Page 1

Epsilon EP Drive

Installation Manual

Information furnished by Control Techniques Americas LLC (Control Techniques) is believed to be

accurate and reliable. However, no responsibility is assumed by Control Techniques for its use.

Control Techniques reserves the right to change the design or operation of the equipment described

herein and any associated motion products without notice. Control Techniques also assumes no

responsibility for any errors that may appear in this document. Information in this document is subject

to change without notice.

P/N 400518-01

Revision: A6

Date: September 30, 2008

© Control Techniques Americas LLC, 2006-2008

Page 2

© Control Techniques Americas LLC, 2006-2008

Part Number: 400518-01

Revision: A6

Date: September 2008

Printed in United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of Control Techniques Americas LLC.

Control Techniques Americas LLC a division of EMERSON Co.

Control Techniques Americas LLC is not affiliated with Microsoft Corporatio n, owner of the

Microsoft, Windows, and Windows NT trademarks.

Modbus is a trademark of Gould, Inc.

Schaffner is a trademark of Schaffner

Mate-N-Lok is a trademark of Amp Incorporated Corp.

DeviceNet is a trademark of Open DeviceNet Vendor Association.

This document has been prepared to conform to the current released version of the product. Because

of our extensive development efforts and our desire to further improve and enhance the product,

inconsistencies may exist between the product and documentation in some instances. Call your

customer support representative if you encounter an inconsistency.

ii

Page 3

Customer Support

Control Techniques Americas LLC

12005 Technology Drive

Eden Prairie, Minnesota 55344-3620

U.S.A.

Telephone: (952) 995-8000 or (800) 893-2321

It is Control Techniques’ goal to ensure your greatest possible satisfaction with the

operation of our products. We are dedicated to providing fast, friendly, and accurate

assistance. That is why we offer you so many ways to get the support you need. Whether

it’s by phone, fax or modem, you can access Con trol Techniques support information 24

hours a day, seven days a week. Our wide range of services include:

FAX (952) 995-8099

You can FAX questions and comments to Control Techniques. Just send a FAX to the

number listed above.

Website and Email www.emersonct.com

Website: www.emersonct.com

Email: info@emersonct.com

If you have Internet capabilities, you also have access to technical support using our

website. The website includes technical notes, frequently asked questions, release notes

and other technical documentation. This direct technical support connection lets you

request assistance and exchange software files electronically.

Technical Support (952) 995-8033 or (800) 893-2321

Email: service@emersonct.com

Control Techniques’ “Motion Made Easy” products are backed by a team of professionals

who will service your installation. Our technical support center in Eden Prairie, Minnesota

is ready to help you solve those occasional problems over the telephone. Our technical

support center is available 24 hours a day for emergency service to help speed any

problem solving. Also, all hardware replacement parts, if needed, are available through our

customer service organization.

When you call, please be at your computer, with your docum entation easily availab le, and

be prepared to provide the following information:

• Product version number, found by choosing About from the Help menu

• The type of controller or product you are using

• Exact wording of any messages that appear on your screen

• What you were doing when the problem occurred

• How you tried to solve the problem

iii

Page 4

Need on-site help? Control Techniques provides service, in most cases, the next day. Just

call Control Techniques’ technical support center when on-site service or maintenance is

required.

Training Services (952) 995-8000 or (800) 893-2321

Email: training@emersonct.com

Control Techniques maintains a highly trained staff of instructors to familiarize customers

with Control Techniques’ “Motion Made Easy” products and their applications. A number of

courses are offered, many of which can be taught in your plant upon request.

Application Engineering (952) 995-8000 or (800) 893-2321

Email: service@emersonct.com

An experienced staff of factory application engineers provides complete customer support

for tough or complex applications. Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

Customer Service (Sales) (952) 995-8000 or (800) 893-2321

Email: customer.service@emersonct.com

Authorized Control Techniques distributors may place orders directly with our Customer

Service department. Contact the Customer Service department at this number for the

distributor nearest you.

Reference Materials

The following related reference manuals may be useful with your particular system.

Epsilon EP-I Indexing Drive and FM-2 Indexing Module Reference Manual (400518-02)

Epsilon EP-B Drive Reference Manual (400518-03)

Epsilon EP-P Drive and FM-3/4 Modules Reference Manual (400518-04)

Epsilon EP-P Drive Connectivity Reference Manual (400518-05)

Epsilon EP-IDN DeviceNet Reference Manual (400518-08)

iv

Page 5

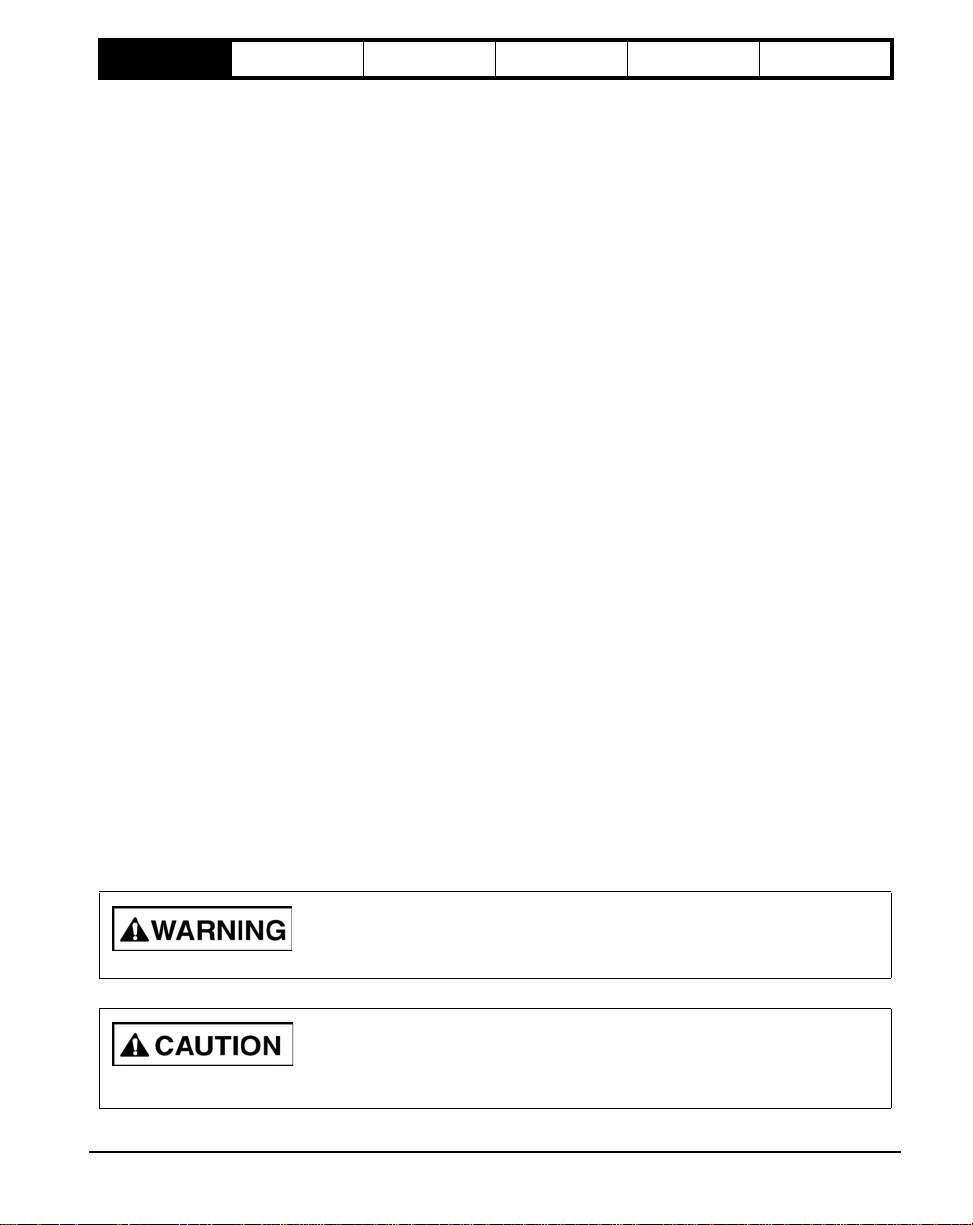

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Safety Information

Safety Precautions

This product is intended for professional incorporation into a complete system by qualified persons. If you install the

product incorrectly, it may present a safety hazard. The product and system may use high voltages and currents,

carry a high level of stored electrical energy, or are used to control mechanical equipment that can cause injury.

You must give close attention to the electrical installation and system design to avoid hazards either in normal

operation or in the event of equipment malfunction. System design, installation, commissioning and maintenance

must be carried out by personnel who have the necessary training and experience. Read and follow this safety

information and this instruction manual carefully.

Qualified Person

For the purpose of this manual and product, a “qualified person” is one who is familiar with the installation,

construction and operation of the equipment and the hazards involved. In addition, this individual has the following

qualifications:

Is trained and authorized to energize, de-energize, clear and ground and tag circuits and equipment in accordance

with established safety practices.

Is trained in the proper care and use of protective equipment in accordance with established safety practices.

Is trained in rendering first aid.

Enclosure

This product is intended to be mounted in an enclosure that prevents access except by qualified persons and that

prevents the ingress of contamination. This product is designed for use in an environment classified as pollution

degree 2 in accordance with IEC664-1. This means that only dry, non-conducting contamination is acceptable.

Setup, Commissioning and Maintenance

It is essential that you give careful consideration to changes to drive settings. Depending on the application, a change

could have an impact on safety. You must take appropriate precautions against inadvertent changes or tampering.

Restoring default parameters in certain applications may cause unpredictable or hazardous operation.

Safety of Machinery

Within the European Union all machinery in which this product is used must comply with Directive 89/392/EEC,

Safety of Machinery.

The product has been designed and tested to a high standard, and failures are very unlikely. However the level of

integrity offered by the product’s control function – for example stop/start, forward/reverse and maximum speed – is

not sufficient for use in safety-critical applications without additional independent channels of protection. All

applications where malfunction could cause injury or loss of life must be subject to a risk assessment, and further

protection provided where needed.

Identification of Safety Information

Safety related information through out this manual is identified with the following markings.

“Warning” indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

“Caution” indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate

injury.

Safety Information v

Page 6

Safety Information Product Overview Installation Diagnostics

“Caution” used without the safety alert symbol indicates a potentially hazardous situation that, if not avoided,

may result in property damage.

For the purpose of this manual and product, “Note” indicates essential information about the product or the

respective part of the manual.

Throughout this manual, the word “drive” refers to an Epsilon EP drive.

Options and

Accessories

Specification

General warning

Failure to follow safe installation guidelines can cause death or serious injury. The voltages used in this unit can

cause severe electric shock and/or burns, and could be lethal. Extreme care is necessary at all times when working

with or adjacent to this equipment. The installation must comply with all relevant safety legislation in the country

of use.

Supply isolation device

The AC supply or high voltage DC supply must be removed from the drive using an approved isolation device or

disconnect before any servicing work is performed, other than adjustments to the settings or parameters specified

in the manual. The drive contains capacitors which remain charged to a potentially lethal voltage after the supply

has been removed. Allow at least 6 minutes for Epsilon EP206/209/216 and 3 minutes for Epsilon EP202/204 after

removing the supply before carrying out any work which may involve contact with electrical connections to the

drive.

Products connected by plug and socket

A special hazard may exist where the drive is incorporated into a product which is connected to the AC supply by

a plug and socket. When unplugged, the pins of the plug may be connected to the drive input, which is only

separated from the charge stored in the bus capacitor by semiconductor devices. To avoid any possibility of

electric shock from the pins, if they are accessible, a means must be provided for automatically disconnecting the

plug from the drive (e.g., a latching contactor).

Grounding (Earthing, equipotential bo nding) - High Leakage Current

The drive must be grounded by a conductor sufficient to carry all possible fault current in the event of a fault. This

equipment has high earth leakage current. You must comply with local safety regulations with respect to minimum

size and special installation requirements on the protective earth conductor for high leakage current equipment.

The ground connections shown in the manual must be followed.

Fuses

Fuses or over-current protection must be provided at the input in accordance with the instructions in the manual.

The drive alone does not provide branch circuit protection. Branch circuit protection must be provided in

accordance with the National Electrical Code and any additional local codes.

Isolation of control circuits

The installer must ensure that the external control circuits are isolated from human contact by at least one layer

of insulation rated for use at the applied AC supply voltage. External control circuits identified as PELV circuits do

not need this isolation when they are completely within a zone of equipotential bonding, generally within a single

enclosure or group of enclosures bonded together.

vi

Page 7

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

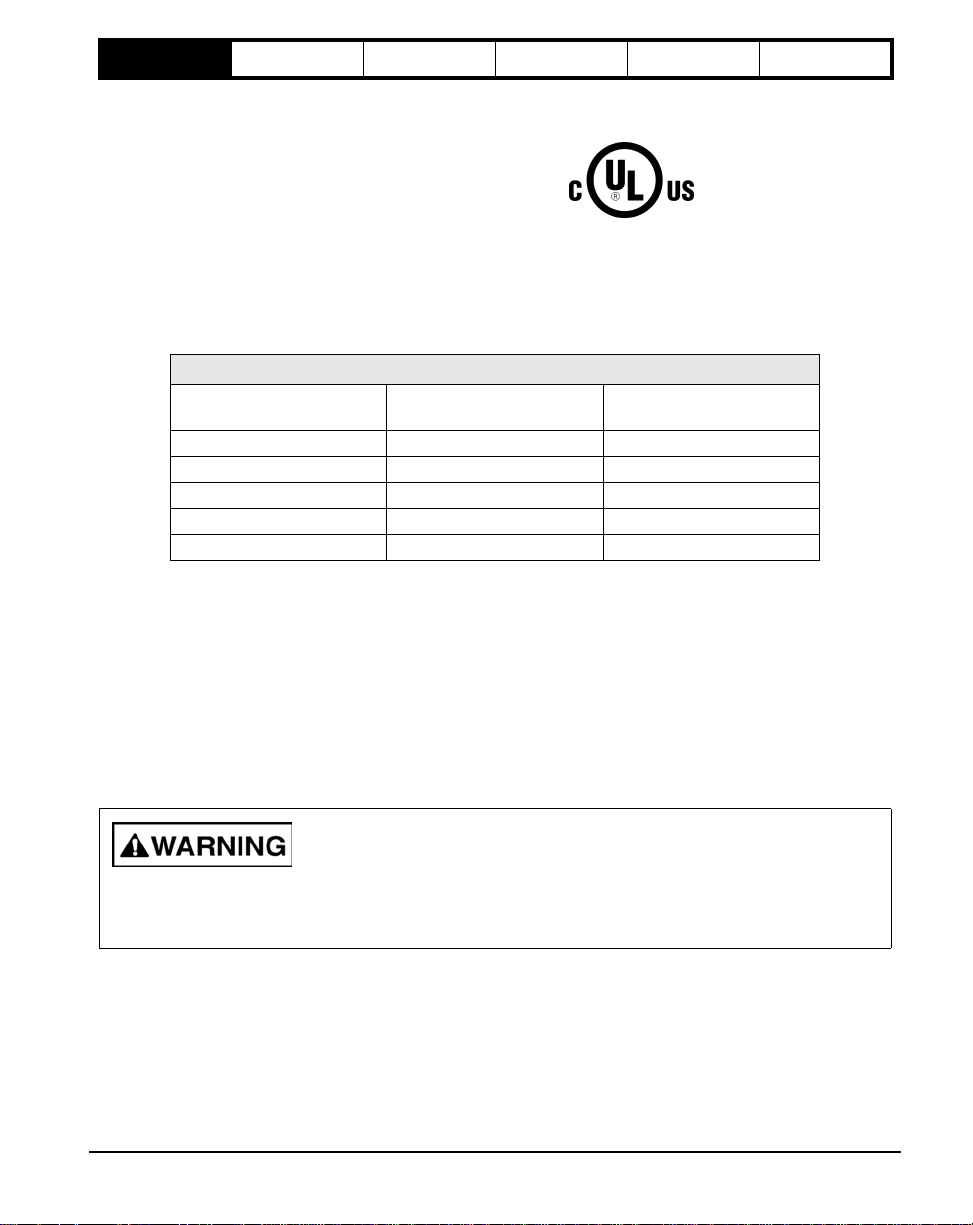

Underwriters Laboratories Listed

LISTED 768R

IND. CONT. EQ.

File E 58592 Sec.5

The Epsilon Digital Servo Drives are marked with the “UL Listed” label after passing a rigorous set of design and

testing criteria developed by UL (UL508C). This label indicates that UL certifies this product to be safe when installed

according to the installation guidelines and used within the product specifications.

The “conditions of acceptability” required by UL are:

• Operating within ratings for Input Voltage, Input Current, and Output Current

Rated Output Current (Amps RMS)

Drive Model

EP202 2.2 4.4

EP204 4.0 8.0

EP206 6.5 13.0

EP209 9.0 18.0

EP216 16.0 32.0

• Epsilon drive maximum surrounding air temperature 40°C (104°F) at rated Full Load Amperes (FLA)

• Epsilon drive maximum surrounding air temperature 50°C (122°F) with output current derated 15% for EP209,

20% for EP206, 10% for EP204, and no derating required for EP202 or EP216

• Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection

must be provided in accordance with the National Electrical Code and any additional local codes

• Copper only conductors with 75°C minimum insulation rating at all power and motor terminals

• This product is suitable for use on a circuit capable of delivering not more than 10,000 RMS symmetrical

amperes, 240 volts maximum, when protected by a Class RK1 or Class CC fuse, rated not more than 20 A

• Logic power and I/O power are to be supplied with a UL listed or "recognized component" power supply rated

as limited voltage/limited current or limited voltage/limited power

• The following warning is presented here and furnished on a label to be placed on the enclosure door

Continuous

(Full Load Amperes)

Peak

Drive has high fault current rating. The opening of the branch circuit protective device may be an indication that

a fault current has been interrupted. All current carrying parts and other components protected by this device

should be examined and replaced if damaged. If burn-out of the current element of an overload relay occurs,

the complete overload relay must be replaced.

Safety Information vii

Page 8

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

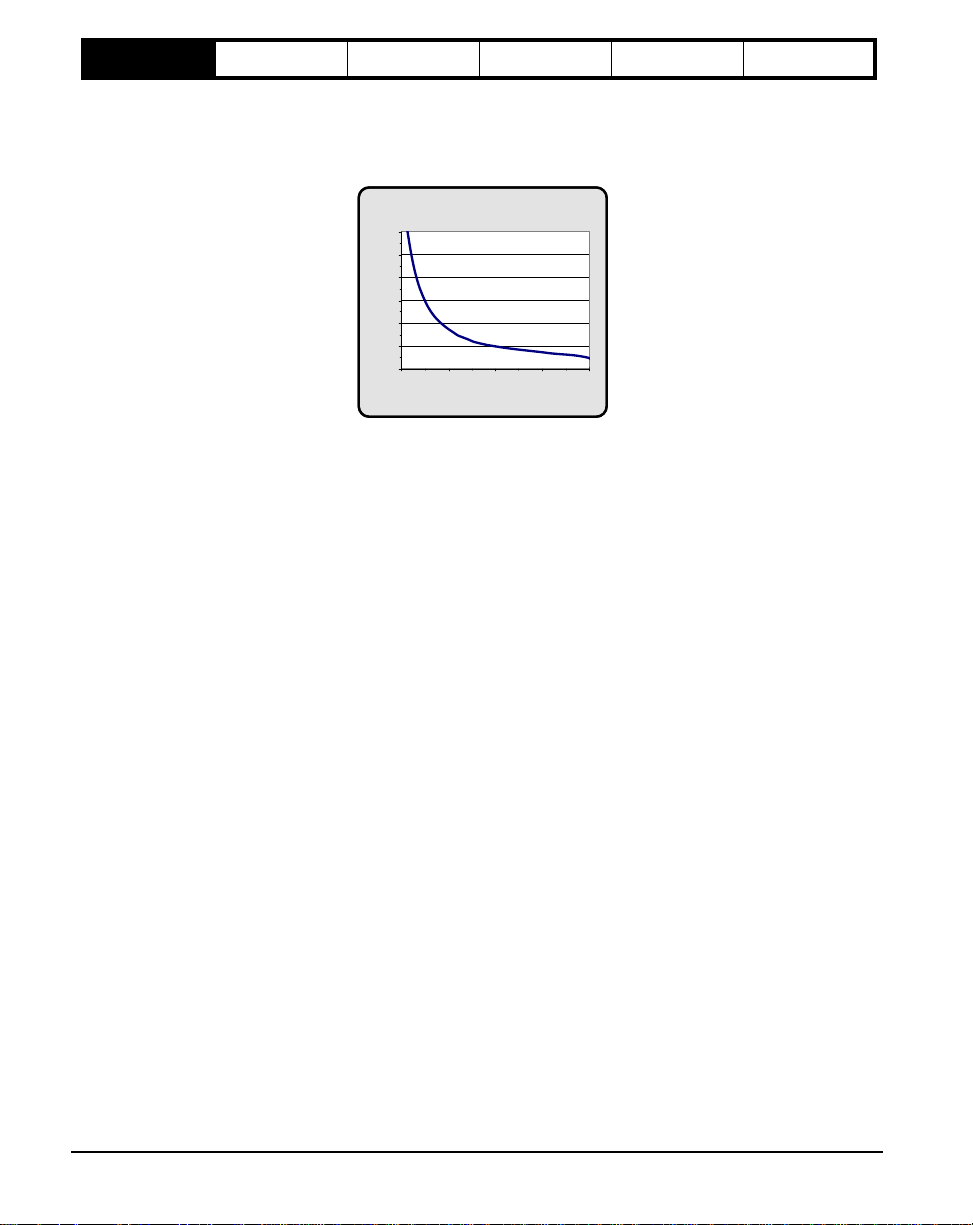

Drive Overload Protection

Solid state motor overload protection is provided in each model at no more than 115% of rated FLA. This overload

protection is based on maximum continuous output current capacity. It will allow up to 200 percent of drive FLA to

be delivered for the amount of time determined by the following chart.

Drive Output Current vs. Time graph

60

50

40

30

20

Time (seconds)

10

0

100 125 150 175 200

% Driv e Rated Current

When motor rated FLA is less than drive FLA, the motor FLA parameter is to be entered into drive configuration.

Drive will then provide motor overload protection at correct value.

viii

Page 9

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

CE Declaration of Conformity

The Epsilon Digital Servo Drives are marked with the “Conformite Europeenne Mark” (CE mark) after passing a

rigorous set of design and testing criteria. This label indicates that this product meets safety and noise immunity and

emissions (EMC) standards when installed according to the installation guidelines and used within the product

specifications.

Declaration of Conformity

Manufacturer’s Name:

Manufacturer’s Address:

Declares that the following products:

Product Name:

EP202-B00, EP202-I00, EP202-IDN, EP202-P00, EP202-PDN, EP202-PPB,

EP204-B00, EP204-I00, EP204-IDN, EP204-P00, EP204-PDN, EP204-PPB,

Model Number:

System Options:

Electomagnetic Compatibility (EMC):

EN 61800-3; 1997, For second environment restricted distribution

Electrical Thermal and Energy Safety Requirements:

EN 61800-5-1:2003

The products herewith comply with the requirements of the Low Voltage Directive (LVD) 73/23/EEC and amended by 93/

This servo drive is intended to be used with an appropriat e mo tor, electrical protection compon ent s a nd oth er equip ment

to form a complete end product or system. It must be installed by a professional assembler who is familiar with safety

and electromagnetic compatibility (“EMC”) requirements. The assembler is responsib le for ensuring that the end prod uct

or system complies with all the relevant laws in the country where it is to be used. Refer to the product manual for

EP206-B00, EP206-I00, EP206-IDN, EP206-P00, EP206-PDN, EP206-PPB,

EP209-B00, EP209-I00, EP209-IDN, EP209-P00, EP209-PDN, EP209-PPB,

EP216-B00, EP216-I00, EP216-IDN, EP216-P00, EP216-PDN, EP216-PPB

STI-24IO Interface Board, STI-SNCOA Analog/Sync Output Interface Board,

STI-SNCI Sync Input Interface Board, BRM-1 Motor Brake Relay, and SM-

Conforms to the following product specification:

Supplementary information:

68/EEC and the EMC Directive 89/336/EEC

installation guidelines.

Control Techniques Americas LLC

12005 Technology Drive

Eden Prairie, MN 55344

Epsilon EP Digital Servo Drive

Heatsink DBR-1 Brake Resistor

USA

December 12, 2006

Steve Bartz, Director, Motion Control Product Line Date

Sobetra Automation

European Contact:

Langeveldpark Lot 10

P. Dasterleusstraat 2

1600 St. Pieters Leeuw, Belgium

Safety Information ix

Page 10

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

x

Page 11

Table of Contents

Customer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Reference Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Safety Information v

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Qualified Person. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Setup, Commissioning and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety of Machinery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Identification of Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Underwriters Laboratories Listed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Drive Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

CE Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Product Overview 1

Epsilon EP Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Installation 3

Step 1: Basic Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Achieving Low Impedance Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrostatic Discharge (ESD) Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Environmental Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wiring Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Panel Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cable to Enclosure Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC Line Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 2: Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Step 3: High Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

System Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

AC Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Transformer Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Line Fusing and Wire Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

AC Input Power Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation on DC Input Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

External Shunt Electrical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Motor Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Step 4: Low Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

xi

Page 12

DC Logic Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Motor Feedback Wiring (J6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Motor Brake Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Input/Output and Drive Enable Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Analog Command Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Encoder Output Signal Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Diagnostics and Troubleshooting 51

Diagnostic Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Status Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Diagnostic Analog Output Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Drive Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Options and Accessories 59

Epsilon EP Drive Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

STI-24IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

STI-SNCOA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

STI-SNCI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

STI-ENC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Specifications 65

Epsilon EP Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Epsilon EP Drive Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

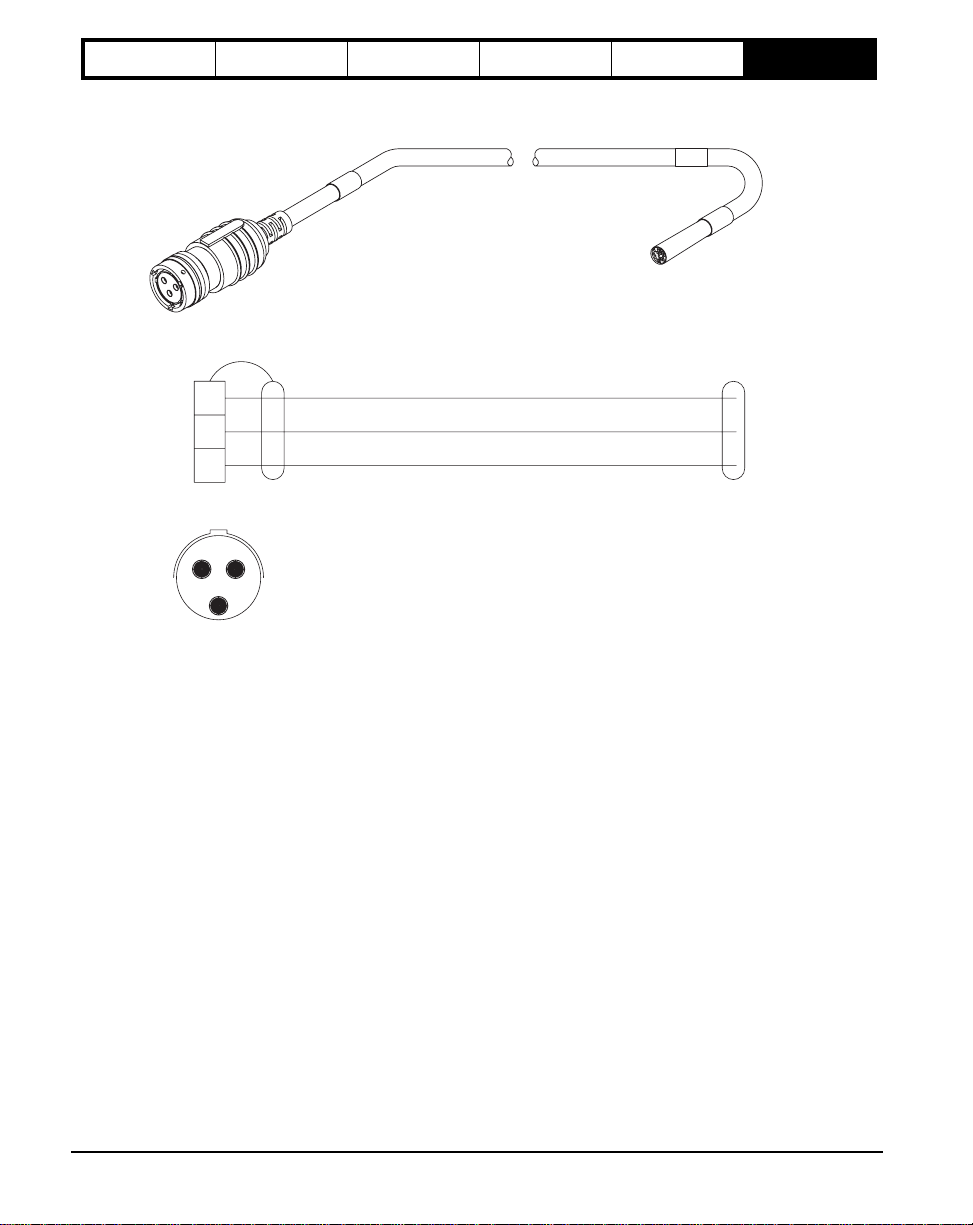

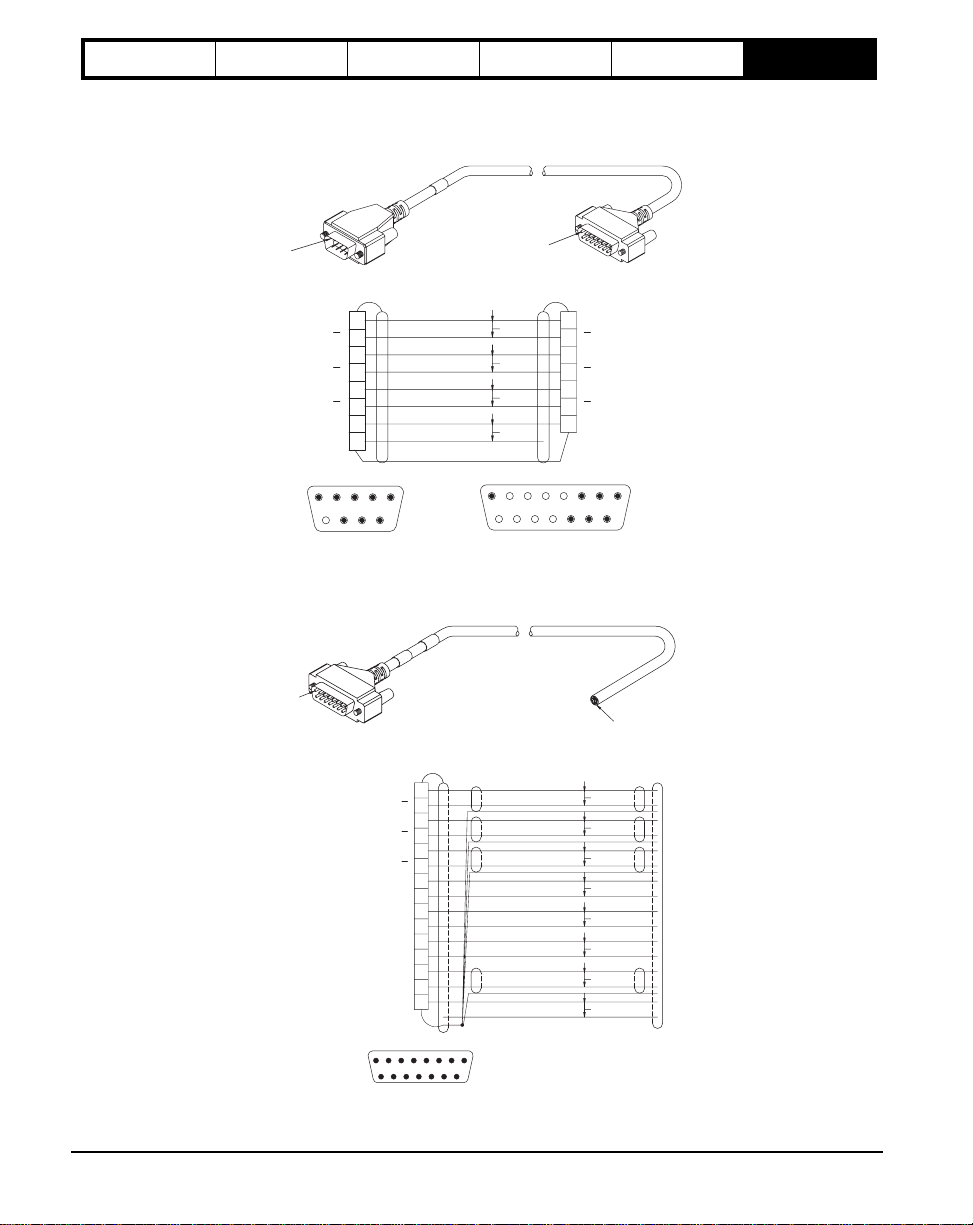

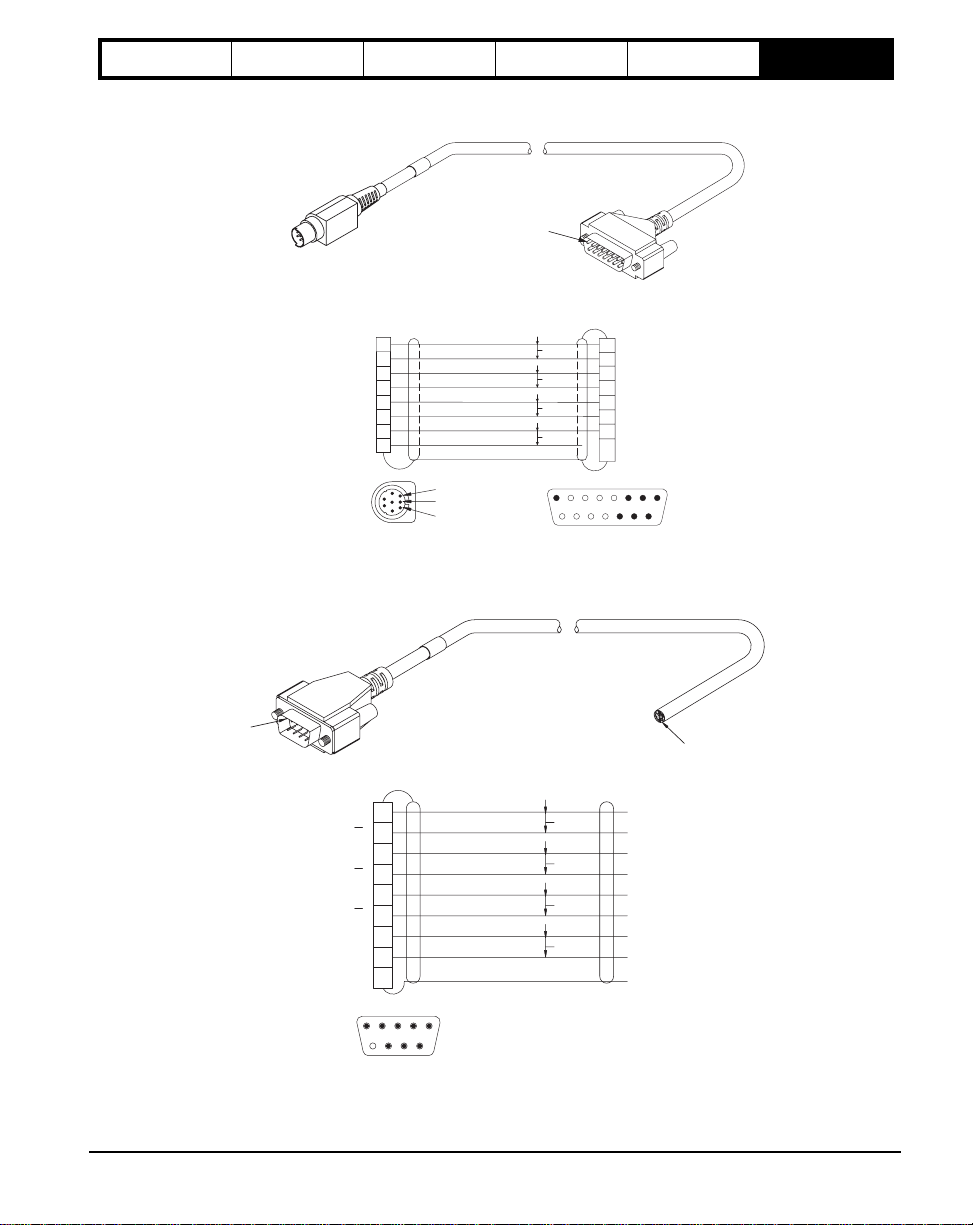

Cable Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

XV Motor Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

NT and MG Motor Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Sync Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Communications Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Index 87

xii

Page 13

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Product Overview

Epsilon EP Drive

The Epsilon EP drive is a stand-alone, fully digital brushless servo drive designed and built to reliably provide high

performance and flexibility without sacrificing ease of use.

The use of State-Space algorithms make tuning very simple and forgiving. The drives are designed to operate with

up to a 10:1 inertia mismatch right out of the box. Higher (50:1 and more) inertia mismatches are possible with two

simple parameter settings.

The Epsilon EP drive can be quickly configured to many applications in less than 5 minutes with PowerTools Pro

software on a PC running Windows® 98, NT 4.0, 2000, ME and XP.

Complete diagnostics are provided for quick troubleshooting. A status/diagnostic display on the front of the drive

informs the user of the operational or fault status. The last 10 faults are stored in non-volatile memory along with a

time stamp for easy recall.

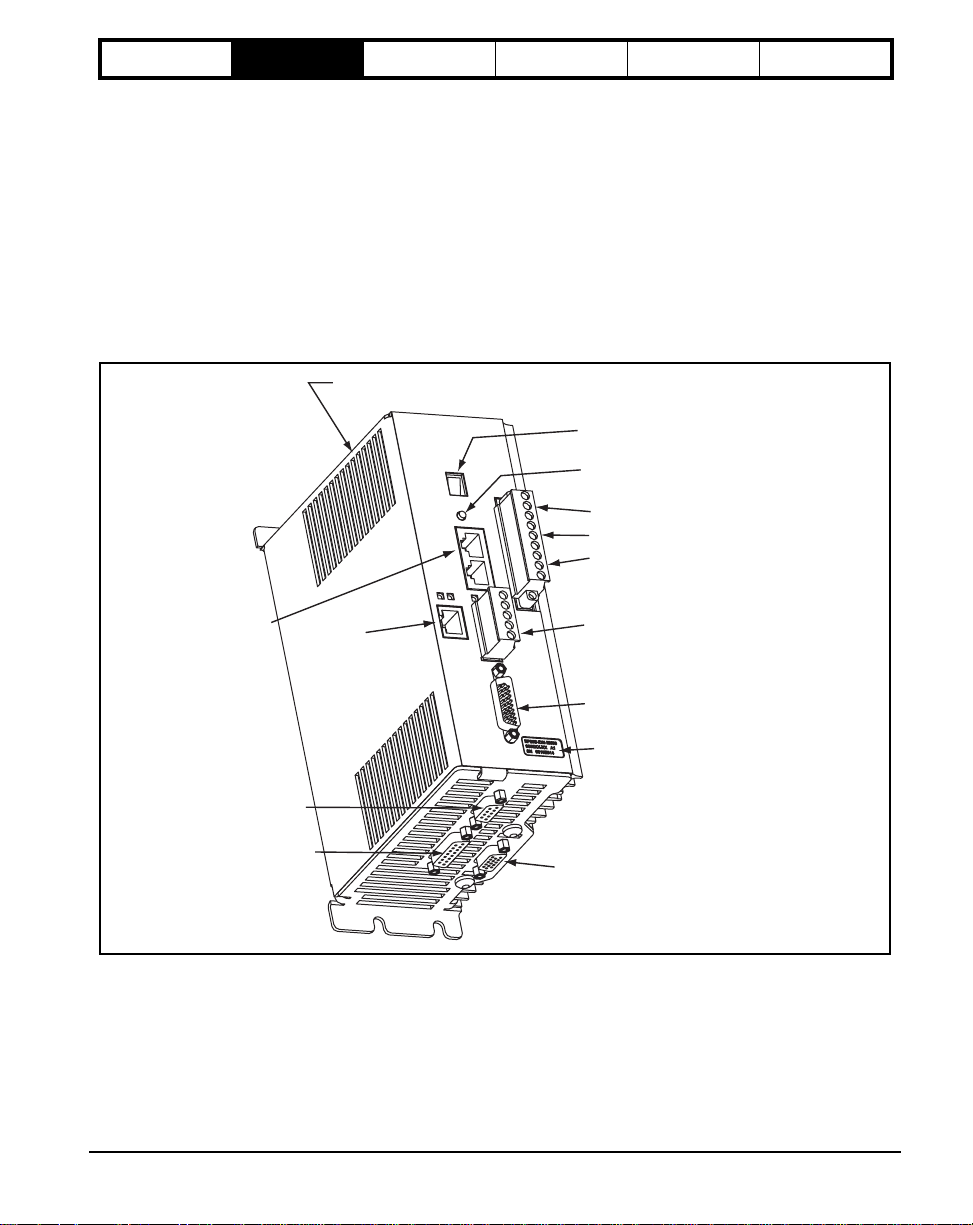

Shunt Connector (J8)

Status/Diagnostic Display

Reset Button

AC Power Connections

Motor Connections

24 Vdc Logic Power Supply Connections

Serial

Connectors (J2)

Ethernet

Connector (J4)

(EP-Pxx only)

DeviceNet Connector (J9)

(EP-IDN or EP-PDN only)

Digital I/O Connector (J3)

Model Number, Part Number,

Revision and Serial Number Label

Sync Input Connector (J10)

Analog/Sync Output

Connector (J5)

Encoder Feedback Connector (J6)

Figure 1: Epsilon EP-PDN Drive Feature Location

Product Overview 1

Page 14

Safety Information Product Overview Installation Diagnostics

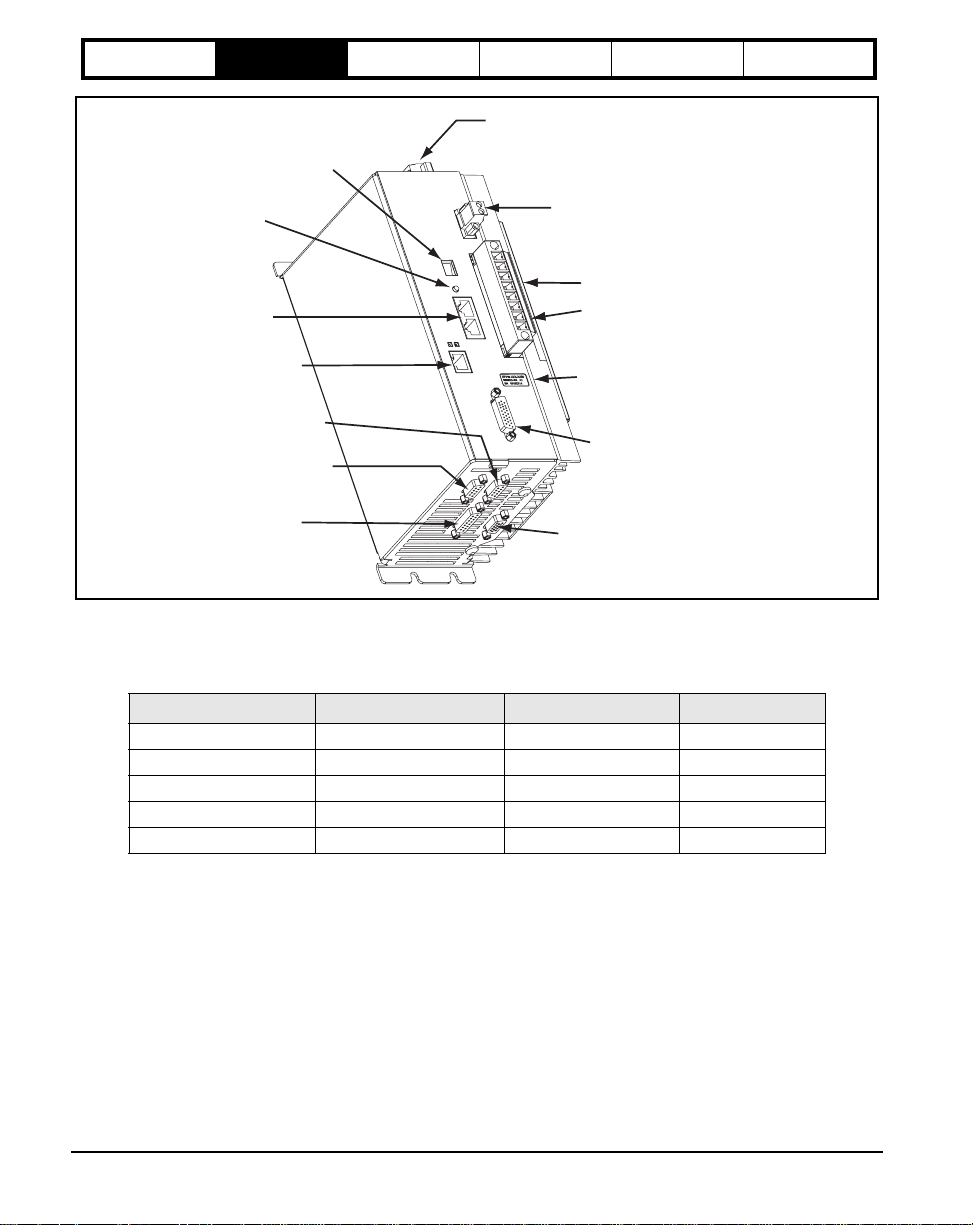

Shunt Connector (J8)

Status/Diagnostic Display

Options and

Accessories

Specification

Reset Button

24 Vdc Logic Power

Supply Connector

AC Power Connections

Serial

Connectors (J2)

Ethernet Connector (J4)

(EP-Pxx only)

Motor Power Connections

Model Number, Part Number,

Revision and Serial Number Label

Sync Input Connector (J10)

Digital I/O Connector (J3)

Profibus Connector (J13)

(EP-PPB only)

Analog/Sync Output

Connector (J5)

Encoder Feedback Connector (J6)

Figure 2: Epsilon EP216 Drive Feature Location

Epsilon EP drives are rated at 240 Vac input voltage and can operate with an input voltage from 20 Vac to 264 Vac.

The EP drives are available in five current ratings.

Drive Model Continuous Power Rating Continuous Current Peak Current

Epsilon EP202 775 W 2.2 A RMS 4.4 A RMS

Epsilon EP204 1275 W 4.0 A RMS 8.0 A RMS

Epsilon EP206 1775 W 6.5 A RMS 13.0 A RMS

Epsilon EP209 2325 W 9.0 A RMS 18.0 A RMS

Epsilon EP216 4800 W 16.0 A RMS 32.0 A RMS

2

Page 15

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Installation

Installation of the Epsilon EP drive is completed by following a simple step-by-step process. The Epsilon EP

installation begins by mounting the drive to a metal mounting panel. Next, the high power connections are made to

the drive, then the low power connections are made.

Step 1: Basic Installation and Panel Layout, page 3

Step 2: Mechanical Installation, page 8

Step 3: High Power Connections, page 13

Step 4: Low Power Connections, page 31

Step 1: Basic Installation Guidelines

You are required to follow all safety precautions during start-up such as providing proper equipment grounding,

correctly fused power and an effective Emergency Stop circuit which can immediately remove power in the case of

a malfunction. See the "Safety Considerations" section for more information.

Electromagnetic Compatibility (EMC)

Drives are designed to meet the requirements of EMC. Under extreme conditions a drive might cause or suffer from

disturbances due to electromagnetic interaction with other equipment. It is the responsibility of the installer to ensure

that the equipment or system into which the drive is incorporated complies with the relevant EMC legislation in the

country of use.

The following instructions provide you with installation guidance designed to help you meet the requirements of the

EMC Directive 89/336/EEC.

Adhering to the following guidelines will greatly improve the electromagnetic compatibility of your system, however,

final responsibility for EMC compliance rests with the machine builder, and Control Techniques Americas LLC cannot

guarantee your system will meet tested emission or immunity requirements.

If you need to meet EMC compliance requirements, EMI/RFI line filters must be used to control conducted and

radiated emissions as well as improve conducted immunity.

Physical location of these filters is very important in achieving these benefits. The filter output wires should be kept

as short as practical and routed away from the filter input wires. In addition:

• Choose an enclosure made of a conductive material such as steel, aluminum or stainless steel.

• Devices mounted to the enclosure mounting plate, which depend on their mounting surfaces for grounding,

must have the paint removed from their mounting surfaces and the mating area on the mounting plate to ensure

a good ground. See “Achieving Low Impedance Connections” on page 3 for more information.

• If grounding is required for cable grommets, connectors and/or conduit fittings at locations where cables are

mounted through the enclosure wall, paint must be removed from the enclosure surface at the contact points.

• Cables should be shielded, and all shields must be grounded to the enclosure.

To meet radiated emissions requirements, the enclosure door must be closed and have electrical conduction at

hinges and closure hardware or be fitted with a conductive gasket. Route cables away from the door where possible

to minimize coupling emissions to door where they can re-radiate. The door generally must be bonded to the

enclosure for electrical safety, but this is not sufficient to meet EMC.

Achieving Low Impedance Connections

Noise immunity can be improved and emissions reduced by making sure that all the components have a low

impedance connection to the same ground point. A low impedance connection is one that conducts high frequency

current with very little resistance. Impedance cannot be accurately measured with a standard ohmmeter, because

an ohmmeter measures DC resistance. For example, a 12 inch long 8 gauge round wire has a significantly higher

impedance than a 12 inch long 12 gauge flat braided conductor. A short wire has less impedance than a long one.

Multiple connections such as at the four corners of a plate provide much lower impedance than a single connection.

Straight line connections provide much lower impedance than ones with bends or corners.

Low impedance connections can be achieved by bringing large areas of conductive surfaces into direct contact with

each other. In most cases this requires paint removal because a ground connection through bolt threads is not

sufficient. However, component materials should be conductive, compatible and exhibit good atmospheric corrosion

Installation 3

Page 16

Safety Information Product Overview Installation Diagnostics

resistance to prevent loss through corrosion that will hinder the low impedance connection. Enclosure manufacturers

offer corrosion resistant, unpainted mounting plates to help.

Bringing components into direct contact cannot always be achieved. In these situations a conductor must be relied

upon to provide a low impedance path between components. Remember a flat braided wire has lower impedance

than a round wire of a large gauge rating.

A low impedance connection should exist between the following components, but not limited to:

• Enclosure and mounting plate

• Enclosure and door, if door does not have RF gaskets

• Servo drive chassis and mounting plate

• EMI/RFI AC line filter chassis and mounting plate

• Other interface equipment chassis and mounting plate

• Cable shields and enclosure, or terminal block, or connector

• Enclosure and conduit fittings or electrical connectors

• Enclosure mounting plate and earth ground

• Motor frame and conduit fittings or electrical connectors

• Encoder chassis and electrical connector

Options and

Accessories

Specification

Electrostatic Discharge (ESD) Protection

Do not allow ESD to the drive while operating.

Though no damage occurs with electrostatic discharge at levels tested for EMC compliance, ESD directly to the drive

cover can interrupt proper drive operation. ESD to terminals on the breakout boards has not been evaluated because

wiring to these terminals is a maintenance activity. When doing any maintenance activity, make sure static electric

charge is drained off by touching the enclosure away from the drive before contacting the drive or its wiring terminals.

Use of ground straps or other techniques to prevent static buildup is a necessary part of any maintenance activity.

Environmental Considerations

The drive is rated to operate only in a pollution degree 2 environment, meaning that normally only non-conductive

pollution occurs and there is no condensation, but occasional condensation may occur when not operating.

If the installation environment contains atmospheric contaminants such as moisture, oils, conductive dust, chemical

contaminants and metallic particles, you must mount it vertically in a metal NEMA type 12 enclosure.

To prevent operation with condensation present, it is best to energize the logic power several minutes before

applying main power or keep logic power applied continuously.

If the ambient temperature inside the enclosure will exceed 40°C (104°F), you must consider forced air cooling.

It is necessary to maintain the drive surrounding air temperature at 40°C (104°F) or 50°C (122ºF) with

appropriate derating or below to maintain the drive UL ratings. See “Specifications” on page 65.for derating

by model.

The amount of cooling depends on the size of the enclosure, the thermal transfer of the enclosure to the ambient air

and the amount of power being dissipated inside the enclosure. Consult your enclosure manufacturer for assistance

with determining cooling requirements.

The power dissipated by a EP202-P is 35 W, a EP204-P is 55 W, a EP-206-P is 85 W, a EP209-P is 115 W and a

EP216 is 200 W. The power dissipation values includes up to 12 W of power from the logic power supply.

Wiring Notes

• To avoid problems associated with EMI (electromagnetic interference), you should route high power lines (AC

input power and motor power) away from low power lines (encoder feedback, serial communications, etc.).

4

Page 17

Safety Information Product Overview Installation Diagnostics

• If a neutral wire (not the same as Earth Ground) is supplied from the building distribution panel, it should never

be bonded with PE wire in the enclosure.

• You should consider future troubleshooting and repair when installing all wiring. All wiring should be either color

coded and/or tagged with industrial wire tabs.

Options and

Accessories

Specification

• As a general rule, the minimum cable bend radius is ten times the cable outer diameter.

• All wiring and cables, stationary and moving, must be protected from abrasion.

• Ground wires should not be shared or "daisy-chained" with other equipment.

• Ensure that full metal to metal surface contact is made between the enclosure ground lug and the metal

enclosure, not simply through the mounting bolt and threads.

• All inductive coils must be suppressed with appropriate devices, such as diodes or resistor/capacitor (RC)

networks, except as described in this manual.

• If using a non-shielded Ethernet cable, install a clamp on ferrite, Control Techniques part number 157016-07,

Steward 28A0593-0A2 or equivalent.

Installation 5

Page 18

Safety Information Product Overview Installation Diagnostics

A

Panel Layout

Options and

Accessories

Specification

Metallic

Raceway

PE

C In

L2

L1

External Encoder

Fuses

NEMA Enclosure

Filter

Through wall shield grommets

Customer supplied

terminal strip (optional)

Connect shield through

and to mounting plate

Motor

Motor Feedback Cable

Motor Power Cable

Bonded to mounting plate

and enclosure wall

Drive

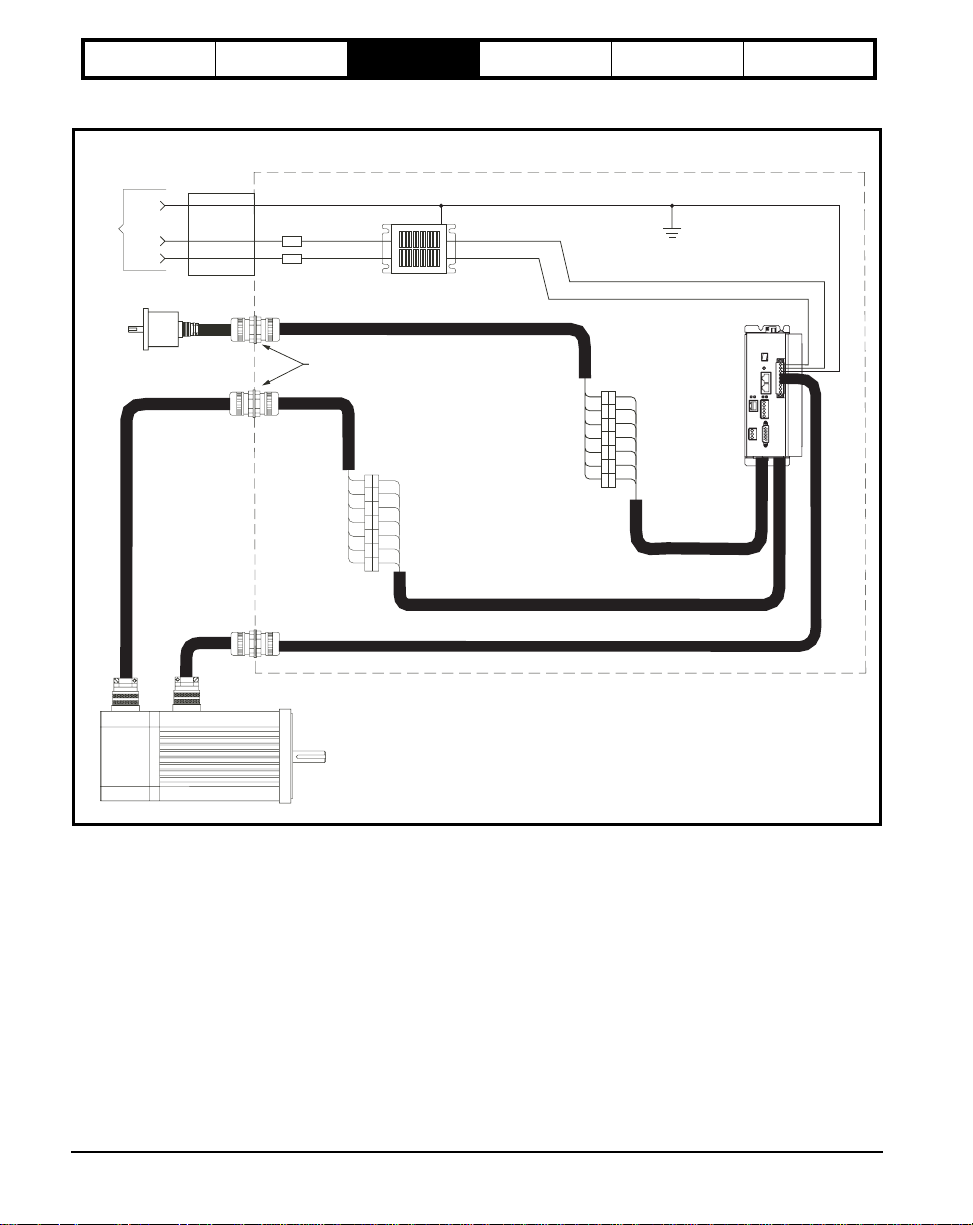

Figure 3: AC Filter and Cable Connections

6

Page 19

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

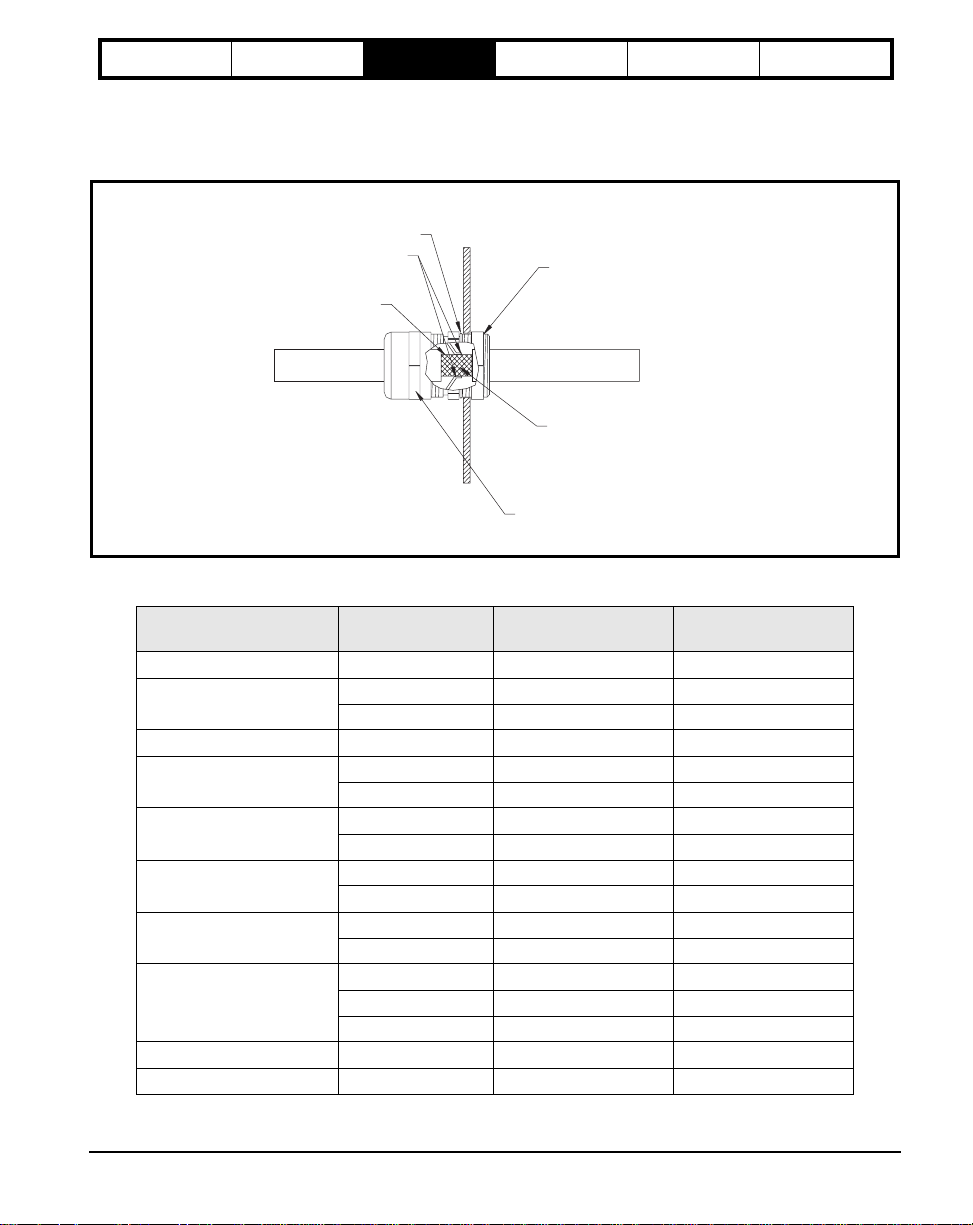

Cable to Enclosure Shielding

Shielded motor, feedback, serial communications and external encoder cables were used for compliance testing and

are necessary to meet the EMC requirements. Each cable shield was grounded at the enclosure wall by the type of

grommet described earlier and shown in the following figure.

Outside Enclosure

O-Ring seals against outside of enclosure

to meet IP68 (comparable to NEMA 6)

Spring Contacts

Cable Shielding

Cable Jacket

Figure 4: Through Wall Shield Grommet

Inside Enclosure

When Lock Nut is tightened to inside of

enclosure, lock nut will cut through varnished,

anodized, and powder coated finishes.

Tighten lock nut so it cuts through the

finish and into housing.

Remove 1/2 to 1 inch of cable jacket.

The Spring Contacts will make a continuous

electrical path from the shield of the cable to

equipment ground.

After tightening lock nut and positioning cable

so that Spring Contacts are contacting the

cable shield, tighten Cable Seal Housing.

Cable Type Cable Model

Shielded Cable Grommet

Kit Model

Actual Hole Size

Motor Cable, 18 Ga XTMDS CGS-047 0.8125 or 13/16"

Motor Cable, 16 Ga

CMDS CGS-047 0.8125 or 13/16"

4X16SS CGS-047 0.8125 or 13/16"

Motor Cable, 18 Ga XCMDS CGS-047 0.8125 or 13/16"

Motor Cable, 12 Ga

Feedback Cable

Flex Motor Cable, 16 Ga

Flex Motor Cable, 12 Ga

CMMS CGS-069 1.125 or 1 1/8"

4X12SS CGS-069 1.125 or 1 1/8"

CFOS CGS-047 0.8125 or 13/16"

MGFS CGS-047 0.8125 or 13/16"

CMDF CGS-047 0.8125 or 13/16"

4X16SF CGS-047 0.8125 or 13/16"

CMMF CGS-069 1.125 or 1 1/8"

4X12SF CGS-069 1.125 or 1 1/8"

CFCF CGS-069 1.125 or 1 1/8"

Flex Feedback Cable

CFOF CGS-069 1.125 or 1 1/8"

MGFF CGS-069 1.125 or 1 1/8"

External Encoder ENCO CGS-047 0.8125 or 13/16"

AC Power user supplied user supplied user supplied

Installation 7

Page 20

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

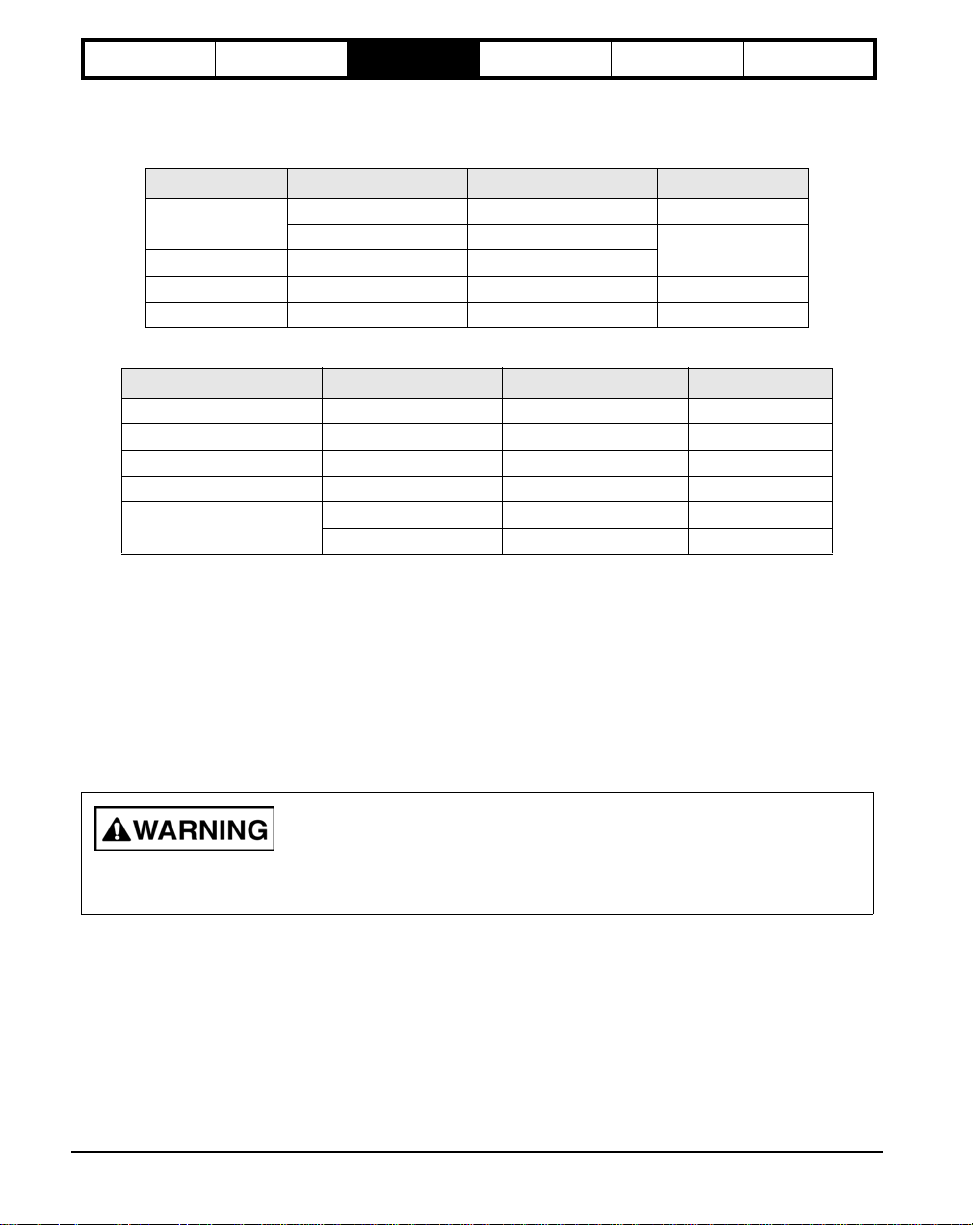

AC Line Filters

The AC line filters are necessary to comply with EMC emission and immunity standards. The drive was tested with

the filters presented in the table below and recommended by Control Techniques.

Epsilon EP Part # Control Techniques Part # Rating

EP202, EP204

EP206 Sch affner FS5278-16/08 960305-01

EP209 Corcom 20EQ1 960308-01 20 A, 240 V, 1 Ø

EP216 Schaffner FN3258-16-44 960310-01 16 A, 480 V, 3 Ø

The following filters are a suitable alternative:

Epsilon EP Part # Control Techniques Part # Rating

EP202 Schaffner FN2070-6/06 6 A, 240 V, 1 Ø

EP202, EP204, EP206 Corcom 20EQ1 20 A, 240 V, 1 Ø

EP206 Schaffner FN2070M-16/08 16 A, 240 V, 1 Ø

EP209 Schaffner FN2070-25/08 25 A, 240 V, 1 Ø

EP216

AC Line Filter Installation Notes

• It is important to keep the filter inputs routed away from any electrical noise sources.

• EMC criteria can be met in installations where multiple drives are supplied through a single filter, however, it is

the installers responsibility to verify EMC compliance.

Schaffner FN2070-10/06 960307-01 10 A, 240 V, 1 Ø

Schaffner FS5278-16/08 960305-01

Schaffner FN3270H-20-29 20 A, 480 V, 3 Ø

Schaffner FN258/16 960304-01 16 A, 480 V, 3 Ø

16 A, 240 V, 1 Ø

Step 2: Mechanical Installation

The drive must be back mounted vertically on a metal mounting panel such as a NEMA enclosure, Additional space

is necessary above and below the drive for wiring and cable connections.

To allow sufficient air flow for cooling, leave at least 0.25" [6.3 mm] clear space on vented cover (left) side plus 0.50"

[12.7 mm] on heatsink (right) side. Leave additional space if cables are routed through this space.

When drilling holes in mounting plate or trimming wires during installation of this or other equipment, do not

allow drill shavings or wire trimmings to enter the EP drive. Such foreign objects can compromise electrical

isolation creating a hazard or result in equipment failure.

8

Page 21

Safety Information Product Overview Installation Diagnostics

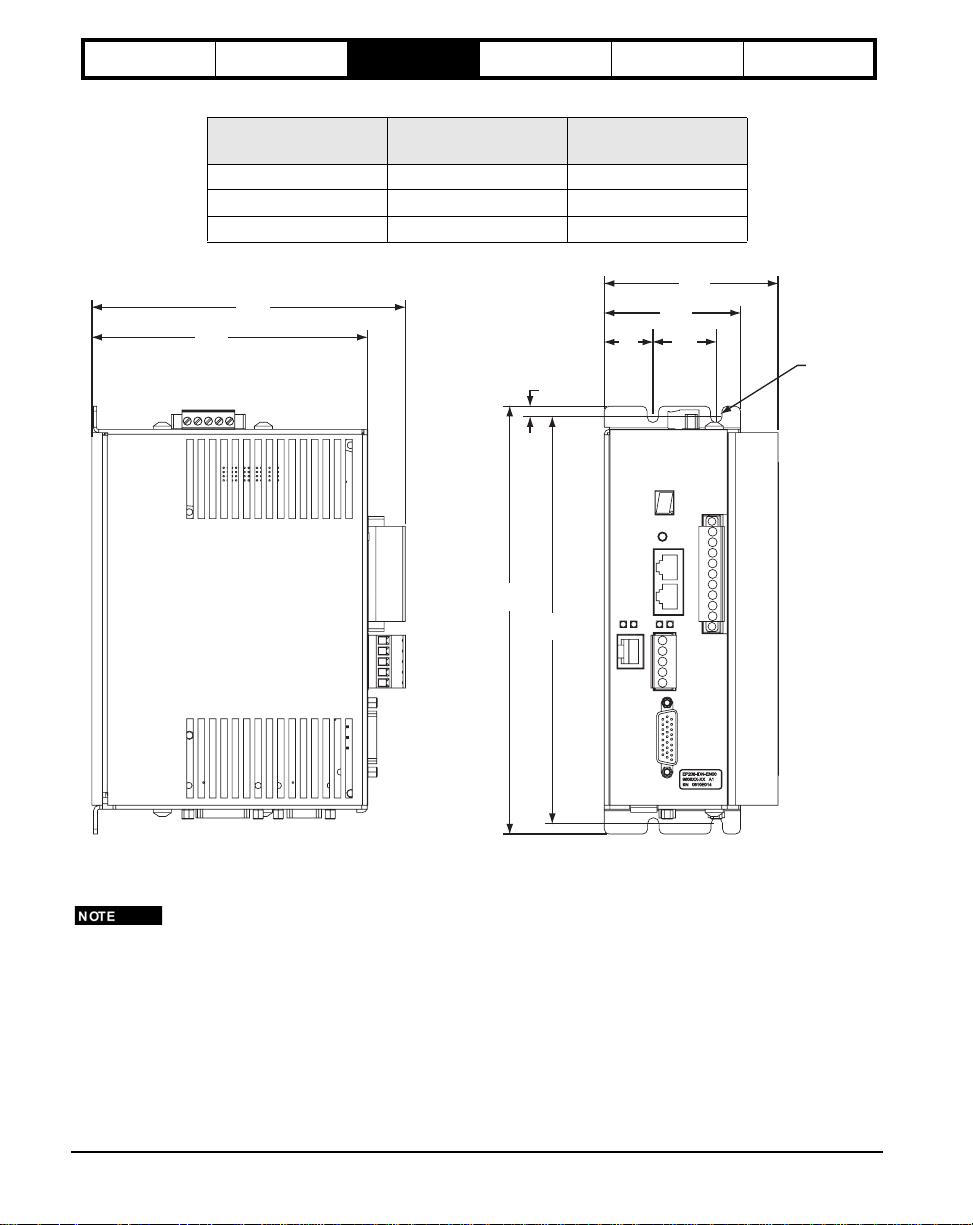

The following table applies to the "A" dimension as shown in figure 5 below for the EP202 - EP206 base and indexing

drives.

Options and

Accessories

Specification

Drive Model

Dimension "A"

inches [mm]

Minimum Panel Width

EP202-B, -I, -IDN 2.11 [53. 59] 2.90 [74]

EP204-B, -I, -IDN 2.11 [53. 59] 2.90 [74]

EP206-B, -I, -IDN 2.82 [71.63] 3.60 [91]

5.94

[150.88]

5.22

[132.59]

.200

[5.08]

8.099

[205.72]

7.70

[195.58]

inches [mm]

2.11

[53.59]

1.20

[30.48]

0.45

[23.4]

“A”

(4X)Ø.219

[5.56]

Figure 5: Mechanical Drawing for Epsilon EP202-206 Base and Indexing Drives

Installation 9

Page 22

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

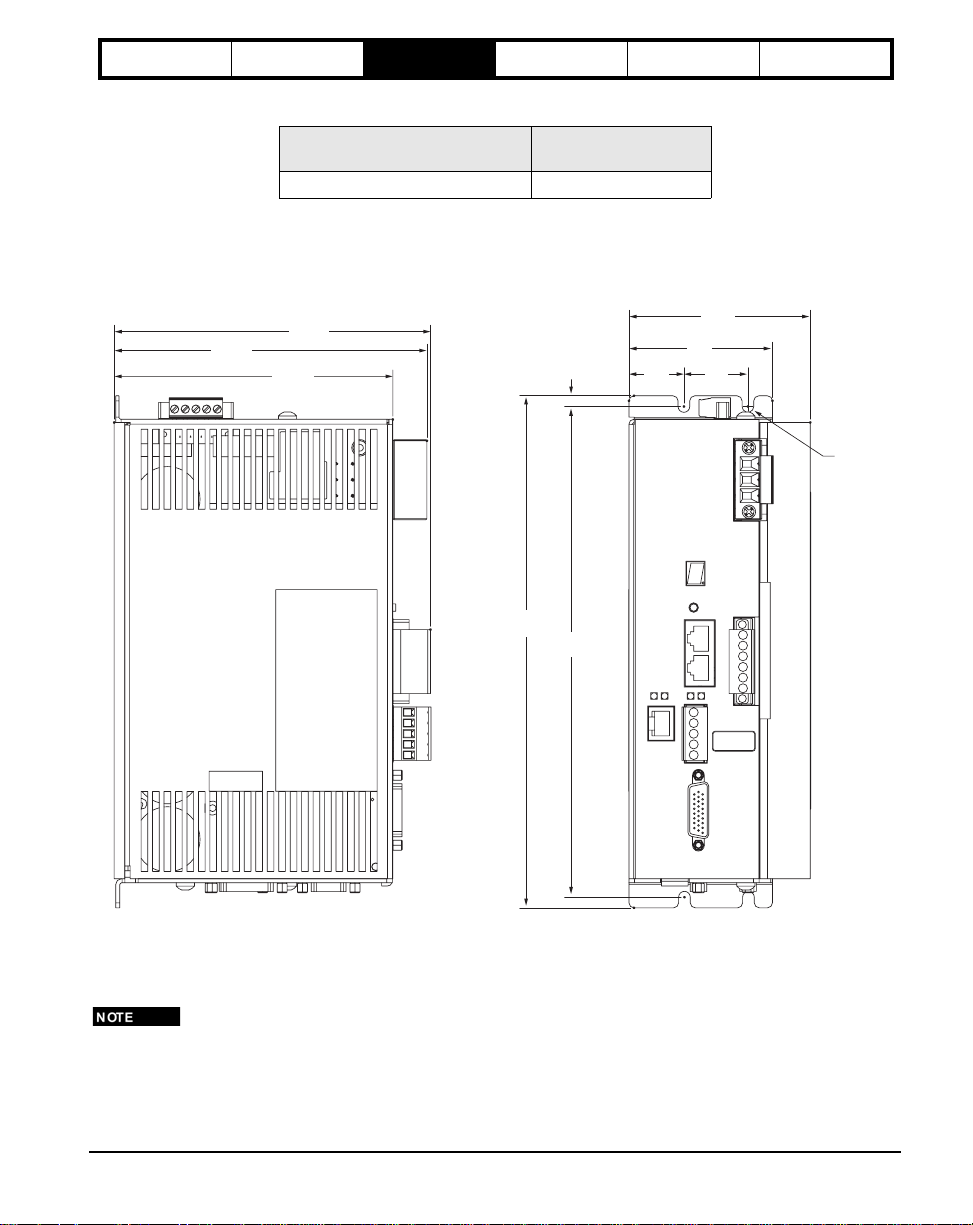

The following table applies to the "A" dimension as shown in figure 6 for the EP202 - EP206 programming drives.

Drive Model

Dimension "A"

inches [mm]

Minimum Panel Width

EP202-P, -PDN, -PPB 2.69 [68.3] 3.45 [88]

EP204-P, -PDN, -PPB 2.69 [68.3] 3.45 [88]

EP206-P, -PDN, -PPB 3.40 [86.4] 4.15 [105]

5.94

[150.88]

5.22

[132.59]

.200

[5.08]

8.099

[205.72]

7.70

[195.58]

inches [mm]

2.69

[68.3]

1.20

1.03

[30.48]

[26.16]

“A”

(4X)Ø.219

[5.56]

Figure 6: Mechanical Drawing for Epsilon EP202-206 Programming Drive

To prevent drive from dropping out of position during installation, partially pre-install lower mounting screws,

then set drive in place with lower mounting screws in slots and then install at least one upper mounting screw.

For removal, loosen lower screws, remove upper screws and lift drive out.

10

Page 23

Safety Information Product Overview Installation Diagnostics

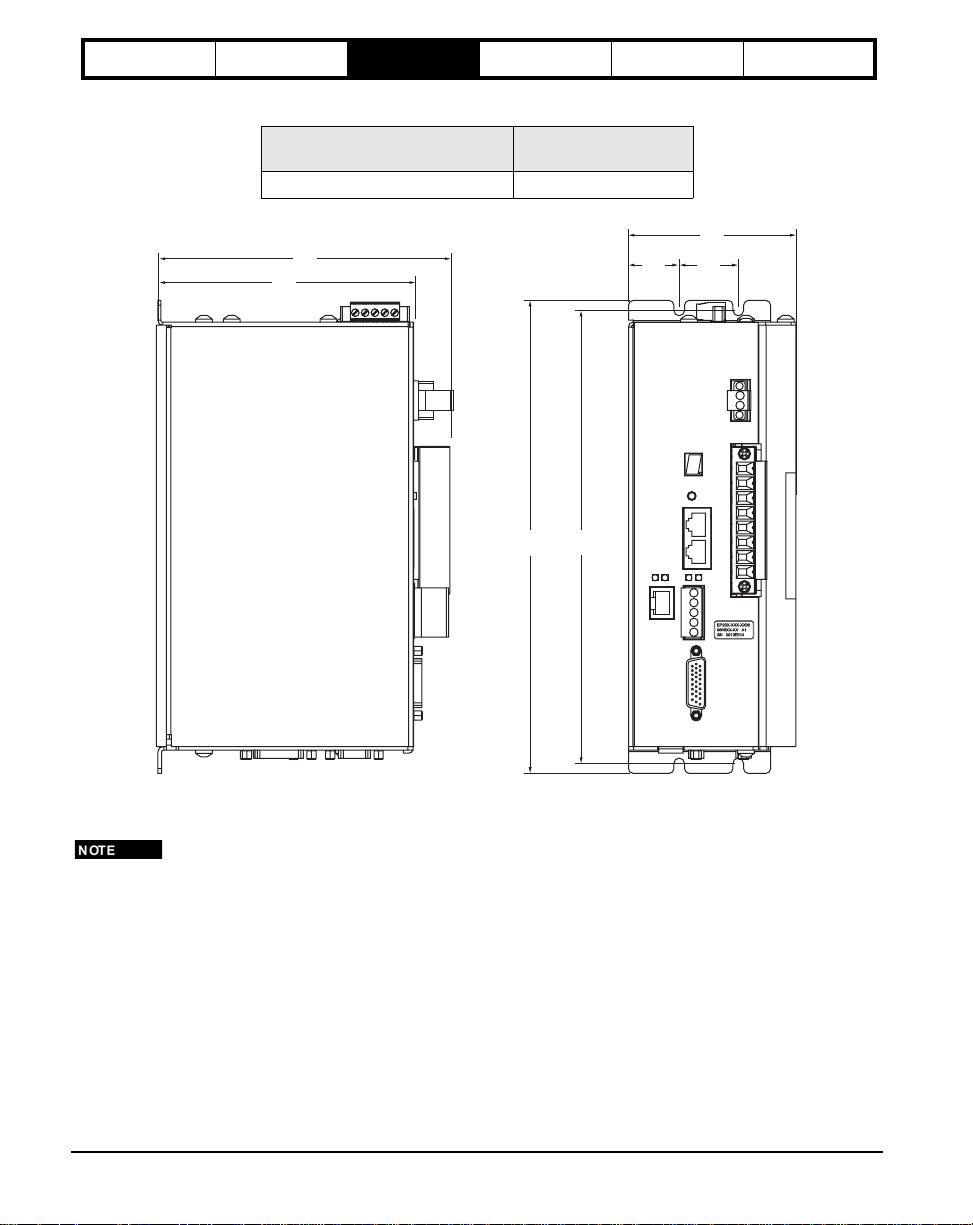

The following table applies to the minimum panel width for the EP209 drive.

Options and

Accessories

Specification

5.86

[148.85]

Drive Model

Minimum Panel Width

inches [mm]

EP209-B, -I, -IDN, -P, -PDN, -PPB 4.15 (105)

5.94

[150.88]

5.23

[132.84]

9.60

[243.84]

0.20 [5.08]

9.20

[233.68]

1.03

[26.16]

2.69

[68.33]

3.40

[86.36]

1.20

[30.48]

4X Ø.219

EP209-XXX-XX00

9606XX-XX A1

SN 0610E014

Figure 7: Mechanical Drawing for All Epsilon EP209 Models (EP209-PDN shown)

To prevent drive from dropping out of position during installation, partially pre-install lower mounting screws,

then set drive in place with lower mounting screws in slots and then install at least one upper mounting screw.

For removal, loosen lower screws, remove upper screws and lift drive out.

Installation 11

Page 24

Safety Information Product Overview Installation Diagnostics

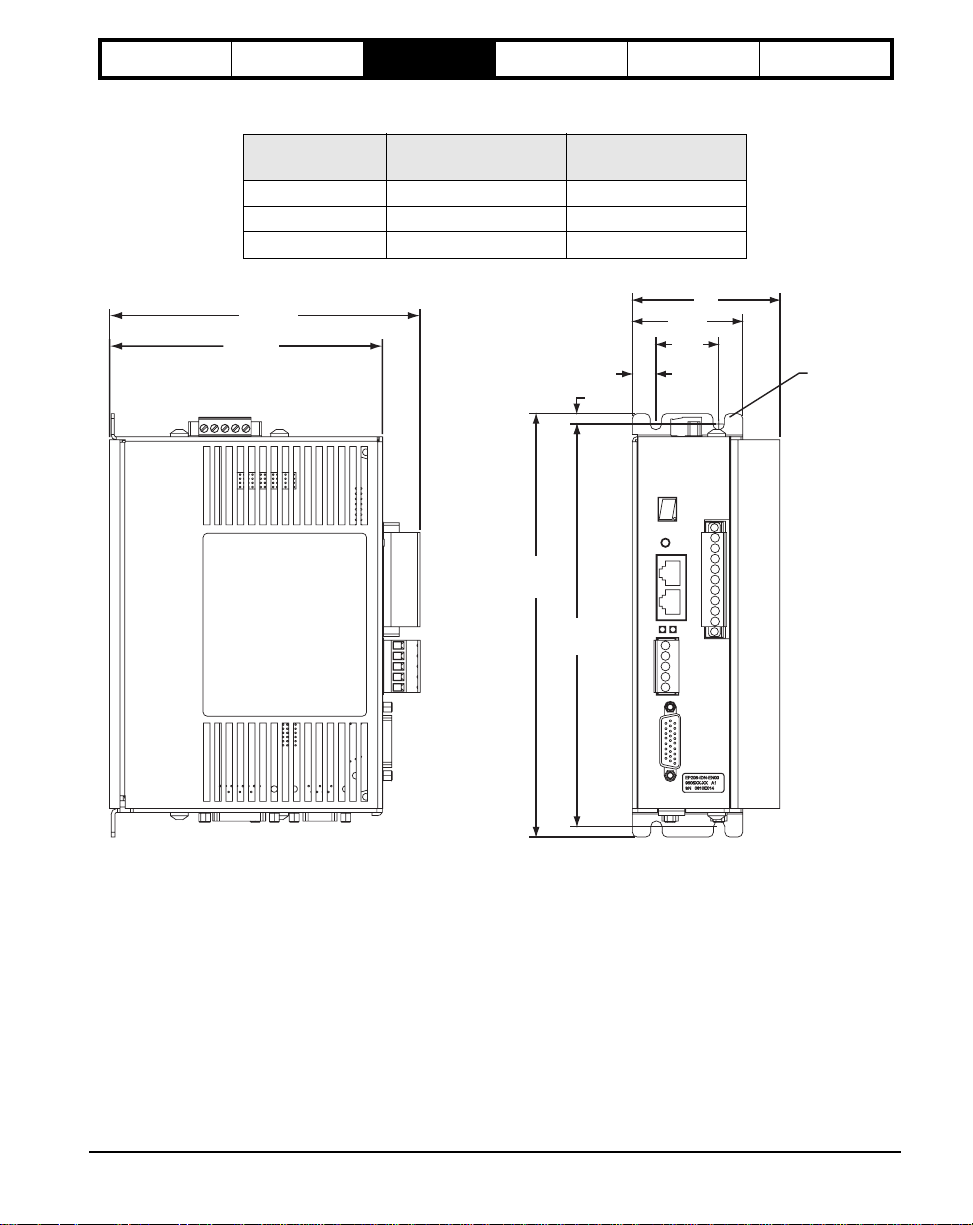

The following table applies to the minimum panel width for the EP216 drive.

Options and

Accessories

Specification

Drive Model

Minimum Panel Width

inches [mm]

EP216-B, -I, -IDN, -P, -PDN, -PPB 4.15 (105)

5.96

[151.38]

5.23

[132.84]

9.60

9.20

[243.84]

[233.68]

1.03

[26.16]

3.40

[86.36]

1.20

[30.48]

Figure 8: Mechanical Drawing for All Epsilon EP216 Models (EP216-PDN shown)

To prevent drive from dropping out of position during installation, partially pre-install lower mounting screws,

then set drive in place with lower mounting screws in slots and then install at least one upper mounting screw.

For removal, loosen lower screws, remove upper screws and lift drive out.

12

Page 25

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

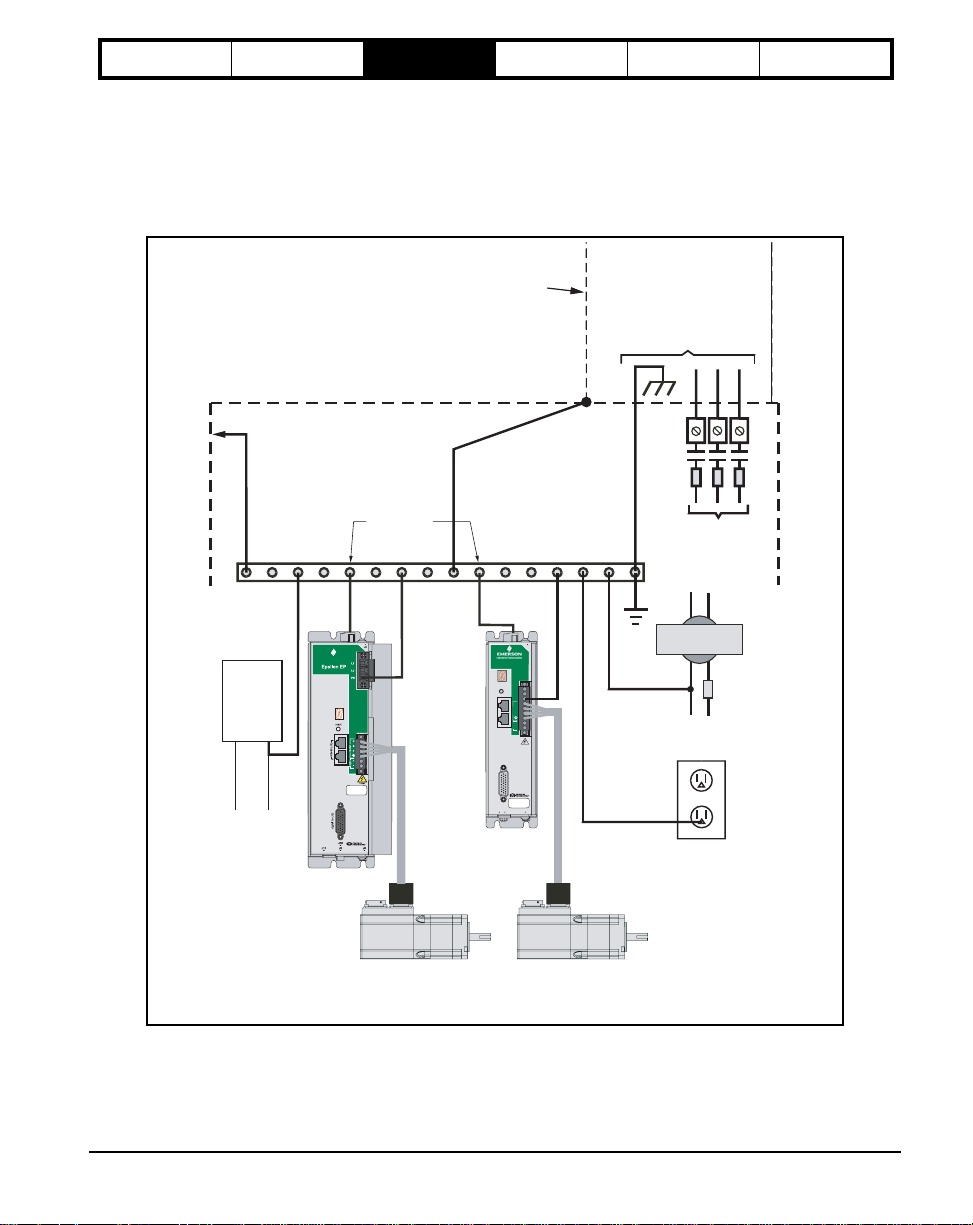

Step 3: High Power Connections

System Grounding

To insure a safe and quiet electrical installation, good system grounding is imperative. The figure below is an

overview of the recommended system grounding. For more information on achieving an electrically quiet installation

refer to “Step 1: Basic Installation Guidelines” on page 3.

Conduit or

Metal

Raceway

AC Power Supply

Enclosure

To Enclosure Door

Door Bond Wire

Redundant PE

Connection

Conduit Raceway Bond

Single Point Ground

(Bonded to Enclosure)

Fuses

3 Phase

Line Power

PE

Connection

J8

Epsilon EP

reset

L1

L2

PE

R

S

T

serial (J2)

+

_

logic motor

3 MIN

digital i/o (J3)

EP204-I00-0000

9606XX-XX A1

SN 0610E014

J6J5J10

Epsilon

EP202-206

Drive

Control

Transformer

Output

Neutral Hot

Convenience

Outlet

Logic

Power

Supply

24 Vdc

+ -

Epsilon

EP209

Drive

EMERSON

Industrial Automation

Epsilon

Drive

PE

Connection

TM

EP209-I00-0000

9606XX-XX A1

SN 0610E014

Motor Motor

NOTE: The aluminum heatsink is electrically connected to the PE terminal.

Figure 9: Typical System Grounding Diagram

Installation 13

Page 26

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Fixed Protective Earth (PE) connections are mandatory for human safety and proper operation. These

connections must not be fused or interrupted by any means. Failure to follow proper PE wiring can cause

death or serious injury. This equipment has high earth leakage current and requires a redundant PE

connection from either terminal marked PE at J8 to PE connection point.

AC Power Requirements

The Epsilon EP drives require 20 Vac to 264 Vac single phase power but, may operate on DC supplies, (See

Operation on DC Supply). An Epsilon EP drive can be connected to any pair of power phases on a 1 Ø or 3 Ø power

source that is grounded as shown in the following diagrams. Local electrical codes should be consulted before

installation.

When operating the drive at 90 V or less disable the Low DC Bus fault so the drive does not fault.

Where regeneration occurs, bus voltage will rise to 400 Vdc before shunt operation or a High DC Bus fault

limit voltage, whether shunt resistor is installed or not. Motors must have insulation rated for inverter duty at

240 Vac no matter what the operating voltage is, or bus voltage must be limited by other means.

The maximum voltage applied to the drive terminals must not exceed 264 Vac phase to phase and phase to

PE ground. The AC supply must be earthed (type TN) with PE connected to the earthed point at the source,

which is usually a distribution transformer but could be a service entrance.

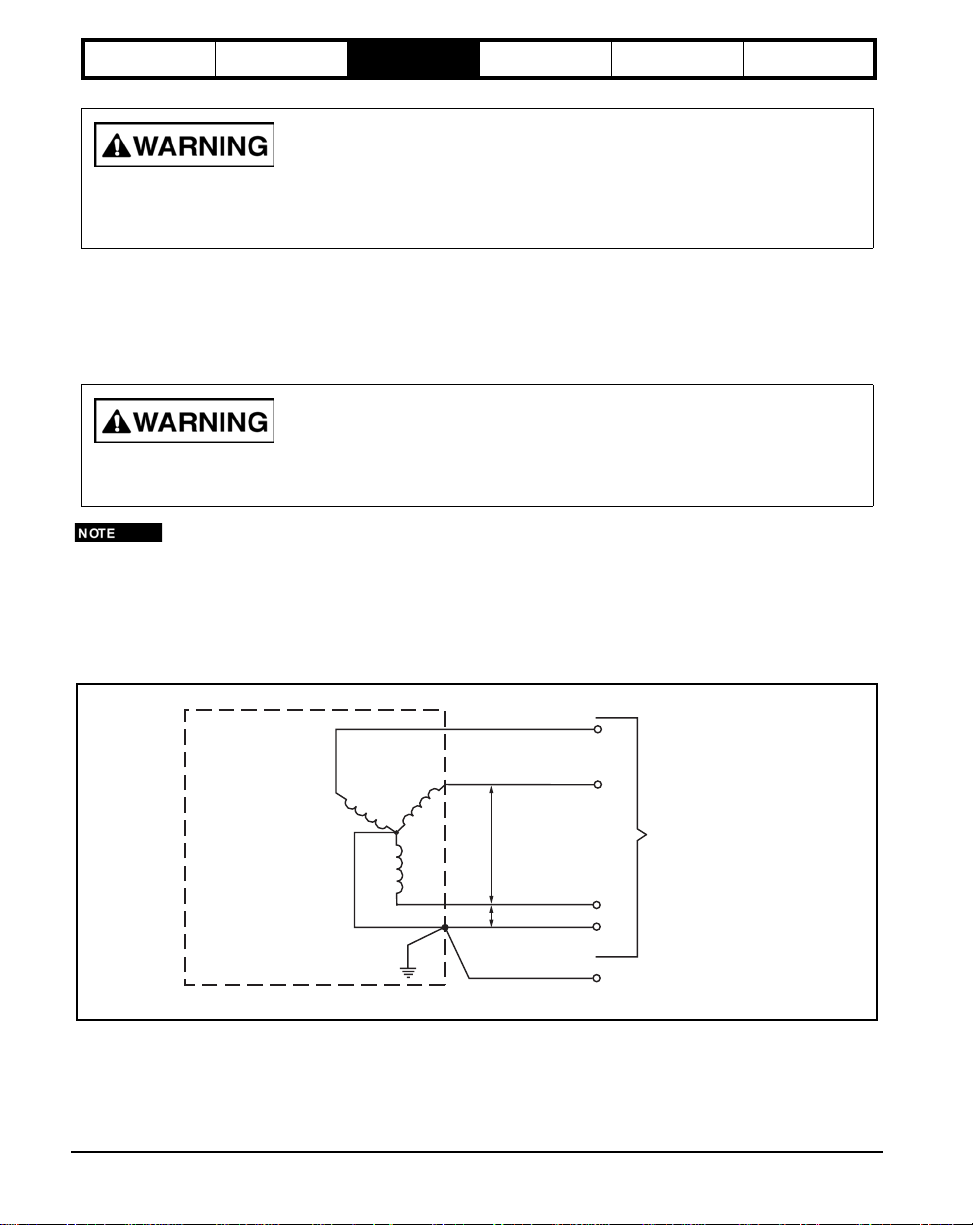

AC Supplies NOT Requiring Transformers

If the distribution transformer is configured as shown in the figures below, the AC power supply can be connected

directly to the drive terminals.

DISTRIBUTION PANEL

L3

14

SECONDARY

EARTH

GROUND

Typ. 208 Vac

120 Vac

(Protective Earth)

Neutral is used only when 120 Vac operation

is desired. It is never fused.

L2

L1

PE

N

To Fusing and

Drive Terminals

Figure 10: Earth Grounded WYE Distribution Transformer, 120/208Y 3Ø

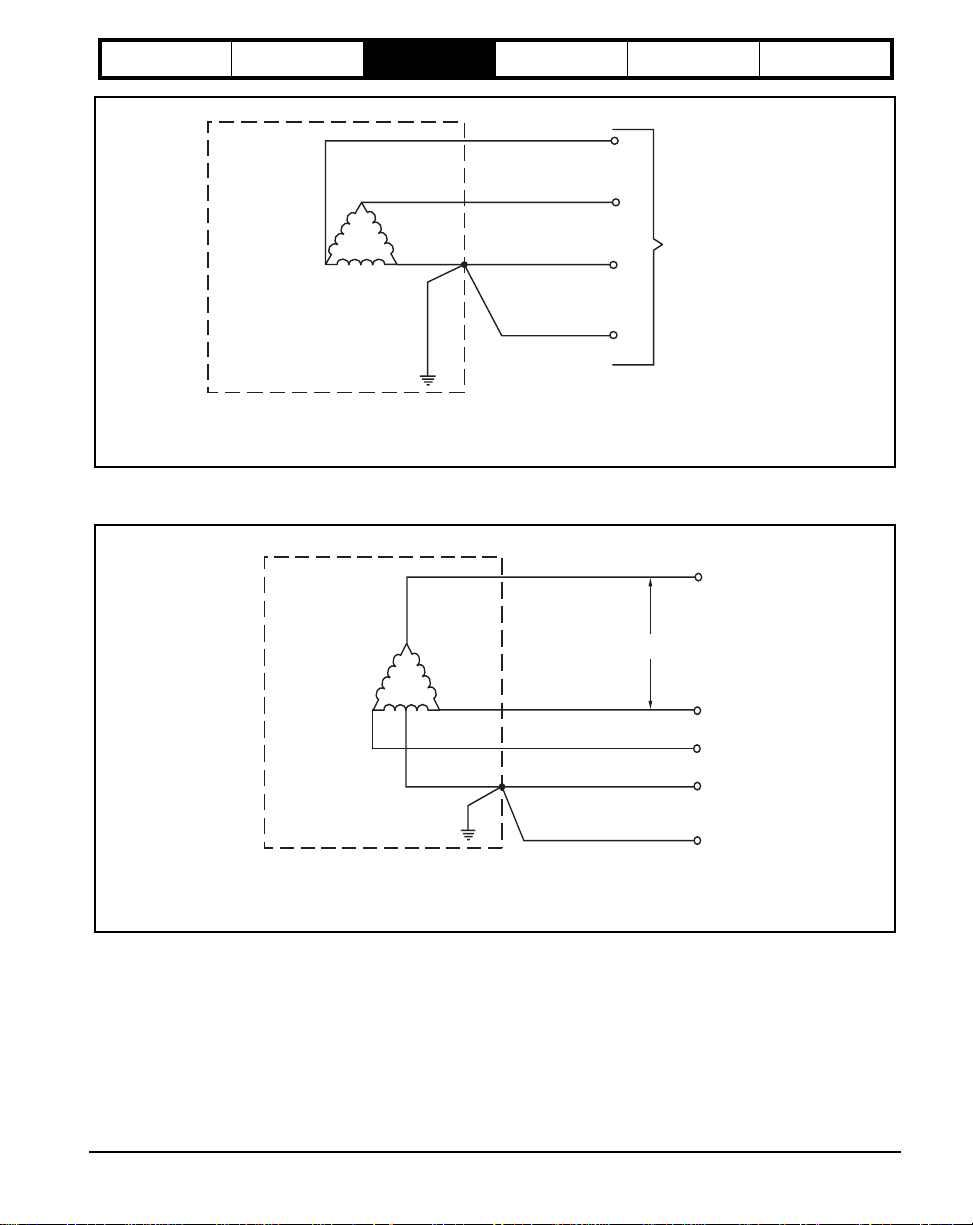

Page 27

Safety Information Product Overview Installation Diagnostics

DISTRIBUTION PANEL

L3

Options and

Accessories

Specification

SECONDARY

230 Vac

No Fuse

EARTH

GROUND

NOTE: For single phase drives using lines L1 & L2 or L1 & L3, only one fuse is

required on the high leg (L2 or L3). Lines L2 & L3 may be used to balance

the load, requiring two fuses.

(Protective Earth)

(N)

L2

L1

PE

To Fusing and

Drive Terminals

Figure 11: Earth Grounded Delta Distribution Transformer, 240 Vac 3Ø

DISTRIBUTION PANEL

L3

SECONDARY

Typ. 240 Vac

L2

L1

EARTH

GROUND

Used only for 120 Vac operation

NOTE: L3 is a high leg, 208 Vac from Neutral/PE.

For single phase drives it is best to use lines L1 and L2.

L1 & L3 or L2 & L3 maybe used to balance loads.

(Protective Earth)

PE

N

with L1 or L2.

Figure 12: Three Phase Delta (with mid-phase GND) Distribution,

120 Vac split/240 Vac 3Ø supply

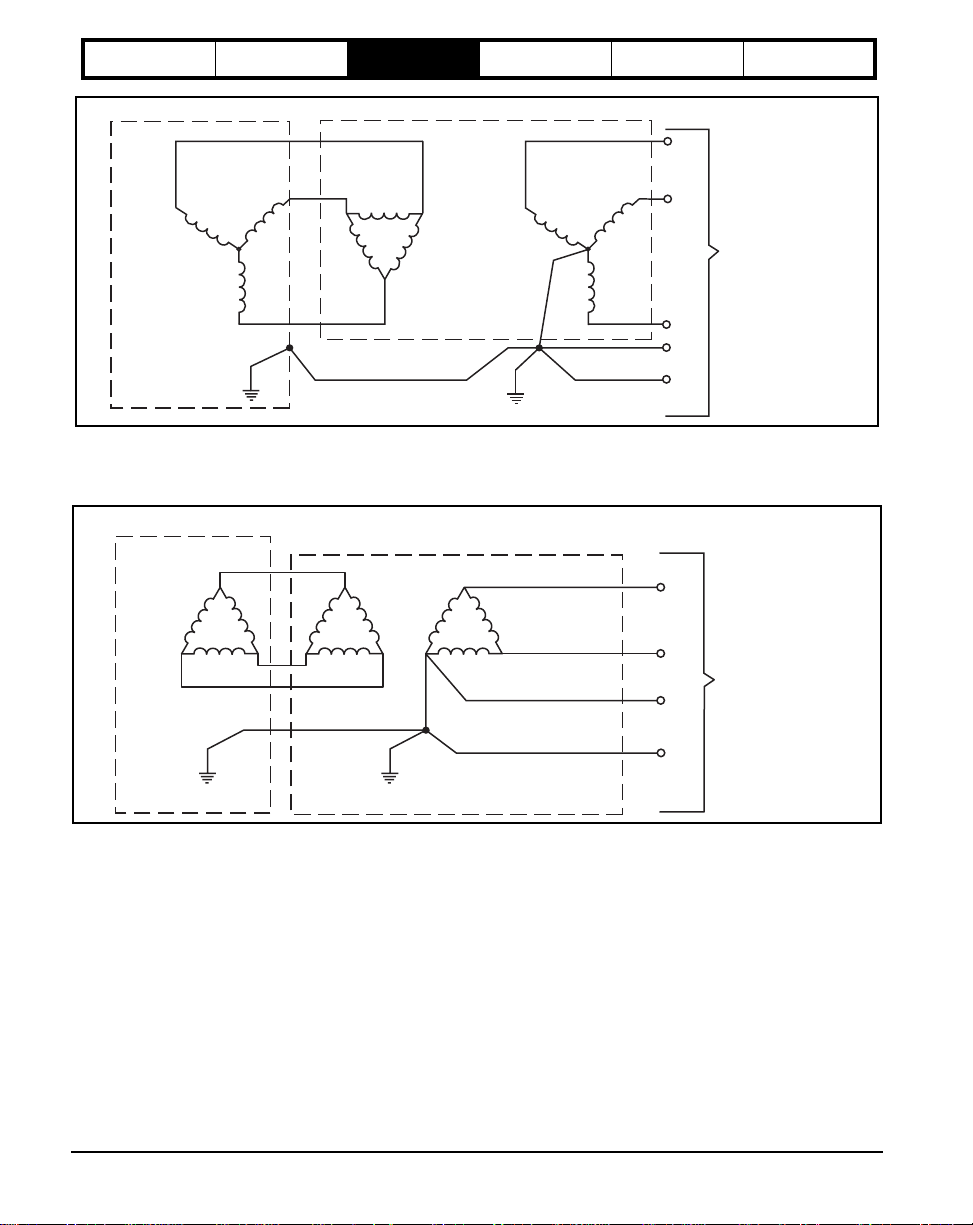

AC Supplies Requiring Transformers

If the distribution transformer is configured as shown in the figures below, an isolation transformer is required.

If an isolation transformer is used between the power distribution point and the drives, the transformer secondary

must be grounded for safety reasons as shown in the figures below.

Installation 15

Page 28

Safety Information Product Overview Installation Diagnostics

DISTRIBUTION PANEL 3 Ø Isolation Transformer

Options and

Accessories

L3

L2

To Fusing and

Drive Terminals

L1

N

EARTH

GROUND

(Protective Earth)

PE

Figure 13: Three-Phase WYE (ungrounded) Distribution to a Three-Phase Delta/WYE

Isolation Transformer

Specification

DISTRIBUTION PANEL

EARTH

GROUND

3 Ø Isolation Transformer

(Protective Earth)

No Fuse

L3

L2

L1

PE

To Fusing and

Drive Terminals

Figure 14: Three-Phase Delta (ungrounded) Distribution to a Three-Phase Delta

Isolation Transformer

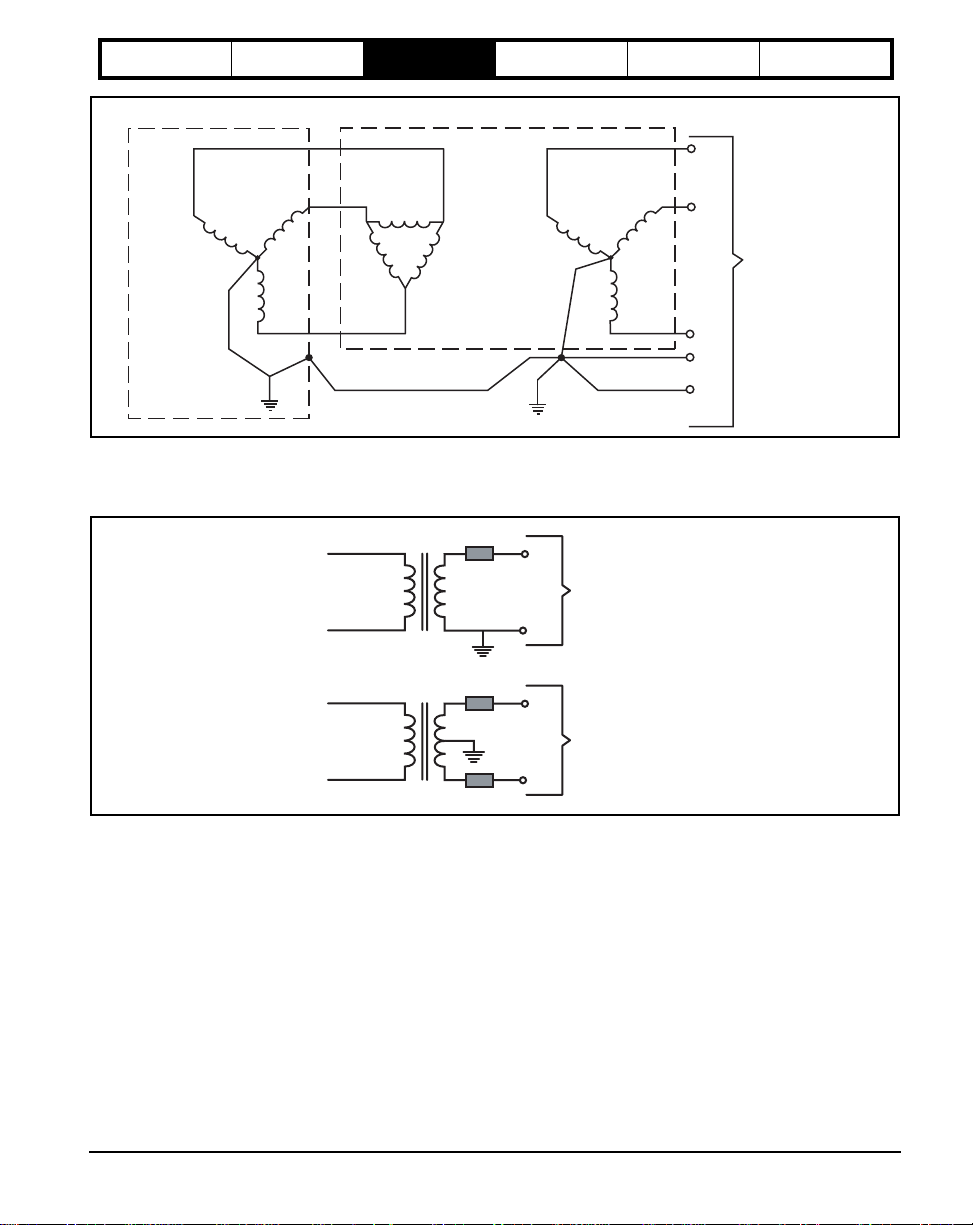

16

Page 29

Safety Information Product Overview Installation Diagnostics

s

s

DISTRIBUTION PANEL 3 Ø Isolation Step Down Transformer

Options and

Accessories

L3

L2

Specification

> 140 Vac

EARTH

GROUND

(Protective Earth)

To Fusing and

Drive Terminals

L1

N

PE

Figure 15: Grounded WYE Distribution >140 Vac Phase to Neutral. Recommend Using

Step Down Transformer so Line to Line is 240 Vac or less.

Fuse

Fuse

Fuse

L1

To Drive

Terminal

L2

L1

To Drive

Terminal

L2

Figure 16: Single Phase Power Supply Connections

Transformer Sizing

If your application requires a transformer, choose a transformer with a continuous power rating greater then the

maximum power usage of the drive/motor combination. Other factors that may influence the required KVA rating are

high transformer ambient temperatures (>40° C or >104° F) and drive operation near the maximum speeds.

Transformer output voltage drop may become a limiting factor at motor speeds and loads near maximum ratings.

Typically, higher KVA transformers have lower voltage drop due to lower impedance.

When multiple drives are connected to a single isolation transformer, add the suggested KVA ratings of the drives

that would be operating simultaneously together for transformer sizing.

Installation 17

Page 30

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Line Fusing and Wire Size

You must incorporate over current protection for the incoming AC power with the rating shown here. The drive alone

does not provide branch circuit protection. Branch circuit protection must be provided in accordance with the National

Electrical Code and any additional local codes.

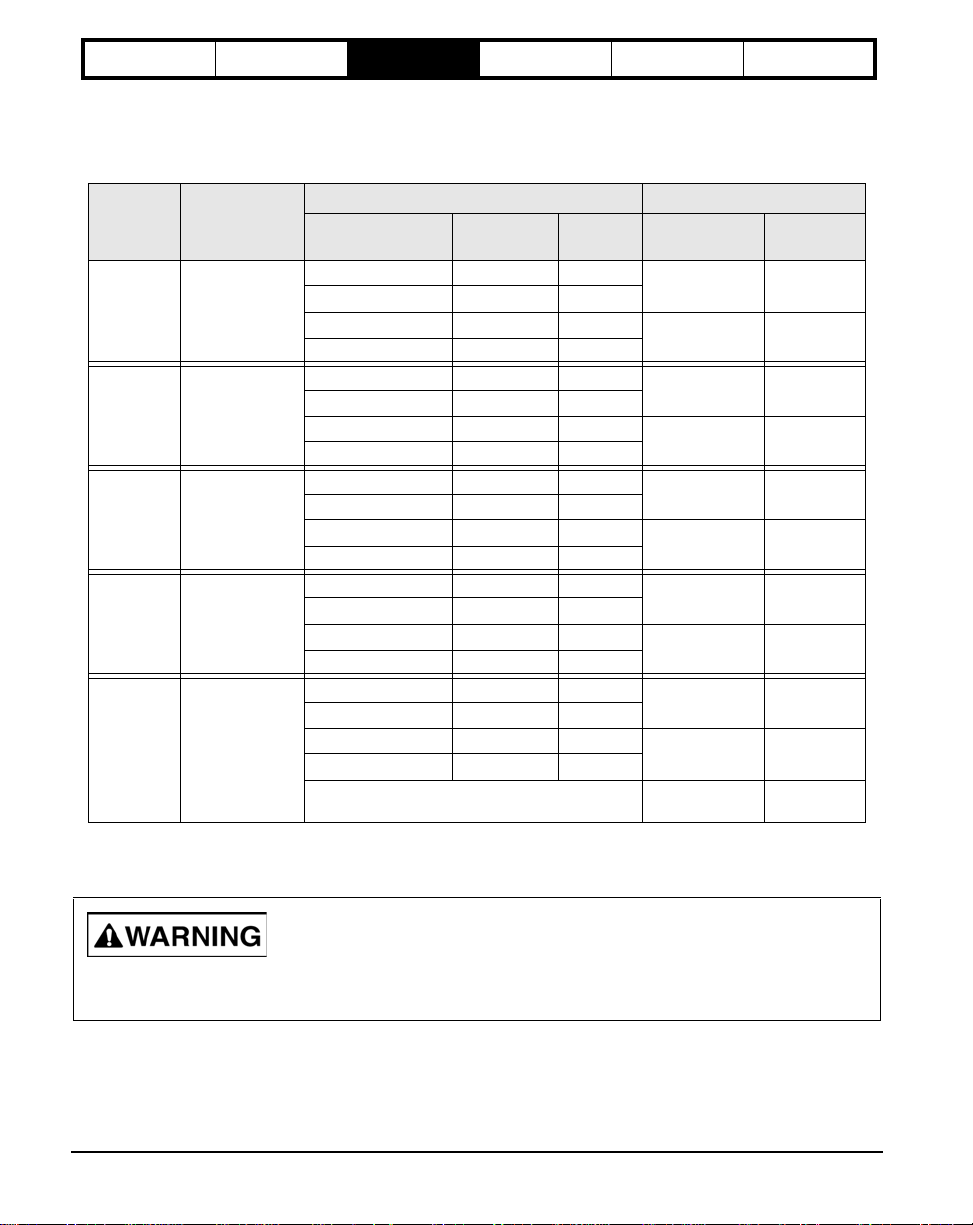

Fuse Miniature Circuit Breaker

Ferraz-

Shawmut

Allen Bradley Square D

1489-A1D060

6 A, 1 pole

1489-A2 D060

6 A, 2 pole

1489-A1D100

10 A, 1 pole

1489-A2D100

10 A, 2 pole

1489-A1D150

15 A, 1 pole

1489-A2D150

15 A, 2 pole

1489-A1D200

20 A, 1 pole

1489-A2D200

20 A, 2 pole

1489-A1D200

20 A, 1 pole

1489-A2D200

20 A, 2 pole

1489-A3D200

20 A, 3 pole

60124

6 A. 1 pole

60158

6 A, 2 pole

60127

10 A, 1 pole

60161

10 A, 2 pole

60129

15 A, 1 pole

60163

15 A, 2 pole

60130

20 A, 1 pole

60164

20 A, 2 pole

60130

20 A, 1 pole

60164

20 A, 2 pole

60196

20 A, 3 pole

Drive Model

EP202

EP204

EP206

EP209

EP216

Recommended

Minimum AC/PE

Line Wire Gauge

16 AWG

ISO 1,5

16 AWG

ISO 1,5

14 AWG

ISO 2,5

12 AWG

ISO 4

12 AWG

ISO 4

Fuse Class & Action Bussman

RK1 Time-Delay LPN-RK-6SP A2D6R

RK1 Quick-Acting KTN-R-6 A2K6R

CC Time-Delay LP-CC-6 ATDR6

CC Quick-Acting KTK-R-6 ATMR6

RK1 Time-Delay LPN-RK-10SP A2D10R

RK1 Quick-Acting KTN-R-10 A2K10R

CC Time-Delay LP-CC-10 ATDR10

CC Quick-Acting KTK-R-10 ATMR10

RK1 Time-Delay LPN-RK-15SP A2D15R

RK1 Quick-Acting KTN-R-15 A2K15R

CC Time-Delay LP-CC-15 ATDR15

CC Quick-Acting KTK-R-15 ATMR15

RK1 Time-Delay LPN-RK-20SP A2D20R

RK1 Quick-Acting KTN-R-20 A2K20R

CC Time-Delay LP-CC-20 ATDR20

CC Quick-Acting KTK-R-20 ATMR20

RK1 Time-Delay LPN-RK-20SP A2D20R

RK1 Quick-Acting KTN-R-20 A2K20R

CC Time-Delay LP-CC-20 ATDR20

CC Quick-Acting KTK-R-20 ATMR20

Use copper conductors only. Conductors must be rated 75°C or higher, preferably 90°C.

Suitable for use on a circuit capable of delivering not more than 10,000 rms symmetrical Amperes. When one of the

above current protection devices are used.

The Protective Earth (PE) wire connection is mandatory for human safety and proper operation. This

connection must not be fused or interrupted by any means. Failure to follow proper PE wiring can cause death

or serious injury.

18

Page 31

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Drive Model Input Voltage (Vac)

EP202

EP204 8.5 65 (5 ms)

EP206 12.0 100 (5 ms)

EP209 16.0 34 (5 ms)

EP216

This inrush current specification assumes the drive has been powered off for at least 8 minutes at 40ºC (104ºF)

ambient or 5 minutes at 25ºC (77ºF) ambient. If this amount of time has not elapsed since power off, the inrush

current will be higher. Exception is the EP209 and EP216, they use active inrush limiting. Listed inrush current is

240 / 1 Ø

240 / 3 Ø or

240 / 1 Ø

Frequency

(Hz)

47 - 63

Input Current (Amps RMS) at

Full Drive Output Current

5.0 40 (5 ms)

16.0 34 (5 ms)

Inrush Current

(Amps)

maximum.

AC Input Power Connections

Power must be "Off" for a minimum of 6 minutes for the Epsilon EP206, EP209 and EP216 drives and 3

minutes for the Epsilon EP202 and EP204 drives before unplugging the power connection. This will ensure the

bus voltage has bled down to a safe level (below 50 Vdc).

Do not connect or disconnect AC power by inserting or removing the AC power connector. Using the

connector in this manner, even once, will damage the connector making it unusable.

Installation 19

Page 32

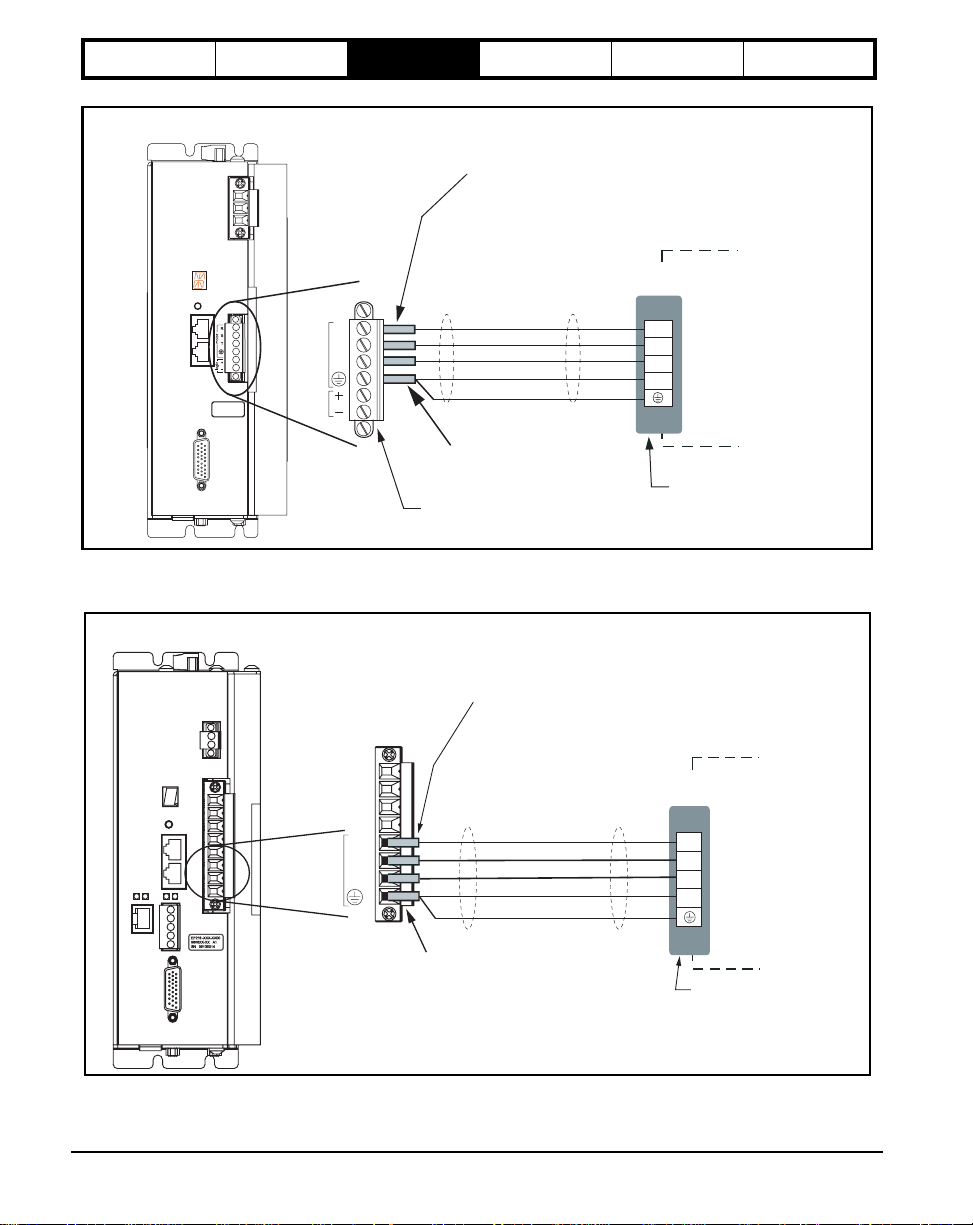

Safety Information Product Overview Installation Diagnostics

B-

Front View

PE

SH

PE

B+

J8

Options and

Accessories

Redundant PE connection

PE

Specification

L1

L2

PE

R

EP204-I00-0000

9606XX-XX A1

SN 0610E014

S

T

MOTOR

24 Vdc

J1

Terminals are suitable for one 16 AWG to 12 AWG

Tighten screws

to 5 in-lb.

or ISO 1,5 or ISO 2,5 stranded conductors.

* Note: If L2 is 120 Vac neutral it should not be fused.

Figure 17: Epsilon EP202-206 AC Power Wiring Diagram

B-

PE

SH

PE

B+

J8

Redundant PE connection

PE

L1

L2

PE

*

50/60 Hz

90-264 Vac

L1

L2

PE

*

50/60 Hz

90-264 Vac

20

Tighten screws

to 5 in-lb.

EP209-I00-0000

9606XX-XX A1

SN 0610E014

J1

Terminals are suitable for one 16 AWG to 12 AWG

or ISO 1,5 or ISO 4 stranded conductors.

* Note: If L2 is 120 Vac neutral it should not be fused.

Figure 18: Epsilon EP209 AC Power Wiring Diagram

Page 33

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

B-

PE

SH

PE

B+

Redundant PE connection

PE

J8

L1

L2

L3

PE

R

S

T

MOTOR

Terminals are suitable for one 16 AWG to 10 AWG

or ISO 1,5 to ISO 6 stranded conductors.

* Note: If L2 or L3 is 120Vac Neutral it should not be fused.

Tighten screws

to 5 in-lb.

Figure 19: Epsilon EP216 AC Power Wiring Diagram

L1

L2*

50/60 Hz

90-264 Vac

L3*

PE

Operation on DC Input Supply

At this time, the EP drive is NOT UL listed for operation on a DC input supply,

The Epsilon EP202, EP204 and EP206 drive can operate on DC input as low as 20 Vdc, recommended minimum is

24 Vdc. The Epsilon EP209 and EP216 drive’s minimum is 140 Vdc. It can also operate from a common DC link with

voltage to 373 Vdc, the voltage resulting from 264 Vac applied to a rectifier, with regen to 400 Vdc intermittently.

For DC input supply less than 24 Vdc, the DC input should be connected to the B+ and B- terminals at J8 to avoid

losses in the rectifier and inrush limiter. At such low voltages the bus caps do not need inrush protection. For DC

supply greater than 24 Vdc, the supply should be connected to L1 and L2 terminals on J1. Polarity does not matter.

The rectifier blocks reverse current so regen energy will not come back to the supply. DC supply greater than 24 Vdc

may be applied to the B+ and B- terminals of J8, but the supply must provide soft-start or inrush current limiting and

must be able to handle any anticipated regen energy.

Both supply conductors must be fused except one that is grounded. The fuse must be rated for at least the voltage

applied. The current rating of the fuse should match the rated output current of the drive. A slow-blow fuse should

be used if high peak loads are expected.

Please contact Technical Support at Control Techniques Americas before connecting any EP drives with a

common DC link.

Installation 21

Page 34

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

External Shunt Electrical Installation

Shunt connections at J8 remain at dangerous Voltages after disconnecting AC Power. Power must be "Off"

for a minimum of 6 minutes for an EP206/209/216 and 3 minutes for an EP202/204 before touching these

terminals.

The EP204, EP206, EP209, and EP216 drives provide an internal shunt transistor to direct regen energy to an

external shunt or braking resistor. The resistor is connected to the B+ and SH terminals at J8 on the top of the drive.

Shunt Control

The shunt transistor turns on when the bus voltage reaches 405 Vdc and shuts off when the bus voltage falls below

390 Vdc. An internal shunt control algorithm is used to prevent the external shunt resistor from overloading. It is

necessary to enter shunt energy rating, power rating and resistance for the attached shunt resistor in PowerTools

Pro software. Energy rating is the amount of energy that the resistor can absorb in a single shunt event assumed to

be so short that power dissipation is negligible. Power rating is the long term average power that can be dissipated.

PowerTools Pro default values are for the Control Techniques "SM-Heatsink DBR-1" resistor kit, marked P/N 12202756-01 on the resistor.

External Shunt Resistor

Control Techniques offers an external shunt resistor kit, SM-Heatsink DBR-1, that attaches directly to the EP drive

heatsink. The resistance is 75 Ohms and has 1500 Joule energy rating and 50 W continuous power rating. It is

adequate for most infrequent machine stop sequences due to relatively high energy rating for its power rating. It

should be suitable for any EP204 application unless average power exceeds 50 W for repetitive cycles. For EP206,

EP209 and EP216, some applications may require lower resistance to prevent a high bus fault or higher energy

rating for a single event, as well as higher average power rating. The resistor in the kit is designed to eventually open

in the event of a shorted control transistor when operating with an AC input greater than 200 Vac. At this time the kit

should be used only when the drive is operating at 200 Vac to 240 Vac.

A different external shunt resistor should be used if average power is above 50 W, or other limits are exceeded as

described above. Higher power resistors should be mounted away from the drive to prevent overheating. If thermal

loading inside a cabinet is an issue, a resistor with suitable enclosure may be installed external to the drive enclosure.

The minimum resistance for an external shunt resistor is 33 Ohms. The resistor must have thermal overload

protection to remove power in the event of a shorted control transistor. The protection can simply open the circuit, in

which case a high bus fault will occur, or be wired to a contactor that isolates input power from the drive on overtemp.

Shunt Resistor Kit Installation

The SM-Heatsink DBR-1 attaches to the side of the EP204, EP206, EP209, or EP216 drive by lining up the two

captive screws to the special width slots in the heat sink. The exact position along the slot does not matter as long

as the body of the resistor does not extend beyond the top or bottom of the drive. Use a T-20 Torx driver to thread

the screws into position. After both are well started but not tight, carefully turn each screw until it is seated against

the resistor and the resistor back is seated against the heat sink. Then turn the screw 1/8 turn more. Do not

overtighten.

Strip 0.12 inch [3.0 mm] insulation from the ends of the resistor wires. Install the wires in the SH and B+ terminals of

J8 and tighten to 5 in-lb. Make sure the locking screws are installed on J8 to prevent the connector from pulling out.

22

Page 35

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

SELF TAPPING SCREW (2)

Specification

SH

B-

B+

PE

PE

B+

SH

Figure 20:Shunt Resistor Installation for the Epsilon EP and SM-Heatsink DBR-1 Kit

Do Not make any shunt resistor connections to B-.

Shunt connections are at main voltage potential. Components connected must be rated for the voltage and

selected for safety. The external shunt resistor must have protection for a failed ON state of the shunt control.

Installation 23

Page 36

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

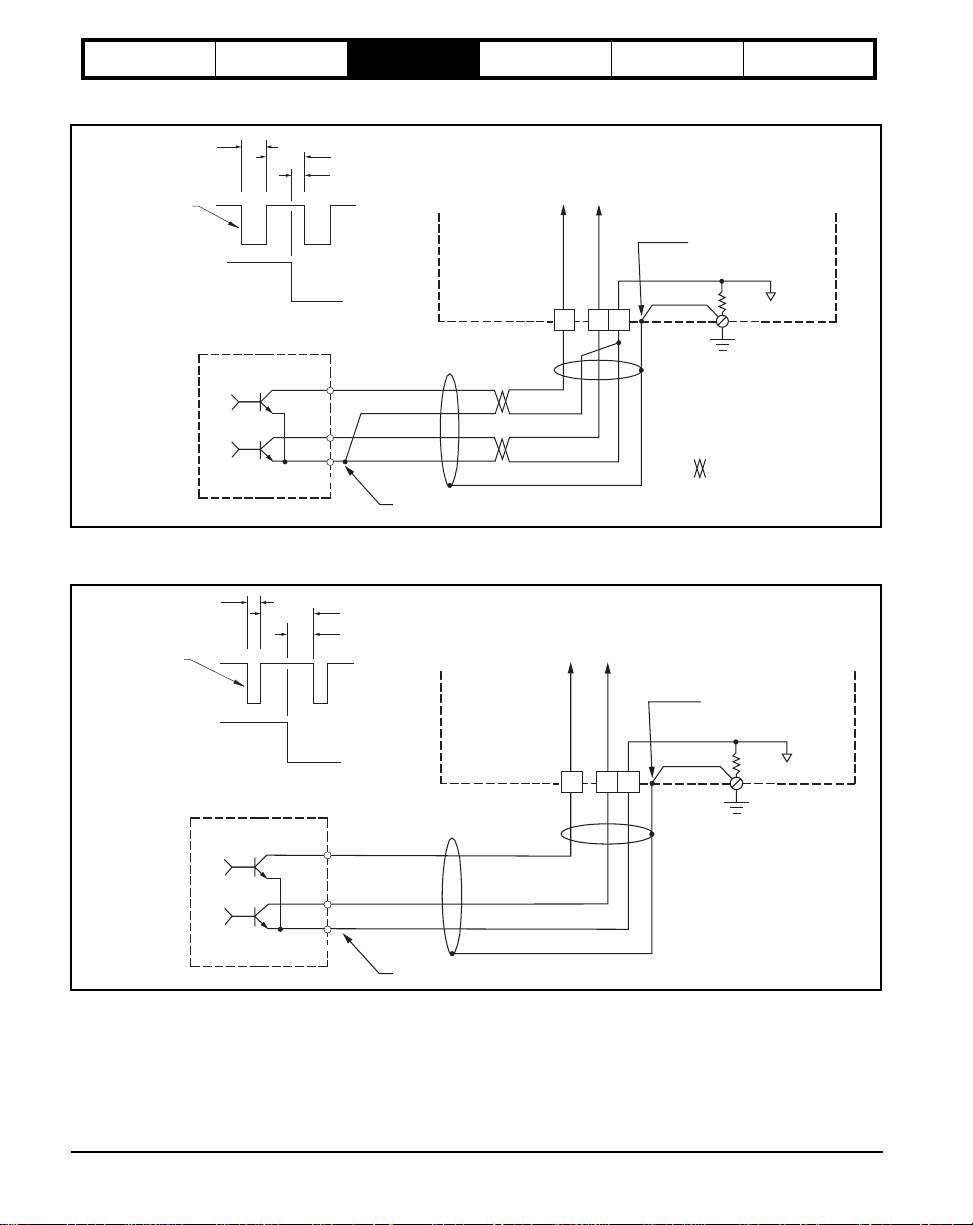

Motor Power Wiring

The following paragraphs provide details of motor connections. When motor power cables are long, 100ft. [30 m], a

ferrite (Control Techniques p/n 157016-13, Steward p/n 28A3851-0A2 or equivalent) installed on the three phase

conductors but not the shield, near J1 can significantly reduce high frequency switching harmonics that in some

cases can cause communications and encoder errors, see figures below. Maximum cable length is 200 ft [60 m].

With the Epsilon EP202/204/206/209 drive the J1 terminals are suitable for one 18 AWG to 14 AWG or ISO 0,75 to

ISO 2,5 stranded conductors. The Epsilon EP216 drive J1 terminals are suitable for one 16 AWG to 10 AWG or ISO

1,5 to ISO 6 stranded conductors. The ground/shield terminal may contain the shield and ground conductors together

if each is 16 AWG or ISO 0,75 or ISO 1,5. Otherwise a ferrule must be used to crimp both connectors together.

Front View

EP204-I00-0000

9606XX-XX A1

SN 0610E014

L1

L2

PE

R

S

T

MOTOR

24 Vdc

Ferrite

Motor

Power Connections

R

S

T

Ground

Connector Shell

Figure 21: EP202-206 Ferrite Placement with Cable Lengths Longer Than 100 FT.

Front View

EP209-I00-0000

9606XX-XX A1

SN 0610E014

Ferrite

R

S

T

MOTOR

logic

Motor

Power Connections

R

S

T

Ground

Connector Shell

24

Figure 22: EP209 Ferrite Placement with Cable Lengths Longer Than 100 FT.

Page 37

Safety Information Product Overview Installation Diagnostics

Front View

Options and

Accessories

Specification

L1

L2

L3

PE

R

S

T

MOTOR

Ferrite

Motor

Power Connections

R

S

T

Ground

Connector Shell

Figure 23: EP216 Ferrite Placement with Cable Lengths Longer Than 100 FT.

Installation 25

Page 38

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

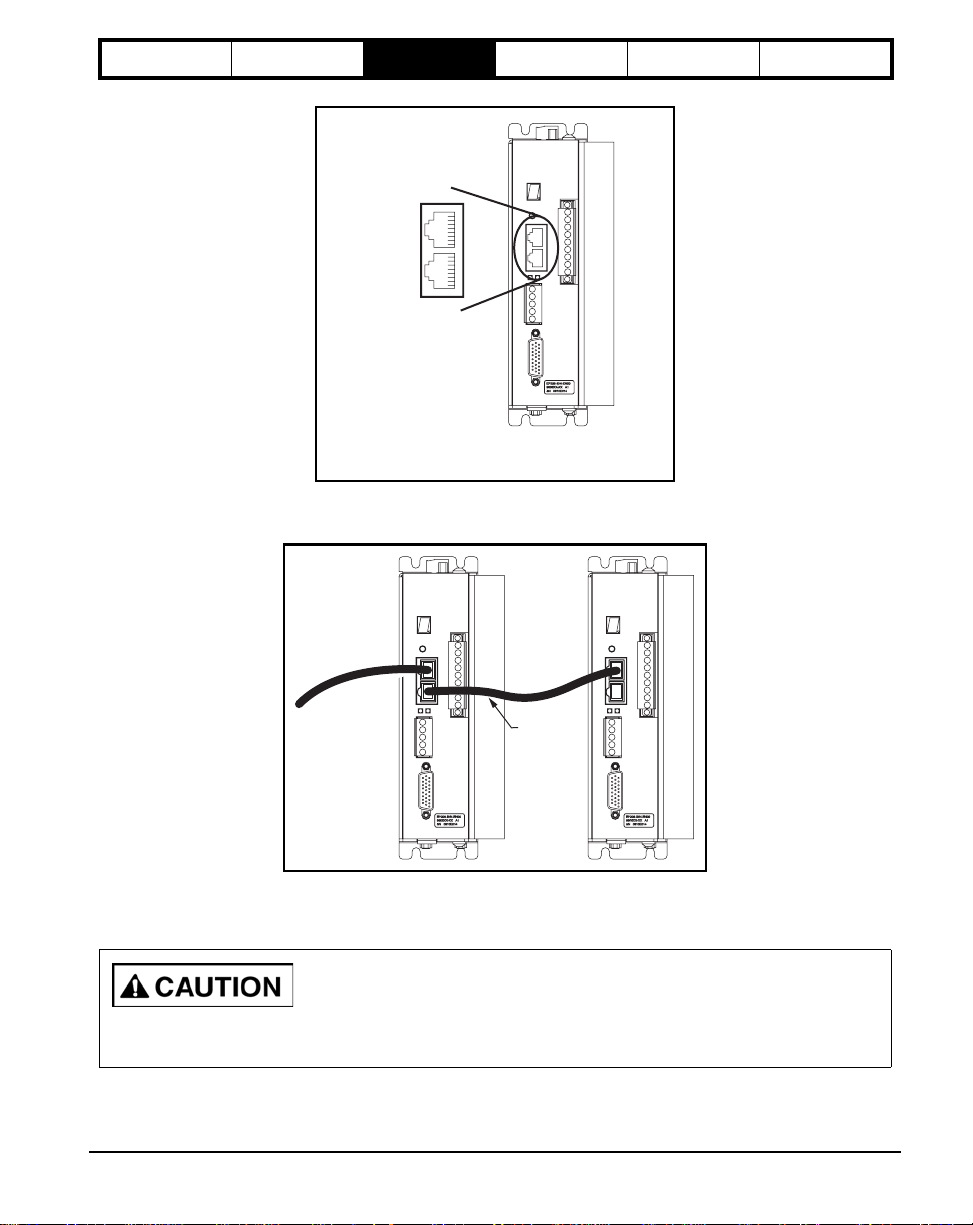

NT and MG Motors

NT and MG motors are equipped with up to three male MS (Military Standard) connectors, one for stator

connections, one for encoder connections and one for the brake (if so equipped).

Stator connections from the drive to the motor are made with the CMDS or CMMS cable have a female MS style

connector on the motor end and four individual wires and shield that connect to the motor power connector on the

front of the drive.

The motor ground wire and shields must be run all the way back to the drive terminal and must not be

connected to any other conductor, shield or ground except the enclosure wall for EMC.

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1, 5-8Bk/32 00 82 3

American Electrical/DigiKey 1381015/288-1130-ND

For motor leads use Pheonix Contact p/n AI 1,5-8 RD/32 01 13 6 or

Front View

EP204-I00-0000

9606XX-XX A1

SN 0610E014

L1

L2

PE

R

S

T

MOTOR

24 Vdc

ALTEC p/n H1.5/14 2204.0 Pk/100

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground

should connect to drive

and motor only. Nothing

should be connected

between these devices.

Tighten screws to 5 in-lb.

NT or MG Motor

Power Connection

R

S

T

Ground

Connector Shell

2" and 3" motor cable

connector (CMDS-xxx cable)

26

Figure 24: Epsilon EP202-EP206 Drive - NT/MG Motor Power Wiring Diagram

Page 39

Safety Information Product Overview Installation Diagnostics

Front View

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1, 5-8Bk/32 00 82 3

American Electrical/DigiKey 1381015/288-1130-ND

For motor leads use Pheonix Contact p/n AI 1,5-8 RD/32 01 13 6 or

ALTEC p/n H1.5/14 2204.0 Pk/100

Options and

Accessories

NT or MG Motor

Power Connection

Specification

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground

should connect to drive

and motor only. Nothing

should be connected

between these devices.

R

S

T

Ground

Connector Shell

2" and 3" motor cable

connector (CMDS-xxx cable)

EP209-I00-0000

9606XX-XX A1

SN 0610E014

MOTOR

logic

R

S

T

Tighten screws to 5 in-lb.

Figure 25: Epsilon EP209 - NT/MG Motor Power Wiring Diagram

Front View

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1, 5-8Bk/32 00 82 3

American Electrical/DigiKey 1381015/288-1130-ND

For motor leads use Pheonix Contact p/n AI 1,5-8 RD/32 01 13 6 or

L1

L2

L3

PE

R

S

T

MOTOR

ALTEC p/n H1.5/14 2204.0 Pk/100

Brown

Black

Blue

Green/Yellow

Shield

NT or MG Motor

Power Connections

R

S

T

Ground

Connector Shell

Important: PE ground should connect to drive

and motor only. Nothing should be connected

between these devices.

3" motor cable

connector (CMDS-xxx cable)

Figure 26: Epsilon EP216 - NT/MG Motor Power Wiring Diagram

Installation 27

Page 40

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

XV Motor Power Wiring

The XV 40 mm to 80 mm motors are equipped with up to three connectors, one for stator connections, one for

encoder connections and one for the brake (if so equipped).

Stator connections from the drive to the motor are made using the XTMDS cable, the motor end of the cable has an

Amp "Mate-N-Lok"® connector and the drive end has four individual wires and shield that connect to the motor power

connector on the front of the drive.

Front View

EP204-I00-0000

9606XX-XX A1

SN 0610E014

Figure 27: Epsilon EP202-EP206 - XV 40 mm - 80 mm Motor Power Wiring Diagram

L1

L2

PE

R

S

T

MOTOR

24 Vdc

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1-8RD/32 00 81 0 or

American Electrical/DigiKey 1381010/288-1127-ND

For motor leads use Pheonix Contact p/n AI 1-RD/32 00 03 0 or

American Electrical/DigiKey 1181010/288-1015-ND

XVM 40M, 60M, 80M Motor

Power Connection

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground

should connect to drive

and motor only. Nothing

should be connected

between these devices.

Tighten screws to 5 in-lb.

R

1

S

3

T

2

Ground

4

Connector Shell

motor cable

connector (XTMDS-xxx)

28

Front View

EP209-I00-0000

9606XX-XX A1

SN 0610E014

MOTOR

logic

R

S

T

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1-8RD/32 00 81 0 or

American Electrical/DigiKey 1381010/288-1127-ND

For motor leads use Pheonix Contact p/n AI 1-RD/32 00 03 0 or

American Electrical/DigiKey 1181010/288-1015-ND

XVM 40M, 60M, 80M Motor

Power Connection

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground

should connect to drive

and motor only. Nothing

should be connected

between these devices.

R

1

S

3

T

2

Ground

4

Connector Shell

motor cable

connector (XTMDS-xxx)

Tighten screws to 5 in-lb.

Figure 28: Epsilon EP209 - XV 40 mm - 80 mm Motor Power Wiring Diagram

Page 41

Safety Information Product Overview Installation Diagnostics

Options and

Accessories

Specification

Front View

Wire crimp ferrules are recommanded:

For ground lead use Pheonix Contact p/n AI-TWIN 2X1-8RD/32 00 81 0 or

American Electrical/DigiKey 1381010/288-1127-ND

For motor leads use Pheonix Contact p/n AI 1-RD/32 00 13 0 or

L1

L2

L3

PE

R

S

T

MOTOR

American Electrical/DigiKey 1181010/288-1015-ND

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground should connect to drive

and motor only. Nothing should be connected

between these devices.

XVM 40M, 60M, 80M Motor

Power Connections

1

R

S

3

T

2

Ground

4

Connector Shell

motor cable

connector (XTMDS-xxx cable)

Figure 29: Epsilon EP216 - XV 40 mm - 80 mm Motor Power Wiring Diagram

The XV 130 mm motors have two MS (Military Standard) connectors, one for the stator connections and one for the

encoder connections. Stator connections from the drive to the motor are made with the XCMDS (motor without

brake) or the XCMDBS (motor with brake) cable.

Wire crimp ferrules are recommanded:

For ground lead use Panduit p/n PV10-P55-L

For motor leads use Pheonix Contact p/n AI 1,5-8 BU/32 00 52 2

Front View

XVM 130M Motor

Power Connection

A

C

B

D

motor cable

connector (XCMDS-xxx)

U

V

W

Ground

Connector Shell

EP204-I00-0000

9606XX-XX A1

SN 0610E014

L1

L2

PE

MOTOR

24 Vdc

R

S

T

Brown

Black

Blue

Green/Yellow

Shield

Important: PE ground

should connect to drive

and motor only. Nothing

should be connected