Page 1

EF

www.controltechniques.com

Technical Data

Commander SL

AC variable speed drive for 3

phase induction motors from

0.25kW to 4kW, 0.33hp to 5hp

Part Number: 0472-0093-01

Issue: 1

Page 2

General Information

The manufacturer accepts no liability for any consequences resulting from inappropriate, negligent or incorrect

installation or adjustment of the optional parameters of the eq uipment or from mismatching the var iable speed drive with

the motor.

The contents of this guide are believed to be correct at the time of printing. In the interests of commitment to a policy of

continuous development and improvement, the manufacturer reserves the right to change the specification of the product

or its performance, or the content of the guide without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical or

mechanical including, photocopying, recording or by an information storage or retrieval system, without permission in

writing from the publisher.

Drive software version

This product is supplied with the latest version of user-interface and machine control software. If this product is to be

used in a new or existing system with other drives, there may be some differences between their software and the

software in this product. These differences may cause the product to function differently. This may also apply to drives

returned from the Control Techniques Service Centre.

If there is any doubt, please contact your local Control Techniques Drive Centre or Distributor.

Environmental Statement

Control Techniques is committed to minimising the environmental impacts of its manufacturing operations and of its

products throughout their life cycle. To this end, we operate an Environmental Management System (EMS) which is

certified to the International Standard ISO 14001. Further information on the EMS, our Environment Policy and other

relevant information is available on request, or can be found at www.greendrives.com.

The electronic variable speed drives manufactured by Control Techniques have the potential to save energy and

(through increased machine/process efficiency) reduce raw materia l consumption and scrap throughout their long

working lifetime. In typical applications, these positive environmental effects far outweigh the negative impacts of product

manufacture and end-of-life disposal.

Nevertheless, when the products eventually reach the end of their useful life, they can very easily be dismantled into their

major component parts for efficient recycling. Many parts snap together and can be separated without the use of tools,

while other parts are secured with conventional screws. Virtually all parts of the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden crates, while smaller

products come in strong cardboard cartons which themselves have a high-recycled fibre content. If not re-used, these

containers can be recycled. Polythene, used on the protective film a nd bag s fr om wrap ping pr oduct, can be re cycled in

the same way. Control Techniques' packaging strategy favours easily recyclable materials of low environmental impact,

and regular reviews identify opportunities for improvement.

When preparing to recycle or dispose of any pr od uc t or pa ck ag ing , ple a se ob se rv e loca l leg islation and best practice.

Copyright © September 2006 Control Techniques Drives Ltd

Issue: 1

Page 3

Contents

1 Technical data................................................................................................................5

1.1 Commander SL 200V units ....................................................................................................................5

1.2 Commander SL 400V units ....................................................................................................................6

2 Derating curves and losses..........................................................................................7

2.1 Size A ....................................................................................................................................................7

2.2 Size B ..................................................................................................................................................10

2.3 Size C ..................................................................................................................................................15

3 Drive voltage levels.....................................................................................................18

3.1 Input voltage ........................................................................................................................................18

4 DC bus design..............................................................................................................19

5 Mechanical installation ...............................................................................................20

5.1 Mechanical dimensions .......................................................................................................................20

5.2 Minimum mounting clearances ............................................................................................................23

6 EMC filters....................................................................................................................24

6.1 Filter data .............................................................................................................................................24

6.2 Conformity ...........................................................................................................................................25

7 AC line reactor values.................................................................................................28

7.1 Line reactors ........... ... ... .... ... ... ....................................... ... ... .... ... ... ... ... .... ............................................28

7.2 Reactor current ratings ........................................................................................................................28

7.3 Input line reactors for harmonics standards EN61000-3-2 and IEC61000-3-2 ..................... ...............29

7.4 Voltage fluctuation (Flicker) standard EN61000-3-3 (IEC61000-3-3) .. .... ... ... ... .... ... ... ... ... .... ... ... ... .... .. 29

8 Motor cable lengths.....................................................................................................31

9 General data.................................................................................................................32

9.1 Ratings ................................................................................................................................................32

9.2 Input phase imbalance .........................................................................................................................32

9.3 Ambient temperature ...........................................................................................................................32

9.4 Storage temperature ......................... ................................ ................................ ...................................32

9.5 Altitude ................................. ............................. ............................. ......................................................32

9.6 Humidity .................................. ................................ .................................... .........................................32

9.7 Storage humidity ..................................................................................................................................32

9.8 Pollution degree ...... ... ... .... ... ... .......................................... .......................................... .........................32

9.9 Materials ..............................................................................................................................................32

9.10 Vibration ..............................................................................................................................................32

9.11 Frequency accuracy ............................................................................................................................33

9.12 Resolution .................................. ............................. ............................. ................................................33

9.13 Output frequency range .......................................................................................................................33

9.14 Starts per hour .....................................................................................................................................33

9.15 Start-up time ........................................................................................................................................33

9.16 Serial communications ............................... .... ... ... ... .......................................... ...................................33

9.17 Switching frequencies ... .... .......................................... .......................................... ... ............................33

9.18 Harmonics ............................................................................................................................................33

9.19 Acoustic noise ......................................................................................................................................34

9.20 HF trips ................................................................................................................................................34

10 I/O specification...........................................................................................................35

10.1 Drive reset .... ... .... ... ... ... ....................................... ... .... ... ... ... .... ... ... ......................................................36

10.2 Sample/update times ...........................................................................................................................36

10.3 Task routine times ...............................................................................................................................37

Commander SL Technical Data 3

Issue Number: 1 www.controltechniques.com

Page 4

11 Supply types................................................................................................................ 38

11.1 AC supply requirements ..................................................................................................................... 38

11.2 Safety ................................................................................................................................................. 38

11.3 Cables ....................................... ................ ............. ................ ................ ............................................. 38

11.4 Fuses .................................................................................. ................................................................ 39

11.5 Ground connections ............................................................................................................................ 39

11.6 Use of earth leakage circuit breakers (ELCB)/residual current device (RCD) .................................... 40

12 Options ........................................................................................................................ 41

4 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 5

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

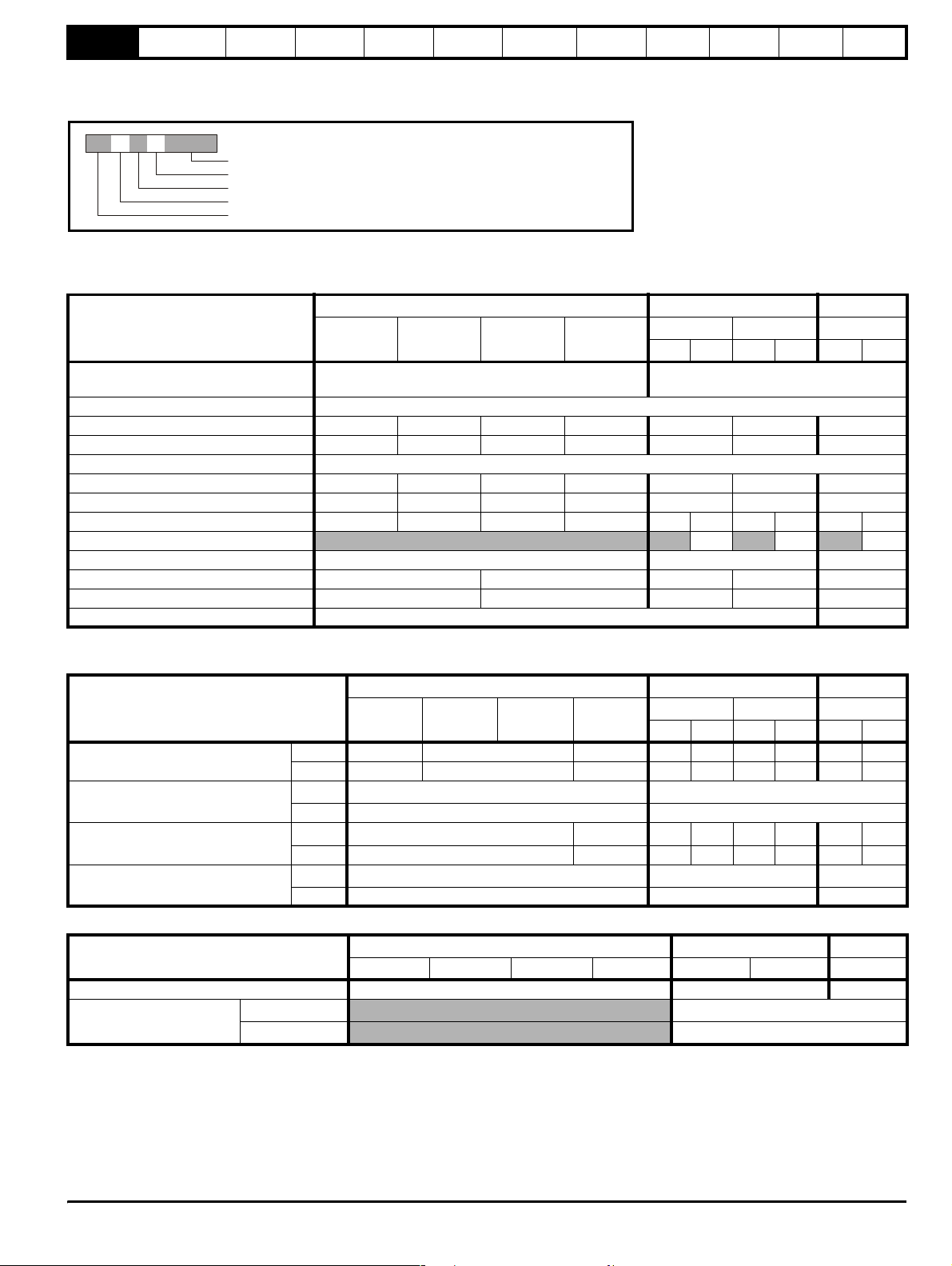

1 Technical data

Figure 1-1 Model code explanation

SL A 1 2 XXXXX

Drive kilowatt rating: 00025 = 0.25kW

Drive voltage rating: 2 = 230V, 4 = 400V

Number of input phases: 1 = 1phase, 3 = 3phase, D = 1 and 3phase

Frame size

Model: Commander SL

1.1 Commander SL 200V units

Table 1-1 Ratings

SLA12 SLBD2 SLCD2

MODEL

00025 00037 00055 00075

AC supply voltage and frequency Single phase 200 to 240V ±10% 48Hz to 62Hz

Input displacement factor (cos∅) >0.97

Nominal motor power (kW) 0.25 0.37 0.55 0.75 1.1 1.5 2.2

Nominal motor power (hp) 0.33 0.50 0.75 1.0 1.5 2.0 3.0

Output voltage and frequency 3 phase, 0 to drive rating (240), 0 to 1500Hz

100% RMS output current (A) 1.7 2.2 3.0 4.0 5.2 7.0 9.6

150% overload current for 60s (A) 2.6 3.3 4.5 6 7.8 10.5 14.4

Typical full load input current (A) 4.3 5.8 8.1 10.5 14.2 6.7 17.4 8.7 23.2 11.9

Maximum continuous input current (A)*

Typical inrush current (A) (<10ms) 17.9 8.9 6.0

Weight (kg) 0.95 1.0 1.3 1.4 2.1

Weight (Ib) 2.1 2.2 2.9 3.1 4.6

Din rail mounting Yes No

* For 3ph input only at 2% negative phase sequence.

Table 1-2 Cables

SLA12 SLBD2 SLCD2

MODEL

Recommended input supply fuse (A)

Control cable

Recommended input cable

Recommended motor cable

IEC 6 10 16 16 10 20 16 25 20

gG 5 10 15 1510201525 20

(mm

(AWG) 20 20

(mm

(AWG) 16 14 121412141012

(mm

(AWG) 16 16 14

00025 00037 00055 00075

2

)

2

)

2

)

≥0.5 ≥0.5

1.0 1.5 2.5 1.5 2.5 1.5 4.0 2.5

1.0 1.0 1.5

00110 00150 00220

1ph 3ph 1ph 3ph 1ph 3ph

Single or 3 phase 200 to 240V ±10% 48Hz

to 62Hz

9.2 12.6 17

00110 00150 00220

1ph 3ph 1ph 3ph 1ph 3ph

Table 1-3 Cooling fan

MODEL

00025 00037 00055 00075 00110 00150 00220

SLA12 SLBD2 SLCD2

Cooling fan fitted No Yes Yes

Air flow

(feet

(m

3

/minute)

3

/minute)

3.8

0.4

Commander SL Technical Data 5

Issue Number: 1 www.controltechniques.com

Page 6

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

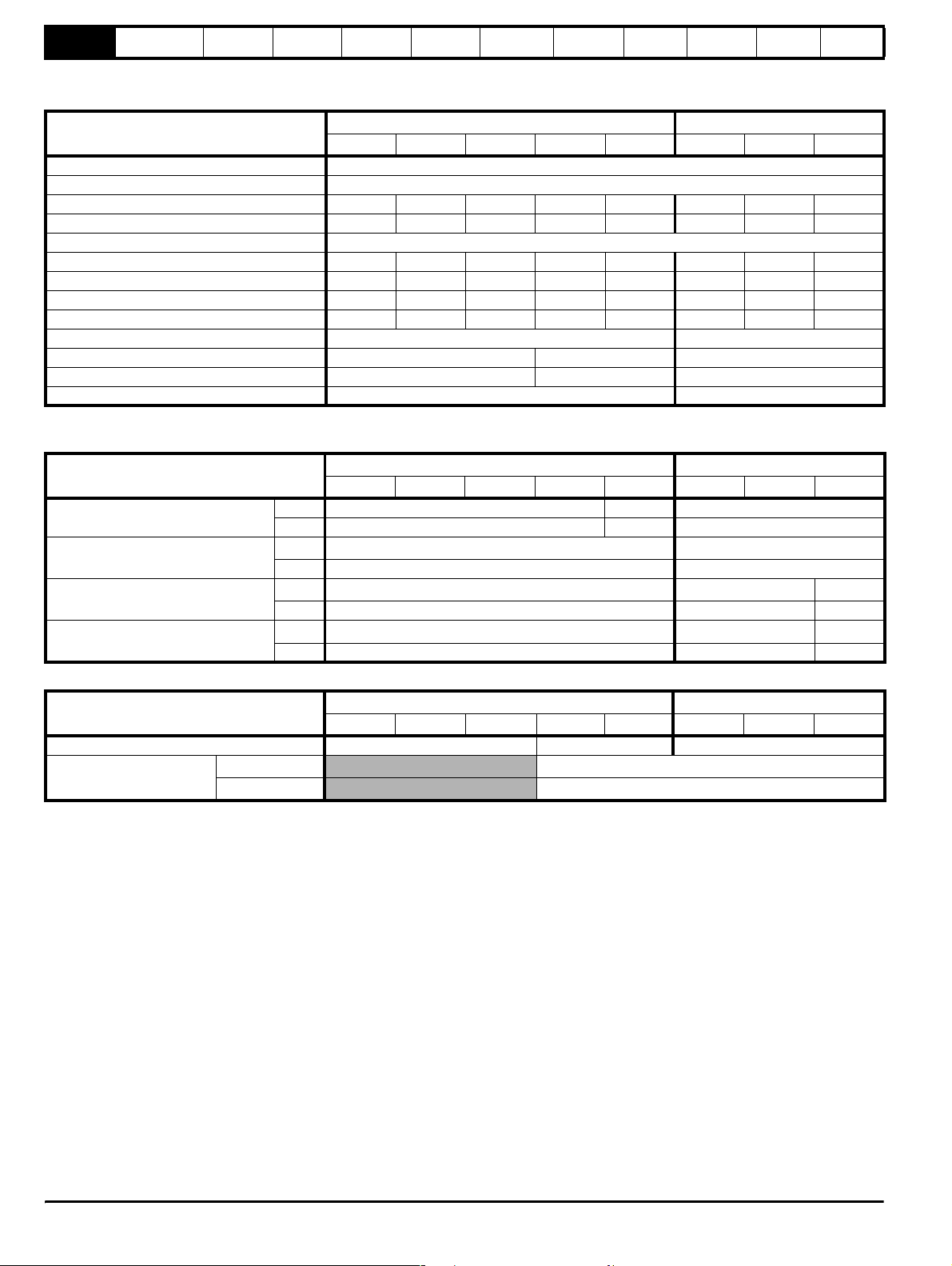

1.2 Commander SL 400V units

Table 1-4 Ratings

MODEL

00037 00055 00075 00110 00150 00220 00300 00400

AC supply voltage and frequency 3 phase 380 to 480V ±10% 48Hz to 62Hz

Input displacement factor (cos∅)>0.97

Nominal motor power (kW) 0.37 0.55 0.75 1.1 1.5 2.2 3.0 4.0

Nominal motor power (hp) 0.5 0.75 1.0 1.5 2.0 3.0 3.0 5.0

Output voltage and frequency 3 phase, 0 to drive rating (480), 0 to 1500Hz

100% RMS output current (A) 1.3 1.7 2.1 2.8 3.8 5.1 7.2 9.0

150% overload current for 60s (A) 2 2.6 3.2 4.2 5.7 7.7 10.8 13.5

Typical full load input current (A) 1.7 2.5 3.1 4 5.2 7.3 9.5 11.9

Maximum continuous input current (A)* 2.5 3.1 3.75 4.6 5.9 9.6 11.2 13.4

Typical inrush current (A) (<10ms) 17.9 11.9

Weight (kg) 1.2 1.3 2.1

Weight (lb) 2.7 2.9 4.6

Din rail mounting Yes No

* For 3phase input only at 2% negative phase sequence.

Table 1-5 Cables

MODEL

Recommended input supply fuse (A)

Control cable

Recommended input cable

Recommended motor cable

IEC 6 10 16

gG 5 10 15

(mm

(AWG) 20 20

(mm

(AWG) 16 14 12

(mm

(AWG) 16 16 14

00037 00055 00075 00110 00150 00220 00300 00400

2

)

2

)

2

)

SLB34 SLC34

SLB34 SLC34

≥0.5 ≥0.5

1.0 1.5 2.5

1.0 1.0 1.5

Table 1-6 Cooling fan

MODEL

00037 00055 00075 00110 00150 00220 00300 00400

SLB34 SLC34

Cooling fan fitted No Yes Yes

Air flow

(feet

(m

3

/minute)

3

/minute)

3.8

0.4

6 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 7

Technical

(

)

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

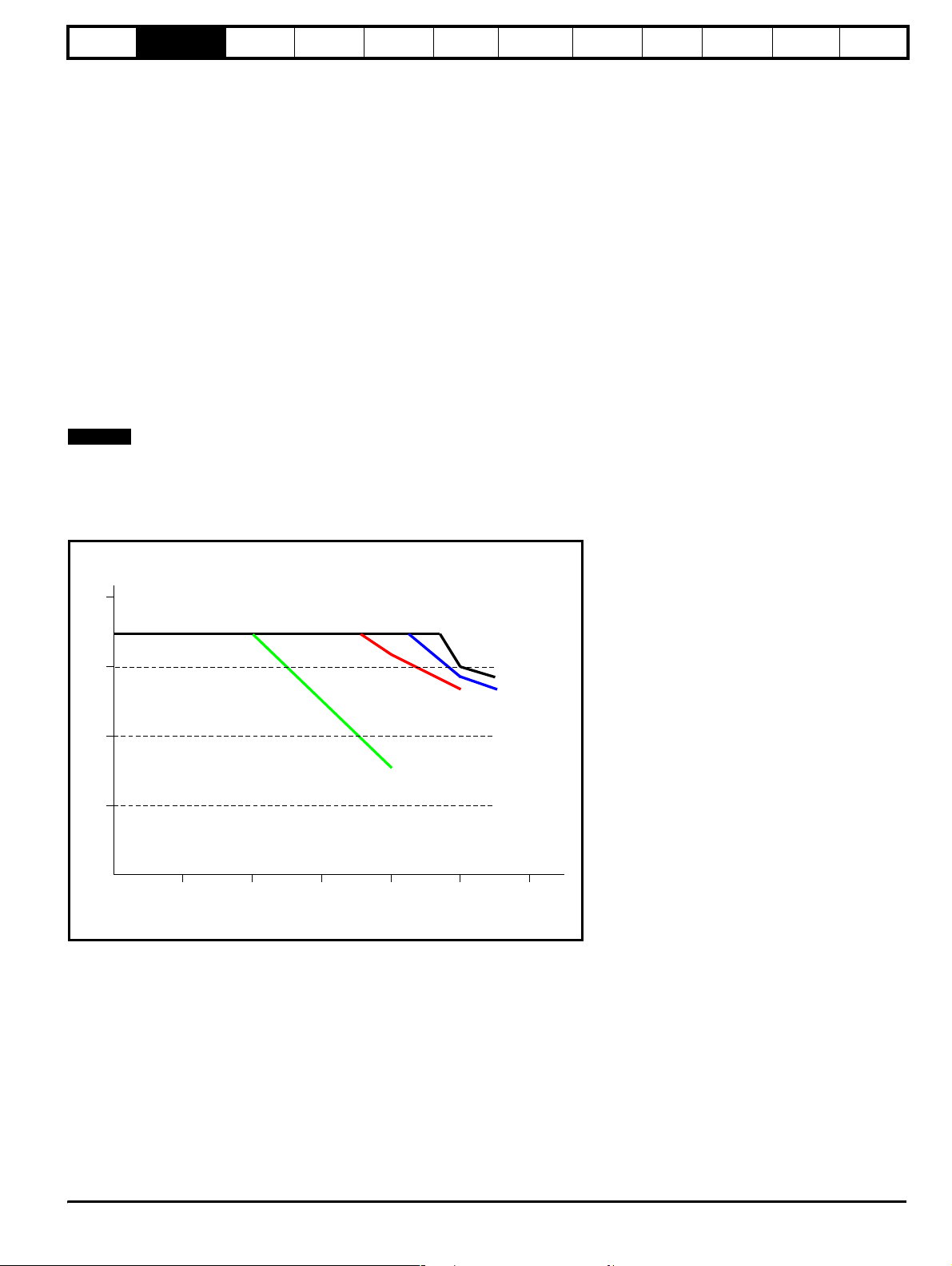

2 Derating curves and losses

The derating curves are based on the results of heatruns that are carried out to measure temperatures of various components and at various key

points within the drive at different switching frequencies, different loads and different ambient temperatures. The key components/points are:

• Heatsink

• Bridge rectifier

•IGBTs

• DC bus capacitors

• Various electrolytic capacitors

• Various resistors

• Various semiconductor components

•etc.

It is not always the heatsink temperature that is the limiting factor for the de-rating curves.

At 3 and 6kHz, the limiting factor tends to be the capacitor temperatures. Operating outside the derating curves will cause some of the capacitors

within the drive to run outside of their maximum operating temperature and this could lead to the drives design lifetime being reduced.

At 12 and 18kHz (18kHz where applicable) the limiting factor tends to be the heatsink temperatures. Operating outside the de-rating curves will cause

the heatsink temperature to increase and may cause the drive to trip on O.ht2.

If the auto-switching frequency change is enabled (Pr 5.35 = 0 [by default]), the drive will automatically decrease the switching frequency when the

heatsink temperature rises above pre-determined levels to reduce the heatsink temperature. When the drive switches down the switching frequency,

the drives display will flash 'hot'.

NOTE

It is important that these de-rating curves are observed.

2.1 Size A

2.1.1 Derating curves

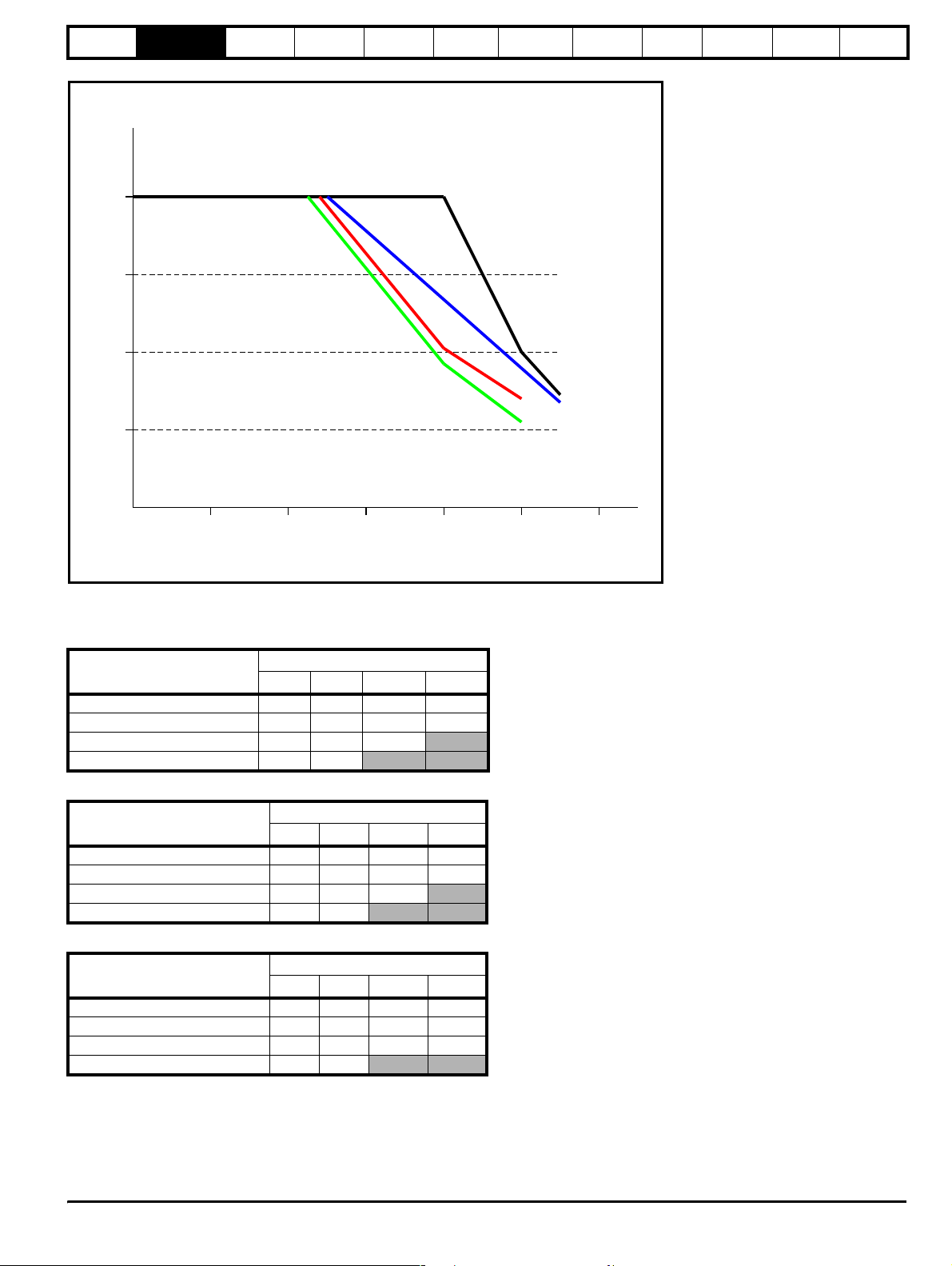

Figure 2-1 Commander SL Size A 0.25kW derating curve

Output

current (A)

2.0

1.5

1.0

0.5

3kHz

12kHz

6kHz

18kHz

0

10

20

30

Ambient Temperature

40

50

o

C

60

Commander SL Technical Data 7

Issue Number: 1 www.controltechniques.com

Page 8

Technical

O

O

(°C)

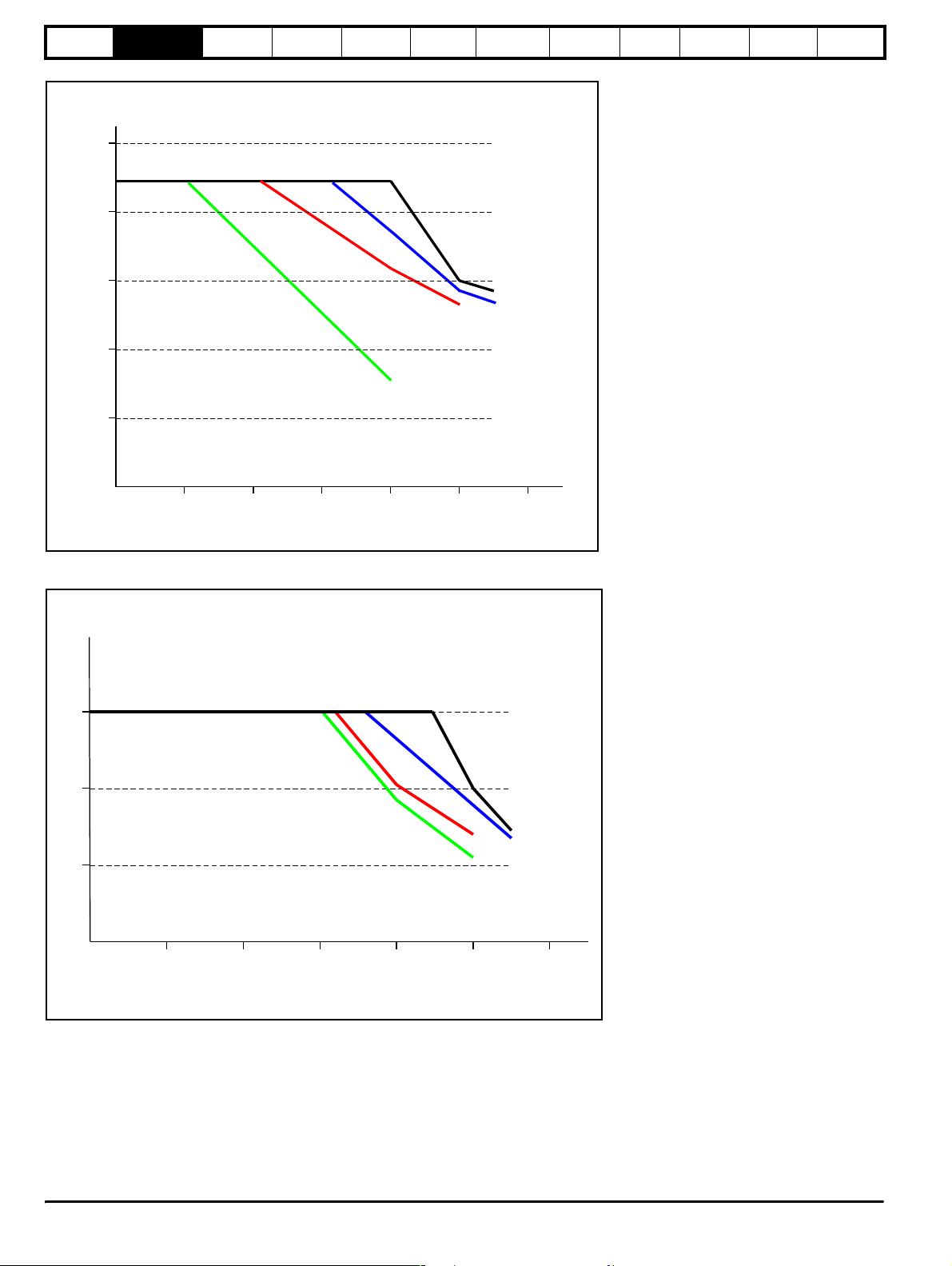

Figure 2-2 Commander SL Size A 0.37kW derating curve

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

utput

current (A)

2.5

2.0

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

1.5

1.0

0.5

0

10

20

30

Ambient T emperature (

Figure 2-3 Commander SL Size A 0.55kW derating curve

utput

Current (A)

3

18kHz

40

3kHz

50

6kHz

60

12kHz

o

C)

2

1

0

10

3020

40

18kHz

Ambient Temperature

12kHz

3kHz

6kHz

6050

8 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 9

Technical

O

(°C)

Figure 2-4 Commander SL Size A 0.75kW derating curve

data

utput

Current (A)

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

4

3

2

1

EMC filters

AC line

reactor values

12kHz

18kHz

Motor cable

lengths

3kHz

6kHz

General

data

I/O

specification

Supply types Options

0

10

Ambient T emperature

3020

2.1.2 Drive losses

The following tables indicate the total drive losses at the de-rating curve points.

Table 2-1 Commander SL size A 0.25kW losses

Ambient Temperature (°C)

30 30 32 36 35

40 30 32 38 30

50 29 31 34

55 29 30

Table 2-2 Commander SL size A 0.37kW losses

Ambient Temperature (°C)

30 34 36 38 35

40 34 33 38 30

50 29 31 34

55 29 30

Table 2-3 Commander SL size A 0.55kW losses

Ambient Temperature (°C)

30 42 46 53 61

40 42 43 44 47

50 35 36 37 38

55 31 33

3kHz 6kHz 12kHz 18kHz

3kHz 6kHz 12kHz 18kHz

3kHz 6kHz 12kHz 18kHz

Loss (W)

Loss (W)

Loss (W)

40

6050

Commander SL Technical Data 9

Issue Number: 1 www.controltechniques.com

Page 10

Technical

O

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Table 2-4 Commander SL size A 0.75kW losses

Ambient Temperature (°C)

3kHz 6kHz 12kHz 18kHz

30 48 50 59 62

40 48 43 44 47

50 35 36 37 38

55 31 33

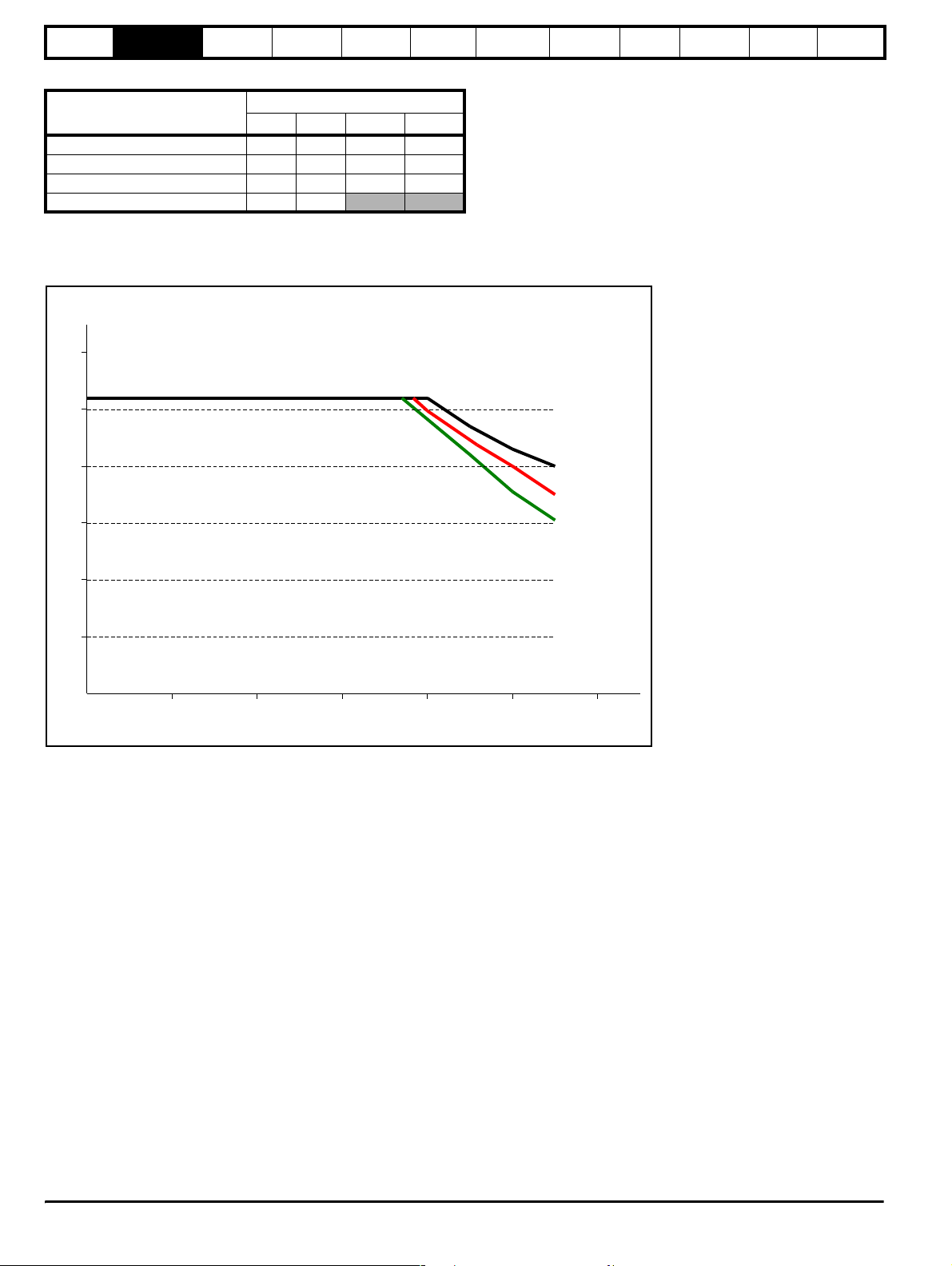

2.2 Size B

2.2.1 Derating curves

Figure 2-5 Commander SL Size B, 200V, 1.1kW

utput

current (A)

6

5

Mechanical

installation

Loss (W)

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

4

3

2

1

0

10 20

30

Ambient Temperature (

40

o

C)

50

3 & 6kHz

12kHz

18kHz

60

10 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 11

Technical

(

)

O

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Figure 2-6 Commander SL Size B, 200V, 1.5kW

Output

current (A)

8

7

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

6

3kHz

6kHz

5

12kHz

4

3

18kHz

2

1

0

10 20

30

Ambient T emperature

40

o

C

50

60

With the 0.37, 0.55 & 0.75kW drives, no 12kHz derating information is shown on the graphs. This is because the losses at 12kHz is too great to run

the drive continuously. Depending on the duty cycle etc. it is still possible to run the drive at 12kHz but if the heatsink gets too hot, the drive will

automatically switch down the switching frequency to 6kHz. When the drive does this, the display will flash 'hot' to indicate that the drive has

automatically switched down the switching frequency.

Figure 2-7 Commander SL Size B, 400V, 0.37kW

utput

current (A)

1.4

1.2

1.0

0.8

0.6

0.4

0.2

3kHz

6kHz

0

10 20

30

Ambient Temperature (

40

o

C)

50

60

Commander SL Technical Data 11

Issue Number: 1 www.controltechniques.com

Page 12

Technical

(

)

O

(

)

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Figure 2-8 Commander SL Size B, 400V, 0.55kW

Output

current (A)

1.8

1.6

1.4

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

1.2

1.0

0.8

0.6

0.4

0.2

0

10 20

30

Ambient T emper ature

Figure 2-9 Commander SL Size B, 400V, 0.75kW

utput

current (A)

2.5

2.0

3kHz

6kHz

40

o

C

50

60

1.5

1.0

0.5

3kHz

6kHz

0

10 20

30

Ambient Temperature

40

o

C

50

60

12 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 13

Technical

(

)

O

(

)

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Figure 2-10 Commander SL Size B, 400V, 1.1kW

Output

current (A)

3.0

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

2.5

2.0

1.5

1.0

0.5

0

10 20

30

Ambient T emperature

Figure 2-11 Commander SL Size B, 400V, 1.5kW

utput

current (A)

4.0

3.5

3kHz

6kHz

12kHz

40

o

C

50

60

3.0

3kHz

6kHz

2.5

2.0

1.5

12kHz

1.0

0.5

0

10 20

30

Ambient T emperature

40

o

C

50

60

Commander SL Technical Data 13

Issue Number: 1 www.controltechniques.com

Page 14

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

reactor values

2.2.2 Drive losses

The following tables indicate the total drive losses at the de-rating curve points.

Table 2-5 Commander SL Size B, 200V, 1.1kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz 18kHz

30 58 63 73 84

40 58 63 70 78

50 51 55 60 62

55 48 51 54 57

Table 2-6 Commander SL Size B, 200V, 1.5kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz 18kHz

30 72 79 85 92

40 72 76 82 80

50 66 69 71 59

55 63 65 57 50

Table 2-7 Commander SL Size B, 400V, 0.37kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz

30 24 27

40 24 21

50 24

55 22

Loss (W)

Loss (W)

Loss (W)

AC line

Motor cable

lengths

General

data

I/O

specification

Supply types Options

Table 2-8 Commander SL Size B, 400V, 0.55kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz

Loss (W)

30 27 26

40 27 21

50 27

55 22

Table 2-9 Commander SL Size B, 400V, 0.75kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz

Loss (W)

30 31 27

40 31 21

50 26

55 22

Table 2-10 Commander SL Size B, 400V, 1.1kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz

Loss (W)

30 43 51 68

40 43 51 62

50 43 49 35

55 40 44

Table 2-11 Commander SL Size B, 400V, 1.5kW

Ambient Temperature (°C)

3kHz 6kHz 12kHz

Loss (W)

30 53 65 87

40 53 65 76

50 49 55 55

55 46 51 45

14 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 15

Technical

O

(

)

(

)

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

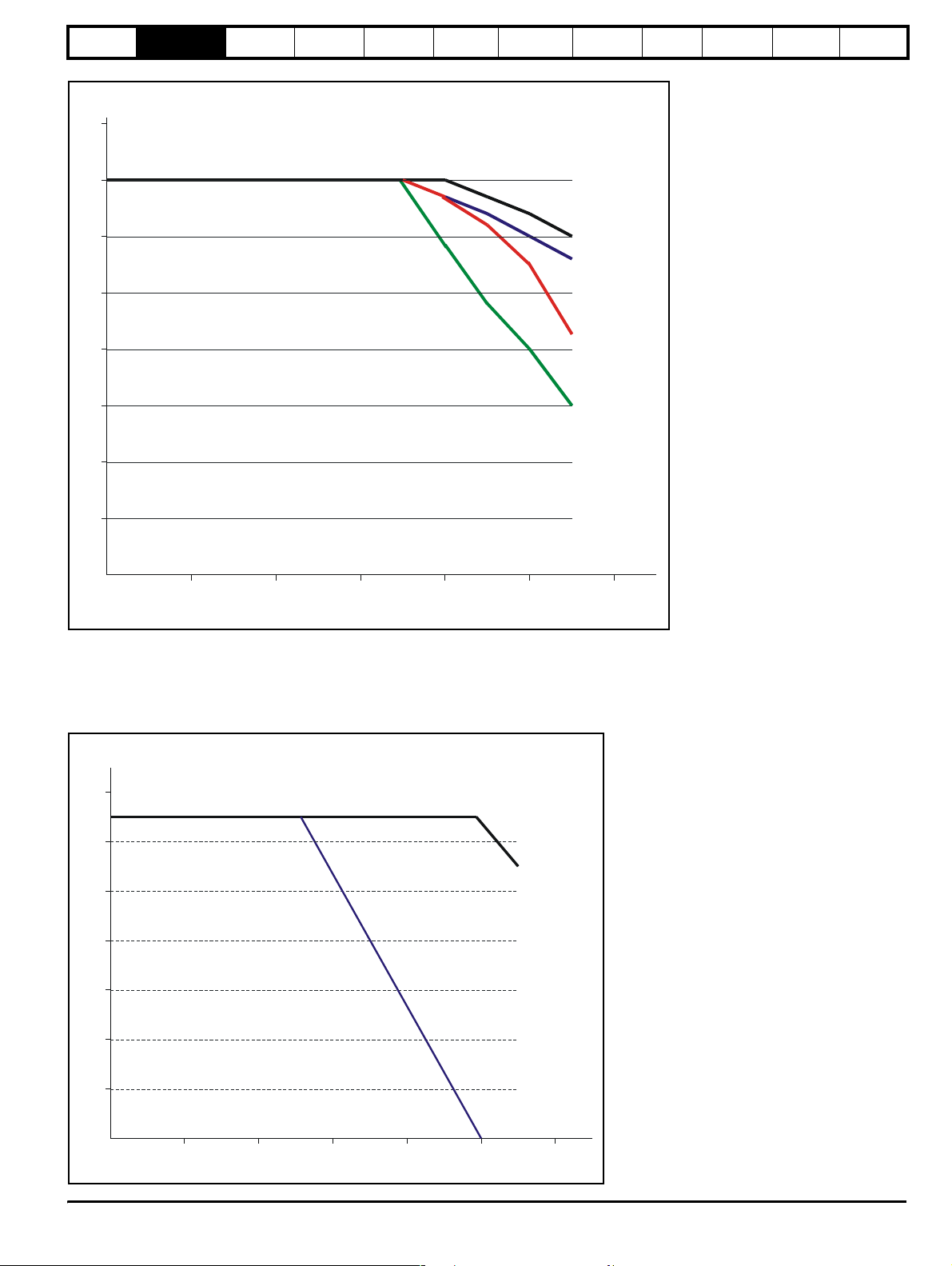

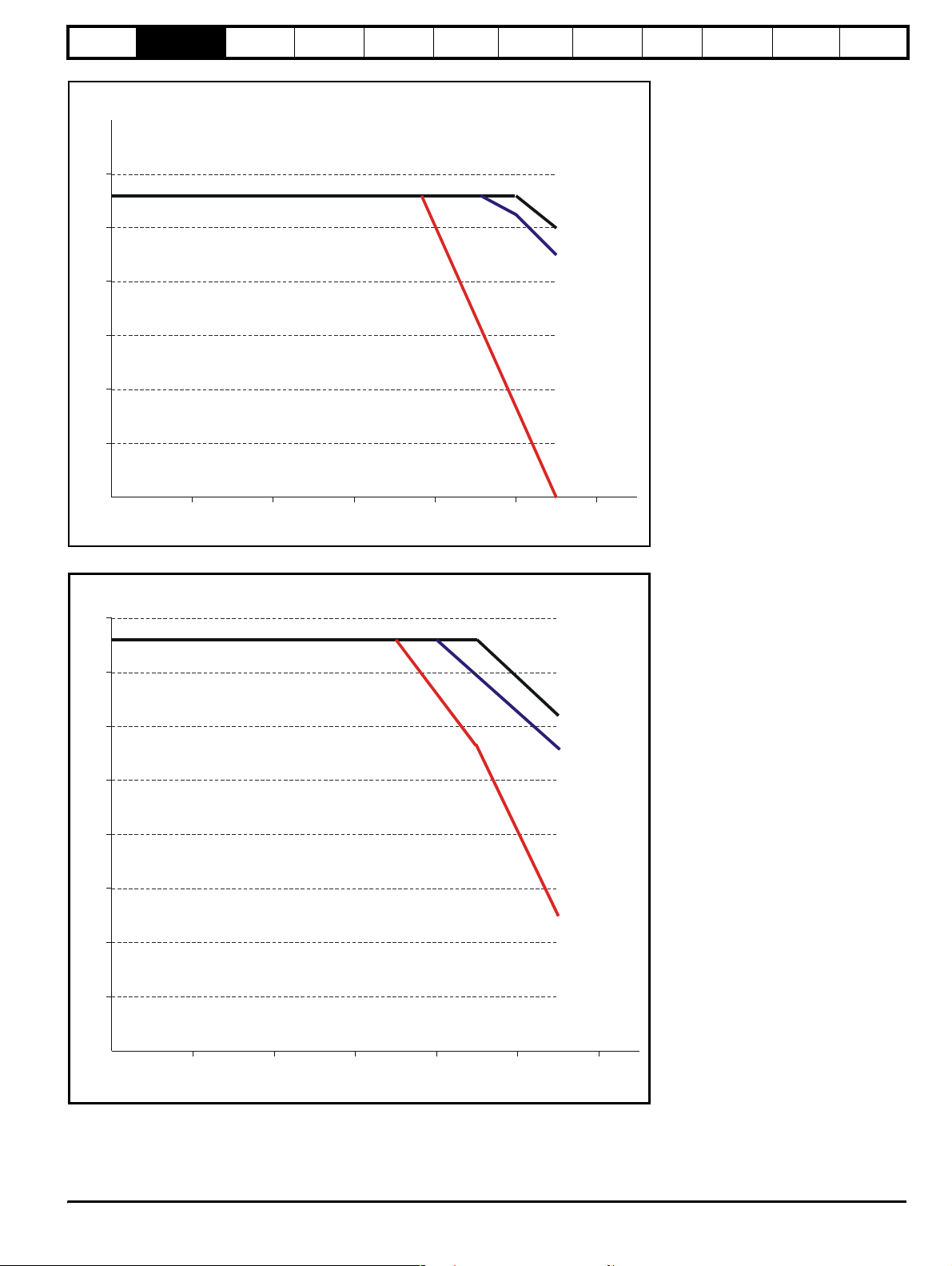

2.3 Size C

2.3.1 Derating curves

Table 2-12 Commander SL Size C, 200V, 2.2kW

utput

current (A)

10.0

9.0

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

10 20

30

Ambient Temperature

Table 2-13 Commander SL Size C, 400V, 2.2kW

Output

current (A)

6.0

3kHz

6 & 12kHz

18kHz

40

o

C

50

60

5.0

4.0

3 & 6kHz

3.0

2.0

12kHz

1.0

0

10 20

30

Ambient T emperature

40

o

C

50

60

Commander SL Technical Data 15

Issue Number: 1 www.controltechniques.com

Page 16

Technical

(

)

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Table 2-14 Commander SL Size C, 400V, 3.0kW

Output

current (A)

8.0

7.0

6.0

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

5.0

4.0

3.0

2.0

1.0

0

10 20

30

Ambient Temperature

Table 2-15 Commander SL Size C, 400V, 4.0kW

9.0

8.0

7.0

6.0

3kHz

6kHz

12kHz

40

o

C

50

60

5.0

4.0

3.0

2.0

1.0

3kHz

6kHz

12kHz

0

10 20

30

Ambient Temperature (

40

o

C)

50

60

16 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 17

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

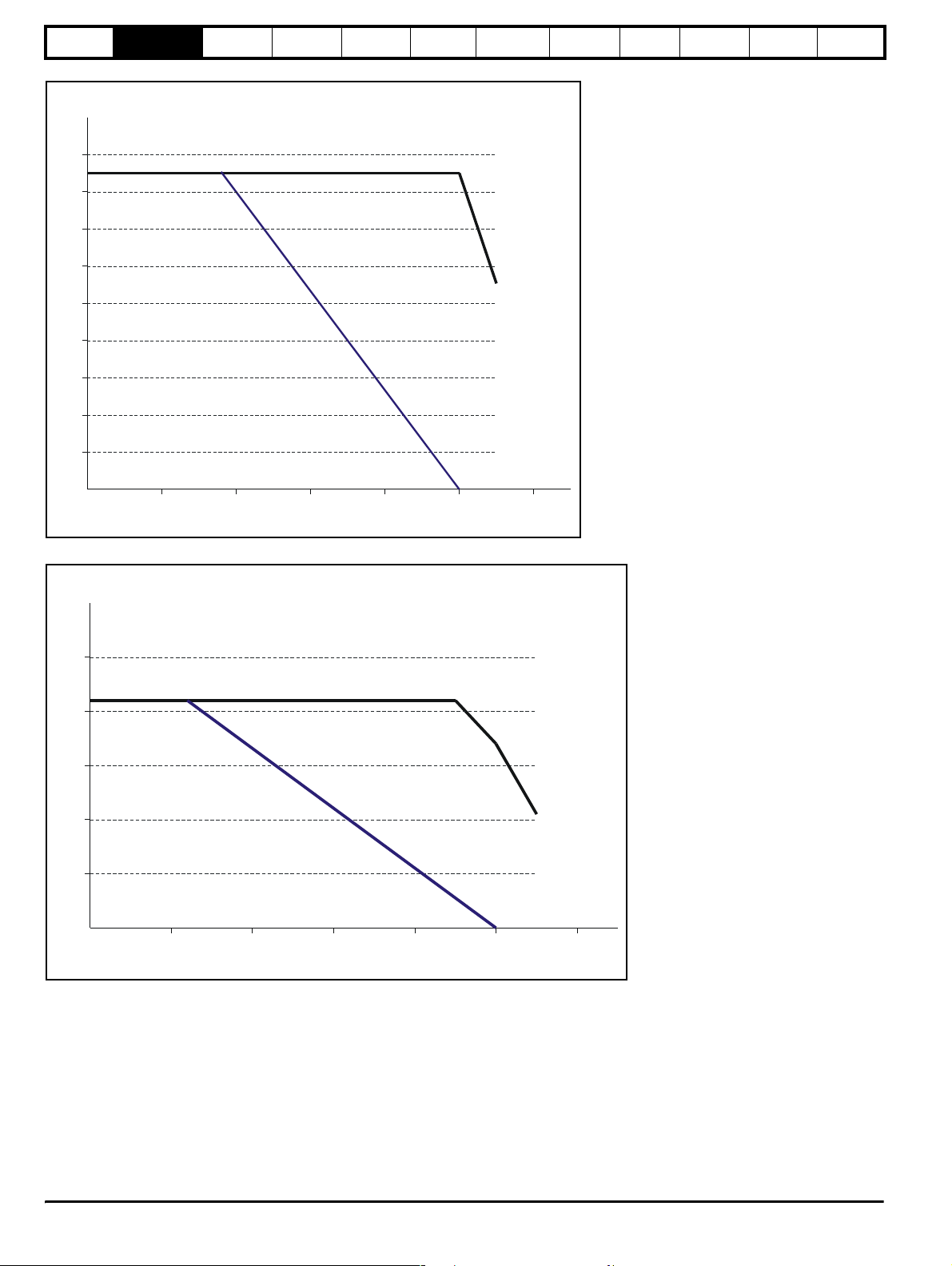

2.3.2 Drive losses

Table 2-16 Commander SL Size C, 200V, 2.2kW

Ambient Temperature (°C)

30 93 107 133 158

40 93 107 133 158

50 84 93 115 133

55 80 88 109 111

Table 2-17 Commander SL Size C, 400V, 2.2kW

Ambient Temperature (°C)

30 78 108 118

40 78 108 101

50 78 108 88

55 78 108 60

Table 2-18 Commander SL Size C, 400V, 3.0kW

Ambient Temperature (°C)

30 91 117 93

40 91 117 78

50 91 94 62

55 70 77 47

3kHz 6kHz 12kHz 18kHz

Loss (W)

3kHz 6kHz 12kHz

Loss (W)

3kHz 6kHz 12kHz

Mechanical

installation

Loss (W)

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

Table 2-19 Commander SL Size C, 400V, 4.0kW

Ambient Temperature (°C)

Loss (W)

3kHz 6kHz 12kHz

30 116 149 99

40 116 132 84

50 96 100 69

55 75 83 54

Commander SL Technical Data 17

Issue Number: 1 www.controltechniques.com

Page 18

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply types Options

3 Drive voltage levels

Condition 200V drives 400V drives

OV trip level 415 Vdc 830 Vdc

Rated upper level (AC mains +10% x 1.4142) 373 Vdc 747 Vdc

Rated lower level (AC mains -10% x 1.4142) 255 Vdc 484 Vdc

*UV reset level 215 Vdc 425 Vdc

UV trip level 175 Vdc 330 Vdc

Standard ramp voltage 375 Vdc

* These are the absolute minimum DC voltages that the drive can be supplied with. If the drive is not supplied with at least this voltage, it will not reset

out of a UU trip at power up.

Output frequency: 0 to 1500Hz

Output voltage: 3 phase, 0 to drive rating (240 or 480Vac maximum set by Pr 08).

3.1 Input voltage

3.1.1 Single phase

200V to 240V ±10%

48Hz to 62Hz

3.1.2 Three phase 200V

200V to 240V ±10%

48Hz to 62Hz

Phase imbalance 3% (between phases) or 2% negative phase sequence (IEC 146-1-1 Immunity class C)

3.1.3 Three phase 400V

380V to 480V ±10%

48Hz to 62Hz

Phase imbalance 3% (between phases) or 2% negative phase sequence (IEC 146-1-1 Immunity class C)

It is possible to run the drives on lower supply voltages than those specified above (up to -20%) but only with de-rating of the product.

On products without a DC bus choke (up to 4kW), the maximum supply capacity connected to the drive without using external line chokes will be 5kA

short circuit current.

Eur: 750 Vdc

USA: 775 Vdc

18 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 19

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

4 DC bus design

Table 4-1 Commander SL 200V units DC bus data

Model

DC Bus Capacitance

µF

Inrush resistance at 25

Ω

SLA1200025 330 22 17

SLA1200037 390 22 17

SLA1200055 660 22 17

SLA1200075 780 22 17

SLBD200110 940 13.6 27.4

SLBD200150 1410 13.6 27.4

SLCD200220 1880 20.4 18.3

Table 4-2 Commander SL 400V units DC bus data

Model

DC Bus Capacitance

µF

Inrush resistance at 25

Ω

SLB3400037 165 44 17

SLB3400055 165 44 17

SLB3400075 165 44 17

SLB3400110 195 44 17

SLB3400150 235 44 17

SLC3400220 470 66 11.3

SLC3400300 470 66 11.3

SLC3400400 470 66 11.3

o

Peak inrush current

C

o

Peak inrush current

C

A

A

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

Commander SL Technical Data 19

Issue Number: 1 www.controltechniques.com

Page 20

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

5 Mechanical installation

5.1 Mechanical dimensions

Figure 5-1 Size A mounting dimensions

E

D

C

ABH

EMC filters

G

AC line

reactor values

Motor cable

lengths

F

General

data

I/O

specification

Supply

types

Options

Dimension mm in

A

B

C

F

D

E

F

G

H

Holesize 4 x M4

NOTE

If DIN rail mounting is used in an installation where the drive is to be subjected to shock or vibration, it is recommended that the bottom mounting

screws are used to secure the drive to the back plate. If the installation is going to be subjected to heavy shock and vibration, then it is recommended

that the drive is surface mounted rather than DIN rail mounted

N

140

154

11

64

75

145

104

143

5.51

6.06

0.43

2.52

2.95

5.7

4.1

5.63

20 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 21

Technical

E

Figure 5-2 Size B mounting dimensions

data

Derating curves

and losses

Drive voltage

levels

D

DC bus

design

C

Mechanical

installation

B

A

EMC filters

I

H

AC line

reactor values

Motor cable

lengths

General

G

data

I/O

specification

Supply

types

Options

F

Dimension mm in

A

B

C

D

G

E

190

205

10.9

65.9

F

G

H

I

Holesize 4 x M4

NOTE

If DIN rail mounting is used in an installation where the drive is to be subjected to shock or vibration, it is recommended that the bottom mounting

screws are used to secure the drive to the back plate. If the installation is going to be subjected to heavy shock and vibration, then it is recommended

that the drive is surface mounted rather than DIN rail mounted

N

156

155.5

194

85

77

7.48

8.07

0.43

2.6

3.35

3

6.15

6.1

7.64

Commander SL Technical Data 21

Issue Number: 1 www.controltechniques.com

Page 22

Technical

Figure 5-3 Size C mounting dimensions

data

Derating curves

and losses

Drive voltage

levels

E

D

DC bus

design

C

Mechanical

installation

BH

A

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

G

I/O

specification

Supply

types

Options

Size C is not DIN rail mountable.

F

Dimension mm in

A

B

C

D

G

E

F

G

H

Holesize 4 x M4

240

258

10.4

81.1

100

91.9

173

244

9.45

10.16

0.41

3.2

3.94

3.62

6.8

9.61

22 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 23

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

5.2 Minimum mounting clearances

Figure 5-4 Minimum mounting clearances

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

ABCA

Drive size

A

B (≤0.75kW) 10* 0.39*

B (≥1.1kW) 0 0

ABC

mm in mm in mm in

00

10 0.39

C

100 3.94

C 50* 1.97*

*This is the minimum spacing between drives measured at the base of the drives where it is mounted against a back plate/flat surface.

Commander SL Technical Data 23

Issue Number: 1 www.controltechniques.com

Page 24

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

6 EMC filters

EMC filters are available as optional extra parts where required.

Table 6-1 EMC filters

Number

Used with

phases

SLA1200025

and

SLA1200037

SLA1200055

and

SLA1200075

SLBD200110 to

SLBD200150

SLBD200110 to

SLBD200150

SLB3400037 to

SLB3400150

SLCD200220 1

SLCD200220 3

SLC3400220 to

SLC3400400

of

1

1

1

3

3

3

Filter part number Filter type Mounting

CT Schaffner Standard Low leakage Footprint Side

4200-6122 FS6512-12-07 Y

4200-6123 FS6512-12-07-LL

4200-6122 FS6512-12-07 Y

4200-6123 FS6512-12-07-LL

4200-6212 FS6513-20-07 Y

4200-6214 FS6513-20-07-LL

4200-6213 FS6513-10-07 Y

4200-6215 FS6513-10-07-LL

4200-6213 FS6513-10-07 Y

4200-6215 FS6513-10-07-LL

4200-6310 FS6514-24-07 Y

4200-6312 FS6514-24-07-LL

4200-6311 FS6514-14-07 Y

4200-6217 FS6514-14-07-LL

4200-6311 FS6514-14-07 Y

4200-6217 FS6514-14-07-LL

EMC filters

AC line

reactor values

YYY10

YYY30

YYY10

YYY50

YYY20

YYY10

YYY50

YYY20

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

Max motor

cable length (m)

YY75

YY75

Y Y 100

Y Y 100

Y Y 100

Y Y 100

Y Y 100

Y Y 100

6.1 Filter data

Table 6-2 EMC filter data

Number

Used with

SLA1200025

to

SLA1200075

SLBD200110

to

SLBD200150

SLBD200110

to

SLBD200150

SLB3400037

to

SLB3400150

SLCD200220 1

SLCD200220 3

SLC3400220

to

SLC3400400

of

phases

1

1

3

3

3

Worst

case

leakage

current

Filter terminal

tightening

torque

Filter

current

rating

Filter part number

Power

losses

at rated

current

IP

rating

Weight

Operational

leakage

current

CT Schaffner W Kg lb mA mA Nm lb ft A

4200-6122 FS6512-12-07 4.1 20 0.42 0.9 25.7 49.5 0.8 0.6 12

4200-6123 FS6512-12-07-LL 6.7 20 0.44 1.0 2.5 5 0.8 0.6 12

4200-6212 FS6513-20-07 11.2 20 0.57 1.3 25.7 50 0.8 0.6 20

4200-6214 FS6513-20-07-LL 12.8 20 0.64 1.4 3.6 7 0.8 0.6 20

4200-6213 FS6513-10-07 7.5 20 0.63 1.4 40 137.2 0.8 0.6 10

4200-6215 FS6513-10-07-LL 7.5 20 0.63 1.4 3 18.3 0.8 0.6 10

4200-6213 FS6513-10-07 7.5 20 0.63 1.4 40 137.2 0.8 0.6 10

4200-6215 FS6513-10-07-LL 7.5 20 0.63 1.4 3 18.3 0.8 0.6 10

4200-6310 FS6514-24-07 16.2 20 0.84 1.9 25.7 50 0.8 0.6 24

4200-6312 FS6514-24-07-LL 18.5 20 0.91 2.0 3.6 7 0.8 0.6 24

4200-6311 FS6514-14-07 11.8 20 0.75 1.7 40 137.2 0.8 0.6 14

4200-6217 FS6514-14-07-LL 11.8 20 0.74 1.6 3 18.3 0.8 0.6 14

4200-6311 FS6514-14-07 11.8 20 0.75 1.7 40 137.2 0.8 0.6 14

4200-6217 FS6514-14-07-LL 11.8 20 0.74 1.6 3 18.3 0.8 0.6 14

24 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 25

Technical

data

Derating curves

and losses

Drive voltage

6.2 Conformity

Table 6-3 Conformity

Used with

SLA1200025 and

SLA1200037

SLA1200055 and

SLA1200075

SLBD200110 to

SLBD200150

SLBD200110 to

SLBD200150

SLB3400037 to

SLB3400150

SLCD200220 1

SLCD200220 3

SLC3400220 to

SLC3400400

* Cable capacitance, Cy = 47nF

Number

Phases

levels

Of

1

1

1

3

3

3

DC bus

design

Motor

cable length

(m)

Mechanical

installation

EMC filters

AC line

reactor values

Standard Low leakage

3kHz 6kHz 12kHz 18kHz 3kHz 6kHz 12kHz 18kHz

Motor cable

lengths

General

data

specification

Filter and switching frequency

I/O

Supply

types

5RRRR

10 RRRRRI I I

20 R R I I

30 I I I I

50 I I I I

75 I

5RRRR

10 RRRRRI I I

20 R R I I

30 I I I I

50 I I I I

75 I

10 RI I I

20 R I I I

100 I

2RRII

5RRRI

10 R I I I R I I I

15 R R I I R I I I

20 R I I III

50 I

100 R I I I

2RRRR

5RRRR

10 R R I I R I I I

15 R R I I I I I

20 R I I I I I

50

100 I

2RRRR

5RRRR

10 R R R R R*

15 R R R R

20 R R R R

50 I I I I

75 I I I I

100 I

2RRRR

5RRRR

10 R R R R I I I I

15 R R R R I I I I

20 R R R R I I I

50 R R I I I

75 I I I I

100 I I I I

2RRRR

5RRRR

10 R R R I I I I I

15 R R R I I I I

20 R R R I I I

50 R I I I

75 I I I

100 I

Options

Commander SL Technical Data 25

Issue Number: 1 www.controltechniques.com

Page 26

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

Key to Table 6-3 Conformity

The requirements are listed in descending order of severity, so that if a particular requirement is met then all requirements listed after it are also met.

Standard Description Frequency range Limits Application

R

I

E2U

E2R

EN 61000-6-3

(previously EN

50081-1)

EN 61800-3

IEC 61800-3

EN 61000-6-4

(previously EN

50081-2)

EN 61800-3

IEC 61800-3

EN 61800-3

IEC 61800-3

EN 61800-3

IEC 61800-3

Generic emission

standard for the

residential commercial

and light - industrial

environment

Product standard for

adjustable speed power

drive systems

Generic emission

standard for the

industrial environment

Product standard for

adjustable speed power

drive systems

Product standard for

adjustable speed power

drive systems

Product standard for

adjustable speed power

drive systems

0.15 - 0.5MHz

limits decrease linearly

with log frequency

5 - 30MHz

Requirements for the first environment

0.15 - 0.5MHz

0.5 -30MHz

Requirements for the first environment

Requirements for the second environment with unrestricted

Requirements for the second environment with restricted

66-56dBµV quasi peak

56-46dBµV average

56dBµV quasi peak

46dBµV average

60dBµV quasi peak

50dBµV average

1

, with unrestricted

distribution

79dBµV quasi peak

66dBµV average

73dBµV quasi peak

60dBµV average

1

with restricted

distribution

2

distribution

distribution

2

AC supply

lines0.5 - 5MHz

AC supply

lines

Operation in this condition is not recommended

1 The first environment is one where the low voltage supply network also supplies domestic premises

2 When distribution is restricted, drives are available only to installers with EMC competence

Key (shown in decreasing order of permitted emission level):

E2R EN 61800-3 second environment, restricted distribution (Additional measures may be required to prevent interference)

E2U EN 61800-3 second environment, unrestricted distribution

I Industrial generic standard EN 50081-2 (EN 61000-6-4)

EN 61800-3 first environment restricted distribution (The following caution is required by EN 61800-3)

This is a product of the restricted distribution class according to IEC 61800-3. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

CAUTION

R Residential generic standard EN 50081-1 (EN 61000-6- 3)

EN 61800-3 first environment unrestricted distribution

EN 61800-3 defines the following:

• The first environment is one that includes domestic premises. It also includes establishments directly connected without inter mediate

transformers to a low-voltage power supply network which supplies buildings used for domestic purposes.

• The second environment is one that includes all establishments other than those directly connected to a low-voltage power supply network which

supplies buildings used for domestic purposes.

Restricted distribution is defined as a mode of sales distribution in which the manufacturer restricts the supply of equipment to suppliers,

customers or users who separately or jointly have technical competence in the EMC requirements of the application of drives.

NOTE

N

Where the drive is incorporated into a system with rated input current exceeding 100A, the higher emission limits of EN 61800-3 for the second

environment are applicable, and no filter is then required.

26 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 27

Technical

A

g

data

Derating curves

and losses

Drive voltage

levels

Table 6-4 EMC filter dimensions

Y

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

Z

I/O

specification

Supply

types

Options

CT part

no.

4200-6122

4200-6123

4200-6212

4200-6214

4200-6213

4200-6215

4200-6310

4200-6312

4200-6311

4200-6217

W

D

Schaffner

part no.

FS6512-

12-07

FS6512-

12-07-LL

FS6513-

20-07

FS651320-07-LL

FS6513-

10-07

FS651310-07-LL

FS6514-

24-07

FS651424-07-LL

FS6514-

14-07

FS651414-07-LL

C

X

X

V

U

F

H

B

Z

E

V: Ground stud:

X:Threaded holes for footprint mounting of the drive

∅

Y: Footprint mounting holes

Z: Bookcase mountin

holes

∅

ABCDEFHUVWXYZ

155mm

(6.10in)

155mm

(6.10in)

209mm

(8.22in)

209mm

(8.22in)

209mm

(8.22in)

209mm

(8.22in)

260mm

(10.23in)

260mm

(10.23in)

260mm

(10.23in)

260mm

(10.23in)

183.5mm

(7.22in)

183.5mm

(7.22in)

237.7mm

(9.35in)

237.7mm

(9.35in)

237.7mm

(9.35in)

237.7mm

(9.35in)

288.5mm

(11.35in)

288.5mm

(11.35in)

288.5mm

(11.35in)

288.5mm

(11.35in)

45mm

(1.77in)

45mm

(1.77in)

50mm

(1.96in)

50mm

(1.96in)

50mm

(1.96in)

50mm

(1.96in)

65mm

(2.55in)

65mm

(2.55in)

65mm

(2.55in)

65mm

(2.55in)

40mm

(1.57in)

40mm

(1.57in)

40mm

(1.57in)

40mm

(1.57in)

40mm

(1.57in)

40mm

(1.57in)

45mm

(1.77in)

45mm

(1.77in)

45mm

(1.77in)

45mm

(1.77in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

20mm

(0.78in)

144mm

(5.66in)

144mm

(5.66in)

193.5mm

(7.61in)

193.5mm

(7.61in)

193.5mm

(7.61in)

193.5mm

(7.61in)

244mm

(9.60in)

244mm

(9.60in)

244mm

(9.60in)

244mm

(9.60in)

203mm

(7.99in)

203mm

(7.99in)

257.2mm

(10.12in)

257.2mm

(10.12in)

257.2mm

(10.12in)

257.2mm

(10.12in)

308mm

(12.12in)12AWG

308mm

(12.12in)12AWG

308mm

(12.12in)16AWG

308mm

(12.12in)16AWG

16

AWG

16

AWG

14

AWG

14

AWG

14

AWG

14

AWG

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

75mm

(2.95in)

75mm

(2.95in)

80mm

(3.15in)

80mm

(3.15in)

80mm

(3.15in)

80mm

(3.15in)

94mm

(3.70in)

94mm

(3.70in)

94mm

(3.70in)

94mm

(3.70in)

M4

M4

M4

M4

M4

M4

M4

M4

M4

M4

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

8.7mm

(0.34in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

4.5mm

(0.17in)

Commander SL Technical Data 27

Issue Number: 1 www.controltechniques.com

Page 28

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

specification

7 AC line reactor values

Table 7-1 AC line reactor values

Continuous

rms current

Drives used with

SLA1200025

SLA1200037

Reactor part

number

Input

phases

Inductance

mH A A Kg L D H

4402-0224 1 2.25 6.5 13 0.8 72 65 90

SLA1200055

4402-0225 1 1.0 15.1 30.2 1.1 82 75 100SLA1200075

SLBD200110

SLBD200150

SLCD200220

SLBD200110

SLBD200150

4402-0226 1 0.5 26.2 52.4 1.5 82 90 105

4402-0228 3 1.0 15.4 47.4 3.8 150 90 150

SLCD200220 4402-0229 3 0.4 24.6 49.2 3.8 150 90 150

SLB3400037

SLB3400055

SLB3400075

4402-0227 3 2.0 7.9 15.8 3.5 150 90 150

SLB3400110

SLB3400150

SLC3400220

4402-0228 3 1.0 15.4 47.4 3.8 150 90 150SLC3400300

SLC3400400

Peak

current

Weight Dimensions

I/O

Supply

types

Options

7.1 Line reactors

Input line reactors reduce the risk of damage to the drive resulting from poor phase balance or severe disturbances on the supply network.

Where line reactors are to be used, reactance values of approximately 2% are recommended. Higher values may be used if necessary, but may result

in a loss of drive output voltage because of voltage drop. This may reduce torque at high speed.

For all drive ratings, 2% line reactors permit drives to be used with a supply imbalance of up to 3.5% negative phase sequence (equivalent to 5%

voltage imbalance between phases).

A line reactor should be connected in each phase of the supply. Each drive should have its own line reactor . Three individual reactors or a single three

phase reactor can be used. Single phase drives only require one single phase line reactor.

Severe disturbances may be caused by the following factors:

• Power factor correction equipment connected close to the drive

• Large DC drives having no or inadequate line reactors connected to the supply

• Direct-on-line started motor(s) connected to the supply such that when any of these motors are started, the voltage dip exceeds 20%.

• Supply capacity exceeds 200kVA

• Fault current exceeds 5kA

Such disturbances may cause excessive peak currents to flow in the input power circuit of the drive. This may cause nuisance tripping and in extreme

cases, failure of the drive.

Low power drives may also be susceptible to disturbance when connected to supplies with high rated capacity.

NOTE

N

RFI filters (for EMC purposes) do not give adequate protection against these conditions.

7.2 Reactor current ratings

Continuous current:

Not less than the continuous input current rating of the drive.

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive.

Voltage fluctuation (Flicker) standard EN61000-3-3 (IEC61000-3-3)

Those models that fall within the scope of EN61000-3-3, as stated in the declaration of Conformity, conform to the requirements for manual switching,

i.e. the voltage dip caused when a drive at room temperature is switched on is within the permitted limits.

The drive does not of itself cause periodic voltage fluctuation in normal operation. The installer must ensure that the control of the drive is such that

periodic fluctuations in supply current do not infringe the flicker requirements where applicable. Note that large periodic load fluctuations in the

frequency range of between 1Hz and 30Hz are particularly inclined to cause irritating lighting flicker and are subject to stringent limits under

EN61000-3-3.

28 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 29

Technical

A

G

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

7.3 Input line reactors for harmonics standards EN61000-3-2 and IEC61000-3-2

The following input line reactors allow the Commander SL 0.25 - 0.55kW drives to conform to harmonic standards EN61000-3-2 and IEC61000-3-2.

Table 7-2 Input line reactors for harmonics standards EN61000-3-2 and IEC61000-3-2

Drive

Reactor part

number

Drive power

de-rating

Input

power

Inductance

WmH

Continuous

rms current

SLA12200025 4400-0239 None 374 4.5 2.4

SLA12200037 4400-0238 None 553 9.75 3.2

SLA12200055 4400-0237 18% 715 16.25 4.5

EN61000-3-2 and IEC61000-3-2 applies to equipment with a supply voltage of 230VAC and a line current up to 16A, single or three phase.

Professional equipment with rated input power exceeding 1kW has no limits - this applies to the 0.75kW drive.

Further information on EN61000-3-2 and IEC61000-3-2 is included on the EMC data sheets available from your local Control Techniques drive centre

or distributor.

7.4 Voltage fluctuation (Flicker) standard EN61000-3-3 (IEC61000-3-3)

Those models which fall within the scope of EN61000-3-3, as stated in the Declaration of Conformity, conform to the requirements for manual

switching, i.e. the voltage dip caused when a drive at room temperature is switched on is within the permitted limits.

The drive does not of itself cause periodic voltage fluctuation in normal operation. The installer must ensure that the control of the drive is such that

periodic fluctuations in supply current do not infringe the flicker requirements where applicable. Note that large periodic load fluctuations in the

frequency range of between 1Hz and 30Hz are particularly inclined to cause irritating lighting flicker and are subject to stringent limits under

EN61000-3-3.

Figure 7-1 Input line reactor 4402-0224, 4402-0225 and 4402-0226

round

terminal

C

B

D

E

Table 7-3 Dimensions

Part No

ABCDEFixing hole

Dimensions

4402-0224 90mm (3.54in) 72mm (2.84in) 44.5mm (1.75in) 35mm (1.38in) 65mm (2.56in)

4402-0226 105mm (4.13in) 53mm (2.09in) 90mm (3.54in)

82mm (3.23in) 54mm (2.13in)

40mm (1.58in) 75mm (2.95in)

8mm x 4mm

(0.32in x 0.16in)

Ground

terminal

M34402-0225 100mm (3.94in)

Commander SL Technical Data 29

Issue Number: 1 www.controltechniques.com

Page 30

Technical

A

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

Figure 7-2 Input line reactor 4402-0227, 4402-0228, 4402-0229

Ground

terminal

C

B

Table 7-4 Dimensions

Part No

A B C D E Fixing slot

4402-0227

150mm (5.91in) 150mm (5.91in) 120mm (4.72in) 47mm (1.85in) 90mm (3.54in)

4402-0229

reactor values

D

E

Dimensions

AC line

Motor cable

lengths

General

data

I/O

specification

17mm x 7 mm

(0.67in x 0.28in)

Supply

types

Options

Ground

terminal

M54402-0228

30 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 31

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line reactor

values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

8 Motor cable lengths

Table 8-1 Motor cable lengths

Drive frame size kW rating Maximum motor cable length

A

B

C

The capacitive loading of the drive by the motor cable means that the cable length limits shown in table 8-1 must be observed. Failure to do so can

result in spurious OI.AC tripping of the drive. If longer cable lengths are required, consult your local Drive Centre or Distributor.

The maximum cable lengths were measured using cable with capacitance of 130pF/m.

This capacitance was measured by taking one phase as one node and the screen (shield) and earth (ground) (if any) as the other node, then

measuring the capacitance between the two points.

0.25 and 0.37 50m

0.55 and 0.75 75m

100m

100m

Commander SL Technical Data 31

Issue Number: 1 www.controltechniques.com

Page 32

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line reactor

9 General data

9.1 Ratings

9.1.1 IP rating

IP20

• The drive complies with the requirements of IP20 as standard.

First digit: Protection against contact and ingress of foreign bodies.

2 - Protection against medium size foreign bodies ∅> 12mm (e.g. fingers)

Second digit: Protection against ingress of water.

0 - No protection

9.2 Input phase imbalance

3% between phases or 2% negative phase sequence.

9.3 Ambient temperature

-10°C (14°F) to 40°C (104°F) at 3kHz

Operation up to 55°C (131°F) with de-rating.

(see de-rating curves for further information)

NOTE

The drive can be powered up and run at a minimum temperature of -10°C (14°F).

N

values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

9.4 Storage temperature

-40 to +60°C (-40 to +140°F) for 12 months max

9.5 Altitude

Rated altitude: 1000m (3250 ft)

Reduce the normal full load current by 1% for every 100m (325 ft) above 1000m (3250 ft) up to a maximum of 3000m (9750 ft).

9.6 Humidity

Maximum relative humidity 95% (non-condensing).

9.7 Storage humidity

Maximum relative humidity 93%, 40°C, 4 days.

9.8 Pollution degree

Designed for operation in Pollution degree 2 environments (dry, non-conductive contamination only)

9.9 Materials

Flammability rating of main enclosure: UL94 - 5VA

9.10 Vibration

9.10.1 Random

Standard: In accordance with IEC68-2-64 and IEC68-2-36: Test Fh

Severity: 1.0 m

Duration: 30 minutes in each of 3 mutually perpendicular axes.

9.10.2 Sinusiodal

Standard: IEC68-2-6: Test Fc

Frequency range: 2 to 500Hz

Severity: 3.5mm peak displacement from 2 to 9Hz

Sweep rate: 1 octave/minute

Duration: 15 minutes in each of 3 mutually perpendicular axes.

2/s3

(0.01g2/Hz) ASD from 5 to 20Hz, -3dB/octave from 20 to 200Hz

2

peak displacement from 9 to 200Hz

10m/s

2

15m/s

peak displacement from 200 to 500Hz

32 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 33

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line reactor

values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

9.10.3 Bump

Standard: IEC68-2-29: Test Eb

Severity: 18g, 6ms, half sine

Number of bumps: 600 (100 in each direction of axes)

9.11 Frequency accuracy

0.01%

9.12 Resolution

0.1Hz

9.13 Output frequency range

0 to 1500Hz

9.14 Starts per hour

Electric starts

With the supply permanently connected the number of electronic motor starts per hour is only limited by motor and drive thermal limits.

Power starts

The number of starts by connection of the ac supply is limited. The start up circuit will allow for three consecutive starts at 3-second intervals on initial

power up. Exceeding the rated number of starts per hour, presented in the table below, could result in damage to the start up circuit.

Drive frame size

A, B & C 20

Maximum AC line starts per hour

evenly spaced in time

9.15 Start-up time

The soft-start circuit must charge the dc bus and SMPS outputs and stabilise to allow the control processor to start operation in the following times:-

Drive frame

size

A 200 1s

B and C 200 2s

B and C 400 1s

Voltage

Maximum time taken to charge DC bus

and SMPS outputs to stabilise

9.16 Serial communications

Modbus RTU

9.17 Switching frequencies

The software allows for the following switching frequencies:

Size A, B and C, 200V: 3, 16, 12, 18kHz.

Size B and C, 400V: 3, 6, 12kHz.

9.18 Harmonics

The Commander SL industrial AC variable speed drives are classified as class A professional equipment as defined in BS EN61000-3-2: 1995.

Drives with input power equal to or below 1kW that do not meet the requirements of EN61000-3-2 are to be corrected, to ensure compliance, at the

point of installation using suitable AC line chokes. See 7.2 (Reactor current ratings)

Commander SL Technical Data 33

Issue Number: 1 www.controltechniques.com

Page 34

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line reactor

values

Motor cable

lengths

9.19 Acoustic noise

Frame Power ratings Condition Max SPL measurement (dBA)

A All ratings N/A None contributed by drive (no fan).

B ≤0.75kW N/A None contributed by drive (no fan).

B ≥1.1kW rd mode, fan on 50

C All ratings rd mode, fan on 53

9.20 HF trips

HF fault code Reason for trip

01 to 03 Not used

04 Low DC bus at power up

05 No signal from DSP at start up

06 Unexpected interrupt

07 Watchdog failure

08 Interrupt crash (code overrun)

09 to 10 Not used

11 Access to the EEPROM failed

12 to 19 Not used

20 Power stage - code error

21 Power stage - unrecognised frame size

22 OI failure at power up

23 DSP software overrun

24 Not used

25 DSP Communications failure

26 Soft start relay failed to close, or soft start monitor failed

27 Power stage thermistor fault

29 Fan failure (current too high)

General

data

I/O

specification

Supply

types

Options

34 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 35

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

10 I/O specification

The control circuits are isolated from the power circuits in the drive by basic insulation (single insulation) only. The installer must ensure

that the external control circuits are insulated from human contact by at least one layer of insulation (supplementary insulation) rated for

WARNING

WARNING

Voltage: Current input 0 to 10V: mA as parameter range

Input range 0 to +10V / 4 to 20mA / 0 to +24V

Scaling

Input impedance 200Ω (current): 100kΩ (voltage): 6k8 (digital)

Resolution 0.1%

Accuracy ± 2%

Sample time 6ms

Absolute maximum voltage range +35V to -18V with respect to 0V common

Nominal threshold voltage +10V (positive logic only)

use at the AC supply voltage.

If the control circuits are to be connected to other circuits classified as Safety Extra Low Voltage (SELV) (e.g. to personal computer), an

additional isolating barrier must be included in order to maintain the SELV classification.

T1 0V common

T2 Analogue input 1 (A1), voltage, current or digital input

Input range automatically scaled to Pr 01 (Minimum set

speed) to Pr 02 (Maximum set speed)

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

T3 +10V reference output

Maximum output current 5mA

Protection Tolerates continuous short circuit to 0V

Accuracy ± 2%

T4 Analogue output voltage or digital output

Voltage: Digital output 0 to +10V: 0 to +24V

Scaling (as voltage output) Output range automatically scaled to output mode

Resolution 0.1%

Accuracy ± 5%

Sample time 21ms

Nominal threshold voltage +10V (positive logic only)

Maximum output current 5mA (analogue): 50mA (digital)

T5 +24V output

Maximum output current 100mA

Protection Tolerates continuous short circuit to 0V

Accuracy ± 15%

NOTE

N

The total available current from the digital output plus the +24V output is 100mA

Commander SL Technical Data 35

Issue Number: 1 www.controltechniques.com

Page 36

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

T6

T7

T8

Digital Input - Enable/Reset */**

Digital Input - Run Forward **

Digital Input - Run Reverse **

Logic Positive logic only

Voltage range 0 to +24V

Input impedance 6.8kΩ

Sample time 1.5ms

Nominal threshold voltage +10V

Absolute maximum voltage range +35V to -18V with respect to 0V common

T9

T10

Voltage rating

Status relay - Drive healthy (Normally open)

240Vac

30DC

2Aac 240V

Current rating

4Adc 30V resistive load (2A 35Vdc for UL requirements)

0.3Adc 30V inductive load (L/R = 40ms)

Contact isolation 1.5kVac (over voltage category II)

Update time 1.5ms

OPEN

- AC supply removed from drive.

Operation of contact

- AC supply applied to drive with drive in tripped condition.

CLOSED

- AC supply applied to drive with drive in a 'ready to run' or

'running' condition (not tripped)

Provide fuse or other over-current protection in status relay circuit.

WARNING

NOTE

N

If the drives enable terminal is opened, the drives output is disabled and the motor will coast to a stop. The drive will not re-enable for 0.5s after the

enable terminal is closed again.

10.1 Drive reset

If the enable terminal is opened, the drive’s output is disabled and the motor will coast to a stop. The drive will not re-enable for 1.0s after the enable

terminal is closed again.

*Following a drive trip, opening and closing the enable terminal will reset the drive. If the run forward or run reverse terminal is closed, the drive will

run straight away.

**Following a drive trip and a reset via the stop/reset key, the enable, run forward or run reverse terminals will need to be opened and closed to allow

the drive to run. This ensures that the drive does not run when the stop/reset key is pressed.

The enable, run forward and run reverse terminals are level triggered apart from after a trip where they become edge triggered. See * and ** above.

If the enable and run forward or enable and run reverse terminals are closed when the drive is powered up, the drive will run straight away up to a set

speed.

If both the run forward and run reverse terminals are closed, the drive will stop under the control of the ramp and stopping modes set in Pr 30 and

Pr 31.

10.2 Sample/update times

The sample/update times shown in the control terminal specification within the Commander SL Technical Guide are the default sample/update times

for the default terminal set-up. The sample/update time depends on the destination/source parameter of the digital or analogue inputs/outputs.

These sample/update times are the sample or update times for the control microprocessor. The actual sample/update time maybe slightly longer due

to the design of the Commander SL.

36 Commander SL Technical Data

www.controltechniques.com Issue Number: 1

Page 37

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

10.3 Task routine times

At the beginning of each menu, there is a single line parameter description and this contains the update rate for each parameter. This time signifies

the task routine time in the software that the parameter is updated on. For a background task, the time depends on processor loading i.e. what

functions the drive is carrying out and what advanced menus are being used.

Update rate Microprocessor update time Comments

2ms 2ms Updated every 2ms

5ms 5ms Updated every 5ms

21ms 21ms Updated every 21ms

128ms 128ms Updated every 128ms

B Background

BR Background read

BW Background write

From practical tests carried out:

Condition

Time for drive to respond to a run command 4.1 5.62 5.02

Time for the drive to respond to a stop command 2.82 3.94 3.31

Time for the drive to respond to a step change in analogue input

voltage

Updated as a background task. Update rate depends

on processor loading.

Minimum

ms

Maximum

ms

Average

ms

7.93

Commander SL Technical Data 37

Issue Number: 1 www.controltechniques.com

Page 38

Technical

data

Derating curves

and losses

Drive voltage

levels

DC bus

design

Mechanical

installation

EMC filters

AC line

reactor values

Motor cable

lengths

General

data

I/O

specification

Supply

types

Options

11 Supply types

Commander SL is suitable for use with any supply type, i.e. TN-S, TN-C-S, TT, IT, with a grounding at any potential, i.e. neutral, centre or co rner

('grounded-delta').

Drives are suitable for use on supplies of installation category III and lower, according to IEC60664-1. This means they may be connected

permanently to the supply at its origin in a building, but for outdoor installation, additional over-voltage suppression (transient voltage surge

suppression) must be provided to reduce category IV to category III.

1 1.1 AC supply requirements

Single phase drives

Single phase - Between one phase and neutral of a star connected three phase supply.

- Between two phases of a three phase supply.

Three phase models

Three-phase star or delta supply of the correct voltage.

Dual rated models

Any of the above supplies can be used.

11.2 Safety

Electric shock risk

The voltages present in the following locations can cause severe electric shock and may be lethal:

• AC supply cables and connections

WARNING

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

Isolation device

The AC supply must be disconnected from the drive using an approved isolation device before any cover is removed from the drive or

before any servicing work is performed.

WARNING

STOP function

The STOP function does not remove dangerous voltages from the drive, the motor or

any external option units.

WARNING

Stored charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply has been disconnected. If the drive

has been energized, the AC supply must be isolated at least ten minutes before work may continue.

WARNING

Normally, the capacitors are discharged by an internal resistor. Under certain, unusual fault conditions, it is possible that the capacitors