Page 1

DIGITAX HD

SERVO DRIVE SERIES

Minimum size,

maximum performance

0.7 – 51 Nm, 300% overload

(6.2 – 451 lb-in, 300% overload)

1.5 – 16 A, 300% overload

200 V | 400 V

0.25 – 7.5 kW (0.6 - 9.8 hp)

Page 2

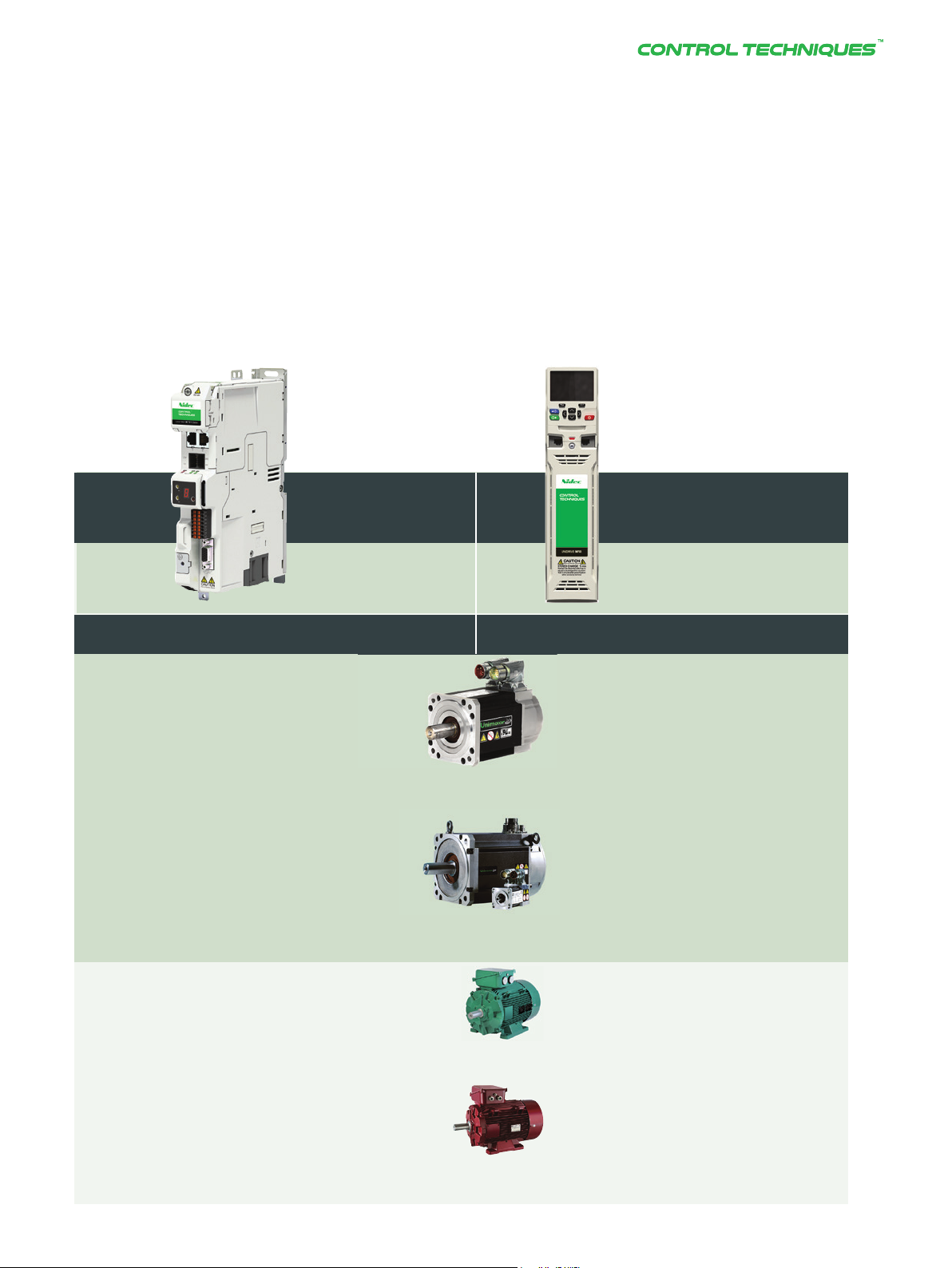

SERVO DRIVE SERIES

SERVO DRIVE SERIES

Servo solutions

for continuous

and pulse duty

applications

Control Techniques’ servo solutions provide

ultimate performance and fl exibility for

machinery manufacturers with a wide range of

servo drives and motors.

Digitax HD

The Digitax HD range brings ultimate

performance to high dynamic, pulse duty

applications, where high peak torque is

required for fast acceleration.

Unidrive M700

Unidrive M700, with high performance and an extensive

power range, is the ideal option for continuous duty

applications, where precise, continuous torque delivery is

required.

Unimotor

Unimotor is a comprehensive family of high performance AC

brushless servo motors. With a wide torque and speed range,

and a broad selection of feedback options, Unimotor off ers

the perfect match for Digitax HD and Unidrive M700 to meet

any application requirement.

2

2

Page 3

Drive and Motor

Compatibility

Digitax HD

0.25 kW - 7.5 kW

(0.6 hp - 9.8 hp)

200 V | 400 V

300% OVERLOAD

(Optimized with the Control Techniques pulse duty drive)

Unidrive M700

0.75 kW - 2.8 MW

(1 hp - 4,200 hp)

200 V | 400 V | 575 V | 690 V

200% OVERLOAD

Pulse Duty Servo Range - Unimotor HD

Continuous Duty Servo Range - Unimotor FM

(Optimized with the Control Techniques continuous duty drive)

Induction

High efficiency motors

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 3

3

Page 4

SERVO DRIVE SERIES SERVO DRIVE SERIES

4

4

Page 5

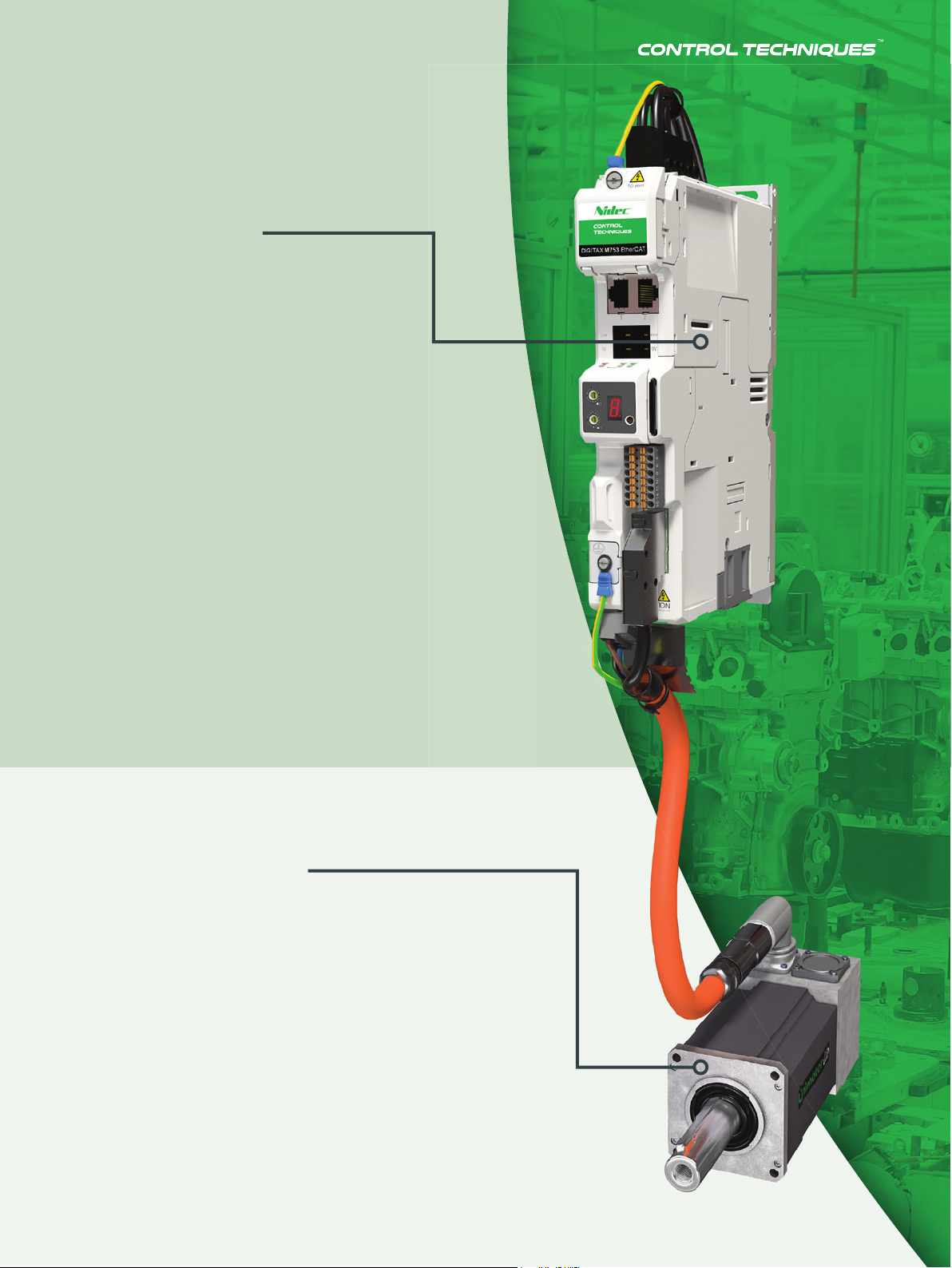

Digitax HD

Optimized for high-dynamic

applications, Digitax HD provides

the fl exibility of both standalone

and modular confi gurations. The

drive off ers full servo control plus

open loop permanent magnet and

induction motor control across

four functionality levels: EtherCAT,

MCi machine control, multiprotocol

EtherNet and the fl exible Base drive.

Unimotor HD

Unimotor HD is Control Techniques’ highly

dynamic brushless AC servo motor range.

With high peak torque, low inertia and

compact dimensions, Unimotor HD is

optimized for applications requiring rapid

acceleration and deceleration.

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 5

5

Page 6

SERVO DRIVE SERIES

SERVO DRIVE SERIES

Minimum size

Actual size

servo solutions

Reduce cost and maximize floor space

Minimal footprint and exceptional power density

make Digitax HD one of the smallest servo drives

on the market today. This means that you can

build the most compact cabinets possible.

The market’s narrowest

servo drive

• Digitax HD is just 40mm (1.6 in) wide

• 25 drives, up to 16A per drive, can fi t in

just 1 meter (40 in) of cabinet space

Digitax HD

40mm (1.6 in)

Typical competitors

Drive dimensions

Dimensions Frame 1 Frame 2 Frame 3

in mm in mm in mm

Width 1.57 40 1.57 40 1.57 40

Depth 6.85 174 6.85 174 6.85 174

Height 9.17 233 11.0 278 12.9 328

Nominal current

@ 400 V

Peak current

@ 400 V

4.2 A 10.5 A 12.9 A

12.6 A 31.5 A 48 A

Just 40 mm (1.6 in)

6

6

Page 7

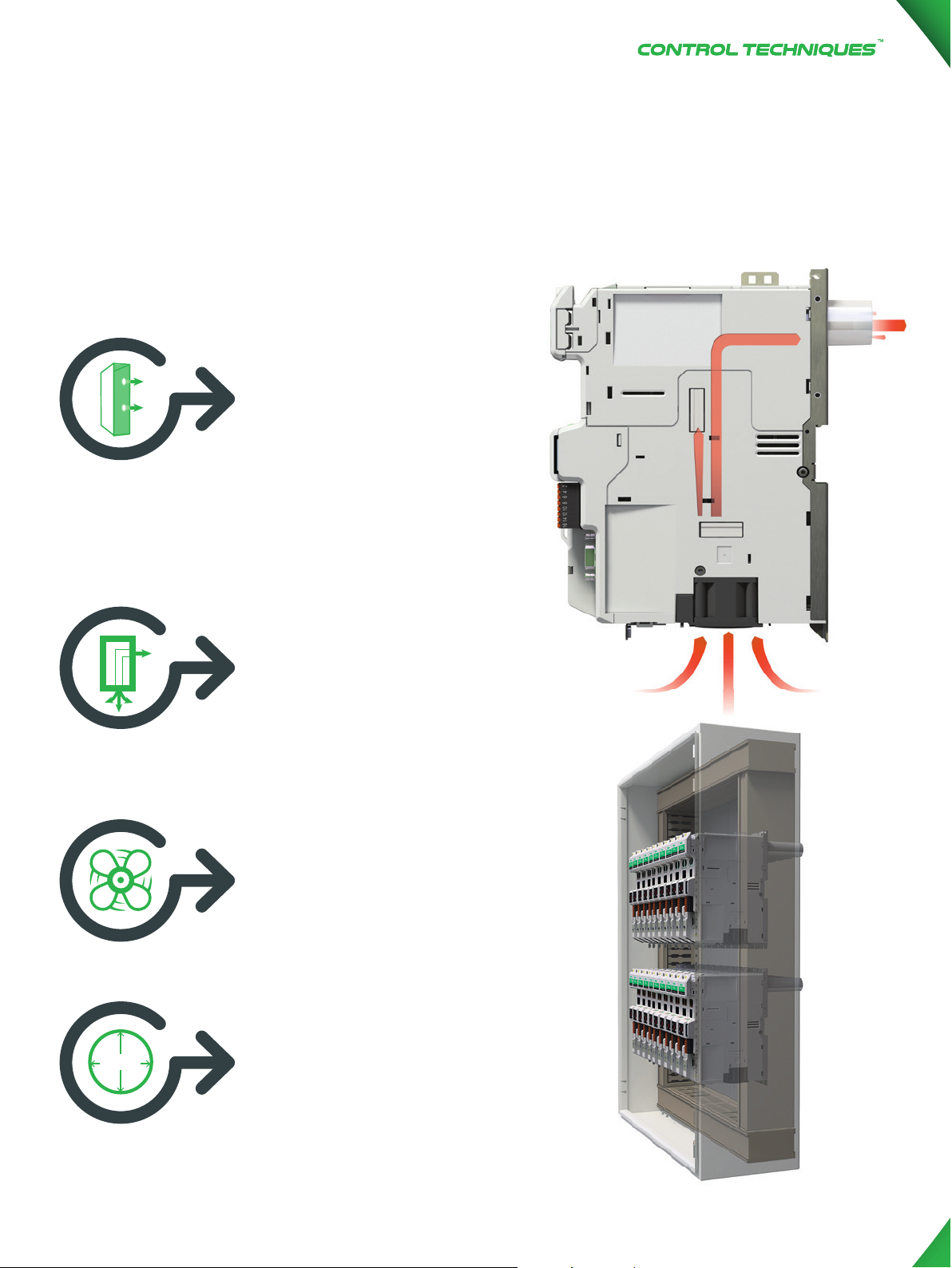

Further reduce cabinet size

with Ultraflow

TM

thermal management

Reduce cabinet height

by directly stacking

rows of drives. Control

Techniques’ patented

Ultrafl ow™ technology

expels heat directly

outside of the cabinet

through the rear of the

drive* and removes heat

build-up in the cabinet.

Ultrafl ow™’s guided

internal airfl ow prevents

32mm

ingress on drive circuits and,

combined with conformal

coating, minimizes

contamination risk.

An intelligently controlled

fan optimizes fan lifetime

and minimizes acoustic

noise, while contributing

to the maximum thermal

cooling by Ultrafl ow™.

Ultrafl ow™ requires only

a 32 mm (1.25 in) hole

in the cabinet meaning

rapid, trouble-free

installation**

Ultrafl owTM is a registered Trademark of Control Techniques

* Drive heat dissipation can also be achieved via vents on top of the drive, as standard.

** Frames 2 and 3 require 2 x 32mm (1.5 in) holes

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 7

7

Page 8

SERVO DRIVE SERIES

SERVO DRIVE SERIES

From

standalone...

...to a modular

common dc

bus system

SINGLE AC

INPUT

COMMUNICATION

LINKS

COMMON

DC BUS

AND EARTH

24 Vdc LINKS

8

8

Page 9

PERFORMANCE

SPEED

Maximum performance

servo solutions

Boost throughput with maximum control

Optimized for highly-dynamic applications and with

high speed control loops, Digitax HD brings maximum

throughput and production quality to your machines.

◼ 300% peak current performance

◼ Optimized control loops for high dynamic performance

– 62.5 μs current loop

– 250 μs position and speed loop

◼ Unique ‘dead beat’ current controller for maximum bandwidth

◼ Up to 16 kHz switching frequency (default ratings specifi ed at 8 kHz)

◼ Advanced bi-quad fi lters for suppression of mechanical

resonances

Current

300 %

PRECISION

I rated

250 ms

Time

Improving accuracy through precision

encoder feedback

The fl exible speed and position feedback interface

supports a wide range of feedback technologies, from

robust resolvers to high resolution encoders.

• Up to three onboard encoder channels simultaneously e.g.

1 feedback encoder, 1 reference encoder and 1 simulated output

• Quadrature, AB Servo, SinCos (including absolute), SSI, BiSS,

EnDat 2.1/2.2, Hiperface and resolvers

• Simulated encoder output can provide position reference

for cams, digital lock and electronic gearbox

• Up to 25 bit encoder resolution

• Feedback accuracy as low a ±20”

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 9

9

Page 10

SERVO DRIVE SERIES

SERVO DRIVE SERIES

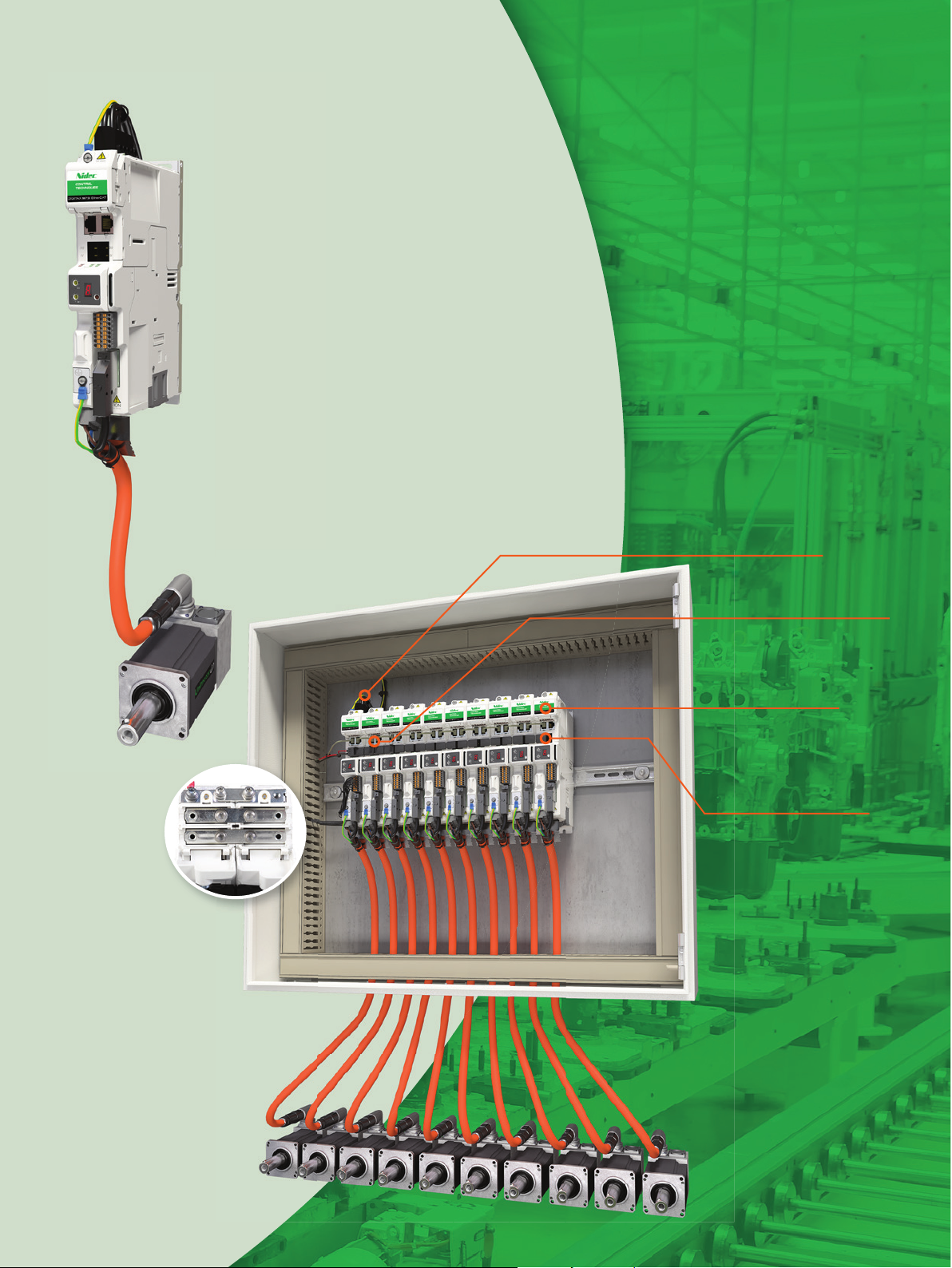

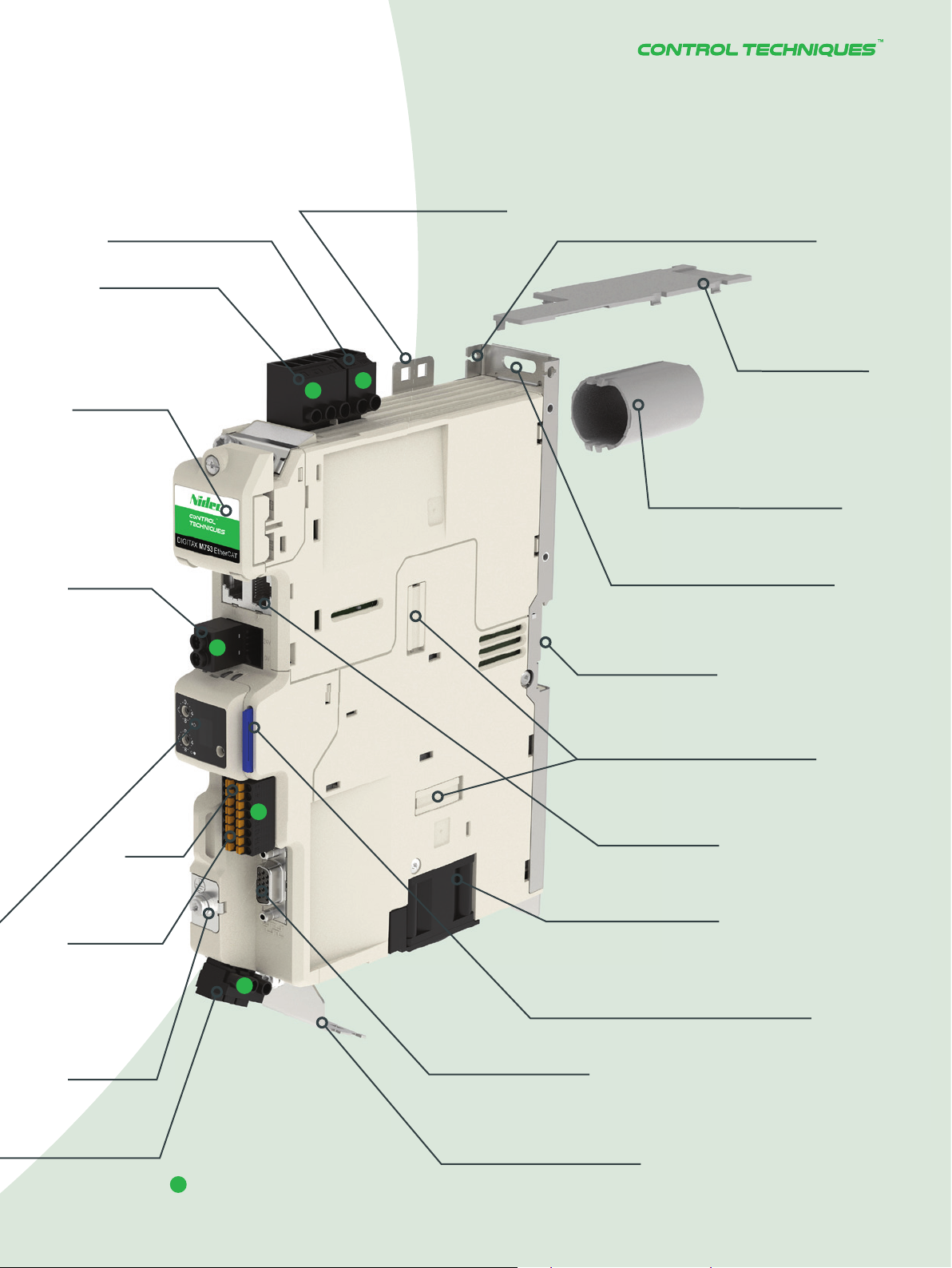

DIN rail alignment

Remote mountable,

plain text,

multi-language

LCD keypad

Single cable

technology with

electronic motor

name plate for

fast setup

Rapid

installation and

commissioning

The multi-axis paralleling kit includes busbars

for quick connection of DC bus and earth link,

as well as Quick Links to distribute 24 Vdc

supply across drives.

• Reduces installation time and cost

• Improves energy effi ciency and footprint

Easy access

pluggable

connectors

Fast

commissioning

with PC tools or

SD cards

Unimotor’s electronic

nameplate provides

support for parameter

set-up between

motor and drive

+ DC

- DC

24 Vdc

The LED display ensures access to drive

diagnostics even in the absence of network

connectivity.

Includes 2 rotary switches for hardware

setting of the node address for faster

commissioning of the motion network.

10

10

The motor power connector is in the same

position for all frame sizes, making cable

routing easier and tidier.

Page 11

External Brake

Resistor Connector

AC input

Fixing points for cable ties on

the top, front and base of the

drive for compact wire routing

Drive alignment aid (alternative

to DIN rail alignment)

DC bus cover

24 Vdc Input

Ultrafl ow

cover (optional)

Rear duct for Ultrafl ow

thermal management

technology (optional)

Screw slot allows a fi xed

hole pattern to fi t any drive

combination.

DIN rail alignment

SI-Option module slots allow for

expansion of drive capabilities

TM

Vent

TM

I/O

Dual Safe

Torque Off

(STO)

Motor earth

Easy access pluggable connectors

Communication

ports

Easily replaceable fan

SD card slot for local backup, quick drive

replacement and repeat commissioning

Encoder input/output

Removable cable screen

bracket for quick installation

or replacement

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 11

11

Page 12

SERVO DRIVE SERIES

Fast programming

and commissioning

SOFTWARE

Application Programming

Machine Control Studio

The Machine Control Studio programming environment

provides a fl exible and intuitive environment for

programming automation and motion control features.

The software provides programming for:

◼ Onboard PLC

◼ MCi200 or MCi210 integrated machine control modules

◼ EtherNet network data confi gurations

Familiar automation programming languages

The programming environment is fully IEC 61131-3

compliant and therefore familiar, fast and easy to

use for control engineers around the world.

The following IEC 61131-3 programming

languages are supported:

◼ Structured Text (ST)

◼ Function Block Diagram (FBD)

◼ Structured Function Chart (SFC)

◼ Ladder Diagram (LD)

◼ Instruction List (IL)

◼ Continuous Function Chart (CFC)

Productivity features also supported:

◼ Intuitive IntelliSense functionality helps to

write consistent and robust programs

speeding up software development

◼ Programmers have access to a vibrant

Open-source community for function blocks

◼ Machine Control Studio also supports

customers’ own function block libraries

Features

Breakpoints - Yes

Source code

upload/download

Online change - Yes

Trigonometric

functions

64 bit data types - Yes

Real-time task(s) Yes (min 4ms) Yes (min 250 µs)

Customizable

drive menu

Variable tracing - Yes

Tasks available

Centralized

controller

Decentralized

controller

Digitax HD

onboard PLC

- Yes

- Yes

Yes Yes

1 x Freewheeling

task,

1 x Clock task

- Yes

Yes Yes

MCi Option Module

1 x Freewheeling task,

1 x Position task,

1 x Initial task,

4 x Clock tasks,

1 x Error task,

4 x Event tasks

12

Page 13

Commissioning

Connect

The Connect PC tool is for rapid

commissioning, plus optimizing and

monitoring drive/system performance.

◼ Task-based drive operations are simplifi ed with

intuitive graphical tools in a familiar Windows

environment

◼ CTScope – a realtime software oscilloscope –

facilitates tuning and monitoring

◼ Dynamic logic diagrams and searchable

parameter listings

◼ Tool is scalable, through optional add-ins, to

match application requirements

◼ Multiple communications channels for a more

complete overview of the system

◼ Drive discovery gives the ability to fi nd drives

on a network automatically without the user

having to specify their addresses

◼ Offl ine confi guration

SD card

Standard SD cards can be

used for quick and easy

parameter and program storage.

DRIVE SPECIALISTS SINCE 1973

13

Page 14

SERVO DRIVE SERIES

Motion Control

System Architecture

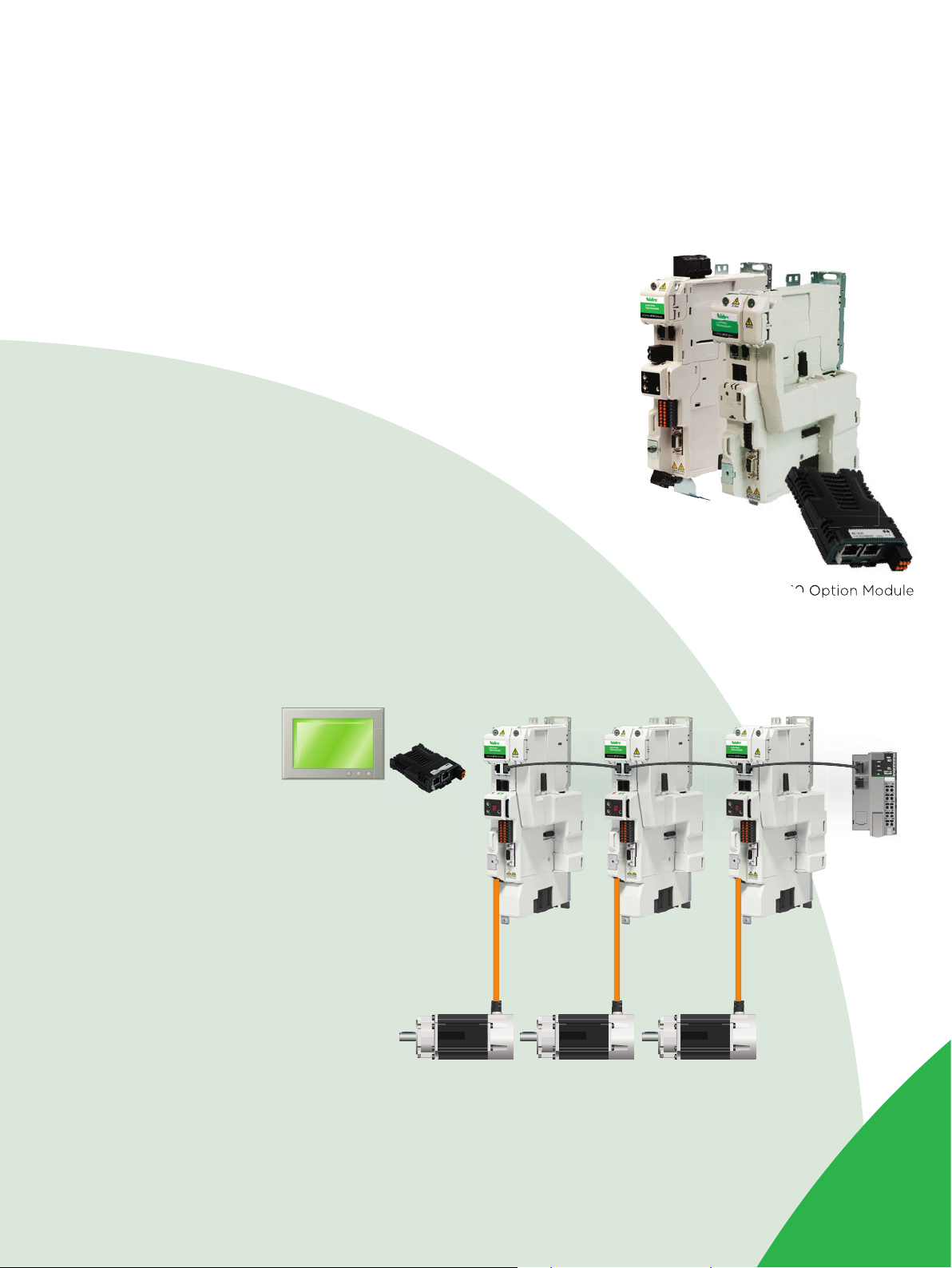

Drive-based Motion

(Decentralised/Distributed

Motion Intelligence)

In a distributed motion control system, the motion

control capability is distributed on-board the

individual drives. This includes the position loop,

motion profi le and sometimes even all or part of

the PLC logic.

◼ Each axis is fully independent, but coordination

can be achieved by synchronizing drives over

the network using Real-Time Motion over

EtherNet (RTMoE).

◼ In small machines, a drive-based system can be

standalone, whereas in larger systems it is more

commonly connected to a PLC (or IPC) over a

fi eldbus which, in this case, does not need to be

strictly deterministic.

M750 EtherNet

M751 Base

MCi210 Option Module

Key advantages

◼ A drive-based system off ers superior

motor control performance, as the

on-board loops typically run faster,

and it avoids the delays of network

communication.

◼ A distributed motion architecture can be

very cost-eff ective, as it forgoes the need

of an expensive central motion controller

and, by using the onboard logic, allows to

take some load off the central PLC.

◼ It is easily scalable, as the load of the

PLC, where present, does not increase

signifi cantly with the number of drives

connected.

◼ PC Tools provide similar ease of

commissioning and maintenance to a

centralised solution.

14

Page 15

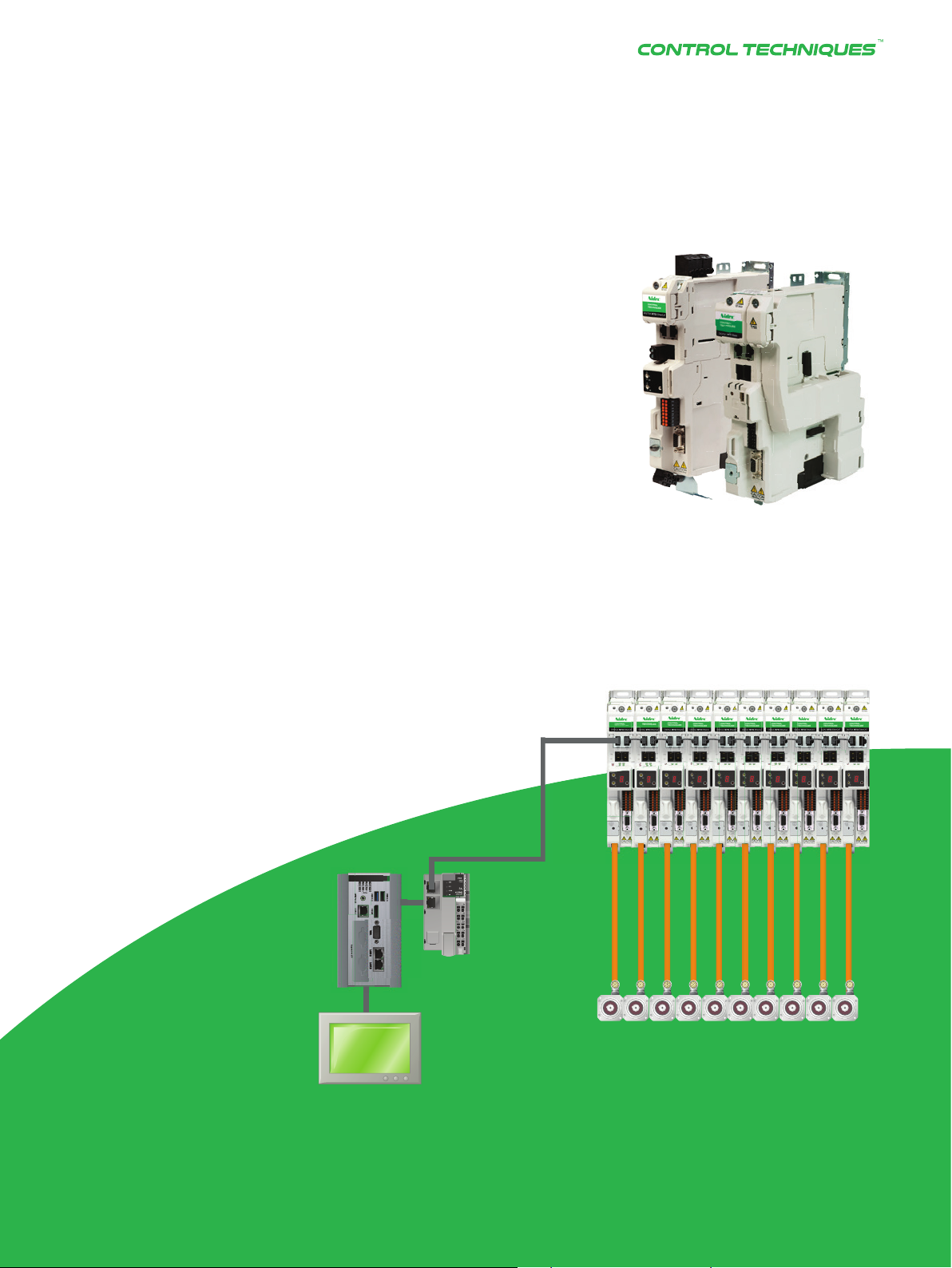

Controller-based Motion

(Centralized Motion

Intelligence)

A central controller generates the motion profi les of all axes

and in some cases even closes the position loop. In this

architecture the servo drives, often referred to as amplifi ers,

simply follow the setpoint they receive from the controller.

◼ The servo drives are normally connected over an EtherNet

network, using a fast and deterministic protocol such as

EtherCAT.

◼ In modern systems, the central controller, PLC-based or

IPC-based, tends to also implement all the machine logic.

Key advantages

◼ Ease of coordinating the motion of multiple axes in a single

program.

◼ Single storage location for the whole machine program,

and potentially even drive parameters, simplifying

maintenance.

M753 EtherCAT

M751 Base

DRIVE SPECIALISTS SINCE 1973

15

Page 16

SERVO DRIVE SERIES

SERVO DRIVE SERIES

M750

EtherNet

(multiprotocol)

Network drive for centralized

and decentralized motion

application

Digitax M750 EtherNet

Onboard multiprotocol EtherNet, supporting

Real Time Motion over EtherNet (RTMoE),

EtherNet/IP, Modbus TCP/IP and PROFINET RT

Onboard advanced motion controller for 1.5 axis

motion control

EtherNet webpages hosted onboard the M750

EtherNet drive

Reduced downtime with machine safety

- Integrated Dual Safe Torque Off

- Meets SIL3 and PLe

RTMoE

Digitax HD’s standard EtherNet supports

RTMoE (Real-Time Motion over EtherNet)

which provides synchronized communication

between drives using the Precision Time

Protocol as defi ned by IEEE1588 V2:

Distributed clocks are used to automatically

synchronize the position, speed and current

loops across all drives

High speed network synchronization of

less than 1 μs jitter (typically <200 ns) and

1 ms cycle time for synchronous cyclic data

Advanced Motion

Controller onboard

Advanced 1.5 axes motion controller,

key features include:

- 250 μs cycle time

- Motion profi le generator

- Electronic gearbox

- Interpolated cam

- Homing functions

- High speed position freeze

16

16

READY

4.0

PLe RTMoE

Page 17

Machine controllers

MCi200 & MCi210

Second processor for PLC

programs and multi-axis control CONTROL

MCi200 and MCi210 modules add a powerful

processor to Digitax HD. They extend the

drives system and machine control capability

to run application programs up to four times

faster than a standard PLC.

Programs are fast and easy to develop thanks to the

user-friendly Machine Control Studio software which uses

industry standard IEC 61131-3 programming languages.

MCi programs can access and manage the drive

embedded Advanced Motion Controller, providing

perfectly synchronized multi-axis machine performance.

Segregated network control

Network 1

DI8xDC24V

CPU314C-2 DP

AI5/A02x12Bit

SF

BF

DC5V

FRCE

RUN

STOP

PUSH

RUN

STOP

MRES

System Controller

DI16/D016xDC24V

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

DI+2 DI+0

IN IN OUT

DI+1

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

D0+0

D0+1

0

1

2

3

4

5

6

7

M751

• Two EtherNet ports with an internal switch

• Support for standard EtherNet protocols

• RTMoE for synchronized cyclic data at 250 µs

• Modbus TCP/IP master

• Machine control over two segregated EtherNet

networks enables greater fl exibility in machine design

• Extended fast I/O (3 x digital inputs, 1 x digital output,

1 x digital I/O)

Network 2

Machine 1

MCi Controller

MCi Controller

Network 3

M751

Machine 2

DRIVE SPECIALISTS SINCE 1973

17

Page 18

SERVO DRIVE SERIES

SERVO DRIVE SERIES

M751 Base

Base drive for

confi guration

fl exibility

Digitax M751 fl exibility

Two option slots for functionality extension

and customization – refer to page 21 for the

comprehensive option module list

Built-in Modbus RTU over RS485

communications

Onboard Advanced Motion Controller for

1.5 axis motion control

Analog and pulse/direction control for

centralized motion

Reduced downtime with machine safety

- Integrated Dual Safe Torque Off

- Meets SIL3 and PLe

Advanced Motion

Controller onboard

Advanced 1.5 axes motion controller,

key features include:

- 250 μs cycle time

- Motion profi le generator

- Electronic gearbox

- Interpolated cam

- Homing functions

- High speed position freeze

18

18

PLe

Page 19

M753

S

IL

3

Safety Integrity Level

EtherCAT

EtherCAT drive

for centralized

motion control

applications

Digitax M753 EtherCAT

Digitax M753 features an integrated 2-port

EtherCAT switch for easy integration in

centralized motion control applications

EoE (EtherNet over EtherCAT) support

allows PC tool connection for commissioning

and monitoring over the EtherCAT network

The station alias can be dynamically

assigned by the EtherCAT master, or

hardwired with the two rotary switches

built into the display

An optional RS485 adaptor is available,

providing a back-up PC tool connection

in case of network failure

High performance with fl exibility

Operate with any automation product

via EtherCAT

- Operate with motion controllers,

motion PLCs and Industrial PCs

via built-in EtherCAT

- Dual 100Mbps EtherCAT interfaces for

use with in-line topologies

- Non-cyclic data communication using

the CoE mailbox

Flexibility for all applications achieved

through full access to drive functions

- CANopen over EtherCAT (CoE) including:

> CIA-402 profi le

> Cyclic sync position mode

> Interpolated position mode

> Velocity mode

> Profi le torque mode

> SDO access to all profi le objects

and drive parameters

Reduced downtime with machine safety

- Integrated Dual Safe Torque Off

- Meets SIL3 and PLe

PLe

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 19

19

Page 20

SERVO DRIVE SERIES

SERVO DRIVE SERIES

Option module flexibility

Our innovative design means

you only increase drive size

when option modules are used,

therefore achieving signifi cant

space saving in the overall

confi guration.

20

20

Adding the option mounting

kit only adds an additional 22

mm (0.86 in) width, providing a

maximum drive width of 62 mm

(2.44 in).

Page 21

Option modules

Digitax HD supports a range of

communications, I/O, feedback and

machine control option modules.

Feedback

SI-Universal

Encoder

Encoder input and output

interface supporting

Quadrature, SinCos,

EnDat and SSI encoders.

I/O

SI-I/O

Extended I/O interface

module to increase the

number of analog and digital

I/O points on the drive.

Communications

SI-Encoder

Quadrature encoder

input interface module.

Applications with

PLC or Motion

Functionality

MCi200

Advanced machine

control using industry

standard IEC61131-3

programming languages

MCi210

Extended advanced machine

control using industry

standard IEC61131-3

programming languages

and integrated EtherNet

connectivity

SI-EtherCAT

SI-DeviceNet

* Support of real-time EtherNet (RTMoE), HTTP, SMTP, EtherNet/IP and Modbus TCP/IP

SI-PROFINET

SI-CANopen

SI-EtherNet*

SI-PROFIBUS

SI-Apps Compact

Compatible module

allows legacy SyPTPro

application programs

to be re-compiled for

Digitax HD

21DRIVE SPECIALISTS SINCE 1973 21

Page 22

SERVO DRIVE SERIES

SERVO DRIVE SERIES

Unimotor HD

High dynamic

servo motor

0.7 Nm to 85.0 Nm (6.2 lb-in to 752 lb-in)

and up to 300% overload

Unimotor HD is a high dynamic brushless

AC servo motor range designed for use in

pulse duty applications where rapid acceleration

and deceleration is required.

for pulse duty

applications

• Patented rotor

technology – High

torque to inertia ratio for

high dynamic performance

High torque to inertia ratio

Unimotor HD has a high power to weight ratio,

meaning that it can be easily integrated into the

smallest, most demanding applications such as

industrial robotics, pick & place and packaging.

• Compact but powerful

• Parking brake available

• IP65 conformance: sealed

against water spray and dust

when mounted and connected

• Segmented stator design for high

power density and compactness

• Supported by rigorous testing for

performance and reliability

• Windings to suit 400 V and 200 V

• Rated speeds include

1,000 rpm – 6,000 rpm

depending on motor size

• Customized motor build available

22

22

Page 23

DATA

Order information

and technical data

Motor & drive

combinations .............................24

Cables &

connections ................................ 33

Dimensioning

the common DC bus ............. 27

Specifi cations ........................... 35

Digitax HD kits

& accessories .............................28

Digitax HD

ordering information ............. 32

Unimotor HD

ordering information ............. 32

Drive ratings ............................... 36

Environmental

safety & conformance .......... 37

Digitax HD | Unimotor HD

dimensions .................................. 38

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 23

23

Page 24

SERVO DRIVE SERIES

Digitax HD & Unimotor HD

motor and drive combinations

400 V range – 0.7 to 51 Nm (6.2 to 451 lb-in) with 300% peak stall torque

200 V range – 0.7 to 45 Nm (6.2 to 398 lb-in) with 300% peak stall torque

1000.00 Nm

(8850 lb-in)

100.00 Nm

(885.0 lb-in)

10.00 Nm

(88.50 lb-in)

1.00 Nm

(8.85 lb-in)

Torque

134.2

(1187.8)

44.7

(395.6)

22.8

(201.8)

153.1

(1355)

51.0

(451.4)

22.8

(201.8)

67.2

(594.8)

22.4

(198.3)

10.0

(88.5)

103.7

(917.8)

34.6

(306.2)

10.0

(88.5)

44.6

(394.7)

14.9

(131.9)

0.7

(6.2)

76.8

(679.7)

25.6

(226.6)

0.7

(6.2)

23.3

(206.2)

7.8

(69.0)

3.1

(27.4)

23.3

(206.2)

7.8

(69.0)

3.1

(27.4)

22.6

(200.0)

7.5

(66.4)

0.7

(6.2)

23.3

(206.2)

6

7.8

5

(69.0)

0.7

(6.2)

Peak torque 200 VPeak torque 400 V

Stall torque 200 VStall torque 400 V

0.10 Nm

(0.89 lb-in)

200 V

400 V

1000 1500

200 V

400 V

200 V

400 V

200 V

400 V

200 V

2000 3000 4000 6000

Speed (rpm) and input voltage (V)

400 V

Page 25

200 V THREE PHASE

Nominal speed 6000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

Motor Drive Hybrid Cable

055EDA60 M75x-01200022 HYBAxAxxx 0.69 6.1 2 .1 18.6 0.1 4 0.00012 2.2 580 0.43 0.58 8.5

055EDB60 M75x-01200040 HYBAxAxxx 1 .1 9.7 3.4 30.1 0.25 0.00022 4 580 0.57 0.76 9.2

055EDC60 M75x-01200040 HYBAxAxxx 1.6 14.2 4.8 42.5 0.36 0.00032 4 580 0.75 1.01 9.5

067EDA60 M75x-01200040 HYBAxAxxx 1.4 12.4 4.3 38.1 0.30 0.00027 4 580 0.82 1.10 8.8

067EDB60 M75x-01200065 HYBAxAxxx 2.5 22.1 7. 5 66.4 0.53 0.00047 6.5 580 1.4 1.88 8.9

089EDA60 M75x-02200090 HYBAxAxxx 3.1 27. 4 9.3 82.3 0.87 0.00077 6.5 1160 1.7 2.28 11.7

089EDB60 M75x-02200120 HYBAxAxxx 5.3 46.9 16.0 141.6 1.6 0.00142 12 1160 2.4 3.22 12.6

089EDC60 M75x-03200160 HYBBxAxxx 7.5 66.4 22.6 200.0 2.3 0.00204 16 1880 3.1 4.16 13.0

Motor Drive Hybrid Cable

089EDA40 M75x-01200065 HYBAxAxxx 3 .1 27. 4 9.3 82.3 0.87 0.00077 6.5 580 1.2 1.61 7.8

089EDB40 M75x-02200090 HYBAxAxxx 5.3 46.9 16.0 141.6 1.6 0.00142 9 1160 1.9 2.55 8.4

089EDC40 M75x-02200120 HYBAxAxxx 7.8 69.0 23.3 206.2 2.3 0.00204 12 1160 2.7 3.62 8.4

Motor Drive Hybrid Cable

055EDA30 M75x-01200022 HYBAxAxxx 0.69 6.1 2.1 18.6 0.14 0.00012 2.2 580 0.21 0.28 4.2

055EDB30 M75x-01200022 HYBAxAxxx 1.1 9.7 3.4 30.1 0.25 0.00022 2.2 580 0.32 0.43 4.6

067EDA30 M75x-01200022 HYBAxAxxx 1.4 12.4 4.3 38.1 0.30 0.00027 2.2 580 0.43 0.58 4.4

055EDC30 M75x-01200022 HYBAxAxxx 1.6 14.2 4.8 42.5 0.36 0.00032 2.2 580 0.45 0.60 4.8

067EDB30 M75x-01200040 HYBAxAxxx 2.5 22.1 7. 5 66.4 0.53 0.00047 4 580 0.75 1.01 4.4

089EDA30 M75x-01200040 HYBAxAxxx 2.8 24.8 8.4 74.3 0.87 0.00077 4 580 0.88 1.18 6.5

200 V Three phase

067EDC30 M75x-01200040 HYBAxAxxx 3.6 31.9 10.9 96.5 0.75 0.00066 4 580 1 .1 1.48 4.3

089EDB30 M75x-01200065 HYBAxAxxx 5.3 46.9 16.0 141.6 1.6 0.00142 6.5 580 1.5 2.01 6.3

089EDC30 M75x-02200090 HYBAxAxxx 7. 8 69.0 23.3 206.2 2.3 0.00204 9 1160 2.1 2.82 6.3

115EDB30 M75x-02200120 HYBAxAxxx 10.0 88.5 30.0 265.5 4.4 0.00389 12 1160 2.4 3.22 9.2

115EDC30 M75x-03200160 HYBBxAxxx 14.3 126.6 42.9 379.7 6.4 0.00566 16 1880 3.2 4.29 9.4

142EDC30 M75x-03200160 HYBBxBxxx 14.9 131.9 44.6 394.7 17. 0 0.01505 16 1880 4.7 6.30 23.9

[Nm] [lb-in] [Nm] [lb-in] [kg·cm2] [lb-in-sec2]

Nominal speed 4000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm2] [lb-in-sec2]

Nominal speed 3000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm2] [lb-in-sec2]

Cont.

Current

[A]

Cont.

Current

[A]

Cont.

Current

[A]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

Time to

6000 rpm

[ms]*

Time to

4000 rpm

[ms]*

Time to

3000 rpm

[ms]*

Nominal speed 2000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

Motor Drive Hybrid Cable

115EDB20 M75x-02200090 HYBAxAxxx 10.0 88.5 30.0 265.5 4.4 0.00389 9 1160 1.8 2.41 6.2

115EDC20 M75x-02200120 HYBAxAxxx 14.3 126.6 42.9 379.7 6.4 0.00566 12 1160 2.4 3.22 6.2

115EDD20 M75x-03200160 HYBBxAxxx 18.4 162.9 55.3 489.4 8.4 0.00743 16 1880 3.2 4.29 6.4

142EDC20 M75x-03200160 HYBBxBxxx 22.4 198.3 67.2 594.8 17. 0 0.01505 16 1880 4.1 5.50 10.6

Motor Drive Hybrid Cable

142EDC10 M75x-02200090 HYBAxAxxx 22.8 201.8 68.3 604.5 17. 0 0.01505 9 1160 2.2 2.95 5.2

142EDD10 M75x-02200120 HYBAxAxxx 28.7 254.0 86.0 761.2 22.1 0.01956 12 1160 2.8 3.75 5.4

142EDE10 M75x-03200160 HYBBxAxxx 34.6 306.2 103.7 917.8 2 7.2 0.024 07 16 1880 3.3 4.43 5.5

190EDC10 M75x-03200160 HYBBxBxxx 44.7 395.6 134.2 1187.8 54.6 0.04833 16 1880 4.7 6.30 8.5

[Nm] [lb-in] [Nm] [lb-in] [kg·cm2] [lb-in-sec2]

Nominal speed 1000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm2] [lb-in-sec2]

For drive ratings, please see page 34 and motor ratings from page 38 to 43

* Acceleration time to nominal speed is based on 1:1 motor to load inertia ratio

Cont.

Current

[A]

Cont.

Current

[A]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

DRIVE SPECIALISTS SINCE 1973www.controltechniques.com24 25

Time to

2000 rpm

[ms]*

Time to

1000 rpm

[ms]*

Page 26

SERVO DRIVE SERIES

400 V THREE PHASE

Nominal speed 6000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

Motor Drive Hybrid Cable

055UDA60 M75x-01400015 HYBAxAxxx 0.69 6.1 2 .1 18.6 0.1 4 0.00012 1.5 110 0.43 0.6 8.5

055UDB60 M75x-01400015 HYBAxAxxx 1.1 9.7 3.4 3 0.1 0.25 0.00022 1.5 110 0.57 0.8 9.2

055UDC60 M75x-01400030 HYBAxAxxx 1.6 14.2 4.8 42.5 0.36 0.00032 4.2 110 0.75 1.0 9.5

067UDA60 M75x-01400030 HYBAxAxxx 1.4 12.4 4.3 38.1 0.30 0.00027 4.2 110 0.82 1.1 8.8

067UDB60 M75x-01400042 HYBAxAxxx 2.5 22.1 7. 5 66.4 0.53 0.00047 4.2 110 1.4 1.9 8.9

067UDC60 M75x-02400060 HYBAxAxxx 3.6 31.9 10.9 96.5 0.75 0.00066 6.0 290 1.9 2.5 8.7

089UDA60 M75x-01400042 HYBAxAxxx 3.1 27. 4 9.3 82.3 0.87 0.00077 4.2 110 1.7 2.3 11.7

089UDB60 M75x-02400080 HYBAxAxxx

089UDC60 M75x-02400105 HYBBxAxxx 7. 8 69.0 23.3 206.2 2.3 0.00204 10.5 290 3.1 4.2 12.6

Motor Drive Hybrid Cable

089UDA40 M75x-01400030 HYBAxAxxx 3.1 2 7.4 9.3 82.3 0.87 0.00077 4.2 110 1.2 1.6 7. 8

089UDB40 M75x-02400060 HYBAxAxxx 5.3 46.9 16.0 141.6 1.6 0.00142 6.0 290 1.9 2.5 8.4

089UDC40 M75x-02400080 HYBAxAxxx 7. 8 69.0 23.3 206.2 2.3 0.00204 8.0 290 2.7 3.6 8.4

Motor Drive Hybrid Cable

055UDA30 M75x-01400015 HYBAxAxxx 0.69 6.1 2.1 18.6 0.14 0.00012 1.5 110 0.21 0.3 4.2

055UDB30 M75x-01400015 HYBAxAxxx 1.1 9.7 3.4 30.1 0.25 0.00022 1.5 110 0.32 0.4 4.6

055UDC30 M75x-01400015 HYBAxAxxx 1.6 14.2 4.8 42.5 0.36 0.00032 1.5 110 0.45 0.6 4.8

067UDA30 M75x-01400030 HYBAxAxxx 1.4 12.4 4.3 38.1 0.30 0.00027 4.2 110 0.43 0.6 4.4

067UDB30 M75x-01400015 HYBAxAxxx 2.4 21.2 7. 2 63.7 0.53 0.00047 1.5 110 0.75 1.0 4.6

067UDC30 M75x-01400030 HYBAxAxxx 3.6 31.9 10.9 96.5 0.75 0.00066 4.2 110 1.1 1.5 4.3

089UDA30 M75x-01400030 HYBAxAxxx 3.1 27. 4 9.3 82.3 0.87 0.00077 4.2 110 0.91 1.2 5.9

400 V Three phase

089UDB30 M75x-01400042 HYBAxAxxx

089UDC30 M75x-02400060 HYBAxAxxx 7. 8 69.0 23.3 206.2 2.3 0.00204 6.0 290 2 .1 2.8 6.3

115UDB30 M75x-02400080 HYBAxAxxx 10.0 88.5 30.0 265.5 4.4 0.00389 8.0 290 2.4 3.2 9.2

115UDC30 M75x-02400105 HYBBxAxxx 14.3 126.6 42.9 379.7 6.4 0.00566 10.5 290 3.2 4.3 9.4

115UDD30 M75x-03400135 HYBBxAxxx 18.4 162.9 55.3 489.4 8.4 0.00743 13.5 470 4.2 5.6 9.5

142UDC30 M75x-03400160 HYBBxAxxx 22.8 201.8 68.3 604.5 1 7.0 0.01505 16.0 470 5.3 7.1 15.7

142UDD30 M75x-03400160 HYBBxBxxx 25.6 226.6 76.8 679.7 22.1 0.01956 16.0 470 6.0 8.0 18.1

[Nm] [lb-in] [Nm] [lb-in] [kg·cm

5.3 46.9 16.0 141.6 1.6 0.00142 8.0 290 2.4 3.2 12.6

Nominal speed 4000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm

Nominal speed 3000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm

5.3 46.9 16.0 141.6 1.6 0.00142 4.2 110 1.5 2.0 6.3

2

] [lb-in-sec2]

2

] [lb-in-sec2]

2

] [lb-in-sec2]

Cont.

Current

[A]

Cont.

Current

[A]

Cont.

Current

[A]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

Time to

6000 rpm

[ms]*

Time to

4000 rpm

[ms]*

Time to

3000 rpm

[ms]*

Nominal speed 2000 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

Motor Drive Hybrid Cable

115UDB20 M75x-01400042 HYBAxAxxx 10.0 88.5 30.0 265.5 4.4 0.00389 4.2 110 1.8 2.4 6.2

115UDC20 M75x-02400060 HYBAxAxxx 14.3 126.6 42.9 379.7 6.4 0.00566 6.0 290 2.4 3.2 6.2

115UDD20 M75x-02400080 HYBAxAxxx 18.4 162.9 55.3 489.4 8.4 0.00743 8.0 290 3.2 4.3 6.4

142UDC20 M75x-02400105 HYBBxAxxx 22.8 201.8 68.3 604.5 17. 0 0.01505 10.5 290 4.1 5.5 10.4

142UDD20 M75x-03400135 HYBBxAxxx 28.7 254.0 86.0 761.2 22.1 0.01956 13.5 470 4.9 6.6 10.8

142UDE20 M75x-03400160 HYBBxAxxx 34.6 306.2 103.7 917.8 27.2 0.02407 16.0 470 5.6 7. 5 11.0

Motor Drive Hybrid Cable

142UDC15 M75x-02400080 HYBAxAxxx 22.8 201.8 68.3 604.5 1 7.0 0.01505 8.0 290 3.2 4.3 7.8

142UDD15 M75x-02400105 HYBAxAxxx 28.7 254.0 86.0 761.2 22.1 0.01956 10.5 290 3.9 5.2 8.1

142UDE15 M75x-03400135 HYBAxAxxx 34.6 306.2 103.7 917.8 2 7.2 0.024 07 13.5 470 4.5 6.0 8.2

190UDC15 M75x-03400160 HYBBxBxxx 51.0 451.4 153.1 1355.0 54.6 0.04833 16.0 470 7. 3 9.8 11.2

[Nm] [lb-in] [Nm] [lb-in] [kg·cm

Nominal speed 1500 rpm - 300% overload

Stall Torque Peak Torque Inertia Drive

[Nm] [lb-in] [Nm] [lb-in] [kg·cm

For drive ratings, please see page 36 and motor ratings from page 40 to 45.

* Acceleration time to nominal speed is based on 1:1 motor to load inertia ratio

26

2

] [lb-in-sec2]

2

] [lb-in-sec2]

Cont.

Current

[A]

Cont.

Current

[A]

Drive

Capacitance

[μF]

Drive

Capacitance

[μF]

Motor Cont.

power

[kW] [hp]

Motor Cont.

power

[kW] [hp]

Time to

2000 rpm

[ms]*

Time to

1500 rpm

[ms]*

Page 27

Modular multi-axis configuration

* External AC Line Reactor required. Please refer to the Installation and Technical Guide.

ADDITIONAL

Dimensioning the common DC bus

4 easy steps to

1

1

2

4

3

Digitax HD drives have a high capacity input power stage,

allowing for a group of drives on a common DC bus to be

powered by a single AC connection.

Alternatively, for larger confi gurations an external DC

source can be used, such as a larger frame Unidrive M.

NOTE: The number of drives that can be connected on

a common DC bus group depends on the total

installed capacitance, the power

rating of the input stage and

the power profi le of each axis.

There is also a limit of

10 drives for the 24 Vdc link.

ADDITIONAL

INFORMATION:

For optimized dimensioning

please refer to the Installation

and Technical Guide.

accurately dimension

your system

Choose drive & motor combination

1

based on speed and torque

requirements see pages 25 and 26

Note nominal power & drive

2

capacitance for each combination

Choose the drive to act as power

3

supply for the drive group

Usually the largest drive

Check that:

4

1. sum of drive capacitance

<= maximum capacitance**

2. sum of nominal power

<= maximum input power**

(Refer to tables below)

Max

200V

M75x-01200022

Size 1

M75x-01200040

M75x-01200065

M75x-02200090

Size 2

M75x-02200012

Size 3 M75x-03200160 376 0 1880 6.3 / 10* 8.5 / 13.4*

400V

M75x-01400015

Size 1

M75x-01400030

M75x-01400042

M75x-02400060

Size 2

M75x-02400080

M75x-02400105

M75x-03400135

Size 3

M75x-03400160

Capacitance

(µF)

5800 580 4 / 5.2* 5.4 / 7.0*

4640 1160 5.3 / 6.9* 7.1 / 9.3*

Max

Capacitance

(µF)

1900 110 6.5 / 8.5* 8.7 / 11.4*

2030 290 8.7 / 11.4* 11.7 / 15.3*

2210 470 10 / 13* 13.4 / 17.4*

Internal

Capacitance

(µF)

Internal

Capacitance

(µF)

Max

Input

Power

(kW)

Max

Input

Power

(kW)

Max Input

Power

(hp)

Max Input

Power

(hp)

* External AC Line Reactor required. Please refer to the Installation and Technical Guide.

** If any of the values are exceeded, the system needs to be split in groups and the

procedure repeated for each group.

DRIVE SPECIALISTS SINCE 1973

27

Page 28

SERVO DRIVE SERIES

SERVO DRIVE SERIES

Multi-axis Kit

Description Order code

Multi-axis Kit (standard – without

SI-Option Mounting Kit fi tted)

Multi-axis Kit (with SI-Option

Mounting Kit fi tted)

Description Order code

External Cable Grommet Kit up

External DC Cable Connection

Kit up to 16mm

to 6mm

2

2

Digitax HD

kits and accessories

9500-1047

9500-1048

3470-0145

9500-1050

Description Order code

USB to EIA485 Communications

Converter Cable

Description Order code

KI-Compact 485 Adaptor 82700000020300

Description Order code

KI-Compact Display 82700000020400

4500-0096

Standard cables available

Description Order code

Refer to pages 33 and 34

28

28

Page 29

Description Order code

Input Line Choke 4401-0236

Description Order code

Remote Keypad RTC 82400000019600

Description Order code

TM

Frame 1 Rear Ultrafl ow

Frame 2/3 Rear Ultrafl ow

Vent Kit

Retrofi t Kit – Epsilon 202-206 3470-0185

Retrofi t Kit – Epsilon 209-216 3470-0184

Retrofi t Kit – Digitax ST/SP0 3470-0182

Retrofi t Kit – M’Ax 3470-0183

Description Order code

SI-Option Mounting Kit 9500-1055

Vent Kit 3470-0158

TM

Description Order code

3470-0181

Drive – Mountable Brake Resistor

Description Order code

Compact Brake Resistor Kit – 50 W, 70 Ω 9500-1049

External Brake Resistor

Description Order code

External Brake Resistor – DBR 100 W, 20 Ω 1220-2201

External Brake Resistor – DBR 100 W, 40 Ω 1220-2401

External Brake Resistor – DBR 100 W, 80 Ω 1220-2801

Description Order code

Fan Replacement Kit (frame 1 and 2) 9500-1053

Fan Replacement Kit (frame 3) 9500-1054

Description Order code

Encoder breakout kit 82700000020200

DRIVE SPECIALISTS SINCE 1973

DRIVE SPECIALISTS SINCE 1973 29

29

Page 30

SI-PROFIBUS

SI-Encoder

SI-DeviceNet

SI-CANopen

SI-EtherNet

SI-PROFINET RT

SI-Universal Encoder

MCi200

MCi210

SI-I/O

SI-Apps Compact

SERVO DRIVE SERIES

Digitax HD

kits and

accessories

EMC Filters

Voltage Model (M75X-...) Phases Order code

1200022 1

4200-35031200040 1

1200065 1

2200090 1

2200120 1

200 V

400 V

* EMC fi lter ratings provided at maximum continuous current at 40 °C

(104 °F). Please refer to the installation and Technical Guide.

3200160 1 4200-6034

1200022 3 4200-8744

1200040 3 4200-6002

1200065 3 4200-6001

2200090 3 4200-5833

2200120 3 4200-5833

3200160 3 4200-5833

01400015 to 01400042 3 4200-8744

02400060 to 02400105 3 4200-1644

03400135 to 03400160 3 4200-5833

* Multi-axis up to 46 A 4200-0033

* Multi-axis up to 60.2 A 4200-5534

* Multi-axis up to 82.2 A 4200-7534

* Multi-axis up to 109.5 A 4200-0035

4200-5033

In the box for each Digitax HD M75x

Description Part Number

KI-Compact Display 82700000020400 Ye s No Ye s N /A

SI-Option Mounting Kit 9500-1055 No Yes No N/A

Removable cable screen bracket

Brake Connector Yes Yes Ye s N /A

Power Input Connector Yes Yes Ye s N /A

24 Vdc Supply Input Connector Yes Yes Ye s Ye s

I/O Connector Yes Yes Ye s N /A

Motor Connector Yes Ye s Yes N/A

M4 x 8 Screws (Motor earth, Input

earth and cable screen bracket)

N/A

M750

EtherNet

Yes Yes Ye s N /A

Yes Yes Ye s N /A

M751

Base

M753

EtherCAT

M75C

CapShare

30

Description Order code

DC bus conn. kit -

Unidrive M fr03 (panel mount)

DC bus conn. kit -

Unidrive M fr03 (through mount)

DC bus conn. kit -

Unidrive M fr06 (panel mount)

DC bus conn. kit -

Unidrive M fr06 (through mount)

System Integration Option Modules

Option Order code

MCi200 82400000017000

MCi210 82400000016700

SI-Apps Compact 82400000020700

SI-EtherNet 82400000017900

SI-PROFINET RT 82500000018200

SI-PROFIBUS 82400000017500

SI-CANopen 82400000017600

SI-DeviceNet 82400000017700

SI-Universal Encoder 82400000018300

SI-Encoder 82400000018100

SI-I/O 82400000017800

SI-EtherCAT 82400000018000

3470-0146

3470-0147

3470-0148

3470-0149

Page 31

M75C CapShare

Capacitor Module

DIN rail

alignment

Status LED

Top vent

for natural

convection

cooling

Common DC

bus links &

parallel

connection

24 Vdc

parallel

connection

Status

relay

contacts

M75C Capabilities

Available in 200 V and 400 V

variants, the M75C CapShare Capacitor

Module is contained within a M75x Frame

1 chassis measuring 40mm width. M75C

CapShare is designed for use in multi-axis

applications to off er:

◼ Robustness against fl uctuations in power

supply, increasing the ability to ride through

brief mains losses

◼ Dynamic performance with quick-access energy

storage for fast acceleration / deceleration

◼ Energy effi ciency as more energy can be stored,

rather than dissipated into heat

Multiple M75C CapShare units can be paralleled in

a scalable architecture, which is also quick and easy

to install with DIN rail alignment, and easy DC bus

paralleling.

M75C CapShare Capacitor Module

Part Number M75C-01201740 M75C-01400725

Rated Voltage 200 V 400 V

Energy efficiency

◼ Easy common DC bus connection enables braking

energy to be recycled within the drive system,

optimizing energy useage.

◼ Any Digitax HD drive can be used as an Active Front

End (AFE) to create a regenerative AC drive system.

Active Front End kits

Voltage Model (M75X-…) Switching Frequency Filter

2200090 1610-8104 4401-0310 4401-1311

200 V

400 V

2200120 1610-8104 4401-0312 4401-1312

3200160 1610-8104 4401-0313 4401-1313

2400080 1610-8104 4401-0405 4401-0162

2400105 1610-8104 4401-0406 4401-0163

3400135 1610-8104 4401-0407 4401-0164

3400160 1610-8104 4401-0407 4401-0164

Capacitors

Order Codes Order Codes Order Codes

Onboard capacitance 1740 µF 725 µF

DC supply 200-370 Vdc 360-760 Vdc

External 24 Vdc supply for control Yes

Internal Current Inrush limitation Circuit Yes

Status Relay (Potential Free Contacts) Yes

Status Indication On Front Panel Single LED

Thermal Protection Yes

Easy connection to a drive or drive group can be achieved with the

multiaxis kit (9500-1048) – no additional fusing required.

Regenerative Choke Switching Frequency Filter

Choke

DRIVE SPECIALISTS SINCE 1973

31

Page 32

SERVO DRIVE SERIES

Digitax HD ordering information

Drive part number key:

Identification Label

Derivative

Electrical Specification

Configuration

M753 - A 101 2 00022

Digitax HD range

M750 - EtherNet

M751 – Base

M753 – EtherCAT

Frame Size:

01 – frame 1

02 – frame 2

03 – frame 3

Voltage Rating:

2-200 V (200-240 ± 10%)

4-400 V (380-480 ± 10%)

Current Rating:

Nominal current rating x 10

Safety:

1 – Standard (2 x STO)

*For EtherNet and MCi versions, Option Modules are required separately. See page 29 for order codes.

Encoder

Interface

0

Documentation

1 00

Default

Region:

00 - 50 Hz

01 - 60 Hz

Optional Build

A 1B 1 0

Display option:

0 – KI-Compact Display not fitted

1 – KI-Compact Display fitted –

M750 and M753 only

Option module support:

AB10 – Not fitted

AB11 – Fitted – M751 only

Documentation:

1 – Multilingual

Encoder Interface:

0 – Standard

Unimotor HD ordering information

Motor part number key:

Frame

size

089

055

067

089

115

142

190

ED = 200V

UD = 400V

Motor

voltage

Stator

length*

Rated

speed

UD 0 B

055-

067

A

B

C

089

A

B

C

115

B

C

D

142

C

D

E

190

C

D

F

055 Frame

30 = 3000 rpm

60 = 6000 rpm

067 Frame

30 = 3000 rpm

60 = 6000 rpm

089 Frame

30 = 3000 rpm

40 = 4000 rpm

60 = 6000 rpm

115 Frame

20 = 2000 rpm

30 = 3000 rpm

142 Frame

10 = 1000 rpm

15 = 1500 rpm

20 = 2000 rpm

30 = 3000 rpm

190 Frame

10 = 1000 rpm

15 = 1500 rpm

20 = 2000 rpm

Brake Connection

0 = Not fitted

5 = Parking

Brake (fibre)

6 = Parking

Brake (resin)

x = Special

Size 1

B = Power and signal

90° rotatable

D= Single cable, power

& Signal combined,

90° rotatable

Size 1.5

J = Power and signal 90°

rotatable

E = Single cable, power

& signal combined,

90° rotatable

Single cable only must be

fitted with KTY thermistor

and is only available with

certain feedback options.

Please check before

ordering.

1

type*

Output shaft Feedback

device

A CA30

A = Key

B = Plain

E = Key with half

F = Key and half key supplied separately

Code Type Incremental

2

key fitted

055 and 067 frame sizes

resolution

AR Resolver 14 bit - ±600” no

EG Absolute (Multi turn) 19 bit 12 bit ±120” yes

FG Absolute (Single turn) 19 bit - ±120” yes

TL Absolute (Multi turn) 17 bit 12 bit ±120” no

UL Absolute (Single turn) 17 bit - ±120” no

089 to 190 frame sizes

AE Resolver 14 bit - ±720” no

EF Absolute (Multi turn) 19 bit 12 bit ±65” yes

FF Absolute (Single turn) 19 bit - ±65” yes

RA Absolute (Multi turn) 20 bit 12 bit ±52” no

SA Absolute (Single turn) 20 bit - ±52” no

A = Standard + PTC

C = Standard inertia +

2

E = Standard + PTC

Absolute

resolution

KTY84-130

Thermistor

Thermistor + Lifting

brackets (190 frame)

Accuracy Single

Inertia +

thermistor

type

AB

cable

*For stator length and connection type see pages 38 - 43

1

not available for 055 & 190 frames

2

n

ot available on 055 frame.

32

Additional feedback options available on request.

Page 33

Cables and connections

Power cable part number key:

FIELD NUMBER

1 32 4 5 76 8 9 1110 12

M BB A A OA O 2 S5 S

Cable & jacket type (field No 1,2 &3)

MBB = power braked

4 w + 2 w + screen, PUR jacket

MSB = power

4 w + screen, PUR jacket

Phase & conductor size (field No 4)

MSB = Un-braked MBB = Braked

2

A = 1 mm

B = 2.5 mm

C = 4 mm + 1 mm

D = 6 mm + 1 mm

E = 10 mm + 1 mm

F = 16 mm + 1 mm

G = 25 mm + 1 mm

*Length meter / cable requiring (cm) lengths will be rounded up to the next highest half meter; Eg. 2.1 will be changed to a 2.5 meter cable.

Maximum cable length refer to page 34

2

+ 0.5 mm

+ 0.5 mm

2

2

Drive end connection * (field No 5)

A = Ultrasonic welding

X = Cut end

Length meter * (field No 7, 8, 9 & 10)

0010 = 1 meter

0025 = 2.5 meter

0500 = 50 meters

Motor end connection (field No 6)

A = 6 way power size 1 from 1 to 4 mm

C = 6 way power size 1.5 from 6 to 16 mm

X = Cut end

Optional:

Progressive alphanumeric

code for custom special

requests (field No 11 & 12)

2

Signal cable part number key:

FIELD NUMBER

1 32 4 5 76 8 9 1110 12

S BI A B OA O 2 S5 S

Jacket type (field No 3)

A = PVC fixed installation

B = PUR dynamic installation

Cable & jacket type* (field No 1,2 & 4)

SI*A = CR, CA, EM, FM, EC, FC, EB, FB

SR*B = AR, AE

SS*C = TL, UL, RA, SA

SE*E = EF, FF, EG, FG, GB, HB, EN, FN

* Length meter/cable requiring (cm) lengths will be rounded up to the next highest half meter; Eg. 2.1 will be changed to a 2.5 meter cable.

Maximum cable length refer to page 34

Drive end connection (field No 5)

B = Flying leads

F = Low profile 90 deg 15 way connector

(inc. SC Endat)

T = Endat only low profile 90 Deg 15

way connector

X = Cut end

Length meter * (field No 7, 8, 9 & 10)

0010 = 1 meter

0025 = 2.5 meters

0500 = 50 meters

Motor end connection (field No 6)

A = Unimotor 17 way no speedtec connector

B = Unimotor 12 way no speedtec connector

X = Cut end

DRIVE SPECIALISTS SINCE 1973www.controltechniques.com32 33

Optional:

Progressive alphanumeric

code for custom special

requests (field No 11 & 12)

Page 34

SERVO DRIVE SERIES

Cables and connections

Hybrid cable part number key:

FIELD NUMBER

1 32 4 5 76 8 9 1110 12

H BY A A OA O 2 S5 S

Cable & jacket type (fi eld No 1,2 &3)

HYB = power standard

4 w + 2 brake + 6 signal +

screen, PUR desina orange.

Phase & conductor size (fi eld No 4)

A = 1.5 mm

B = 2.5 mm2 + 1 mm

C = 4 mm2 + 1 mm

2

+ 0.75 mm

2

2

2

Length meter * (fi eld No 7, 8, 9 & 10)

0010 = 1 meter

0025 = 2.5 meters

0500 = 50 meters

Drive end connection (fi eld No 5)

A = ULTRASONIC WELDING and 15 way High Density D Sub

for signal

D = Digitax HD Size 01, 02 & 03

E = Digitax HD Size 01 & 02 complete with EMC bracket and

terminal block fi tted

F = Digitax HD Size 03 complete with EMC bracket and terminal

block fi tted

X = Cut end

* Length meter / cable requiring (cm) lengths will be rounded up to the next highest

half meter; Eg. 2.1 will be changed to a 2.5 meter cable

Maximum cable assembly length refer to table below

Optional:

Progressive alphanumeric

code for custom special

requests (fi eld No 11 & 12)

Motor end connection (fi eld No 6)

A = Hybrid connector Size 1

B = Hybrid connector Size 1.5

X = Cut end

34

Page 35

Digitax HD

Servo series specifi cation

M753 EtherCAT M751 Base M750 EtherNet M751 + MCi210

Update Rates

Performance

Ultrafl ow™

Technology

Onboard

Intelligence

Control

Interface

Commissioning

General

Overload

Max Output Frequency

Switching Frequency

Adjustable Venting

Intelligent Fan Control

Managed Internal

Airfl ow

Motion

PLC

Motor Control Modes

Control Modes

Control Features

Onboard

Communications

Fieldbus

Real Time Motion

Analog I/O

Digital I/O

Pulse Train Input

Encoder Feedback

Supported Encoders

Safety

Interface

Commissioning Tool

Motion Programming

Tool

Mechanical Attributes

Backup

Braking

Multi-axis

Display

RFC-S: Rotor Flux Control for Synchronous (permanent magnet brushless) motors

RFC-A: Rotor Flux Control for Asynchronous (induction) motors

* The stated percentages apply only to three phase continuous current

*Open-loop Overload: Maximum open loop peak current for 8 s (from cold: 150 % for 100 s)

V/F, Open loop vector, Rotor fl ux control-Asynchronous for induction motors (Sensorless or with feedback

‘Closed Loop’), Rotor fl ux control-Synchronous (Sensorless or with feedback ‘Closed Loop’)

2-port EtherCAT

switch

EtherCAT Modbus RTU

EtherCAT (CoE) None RTMoE RTMoE

EtherNet over

EtherCAT (EoE)

– Machine Control Studio

Yes Optional Ye s Optional

Current Loop Update: 62 µs

Speed Loop Update: 250 µs

Position Loop Update: 250 µs

*Closed-loop Overload: Maximum closed loop peak current for 0.25 s

Temperature controlled fan operation with user adjustable speed limit

Advanced bi-quad fi lters for suppression of mechanical resonances

Resolver, Quadrature, AB Servo, SinCos, EnDat (2.1/2.2), SSI, BiSS, Hiperface

Electronic motor nameplate parameter storage (HIPERFACE, Endat 2.2)

(from cold: 300 % for 8 s or 200 % for 60 s)

550 Hz (RFC-A and RFC-S) 599 Hz (Open Loop)

Confi gurable range: 2, 3, 4, 6, 8, 12, 16 kHz

Default: 8kHz

Top venting or rear venting (with optional kit)

Managed airfl ow for maximum ingress protection

Advanced Motion Controller MCi210

Parameterised motion Programmable motion

1.5 Axes Up to 5 Axes

Positioning

digital lock control

Real-time tasks

Onboard PLC Onboard Machine Controller

IEC61131-3 programming (IL, LD, FBD, SFC, ST, CFC)

Position control, speed control, torque control

Stationary autotune for permanent magnet motors

2-port RS485 2-port EtherNet switch

Modbus RTU, Modbus TCP/

IP, EtherNet/IP, PROFINET

1 Analog Input ± 10V, 12 bits (11 bits + sign)

2 DI, 2 DO (100 mA), 1 motor brake output (1 A, max 1.3 A)

Frequency/Direction 5 V di erential, 500 kHz

2 x Encoder input and 1 simulated encoder output

2 x Safe Torque O (STO) via terminal, PLe, SIL3

RS485 EtherNet RS485 / EtherNet

Removable cable screen clamp

User replaceable fan(s)

Conformal coating

Braking resistor: external / drive mountable

Braking chopper: integrated

Busbars for common DC bus and earthing

Quick Links for 24 V distribution

Common braking resistor

RT

Connect

SD Card

Positioning

digital lock control

camming

2-port RS 485

2-port EtherNet switch

Modbus RTU, Modbus TCP/IP,

EtherNet/IP

DRIVE SPECIALISTS SINCE 1973

35

Page 36

SERVO DRIVE SERIES

Drive ratings

Frame Size

W x D x H mm (in)

Line Supply Single Phase AC 200 V…240 V (± 10%) @ 45...66 Hz

Output Servo

Rated Current (A) 1.1 2.2 3.5 5.6 7.5 10.8

Max Peak Current (A) 6.6 12 19.5 27 36 48

Output AC Induction

Max Continuous Current (A) 1.1 2.2 3.5 5.6 7.5 10.8

Open Loop Peak Current (A) 3.3 6 9.8 13.5 18 24

Closed Loop Peak Current (A) 6.6 12 19.5 27 36 48

200 V Single Phase

Motor Power at 230 V (kW) 0.18 0.37 0.75 1.1 1.5 2.2

Motor Power at 230 V (hp) 0.25 0.5 1.0 1.5 2.0 3.0

Overload

Closed-loop Overload Maximum closed loop peak current for 0.25 s

Open-loop Overload Maximum open loop peak current for 8 s

Frame Size 01

40 x 174 x 233 (1.57 x 6.85 x 9.17)

M75X-... 01200022 01200040 01200065 02200090 02200120 03200160

Frame Size 02

40 x 174 x 278 (1.57 x 6.85 x 10.94)

Frame Size 03

40 x 174 x 328 (1.57 x 6.85 x 12.91)

Frame Size

W x D x H mm (in)

Line supply Three Phase AC 200 V…240 V (± 10%) @ 45...66 Hz

M75X-... 01200022 01200040 01200065 02200090 02200120 03200160

Input

Max Power (kW) 4 5.3 10*

Output Servo

Rated Current (A) 2.2 4 6.5 9 12 16

Max Peak Current (A) 6.6 12 19.5 27 36 48

Output AC Induction

Max Continuous Current (A) 2.2 4 6.5 9 12 16

Open Loop Peak Current (A) 3.3 6 9.8 13.5 18 24

200 V Three Phase

Closed Loop Peak Current (A) 6.6 12 19.5 27 36 48

Motor Power at 230 V (kW) 0.37 0.75 1.1 2.2 2.2 4.0

Motor Power at 230 V (hp) 0.5 1.0 1.5 2 .0 3.0 5.0

Overload

Closed-loop Overload 300 % for 0.25 s or 200 % for 4 s

Open-loop Overload 150 % for 8 s

Frame Size

W x D x H mm (in)

Line Supply Three Phase AC 380 V…480 V (± 10%) @ 45...66 Hz

Input

Max Power (kW) 6.5 8.7 10/13*

Output Servo

Rated Current (A) 1.5 3 4.2 6 8 10.5 13.5 16

Max Peak Current (A) 4.5 9 12.6 18 24 31.5 40.5 48

Output AC Induction

Max Continuous Current (A) 1.5 3 4.2 6 8 10.5 13.5 16

400 V Three Phase

Open Loop Peak Current (A) 2.3 4.5 6.3 9 12 15.8 20.3 24

Closed Loop Peak Current (A) 4.5 9 12.6 18 24 31.5 40.5 48

Motor Power at 400 V (kW) 0.37 0.75 1.5 2.2 3.0 4.0 5.5 5.5

Motor Power at 400 V (hp) 0.75 1.5 2.0 3.0 5.0 5.0 7.5 10.0

Overload

Closed-loop Overload 300 % for 0.25 s or 200 % for 4 s

Open-loop Overload 150 % for 8 s

* External AC line reactor required.

Frame Size 01

40 x 174 x 233 (1.57 x 6.85 x 9.17)

Frame Size 01

40 x 174 x 233 (1.57 x 6.85 x 9.17)

M75X-... 01400015 01400030 01400042 02400060 02400080 02400105 03400135 03400160

Frame Size 02

40 x 174 x 278 (1.57 x 6.85 x 10.94)

Frame Size 02

40 x 174 x 278 (1.57 x 6.85 x 10.94)

Frame Size 03

40 x 174 x 328 (1.57 x 6.85 x 12.91)

Frame Size 03

40 x 174 x 328 (1.57 x 6.85 x 12.91)

36

Page 37

Environment,

S

IL

3

Safety Integrity Level

safety

and electrical

conformance

Environment

IP rating: M75x drives are rated

to IP20 (dry, non-conductive

contamination)

UL open class

Ambient temperature -20 °C (-4 °F)

to 40 °C (104 °F) as standard. Up to

55 °C (131 °F) with derating

Humidity 95 % maximum

(non-condensing) at 40 °C (104 °F)

1,000 m to 3,000 m (3,300 ft to

9,900 ft) above sea level: de-rate

the maximum output current from

the specifi ed fi gure by 1% per 100 m

(330 ft) above 1,000 m (3,300 ft)

Storage temperature

-40 °C (-40 °F) to 70 °C (158 °F)

Mechanical Shock Tested

in accordance with IEC 60068-2-27

Random Vibration: Tested

in accordance with IEC 60068-2-64

Safety

Safe Torque Off independently

assessed by TÜV to IEC 61800-5-2

SIL 3 and EN ISO

13849-1 PLe

UL 61800-5-1

(Electrical Safety)

Electrical conformance

Electromagnetic Immunity complies

with EN 61800-3 and EN 61000-6-2

With onboard EMC fi lters, complies

with EN 61800-3 (2nd environment)

EN 61000-6-3 and EN

61000-6-4 with optional

EMC fi lter

IEC 60146-1-1 supply conditions

IEC 61800-5-1

(Electrical Safety)

IEC 61131-2 I/O

E171230

PLe

DRIVE SPECIALISTS SINCE 1973

37

Page 38

SERVO DRIVE SERIES

Digitax HD

& Unimotor HD

DIMENSIONS

Frame 1

dimensions

40 mm

(1.58 in)

174 mm (6.85 in)

Ø 5.2 mm

(0.21 in)

6 mm

(0.24 in)

233 mm (9.17 in)

222 mm (8.74 in)

6 mm

(0.24 in)

12 mm

(0.47 in)

40 mm (1.58 in)

Ø 5.2 mm

(0.21 in)

28 mm

(1.10 in)

Ø32 mm

(1.26 in)

Ø 5.2 mm

(0.21 in)

*

Frame 2

40 mm

(1.58 in)

174 mm (6.85 in)

Ø 5.2 mm

(0.21 in)

6 mm

(0.24 in)

278 mm (10.95 in)

267 mm (10.51 in)

6 mm

(0.24 in)

12 mm

(0.47 in)

40 mm (1.58 in )

Ø 5.2 mm

(0.21 in)

(1.10 in)

28 mm

(1.38 in)

35 mm

Ø32 mm

(1.26 in)

Ø 5.2 mm

(0.21 in)

*

38

Page 39

Frame 3

40 mm

(1.58 in)

174 mm (6.85 in)

Ø 5.2 mm

(0.21 in)

6 mm

(0.24 in)

328 mm (12.91 in)

317 mm (12.48 in)

12 mm

(0.47 in)

(1.10 in)

28 mm

(1.38 in)

35 mm

Ø32 mm

(1.26 in)

Ø 5.2 mm

(0.21 in)

*

Notes:

Additional space above and below the drive may be required for cable routing.

Option module frame adds 22mm width.

Alternative screw mounting options available. Please refer to the Installation Guide.

6 mm

(0.24 in)

40 mm (1.58 in)

DRIVE SPECIALISTS SINCE 1973

39

Page 40

SERVO DRIVE SERIES

Unimotor hd Servo Series

Frame size 055

Motor frame size (mm) 055ED 055UD

Voltage (Vrms) 200-240 380-480

Frame length A B C A B C

Continuous stall torque (Nm) 0.69 1.13 1.58 0.69 1.13 1.58

Continuous stall torque (lb-In) 6.11 10.0 13.98 6.11 10.0 13.98

Standard inertia (lb-in-sec

Winding thermal time constant (sec) 34 38 42 34 38 42

Motor weight unbraked (kg) 2.0 2.6 3.2 1.96 2.56 3.16

Speed 3000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Speed 6000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Peak torque (Nm) 2.07 3.4 4.75 2.07 3.4 4.75

Peak torque (lb-In) 18.32 30.09 42.04 18.32 30.09 42.04

Standard inertia (kgcm

Motor weight unbraked (lb) 4.41 5.73 7.0 5 4.32 5.64 6.97

Motor weight braked (kg) 2.6 3.2 3.8 2.56 3.16 3.76

Motor weight braked (lb) 5.73 7. 05 8.38 5.64 6.97 8.29

Number of poles 8 8 8 8 8 8

Kt (Nm/A) =

Kt (lb-in/A) = 6.55 7.7 8.05 6.55 13.19 14.6

Ke (V/krpm) =

Rated torque (Nm) 0.67 1.01 1.42 0.67 1.01 1.42

Rated torque (lb-in) 5.93

Stall current (A) 0.74 1.22 1.7 0.93 0.76 0.96

Rated power (kW) 0.21 0.32 0.45 0.21 0.32 0.45

R (ph-ph) (Ohms) 28 14.12 9.53 28 45 31

L (ph-ph) (mH) 50 32 23 50 100 75

Kt (Nm/A) =

Kt (lb-in/A) = 3.98 3.81 4.25 6.55 6.99 7. 35

Ke (V/krpm) =

Rated torque (Nm) 0.68 0.9 1.2 0.68 0.9 1.2

Rated torque (lb-in) 6.02 7.9 7 10.62 6.02 7.97 10.62

Stall current (A) 1.61 2. 74 3.44 0.93 1.43 1.91

Rated power (kW) 0.43 0.57 0.75 0.43 0.57 0.75

R (ph-ph) (Ohms) 8.5 3.55 2.38 28 10.7 7. 8

L (ph-ph) (mH) 16 8.2 6.3 50 25 20

2

) 0.14 0.25 0.36 0.14 0.25 0.36

2

0.00012 0.00022 0.00032 0.00012 0.00022 0.00032

)

0.74 0.87 0.91 0.74 1.49 1.65

45 52.5 55 45 90 100

8.94 12.57 5.93 8.94 12.57

0.45 0.43 0.48 0.74 0.79 0.83

27 26 29 45 4 7.5 50

• ∆ t= 100°C winding 40°C (104 °F) maximum ambient

All data subject to +/-10% tolerance

• Stall torque, rated torque and power relate to maximum

continuous operation tested in a 20°C (68 °F) ambient at

8 kHz drive switching frequency

• All other figures relate to a 20°C (68 °F) motor temperature.

• Maximum intermittent winding temperature is 140°C (284 °F)

Motor dimension Drawing number: GM496400

mm

in

Feedback AR, CR, EM, FM

Unbraked length Braked length

A B A B K L M (j6) N P R (H14) S T

055A 118.0 90.0 158.0 130.0

055B 142.0 114.0 182.0 154.0

055C 166.0 138.0 206.0 178.0

055A 4.65 3.54 6.22 5.12

055C 6.54 5.43 8.11 7.01

Flange

thickness

0.28 0.10 1.57 3.90 2.17 0.23 2.48 2.17055B 5.59 4.49 7. 17 6.06

Register

length

7.0 2.5 40.0 99.0 55.0 5.8 63.0 55.0

Register

diameter

Overall

height

Flange

square

Fixing hole

diameter

Fixing

hole PCD

Motor

housing

Mounting

bolts

M5

Shaft dimensions

Shaft

diameter

C (j6) D E F G H (h9) I J

9.0 Opt 9 20 10.2 15 1 3.0 M4 x 10 10

mm

11.0 Std 11 23 12.5 15 1.5 4.0 M4 x 10 10

14.0 Std 14 30.0 16.0 25.0 1.5 5.0 M5x x12.5 12.5

9.0 Opt 0.354 0.787 0.402 0.591 0.039 0.118 M4 x 10 0.394

in

11.0 Std 0.433 0.906 0.492 0.591 0.059 0.157 M4 x 10 0.394

14.0 Std 0.551 1.181 0.630 0.984 0.059 0.197 M5 x 12.5 0.492

Shaft

length

Key

height

Key

length

Key to

shaft end

Key

width

Tapped hole

thread size

Tapped hole

depth

Page 41

Frame size 067

Motor frame size (mm) 067ED 067UD

Voltage (Vrms) 200-240 380-480

Frame length A B C A B C

Continuous stall torque (Nm) 1.42 2.5 3.63 1.42 2.5 3.63

Continuous stall torque (lb-In) 12.57 22.13 32.13 12.57 22.13 32.13

Standard inertia (lb-in-sec

Winding thermal time constant (sec) 54 61 65 54 61 65

Motor weight unbraked (kg) 2 2.6 3.2 1.96 2.56 3.16

Speed 3000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Speed 6000

(rpm)

Recommended power conn' size 1 1 1 1 1

Peak torque (Nm) 4.26 7. 5 10.88 4.26 7. 5 10.88

Peak torque (lb-In) 37. 7 66.38 96.3 3 7.7 66.38 96.3

Standard inertia (kgcm

Motor weight unbraked (lb) 4.41 5.73 7.0 5 4.32 5.64 6.97

Motor weight braked (kg) 2.6 3.2 3.8 2.56 3.16 3.76

Motor weight braked (lb) 5.73 7. 05 8.38 5.64 6.97 8.29

Number of poles 10 10 10 10 10 10

Kt (Nm/A) =

Kt (lb-in/A) = 8.23 7.0 8 14.16

Ke (V/krpm) =

Rated torque (Nm) 1.37 2.4 3.43 1.37 2.4 3.43

Rated torque (lb-in) 12.13 21.24 30.36 12.13 21.24 30.36

Stall current (A) 1.53 2.69 3.9 1.78

Rated power (kW) 0.43 0.75 1.08 0.43 0.75 1.08

R (ph-ph) (Ohms) 14.92 4.88 3.33 11.69 15.2 10.7

L (ph-ph) (mH) 45.43 17.4 12.7 35.18 54.2 40.8

Kt (Nm/A) =

Kt (lb-in/A) = 4.16 7.0 8

Ke (V/krpm) =

Rated torque (Nm) 1.3 2.2 1.3 2.2 3 .1

Rated torque (lb-in) 11.51 19.47 11.51 19.47 27.44

Stall current (A) 3.02 5.32 1.78 3.12 4.53

Rated power (kW) 0.82 1.38 0.82 1.38 1.95

R (ph-ph) (Ohms) 3.86 1.22 11.69 3 .79 2.68

L (ph-ph) (mH) 11.06 4.35 35.18 13.6 10.2

2

) 0.30 0.53 0.75 0.30 0.53 0.75

2

0.00027 0.00047 0.00066 0.0 0027 0.00047 0.00066

)

0.93 0.8 1.6

57 49 98

1.56 2.27

0.47 0.8

28.5 49

• ∆ t= 100°C winding 40°C (104 °F) maximum ambient

All data subject to +/-10% tolerance

• Stall torque, rated torque and power relate to maximum

continuous operation tested in a 20°C (68 °F) ambient at

8 kHz drive switching frequency

• All other figures relate to a 20°C (68 °F) motor temperature.

• Maximum intermittent winding temperature is 140°C (284 °F)

Motor dimension Drawing number: IM/0694/GA

mm

mm

in

Feedback AR, CR, EM, FM

Unbraked length Braked length

LB (± 0.9) LC (± 1.0) LB (± 0.9) LC (± 1.0) LA (± 0.5) T (± 0.1) N (j6) LD (± 0.3) P (± 0.3) S (H14) M (± 0.5) PH (± 0.5)

067A 142.9 109.0 177.9 144.0

067B 172.9 139.0 207.9 174.0

067C 202.9 169.0 237.9 204.0

067A 5.626 4.291 7.004 5.669

in

067C 7.988 6.654 9.366 8.031

Feedback

TL, UL

Unbraked

length

LB (± 0.9) LB (± 0.9)

067A 157.4 192.4

067B 187.4 222.4

067C 217.4 252.4

067A 6.197 7. 57 5

067B 7.37 8 8.752

067C 8.559 9.937

Braked

length

Shaft dimensions

mm

In 0.551 1.181 0.630 .0984 0.059 0.197 0.531

14.0 (Std)

Flange

thickness

0.303 0.098 2.362 4.390 2.756 0.228 2.953 2.638067B 6.807 5.472 8.185 6.850

Register

length

7.7 2.5 60.0 111.5 70.0 5.8 75.0 67.0 0

Shaft

diameter

D (j6) E GA GF G F (h9) I J (± 1)

14.0 30.0 16.0 25.0 1.5 5.0

Shaft

length

Register

diameter

Key

height

Overall

height

Flange

square

Key

length

Fixing hole

diameter

Key to shaft

end

Key

width

Fixing

hole PCD

Motor

housing

Tapped hole

thread size

M5 x 0.8

DRIVE SPECIALISTS SINCE 1973www.controltechniques.com40 41

Mounting

bolts

Tapped hole

depth

13.5

M5

Page 42

SERVO DRIVE SERIES

Frame size 089

Motor frame size (mm) 089ED 089UD

Voltage (Vrms) 200-240 380-480

Frame length A B C A B C

Continuous stall torque (Nm) 3 .1 5.34 7.76 3.1 5.34 7.76

Continuous stall torque (lb-In) 27.44 47.26 68.68 27.44 47.26 68.68

Standard inertia (lb-in-sec

Winding thermal time constant (sec) 85 93 98 85 93 98

Motor weight unbraked (kg) 3.18 4.28 5.38 3.18 4.28 5.38

Speed 3000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Speed 4000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Speed 6000

(rpm)

Recommended power conn’ size 1 1 1 1 1 1

Peak torque (Nm) 9.31 16.01 23.28 9.31 16.01 23.28

Peak torque (lb-In) 82.4 141.7 206.05 82.4 141.7 206.05

Standard inertia (kgcm

Motor weight unbraked (lb) 7.0 1 9.44 11.86 7. 01 9.44 11.86

Motor weight braked (kg) 3.18 4.28 5.38 3.18 4.28 5.38

Motor weight braked (lb) 9.44 11.86 14.29 9.44 11.86 14.29

Number of poles 10 10 10 10 10 10

Kt (Nm/A) =

Kt (lb-in/A) = 8.23 14.16

Ke (V/krpm) =

Rated torque (Nm) 2.91 4.7 6.69 2.91 4.7 6.69

Rated torque (lb-in) 25.76 41.6 59.21 25.76 41.6 59.21

Stall current (A) 3.34 5. 74 8.34 1.94 3.33 4.85

Rated power (kW)

R (ph-ph) (Ohms) 3.28 1.57 0.89 1 0.1 5.05 2.68

L (ph-ph) (mH) 21.55 11.84 7.0 9 65.17 38.36 21.72

Kt (Nm/A) =

Kt (lb-in/A) = 6.20 10.62

Ke (V/krpm) =

Rated torque (Nm) 2.9 4.55 6.35 2.9 4.55 6.35

Rated torque (lb-in) 25.67 40.27 56.2 25.67 40.27 56.2

Stall current (A) 4.43 7.62 11.09 2.59 4.45 6.47

Rated power (kW) 1.21 1.91 2.66 1.21 1.91 2.66

R (ph-ph) (Ohms) 2.04 0.79 0.54 6.16 2.47 1.75

L (ph-ph) (mH) 13.2 5.97 4.38 39.78 18.8 14.03

Kt (Nm/A) =

Kt (lb-in/A) = 4.16 7.0 8

Ke (V/krpm) =

Rated torque (Nm) 2.65 3.8 5 2.65 3.8 5

Rated torque (lb-in) 23.45 33.63 44.25 23.45 33.63 44.25

Stall current (A) 6.6 11.35 16.51 3.88 6.67 9.7

Rated power (kW) 1.67 2.39 3.14 1.67 2.39 3.14

R (ph-ph) (Ohms) 0.98 0.39 0.23 2.52 1.27 0.83

L (ph-ph) (mH)

2

) 0.87 1.61 2.34 0.87 1.61 2.34

2

0.00077 0.00142 0.00207 0.00077 0.000142 0.0 0207

)

0.93 1.6

57 98

0.91 1.48 2 .1 0.91 1.48 2.1

0.7 1.2

42.75 73.5

0.47 0.8

28.5 49

6.24 2.96 1.89 16.29 9.59 6.66

• ∆ t= 100°C winding 40°C (104 °F) maximum ambient

All data subject to +/-10% tolerance

• Stall torque, rated torque and power relate to maximum

continuous operation tested in a 20°C (68 °F) ambient at

8 kHz drive switching frequency

• All other figures relate to a 20°C (68 °F) motor temperature.

• Maximum intermittent winding temperature is 140°C (284 °F)

Motor dimension Drawing number: IM/0688/GA

Feedback EC, FC, LC, NC

Unbraked length Braked length

LB (± 0.9) LC (± 1.0) LB (± 0.9) LC (± 1.0) LA (± 0.5) T (± 0.1) N (j6) LD (± 0.3) P (± 0.3) S (H14) M (± 0.5) PH (± 0.5)

089A 147.8 110.5 187.9 150.6

089B 177.8 140.5 217.9 180.6

mm

089C 207.8 170.5 2 47. 9 210.6

089A 5.819 4.350 7.398 5.929

in

089C 8.181 6.713 9.760 8.291

Feedback

EB, FB, CA, SA, RA

Unbraked

length

LB (± 0.9) LB (± 0.9) LB (± 0.9) LB (± 0.9)

089A 160.8 200.9 137.8 177.9

mm

089B 190.8 230.9 167.8 207.9

089C 220.8 260.9 197.8 237.9

089A 6.331 7.909 5.425 7.004

in

089B 7.512 9.091 6.606 8.185

089C 8.693 10.272 7.787 9.366

Braked

length

Unbraked

length

Feedback

Flange

thickness

10.3 2.2 80.0 130.5 91.0 7. 00 100.0 89.0

0.406 0.087 3.150 5.138 3.583 0.276 3.937 3.504089B 7.000 5.531 8.579 7.110

AE

Braked

length

Register

length

Register

diameter

Overall

height

Flange

square

Fixing hole

diameter

Shaft dimensions

Shaft

diameter

D (j6) E GA GF G F (h9) I J (± 1)

mm

19.0 Std

in 0.748 1.575 0.846 1.260 0.146 0.236 0.669

Shaft

length

19.0 4 0.0 21.5 32.0 3.7 6.0

Key

height

Key

length

Key to

shaft end

Fixing

hole PCD

Key

width

Motor

housing

Tapped hole

thread size

M6 x 1.0

Mounting

bolts

M6

Tapped hole

depth

17. 0

Page 43

Frame size 115

Motor frame size (mm) 115ED 115UD

Voltage (Vrms) 200-240 380-480

Frame length B C D B C D

Continuous stall torque (Nm) 10 14.31 18.42 10 14.31 18.42

Continuous stall torque (lb-In) 88.51 126.65 163.03 88.51 126.65 163.03

Winding thermal time constant (sec) 164 168 175 164 168 175

Motor weight unbraked (kg) 6.95 8.72 10.49 6.95 8.72 10.49

Speed 2000

(rpm)

Recommended power conn' size 1 1 1 1 1 1

Speed 3000

(rpm)

Recommended power conn' size 1 1 1 1 1

Peak torque (Nm) 29.99 42.92 55.27 29.99 42.92 55.27

Peak torque (lb-In) 265.43 379.87 489.18 265.43 279.87 489.18

Standard inertia (kgcm

Standard inertia (lb-in-sec

Motor weight unbraked (lb) 15.32 19.22 23.13 15.32 19.22 23.13

Motor weight braked (kg) 8.45 10.22 11.99 8.45 10.22 11.99

Motor weight braked (lb) 18.63 22.53 26.43 18.63 22.53 26.43

Number of poles 10 10 10 10 10 10

Kt (Nm/A) =

Kt (lb-in/A) = 12.39 21.24

Ke (V/krpm) =

Rated torque (Nm) 8.43 11.66 15.29 8.43 11.66 15.29

Rated torque (lb-in) 74.61 103.2 135.33 74.61 103.2 135.33

Stall current (A) 7. 14 10.22 13.16 4.17 5.96 7.68

Rated power (kW)

R (ph-ph) (Ohms) 1.4 0.77 0.61 4.41 2.41 1.8

L (ph-ph) (mH) 12.84 7. 87 6.62 40.6 24.69 19.45

Kt (Nm/A) =

Kt (lb-in/A) = 8.23 14.16

Ke (V/krpm) =

Rated torque (Nm) 7.55 10.29 7.55 10.29 13.33

Rated torque (lb-in) 66.82 91.07 66.82 91.07 117.98

Stall current (A) 10.75 15.38 6.25 8.94 11.52

Rated power (kW) 2.37 3.23 2.37 3.23 4.19

R (ph-ph) (Ohms) 0.58 0.39 1.83 1.21 0.78

L (ph-ph) (mH) 5.4 4.01 16.93 12.72 8.65

2

) 4.41 6.39 8.38 4.41 6.39 8.38

2

0.00390 0.00566 0.00742 0.0039 0 0.00566 0.00742

)

1.4 2.4

85.5 147

1.76 2.39 3.14 1.77 2.44 3.2

0.93 1.6

57 98

• ∆ t= 100°C winding 40°C (104 °F) maximum ambient

All data subject to +/-10% tolerance

• Stall torque, rated torque and power relate to maximum