted on a piece of curtis

track (included with kit). Because the board has a unipolar output, it is typically used on single directional

applications

Specifications

Input Power 17 to 30 VDC @ 50 mA max.

(for control circuitry)

Control Relay 24 VDC @ 12.1 mA (JP5 = 24 VDC)

115 VAC @ 20 mA (JP5 = 120 VAC)

Relay Contacts (qty. 2) Form A, 1A @ 250 VAC

Isolation Voltage 240 VAC line voltage

2000 VAC hi-pot for 1 minute

Voltage Ranges 5, 12, 26, 52, 98 & 208 VDC

180 Ohms/volt

Current Ranges 0 - 5 or 1- 5 mA

910 Ohms input impedance

0 - 20 or 4 - 20 mA

250 Ohms input impedance

Speed Pot 5k Ohms, 2 watts (includes

+10 VDC power supply for the pot)

Output 0 to +10 VDC (uni-polar)

Description Order Code

Signal Isolator Board F3NSBD

Description Order Code

Ten-Turn Speed Potentiometer 6160-9001

DC Drives

191

Loading...

Loading...