Page 1

FM-3

Programming Module

Reference Manual

P/N 400508-01

Revision: A8

Date: March 10, 2004

© Control Techniques Drives, I nc. 2000-2004

Page 2

Page 3

FM-3

Programming Module

Reference Manual

Information furnished by Control Techniques Drives Inc. (Control Techniques) is believed to be

accurate and reliable. However, no responsibility is assumed by Control Techniques for its use.

Control Techniques reserves the right to change the design or operation of the equipment described

herein and any associated motion products without notice. Control Techniques also assumes no

responsibility for any errors that may appear in this document. Information in this document is subject

to change without notice.

P/N 400508-01

Revision: A8

Date: March 10, 2004

© Control Techniques Drives, Inc. 2000-2004

Page 4

© Control Techniques Drives, Inc. 2000-2004

Part Number: 400508-01

Revision: A8

Date: March 2004

Printed in United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of Control Techniques.

The following are trademarks of Control Techniques and may not be reproduced in any fashion

without written approval of Control Techniques: EMERSO N M otion Control,

EMERSON Motion Control PowerTools, AXIMA, “Motion Made Easy.”

Control Techniques is a division of EMERSON Co.

Control Techniques, Inc. is not affiliated with Microsoft Corporation, owner of the Microsoft,

Windows, and Windows NT tradema rks.

This document has been prepared to conform to the current released version of the product. Because

of our extensive development efforts and our desire to further improve and enhance the product,

inconsistencies may exist between the product and documentation in some instances. Call your

customer support representative if you encounter an inconsistency.

ii

Page 5

Customer Support

Control Techniques

12005 Technology Drive

Eden Prairie, Minnesota 55344-3620

U.S.A.

Telephone: (952) 995-8000 or (800) 893-2321

It is Control Tech niques’ goal t o ensure yo ur greatest possible satis faction with the operation

of our products. We are dedicated to providing fast, friendly, and accurate assistance. That is

why we offer you so many ways to get the support you need. Whether it’s by phone, fax or

modem, you can access Control Techniques support information 24 ho urs a day, seven days

a week. Our wide range of services include:

FAX (952) 995-8099

You can FAX questions and comments to Control Techniques. Just send a FAX to the number

listed above.

Website and Email www.emersonct .com

Website: www.emersonct.com

Email: info@emersonct.com

If you have Internet capabilities, you also have access to technical support using our website.

The website includes technical notes, frequently asked questions, release notes and other

technical documentation. This di rect technical suppo rt connection lets you request assistance

and exchange software files electronically.

Technical Support (952) 995-8033 or (800) 893-2321

Email: service@emersonct.com

Control Techniques’ “Motion Made Easy” products are backed by a team of professionals

who will service your installation. Our technical support center in Eden Prairie, Minnesota is

ready to help you solve those occasional prob lems over the telephone. Our techni cal support

center is available 24 hours a day for emergency service to help speed any problem solving.

Also, all hardware replacement parts, if needed, are available through our customer service

organization.

When you call, please be at your computer, with y our documen tation easily available, and b e

prepared to provide the following information:

• Product version number, found by choosing About from the Help menu

• The type of controller or product you are using

iii

Page 6

• Exact wording of any messages that appear on your screen

• What you were doing when the problem occurred

• How you tried to solve the problem

Need on-site help? Control Techniques provides service, in most cases, the next day. Just call

Control Techniques’ technical support center when on-site service or maintenance is

required.

Training Services (952) 995-8000 or (800) 893-2321

Email: training@emersonct.com

Control Techniques maintains a highly trained s taf f of ins tructo r s to familiarize customers

with Control Techniqu es’ “Motion Made Easy” prod ucts and their applicatio ns. A number of

courses are offered, many of which can be taught in your plant upon request.

Application Engineering (952) 995-8000 or (800) 893-2321

Email: applengr@emersonct.com

An experienced staff of factory application engi neers provides complete customer support for

tough or complex applications. Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

Customer Service (Sales) (952) 995-8000 or (800) 893-2321

Email: customer.service@emersonct.com

Authorized Control Techniques distributors may place orders directly with our Customer

Service department. Contact the Customer Service department at this number for the

distributor nearest you.

Document Conventions

Manual conventions have been established to help you learn to use this manual quickly and

easily. As much as possible, these conventions correspond to those found in other Microsoft®

Windows® compatible software documentation.

Menu names and options are printed in bold type: the File menu.

Dialog box names begin with uppercase letters: the Axis Limits dialog box.

Dialog box field names are in quotes: “Field Name.”

Button names are in italic: OK button.

Source code is printed in Courier font: Case ERMS.

iv

Page 7

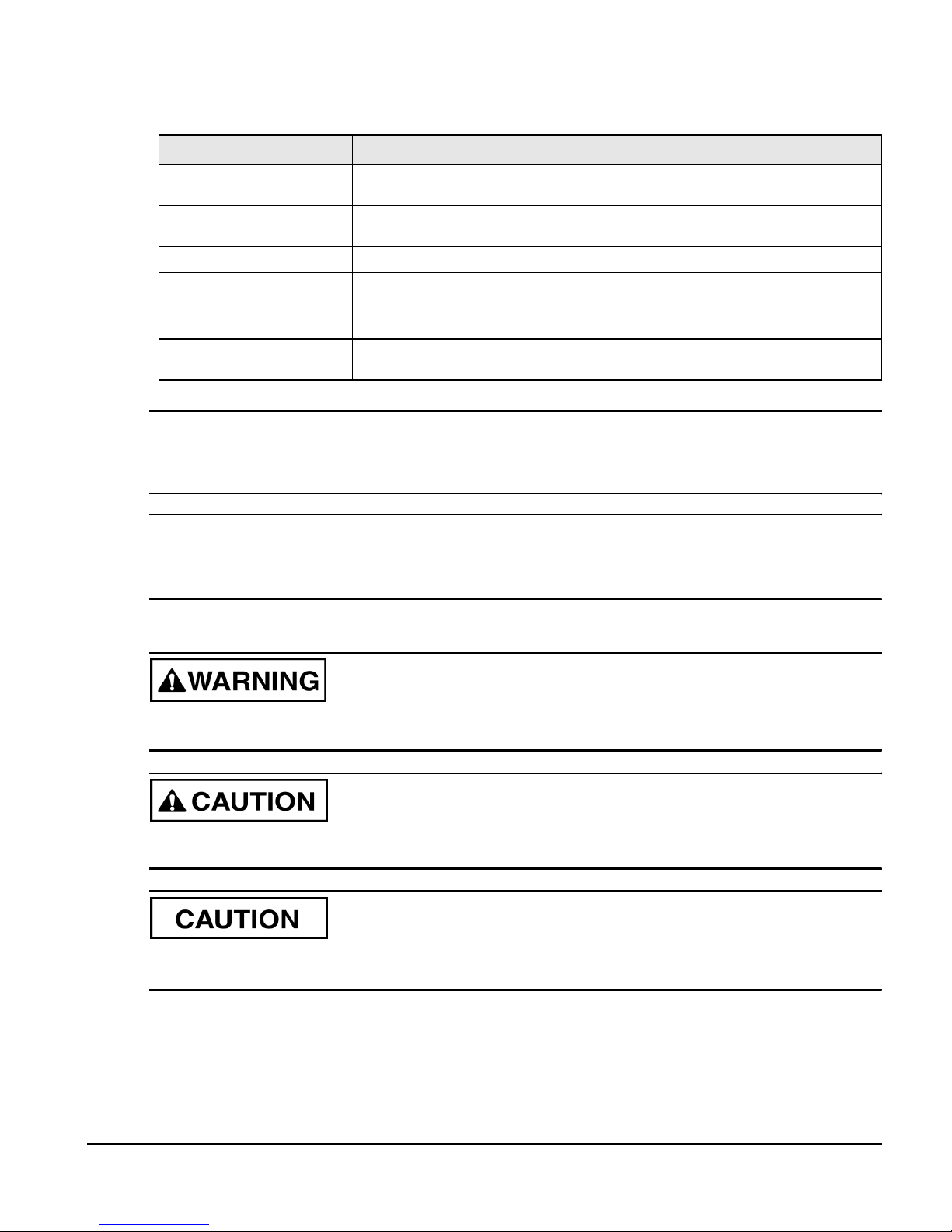

In addition, you will find the following typographic conventions throughout this manual.

EN

This Represents

bold

italic

ALL CAPITALS Directory names, file names, key names, and acronyms.

SMALL CAPS Non-printable ASCII control characters.

KEY1+KEY2

example: (Alt+F)

KEY1,KEY2

example: (Alt,F)

Characters that you must type exactly as they appear. For example, if you are directed to type

a:setup, you should type all the bold characters exactly as they are printed.

Placeholders for information you must provide. For example, if you are directed to type

filename, you should type the actual name for a file instead of the word shown in italic type.

A plus sign (+) between key names means to press and hold down the first key while you press

the second key.

A comma (,) between key names means to press and release the keys one after the other.

Note

For the purpose of this manual and p roduct , “Note” indicates essential inform ation about

the product or the respective part of the manual.

EN Only

For the purpose of thi s manual and product , the “EN” symbol indicates information about

the EN drive specifically.

Throughout this manual, the word “drive” refers to an EN or MDS drive.

“Warning” indicates a potentially hazard ous situation that, if not av oided, co uld result in

death or serious injury.

“Caution” indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

“Caution” used without the safety alert symbol indicates a potentially hazardous situation

that, if not avoided, may result in property damage.

v

Page 8

Safety Instructions

General Warning

Failure to follow safe installation guidelines can cause death or serious injury. The voltages

used in the product can cause se vere electric shock and/or burns and could be lethal . Extreme

care is necessary at all times when working with or adjacent to the product. The installation

must comply with all relevant safety legislation in the country of use.

Qualified Per s on

For the purpose of this manual and product, a “qualified person” is one who is familiar with

the installation, construction and operation of the equipment and the hazards involved. In

addition, this individual has the following qualif ications:

• Is trained and authorized to energize, de-energize, clear and ground and tag circuits and

equipment in accordance with established safety practices.

• Is trained in the proper care and use of protective equipment in accordance with

established safety practices.

• Is trained in rendering first aid.

Reference Materials

The following related reference and installation manuals may be useful with your particular

system.

• Function Module Installation Manual (P/N 400506-03)

• Epsilon Eb and EN Drives Reference Manual (P/N 400501-01)

• PowerTools Software User’s Guid e (P/N 400503-01)

• FM-3 and FM-4 Connectivity Modules Reference Manual (P/N 400508-04)

• Modular Drive System (MDS) Reference Manual (P/N 400525-01)

vi

Page 9

Safety Precautions

This product is intended for professional integration into a complete system. If you install the

product incorrectly, it may present a safety hazard. The product and system may use high

voltages and currents, carry a high level of stored electrical energy, or control mechanical

equipment that can cause injury.

You should give close attention to the electrical installation and system design to avoid

hazards either in normal op eration or in the event of eq uipmen t malf unction . Sy stem des ign,

installation, commiss ionin g and mainten ance mu st be carri ed out b y perso nnel who hav e the

necessary training and experience. Read and follow this safety information an d the instruction

manual carefully.

Enclosure

This product is intended to be mounted in an enclosure which prevents access except by

trained and authorized personnel, and which prevents the ingress of contamination. This

product is designed for use in an environment classified as pollution degree 2 in accordance

with IEC664-1. This means that only dry, non-conducting contamination is acceptable.

Safety Considerations

Setup, Commissioning and M aintenance

It is essential that you give careful consideration to changes to drive settings. Depending on

the application, a change could have an impact on safety. You must take appropriate

precautions against inadvertent changes or tampering. Restoring default parameters in certain

applications may cause unpredictable or hazardous operation.

Safety of Machinery

Within the European Union all machinery with which this product is used must comply with

Directive 89/392/EEC, Safety of Machinery.

The product has been designed and tested to a high standard, and failures are very unlikely.

However the level of integrity offered by the product’s control function – for example stop/

start, forward/reverse and maximum speed – is not sufficient for use in safety-critical

applications without additional independent channels of protection. All applications where

malfunction coul d cause injury or loss of lif e must be s ubject to a risk assessment, an d further

protection provided where needed.

General warning

Failure to follow safe installation guidelines can cause dea th or seriou s injury. The voltage s used in

this unit can cause severe electric shock and/or burns, and could be lethal. Extreme care is necessary

at all times when work ing with or a djacent to th is equipment. T he installatio n must comply with all

vii

Page 10

relevant safety legislation in the country of use.

AC supply isolati on device

The AC supply must be removed from the drive using an approved isolation device or disconnect

before any servicing work is performed, other than adjustments to the settings or parameters

specified in the manual. The driv e contain s capacitors whi ch remain charged to a poten tially lethal

voltage after the supply has been removed. Allow at least 3 mi nutes after removing the suppl y

before carrying out any work whic h may involve contact with electrical connections to the drive.

Products connected by plug and socket

A special hazard may exist where the drive is incorporated into a product which is connected to the

AC supply by a plug and socket. When unplugged, the pi ns of the plug may be connected to the

drive input, which is only separated from the charge stored in the bus capacitor by semiconductor

devices. To avoid any possibility of electric shock from the pins, if they are accessible, a means

must be provided for automatically disconnecting the plug from the drive (that is, a latching

contactor).

Grounding (Earthing, equipotential bonding)

The drive must be grounded by a conductor sufficient to carry all possible fault current in the event

of a fault. The ground connections shown in the manual must be followed.

Fuses

Fuses or over-current protection must be provided at the input in accordance with the instructions

in the manual.

Isolation of control circuits

The installer must ensure that t he external control circuits are isolated from human contact by at

least one layer of insulation rated for use at the applied AC supply voltage.

viii

Page 11

Table of Contents

Introduction 1

Operational Overview 3

Software Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

PowerTools Pro Setup Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Keypad Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How Motion Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How Jogging Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How Home Works. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How Indexes Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How Communications Work. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Brake Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Setting Up Parameters 31

Setup View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Status Online Tab (Online Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Information Tab (Online Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

User Units View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Master Units View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Position View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Velocity View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Ramps View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Torque View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Tuning View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Faults View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

PLS View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Setup NVM View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

User Variables View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

User Bits View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

I/O Setup Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Assignments View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Selector View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Input Lines View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Output Lines View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Analog Inputs View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

ix

Page 12

Jog View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Home View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Index View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Gearing View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Stopping Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Network Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Modbus View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

DeviceNet View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Profibus View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Ethernet View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Programming 115

Program Toolbar Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Program Instruction Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Adding and Deleting Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Run Anytime Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Example Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Parameter Descriptions 143

Installation 183

Basic Installation Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Software Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Starting and Exiting PowerTools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Accessing Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Quick Start 189

Basic Setup Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Example Application Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Tuning Procedures 213

PID vs. State-Space. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Tuning Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Determining Tuning Parameter Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

x

Page 13

Diagnostics and Troubleshooting 225

Diagnostic Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Analog Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Diagnostic Analog Output Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Drive Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Programming Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Online Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Specifications 249

Dimensions and Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Glossary 265

Index 273

xi

Page 14

xii

Page 15

FM-3 Programming Module Reference Manual

Introduction

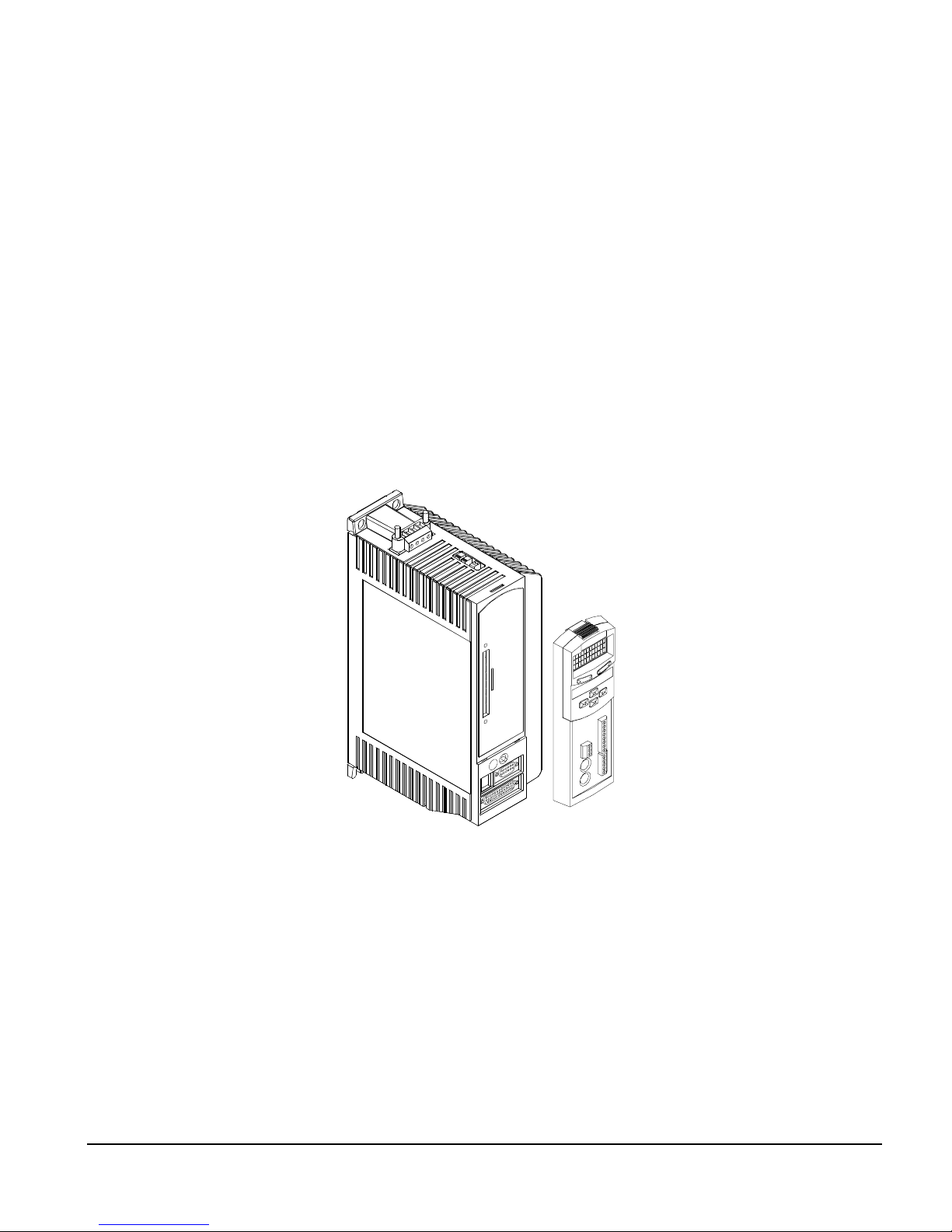

The FM-3 module is a compact and rugged function module that attaches to the front of the

drive. It provides eight digital input lines and four digital output lines, in addition to the four

input and three output lines available on the drive.

Unlike other function modules, the FM-3 module offers complex motion profiling. A

complex motion profile consists of two or more indexes that are executed in sequence such

that the final velocity of each index except the last is non-zero. Logical instructions between

index statements can provide a powerful tool for altering motion profiles "on the fly". The

FM-3 module defines complex motion by a configuration file that includes setups, function

assignments and programs . The configuration file is created using PowerTools Pro software

Setup views have the same look and feel as dialog boxes. The wiring of input and output

functions is done through assignments in the software. PowerTools Pro is an easy-to-use

Microsoft® Windows® based setup and diagnostics tool.

1

.

Figure 1: EN Drive with FM-3 Function Module

Note that the drive’s firmware is disabled whenever a Function Module such as the FM-3

module is attached. Therefore, if the drive’s hardware is FM compatible, then the drive’s

firmware can be any version because the programming features reside in the function

module’s flash memory. Flash files used fo r firmware up grad es are available on the Control

Techniques webpage.

The FM-3 module stores drive setup parameters within the module itself. This allows you to

transfer the FM-3 module to another drive without losing setup parameters.

1.In this manual, Emerson Motion Control PowerT ools Pro software will be refer red to as PowerTools Pro.

1

Page 16

FM-3 Programming Module Reference Manual

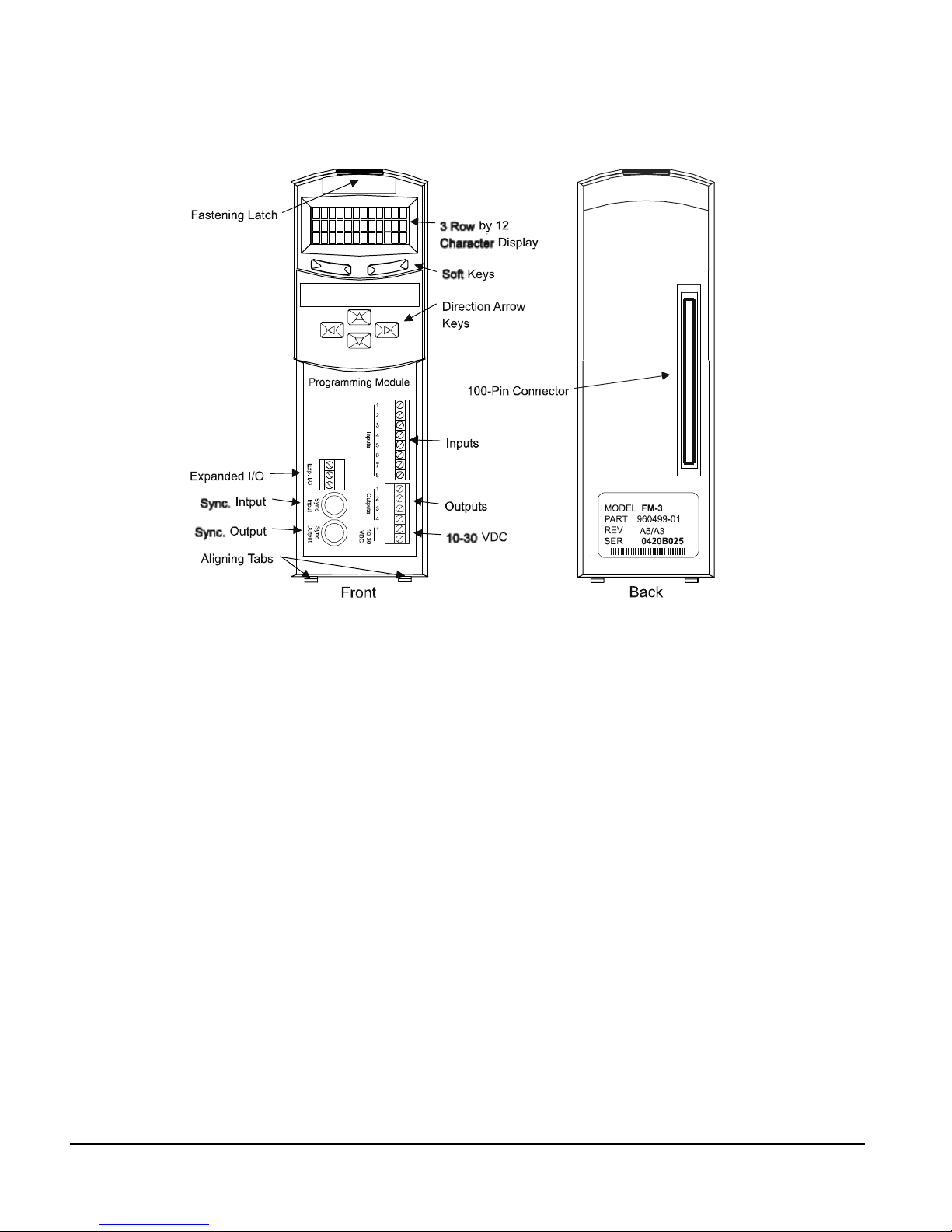

Figure 2: FM-3 Programming Module Features

2

Page 17

FM-3 Programming Module Reference Manual

Operational Overview

This section provides a complete functional description of the FM-3. It is intended to provide

you with a thorough understanding of all operations. The description includes references to

many FM-3 module and drive parameters which can be displayed and/or edited using

PowerTools Pro software, or through any Modbus interface.

The FM-3 module augments the drive by providing the ability to implement programs written

using PowerTools Pro. When a FM-3 module is attached to an drive, it overrides the operation

and user accessible features o f the d rive. The drive’s basic operating modes (Pulse, Velocity

and Torque) are not available when a F M-3 module is attached.

The FM-3 module stores drive setup parameters within the module itself. This allows you to

transfer the FM-3 module to another drive without losing setup parameters.

The FM-3 module allows you to set up 55 different indexes, Jog functions and mult iple

Homes. It also provides eight digital input lines and four digital output lines in addition to the

four input and three output lines available on the drive.

Software Interface

The FM-3 module is set up using PowerTools Pro software. PowerTools Pro is an easy-to-use

Windows® based setup and diagnost ics tool. It provides you with the ability to create, edit

and maintain your drive’s setup. You can download or upload your setup data to or from a

device. You can also save it to a file on your PC or print it for review or permanent storage.

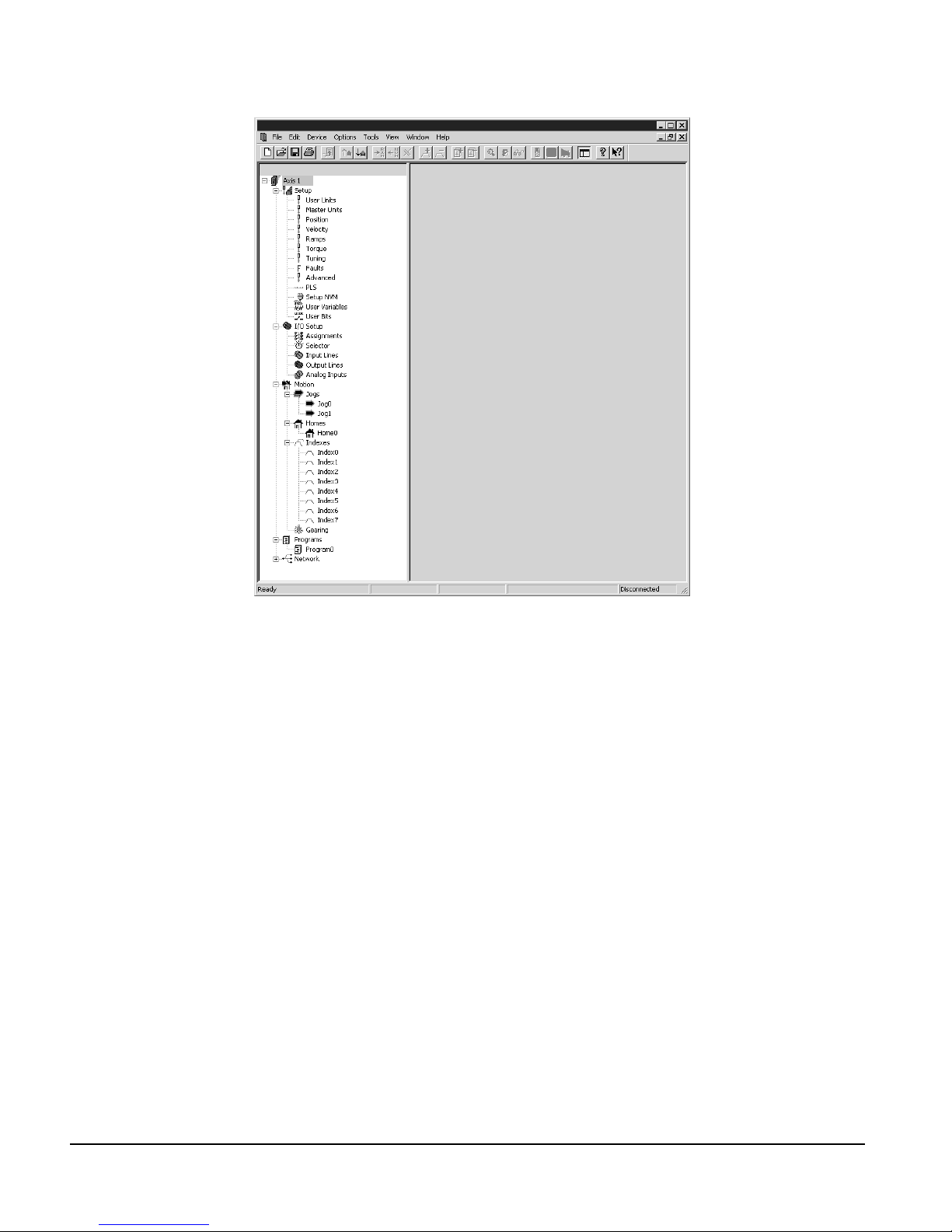

PowerTools Pro Setup Software

PowerTools Pro is designed to be the easiest to use software available for single axis motion

controllers.

Features

• “Hierarchy View” for quick navigation to any setup screen

• Simple I/O function assignments

• Powerful online diagnostic capabilities

•Programming

3

Page 18

FM-3 Programming Module Reference Manual

Figure 3: Hierarchy View

The “Hierarchy View” (sho wn above) contains expa ndable groups of parameters. The groups

can be expanded and contracted just like folders in Windows Explorer. Left clicking on a

view name in the Hierarchy view dis plays that View on the right side of the comp uter scr een.

To setup a drive the user simply steps through the Hierarchy View from top to bottom.

Simple applicati ons can be set up in a matt er of mi nutes. Many of t he views have Assignm ent

tabs that display t he assignments pertaining to the view (i.e. on the Positio n view, the position

assignments are displayed).

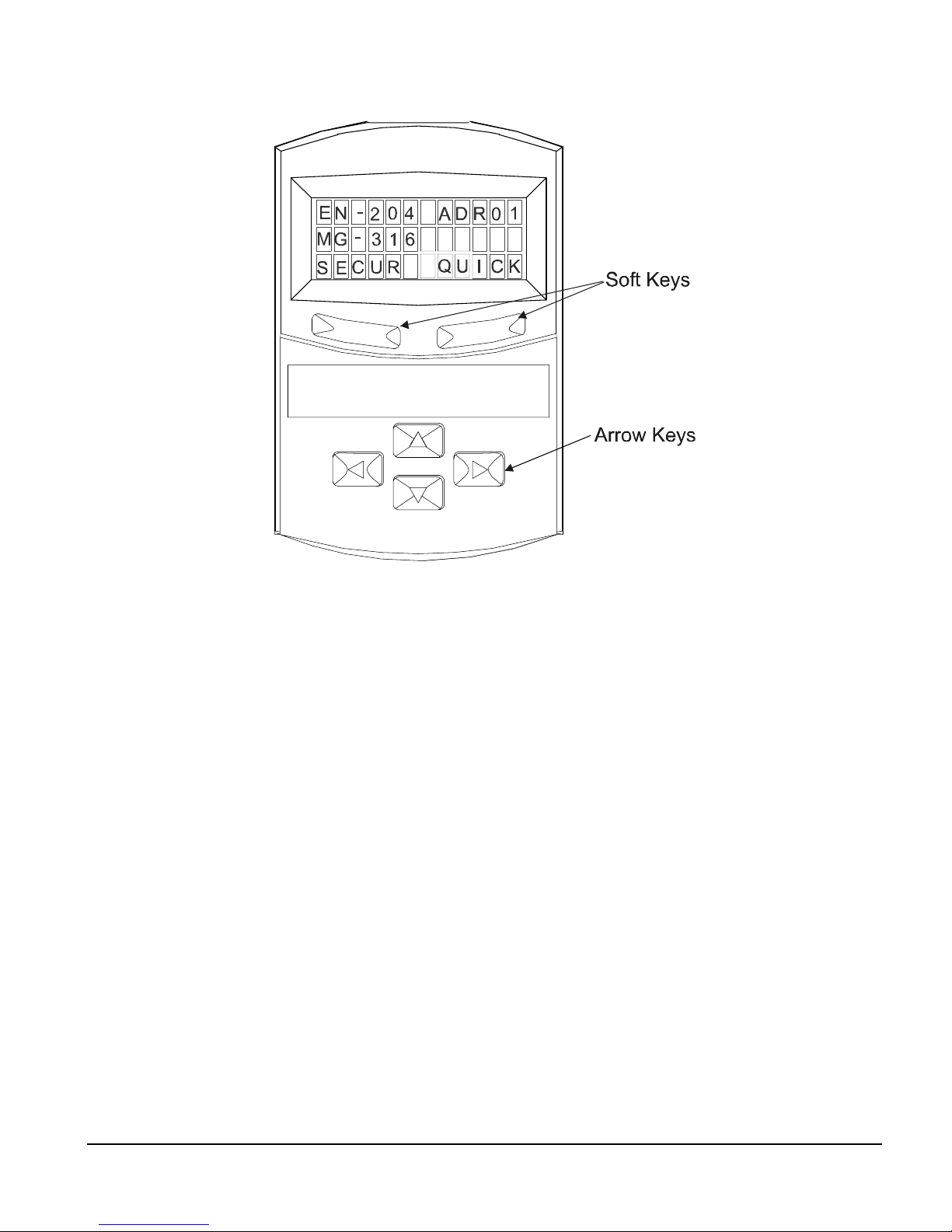

Keypad Interface

The keypad on the f ront of the FM-3 module provides navi gation through a menu of common

parameters and displays of current functions. Navigation through the menu is accomplished

with the six keys located below the display. The top two keys are called the "soft keys"

because they relate to the comm ands located directly above each key on the LCD. These keys

are used to select the operation (e.g. Mo dify, Ok, Cancel), parameter grou p, and/or to validate

information. The four arrow keys are used to navigate through parameter groups, select a

specific parameter to be modified, and to modify digital and numeric data.

The operation of the arrow keys is dependent upon the type of parameter which is being

modified.

4

Page 19

Operational Overview

Figure 4: FM-3 Display Screen and Keypad

On the Menu screen, the drive type and axis address are always shown on the top line of the

display. The second line shows the motor type. If a user defined motor is selected, the user

defined motor name will appear. The third line shows two parameter group names, one above

each of the soft keys.

From the Menu screen, the user selects a group of drive parameters to wor k wi t h. The g rou p

names are scrolled using the left/right direction keys. The groups correspond roughly to the

tabs used by the PowerTools software. The groups are shown cyclically and wrap around.

The drive parameters available with the FM-3 keypad ar e arranged into seven grou ps (see list

below). Upon power-up the FM-3 module will display the default parameter groups

“SECUR” (left soft key) and “QUICK” (right soft key).

• QUICK (Quick)

• PROG (Program)

• INDEX (Index)

• HOME (Home)

• JOG (Jog)

• RAMPS (Ramps)

• SECUR (Security)

5

Page 20

FM-3 Programming Module Reference Manual

Security: 1

Screen

EN-204 Adr01

MG-316

SECUR

Menu

PBus-

Group

Slave Address

MODIF MENU

Security: 1

Baud Rate

MENU

Security: 0

Network Sts

MENU

Security: 0

Module Sts

MODIF MENU

Security: 0

MasterAddr

MENU

Security: 0

MsgProcessed

MENU

Security: 0

DVNET+

Group

MacID

MODIF MENU

Security: 1

Baud Rate

MODIF MENU

Security: 1

Security: 1

Network Sts

MENUMODIF

Security: 0

Module Sts

MENU

Security: 0

Net OK

MENU

Security: 0

Conn Type

MENU

Security: 0

Mster MacID

MENU

Security: 0

Transmit Cntr

MENU

Security: 0

Receive Cntr

MENU

Security: 0

SECUR

Group

Auto Log Out

MODIF MENU

Security: 3

Password 1

MODIF MENU

Security: 3

Password 2

MODIF MENU

Security: 3

Log Out Now?

OK

Security: 0

* Jog Group contains 2 Jogs (Jog.0 and Jog.1)

Index Group contains 7 Indexes (Index.0 to Index.7)

Prog Group contains 4 Programs (Prog.0 to Prog.3)

+ DeviceNet Group is only available on FM-3DN and FM-4DN modules

- Profibus Group is only available on FM-3PB and FM-4PB modules

On all screens with < > symbols, scroll left and right to select the specific Instance

RAMPS

Group

Stop

MODIF MENU

Security: 0

Stop.Decel

MODIF MENU

Security: 1

JOG*

Group

<Jog.0.Vel>

MODIF MENU

Security: 1

<Jog.0.Accl>

MODIF MENU

Security: 1

<Jog.0.Decl>

MODIF MENU

Security: 1

<Jog.0.Plus>

MODIF MENU

Security: 1

<Jog.0.Mius>

MODIF MENU

Security: 1

Posn Fdbk Ct

MENU

Security: 0

HOME

Group

Home.0.Vel

MODIF MENU

Security: 1

Home.0.Accl

MODIF MENU

Security: 1

Home.0.Decl

MODIF MENU

Security: 1

Home.0.Init

MODIF MENU

Security: 1

Calc Offset

MENU

Security: 1

Spec Offset

MODIF MENU

Security: 1

Select Offst

MODIF MENU

Security: 1

INDEX*

Group

<Ind.0.Vel>

MODIF MENU

Security: 1

<Ind.0.Accl>

MODIF MENU

Security: 1

<Ind.0.Decl>

MODIF MENU

Security: 1

<Ind.0.Dist>

MODIF MENU

Security: 1

<Ind.0.Init>

MODIF MENU

Security: 1

PROG*

Group

<Prg.0.Init>

MODIF MENU

QUICK

Group

Posn Fdbk

GRAPH MENU

Security: 0

Vel Fdbk

GRAPH MENU

Security: 0

Following Er

GRAPH MENU

Security: 0

Axis Address

MODIF MENU

Security: 0

Baud Rate

MODIF MENU

Security: 3

DriveInput

MENU

Security: 0

ModuleInput

MENU

Security: 0

DriveOutput

MENU

Security: 0

ModuleOutput

MENU

Security: 0

Fault Sts 1

MENU

Security: 3

Fault Sts 2

MENU

Security: 0

Clear Fault?

OK MENU

Security: 0

Module Rev

MENU

Security: 0

Boot Rev

MENU

Security: 0

Parameter Screens

After selecting a group using one of the soft keys, the FM-3 module will display a Parameter

screen for that group. This screen could be either the first screen in the group or the last screen

you used in that group. The FM-3 module keeps track of the last Parameter screen viewed in

6

Page 21

each group and returns to that screen when you come back to the group. This is reset on

power-up and the FM-3 keypad displays the first Parameter screen in the group.

In this screen, the parameter name is shown on the first line of the display. The up/down arrow

keys are used to scroll through the parameters available in the selected group.The second line

displays the condition or value of parameters. The third line displays the soft key actions.

The left/right arrow keys are used to scroll through the parameters when the “<“ and “>”

symbols are shown.

Numeric parameter units are sometimes shown before the actual value, because the parameter

value and the units cannot be displayed on one line. The unit of measure will appear on the

second line for about one second. Then the actual parameter value will appear. The parameter

value is updated about five times a second.

How Motion Works

The FM-3 module provides four types of motion: jogging, homing, indexing, and gearing.

Only one index, jog, home, or gear may be in process at any given moment (exclusionary

motion types). Through assignments and programs, the FM-3 module can sequentially run

various motion routines. The Positive direction parameter af fect s all m otion types by

specifying which direction of motor revolution (CW or CCW) is considered motion in the “+”

direction.

Operational Overview

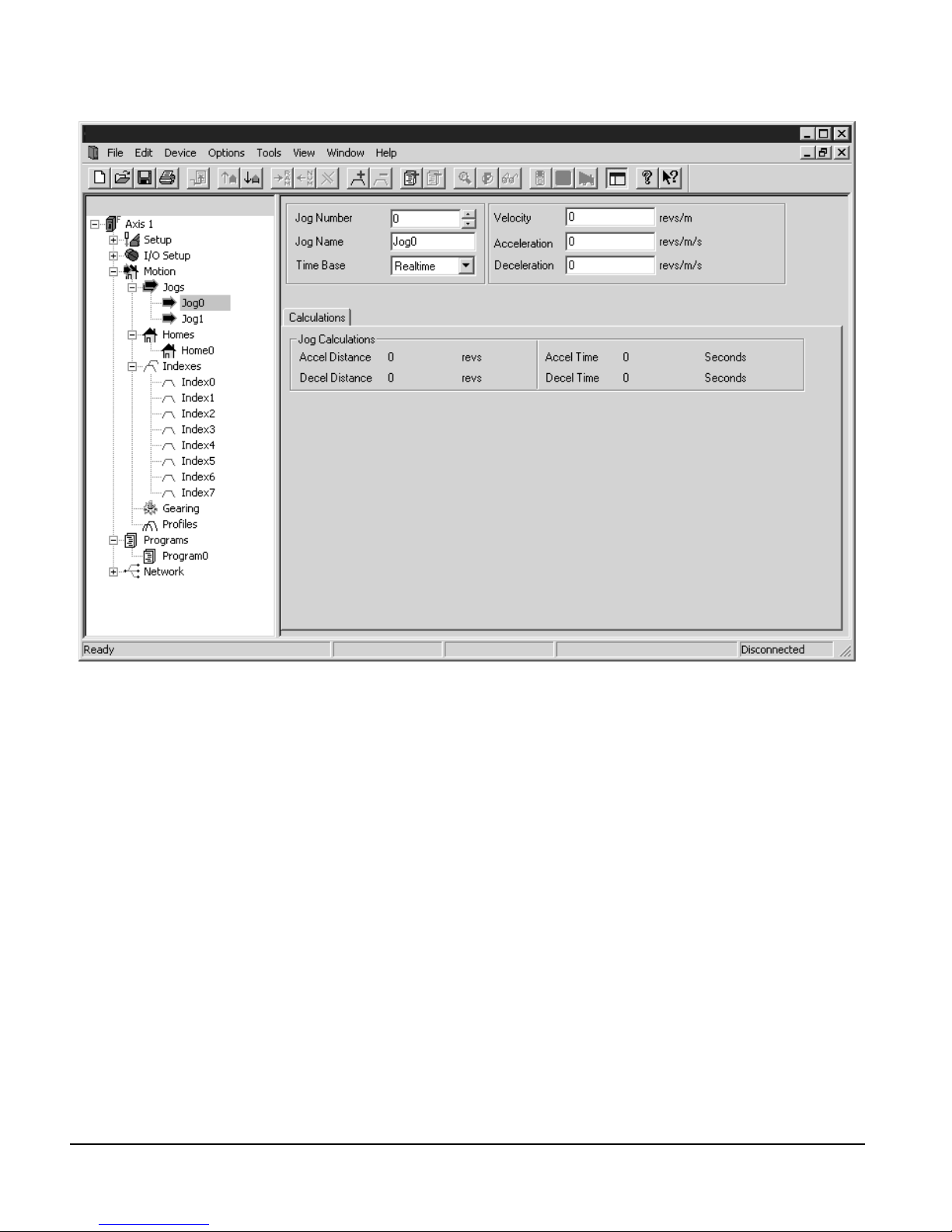

How Jogging Works

Jogging produces rotation of the motor at controlled velocities in a positive or negative

direction.

Assignments to jogs are level sensitive such that when the jog input is turned on, jogging

begins and continues jogging until the jog input is removed.

Each jog has its own acceleration and deceleration ramp along with a specified velocity.

Jogging has no distance parameter associated with it. If trying to move a specific distance

or to a known position, then an index is used.

7

Page 22

FM-3 Programming Module Reference Manual

Figure 5: Jog Tab

How Home Works

The Home is used in applications in which the axis must be precisely aligned with some part

of the machine. The Home is initiated in one of three ways: with the Initiate Destination

function found in the Ass ignments view, throu gh a program, or with t he Online tab. A Home

or Define Home is required to set the Absolute Position Valid so that any index to absolute

position can work.

The FM-3 module can home the motor to an external sensor, the motor’s encoder marker

pulse, or to a sensor and then to the encoder marker pulse.

8

Page 23

Operational Overview

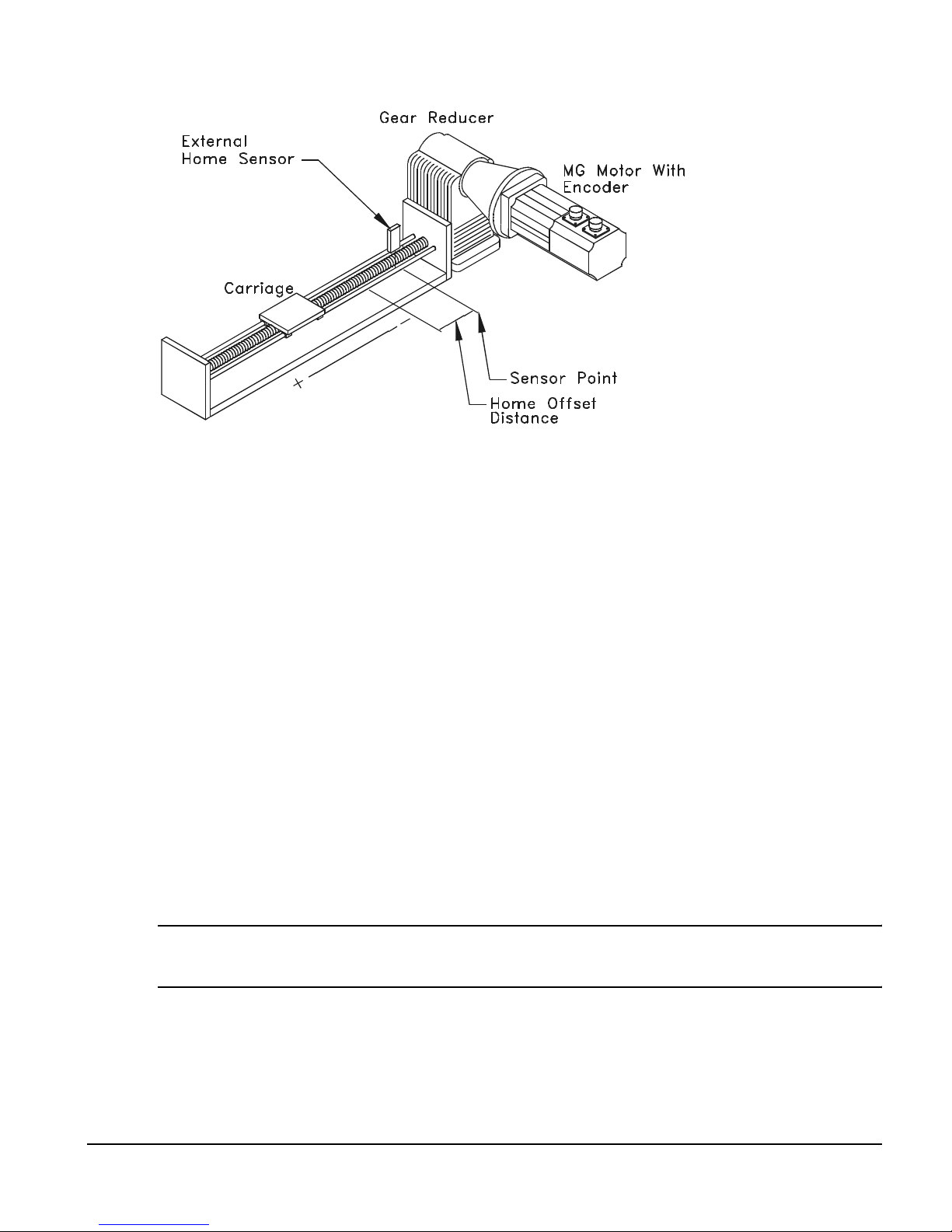

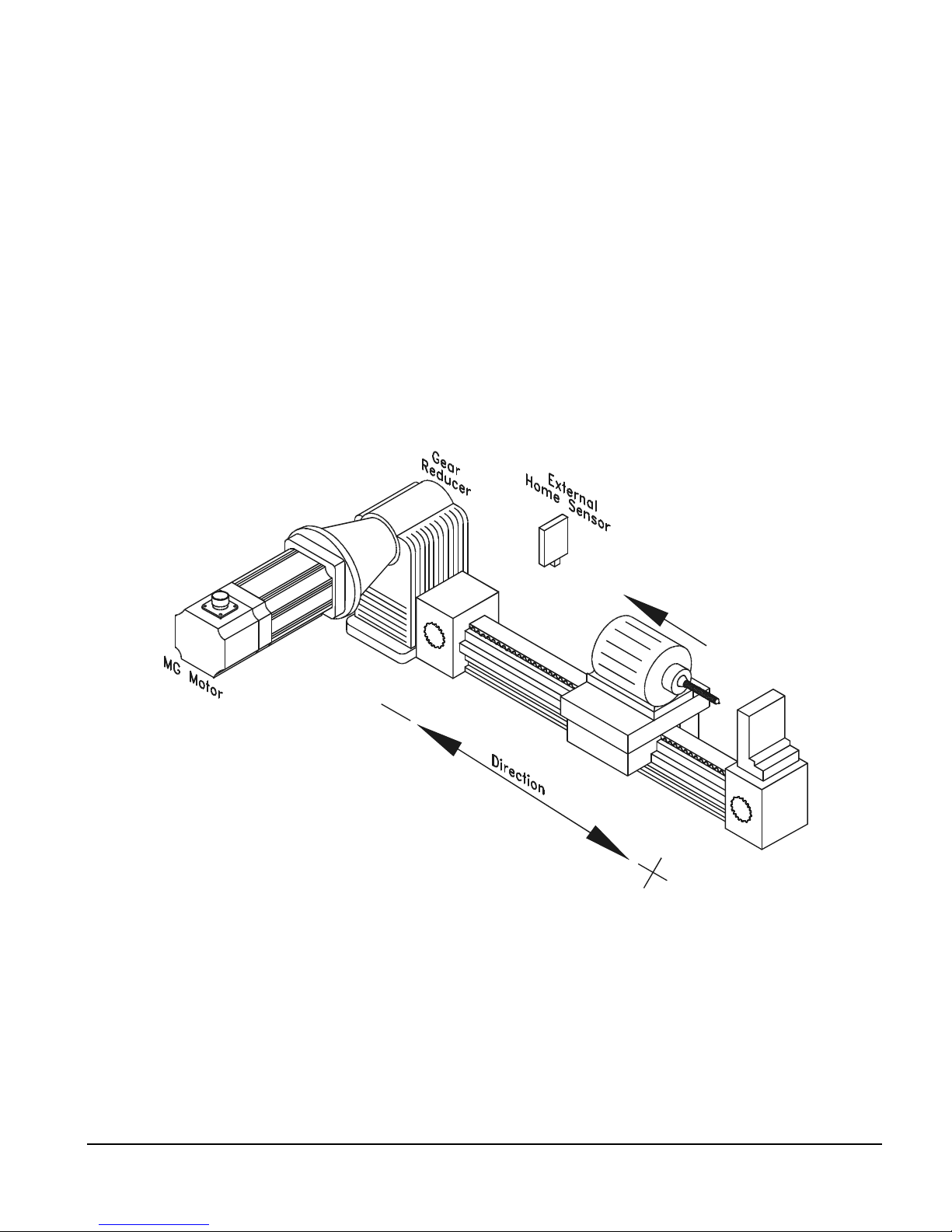

Figure 6: Basic Home Function, Example

The figure above show a basic home f unction us ing a ball scr ew. This examp le us es most o f

the setup features in the PowerTools Pro Home tab.

Home Sequence

1. Back off the sensor (if on the sensor. This step is optional).

2. Move to the external home sensor to establish a home reference point.

3. Next it will move to the Offset position.

4. Then the command and feedback positions are set to the value entered into the End of

Home Position.

Homing to the motor’s encoder marker will establish the most accurate and repeatable home

position. This method will position the motor relative to the location of the rising edge of the

encoder marker pulse. Most applications will use a sensor and marker to find an accurate

home position in the vicinity of the home sensor.

Several parameters affect how the Home function operates. Each of these parameters are

explained in detail on the following pages.

Note

The Home function will NOT be initiated when any other motion command is in progress .

Establishing a Home Reference Position

The first step in setting up a home is to select the desired home reference type. The Home

Reference parameter selected determines how the Home Refe r e nce Position is established.

9

Page 24

FM-3 Programming Module Reference Manual

PowerTools Pr o allows selection o f one of three diff erent Home References: Sensor, Marker,

or Sensor and Marker.

Sensor

Selecting Sensor means the ri sing edge of the Home Sensor inpu t function is used to establish

the home reference position.

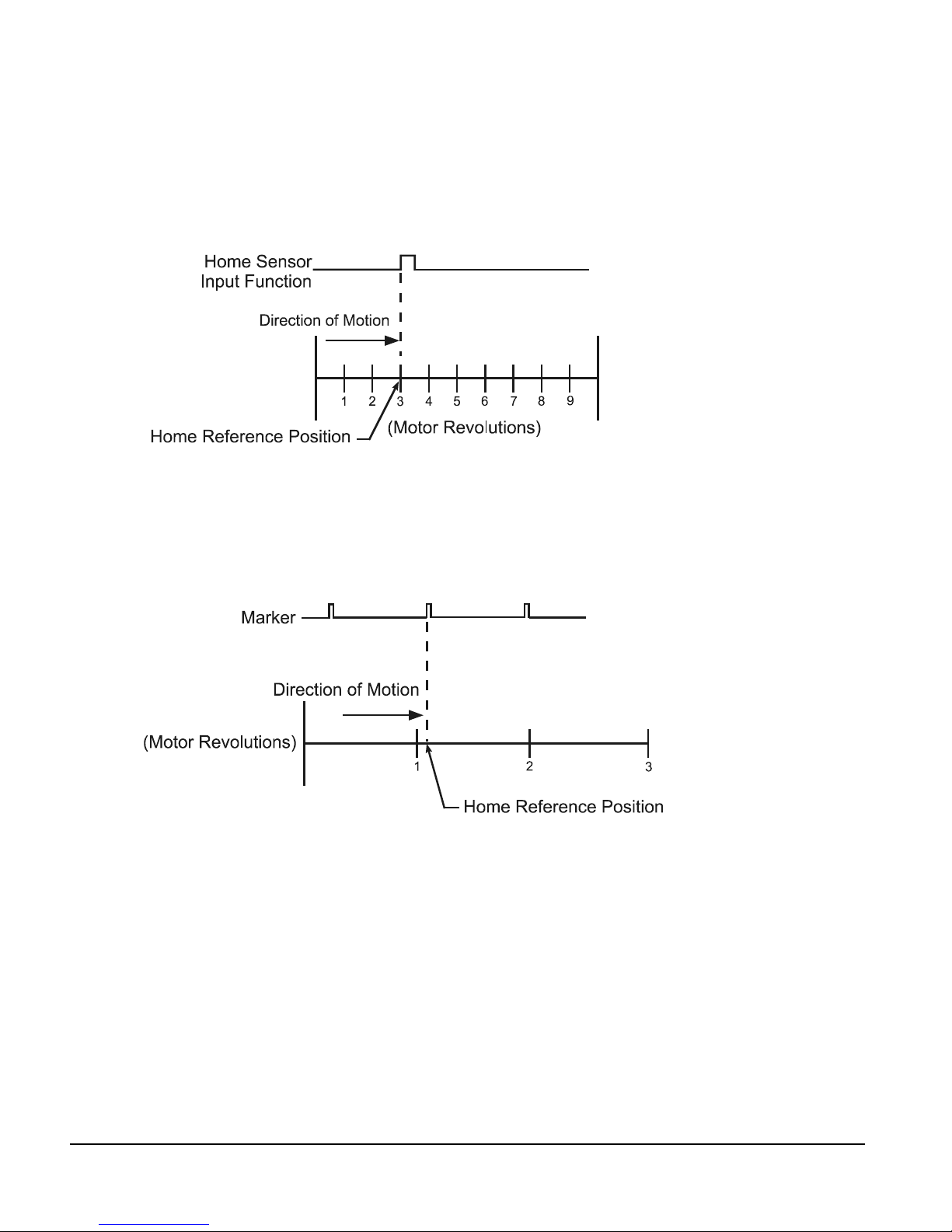

Figure 7: Sensor Home Reference Position

Marker

Selecting Marker means the rising edge of the motor’s encoder marker channel is used to

establish the reference position.

Figure 8: Marker Home Reference Position

10

Page 25

Operational Overview

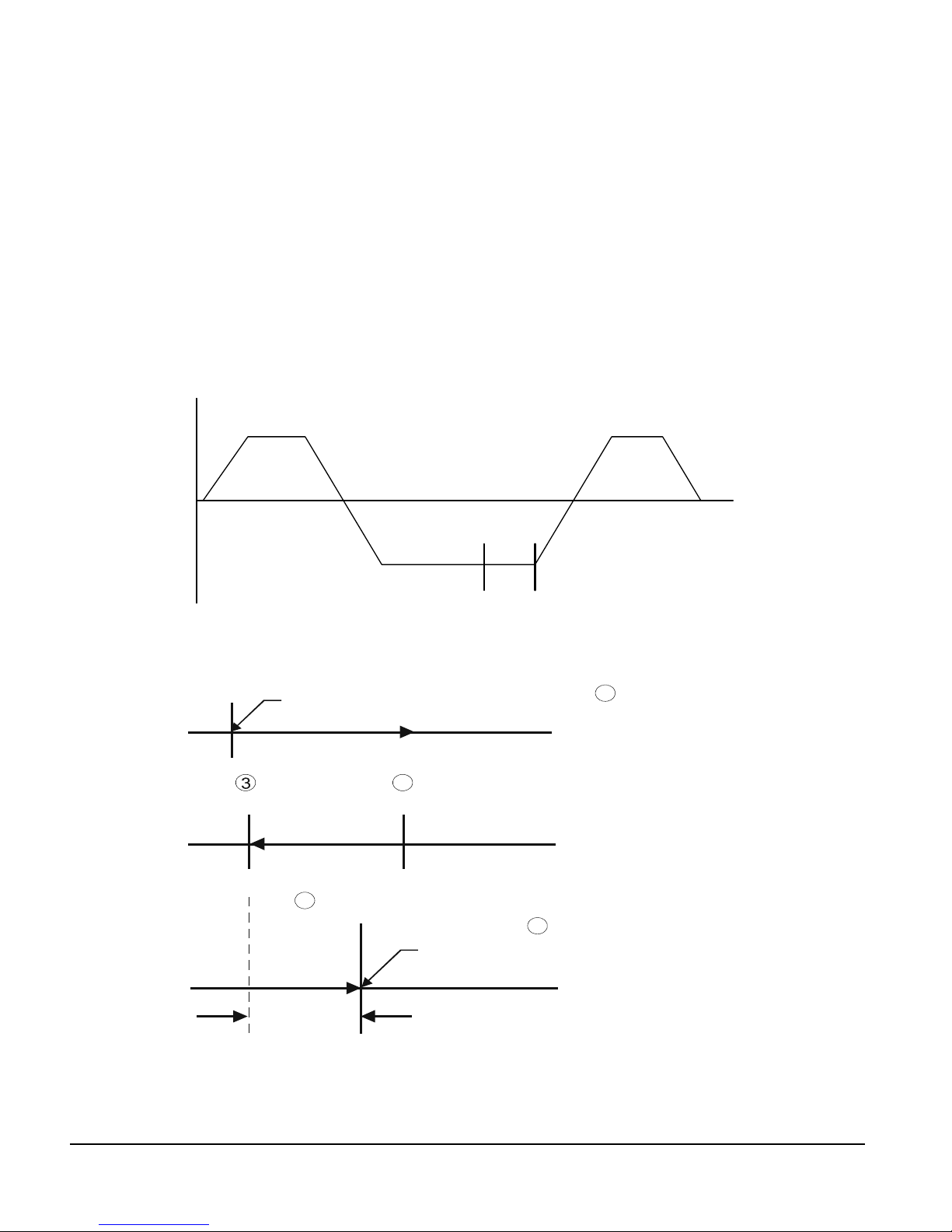

Sensor and Marker

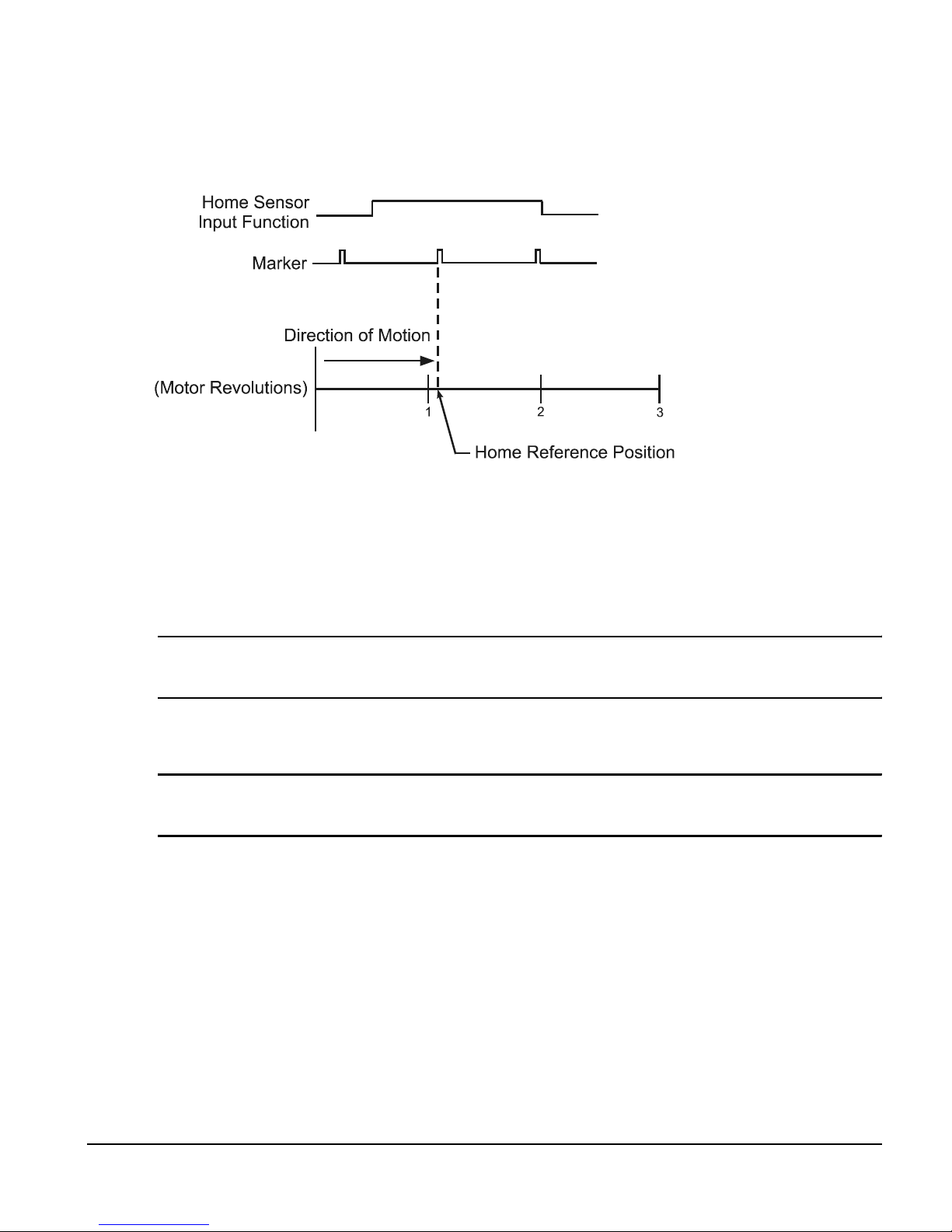

Selecting Sensor and Marker means the reference position is establis hed using the first

marker rising edge after the device sees the rising edge of the Home Sensor input function.

Figure 9: Sensor and Marker Home Reference Position Example 1

Accuracy and Repeatability

The amount of accuracy your application requires will determine the Home Reference option

you select. Homing to an external sensor only will establish a repeatable home position within

0.04 revolutions at 3000 RPMs (800 µsec sensor capture interval).

Note

The data above assumes the use of a perfectly repeatable home sensor.

In Sensor and Marker app lications, the mar ker must be at least 8 00 µsec after the rising edge

of the sensor input to be considered a valid marker pulse.

Note

At 1000 RPM, the motor will travel 0.0133 revolutions (or 4.8°) in 800 µsec.

11

Page 26

FM-3 Programming Module Reference Manual

Sensor Min.

800 µsec

Sensor

Marker

Direction of Tr avel

Figure 10: Sensor and Marker H ome Reference Position Example 2

The Home Sensor must be “On” for at least 800 µsec to guarantee that it will be recognized.

Figure 11: Sensor and Marker H ome Reference Position Example 3

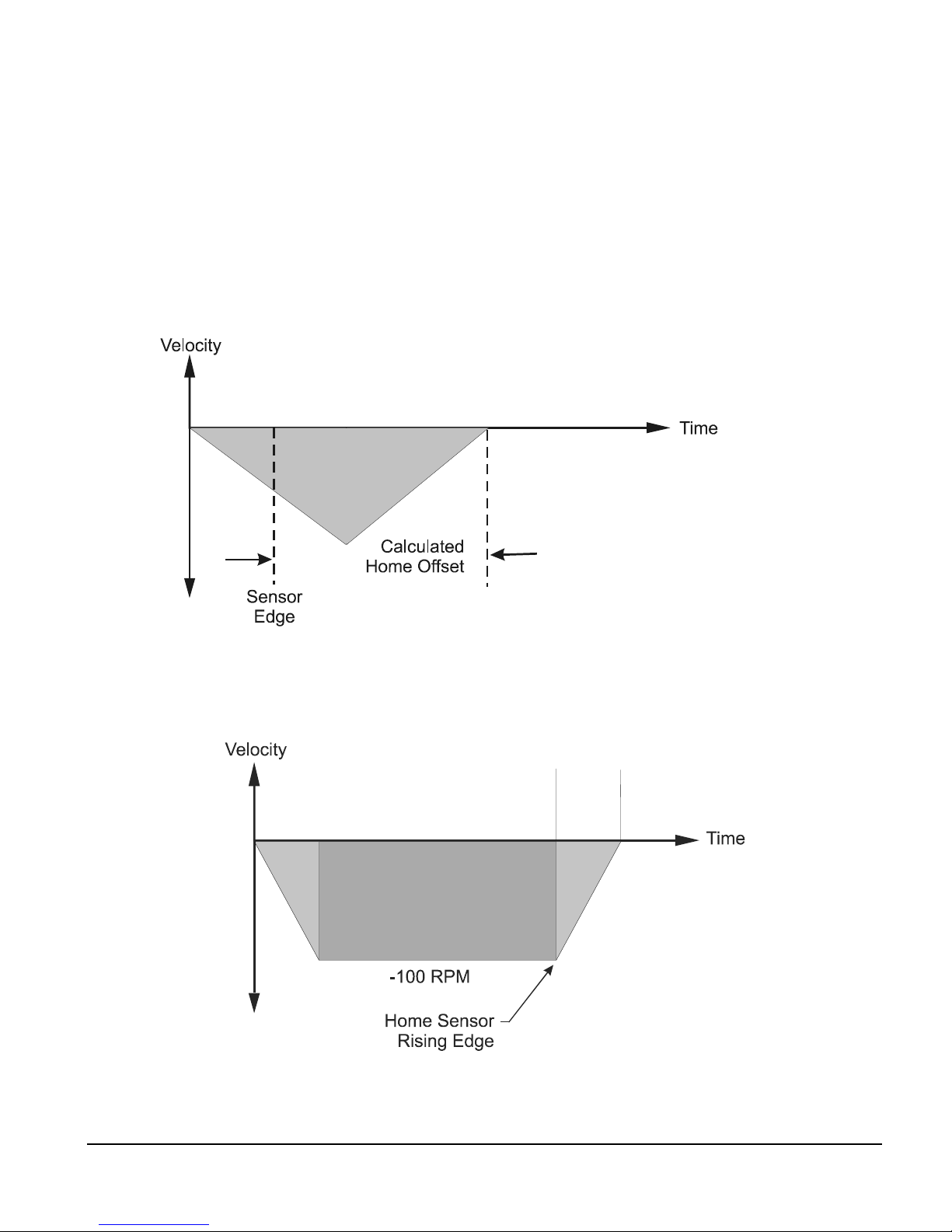

Home Offset

The Home Offset is the distance from the Reference Position to the final stopping point at the

end of the homing sequence. Regardless of the value you enter for the Offset or which Home

Reference you choose, there is always an offset inherent in the homing process.

The user may either specify a desired offset or allow the drive to calculate an offset

automatically. The drive calculates an offset that guarantees that the motor will not have to

backup to get to the offset position. This is very convenient for unidirectional applications.

On Time

Sensor

800 µsec

The calculated offset is the distance travelled during deceleration ramp from the home

velocity to a stop plus the distance travelled at the home velocity for 800 µsec. This extra

distance is used to guarantee that the motor will not need to backup after the deceleration

ramp.

12

Page 27

Operational Overview

Calculated

The Specified Offset allows the user to choose an exact offset from the Home Reference.

Once the home reference is detected, the device will do whatever is necessary to reach the

offset position. This may be as simple as a deceleration to a stop, a continuation at speed

followed by a deceleration to a stop, or a deceleration followed by a move in the opposite

direction.

To enter a specified home offset, select the Specified Offset radio button. PowerTools Pro

always displays the calculated offset value as a reference. If the home reference is detected

before the axis has reached its peak velocity, the axis will still co nti nue to the precise offset

position.

Figure 12: Calculated Home Offset, Peak Velocity Not Reached

If the Home Reference is detected after the axis has reached its peak velocity, the axis will

decelerate to the precise offset position.

Home Offset

Figure 13: Calculated Home Offset, Peak Velocity Reached

13

Page 28

FM-3 Programming Module Reference Manual

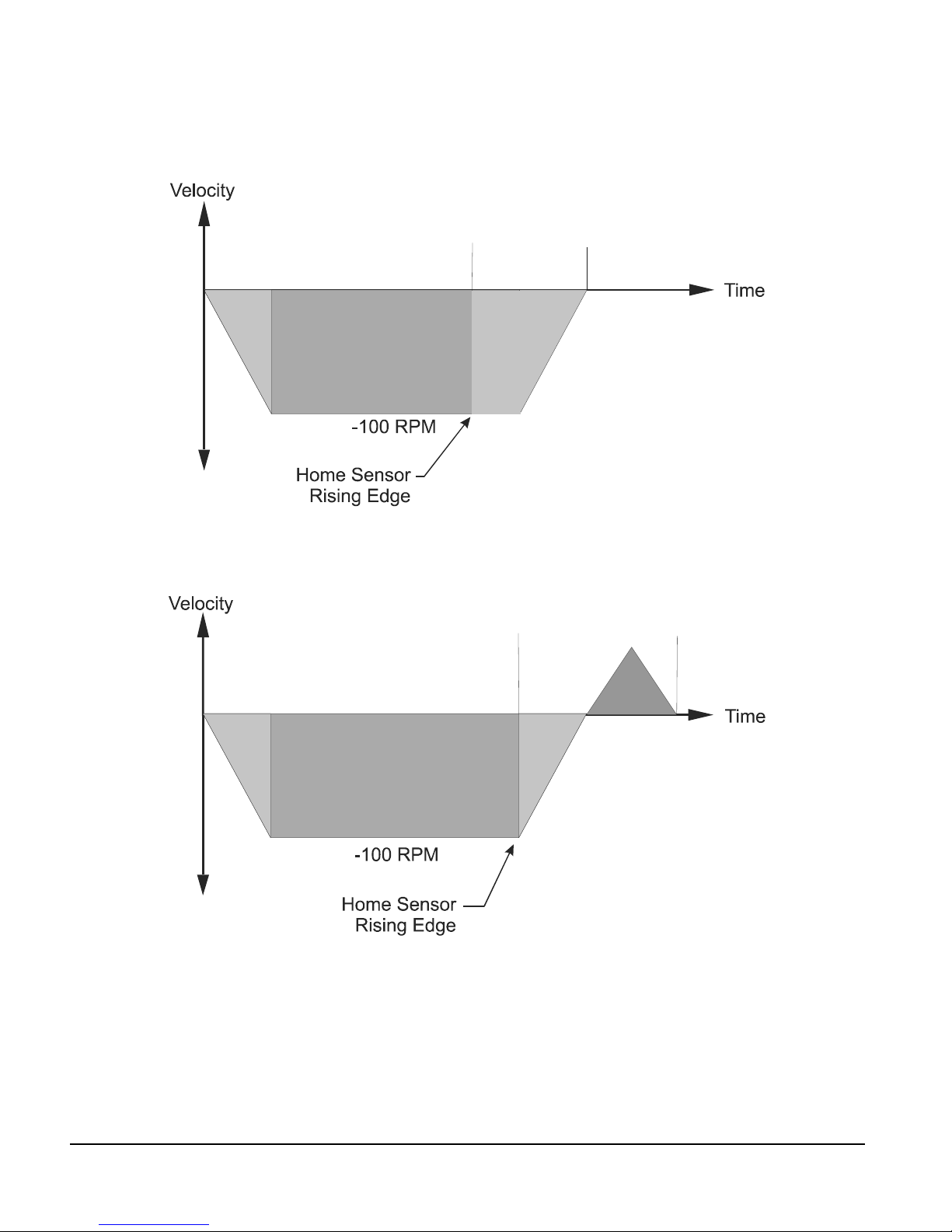

Two examples below show operation when the specified offset is greater or less than the

calculated offset. This causes the axis to continue on at speed before decelerating and

stopping at the offset position, or backing up after the home sensor.

Specified

Offset

Figure 14: Specified Home Offset, Greater than Calculated Offset

Specified

Offset

Figure 15: Specified Home Offset, Backup Required

End of Home Position

The End of Home Position (End Posn) defines the home position in relation to the machine’s

coordinate system. At the completion of the home, the value of the End of Home Position is

put into the command position.

14

Page 29

Home Limit Distance

This parameter places an upper limit on the incremental distance the motor will travel during

the home.

If no reference is found, the system will decelerate and stop at the limit distance. The Home

Limit Distance Hit function will be activated if the home stops at the limit d istance without

finding the reference. Additionally, the Home.CommandComplete f unc tio n will not turn

“On” if the limit distance is hit.

Home Examples

Example 1: Linear Application

In this example, the system uses an external sensor and the motor’s encoder marker channel

to establish a Home Reference Position. This is the most accurate and most common way to

home.

Operational Overview

Figure 16: Home to Sensor and M arker, Ex ample

When the FM-3 module sees the Home Initiate, it accelerates the motor to the Home Velocity.

The motor continues at that velocity until it first senses the Home Sensor in put. It continues

at the same velocity until the motor’s encoder marker channel is sensed. The rising edge of

the motor’s encoder marker chan nel is used to establish the reference position. Once the

home reference is detected, the motor decelerates to a stop and moves to the offset position.

15

Page 30

FM-3 Programming Module Reference Manual

n

Home Sequence

1. If on sensor then back off (if enabled)

2. Search for se nsor

3. Search for marker

4. Go to offset (2.0 Revs)

5. Set feedback position equal to End of Home Position

Velocity

+ 100

Back off

Sensor

- 100

Figure 17: Home Velocity Profile

Start of Home

2

Marker

Sensor

Sensor

+ 100

Time

Marker

1

Back Off Sensor

Home Move

4

Offset Move

2.0 Revs

Offset

Figure 18: Home Move Sequence

16

5

Final Position = End of Home Positio

Page 31

Operational Overview

Example 2: Rotary Application

This example uses an external sensor and the motor’s encoder marker pulse to establish a

home reference position.

Figure 19: Home Sensor and Marker then Offset, Example

When the device sees the rising edge of the Home Initiate function, it accelerates the motor

to the Home Velocity. The motor continues at that velocity until it first senses the Home

Sensor input. The motor continues on at the home velocity until the marker is activated.

The rising edge of the motor’s encoder marker channel is used to establish the reference

position.

After sensing th e rising edge of the mo tor’s marker channel, the dev ice will cont inue movi ng

and will decelerate to a stop at the specified offset position.

Figure 20: Home Velocity Profile

17

Page 32

FM-3 Programming Module Reference Manual

How Indexes Work

An index is a complete motion sequence that moves the motor a specific incremental distance

or to an absolute position. This motion sequence includes an acceleration ramp to a

programmed velocity, a run at velocity, and a deceleration to a stop.

Velocity

Run at Velocity

Acceleration

Figure 21: Index Moti on Sequence

Deceleration

Time

18

Page 33

Operational Overview

Figure 22: Indexes View

Indexes use acceleration and deceleration ramps which may or may not reach the specified

velocity depending on the total distance and the ramp values. For example, a short move with

long acceleration and deceleration ramps may not reach the target velocity entered.

Indexes cannot be initiated when any other motion (jogging, homing, or program) is in

progress. Indexes can be aborted with the Stop destination found in t he Ramps group on the

Assignments View.

The FM-3 module supports five types of indexes: absolute, incremental, registration, rotary

plus and rotary minus.

19

Page 34

FM-3 Programming Module Reference Manual

Absolute Index

Absolute Index

Absolute vs. Incremental

The difference between absolute and incremental index e s is that absolute indexes move to a

specific absolute position and incremental indexes move the motor a specific distance. The

figures and explanations below demonstrate this concept.

Absolute Indexes

Absolute indexes are used in applications where the motor must trav el to a s pecific po sition,

regardless of where the motor is when the index is initiated.

The FM-3 module calculates the distance required to mov e to t he spe cif ied p ositi on f rom the

current position.

Absolute Index

Start Position = 1 Rev

Index Position = 5 Revs

Figure 23: Absolute Index Example 1

In the example above, the current position is 1 rev. If this index is initiated, the motor will

travel to a position o f 5 revs no m atter where it i s sitting bef ore the move. Fr om 3 revs, i t will

travel 2 revs to finish at 5 revs. If the absolute index to 5 revs is initiated a second time

immediately after the index, no motion will occur because the motor will already be at a

position of 5 revs.

The direction of an Absolute Index is determined by the starting position and the absolute

index position. If the starting position for the above index is 9 revs, then the motor will rotate

in the negative direction to end up at 5 revs. The diagram below shows this.

Start Position = 9 Revs

Index Position = 5 Revs

Figure 24: Absolute Index Example 2

20

Page 35

Operational Overview

Incremental Index

Incremental Index

Absolute indexes with Rotary Rollover enabled wi ll take the shortest path to the position

entered in the index position parameter.

Note

Absolute indexes move to positions re lative to where the machine was homed using the

Home, or the DefineHome destination.

Incremental Indexes

An incremental index will move the motor a specified distance in the + or - direction

regardless of the starting position. The directio n of the incremen tal index motion is

determined by the sign (+ or -) of the Index Distance parameter.

Incremental Index

Start Position = 1 Rev

Index Distance = 2 Revs

Figure 25: Incremental Index Example

In the example above, the motor starts at 1 rev, travels a distance of 2 revs and stop s at 3 revs.

If the same index is initiated a second time, the FM-3 module would move the m otor another

2 revs to a position of 5 revs. If initiated a third time, the motor would travel another 2 revs

to a final position of 7 revs. The example below shows this operation.

Figure 26: Incremental Index Example 2

Start Position = 1 Rev

Index Distance = 2 Revs

21

Page 36

FM-3 Programming Module Reference Manual

Registration Index

A Registration Index is used in applications where the motor must move until an object is

detected and then move a specific distance from the point of detection, such as finding a

registration mark and moving a distance beyond.

The Registration Index consists of two parts. The first part accelerates the motor to the target

velocity and continues at this velocity until it receives a registration trigger (sensor or analog).

Upon receipt of a registration trigger, the regis tration offset will be executed at the target

velocity. The Sensor Limit Distance Hit source can be used to turn on an output, if a sensor

input or analog limit is not received within the Limit Distance. A registration window can

also be used to determine the validity of a registration trigger. If a regi str a tion trigger is

received outside of the registration window, it will be ignored.

Rotary Plus and Rotary Minus Indexes

Rotary Plus and Rotary Minus Indexes provide forced directional control of moves to

absolute positions. The position entered for a Rotary Plus or Minus type index must be within

the rotary range (i.e. 0 ≤ Position < Rotary Rollover Point). All other parameters function the

same as they do with absolute indexes. An Absolute Index is a direct move to a specific

position, regardless of the starting point. A Rotary Plus Index moves to the specified position,

but is forced in a positive direction. Similarly, a Rotary Minus index moves to the sp ecific

position, but is forced in a negative direction.

Rotary Plus and Minus Indexes are usually used in rotary applications, therefore the rotary

rollover feature on the S etup - Positio n view in the Power Tools Pro softwar e must be enabled

to use them.

1. In the fo llowing examples the term “D” = (absolute position specified) - (current

position). If “D” is negative, motion in the negative direction is implied.

2. In the following examples the Rotary Rollover parameter on the Setup - Position view is

set to 360.00°. This means that with each revolution of the motor (or rotary table),

feedback will count up to 359.99°, then roll over to Ø°.

Indexes with Rotary Rollover Enabled

Incremental move distances can be outside of the rotary rollover range. See the Setting

Up Parameters section for an explanation of Rotary Rollover.

Example 1: If the starting position is at Ø° and 720° is the specified distance, an

Incremental index would move 2 revolutions in the positive direction. At the completion

of this index the motor position would be Ø°.

Absolute indexes will take the shortest path to the specified position. Absolute index

positions must be within the rotary rollo ver r a nge.

Example 2: If the starting position is at 90° and 80° is the specified position, an Absolute

index would travel 10° in the negative direction. At the completion of this index the

motor position would be 80°.

22

Page 37

Operational Overview

Example 3: If the starting position is 45° and 315° is the specified position, an Absolute

index would travel 90° in the negative direction because that is the shortest path between

45° and 315°.

Rotary Plus indexes will move to the specified position and are forced in a positive (or

plus) direction. Rotary Plus index distances must be within the rotary rollover range.

Example 4: As in example 2 abov e, the starting position is at 90° and 80° is the specified

position. A Rotary Plus index would travel 350° in the positive direction. At the

completion of this index the motor position would be 80°.

Example 5: If the starting position is 10° and the specified position is 350°, a Rotary Plus

index will travel 340° in the positive direction.

Rotary Minus indexes move to the specified position, but are forced to travel in the

negative (or minus) direction. Rotary Minus index positions must be within the rotary

rollover range.

Example 6: As in examples 2 and 4 above, the starting position is at 90° and 80° is the

specified position. A R ot ary Mi nus index would travel 10° in the negati ve di rect ion. A t

the completion of this index the motor position would be 80°.

Example 7: If the starting position is 15° and the specified position is 270°, a Rotary

Minus index would travel 105° in the negative direction.

How Communications Work

Uploading

Uploading is the process of reading information back from the drive to the PowerTools Pro

configuration screens.

To upload inform ation from a driv e, click on the upload button on the PowerTools Pro t oolbar

or select upload from the Device menu.

Downloading

Downloading is the process of s ending your co nfiguration created with PowerTools Pro from

the PC to the FM-3 module. Changes made in PowerTools Pro will no t take effect until th e

information has been downloaded or the Update to RAM button has been clicked.

To download information to a FM-3, click on the download button on the PowerTools Pro

toolbar or select download from the Device menu. Powe rTools Pro will lead the us er through

a series of dialog boxes that determine what baudrat e and which communicat ions port on the

user’s P C will be u s ed.

23

Page 38

FM-3 Programming Module Reference Manual

NVM Options for Uploading and Downloading

Uploading

When uploading from a FM-3 module, the values that were last downloaded are uploaded and

put into a PowerTools Pro configuration file. At the completion of the upload, the user will

be asked if they wish to upload the NVM values. This dialog box is shown below.

By selecting Yes, the values of all parameters stored in NVM will be uploaded and en tered

into the PowerTools Pro file values. If No is selected, the values entered into the PowerTools

Pro file will remain the same as those that were last downloaded to the FM-3 module.

Downloading

When downloading to the FM-3 module the user will be required to select how to handle the

NVM parameters upon downloading. The dialog box asking the user to select one of three

options for the download is shown below.

A description of each of the options is as follows:

Overwrite – This option will overwrite all the parameters stored in NVM with the current

values in the user configuration (PowerTools Pro file). The values that are in NVM prior to

the download will be lost.

Update – This option will upload the curre nt NVM parameter values from the FM-3 module

and enter them into the user configu ration (PowerTools Pro file). Once the NVM values have

been stored in the file, the file is fully downloaded.

Keep – This option will download the entire user configuration, but then NVM parameters

will be restored to the value prior to download. This is similar to the Update option, but the

24

Page 39

Operational Overview

Keep option does not upload the NVM values into the user configuration (PowerTools Pro

file).

The following table shows an example of how these options work:

PT Pro file value for

Index.0.Vel

NVM value for

Index.0.Vel

Updating to RAM

The Update to RAM button can be used to send changes to the FM-3 module without

performing a complete download. The Update to RAM button is found in the PowerTools Pro

toolbar. This operation will send only those changes that have been made since the last

Update to RAM or Device – Download to the FM-3. The changes will take effect

immediately upon clicking on the button.

Before

Download

150 150 500 150

500 150 500 500

Overwrite

Option

After Download

Update Option

Keep Option

The parameters will be sent to the FM-3 module without stopping motion or disabling the

drives. Because of this, it is important to use caution when changing motion par ameters

while the motor is in motion.

The Update to RAM button saves the parameters only to RAM and not to Non-Volatile

Memory (NVM). Therefore, if the system power is removed, any changes made using the

Update to RAM button will be lost. In order to save changes to NVM, a full-download must

be performed.

The flowchart below describes a typical process using the Update to RAM to make change s,

and then downloading when complete to save changes to NVM.

25

Page 40

FM-3 Programming Module Reference Manual

Figure 27: Update to RAM Flow Chart

The Update to RAM button operates according to the following rules:

If no parameters have been modified by the user, the Upd ate to RAM button will be disabled.

If the user modifies a parameter that does not require a full download, the Update to RAM

icon will be enabled.

If while the icon is enabled, the user modifies a parameter that requires a full download, the

Update to RAM icon will become disabled.

When the user clicks on the Update to RAM icon, all the modified parameters are transmitted

to the FM-3. Once transmitted, the icon will become disabled again until another parameter

is changed.

If the user performs a full download while the button is enabled, when the download is

complete, the Update to RAM button will be disabled.

If the user modifies parameters , and dis connects, the update button will be dis abled, and the

changes will not be sent.

Options/Preferences/Ptools Operation

This menu controls the pop-ups that the user encounters when uploading and downloading

the FM-3/4 configuration.

Download Section:

“Ignore saving file on Ptools/Drive revision conversion.”

On a download PowerTools Pro checks the firmware revision of the module that it is about

to be downloaded to and is required to make changes to the files that are to be downloaded to

older firmware revisions. This checkbox allows the user to avoid saving the newer file before

converting it to a previous revision.

“Overwrite – Reset the NVM configuration”

26

Page 41

Operational Overview

When this checkbox is selected the “Overwrite” function will default on ever y download to

the module. This function will overwrite the entire FM-3 configuration including user defined

NVM parameters as set in the NVM setup area of PowerTools Pro.

Note

It is required to Overwrite the Non-Volatile Memory on the first download to the module

since no Non-Volatile Memory parameters have been loaded into the drive on initial

startup.

“Update – Upload the values into the current Update PowerTools Pro configuration”

When this checkbox is selected the “Update” function will Update the NVM on every

dowload to the module. Upon download the Update function uploads the configured NVM

from the drive and places the data into the PowerTools Pro configuration file. The software

then downloads this newly updated file to the module.

“Keep – Remember the values and res tore them after the download”

This option was created to allow users to save the values that have been changed via HMI,

PLC or internally in a program so long as they have been added to the NVM list. When this

checkbox is selected PowerTools Pro will poll the drive on download for all of the values that

have been added to the NVM list. PowerTools Pro then stores these values into a temporary

memory location and after the program download is complete PowerTools Pro rein states

these values to the parameters before the drive can be enabled.

“Ask on each download”

This option was created for users who want control of whether they will overwrite or keep the

NVM on download. When this checkbox is selected, PowerTools Pro will display a pop-up

window that gives the user the option to Overwrite, Update, or Keep as described above.

Upload Section:

“Always convert Application to latest Ptool capabilit y”

When this checkbox is selected, PowerTools Pro will automatically update an uploaded file

to match the current functionality of PowerTools Pro.

"Always leave Application matching Module capability”

When this checkbox is selected, PowerTools Pro will default to upload and disp lay the

configuration to match the firmware revision and capabilities of the module.

“Ask on each upload”

When this checkbox is selected, PowerTools Pro will default to asking the user to convert the

application to the latest PowerTools Pro capability, or leave the application to match module

capability.

27

Page 42

FM-3 Programming Module Reference Manual

Upload Non-Volatile Memory (NVM) Section:

“Always upload NVM”

When this checkbox is selected, PowerTools Pro will default on an upload to uploading all of

the parameters that have been mapped to the NVM and updating the display of these

parameters in PowerTools Pro.

“Always bypass NVM upload”

When this checkbox is selected, PowerTools Pro will not upload the NVM and the values that

were originally downloaded to the drive will be displayed in the PowerTools Pro

configuration.

“Ask on each upload”

When this checkbox is selected, PowerTools Pro will default to asking t he u ser vi a a pop -up

window whether to upload the NVM or to bypass the NVM upload.

Secure Downloading

The Secure Download feature allows the user to download a configuration that prevents

anyone from uploading the file, or going online with the system. This is used to protect a file

from being accessed by unauthorized personn el. If a secure file is downloaded to the system,

all diagnostics capabilities in the software are lost. The only way to go online with the system

again is to download the origin al (non-secure) file over the secure version, or to download a

completely new file.

Before performing a secure download, the file must first be saved in the secure file format.

To do this, open the file you wish to save in the secure format using PowerTools Pro. Then

click File\SaveAs on the Menu Bar. The following SaveAs window should appear on your

screen

On this window, check the “Save also as secure download format” check box located at the

bottom of the window, then click on the Save button. Doing this will save your file in BOTH

28

Page 43

Operational Overview

the standard file format (. fm3), as well as in the secure file format (.fm3s) . The “s” at the end

of the file extension stands for “secure”. The secure file will be saved to the same directory

as the standard file.

To perform the Secure Download, close all open files in PowerTools Pro. Then click on

Device\ Secure Download on the menu bar as shown below.

A window will then pop up asking the user to select the secure file that they wish to download.

Select the secure file that was just saved, and then click on the “Open” button. This will

download the secure file to the target device.

A secure file (.fm3s) cannot b e opened o r modified . The file extens ion cann ot be changed to

allow the user to open it. The secure file is only valid for use by the secure download function.

If a user attempts to upload a secure file, a message will appear indicating that the file residing

in the system has been protected by the user. An example of this is shown below.

Brake Operation

MG motor brake operation is controlled by the Brake Release and Brake Control destinations.

These destinations can be used together to control the state of the Brake source. The table

below shows the relationship between the Brake sources and destinations (see “Diagnostic

Display”).

Note

No motion should be commanded while the brake is engaged.

Brake Release Destination Off On

Brake Ac tivate Destination On Off On Off

Drive Power

Stage

Enabled

Disabled

0111

0011

29

Page 44

FM-3 Programming Module Reference Manual

Brake Release

The Brake.Release destination function will release the brake under all conditions. When this

function is active, the Brake output will be on (that is, release brake). This function overrides

all other brake control, thus allowing the brake to be released while a fault is active or the

power stage is disabled. See also Brake source function.

Brake Acti va te

The Brake.Activate destination function, when active, will engage the brake unless

overridden by the Brake Release function. This function lets you externally engage the brake

while allowing the drive to also control the brake during fault and disabled conditions.

Brake Dise nga g ed

The Brake.Disengaged source function is used to control the motor holding brake. If the

Brake function is off, the brake is mechanically engaged. When the brake is engaged, the

diagnostic display on the front of the drive will display a “b”.

The drive outputs are limited to 150 mA capacity, therefore, a suppressed relay is required to

control motor coil. Control Techniques offers a relay, model # BRM-1.

30

Page 45

FM-3 Programming Module Reference Manual

Setting Up Parameters

Setup View

The Setup View contains all of the primary system setup parameters. These parameters mus t

be setup prior to using your system.

By selecting Setup in the Hierarchy View, the Setup view will appear on the right sid e of the

view (see Figure 28). The Setup view is divided into six groups, with an ex planation of each

function. The groups are Identification, Configuration, Drive Encoder Output, Positive

Direction, Update Rate and Switching Frequency. Status Online will be shown when online

with the FM-3 module.

Figure 28: Setup View

Identification Group

The identification group consists of the Device Name and the Target Drive Address.

31

Page 46

FM-3 Programming Module Reference Manual

EN

Name

This is a 12-character alpha/numeric user-configured name for this axis. Enter this name for

the device you are currently setting up. Assigning a unique name for each device in your

system allows you to quickly identify a device when downloading, editing, and

troubleshooting. All keyboard characters are valid. This will default to Axi s 1.

Target Drive Address

This is the Modbus address of the target drive to which you will download the configuration.

The default target drive address is 1.

Configura tion Group

The configuration gr oup consists of li st boxes for Drive Ty pe, Motor Type, and Lin e Voltage.

Drive Type List Box

Select the drive model for the system you are currently setting up.

Motor Type List Box

Select the motor you want to use.PowerTools Pro software will only display the motor models

that are compatible with the drive you selected and any user defined motors.

Selecting the wrong motor type can cause instability and may cause property damage to

the moto r and/or dr ive.

EN Only

Line Voltage List Box

Line Voltage specifies the applied power and adjusts the internal gains to compensate for

it. This parameter has two choices: 115 VAC and 230 VAC. If the Line Voltage is set to

230 VAC when the actual applied voltage is 115 VAC, the motor will be slig htly less

responsive to commands and load disturbances.

The Line voltage must never be set to 115 VAC if the applied voltage is actually 230

VAC. This can cause drive instability and failure, resulting in property damage.

Drive Encoder Output Group

The drive encoder output group consists of the encoder scaling check box and encoder

scaling.

32

Page 47

Encoder Scaling Check Box

This check box enables the Scaling parameter of the Drive Encoder Output.

Encoder Scaling

This parameter defines the encoder resolution (lines per re volution) of the drive's encoder

output. This feature allows you to change the drive encoder output resolution in increments

of 1 line per revolution up to the density of the encoder in the motor. If the Encoder Output

Scaling parameter is set to a value higher than the motor encoder density, the drive encoder

output density will equal that of the motor encoder.

Positive Direction Group

The Positive Direction group consists of a clockwise (CW) Motor Rotation Radio Button or

a counter-clockwise (CCW) Motor Rotation Radio Button.

The motion will move in either CW direction or counter-clockwise CCW direction.

Perspective of rotation is defined as you face the motor shaft from the front of the motor.

CW Motor Rotation Radio Button

Setting Up Parameters

Select this radio button for applications in which CW motor rotatio n is consid er ed to be

motion in the positive direction (increasing abso lute position).

CCW Motor Rotation Radio Button

Select this radio button for applications in which CCW motor rotation is co nsidered to be

motion in the positive direction (increasing abso lute position).

Update Rate Group

This parameter configures the interrupt interval for the FM-3 processor. This defines how

often the motion program is interrupted and the Control Lo op is processed. In the Control

Loop, the feedback information is processed and a new position command is generated. Also

in the Control Loop, the I/O is scanned. After Control Loop is complete, all messages are

handled. Messages are Modbus data, DeviceNet data, Keypad/Display information, and are

only processed if a message is wai ting. If no device is querying data from t he FM-3 or sending

data to the FM-3, then messages do not take up any time. Once messages have been

processed, the remainder of the int errupt is dedi cated to runni ng the motion programs of user

programs.

Available selections for Trajectory Update are 800, 120 0, and 1600 microseconds. The l onger

the update, the more time is dedicated to the user programs, and the less time dedicated to

servo performance. Th e shorter the updat e , the mor e precis e the servo perform ance, b ut less

time is available to process user progra ms. Diagnostics are available on the Status Online tab

when online with the device to help select the ideal setting. (See description of Control Loop

Group of online parameters for further information)

33

Page 48

FM-3 Programming Module Reference Manual

Switching Frequ ency Group

This parameter defines the s witching frequency of the electro nic amplifier. For EN drives, the

switching frequency must be 20 kHz and cannot be changed. For MDS, the switching

frequency can be modified to change system performance. Available selections are 5 kHz,

and 10 kHz. For more information on this setting refer to the MDS Reference Manual, P/N

400525-01.

Status Online Tab (Online Only)

The Status Online tab (s ee Figure 29) is visible when online and consists of the Motor

Position group, Motor Velo city gr oup, C ontro l Loop g roup, Mas ter Feedb ack grou p, and the

Torque group.

Figure 29: Setup View - Online Status Tab

34

Page 49

Motor Position Group

Position Command

Position command is the commanded motor position sent to the drive by the FM-3 module.

This parameter does not take following error into account. See also PosnFeedback and

FollowingError. Units are in user units.

Position Feedback

Feedback position is the actual motor position in user units. PosnCommand minus the

PosnFeedback is the FollowingError

Following Error

The Following Error is the difference between the Position Command and the Position

Feedback. It is positive when the Position Command is greater than the Positio n Feedb ack.

Encoder Position

Motor encoder position in encoder counts. This position reflects the feedback position of the

motor and is not scaled into user units. This is a signed 32 bit value.

Setting Up Parameters

Motor Veloci ty Group

Velocity Command

The Velocity Command is the velocity that the FM-3 module is commanding the motor to run

at. This command is generated by the drive velocity control loop and position loop. It is

displayed in user units.

Velocity Feedback

This is the feedback (or actual) velocity. It is calculated using the change in position of the

motor encoder. It will always return the actual motor velocity - even in synchronized

applications in which the master axis is halted during a move.

Control Loop Group

Changing the Trajectory Update Rate can have a major effect on the performance of your

servo system. A longer trajectory update rate mean s that more time is available to process user

programs. A shorter update rate means that the control loop is updated more often and

provides the most accu rate p erfo rmance. W ithout pro per diagnostics, it can be impossible to

tell how much time is being consumed by the control loop update, and how much time is

available to run user programs.

The Control Loop group of parameters on the Status Online tab shows the user how much

time is available to run programs. There are two parameters available to help with this. They

are as follows:

35

Page 50

FM-3 Programming Module Reference Manual

Control Loop Limit

This parameter shows the lowest measured time difference (in microseconds) between the

Trajectory Update Rate and the time taken to process the control loop since the last reset.

Certain features in the FM-3 require more time to process (i.e. PLS, Capture, Compound

Indexes), and therefore will cause lower limits. The software records the lowest measured

value and displays it as the limit. To reset the limit to the average and continue tracking the

lowest value, the user can click on the Limit button. If the Limit reaches 0, a fault will be

generated. If a Limit of less th en 75 - 100 usec is seen, it is recommended to swi tch the update

rate to the next higher value.

Margin Average

This parameter shows a running average of the difference (in microseconds) between the

Trajectory Update Rate and the time taken to process the control loop since the Status Online

tab was brought up. The high er the val ue, the more time available to run user programs. For

Averages less than 150 usec, it is recommended to switch the update rate to the next higher

value.

Master Feedback Group

Master Position

Used for synchronized motion, this displays the position of the master encoder in units

defined on the Master Units Setup View.

Encoder Position

This displays the position of the master encoder in counts.

Master Velocity

This displays the velocity of the master encoder in master units/second.

Torque Group

Torque Command

This displays the torque command value before it is limited. The torque command may be

limited by either the Torque Limit (if the Torque Limit Enable destination is active) or current

foldback. Units for this parameter are defined in the Torque Group on the User Units View.

Limited Torque

This is the actual torque commanded to the motor. This value is the result after the

TorqueCommand is limited by the current foldback or the TorqueLimit value (if enabled).

36

Page 51