Page 1

Commander C200/C300

Step By Step Guide

Guide pas à pas

Schritt-für-Schritt-Anleitung

Guida dettagliata

Guía detallada

Frame sizes 5 to 9

Tailles 5 à 9

Baugrößen 5 bis 9

Taglie da 5 a 9

Tamaños 5 a 9

Page 2

English

PE

+DC -DC

U

V

W

L1 L2 L3

6

5

5

1

41 42

2

3

4

7

7

8

9

+DC

BRAKE

8

10

11

13

7 8

9

12

5

1

2

7

U V W

5

12

12

12 12

910

8

12

1

1

2

3

13

11

4

5

6

7

6

5

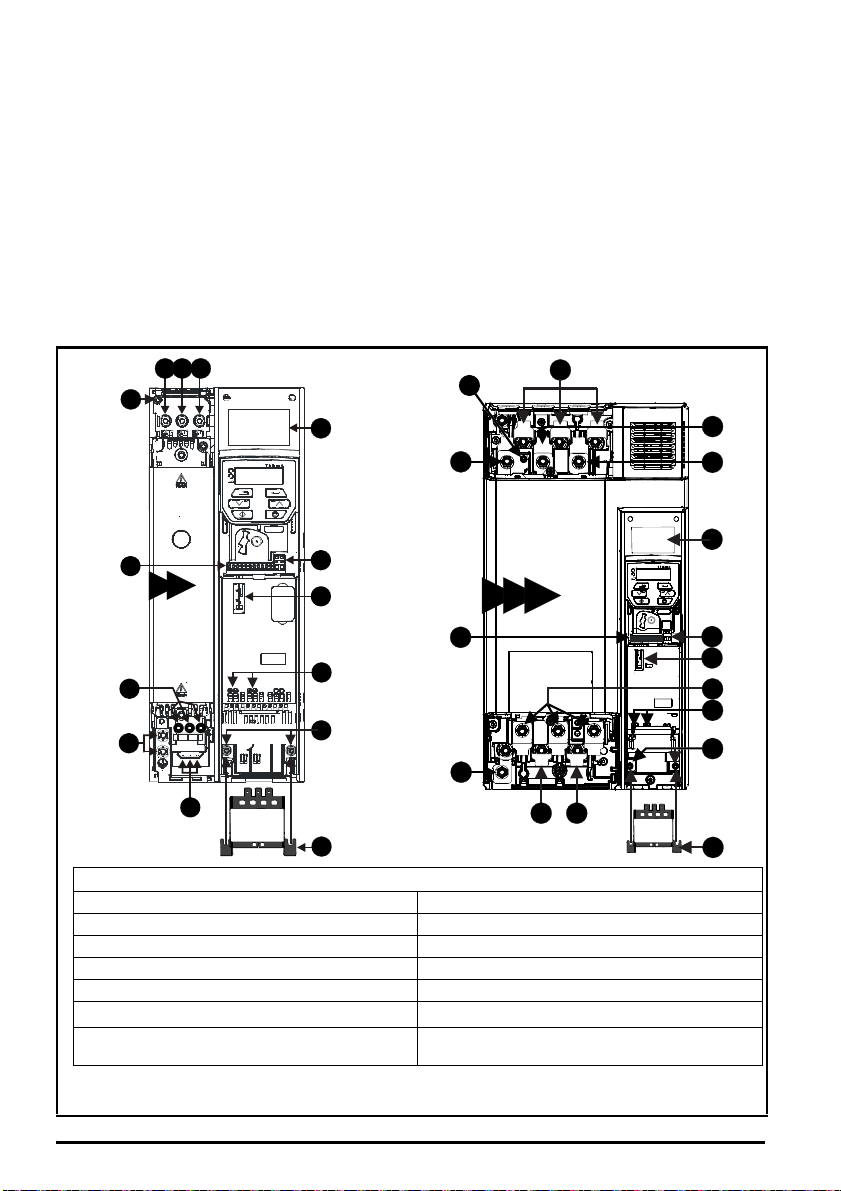

Key

1. Rating label 2. Relay connections (Refer to Fig. 6-5)

3. Option module slot 1 4. Motor connections (Refer to Fig. 6-1 to Fig. 6-4)

5. Ground connections (Refer to Fig. 6-1 to 6-4) 6. AC supply connections (Refer to Fig. 6-1 to Fig. 6-4)

7. Control connections (Refer to Fig. 6-5) 8. DC bus +

9. DC bus - 10. Braking terminal

11. Cable bracket to ground terminals

12. Internal EMC filter screw

*

13. Safe Torque Off terminals (STO)**

(Refer to Fig 6-5)

* Before removing the screw, refer to Chapter 4 in the Power Installation Guide.

** Commander C300 only

Introduction

The Commander C200 and C300 is a simple and flexible range of drives from 0.25 kW to 132 kW in 9 frame sizes

and two input voltage ranges (200 V, and 400 V).

This Step-by Step guide provides simple step-by-step instructions on how to mount the drive, fuse and cable

selection, wiring the drive-up, programming the drive and running the motor in analog input mode or keypad mode

on frames 5 to 9.

Features of the drive

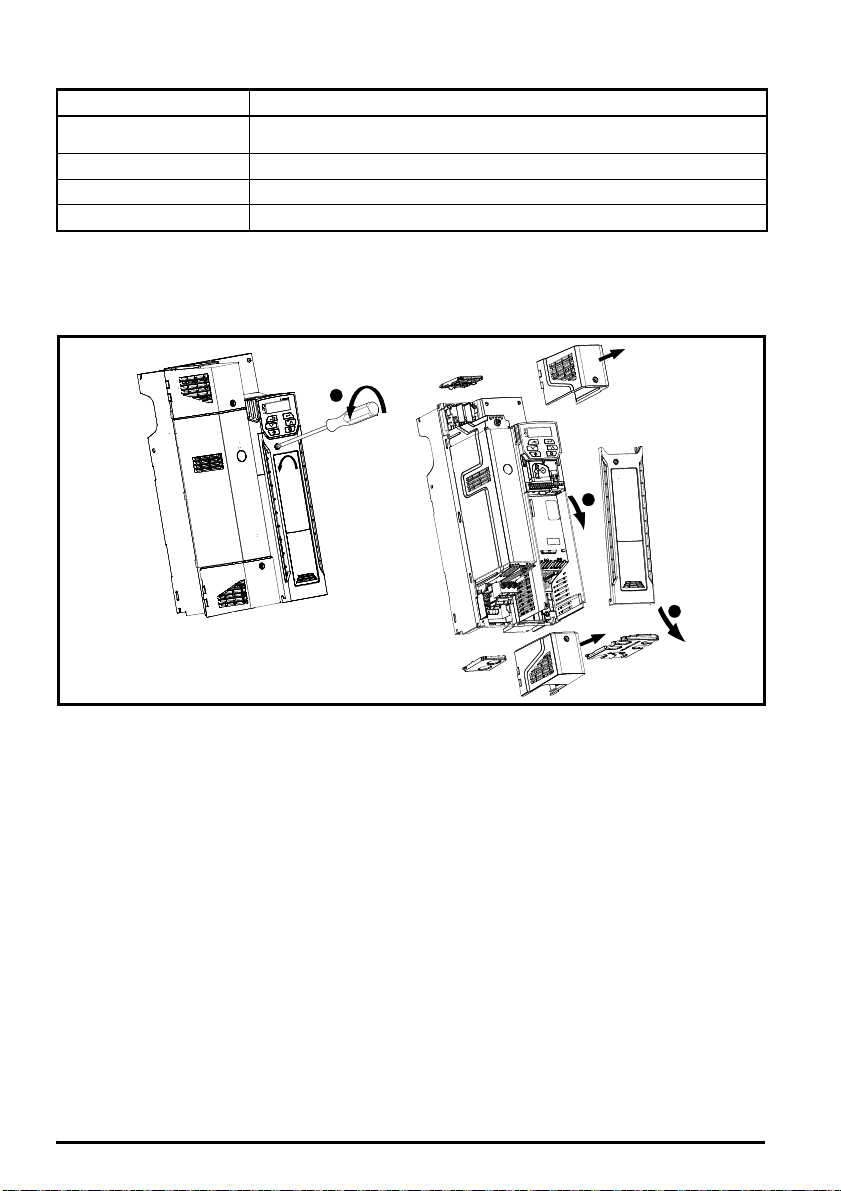

Figure 1-1 Feature diagram

2 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 3

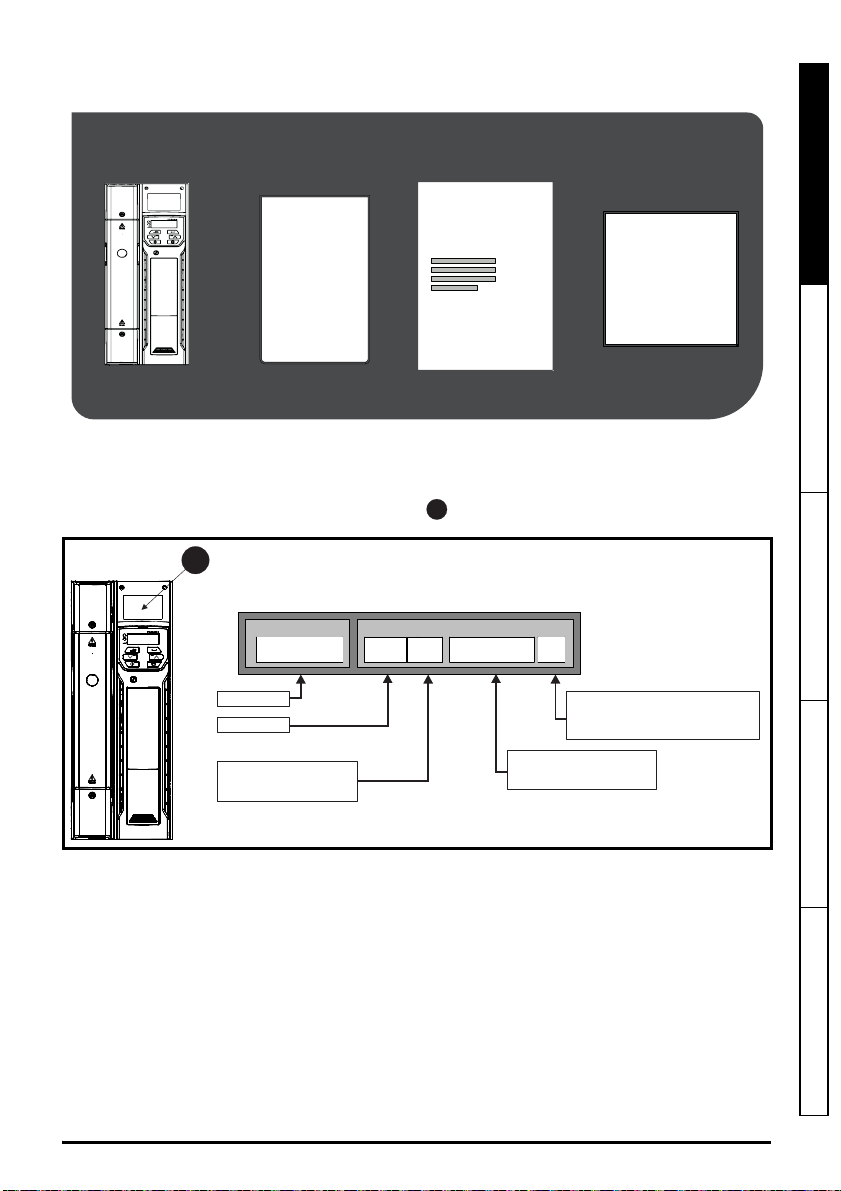

STEP 1: Check the contents of the box

KIT BOX*

SAFETY

INFORMATION

+

+

+

STEP BY

STEP

GUIDE

1

Product line:

Frame size:

Current Rating :

Heavy Duty current rating x10

Drive Format :

A - AC inAC out

E - AC in AC out (without internal choke)

Voltage rating

:

2 - 200 V (200 - 240 ± 10 %)

4 - 400 V (380 - 480 ± 10 %)

Derivative

Electrical Specifications

C300

-

05 4 00270 A

1

Check you have all the components and your drive has not been damaged during transportation.

* With frame size 7, 8 and 9, surface mounting brackets are also supplied with the drive.

STEP 2: Check model and voltage

The model number can be found on the identification label on the top of the drive. Please check that the model

and the drive voltage range is suitable for the installation.

English

Français Deutsch Italiano Español

Commander C200/C300 Step By Step Guide 3

Issue Number: 2

Page 4

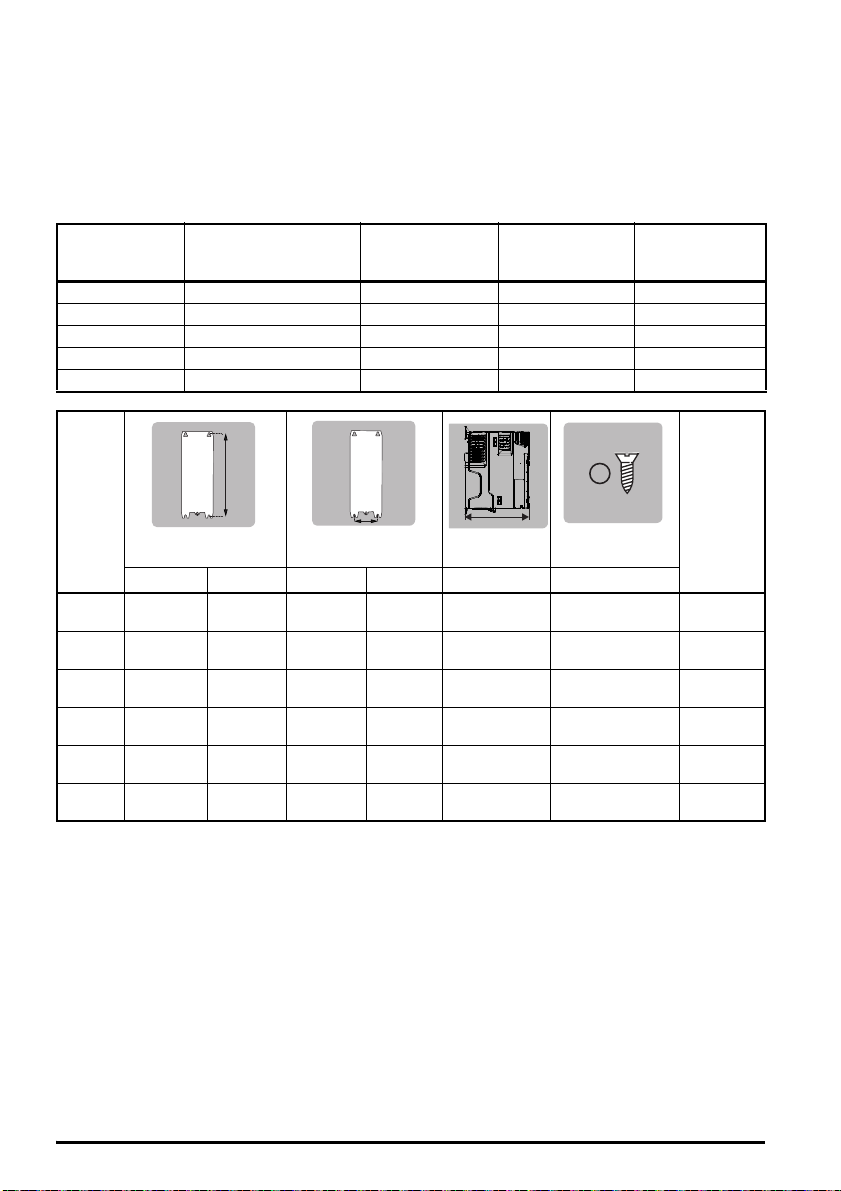

STEP 3: Mount the drive

The drive should be mounted in an ambient temperature range of - 20 °C to 60 °C (- 4 °F to 140 °F).

Output current derating may be required at ambient temperatures >40 °C (104 °F). Refer to the relevant Power

Installation Guide (section 5.1). For UL installations, the maximum ambient temperature permitted is 50 °C (122 °F)

with any specified derating applied.

The drive can be screwed on a wall or Through-panel mounted (Refer to chapter 3 in the Power Installation Guide).

Table 3-1 highlights the clearances.

Table 3-1 Recommended spacing

Frame size

5 30 mm (1.18 in) 0 mm (0.00 in) 100 mm (4.0 in) 100 mm (4.0 in)

6 30 mm (1.18 in) 0 mm (0.00 in) 100 mm (4.0 in) 100 mm (4.0 in)

7 45 mm (1.77 in) 30 mm (1.18 in) 60 mm (2.37 in) 100 mm (4.0 in)

8 45 mm (1.77 in) 30 mm (1.18 in) 60 mm (2.37 in) 100 mm (4.0 in)

9 45 mm (1.77 in) 60 mm (2.37 in) 60 mm (2.37 in) 100 mm (4.0 in)

Frame Weight

Spacing between drive

and enclosure /

EMC filter

Spacing between

drives

Spacing above

drive

Spacing below

drive

HW

Mounting Overall Mounting Overall Overall Diameter

9E

9A

375 mm

5

(14.76 in)

378 mm

6

(14.88 in)

538 mm

7

(21.18 in)

784 mm

8

(30.87 in)

1051 mm

(41.38 in)

1090 mm

(42.91 in)

391 mm

(15.39 in)

391 mm

(15.39 in)

557 mm

(21.93 in)

804 mm

(31.65 in)

1069 mm

(42.09 in)

110 8 mm

(43.62 in)

106 mm

(4.17 in)

196 mm

(7.72 in)

220 mm

(8.66 in)

259 mm

(10.20 in)

259 mm

(10.20 in)

259 mm

(10.20 in)

143 mm

(5.63 in)

210 mm

(8.27 in)

270 mm

(10.63 in)

310 mm

(12.21 in)

310 mm

(12.21 in)

310 mm

(12.21 in)

D

200 mm

(7.87 in)

227 mm

(8.94 in)

280 mm

(11.02 in)

290 mm

(11.42 in)

290 mm

(11.42 in)

290 mm

(11.42 in)

Ø

6.5 mm (0.26 in)

7.0 mm (0.28 in)

9.0 mm (0.35 in)

9.0 mm (0.35 in)

9.0 mm (0.35 in)

9.0 mm (0.35 in)

7.4 kg

(16.3 Ib)

14 kg

(30.9 Ib)

28 kg

(61.70 Ib)

52 kg

(114.6 Ib)

46 kg

(101.4 Ib)

66.5 kg

(146.6 Ib)

4 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 5

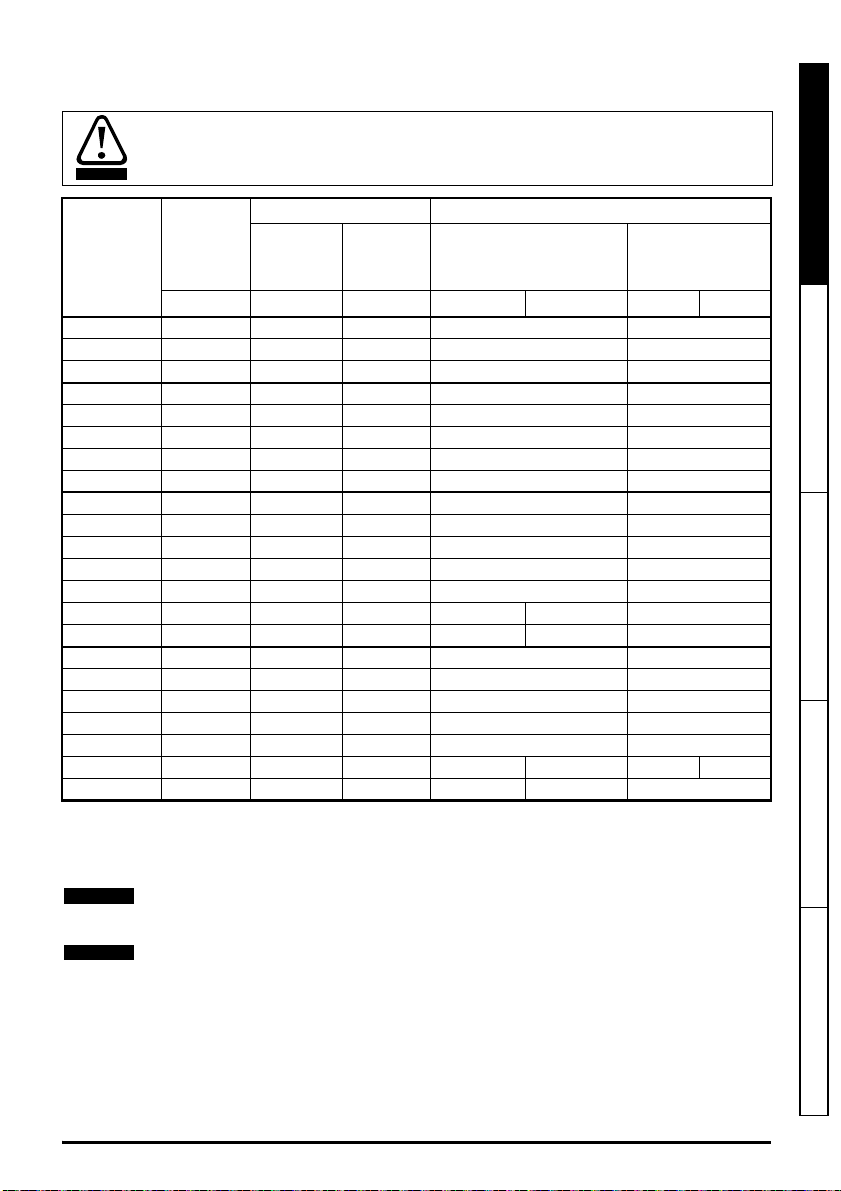

STEP 4: Select supply / motor cables and fuses

WARNING

NOTE

NOTE

The supply/motor cables and fuses or MCB’s used should follow the ratings provided in the table below:

The voltage rating of fuses must be greater than or equal to the highest supply voltage of the system.

Fuses: The AC supply to the drive must be installed with suitable protection against overload. Failure

to observe this requirement will cause risk of fire.

English

Maximum

continuous

Model

05200250 31 40 40 10 8

06200330 48.8 63 60 16 4

06200440 56.6 63 70 25 3

05400270 29 40 35 6 8

05400300 29 40 35 6 8

06400350 36 63** 40 10 6

06400420 46 63** 50 16 4

06400470 60 63** 70 25 3

07200610 67 80 80 35 2

07200750 84 100 100 35 1

07200830 105 125 125 70 1/0

08201160 137 200** 200*** 95 3/0

08201320 166 200** 225*** 2 x 70 2 x 1

09201760 205 250** 250*** 2 x 70 (B1) 2 x 95 (B2) 2 x 2/0

09202190 260 315** 300*** 2 x 95 (B1) 2 x 120 (B2) 2 x 4/0

07400660 74 100 80 35 1

07400770 88 100 100 50 2

07401000 105 125 125 70 1/0

08401340 155 250** 225*** 2 x 50 2 x 1

08401570 177 250** 225*** 2 x 70 2 x 1/0

09402000 232 315** 300*** 2 x 70 (B1) 2 x 95 (B2) 2 x 3/0 2 x 2/0

09402240 267 315** 350*** 2 x 95 (B1) 2 x 120 (B2) 2 x 4/0

input

current

A A A Input Output Input Output

Fuses Cables

IEC Class

gG or gR

UL

Class CC,

*

J, or T

IEC60364-5-52

mm²

UL 508C

AWG

* These fuses are fast acting.

** These fuses are class gR.

*** These fuses are class HSJ.

The product is UL listed for use on a circuit up to 100 kA maximum supply symmetrical fault current,

when protected by fuses.

Français Deutsch Italiano Español

IEC cable sizes assume Copper conductor, PVC insulation, Installation method B2 and ambient

temperature of 40 °C (104 °F). UL cable sizes assume Copper conductor with insulation rated at 75 °C

(167 °F).

Commander C200/C300 Step By Step Guide 5

Issue Number: 2

Page 6

Table 4-1 Protective ground cable ratings

1

2

3

Input phase conductor size Minimum ground conductor size

≤ 10 mm²

> 10 mm² and ≤ 16 mm²

> 16 mm² and ≤ 35 mm² 16 mm²

> 35 mm²

Either 10 mm² or two conductors of the same cross-sectional area as the input

phase conductor

The same cross-sectional area as the input phase conductor

Half of the cross-sectional area of the input phase conductor

STEP 5: Remove the terminal cover and finger guard breakouts

1. Using a flat bladed screwdriver, turn the terminal cover locking clip anti-clockwise by approximately 30°.

2. Slide the terminal cover down.

3. Remove terminal cover in direction shown.

6 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 7

Removing the finger-guard break-outs

A

1

2

2

1

212

1

2

1

3

2

B

C

D

A: Size 5 to 9

B: Size 5 only

C: Size 6 only

D: Size 7 to 9

Place finger-guard on a flat solid surface and hit relevant

break-outs with hammer as shown (1). For sizes 7 to 9 pliers

can be used to remove the break-outs, grasp the relevant

break-out with the pliers and twist it as shown (3).

Continue until all required break-outs are removed (2).

Remove any flash / sharp edges once the break-outs

are removed.

Finger guard grommets are supplied in the kitbox for size 5

and 6.

English

Français Deutsch Italiano Español

STEP 6: Wire the drive up

When wiring the drive the power, ground and control connections, they should be tightened to the recommended

torque settings shown in the table below:

Table 6-1 Recommended torque settings

Model size Terminal description Torque settings

All

5

6 Power and ground terminals 6.0 N m (4.4 lb ft)

7 Power and ground terminals 12 N m (8.85 lb ft)

8 and 9 Power and ground terminals 15 N m (11.1 lb ft)

Commander C200/C300 Step By Step Guide 7

Issue Number: 2

Control terminals 0.2 N m (0.15 lb ft)

Relay terminals 0.5 N m (0.37 lb ft)

Power terminals 1.5 N m (1.1 lb ft)

Ground terminals 2.0 N m (1.4 lb ft)

Page 8

Power and Ground connections

Optional heatsink

mounted brake

resistor (M600

and above)

BR

+DC

-DC

DC / Brake connections

BR

Optional external

braking resistor

Thermal

overload

protection

device

DC -

DC +

L1 L2

L2L1 L3 U V W

Optional EMC

filter

Optional

line reactor

Fuses

L3

Mains

Supply

Motor

Optional ground

connection

Supply

Ground

PE

AC Connections Motor Connections

1

2

Connect the supply and motor connections using the cables and fuses quoted in the table shown in Step 4.

Figure 6-1 Size 5 power and ground connections

The upper terminal block (1) is used for AC supply connection.

The lower terminal block (2) is used for Motor connection.

On size 5, the supply and motor ground connections are made using the M5 studs located near the

plug-in power connector. Refer to Figure 6-1.

Issue Number: 2

8 Commander C200/C300 Step By Step Guide

Page 9

Figure 6-2 Size 6 power and ground connections

L1 L2

L2L1 L3 U V W

Optional EMC

filter

Optional

line reactor

Fuses

L3

Mains

Supply

Motor

Optional ground

connection

Supply

Ground

PE

AC Connections

BR

Optional

braking

resistor

Thermal

overload

protection

device

DC - DC +

DC Connections

(DC and braking)

Motor Connections

6

Ground connection

studs

English

On a size 6, the supply and motor ground connections are made using the M6 studs located above

the supply and motor terminals. Refer to Figure 6-2.

Français Deutsch Italiano Español

Commander C200/C300 Step By Step Guide 9

Issue Number: 2

Page 10

Figure 6-3 Size 7 and 8 power and ground connections (size 7 shown)

UVW

Motor

Optional ground

connection

+DC BR

Optional

braking

resistor

Thermal

overload

protection

device

Output connections

Input connections

Mains

Supply

L1 L2

Optional

line reactor

Optional

EMC filter

Fuses

L3

L1 L2 L3

+DC -DCPE

Supply

ground

8

On size 7 and 8, the supply and motor ground connections are made using the M8 studs located by

the supply and motor connection terminals. Refer to Figure 6-3.

10 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 11

Input connections

Mains

Supply

L1 L2

Optional

EMC filter

Fuses

L3

L1 L2 L3

PE

Supply

ground

+DC -DC

UVW

Motor

Optional ground

connection

+DC BR

Thermal

overload

protection

device

Output connections

Internal EMC

filter

9A

Figure 6-4 Size 9A power and ground connections

English

Français Deutsch Italiano Español

On size 9A, the supply and motor ground connections are made using the M10 studs located by the

supply and motor connection terminals. Refer to Figure 6-4.

Commander C200/C300 Step By Step Guide 11

Issue Number: 2

Page 12

Electrochemical corrosion of grounding terminals

WARNING

WARNING

9

10

11

12

13

14

41

42

1

2

7

4

5

31

32

35

36

24 V user

Zero frequency

Drive enable**

Run forward

Run reverse

Analog input 1/

Analog input 2 select

10 kΩ

10 kΩ

Frequency

reference 1

Frequency

reference 2

Frequency output

Digital I/O

24 V user

Digital I/O1

Digital Input 2

Digital input 3

Digital input 4

Digital input 5

Analog I/O

0V

Analog input 1

10 V user

Analog input 2

Analog output 1

Drive ok

Relay 1*

Safe Torque

Off

ST01

0V

STO1

0VSTO2

ST02

** C300 only

Ensure that grounding terminals are protected against corrosion i.e. as could be caused

by condensation.

The drive must be connected to the system ground of the AC supply. The ground wiring must

conform to local regulations and codes of practice.

The ground loop impedance must conform to the requirements of local safety regulations.

The drive must be grounded by a connection capable of carrying the prospective fault

current until the protective device (fuse, etc.) disconnects the AC supply.

The ground connections must be inspected and tested at appropriate intervals.

Table 6-2 Protective ground cable ratings

Input phase conductor size Minimum ground conductor size

≤ 10 mm²

> 10 mm² and ≤ 16 mm²

Either 10 mm² or two conductors of the same cross-sectional area as the

input phase conductor

The same cross-sectional area as the input phase conductor

> 16 mm² and ≤ 35 mm² 16 mm²

> 35 mm²

Half of the cross-sectional area of the input phase conductor

Control connections

The control terminals are configured by default for the arrangement shown below:

Figure 6-5 Commander C200/C300 control terminal connections

* 250 Vac maximum (UL class1)

** Commander C300 uses ‘Safe Torque Off’ so terminal 11 is unassigned on the Commander C300. When using a

Commander C300 refer to the 'Safe Torque Off' wiring instructions above.

After completing step 6 re-fit the terminal cover (refer to step 5).

12 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 13

STEP 7: Use the keypad

ENTER parameter view or

edit

mod

e, or to accept

a parameter edit.

UP/DOWNarrows can

be used to select

individual parameters

orto edit parameter

values.

STOP / RESET

the drive in keypad

mode. It can also be used

to reset the drive in

terminal mode.

ESCAPE

Is used to exit from the

parameter edit / view

mode.

rdy

START

Is used to start the drive in

keypad mode.

To return to Status Mode,

press button

To return to Parameter View Mode,

press button

Press or to select parameter

Status

Mode

To enter Parameter View Mode,

press button

Parameter

View Mode

Pr. 10

0.00

0.00

To view parameter value

press button

To enter Edit Mode,

press button

0.00

Edit Mode (edited digit flashes)

Holding or increases or decreases value

Parameter

Value View

To return to Parameter Value View

press button to keep the new value

press

button to ignore new value and

return the parameter to the pre-edited value

Pr. 01

rdy

The display provides information to the user regarding the operating status of the drive, alarms and trip codes.

The keypad provides the means for changing parameters, stopping and starting the drive, and the ability to perform

a drive reset.

Keypad key identifier

Instructions to edit parameters

English

Français Deutsch Italiano Español

Commander C200/C300 Step By Step Guide 13

Issue Number: 2

Page 14

STEP 8: Run the motor

Motor rated current in Pr 06 (Amps)

Motor rated speed in Pr 07 (rpm / min-1)

Motor rated voltage in Pr 08 (Volts)

Motor rated power factor in (cos φ) Pr 09

This step will provide instruction on how to set-up the basic drive parameters, perform an auto-tune and run the

motor in analog input terminal mode or keypad mode.

Action Detail

Power Up Ensure:

Minimum and

maximum speed

Accel and Decel

rates

Motor nameplate

details

Ready to autotune

Autotune The drive is able to perform either a stationary or a rotating autotune. The motor must be at

Ready to run (Analog input terminal mode by default)

Run The drive is now ready to run the motor. Close enable (C200) or Safe Torque Off (C300) and

Increasing and

decreasing speed

Stopping To stop the motor by following the selected deceleration rate, open either the run forward or

Ready to run (Keypad mode)

Run The drive is now ready to run the motor. Set Pr 05 to 'PAd'. Close enable (C200) or

Increasing and

decreasing speed

Stopping

• The drive displays: inh (Enable terminal(s) is open)

Enter:

• Minimum speed Pr 01 (Hz)

• Maximum speed Pr 02 (Hz)

Enter:

• Acceleration rate Pr 03 (s)

• Deceleration rate Pr 04 (s)

MOT. 3 LS 80 L T

734570 BJ 002 Kg 9

N

40 C S1IP 55 I cl.F

-1

V Hz min kW cos

230 50 2800 0,75 0,83 0,3

3

2

A

4

1

a standstill before any autotune is enabled and disconnected from the load for a rotating

autotune.

To perform an autotune:

•Set Pr10 to L2

• Go to Pr 38

•Set Pr38 = 1 for a stationary autotune or set Pr 38 = 2 for a rotating autotune

• Close the drive enable signal (apply +24 V to terminal 11 or terminal 31 and 35 on

Commander C300). The drive will display ‘rdy’.

• Give a Run command (apply +24 V to terminal 12 - Run forward or terminal 13 Run reverse. The display will flash ‘tuning’ while the drive is performing the autotune.

• Wait for the drive to display ‘inh’ and for the motor to come to a standstill.

• Remove the drive enable and run signal from the drive.

the Run Forward or Run Reverse terminals.

Changing the selected Analog frequency reference will increase and decrease the speed of

the motor.

run reverse terminals. If the enable terminal is opened while the motor is running, the drive

output is immediately disabled and the motor will coast to a stop.

Safe Torque Off (C300).

Press the start key

Press the up and down keys to increase and decrease the speed.

Press the Stop/Reset key

14 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 15

Additional Information

Troubleshooting

When the drive detects a fault it will display an error code. To locate and solve all error codes, a ‘Diagnostic Tool

(App)’ is available on Microsoft, Android and iOS platform via the ‘Apps’ store on Smartphone / Tablet, search for

‘Control Techniques diagnostics tool in the Apps store’. Alternatively, please download the ‘Diagnostic Tool

(App)’ from the Control Techniques ‘App Center’ or view the diagnostics section in the Control User Guide

available for download from the Control Techniques or Leroy Somer website.

Status Indicators

The table below shows the different status indicators available on the display.

Table 8-1 Status indications

String Description

The drive is inhibited and cannot be run. The Drive Enable signal is not applied

to the drive enable terminal or is set to 0.

The drive is ready to run. The drive enable is active, but the drive inverter is

not active because the final drive run is not active

The drive is stopped / holding zero speed. Enabled

Supply loss condition has been detected Enabled

The drive is applying dc injection braking Enabled

The drive has tripped and no longer controlling the motor. The trip code

appears on the display.

The drive is in the under voltage state. Disabled

Restoring drive defaults

The drive can be restored to the original factory settings by following the procedure below:

1. Ensure the drive is not enabled, i.e. terminal 11(or terminal 31 and 35 on Commander C300) is open.

2. Select ‘Def.50 (50 Hz settings) or Def.60 (60 Hz settings)’ in Pr 00.

3. Press the red reset button.

Basic parameters range and default

For information on parameters beyond Pr 00 to Pr 10 refer to the Quick Start Guide.

Parameter Range () Default ()

01 Minimum Speed 0.00 to Pr 02 Hz 0.00 Hz

02 Maximum Speed 0.00 to 550.00 Hz

03 Acceleration Rate 1 0.0 to 32000.0 s 5.0 s

04 Deceleration Rate 1 0.0 to 32000.0 s 10.0 s

AV (0), AI (1), AV.Pr (2), AI.Pr (3),

05 Drive Configuration

06 Motor Rated Current 0.00 to Drive Rating Amps

07 Motor Rated Speed 0.0 to 33000.0 rpm

08 Motor Rated Voltage 0 to 240 V or 0 to 480 V

09 Motor Rated Power Factor 0.00 to 1.00 0.85

10 User Security Status

PrESEt (4), PAd (5), PAd.rEF (6), E.Pot (7),

Refer to the Control User Guide for further

Refer to the Control User Guide for further

torquE (8), Pid (9)

information

information

Maximum Heavy Duty

400V drive Def.50: 400 V

400V drive Def.60: 460 V

Drive output

stage

Disabled

Disabled

Disabled

Def.50: 50.00 Hz

Def.60: 60.00 Hz

AV ( 0)

Rating Amps

Def.50: 1500.0 rpm

Def.60: 1800.0 rpm

110V drive: 230 V

200V drive: 230 V

LEVEL.1

English

Français Deutsch Italiano Español

Commander C200/C300 Step By Step Guide 15

Issue Number: 2

Page 16

Appendix A UL listing information

A.1 UL file reference

All models are UL Listed to both Canadian and US requirements. The UL file reference is: NMMS/7.E171230.

Products that incorporate the Safe Torque Off function have been investigated by UL. The UL file reference is:

FSPC.E171230.

A.2 Option modules, kits and accessories

Option Modules, Control Pods, Installation Kits and other accessories for use with these drives are UL Listed.

A.3 Enclosure ratings

Open Type

With the exception of free-standing cubicle drives, all models are Open Type as supplied. The drive housing is not

rated as a fire enclosure. A separate fire enclosure must be provided.

Type 1

When fitted with a conduit box the drives meet the requirements for UL Type 1. Type 1 enclosures are intended for

indoor use, primarily to provide a degree of protection against limited amounts of falling dirt.

Plenum rating with conduit box

When fitted with a conduit box, the drives comply with the requirements in the Standard for Fire Test for Heat and

Visible Smoke Release for Discrete Products and Their Accessories Installed in Air-Handling Spaces, UL 2043.

Through-hole mounting

The drives meet the requirements for UL Type 12 when installed inside a Type 12 enclosure with the heatsink

through-hole mounted using the sealing kit and the high-IP insert (where provided).

When through-hole mounted, the drives have been evaluated as suitable for use in surrounding air temperatures

up to 40 °C.

When the drive is through-panel mounted, the main terminal cover(s) must be removed in order to provide access

to the mounting holes. Once the drive has been mounted, the terminal cover(s) can be replaced.

The tightening torque of the securement brackets shall be advised as being 3 N m (26.6 lb.in).

Remote Keypads

Remote keypads are UL Type 12 when installed with the sealing washer and fixing kit provided.

A.4 Mounting

Drives may be surface, through-panel or tile mounted using the appropriate brackets. Drives may be mounted

singly or side by side with suitable space between them (bookcase mounting).

A.5 Environment

Drives must be installed in a Pollution Degree 2 environment or better (dry, non-conductive pollution only).

The drives have been evaluated for use at ambient temperatures up to 40 °C. The drives have additionally been

evaluated for 50 °C and 55 °C ambient air temperatures with a derated output.

A.6 Electrical Installation

OVERVOLTAGE CATEGORY

Drives have been evaluated for OVC III.

SUPPLY

The drives are suitable for use on a circuit capable of delivering not more than 100,000 RMS symmetrical amperes,

600 Volts AC Maximum.

TERMINAL TORQUE

Terminals must be tightened to the rated torque as specified in the Installation Instructions.

WIRING TERMINALS

Drives must be installed using cables rated for 75 °C operation, copper wire only.

Where possible, UL Listed closed-loop connectors sized according to the field wiring shall be used for all field

power wiring connections.

16 Commander C200/C300 Step By Step Guide

Issue Number: 2

Page 17

GROUND CONNECTION INSTRUCTIONS

UL Listed closed-loop connectors sized according to the field wiring shall be used for grounding connections.

BRANCH CIRCUIT PROTECTION

The fuses and circuit breakers required for branch circuit protection are specified in the Installation Instructions.

OPENING OF BRANCH CIRCUIT

Opening of the branch-circuit protective device may be an indication that a fault has been interrupted. To reduce the

risk of fire or electric shock, the equipment should be examined and replaced if damaged. If burnout of the current

element of an overload relay occurs, the complete overload relay must be replaced.

Integral solid state short circuit protection does not provide branch circuit protection. Branch circuit protection must

be provided in accordance with the National Electrical Code (NEC), The Canadian Electrical Code, and any

additional local codes.

A.7 Motor overload protection and thermal memory retention

The devices incorporate solid state overload protection for the motor load. The protection levels are expressed as a

percentage of full-load current. Refer to the Control User Guide for further information.

In order for the motor protection to work properly, the motor rated current must be entered into Pr 06 or Pr 05.007.

The protection level may be adjusted below 150 % if required. Refer to the Control User Guide for further information.

All models are provided with thermal memory retention.

A.8 External Class 2 supply

The external power supply used to power the 24 V control circuit shall be marked: "UL Class 2". The power supply

voltage shall not exceed 24 Vdc.

A.9 Modular Drive Systems

Drives with DC+ and DC- supply connections, rated 230 V or 480 V have been investigated for use in Modular Drive

Systems as inverters when supplied by the converter sections from the Unidrive-M range. In these applications the

inverters are required to be additionally protected by supplemental fuses.

Alternatively, the inverters may be supplied by converter models: Mentor MP25A, 45A, 75A, 105A, 155A or 210A.

Contact the supplier of the drive for more information.

A.10 Requirement for Transient Surge Suppression

This requirement only applies to Frame Size 7 drives with rated input voltage = 575 V.

TRANSIENT SURGE SUPPRESSION SHALL BE INSTALLED ON THE LINE SIDE OF THIS EQUIPMENT

AND SHALL BE RATED 575 Vac (PHASE TO GROUND), 575 Vac (PHASE TO PHASE), SUITABLE FOR

OVERVOLTAGE CATEGORY III, AND SHALL PROVIDE PROTECTION FOR A RATED IMPULSE VOLTAGE

TO WITHSTAND VOLTAGE PEAK OF 6 kV AND A CLAMPING VOLTAGE OF MAXIMUM 2400 V.

English

Français Deutsch Italiano Español

Commander C200/C300 Step By Step Guide 17

Issue Number: 2

Loading...

Loading...