Page 1

INSTRUCTION SHEET

Description

The signal isolator option board provides a means

of isolating both the speed reference, and the start signal

to a non-regenerative drive. Since the circuit common

(or signal common connection) of a typical non-regen

drive is essentially tied directly to the motor A+ terminal,

the user must insure that this connection (or any other

control connection) does not contact Earth ground.

This option when properly installed can help prevent a

drive failure. In applications using a chassis drive (no

enclosure/operators supplied), the operators will most

likely be remotely mounted and thus the possibility of

shorting to earth ground (via vibration or unintentional

connection) exists. T he chassis unit may also be remotely

controlled by a PLC or some other form of proces s control,

which is ground referenced. These applications would

typically benefit from using the signal isolator option.

In addition to providing isolation, the option board can

convert a variety of voltage and current signals to a 0 to

10VDC signal for the drive speed reference.

A control relay has been incorporated into the design to

provide a drive start contact. This relay may be configured

for 24VDC or 120VAC operation. The relay can be

controlled by a PLC having either “open emitter” or “open

collector” outputs or it can be s imply set up as a 120VAC

three wire control.

Unlike many currently available reference isolator boards,

the CT Signal Isolator option board can also support a

remote Speed Potentiometer including the power supply

for the potentiometer.

The option has been designed to operate from a single

power supply derived from the drive (or a separate isolated

supply). The range of this supply is 17 to 30VDC with a

current draw of 50ma max.

For further information, consult the Instruction manual

supplied with control. For further assistance contact:

Control Techniques Drives

Technical Support Services

(800)-893-2321

or

(800) 367-8067

Analog Isolator Option Kit

F3NSBD

WARNING

F

AILURE TO DISCONNECT POWER MAY RESULT IN

ELECTRICAL SHOCK

CANNOT BE INADVERTENTLY RESTORED DURING

THE INSTALLATION PROCEDURE

Procedure

Mounting of the signal isolator option PC board can be

done in one of two ways. Using the supplied 5” gray

mounting track and two plastic rivets, the track can be

easily affixed to a panel in the desired location. The option

board can then be snapped into the track and wired.

The second mounting choice is to use the four nylon

standoffs also inc luded in the kit. These adhesive loc king

standoffs provide easy & accessible board mounting

where space is at a premium . As in the inside of a drive

enclosure or cover.

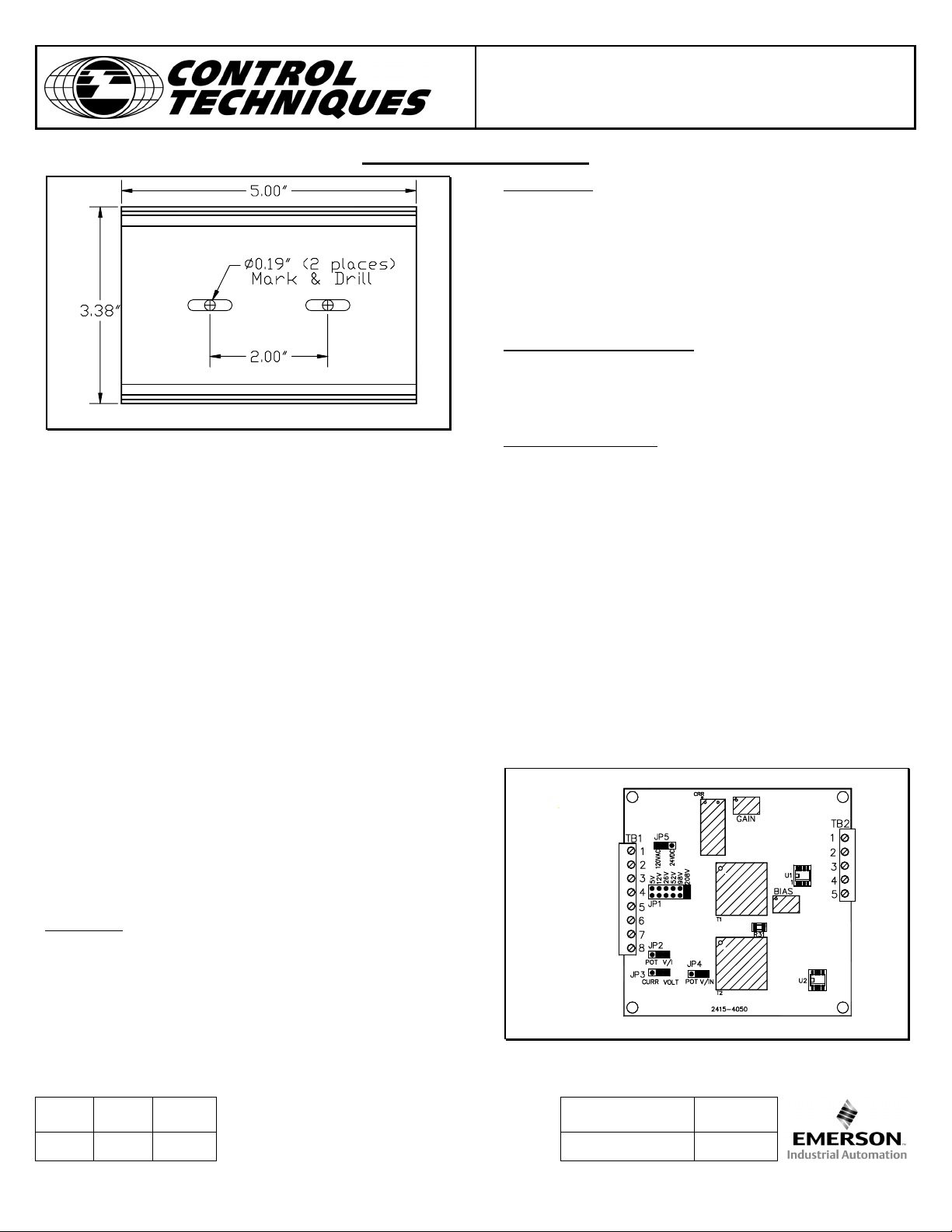

Track Mounting:

1) Locate an area on the panel where the gray mounting

track will fit properly. Mark the centers of the track slots on

the panel per Fig. 2.

. I

NSURE THAT THE POWER

.

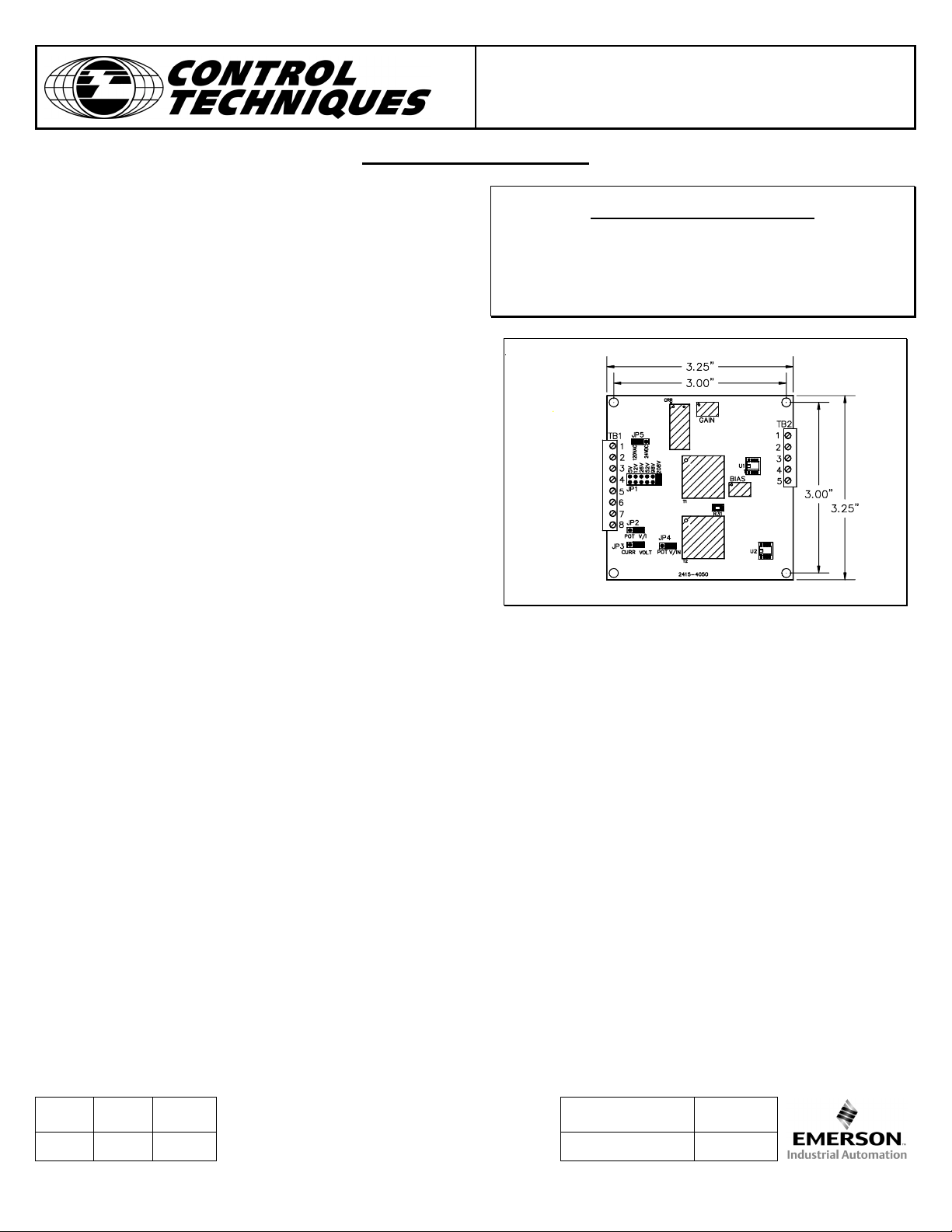

Figure 1.

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 1 of 6

Page 2

Analog Isolator Option Kit

INSTRUCTION SHEET

F3NSBD

Figure 2.

2) Drill two 0.190” holes. Mount the track in place using

the two supplied nylon push-rivets.

3) Snap the board into the mounting track as desired and

wire the terminals.

Standoff Mounting:

1) Remove the four nylon locking standoffs from the k it.

Snap all four into the four corners of the option PC board

from the solder side.

2) Find a suitable location on the panel or inside the drive

cover or enclosure. Remove the paper covering the

adhesive base of the four standoff s. Square up the bases

and mount down on the panel or cover using sufficient

pressure to set the adhesive.

Terminations & Settings

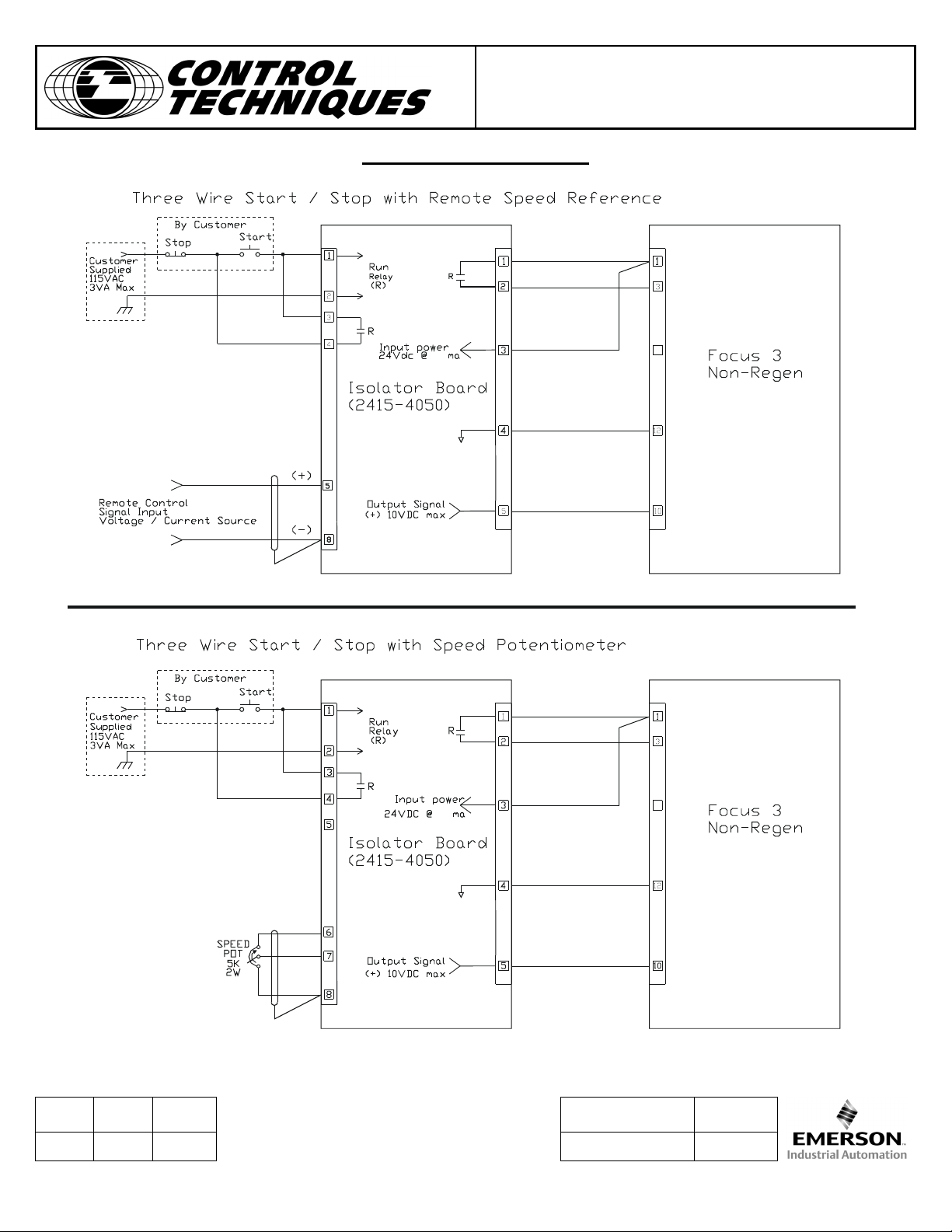

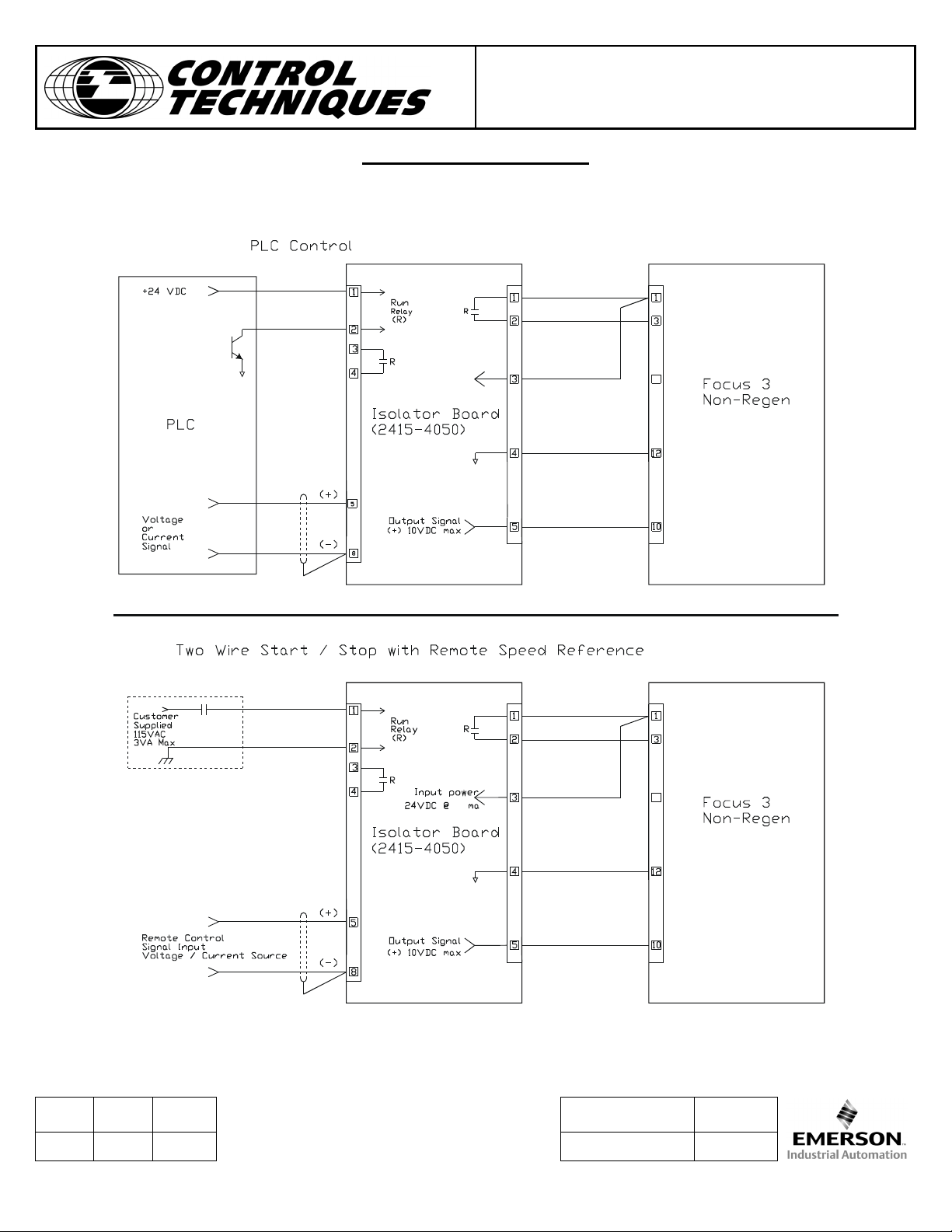

Signal Isolator wiring options and jumper settings are

described on the next pages. Follow diagrams which

indicate the options and features you desire.

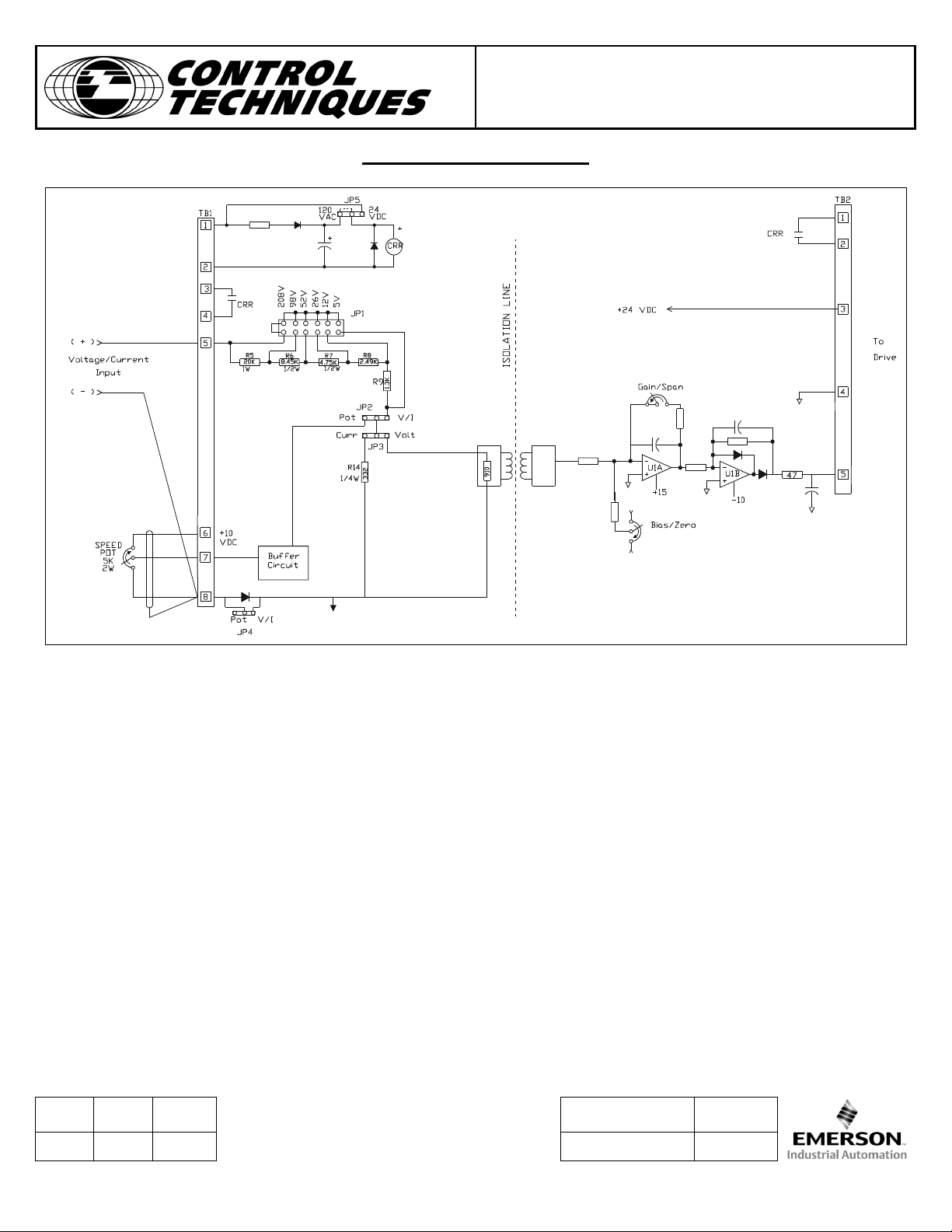

Input (TB1)

1,2 Run relay (TB1-1 positive)

3,4 Normally Open Run Contact

5 Voltage / Current Input

6 + 10VDC Speed Pot Supply (5Kohms Min)

7 Speed Pot or 0 to 10VDC Input (40K Ohms

8 Signal Common

Impedance)

Output (TB2)

1,2 Normally Open Run Contact

3 +24VDC Power Supply Input for Isolator Board

4 Isolated Signal Common to Drive

5 Isolated Speed Reference Output to Drive (0 to

Potentiometer Adjustments:

Gain (Span)

Bias (Zero)

(50ma max.)

+10VDC)

Jumper Programming:

JP1 Selects Input Reference Signal Voltage

Range (5,12,26,52,98 & 208 max.)

JP2 - Speed Potentiometer or External

Voltage/Current Reference Select

(Pot or V/I)

JP3 - Current / Voltage Reference Select

(Curr or Volt)

JP4 - Speed Potentiometer / External

Voltage/Current Reference Select

(Pot or V/I)

JP5 - Control Relay (CRR) Voltage Selection

(24VDC or 120VAC)

Default Jumper Settings

Figure 4.

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 2 of 6

Page 3

Analog Isolator Option Kit

F3NSBD

INSTRUCTION SHEET

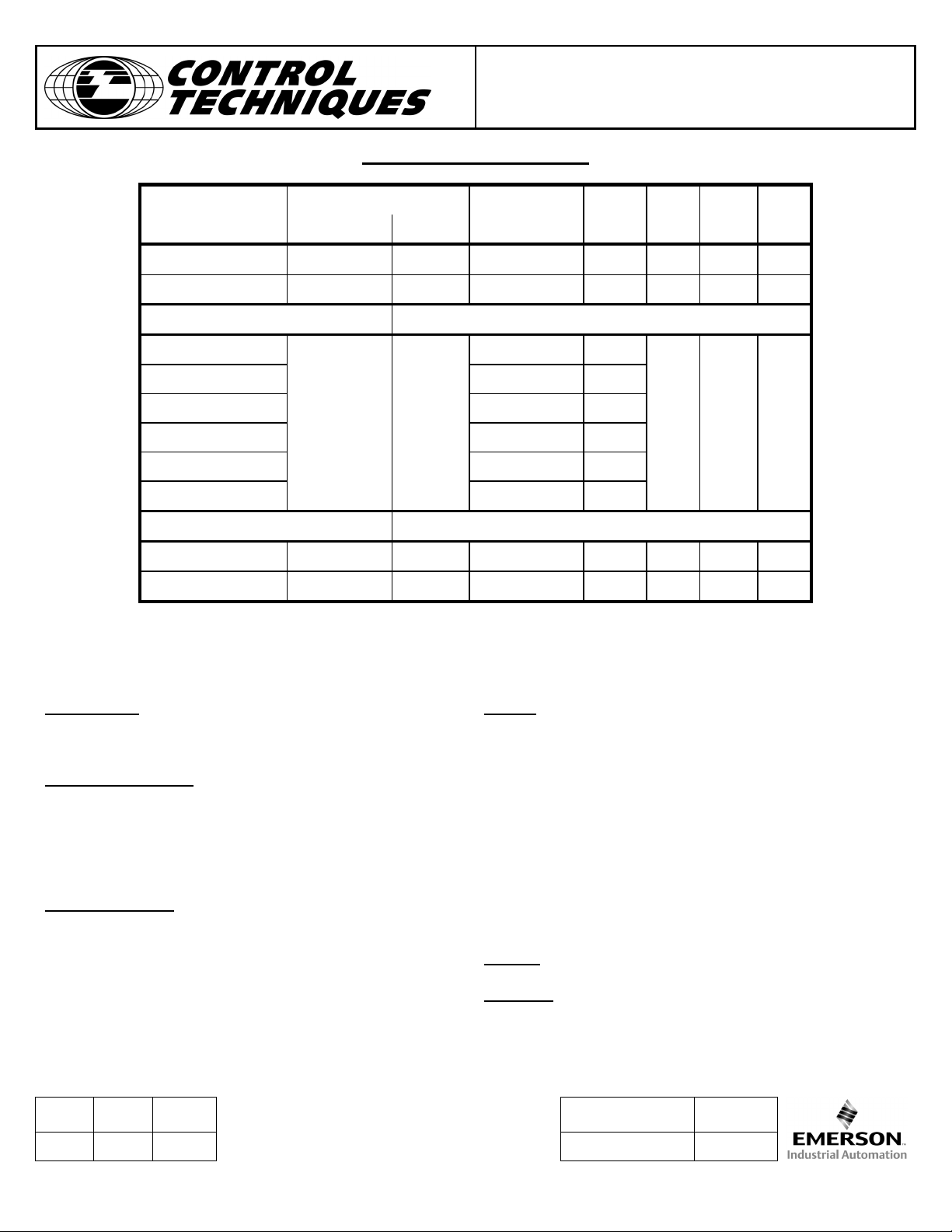

JUMPER PROGRAMMING TABLE

Input Source Term. Strip Conn. Input JP1 JP2 JP3 JP4

(+) (-) Impedance

Speed Pot* TB1 - 7 TB1 - 8 40K Ohms --- Pot Volt Pot

0 to (+)10VDC TB1 - 7 TB1 - 8 40K Ohms --- Pot Volt V/I

Voltage Ref.

0 to 5 TB1 - 5 TB1 - 8 910 Ohms 5V V/I Volt V/I

0 to 12 2.21K Ohm 12V

0 to 26 4.7K Ohms 26V

0 to 52 9.45K Ohms 52V

0 to 98 17.9K Ohms 98V

0 to 208 37.9K Ohms 208V

Current Input

0-5ma / 1-5 ma TB1 - 5 TB1 - 8 910 Ohms 5V V/I Volt V/I

0-20ma / 4-20ma TB1 - 5 TB1 - 8 243 Ohms 5V V/I Curr V/I

* = +10VDC Supply for speed pot is TB1 - 6

--- = Position doesn’t matter

(+) (-)

(+) (-)

Figure 5.

Specifications

Input Power:

17 - 30 VDC @ 50milliamp Max. Voltage Ranges: 5,12,26,52,98 & 208 VDC

(for control circuitry) Impedance 180 Ohms/Volt

Control Relay (CRR)

24VDC @ 12.1 ma (JP5 = 24VDC) 1-5 milliamps

120VAC @ 20 ma (JP5 = 120VAC) Impedance 910 Ohms

Contact Type/Rating – 2 Form A, 0-20 milliamps

1Amp @ 250VAC 4-20 milliamps

Impedance 250 Ohms

Isolation Voltage:

240VAC Power Systems Speed Pot 5K ohms, 2W

2000VAC Hi-Pot for 1 Minute

Inputs:

Current Ranges: 0-5 milliamps

Output:

Linearity:

0 to (+) 10VDC (Uni-polar)

2%

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 3 of 6

Page 4

Analog Isolator Option Kit

INSTRUCTION SHEET

F3NSBD

Set-up Procedure

Voltage Inputs

1. With input voltage sour ce set to zero, adjust the bias

(zero) potentiometer such that the output voltage

(TB2-5 (+) to TB2-4) reads the desired voltage level.

This level may be set to zero, or it may be set to

provide a minimum speed setting for the drive.

2. Set the input voltage source to maximum, adjust the

gain (span) for the m axim um s peed signal to the drive

(+10VDC).

3. Repeat steps 1 and 2 above. Note: Since the bias and

gain potentiometers are interactive, s teps 1 and 2 m ay

have to be performed multiple times.

4. Set-up Complete.

Current Inputs

1. With input current source set to minimum, adjust the

bias (zero) potentiometer such that the output voltage

(TB2-5 (+) to TB2-4) reads the desired voltage level.

This level may be set to zero, or it may be set to

provide a minimum speed setting for the drive.

2. Set the input current source to maximum, adjust the

gain (span) for the maximum speed signal to the drive

(+10VDC).

3. Repeat steps 1 and 2 above. Note: Since the bias and

gain potentiometers are interactive, steps 1 and 2 may

have to be performed multiple times.

4. Set-up Complete

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 4 of 6

Page 5

Analog Isolator Option Kit

INSTRUCTION SHEET

F3NSBD

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 5 of 6

Page 6

Analog Isolator Option Kit

INSTRUCTION SHEET

F3NSBD

Rev. ECO Date Document No. Page

A 3866 7/02 2415-3050 6 of 6

Loading...

Loading...