Page 1

Control User Guide

Commander S100

Variable Speed AC drive for induction

motors

Part Number: 0478-0650-00

Issue: 0

MARSHAL

Page 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC, the English version of this User Guide is the Original Instructions.

User Guides in other languages are Translations of the Original Instructions.

The information contained in this User Guide is believed to be correct at the time of printing and does not form part of any contract. The manufacturer

reserves the right to change the specification of the product and its performance, and the contents of the User Guide, without notice.

Documentation & User Software Tools

User Guides, datasheets and software are available to download from: http://www.drive-setup.com

Marshal (Mobile App) is available to download from the Google Play store and the App Store.

Warranty and Liability

In no event and under no circumstances shall the manufacturer be liable for damages and failures due to misuse, abuse, improper installation, or

abnormal conditions of temperature, dust, or corrosion, or failures due to operation outside the published ratings. The manufacturer is not liable for

consequential and incidental damages. Contact the supplier of the drive for full details of the warranty terms.

Environmental policy

Control Techniques operates an Environmental Management System (EMS) that conforms to the International Standard ISO 14001. Further

information on our Environmental Policy can be found at: http://www.drive-setup.com/environment

Restriction of Hazardous Substances (RoHS)

The products covered by this User Guide comply with European and International regulations on the Restriction of Hazardous Substances including

EU directive 2011/65/EU and the Chinese Administrative Measures for Restriction of Hazardous Substances in Electrical and Electronic Products.

Disposal and Recycling (WEEE)

When electronic products reach the end of their useful life, they must not be disposed of along with domestic waste but should be recycled

by a specialist recycler of electronic equipment. Control Techniques products are designed to be easily dismantled into their major

component parts for efficient recycling. The majority of materials used in the product are suitable for recycling.

Product packaging is of good quality and can be re-used. Smaller products are packaged in strong cardboard cartons which have a high

recycled fibre content. Cartons can be re-used and recycled. Polythene, used in protective film and bags for wrapping the product, can

be recycled. When preparing to recycle or dispose of any product or packaging, please observe local legislation and best practice..

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH) requires the supplier of an article to

inform the recipient if it contains more than a specified proportion of any substance which is considered by the European Chemicals Agency (ECHA)

to be a Substance of Very High Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

Further information on our compliance with REACH can be found at: http://www.drive-setup.com/reach

Registered Office

Nidec Control Techniques Ltd

The Gro

Newtown

Powys

SY16 3BE

UK

Registered in England and Wales. Company Reg. No. 01236886.

Copyright

The contents of this publication are believed to be correct at the time of printing. In the interests of a commitment to a policy of continuous development

and improvement, the manufacturer reserves the right to change the specification of the product or its performance, or the contents of the User Guide,

without notice.

All rights reserved. No parts of this User Guide may be reproduced or transmitted in any form or by any means, electrical or mechanical including

photocopying, recording or by an information storage or retrieval system, without permission in writing from the publisher.

Copyright © February 2021 Nidec Control Techniques Ltd

Page 3

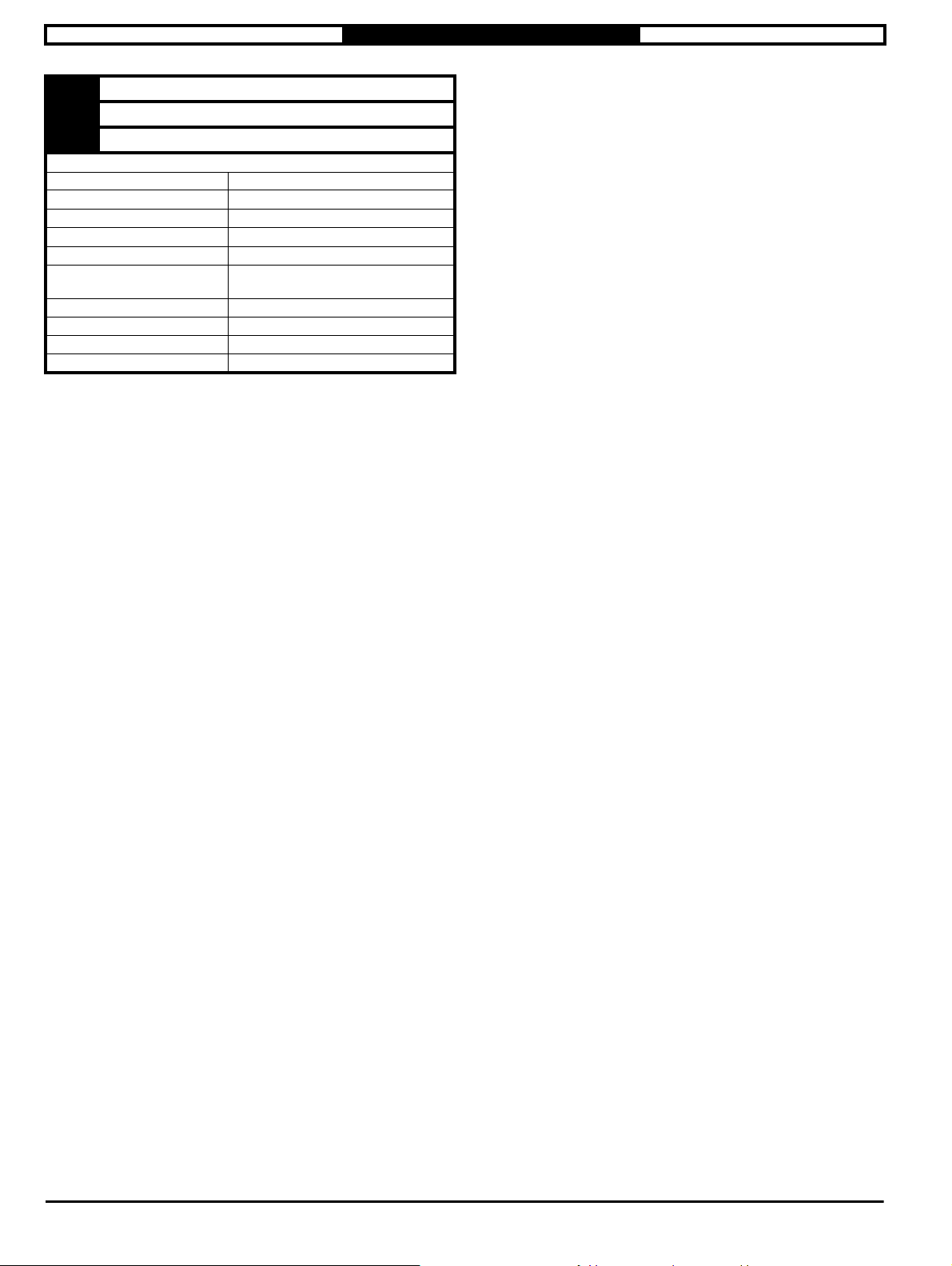

Contents

1 Safety information .................................4

1.1 Important Safety Information .................................4

1.2 Responsibility ........................................................4

1.3 Compliance with regulations .................................4

1.4 Electrical hazards ..................................................4

1.5 Mechanical hazards ..............................................5

1.6 Access to equipment .............................................5

1.7 Environmental limits ..............................................5

1.8 Hazardous environments ......................................5

1.9 Motor .....................................................................5

1.10 Adjusting parameters ............................................5

1.11 Electromagnetic compatibility (EMC) ....................5

1.12 Repairs ..................................................................5

1.13 Maintenance .........................................................5

2 Electrical installation ............................6

2.1 Control connections ..............................................6

3 Drive Parameters ...................................9

3.1 Parameter Groups ................................................9

3.2 Menu 0 - Quick Start ...........................................10

3.3 Full Parameter List ..............................................10

3.4 Menu 1 - Status & Monitoring .............................11

3.5 Menu 2 - Reference & Ramps ...........................12

3.6 Menu 3 – Motor Setup ........................................13

3.7 Menu 4 - General ................................................13

3.8 Menu 5 - PID Controller ......................................14

3.9 Menu 6 - IO Configuration ...................................15

3.10 Parameter Descriptions ......................................16

Commander S100 User Guide 3

Page 4

Safety information Electrical installation Drive Parameters

WARNING

CAUTION

NOTE

1 Safety information

1.1 Important Safety Information

Specific warnings are given at the relevant places in this User Guide as

follows:

A Warning contains information which is essential for

avoiding a safety hazard.

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

A Note contains information which helps to ensure correct operation of

the product.

1.1.1 Hazards

This User Guide applies to the Commander S100 and auxiliary

equipment. In all cases the hazards associated with powerful electrical

drives are present, and all safety information relating to drives and

associated equipment must be observed.

1.1.2 Competence of Designers and Installers

Drives and controllers are intended as components for professional

incorporation into complete systems. If installed incorrectly they may

present a safety hazard. The drive uses high voltages and currents,

carries a high level of stored electrical energy, and is used to control

equipment which can cause injury. Close attention is required to the

electrical installation and the system design to avoid hazards either in

normal operation or in the event of equipment malfunction. System

design, installation, commissioning and maintenance must be carried

out by personnel who have the necessary training and competence.

They must read all of the safety information and instructions in this User

Guide carefully

1.2 Responsibility

It is the responsibility of the installer to ensure that the equipment is

installed correctly with regard to all instructions given in this User Guide.

They must give due consideration to the safety of the complete system,

so as to avoid the risk of injury both in normal operation and in the event

of a fault or of reasonably foreseeable misuse.

The manufacturer accepts no liability for any consequences resulting

from inappropriate, negligent or incorrect installation of the equipment.

1.3 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be given to the cross-sectional areas of conductors, the selection

of fuses or other protection, and protective ground (earth) connections.

This guide contains instructions for achieving compliance with specific

EMC standards.

All machinery to be supplied within the European Union in which this

product is used must comply with the following directives:

2006/42/EC Safety of machinery.

2014/30/EU: Electromagnetic Compatibility.

1.4 Electrical hazards

The voltages used in the drive can cause severe electrical shock and/or

burns, and could be lethal. Extreme care is necessary at all times when

working with or adjacent to the drive. Hazardous voltage may be present

in any of the following locations:

• AC and DC supply cables and connections

• Output cables and connections

• Control terminals and cables

• Many internal parts of the drive, and external option units

The drive must be installed in accordance with the instructions given in

this User Guide. Failure to observe the instructions could result in a fire

hazard

1.4.1 Isolating the Drive

The drive contains capacitors that remain charged to a potentially lethal

voltage after the AC supply has been disconnected. If the drive has been

energized, the AC supply must be isolated by an approved electrical

isolation at least five minutes before work may continue. Ensure the

motor is not able to be driven by another part of the system as this could

produce a regenerating current which could cause unsafe voltages on

the drive terminals.

1.4.2 Stored Charge

Normally, the capacitors are discharged by an internal resistor. Under

certain, unusual fault conditions, it is possible that the capacitors may fail

to discharge or be prevented from being discharged by a voltage applied

to the output terminals. If the drive has failed in a manner that causes the

display to go blank immediately, it is possible the capacitors will not be

discharged. In this case, contact the supplier of the drive.

1.4.3 Products Connected by Plug and Socket

A special hazard may exist where the drive is incorporated into a product

which is connected to the supply by a plug and socket. When unplugged,

the pins of the plug may be connected to the drive input, which is

separated from the charge stored in the capacitor only by semiconductor

devices. To avoid any possibility of electric shock from the pins, if they

are accessible, a means must be provided for automatically isolating the

plug from the drive - e.g. a latching contactor.

1.4.4 Grounding / Earthing

The drive must be grounded by a conductor sufficient to carry the

prospective fault current in the event of a fault and in a zone of

equipotential bonding. The ground loop impedance must conform to the

requirements of local safety regulations. The ground connections must

be inspected and tested at appropriate intervals.

Ground conductor size:- Either a single copper 10 mm² conductor or two

conductors of the same cross-sectional area and material as the input

conductors so long as the size of each conductor is 2.5 mm2. For

location of ground connections refer to Figure 1-1 in the Step by Step

guide.

Each ground connection requires an individual terminal or connection

point. If using two conductors for the input and the cable management

bracket, the motor ground should be connected to the grounding

bracket.

1.4.5 Fuses and Circuit Breakers

The AC supply to the drive must be installed with suitable protection

against overload. Failure to observe this requirement will cause risk of

fire. Integral solid-state short circuit protection does not provide branch

circuit protection. Branch circuit protection must be provided in

accordance with the National Electrical Code (NEC), The Canadian

Electrical Code, and any additional local codes. Opening of the branchcircuit protective device may be an indication that a fault has been

interrupted. To reduce the risk of fire or electric shock, the equipment

should be examined and replaced if damaged. If burnout of the current

element of an overload relay occurs, the complete overload relay must

be replaced. If opting to use a residual current device, only type B should

be used with the drive.

4 Commander S100 User Guide

I

Page 5

Safety information Electrical installation Drive Parameters

1.4.6 Over-Current Protection

The devices incorporate solid state overload protection for the motor

load. The protection levels are expressed as a percentage of full-load

current. For the motor protection to work properly, Motor Rated Current

(P0.06) must be set correctly. The protection level may be adjusted

below 150 % if required using Motor Output Current Limit (P3.17). All

models are provided with thermal memory retention.

1.4.7 Isolation of control circuits

Unless otherwise indicated, control terminals and the EIA-485

Communications port are isolated from the power circuits in the drive by

double/reinforced insulation. The installer must ensure that the external

control circuits do not compromise this insulation barrier. If the control

circuits are to be connected to circuits classified as Safety Extra Low

Voltage (SELV) - for example, to a personal computer - an additional

basic barrier must be included in order to maintain the SELV

classification.

1.4.8 Terminal Connections and Torque Settings

Loose power connections are a fire risk. Always ensure that terminals

are tightened to the specified torques. Refer to the tables in chapter 4

Electrical Installation.

1.5 Mechanical hazards

Careful consideration must be given to the functions of the drive or

controller which might result in a hazard, either through their intended

behaviour or through incorrect operation due to a fault. In any application

where a malfunction of the drive or its control system could lead to or

allow damage, loss or injury, a risk analysis must be carried out, and

where necessary, further measures taken to reduce the risk - for

example, an over-speed protection device in case of failure of the speed

control, or a fail-safe mechanical brake in case of loss of motor braking.

None of the drive functions must be used to ensure safety of

personnel. i.e. they must not be used for safety-related functions.

The system designer is responsible for ensuring that the complete

system is safe and designed correctly according to the relevant safety

standards.

The design of safety-related control systems must only be done by

personnel with the required training and experience. The system must

be subject to a risk assessment to confirm that the residual risk of an

unsafe event is at an acceptable level for the application.

The values of the motor parameters set in the drive affect the protection

of the motor. The default values in the drive must not be relied upon. It is

essential that the correct value is entered in the Motor Rated Current

(P3.01).

1.9.1 Motor Sizing

The motor rated current should not exceed the maximum continuous

output current of the drive. The maximum output voltage of the drive is

not able to exceed the input voltage and the rated voltage of the motor

should therefore be less than this value. Typical overloads are 150% for

60 s (from cold) or 150% for 8 s (from hot). The drive will initiate an error

if the drive output current exceeds the over-current threshold which

could occur in the event of a short circuit of the motor output cables. The

over-current threshold is the maximum current the drive can measure.

1.10 Adjusting parameters

It is essential that changes to the drive parameters are given careful

consideration. Depending on the application, a change could result in

unexpected motor behaviour. Appropriate precautions must be taken

against inadvertent changes or tampering. Some specific parameters

which require particular care are: parameters in IO Configuration (Menu

6) (the drive may start unexpectedly if the logic or functions are

changed); Restore Factory Defaults (P4.01) (depending on the

application this may cause unpredictable or hazardous operation);

parameters in Motor Setup (Menu 3) (overheating and possible fire risk

could result from seriously incorrect settings).

1.11 Electromagnetic compatibility (EMC)

Installation instructions for a range of EMC environments are provided in

section 4.5 Electromagnetic compatibility (EMC). If the installation is

poorly designed or other equipment does not comply with suitable

standards for EMC, the product might cause or suffer from disturbance

due to electromagnetic interaction with other equipment. It is the

responsibility of the installer to ensure that the equipment or system into

which the product is incorporated complies with the relevant EMC

legislation in the place of use.

1.12 Repairs

Users must not attempt to repair a drive if it is faulty. It must be returned

to the supplier of the drive. Users must not make any attempt at

removing drive plastics to inspect the internal parts of the drive.

1.6 Access to equipment

Access must be restricted to authorized personnel only. Safety

regulations which apply at the place of use must be complied with.

1.7 Environmental limits

Instructions in this guide regarding transport, storage, installation and

use of the equipment must be complied with, including the specified

environmental limits. This includes temperature, humidity,

contamination, shock and vibration. Drives must not be subjected to

excessive physical force.

1.13 Maintenance

Regular inspections and maintenance should be carried out to ensure

drive's reliability is maximized. See detailed information in the in section

3.11 Routine Maintenance.

1.8 Hazardous environments

The equipment must not be installed in a hazardous environment

(i.e. a potentially explosive environment).

1.9 Motor

The safety of the motor under variable speed conditions must be

ensured.

To avoid the risk of physical injury, do not exceed the maximum specified

speed of the motor.

Low speeds may cause the motor to overheat because the cooling fan

becomes less effective, causing a fire hazard. If possible, the motor

should be installed with a protection thermistor. If necessary, an electric

forced vent fan should be used.

Commander S100 User Guide 5

Page 6

Safety information Electrical installation Drive Parameters

CAUTION

CAUTION

NOTE

2 Electrical installation

2.1 Control connections

2.1.1 General Warnings

If any of the digital inputs are connected in parallel with an inductive load (i.e. contactor or motor brake) then suitable suppression (i.e.

diode or varistor) should be used on the coil of the load. If no suppression is used, then over voltage spikes can cause damage to the

digital inputs and outputs on the drive.

The control 0 V terminals are connected to earth but must not be used for protective purposes.

N

Any signal cables which are carried inside the motor cable (i.e. motor thermistor, motor brake) will pick up large pulse currents via the cable

capacitance. The shield of these signal cables must be connected to ground close to the point of exit of the motor cable, to avoid this noise current

spreading through the control system.

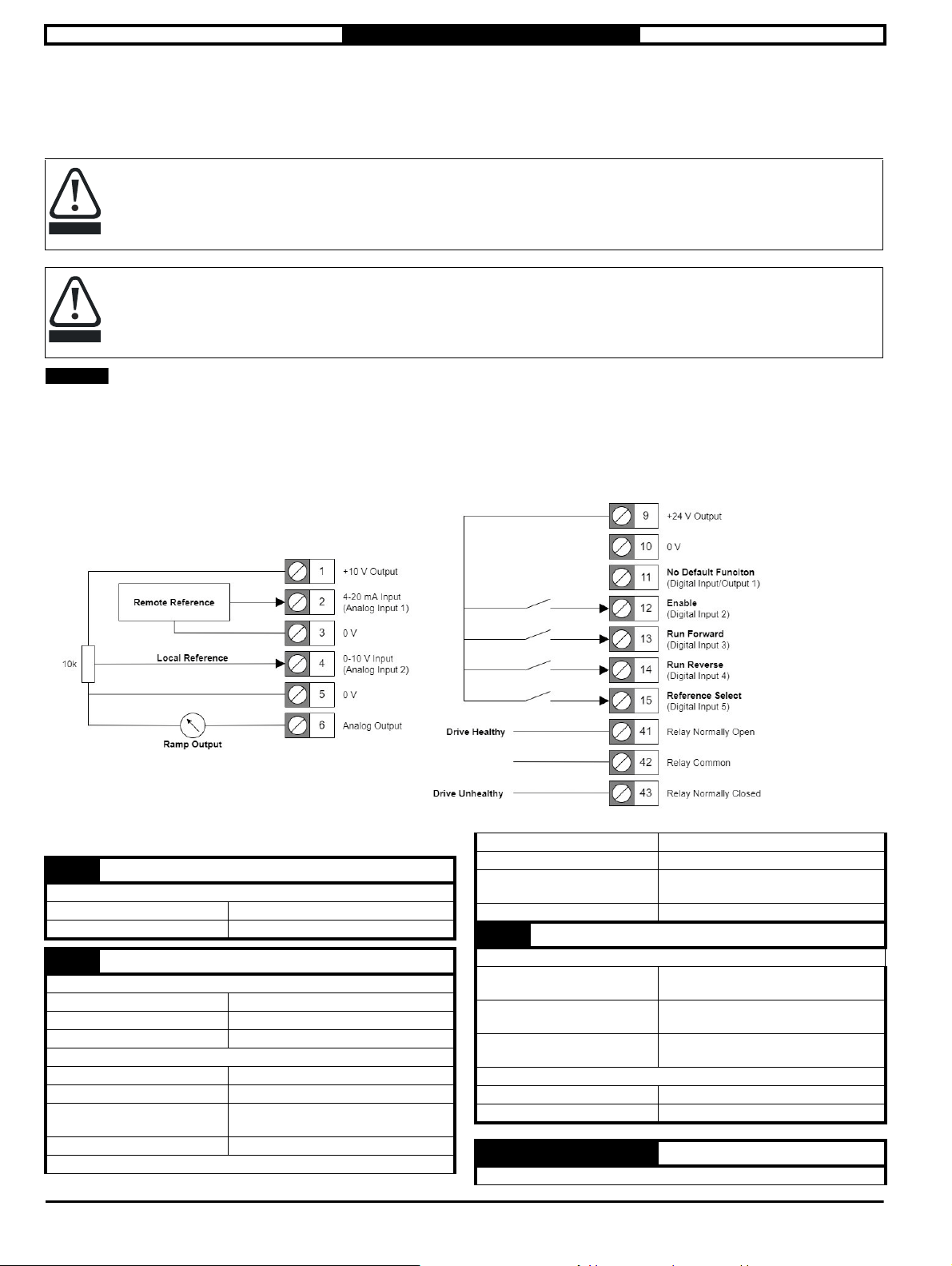

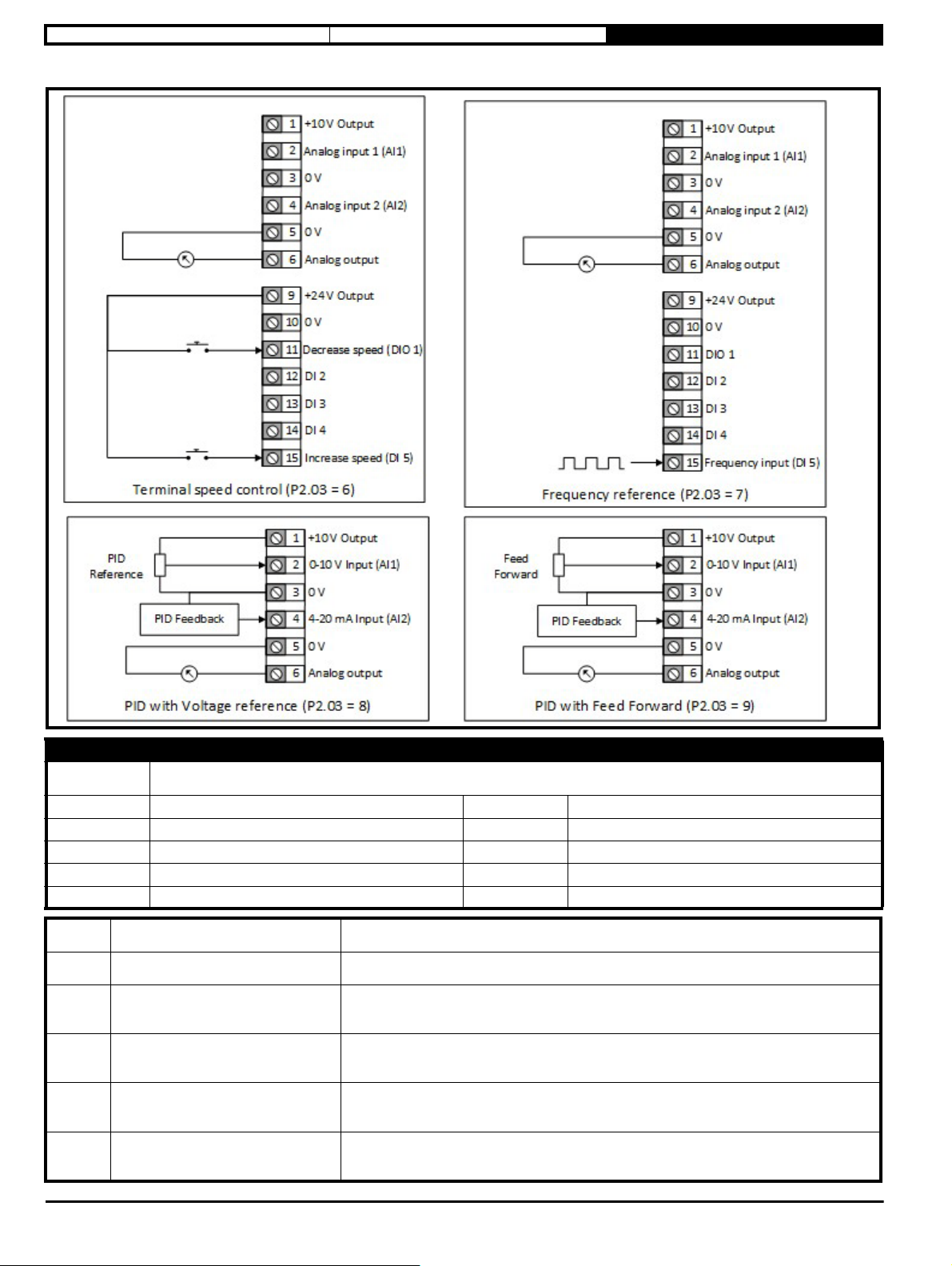

2.1.2 Control Terminal Connections

The default connections are suitable for basic motor speed control using analog inputs to define a frequency reference.

Figure 2-1 Default Control Terminal Connections

2.1.3 Control Terminal Specification

Control and relay terminals maximum cable size is 1.5 mm

2

T1 +10 V User Output

Supply for external analog devices

Nominal voltage 10.2 V

Voltage tolerance ±3 %

T2 Analog Input 1

Unipolar single-ended analog voltage or unipolar current input

Default function Remote Frequency Reference

Default Type 4 to 20 mA

Type Select Parameter T2 Analog Input 1 Type (P6.01)

As a Voltage Input (Default)

Full scale voltage range 0 V to +10 V ±3 %

Maximum offset ±30 mV

Absolute maximum voltage

range

Input resistance 100k Ω

As a Current Input

-18 V to +30 V relative to 0V

Current ranges 0 to 20 mA ±5 %, 4 to 20 mA ±5 %

Maximum offset 250 µA

Absolute maximum voltage

(reverse bias)

Absolute maximum current 25 mA

-18 V to +30 V relative to 0V

T2 Analog Input 1 (Continued)

As a Digital Input

Digital Function Select

Parameter

Switching Threshold as a

Voltage Input

Switching Threshold as a

Current Input

Common to all modes

Resolution 11 bits

Sample rate 4 ms

T2 Analog Input 1 Digital Function Select

(P6.14)

70 to 80 % *

45 to 55 %

1

T3,T5, T10 0 V Common

Unipolar single-ended analog voltage or unipolar current input

6 Commander S100 User Guide

Page 7

Safety information Electrical installation Drive Parameters

T4 Analog Input 2

Unipolar single-ended analog voltage or unipolar current input

Default function Ramp Output

Default Type 0 to 10 V

Type Select Parameter T4 Analog Input 2 Type (P6.02)

As a Voltage Input (Default)

Full scale voltage range 0 V to +10 V ±3 %

Maximum offset ±30 mV

Absolute maximum voltage

range

Input resistance 100k Ω

-18 V to +30 V relative to 0V

As a Current Input

Current ranges 0 to 20 mA ±5 %, 4 to 20 mA ±5 %

Maximum offset 250 µA

Absolute maximum voltage

(reverse bias)

Absolute maximum current 25 mA

-18 V to +30 V relative to 0V

As a Digital Input

Digital Function Select

Parameter

Switching Threshold as a

Voltage Input

Switching Threshold as a

Current Input

T4 Analog Input 2 Digital Function Select

(P6.15)

70 to 80 % *1

45 to 55 %

Common to all modes

Resolution 11 bits

Sample rate 4 ms

T6 Analog Output

Unipolar single-ended analog voltage or unipolar current output

Default function Ramp Output

Function Select Parameter T6 Analog Output Function Select

Default type 0 to 10 V

Type Select Parameter T6 Analog Output Type (P6.03)

Voltage Range 0 to 10 V

Current Range 0 to 20 mA or 4 to 20 mA

Maximum offset 15 mV

Load resistance ± 2k Ω

Protection Short circuit relative to 0 V

Resolution 0.1 %

Sample rate 4 ms

(P6.06)

T9 +24 V User Output

Supply for external analog devices

Voltage tolerance ±20 %

Maximum output current 100 mA (Shared with T11 Digital Output)

T11 Digital Input/Output 1

Multi-functional digital input or output

Default Function None

Function Select Parameters T11 Digital Input 1 Function (P6.16)

T11 Digital Output Function Select

(P6.09)

Default type Digital Input (Positive Logic)

Type Select Parameter

T11 Digital IO 1 Type (P6.04)

As a digital input (default)

Lower Threshold < 5 V

Upper Threshold > 11 V

T11 Digital Input/Output 1 (Continued)

Absolute maximum applied

voltage range -8 V to +30 V relative to 0V

Impedance 6.8 kΩ

Input threshold 10 V ±0.8 V (IEC 61131-2)

As a digital output

Maximum Source Current 50 mA (100 mA total limit on T9 and T11)

As a Frequency or PWM Output

Maximum Output

PWM Output

Resolution at Maximum Output

Resolution at Minimum Input

Common to all output types

Voltage Range 0 V to +24 V

Sample rate 4 ms

T12 Digital Input 2

T13 Digital Input 3

T14 Digital Input 4

Programmable Digital Inputs

T12 Default Function Enable

T13 Default Function Run Forward

T14 Default Function Run Reverse

Function Select Parameters

Default Logic Positive Logic

Lower Threshold < 5 V

Upper Threshold > 11 V

Absolute maximum applied

voltage range

Impedance 6.8 kΩ

Input threshold 10 V ±0.8 V (IEC 61131-2)

Voltage Range 0 V to +24 V

Sample rate 4 ms

T12 Digital Input 2 Function (P6.17)

T13 Digital Input 3 Function (P6.18)

T14 Digital Input 4 Function (P6.19)

-8 V to +30 V relative to 0V

T15 Digital Input 5

Programmable Digital Input or Frequency Input

T15 Default Function Enable

Function Select Parameter T15 Digital Input 5 Function (P6.20)

Default Logic Positive Logic

Lower Threshold < 5 V

Upper Threshold > 11 V

Absolute maximum applied

voltage range

Impedance 6.8 kΩ

Input threshold 10 V ±0.8 V (IEC 61131-2)

Voltage Range 0 V to +24 V

Sample rate 4 ms

-8 V to +30 V relative to 0V

As a Frequency Input

Maximum Frequency 100 kHz

Commander S100 User Guide 7

Page 8

Safety information Electrical installation Drive Parameters

T41 Relay Normally Open

T42 Relay Common

T43 Relay Normally Closed

Programmable Relay

Relay Default Function Drive Healthy

Function Select Parameter T12 Digital Input 2 Function (P6.17)

Default Logic Positive Logic

Lower Threshold

Upper Threshold > 11 V

Absolute maximum applied

voltage range

Impedance 6.8 kΩ

Input threshold 10 V ±0.8 V (IEC 61131-2)

Voltage Range 0 V to +24 V

Sample rate 4 ms

< 5 V

-8 V to +30 V relative to 0V

8 Commander S100 User Guide

Page 9

Safety information Electrical installation Drive Parameters

3 Drive Parameters

Parameters are variables within the drive that can be used to monitor output levels and drive statuses or to control the settings within the drive.

Parameters are divided into six menus based on their function which are:.

Menu 1 - Status & Monitoring (All read-only parameters)

Menu 2 - References and Ramps

Menu 3 - Motor Setup

Menu 4 - General

Menu 5 - PID Controller

Menu 6 - IO Configuration

There is also a quick start menu (Menu 0) that contains shortcuts to ten parameters used for basic drive setup. Because parameters in menu 0 are

shortcuts, changing the value of the parameter in menu 0 will also change the value in its original menu and vice versa.

3.1 Parameter Groups

The parameter groups listed below are parameters that behave in the same way.

Configuration Parameters

Automatically adjust settings of multiple parameters to quickly setup a certain function.

• Frequency Reference Configuration (P0.05)

• Enable/Run Configuration (P0.10)

Selector Parameters

Select an analog value to be used as an input.

• Reference Selector 1 (P2.21)

• Reference Selector 2 (P2.22)

• Reference Selector 3 (P2.23)

• Reference Selector 4 (P2.24)

• PID Reference Selector (P5.02)

• PID Feedback Selector (P5.03)

• PID Feedforward Selector (P5.04)

• PID Enable Selector (P5.10)

• Threshold Detector Selector (P5.11)

Input Function Select Parameters

Define the function of an input

• Keypad Run/Stop Key Function Select (P4.07)

• T2 Analog Input 1 Digital Function Select (P6.14)

• T4 Analog Input 2 Digital Function Select (P6.15)

• T11 Digital Input 1 Function Select (P6.16)

• T12 Digital Input 2 Function Select (P6.17)

• T13 Digital Input 3 Function Select (P6.18)

• T14 Digital Input 4 Function Select (P6.19)

• T15 Digital Input 5 Function Select (P6.20)

Output Function Select Parameters

Define the function of an output

• T6 Analog Output Function Select (P6.06)

• T11 Digital Output 1 Function Select (P6.09)

• T11 Frequency/PWM Output Function Select (P6.10)

Commander S100 User Guide 9

Page 10

Safety information Electrical installation Drive Parameters

WARNING

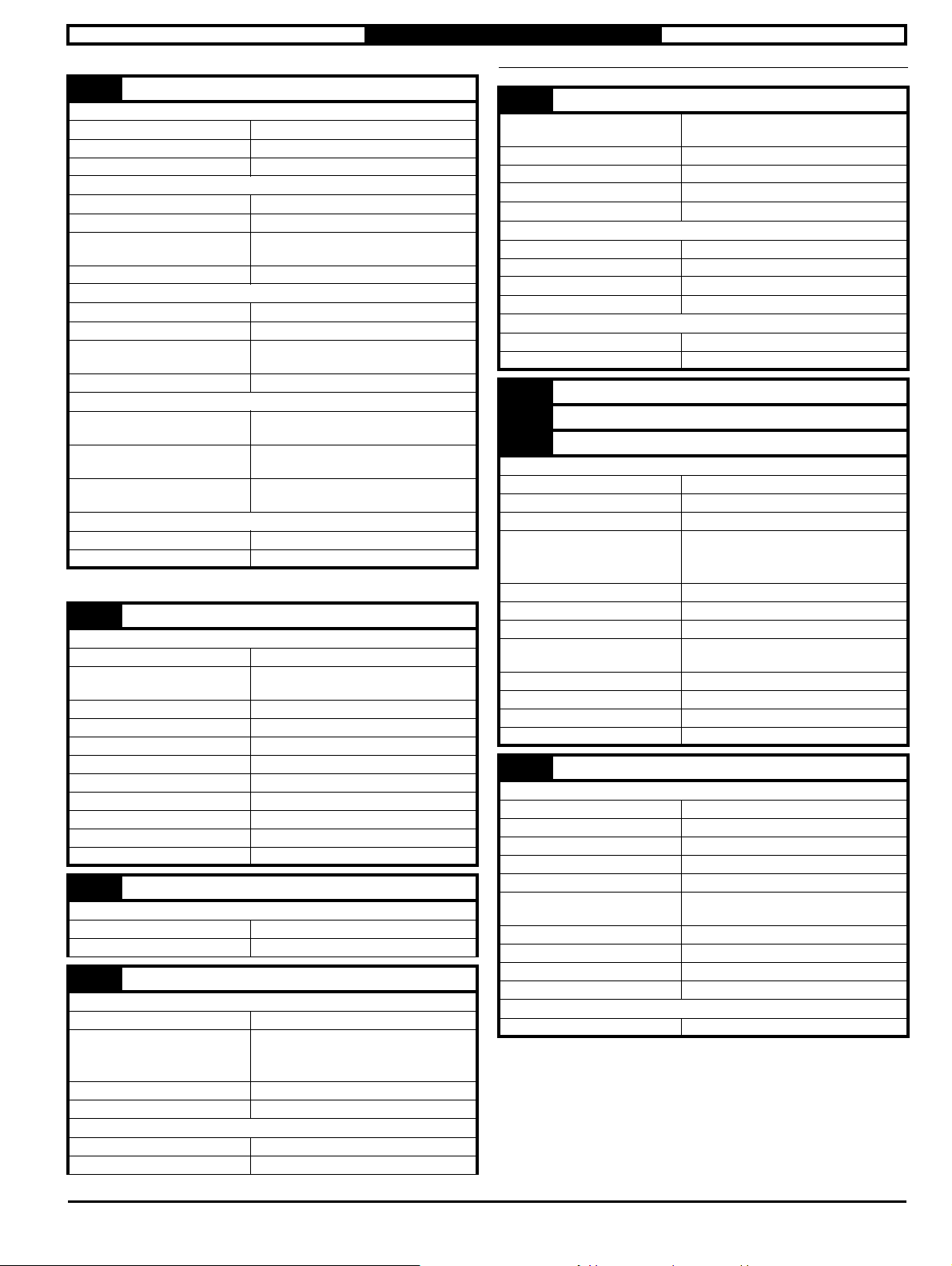

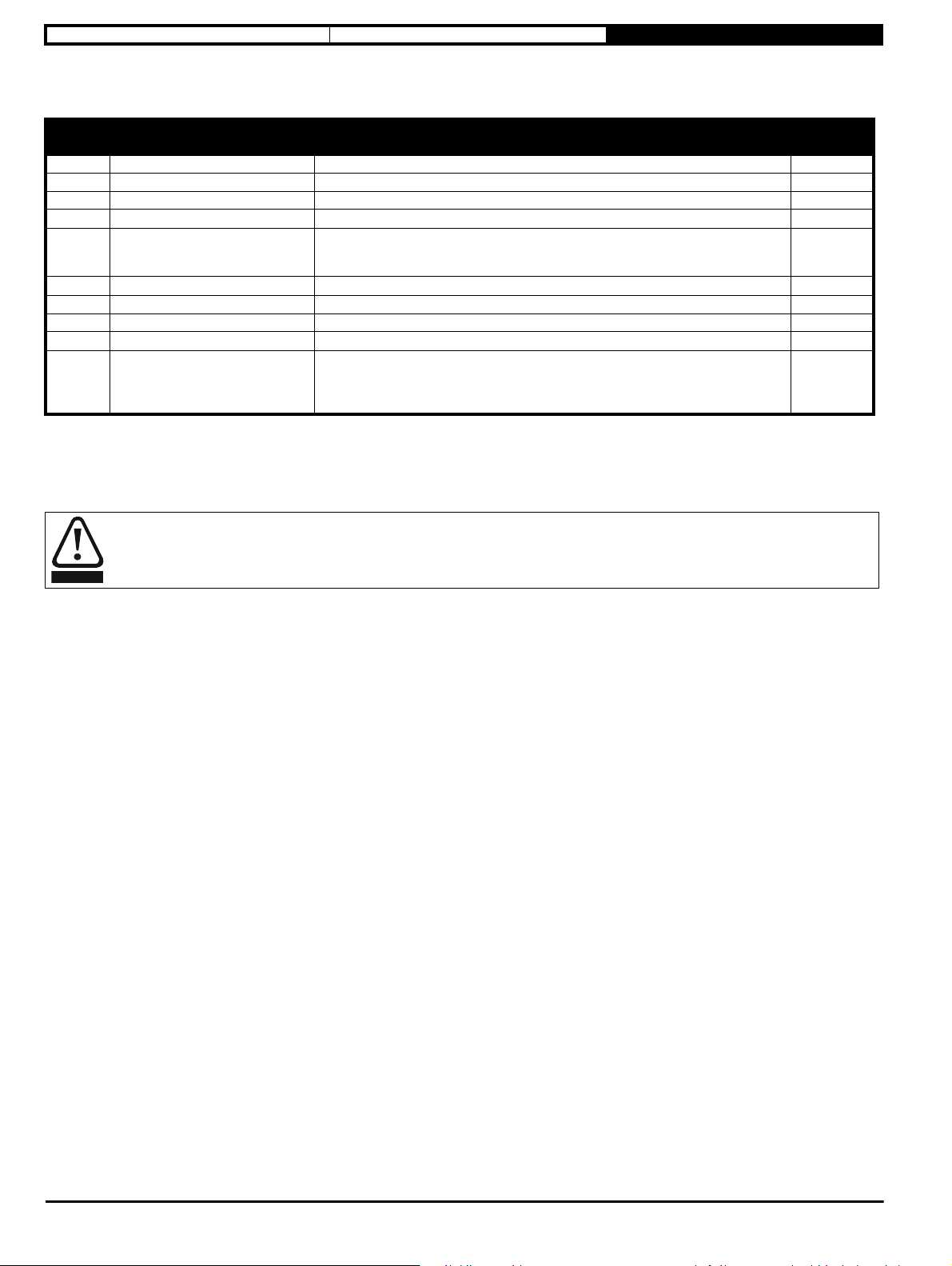

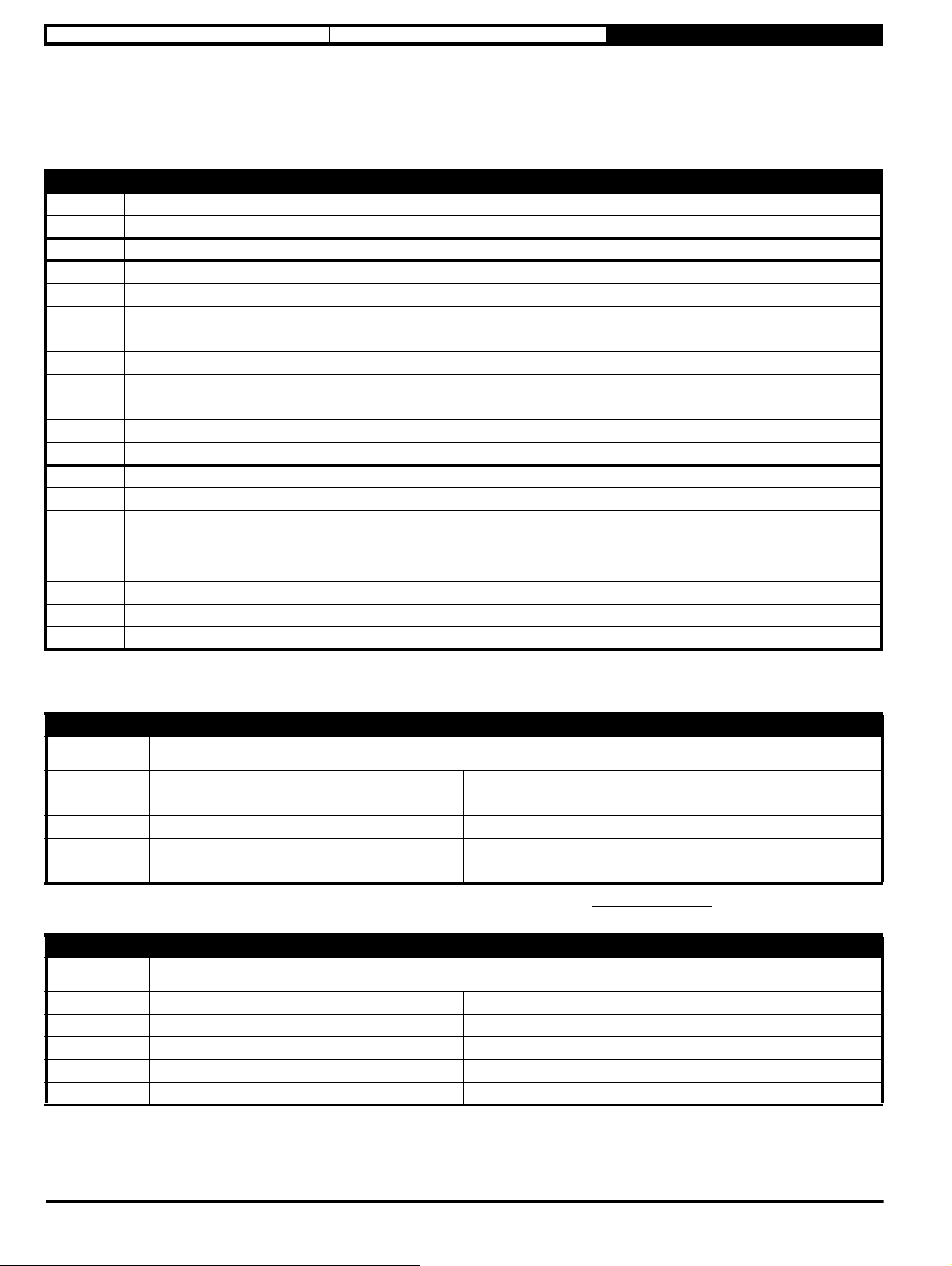

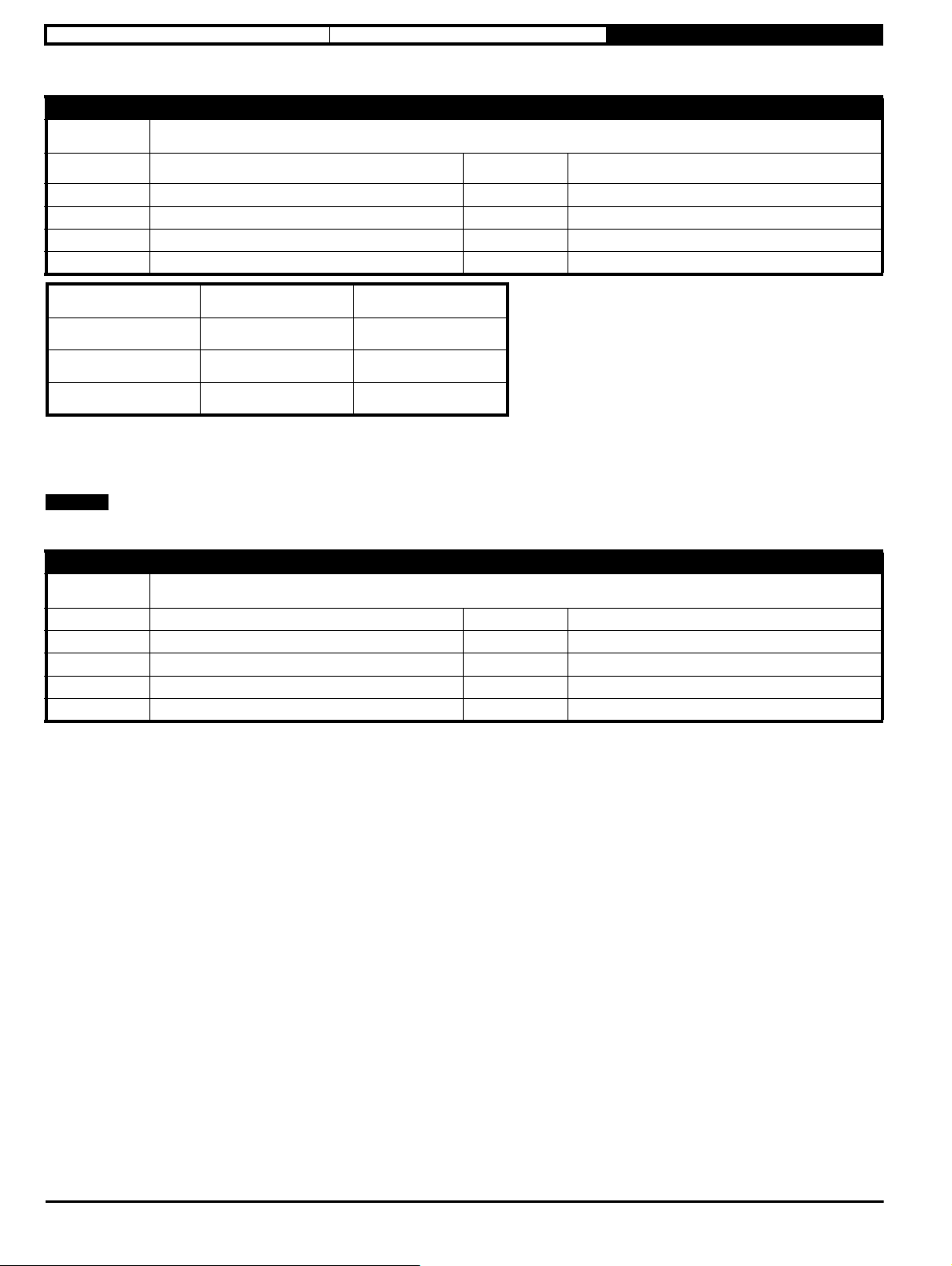

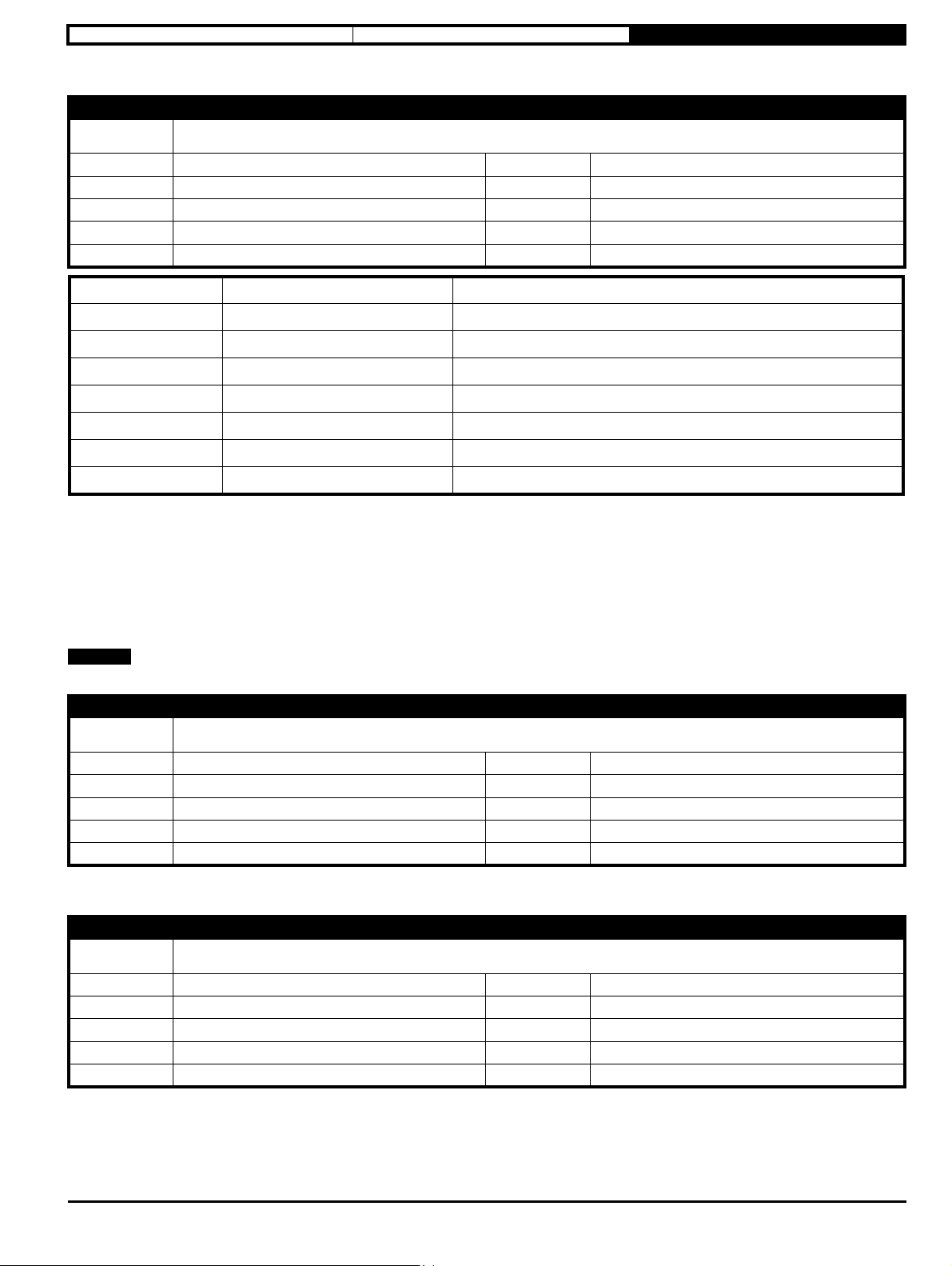

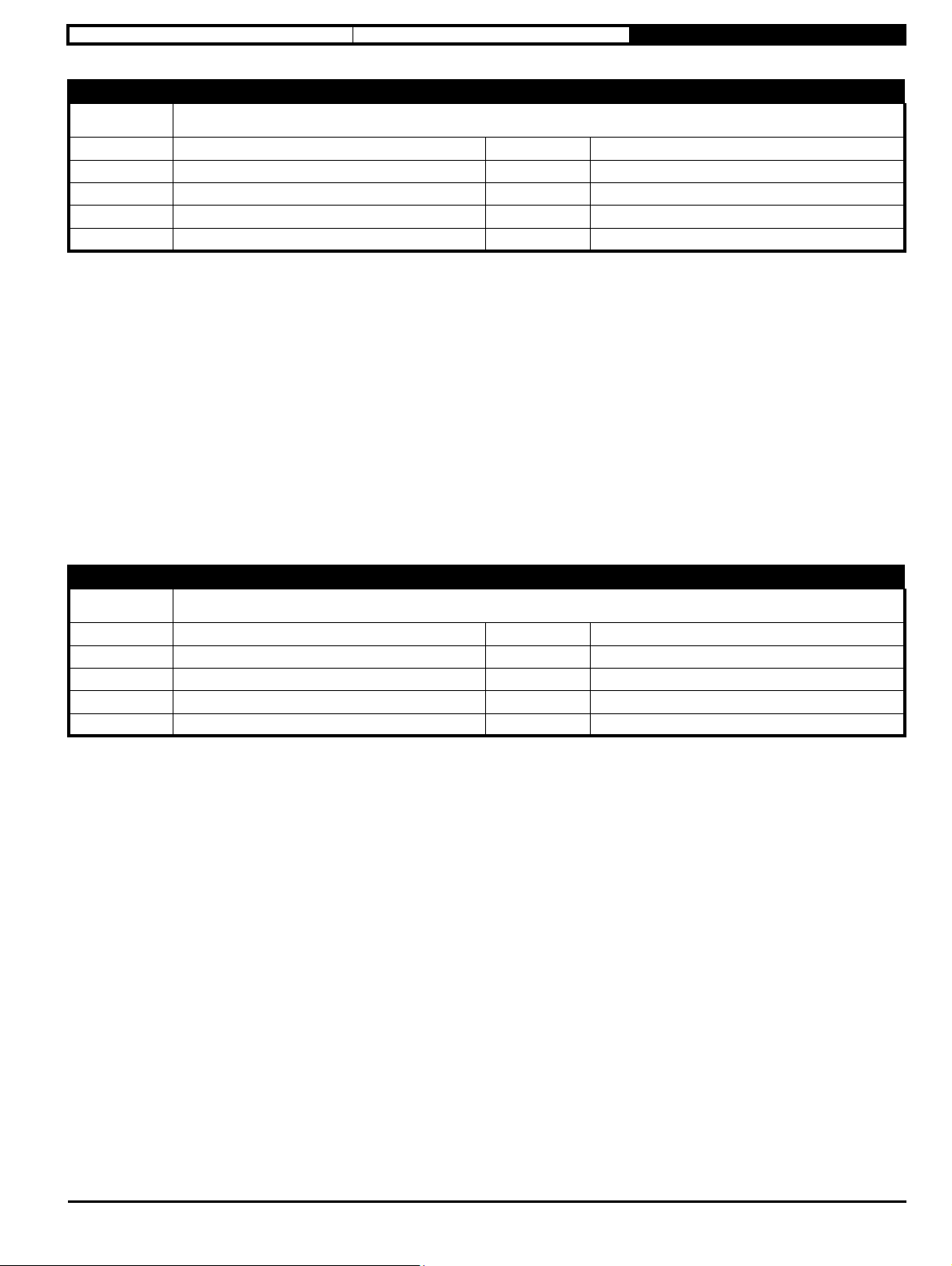

3.2 Menu 0 - Quick Start

For a description of a parameter in menu 0, refer to the alternative location of the parameter in the section 7.4 Parameter Descriptions.

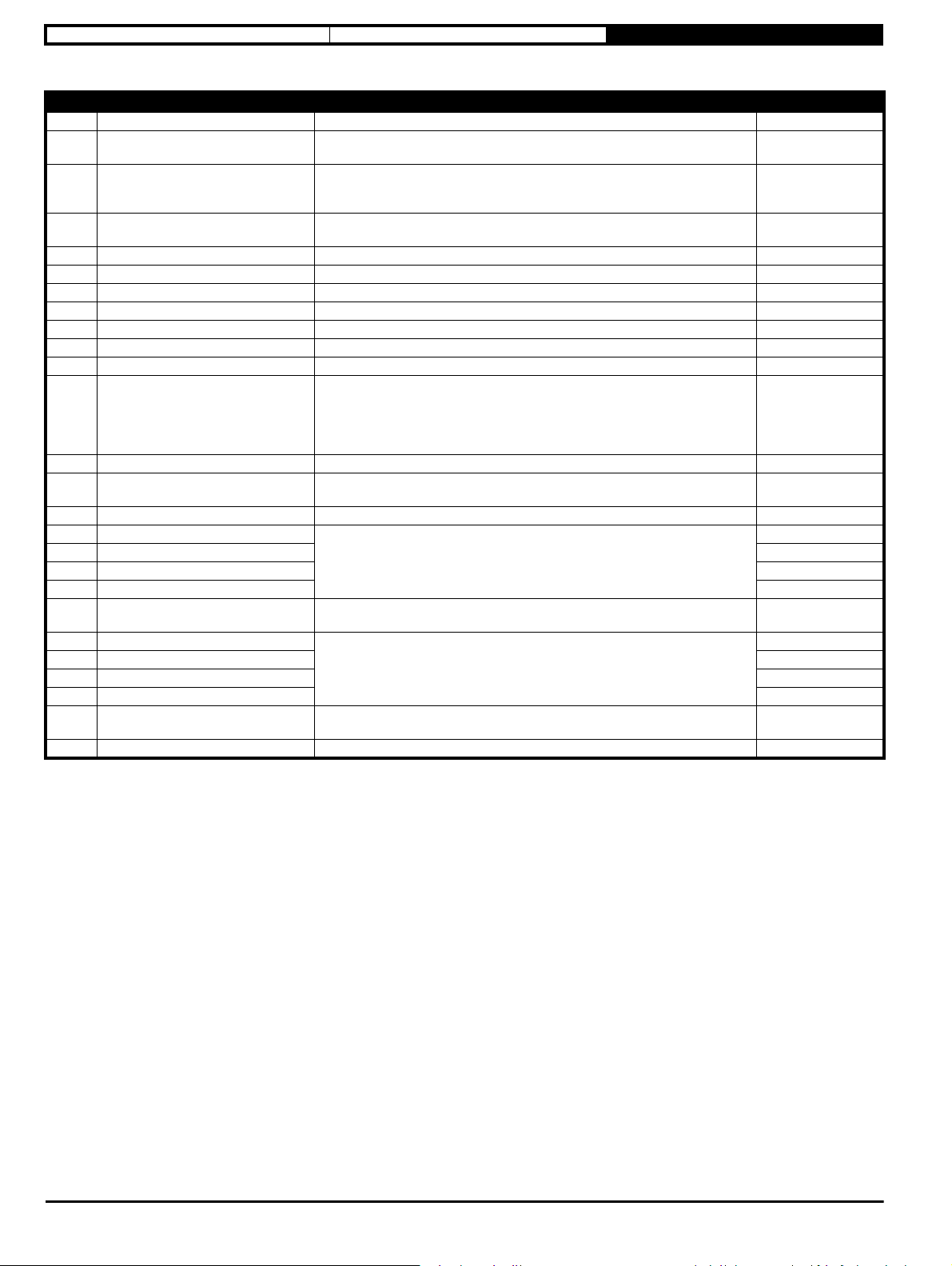

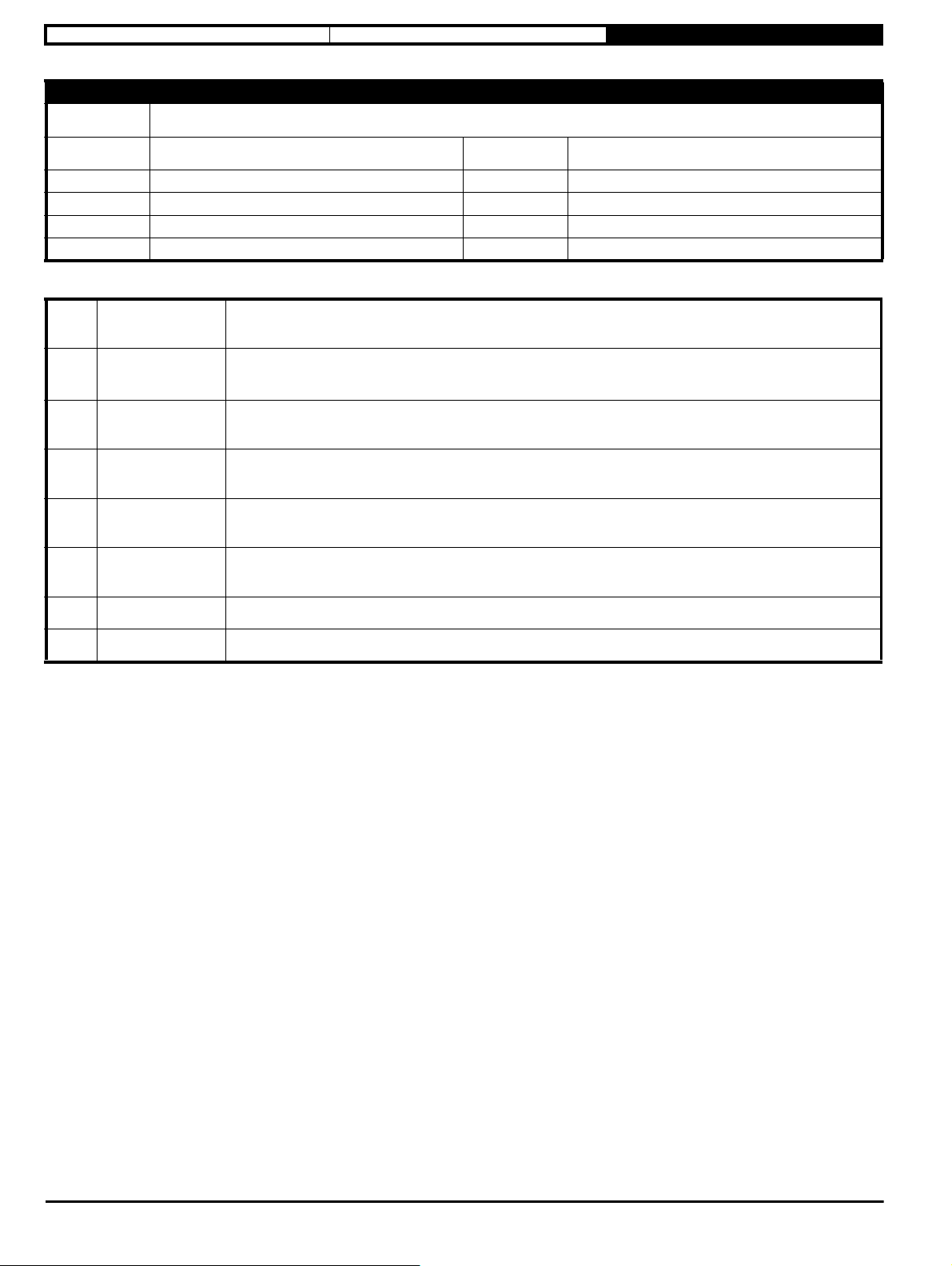

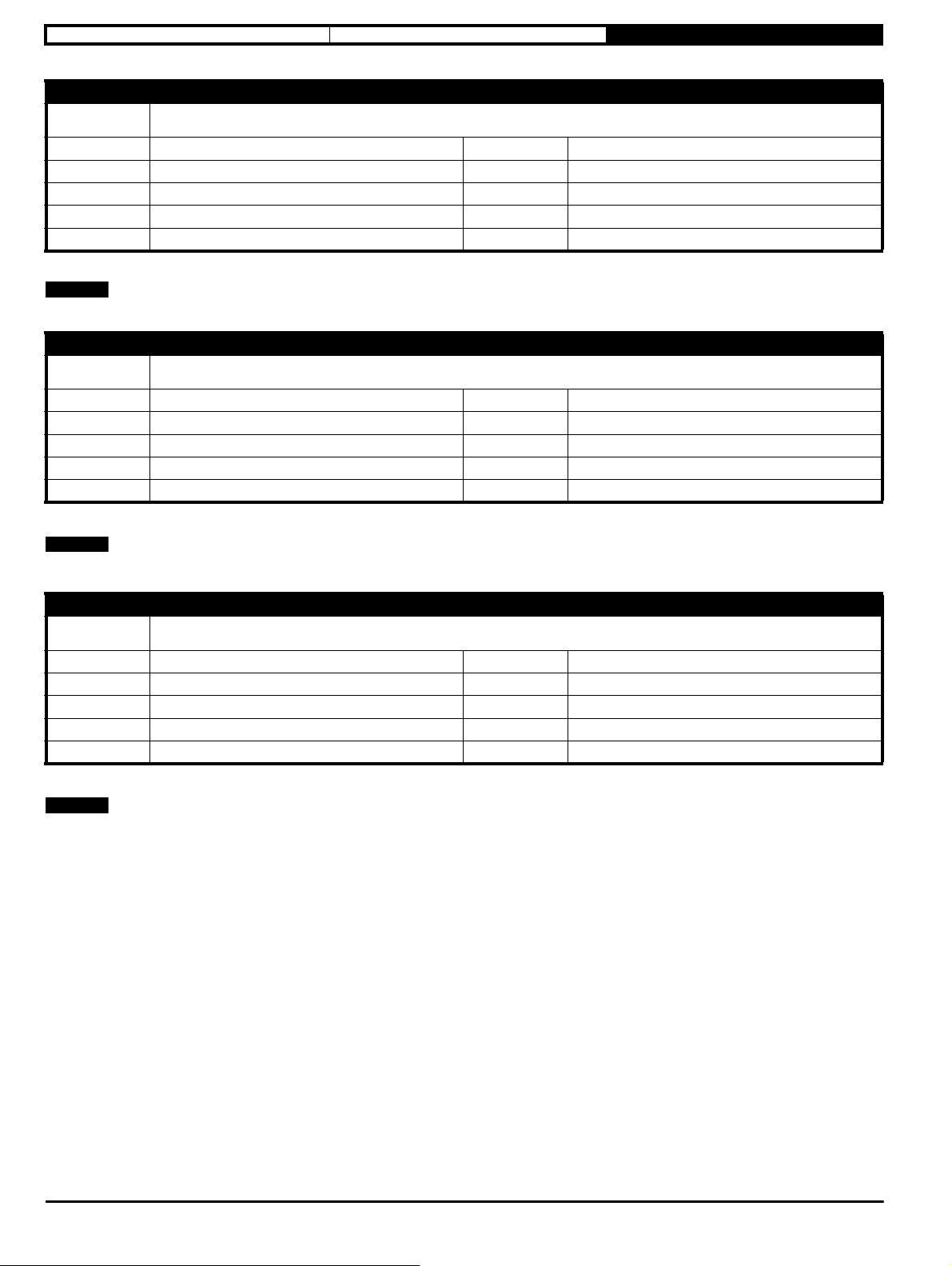

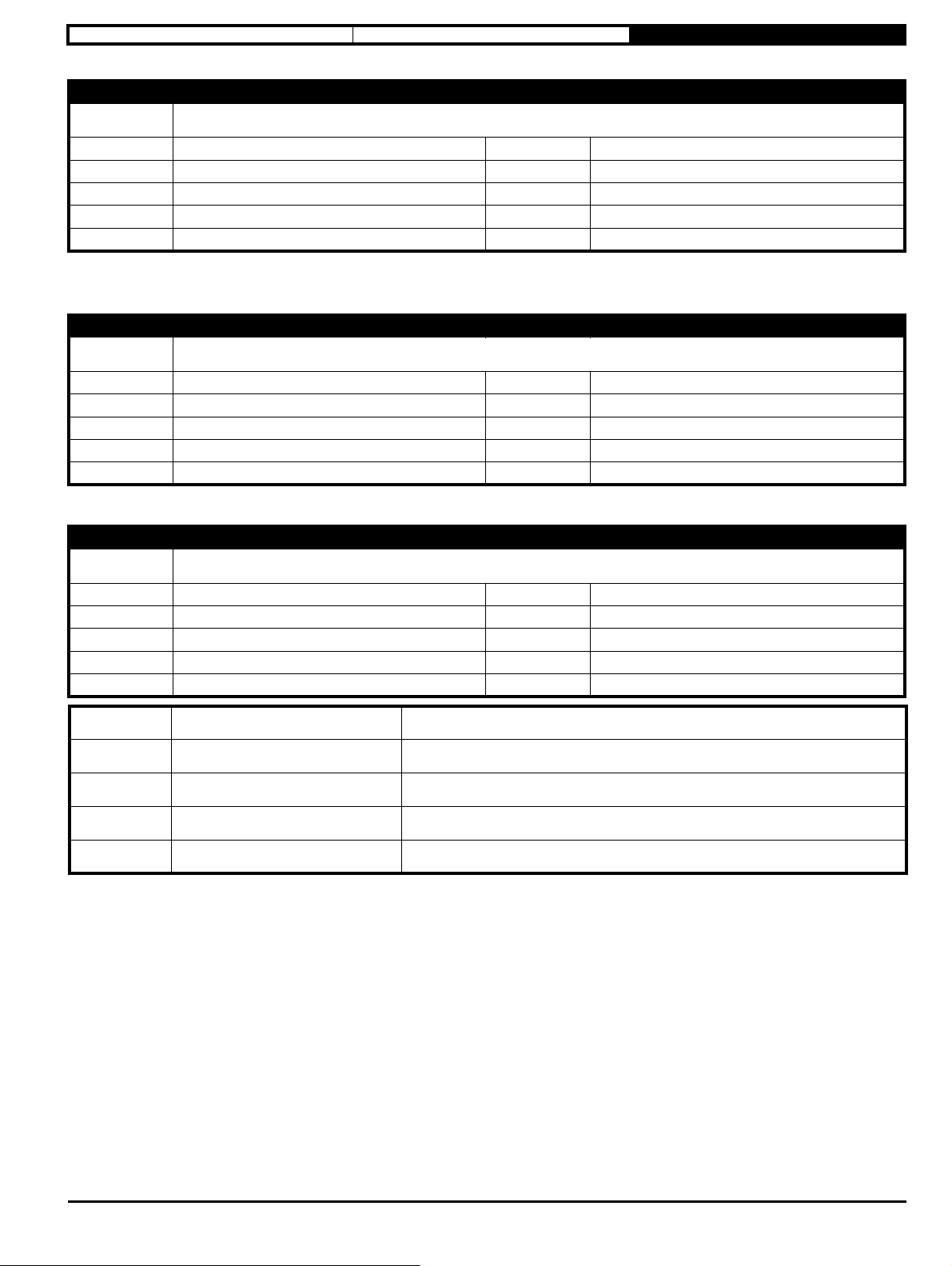

Parameter

P0.01 Minimum Frequency Clamp 0.0 to 300.0 Hz (50 Hz: -50.0 Hz, 60 Hz: -60.0 Hz) P2.01

P0.02 Maximum Frequency Clamp 0.0 to 300.0 Hz (50 Hz: 50.0 Hz, 60 Hz: 60.0 Hz) P2.02

P0.03 Acceleration Rate 1 0.0 to 6000.0 s/Hz(max) (5.0 s/Hz(max)) P2.07

P0.04 Deceleration Rate 1 0.0 to 6000.0 s/Hz(max) (10.0 s/Hz(max)) P2.08

P0.05 Frequency Reference Configuration

P0.06 Motor Rated Current 0.00 to Drive Rated Current A (Rating Dependent) P3.01

P0.07 Motor Rated Speed 0 to 18000 rpm (50 Hz: 1500 rpm, 60 Hz: 1800 rpm) P3.02

P0.08 Motor Rated Voltage 0 to Drive Rated Voltage (Rating Dependent) P3.03

P0.09 Motor Rated Power Factor 0.00 to 1.00 (0.80) P3.04

P0.10 Run/Stop Configuration

Range (Default)

Custom (0), Local/Remote (1), Voltage/Preset Input (2), Current/Preset Input (3),

Presets (4), Keypad (5), Terminal Up/Down (6), Frequency Input (7),

PID Voltage Ref. (8), PID + Feed Forward (9)

Custom (0), Enable + Run Forward + Run Reverse (1), Run Forward + Run Reverse

(3 Wire) (2), Enable + Run + Reverse (3), Run + Reverse (4), Run + Jog (5), Run

Forward + Run Reverse (6), Run + Reverse (7), Keypad (8), Keypad With Enable (9),

Keypad Jog (10)

Alternative

Location

P2.03

P6.13

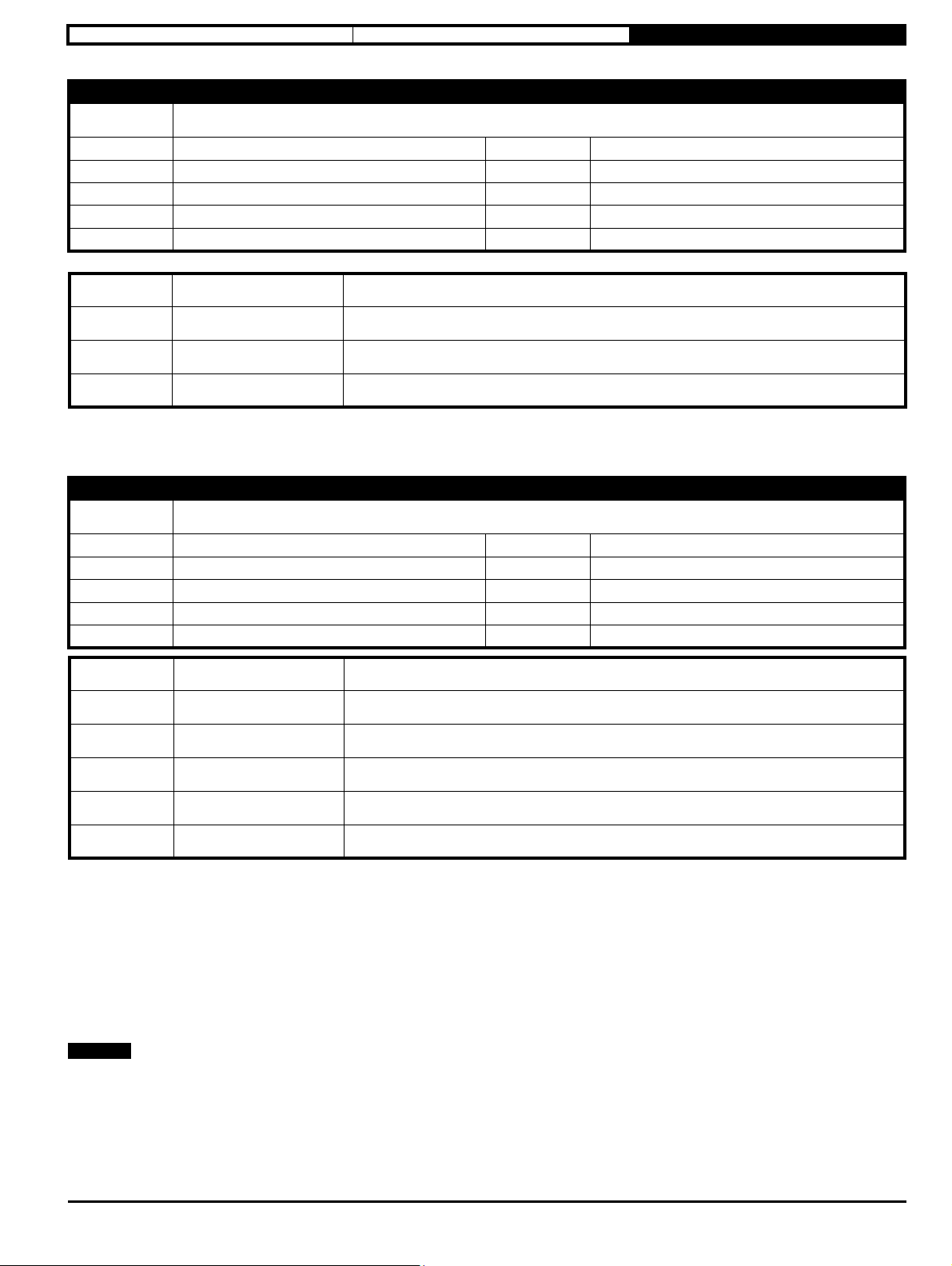

3.3 Full Parameter List

The list below contains all parameters within the drive and states the possible settings of the parameter with the default value outlined in bold where

applicable. For further description of the parameters refer to section 7.4 Parameter Descriptions or the help within the Marshal App that contain useful

graphics.

The lists in this table are for reference only and do not include sufficient information for adjusting these parameters. Incorrect

adjustment can affect the safety of the system and damage the drive and or external equipment. Before attempting to adjust any

of these parameters, refer to section 7.4 Parameter Descriptions.

10 Commander S100 USer Guide

Page 11

Safety information Electrical installation Drive Parameters

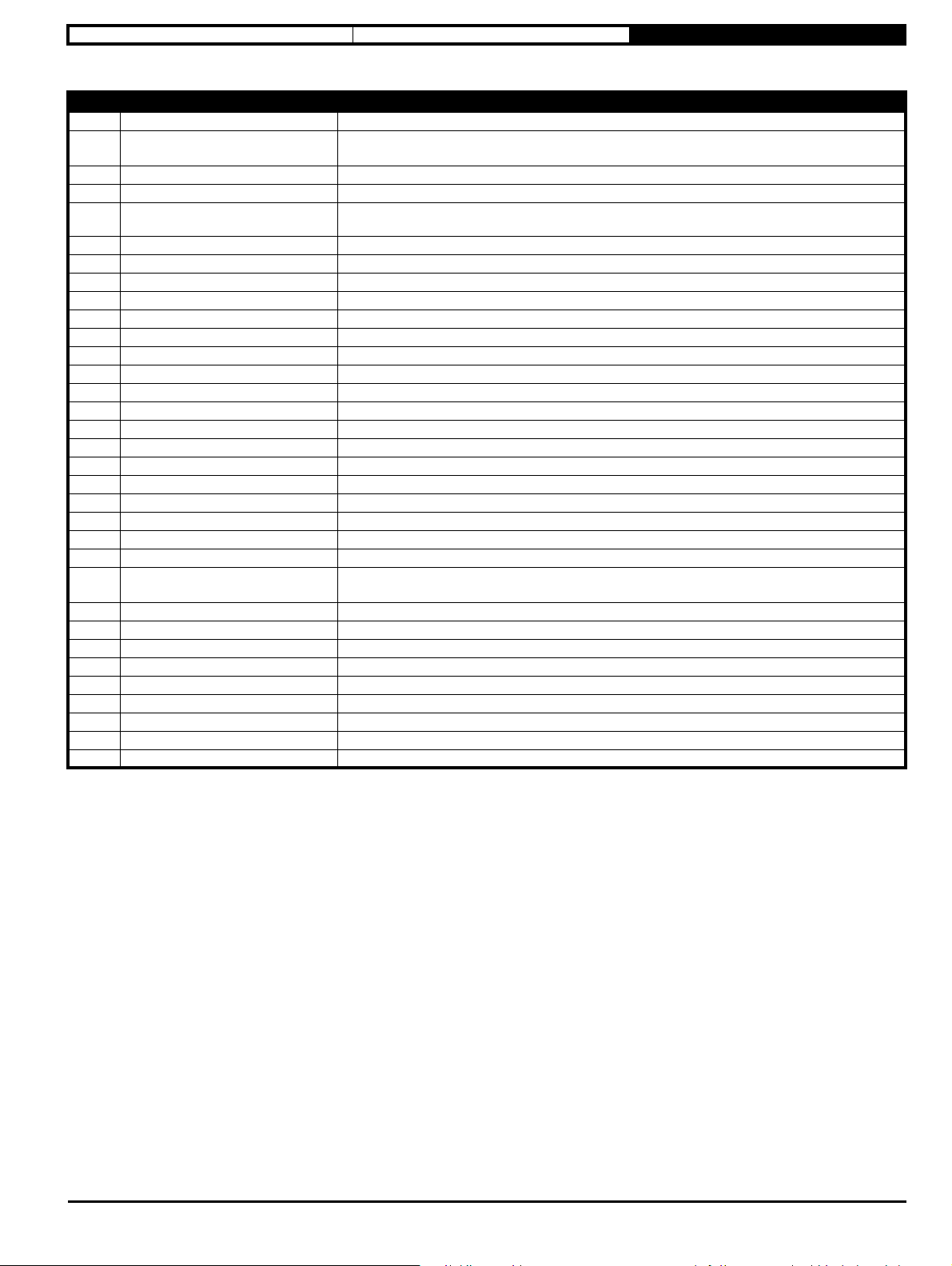

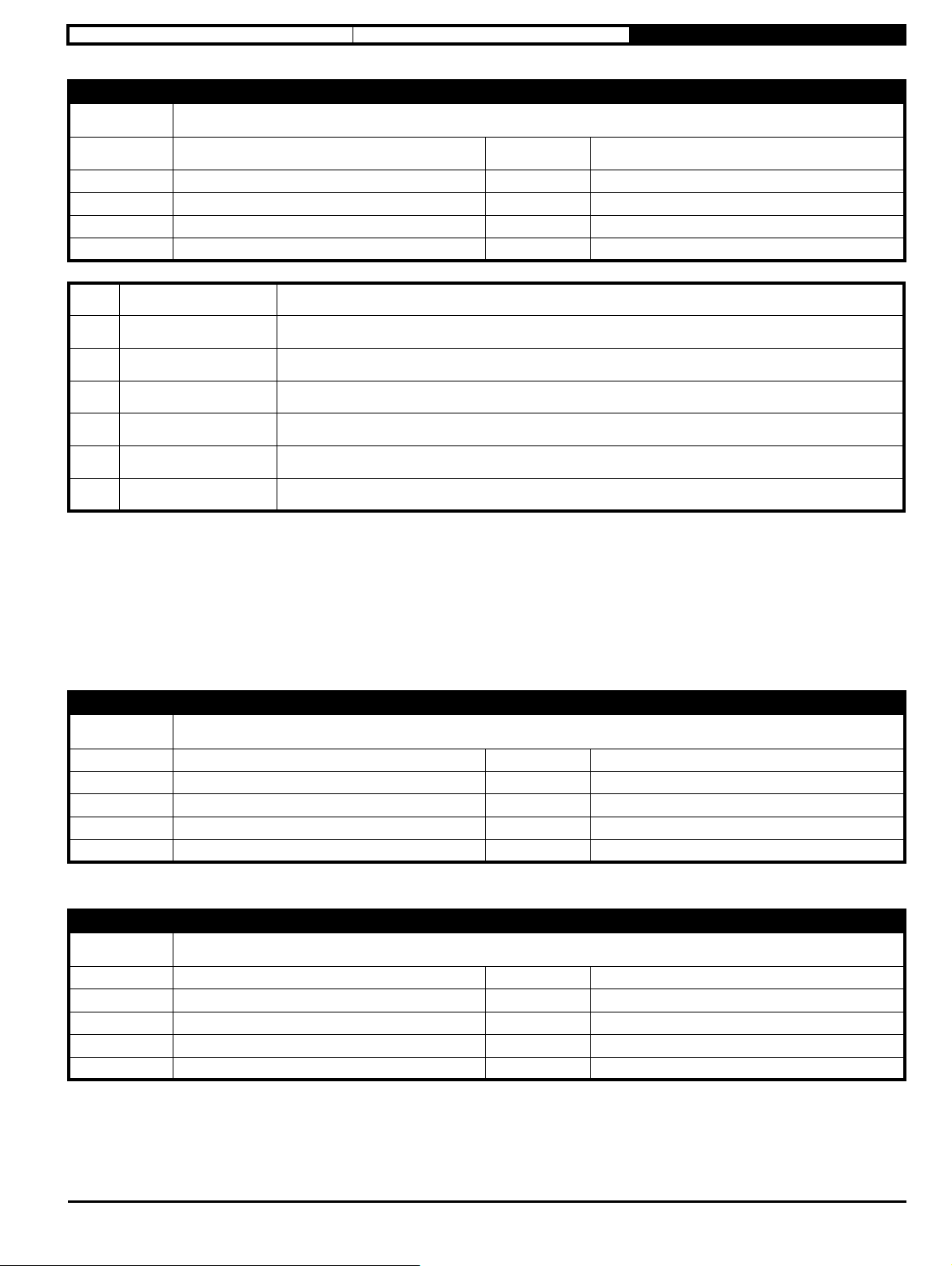

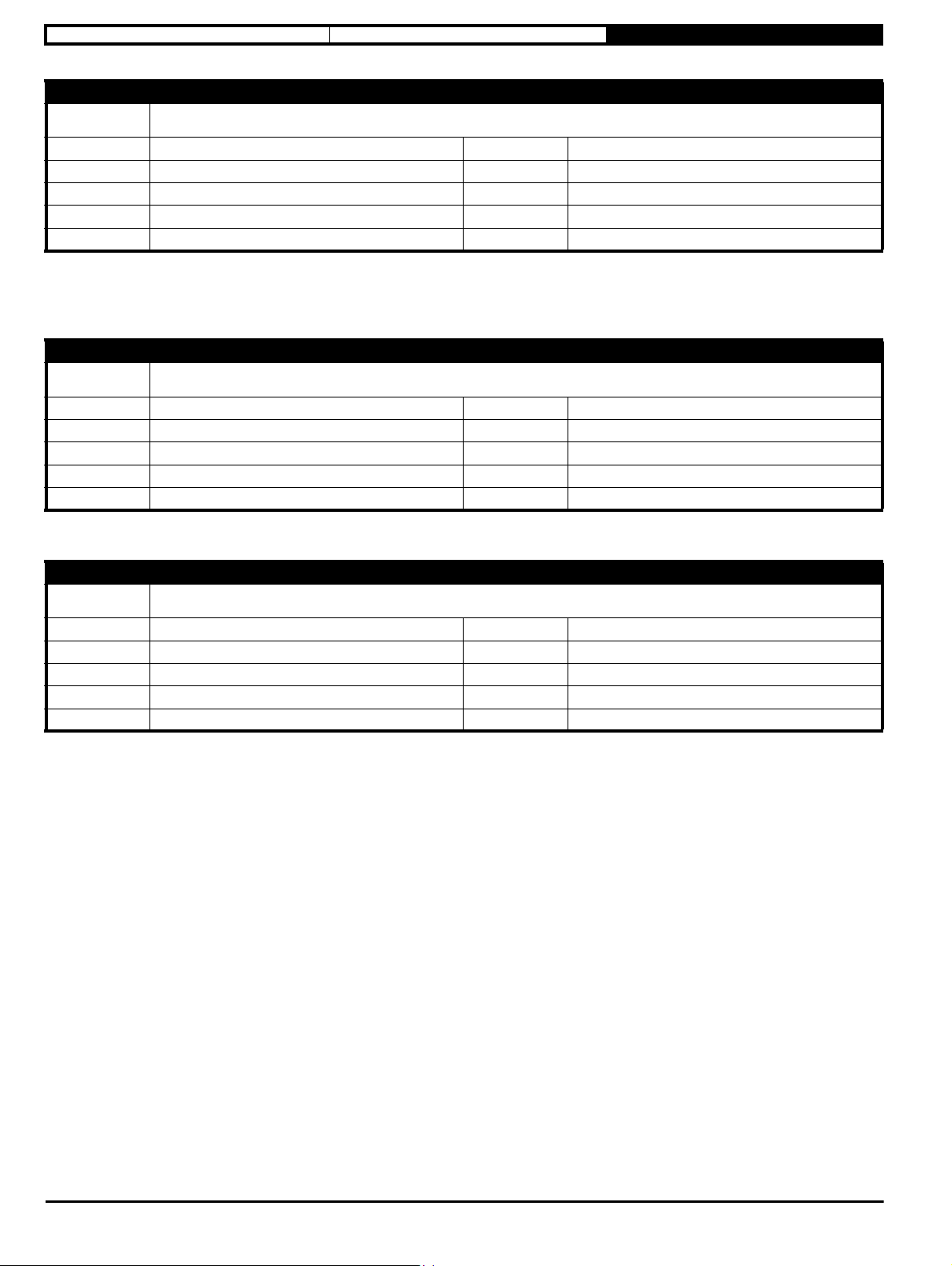

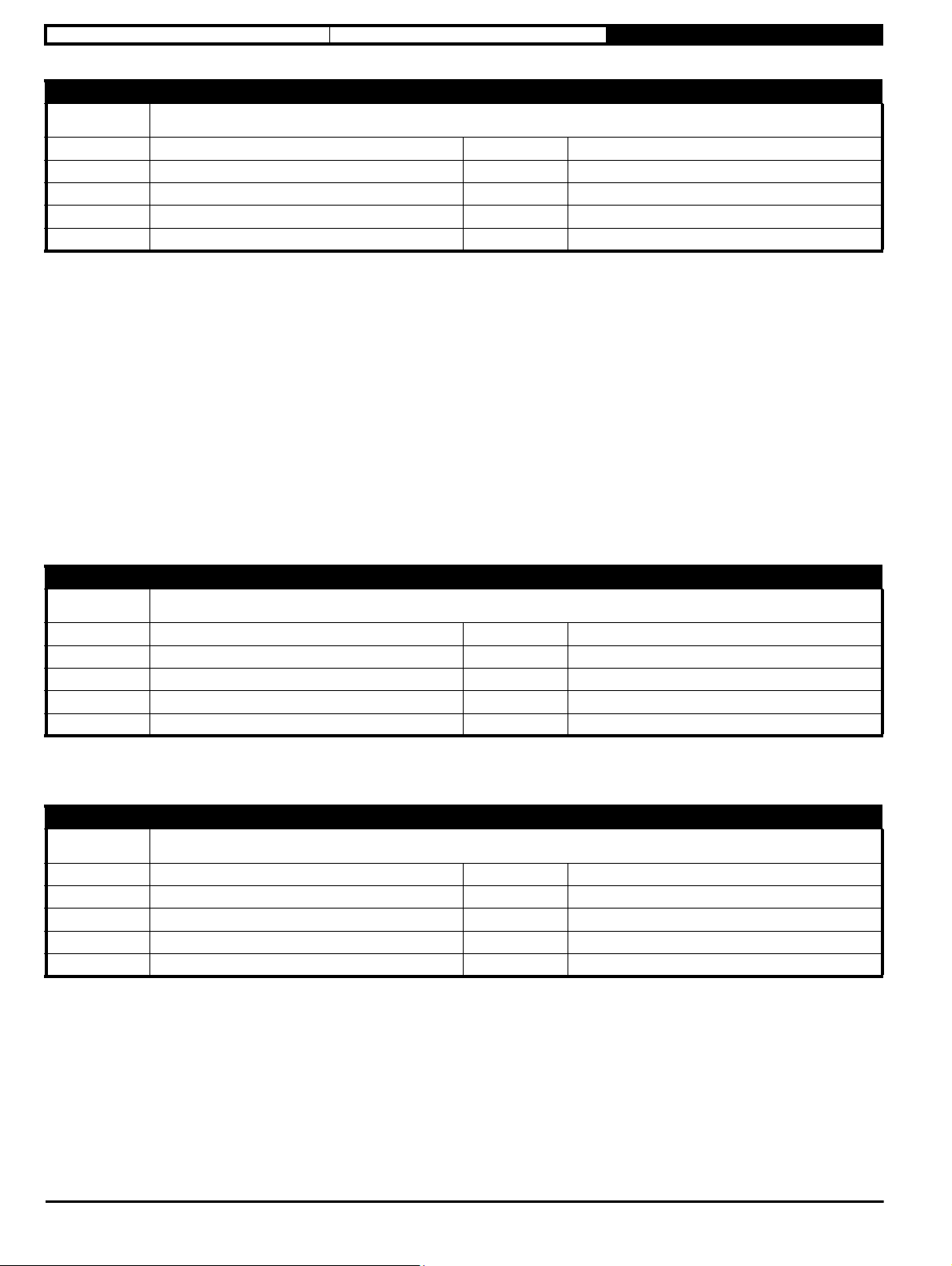

3.4 Menu 1 - Status & Monitoring

Parameter

P1.01 Output Frequency - Maximum Frequency Reference (P2.02) to Maximum Frequency Reference (P2.02) Hz

Output Voltage

P1.02

P1.03 Output Power Drive Rating Dependent kW

P1.04 Motor RPM ±18000 rpm

P1.05 Drive State

P1.06 Output Current - Drive Rated Current to Drive Rated Current A

P1.07 Torque Producing Current - Drive Rated Current to Drive Rated Current A

P1.08 Percentage Load - Motor Output Current Limit (Max) to Motor Output Current Limit (Max) %

P1.09 Alarm Indicators 00000000 to 11111111

P1.10 Drive Status Indicators 00000000 to 11111111

P1.11 Sequencer Input and Output Indicators 00000000 to 11111111

P1.12 Run & Direction Indicators 00000000 to 11111111

P1.13 Ramp Input ± Maximum Frequency Reference (P2.02) Hz

P1.14 Ramp Output ± Maximum Frequency Reference (P2.02) Hz

P1.15 T2 Analog Input 1 Percentage ±100.00 %

P1.16 T4 Analog Input 2 Percentage ±100.00 %

P1.17 T15 Frequency Input Percentage ±100.00 %

P1.18 Up/Down Percentage 0.00 to 100.00 %

P1.19 PID Percentage ±100.00 %

P1.20 PID Status Indicators 00000000 to 11111111

P1.21 PID Error ±100.00 %

P1.22 Motor Thermal Percentage 0 to 100 %

P1.23 Drive Thermal Percentage 0 to 100 %

P1.24 DC Bus Voltage

P1.25 Digital IO Indicators 00000000 to 11111111

P1.26 Parameter 1 Saved Value on Error -32768 to 32767

P1.27 Parameter 2 Saved Value on Error -32768 to 32767

P1.28 Parameter 3 Saved Value on Error -32768 to 32767

P1.29 Error 0to255

P1.30 Error History 1 0to255

P1.31 Error History 2 0to255

P1.32 Error History 3 0to255

P1.33 Drive Diagnostic 0to15

Inhibited (0), Ready (1), NA (2), NA (3), Running (4), Supply Loss (5), Deceleration (6), Injecting DC (7),

NA (8), Error (9), NA (10), NA (11), NA (12), NA (13), NA (14), Under Voltage (15)

(110 V, 200 V Drives = 240 V, 400 V Drives = 480 V)

(110 V, 200 V Drives = 415 V, 400 V Drives = 830 V)

0 to Maximum Output Voltage V

0 to Maximum D.C. Link Voltage V

Range

Commander S100 User Guide 11

Page 12

Safety information Electrical installation Drive Parameters

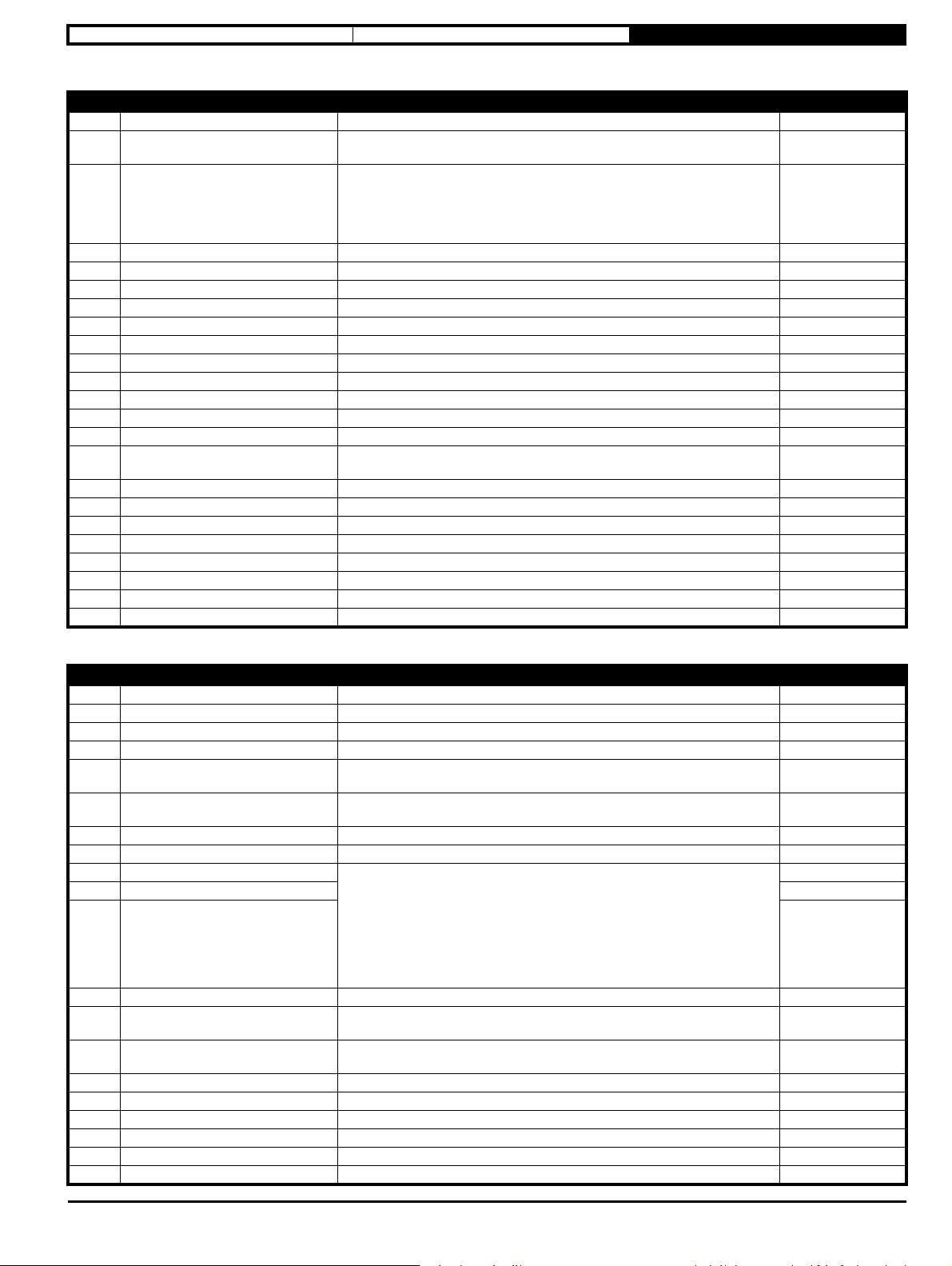

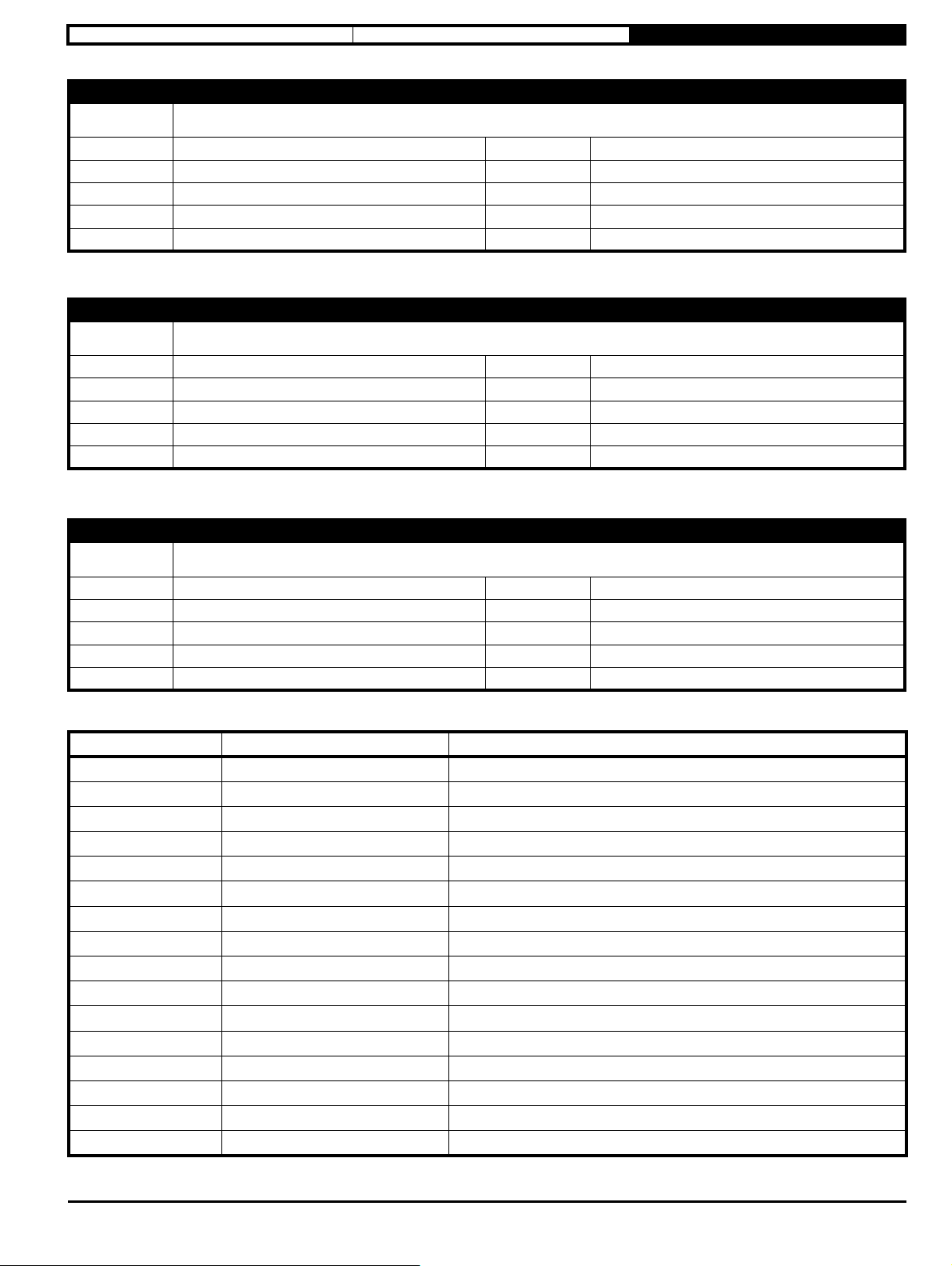

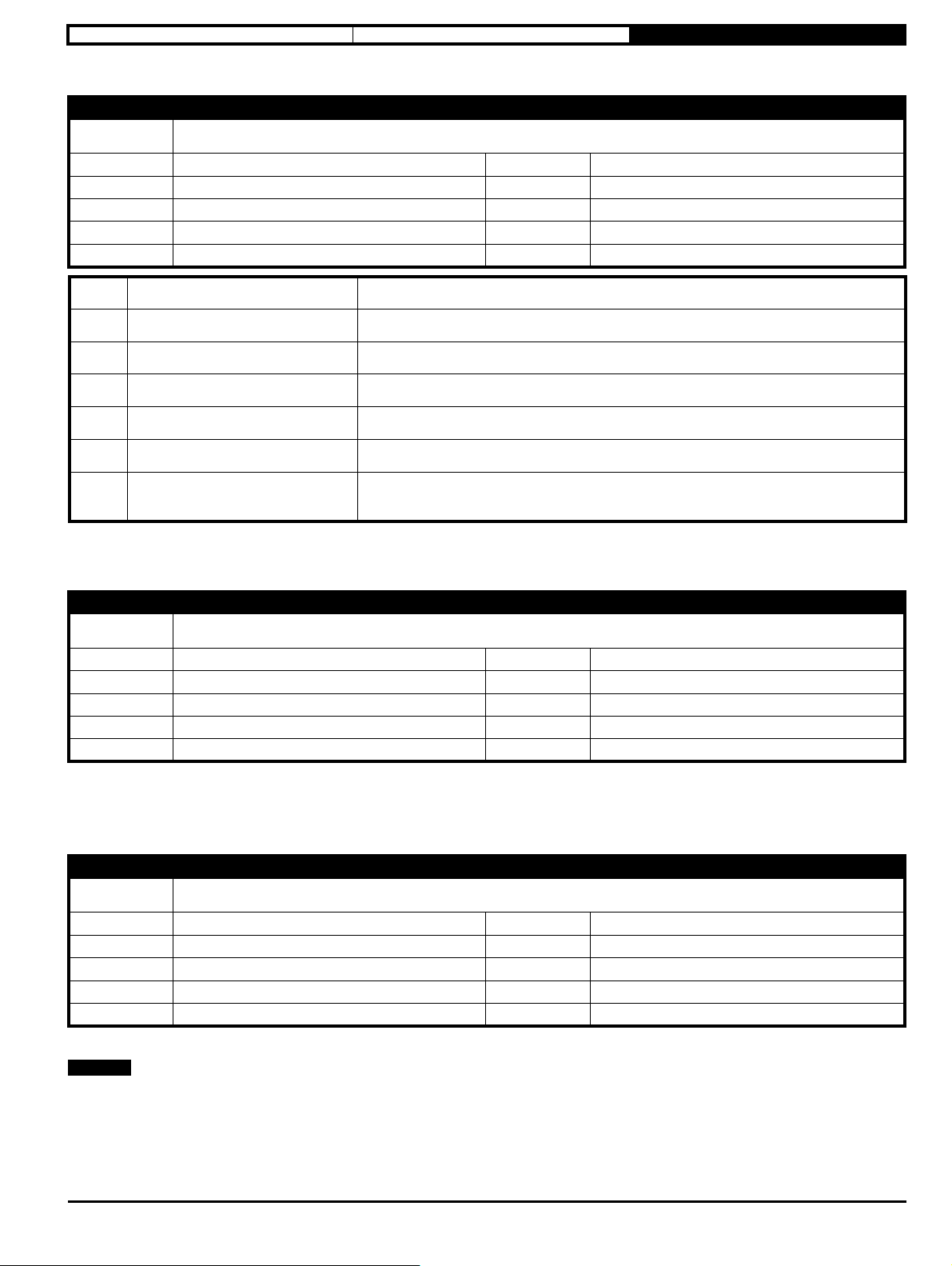

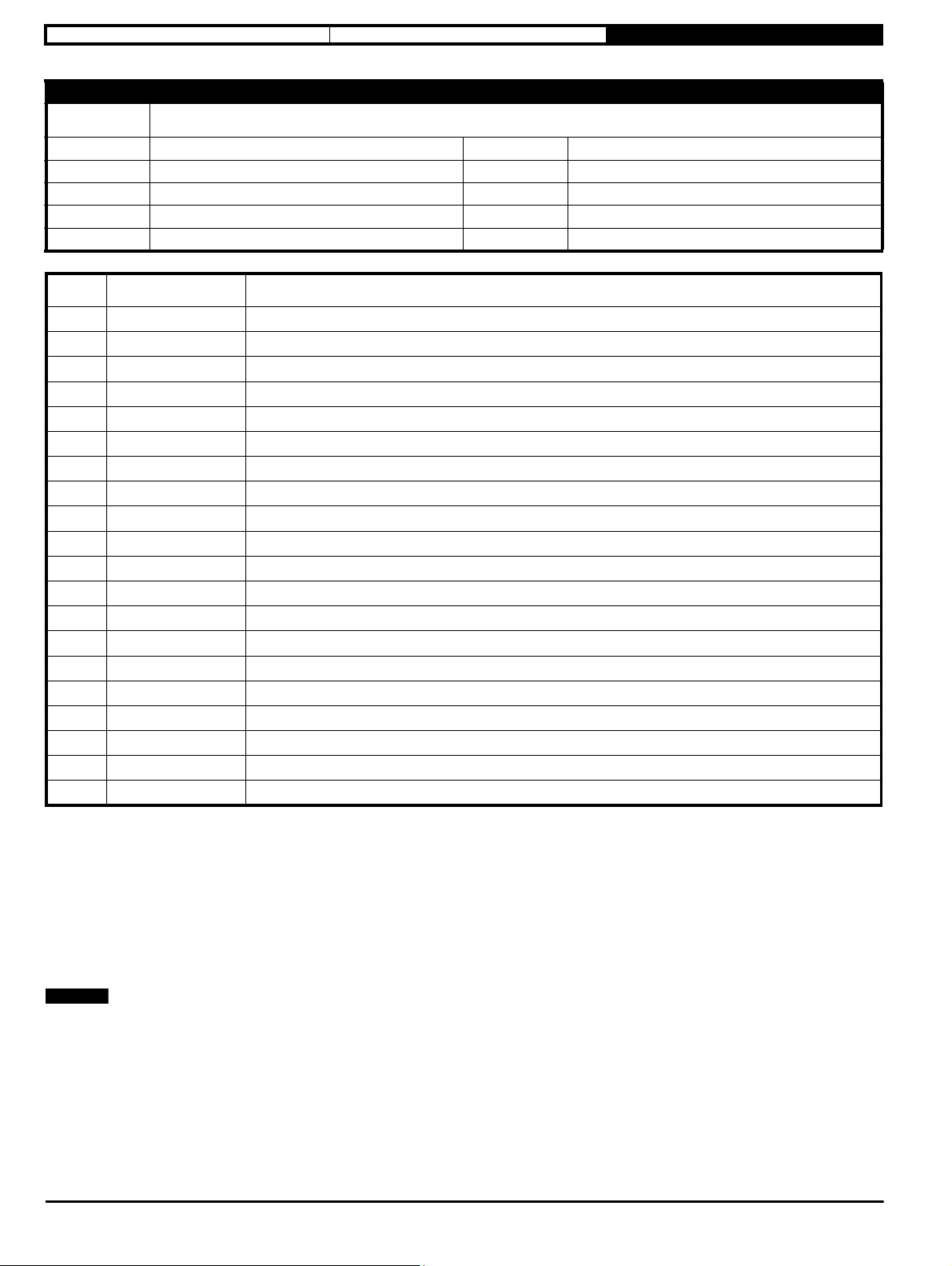

3.5 Menu 2 - Reference & Ramps

Parameter

P2.01 Minimum Frequency Limit 0.0 to 300.0 Hz 0.0 Hz

Maximum Frequency Limit

P2.02

P2.03 Frequency Reference Configuration

P2.04 Stopping Mode Selector

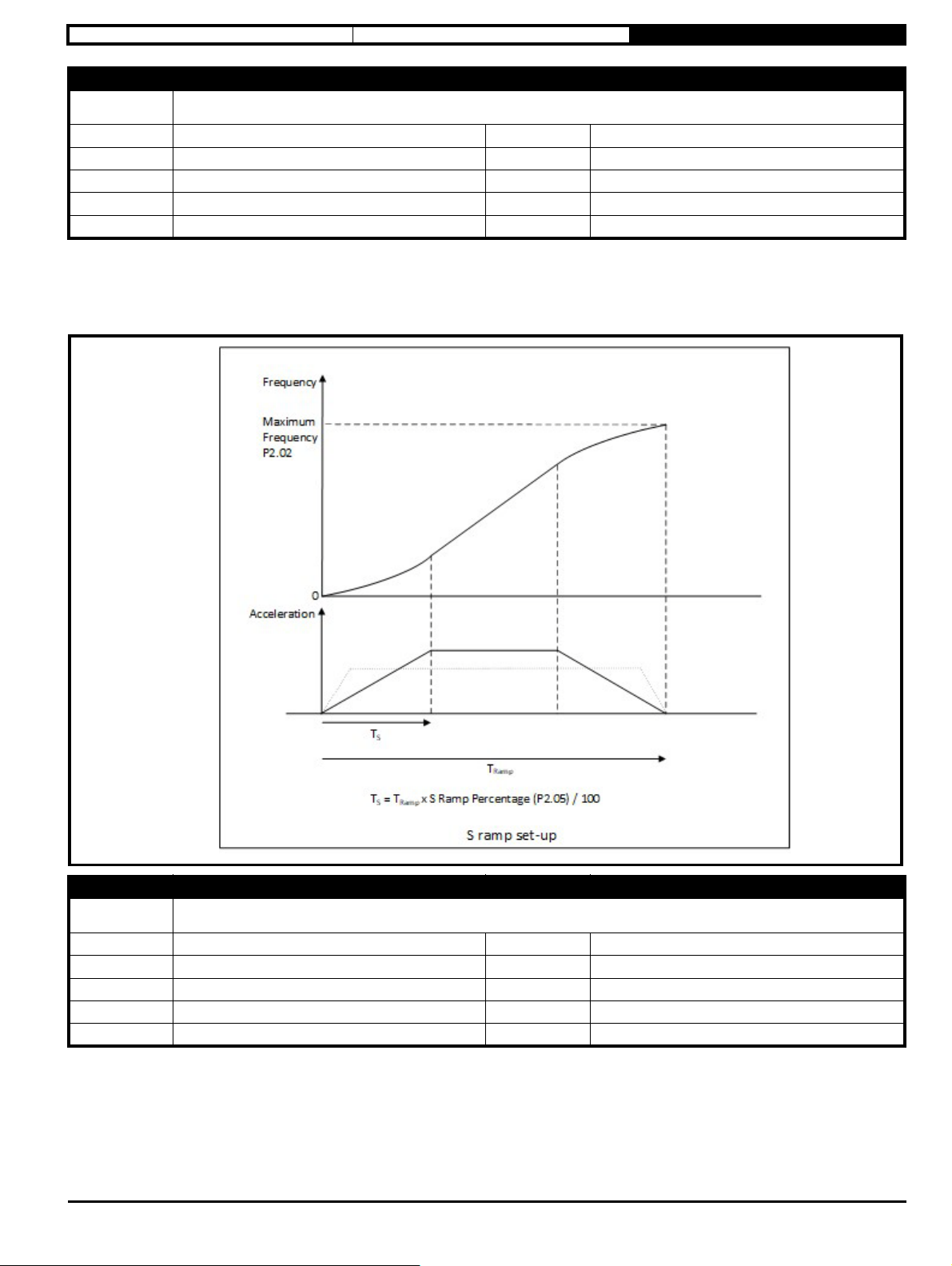

P2.05 S-Ramp Percentage 0.0 to 50.0 0.0

P2.06 Acceleration Rate 1 0.0 to 6000.0 s 5.0 s

P2.07 Deceleration Rate 1 0.0 to 6000.0 s 10.0 s

P2.08 Acceleration Rate 2 0.0 to 6000.0 s 5.0 s

P2.09 Deceleration Rate 2 0.0 to 6000.0 s 10.0 s

P2.10 Ramp Rate Selector 0 to 2 0

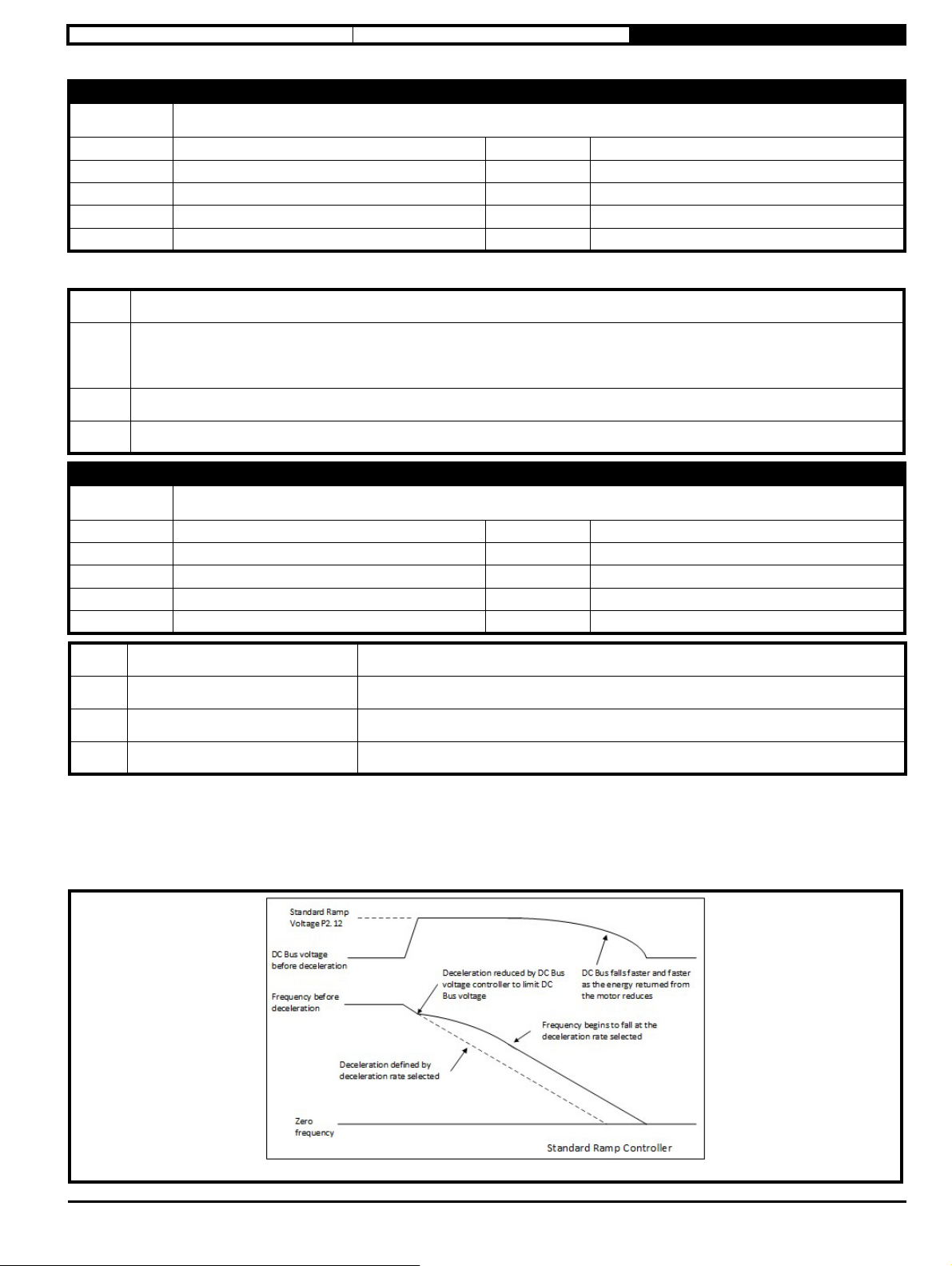

P2.11 Deceleration Ramp Type Fast (0), Standard Ramp (1), Standard Ramp + Motor (2) Standard Ramp (1)

P2.12 Standard Ramp Voltage 0 to DC Link Voltage (Max) V

P2.13 Jog Frequency ± Maximum Frequency Reference (P2.02) Hz 1.5 Hz

P2.14 Up/Down Percent Configuration

P2.15 Up/Down Percentage Time to Max 0 to 250 s 20 s

P2.16 Preset Frequency 1

P2.17 Preset Frequency 2 10.0 Hz

P2.18 Preset Frequency 3 25.0 Hz

P2.19 Preset Frequency 4 50.0 Hz

P2.20 Frequency Reference 1 to 4 Selector

P2.21 Frequency Reference 1 Selector

P2.22 Frequency Reference 2 Selector Analog 2 Percent (7)

P2.23 Frequency Reference 3 Selector None (0)

P2.24 Frequency Reference 4 Selector None (0)

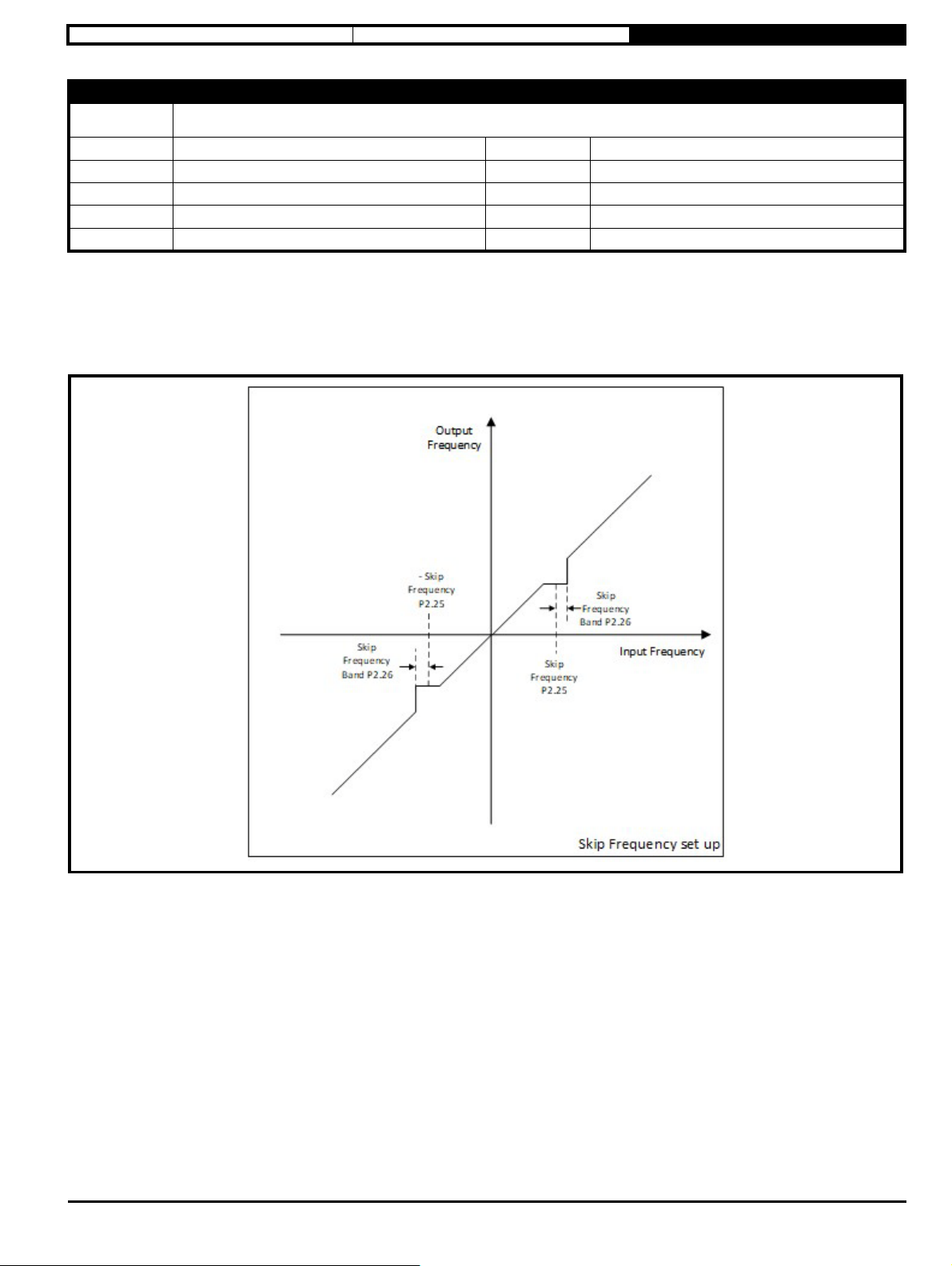

P2.25 Skip Frequency

P2.26 Skip Frequency Band 0.0 to 25.0 Hz 0.0 Hz

Custom (0), Local/Remote (1), Voltage/Preset Input (2), Current/Preset Input (3),

Presets (4), Keypad (5), Terminal Up/Down (6), Frequency Input (7),

PID Voltage Ref. (8), PID + Feed Forward (9)

Coast (0), Ramp (1), Ramp & Brake (2), DC Brake, 0Hz detect (3),

Reset (0), Last (1), Preset 1 (2), Keypad and Reset (3), Keypad and Last (4),

± Maximum Frequency Reference (P2.02) Hz

Binary (0), Freq. Reference 1 (1), Freq. Reference 2 (2), Freq. Reference 3 (3),

None (0), Preset 1 (1), Preset 2 (2), Preset 3 (3), Preset 4 (4), Up/

Down Percent (5), Analog 1 Percent (6), Analog 2 Percent (7),

Frequency Input % (8), PID Percent (9)

- Maximum Frequency Reference (P2.02) to Maximum Frequency Reference

Range Default

0.0 to 300.0 Hz

Timed DC Brake (4)

Keypad and Preset 1 (5)

Freq. Reference 4 (4)

(P2.02) Hz

50Hz: 50.0 Hz

60Hz: 60.0 Hz

Local/Remote (1)

Ramp (1)

400V drive 50Hz: 375

V

400V drive: 750 V

400V drive 60Hz: 775

V

Reset (0)

5.0 Hz

Binary (0)

Analog 1 Percent (6)

0.0 Hz

12 Commander S100 USer Guide

Page 13

Safety information Electrical installation Drive Parameters

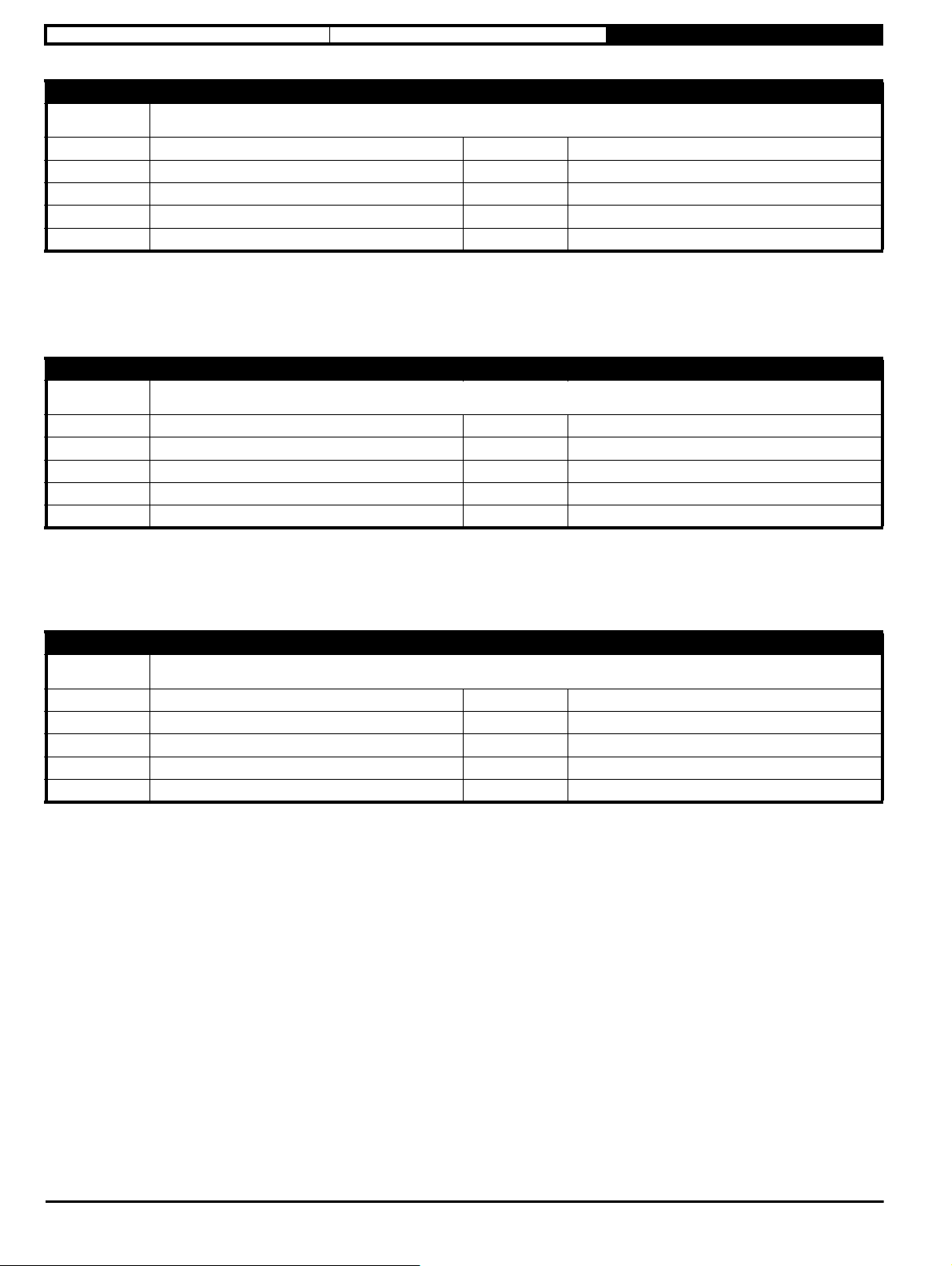

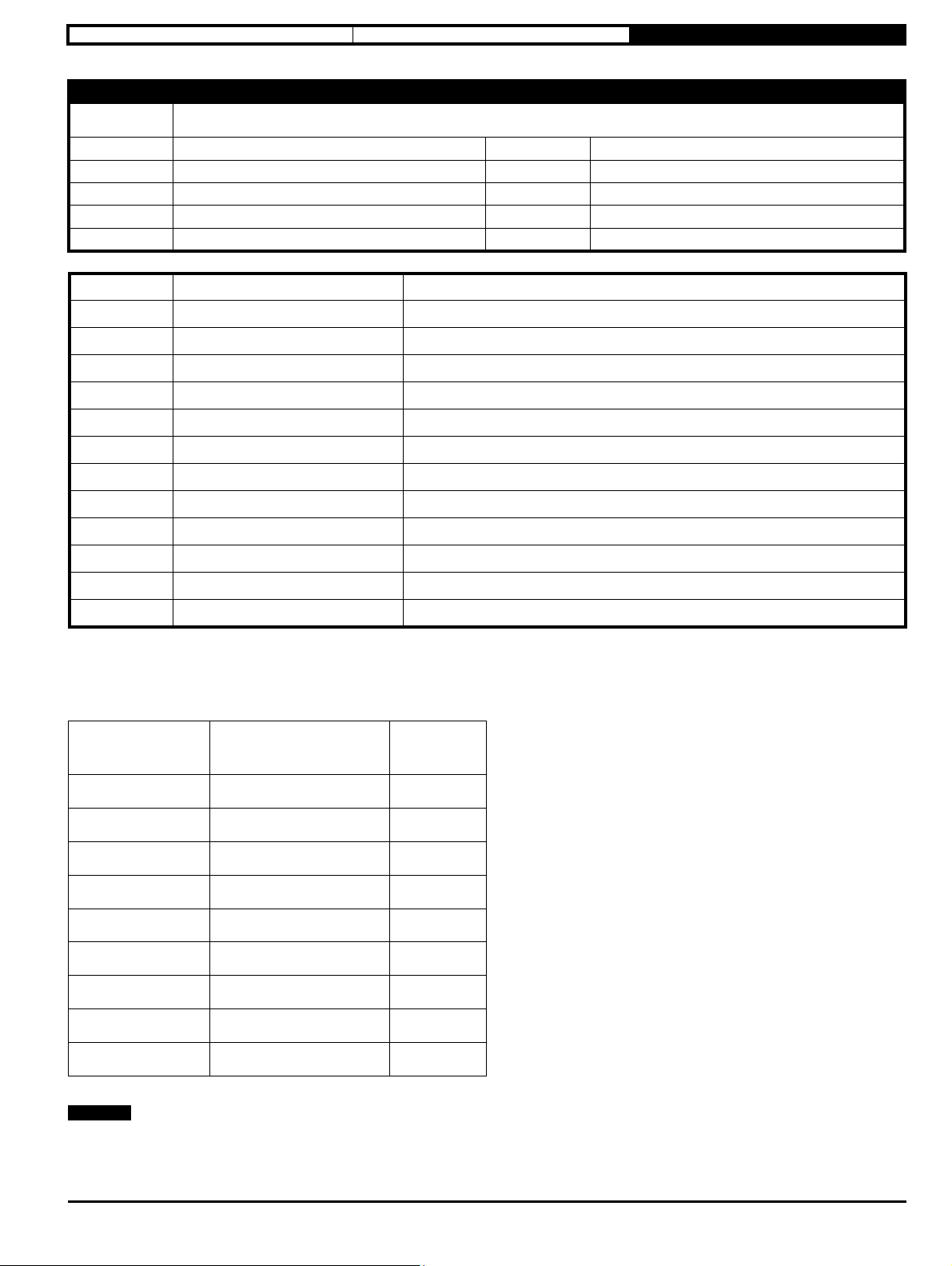

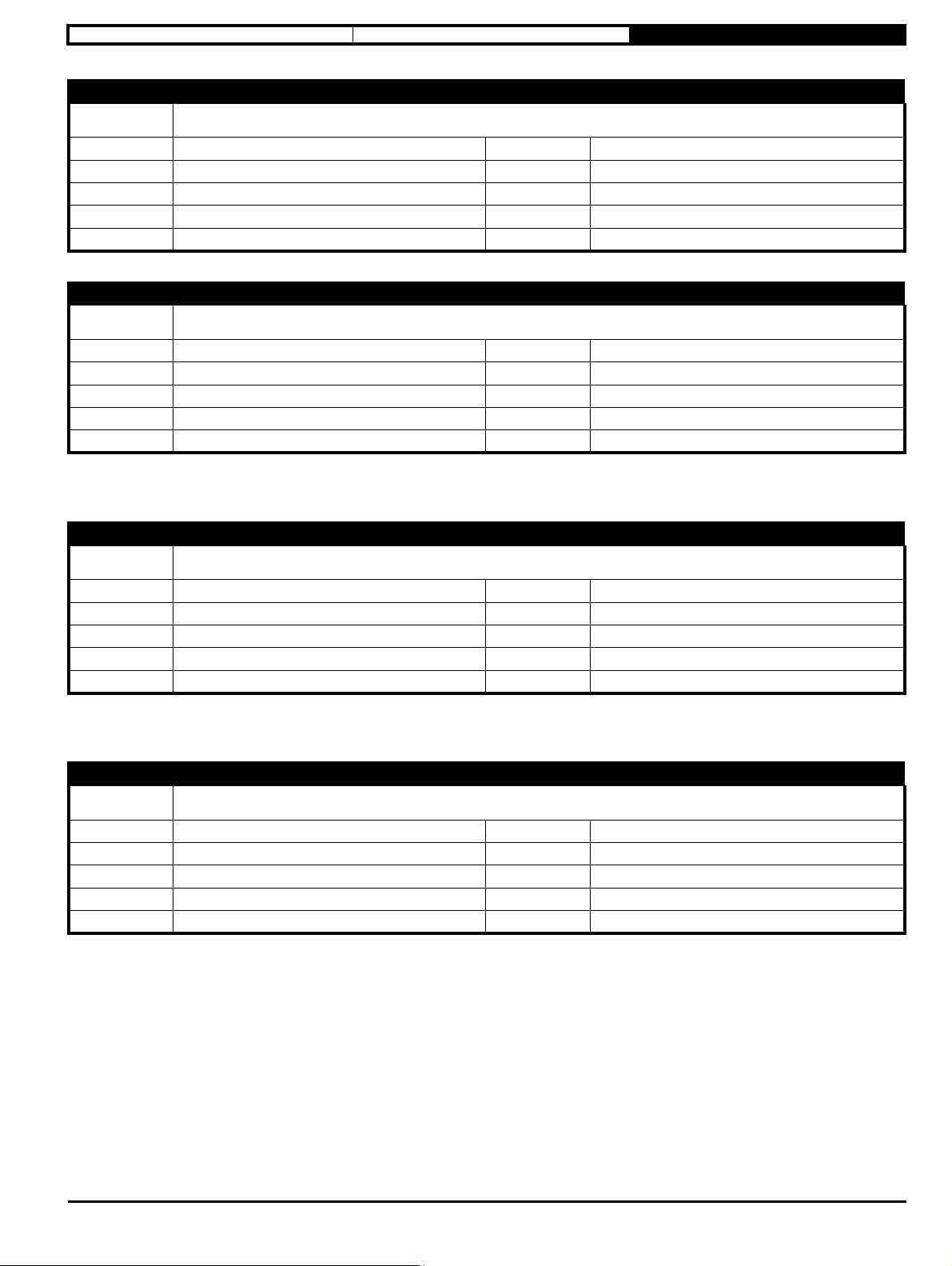

3.6 Menu 3 – Motor Setup

Parameter

P3.01 Motor Rated Current VM_RATED_CURRENT[MIN] to VM_RATED_CURRENT[MAX] A 6.80 A

Motor Rated Speed

P3.02

P3.03 Motor Rated Voltage 0 to Drive Rated Voltage V

P3.04 Motor Rated Power Factor 0.00 to 1.00 0.80

P3.05 Motor Control Mode Resistance Comp (0), Linear V to F (1), Square V to F (2) Linear V to F (1)

P3.06 Motor Starting Boost 0.0 to 25.0 5.0

P3.07 Motor Starting Boost End Voltage 0.0 to 100.0 50.0

P3.08 Motor Starting Boost End Frequency 0.0 to 100.0 50.0

P3.09 Perform Auto-tune Off (0) or On (1) Off (0)

P3.10 Energy Optimiser Off (0) or On (1) Off (0)

P3.11 Catch An Already Spinning Motor Disabled (0), Enabled (1), Forwards Only (2), Reverse Only (3) Disabled (0)

P3.12 PWM Switching Frequency Off (0) or On (1) Off (0)

P3.13 DC Braking Current Level 0.0 to 150.0 100.0

P3.14 DC Braking Time 0.0 to 100.0 s 1.0 s

P3.15 Motor Rated Frequency 0.0 to 300.0 Hz

P3.16 Number Of Motor Poles 0 to 8 0

P3.17 Motor Output Current Limit VM_MOTOR_CURRENT[MIN] to VM_MOTOR_CURRENT[MAX] 171.0

P3.18 Stator Resistance 0.00 to 199.99 Ω 2.00 Ω

P3.19 Motor Stability Optimiser Off (0) or On (1) Off (0)

P3.20 Reverse Motor Direction Off (0) or On (1) Off (0)

P3.21 Thermal Protection Action Disabled (0), Error with Save (1), Error (2), Limit with Save (3), Limit (4) Limit with Save (3)

P3.22 Low Frequency Thermal Protection Off (0) or On (1) On (1)

P3.23 Current Controller Gain 0 to 250 40

Range Default

0 to 18000 rpm

50 Hz: 1500 rpm

60 Hz: 1800 rpm

400 V drive 50

400 V drive: 400 V

400 V drive 60

50 Hz: 50.0 Hz

60 Hz: 60.0 Hz

Hz: 230 V

Hz: 460 V

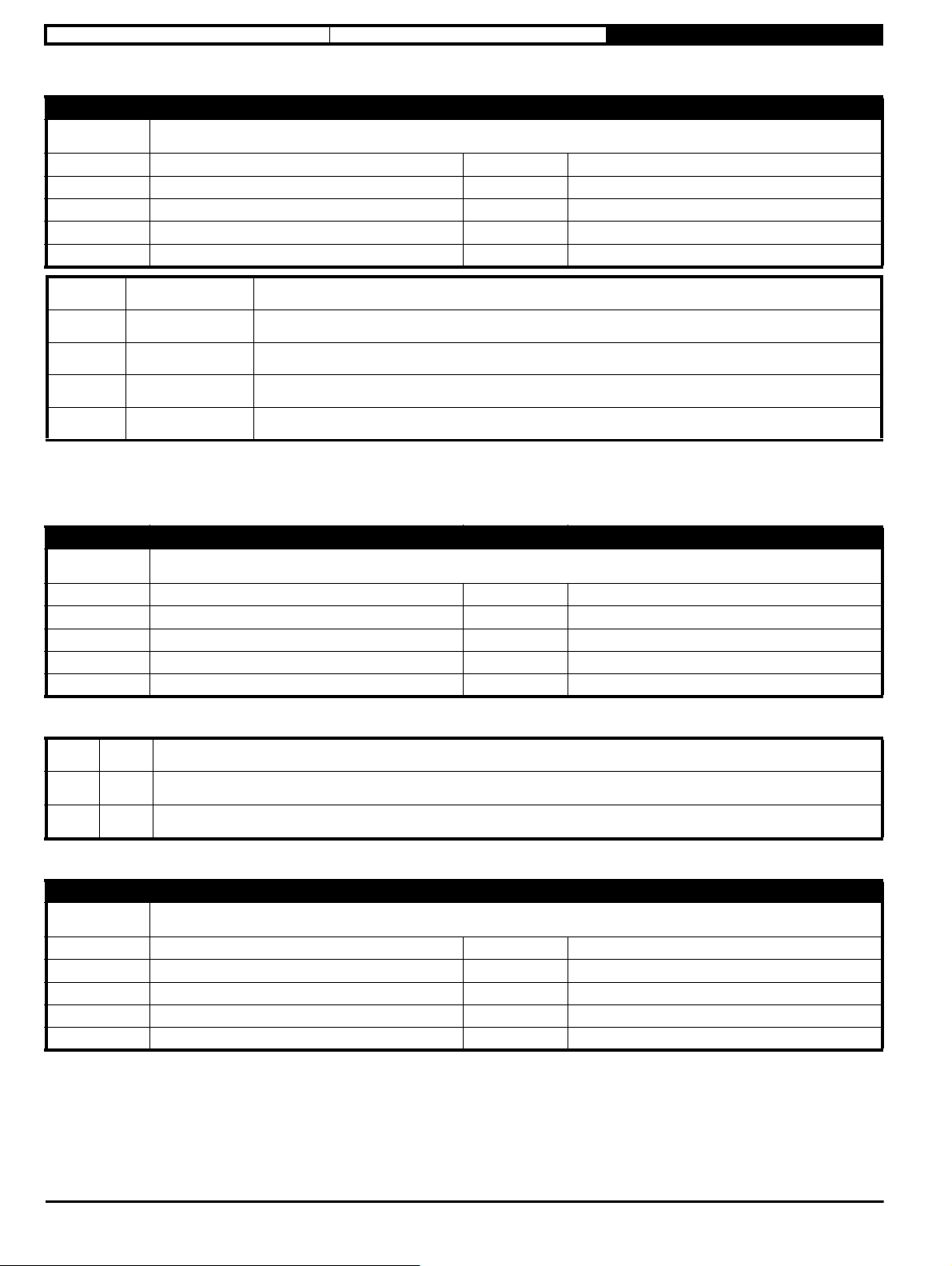

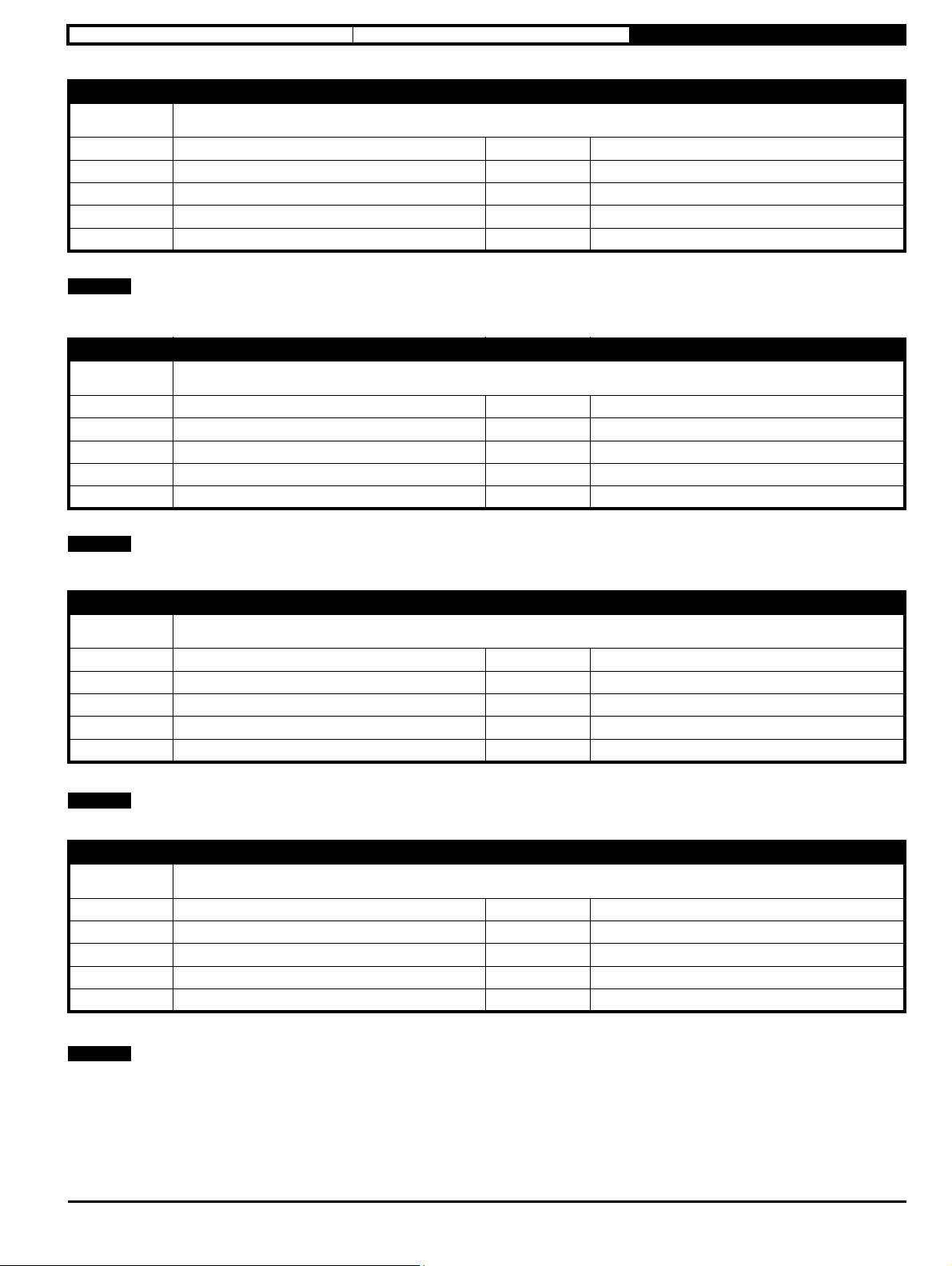

3.7 Menu 4 - General

Parameter

P4.01 Restore Factory Defaults None (0), 50Hz (1), 60Hz (2) None (0)

P4.02 Security Pin 0 to 9999 0

P4.03 Serial Node Address 1 to 247 1

P4.04 Serial Mode 8.2NP (0), 8.1NP (1), 8.1EP (2), 8.1OP (3) 8.2NP (0)

P4.05 Serial Baud Rate

Minimum Serial Comms Transmit

P4.06

Delay

P4.07 Keypad Run and Stop Function Select 0 to 2 0

P4.08 Supply Loss Action Disable (0), Ramp Stop (1), Ride Through (2) Disable (0)

P4.09 Parameter 1 Save on Error Selector None (0), Output Frequency (1), Output Voltage (2), Output Power (3),

P4.10 Parameter 2 Save on Error Selector Motor RPM (4)

P4.11 Parameter 3 Save on Error Selector Drive State (5)

P4.12 Number of Auto Reset Attempts None (0), One (1), Two (2), Three (3), Four (4), Five (5), Continuous (6) None (0)

Hold Drive Healthy on Auto Reset Atte

P4.13

mpts

Drive Reset When Enable or Run Appli

P4.14

ed

P4.15 Motor Phase Loss Detection Off (0) or On (1) Off (0)

P4.16 User Error 0 to 255 0

P4.17 Drive Enable Off (0) or On (1) On (1)

P4.18 Binary Control Word 0000000000000000 to 1111111111111111 0000000000000000

P4.19 Save Parameters Off (0) or On (1) Off (0)

P4.20 Near Field Communication (NFC) Disabled (0), Read Only (1), Read & Write (2) Read & Write (2)

Disabled (0), 600 (1), 1200 (2), 2400 (3), 4800 (4), 9600 (5), 19200 (6), 38400 (7),

57600 (8), 76800 (9), 115200 (10)

Motor RPM (4), Drive State (5), Output Current (6), Torque Prod. Current (7),

Percentage Load (8), Alarm Indicators (9), Drive Status Indica. (10),

Sequ. In and Out (11), Run and Direction (12), Ramp Input (13),

Ramp Output (14), T2 Analog 1 Percent (15), T4 Analog 2 Percent (16),

T15 Freq. Input % (17), Up/Down Percentage (18), PID Percentage (19),

PID Status Indica. (20), PID Error (21), Motor Therm. Percent (22),

Drive Therm. Percent (23), DC Bus Voltage (24), Digital IO Indica. (25)

Range Default

115200 (10)

0to250ms 0ms

Output Power (3)

Off (0) or On (1) Off (0)

Off (0) or On (1) On (1)

Commander S100 User Guide 13

Page 14

Safety information Electrical installation Drive Parameters

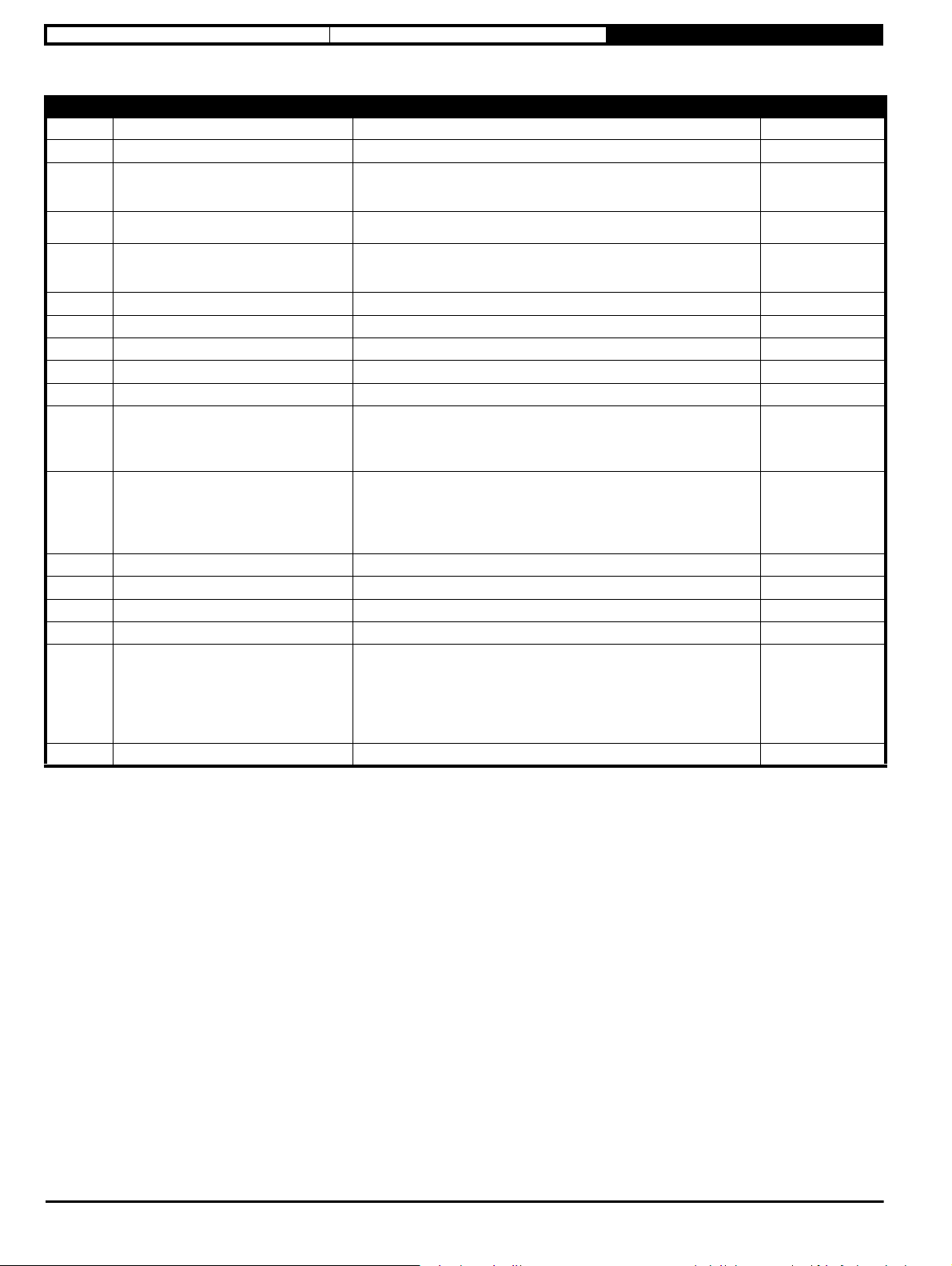

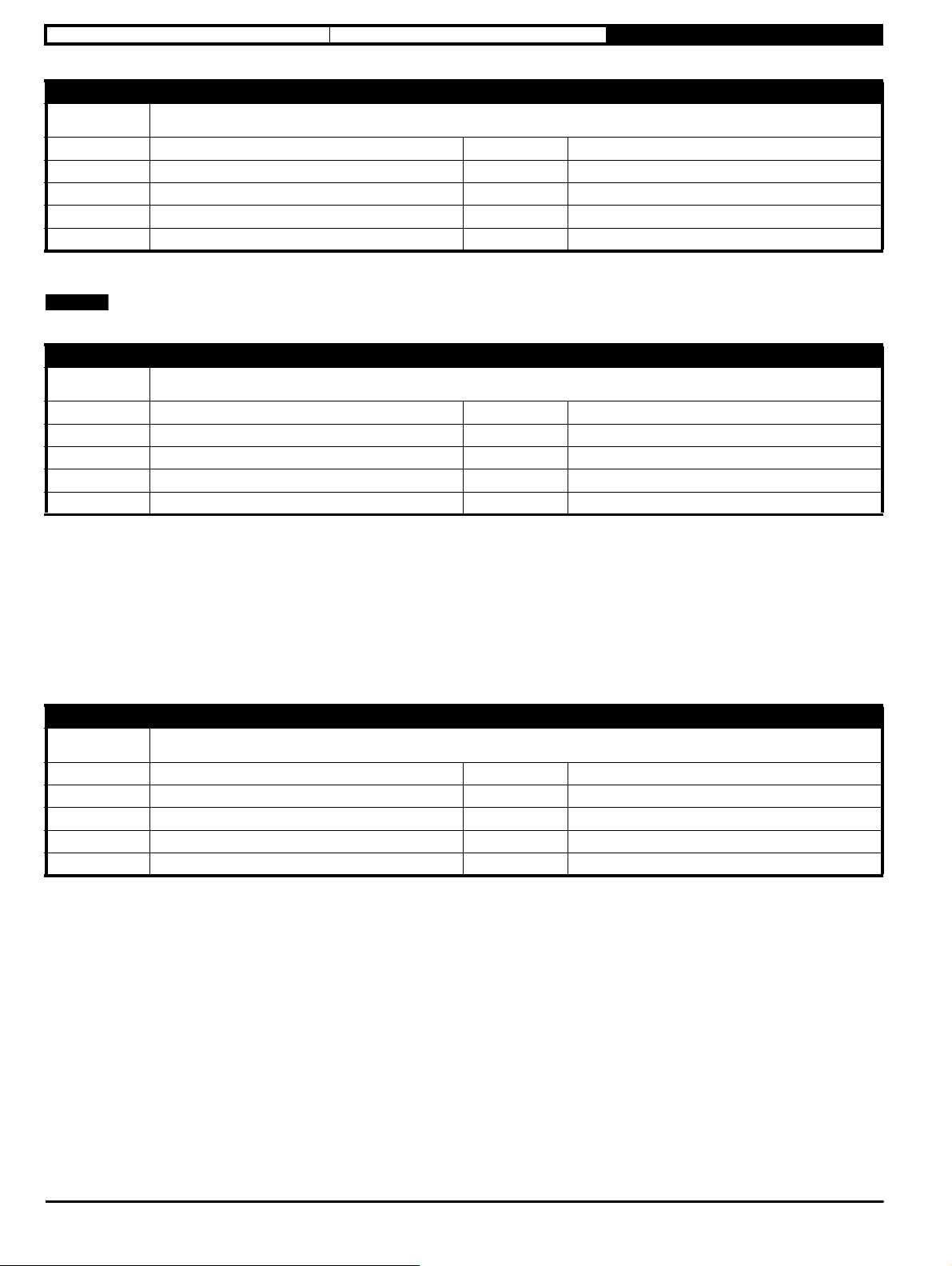

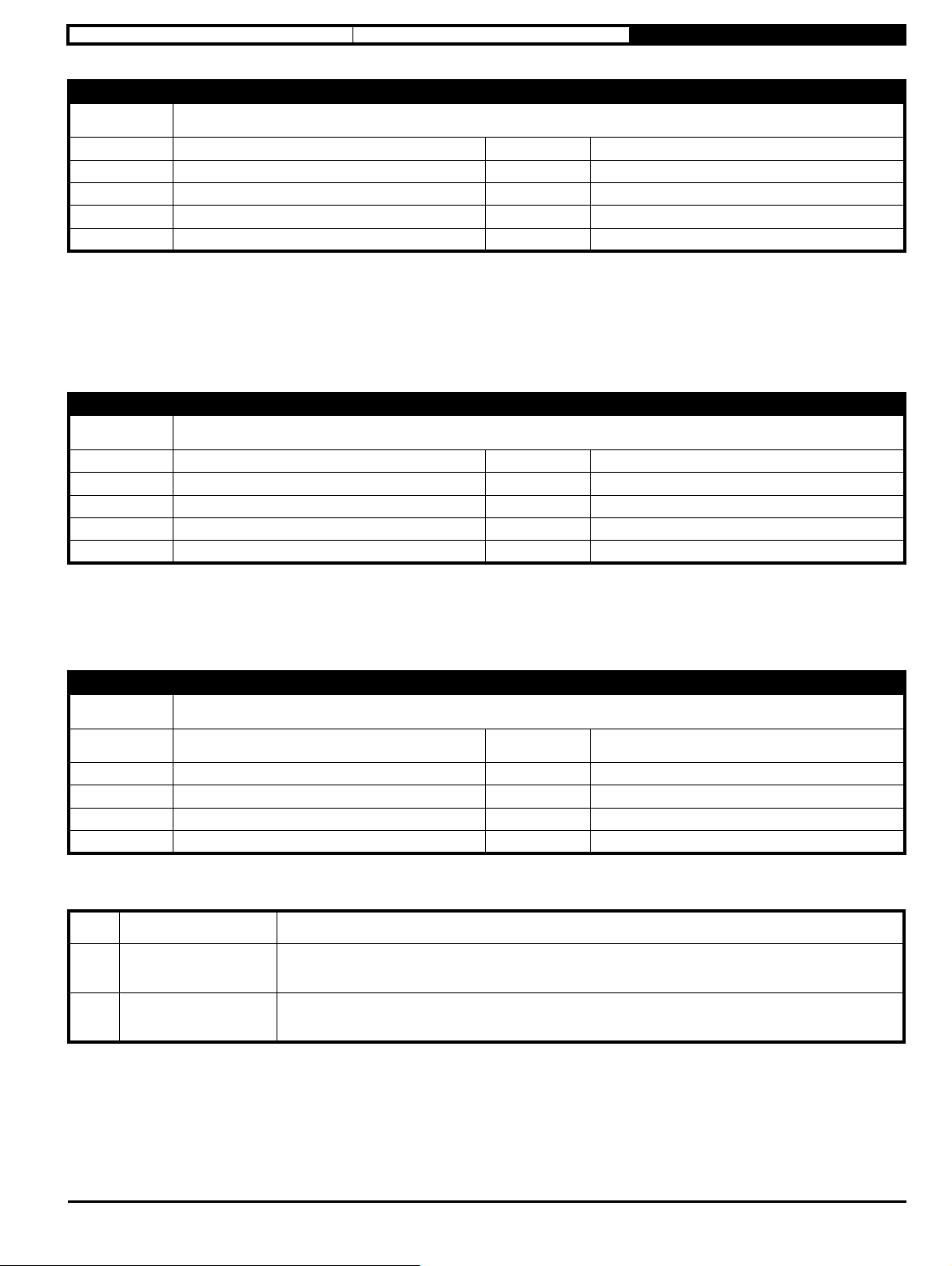

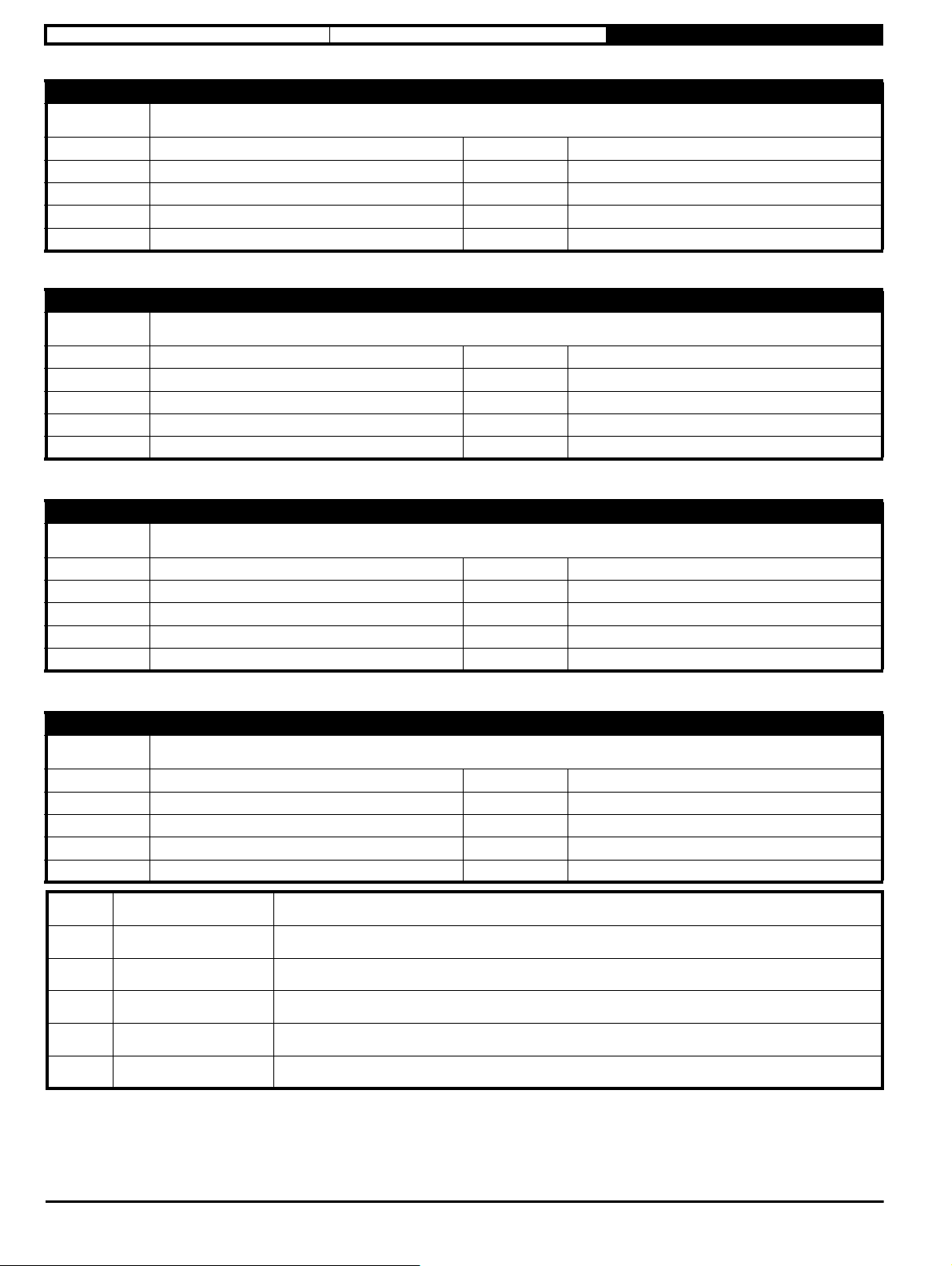

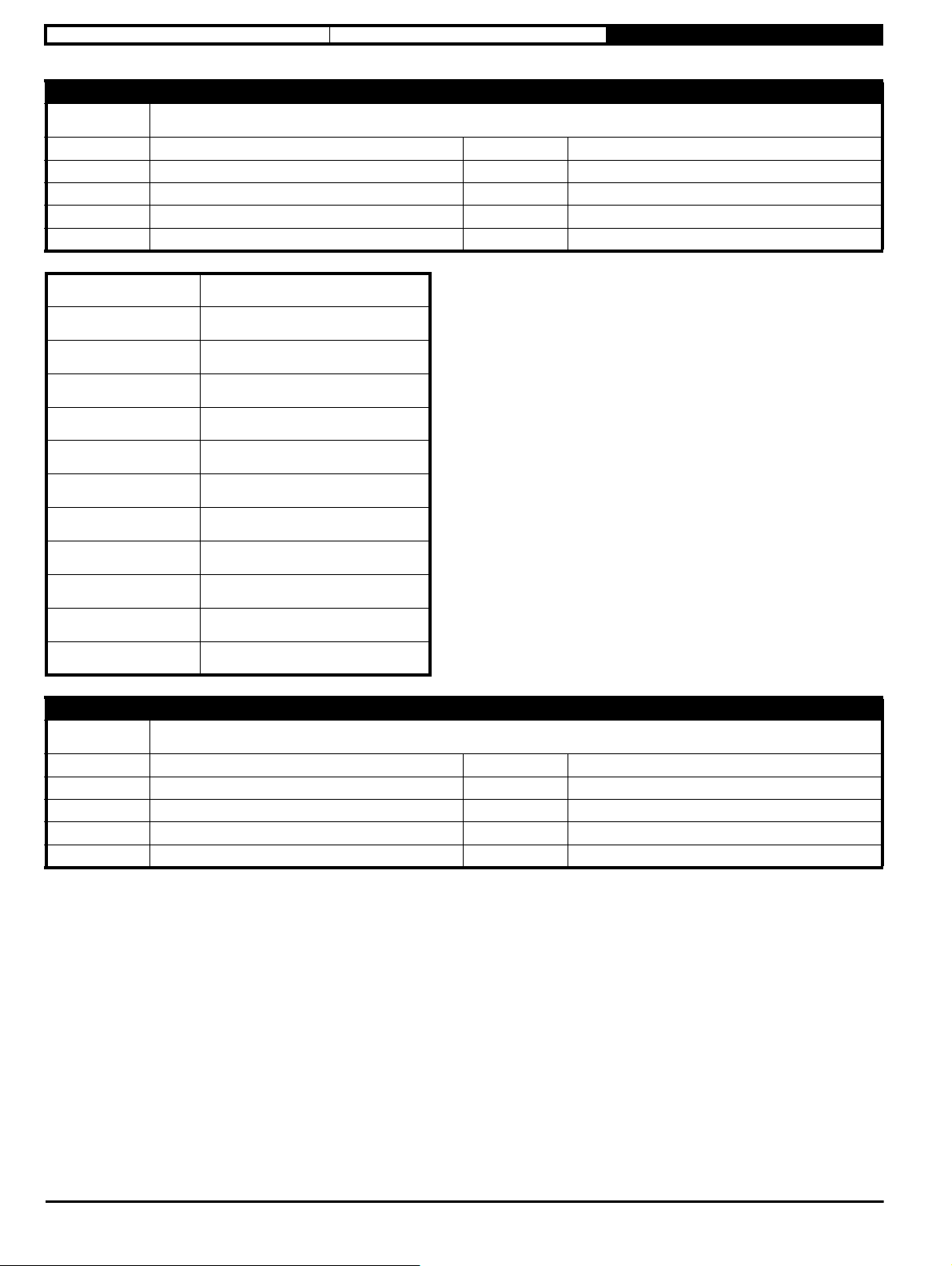

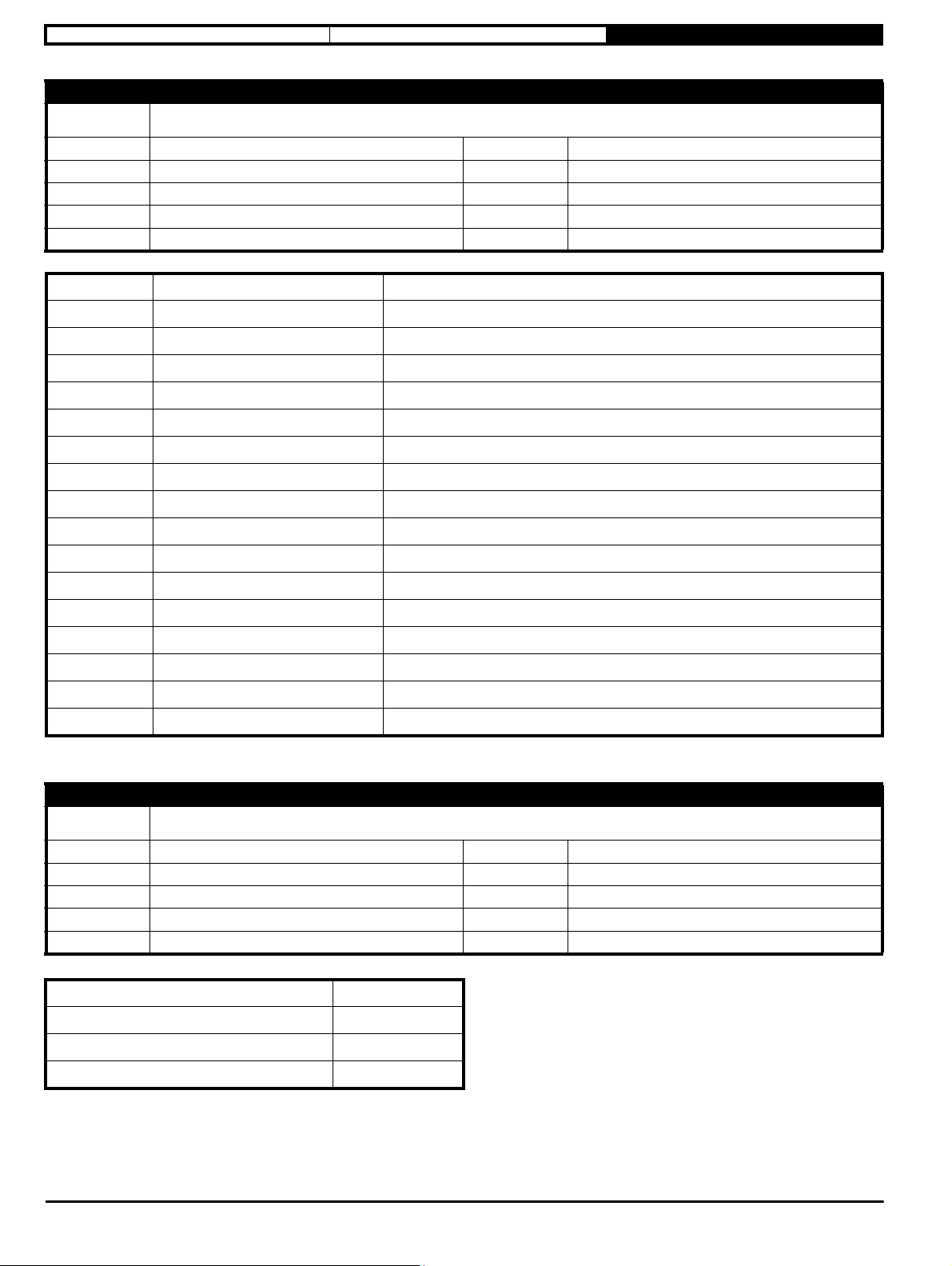

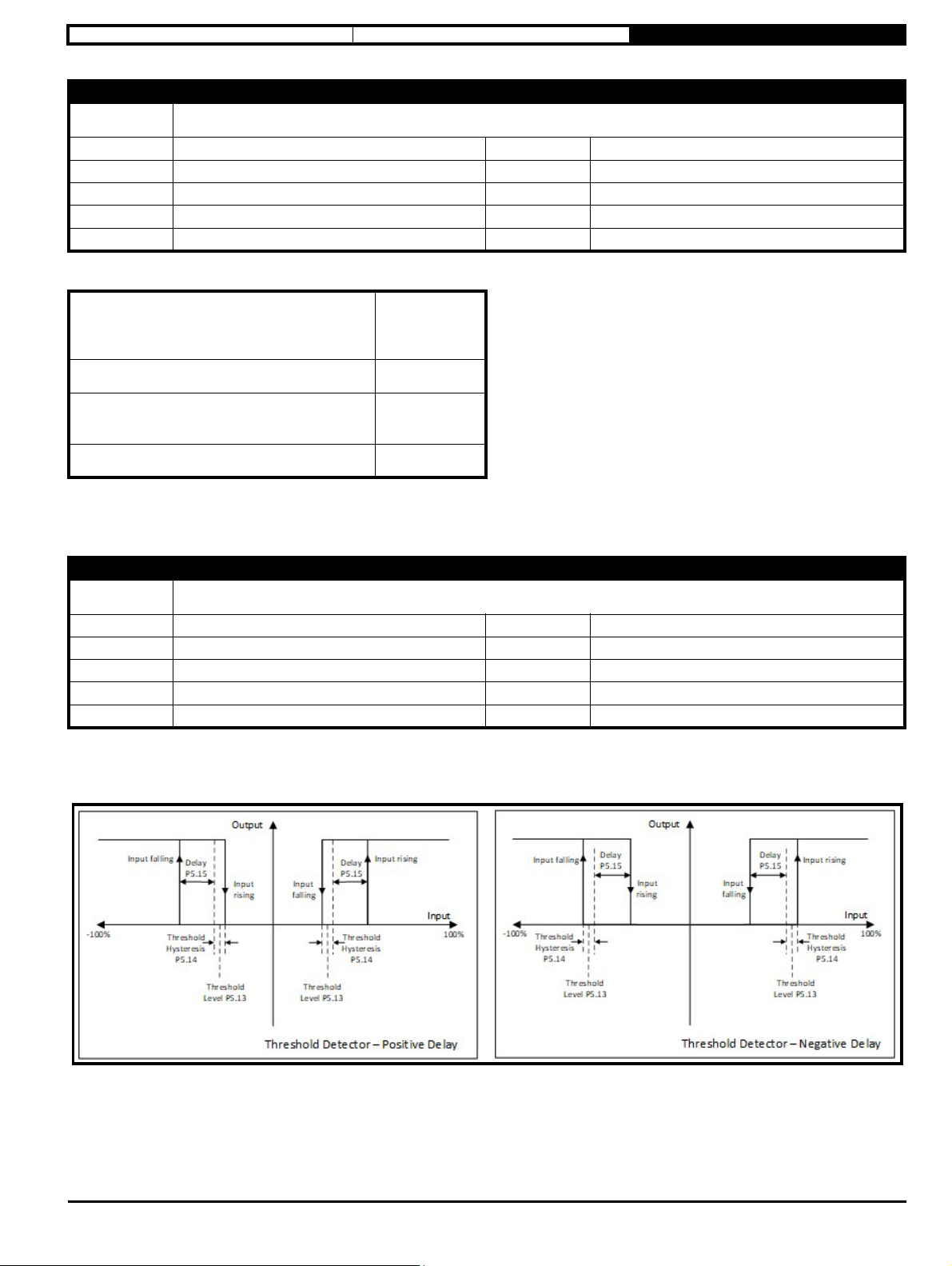

3.8 Menu 5 - PID Controller

ParameterParameter RangeRange DDefaultefault

P5.01 PID Fixed Reference Set-Point 1 ±100.00 % 0.00 %

P5.02 PID Fixed Reference Set-Point 2 ±100.00 % 0.00 %

None (0), Analog 1 Percent (1), Analog 2 Percent (2),

P5.03 PID Reference Selector

P5.04 PID Feedback Selector

P5.05 PID Feed Forward Selector

P5.06 PID Reference Slew Rate Limit 0.0 to 3200.0 s 0.0 s

P5.07 PID Proportional Gain 0.000 to 4.000 1.000

P5.08 PID Integral Gain 0.000 to 4.000 0.500

P5.09 PID Output Lower Limit ±100.00 % 0.00 %

P5.10 PID Output Upper Limit 0.00 to 100.00 % 100.00 %

P5.11 PID Enable Selector

P5.12 Threshold Detector Selector

P5.13 Threshold Detector Level 0.00 to 100.00 % 0.00 %

P5.14 Threshold Detector Hysteresis 0.00 to 25.00 % 0.00 %

P5.15 Threshold Detector Delay ±25.0 s 0.0 s

P5.16 Threshold Detector Output Invert Off (0) or On (1) Off (0)

P5.17 Threshold Detector Function Select

P5.18 PID Lower Limit Off (0) or On (1) Off (0)

Frequency Input % (3), Up/Down Percent (4), Fixed Reference 1 (5),

Fixed Reference 2 (6)

None (0), Analog 1 Percent (1), Analog 2 Percent (2),

Frequency Input % (3)

None (0), Analog 1 Percent (1), Analog 2 Percent (2),

Frequency Input % (3), Up/Down Percent (4), Fixed Reference 1 (5),

Fixed Reference 2 (6)

None (0), Drive Active Running (1), At Speed (2), At Zero (3),

Under Voltage (4), External Error (5), Drive Ready (6), Drive Healthy (7),

Current Limit Active (8), Reverse Selected (9), An In Current Loss (10),

Threshold Detector (11)

None (0), Ramp Input (1), Ramp Output (2), Output Frequency (3),

Output Current (4), Torque Prod Current (5), Output Voltage (6),

DC Bus Voltage (7), Analog 1 Percentage (8), Analog 2 Percentage (9),

Freq. input Percent (10), Output Power (11), Motor RPM (12),

Percentage Load (13), PID Percentage (14), PID Error (15)

None (0), Hardware Enable (1), Run Forward (2), Run Reverse (3),

Run Permit (/Stop) (4), Forward Limit Switch (5), Reverse Limit Switch (6),

Up/Down % Increase (7), Up/Down % Decrease (8), Up/Down % Reset (9),

Ref Sel Bit 0 (10), Ref Sel Bit 1 (11), Ramp Select (12),

PID Hardware Enable (13), External Error (14), Drive Reset (15), Run (16),

Reverse(17), JogForward(18), JogReverse(19)

Fixed Reference 2 (6)

None (0)

None (0)

None (0)

None (0)

None (0)

14 Commander S100 USer Guide

Page 15

Safety information Electrical installation Drive Parameters

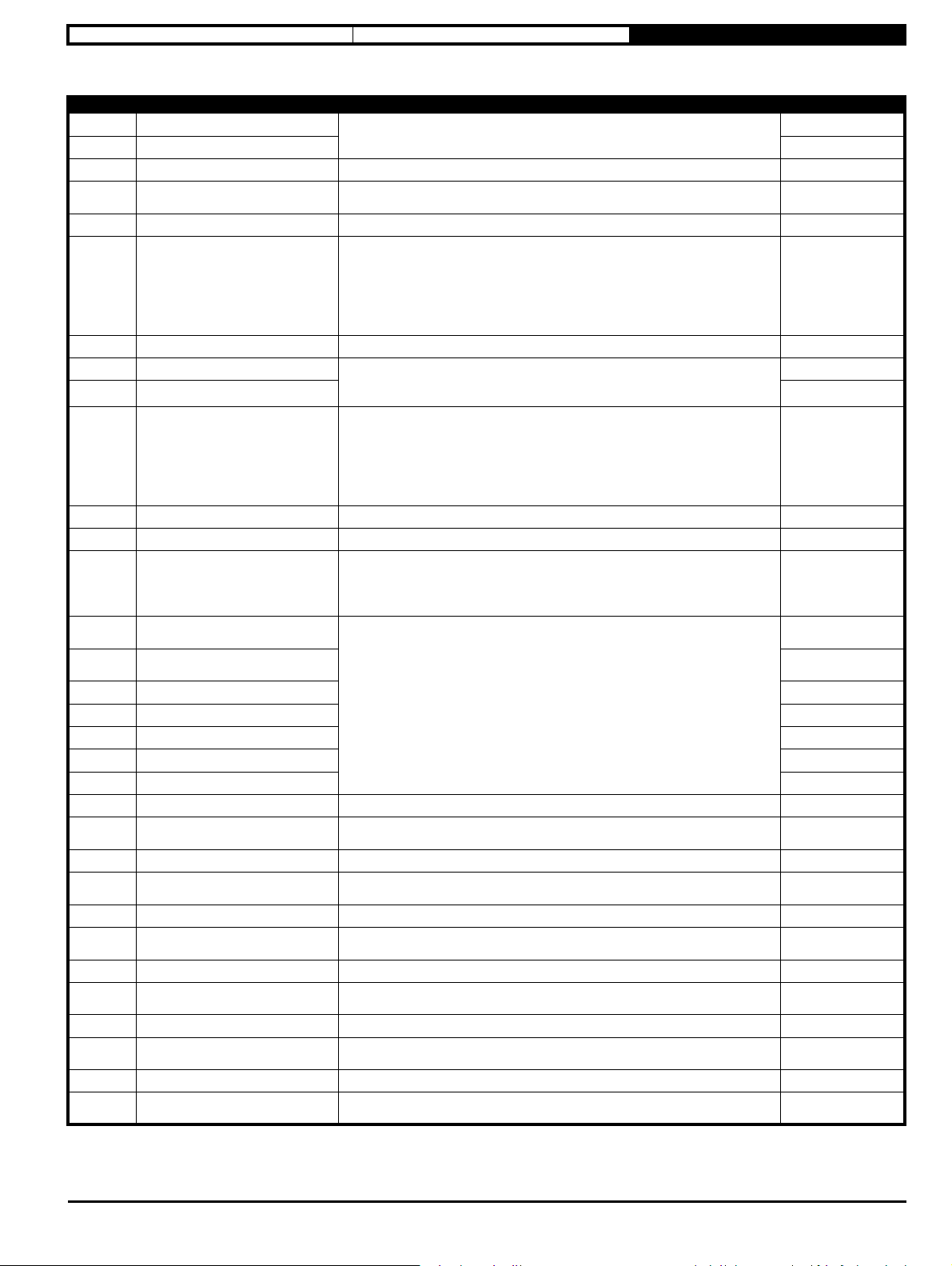

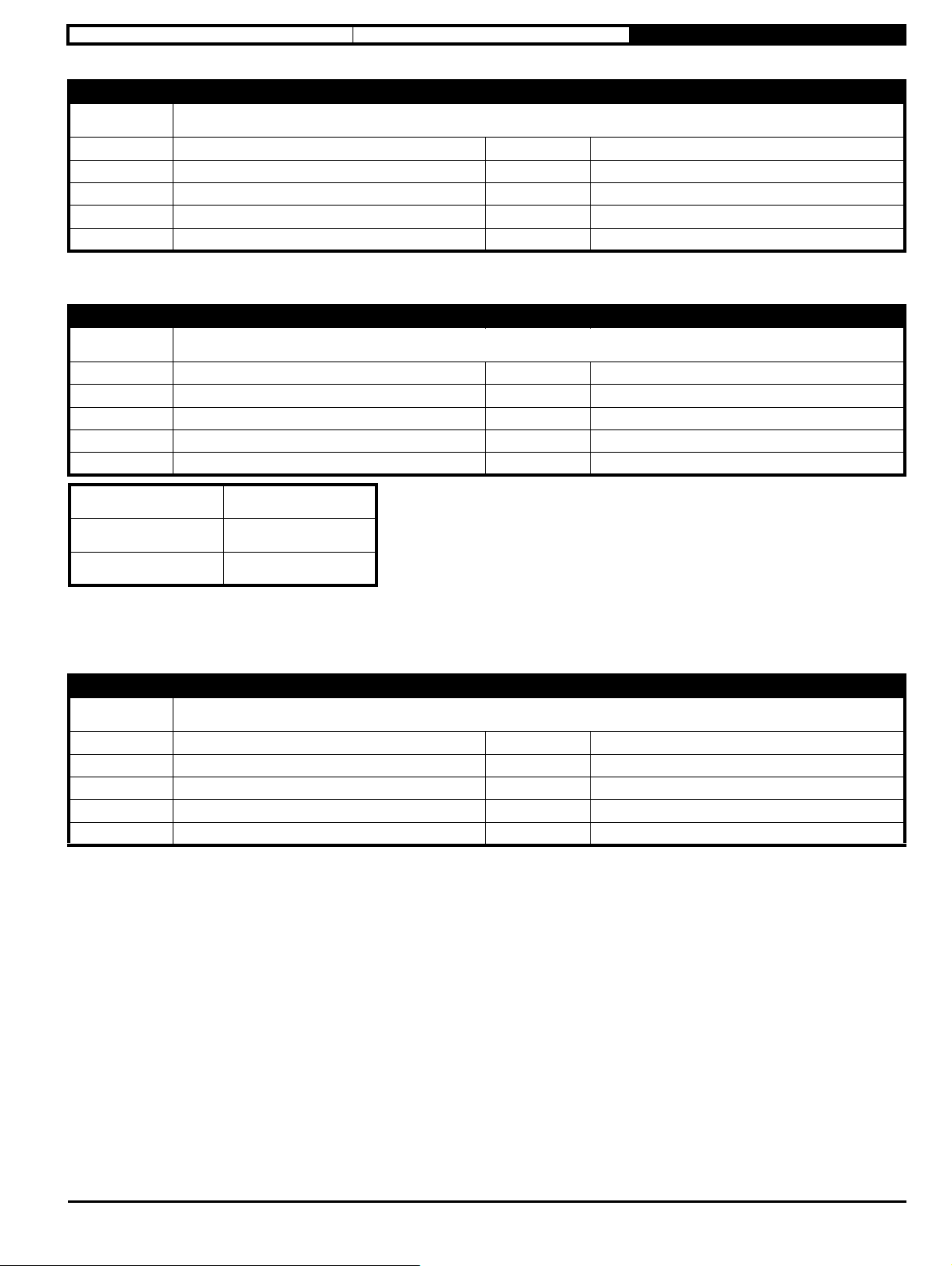

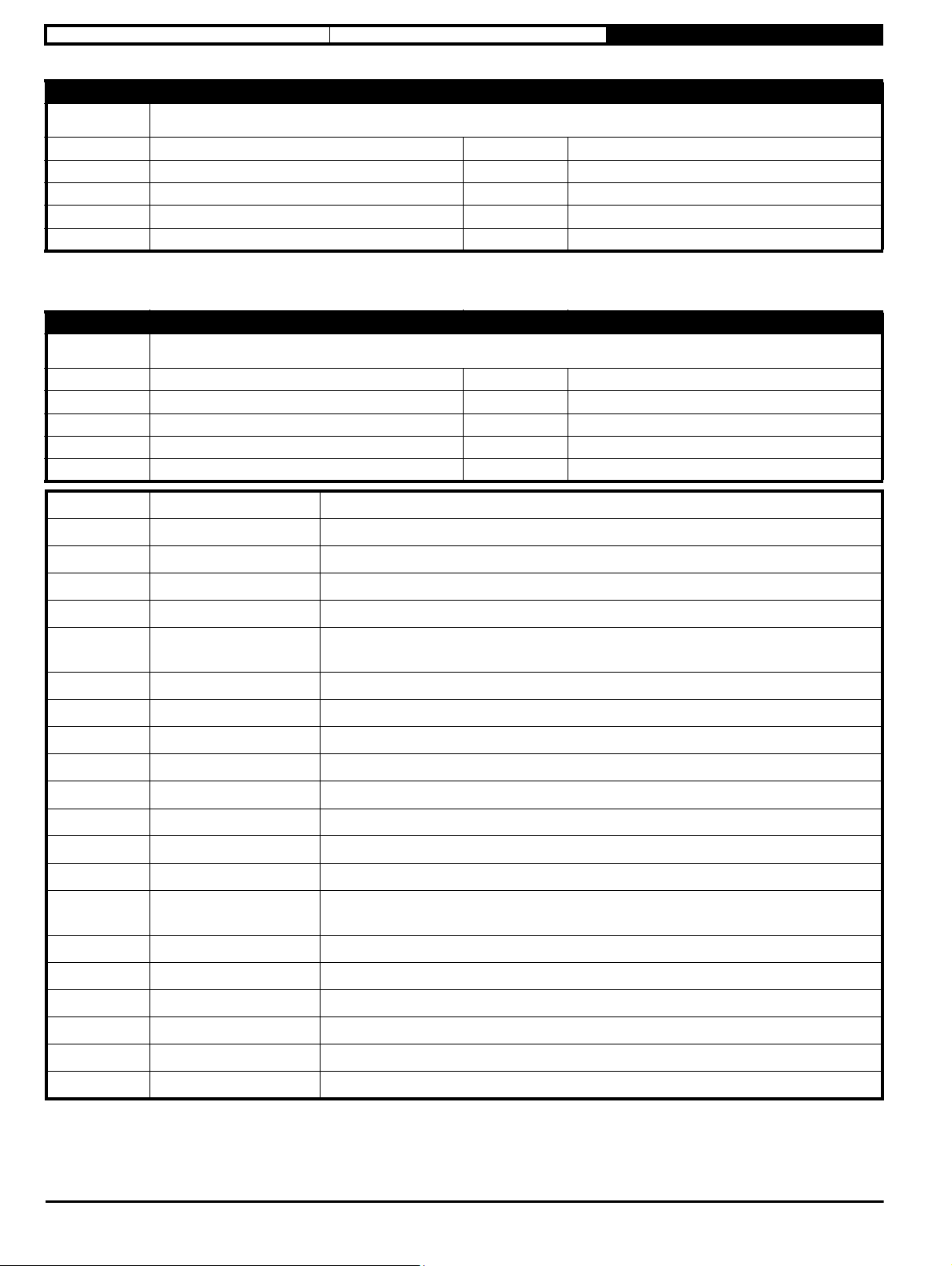

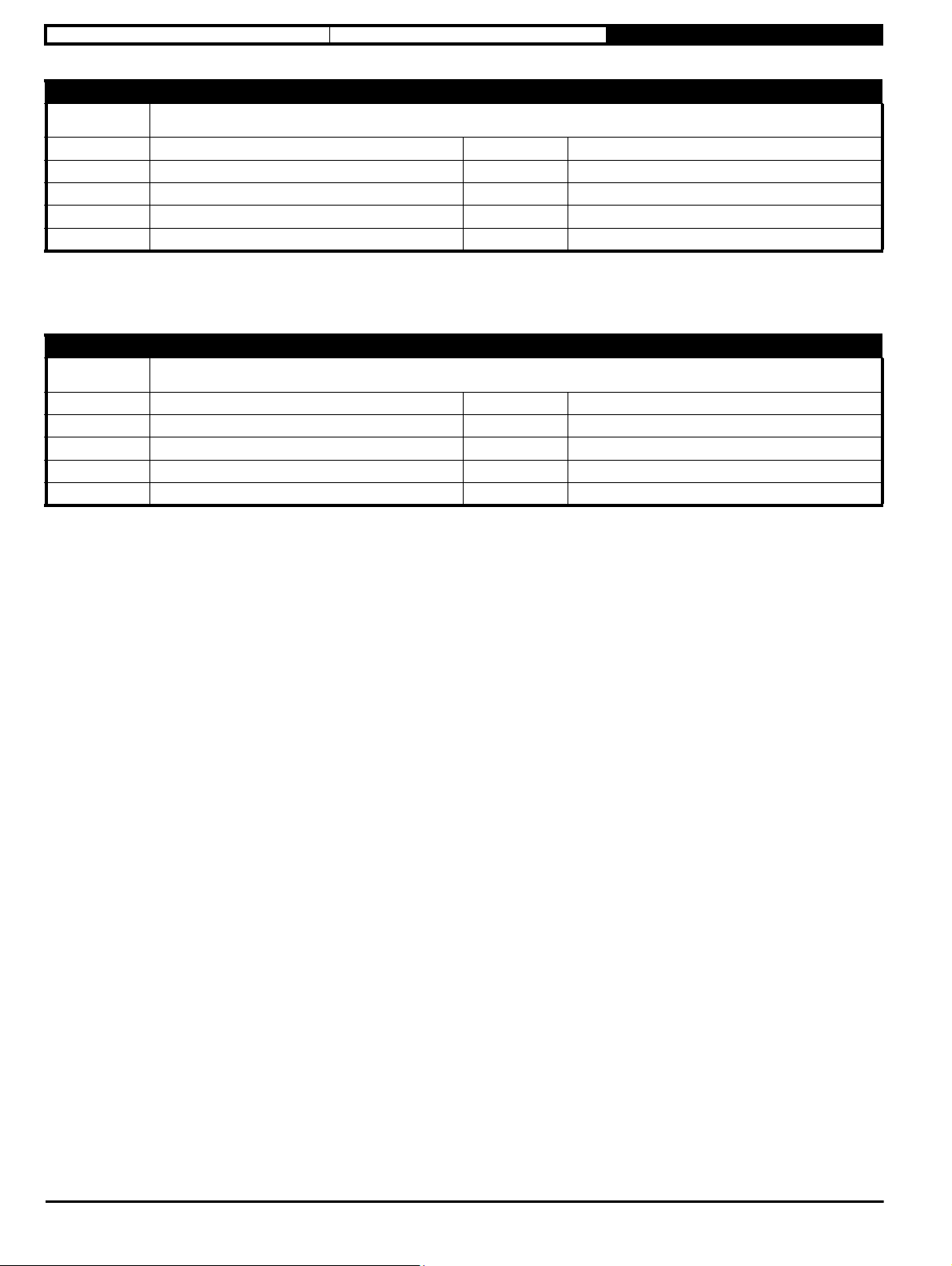

3.9 Menu 6 - IO Configuration

Parameter Range Default

P6.01 T2 Analog Input 1 Type

P6.02 T4 Analog Input 2 Type 0-10V (0)

P6.03 T6 Analog Output Type 0-10V (0), 0-20mA (1), 4-20mA (2) 0-10V (0)

P6.04 T11 Digital IO 1 Type

P6.05 T15 Digital Input 5 Type Digital Input (0), Frequency Input (1) Digital Input (0)

P6.06 T6 Analog Output Function Select

P6.07 T6 Analog Output Scaling 0.000 to 40.000 1.000

P6.08 T41-T43 Relay Function Select

P6.09 T11 Digital Output 1 Function Select None (0)

P6.10

P6.11 T11 Frequency/PWM Output Scaling 0.000 to 40.000 1.000

P6.12 Negative Logic (NPN Sensor) Select Off (0) or On (1) Off (0)

P6.13 Run/Stop Configuration

P6.14

P6.15

P6.16 T11 Digital Input 1 Function Select None (0)

P6.17 T12 Digital Input 2 Function Select Hardware Enable (1)

P6.18 T13 Digital Input 3 Function Select Run Forward (2)

P6.19 T14 Digital Input 4 Function Select Run Reverse (3)

P6.20 T15 Digital Input 5 Function Select Ref Sel Bit 0 (10)

P6.21 T2 Analog Input 1 Minimum Input 0.00 to 100.00 % 0.00 %

P6.22

P6.23 T2 Analog Input 1 Maximum Input 0.00 to 100.00 % 100.00 %

P6.24

P6.25 T4 Analog Input 2 Minimum Input 0.00 to 100.00 % 0.00 %

P6.26

P6.27 T4 Analog Input 2 Maximum Input 0.00 to 100.00 % 100.00 %

P6.28

P6.29 T15 Frequency Input Minimum Input 0.00 to 100.00 % 0.00 %

P6.30

P6.31 T15 Frequency Input Maximum Input 0.00 to 100.00 % 100.00 %

P6.32

T11 Frequency/

PWM Output Function Select

T2 Analog Input 1 Digital Function

Select

T4 Analog Input 2 Digital Function

Select

T2 Analog Input 1 Percentage at

Minimum Input

T2 Analog Input 1 Percentage at

Maximum Input

T4 Analog Input 2 Percentage at

Minimum Input

T4 Analog Input 2 Percentage at

Maximum Input

T15 Frequency Input Percentage at

Minimum Input

T15 Frequency Input Percentage at

Maximum Input

0-10V (0), 0-20mA (1), 4-20mA (2), 4-20mA Hold (3), 4-20mA Stop (4),

4-20mA Error (5)

Digital Input (0), Digital Output (1), Frequency Output (2), PWM Output (3),

Digital Out Inverted (4)

None (0), Ramp Input (1), Ramp Output (2), Output Frequency (3),

Output Current (4), Torque Prod Current (5), Output Voltage (6),

DC Bus Voltage (7), Analog 1 Percentage (8), Analog 2 Percentage (9),

Freq. input Percent (10), Output Power (11), Motor RPM (12),

Percentage Load (13), PID Percentage (14), PID Error (15), Motor Thermal % (16),

Drive Thermal % (17)

None (0), Drive Active Running (1), At Speed (2), At Zero (3), Under Voltage (4),

External Error (5), Drive Ready (6), Drive Healthy (7), Current Limit Active (8),

Reverse Selected (9), An In Current Loss (10), Threshold Detector (11)

None (0), Ramp Input (1), Ramp Output (2), Output Frequency (3),

Output Current (4), Torque Prod Current (5), Output Voltage (6),

DC Bus Voltage (7), Analog 1 Percentage (8), Analog 2 Percentage (9),

Freq. input Percent (10), Output Power (11), Motor RPM (12),

Percentage Load (13), PID Percentage (14), PID Error (15), Motor Thermal % (16),

Drive Thermal % (17)

Custom (0), Enable + Run Forward + Run Reverse (1),

Run Forward + Run Reverse (3 Wire) (2), Enable + Run + Reverse (3),

Run + Reverse (4), Run + Jog (5), Run Forward + Run Reverse (6),

Run + Reverse (7), Keypad (8), Keypad With Enable (9), Keypad Jog (10)

None (0), Hardware Enable (1), Run Forward (2), Run Reverse (3), Run Permit (/

Stop) (4), Forward Limit Switch (5), Reverse Limit Switch (6), Up/

Down % Increase (7), Up/Down % Decrease (8), Up/Down % Reset (9),

Ref Sel Bit 0 (10), Ref Sel Bit 1 (11), Ramp Select (12), PID Hardware Enable (13),

External Error (14), Drive Reset (15), Run (16), Reverse (17), Jog Forward (18),

Jog Reverse (19)

±100.00 % 0.00 %

±100.00 % 100.00 %

±100.00 % 0.00 %

±100.00 % 100.00 %

±100.00 % 0.00 %

±100.00 % 100.00 %

4-20mA (2)

Digital Input (0)

Ramp Output (2)

Drive Healthy (7)

None (0)

Enable + Run Forward

+ Run Reverse (1)

None (0)

None (0)

Commander S100 User Guide 15

Page 16

Safety information Electrical installation Drive Parameters

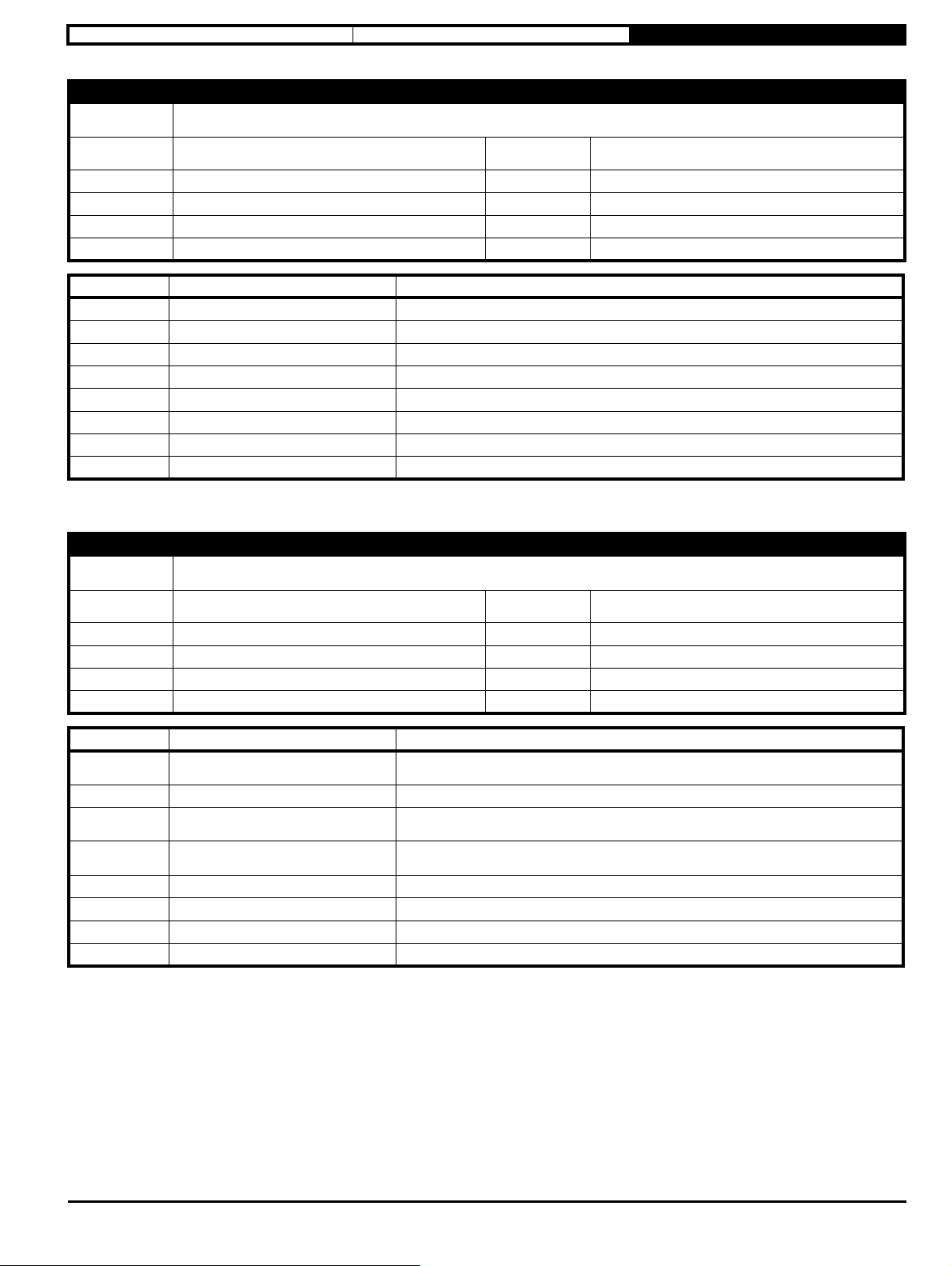

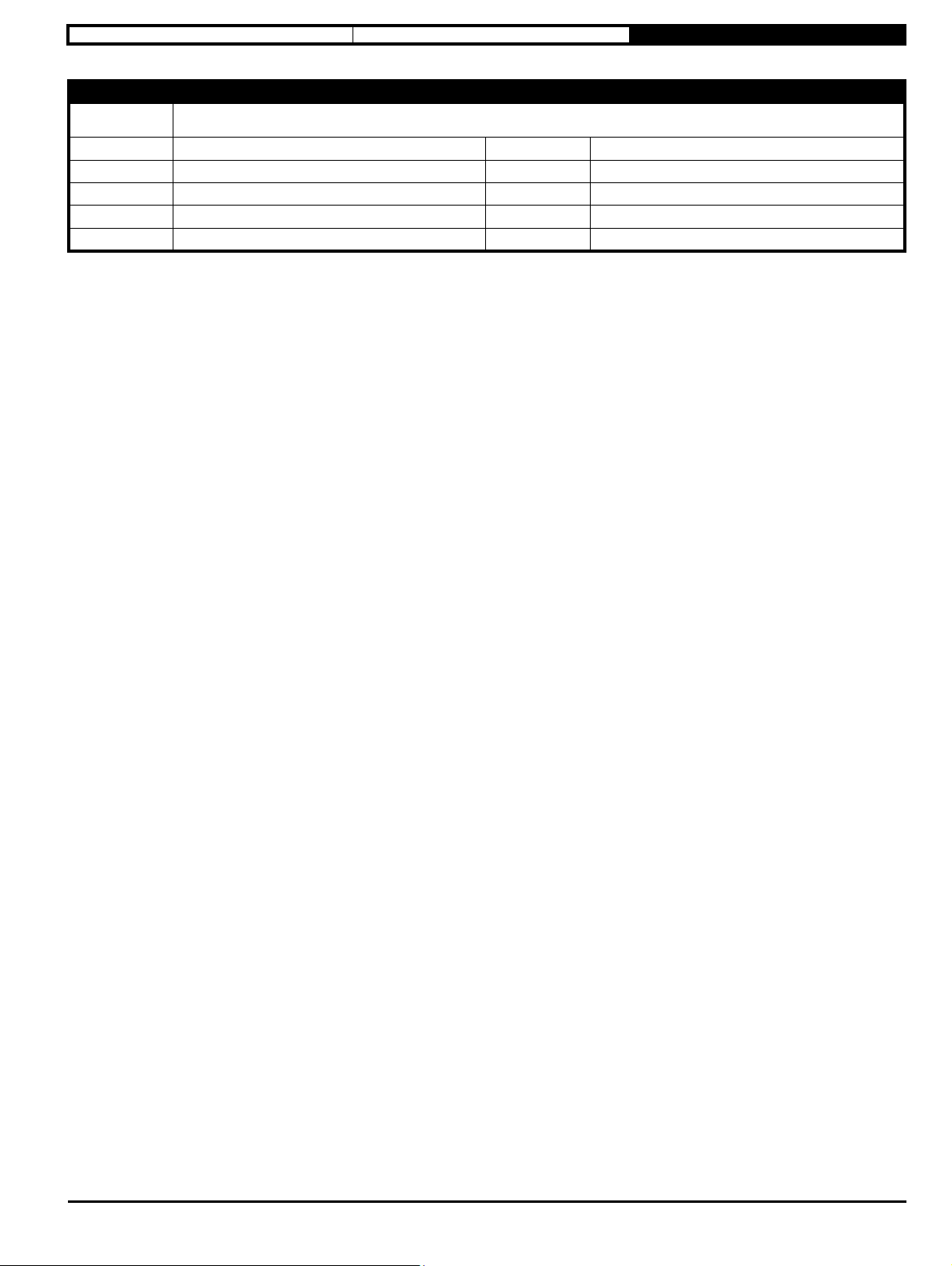

3.10 Parameter Descriptions

This section provides detailed descriptions on the functions of all parameters within the drive. Not all parameters of the parameters listed can be

accessed via the keypad as they are intended for use via Modbus RTU and are therefore marked Communication. The table below shows a list of

additional attributes a parameter may have.

Tab le 3- 1

Coding Attribute

RW Read/Write: can be written by the user

RO Read only: can only be read by the user

Bit 1 bit parameter. ‘On’ or ‘Off’ on the display

Num Number: can be uni-polar or bi-polar

Txt Text: the parameter uses text strings instead of numbers.

Bin Binary parameter

IP IP Address parameter

Mac Mac Address parameter

Date Date parameter

Time Time parameter

Chr Character parameter

FI Filtered: Some parameters which can have rapidly changing values are filtered when displayed on the drive keypad for easy viewing

DE Destination: This parameter selects the destination of an input or logic function

Rating dependent: this parameter is likely to have different values and ranges with drives of different voltage and current ratings. Parameters

RA

ND No default: The parameter is not modified when defaults are loaded

NC Not copied: not transferred to or from non-volatile media during copying.

PT Protected: Cannot be used as a destination

with this attribute will be transferred to the destination drive by non-volatile storage media when the rating of the destination drive is different

from the source drive and the file is a parameter file.

However, the values will be transferred if only the current rating is different and the file is a difference from default type file.

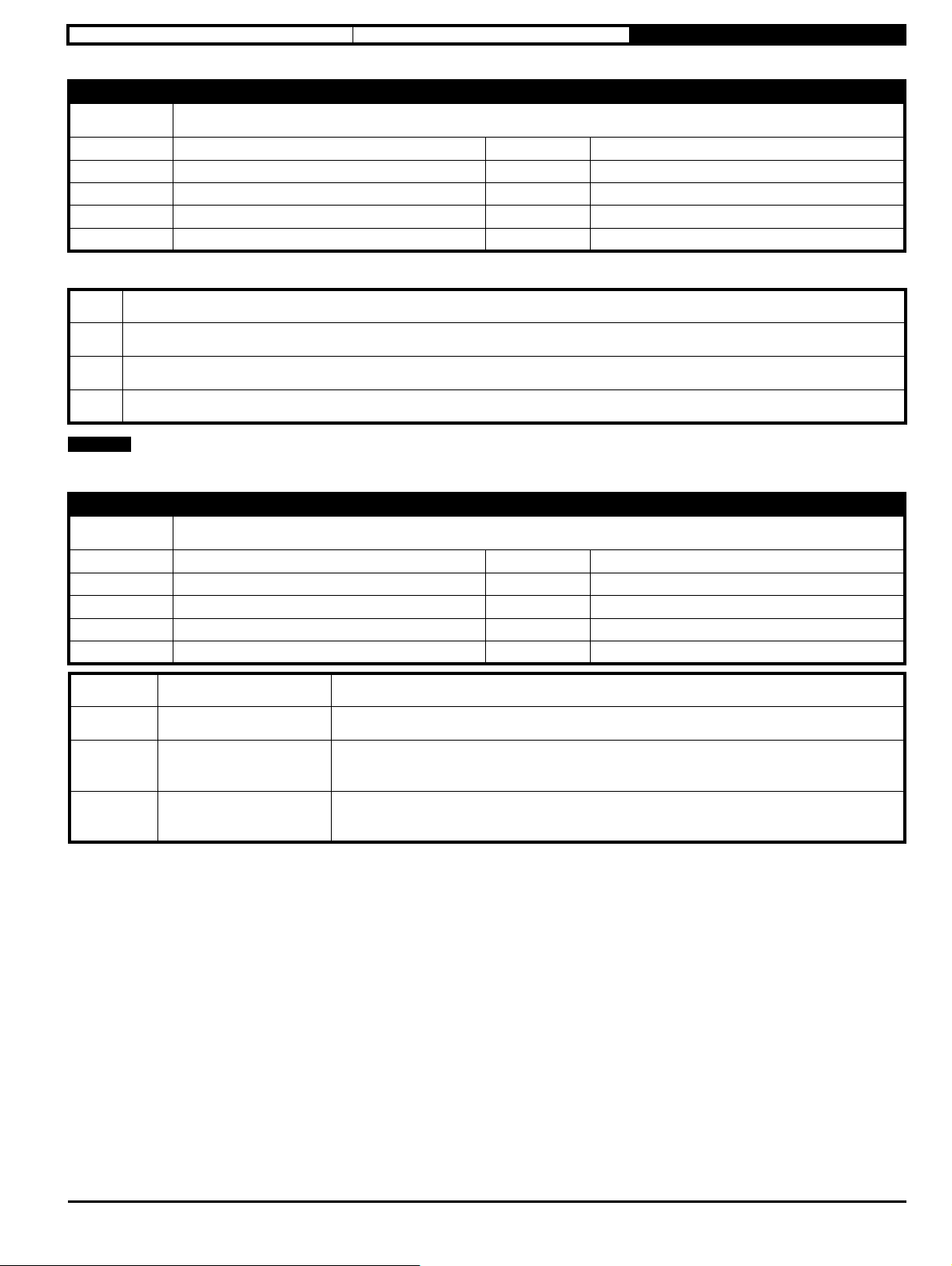

3.10.1 Menu 1 – Status & Monitoring

This menu contains all parameters that show an output variable of the drive for status and monitoring purposes. All parameters are read-only.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

Displays the drive output frequency in Hz. This can be higher than motor rotation frequency and Ramp Output

compensation. A positive value is used for forward rotation, a negative value is used for reverse rotation.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

Displays the r.m.s. line to line voltage at the output terminals of the drive.

(U to V; V to W; W to U.)

P1.01 Output Frequency

The output frequency of the drive

−Maximum Frequency Limit (P2.02)

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

P1.02 Output Voltage

The r.m.s. line to line voltage at the output of the drive

-Drive Rated Voltage

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

Maximum

Units

Update Rate

Decimal Places

Maximum Frequency Limit (P2.02)

Hz

1

(P1.13) due to motor slip

Drive Rated Voltage

V

0

16 Commander S100 USer Guide

Page 17

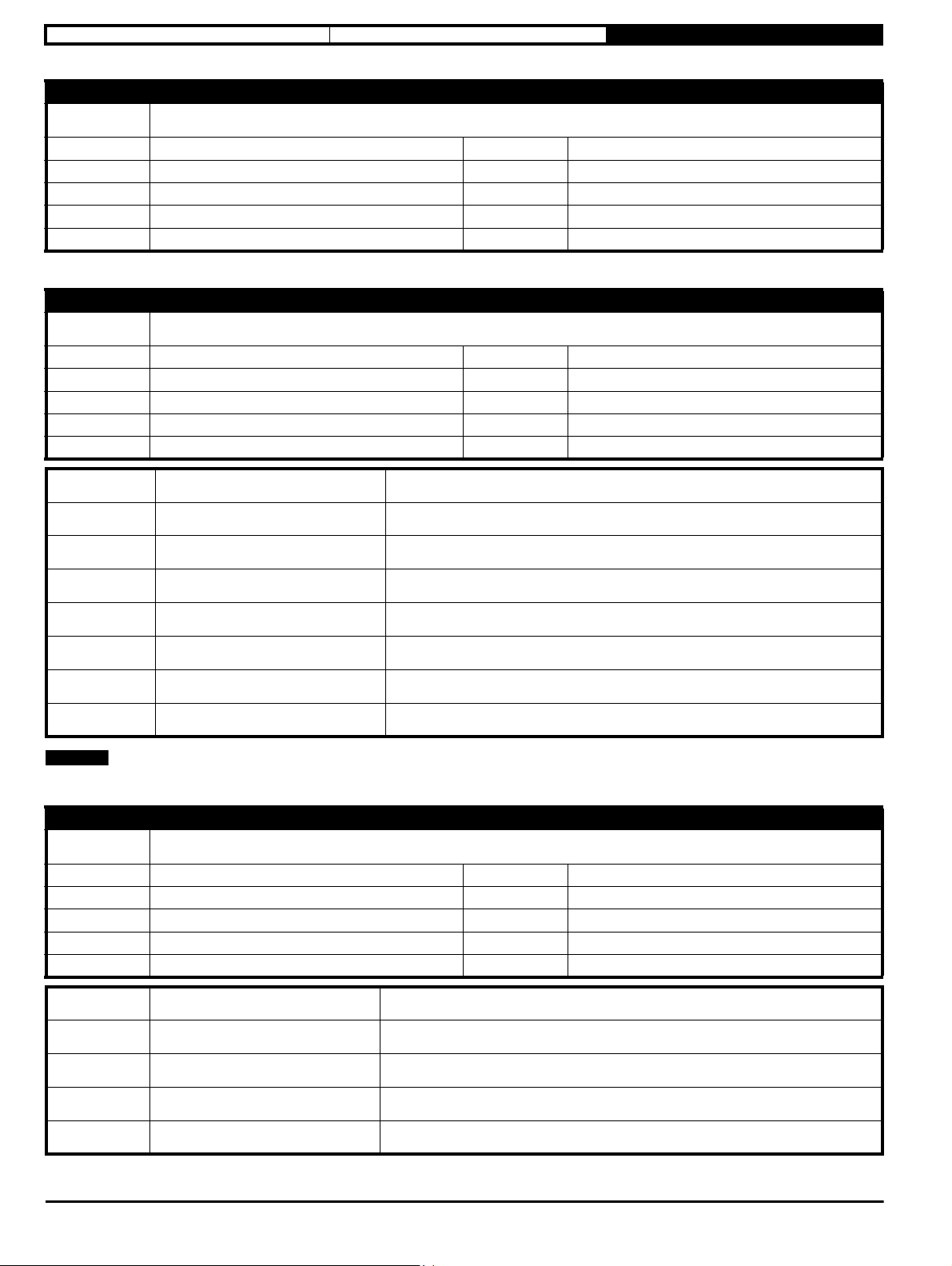

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.03 Output Power

Displays the power flowing through the output terminals of the drive

−VM_POWER

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

VM_POWER

kW

2

Displays the power flowing through the output terminals of the drive. This parameter should be used for indication purposes only. A positive value

indicates power flowing from the drive to the motor.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.04 Motor RPM

The drive output in terms of motor rpm

-18000

16 Bit Volatile

Standard

RO, FI, ND, NC

Maximum

Units

Update Rate

Decimal Places

18000

rpm

0

The drive output frequency is converted to the equivalent RPM using the number of motor poles. The actual motor RPM could be lower due to the

load and slip frequency if motor rated speed is not set correctly.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.05 Drive State

Displays the current state of the drive

0

8 Bit Volatile

Standard

RO, VM, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

DriveState

0

This parameter shows the present state of the drive as described below.

Value Text Description

0 Inhibited The drive is not enabled

1 Ready The drive is enabled but has not received a run command

2NA

3NA

4 Running The drive is running

5 Supply Loss Supply loss has been detected

6 Deceleration The drive is stopping the motor with a decelerating ramp

7 Injecting DC The drive is injecting DC braking current into the motor

8NA

9 Error The drive in an error state, check the error log for more information

10 NA

11 NA

12 NA

13 NA

14 NA

15 Under Voltage The drive is in the under-voltage state

Commander S100 User Guide 17

Page 18

Safety information Electrical installation Drive Parameters

NOTE

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.06 Output Current

The total output current to the motor

−Drive Rated Current

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

Drive Rated Current

A

2

Displays the total r.m.s phase current being delivered to the motor. This is made up of two components, motor magnetising current

and motor Torque Producing Current (P1.07).

This is an equivalent r.m.s. current at 0 Hz or low output frequency.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.07 Torque Producing Current

The output current that produces torque in the motor

−Drive Rated Current

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

Drive Rated Current

A

2

This parameter displays the component of the Output Current (P1.06) that is in phase with the voltage and does not include the magnetising current

of the motor. The value is proportional to the torque produced by the motor provided the frequency applied to the motor is at or below the motor rated

frequency.

This torque includes the load torque and acceleration torque.

If the Output Frequency is positive (forward), a positive value of Torque Producing Current would hold the motor load or cause the motor to

accelerate, a negative value would decelerate the motor.

If the Output Frequency is negative (reverse), a negative value of torque producing current would hold the motor load or cause the motor to

accelerate, a positive value would decelerate the motor.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.08 Percentage Load

The load as a percentage of motor rated torque

−Motor Output Current Limit (Max)

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

Motor Output Current Limit (Max)

%

1

Percentage Load (P1.08) indicates the load on the motor as a percentage of the rated load of the motor.

For forward rotation, this value is positive for a motoring load and negative for a regenerating load. For reverse rotation this value is negative for a

motoring load and positive for a regenerating load.

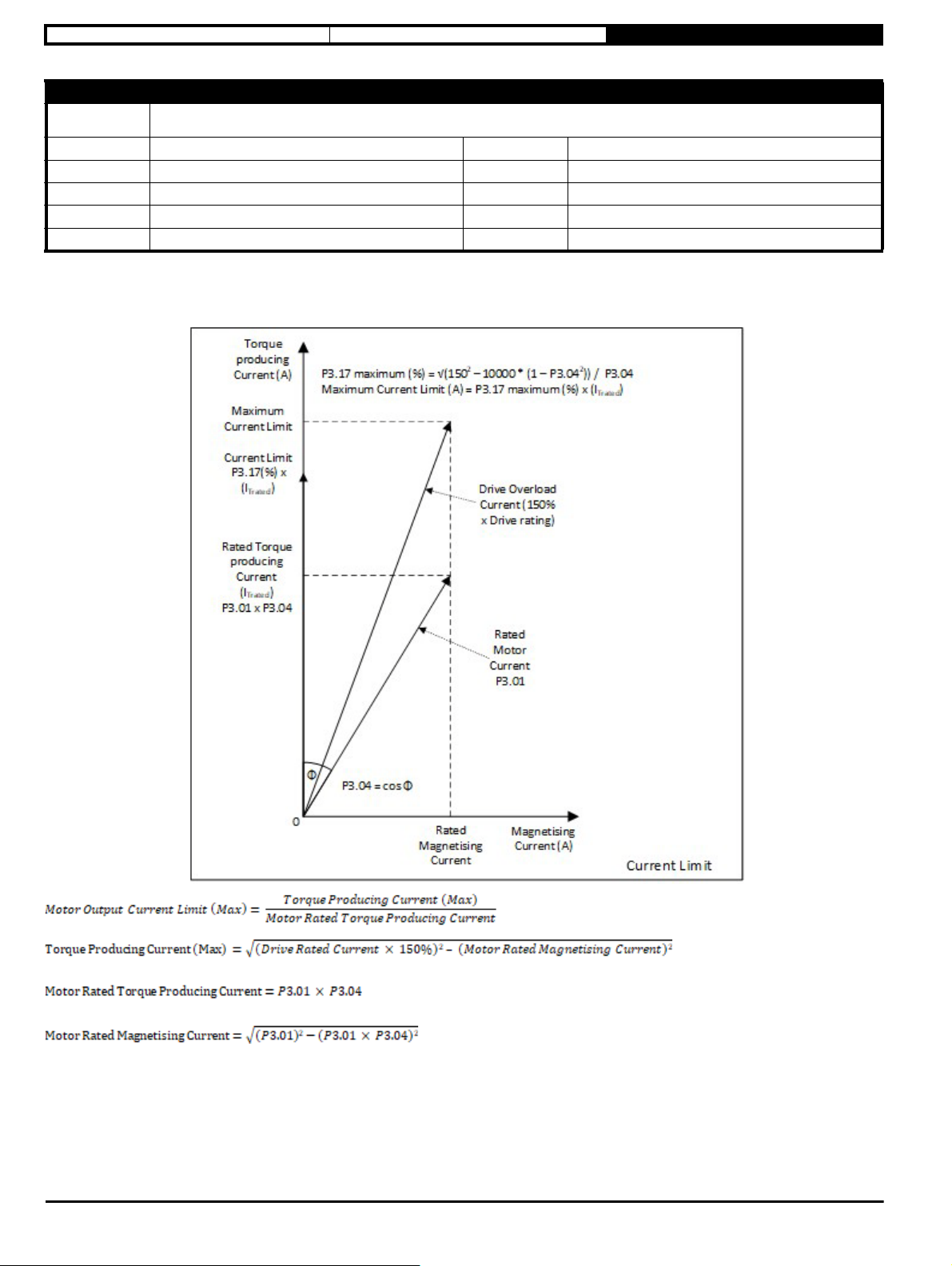

Percentage Load (P1.08) = Torque Producing Current (P1.07) / I

I

= Rated Torque Current = Motor Rated Current (P3.01) x Motor Rated Power Factor (P3.04)

Trated

Trated

x 100

See Motor Output Current Limit (P3.17)

18 Commander S100 USer Guide

Page 19

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.09 Alarm Indicators

A set of indicators that represent the drive alarms

0

(Display: 00000000)

8 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(Display: 11111111)

0

Bit Alarm How to remove the alarm

Bit 0 Motor Overload Reduce the load on the motor

Bit 1 Drive Overload Reduce the load on the motor or ambient temperature of the drive

Bit 2 Auto-tune Active Will be reset when Autotune complete

Bit 3 Limit Switch Active Rotate the motor away from the limit switch

Bit 4 Input Phase Loss or Imbalance Check input fuses to the drive

Bit 5 Analog Input Current Loop Loss Check current loop master is powered and the integrity of the wiring is good

Bit 6 Current Limit Active Reduce the load on the motor

Bit 7 I/O Overload Check 24 V output and digital output for an overload condition

An alarm is used by the drive to give an early warning of a problem which could lead to a drive error. In some alarm conditions, the drive may take

action to prevent an error for example reducing the motor current or speed.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.10 Drive Status Indicators

A set of indicators that represent the drive status

0

(Display: 00000000)

8 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(Display: 11111111

0

)

Bit Alarm How to remove the alarm

Bit 0 Supply Loss

Bit 1 Limit Switch Active Indicates at least one limit switch is active.

Bit 2Thermal Limit Active

Bit 3 Current Limit Active

Bit 4 Drive Active Indicates the drive is applying voltage to the motor.

Bit 5 Healthy Indicates the drive is healthy and there are no errors.

Bit 6At Speed ± 1 Hz Indicates the output frequency of the drive is within 1 Hz of the demand.

Bit 7 At Zero ± 2 Hz Indicates the output frequency of the drive is within 2 Hz of 0Hz

Indicates supply loss has been detected. The behaviour in this situation is controlled

by Supply Loss Action (P4.08).

Indicates the output current is being limited further than that defined by

Motor Output Current Limit (P3.17) for thermal protection.

Indicates the output current is being limited by the current limit defined

by Motor Output Current Limit (P3.17) or Bit 2 above.

Commander S100 User Guide 19

Page 20

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

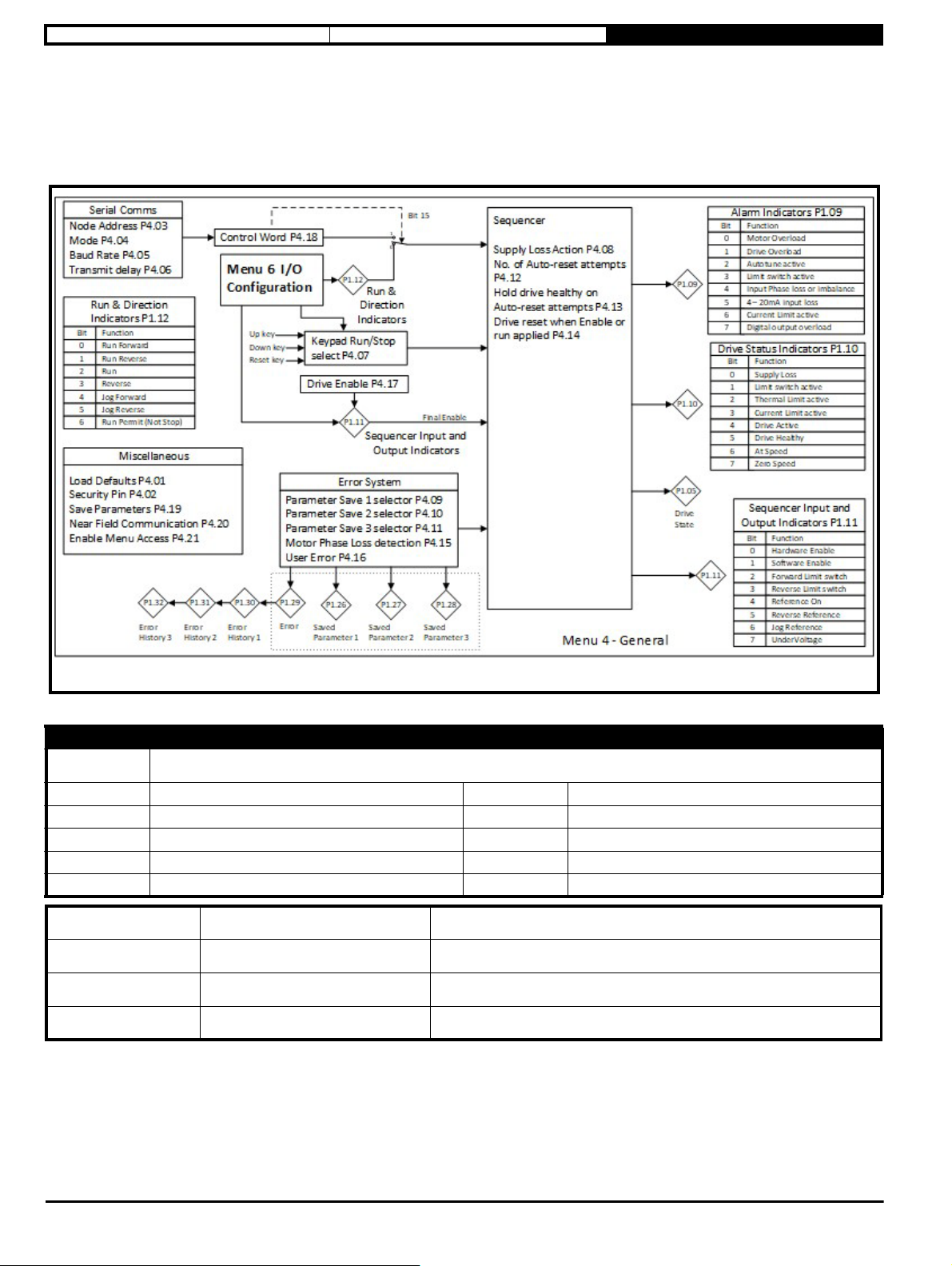

P1.11 Sequencer Input and Output Indicators

A set of indicators that represent the enable inputs, the Limit Switch inputs, and the sequencer outputs

0

(Display: 00000000)

8 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(Display: 11111111)

0

Displays a set of indicators that represent the enable inputs, the Limit Switch inputs, and the sequencer outputs.

Bit 0 Hardware Enable

Bit 1 Software Enable

Bit 2

Bit 3

Bit 4 Reference On

Limit Switch

Forwards

Limit Switch

Reverse

Set to 1 if an active digital input has been configured as the Hardware Enable function (1), or if no digital input has been

configured as a Hardware Enable

If the Binary Control Word (P4.18) is enabled this is set to 1 when the enable bit of the control word is set otherwise this is

set to 1 if Drive Enable (P4.17) is set to true

Set to 1 if an active digital input has been configured as the Forward Limit Switch function (5). The drive will stop if there

is with a positive reference

Set to 1 if an active digital input has been configured as the Forward Limit Switch function (6). The drive will stop if there

is a negative reference

Set to 1 by the sequencer to switch the selected reference through to the Ramps when a start command is detected.

See References & Ramps

Bit 5 Reverse

Bit 6 Jog Set to 1 by the sequencer to select the Jog reference when a Jog command is detected. See References & Ramps

Bit 7 Under Voltage Set to 1 by the sequencer if the drive is in an under voltage state

Set to 1 by the sequencer to reverse the selected reference when a Reverse command is detected.

See References & Ramps

Bits 0, 2 & 3 shown here can be set by any of the digital inputs using their function selector parameters such as T11 Digital Input 1 Function Select

(P6.16) or by selecting an appropriate Run/Stop Configuration (P6.13).

Before the drive can run the motor, it must check that certain conditions are met. These are handled by the drive sequencer. The drive sequencer

monitors all drive inputs and compares them to the drive's configuration, set by the user, to ensure the motor only runs when it should.

For example:

1. If a drive input is configured as a Hardware Enabled (1), the drive will not be able to run the motor, even if a Run Forward (2) signal is provided,

until the enable signal is given on that input.

2. If Limit Switch Forward is active, only a Run Reverse signal would allow the motor to run.

3. If a drive input is configured as a Run Permit (4), the drive will not be able to run the motor while a Run Permit (4) signal is not provided.

20 Commander S100 USer Guide

Page 21

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

Bit 0 Run Forward Set to 1 if a digital input has been configured as the Run Forward function (2) and is active.

Bit 1 Run Reverse Set to 1 if a digital input has been configured as the Run Reverse function (3) and is active.

Bit 2 Run Set to 1 if a digital input has been configured as the Run function (16) and is active.

Bit 3 Reverse Set to 1 if a digital input has been configured as the Reverse function (17) and is active.

Bit 4 Jog Forward Set to 1 if a digital input has been configured as the Jog Forward function (18) and is active.

Bit 5 Jog Reverse Set to 1 if a digital input has been configured as the Jog Reverse function (19) and is active.

Bit 6 Run Permit (Not Stop) Set to 1 if a digital input has been configured as the Run Permit (Not Stop) function (4) and is active.

P1.12 Run & Direction Indicators

A set of indicators that represent the sequencer run and direction inputs

0

(Display: 00000000)

8 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(Display: 11111111)

0

The Indicators that are shown here can be set by any of the digital inputs using their function selector parameters such as T11 Digital Input 1 Function

Select (P6.16) or by selecting an appropriate Run / Stop Config in Run/Stop Configuration (P6.13) .

Before the drive can run the motor, it must check that certain conditions are met. These are handled by the drive sequencer. The drive sequencer

monitors all drive inputs and compares them to the drive's configuration, set by the user, to ensure the motor only runs when it should.

For example:

4. If a drive input is configured as a Hardware Enabled (1), the drive will not be able to run the motor, even if a Run Forward (2) signal is provided,

until the enable signal is given on that input.

5. If Limit Switch Forward is active, only a Run Reverse signal would allow the motor to run.

6. If a drive input is configured as a Run Permit (4), the drive will not be able to run the motor if a Run Permit (4) signal is not provided.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.13 Ramp Input

The selected reference fed into the Ramp System

−MAXIMUM FREQUENCY LIMIT (P2.02)

8 Bit Volatile

Standard

RO, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

MAXIMUM FREQUENCY LIMIT (P2.02)

Hz

1 ms

1

Displays the reference frequency after the skip band and frequency limits have been applied but before it is fed into the ramp system. See References

& Ramps .

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.14 Ramp Output

The frequency output from the Ramp System

−MAXIMUM FREQUENCY LIMIT (P2.02

8 Bit Volatile

Standard

RO, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

MAXIMUM FREQUENCY LIMIT (P2.02)

Hz

1

Displays the reference frequency after the skip band and frequency limits have been applied but before it is fed into the ramp system. See References

& Ramps .

Commander S100 User Guide 21

Page 22

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

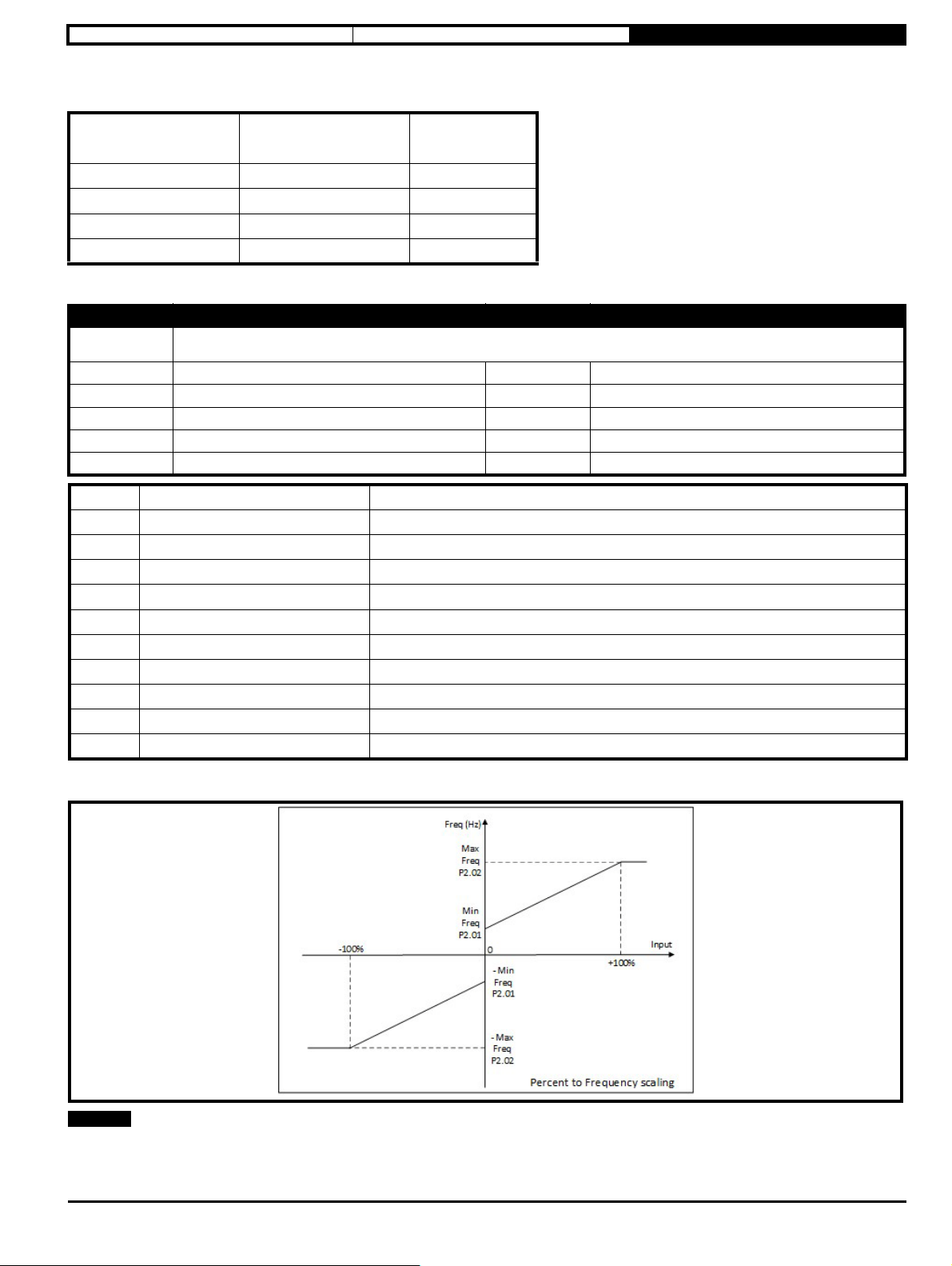

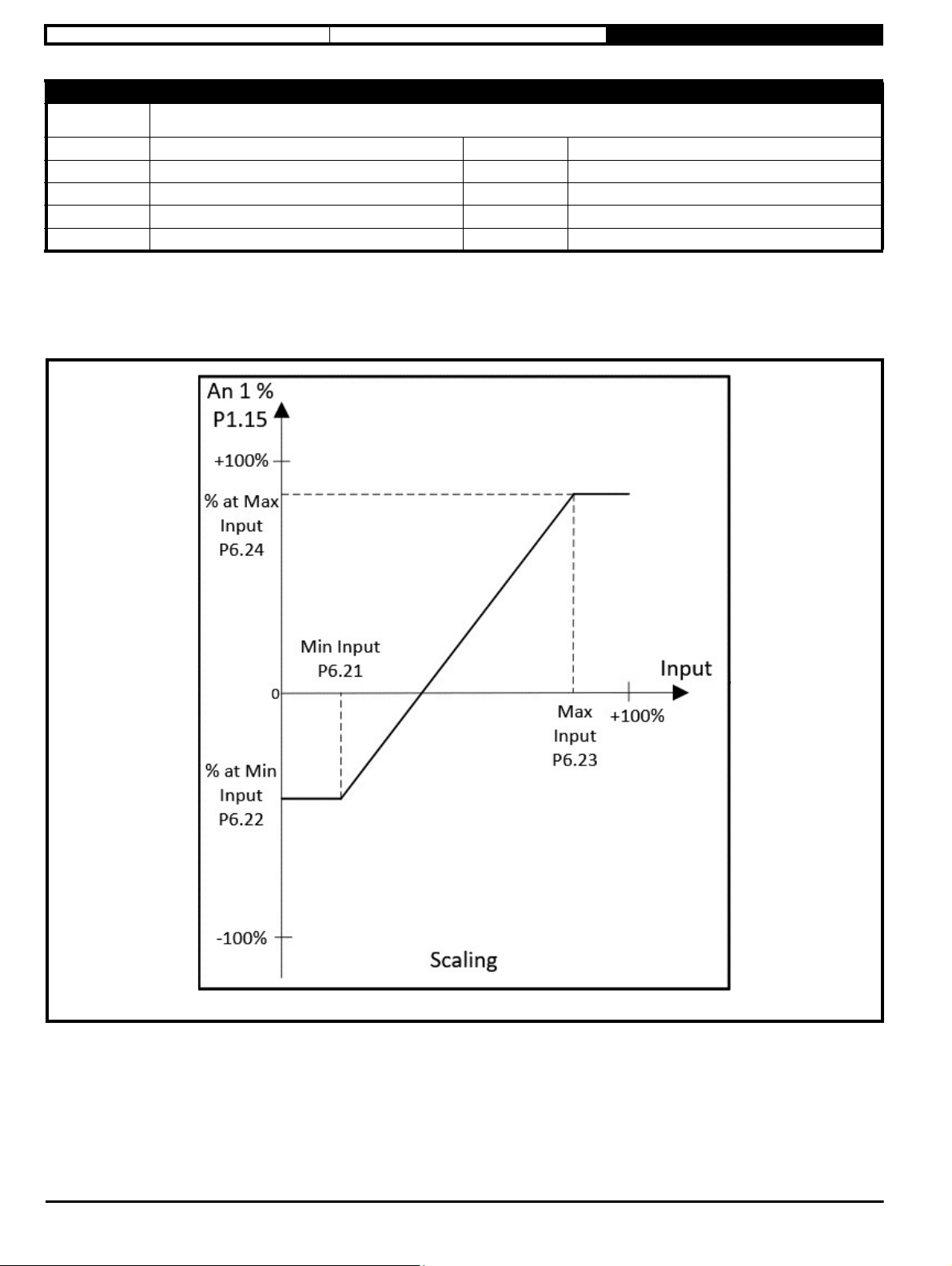

P1.15 T2 Analog Input 1 Percentage

The input level of analog input 1 as a percentage after it has been scaled

-100

16 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

100

%

0

Displays the input level of analog input 1 as a percentage after it has been scaled according to the terminal's scaling parameters. See T2 Analog Input

1 Minimum Input (P6.21).

This can be configured to set the motor frequency by selecting it as one of the 4 references (P2.21 - P2.24). See Frequency Reference 1 Selector

(P2.21). This value can then be used as a frequency reference, where 0% is the Minimum Frequency Limit (P2.01) and 100% is the Maximum

Frequency Limit (P2.02).

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.16 T4 Analog Input 2 Percentage

The input level of analog input 2 as a percentage after it has been scaled

-100.00

16 Bit Volatile

Standard

RO, FI, ND, NC

Maximum

Units

Update Rate

Decimal Places

100.00

%

2

Displays the input level of analog input 2 as a percentage after it has been scaled according to the terminal's scaling parameters. See T4 Analog Input

2 Minimum Input (P6.25).

This can be configured to set the motor frequency by selecting it as one of the 4 references (P2.21 - P2.24). See Frequency Reference 1 Selector

(P2.21). This value can then be used as a frequency reference, where 0% is the Minimum Frequency Limit (P2.01) and 100% is the Maximum

Frequency Limit (P2.02).

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.17 T15 Frequency Input Percentage

The input level of T15 Frequency Input as a percentage after it has been scaled

-100.00

16 Bit Volatile

Standard

RO, FI, ND, NC

Maximum

Units

Update Rate

Decimal Places

100.00

%

2

Displays the input level of T15 Frequency Input as a percentage after it has been scaled according to the frequency input's scaling parameters. See

T15 Frequency Input Minimum Input (P6.29).

This can be configured to set the motor frequency by selecting it as one of the 4 references (P2.21 - P2.24). See Frequency Reference 1 Selector

(P2.21). This value can then be used as a frequency reference, where 0% is the Minimum Frequency Limit (P2.01) and 100% is the Maximum

Frequency Limit (P2.02).

22 Commander S100 USer Guide

Page 23

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.18 Up/Down Percentage

The value of the Up/Down reference as a percentage which can be increased or decreased by the keypad or drive control terminals

0.00

16 Bit Power Down Save

Standard

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

100.00

%

2

This can be configured to set the motor frequency by selecting it as one of the 4 references (P2.21 - P2.24). See Frequency Reference 1 Selector

(P2.21). This value can then be used as a frequency reference, where 0% is the Minimum Frequency Limit (P2.01) and 100% is the Maximum

Frequency Limit (P2.02). The value can be increased or decreased using the UP and DOWN keys on the keypad (when in Status View) or, if selected,

by the drive control terminals.

See Up/Down Percent Configuration (P2.14) and Up/Down Percentage Time to Max (P2.15) for information on Up/Down control configuration.

This parameter is unidirectional with motor direction set by run forward / run reverse.

This feature is sometimes referred to as a Motorised Pot.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.19 PID Percentage

The percentage output for the PID controller including the Feed Forward

-100.00

16 Bit Volatile

Standard

RO, ND, NC

Maximum

Units

Update Rate

Decimal Places

100.00

%

2

This is derived from the output of the PID controller plus the Feed Forward term selected by PID Feed Forward Selector (P5.05).

The derivative term in the PID controller is fixed to 0.

This can be configured to set the motor frequency by selecting it as one of the 4 references (P2.21 - P2.24). See Frequency Reference 1 Selector

(P2.21). This value can then be used as a frequency reference, where 0% is the Minimum Frequency Limit (P2.01) and 100% is the Maximum

Frequency Limit (P2.02).

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.20 PID Status Indicators

A set of indicators that represent the status of the PID and Threshold Detector

0

(Display: 00000000)

8 Bit Volatile

Standard

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(D i spla y : 11111111)

%

0

If a source has been set at PID Enable Selector (P5.11) or Threshold Detector Selector (P5.12) they must be true to enable the PID controller. If an

input has been routed to PID Hardware Enable (13) this must also be true to enable the PID controller.

Bit 0 PID Enabled Indicates that the PID is enabled and active

Bit 1 PID limit applied

Bit 2

Threshold Detector

Output

Indicates that the PID output is being limited by PID Output Lower Limit (P5.09) or PID Output Upper Limit (P5.10),

or a limit following the addition of the Feed Forward is being applied

Indicates that the Threshold Detector output is active

Commander S100 User Guide 23

Page 24

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.21 PID Error

The error the PID controller is operating on

-100.00

16 Bit Volatile

Standard

RO, ND, NC

Maximum

Units

Update Rate

Decimal Places

100.00

%

2

The PID Error is the difference between the PID reference and PID feedback which are selected by PID Reference Selector (P5.03) and PID

Feedback Selector (P5.04).

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

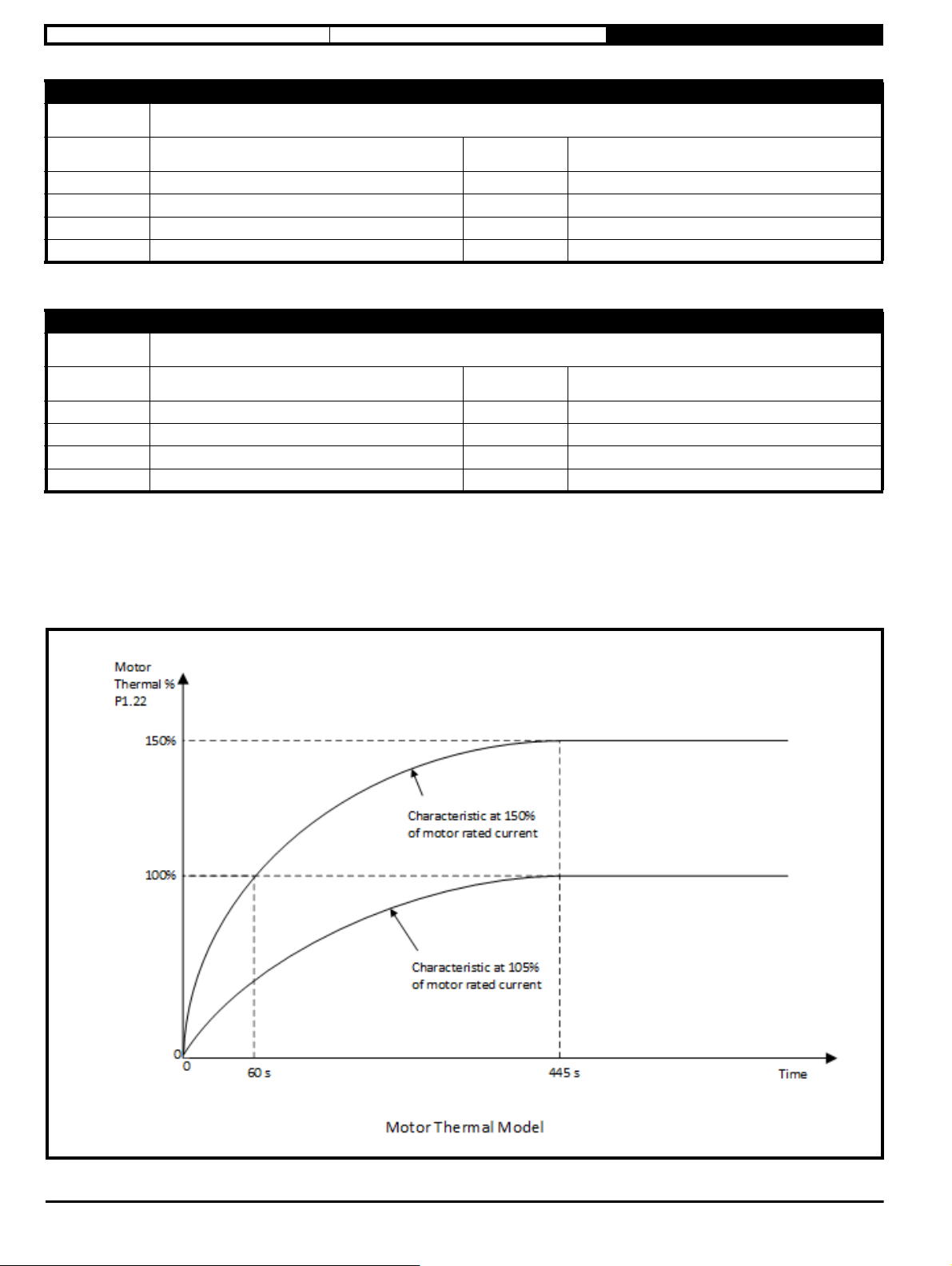

P1.22 Motor Thermal Percentage

The percentage of the maximum allowed temperature for the motor

0

8 Bit Power Down Save

Standard

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

100

%

0

The drive estimates the percentage of the motor maximum temperature from the output current and uses this to limit the overload period to protect the

motor. This function allows a longer overload period when the motor is cool and reduces the allowable overload period as the motor heats.

The overload period depends on the percentage overload current and motor starting temperature.

The action taken by the drive can be set in Thermal Protection Action (P3.21).

If Thermal Protection Action (P3.21) is set to Limit, the output current will be limited if this parameter > 90%.

If Thermal Protection Action (P3.21) is set to Error, the error will occur when this parameter = 100%.

An alarm is indicated if this percentage is >95% and cleared when <75% (Alarm Indicators (P1.09)).

24 Commander S100 USer Guide

Page 25

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.23 Drive Thermal Percentage

The percentage of the maximum allowed temperature in the drive

0

8 Bit Volatile

Standard

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

100

%

0

The drive measures its internal temperature which changes depending on the output current. This is displayed as a percentage of the maximum

allowed drive temperature.

The action taken by the drive can be set in Thermal Protection Action (P3.21).

If Thermal Protection Action (P3.21) is set to Limit, the output current will be limited if this parameter > 90%.

If Thermal Protection Action (P3.21) is set to Error, the error will occur when this parameter = 100%.

An alarm is indicated if this percentage is >95% and cleared when <75% (Alarm Indicators (P1.09)).

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.24 DC Bus Voltage

The voltage on the DC Bus of the drive

0

16 Bit Volatile

Standard

RO, FI, VM, ND, NC

Maximum

Units

Update Rate

Decimal Places

Maximum D.C. Link Voltage

(110 V, 200 V Drives = 415 V, 400 V Drives = 830 V)

V

0

Displays the voltage on the DC Bus of the drive. This is the Supply Voltage x √2.

This voltage must exceed the under-voltage (UV) level for the drive to run.

100 V and 200 V drives (UV) = 175 V

400 V UV = 330 V

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

Bit 0 T11 Digital IO 1 Set to 1 if the input or output is active

Bit 1 T12 Digital Input 2 Set to 1 if the input is active

Bit 2 T13 Digital Input 3 Set to 1 if the input is active

Bit 3 T14 Digital Input 4 Set to 1 if the input is active

Bit 4 T15 Digital Input 5 Set to 1 if the input is active when a digital input, otherwise 0

Bit 5 T2 Analog Input 1 Set to 1 if the input is active

P1.25 Digital IO Indicators

A set of indicators that represent the status of the digital I/O

0

(Display: 00000000)

8 Bit Volatile

Binary

RO, ND, NC, BU

Maximum

Units

Update Rate

Decimal Places

255

(D i spla y : 11111111)

0

Bit 6 T4 Analog Input 2 Set to 1 if the input is active

Bit 7 T41 Relay Set to 1 if the relay is active

Commander S100 User Guide 25

Page 26

Safety information Electrical installation Drive Parameters

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.26 Parameter 1 Saved Value on Error

The value of a designated parameter when the latest error occurred

-32768

16 Bit Power Down Save

Standard

RO, ND, NC

Maximum

Units

Update Rate

Decimal Places

32767

Write on Error

0

If an error occurs the drive will save the value of the parameter selected by Parameter 1 Save on Error Selector (P4.09). There are two other saved

parameters that behave in the same way, Parameter 2 Saved Value on Error (P1.27) & Parameter 3 Saved Value on Error (P1.28) . All of these

parameters are saved at the point when an Error (P1.29) occurs.

Parameter

Short

description

Minimum

Default

Typ e

Display Format

Coding

P1.27 Parameter 2 Saved Value on Error

The value of a designated parameter when the latest error occurred

-32768

16 Bit Power Down Save

Standard

RO, ND, NC

Maximum

Units

Update Rate

Decimal Places

32767

Write on Error

0

See Parameter 1 Saved Value on Error (P1.26).

Parameter

Short

description

Minimum

P1.28 Parameter 3 Saved Value on Error

The value of a designated parameter when the latest error occurred

-32768

Maximum

32767

Default

Typ e

Display Format

Coding

16 Bit Power Down Save

Standard

RO, ND, NC

Units

Update Rate

Decimal Places

Write on Error

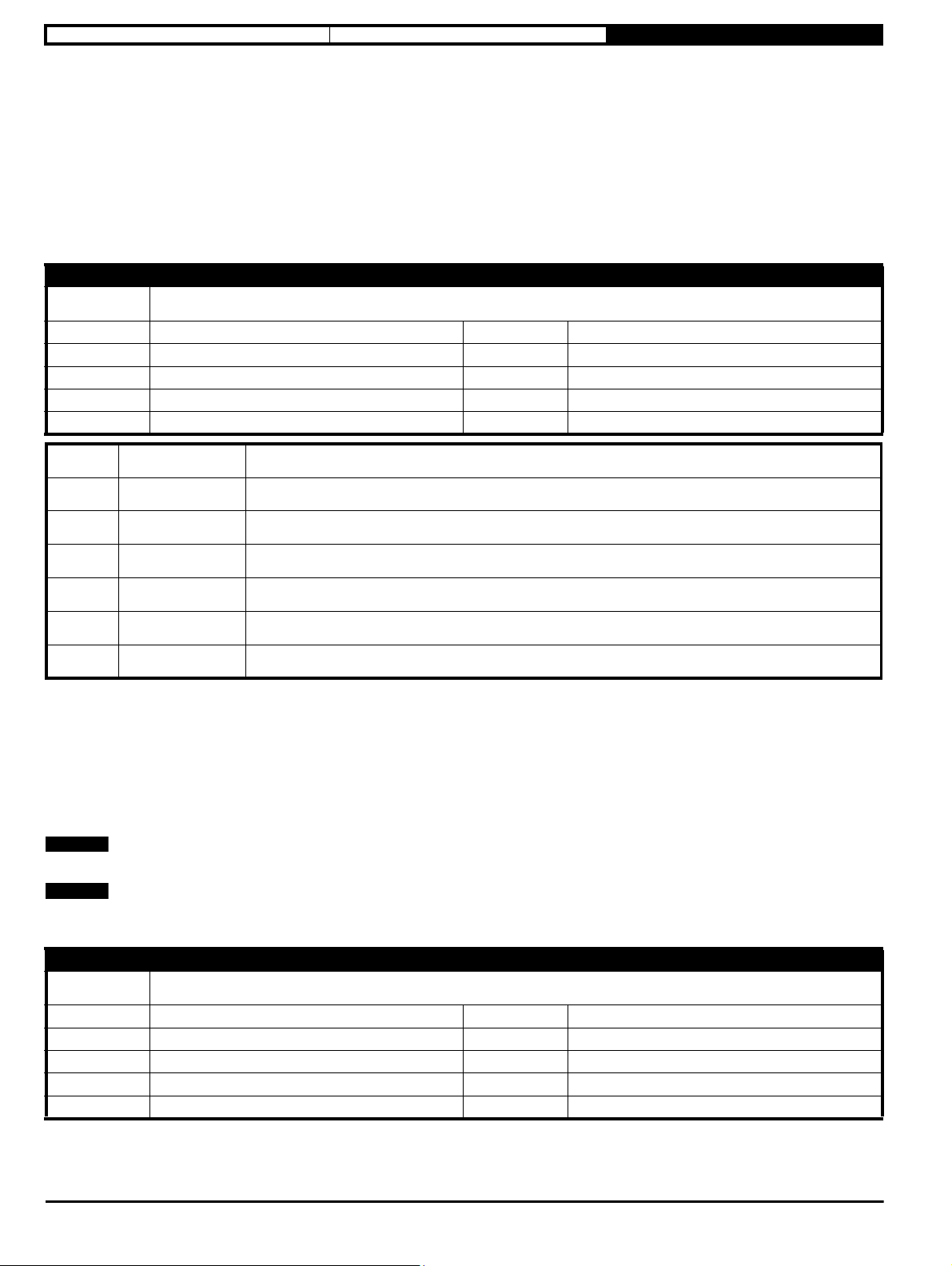

0