Page 1

Power Accessories

for

AC and DC Drives

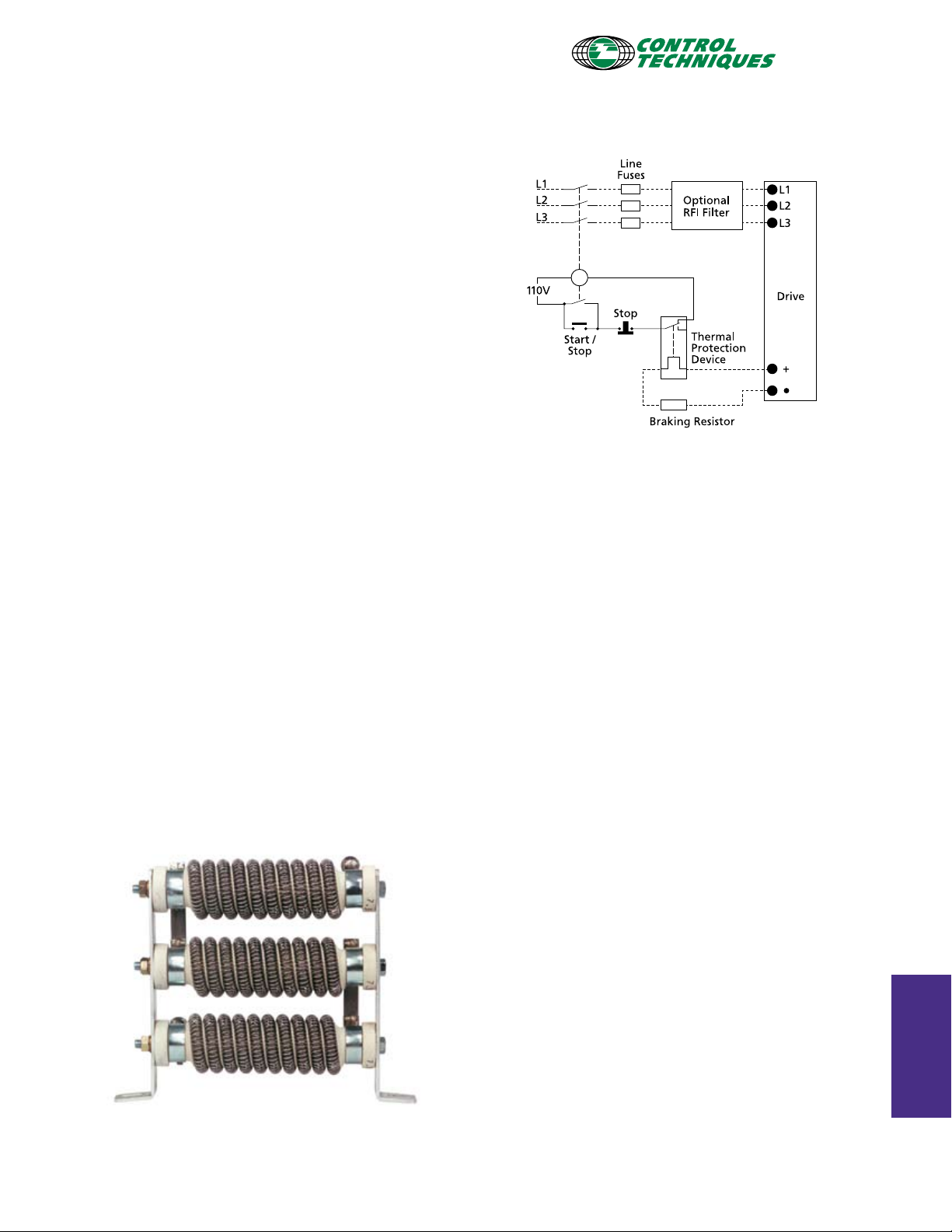

DYNAMIC BRAKING RESISTORS

The DC bus voltage level of a drive increases while

the motor is re-generating, i.e. ramping to a stop.

Dynamic braking resistors provide a means of rapidly

stopping a rotating motor and load while maintaining

an acceptable bus voltage level. The mechanical energy

stored in the spinning mass is converted into electrical

energy and quickly dissipated as heat through a resistor.

Control Techniques offers resistor kits available for both

AC and DC drives.

Dynamic Braking for DC Drives

DC drives provide an exponential stopping profile when

a dynamic brake resistor is applied across the motor’s

armature circuit (when the motor acts as a DC

generator). This type of braking can occur only when the

drive is configured for coast stop and power has been

removed from the motor (stop commanded). To apply a

dynamic brake resistor to a DC drive, a motor contactor

with a DB pole is required. This motor contactor is

standard on Quantum III DC drives up through 250 hp.

OVERLOAD PROTECTION

Dynamic Braking for AC Drives

AC drives provide a constant torque stopping profile

when a dynamic brake resistor is applied across the DC

bus circuit. Dynamic braking can be employed under a

stop command or anytime a decrease in motor speed

is commanded, provided the AC drive is enabled and

programmed for ramp stop (fast ramp mode).

Regen to line is also a preferred way to handle dynamic

braking and is an option on Focus 3, Mentor II and

Quantum III DC drives.

The brake is active anytime the system is enabled.

Therefore, the braking circuit must be protected with an

overload device.

The Commander SK, GP20 and Unidrive SP drives

are equipped standard with built-in dynamic braking

transistors. Simply select the proper braking resistor

needed for the size of drive and duty cycle.

Control Techniques offers two types of dynamic braking

kits for AC Drives. The E-stop duty kits provide a means

of quickly stopping a motor / load as well as providing

the ability to dissipate energy created by either a change

in motor speed or a line transient.

The cyclic duty kits are intended for more severe

applications that need the capability to dissipate

regenerated energy on a more continuous or repetitive

basis such as indexers, feeders and dynamometers.

Power

Accessories

383

Page 2

DB Resistors for AC Drives

E-STOP DUTY

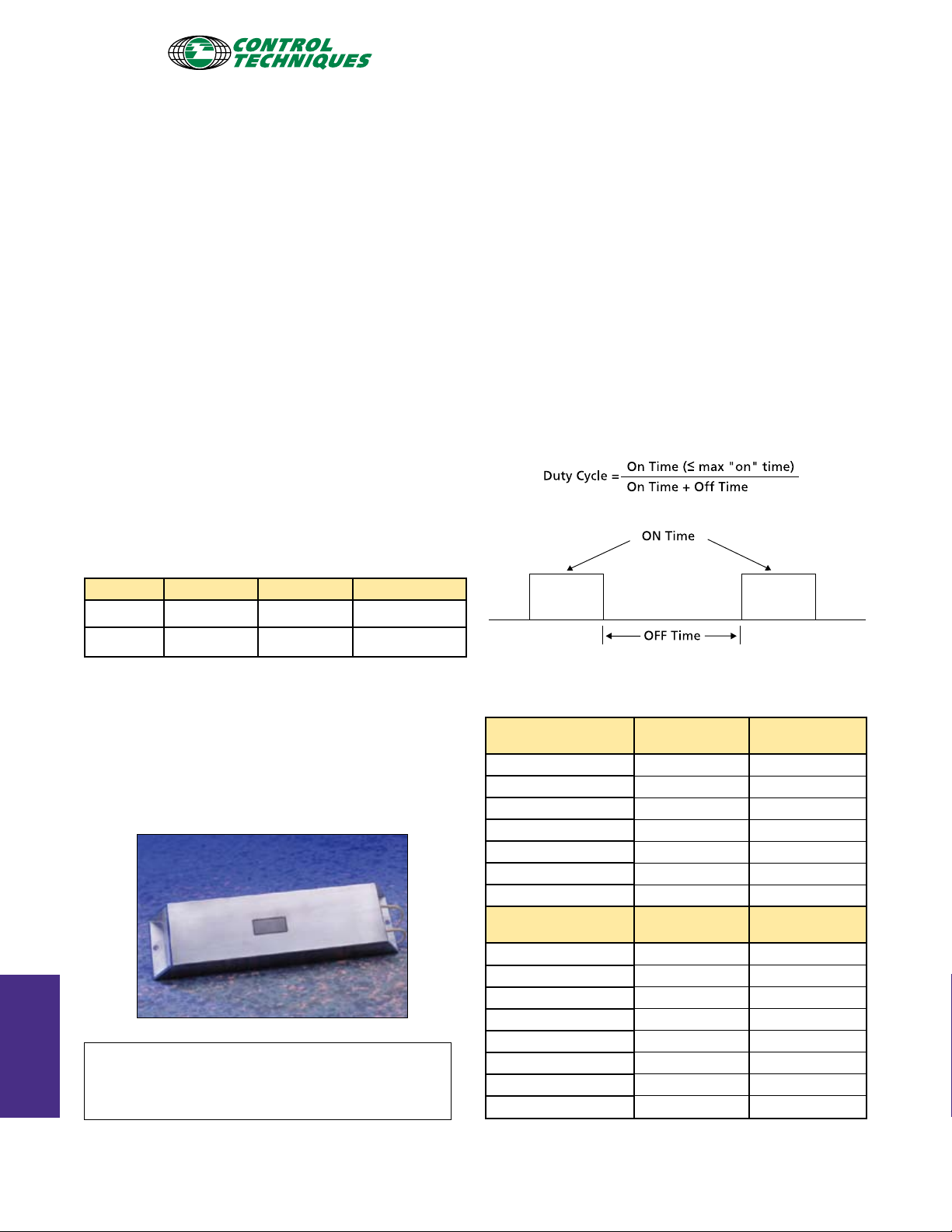

Panel mounted DB resistors are designed for non-cyclic

use where energy dissipation from an active drive is

required. Resistors are supplied with mounting hardware

unless otherwise noted.

These kits are designed to meet or exceed NEMA

standard 7-15-1970, which states “DB resistors will not

exceed their rated temperature rise when the drive is

braked from maximum speed to standstill three times

in rapid succession with a load inertia equal to or less

than the motor inertia”. They are designed to provide

150% braking torque (peak at max speed for DC drives,

constant for AC drives) for 1800 rpm base speed motors.

Note: The Commander GP20 and Unidrive SP Size 1

and 2 can be equipped with a zero-space, heatsink

mountable DB resistors.

INTERNAL DYNAMIC BRAKING RESISTORS

Commander SK (size 2), GP20 and Unidrive SP

Frame Size DC Resistance Power Rating Order Code

1

75 W

50W SM-Heatsink-DBR1

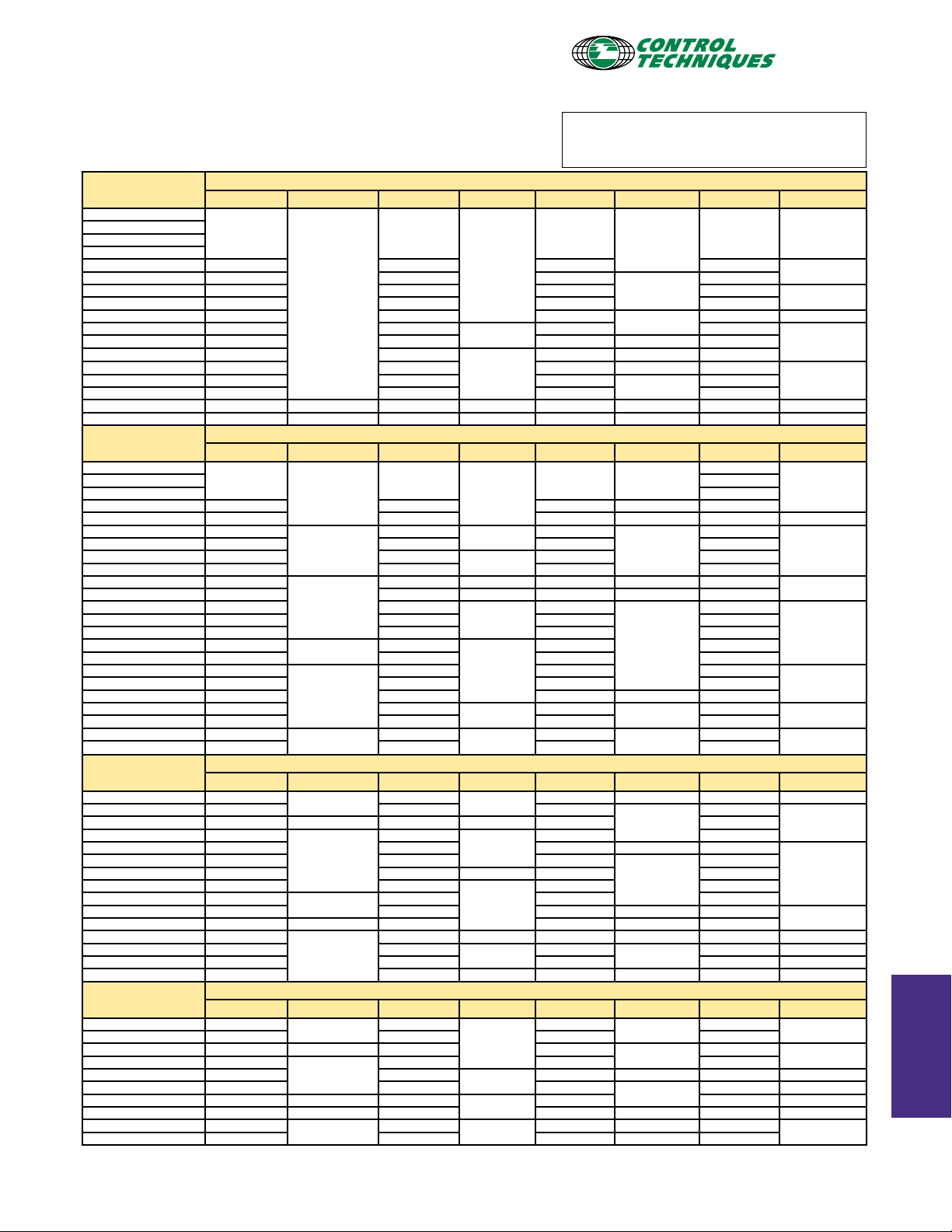

CYCLIC DUTY

NEMA 1 DB resistor kits include a wall mount enclosure

with built-in junction box, a terminal strip,

a normally closed thermal contact (klixon switch) and

resistors pre-wired with high-temperature Teflon wire.

These heavy-duty kits have been designed to provide

dynamic braking for cyclic and continuous braking

applications. There are three levels available: 10%, 25%

and 33%. These levels refer to the continuous allowable

braking level (ie. 25% equals 25% of rated motor

braking torque) or the maximum allowable duty cycle

rates with maximum specified “on-time” limitations

(refer to illustration below).

Duty Cycle

E-STOP DUTY CASE DB RESISTORS FOR COMMANDER SK, GP20 & UNIDRIVE SP SERIES AC DRIVES

Control Techniques E-Stop duty case dynamic braking

resistors provide the energy dissipation required for a

drive system while keeping the installation as compact

as possible. See drive heatsink options in the drive

section of the catalog.

Accessories

Power

2

DRIVE ORDER CODE LEGEND

y= SK for Commander SK, or CGP for Commander GP20,

or SP for Unidrive SP

z= CGP for Commander GP20, or SP for Unidrive SP

37.5 W

100W SM-Heatsink-DBR2

230VAC

Drive Order Code

SKA1200025 8200-00450 9 x 1.5 x 0.75

SKA1200037 8200-00451 6 x 3 x 1.5

SKA1200055 8200-00452 6 x 3 x 1.5

z1201 & SKA1200075 8200-00453 6 x 3 x 1.5

z1202 & SKBD200110 8200-00454 6 x 3 x 1.5

z1203 & SKBD200150 8200-00455 6 x 3 x 1.5

z1204 & SKCD200220 8200-00456 9 x 3 x 1.5

460VAC

Drive Order Code

SKB3400037 8200-00412 6 x 3 x 1.5

SKB3400055 8200-00413 7.5 x 3 x 1.5

z1401 & SKB3400075 8200-00414 7.5 x 3 x 1.5

SKB3400110 8200-00415 9 x 3 x 1.5

z1402 & SKB3400150 8200-00416 9 x 3 x 1.5

z1403 & SKC3400220 8200-00417 12 x 3 x 1.5

z1404 & SKC3400300 8200-00418 12 x 3 x 1.5

z1405 & SKD3200400

Case Resistor

Order Number

Case Resistor

Order Number

8200-00419 12 x 3 x 1.5

Dimensions (in.)

L x D x H

Dimensions (in.)

L x D x H

384

Page 3

DB Resistors for AC Drives

COMMANDER SK, COMMANDER GP20, UNIDRIVE SP AC DRIVES

230VAC

Drive Order Code

SKA1200025

SKA1200037

SKA1200055

z1201 & SKA1200075

z1202 & SKBD200110 8200-00208 8200-00002 8200-00016 8200-00030

z1203 & SKBD200150 8200-00209 8200-00003 8200-00017

z1204 & SKCD200220 8200-00210 8200-00004 8200-00018 8200-00032

y2201 & SKD3200400 8200-00210 8200-00004 8200-00018 8200-00032

y2202 8200-00211 8200-00005 8200-00019

y2203 8200-00212 8200-00006

y3201 8200-00213 8200-00007 8200-00021 28 x 13 x 5 8200-00035

y3202 8200-00214 8200-00008

y4201 8200-00215 8200-00009 8200-00023 29 x 18 x 14 8200-00037

y4203 8200-00217 8200-00010 8200-00024 8200-00038

y5201 8200-00221 Consult Factory 8200-00012 29 x 18 x 14 8200-00026 29 x 18 x 14 8200-00040 29 x 18 x 21

y5202 8200-00222 Consult Factory 8200-00250 Consult Factory 8200-00251 Consult Factory 8200-00252 Consult Factory

460VAC

Drive Order Code

SKB3400037

SKB3400055

z1401 & SKB3400075

SKB3400110 8200-00152 8200-00044 8200-00061 14 x 10 x 5 8200-00078

z1402 & SKB3400150 8200-00153 8200-00045 8200-00062 14 x 13 x 5 8200-00079 14 x 13 x 5

z1403 & SKC3400220 8200-00155

z1404 & SKC3400300 8200-00155 8200-00046 8200-00063 8200-00080

z1405 & SKD3200400 8200-00156 8200-00047

z1406 & SKD3400550 8200-00156 8200-00047 8200-00064 8200-00081

y2401 & SKD3400750 8200-00157

y2402 8200-00158 8200-00049 21 x 13 x 5 8200-00066 28 x 13 x 5 8200-00083

y2403 8200-00161 8200-00051

y2404 8200-00162 8200-00052 8200-00069 8200-00086

y3401 8200-00162 8200-00052 8200-00069 8200-00086

y3402 8200-00163

y3403 8200-00163 8200-00053 8200-00070 8200-00087

y4401 8200-00165

y4403 8200-00167 8200-00056 8200-00073 29 x 18 x 21 8200-00090

y5401 8200-00170 8200-00057

y5402 8200-00170 8200-00057 8200-00074 8200-00091

y6401 8200-00205

y6402 8200-00205 8200-00260 8200-00261 8200-00262

575VAC

Drive Order Code

y3501 8200-03501

y3502 8200-03502 8200-13502 8200-23502

y3504 8200-03504

y3505 8200-03505 8200-13505 8200-23505 29 x 18 x 7 8200-33505

y3506 8200-03506 8200-13506 8200-23506

y3507 8200-03507 8200-13507 29 x 18 x 7 8200-23507 8200-33507

y4603 8200-03508 8200-13508

y4604 8200-03509

y4605 8200-03510 8200-13510 8200-23510 29 x 18 x 21 8200-33510

y4606 8200-03511 29 x 18 x 7 8200-13511 8200-23511 8200-33511

y5601 8200-03512

y5602 8200-03513 8200-13513

y6601 8200-03514 8200-13514 8200-23514 8200-33514 29 x 18 x 49

y6602 8200-03515 8200-13515 29 x 18 x 42 8200-23515 29 x 18 x 49 8200-33515 29 x 18 x 56

690VAC

Drive Order Code

y4601 8200-03601

y4602 8200-03602 8200-13602 8200-23602 8200-33602

y4603 8200-03603 21 x 13 x 5 8200-13603 8200-23603

y4604 8200-03604

y4605 8200-03605 8200-13605

y4606 8200-03606 8200-13606 8200-23606

y5601 8200-03607 28 x 13 x 5 8200-13607

y5602 8200-03608 29 x 18 x 7 8200-13608 8200-23608 29 x 18 x 49 8200-33608 29 x 18 x 56

y6601 8200-03609

y6602 8200-03610 8200-13610 8200-23610 58 x 18 x 35 8200-33610

* For larger drives and SPM modules please consult factory.

E-Stop Dimensions 10% Dimensions 25% Dimensions 33% Dimensions

8200-00218

10.25 x 2 x 2.75

E-Stop Dimensions 10% Dimensions 25% Dimensions 33% Dimensions

8200-00151

11.75 x 2 x 2.75

10.25 x 2 x 2.75

10.25 x 2 x 5.75

16.5 x 8 x 4

21 x 8 x 4

30 x 8 x 4

E-Stop Dimensions 10% Dimensions 25% Dimensions 33% Dimensions

14 x 4 x 5

14 x 13 x 5

21 x 13 x 5

29 x 18 x 14

E-Stop Dimensions 10% Dimensions 25% Dimensions 33% Dimensions

14 x 13 x 5

29 x 18 x 7

29 x 18 x 14

Duty Cycle / Order Code / Dimensions (L x D x H in inches)

8200-00001

14 x 4 x 5

21 x 10 x 5

28 x 13 x 5

Duty Cycle / Order Code / Dimensions (L x D x H in inches)

8200-00043

8200-00046

8200-00048 21 x 10 x 5 8200-00065 21 x 13 x 5 8200-00082

8200-00053

8200-00055 8200-00072 8200-00089

8200-00260

Duty Cycle / Order Code / Dimensions (L x D x H in inches)

8200-13501

8200-13504

8200-13509 8200-23509 8200-33509

8200-13512 29 x 18 x 21 8200-23512 29 x 18 x 28 8200-33512 29 x 18 x 35

Duty Cycle / Order Code / Dimensions (L x D x H in inches)

8200-13601

8200-13604 8200-23604 8200-33604

8200-13609

4 x 7 x 5

14 x 10 x 5

14 x 13 x 5

29 x 18 x 7

29 x 18 x 14

29 x 18 x 21

29 x 18 x 35

14 x 13 x 5

28 x 13 x 5

29 x 18 x 14

29 x 18 x 28

29 x 18 x 14

29 x 18 x 21

29 x 18 x 28

29 x 18 x 42

DRIVE ORDER CODE LEGEND

y= SK for Commander SK, or CGP for Commander GP20,

or SP for Unidrive SP

z= CGP for Commander GP20, or SP for Unidrive SP

8200-00015

8200-00020 8200-00034

8200-00022 29 x 18 x 7 8200-00036

8200-00060 14 x 7 x 5

8200-00063

8200-00064 8200-00081

8200-00068

8200-00070 8200-00087

8200-00074

8200-00261

8200-23501 14 x 13 x 5 8200-33501 14 x 13 x 5

8200-23504 8200-33504

8200-23508 8200-33508

8200-23513

8200-23601

8200-23605 29 x 18 x 28 8200-33605 29 x 18 x 35

8200-23607 8200-33607 29 x 18 x 49

8200-23609 29 x 18 x 56 8200-33609

14 x 7 x 5

14 x 10 x 5

21 x 10 x 5

29 x 18 x 7

21 x 10 x 5

29 x 18 x 14

29 x 18 x 28

29 x 18 x 49

28 x 13 x 5

29 x 18 x 14

29 x 18 x 35

29 x 18 x 14

29 x 18 x 21

29 x 18 x 35

8200-00029 14 x 7 x 5

8200-00031

8200-00033 21 x 10 x 5

8200-00038

8200-00077

8200-00080

8200-00085

8200-00091

8200-00262

8200-33502

8200-33506

8200-33513 29 x 18 x 42

8200-33601

8200-34603

8200-33606 29 x 18 x 42

14 x 10 x 5

14 x 13 x 5

28 x 13 x 5

29 x 18 x 14y4202 8200-00216 8200-00010 8200-00024

14 x 10 x 5

21 x 10 x 5

28 x 13 x 5

29 x 18 x 14

29 x 18 x 21y4402 8200-00165 8200-00055 8200-00072 8200-00089

29 x 18 x 28

29 x 18 x 56

28 x 13 x 5y3503 8200-03503 14 x 7 x 5 8200-13503 21 x 13 x 5 8200-23503 8200-33503

29 x 18 x 14

29 x 18 x 21

29 x 18 x 14

29 x 18 x 21

58 x 18 x 35

Power

Accessories

385

Page 4

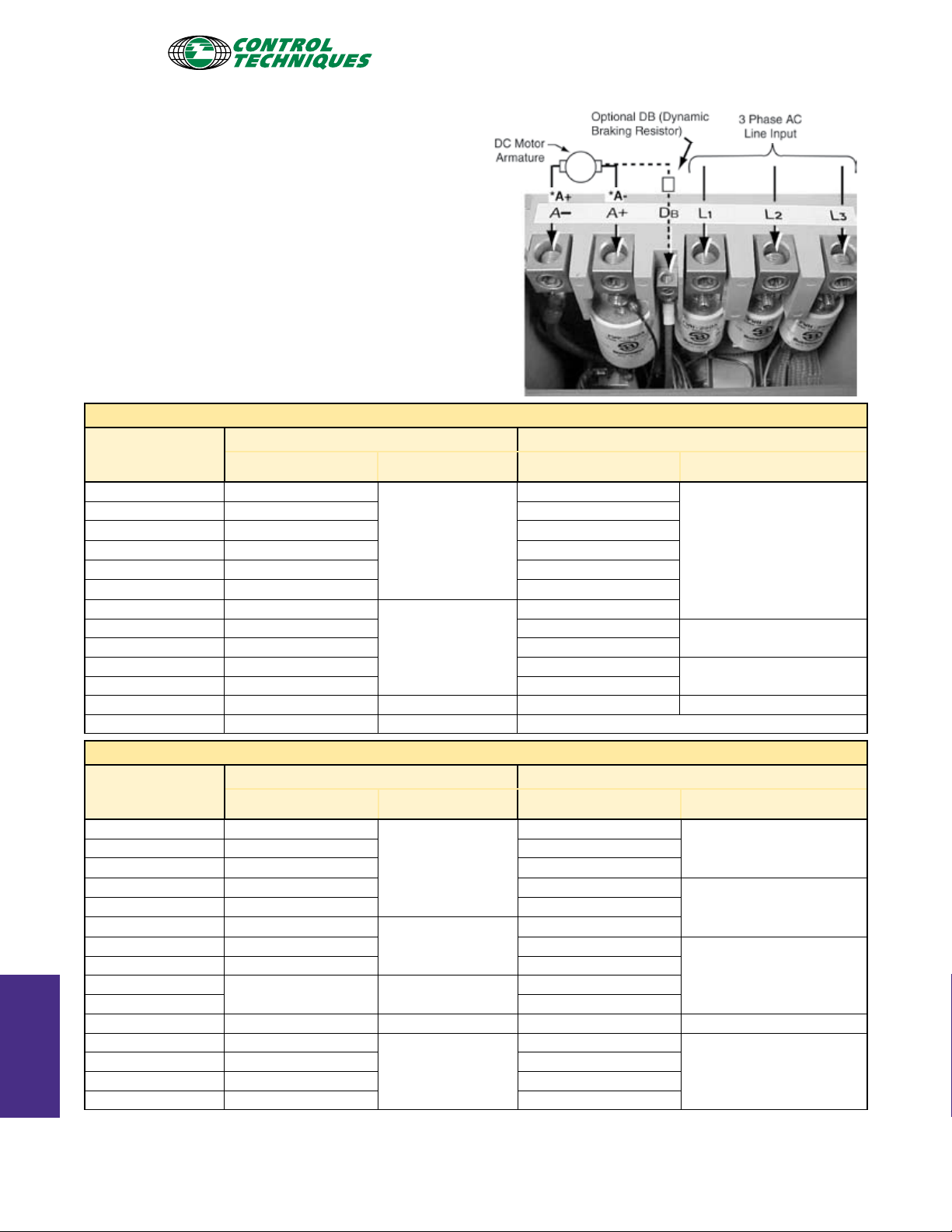

DB Resistors for DC Drives

E-stop duty dynamic braking resistors are available

to provide for the fast stopping of DC motors.

Quantum III DC drives come supplied with a DB

Resistor Pole, which is conveniently located adjacent

to the either A- on non-regen models, or A+ in

regen models.

DB resistors are shipped loose and mounted external

to the drive (by customer). NEMA 1 Enclosure is

Galvanized Steel and meets UL508A standard.

230VAC DB Resistors

HP

5 8200-00100

7.5 8200-00101 005-4302

10 8200-00102 005-4303

15 8200-00103 005-4304

20 8200-00104 005-4305

25 8200-00105 005-4306

30 8200-00106*

40 8200-00107* 005-4308

50 8200-00108* 005-4309

60 8200-00109* 005-4310

75 8200-00110* 005-4311

100 8200-00111* 14 x 10 x 5 005-4312 5 x 14 x 10

125 8200-00112* 14 x 13 x 5 n/a

Order Code

Chassis NEMA 1

Dimensions (in.)

H x W x D

10.25 x 2 x 2.75

14 x 4 x 5

Order Code

005-4301

005-4307

Dimensions (in.)

H x W x D

5 x 14 x 4

5 x 14 x 7

5 x 14 x 4

460VAC DB Resistors

Accessories

Power

The DC Dynamic braking components have been sized for occasional non-repeated use,

assuming load inertia is equal to or less than motor inertia. The Dynamic resistor will be sized

at approximately 150% of rated motor current. The DB enclosures are galvanized NEMA 1

386

HP

5-7.5 8200-00115

10 8200-00116 005-4352

15 8200-00117 005-4353

20 8200-00118 005-4354

25 8200-00119 005-4355

30 8200-00120

40 8200-00121 005-4357

50 8200-00122 005-4358

60

75 005-4360

100 8200-00125* 14 x 10 x 5 005-4361 5 x 14 x 13

125 8200-00126*

150 8200-00127* 005-4363

200 8200-00128* 005-4364

250 8200-00129* 005-4365

Order Code

8200-00124* 14 x 7 x 5

Dimensions (in.)

H x W x D

10.25 x 2 x 2.75

10.25 x 2 x 5.5

14 x 13 x 5

enclosure shipped loose and mounted external to the drive to meet UL508A standard. The DC

drive will also require a DB contactor option for dynamic braking action.

* Resistor is wall mounted, not panel mounted.

Order Code

005-4351

005-4356

005-4359

005-4362

Dimensions (in.)

H x W x D

5 x 12 x 4

5 x 14 x 7

5 x 14 x 10

5 x 21 x 10

Chassis NEMA 1

Loading...

Loading...