Page 1

Advanced User Guide

Digitax ST

AC variable speed drive for servo

motors

Part Number: 0475-0023-03

Issue: 3

Page 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC, the English version of this manual is the Original Instructions. Manuals

in other languages are Translations of the Original Instructions.

Documentation

Manuals are available to download from the following locations: http://www.drive-setup.com/ctdownloads

The information contained in this manual is believed to be correct at the time of printing and does not form part of any contract. The manufacturer

reserves the right to change the specification of the product and its performance, and the contents of the manual, without notice.

Warranty and Liability

In no event and under no circumstances shall the manufacturer be liable for damages and failures due to misuse, abuse, improper installation, or

abnormal conditions of temperature, dust, or corrosion, or failures due to operation outside the published ratings. The manufacturer is not liable for

consequential and incidental damages. Contact the supplier of the drive for full details of the warranty terms.

Environmental policy

Control Techniques Ltd operates an Environmental Management System (EMS) that conforms to the International Standard ISO 14001.

Further information on our Environmental Policy can be found at: http://www.drive-setup.com/environment

Restriction of Hazardous Substances (RoHS)

The products covered by this manual comply with European and International regulations on the Restriction of Hazardous Substances including EU

directive 2011/65/EU and the Chinese Administrative Measures for Restriction of Hazardous Substances in Electrical and Electronic Products.

Disposal and Recycling (WEEE)

When electronic products reach the end of their useful life, they must not be disposed of along with domestic waste but should be recycled

by a specialist recycler of electronic equipment. Control Techniques products are designed to be easily dismantled into their major

component parts for efficient recycling. The majority of materials used in the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates. Smaller products are packaged

in strong cardboard cartons which have a high recycled fibre content. Cartons can be re-used and recycled. Polythene, used in protective

film and bags for wrapping the product, can be recycled. When preparing to recycle or dispose of any product or packaging, please

observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier of an article to

inform the recipient if it contains more than a specified proportion of any substance which is considered by the European Chemicals Agency (ECHA)

to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

Further information on our compliance with REACH can be found at: http://www.drive-setup.com/reach

Registered Office

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

SY16 3BE

UK

Registered in England and Wales. Company Reg. No. 01236886.

Copyright

The contents of this publication are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development

and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of the guide, without

notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Copyright © December 2017 Nidec Control Techniques Ltd

Page 3

Contents

1 Parameter structure.......................................................................................................5

1.1 Menu 0 ...................................................................................................................................................5

1.2 Advanced menus ...................................................................................................................................7

1.3 Solutions Modules .................................................................................................................................7

1.4 Drive software version ...........................................................................................................................7

2 Keypad and display .......................................................................................................8

2.1 Understanding the display .....................................................................................................................8

2.2 Keypad operation ..................................................................................................................................8

2.3 Status mode ..........................................................................................................................................9

2.4 Parameter view mode ............................................................................................................................9

2.5 Edit mode ..............................................................................................................................................9

2.6 SM-Keypad Plus ..................................................................................................................................10

2.7 Parameter access level and security ...................................................................................................11

2.8 Alarm and trip display ..........................................................................................................................12

2.9 Keypad control mode (SM-Keypad Plus only) .....................................................................................12

2.10 Drive reset ...........................................................................................................................................12

2.11 Second motor parameters ...................................................................................................................12

2.12 Special display functions .....................................................................................................................12

3 Parameter x.00 .............................................................................................................13

3.1 Parameter x.00 reset ...........................................................................................................................13

3.2 Saving parameters in drive EEPROM .................................................................................................13

3.3 Loading defaults ..................................................................................................................................14

3.4 SMARTCARD transfers .......................................................................................................................14

3.5 Electronic nameplate transfers ............................................................................................................14

3.6 Display non-default values or destination parameters .........................................................................14

4 Parameter description format.....................................................................................15

4.1 Parameter ranges and variable maximums: ........................................................................................16

4.2 Sources and destinations ....................................................................................................................17

4.3 Update rates ........................................................................................................................................18

5 Advanced parameter descriptions.............................................................................19

5.1 Overview ..............................................................................................................................................19

5.2 Feature look-up table ...........................................................................................................................20

5.3 Menu 1: Speed reference ....................................................................................................................22

5.4 Menu 2: Ramps ...................................................................................................................................34

5.5 Menu 3: Speed feedback and speed control .......................................................................................41

5.6 Menu 4: Torque and current control ....................................................................................................68

5.7 Menu 5: Motor control ..........................................................................................................................78

5.8 Menu 6: Sequencer and clock .............................................................................................................88

5.9 Menu 7: Analog I/O ..............................................................................................................................99

5.10 Menu 8: Digital I/O .............................................................................................................................108

5.11 Menu 8: Digital I/O .............................................................................................................................110

5.12 Menu 9: Programmable logic, motorized pot, binary sum and timers ................................................116

5.13 Menu 10: Status and trips ..................................................................................................................122

5.14 Menu 11: General drive set-up ..........................................................................................................144

5.15 Menu 12: Threshold detectors, variable selectors and brake control function ...................................156

5.16 Menu 13: Position control ..................................................................................................................166

5.17 Menu 14: User PID controller ............................................................................................................176

5.18 Menus 15 and 16: Solutions Module slots .........................................................................................181

5.19 Menu 17: Motion Processors .............................................................................................................182

5.20 Menu 18: Application menu 1 ............................................................................................................199

5.21 Menu 19: Application menu 2 ............................................................................................................200

5.22 Menu 20: Application menu 3 ............................................................................................................201

5.23 Menu 21: Second motor parameters .................................................................................................202

5.24 Menu 22: Additional menu 0 set-up ...................................................................................................208

Digitax ST Advanced User Guide 3

Issue Number: 3

Page 4

5.25 32 bit parameters .............................................................................................................................. 209

6 Serial communications protocol ............................................................................. 210

6.1 ANSI communications protocol ......................................................................................................... 210

6.2 CT Modbus RTU specification .......................................................................................................... 211

7 Electronic nameplate................................................................................................ 216

7.1 Motor object ...................................................................................................................................... 217

7.2 Performance objects ......................................................................................................................... 218

8 Performance .............................................................................................................. 220

8.1 Digital speed reference ..................................................................................................................... 220

8.2 Analog reference .............................................................................................................................. 220

8.3 Analog outputs .................................................................................................................................. 220

8.4 Digital inputs and outputs ................................................................................................................. 220

8.5 Current feedback .............................................................................................................................. 220

8.6 Bandwidth ......................................................................................................................................... 220

4 Digitax ST Advanced User Guide

Issue Number: 3

Page 5

Parameter

*

*

Moves

between

parameters

Moves between Menus

Menu 0

....XX.00....

0.50

0.49

0.48

0.47

0.46

0.01

0.02

0.03

0.04

0.05

M

e

n

u

2

2

M

e

n

u

1

M

e

n

u

2

M

e

n

u

2

1

2

2

.

2

9

2

2

.

2

8

2

2

.

2

7

2

2

.

2

6

2

2

.

2

5

2

2

.

0

1

2

2

.

0

2

2

2

.

0

3

2

2

.

0

4

2

2

.

0

5

1

.

0

1

1

.

0

2

1

.

0

3

1

.

0

4

1

.

0

5

1

.

5

0

1

.

4

9

1

.

4

8

1

.

4

7

1

.

4

6

Menu 0

0.04

0.05

0.06

Menu 2

2.21

Menu 1

1.14

Menu 4

4.07

5

0

150

0

150

5

structure

Keypad and display Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

1 Parameter structure

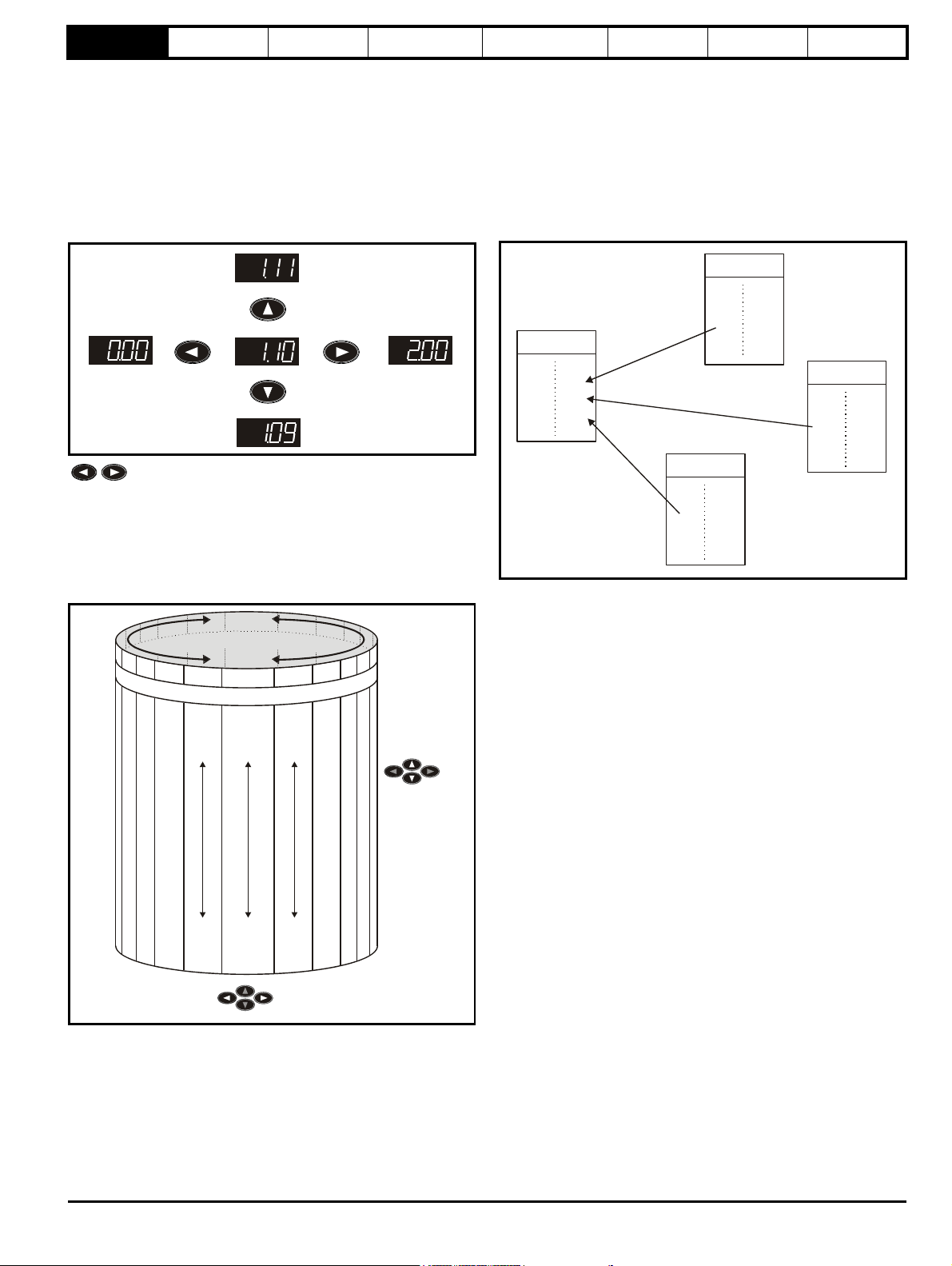

The drive parameter structure consists of menus and parameters.

The drive initially powers up so that only menu 0 can be viewed. The up

and down arrow buttons are used to navigate between parameters and

once level 2 access (L2) has been enabled in Pr 0.49, and the left and

right buttons are used to navigate between menus. For further

information, see section 2.7 Parameter access level and security on

page 11.

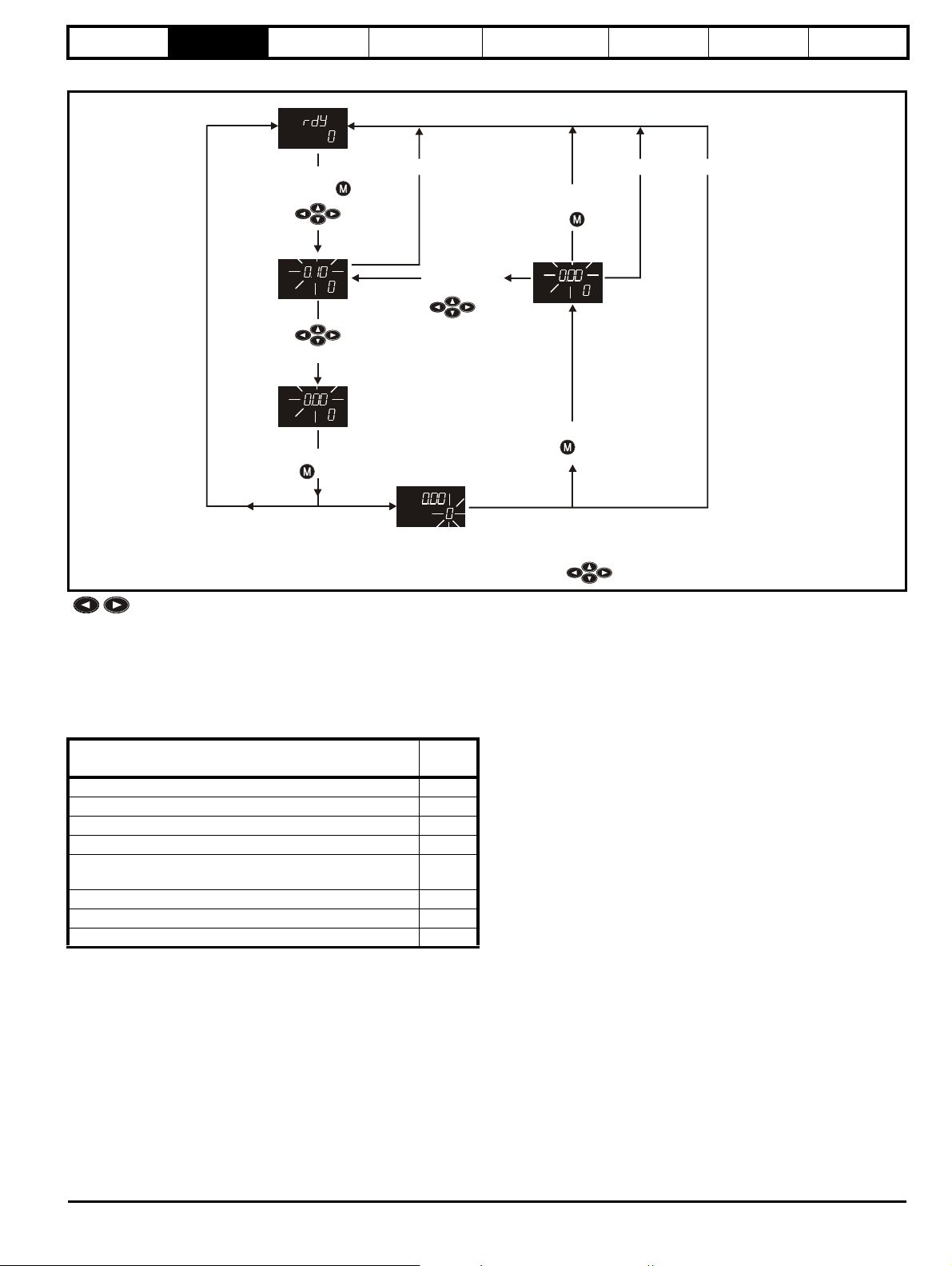

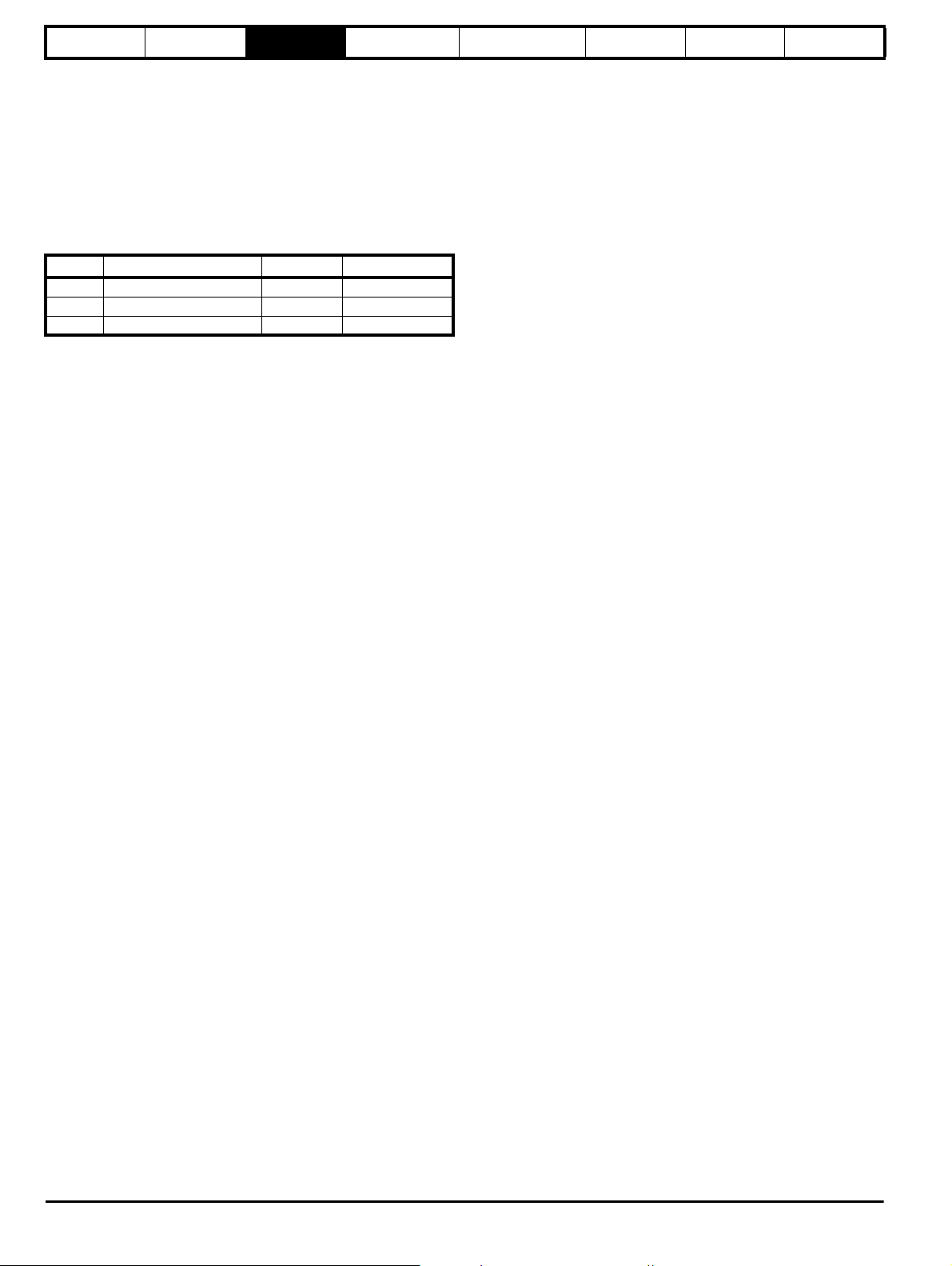

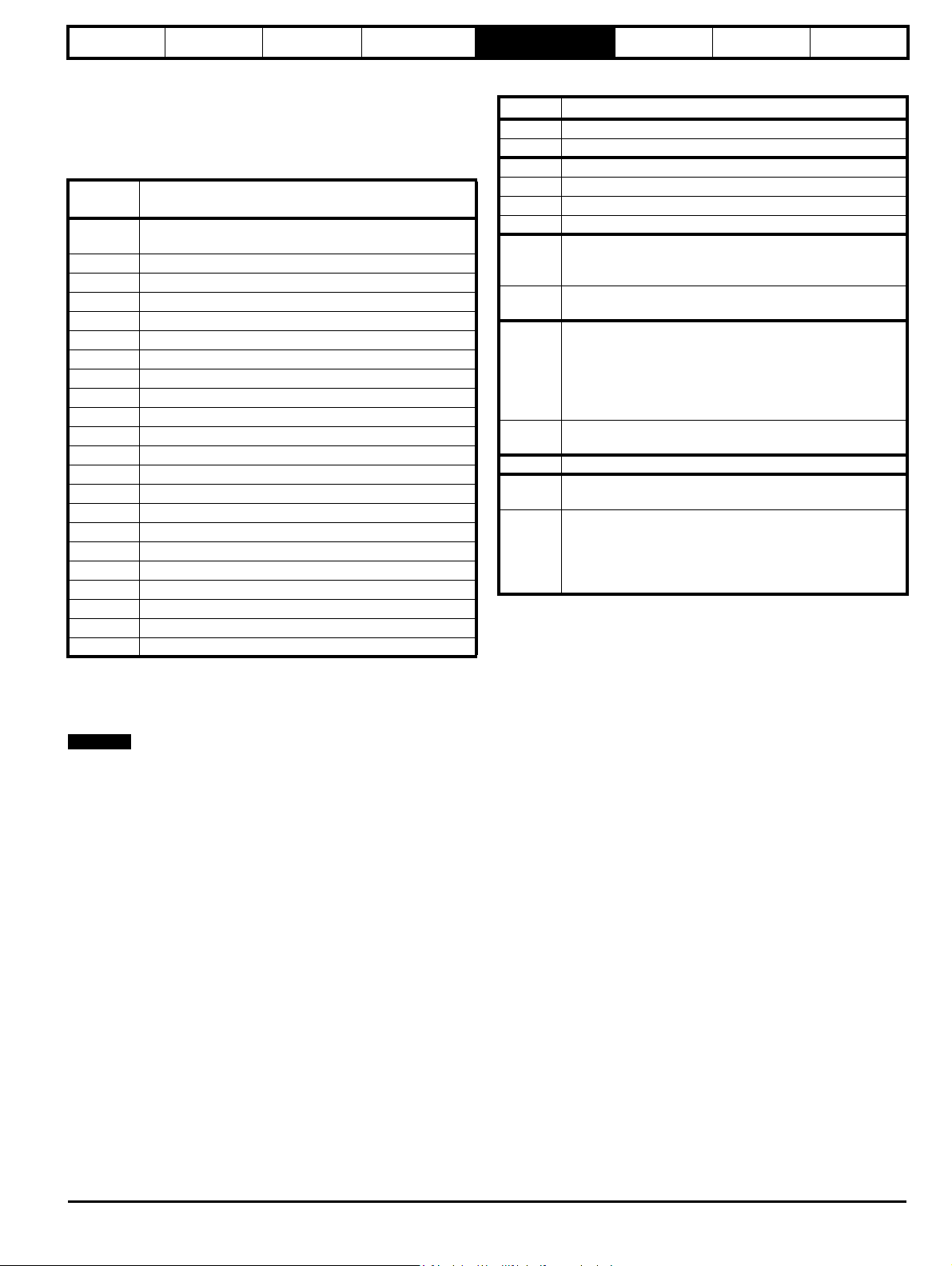

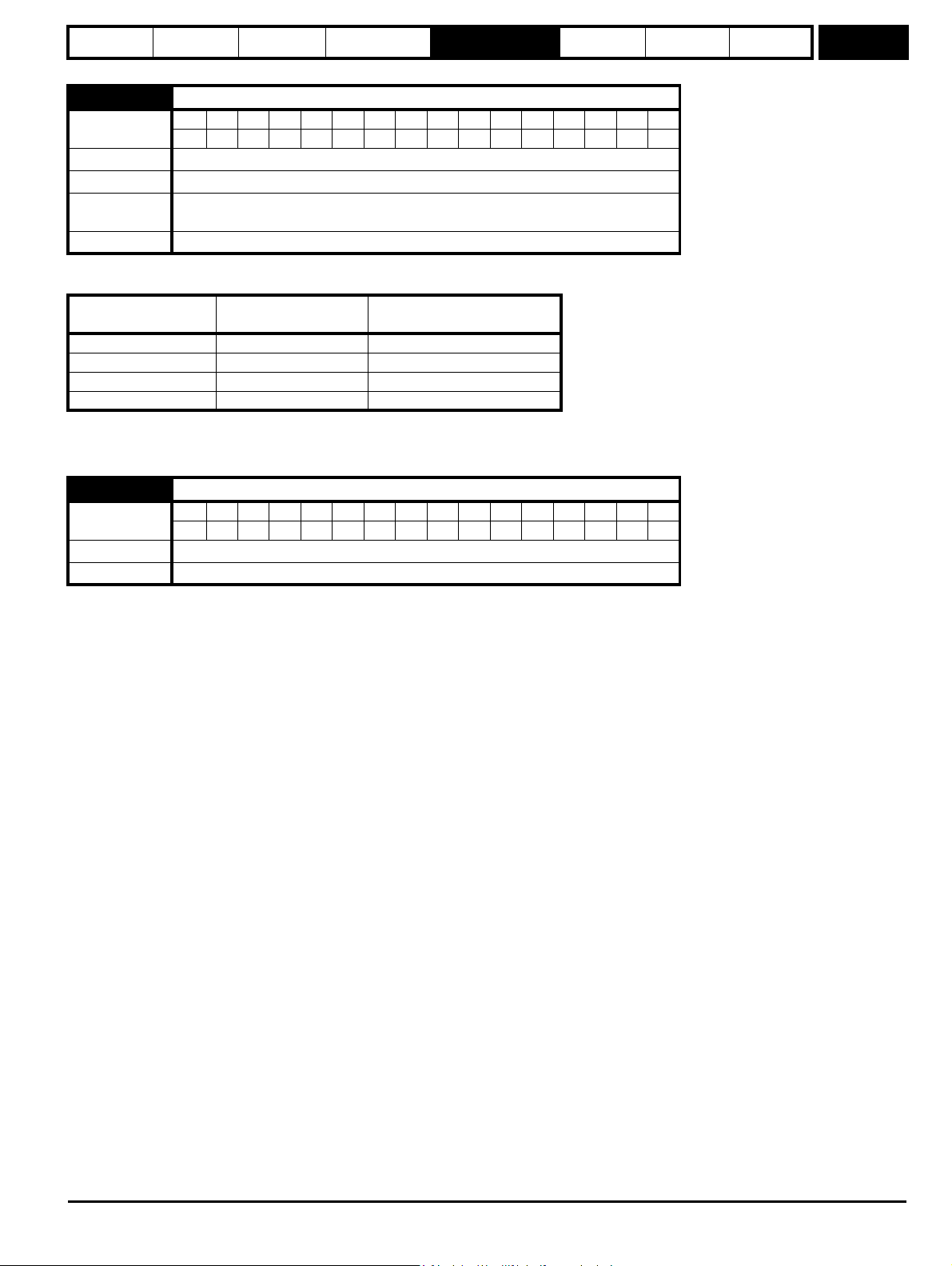

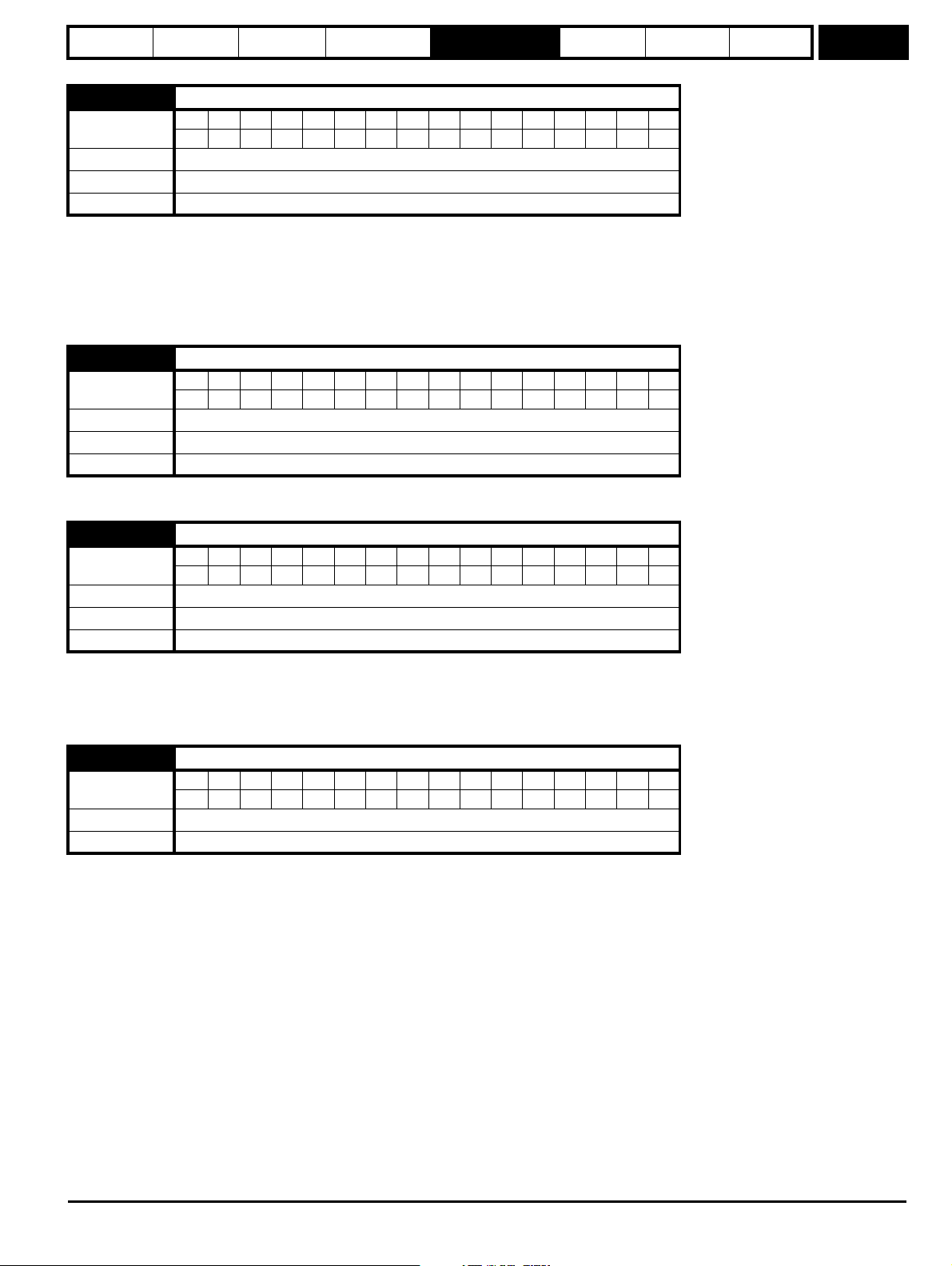

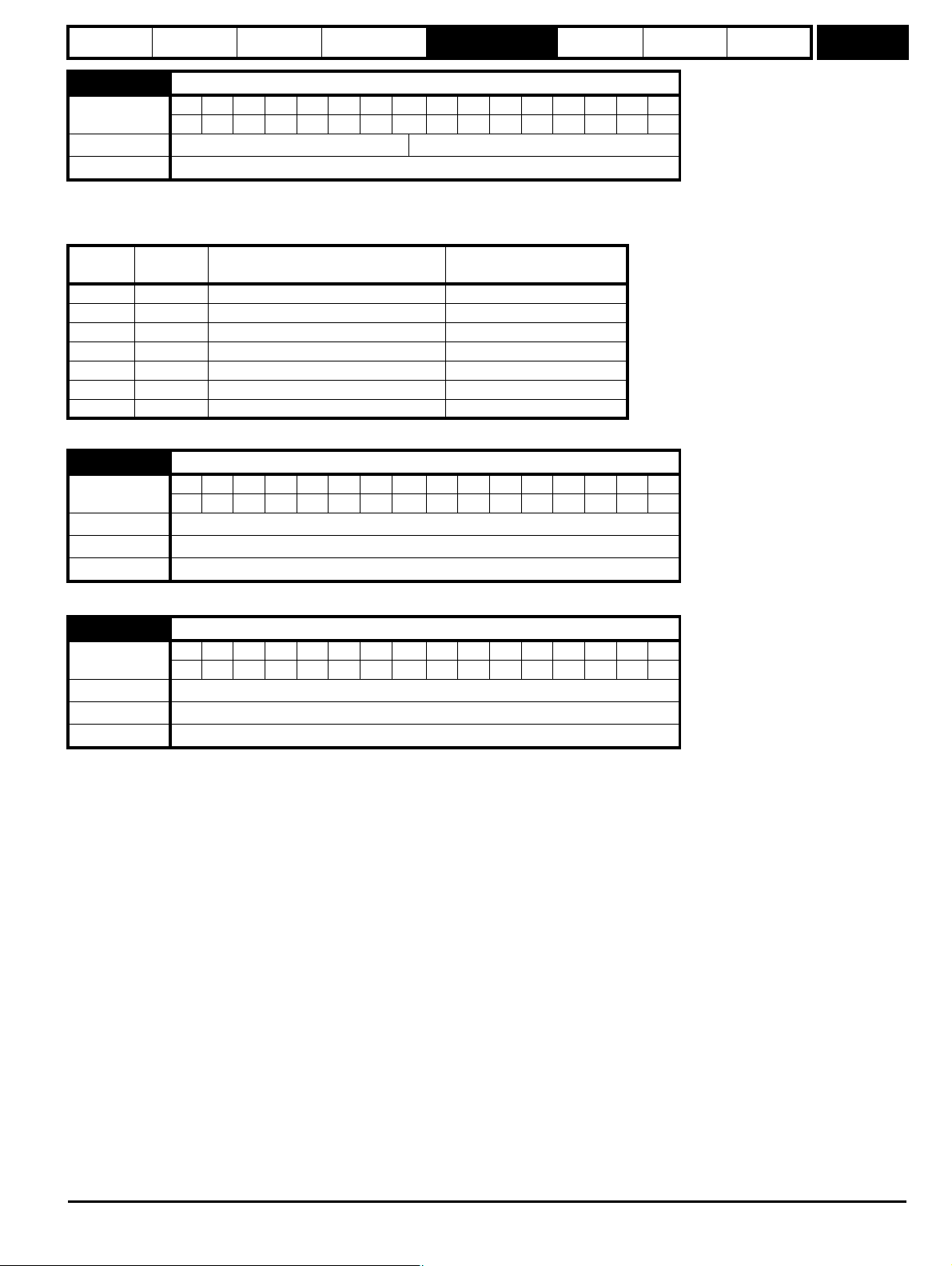

Figure 1-1 Parameter navigation

* can only be used to move between menus if L2 access

has been enabled (Pr 0.49).

The menus and parameters roll over in both directions; i.e. if the last

parameter is displayed, a further press will cause the display to rollover

and show the first parameter.

When changing between menus the drive remembers which parameter

was last viewed in a particular menu and thus displays that parameter.

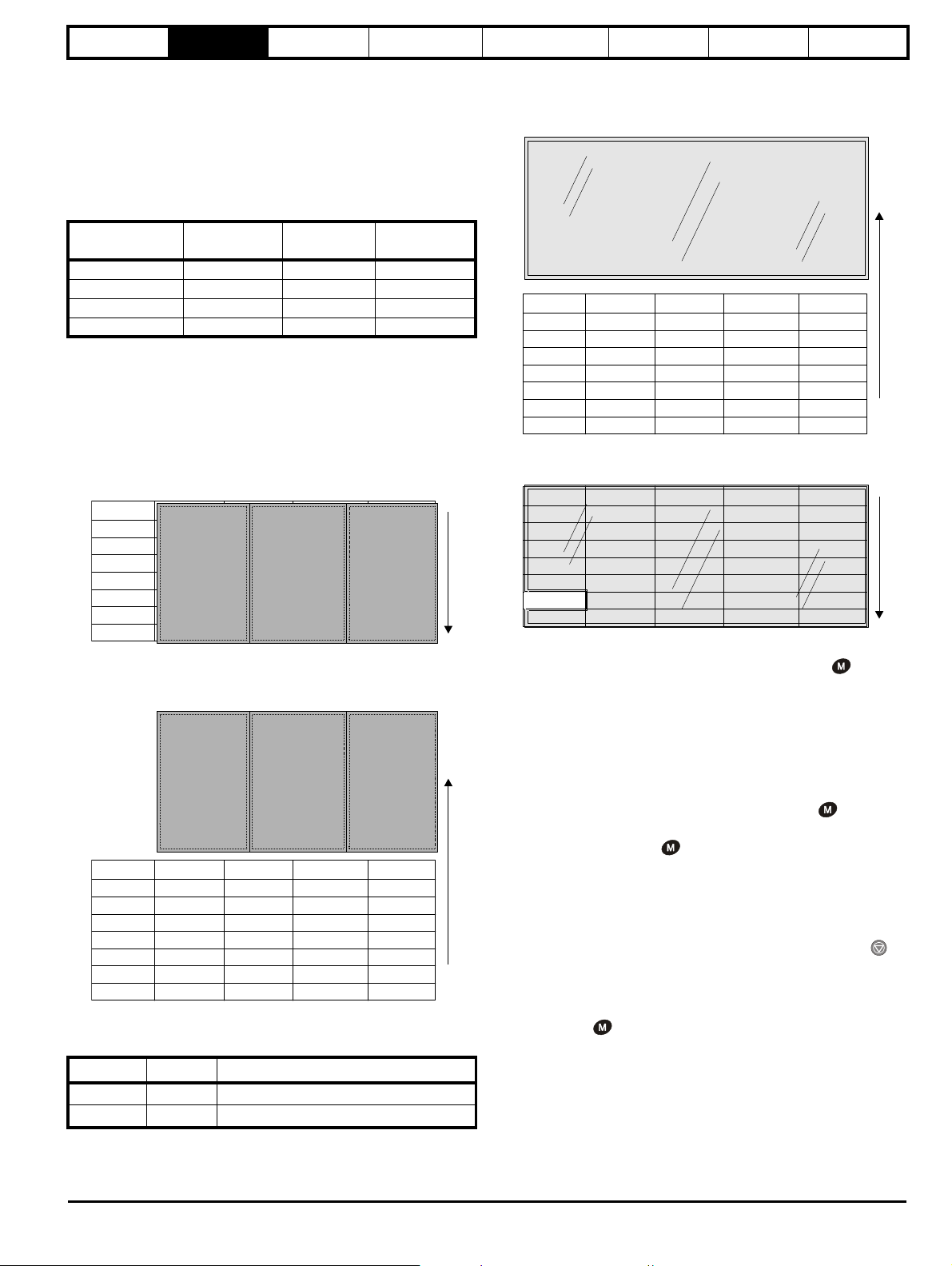

Figure 1-2 Menu structure

1.1 Menu 0

Menu 0 has up to 19 fixed parameters and 40 programmable parameters

that are defined in menu 11 and menu 22. Menu 0 parameters are

copies of advanced menu parameters, and although these parameters

are accessible via drive serial comms, they are not accessible to any

Solutions Modules. All menu 0 read/write parameters are saved on

exiting the edit mode. Table 1-1 gives the default structure for menu 0.

Where alternative parameters are selected with motor map 2 from menu

21 these are shown below the motor map 1 parameters.

Figure 1-3 Menu 0 copying

Menu 0 is used to bring together various commonly used parameters for

basic easy set up of the drive. All the parameters in menu 0 appear in

other menus in the drive (denoted by {…}).

Menus 11 and 22 can be used to change most of the parameters in

menu 0. Menu 0 can also contain up to 59 parameters by setting up

menu 22.

Digitax ST Advanced User Guide 5

Issue Number: 3

Page 6

Parameter

structure

Keypad and display Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

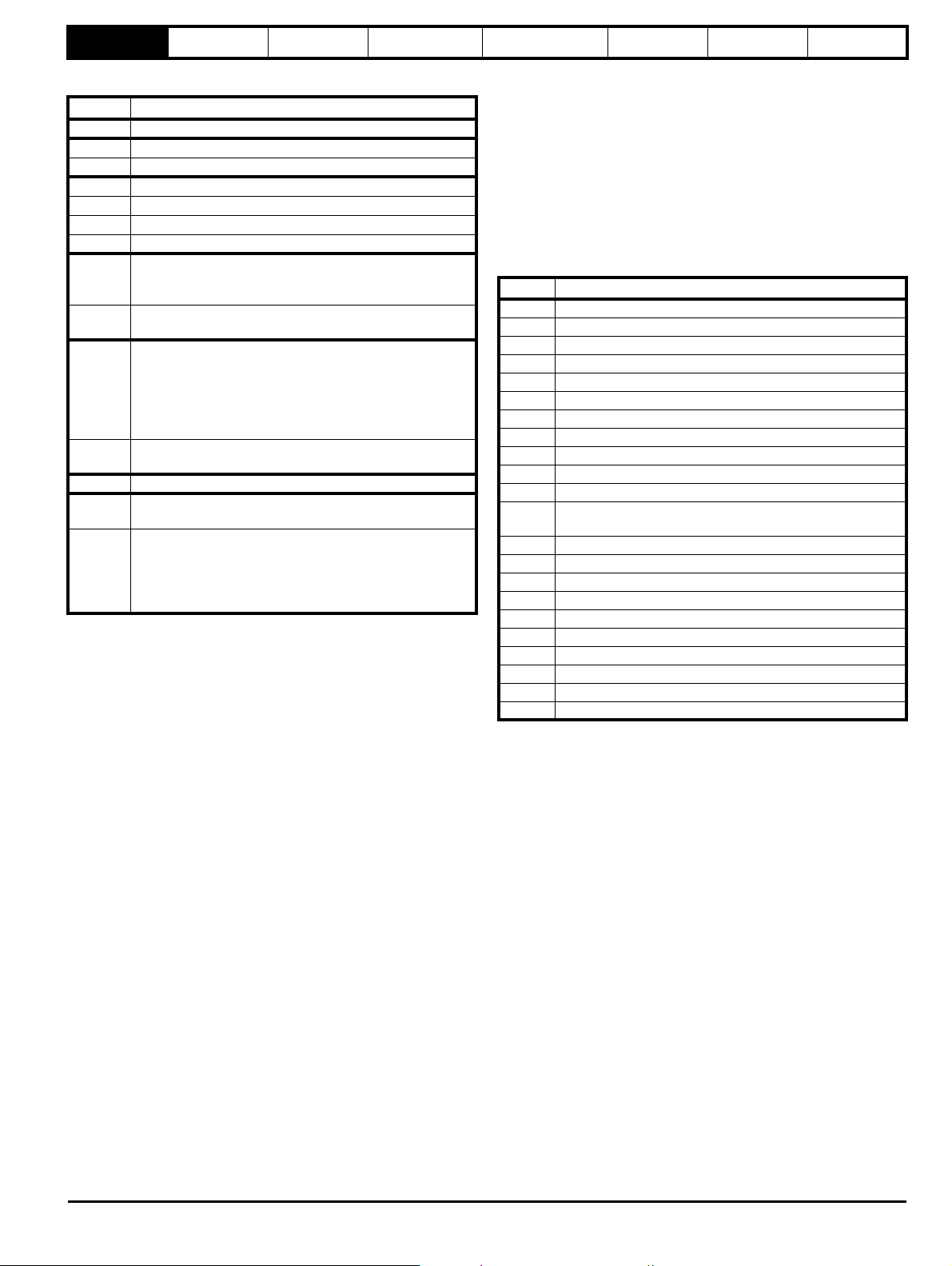

Table 1-1 Menu 0 parameters

Parameter

0.00 xx.00 {x.00} 0 to 32,767 0 RW Uni

0.01 Minimum reference clamp {1.07} ±SPEED_LIMIT_MAX rpm 0.0 RW Bi PT US

0.02 Maximum reference clamp {1.06} SPEED_LIMIT_MAX rpm 3,000.0 RW Uni

0.03 Acceleration rate

0.04 Deceleration rate {2.21}

0.05 Reference select {1.14}

0.06 Current limit {4.07} 0 to CURRENT_LIMIT_MAX % 300.0 RW Uni RA US

0.07 Speed controller P gain {3.10}

0.08 Speed controller I gain {3.11} 0.00 to 655.35 1/rad 1.00 RW Uni US

0.09 Speed controller D gain {3.12} 0.00000 to 0.65535 (s) 0.00000 RW Uni US

0.10 Motor speed {3.02} ±SPEED_MAX rpm

0.11 Drive encoder position {3.29}

0.12 Total motor current {4.01} 0 to Drive_current_max A

0.13

Analog input 1 offset trim

0.14 Torque mode selector {4.11} 0 to 4 Speed control mode (0) RW Uni US

0.15 Ramp mode select {2.04}

0.16 Ramp enable {2.02} OFF (0) or On (1) On (1) RW Bit US

Current demand filter time

0.17

constant

0.18 Positive logic select {8.29} OFF (0) or On (1) On (1) RW Bit PT US

0.19 Analog input 2 mode {7.11}

0.20 Analog input 2 destination {7.14}Pr 0.00 to Pr 21.51 Pr 1.37 RW Uni DE PT US

0.21 Analog input 3 mode {7.15}

0.22 Bipolar reference select {1.10} OFF (0) or On (1) OFF (0) RW Bit US

0.23 Jog reference {1.05} 0 to 4000.0 rpm 0.0 RW Uni US

0.24 Pre-set reference 1 {1.21} ±SPEED_LIMIT_MAX rpm 0.0 RW Bi US

0.25 Pre-set reference 2 {1.22} ±SPEED_LIMIT_MAX rpm 0.0 RW Bi US

0.26 Overspeed threshold {3.08} 0 to 40,000 rpm 0 RW Uni US

Drive encoder lines per

0.27

revolution

0.28 Keypad fwd/rev key enable {6.13} OFF (0) or On (1) OFF (0) RW Bit US

SMARTCARD parameter

0.29

data

0.30 Parameter copying {11.4 2} nonE (0), rEAd (1), Prog (2), AutO (3), boot (4) nonE (0) RW Txt NC *

0.31 Drive rated voltage {11.33} 200 (0), 400 (1)

0.32 Drive rated current {11.32} 0.00 to 9999.99A

0.34 User security code {11 .30}0 to 999 0 RWUniNCPTPS

0.35 Serial comms mode {11.24 } AnSI (0), rtu (1), Lcd (2) rtU (1) RW Txt US

0.36 Serial comms baud rate {11. 25}

0.37 Serial comms address {11 .23}0 to 247 1 RWUniUS

0.38 Current loop P gain {4.13} 0 to 30,000

0.39 Current loop I gain {4.14}

0.40 Autotune {5.12}0 to 6 0RWUni

Maximum switching

0.41

frequency

0.42 No. of motor poles {5.11} 0 to 60 (Auto to 120 pole) 6 POLE (3) RW Txt US

0.43 Encoder phase angle {3.25} 0.0 to 359.9° 0.0 RW Uni US

0.44 Motor rated voltage {5.09} 0 to AC_voltage_set_max V

0.45 Motor thermal time constant {4.15} 0.0 to 3000.0 20.0 RW Uni US

0.46 Motor rated current {5.07} 0 to Rated_current_max A Drive rated current [11. 32] RW Uni RA US

0.48 User drive mode {11.32 } SErVO (3) SErVO (3) RO Txt NC PT

0.49 Security status {11 .44} L1 (0), L2 (1), Loc (2)

0.50 Software version {11.29 } 1.00 to 99.99

0.51 Action on trip detection {10.37} 0 to 15 0 RW US

{2.11} 0.000 to 3,200.000

A1.A2 (0), A1.Pr (1), A2.Pr (2), Pr (3), PAd (4),

{7.07} ±10.000 % 0.000 RW Bi US

{4.12} 0.0 to 25.0 ms 0.0 RW Uni US

0-20 (0), 20-0 (1), 4-20tr (2), 20-4tr (3),

0-20 (0), 20-0 (1), 4-20tr (2), 20-4tr (3),

4-20 (4), 20-4 (5), VOLt (6), th.SC (7),

{3.34} 0 to 50,000 4096 RW Uni US

{11.36 } 0 to 999 0 RO Uni NC PT US

300 (0), 600 (1), 1200 (2), 2400 (3), 4800 (4),

{5.18} 3 (0), 4 (1), 6 (2), 8 (3), 12 (4) 6 (2) RW Txt RA US

Range(

Ú) Default(Ö)

s/1,000rpm

0.000 to 3,200.000

s/1,000rpm

Prc (5)

0.0000 to 6.5535 1/rad s

0 to 65,535

16

ths of a revolution

1/2

FASt (0)

Std ( 1)

4-20 (4), 20-4 (5), VOLt (6)

th (8), th.diSp (9)

9600 (5), 19200 (6), 38400 (7),

57600 (8) Modbus RTU only,

115200 (9) Modbus RTU only

0 to 30,000 200V drive: 1000

-1

0.200 RW Uni

0.200 RW Uni US

A1.A2 (0) RW Txt NC US

0.0100 RW Uni US

Std ( 1) RW Txt US

VOLt (6) RW Txt US

th (8) RW Txt PT US

19200 (6) RW Txt US

200V drive: 75

400V drive: 150

400V drive: 2000

200V drive: 230

400V drive: EUR> 400, USA> 460

RO Bi FI NC PT

RO Uni FI NC PT

RO Uni FI NC PT

RO Txt NC PT

RO Uni NC PT

RW Uni US

RW Uni US

RW Uni RA US

RW Txt PT US

RO Uni NC PT

Typ e

US

US

* Modes 1 and 2 are not user saved, modes 0, 3 and 4 are user saved

6 Digitax ST Advanced User Guide

Issue Number: 3

Page 7

Parameter

structure

Keypad and display Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

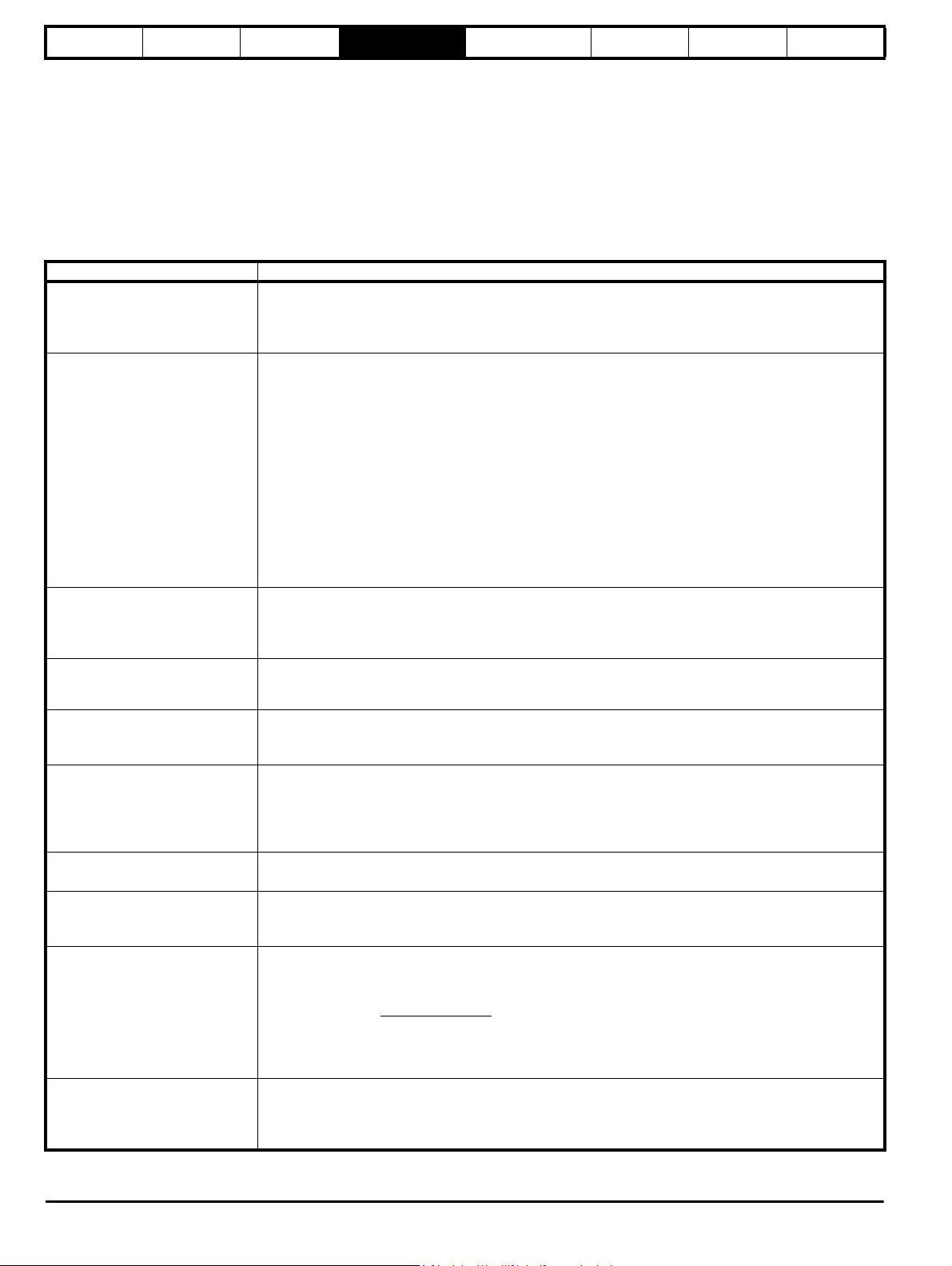

Table 1-2 Parameter type key 1.2 Advanced menus

Coding Attribute

{X.XX} Copied advanced parameter

RW Read/write: can be written by the user

RO Read only: can only be read by the user

Bit 1 bit parameter. ‘On’ or ‘OFF’ on the display

Bi Bipolar parameter

Uni Unipolar parameter

Txt Text: the parameter uses text strings instead of numbers.

Filtered: some parameters which can have rapidly changing

FI

values are filtered when displayed on the drive keypad for

easy viewing.

Destination: This parameter selects the destination of an

DE

input or logic function.

Rating dependent: this parameter is likely to have different

values and ranges with drives of different voltage and

current ratings. Parameters with this attribute will not be

RA

transferred to the destination drive by SMARTCARDs when

the rating of the destination drive is different from the

source drive and the file is a parameter file.

Not copied: not transferred to or from SMARTCARDs

NC

during copying.

PT Protected: cannot be used as a destination.

User save: parameter saved in drive EEPROM when the

US

user initiates a parameter save.

Power-down save: parameter automatically saved in drive

EEPROM when the under volts (UV) trip occurs.

PS

With software version V01.08.00 and later, power-down

save parameters are also saved in the drive when the user

initiates a parameter save.

The advanced menus consist of groups or parameters appropriate to a

specific function or feature of the drive. These are accessible via the

keypad, drive serial comms and Solutions Modules. All advanced menu

parameters are only saved by setting Pr x.00 to 1000 and applying a

reset (except parameters shown as power-down saved which are saved

automatically at power-down). The advanced menus are accessible

when the user selects L2 in Pr 11.44 (Pr 0.49 in menu 0). This can be

done even if security is programmed. Pr 11. 44 can be saved in

EEPROM so that either Menu 0 only, or Menu 0 and the advanced

menus are accessible at power-up.

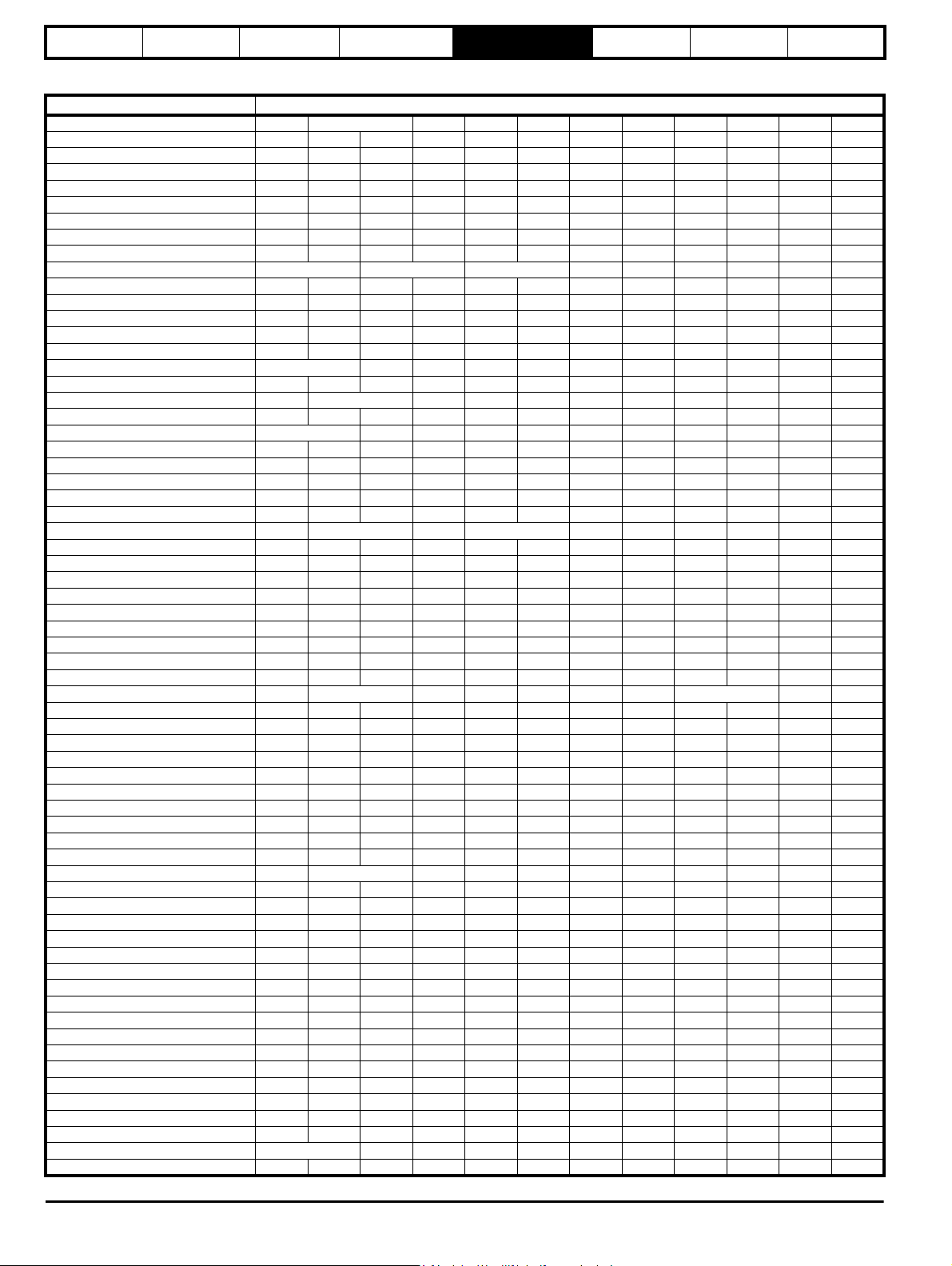

Table 1-3 Digitax ST menus

Menu Function

1 Speed reference selection, limits and filters

2Ramps

3 Speed feedback and control

4 Current control

5 Motor control

6 Sequencer and clock

7 Analog I/O

8 Digital I/O

9 Programmable logic and motorized pot

10 Drive status and trip information

11 Miscellaneous

Programmable threshold, variable selector and brake control

12

function

13 Position control

14 User PID controller

15 Slot 1 Solutions Module menu

16 Slot 2 Solutions Module menu

17 Motion Processor

18 User application menu 1 (saved in drive EEPROM)

19 User application menu 2 (saved in drive EEPROM)

20 User application menu 3 (not saved in drive EEPROM)

21 Second motor map

22 Additional menu 0 set-up

Electronic

nameplate

Performance

1.3 Solutions Modules

Any Solutions Module type is recognized with all drive types in any slots.

The relevant template is used to define menu 15 for the module type

installed in slot 1 and menu 16 for slot 2. The slot 3 is enclosed within

Digitax ST and cannot be physically accessed by the user.

1.4 Drive software version

This product is supplied with the latest software version. If this drive is to

be connected to an existing system or machine, all drive software

versions should be verified to confirm the same functionality as drives of

the same model already present. This may also apply to drives returned

from a Control Techniques Service Centre or Repair Centre. If there is

any doubt please contact the supplier of the product.

The software version of the drive can be checked by looking at Pr 11.29

and Pr 11.34. This takes the form of xx.yy.zz where Pr 11.29 displays

xx.yy and Pr 11.34 displays zz. (e.g. for software version 01.01.00,

Pr 11.29 = 1.01 and Pr 11.34 displays 0).

Digitax ST Advanced User Guide 7

Issue Number: 3

Page 8

Parameter

WARNING

Upper display

Lower display

Mode (black) button

Programming buttons

Stop/reset (red) button

Mode (black) button

Joypad

Fwd / Rev (blue) button

Stop/reset (red) button

Start (green) button

Control buttons

Help button

NOTE

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

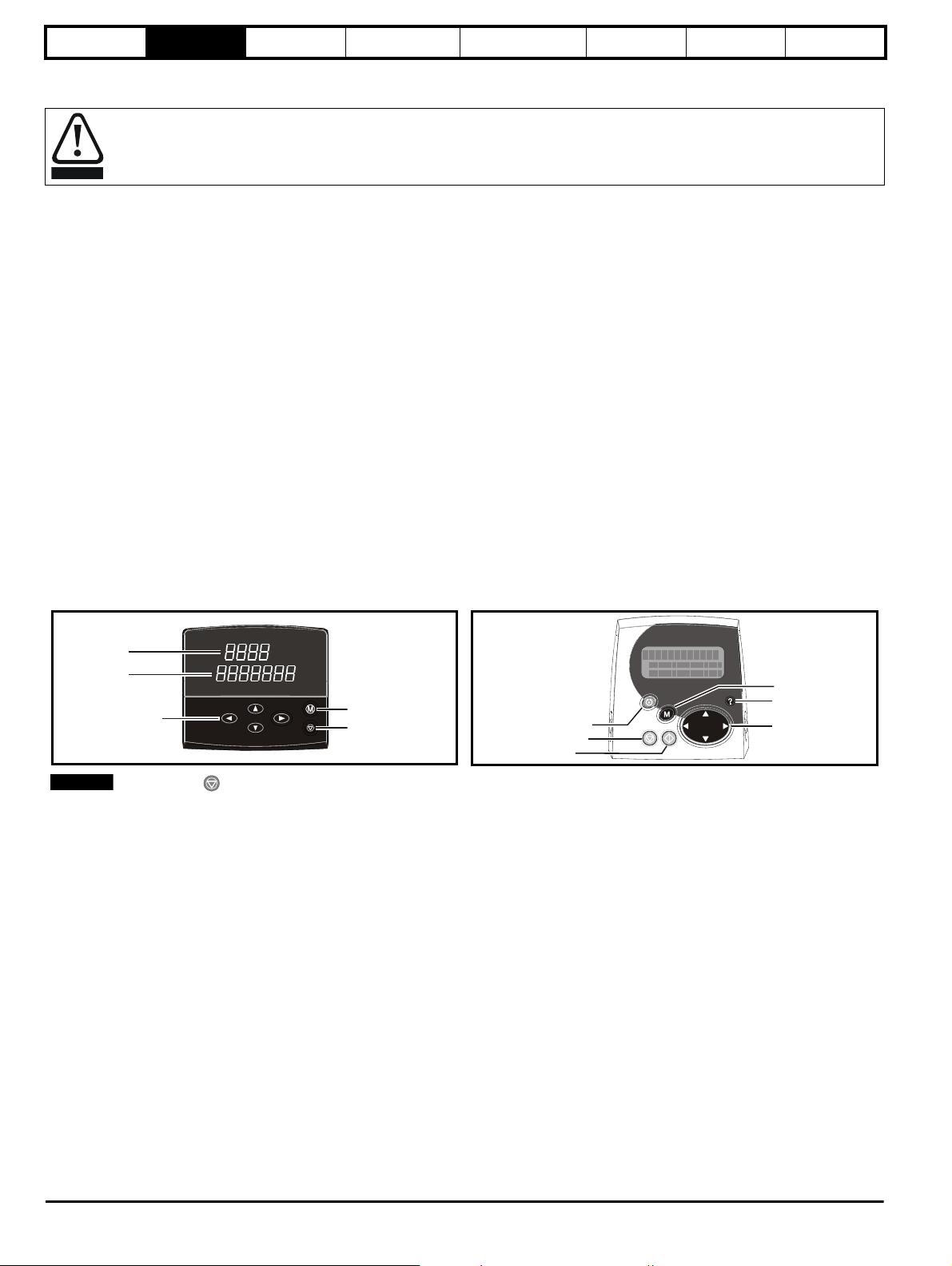

2 Keypad and display

Beware of possible live terminals when installing the keypad.

2.1 Understanding the display

There are two keypads available for the Digitax ST. The Digitax ST Keypad has an LED display and the SM-Keypad Plus has an LCD display. The

Digitax ST Keypad can be installed to the drive and the SM-Keypad Plus is remotely mounted on an enclosure door.

2.1.1 Digitax ST Keypad (LED)

The display consists of two horizontal rows of 7 segment LED displays.

The upper display shows the drive status or the current menu and

parameter number being viewed.

The lower display shows the parameter value or the specific trip type.

Figure 2-1 Digitax ST Keypad Figure 2-2 SM-Keypad Plus (remote mount only)

2.1.2 SM-Keypad Plus

The display consists of three lines of text.

The top line shows the drive status or the current menu and parameter

number being viewed on the left, and the parameter value or the specific

trip type on the right.

The lower two lines show the parameter name or the help text.

Features :

• Parameter names displayed

• Units displayed (Hz, A, rpm, %)

• Parameter help text

• Diagnostics help text

• 5 language support: (English, French, German, Spanish and Italian)

• Displays SM-Applications virtual parameters: Menus 70 to 91

• Hardware key using the SM-Keypad Plus as a key to modify the

drive set-up

• User defined parameter set

• Browsing filter

• Adjustable contrast

The red stop button is also used to reset the drive.

2.2 Keypad operation

2.2.1 Control buttons

The keypad consists of:

1. Programming buttons: used to navigate the parameter structure and change parameter values.

2. Mode button: used to change between the display modes – parameter view, parameter edit, status.

3. Reset button

4. Help button (Keypad Plus only) - displays text briefly describing the selected parameter.

5. Start, Fwd/Rev buttons (Keypad Plus only) - used to control the drive if Keypad mode is selected.

The Help button toggles between other display modes and parameter help mode. The up and down functions on the joypad scroll the help text to

allow the whole string to be viewed. The right and left functions on the joypad have no function when help text is being viewed.

The display examples in this section show the DST-Keypad 7 segment LED display. The examples are the same for the SM-Keypad Plus except

that the information displayed on the lower row on the DST-Keypad is displayed on the right hand side of the top row on the SM-Keypad Plus.

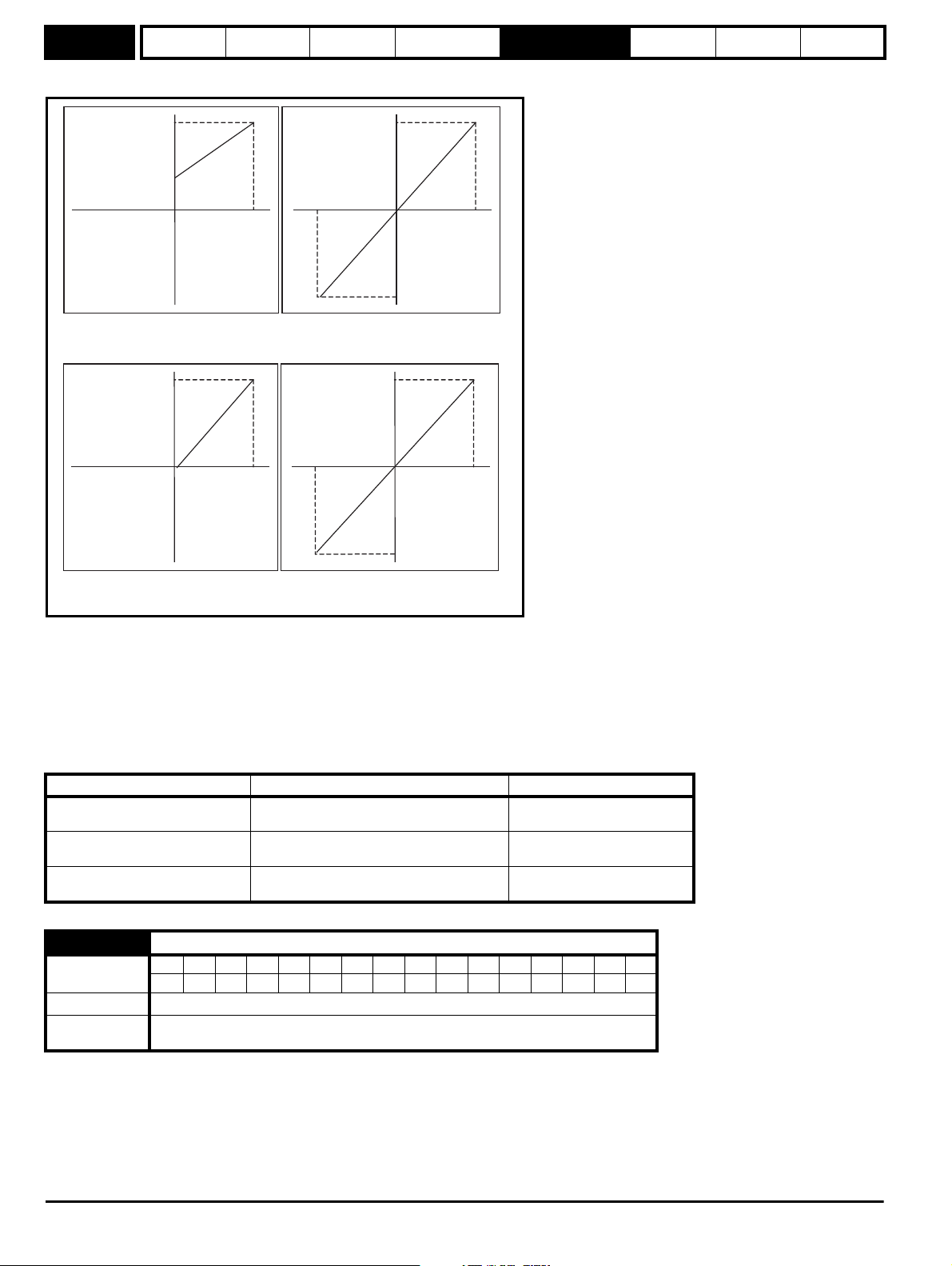

The drive parameters are accessed as shown in Figure 2-3.

8 Digitax ST Advanced User Guide

Issue Number: 3

Page 9

Parameter

Use

* keys

to select parameter for editing

To enter Edit Mode,

press key

Status

Mode

(Display

not

flashing)

Parameter

Mode

(Upper

display

flashing)

Edit Mode

(Character to be edited in lower line of display flashing)

Change parameter values

using keys.

When returning

to Parameter

Mode use the

keys to select

another parameter

to change, if

required

To exit Edit Mode,

press key

To enter Parameter

Mode, press key or

*

Temporary

Parameter

Mode

(Upper display

flashing)

Timeout**

Timeout**

Timeout**

To return to

Status Mode,

press

key

RO

parameter

R/W

parameter

structure

Keypad and

display

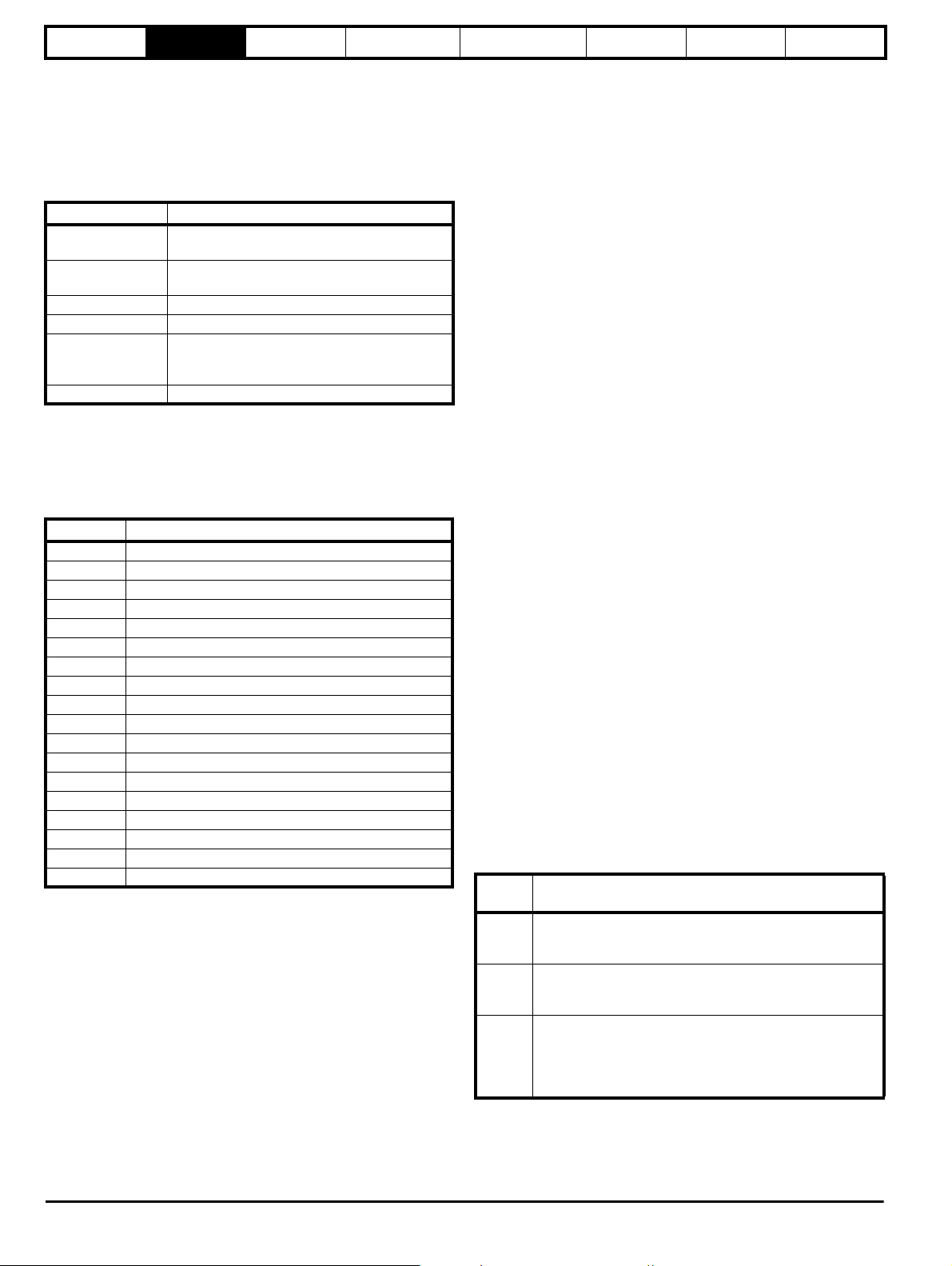

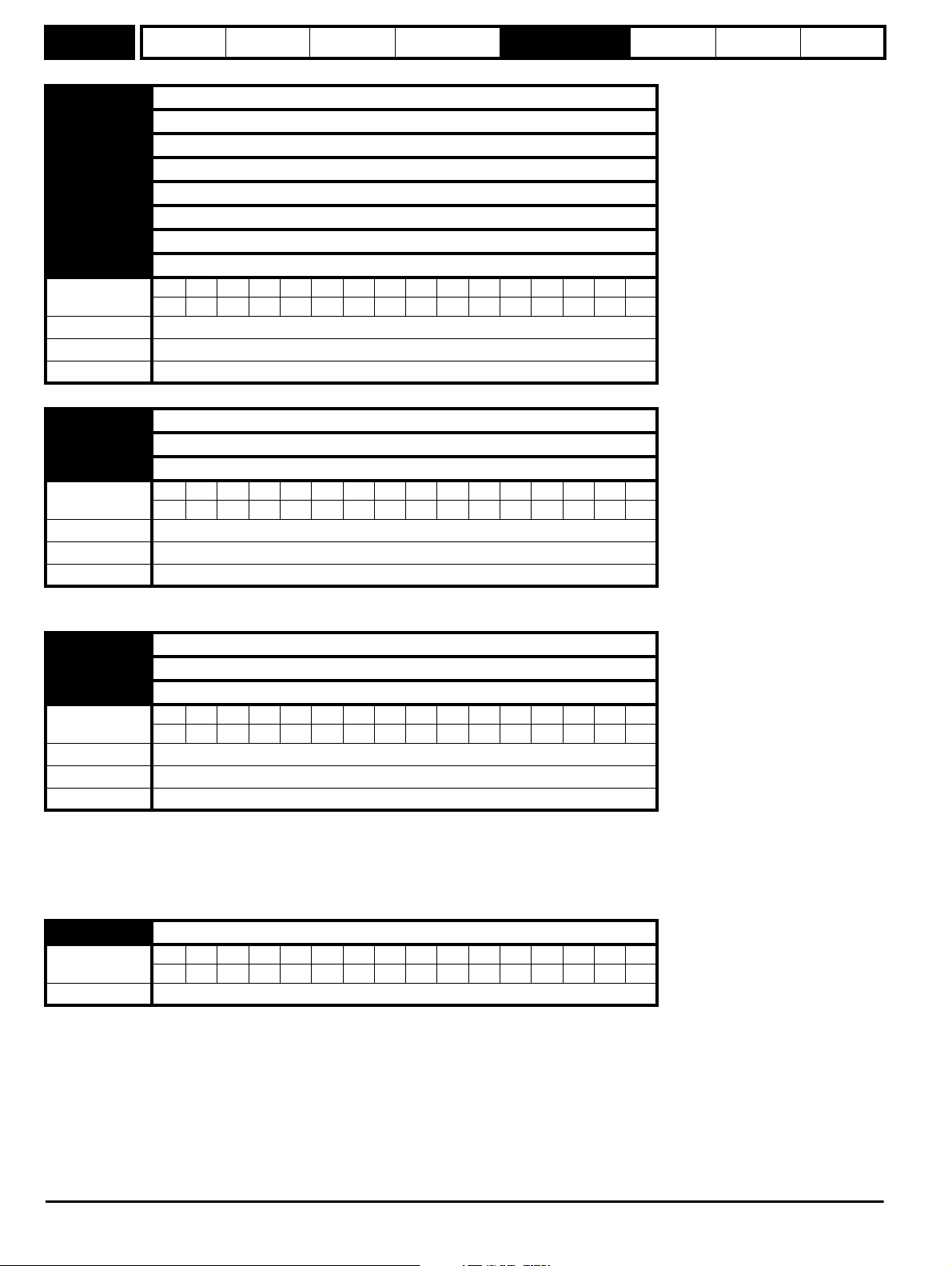

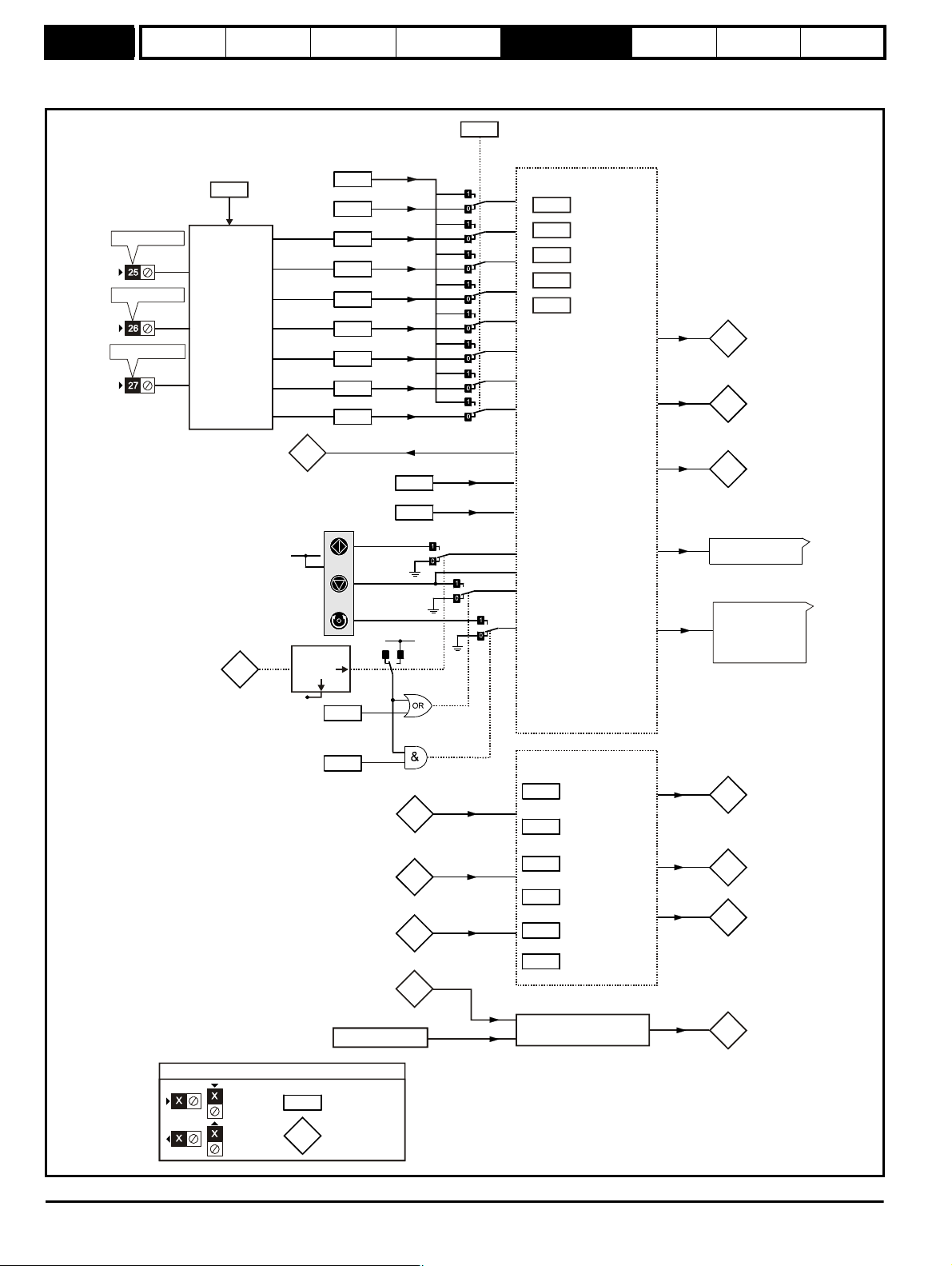

Figure 2-3 Display modes

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

2.3 Status mode

In status mode the 1st row shows a four letter mnemonic indicating the

status of the drive. The second row show the parameter last viewed or

edited.

State

Inhibited: enable input is inactive inh

Ready: enable closed, but inverter not active rdY

Stopped: inverter active, but holding zero speed StoP

Running: inverter active and motor running run

Mains loss: decelerating to zero in mains loss ride-through or

stop modes

Decelerating: speed is ramping to zero after a stop dEC

Position: position control active during orientation stop POS

Tripped: drive is tripped triP

2.4 Parameter view mode

In this mode the 1st row shows the menu.parameter number and the 2nd

row the parameter value. The 2nd row gives a parameter value range of

-999,999 to 9,999,999 with or without decimal points. (32 bit parameters

can have values outside this range if written by an application module. If

the value is outside this range “-------“ is shown and the parameter value

cannot be changed from the keypad.) The Up and Down keys are used

to select the parameter and the Left and Right keys are used to select

the menu. In this mode the Up and Down keys are used to select the

parameter within the selected menu. Holding the Up key will cause the

parameter number to increment until the top of the menu is reached. A

single Up key action when the last parameter in a menu is being

displayed will cause the parameter number to roll over to Pr x.00.

Digitax ST Advanced User Guide 9

Issue Number: 3

*Can only be used to move between menus if L2 access has been enabled (Pr 0.49). Refer to section 2.7 Parameter access level

and security on page 11.

**Timeout defined by Pr 11.4 1 (default value = 240 s).

Similarly holding the Down key will cause the parameter number to

decrement until Pr x.00 is reached and a single Down key action will

cause the parameter number to roll under to the top of the menu.

Pressing the Up and Down keys simultaneously will select Pr x.00 in the

currently selected menu.

Upper

row

The Left and Right keys are used to select the required menu (provided

the security has been unlocked to allow access to menus other than 0).

Holding the Right key will cause the menu number to increment until the

Menu 22 is reached. A single Right key action when Menu 22 is being

displayed will cause the menu number to roll over to 0. Similarly holding

the Left key will cause the menu number to decrement to 0 and a single

key action will cause the menu number to roll under to Menu 22.

Pressing the Left and Right keys simultaneously will select Menu 0.

The drive remembers the parameter last accessed in each menu such

that when a new menu is entered the last parameter viewed in that menu

will re-appear.

2.5 Edit mode

Up and Down keys are used to increase and decrease parameter values

respectively. If the maximum value of a parameter is greater than 9 and it

is not represented by strings, then the Left and Right keys can be used

to select a digit to adjust. The number of digits which can be

independently selected for adjustment depends on the maximum value

of the parameter. Pressing the Right key when the least significant digit

ACUU

is selected will cause the most significant digit to be selected, and viceversa if the Left key is pressed when the most significant digit is

selected. When a digit value is not being changed by the Up or Down

keys the selected digit flashes to indicate which one is currently

selected. For string type parameters the whole string flashes when

adjustment is not occurring because there is no digit selection.

During adjustment of a parameter value with the Up or Down keys the

display does not flash, providing the parameter value is in range, such

Page 10

Parameter

structure

that the user can see the value being edited without interruption.

Adjustment of a numerical value can be done in one of two ways; firstly

by using the Up and Down keys only, the selected digit remaining the

least significant digit; and secondly by selecting each digit in turn and

adjusting them to the required value. Holding the Up or Down key in the

first method will cause the parameters value to change more rapidly the

longer the key is held, until such time that the parameters maximum or

minimum is reached. However with the second method an increasing

rate of change does not take place when adjusting any other digit other

than the least significant digit since a digit can only have one of 10

different values. Holding the Up or Down will cause an auto repeat and

roll over to more significant digits but the rate of change is unaltered. If

the maximum or minimum is exceeded when adjusting any other digit

than the least significant one, the maximum value will flash on the

display to warn the user that the maximum or minimum has been

reached. If the user releases the Up or Down key before the flashing

stops the last in range value will re-appear on the display. If the Up or

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Down key is held the display will stop flashing after 3 seconds and the

maximum value will be written to the parameter.

Parameters can be set to 0 by pressing the Up and Down keys

simultaneously.

2.6 SM-Keypad Plus

All SM-Keypad Plus displays built after data code N10 have software

version 4.02.00 programmed and support 5 languages (English, French,

German, Spanish and Italian) in addition to a user defined parameter set.

This software also gives the user access to two menus for SM-Keypad

Plus. Menu 40 is for SM-Keypad Plus set up, menu 41 selects commonly

used parameters for quick browsing.

Keypads built prior to N10 only support one user defined extra

parameter set only.

The SM-Keypad Plus contains two menus, menu 40 and menu 41. The

parameters in these menus are listed below.

Table 2-1 Menu 40 parameter descriptions

Parameter

Range(

Ú) Default(Ö)

40.00 Parameter 0 0 to 32767 0 RW Uni

English (0), Custom (1),

40.01 Language selection

French (2), German (3),

English (0) RW Txt US

Spanish (4), Italian (5)

40.02 Software version

40.03 Save to flash

40.04 LCD contrast

Drive and attribute database upload was

40.05

bypassed

Idle (0), Save (1), Restore (2),

999999 RO Uni PT

Default (3)

Idle (0) RW Txt

0 to 31 16 RW Uni US

Updated (0), Bypass (1) RO Txt PT

40.06 Browsing favourites control Normal (0), Filter (1) Normal (0) RW Txt

40.07 Keypad security code

40.08 Communication channel selection

40.09 Hardware key code

40.10 Drive node ID (Address)

40.11 Flash ROM memory size

40.19 String database version number

40.20 Screen saver strings and enable

40.21 Screen saver interval

40.22 Turbo browse time interval

Disable (0), Slot1 (1), Slot2 (2),

Slot3 (3), Slave (4), Direct (5)

None (0), Default (1), User (2) Default (1) RW Txt US

0 to 999 0RWUniUS

Disable (0) RW Txt US

0 to 999 0RWUniUS

0 to 255 1RWUniUS

4Mbit (0), 8Mbit (1) RO Txt PT US

0 to 999999 RO Uni PT

0 to 600 120 RW Uni US

0 to 200ms 50ms RW Uni US

Performance

Typ e

Table 2-2 Menu 41 parameter descriptions

Parameter

Range(

Ú) Default(Ö)

Typ e

41.00 Parameter 0 0 to 32767 0 RW Uni

41.01

to

Browsing filter source F01 to F50 Pr 0.00 to Pr 391.51 0RWUni

41.50

41.51 Browsing favourites control Normal (0), Filter (1) Normal (0) RW Txt

RW Read / Write RO Read only Uni Unipolar Bi Bi-polar

Bit Bit parameter Txt Text string FI Filtered DE Destination

NC Not copied RA Rating dependent PT Protected US User save

PS Power down save

For more information about the SM-Keypad Plus, see the SM-Keypad Plus User Guide.

10 Digitax ST Advanced User Guide

Issue Number: 3

Page 11

Parameter

Pr 0.00

Pr 0.01

Pr 0.02

Pr 0.03

Pr 0.49

Pr 0.50

Pr 1.00

Pr 1.01

Pr 1.02

Pr 1.03

Pr 1.49

Pr 1.50

Pr 22.00

Pr 22.01

Pr 22.02

Pr 22.03

Pr 22.28

Pr 22.29

............

............

............

............

............

............

............

............

L2 access selected

- All parameters visible

Pr 0.00

Pr 0.01

Pr 0.02

Pr 0.03

Pr 0.49

Pr 0.50

Pr 1.00

Pr 1.01

Pr 1.02

Pr 1.03

Pr 1.49

Pr 1.50

Pr 19.00

Pr 19.01

Pr 19.02

Pr 19.03

Pr 19.49

Pr 19.50

Pr 20.00

Pr 20.01

Pr 20.02

Pr 20.03

Pr 20.49

Pr 20.50

............

............

............

............

............

............

............

............

L1 access selected

- Menu 0 only visible

Pr 21.00

Pr 21.01

Pr 21.02

Pr 21.03

Pr 21.30

Pr 21.31

Pr 0.00

Pr 0.01

Pr 0.02

Pr 0.03

Pr 0.50

Pr 1.00

Pr 1.01

Pr 1.02

Pr 1.03

Pr 1.49

Pr 1.50

............

............

............

............

............

............

............

............

Pr 0.00

Pr 0.01

Pr 0.02

Pr 0.03

Pr 0.49

Pr 0.50

Pr 1.00

Pr 1.01

Pr 1.02

Pr 1.03

Pr 1.49

Pr 1.50

Pr 22.00

Pr 22.01

Pr 22.02

Pr 22.03

Pr 22.28

Pr 22.29

............

............

............

............

............

............

............

............

User security open

- All parameters: Read / Write access

User security closed

0.49 11.44

- All parameters: Read Only access

(except Pr and Pr )

Pr 22.00

Pr 22.01

Pr 22.02

Pr 22.03

Pr 22.28

Pr 22.29

Pr 0.49

Pr 21.00

Pr 21.01

Pr 21.02

Pr 21.03

Pr 21.30

Pr 21.31

Pr 21.00

Pr 21.01

Pr 21.02

Pr 21.03

Pr 21.30

Pr 21.31

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

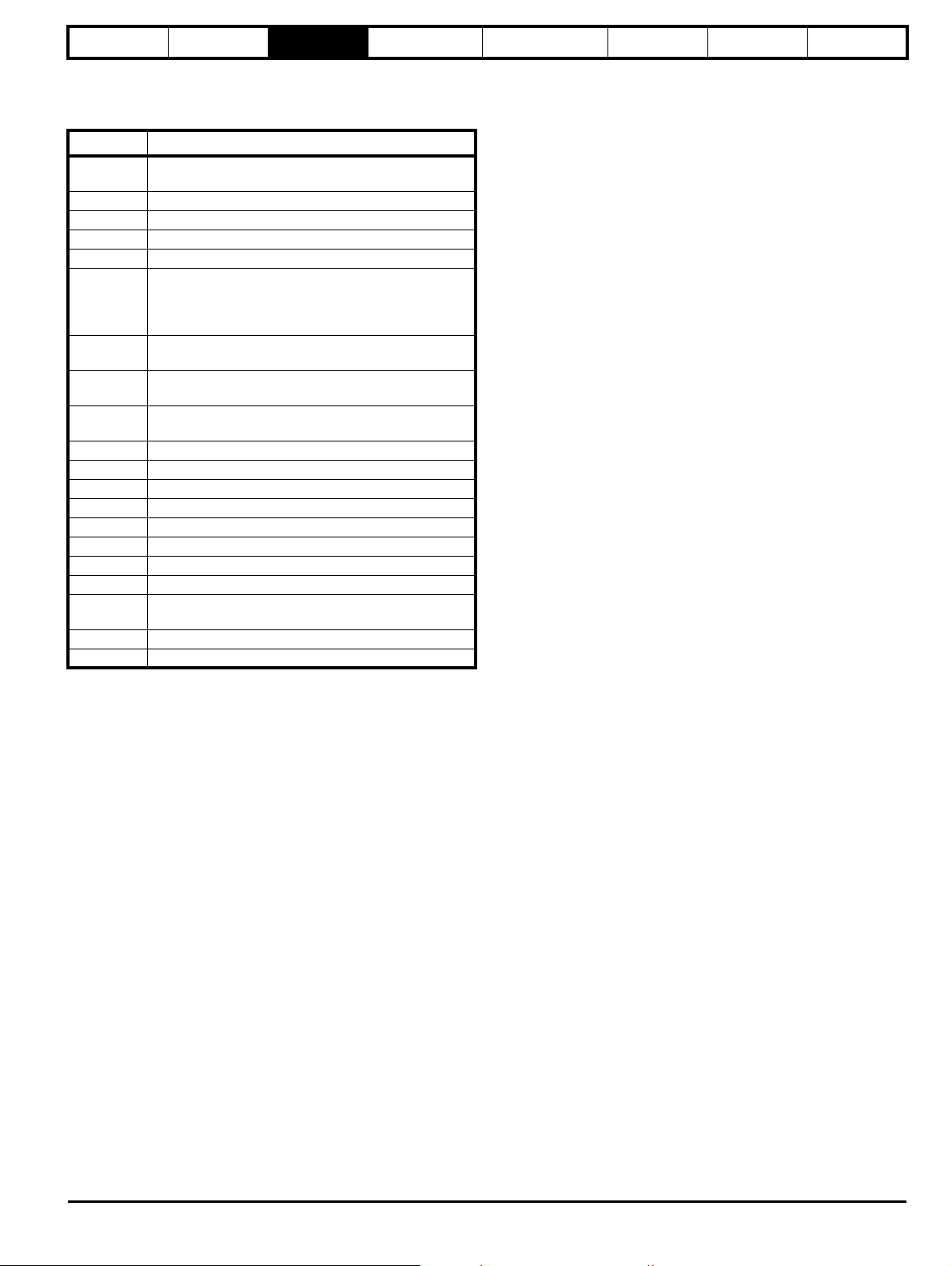

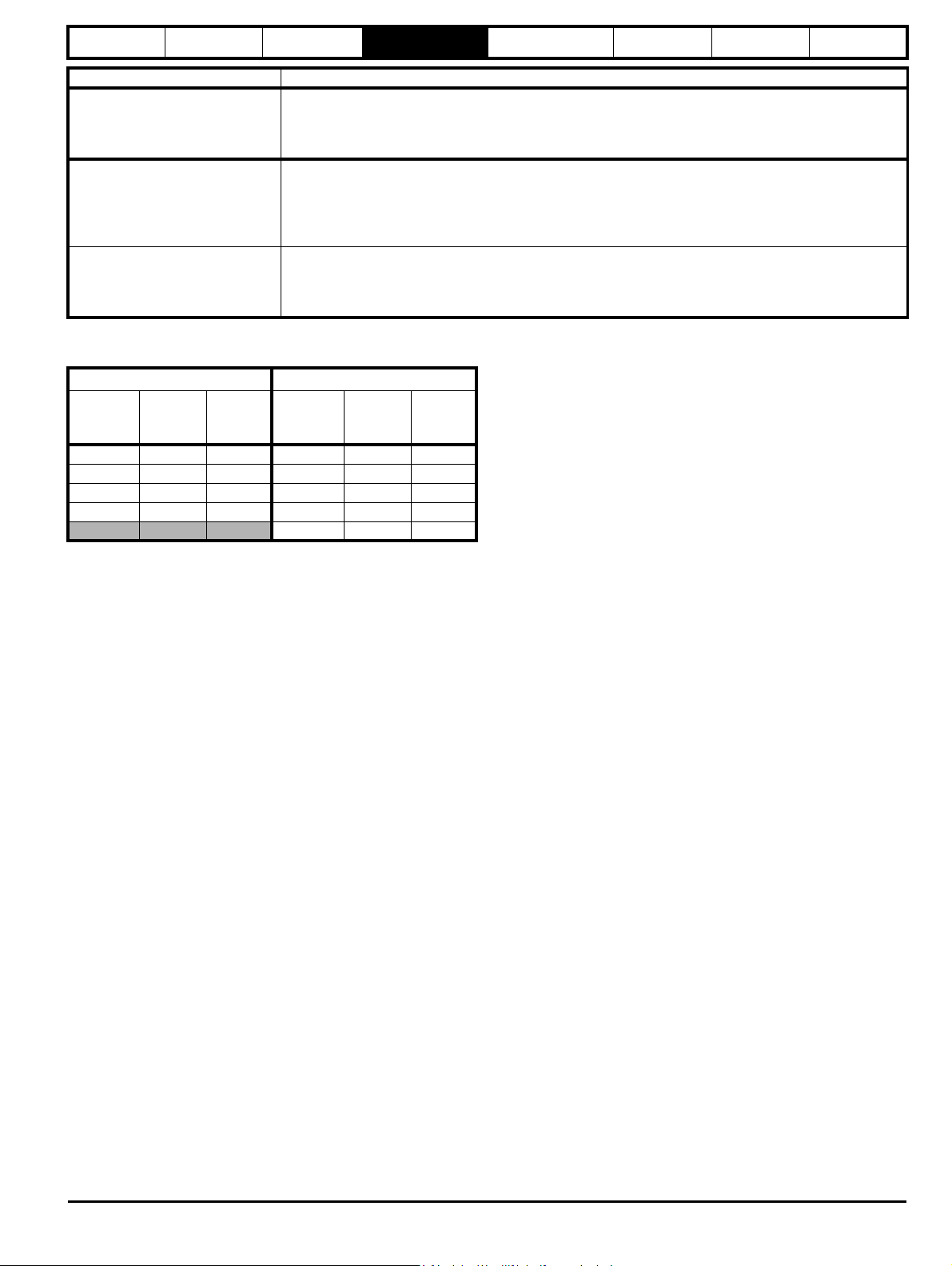

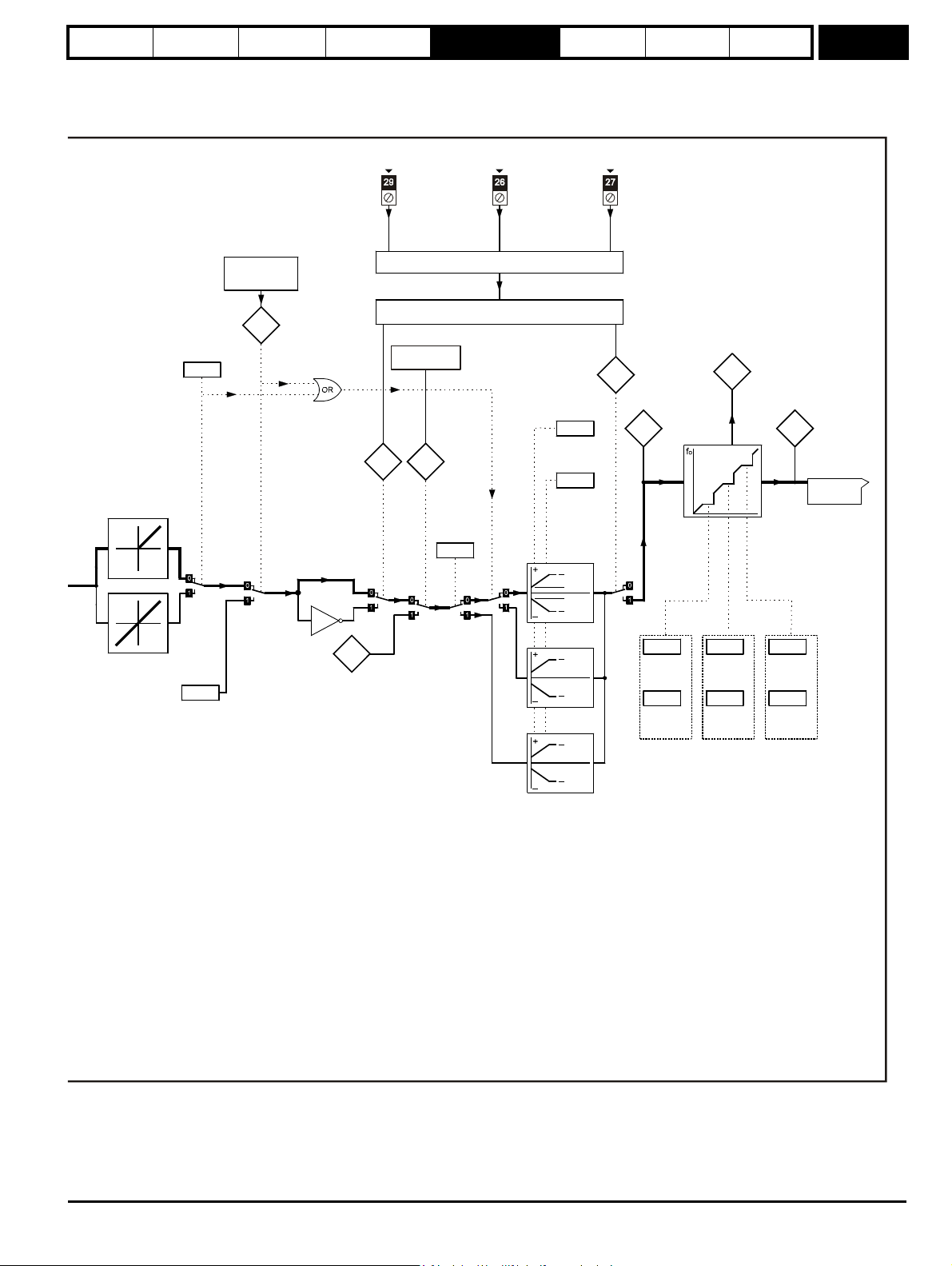

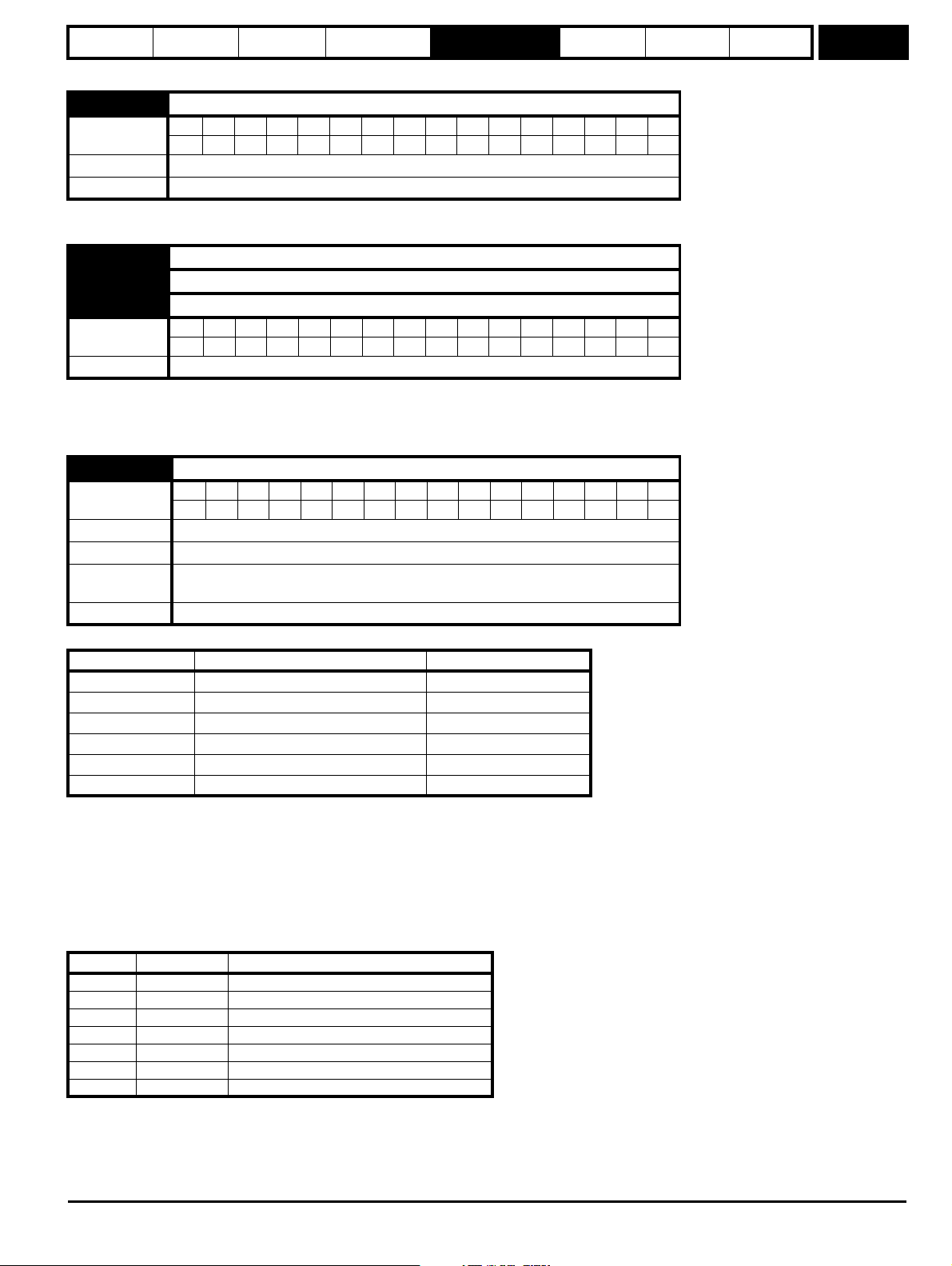

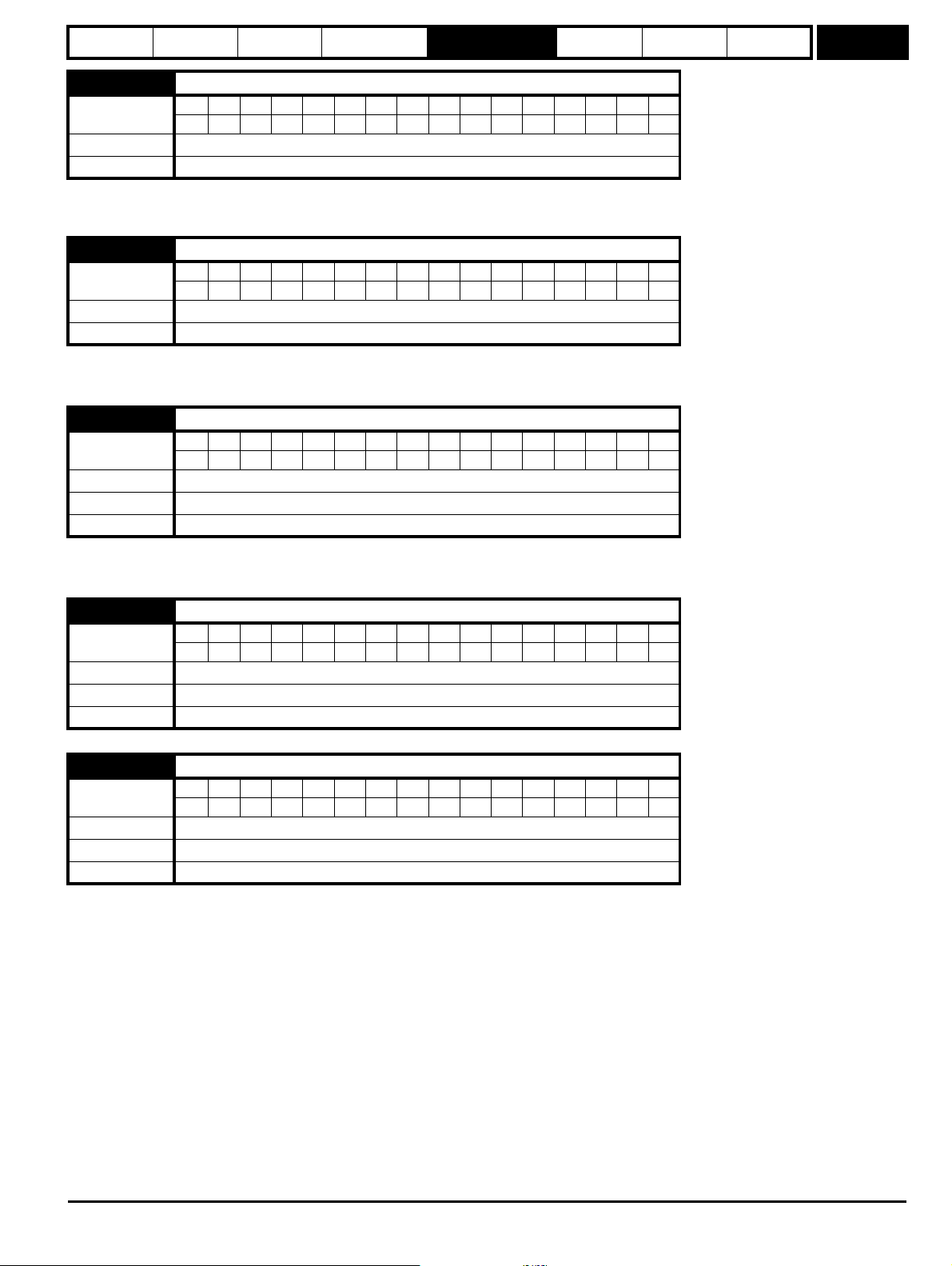

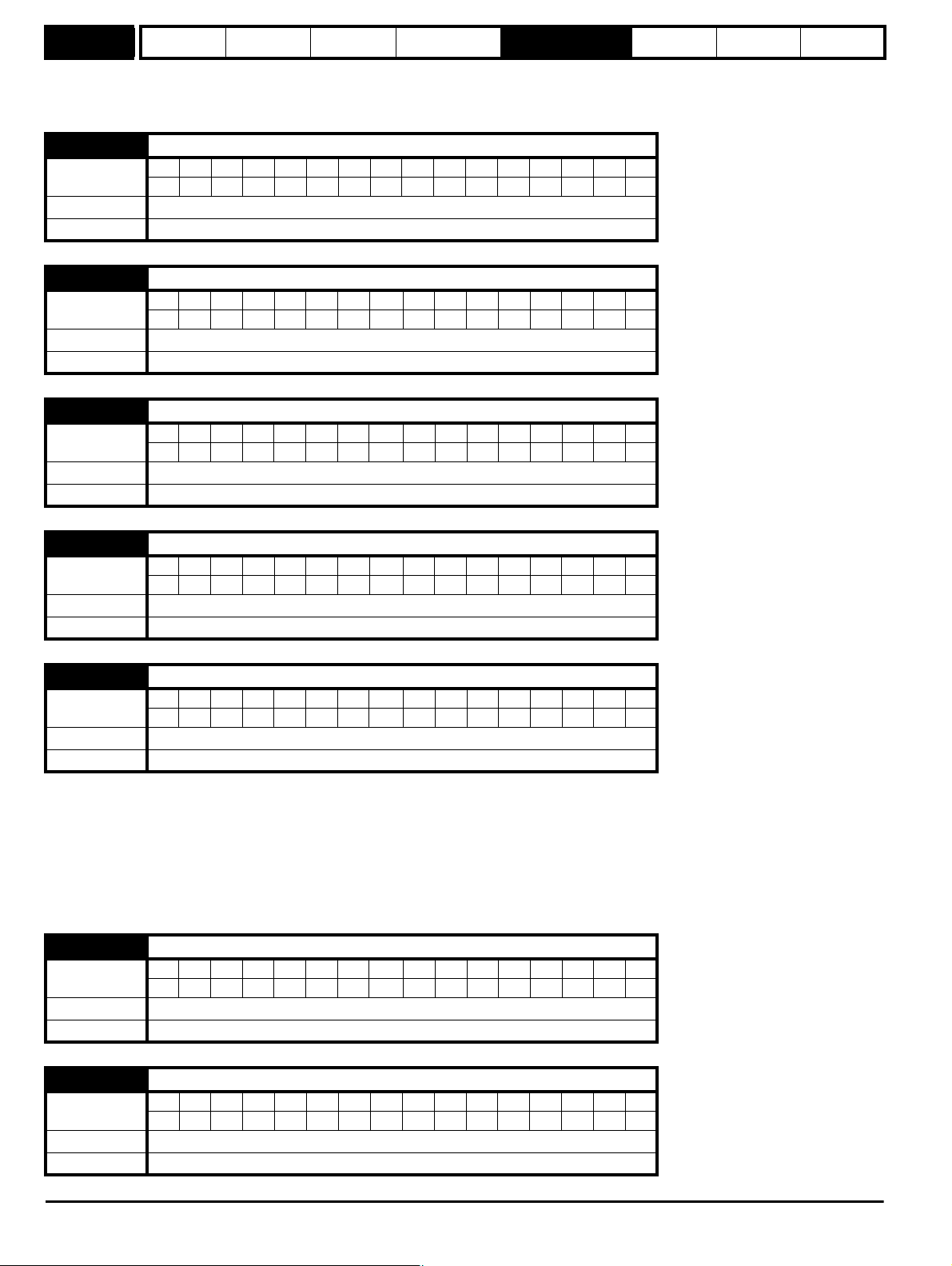

2.7 Parameter access level and security

The parameter access level determines whether the user has access to

menu 0 only or to all the advanced menus (menus 1 to 22) in addition to

menu 0.

The User Security determines whether the access to the user is read

only or read write.

Both the User Security and Parameter Access Level can operate

independently of each other as shown in the table below:

Parameter

Access Level

User Security

Menu 0

status

L1 Open RW Not visible

L1 Closed RO Not visible

L2 Open RW RW

L2 Closed RO RO

RW = Read / write access RO = Read only access

The default settings of the drive are Parameter Access Level L1 and

user Security Open, i.e. read / write access to Menu 0 with the advanced

menus not visible.

2.7.1 Access Level

The access level is set in Pr 0.49 and allows or prevents access to the

advanced menu parameters.

Advanced

menus status

2.7.3 User Security

The User Security, when set, prevents write access to any of the

parameters (other than Pr. 0.49 Access Level) in any menu.

2.7.2 Changing the Access Level

The Access Level is determined by the setting of Pr 0.49 as follows:

String Value Effect

L1 0 Access to menu 0 only

L2 1 Access to all menus (menu 0 to menu 22)

The Access Level can be changed through the keypad even if the User

Security has been set.

Digitax ST Advanced User Guide 11

Issue Number: 3

Setting User Security

Enter a value between 1 and 999 in Pr 0.34 and press the button;

the security code has now been set to this value. In order to activate the

security, the Access level must be set to Loc in Pr 0.49. When the drive

is reset, the security code will have been activated and the drive returns

to Access Level L1. The value of Pr 0.34 will return to 0 in order to hide

the security code. At this point, the only parameter that can be changed

by the user is the Access Level Pr 0.49.

Unlocking User Security

Select a read write parameter to be edited and press the button, the

upper display will now show CodE. Use the arrow buttons to set the

security code and press the button.

With the correct security code entered, the display will revert to the

parameter selected in edit mode.

If an incorrect security code is entered the display will revert to

parameter view mode.

To lock the User Security again, set Pr 0.49 to Loc and press the

reset button.

Disabling User Security.

Unlock the previously set security code as detailed above. Set Pr 0.34 to

0 and press the button. The User Security has now been disabled,

and will not have to be unlocked each time the drive is powered up to

allow read / write access to the parameters.

Page 12

Parameter

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

2.8 Alarm and trip display

An alarm can flash alternately with the data displayed on the 2nd row

when one of the following conditions occur. If action is not taken to

eliminate the alarm, except "Auto tunE", "Lt" and "PLC", the drive may

eventually trip. Alarms flash once every 640ms except "PLC" which

flashes once every 10s. Alarms are not displayed when a parameter is

being edited.

Alarm string Alarm condition

br.rS

OVLd

hot Heatsink or control board alarms are active

Auto tunE Auto tune in progress

Lt

PLC On-board PLC program is running

When a trip occurs the drive switches to status mode and "trip" is shown

on the 1st row and the trip string flashes on the 2nd row. The read only

parameters listed below are frozen with any trip except UV trip until the

trip is cleared. For a list of the possible trip strings see Pr 10.20.

Pressing any of the parameter keys changes the mode to the parameter

view mode. If the trip is HF01 to HF16 then no key action is recognized.

Parameter Description

1.01 Speed reference

1.02 Speed reference

1.03 Pre-ramp reference

2.01 Post-ramp reference

3.01 Final speed reference

3.02 Speed feedback

3.03 Speed error

3.04 Speed controller output

4.01 Current magnitude

4.02 Active current

4.17 Magnetising current

5.01 Output frequency

5.02 Output voltage

5.03 Power

5.05 DC bus voltage

7.01 Analog input 1

7.02 Analog input 2

7.03 Analog input 3

Braking resistor (Pr 10.39 > 75.0% and the

braking IGBT is active)

Motor overload (Pr 4.20 > 75% and the drive

output current > Pr 5.07)

Indicates that a limit switch is active and that it is

causing the motor to be stopped (i.e. forward

limit switch with forward reference etc.)

2.9 Keypad control mode (SM-Keypad Plus only)

The drive can be controlled from the keypad if Pr 1.14 is set to 4. The

Stop and Run keys automatically become active (the Reverse key may

be optionally enabled with Pr 6.13). The speed reference is defined by

Pr 1.17. This is a read only parameter that can only be adjusted in status

mode by pressing the Up or Down keys. If keypad control mode is

selected, then pressing the Up or Down keys in status mode will cause

the drive to automatically display the keypad reference and adjust it in

the relevant direction. This can be done whether the drive is disabled or

running. If the Up or Down keys are held the rate of change of keypad

reference increases with time. The units used for to display the keypad

reference is rpm.

2.10 Drive reset

A drive reset is required to: reset the drive from a trip (except some

“HFxx” trips which cannot be reset); and other functions as defined in

section 3 Parameter x.00 on page 13. A reset can be performed in four

ways:

1. Stop key: If the drive has been set up such that the stop key is not

operative then the key has a drive reset function only. When the stop

function of the stop key is enabled, a reset is initiated while the drive

is running by holding the Run key and then pressing the Stop key.

When the drive is not running the Stop key will always reset the

drive.

2. The drive resets after a 0 to 1 transition of the Drive Reset parameter

(Pr 10.33). A digital input can be programmed to change this

parameter.

3. Serial comms, fieldbus or applications Solutions Module: Drive reset

is triggered by a value of 100 being written to the User trip parameter

(Pr 10.38).

4. Auto-reset: Pr 10.34 can be used to provide an auto-reset function.

If the drive trips EEF (internal EEPROM error) then it is not possible to

reset the drive using the normal reset methods described above. 1233 or

1244 must be entered into Pr x.00 before the drive can be reset. Default

parameters are loaded after an EEF trip, and so the parameters should

be reprogrammed as required and saved in EEPROM.

If the drive is reset after a trip from any source other than the Stop key,

the drive restarts immediately, if:

1. A non-latching sequencer is used with the enable active and one of

run forward, run reverse or run active

2. A latching sequencer is used if the enable and “not stop” are active

and one of run forward, run reverse or run is active.

If the drive is reset with the Stop key the drive does not restart until a not

active to active edge occurs on run forward, run reverse or run.

2.11 Second motor parameters

An alternative set of motor parameters are held in menu 21 which can be

selected by Pr 11.45 . When the alternative parameter set is being used

by the drive the decimal point after the right hand digit in the 1st row is

on.

2.12 Special display functions

The following special display functions are used.

1. If the second motor map is being used the decimal point second

from the right of the first row is on.

2. When parameters are saved to a SMARTCARD the right-most

decimal point on the first row flashes for 2 seconds.

During power up one or more of the following actions may be required.

Each action may take several seconds, and so special display strings

are shown.

Display

string

loading

Action

If a SMARTCARD is present with Pr 11.42 set to boot the

boot

parameters from the card must be transferred to the drive

EEPROM.

If the drive is in auto or boot mode (Pr 11.42 set to 3 or 4) the

card

drive ensures that the data on the card is consistent with the

drive by writing to the card.

It may be necessary for a Solutions Module to transfer

parameter information from the drive. This is only carried out

if the parameter information held by the Solutions Module is

for a different drive software version. The drive allows up to 5

seconds for this process.

12 Digitax ST Advanced User Guide

Issue Number: 3

Page 13

Parameter

structure

Keypad and display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

3 Parameter x.00

Parameter x.00 is available in all menus and has the following functions.

Value Action

1000

1001 Save parameters under all conditions

1070 Reset all Solutions Modules

1233 Load standard defaults

1244 Load US defaults

2001

3yyy

4yyy

5yyy

6yyy Transfer SMARTCARD data block yyy to the drive

7yyy Erase SMARTCARD data block yyy

8yyy Compare drive parameters with block yyy

9555 Clear SMARTCARD warning suppression flag

9666 Set SMARTCARD warning suppression flag

9777 Clear SMARTCARD read-only flag

9888 Set SMARTCARD read-only flag

9999 Erase SMARTCARD

110zy

*12000 Display non-default values only

*12001 Display destination parameters only

*These functions do not require a drive reset to become active. All other

functions require a drive reset.

3.1 Parameter x.00 reset

When an action is started by setting Pr x.00 to one of the above values

and initiating a drive reset this parameter is cleared when the action is

completed successfully. If the action is not started, e.g. because the

drive is enabled and an attempt is made to load defaults, etc., Pr x.00 is

not cleared and no trip is produced. If the action is started and then fails

for some reason a trip is always produced and Pr x.00 is not cleared. It

should be noted that parameter saves etc. can also be initiated with the

copying parameter (Pr 11. 42). If actions that can be initiated by either

parameter are started and then completed successfully Pr x.00 is

cleared and Pr 11.42 is cleared if it has a value of less than 3.

It should be noted that there could be some conflict between the actions

of Pr x.00 and Pr 11.42 (Parameter copying) when the drive is reset. If

Pr 11.42 has a value of 1 or 2 and a valid action is required from the

value of Pr x.00 then only the action required by Pr x.00 is performed.

Pr x.00 and Pr 11.42 are then reset to zero. If Pr 11.4 2 has a value of 3

or 4 it will operate correctly causing parameters to be save to a

SMARTCARD each time a parameter save is performed.

Save parameters when under voltage is not active

(Pr 10.16 = 0) and 48V supply is not active (Pr 6.44 = 0).

Transfer drive parameter to a card and create a bootable

difference from default SMARTCARD block with data

block number 1 and clear Pr 11.42 . If data block 1 exists

it is over written.

Transfer drive EEPROM data to a SMARTCARD block

number yyy

Transfer drive data as difference from defaults to

SMARTCARD block number yyy

Transfer drive ladder program to SMARTCARD block

number yyy

Transfer electronic nameplate parameters to/from drive

from/to encoder

3.2 Saving parameters in drive EEPROM

Drive parameters are saved to drive EEPROM by setting Pr x.00 to 1000

or 1001 and initiating a drive reset. In addition to user save parameters,

power down save parameters are also saved by these actions, but not

by any other actions that result in parameters being saved to drive

EEPROM (i.e. loading defaults). Power down save parameters are not

saved at power down unless the drive is supplied from a normal line

power supply, and so this gives the user the option of saving these

parameters when required. When the parameter save is complete

Pr x.00 is reset to zero by the drive. Care should be taken when saving

parameters because this action can take between 400ms and several

seconds depending on how many changes are stored in the EEPROM. If

the drive is powered down during a parameter save it is possible that

data may be lost. When the drive is operating from a normal line power

supply then it will stay active for a short time after the power is removed,

however, if the drive is being powered from a 24V control supply, or it is

being operated from a low voltage battery supply, the drive will power

down very quickly after the supply is removed. The drive provides two

features to reduce the risk of data loss when the drive is powered down.

1. If Pr x.00 is set to 1000 a parameter save is only initiated on drive

reset if the drive is supplied from a normal line power supply

(Pr 10.16 = 0 and Pr 6.44 = 0). 1001 must be used to initiate a save

if the drive is not supplied from a normal line power supply.

2. Two banks of arrays are provided in EEPROM to store the data.

When a parameter save is initiated the data is stored in a new bank

and only when the data store is complete does the new bank

become active. If the power is removed before the parameter save is

complete a SAVE.Er trip (user save parameter save error) or

PSAVE.Er trip (power down save parameter save error) will be

produced when the drive is powered up again indicating that the

drive has reverted to the data that was saved prior to the last

parameter save.

The second feature will significantly reduce the possibility of completely

invalidating all saved data, which would result in an EEF trip on the next

power-up. However the following points should be noted:

1. If the power is removed during a parameter save the current data

that is being saved to the EEPROM that is different from the last

data saved in the EEPROM will be lost and SAVE.Er or PSAVE.Er

trip will occur on power-up.

2. This feature does not apply when user save parameters are saved

automatically by adjusting the values in menu 0 with an LED keypad.

However, the time taken to save parameters in this way is very short,

and is unlikely to cause data loss if the power is removed after the

parameter has been changed. It should be noted that any parameter

changes made in this way are included in the currently active bank in

the EEPROM, so that if the power is removed during a subsequent

save initiated via Pr x.00 that results in an SAVE.Er trip, the changes

made via menu 0 will be retained and not lost.

3. User save parameters are saved to drive EEPROM after a transfer

of data from an electronic nameplate in an encoder.

4. User save parameters are saved to drive EEPROM after a transfer

of data from a SMARTCARD.

5. This feature is not provided for data saved to a SMARTCARD, and

so it is possible to corrupt the data files on a SMARTCARD if the

power is removed when data is being transferred to the card.

6. User save parameters are saved to drive EEPROM after defaults

are loaded.

7. When a Solutions Module is changed for a different type in a slot, or

a module is inserted when one was not present previously or a

module is removed the EEPROM is forced to re-initialise itself on the

next parameter saves. On the first parameter save one bank is

cleared and then written and on the next parameter save the other

bank is cleared and rewritten. Each of these parameter saves takes

slightly longer than a normal parameter save.

8. When the firmware is updated from an earlier version the drive will

automatically update the EEPROM correctly. If the software is

Digitax ST Advanced User Guide 13

Issue Number: 3

Page 14

Parameter

structure

changed back to an earlier version defaults should be loaded after

the change.

Keypad and display

Parameter x.00

Parameter description

format

3.3 Loading defaults

When defaults are loaded the user save parameters are automatically

saved to the drive EEPROM in all modes. Standard defaults are loaded

by setting 1233 in Pr x.00 performing a drive reset.

The following differences from standard defaults are available when

different values are set in Pr x.00.

US Default Differences (Pr x.00 = 1244 and perform a drive reset)

Pr Description Default Voltage rating

2.08 Standard ramp volts 775V 400V

5.09 Rated voltage 460V 400V

21.09 M2 Rated voltage 460V 400V

3.4 SMARTCARD transfers

Drive parameters, set-up macros and internal ladder programs can be

transferred to/from SMARTCARDs. See Pr 11.36 to Pr 11.4 0.

3.5 Electronic nameplate transfers

Some encoders using Stegmann Hiperface or EnDat comms can hold

motor data. The data can be transferred to/from the encoder by writing

110zy to parameter x.00 and resetting the drive where z is 0 for the drive

or 1, 2 or 3 for Solutions Module slots 1, 2 or 3 respectively. See Chapter

7 Electronic nameplate on page 216 for details.

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

3.6 Display non-default values or destination parameters

If a value of 12000 is written to Pr x.00, then only parameters that are

different from the last defaults loaded and Pr x.00 are displayed. If a

value of 12001 is written to Pr x.00, then only destination parameters are

displayed. This function is provided to aid locating destination clashes if

a dESt trip occurs.

14 Digitax ST Advanced User Guide

Issue Number: 3

Page 15

Parameter

NOTE

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

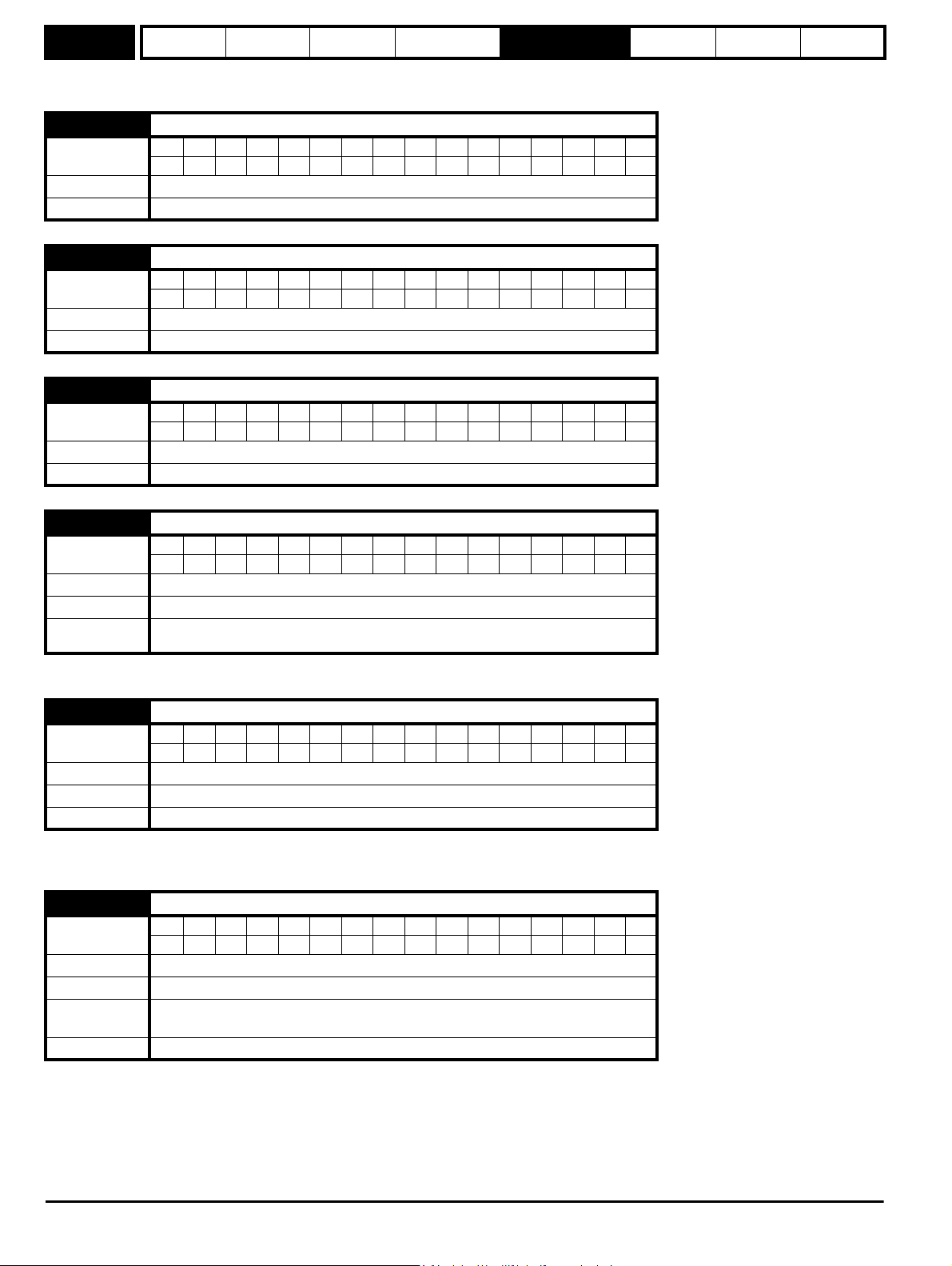

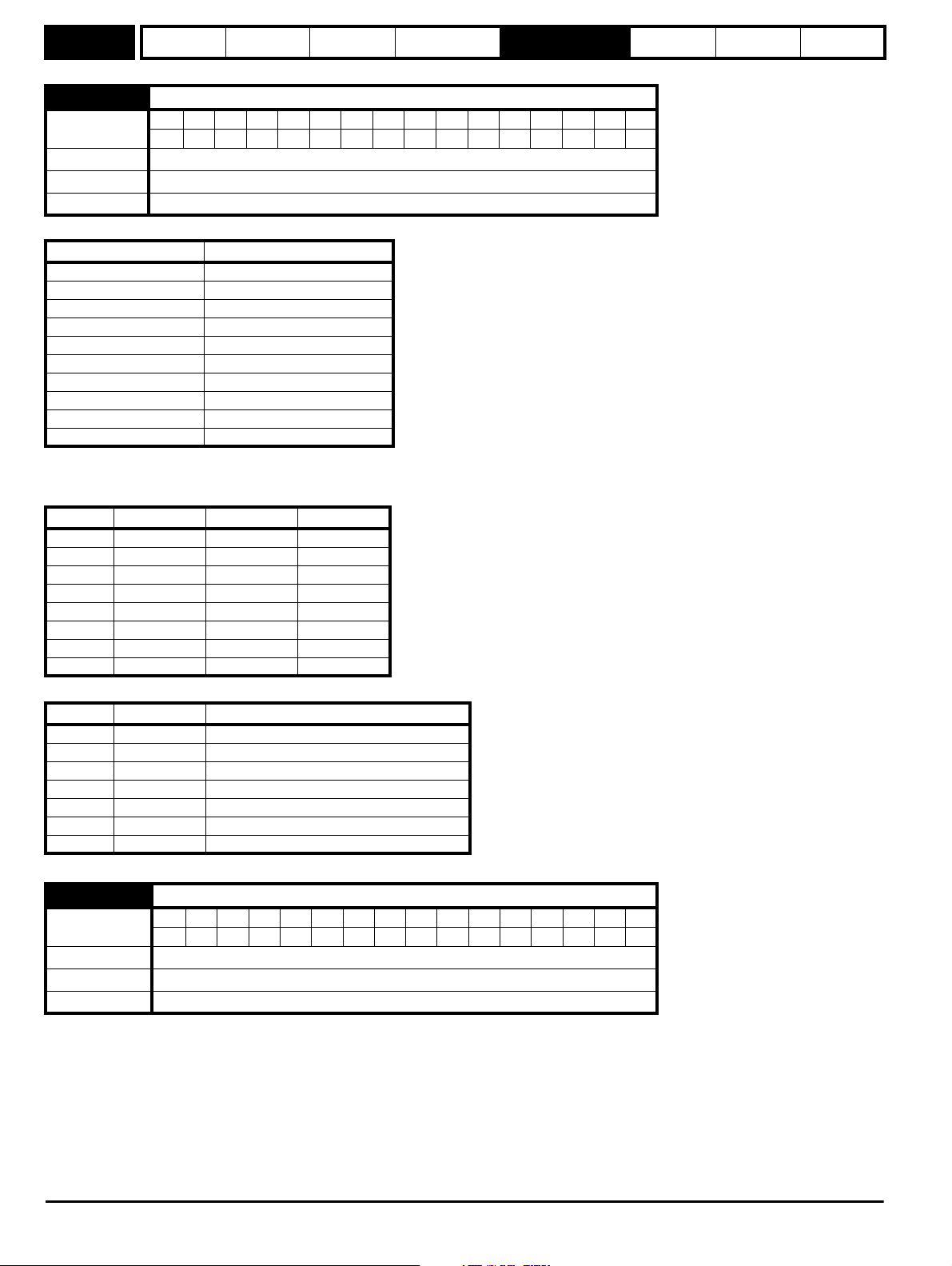

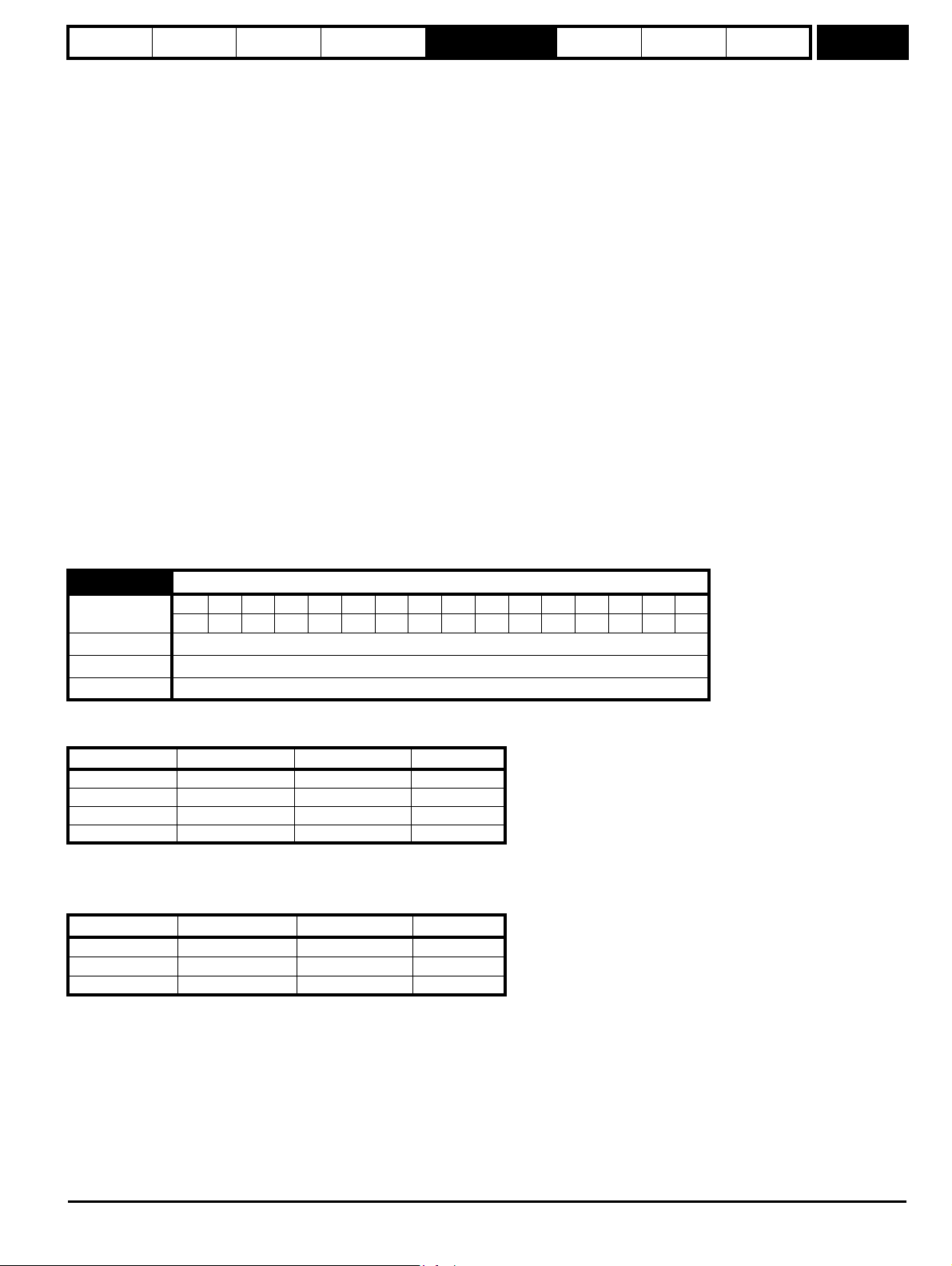

4 Parameter description format

In the following sections descriptions are given for the advanced parameter set. With each parameter the following information block is given.

5.11 Number of motor poles

Coding

Range 0 to 60 (Auto to 120 POLE)

Default 3 (6 POLE)

Second motor

parameter

Update rate

The top row gives the menu.parameter number and the parameter name. The other rows give the following information.

Coding

This guide will show all bit parameters (with the Bit coding), as having a parameter range of "0 to 1", and a default value of either "0" or "1". This

reflects the value seen through serial communications. The bit parameters will be displayed on the DST-Keypad or SM-Keypad Plus (if used) as being

"OFF" or "On" ("OFF"= 0, "On" = 1).

The coding defines the attributes of the parameter as follows:

Coding Attribute

RW Read/write: can be written by the user

RO Read only: can only be read by the user

Bit 1 bit parameter. ‘On’ or ‘OFF’ on the display

Bi Bipolar parameter

Uni Unipolar parameter

Txt Text: the parameter uses text strings instead of numbers.

FI

DE

RA

NC

PT Protected: cannot be used as a destination.

US

PS

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1111

Pr 21.11

Background read

Filtered: some parameters which can have rapidly changing

values are filtered when displayed on the drive keypad for

easy viewing.

Destination: This parameter selects the destination of an

input or logic function.

Rating dependent: this parameter is likely to have different

values and ranges with drives of different voltage and

current ratings. Parameters with this attribute will not be

transferred to the destination drive by SMARTCARDs when

the rating of the destination drive is different from the

source drive and the file is a parameter file.

Not copied: not transferred to or from SMARTCARDs

during copying.

User save: parameter saved in drive EEPROM when the

user initiates a parameter save.

Power-down save: parameter automatically saved in drive

EEPROM when the under volts (UV) trip occurs.

With software version V01.08.00 and later, power-down

save parameters are also saved in the drive when the user

initiates a parameter save.

Digitax ST Advanced User Guide 15

Issue Number: 3

Page 16

Parameter

Maximum

current limit

=

[

Maximum current

]

x 100%

Motor rated current

structure

Keypad and

display

Parameter x.00

Parameter description

format

Advanced parameter

4.1 Parameter ranges and variable maximums:

The two values provided define the minimum and maximum values for

the given parameter. In some cases the parameter range is variable and

dependant on either:

• other parameters,

• the drive rating,

• or a combination of these.

The values given in Table 4-1 are the variable maximums used in the

drive.

Table 4-1 Definition of parameter ranges & variable maximums

Maximum Definition

Maximum speed reference

SPEED_REF_MAX

[40000.0rpm]

SPEED_LIMIT_MAX

[40000.0rpm]

SPEED_MAX

[40000.0rpm]

DRIVE_CURRENT_MAX

[9999.99A]

AC_VOLTAGE_SET_MAX

[690V]

AC_VOLTAGE_MAX

[930V]

DC_VOLTAGE_SET_MAX

[1150V]

DC_VOLTAGE_MAX

[1190V]

MOTOR1_CURRENT_LIMIT_MAX

[1000.0%]

MOTOR2_CURRENT_LIMIT_MAX

[1000.0%]

If Pr 1.08 = 0: SPEED_REF_MAX = Pr 1.06

If Pr 1.08 = 1: SPEED_REF_MAX is Pr 1.06 or – Pr 1.07 whichever is the largest

(If the second motor map is selected Pr 21.01 is used instead of Pr 1.06 and Pr 21.02 instead of Pr 1.07)

Maximum applied to speed reference limits

A maximum limit may be applied to the speed reference to prevent the nominal encoder frequency from

exceeding 500kHz. The maximum is defined by

SPEED_LIMIT_MAX (in rpm) = 500kHz x 60 / ELPR = 3.0 x 10

40,000 rpm.

ELPR is equivalent encoder lines per revolution and is the number of lines that would be produced by a

quadrature encoder.

Quadrature encoder ELPR = number of lines per revolution

F and D encoder ELPR = number of lines per revolution / 2

Resolver ELPR = resolution / 4

SINCOS encoder ELPR = number of sine waves per revolution

Serial comms encoder ELPR = resolution / 4

This maximum is defined by the device selected with the speed feedback selector (Pr 3.26) and the ELPR set

for the position feedback device.

Maximum speed

This maximum is used for some speed related parameters in menu 3. To allow headroom for overshoot etc. the

maximum speed is twice the maximum speed reference.

SPEED_MAX = 2 x SPEED_REF_MAX

Maximum drive current

The maximum drive current is the current at the over current trip level and is given by:

DRIVE_CURRENT_MAX = K

Maximum output voltage set-point

Defines the maximum motor voltage that can be selected.

200V drives: 240V, 400V drives: 480V

Maximum AC output voltage

This maximum has been chosen to allow for maximum AC voltage that can be produced by the drive including

quasi-square wave operation as follows:

AC_VOLTAGE_MAX = 0.78 x DC_VOLTAGE_MAX

200V drives: 325V, 400V drives: 650V

Maximum DC voltage set-point

200V rating drive: 0 to 400V, 400V rating drive: 0 to 800V

Maximum DC bus voltage

The maximum measurable DC bus voltage.

200V drives: 415V, 400V drives: 830V

Maximum current limit setting for motor map 1

The maximum current limit setting is the maximum applied to the current limit parameters in motor map 1.

Where:

The Maximum current is (1.75 x

Motor rated current is given by Pr 5.07

Maximum current limit settings for motor map 2

This maximum current limit setting is the maximum applied to the current limit parameters in motor map 2.

The formulae for MOTOR2_CURRENT_LIMIT_MAX are the same for MOTOR1_CURRENT_LIMIT_MAX

except that Pr 5.07 is replaced with Pr 21.07 and Pr 5.10 is replaced with Pr 21.10.

/ 0.45

C

KC).

descriptions

Serial comms

protocol

7

/ ELPR subject to an absolute maximum of

Electronic

nameplate

Performance

16 Digitax ST Advanced User Guide

Issue Number: 3

Page 17

Parameter

structure

TORQUE_PROD_CURRENT_MAX

[1000.0%]

USER_CURRENT_MAX

[1000.0%]

POWER_MAX

[9999.99kW]

Keypad and

display

Maximum Definition

Parameter x.00

Maximum torque producing current

This is used as a maximum for torque and torque producing current parameters. It is

MOTOR1_CURRENT_LIMIT_MAX or MOTOR2_CURRENT_LIMIT_MAX depending on which motor map is

currently active.

Current parameter limit selected by the user

The user can select a maximum for Pr 4.08 (torque reference) and Pr 4.20 (percentage load) to give suitable

scaling for analog I/O with Pr 4.24. This maximum is subject to a limit of MOTOR1_CURRENT_LIMIT_MAX. or

MOTOR2_CURRENT_LIMIT_MAX depending on which motor map is currently active.

USER_CURRENT_MAX = Pr 4.24

Maximum power in kW

The maximum power has been chosen to allow for the maximum power that can be output by the drive with

maximum AC output voltage, maximum controlled current and unity power factor. Therefore

POWER_MAX = √3 x AC_VOLTAGE_MAX x DRIVE_CURRENT_MAX

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Electronic

nameplate

Performance

The values given in square brackets indicate the absolute maximum value allowed for the variable maximum.

Table 4-2 Maximum motor rated current

200 V 400 V

Size

DST1201x 2.92 1.70 DST1401x 2.58 1.50

DST1202x 6.52 3.80 DST1402x 4.63 2.70

DST1203x 9.26 5.40 DST1403x 6.86 4.00

DST1204x 13.03 7.60 DST1404x 10.12 5.90

Current

scaling

(Kc) A

Max

current

rating A

Size

DST1405x 13.72 8.00

Current

scaling

(Kc) A

Max

current

rating A

3. If the source is a bit, i.e. a digital output, and the source data

parameter is a bit parameter then the input to the source function

follows the value of the source data parameter.

4. If the source is a bit, i.e. a digital output, and the source data

parameter is not a bit parameter the source input is zero if the

source data value is less than source data parameter maximum / 2

rounded down to the nearest unit. The source input is one if the

source data value is greater than or equal to source data parameter

maximum / 2 rounded down to the nearest unit. For example if the

source pointer parameter is set to Pr 18.11, which has a maximum of

32767, the source input is zero if the source data value is less than

16383 and one if it is greater than this.

4.2.2 Destinations

4.1.1 Default

The default values given are the standard drive defaults which are

loaded after a drive reset with 1233 in Pr x.00.

4.1.2 Second motor parameter

Some parameters have an equivalent second motor value that can be

used as an alternative when the second motor is selected with Pr 11.4 5.

Menu 21 contains all the second motor parameters. In this menu the

parameter specifications include the location of the normal motor

parameter which is being duplicated.

4.1.3 Update rate

Defines the rate at which the parameter data is written by the drive

(write) or read and acted upon by the drive (read). Where background

update rate is specified, the update time depends on the drive processor

load. Generally the update time is between 2ms and 30ms, however, the

update time is significantly extended when loading defaults, transferring

data to/from a SMARTCARD, or transferring blocks of parameters or

large communications messages to/from the drive (not a Solutions

Module) via the drive serial comms port.

4.2 Sources and destinations

4.2.1 Sources

Some functions have source pointer parameters, i.e. drive outputs, PID

controller etc.. The source pointer parameter range is Pr 0.00 to

Pr 21.51. The source pointer is set up to point to a parameter, which

supplies the information to control the source and this is referred to as

the source data parameter. For example, Pr 7.19 is the source pointer

parameter for analog output 1. If Pr 7.19 is set to a value of 18.11, then

Pr 18.11 is the source data parameter, and as the value of Pr 18.11 is

modified the analog output level is changed.

1. If the parameter number in the source pointer parameter does not

exist the input is taken as zero.

2. If the source is not a bit type source (i.e. not a digital output etc.)

then the source level is defined by (source data value x 100%) /

source data parameter maximum. Generally the result is rounded

down to the nearest unit, but other rounding effects may occur

depending on the internal scaling of the particular source function.

Some functions have destination pointer parameters, i.e. drive inputs,

etc.. The destination pointer parameter range is Pr 0.00 to Pr 21.51. The

destination pointer parameter is set up to point to a parameter, which

receives information from the function referred to as the destination

parameter.

1. If the parameter number in the destination pointer parameter does

not exist then the output value has no effect.

2. If the destination parameter is protected then the output value has

no effect.

3. If the function output is a bit value (i.e. a digital input) the destination

parameter value does not operate in the same way as a source

described above, but is always either 0 or 1 depending on the state

of the function output whether the destination parameter is a bit

parameter or not.

4. If the function output is not a bit value (i.e. analog input) and the

destination parameter is not a bit parameter, the destination value is

given by (function output x destination parameter maximum) / 100%.

Generally the result is rounded down to the nearest unit, but other

rounding effects may occur depending on the internal scaling of the

particular source function (rounded down to nearest unit). Pr 1.36

and Pr 1.37 are a special case. The scaling shown in the description

of parameter Pr 1.08 is used when any non-bit type quantity is

routed to these parameters.

5. If the function output is not a bit value and the destination parameter

is a bit value, the destination value is 0 if the function output is less

than 50% of its maximum value, otherwise it is 1.

6. If more than one destination selector is routed to the same

destination, the value of the destination parameter is undefined. The

drive checks for this condition where the destinations are defined in

any menu except menus 15 to 17. If a conflict occurs a dESt trip

occurs that cannot be reset until the conflict is resolved.

Digitax ST Advanced User Guide 17

Issue Number: 3

Page 18

Parameter

structure

Keypad and

display

Parameter x.00

Parameter description

format

4.2.3 Sources and destinations

1. Bit and non-bit parameters may be connected to each other as

sources or destinations. The scaling is as described previously.

2. All new source and destination routing only changes to new set-up

locations when the drive is reset.

3. When a destination pointer parameter within the drive or a dumb

Solutions Module (SM-Resolver, SM-Encoder Plus, SM-Encoder

4.3 Update rates

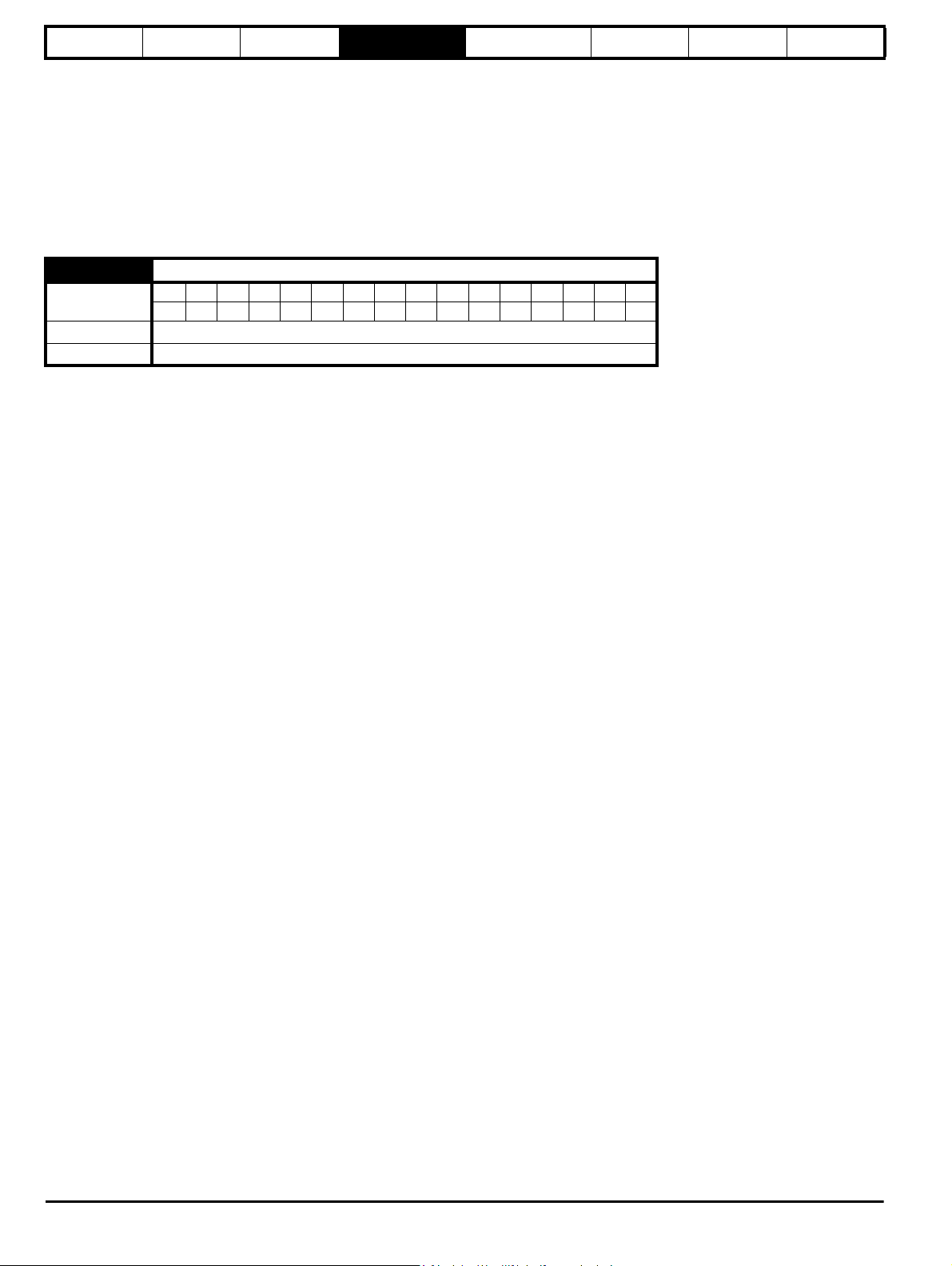

Update rates are given for every parameter in the header table as shown

below.

3.03 Speed error

Coding

Range ±SPEED_MAX rpm

Update rate 4ms write

Bit SP FI DE Txt VM DP ND RA NC NV PT US RW BU PS

1 11111

Advanced parameter

descriptions

Output Plus, SM-I/O plus) is changed the old destination is written to

zero, unless the destination change is the result of loading defaults

or transferring parameters from a SMARTCARD. When defaults are

loaded the old destination is set to its default value. When

parameters are loaded from a SMARTCARD the old destination

retains its old value unless a SMARTCARD value is written to it.

Serial comms

protocol

Electronic

nameplate

Performance

Some parameters have an increased update in special circumstances.

4.3.1 Speed reference update rate

The normal update rate for the speed references (via menu 1) is 4ms,

however it is possible to reduce the sample time to 250μs by selecting

the reference from particular sources. The fast update rate is only

possible provided the conditions given below are met.

Analog input references (not including I/O expansion Solutions

Module)

1. The reference must be derived via Pr 1.36 or Pr 1.37

2. The analog inputs must be in voltage mode with zero offset

3. Bipolar mode must be used or unipolar mode with the minimum

speed (Pr 1.07) set to zero

4. No skip bands are enabled, i.e. Pr 1.29, Pr 1.31 and Pr 1.33 must be

zero.

5. The jog and velocity feed-forward references must not be enabled.

Applications and fieldbus Solutions Modules