Page 1

EF

www.controltechniques.com

Advanced User Guide

Commander SL

AC variable speed drive for 3

phase induction motors from

0.25kW to 4kW, 0.33hp to 5hp

Part Number: 0472-0078-01

Issue: 1

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional parameters of the eq uipment or from mismatching the var iable speed drive with

the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of commitment to a policy of

continuous development and improvement, the manufacturer reserves the right to change the specification of the product

or its performance, or the content of the guide without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including, photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is supplied with the latest version of user-interface and machine control software. If this product is to be

used in a new or existing system with other drives, there may be some differences between their software and the

software in this product. These differences may cause the product to function differently. This may also apply to drives

returned from the Control Techniques Service Centre.

If there is any doubt, please contact your local Control Techniques Drive Centre or Distributor.

Environmental Statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is

certified to the International Standard ISO 14001. Further information on the EMS, our Environment Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable speed drives manufactured by Control Techniques have the potential to save energy and

(through increased machine/process efficiency) reduce raw materia l consumption and scrap throughout their long

working lifetime. In typical applications, these positive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they can very easily be dismantled into their

major component parts for efficient recycling. Many parts snap together and can be separated without the use of tools,

while other parts are secured with conventional screws. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller

products come in strong cardboard cartons which themselves have a high-recycled fibre content. If not re-used, these

containers can be recycled. Polythene, used on the protective film a nd bag s fr om wrap ping pr oduct, can be re cycled in

the same way. Control Techniques' packaging strategy favours easily recyclable materials of low environmental impact,

and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any pr od uc t or pa ck ag ing , ple a se ob se rv e loca l leg islation and best practice.

Copyright © September 2006 Control Techniques Drives Ltd

Issue: 1

Software version: V01.04.00

Page 3

Contents

1 Introduction....................................................................................................................4

2 Default parameters ........................................................................................................5

3 Parameter description format.......................................................................................6

3.1 Software variable maximum term definitions .........................................................................................6

3.2 Parameter information ...........................................................................................................................6

3.3 Key to parameter codes .........................................................................................................................7

3.4 Sample/update times .............................................................................................................................7

4 Keypad and display.......................................................................................................9

4.1 Programming keys .. ... ... .... ... .......................................... .......................................... ..............................9

4.2 Control keys ..... .... ... ... ... .... ...................................... .... ... ... ... .... ... ... ........................................................9

4.3 Selecting and changing parameters ......................................................................................................9

5 Menu 0 ..........................................................................................................................11

Commander SL Advanced User Guide 3

Issue Number: 1 www.controltechniques.com

Page 4

Introduction Default parameters Parameter description format Keypad and display Menu 0

1 Introduction

This Advanced User Guide provides detailed information on the following features of Commander SL:

• Parameter types

• Keypad and display information

• Full parameter descriptions

The Commander SL

The Commander SL is an open loop AC variable speed inverter drive used to control the speed of an AC induction motor.

As default the Commander SL is set up in fixed boost mode (see Pr 41 on page 24). The drive produces a linear voltage to frequency profile to be

applied to the motor. At low speed, a voltage boost can be applied to the motor to increase starting torque in high starting torque application (see

Pr 42 on page 24).

The Commander SL can also be set up in open loop vector mode (see Pr 41 on page 24). In open loop vector mode, the drive uses an open loop

vector control strategy to maintain almost constant flux in the motor by dynamically adjusting the motor voltage according to the load on the motor. At

low speed, the drive will automatically increase the motor voltage to increase starting torque in high starting torque applications.

The AC supply is rectified through a bridge rectifier and then smoothed across high voltage capacitors to produce a constant voltage DC bus. The DC

bus is then switched through an IGBT bridge to produce AC at a variable voltage and a variable frequency. This AC output is synthesized by a pattern

of on-off switching applied to the gates of the IGBTs. This method of switching the IGBTs is known as Pulse Width Modulation (PWM).

Software Structure

The Commander SL's keypad and display can be used to change and monitor parameter values and also to change the terminal settings of the drive.

The parameter menu is structured to give an extreme ease of set-up for a simple drive for simple applications.

4 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 5

Introduction Default parameters Parameter description format Keypad and display Menu 0

2 Default parameters

Setting default parameters sets all parameters back to their factory setting.

To set default parameters, set Pr 29 to Eur or USA. Eur sets 50Hz defaults, USA sets 60Hz defaults. See Pr 29 on page 19 for further details.

When default parameters are set, these parameters are automatically saved to the drives EEPROM.

Eur/USA parameter set differences

The following table gives the differences between Eur and USA default parameter sets:

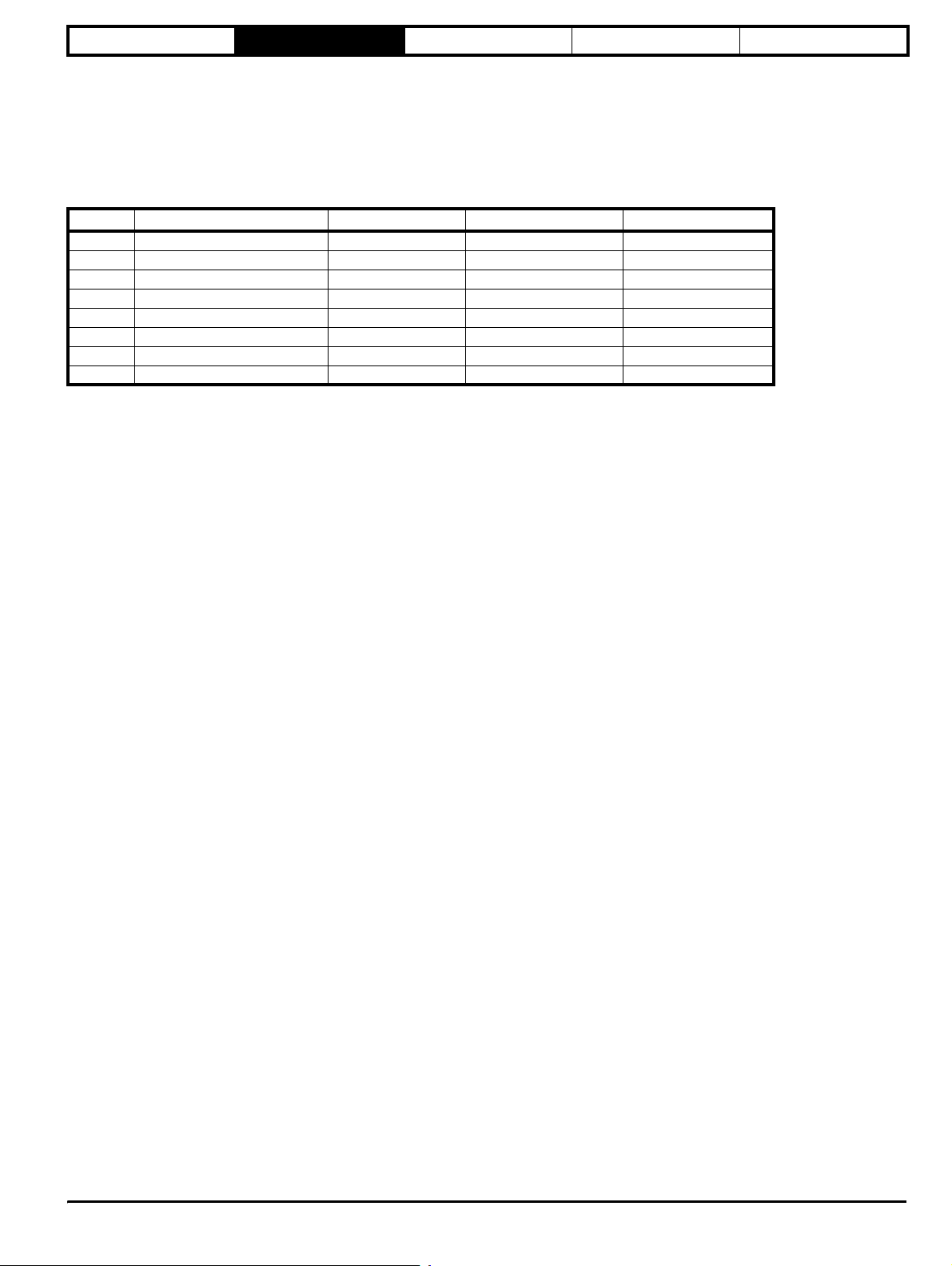

Pr Description Eur default USA default Drive voltage rating

02 Maximum set speed 50.0 Hz 60.0Hz All

03 Acceleration rate 5.0 s/100Hz 33.0 s/100Hz All

04 Deceleration rate 10.0 s/100Hz 33.0 s/100Hz All

05 Drive configuration AV PAd All

07 Motor rated full load rpm 1500 rpm 1800 rpm All

08 Motor rated voltage 400 V 460V 400V

11 Start/Stop logic 0 4 All

39 Motor rated frequency 50.0 Hz 60.0Hz All

Commander SL Advanced User Guide 5

Issue Number: 1 www.controltechniques.com

Page 6

Introduction Default parameters

Parameter description format

Keypad and display Menu 0

3 Parameter description format

3.1 Software variable maximum term definitions

Table 3-1

Maximum Definition

FREQ_MAX

[1500.0Hz]

RATED_CURRENT_MAX

[999.9A]

DRIVE_CURRENT_MAX

[999.9A]

MOTOR1_CURRENT_LIMIT_MAX

[999.9%]

AC_VOLTAGE_SET_MAX

[480V]

DC_VOLTAGE_MAX

[830V]

POWER_MAX

[999.9kW]

The values given in square brackets indicate the maximum value allowed for the variable maximum.

Maximum frequency reference

FREQ_MAX = Pr 02

Maximum motor rated current

RATED_CURRENT_MAX ≤ 1.36 x Rated drive current

Maximum drive current

The maximum drive current is the current at the over current trip level and is given by:

DRIVE_CURRENT_MAX = rated drive current x 2

Maximum current limit settings

This maximum current limit setting is the maximum applied to the current limit.

Maximum output voltage set-point

Defines the maximum motor voltage that can be selected.

200V drives: 240V

400V drives: 480V

Maximum DC bus voltage

The maximum measurable DC bus voltage.

200V drives: 415V

400V drives: 830V

Maximum power in kW

The maximum power has been chosen to allow for the maximum power that can be output by the drive

with maximum AC output voltage, maximum controlled current and unity power factor. Therefore

POWER_MAX = √3 x AC_VOLTAGE_MAX x RATED_CURRENT_MAX x 2

3.2 Parameter information

3.2.1 Parameter types

There are two fundamental types of parameters in the drive, read only (RO) and read/write (RW). The read only parameters cannot be changed by

the user and are there to give the user useful information about the state of the drive. Read/write parameters are for the user to set up the way in

which the drive operates.

Parameters can be further broken down into Bit parameters and Non-bit parameters. Bit parameters are two state only (0 or 1) and if RW are used as

switches or two state input variables to the drive logic, or if RO indicate various drive conditions which are either true (1) or false (0). Non-bit

parameters have more than two values the range of each being given in the following descriptions.

3.2.2 Drive reset

A drive reset is required for a number of reasons:

• To reset the drive from a tripped state

• To initiate loading of default parameters

• To implement a change in the value of certain parameters

• To initiate the saving of parameters in EEPROM

The later two of these can be done while the drive is running.

The drive can be reset in one of four ways:

1. The drive will be reset with a 0 to 1 transition of the enable input when the drive is tripped, such that a dedicated reset terminal is not required.

2. The Stop/Reset key. If the drive is not in keypad mode, then the key has a drive reset function only. In keypad mode a drive reset can be done

while the drive is running by holding the Run key while the Stop/Reset key is activated. When the drive is not running the Stop/Reset key will

always reset the drive.

3.2.3 Storing drive parameters

When the keypad is used to edit a parameter, the parameter is stored when the mode key is pressed after adjustment has been made.

6 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 7

Introduction Default parameters

Parameter description format

Keypad and display Menu 0

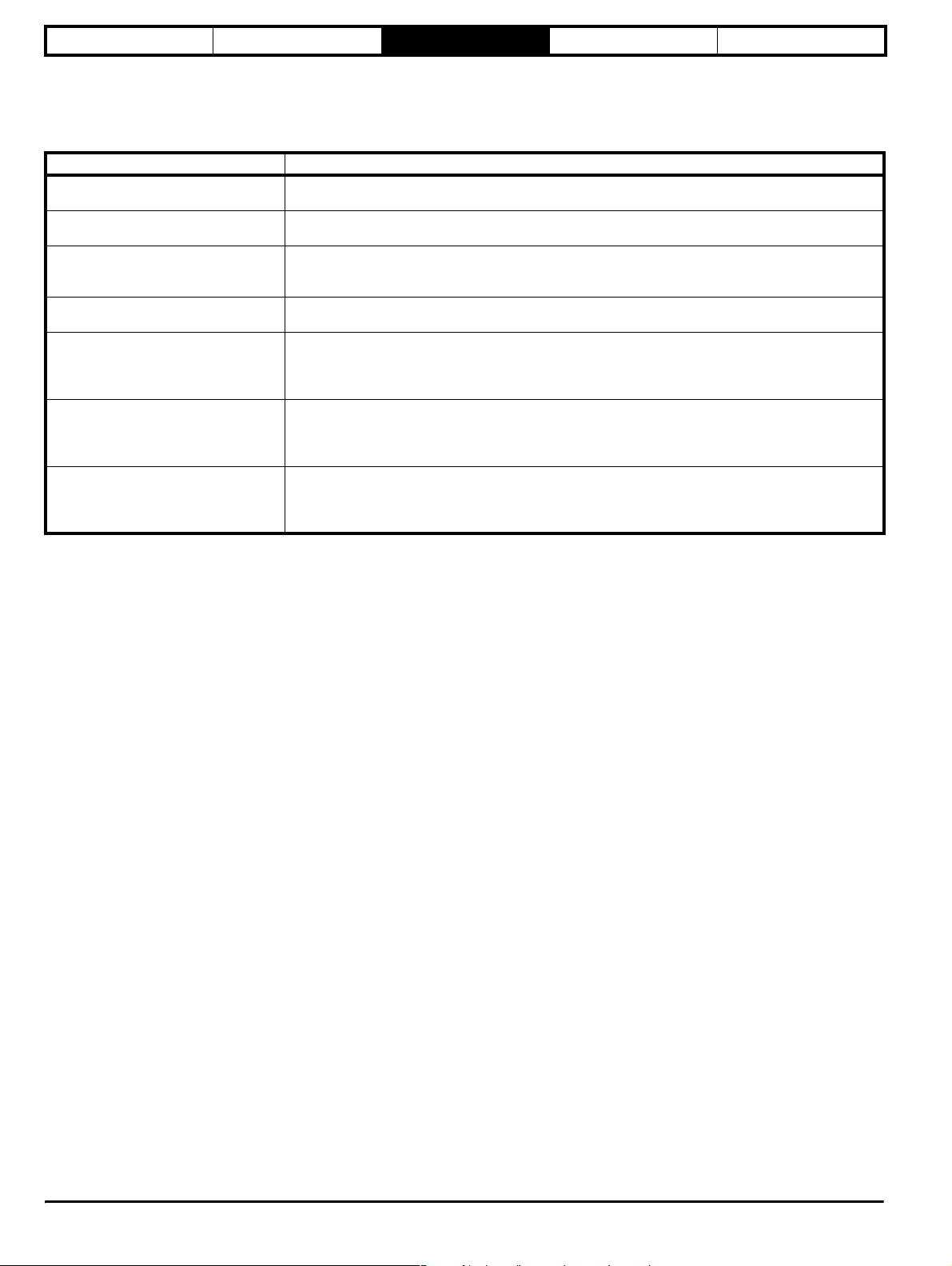

3.3 Key to parameter codes

With each parameter the following information block is given.

40 Number of motor poles

Coding

Range Auto 2P, 4P, 6P, 8P

Default Auto

Update rate Background

The top row gives the parameter number and the parameter name. The other rows give the following information.

3.3.1 Coding

The coding defines the attributes of the parameter as follows.

Coding Attribute

Bit 1 bit parameter

SP Spare: not used

FI

Txt Text: the parameter uses text strings instead of numbers.

VM Variable maximum: the maximum of this parameter can vary.

DP Decimal place: indicates the number of decimal places used by this parameter.

ND

RA Rating dependant: this parameter is likely to have different values and ranges with drives of different voltage and current ratings.

NV Not visible: not visible on the keypad.

RW Read/write: can be written by the user.

BU

PS Power-down save: automatically saved in drive EEPROM at power-down.

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Filtered: some parameters which can have rapidly changing values are filtered when displayed on the drive keypad for easy

viewing.

No default: when defaults are loaded (except when the drive is manufactured or on EEPROM failure) this parameter is not

modified.

Bit default one/unsigned: Bit parameters with this flag set to one have a default of one (all other bit parameters have a default of

zero. Non-bit parameters are unipolar if this flag is one.

3.3.2 Term definitions

Range

This gives the range of the parameter and the values it can be adjusted to.

Default

The default values given are the standard drive defaults.

Update rate

Defines the rate at which the parameter data is written by the drive or read and acted upon by the drive. Where background update rate is specified,

the update time depends on the drive processor load. Generally the update time is between 10ms and 100ms, however, the update time is

significantly extended when loading defaults.

3.4 Sample/update times

The sample/update times shown in the control terminal specification within the Commander SL Technical Guide are the default sample/update times

for the default terminal set-up.

These sample/update times are the sample or update times for the control microprocessor. The actual sample/update time maybe slightly longer due

to the design of the Commander SL.

3.4.1 Task routine times

There is a single line parameter description and this contains the update rate for each parameter. This time signifies the task routine time in the

software that the parameter is updated on. For a background task, the time depends on processor loading i.e. what functions the drive is carrying out.

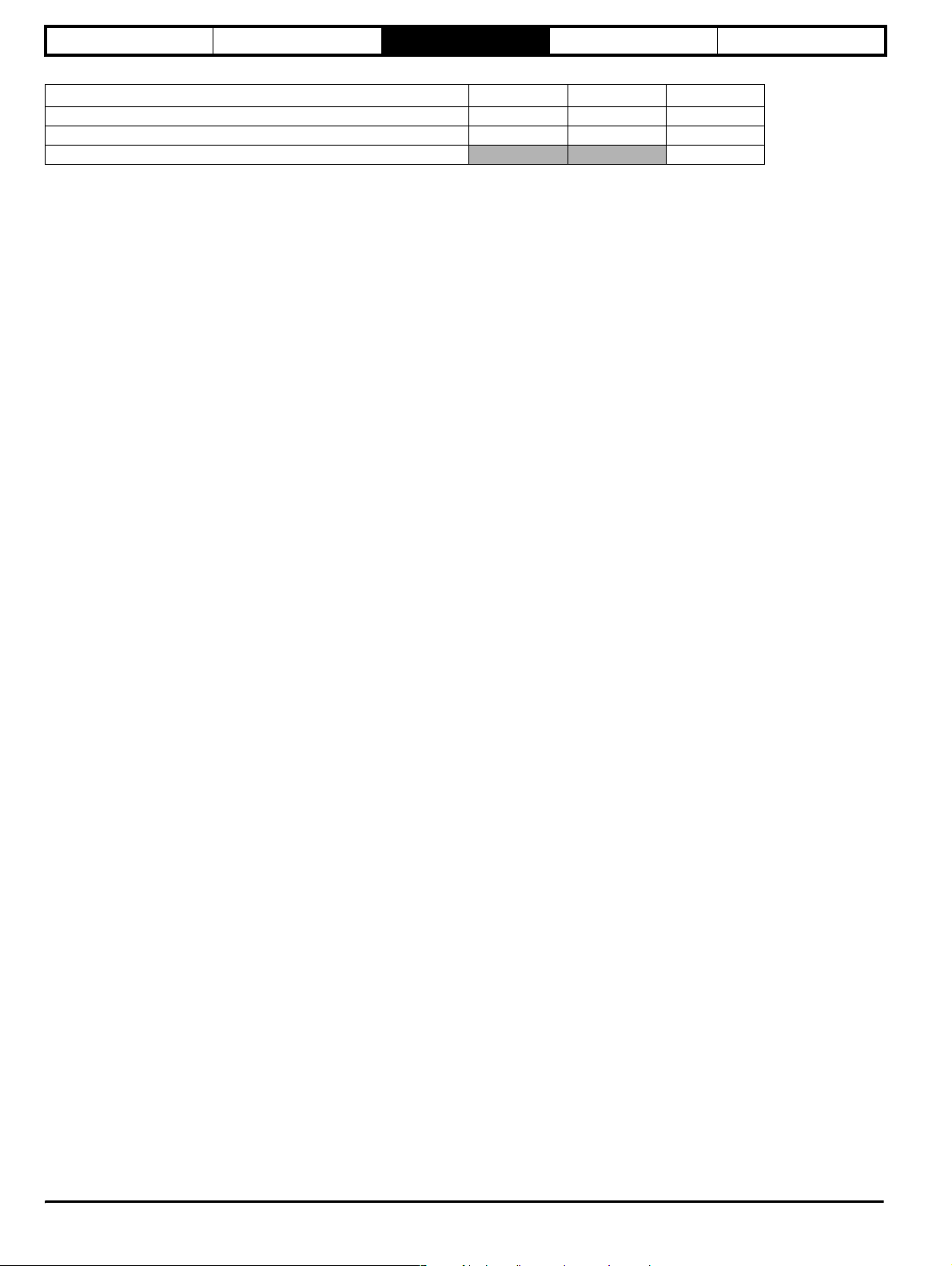

Update rate Microprocessor update time Comments

2ms 2ms Updated every 2ms

5ms 5ms Updated every 5ms

21ms 21ms Updated every 21ms

128ms 128ms Updated every 128ms

Reset N/A Destination/source parameter changed on a Reset

B Background

BR Background read

BW Background write

Edit mode exit N/A

Updated as a background task. Update rate

depends on processor loading.

Parameter change actioned on exit of edit mode.

Parameter change automation saved.

Commander SL Advanced User Guide 7

Issue Number: 1 www.controltechniques.com

Page 8

Introduction Default parameters

From practical tests carried out:

Condition Minimum Maximum Average

Time for drive to respond to a run command 4.1ms 5.62ms 5.02ms

Time for the drive to respond to a stop command 2.82ms 3.94ms 3.31ms

Time for the drive to respond to a step change in analogue input voltage

Parameter description format

Keypad and display Menu 0

7.93ms

8 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 9

Introduction Default parameters Parameter description format Keypad and display Menu 0

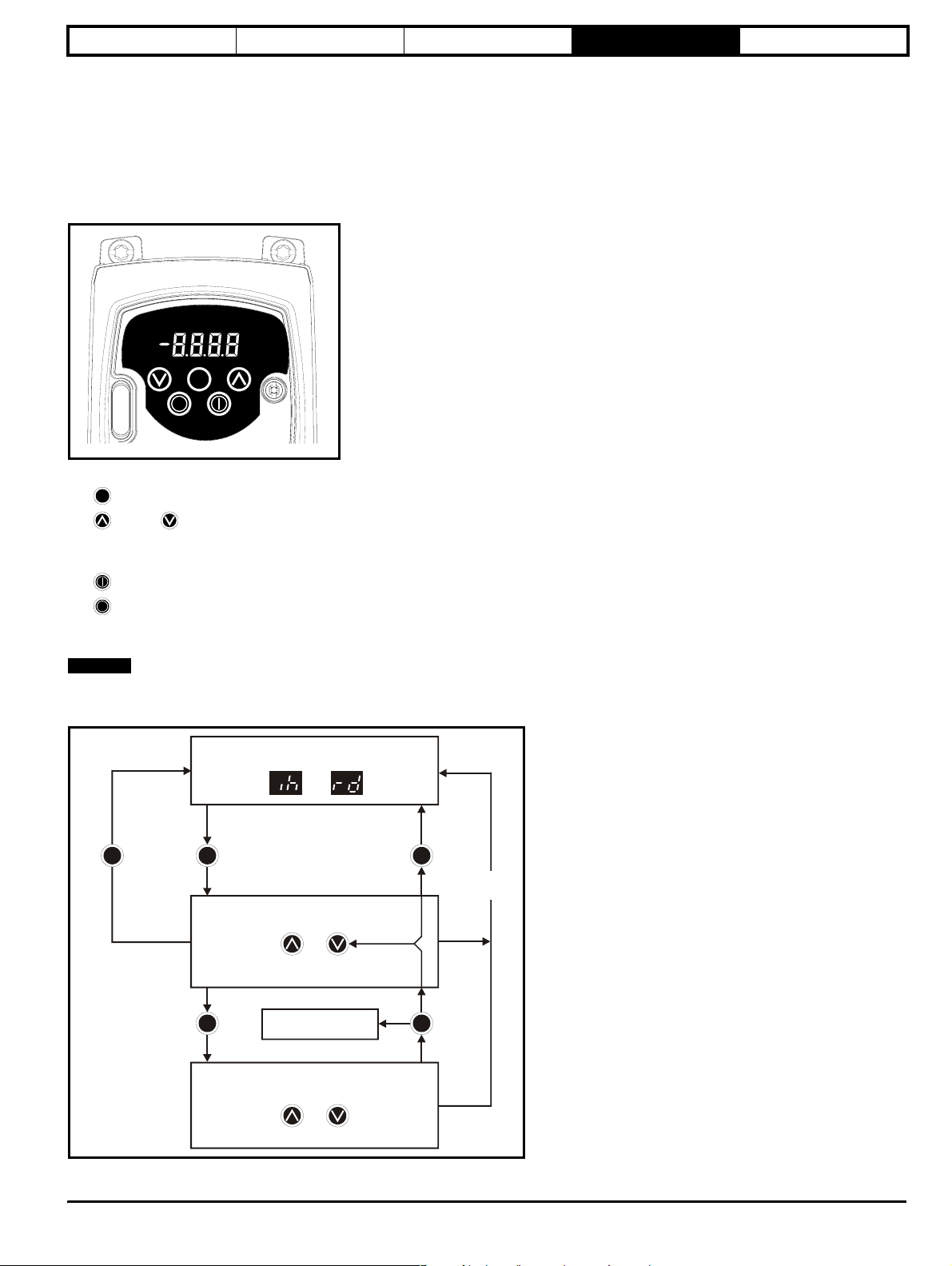

4 Keypad and display

The keypad and display are used for the following:

• Displaying the operating status of the drive

• Displaying a fault or trip code

• Reading and changing parameter values

• Stopping, starting and resetting the drive

Figure 4-1 Keypad and display

M

4.1 Programming keys

M

The MODE key is used to change the mode of operation of the drive.

The UP and DOWN keys are used to select parameters and edit their values. In keypad mode, they are used to increase and decrease the

speed of the motor.

4.2 Control keys

The START key is used to start the drive in keypad mode.

The STOP/RESET key is used to stop and reset the drive in keypad mode. It can also be used to reset the drive in terminal mode.

4.3 Selecting and changing parameters

M

Press and

release

Press and

release

STATUS MODE

or

M

PARAMETER VIEW MODE

Select parameter to view

orPress

Parameter number and parameter

value flashing alternately

M M

Parameters

saved

PARAMETER EDIT MODE

Change parameter value

orPress

Parameter value flashing

Press and

M

release

Press and

release

4 mins

timeout

NOTE

This procedure is written from the first power up of the drive and assumes no terminals have been connected, no parameters have been changed and

no security has been set.

Figure 4-2 Display modes

Hold

for 2s

Commander SL Advanced User Guide 9

Issue Number: 1 www.controltechniques.com

Page 10

Introduction Default parameters Parameter description format Keypad and display Menu 0

Pressing and releasing the MODE key will change the display from status mode to parameter view mode. In parameter view mode, the display

M

flashes the parameter number and the parameter value alternately.

Pressing and releasing the MODE key again will change the display from parameter view mode to parameter edit mode. In parameter edit mode,

M

the display flashes the value in the parameter.

Pressing the MODE key in parameter edit mode will return the drive to the parameter view mode. If the MODE key is pressed again then the

drive will return to status mode, but if either of the UP or DOWN keys are pressed to change the parameter being viewed before the MODE

key is pressed, pressing the MODE key will change the display to the parameter edit mode again. This allows the user to very easily change

M M

M

M

between parameter view and edit modes whilst commissioning the drive.

Status Modes

Left hand

display

When the drive is running, the display indicates the drive output frequency.

When in parameter edit mode, the UP and DOWN keys are used to change parameter values. This will increase or decrease the parameter

value by the minimum unit value on display.

To allow values to be changed more quickly, it is possible to press the MODE and UP or the MODE and DOWN keys together to allow

either 1000’s of units, 100’s of units, 10’s of units or units to be adjusted.

Example:

It is required that a deceleration ramp of 2500 seconds is required.

Select Pr 04 using the normal procedure.

Status Explanation

Drive ready The drive is enabled and ready for a start command. The output bridge is inactive.

Drive inhibited

The drive is inhibited because there is no enable command, or the drive is inhibited

during a trip reset.

DC injection braking DC injection braking current is being applied to the motor.

M M

• Press the MODE key to enter parameter edit mode

• Press the MODE and UP keys together

M

M

• Press the UP key to adjust the 100’s of units

• Press the MODE and UP keys together again

M

• Press the DOWN key once to adjust the 10’s of units

• Press the MODE key to go back to parameter view mode

• Press the MODE key again to go back to status mode

M

M

10 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 11

Introduction Default parameters Parameter description format Keypad and display Menu 0

5 Menu 0

Table 5-1 Menu 0 parameters: single line descriptions

Par Description

01 Minimum set speed (Hz) 0.0

02 Maximum set speed (Hz) 50.0 60.0

03 Acceleration rate (s/100Hz) 5.0 33.0

04 Deceleration rate (s/100Hz) 10.0 33.0

05 Drive configuration AV PAd

06 Motor rated current (A) Drive rating

07 Motor rated speed (rpm) 1500 1800

08 Motor rated voltage (V) 230/400 230/460

09 Motor power factor (cos ϕ)0.85

10 Parameter access OPEn

11 Start/Stop logic select 0 4

15 Jog reference (Hz) 1.5

17 Enable negative preset speeds OFF

18 Preset speed 1 (Hz) 0.0

19 Preset speed 2 (Hz) 0.0

20 Preset speed 3 (Hz) 0.0

21 Preset speed 4 (Hz) 0.0

25 User security code 0

27 Power up keypad reference 0

29 Load defaults no

30 Ramp mode select 1

31 Stop mode select 1

32 Dynamic V to f select OFF

33 Catch a spinning motor select 0

35 Terminal T4 output mode selector Fr

37 Maximum switching frequency (kHz) 3

39 Motor rated frequency (Hz) 50.0 60.0

40 Number of motor poles Auto

41 Voltage mode select Fd

42 Low frequency voltage boost (%) 3.0

45 Software version

55 Last trip

56 Trip before Pr 55

57 Trip before Pr 56

58 Trip before Pr 57

81 Frequency reference selected

82 Pre-ramp reference

83 Post-ramp reference

84 DC Bus voltage

85 Motor frequency

86 Motor voltage

87 Motor speed

88 Motor current

91 Reference enabled indicator

92 Reverse selected indicator

93 Jog selected indicator

94 Analogue input 1 level

Read only diagnostic parameters

Default

Eur USA

Setting

Commander SL Advanced User Guide 11

Issue Number: 1 www.controltechniques.com

Page 12

Introduction Default parameters Parameter description format Keypad and display Menu 0

Figure 5-1 Menu 0 logic diagram

Analogue

input

T2

Digital I/O

T10

T9

T4

T6

T7

T8

B4

B3

Analogue

input 1

Sequencer

logic select

Stop mode

Input

terminals

Output

terminals

(%)

94

Start/stop

11

select

31

Key

XX

XX

Reference

selected

(Hz)

81

Jog

selected

93

Reverse

selected

92

Reference

enabled

91

Read-write (RW)

parameter

Read-only (RO)

parameter

Jog

reference

15

Speed clamps

Minimum

01

speed

Maximum

02

speed

1

0

1

X-1

Pre-ramp

reference (Hz)

1

0

0

0Hz

82

Post-ramp

reference

(Hz)

03

04

30

Ramps

Acceleration

rate

Deceleration

rate

Ramp mode

select

83

Motor

frequency

Motor control

85

Motor

voltage

86

Motor

speed

rpm

87

Current

measurement

DC bus

voltage

84

Motor current

88

06

07

08

09

32

37

39

40

41

42

Motor rated

current

Motor rated

speed

Motor rated

voltage

Motor power

factor

Dynamic V to f

select

Switching

frequency

Motor rated

frequency

No. of motor

poles

Voltage

mode select

Voltage

boost

Parameter

access

10

01 Minimum set speed

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11 11

Range 0.0 to 1500.0 Hz

Default 0.0

Update rate Background

Used to define drive minimum set speed. This can be overridden if the maximum set speed clamp Pr 02 is adjusted to be less than Pr 01. Inactive

during jogging. With Pr 17 set to On, Pr 01 is 0.0.

02 Maximum set speed

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range 0.0 to 1500.0 Hz

Default

EUR: 50.0

USA: 60.0

Update rate Background

This parameter is a symmetrical limit on both directions of rotation.

Defines drive absolute maximum frequency reference. Slip compensation and current limit can increase the motor frequency further.

12 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 13

Introduction Default parameters Parameter description format Keypad and display Menu 0

03 Acceleration rate

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range 0 to 3200.0s/100 Hz

Default

Eur: 5.0

USA: 33.0

Update rate 5ms

Sets the acceleration rate of the motor in both directions in seconds/100Hz.

04 Deceleration rate

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range 0 to 3200.0 s/100 Hz

Default

Eur: 10.0

USA: 33.0

Update rate 5ms

Sets the deceleration rate of the motor in both directions in seconds/100Hz.

05 Drive configuration

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range AV, AI, AV.Pr, AI.Pr, Pr, PAd

Default

Eur: AV

USA: PAd

Update rate Actioned on exit of edit mode or drive reset.

This parameter is used to automatically set up the user control terminals to the required drive configuration. Other default parameters may also be

changed automatically by the drive configuration.

A change to Pr 05 is set on the exit of parameter edit mode or on a drive reset. The drive must be disabled, stopped or tripped for a change to take

place. If Pr 05 is changed while the drive is running, the parameter will return to its pre-altered value. Following a drive configuration change, the

parameters are automatically stored in EEPROM.

In all of the following settings, the status relay is set up as a drive healthy relay.

T9

OK Fault

T10

Configuration Description

AV Voltage input

AI Current input

AV.Pr Voltage input with 1 preset speed

AI.Pr Current input with 1 preset speed

Pr 4 preset speeds

PAd Keypad control

Commander SL Advanced User Guide 13

Issue Number: 1 www.controltechniques.com

Page 14

Introduction Default parameters Parameter description format Keypad and display Menu 0

y

t

t

e

Figure 5-2 Key to switches

Latching switch

Momentar

switch

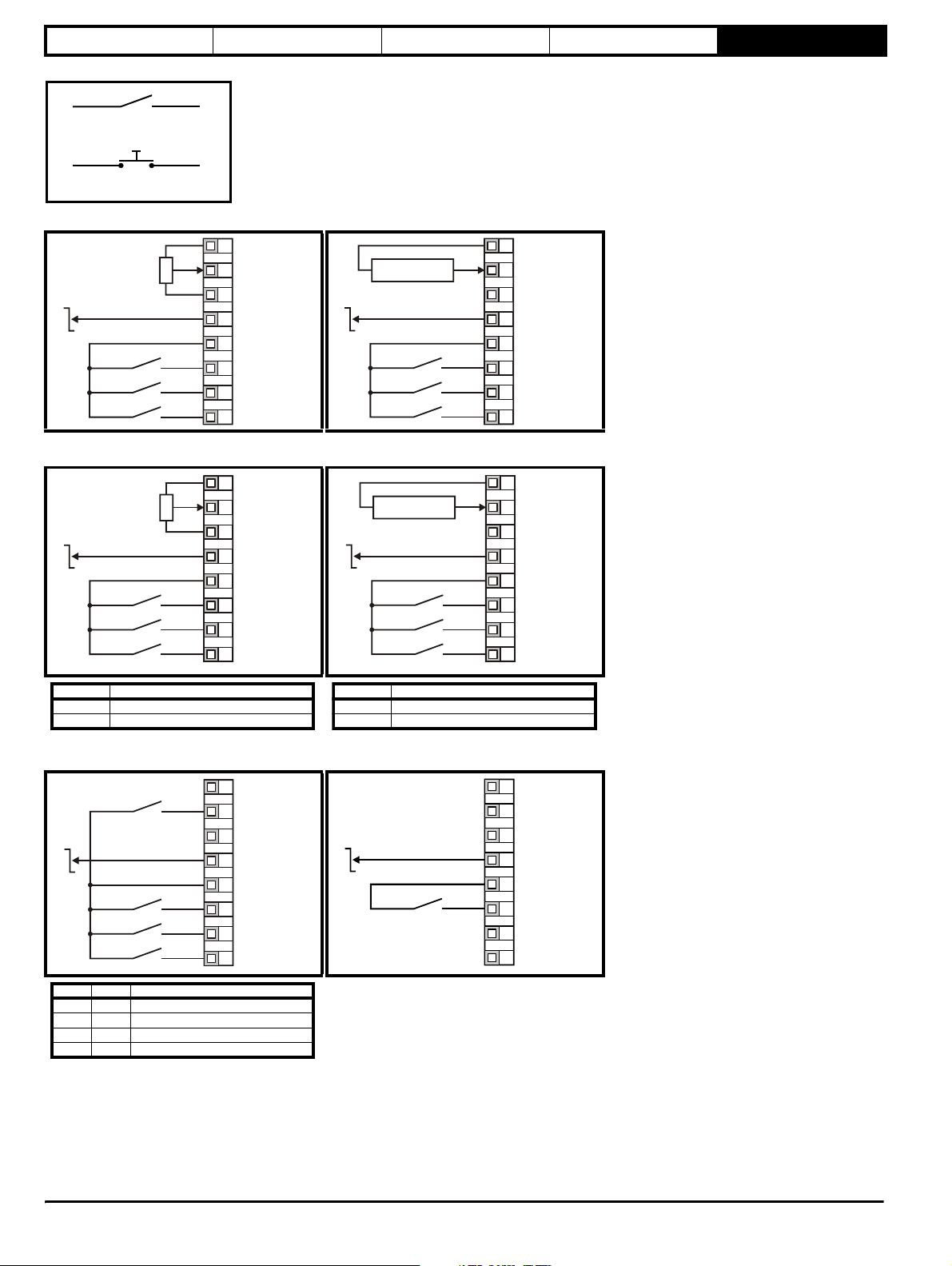

Figure 5-2 Pr 05 = AV Figure 5-3 Pr 05 = AI

T1

0V

reference input (AI)

0V

Current speed

+24V

10k

(2kmin)

0V

Voltage speed

T2

reference input (AV)

+10V reference

T3

output

Digital output

T4

(zero speed)

+24V output

T5

Drive enable/reset

T6

(USA: /Stop)

Run forward

T7

(USA: Run)

Run reverse

T8

(USA: Jog)

+24V

Figure 5-4 Pr 0 5 = AV.Pr Figure 5-5 Pr 05 = AI.Pr

T1

0V

Voltage speed

T2

reference input (AV)

+10V reference

T3

output

Digital output

T4

(zero speed)

+24V output

T5

Drive enable/reset

T6

(USA: /Stop)

Run forward

T7

(USA: Run)

Voltage speed

reference input /

T8

preset speed select

+24V

10k

(2kmin)

0V

T8 Reference selected

Open Voltage speed reference input (AV)

Closed Preset speed 2 (Pr 19)

+24V

Current speed

reference input (AI)

0V

T8 Reference selected

Open Current speed reference input (AI)

Closed Preset speed 2 (Pr 19)

T1

0V

Current speed

T2

reference input (AI)

+10V reference

T3

output

Digital output

T4

(zero speed)

+24V output

T5

Drive enable/reset

T6

(USA: /Stop)

Run forward

T7

(USA: Run)

Run reverse

T8

(USA: Jog)

T1

0V

Current speed

T2

reference input (AI)

+10V reference

T3

output

Digital output

T4

(zero speed)

+24V output

T5

Drive enable/reset

T6

(USA: /Stop)

Run forward

T7

(USA: Run)

Current speed

reference input /

T8

preset speed selec

Figure 5-6 Pr 0 5 = Pr Figure 5-7 Pr 05 = PAd

T1

0V

Not used

T2

+10V referenc

T3

output

Digital output

T4

(zero speed)

+24V output

T5

Drive enable/

T6

reset

T7

Not used

T8

Not used

+24V

T1

0V

T2

Reference select

+10V reference

T3

output

Digital output

T4

0V

(zero speed)

+24V output

T5

Drive enable/rese

T6

(USA: /Stop)

Run forward

T7

(USA: Run)

T8

Reference select

+24V

0V

T2 T8 Reference selected

Open Open Preset speed 1 (Pr 18)

Closed Open Preset speed 2 (Pr 19)

Open Closed Preset speed 3 (Pr 20)

Closed Closed Preset speed 4 (Pr 21)

14 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 15

Introduction Default parameters Parameter description format Keypad and display Menu 0

06 Motor rated current

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

12111

Range 0 to RATED_CURRENT_MAX A

Default Drive rated current

Update rate Background

The motor rated current should be set at the machine nameplate value for rated current.

This value is used in the following:

Current limit

Motor protection system

Slip compensation, see Pr 07

Vector mode voltage control, see Pr 08

Dynamic V to f control, see Pr 32 on page 21.

Pr 06 motor rated current must be set correctly to avoid risk of fire in the event of a motor overload.

WARNING

07 Motor rated full load rpm

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Range 0 to 9999

Default Eur: 1500, USA 1800

Update rate Background

The rated full load rpm is used with the motor rated frequency and No. of motor poles to calculate the rated slip of the induction machine in Hz.

Rated slip Motor rated frequency No. of motor pole pairs Motor full load rpm 60⁄×()– Pr 39 Pr 40 2⁄()Pr 07 60⁄()×[]–= =

The rated slip is used to calculate the frequency adjustment required to compensate for slip from the following equation:

Slip compensation Rated slip Active current Rated active current⁄×=

If slip compensation is required, this parameter should be set to the nameplate value, which should give the correct rpm for a hot machine.

Sometimes it will be necessary to adjust this when the drive is commissioned because the nameplate value may be inaccurate. Slip compensation will

operate correctly both below rated speed and within the field weakening region. Slip compensation is normally used to correct for the motor speed to

prevent speed variation with load. The rated load rpm can be set higher than synchronous speed to deliberately introduce speed droop. This can be

useful to aid load sharing with mechanically coupled motors.

NOTE

If Pr 07 is set to 0 or to synchronous speed, slip compensation is disabled.

NOTE

If the full load speed of the motor is above 9999rpm, slip compensation should be disabled. This is because a value above 9999 cannot be entered in

Pr 07.

08 Motor rated voltage

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

1111

Range 0 to AC_VOLTAGE_SET_MAX V

Default

200V rating drive: 230V

400V rating drive: Eur: 400V, USA: 460V

Update rate 128ms

The rated voltage is used in conjunction with the motor rated frequency (Pr 39) to define the voltage to frequency characteristic applied to the motor.

NOTE

If the motor is not a standard 50 or 60 Hz motor, see Pr 39 on page 23 and adjust accordingly.

The following operating methods selected by Pr 41 are used to define the drive frequency to voltage characteristic.

Open-loop vector mode: Ur S, Ur A, Ur or Ur I

A linear characteristic is used from 0Hz to rated frequency, and then a constant voltage above rated frequency. When the drive operates between

rated frequency/50 and rated frequency/4, full vector based stator resistance (Rs) compensation is applied. However there is a delay of 0.5s when the

drive is enabled during which only partial vector based compensation is applied to allow the machine flux to build up. When the drive operates

Commander SL Advanced User Guide 15

Issue Number: 1 www.controltechniques.com

Page 16

Introduction Default parameters Parameter description format Keypad and display Menu 0

y

O

39

between rated frequency/4 and rated frequency/2 the Rs compensation is gradually reduced to zero as the frequency increases. For the vector

modes to operate correctly the stator resistance motor rated power factor (Pr 09) and voltage offset are all required to be set-up accurately.

Fixed boost mode: Fd

A linear characteristic is used from 0Hz to rated frequency, and then constant volt age above rated frequency. Low frequency voltage boost as defined

by Pr 42 is applied as shown below.

utput voltage char acteristic

Pr / 239Pr

39

Output

frequenc

Pr / 2

Voltage

boost Pr

Output

voltage

08

Pr

08

42

Square law mode: SrE

A square law characteristic is used from 0Hz to rated frequency, and then constant voltage above rated frequency. Low frequency voltage boost

raises the start point of the square law characteristic as shown below.

Pr

08

Pr + [(freq/Pr ) x (Pr - Pr )]

42 39 08 42

2

Pr

42

Pr

09 Motor rated power factor

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

2111

Range 0.00 to 1.00

Default 0.85

Update rate Background

The power factor is the true power factor of the motor, i.e. the angle between the motor voltage and current. The power factor is used in conjunction

with the motor rated current (Pr 06) to calculate the rated active current and magnetising current of the motor. The rated active current is used

extensively to control the drive, and the magnetising current is used in vector mode Rs compensation. It is important that this parameter is set up

correctly.

16 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 17

Introduction Default parameters Parameter description format Keypad and display Menu 0

10 Security status

Coding

Range OPEn, LoC

Default OPEn

Update rate Actioned on exit of edit mode

This read write parameter defines the level of security for menu 0.

Level Access permitted

OPEn All parameters can be accessed.

LoC

The LED keypad can adjust this parameter even when user security is set.

11 Start/stop logic select

Coding

Range 0 to 4

Default Eur: 0, USA: 4

Update rate Actioned on exit of edit mode or drive reset

This parameter changes the functions of terminals T6, T7 and T8, which are normally associated with the enabling, starting and stopping the drive.

Pr 11 Terminal T6 Terminal T7 Terminal T8 Latching

0 Enable Run Forward Run Reverse No

1 /Stop Run Forward Run Reverse Yes

2 Enable Run Fwd/Rev No

3 /Stop Run Fwd/Rev Yes

4 /Stop Run Jog Yes

A change to this parameter is only actioned when the drive is stopped, tripped or disabled. If the drive is active when this parameter is changed, the

parameter will return to its pre-altered value on exit of edit mode or drive reset.

NOTE

The function of terminal T8 is automatically changed by the setting of parameter Pr 05 if preset speeds are being used. See Pr 05 on page 13.

Bit SP FI Txt VM DP ND RA NV RW BU PS

1111

Lock security, so that the security code must be entered before a parameter can

be edited and set security status to OPEn.

Bit SP FI Txt VM DP ND RA NV US RW BU PS

1 111

Pr 11=0

T5

+24V

Enable

T6

Run Forward

T7

Run Reverse

T8

Pr 11=1

T5

+24V

/Stop

T6

Run Forward

T7

Run Reverse

T8

Pr 11=2

T5

+24V

Enable

T6

Run

T7

Forward/Reverse

T8

Commander SL Advanced User Guide 17

Issue Number: 1 www.controltechniques.com

Page 18

Introduction Default parameters Parameter description format Keypad and display Menu 0

Pr 11=3

T5

+24V

/Stop

T6

Run

T7

Forward/Reverse

T8

Pr 11=4

T5

+24V

/Stop

T6

Run

T7

Jog

T8

15 Jog reference

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range 0.0 to 400.0 Hz

Default 1.5

Update rate 5ms

Defines the jog speed.

17 Allow negative references

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Default OFF

Update rate Background

OFF: Allow negative references disabled. Direction of rotation controlled by run forward and run reverse terminals.

On: Allow negative references enabled. Direction of rotation controlled by preset speed values (use run forward terminal)

Needs to be set if the user requires to change the direction of rotation with preset speeds. If it is not set, all negative preset speeds are treated as

zero.

NOTE

The analogue input is unipolar and setting this bit does not allow bipolar analogue references to be applied to the drive.

Analogue input scaling

FREQ_MAX

Pr

01

-100% 100%

FREQ_MAX

-100% 100%

-FREQ_MAX

Pr = 0

17

Pr = 1 (Allow negative references mode)

17

18 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 19

Introduction Default parameters Parameter description format Keypad and display Menu 0

18 Preset speed 1

19 Preset speed 2

20 Preset speed 3

21 Preset speed 4

Coding

Range ±1500.0Hz

Default 0.0

Update rate 5ms

Defines preset speeds 1 to 4

The preset speeds are clamped by the maximum set speed (Pr 02).

NOTE

If the maximum speed clamp (Pr 02) is reduced from, for example 50Hz and is set below the preset speed values (Pr 18 to 21), the preset speeds will

follow the reduced maximum speed clamp value.

If the maximum speed clamp is then increased to its original value of 50Hz, the preset speeds will remain at the lower value set by the maximum

speed clamp.

Example:

Original values:

Maximum speed clamp reduced, preset speeds follow maximum speed clamp:

Maximum speed clamp increased, preset speeds remain at the lower value set by the maximum speed clamp:

Pr 02 = 50Hz

Pr 18 = 45Hz, Pr 19 = 42Hz, Pr 20 = 30Hz

Pr 02 = 40Hz

Pr 18 = 40Hz, Pr 19 = 40Hz, Pr 20 = 30Hz

Pr 02 = 50Hz

Pr 18 = 40Hz, Pr 19 = 40Hz, Pr 20 = 30Hz

Bit SP FI Txt VM DP ND RA NV RW BU PS

11 1

25 User security code

Coding

Range 0 to 999

Default 0

Update rate Background

If any number, other than 0 is programmed into this parameter the user security is applied so that no parameters except Pr 10 can be adjusted with

the LED keypad. When this parameter is read via an LED keypad and security is locked it appears as zero.

27 Power-up keypad reference

Coding

Range 0, LASt, PrS1

Default 0

Update rate N/A

Selects the value of the keypad reference on power-up.

Display Function

0 keypad reference is zero

LASt keypad reference is the last used value

PrS1 keypad reference is copied from Preset speed 1 (Pr 18)

29 Load defaults

Coding

Range no, Eur, USA

Default no

Update rate Actioned on exit of edit mode or drive reset

If this parameter is set to Eur or USA and edit mode is exited or the drive is reset when the drive is inactive, the selected default parameters will

automatically be loaded. After the parameters have been set to default values they are automatically saved to the drive’s internal EEPROM. The drive

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Commander SL Advanced User Guide 19

Issue Number: 1 www.controltechniques.com

Page 20

Introduction Default parameters Parameter description format Keypad and display Menu 0

must be in a disabled, stopped or tripped condition to allow default parameters to be set. If the drive is active the display will flash FAIL once and then

Pr 29 will be set back to no.

Display Function

no No action

Eur 50Hz default parameters are loaded

USA 60Hz default parameters are loaded

30 Ramp mode select

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Range 0 to 3

Default 1

Update rate Background

This parameter has 4 settings as follows:

0: Fast ramp

1: Standard ramp with normal motor voltage

2: Standard ramp with high motor voltage

3: Fast ramp with high motor volts

The acceleration ramp is not affected by the ramp mode, and the ramp output will rise at the programmed acceleration rate (subject to the current

limits programmed).

Fast Ramp

In modes 0 and 3, the output of the ramp will fall at the programmed deceleration rate (subject to the current limits). Fast ramp is normally used when

a braking resistor is fitted.

Standard Ramp

In modes 1 & 2, the voltage rising to the standard ramp level causes a proportional controller to operate, the output of which changes the demanded

current in the motor. As the controller regulates the bus voltage, the motor decelerates at a faster and faster rate as it approaches zero speed. When

the motor deceleration rate reaches the programmed deceleration rate the controller ceases to operate and the drive continues to decelerate at the

programmed rate.

Figure 5-3

Controller

operational

DC Bus voltage

Motor Speed

Programmed

deceleration

rate

t

In modes 0 and 1 the motor voltage is correctly set according to the motor rated voltage parameter, while in modes 2 and 3 the motor voltage is

allowed to go up to a factor of 1.2 times its normal value during deceleration. This higher voltage saturates the motor which increases the losses in the

motor and therefore reduces the amount of energy transferring from the motor to the DC bus for a given deceleration rate. For a given amount of

energy being dissipated by the drive at the regulated DC bus level, modes 2 and 3 will allow a faster deceleration than modes 0 and 1, providing that

the motor can stand the extra losses being dissipated in it.

NOTE

Mode 0 may cause an 0V trip if the programmed deceleration rate is too fast (mode 3 can be selected if desired but will cause the motor to heat up

more due to the higher losses in the motor when compared to mode 0).

20 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 21

Introduction Default parameters Parameter description format Keypad and display Menu 0

31 Stop mode select

Coding

Range 0 to 4

Default 1

Update rate 2 ms

0: Coast stop

1: Ramp stop

2: Ramp stop + dc injection

3: DC Injection braking stop with detection of zero speed

4: Timed dc injection braking stop

Stopping is in two distinct phases: decelerating to stop, and stopped. (Table shows default values)

Stopping Mode Phase 1 Phase 2 Comments

0: Coast Inverter disabled

1: Ramp Ramp down to zero frequency

2: Ramp followed by DC injection Ramp down to zero frequency

3: DC injection with zero speed

detection

4: Timed DC injection braking stop

Once modes 3 or 4 have begun the drive must go through the ready state before being restarted either by stopping, tripping or being disabled.

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Drive cannot be re-enabled for

a specific time period which is

drive size dependant.

Wait for 1s with inverter

enabled

Inject DC at level of 100%

motor rated current for 1s

Low frequency current injection with

detection of low speed before next

phase

Inject DC at level of 100% motor

rated current for 1s

Inject DC at level of 100%

motor rated current for 1s

Inject DC at level of 100%

motor rated current for 1s

Delay in phase 2 allows rotor flux to

decay.

The drive automatically senses low

speed and therefore it adjusts the

injection time to suit the application. If

the injection current level is too small

the drive will not sense low speed

(normally a minimum of 50-60% is

required).

The total injection time is 1s for phase 1

and 1s for phase 2, i.e. 2s in total.

32 Dynamic V to f select

Coding

Range OFF or On

Default OFF

Update rate Background

OFF: Dynamic V to f select disabled

On: Dynamic V to f select enabled

Setting this bit to On enables dynamic V to f mode which is intended for applications where power loss should be kept to a minimum under low load

conditions. The V/f ratio is modified with load as follows:

If |active current| < 0.7 x rated active current

V/f ratio = Normal V/f ratio x (0.5 + (active current / (2 x 0.7 x rated active current)))

Else, if |active current| ≥ 0.7 x rated active current

V/f ratio = Normal V/f ratio

Although the rated frequency varies, the value shown as Pr 39 does not vary from that set by the user.

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Commander SL Advanced User Guide 21

Issue Number: 1 www.controltechniques.com

Page 22

Introduction Default parameters Parameter description format Keypad and display Menu 0

33 Catch a spinning motor select

Coding

Range 0 to 3

Default 0

Update rate Background

Pr 33 Function

0 Disabled

1 Detect positive and negative frequencies

2 Detect positive frequencies only

3 Detect negative frequencies only

When the drive is enabled with this bit at 0, the output frequency starts at zero and ramps to the required reference. When the drive is enabled and

this parameter has a non-zero value, the drive performs a start-up test to determine the motor speed and then sets the initial output frequency to the

synchronous frequency of the motor. The test is not carried out, and the motor frequency starts at zero, if the run command is given when the drive is

in the stop state, or when the drive is first enabled after power up with Ur I voltage mode, or when the run command is given in Ur S voltage mode.

NOTE

For the test to operate correctly it is important that the stator resistance is set up correctly. This applies even if fixed boost (Fd) or square law (SrE)

voltage mode is being used. The test uses the rated magnetising current of the motor during the test, therefore the rated current (Pr 06), and the

power factor (Pr 09) should be set to values close to those of the motor, although these parameters are not as critical as the stator resistance.

NOTE

Stationary lightly loaded motors with low inertia may move slightly during the test. The direction of the movement is undefined. Restrictions may be

placed on the direction of this movement and on the frequencies detected by the drive as in the above table.

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

35 Terminal T4 output mode select

Coding

Range

Default Fr

Update rate Action on exit of edit mode

This parameter offers a simple control to change the functionality of the digital output.

Display Function

Fr Voltage proportional to motor speed

Ld Voltage proportional to motor load

A Voltage proportional to output current

Por Voltage proportional to output power

n=0 At zero speed

At.SP At speed

Lo.SP At minimum speed

hEAL Drive healthy

Act Drive active

ALAr General drive alarm

I.Lt Current limit active

At.Ld At 100% load

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Fr, Ld, A, Por, n=0, At.SP, Lo.SP, hEAL, Act, ALAr, I.Lt, At.Ld

22 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 23

Introduction Default parameters Parameter description format Keypad and display Menu 0

37 Maximum switching frequency

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

1111

Range 3, 6, 12, 18 kHz

Default 3

Update rate Background

Display Frequency (kHz)

33

66

12 12

18 18

This parameter defines the required switching frequency.

The drive may automatically reduce the actual switching frequency (without changing this parameter) if the power stage becomes too hot. The

switching frequency can reduce from 18kHz to 12kHz to 6kHz to 3kHz. An estimation of the IGBT junction temperature is made based on the heatsink

temperature and an instantaneous temperature drop using the drive output current and switching frequency.

If the temperature exceeds 135

o

C, the switching frequency is reduced if possible (i.e if the current switching frequency is >3kHz) to reduce the drives

losses and thus reduce the IGBT junction temperature.

If the load condition persists, the junction temperature may continue to rise. If the temperature exceeds 145

o

C and the switching frequency cannot be

reduced the drive will initiate an O.ht1 trip.

Every 20ms the drive will attempt to restore the set switching frequency if the higher switching frequency will not take the IGBT temperature above

o

C.

135

NOTE

The 18kHz switching frequency is not available on Commander SL size B and C, 400V units.

39 Motor rated frequency

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range 0.0 to 1500.0 Hz

Default EUR: 50.0, USA 60.0

Update rate Background

The motor rated frequency and the motor rated voltage (Pr 08) are used to define the voltage to frequency characteristic applied to the drive ( see

Pr 08 on page 15). The motor rated frequency is also used in conjunction with the motor full load rpm to calculate the rated slip for slip compensation

(see Pr 07 on page 15).

40 Number of motor poles

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Range Auto, 2P, 4P, 6P, 8P

Default Auto

Update rate Background

Poles by text

Pole pairs

(value on display)

Auto 0

2P 1

4P 2

6P 3

8P 4

This parameter is used in the calculation of motor speed and in applying the correct slip compensation. When auto is selected the number of motor

poles is automatically calculated from the rated frequency (Pr 39) and the rated load rpm (Pr 07).

The number of poles = 120 x rated frequency / rpm rounded to the nearest even number.

Commander SL Advanced User Guide 23

Issue Number: 1 www.controltechniques.com

Page 24

Introduction Default parameters Parameter description format Keypad and display Menu 0

41 Voltage mode select

Coding

Range Ur S, Ur, Fd, Ur A, Ur I, SrE

Default Fd

Update rate Background

Ur S Stator resistance and voltage offset measured on each run signal

The stator resistance and the voltage offset are measured and the parameters for the selected motor map are over-written each time the drive is

given a run signal. This test can only be done with a stationary machine where the flux has decayed to zero. Therefore this mode should only be used

if the machine is guaranteed to be stationary each time the drive is enabled. To prevent the test from being done before the flux has decayed there is

a period of 1 second after the drive has been in the ready state during which the test is not done if the drive is re-started. In this case, previously

measured values are used.

Ur No measurements

The stator resistance and voltage offset are not measured. The user can enter the motor and cabling resistance into the stator resistance parameter.

However this will not include resistance effects within the drive inverter. Therefore if this mode is to be used, it is best to use another Ur mode to

measure the stator resistance, initially.

Fd Fixed boost mode.

Neither the stator resistance nor the voltage offset are used, instead a fixed characteristic with boost applied as defined by Pr 42 is used. (see Pr 08

on page 15)

NOTE

Fixed boost mode should be used for multiple motor applications

Ur A Stator resistance and voltage offset measured at first drive enable

The stator resistance and voltage offset are measured once, the first time the drive is enabled and run. After the test has been completed successfully

the mode is changed to Ur mode. The stator resistance and voltage offset are written to the parameters for the currently selected motor map and

these parameters along with this parameter are saved in the EEPROM.

NOTE

If the test fails the stator resistance and voltage offset are not updated, the mode is changed to Ur, but no parameters are saved. If the drive is

powered down and back up, the drive will carry out another autotune when the drive is enabled and run.

4 Ur I Stator resistance and voltage offset measured at each power-up and after a drive default

The stator resistance and voltage offset are measured when the drive is first enabled after each power-up and after a drive default.

5 SrE Square law characteristic

Neither the stator resistance nor the voltage offset are used, instead a fixed square law characteristic with boost applied as defined by Pr 42 is used.

(see Pr 08 on page 15)

Bit SP FI Txt VM DP ND NV RW BU PS

111

42 Low frequency voltage boost

Coding

Range 0.0 to 50.0% of motor rated voltage

Default 3.0

Update rate Background

The voltage boost level used in fixed boost mode and square law mode is defined by this parameter. See Pr 08 on page 15.

45 Software version

Coding

Range 0.00 to 99.99

Update rate N/A

The drive software version consists of three numbers xx.yy .zz. xx.yy is di splayed in this parameter. Where xx specifies a change that affects hardware

compatibility, yy specifies a change that affects product documentation, and zz specifies a change that does not affect the product documentation.

The zz number is shown on the drive’s rating label.

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Bit SP FI Txt VM DP ND RA NV RW BU PS

21 1

24 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 25

Introduction Default parameters Parameter description format Keypad and display Menu 0

55 Last trip

56 Trip 1

57 Trip 2

58 Trip 3

Coding

Range 0 to 232

Update rate On drive trip

Contains the last 4 drive trips. Pr 55 is the most recent trip and Pr 58 the oldest. When a new trip occurs all the parameters move down one, the

current trip is put in Pr 55 and the oldest trip is lost off the bottom of the log. Possible trips for Commander SL are shown in Table 5-8 on page 25.

All trips are stored including HF trips which are numbered from 20 to 30. (HF trips numbered from 1 to 19 are not stored in the trip log.) UV trips are

not stored unless the drive is running when the trip occurs.

Table 5-8 Trip indications

String Cause of trip

UV*** DC bus under voltage - Low AC supply voltage.

OV

OI.AC** AC instantaneous over current.

O.SPd Overspeed

It.AC

O.ht1 Drive over-heat (IGBT junctions) based on thermal model (see Pr 37 on page 23)

O.ht2 Drive over-heat based on heatsink temperature

O.Ld1* +24V or Digital output overload

O.ht3

EEF

PH

rS

O.cL Overload on current loop input

HF20 - HF30 Hardware faults (See table Table 5-10 HF trips )

Bit SP FI Txt VM DP ND RA NV RW BU PS

11 11

DC bus over voltage.

Drive voltage rating Instantaneous trip

200V 415V

400V 830V

2

I

t on drive output current

Drive over-heat based on thermal model

The drive will attempt to stop the motor before tripping. If the motor does not stop in 10 seconds the drive trips

immediately.

Internal drive EEPROM failure. All the parameters are set to default. The trip can only be removed by entering a load

default command (see Pr 29 on page 19)

High input voltage phase imbalance or input phase loss. Normally a motor load of between 50 and 100% or drive rating is

required to trigger the trip. The drive will attempt to stop the motor before tripping.

Failure to measure resistance when starting in open-loop voltage modes 0 or 3. This is either because the resistance

exceeds the maximum measurable value or no motor connected to drive (see Pr 41 on page 24)

*The enable/reset terminal will not reset an O.Ld1 trip. Use the stop/reset key.

**This trip cannot be reset for 10 seconds.

***The UV trip is only stored in the drive’s trip log if the drive trips on UV while running.

Trips can be grouped into the following categories:

Category Trips Comments

Hardware faults HF01 to HF19

Self resetting trips UV

Non-resetable trips HF20 to HF30 Cannot be reset.

EEF trip EEF Cannot be reset unless a default parameter set has been loaded.

Normal trips All other trips Can be reset after 1.0s

Normal trips with extended

reset

Phase loss PH

OI.AC Can be reset after 10.0s

These indicate fatal problems and cannot be reset. The drive is inactive after one

of these trips and the display shows HFxx.

Under voltage trip cannot be reset by the user, but is automatically reset by the

drive when the supply voltage is within specification (See table Table 5-9 Under

voltage trip and restart levels )

The drive stops before tripping provided the drive motoring power is suitably

reduced after 500ms of detecting phase loss

Commander SL Advanced User Guide 25

Issue Number: 1 www.controltechniques.com

Page 26

Introduction Default parameters Parameter description format Keypad and display Menu 0

Table 5-9 Under voltage trip and restart levels

Drive voltage rating UV trip level UV restart level 0V trip

200Vac 175Vdc 215Vdc* 415

400Vac 330Vdc 425Vdc* 830

* These are the absolute minimum dc voltages that the drive can be supplied by.

Table 5-10 HF trips

HF fault code Reason for trip

01 to 03 Not used

04 Low DC bus at power up

05 No signal from DSP at start up

06 Unexpected interrupt

07 Watchdog failure

08 Interrupt crash (code overrun)

09 to 10 Not used

11 Access to the EEPROM failed

12 to 19 Not used

20 Power stage - code error

21 Power stage - unrecognised frame size

22 OI failure at power up

23 DSP software overrun

24 Not used

25 DSP Communications failure

26 Soft start relay failed to close, or soft start monitor failed

27 Power stage thermistor fault

28 Fan failure (current too high - only on drives with a fan)

29 Not used

30 Not used

It should be noted that although the UV trip operates in a similar way to all other trips, all drive functions can still operate, but the drive cannot be

enabled. Parameter values are only loaded from EEPROM if the supply voltage is low enough for the switch mode power supply in the drive to shut

down and then it is increased to restart the drive power supplies. The only differences between UV and other trips are as follows:

1. Power down save user parameters are saved when UV trip is activated.

2. The UV trip is self-resetting when the DC bus voltage rises above the drive restart voltage level.

3. When the drive is first powered up a UV trip is initiated if the supply voltage is below the restart voltage level. This does not save power down

save parameters. If another trip occurs during power-up it is the active trip in preference to the UV trip. If this trip is cleared and the supply voltage

is still below the restart voltage threshold a UV trip is then initiated.

The following alarm warnings and display indications will flash on the right hand display when they become active.

Table 5-11 Alarm Warnings

Display Condition

OVL.d Ixt overload

hot Heatsink/IGBT temperature too high (see Pr 37 on page 23)

Table 5-12 Display indications

Display Condition

AC.Lt Drive is in current limit

81 Frequency reference selected

Coding

Range ±1500.0 Hz

Update rate 5ms

Indication of the reference being used by the drive for system setup and fault finding.

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

26 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 27

Introduction Default parameters Parameter description format Keypad and display Menu 0

82 Pre-ramp reference

Coding

Range ±1500.0 Hz

Update rate 5ms

Indication of the reference being used by the drive for system setup and fault finding.

83 Post ramp reference

Coding

Range ±1500.0Hz

Update rate 21ms

Although the range for scaling purposes is ±1500 Hz, the actual parameter value can be increased beyond this range by the current limit controller

(up to 20% > than the maximum frequency).

This is shown on the drive’s display.

84 DC bus voltage

Coding

Range 0 to +DC_VOLTAGE_MAX V

Update rate Background

Voltage across the internal DC bus of the drive.

Bit SP FI Txt VM DP ND RA NV RW BU PS

111

Bit SP FI Txt VM DP ND RA NV RW BU PS

1 111

Bit SP FI Txt VM DP ND RA NV RW BU PS

111 1

85 Motor frequency

Coding

Range ±1500.0 Hz

Update rate 21 ms

Although the range for scaling purposes is ±1500Hz, the actual parameter value can be increased beyond this range by slip compensation. This

parameter gives the output frequency of the drive, i.e. the sum of the post ramp reference and the slip compensation.

86 Motor voltage

Coding

Range 0 to AC_VOLTAGE_MAX V

Update rate Background

This is the modulus of the r.m.s. fundamental line-to-line voltage at the inverter output.

87 Motor speed

Coding

Range ±9999 rpm

Update rate Background

The motor speed is calculated from the post ramp reference (Pr 83). The speed of rotation is calculated as follows:

speed 60 Frequency No. of pole pairs⁄× 60 Pr 83 Pr 40 2⁄()⁄×==

The result will be fairly accurate provided the slip compensation has been set up correctly with the rated full load speed parameter (Pr 07). This

calculation relies on the number of motor poles being set up correctly in Pr 40, or if auto mode is selected (Pr 40 = Auto) then it relies on a reasonably

accurate value of motor rated speed being set in Pr 07 to allow correct calculation of the motor poles.

Bit SP FI Txt VM DP ND RA NV RW BU PS

1 111

Bit SP FI Txt VM DP ND RA NV RW BU PS

111 1

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Commander SL Advanced User Guide 27

Issue Number: 1 www.controltechniques.com

Page 28

Introduction Default parameters Parameter description format Keypad and display Menu 0

A

88 Current magnitude (motor current)

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

1121 1

Range 0 to DRIVE_CURRENT_MAX

Update rate Background

This parameter is the r.m.s. current from each output phase of the drive. The phase currents consist of an active component and a reactive

component. The three phase currents can be combined to form a resultant current vector as shown below:

ctive current

y

Resultant

output current

Pr

88

Reactive current

x

The resultant current magnitude is displayed by this parameter. The active current is the torque producing current, and the reactive current is the

magnetising or flux producing current.

91 Reference enabled indicator

92 Reverse selected indicator

93 Jog selected indicator

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11

Update rate 2ms

These flags are controlled by the drive sequencer. They select the appropriate reference as commanded by the drive logic.

94 Analogue input 1 level (terminal T2)

Coding

Bit SP FI Txt VM DP ND RA NV RW BU PS

11 1

Range 0.0 to 100.0%

Update rate 5 ms

This parameter displays the level of the analogue signal present at analogue input 1.

In voltage mode, this is a unipolar voltage input where the input range is 0 to +10V.

In current mode, this is a unipolar current input having a maximum measurable input of 20mA.

NOTE

If analogue input is 1 set-up as voltage input, and if the potentiometer is supplied from the drive’s +10V rail (terminal T3), they must have a resistance

>2kΩ.

28 Commander SL Advanced User Guide

www.controltechniques.com Issue Number: 1

Page 29

Page 30

0472-0078-01

Loading...

Loading...