Control Techniques Commander C200, Commander C300, Unidrive M100, Unidrive M400 Installation Manual

Page 1

Page 2

Original Instructions

For the purposes of compliance with the EU Machinery Directive 2006/42/EC, the English version of this manual is

the Original Instructions. Manuals in other languages are Translations of the Original Instructions.

Documentation

The information contained in this manual is believed to be correct at the time of printing and does not form part of

any contract. The manufacturer reserves the right to change the specification of the product and its performance,

and the contents of the manual, without notice.

Warranty and Liability

In no event and under no circumstances shall the manufacturer be liable for damages and failures due to misuse,

abuse, improper installation, or abnormal conditions of temperature, dust, or corrosion, or failures due to operation

outside the published ratings. The manufacturer is not liable for consequential and incidental damages. Contact the

supplier of the dive for full details of the warranty terms.

Environmental policy

Control Techniques Ltd operates an Environmental Management System (EMS) that conforms to the International

Standard ISO 14001.

Restriction of Hazardous Substances (RoHS)

The products covered by this manual comply with European and International regulations on the Restriction of Hazardous Substances including EU directive 2011/65/EU and the Chinese Administrative Measures for Restriction of

Hazardous Substances in Electrical and Electronic Products.

Disposal and Recycling (WEEE)

When electronic products reach the end of their useful life, they must not be disposed of along

with domestic waste but should be recycled by a specialist recycler of electronic equipment.

Control Techniques products are designed to be easily dismantled into their major component

parts for efficient recycling. The majority of materials used in the product are suitable for

recycling.

Product packaging is of good quality and can be re-used. Large products are packed in wooden

crates. Smaller products are packaged in strong cardboard cartons which have a high recycled

fibre content. Cartons can be re-used and recycled. Polythene, used in protective film and bags

for wrapping the product, can be recycled. When preparing to recycle or dispose of any product

or packaging, please observe local legislation and best practice.

REACH legislation

EC Regulation 1907/2006 on the Registration, Evaluation, Authorisation and restriction of Chemicals (REACH)

requires the supplier of an article to inform the recipient if it contains more than a specified proportion of any

substance which is considered by the European Chemicals Agency (ECHA) to be a Substance of Very High

Concern (SVHC) and is therefore listed by them as a candidate for compulsory authorisation.

.

Page 3

Copyright

The contents of this publication are believed to be correct at the time of printing. In the interests of a commitment to

a policy of continuous development and improvement, the manufacturer reserves the right to change the

specification of the product or its performance, or the contents of the guide, without notice.

All rights reserved. No parts of this guide may be reproduced or transmitted in any form or by any means, electrical

or mechanical including photocopying, recording or by an information storage or retrieval system, without

permission in writing from the publisher.

Copyright © November 2018 Nidec Control Techniques Ltd

Page 4

Contents

1 Safety information .....................................................................................11

1.1 Warnings, Cautions and Notes ..............................................................................11

1.2 Important safety information. Hazards. Competence of designers and installers ..11

1.3 Responsibility ......................................................................................................... 11

1.4 Compliance with regulations ..................................................................................11

1.5 Electrical hazards ...................................................................................................12

1.6 Stored electrical charge .........................................................................................12

1.7 Mechanical hazards ............................................................................................... 12

1.8 Access to equipment ..............................................................................................12

1.9 Environmental limits ...............................................................................................12

1.10 Hazardous environments .......................................................................................13

1.11 Motor ......................................................................................................................13

1.12 Mechanical brake control ....................................................................................... 13

1.13 Adjusting parameters ............................................................................................. 13

1.14 Electromagnetic compatibility (EMC) .....................................................................13

2 Product information ..................................................................................14

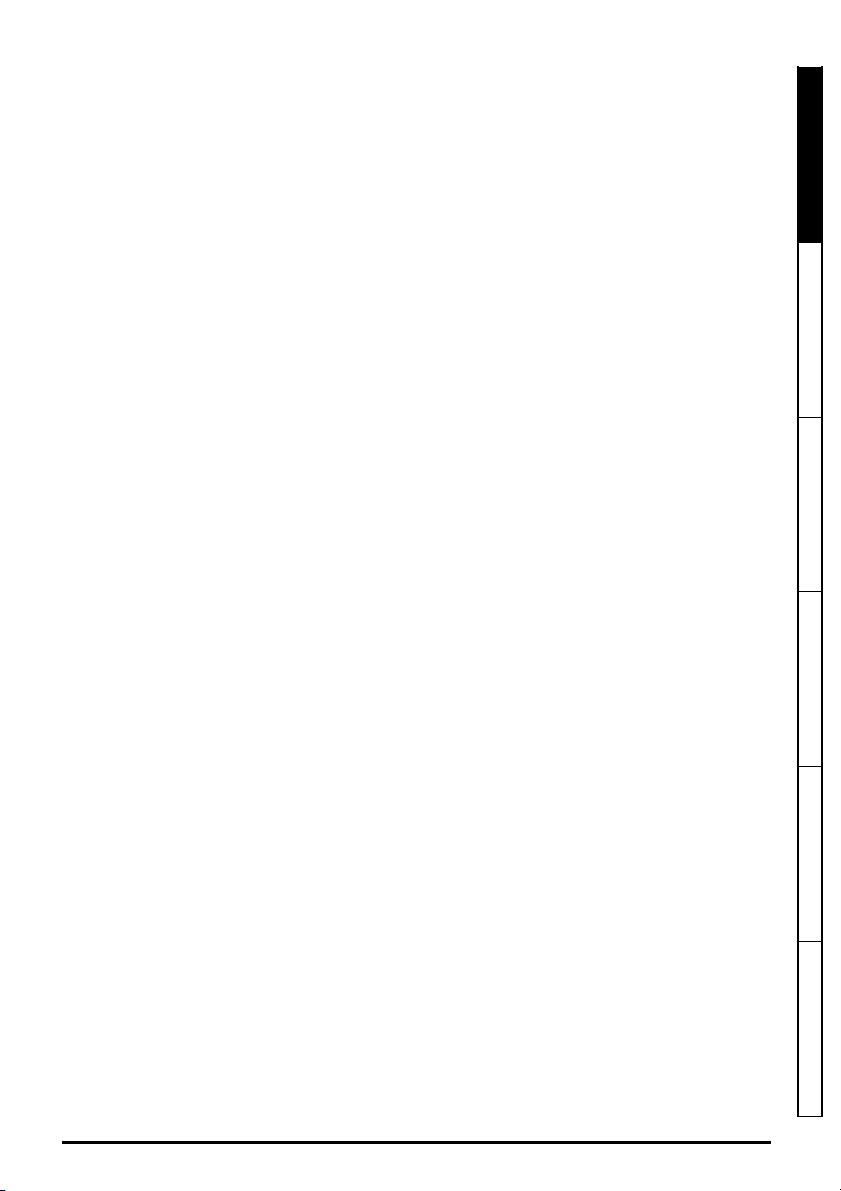

2.1 Model number ........................................................................................................14

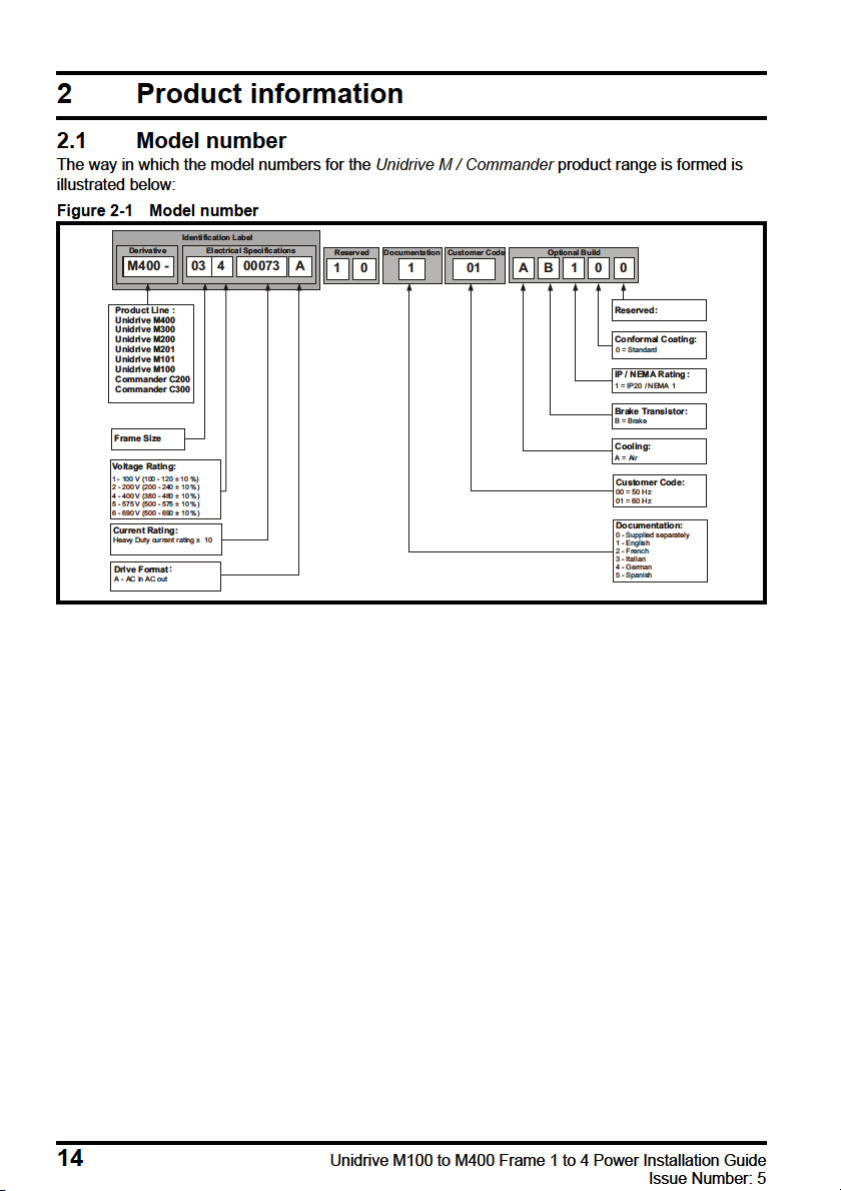

2.2 Nameplate description ...........................................................................................15

2.3 Ratings ...................................................................................................................15

2.4 Drive features .........................................................................................................18

2.5 Items supplied with the drive ..................................................................................19

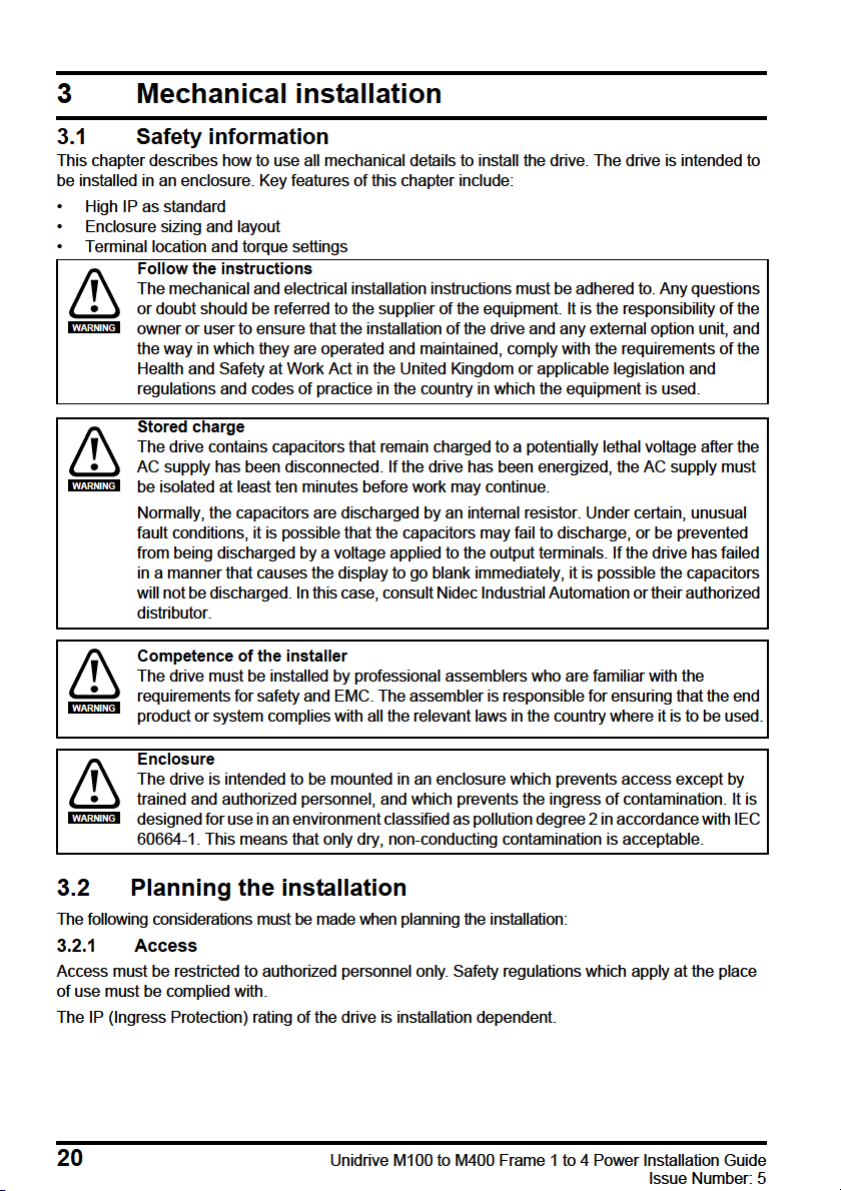

3 Mechanical installation .............................................................................20

3.1 Safety information .................................................................................................. 20

3.2 Planning the installation .........................................................................................20

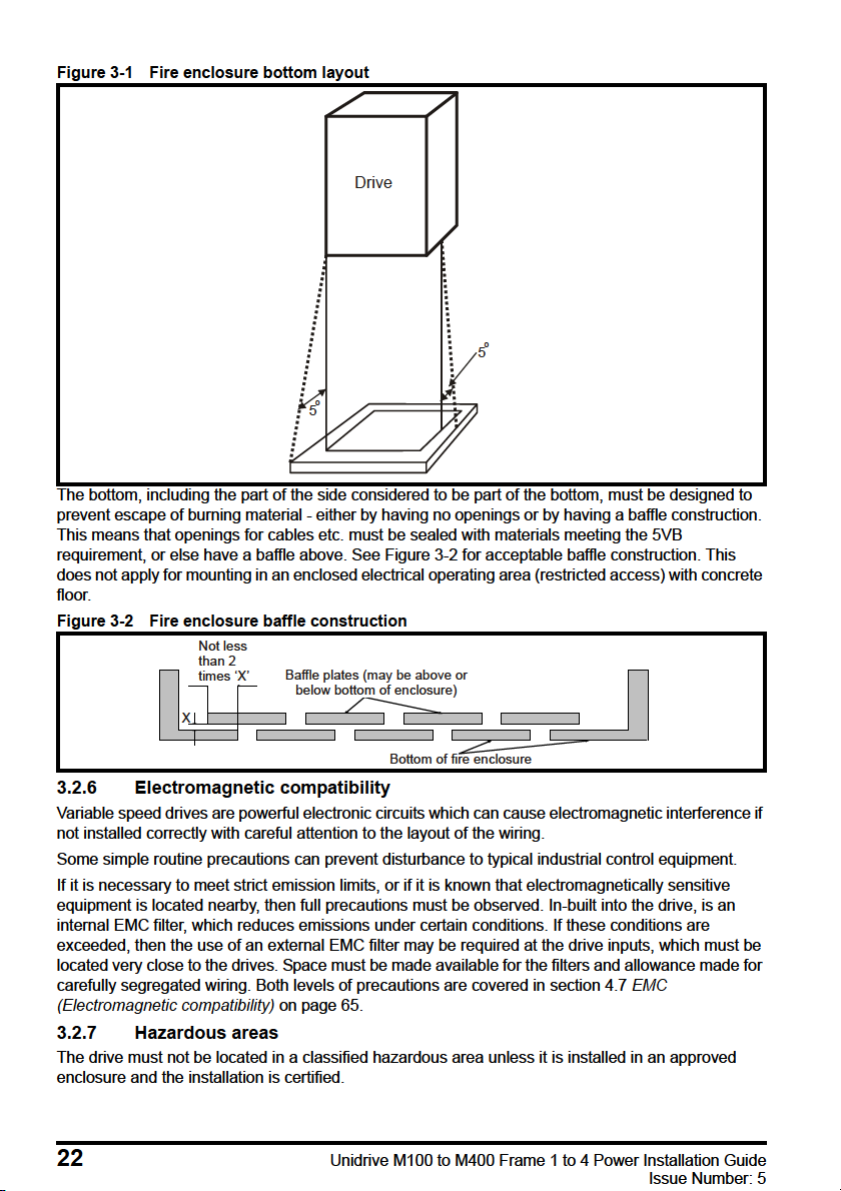

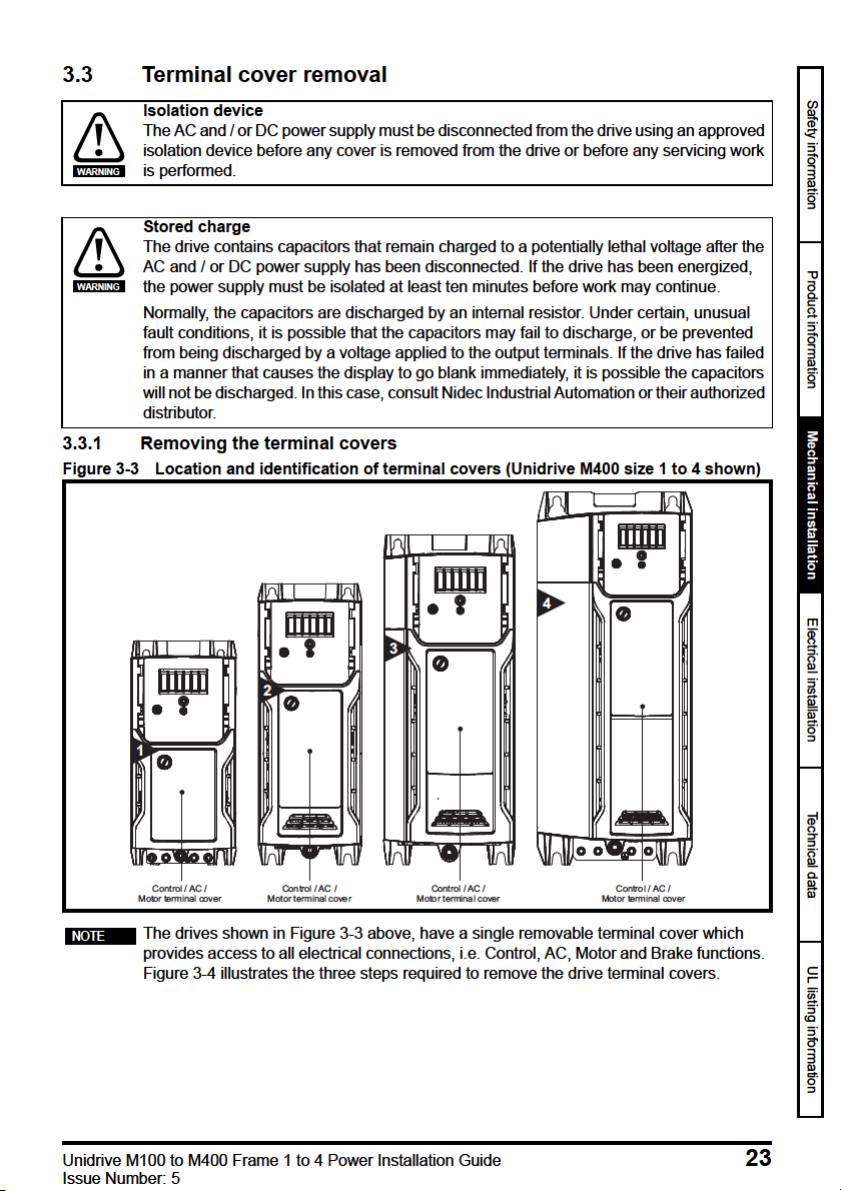

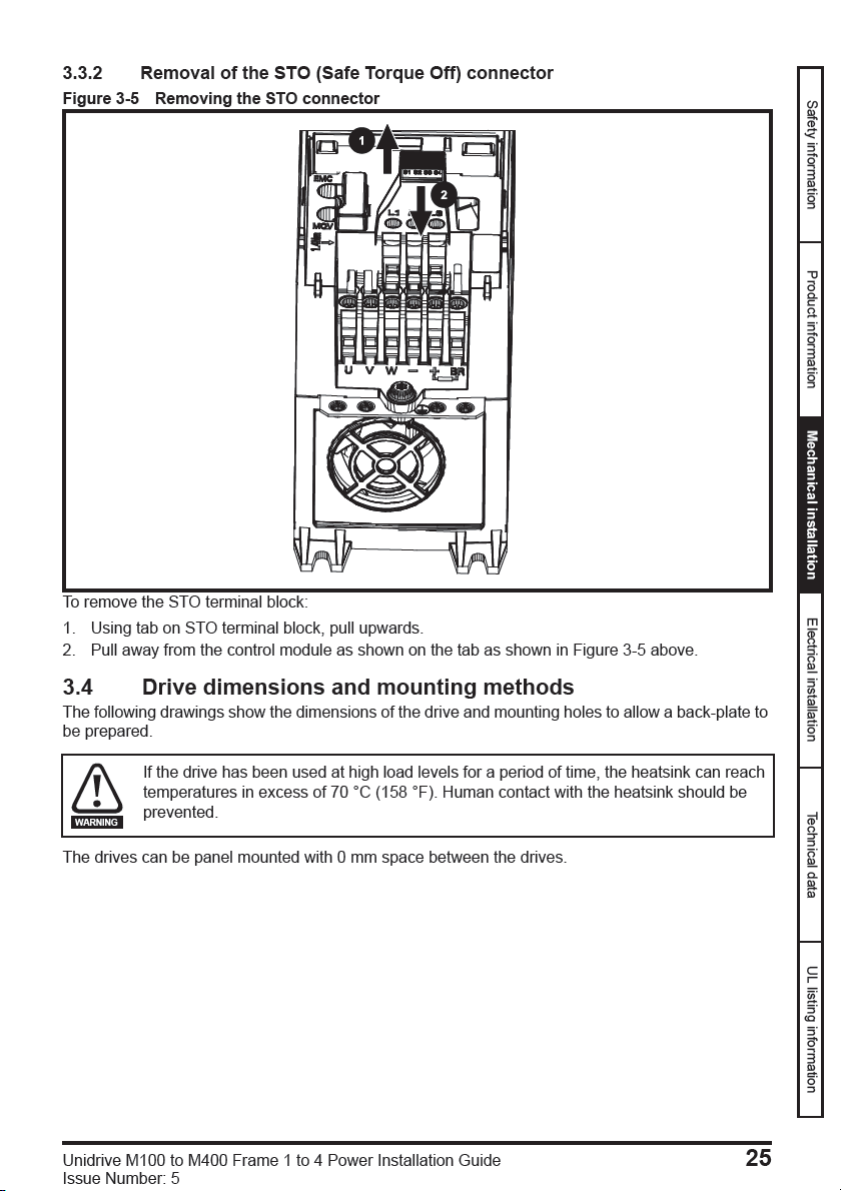

3.3 Terminal cover removal ..........................................................................................23

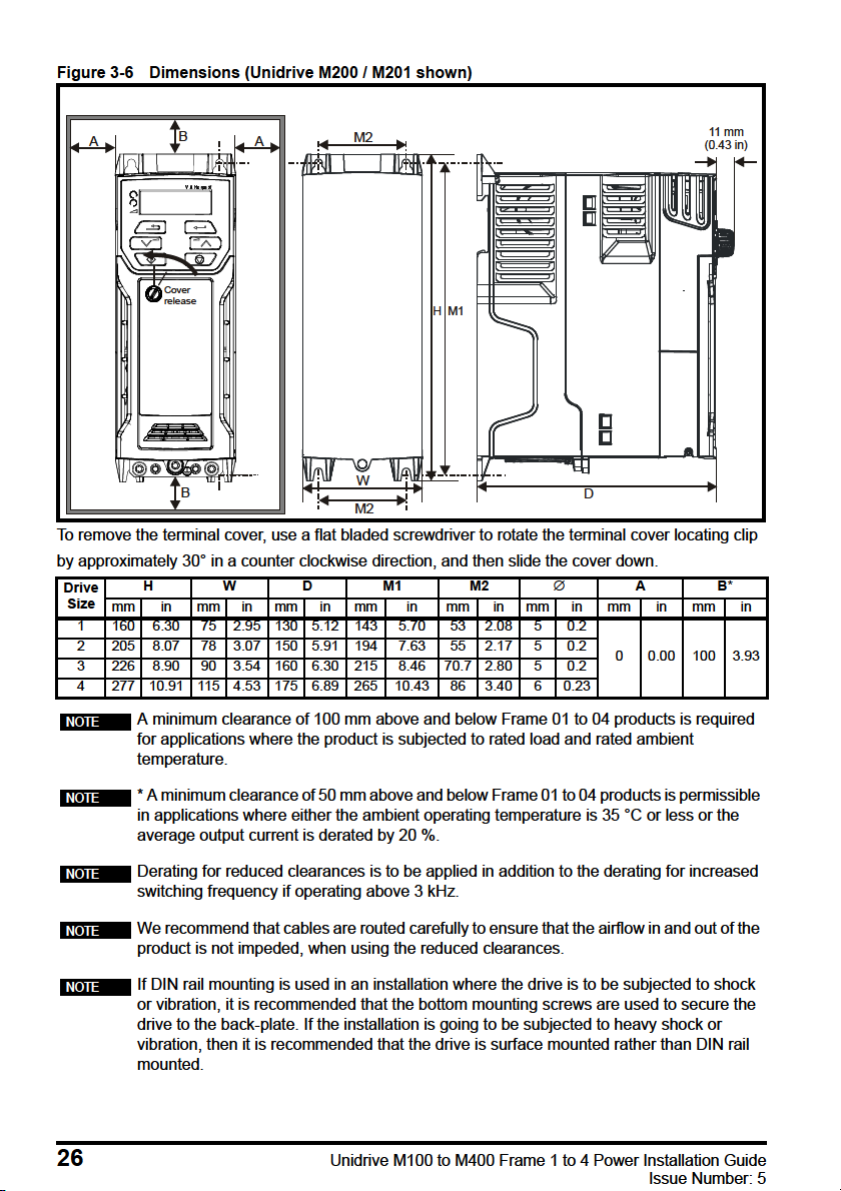

3.4 Drive dimensions and mounting methods ..............................................................25

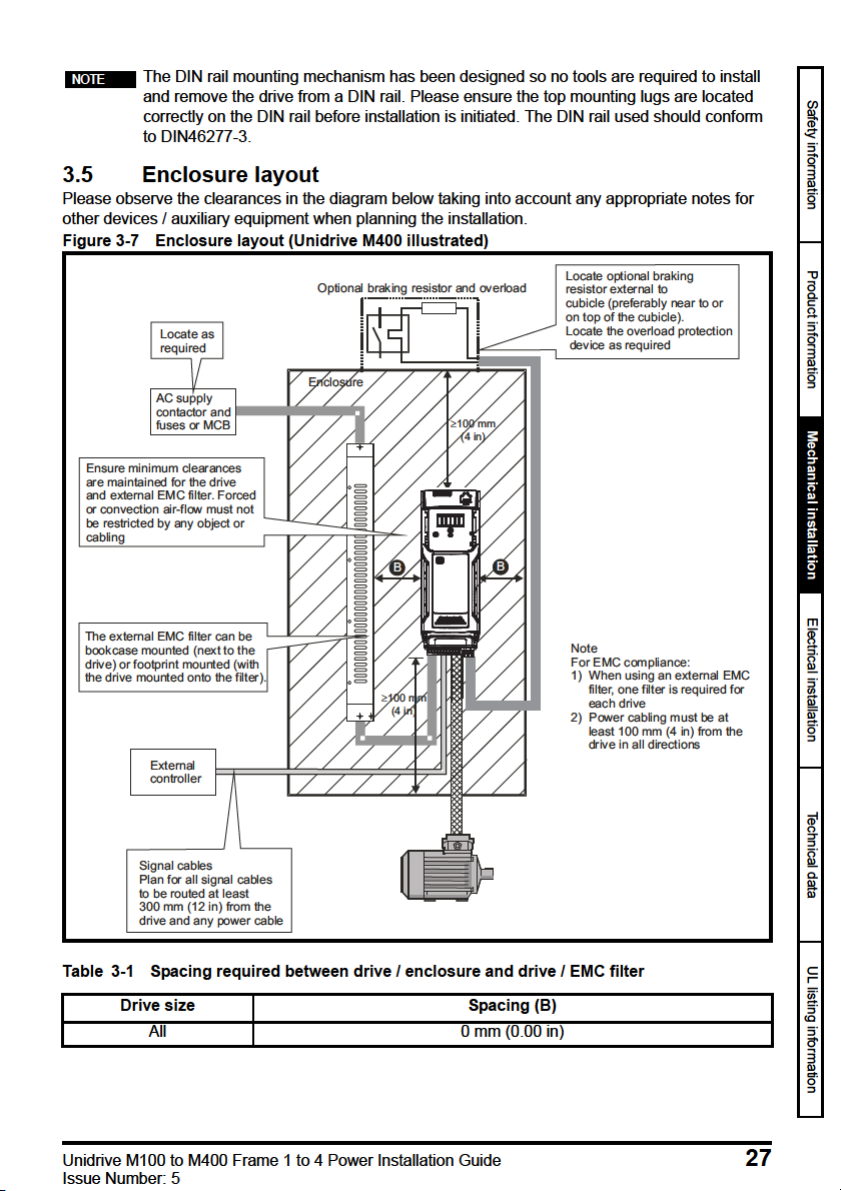

3.5 Enclosure layout .....................................................................................................27

3.6 Heatsink fan operation ...........................................................................................31

3.7 External EMC filter ................................................................................................. 32

3.8 Electrical terminals .................................................................................................37

3.9 Routine maintenance ............................................................................................. 39

4 Electrical installation .................................................................................41

4.1 Power connections .................................................................................................42

4.2 AC supply requirements .........................................................................................45

4.3 Ratings ...................................................................................................................51

4.4 Output circuit and motor protection ........................................................................55

4.5 Braking ................................................................................................................... 60

4.6 Ground leakage ...................................................................................................... 64

4.7 EMC (Electromagnetic compatibility) .....................................................................65

5 Technical data ............................................................................................79

5.1 Drive technical data ................................................................................................79

5.2 Optional external EMC filters ...............................................................................100

6 UL listing information ..............................................................................103

6.1 UL file reference ...................................................................................................103

6.2 Option modules, kits and accessories ..................................................................103

6.3 Enclosure ratings .................................................................................................103

6.4 Mounting .............................................................................................................. 103

6.5 Environment ......................................................................................................... 103

6.6 Electrical Installation ............................................................................................104

6.7 Motor overload protection and thermal memory retention ...................................104

6.8 Electrical supply ...................................................................................................105

6.9 External Class 2 supply ........................................................................................105

6.10 Group Installation and Modular Drive Systems ....................................................105

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 5

EU Declaration of Conformity

G Williams

Vice President, Technology

Date: 17th March 2016

Nidec Control Techniques Ltd

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in

conformity with the relevant European Union harmonization legislation. The declaration applies to the variable

speed drive products shown below:

Model

number

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the

following European harmonized standards:

EN 61800-5-1:2007

EN 61800-3: 2004+A1:2012

EN 61000-6-2:2005

EN 61000-6-4: 2007+A1:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input

power 1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage

Directive (2014/35/EU) and the Electromagnetic Compatibility Directive (2014/30/EU).

Interpretation Nomenclature aaaa - bbc ddddde

M100, M101, M200, M201, M300, M400, M600, M700, M701, M702, F300,

H300, E200, E300, HS30, HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier +

Inverter (external choke), T = 12P Rectifier + Inverter (external choke)

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 3: EMC requirements and

specific test methods

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current

emissions (equipment input current ≤16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes,

voltage fluctuations and flicker in public, low voltage supply systems, for

equipment with rated current ≤16 A per phase and not subject to conditional

connection

These electronic drive products are intended to be used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety

and EMC. Refer to the Product Documentation. An EMC data sheet is available giving detailed information.

The assembler is responsible for ensuring that the end product or system complies with all the relevant

laws in the country where it is to be used.

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 5

Issue Number: 5

Page 6

EU Declaration of Conformity

Jon Holman-White

Director of Research and Development

Date: 9th October 2018

Nidec Control Techniques Ltd

The Gro

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in

conformity with the relevant European Union harmonization legislation. The declaration applies to the variable

speed drive products shown below:

Model

number

aaaa Basic series C200, C300,

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by other characters that do not affect the ratings.

The variable speed drive products listed above have been designed and manufactured in accordance with the

following European harmonized standards:

EN 61800-5-1:2007

EN 61800-3: 2004+A1:2012

EN 61000-6-2:2005

EN 61000-6-4: 2007+A1:2011

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-2:2014 Applicable where input current < 16 A. No limits apply for professional equipment where input

power 1 kW.

These products comply with the Restriction of Hazardous Substances Directive (2011/65/EU), the Low Voltage

Directive (2014/35/EU) and the Electromagnetic Compatibility Directive (2014/30/EU).

Interpretation Nomenclature aaaa - bbc ddddde

A = 6P Rectifier + Inverter with internal choke, E = 6P Rectifier + Inverter

(external choke)

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 3: EMC requirements and

specific test methods

Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for

industrial environments

Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Emission

standard for industrial environments

Electromagnetic compatibility (EMC) - Part 3-2: Limits for harmonic current

emissions (equipment input current ≤16 A per phase)

Electromagnetic compatibility (EMC) - Part 3-3: Limitation of voltage changes,

voltage fluctuations and flicker in public, low voltage supply systems, for

equipment with rated current ≤16 A per phase and not subject to conditional

connection

These electronic drive products are intended to be used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety

and EMC. Refer to the Product Documentation. An EMC data sheet is available giving detailed information.

The assembler is responsible for ensuring that the end product or system complies with all the relevant

laws in the country where it is to be used.

6 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 7

E U De c l a ra t i o n o f C o nf o r m it y

(including 2006 Machinery Directive)

Nidec Control Techniques Ltd

The Gro

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in

conformity with the relevant European Union harmonization legislation. The declaration applies to the variable

speed drive products shown below:

Model

number

aaaa Basic series

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09, 10, 11

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V, 5 = 575 V, 6 = 690 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe

Torque Off function may be used for a safety function of a machine. None of the other functions of the drive

may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive 2006/42/EC and the Electromagnetic

Compatibility Directive (2014/30/EU).

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

EC type-examination certificate numbers:

01/205/5270.01/14 dated 2014-11-11

01/205/5387.01/15 dated 2015-01-29

01/205/5383.02/15 dated 2015-04-21

Notified body identification number: 0035

The harmonized standards used are shown below:

EN 61800-5-1:2007

EN 61800-5-2:2007

EN ISO 13849-1:2008

EN ISO 13849-2:2008 Safety of machinery, Safety-related parts of control systems. Validation

EN 61800-3: 2004+A1:2012

EN 62061:2005

Interpretation Nomenclature aaaa - bbc ddddde

M300, M400, M600, M700, M701, M702, F300, H300, E200, E300, HS30,

HS70, HS71, HS72, M000, RECT

A = 6P Rectifier + Inverter (internal choke), D = Inverter, E = 6P Rectifier +

Inverter (external choke), T = 12P Rectifier + Inverter (external choke)

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements

- Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 5-2: Safety requirements

- Functional

Safety of Machinery, Safety-related parts of control systems, General principles

for design

Adjustable speed electrical power drive systems - Part 3: EMC requirements

and specific test methods

Safety of machinery, Functional safety of safety related electrical, electronic

and programmable electronic control systems

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 7

Issue Number: 5

Page 8

Person authorised to complete the technical file:

G. Williams

Vice President, Technology

Date: 17th March 2016

Place: Newtown, Powys, UK

P Knight

Conformity Engineer

Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. Compliance with

safety and EMC regulations depends upon installing and configuring drives correctly, including using the

specified input filters.

The drives must be installed only by professional installers who are familiar with requirements for safety

and EMC. Refer to the Product Documentation. An EMC data sheet is available giving detailed information.

The assembler is responsible for ensuring that the end product or system complies with all the relevant

laws in the country where it is to be used.

8 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 9

E U De c l a ra t i o n o f C o nf o r m it y

(including 2006 Machinery Directive)

Nidec Control Techniques Ltd

The Gro

This declaration is issued under the sole responsibility of the manufacturer. The object of the declaration is in

conformity with the relevant European Union harmonization legislation. The declaration applies to the variable

speed drive products shown below:

Model

number

aaaa Basic series C300

bb Frame size 01, 02, 03, 04, 05, 06, 07, 08, 09

c Voltage rating 1 = 100 V, 2 = 200 V, 4 = 400 V

ddddd Current rating Example 01000 = 100 A

e Drive format

The model number may be followed by additional characters that do not affect the ratings.

This declaration relates to these products when used as a safety component of a machine. Only the Safe

Torque Off function may be used for a safety function of a machine. None of the other functions of the drive

may be used to carry out a safety function.

These products fulfil all the relevant provisions of the Machinery Directive (2006/42/EC) and the Electromagnetic

Compatibility Directive (2014/30/EU).

EC type examination has been carried out by the following notified body:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

D-51105 Köln

Germany

Interpretation Nomenclature aaaa - bbc ddddde

A = 6P Rectifier + Inverter with internal choke, E = 6P Rectifier + Inverter

(external choke)

EC type-examination certificate numbers:

Frame sizes 1 to 4: 01/205/5383.03/18 dated 2018-08-16

Frame sizes 5 to 9: 01/205/5387.02/18 dated 2018-08-16

Notified body identification number: 0035

The harmonized standards used are shown below:

EN 61800-5-2:2007

EN 61800-5-1:2007 (in

extracts)

EN 61800-3: 2004+A1:2012

EN ISO 13849-1:2008 +

AC:2009

EN 62061:2005 + AC:2010

+ A1:2013

IEC 61508 Parts 1 - 7:2010

Adjustable speed electrical power drive systems - Part 5-2: Safety requirements

- Functional

Adjustable speed electrical power drive systems - Part 5-1: Safety requirements

- Electrical, thermal and energy

Adjustable speed electrical power drive systems - Part 3: EMC requirements

and specific test methods

Safety of Machinery, Safety-related parts of control systems, General principles

for design

Safety of machinery, Functional safety of safety related electrical, electronic

and programmable electronic control systems

Functional safety of electrical/ electronic/programmable electronic safetyrelated systems

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 9

Issue Number: 5

Page 10

Person authorised to complete the technical file:

Jon Holman-White

Director of Research and Development

Date: 9th October 2018

Place: Newtown, Powys, UK

P Knight

Conformity Engineer

Newtown, Powys, UK

IMPORTANT NOTICE

These electronic drive products are intended to be used with appropriate motors, controllers, electrical

protection components and other equipment to form complete end products or systems. It is the

responsibility of the installer to ensure that the design of the complete machine, including its safety-related

control system, is carried out in accordance with the requirements of the Machinery Directive and any

other relevant legislation. The use of a safety-related drive in itself does not ensure the safety of the

machine. Compliance with safety and EMC regulations depends upon installing and configuring drives

correctly, including using the specified input filters. The drive must be installed only by professional

installers who are familiar with requirements for safety and EMC. The assembler is responsible for

ensuring that the end product or system complies with all relevant laws in the country where it is to be

used. For more information regarding Safe Torque Off, refer to the Product Documentation.

10 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 11

Page 12

2014/30/EU: Electromagnetic Compatibility.

1.5 Electrical hazards

The voltages used in the drive can cause severe electrical shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to the drive. Hazardous voltage

may be present in any of the following locations:

• AC and DC supply cables and connections

• Output cables and connections

• Many internal parts of the drive, and external option units

Unless otherwise indicated, control terminals are single insulated and must not be touched.

The supply must be disconnected by an approved electrical isolation device before gaining access to

the electrical connections.

The STOP and Safe Torque Off functions of the drive do not isolate dangerous voltages from the

output of the drive or from any external option unit.

The drive must be installed in accordance with the instructions given in this guide. Failure to observe

the instructions could result in a fire hazard.

1.6 Stored electrical charge

The drive contains capacitors that remain charged to a potentially lethal voltage after the AC supply

has been disconnected. If the drive has been energized, the AC supply must be isolated at least ten

minutes before work may continue.

1.7 Mechanical hazards

Careful consideration must be given to the functions of the drive or controller which might result in a

hazard, either through their intended behaviour or through incorrect operation due to a fault. In any

application where a malfunction of the drive or its control system could lead to or allow damage, loss

or injury, a risk analysis must be carried out, and where necessary, further measures taken to reduce

the risk - for example, an over-speed protection device in case of failure of the speed control, or a

fail-safe mechanical brake in case of loss of motor braking.

With the sole exception of the Safe Torque Off function, none of the drive functions must be

used to ensure safety of personnel, i.e. they must not be used for safety-related functions.

The Safe Torque Off function may be used in a safety-related application. The system designer is

responsible for ensuring that the complete system is safe and designed correctly according to the

relevant safety standards.

The design of safety-related control systems must only be done by personnel with the required

training and experience. The Safe Torque Off function will only ensure the safety of a machine if it is

correctly incorporated into a complete safety system. The system must be subject to a risk

assessment to confirm that the residual risk of an unsafe event is at an acceptable level for the

application.

1.8 Access to equipment

Access must be restricted to authorized personnel only. Safety regulations which apply at the place

of use must be complied with.

1.9 Environmental limits

Instructions in this guide regarding transport, storage, installation and use of the equipment must be

complied with, including the specified environmental limits. This includes temperature, humidity,

contamination, shock and vibration. Drives must not be subjected to excessive physical force.

12 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 13

1.10 Hazardous environments

The equipment must not be installed in a hazardous environment (i.e. a potentially explosive

environment).

1.11 Motor

The safety of the motor under variable speed conditions must be ensured.

To avoid the risk of physical injury, do not exceed the maximum specified speed of the motor.

Low speeds may cause the motor to overheat because the cooling fan becomes less effective,

causing a fire hazard. The motor should be installed with a protection thermistor. If necessary, an

electric forced vent fan should be used.

The values of the motor parameters set in the drive affect the protection of the motor. The default

values in the drive must not be relied upon. It is essential that the correct value is entered in the

Motor Rated Current parameter.

1.12 Mechanical brake control

Any brake control functions are provided to allow well co-ordinated operation of an external brake

with the drive. While both hardware and software are designed to high standards of quality and

robustness, they are not intended for use as safety functions, i.e. where a fault or failure would result

in a risk of injury. In any application where the incorrect operation of the brake release mechanism

could result in injury, independent protection devices of proven integrity must also be incorporated.

1.13 Adjusting parameters

Some parameters have a profound effect on the operation of the drive. They must not be altered

without careful consideration of the impact on the controlled system. Measures must be taken to

prevent unwanted changes due to error or tampering.

1.14 Electromagnetic compatibility (EMC)

Installation instructions for a range of EMC environments are provided in the relevant Power

Installation Guide. If the installation is poorly designed or other equipment does not comply with

suitable standards for EMC, the product might cause or suffer from disturbance due to

electromagnetic interaction with other equipment. It is the responsibility of the installer to ensure that

the equipment or system into which the product is incorporated complies with the relevant EMC

legislation in the place of use.

Safety information

Product information Mechanical installation Electrical installation Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 13

Issue Number: 5

Page 14

Page 15

Page 16

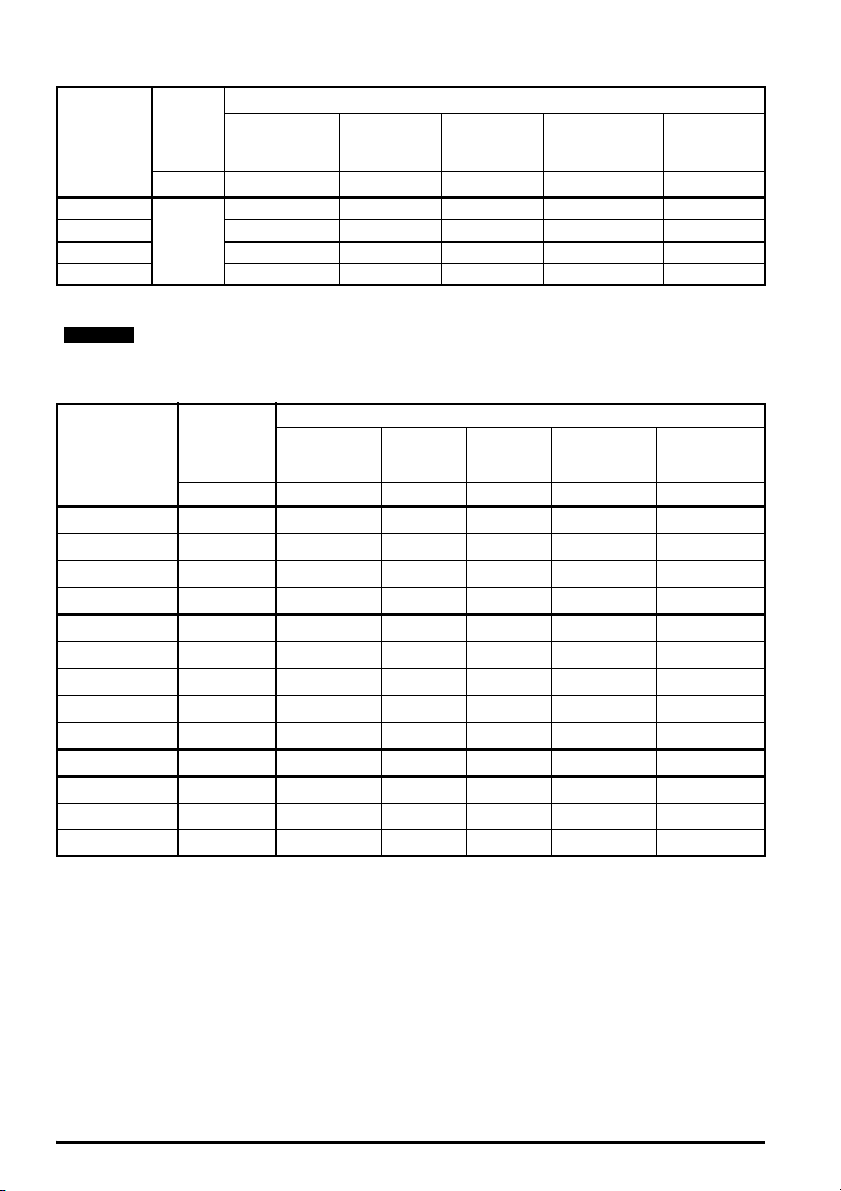

Table 2-1 100 V drive ratings (100 V to 120 V ±10 %)

NOTE

Heavy Duty

Model

Input

phases

Maximum

continuous

output current

Open loop

peak current

RFC peak

current

Nominal power

at

200 V

Motor power

ph A A A kW hp

01100017

01100024 2.4 3.6 4.3 0.37 0.5

02100042 4.2 6.3 7.6 0.75 1

1

1.7 2.6 3.1 0.25 0.33

02100056 5.6 8.4 10.1 1.1 1.5

The 100 V drives have a voltage doubler circuit on the input, therefore the output voltage

is 200 V.

Table 2-2 200 V drive ratings (200 V to 240 V ±10 %)

Heavy Duty

Model

01200017 1 1.7 2.6 3.1 0.25 0.33

01200024 1 2.4 3.6 4.3 0.37 0.5

01200033 1 3.3 5 5.9 0.55 0.75

01200042 1 4.2 6.3 7.6 0.75 1

02200024 1/3 2.4 3.6 4.3 0.37 0.5

02200033 1/3 3.3 5 5.9 0.55 0.75

02200042 1/3 4.2 6.3 7.6 0.75 1

02200056 1/3 5.6 8.4 10.1 1.1 1

02200075 1/3 7.5 11.3 13.5 1.5 2

03200100 1/3 10 15 18 2.2 3

04200133 1/3 13.3 20 23.9 3 3

04200176 1 13.3 20 23.9 3 3

04200176 3 17.6 26.4 31.7 4 5

Input phases

ph A A A kW hp

Maximum

continuous

output current

Open loop

peak current

RFC peak

current

Nominal power

at 230 V

at 200 V

Motor power

at 230 V

16 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 17

Table 2-3 400 V drive ratings (380 V to 480 V ±10 %)

NOTE

Heavy Duty

Model

02400013

02400018 1.8 2.7 3.2 0.55 0.75

02400023 2.3 3.5 4.1 0.75 1

02400032 3.2 4.8 5.8 1.1 1.5

02400041 4.1 6.2 7.4 1.5 2

03400056

03400073 7.3 11 13.1 3 3

03400094 9.4 14.1 16.9 4 5

04400135

04400170 17 25.5 30.6 7.5 10

Input phases

ph A A A kW hp

3

3

3

Maximum

continuous

output current

1.3 2 2.3 0.37 0.5

5.6 8.4 10.1 2.2 3

13.5 20.3 24.3 5.5 7.5

Open loop

peak current

R F C p e a k

current

Nominal

power at 400 V

Motor power

at 460 V

2.3.1 Typical short term overload limits

The maximum percentage overload limit changes depending on the selected motor. Variations in

motor rated current, motor power factor and motor leakage inductance all result in changes in the

maximum possible overload. The exact value for a specific motor can be calculated using the

equations detailed in Menu 4 in the Parameter Reference Guide.

Typical values are shown in the table below for RFC-A and open loop (OL) modes:

Table 2-4 Typical overload limits

Operating mode RFC From cold RFC From 100 %

Heavy Duty overload with motor

rated current = drive rated

current

180 % for 3 s 180 % for 3 s 150 % for 60 s 150 % for 8 s

Open loop from

cold

Open loop from

100 %

Safety information

Product information

Mechanical installation Electrical installation Technical data UL listing information

Generally the drive rated current is higher than the matching motor rated current allowing a higher

level of overload than the default setting.

The time allowed in the overload region is proportionally reduced at very low output frequency on

some drive ratings.

The maximum overload level which can be attained is independent of the speed.

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 17

Issue Number: 5

Page 18

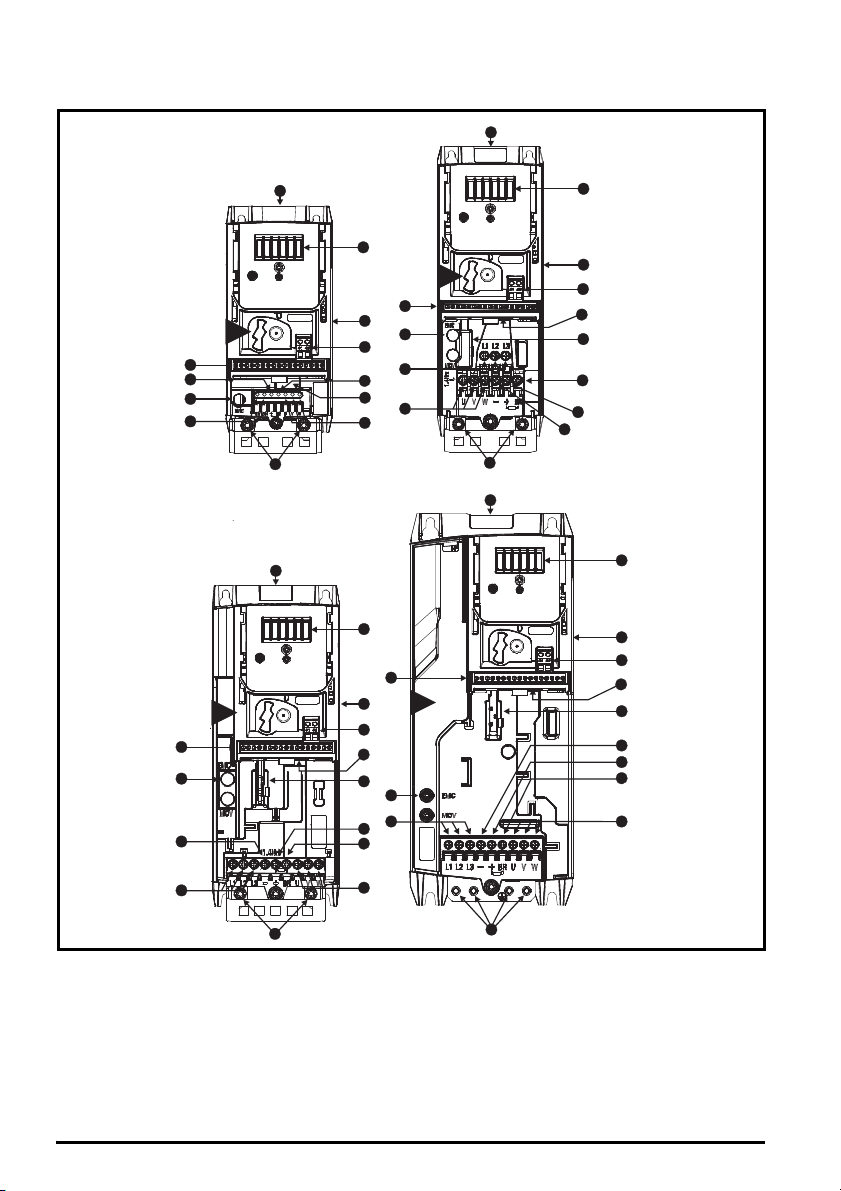

2.4 Drive features

10

5

8

7

7

11

6

4

1

9

9

4

1

3

6

8

2

2

2

2

4

4

1

10

8

6

6

3

3

5

7

11

1

8

11

9

5

11

10

12

12

12

12

10

5

7

14

14

13

13

14

13

14

13

3

4

2

1

Figure 2-3 Features of the drive (Unidrive M400 illustrated)

Key

1. Rating label (On side of

drive)

2. Identification label 6. Braking terminal 10. Motor connections 14. Keypad connection

3. Option module

connection

4. Relay connections 8. DC bus + 12. Ground connections

5. Control connections 9. DC bus - 13. Safe Torque Off

7. Internal EMC filter

screw

11. AC supply connections

connections

18 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 19

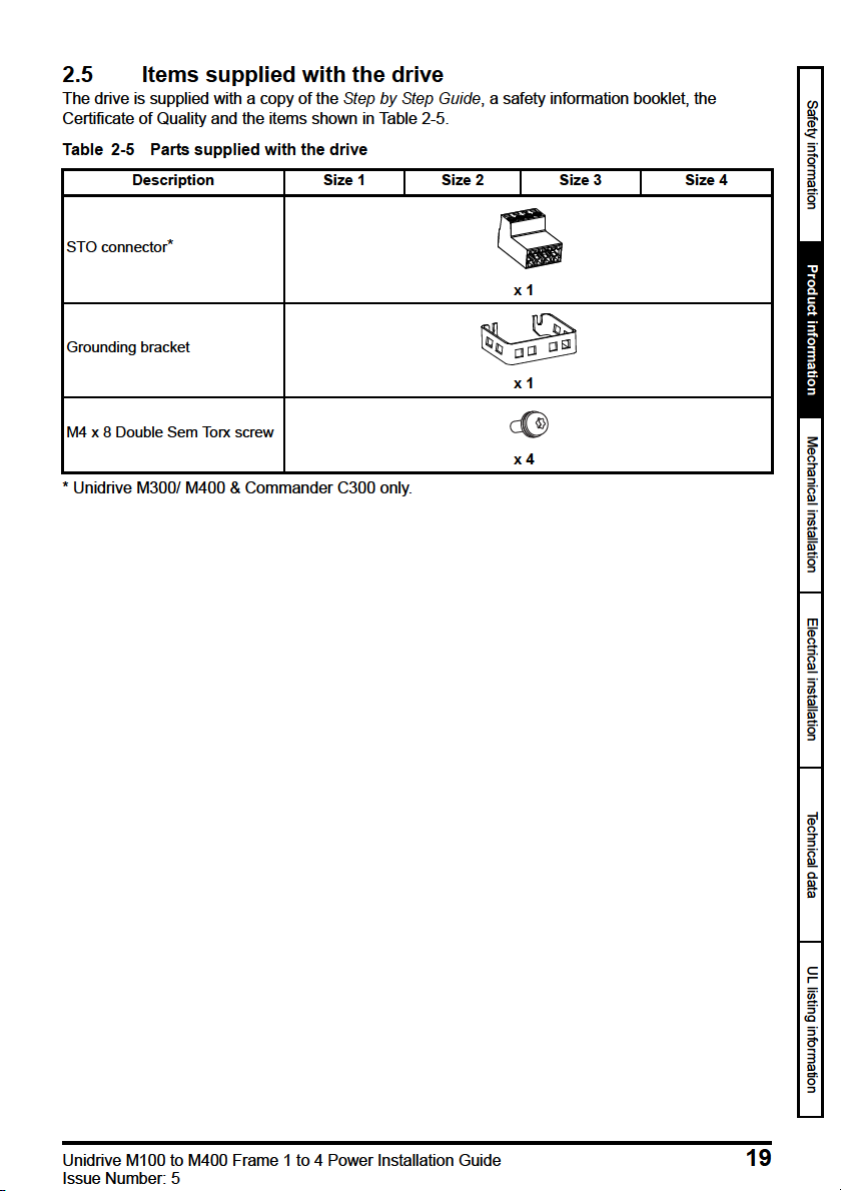

Page 20

Page 21

3.2.2 Environmental protection

NOTE

The drive must be protected from:

• Moisture, including dripping water or spraying water and condensation. An anti-condensation

heater may be required, which must be switched off when the drive is running.

• Contamination with electrically conductive material

• Contamination with any form of dust which may restrict the fan, or impair airflow over various

components

• Temperature beyond the specified operating and storage ranges

• Corrosive gasses

During installation it is recommended that the vents on the drive are covered to prevent

debris (e.g. wire off-cuts) from entering the drive.

3.2.3 Cooling

The heat produced by the drive must be removed without its specified operating temperature being

exceeded. Note that a sealed enclosure gives much reduced cooling compared with a ventilated one,

and may need to be larger and/or use internal air circulating fans.

For further information, refer to section 3.5.1 Enclosure sizing on page 28.

3.2.4 Electrical safety

The installation must be safe under normal and fault conditions. Electrical installation instructions are

given in Chapter 4 Electrical installation on page 41.

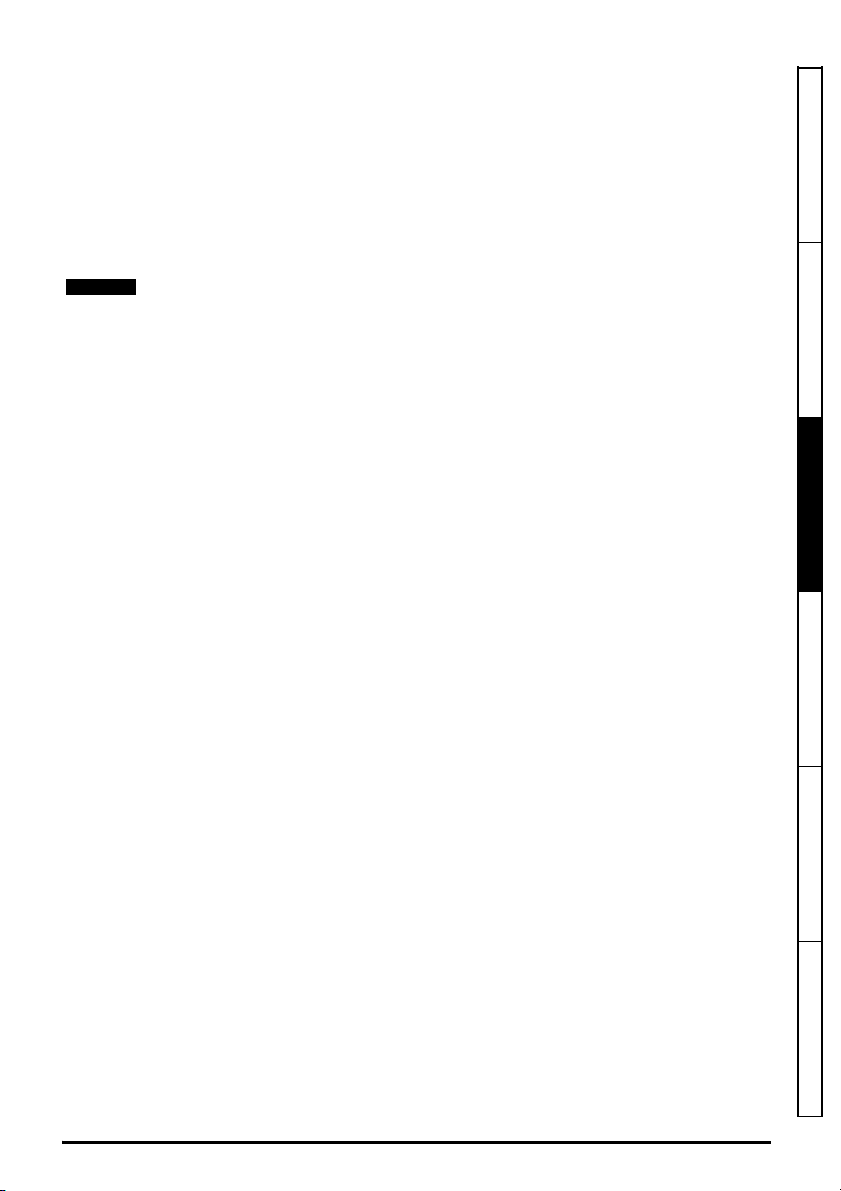

3.2.5 Fire protection

The drive enclosure is not classified as a fire enclosure. A separate fire enclosure must be provided.

For installation in the USA, a NEMA 12 enclosure is suitable.

For installation outside the USA, the following (based on IEC 62109-1, standard for PV inverters) is

recommended.

Enclosure can be metal and/or polymeric, polymer must meet requirements which can be

summarized for larger enclosures as using materials meeting at least UL 94 class 5VB at the point of

minimum thickness.

Air filter assemblies to be at least class V-2.

The location and size of the bottom shall cover the area shown in Figure 3-1. Any part of the side

which is within the area traced out by the 5° angle is also considered to be part of the bottom of the

fire enclosure.

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 21

Issue Number: 5

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

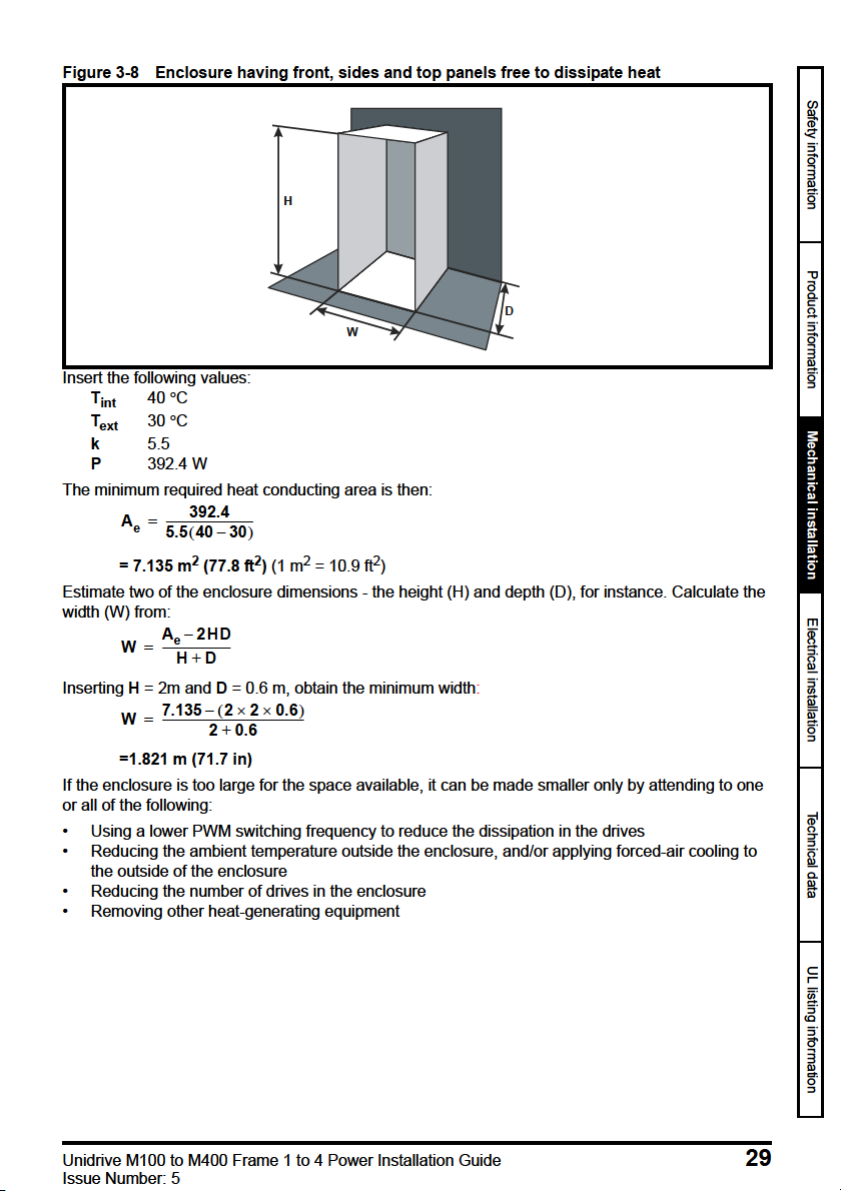

3.5.1 Enclosure sizing

A

e

P

kT

intText

–

-----------------------------------

=

NOTE

1. Add the dissipation figures from section 5.1.2 Power dissipation on page 81 for each drive that is

to be installed in the enclosure.

2. If an external EMC filter is to be used with each drive, add the dissipation figures from section

5.2.1 EMC filter ratings on page 101 for each external EMC filter that is to be installed in the

enclosure.

3. If the braking resistor is to be mounted inside the enclosure, add the average power figures for

each braking resistor that is to be installed in the enclosure.

4. Calculate the total heat dissipation (in Watts) of any other equipment to be installed in the

enclosure.

5. Add the heat dissipation figures obtained above. This gives a figure in Watts for the total heat that

will be dissipated inside the enclosure.

Calculating the size of a sealed enclosure

The enclosure transfers internally generated heat into the surrounding air by natural convection (or

external forced air flow); the greater the surface area of the enclosure walls, the better is the

dissipation capability. Only the surfaces of the enclosure that are unobstructed (not in contact with a

wall or floor) can dissipate heat.

Calculate the minimum required unobstructed surface area A

Where:

Unobstructed surface area in m2 (1 m2 = 10.9 ft2)

A

e

T

Maximum expected temperature in

ext

Maximum permissible temperature in oC inside the enclosure

T

int

o

C outside the enclosure

P Power in Watts dissipated by all heat sources in the enclosure

k Heat transmission coefficient of the enclosure material in W/m

Example

To calculate the size of an enclosure for the following:

• Two drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40 C

• Maximum ambient temperature outside the enclosure: 30 C

For example, if the power dissipation from each drive is 187 W and the power dissipation from each

external EMC filter is 9.2 W.

Total dissipation: 2 x (187 + 9.2) =392.4 W

for the enclosure from:

e

2/o

C

Power dissipation for the drives and the external EMC filters can be obtained from Chapter

5 Technical data on page 79.

The enclosure is to be made from painted 2 mm (0.079 in) sheet steel having a heat transmission

coefficient of 5.5 W/m

2/o

C. Only the top, front, and two sides of the enclosure are free to dissipate

heat.

The value of 5.5 W/m

2

/ºC can generally be used with a sheet steel enclosure (exact values can be

obtained from the supplier of the material). If in any doubt, allow for a greater margin in the

temperature rise.

28 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 29

Page 30

Calculating the air-flow in a ventilated enclosure

V

3kP

T

intText

–

---------------------------

=

P

o

P

l

-------

V

31.3 323.7

40 30–

---------------------------------------

=

The dimensions of the enclosure are required only for accommodating the equipment. The

equipment is cooled by the forced air flow.

Calculate the minimum required volume of ventilating air from:

Where:

V Air-flow in m

T

Maximum expected temperature in C outside the enclosure

ext

T

Maximum permissible temperature in C inside the enclosure

int

3

per hour (1 m3/hr = 0.59 ft3/min)

P Power in Watts dissipated by all heat sources in the enclosure

k Ratio of

Where:

P

is the air pressure at sea level

0

is the air pressure at the installation

P

I

Typically use a factor of 1.2 to 1.3, to allow also for pressure-drops in dirty air-filters.

Example

To calculate the size of an enclosure for the following:

• Three drives operating at the Normal Duty rating

• External EMC filter for each drive

• Braking resistors are to be mounted outside the enclosure

• Maximum ambient temperature inside the enclosure: 40 C

• Maximum ambient temperature outside the enclosure: 30 C

For example, dissipation of each drive: 101 W and dissipation of each external EMC filter: 6.9 W

(max).

Total dissipation: 3 x (101 + 6.9) = 323.7 W

Insert the following values:

T

40 C

int

T

30 C

ext

k 1.3

P 323.7 W

Then:

= 126.2 m

30 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

3

/hr (74.5 ft3 /min) (1 m3/ hr = 0.59 ft3/min)

Issue Number: 5

Page 31

3.5.2 Enclosure design and drive ambient temperature

Drive derating is required for operation in high ambient temperatures

Totally enclosing or through panel mounting the drive in either a sealed cabinet (no airflow) or in a

well ventilated cabinet makes a significant difference on drive cooling.

The chosen method affects the ambient temperature value (T

) which should be used for any

rate

necessary derating to ensure sufficient cooling for the whole of the drive.

The ambient temperature for the four different combinations is defined below:

= T

1. Totally enclosed with no air flow (<2 m/s) over the drive T

2. Totally enclosed with air flow (>2 m/s) over the drive T

rate

rate

= T

3. Through panel mounted with no airflow (<2 m/s) over the drive T

T

int

4. Through panel mounted with air flow (>2 m/s) over the drive T

+ 5 °C

int

int

= the greater of T

rate

= the greater of T

rate

+5 °C, or

ext

or T

ext

int

Where:

= Temperature outside the cabinet

T

ext

= Temperature inside the cabinet

T

int

= Temperature used to select current rating from tables in Chapter 5 Technical data on

T

rate

page 79.

3.6 Heatsink fan operation

The drive is ventilated by an internal heatsink fan. The fan channels air through the heatsink

chamber.

Ensure the minimum clearances around the drive are maintained to allow air to flow freely.

The heatsink fan on all drive sizes is a variable speed fan (except for size 1 which has a single speed

fan). The drive controls the speed at which the fan runs based on the temperature of the heatsink

and the drive's thermal model system. The maximum speed at which the fan operates can be limited

in Pr 06.045. This could incur an output current derating.

Table 3-2 Environmental considerations

Environment Comments

Clean

Dry, dusty (non-conductive)

Dry, dusty (conductive)

Regular cleaning recommended

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 31

Issue Number: 5

Page 32

3.7 External EMC filter

The external EMC filter details for each drive rating are provided in the table below.

Model CT part number

100 V

01100017 to 01100024

02100042 to 02100056 4200-2000 0.90 1.98

200 V

01200017 to 01200042

02200024 to 02200075

03200100

04200133 to 04200176

400 V

02400013 to 02400041

03400056 to 03400094

04400135 to 04400170

Mount the external EMC filter following the guidelines in section 4.7.5 Compliance with generic

emission standards on page 73

4200-1000

4200-1001 (low leakage)

4200-1000

4200-1001 (low leakage)

4200-2001

4200-2002 (low leakage)

4200-2003

4200-2004 (low leakage)

4200-3000

4200-3001 (low leakage)

4200-3004

4200-3005 (low leakage)

4200-4000

4200-4001 (low leakage)

4200-4002

4200-4003 (low leakage)

4200-2005

4200-2006 (low leakage)

4200-3008

4200-3009 (low leakage)

4200-4004

4200-4005 (low leakage)

Weight

kg lb

0.49 1.08

0.49 1.08

0.86 1.89

0.88 1.94

0.92 2.02

0.95 2.09

1.3 2.86

1.4 3.08

0.82 1.80

12.20

1.4 3.08

32 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 33

Figure 3-9 Footprint mounting the EMC filter

Figure 3-10 Bookcase mounting the EMC filter

Safety information Product information

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 33

Issue Number: 5

Page 34

Figure 3-11 Size 1 to 4 external EMC filter

W

C

A

X

X

Y

Y

V

B

H

Y

Y

D

Z

Z

V: Ground stud

Z: Bookcase mounting slot diameter CS: Cable size

Table 3-3 Size 1 external EMC filter dimensions

CT part

number

4200-1000

4200-1001

ABCDHWV/XYZCS

160 mm

(6.30 in)

198.8 mm

(7.83 in)

52.4 mm

(2.06 in)

Table 3-4 Size 2 external EMC filter dimensions

CT part

number

4200-2000

4200-2001

4200-2002

4200-2003

4200-2004

4200-2005

4200-2006

AB CDHWV/XYZCS

206 mm

(8.11 in)

244.8 mm

(9.64 in)

53.4 mm

(2.10 in)

X: Threaded holes for footprint

mounting of the drive

41 mm

(1.61 in)

41 mm

(1.61 in)

215 mm

(8.46 in)

261 mm

(10.2 in)

75 mm

(2.95 in)

78 mm

(3.07 in)

Y: Footprint mounting hole diameter

4.5 mm

M4

(0.18 in)

4.5 mm

M4

(0.18 in)

4.5 mm

(0.18 in)

4.5 mm

(0.18 in)

1.5 mm

(16 AWG)

4.0 mm

(12 AWG)

1.5 mm

(16 AWG)

2

2

2

34 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 35

Table 3-5 Size 3 external EMC filter dimensions

CT part

number

4200-3000

4200-3001

4200-3004

4200-3005

4200-3008

4200-3009

ABCDHWV/XYZCS

227 mm

(8.94 in)

265.8 mm

(10.4 in)

59 mm

(2.32 in)

41 mm

(1.61 in)

282 mm

(11.1 in)

Table 3-6 Size 4 external EMC filter dimensions

CT part

number

4200-4000

4200-4001

4200-4002

4200-4003

4200-4004

4200-4005

ABCDHWV/XYZCS

279 mm

(10.9 in)

318.8 mm

(12.5 in)

80.5 mm

(3.17 in)

41 mm

(1.61 in)

334 mm

(13.1 in)

90 mm

(3.54 in)

115 mm

(4.53 in)

M4

M5

4.5 mm

(0.18 in)

5.5 mm

(0.22 in)

4.5 mm

(0.18 in)

5.5 mm

(0.22 in)

4.0 mm

(12 AWG)

2.5 mm

(14 AWG)

4.0 mm

(12 AWG)

2.5 mm

(14 AWG)

Safety information Product information

2

2

2

2

Mechanical installation

Electrical installation Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 35

Issue Number: 5

Page 36

3.7.1 EMC filter torque settings

Table 3-7 Optional external EMC filter terminal data

CT part

number

Power connections Ground connections

Max cable

size

*

Max torque Ground stud size Max torque

4200-1000

4200-1001

4200-2000

4200-2001

10 mm

(6 AWG)

2

1.8 N m

(1.4 lb ft)

M4

4200-2002

4200-2003

4200-2004

4200-2005

6 mm

(8 AWG)

2

1.8 N m

(1.4 lb ft)

M4

4200-2006

4200-3000

4200-3001

4200-3004

4200-3005

4200-3008

4200-3009

10 mm

(6 AWG)

6 mm

(8 AWG)

6 mm

(8 AWG)

2

2

2

1.8 N m

(1.4 lb ft)

1.8 N m

(1.4 lb ft)

1.8 N m

(1.4 lb ft)

M4

M4

M4

4200-4000

4200-4001

4200-4002

4200-4003

6 mm

(8 AWG)

2

1.8 N m

(1.4 lb ft)

M5

4200-4004

4200-4005

* Flex wire.

Table 3-8 Fastener details for drive footprint mounting on external EMC filter

Type Size 1 Size 2 Size 3 Size 4

Thread size M4 M4 M4 M5

Length (mm) 12 12 12 12

1.7 N m

(1.3 lb ft)

1.7 N m

(1.3 lb ft)

1.7 N m

(1.3 lb ft)

1.7 N m

(1.3 lb ft)

1.7 N m

(1.3 lb ft)

2.2 N m

(1.6 lb ft)

36 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 37

Page 38

Page 39

Page 40

Table 3-13 Heatsink fan replacement kits

Model Part number

Size 1 3470-0092

Size 2 3470-0095

Size 3 3470-0099

Size 4 3470-0103

40 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 41

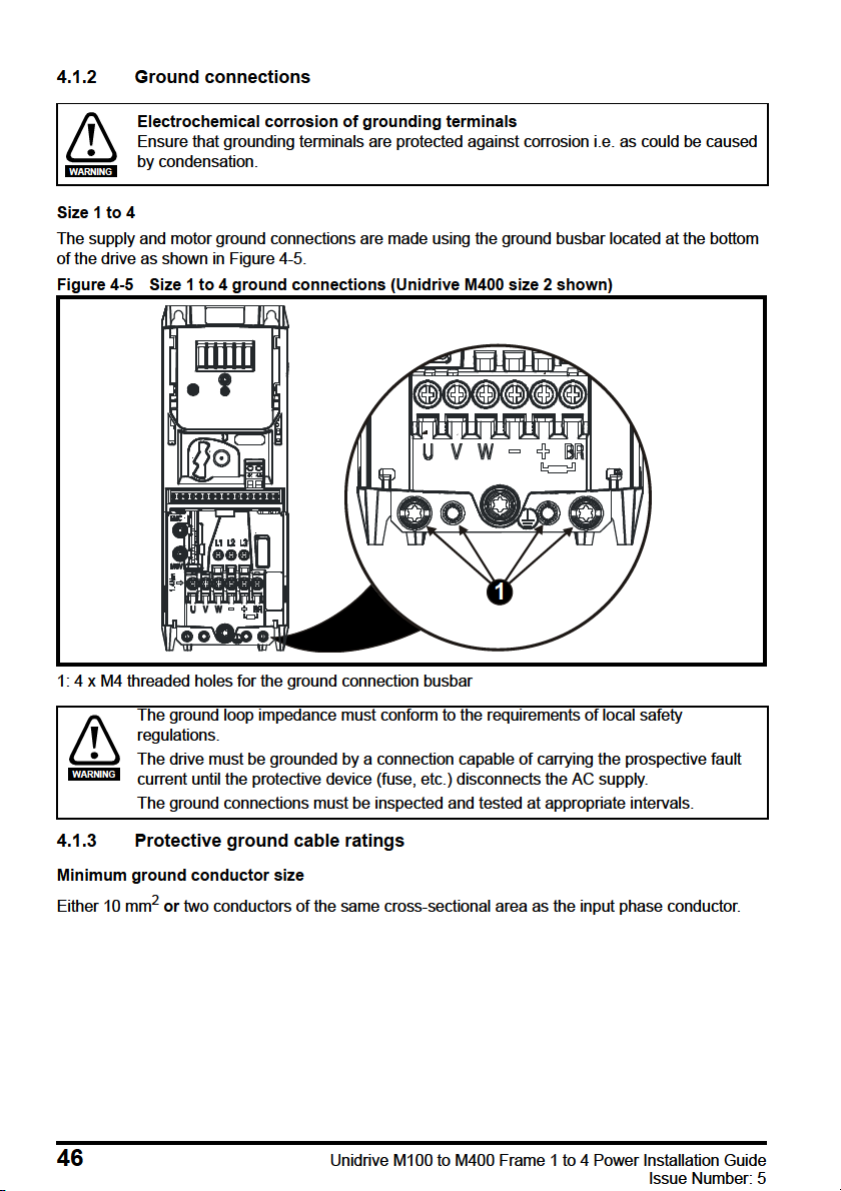

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Line reactors are particularly recommended for use with the following drive models when one of the

L

Y

100

----------

V

3

-------

1

2 f I

------------

=

above factors exists, or when the supply capacity exceeds 175 kVA: Size 1 to 3.

Model sizes 04200133 to 04400170 have an internal DC choke so they do not require AC line

reactors except for cases of excessive phase unbalance or extreme supply conditions.

When required, each drive must have its own reactor(s). Three individual reactors or a single threephase reactor should be used.

Reactor current ratings

The current rating of the line reactors should be as follows:

Continuous current rating:

Not less than the continuous input current rating of the drive

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive

4.2.3 Input inductor calculation

To calculate the inductance required (at Y %), use the following equation:

Where:

I = drive rated input current (A)

L = inductance (H)

f = supply frequency (Hz)

V = voltage between lines

Issue Number: 5

48 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Page 49

4.2.4 Input line reactor specification for size 1 to 4

Table 4-1 AC line reactor values

Drives

used with

01200017

01200024

01200033

01200042

02200024 4402-0224 1 2.25 6.5 13 0.8 72 65 90

02200033

02200056

02200075

03200100

04200133

04200176

02200024 4401-0224 3 1.96 4.3 8.6 1.1 65 110 70

02200033

02200042

02200056

02200075

03200100

04200176

02400013 4401-0232 3 6.1 2.4 4.8 1.1 65 110 70

02400018

02400023

02400032

02400041

03400056 4401-0149 3 1.62 9.1 18.2 1.8 156 70 125

03400073 4401-0234 3 1.12 13 26 2.5 156 72 114

03400094

04400135

04400170 4401-0235 3 0.71 21 42 3.6 156 68 133

Reactor

part

number

4402-0224 1 2.25 6.5 13 0.8 72 65 90

4402-0225 1 1.0 15.1 30.2 1.1 82 75 100

4402-0225 1 1.0 15.1 30.2 1.1 82 75 10002200042

4402-0226 1 0.5 26.2 52.4 1.5 82 90 105

4401-0225 3 1.12 7.5 15 1.2 80 130 65

4401-0143 3 0.79 13.5 27 1.8 156 70 125

4401-0144 3 0.48 20.6 41.2 2.4 156 80 12504200133

4401-0233 3 5.1 3.5 7 1.2 80 130 65

4401-0148 3 2.94 6.6 13.2 1.3 80 130 75

4401-0151 3 1.05 15.8 31.6 2.6 156 80 125

phases

Input

Inductance

mH A A kg

Continuous

rms

c ur r e n t

Peak

current

Weight

Dimensions

(mm)

LDH

mm mm mm

Safety information Product information Mechanical installation

Electrical installation

Technical data UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 49

Issue Number: 5

Page 50

Page 51

Page 52

Table 4-5 AC Input current and fuse ratings (100 V)

Class

gG

Fuse rating

Nominal Maximum

15 15

Class

CC, J or

T*

MCB

rating**

Nominal

15

Model

Maximum

continuous

input

current

AA

Maximum

overload

input

current

IEC UL

Maximum

AAAA

01100017 8.7 12.6 10

01100024 11.1 15.2 16 15 15 15

02100042 18.8 28.2 20 20 20 15

02100056 24.0 37.4 25 25 25 15

Table 4-6 AC Input current and fuse ratings (200 V)

Typical

Model

01200017 4.5 6.9 6

01200024 5.3 8.4 6 6 6 15

01200033

01200042 10.4 16.8 16 16 15 15 15

02200024 - / 3.2 5.3/4.1 8.1/5.9 6 6

02200033 - / 4.3 8.3/6.7 14/9.2 10 10 10 10 15

02200042 - / 5.4 10.4/7.5 16.4/10.8 16 10 16 10 15/10 15 10 15

02200056 - / 8.1 16.0/12.9 24.0/17.5

02200075 - / 9.1 18.1/13.5 30.4/19.5 20/15 15

03200100 - / 12.8 23.9/17.7 30/25 25 20 25 20

04200133 - / 13.5 23.7/16.9 43.3/23.5 25 20 25 20

04200176 - / 17.0 23.7/21.3 43.3/28.6 25 25 25 25 25 25 25 25

current

Maximum

continuous

input

input

current

AA AAAAA AAA AA

Maximum

overload

input

current

8.3 14.2 10 10 15 15 15

Nominal Maximum

1ph 3ph 1ph 3ph 1ph 3ph 1ph 3ph

20 16 20 16

IEC UL / USA

6

Fuse rating MCB

Maximum

66

666

20/15

20 15

25/20 25 20

25/20 25 20

Class

gG

gG

gG

gG

Nominal

Class

CC, J

or T*

CC,

J or

T*

CC,

J or

T*

CC,

J or

T*

rating

Nominal

15

15

15

25 20

25 20

**

* These are fast acting fuses.

** UL Listed DIVQ / DIVQ7 listed, rated voltage is 600 Vac (for USA and Canada). Short circuit rating

is 10 kA. In other countries, EN IEC circuit breakers can be used with 10 kA supply rating.

52 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 53

Page 54

Table 4-9 Cable ratings (200 V)

NOTE

NOTE

Cable size (IEC 60364-5-52)

Model

01200017

01200024

01200033

01200042

02200024

02200033

02200042

02200056 2.5/1.5 12/14

02200075 2.5 12

03200100 4 4 1.5 4 10/12 10 14 10

04200133 4/2.5

04200176 4

Input Output Input Output

Nominal Maximum Nominal Maximum Nominal Maximum Nominal Maximum

1 2.5 1 2.5 16 12 16 12

1

2

mm

16

414

42.54 10 10 12 10

Cable size (UL508C)

AWG

10 16 10

Table 4-10 Cable ratings (400 V)

Cable size (IEC 60364-5-52)

Model

02400013

02400018

02400023

02400032

02400041

03400056 1

03400094 2.5 1.5 14

04400135 2.5

04400170 4

Input Output Input Output

Nominal Maximum Nominal Maximum Nominal Maximum Nominal Maximum

141 416101610

2

mm

4

42.54 101012 10

1

4

14

12

Cable size (UL508C)

AWG

10

16

1003400073 1.5

PVC insulated cable should be used.

Cable sizes are from IEC60364-5-52:2001 table A.52.C with correction factor for 40°C

ambient of 0.87 (from table A52.14) for cable installation method B2 (multicore cable in

conduit).

Installation class (ref: IEC60364-5-52:2001)

B1 - Separate cables in conduit.

B2 - Multicore cable in conduit.

C - Multicore cable in free air.

Cable size may be reduced if a different installation method is used, or if the ambient temperature is

lower.

54 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 55

Page 56

4.4.1 Cable types and lengths

Since capacitance in the motor cable causes loading on the output of the drive, ensure the cable

length does not exceed the values given in Table 4-11 to Table 4-13.

Use 105 °C (221 °F) (UL 60/75 °C temp rise) PVC-insulated cable with copper conductors having a

suitable voltage rating, for the following power connections:

• AC supply to external EMC filter (when used)

• AC supply (or external EMC filter) to drive

• Drive to motor

• Drive to braking resistor

Table 4-11 Maximum motor cable lengths (100 V drives)

100 V Nominal AC supply voltage

Model

01100017

01100024

02100042

02100056

Table 4-12 Maximum motor cable lengths (200 V drives)

Model

01200017

01200024

01200033

01200042

02200024

02200033

02200042

02200056

02200075

03200100 100 m (330 ft)

04200133

04200176

Maximum permissible motor cable length for each of the following switching frequencies

0.667 kHz 1kHz 2 kHz 3 kHz 4 kHz 6 kHz 8 kHz 12 kHz 16 kHz

kHz

37.5 m

(122 ft)

75 m

(245 ft)

3

kHz

37.5 m

(122 ft)

75 m

(245 ft)

75 m

(245 ft)

75 m

(245 ft)

75 m (245 ft)

100 m (330 ft)

200 V Nominal AC supply voltage

Maximum permissible motor cable length for each of the following switching frequencies

0.667

kHz

1

kHz

75 m (245 ft)

100 m (330 ft)

100 m (330 ft)

kHz

2

25 m

50 m

6

kHz

25 m

50 m

(165 ft)

50 m

(165 ft)

50 m

(165 ft)

18.75 m

(61.9 ft)

37.5 m

(122 ft)

18.75 m

(61 ft)

37.5 m

(122 ft)

37.5 m

(122 ft)

37.5 m

(122 ft)

(82.5 ft)

(165 ft)

4

(82.5 ft)

8

kHz

12.5 m

(41.25 ft)

25 m

(82.5 ft)

12

kHz16kHz

12.5 m

(41 ft)

25 m

(82.5 ft)

25 m

(82.5 ft)

25 m

(82.5 ft)

9 m

(29.7 ft)

18 m

(59.4ft)

9 m

(30 ft)

18 m

(60 ft)

18 m

(60 ft)

18 m

(60 ft)

56 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 57

Page 58

Page 59

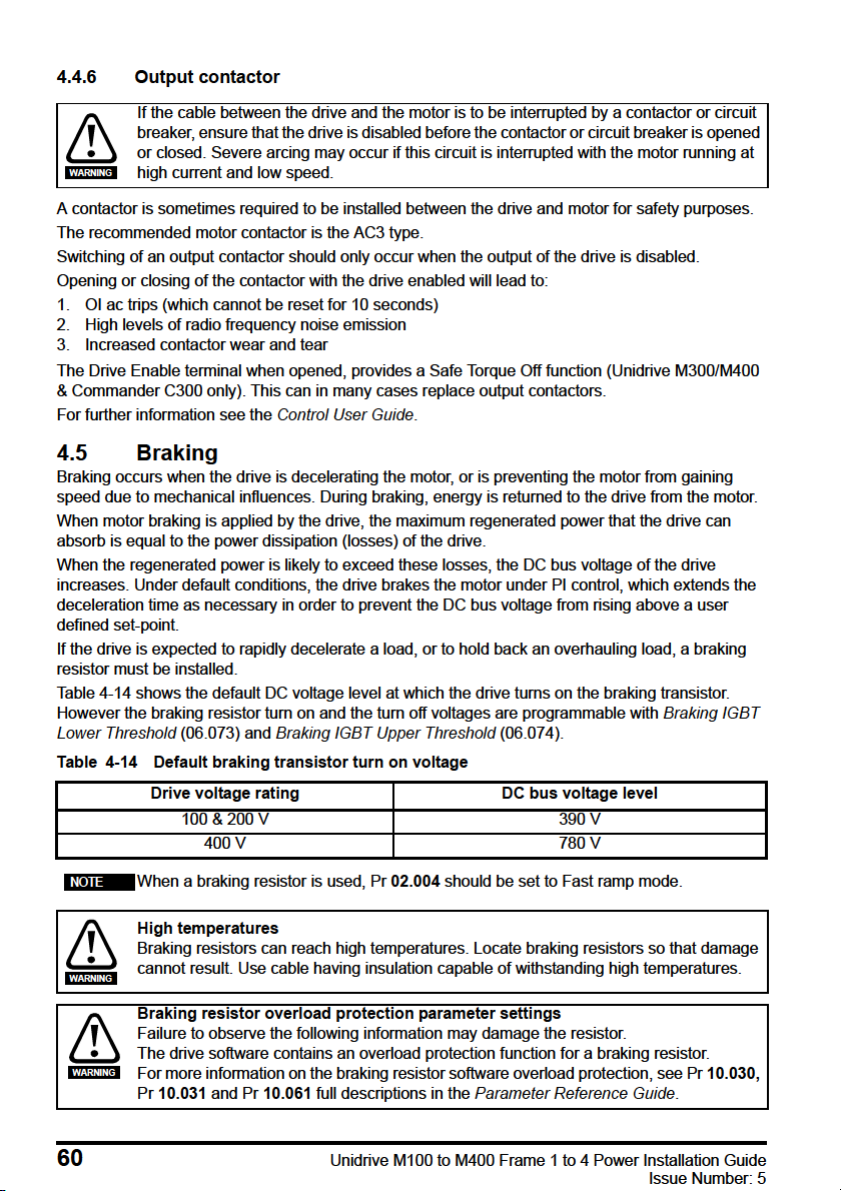

Page 60

Page 61

Page 62

Table 4-17 Braking resistor resistance and power rating (400 V)

Model

02400013

02400018 0.55

02400023 0.75

02400032 1.1

02400041 1.5

03400056

03400073 3

03400094 4

04400135

04400170 7.5

* Resistor tolerance: ±10 %

For high-inertia loads or under continuous braking, the continuous power dissipated in the braking

resistor may be as high as the power rating of the drive. The total energy dissipated in the braking

resistor is dependent on the amount of energy to be extracted from the load.

The instantaneous power rating refers to the short-term maximum power dissipated during the on

intervals of the pulse width modulated braking control cycle. The braking resistor must be able to

withstand this dissipation for short intervals (milliseconds). Higher resistance values require

proportionately lower instantaneous power ratings.

In most applications, braking occurs only occasionally. This allows the continuous power rating of the

braking resistor to be much lower than the power rating of the drive. It is therefore essential that the

instantaneous power rating and energy rating of the braking resistor are sufficient for the most

extreme braking duty that is likely to be encountered.

Optimization of the braking resistor requires careful consideration of the braking duty.

Select a value of resistance for the braking resistor that is not less than the specified minimum

resistance. Larger resistance values may give a cost saving, as well as a safety benefit in the event

of a fault in the braking system. Braking capability will then be reduced, which could cause the drive

to trip during braking if the value chosen is too large.

Thermal protection circuit for the braking resistor

The thermal protection circuit must disconnect the AC supply from the drive if the resistor becomes

overloaded due to a fault. Figure 4-11 shows a typical circuit arrangement.

Minimum

resistance*

Ω

270 2.2

100 6.0

50 11.2

Instantaneous

power rating

kW

Continuous

power rating

kW

0.37

2.2

5.5

62 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Figure 4-28 Surge suppression for analog and bipolar inputs and outputs

Signal from plant Signal to drive

0V 0V

2 x 15V zener diode

e.g. 2xBZW50-15

Surge suppression devices are available as rail-mounting modules, e.g. from Phoenix Contact:

Unipolar TT-UKK5-D/24 DC

Bipolar TT-UKK5-D/24 AC

These devices are not suitable for encoder signals or fast digital data networks because the

capacitance of the diodes adversely affects the signal. Most encoders have galvanic isolation of the

signal circuit from the motor frame, in which case no precautions are required. For data networks,

follow the specific recommendations for the particular network.

78 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 79

5 Technical data

5.1 Drive technical data

5.1.1 Power and current ratings (Derating for switching frequency and

temperature)

For a full explanation of ‘Normal Duty’ and ‘Heavy Duty’ refer to the Control User Guide.

Table 5-1 Maximum permissible continuous output current @ 40 °C (104 °F) ambient

Heavy Duty

Model

100 V

01100017 0.25 0.33 1.7

01100024 0.37 0.5 2.4

02100042 0.75 1.0 4.2

02100056 1.1 1.5 5.6

200 V

01200017 0.25 0.33 1.7

01200024 0.37 0.5 2.4

01200033 0.55 0.75 3.3

01200042 0.75 1.0 4.2

02200024 0.37 0.5 2.4

02200033 0.55 0.75 3.3

02200042 0.75 1.0 4.2

02200056 1.1 1.5 5.6

02200075 1.5 2.0 7.5 7.0

03200100 2.2 3.0 10 9 7.3

04200133 3.0 3.0 13.3

04200176 4.0 5.0 17.6 17.0

400 V

02400013 0.37 0.5 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

02400018 0.55 0.75 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8

02400023 0.75 1.0 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.0

02400032 1.1 1.5 3.2 3.2 3.2 3.2 3.2 3.2 3.2 2.0

02400041 1.5 2.0 4.1 4.1 4.1 4.1 4.1 4.1 3.8 2.0

03400056 2.2 3.0 5.6 5.6 5.6 5.6 5.6 5.6 5.1 3.7 2.4

03400073 3.0 3.0 7.3 7.3 7.3 7.3 7.3 7.1 5.6 3.8

03400094 4.0 5.0 9.4 9.4 9.4 9.4 9.4 8.5 7 4.6

04400135 5.5 7.5 13.5 10.7

04400170 7.5 10.0 17 13.5 10.7

Nominal

rating

kW hp

Maximum permissible continuous output current (A) for the following

0.667

kHz1kHz2kHz3kHz4kHz6kHz8kHz12kHz

switching frequencies

16

kHz

Safety information Product information Mechanical installation Electrical installation

Technical data

UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 79

Issue Number: 5

Page 80

Table 5-2 Maximum permissible continuous output current @ 50 °C (122 °F) (size 1 to 4)

NOTE

Heavy Duty

Model

0.667

kHz

100 V

01100017* 1.7

01100024* 2.4

02100042 4.2

02100056 5.6 5.5 5.3 5.1 4.9

200 V

01200017* 1.7

01200024* 2.4

01200033* 3.3

01200042* 4.2

02200024 2.4

02200033 3.3

02200042 4.2 4.0

02200056 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.4

02200075 7.5 7.5 7.4 7.2 6.8 6.6 6.3 5.8 5.4

03200100 10 10 10 10 9.5 8.6 7.5 6.1 5

04200133 13.3

04200176 17.6 17 15.5

400 V

02400013 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.1

02400018 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.1

02400023 2.3 2.3 2.3 2.3 2.3 2.3 2.3 1.1

02400032 3.2 3.2 3.2 3.2 3.2 3.2 2.5 1.1

02400041 4.1 4.1 4.1 4.1 3.7 3.2 2.5 1.1

03400056 5.6 5.6 5.6 5.6 5 3.5 2.8 1.9

03400073 7.3 7.3 7.3 7.3 6.2 4.5 3.4

03400094 9.4 9.4 9.4 9.4 7.9 6.2 4.7

04400135 13.5 12 9.3

04400170 17 15.3 15.2 12 9.3

Maximum permissible continuous output current (A)

for the following switching frequencies

1

kHz

2

kHz3kHz4kHz6kHz

8

kHz

12

kHz

16

kHz

* CI-Keypad not installed.

Ratings at 55 C are available on request.

80 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 81

5.1.2 Power dissipation

Table 5-3 Losses @ 40 °C (104 °F) ambient (size 1 to 4)

Heavy Duty

Model

100 V

01100017 0.25 0.33 23 23 24 24 25 27 28 32 35

01100024 0.37 0.5 27 27 29 30 31 33 35 39 44

02100042 0.75 1.0 39 40 41 42 43 45 47 51 55

02100056 1.1 1.5 51 51 53 54 55 58 61 67 73

200 V

01200017 0.25 0.33 21 21 22 22 23 25 27 30 33

01200024 0.37 0.5 24 25 26 27 28 30 33 37 41

01200033 0.55 0.75 31 32 33 35 36 39 42 47 53

01200042 0.75 1.0 38 39 40 42 44 47 51 58 65

02200024 0.37 0.5 25 25 25 26 26 28 29 31 33

02200033 0.55 0.75 32 33 33 34 35 36 38 41 44

02200042 0.75 1.0 39 40 41 42 43 45 47 51 55

02200056 1.1 1.5 46 47 48 50 51 54 57 63 69

02200075 1.5 2.0 62 62 65 67 69 73 77 86 87

03200100 2.2 3.0 85 87 91 96 101 110 117 121 117

04200133

04200176 4.0 5.0 149 150 156 161 166 176 186 207 220

400 V

02400013 0.37 0.5 25 26 30 33 36 42 48 60

02400018 0.55 0.75 29 30 34 37 40 47 53 67

02400023 0.75 1.0 33 34 38 41 45 52 59 69

02400032 1.1 1.5 41 42 46 50 54 63 71 70

02400041 1.5 2.0 49 50 55 60 64 74 78 70

03400056 2.2 3.0 55 57 62 68 75 86 90 86 77

03400073 3.0 3.0 72 74 82 90 98 113 101 92

03400094 4.0 5.0 95 99 108 116 129 128 125 113

04400135 5.5 7.5 142 146 159 172 169 196 239 294 292

04400170 7.5 10.0 165 170 186 202 218 251 284 294 292

Nominal rating

kW hp

3.0 3.0 101 102 106 110 114 121 129 144 160

*

Drive losses (W) taking into account any current derating for the given

0.667

kHz1kHz2kHz3kHz4kHz6kHz8kHz12kHz16kHz

conditions

Safety information Product information Mechanical installation Electrical installation

Technical data

UL listing information

* Different losses with single-phase supply (available on request).

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 81

Issue Number: 5

Page 82

Table 5-4 Losses @ 50°C (122°F) ambient (size 1 to 4)

Heavy Duty

Model

100 V

01100017 0.25 0.33 23 23 24 24 25 27 28 32 35

01100024 0.37 0.5 27 27 29 30 31 33 35 39 44

02100042 0.75 1.0 34 34 35 36 37 39 41 46 50

02100056 1.1 1.5 42 43 44 46 47 49 47 47 57

200 V

01200017 0.25 0.33 21 21 22 22 23 25 27 30 33

01200024 0.37 0.5 24 25 26 27 28 30 33 37 41

01200033 0.55 0.75 31 32 33 35 36 39 42 47 53

01200042 0.75 1.0 38 39 40 42 44 47 51 58 65

02200024 0.37 0.5 24 24 24 25 25 26 27 30 32

02200033 0.55 0.75 31 31 32 33 34 35 37 40 43

02200042 0.75 1.0 37 37 38 39 39 40 42 45 46

02200056 1.1 1.5 44 44 46 46 47 48 44 46 50

02200075 1.5 2.0 44 44 45 46 47 48 44 46 50

03200100 2.2 3.0 86 88 92 96 96 97 93 90 86

04200133 3.0 3.0 101 102 106 110 114 121 129 144 160

04200176 4.0 5.0 149 150 156 161 166 176 186 199 199

400 V

02400013 0.37 0.5 25 26 30 33 36 42 48 58

02400018 0.55 0.75 29 30 34 37 40 47 53 58

02400023 0.75 1.0 33 34 38 41 45 52 59 58

02400032 1.1 1.5 41 42 46 50 54 63 62 70

02400041 1.5 2.0 49 50 55 60 60 63 62 58

03400056 2.2 3.0 57 58 64 70 73 63 60 60

03400073 3.0 3.0 73 75 82 91 87 77 71

03400094 4.0 5.0 96 98 109 122 111 104 97

04400135 5.5 7.5 142 146 159 172 169 196 239 260 263

04400170 7.5 10.0 165 170 186 202 202 206 260 260 263

Nominal

rating

kW hp 0.667 kHz 1 kHz 2 kHz 3 kHz 4 kHz 6 kHz 8 kHz 12 kHz 16 kHz

Drive losses (W) taking into account any current derating for the given

conditions

82 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 83

5.1.3 Supply requirements

AC supply voltage:

100 V drive: 100 V to 120 V ±10 %

200 V drive: 200 V to 240 V ±10 %

400 V drive: 380 V to 480 V ±10 %

Maximum supply imbalance: 2 % negative phase sequence (equivalent to 3 % voltage imbalance

between phases).

Frequency range: 45 to 66 Hz

For UL compliance only, the maximum supply symmetrical fault current must be limited to 100 kA

5.1.4 Line reactors

Input line reactors reduce the risk of damage to the drive resulting from poor phase balance or

severe disturbances on the supply network.

Where line reactors are to be used, reactance values of approximately 2 % are recommended.

Higher values may be used if necessary, but may result in a loss of drive output (reduced torque at

high speed) because of the voltage drop.

For all drive ratings, 2 % line reactors permit drives to be used with a supply unbalance of up to 3.5 %

negative phase sequence (equivalent to 5 % voltage imbalance between phases).

Severe disturbances may be caused by the following factors, for example:

• Power factor correction equipment connected close to the drive.

• Large DC drives having no or inadequate line reactors connected to the supply.

• Across the line (DOL) started motor(s) connected to the supply such that when any of these

motors are started, the voltage dip exceeds 20 %

Such disturbances may cause excessive peak currents to flow in the input power circuit of the drive.

This may cause nuisance tripping, or in extreme cases, failure of the drive.

Drives of low power rating may also be susceptible to disturbance when connected to supplies with a

high rated capacity.

Line reactors are particularly recommended for use with the following drive models when one of the

above factors exists, or when the supply capacity exceeds 175 kVA: Size 1 to 3

Model sizes 04200133 to 04400170 have an internal DC choke so they do not require AC line

reactors except for cases of excessive phase unbalance or extreme supply conditions.

When required, each drive must have its own reactor(s). Three individual reactors or a single threephase reactor should be used.

Reactor current ratings

The current rating of the line reactors should be as follows:

Continuous current rating:

Not less than the continuous input current rating of the drive

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive

The recommended AC line reactors are shown in section 4.2.4 Input line reactor specification for size

1 to 4 on page 49.

5.1.5 Motor requirements

No. of phases: 3

Maximum voltage:

200 V drive: 240 V

400 V drive: 480 V

Safety information Product information Mechanical installation Electrical installation

Technical data

UL listing information

Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide 83

Issue Number: 5

Page 84

5.1.6 Temperature, humidity and cooling method

Size 1 to 4:

Ambient temperature operating range:

- 20 °C to 60 °C (- 4 °F to 140 °F).

Output current derating must be applied at ambient temperatures >40 °C (104 °F).

Cooling method: Forced convection

Maximum humidity: 95 % non-condensing at 40 °C (104 °F)

5.1.7 Storage

Size 1 to 4:

-40 °C (-40 °F) to +60 °C (140 °F) for long term storage.

Storage time is 2 years.

Electrolytic capacitors in any electronic product have a storage period after which they require

reforming or replacing.

The DC bus capacitors have a storage period of 10 years.

The low voltage capacitors on the control supplies typically have a storage period of 2 years and are

thus the limiting factor.

Low voltage capacitors cannot be reformed due to their location in the circuit and thus may require

replacing if the drive is stored for a period of 2 years or greater without power being applied.

It is therefore recommended that drives are powered up for a minimum of 1 hour after every 2 years

of storage.

This process allows the drive to be stored for a further 2 years.

5.1.8 Altitude

Altitude range: 0 to 3,000 m (9,900 ft), subject to the following conditions:

1,000 m to 3,000 m (3,300 ft to 9,900 ft) above sea level: de-rate the maximum output current

from the specified figure by 1% per 100 m (330 ft) above 1,000 m (3,300 ft)

For example at 3,000 m (9,900 ft) the output current of the drive would have to be de-rated by 20 %.

5.1.9 IP / UL Rating

The drive is rated to IP20 pollution degree 2 (non-conductive contamination only).

In addition to this, drives are rated to IP21 standard (without an Adaptor Interface module installed).

The IP rating of a product is a measure of protection against ingress and contact to foreign bodies

and water. It is stated as IP XX, where the two digits (XX) indicate the degree of protection provided

as shown in Table 5-5.

84 Unidrive M100 to M400 Frame 1 to 4 Power Installation Guide

Issue Number: 5

Page 85

Table 5-5 IP Rating degrees of protection

First digit Second digit

Protection against foreign bodies and access to

hazardous parts

Protection against ingress of water

0 Non-protected 0 Non-protected

Protected against solid foreign objects of

1

50 mm and greater

(back of a hand)

Protected against solid foreign objects of

2

12.5 mm and greater

(finger)

Protected against solid foreign objects of

3

2.5 mm and greater (tool)

Protected against solid foreign objects of

4

1.0 mm and greater (wire)

Protected against vertically falling water

1

drops

Protected against vertically falling water

2

drops when enclosure tilted up to 15 °

3 Protected against spraying water

4 Protected against splashing water

5 Dust-protected (wire) 5 Protected against water jets

6 Dust-tight (wire) 6 Protected against powerful water jets

7- 7

8- 8