Page 1

Focus 3 “M” Contactor

F3M112 & F3M224

Instruction Sheet

APPLICATION

The Focus 3 “M” Contactor Kits are designed for use with the following Focus 3 drives and DB Kits.

Focus 3 Drive “M” Contactor Kit DB Kit

F3N2C, F3N2E, F3M112 25 - 1 HP @ I 20V

F3R2C, or F3R2E (120V)

F3N2C, F3N2E, F3M224 .50 - 2HP @ 240V F3DB224 2HP @ 240V

F3R2C, or F3R2E (240V)

F3N5C, F3N5E, F3M524* 3 - 5HP @ 240V F3DB324 3HP @ 240V

F3R5C, or F3R5E (240V)

*See F3M51S0698 Instruction Sheet

F3DB224 .5HP @ 120V

F3DB1 524 .25 -.33HP @ 120V

F3DB112 75-1HP@ 120V

F3DB1 524 1.5HP @ 240V

F3DB124 .75 - 1HP @ 240V

F3DB0524 .5HP @ 240V

F3DB524 5HP @ 240V

“M” Contactor Kit

Includes a magnetic contactor, interface pc board, and mounting bracket which can be installed

directly on the heatsink of the chassis mount unit and inside the enclosed control. It provides a

positive disconnect of the motor armature when the control is stopped, preventing motor turnover

in case the SCRs should false fire. In addition, an auxiliary form A N.O. contact is included for

customer use. (This kit may be required by local and/or national electrical codes.)

Dynamic Braking Kit

For use with the “M” contactor kits. Dynamic braking provides rapid motor stopping by

automatically connecting a resistor across the armature of the motor to absorb the energy

produced by the coasting motor (now acting as a generator) and bring it to a stop quickly. Note

that the dynamic brake is not a holding (fail-safe) brake. The standard dynamic brake resistors

have been sized for use with DC motors that have no appreciable load inertia connected to the

shaft and have start/stop cycles no more frequent than 3 quick stops with 10 minutes before the

next stop.

REFERENCE

The Focus 3 User Guide should be read in its entirety, paying particular attention to the Warnings

and Cautions in each section before installing, starting, or maintaining these drives.

ITEMS INCLUDED IN “M” CONTACTOR KIT

1- bracket assembly with driver board and “MC” motor contactor (unassembled)

2- mounting screws for use with the bracket assembly

1- adhesive strip used in mounting the bracket

- wires used to connect the contactor kit and the drive (only eight wires will be used in a

12

single application).

P/N *2415-3513 Rev. A1 1 of 7

F3M2IS0401

Page 2

“M” Contactor Kit

INSTALLATION OF “M” CONTACTOR

CAUTION!

Improper procedures can result in personal injury or equipment damage. Only qualified electrical

maintenance technicians familiar with electronic drives and their standard safety precautions

should be permitted to install, start-up, or maintain this apparatus.

NOTE

Instructions for the installation of the “M” contactor kit are divided into two sections because the

non-regen and regen drives require different wiring connections between the contactor kit and the

drive. In each section, the wiring connections are shown in the table while the other assembly

steps are listed below.

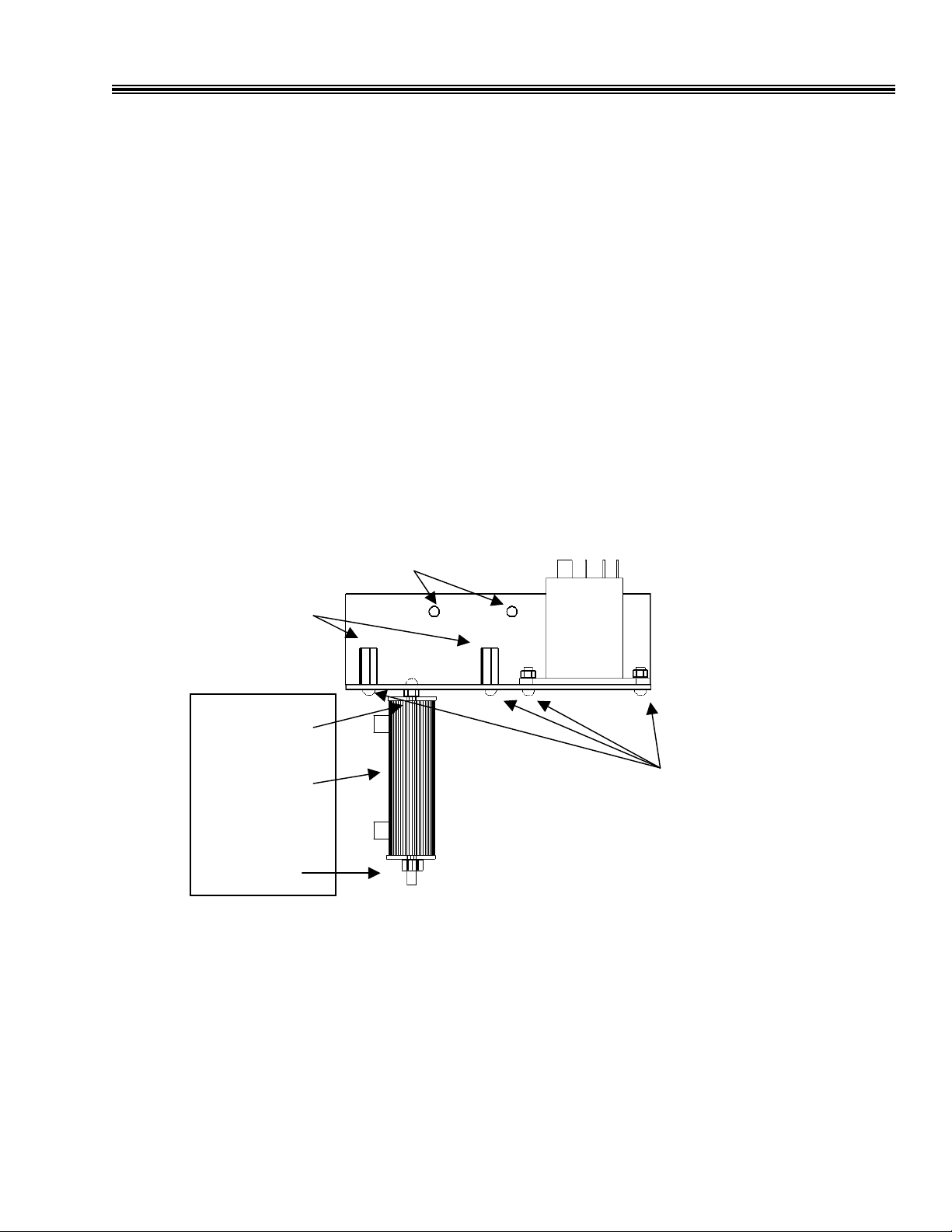

1. Remove drive control board:

Remove the two mounting screws securing the board.

Push the retaining tabs on the two nylon standoffs to free the board.

Lift board up and out of the way.

Do not remove any wires from the control board.

2. Pre-assemble components as shown in figure A below.

3. Mount bracket assembly as shown in figure B below using the two 8-32 x 3/8 machine screws

provided in the kit (use adhesive strip supplied if heat sink does not have threaded holes).

4. Install driver board onto hex standoffs using two 6-32 x 3/8 machine screws as shown in figure B with

orientation as shown in figure C.

6-32x5/8

Hex Stand-off

Internal Tooth

lock washer and

8-32 Hex nut

DB Kit if Used

Lock

washer

and 8-32

Mounting Holes

F3N2C and F3N2E

Figure A

6-32 x 3/8 machine

screw with Hex nut

and lockwasher

2 of 7

Page 3

“M” Contactor Kit

Figure B Figure C

Locate the wires listed below (KIT WIRE) and connect the respective ends as indicated in the table below. Refer to

figures B, C & D.

Step # Kit Wire Term – Location Term – Location Notes

5 A & MC A – motor contactor MC – driver board

6 L1 & 1L1 L1 – driver board 1L1 - control board

7 B & 1L2 B – motor contactor 1L2 - control board

8 6 & A+ 6 – motor contactor A+ - control board

9 4 & X 4 – motor contactor X - control board

10 5 & A- 5 – motor contactor A- - control board

11 3 & F- 3 – motor contactor F- - control board

12 J1 & JP1 J1 – driver board See step#14

* see figure E

13.Replace drive control board:

Use caution to not pinch any wiring.

Secure the board below the retaining tabs on the two nylon standoffs.

Tighten the two mounting screws.

14. Connect the remaining end of wire “J1 & JP1” to the JP1 connector on the control board. Insure that

pin #1 of J1 connects to pin #1 of JP1.

JP1 J1

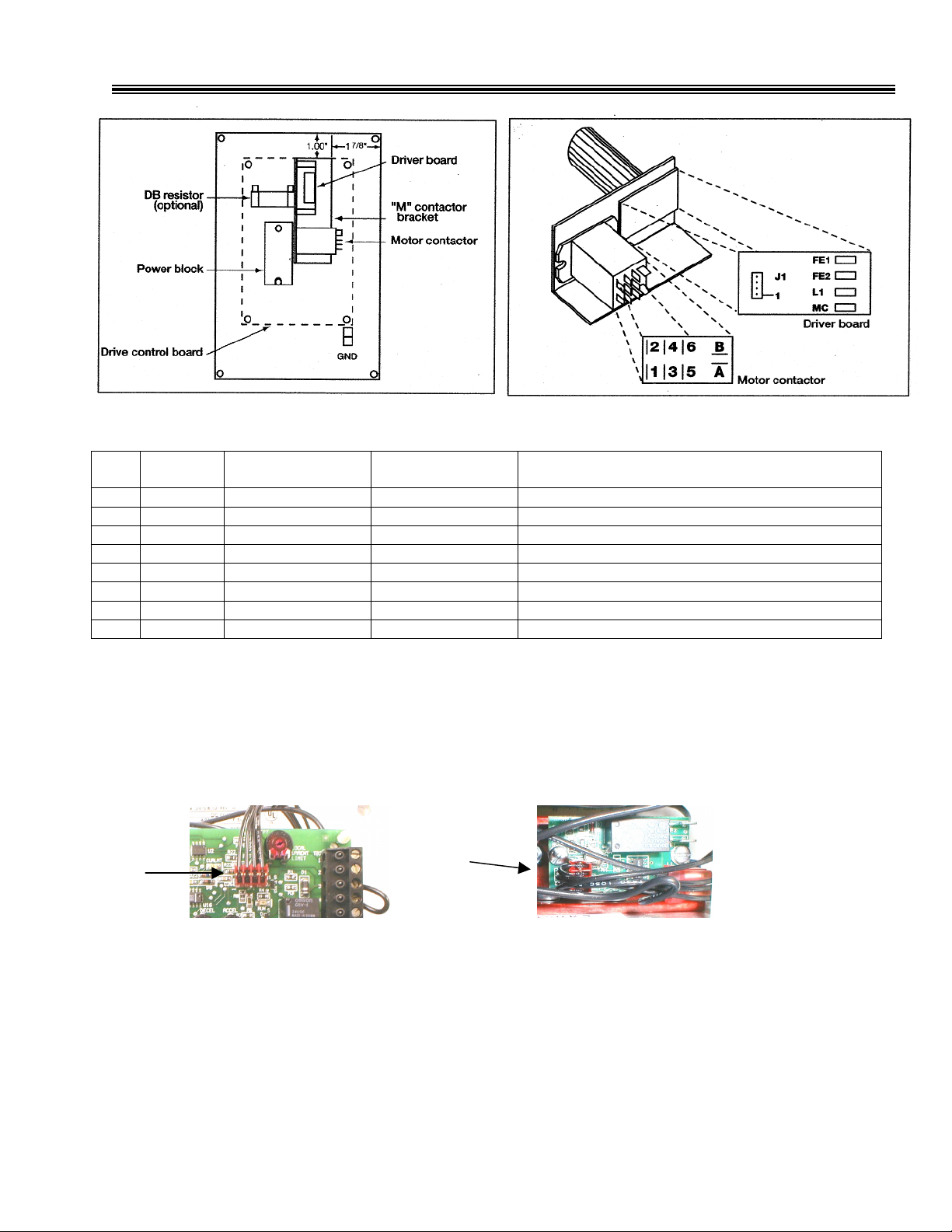

15. Remove and discard factory installed jumper straps located on TB1 of drive control board:

jumper connecting terminals “F-” and “A-” and the jumper connecting terminals “A+” and “X”.

(see figure D below)

16. Installation complete:

Replace cover if necessary and test operation.

The auxiliary form A N.O. contact (terminals FEl and FE2) is located on the driver board

(see figure C).

Route wire under control pcb & up left side to 1L1 *

Route wire under control pcb & up left side to 1L2 *

Route wire over control pcb & down right side to MC by T1 *

Route wire over control pcb & down right side to MC by T1 *

Route wire over control pcb & down right side to MC by T1 *

Route wire over control pcb & down right side to MC by T1 *

Route wire under control pcb & down top side to the driver bd

3 of 7

Page 4

“M” Contactor Kit

1L1

1L2

F-

A-, A+ & X

Jumper Straps

Figure D

Step #6 & #7

Steps 8,9,10 &11

Figure E

4 of 7

Page 5

“M” Contactor Kit

F3R2C and F3R2E

1. Remove drive control board:

Remove the two mounting screws securing the board. Push the retaining tabs on the two nylon

standoffs to free the board.

Remove wires from terminals “1 FEl” and “1 L2” on drive control board.

Swing board up and out of the way.

2. Pre-assemble components as shown in figure A on page 2.

3. Mount bracket assembly as shown in figure E below using the two 8-32 x ½ machine screws provided

in the kit (use adhesive strip supplied if heat sink does not have threaded holes).

4. Install driver board onto hex standoffs using two 6-32 x 3/8 machine screws as shown in figure E with

orientation as shown in figure F.

Locate the wires listed below (KIT WIRE) and connect the respective ends as indicated in the table

below. Refer to figures E, F & G.

Step # Kit Wire Term – Location Term – Location Notes

Figure F Figure E

5 A & MC A – motor contactor MC – driver board

6 L1 & 1FU L1 – driver board 1FU

7 B & 2FU B – motor contactor 2FU

8 6 & A+ 6 – motor contactor TB1 A+

9 4 & A+ 4 – motor contactor A+

10 5 & A- 5 – motor contactor A-

11 3 & A- 3 – motor contactor A2

12 J1 & JP1 J1 – driver board See step #14

Fuse 1FU

Fuse 2FU

TB1 terminal block see note #1

Control board

TB1 terminal block see note #2

Power block

Route wire under control pcb & down top side to the driver bd

Note #1 Cut off faston terminal at wire end marked A+ and strip off 1/4” insulation from the wire.

Remove and discard existing wires from terminal A+ on the drive control board and

terminal TB1- A+.

Note #2 Cut off faston terminal at wire end marked A- and strip off 1/4” insulation from the wire.

Remove and discard existing wires from power block terminal A2 and terminal TB1 -A-.

5 of 7

Page 6

A+

“M” Contactor Kit

13. Replace drive control board:

Use caution to not pinch any wiring.

Secure the board below the retaining tabs on the two nylon standoffs.

Tighten the two mounting screws.

Reconnect wires to terminals “1FE1” and “1L2” on the drive control board (see figure G).

14. Connect the remaining end of wire “J1 & JP1” to the JP1 connector on the control board. Insure that

pin #1 of J1 connects to pin #1 of JP1. (Note: On this model, its is easier to connect wire marked #1

to pin #4 on both (male) connectors).

15. Installation complete:

Replace cover if necessary and test operation. The auxiliary form A N.O. contact (terminals FEl and FE2) is located on the driver board

(see figure F).

Figure G

4 3 2 1

JP1

1FE1

1L2

6 of 7

Page 7

“M” Contactor Kit

Figure H

Step #5

Step #7

Step #6

Step #10

Step #11

Figure I

Step #8

Step #9

Step #6

Step #5

Step #7

7 of 7

Step #12

Loading...

Loading...