Page 1

AXIMA 2000/4000

Multi-Axis Controller

Installation Manual

P/N 400266-00

Revision: A8

Date: December 8, 2005

© Control Techniques Drives, Inc. 1997, 2001, 2005

Page 2

Page 3

AXIMA 2000/4000

Multi-Axis Controller

Installation Manual

Information furnished by Control Techniques Drives Inc. (Control Techniques) is believed to be

accurate and reliable. However, no responsibility is assumed by Control Techniques for its use.

Control Techniques reserves the right to change the design or operation of the equipment described

herein and any associated motion products without notice. Control Techniques also assumes no

responsibility for any errors that may appear in this document. Information in this document is subject

to change without notice.

P/N 400266-00

Revision: A8

Date: December 8, 2005

© Control Techniques Drives, Inc. 1997, 2001, 2005

Page 4

© Control Techniques Drives, Inc. 1997, 2001, 2005

Part Number: 400266-00

Revision: A8

Date: December 2005

Printed in United States of America

Information in this document is subject to change without notice. No part of this document may be

reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose,

without the express written permission of Control Techniques.

The following are trademarks of Control Techniques and may not be reproduced in any fashion

without written approval of Control Techniques: EMERSON Motion Control,

EMERSON Motion Control PowerTools, AXIMA, “Motion Made Easy.”

Control Techniques is a division of EMERSON Co.

Control Techniques Drives, Inc. is not affiliated with Microsoft Corporation, owner of the Microsoft,

Windows, and Windows NT trademarks.

IBM is a registered trademark of International Business Machines Corporation.

Modbus is a registered trademark of Gould, Inc.

Data Highway Plus is a trademark of Allen-Bradley

Littelfuse is a trademark of Littelfuse, Inc.

This document has been prepared to conform to the current released version of the product. Because

of our extensive development efforts and our desire to further improve and enhance the product,

inconsistencies may exist between the product and documentation in some instances. Call your

customer support representative if you encounter an inconsistency.

ii

Page 5

Customer Support

Control Techniques

12005 Technology Drive

Eden Prairie, Minnesota 55344-3620

U.S.A.

Telephone: (952) 995-8000 or (800) 893-2321

It is Control Techniques’ goal to ensure your greatest possible satisfaction with the operation

of our products. We are dedicated to providing fast, friendly, and accurate assistance. That is

why we offer you so many ways to get the support you need. Whether it’s by phone, fax or

modem, you can access Control Techniques support information 24 hours a day, seven days

a week. Our wide range of services include:

FAX (952) 995-8099

You can FAX questions and comments to Control Techniques. Just send a FAX to the number

listed above.

Website and Email www.emersonct.com

Website: www.emersonct.com

Email: info@emersonct.com

If you have Internet capabilities, you also have access to technical support using our website.

The website includes technical notes, frequently asked questions, release notes and other

technical documentation. This direct technical support connection lets you request assistance

and exchange software files electronically.

Technical Support (952) 995-8033 or (800) 893-2321

Email: service@emersonct.com

Control Techniques’ “Motion Made Easy” products are backed by a team of professionals

who will service your installation. Our technical support center in Eden Prairie, Minnesota is

ready to help you solve those occasional problems over the telephone. Our technical support

center is available 24 hours a day for emergency service to help speed any problem solving.

Also, all hardware replacement parts, if needed, are available through our customer service

organization.

When you call, please be at your computer, with your documentation easily available, and be

prepared to provide the following information:

• Product version number, found by choosing About from the Help menu

• The type of controller or product you are using

iii

Page 6

• Exact wording of any messages that appear on your screen

• What you were doing when the problem occurred

• How you tried to solve the problem

Need on-site help? Control Techniques provides service, in most cases, the next day. Just call

Control Techniques’ technical support center when on-site service or maintenance is

required.

Training Services (952) 995-8000 or (800) 893-2321

Email: training@emersonct.com

Control Techniques maintains a highly trained staff of instructors to familiarize customers

with Control Techniques’ “Motion Made Easy” products and their applications. A number of

courses are offered, many of which can be taught in your plant upon request.

Application Engineering (952) 995-8000 or (800) 893-2321

Email: info@emersonct.com

An experienced staff of factory application engineers provides complete customer support for

tough or complex applications. Our engineers offer you a broad base of experience and

knowledge of electronic motion control applications.

Customer Service (Sales) (952) 995-8000 or (800) 893-2321

Email: customer.service@emersonct.com

Authorized Control Techniques distributors may place orders directly with our Customer

Service department. Contact the Customer Service department at this number for the

distributor nearest you.

Document Conventions

Manual conventions have been established to help you learn to use this manual quickly and

easily. As much as possible, these conventions correspond to those found in other Microsoft®

Windows® compatible software documentation.

Menu names and options are printed in bold type: the File menu.

Dialog box names begin with uppercase letters: the Axis Limits dialog box.

Dialog box field names are in quotes: “Field Name.”

Button names are in italic: OK button.

Source code is printed in Courier font: Case ERMS.

iv

Page 7

In addition, you will find the following typographic conventions throughout this manual.

This Represents

bold

italic

ALL CAPITALS Directory names, file names, key names, and acronyms.

SMALL CAPS Non-printable ASCII control characters.

KEY1+KEY2

example: (Alt+F)

KEY1,KEY2

example: (Alt,F)

Characters that you must type exactly as they appear. For example, if you are directed to type

a:setup, you should type all the bold characters exactly as they are printed.

Placeholders for information you must provide. For example, if you are directed to type

filename, you should type the actual name for a file instead of the word shown in italic type.

A plus sign (+) between key names means to press and hold down the first key while you press

the second key.

A comma (,) between key names means to press and release the keys one after the other.

Note

For the purpose of this manual and product, “Note” indicates essential information about

the product or the respective part of the manual.

“Warning” indicates a potentially hazardous situation that, if not avoided, could result in

death or serious injury.

“Caution” indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury.

“Caution” used without the safety alert symbol indicates a potentially hazardous situation

that, if not avoided, may result in property damage.

Safety Instructions

General Warning

Failure to follow safe installation guidelines can cause death or serious injury. The voltages

used in the product can cause severe electric shock and/or burns and could be lethal. Extreme

care is necessary at all times when working with or adjacent to the product. The installation

must comply with all relevant safety legislation in the country of use.

v

Page 8

Qualified Person

For the purpose of this manual and product, a “qualified person” is one who is familiar with

the installation, construction and operation of the equipment and the hazards involved. In

addition, this individual has the following qualifications:

• Is trained and authorized to energize, de-energize, clear and ground and tag circuits and

equipment in accordance with established safety practices.

• Is trained in the proper care and use of protective equipment in accordance with

established safety practices.

• Is trained in rendering first aid.

vi

Page 9

AXIMA® 2000/4000 Multi-axis Controller

CE Declaration of Conformity

The AXIMA 2000/4000 Multi-axis Controllers are marked with the “Conformite Europeenne

Mark” (CE mark) after passing a rigorous set of design and testing criteria. This label

indicates that this product meets safety and noise immunity and emmisions (EMC) standards

when installed according to the installation guidelines and used within the product

specifications.

Installation Manual

vii

Page 10

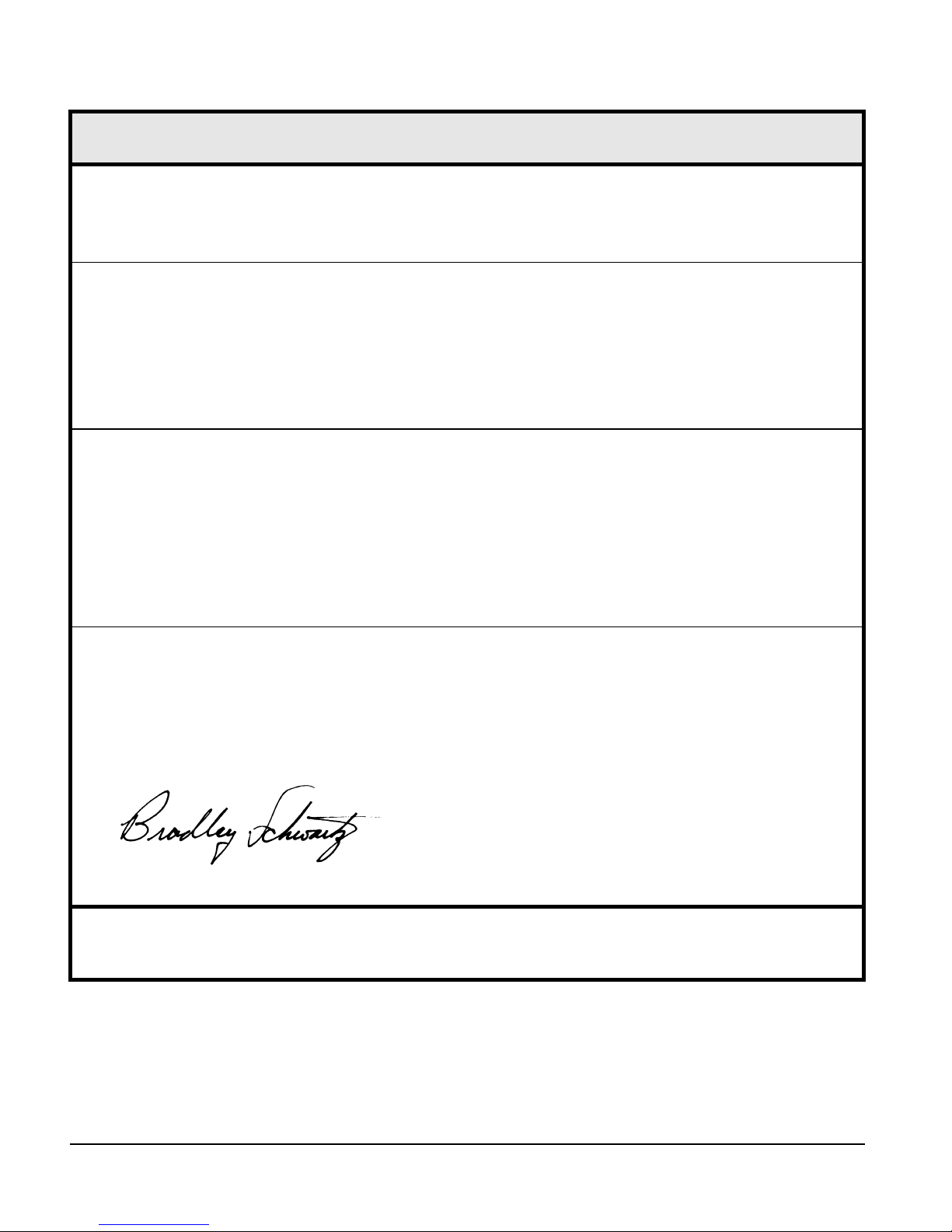

AXIMA® 2000/4000 Multi-axis Controller Installation Manual

Declaration of Conformity

Manufacturer’s Name:

Manufacturer’s Address:

Control Techniques

12005 Technology Drive

Eden Prairie, MN 55344

USA

Declares that the following products:

Products Description:

Model Number:

System Options:

AXIMA 2000/4000 Multi-axis Controller

AXIMA 2000 and AXIMA 4000

This declaration covers the above products with the stepper axis, source mode expanded I/O,

analog inputs, Modbus and Data Highway Plus.

Conforms to the following product specification:

Electomagnetic Compatibility (EMC):

EN 55011/1991 Class A Group 1, CISPR 11/1990 Class A Group 1

EN 50082-2/1995: IEC 1000-4-2/1995; EN 61000-4-2, 4kV CD

IEC 1000-4-3/1995; EN 61000-4-3, ENV 50140/1993, 80% AM, 10V/m @ 3 m

IEC 1000-4-4/1995; EN 61000-4-4, 2 kV ALL LINES

IEC 1000-4-8/1993; EN 61000-4-8, 30 A/m

ENV 50141/1993, 80% AM, 10V, .15-80 MHz

ENV 50204/1995, Pulse, 900 MHz, 50% DTY, 200 Hz

Supplementary information:

The products herewith comply with the requirements of the Low Voltage Directive (LVD) 73/23/EEC and EMC Directive 89/336/EEC

This electronic drive product is intended to be used with an appropriate motor, electrical protection components and other equipment to form a complete end

product or system. It must only be installed by a professional assembler who is familiar with requirements for safety and electromagnetic compatibility

(“EMC”). The assembler is responsible for ensuring that the end product or system complies with all the relevant laws in the country where it is to be used.

Refer to the product manual for installation guidelines.

February 24, 1999

Bradley Schwartz/ VP Engineering Date

European Contact:

Sobetra Automation

Langeveldpark Lot 10

P. Dasterleusstraat 2

1600 St. Pieters Leeuw, Belgium

viii

Page 11

AXIMA® 2000/4000 Multi-axis Controller

Installation Manual

Table of Contents

Introduction 1

Connections and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation 5

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environmental Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Basic Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connections and Cabling 17

Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COM Port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

COM Port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Controller ID Number/Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Axis Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Encoder 1 or 3 Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Input/Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostics Status Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Analog Input Option 51

Axis Inputs Connector Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Expanded I/O Option 55

Sinking Versus Sourcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Direct Wiring Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Connectivity Options 69

Modbus Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Data Highway Plus Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ix

Page 12

AXIMA® 2000/4000 Multi-axis Controller Installation Manual

Stepper Option 75

Specifications 77

AXIMA® 2000/4000 Controller Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Heat Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Dimensions and Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Cable Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Glossary 87

Index 91

x

Page 13

AXIMA® 2000/4000 Multi-Axis Controller

Installation Manual

Introduction

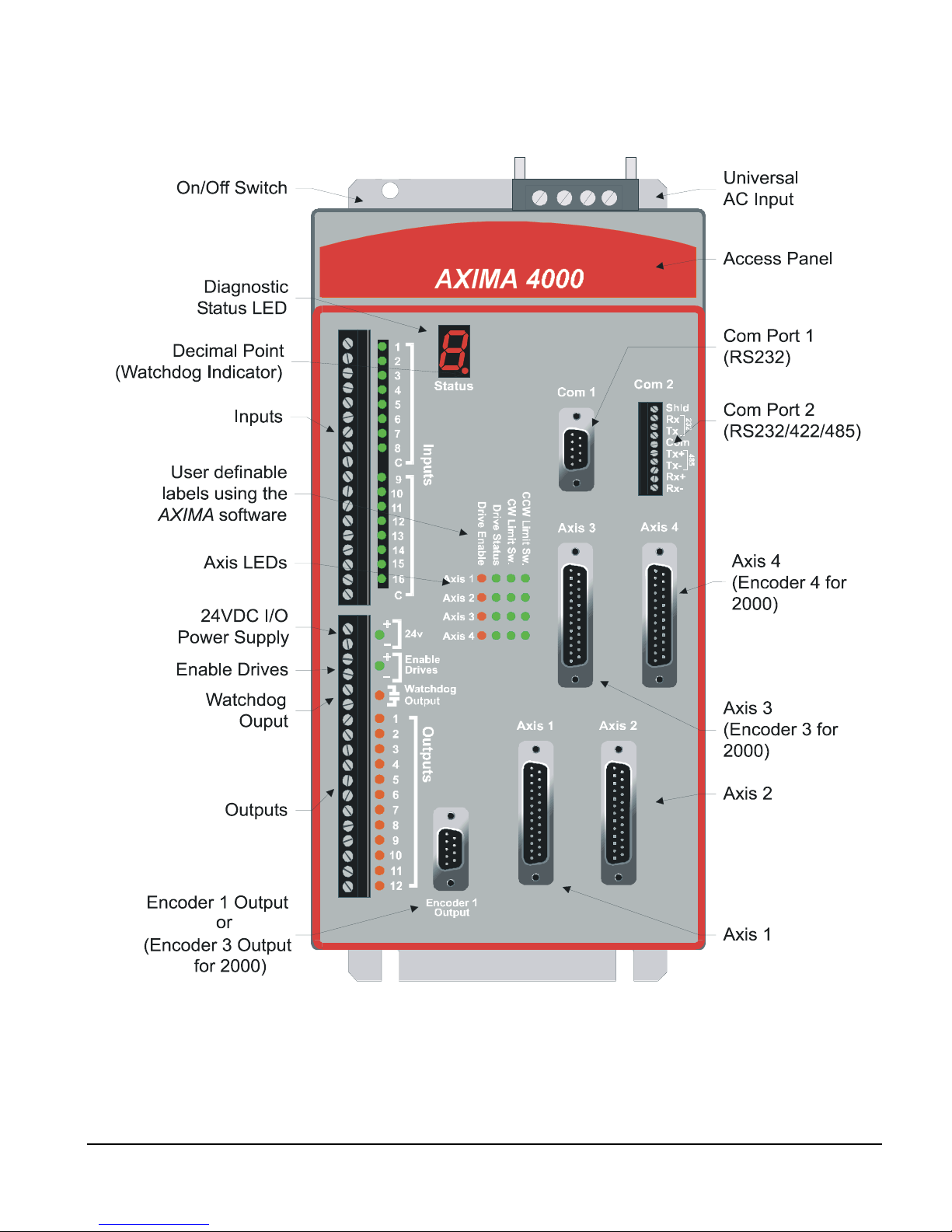

The AXIMA® 2000 or AXIMA 4000 multi-axis controller from Control Techniques provides

a fully integrated solution for servo control motors. It also provides a simple operator

interface, machine I/O and host communications in one unit. Housed in an industrial hardened

chassis, AXIMA 2000/4000 controller combines digital servo control and 41 optically

isolated I/O lines to create a powerful tool for solving motion control applications that require

coordinated control of up to four axes.

Figure 1: AXIMA 2000 and 4000 Multi-Axis Controllers

The AXIMA 2000/4000 controller uses a 32-bit floating point Digital Signal Processor

(DSP). The DSP gives the AXIMA 2000/4000 controller the processing power, flexibility and

functionality to handle the wide range of multi-axis applications found in plant automation

and industrial machinery.

1

Page 14

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

With AXIMA 2000/4000 controller, as many as four Motion, eight PLC and eleven Auxiliary

Programs can be operating simultaneously and control up to four separate coordinate systems,

with one axis of motion each, one coordinate system with up to four axes of motion, or any

combination of up to four coordinate systems and up to four axes of motion.

The onboard executive program allows axis assignments to be made to create one or multiple

coordinate systems. Each coordinate system operates from an independent program. This

allows the programmer to concentrate on one coordinate system at time.

2

Page 15

Connections and Features

Introduction

Figure 2: AXIMA 2000/4000 Controller Front Panel Connections

3

Page 16

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

4

Page 17

AXIMA® 2000/4000 Multi-Axis Controller

Safety Considerations

The AXIMA® multi-axis controller is intended for professional incorporation into a complete

system. If installed incorrectly, it may present a safety hazard. The product uses high voltages

and is used to control mechanical equipment which can cause injury. Close attention is

required to the electrical installation and the system design to avoid hazards either in normal

operation or in the event of equipment malfunction. System design, installation,

commissioning and maintenance must be carried out by personnel who have the necessary

training and experience. They must read this safety information and the instruction manual

carefully.

It is your responsibility to comply with the safety requirements of your system. This includes

installing the system with an appropriate master interlock switch for emergency shutdown

that will remove AC power from the system any time the equipment is not running or the

emergency stop is activated. This reduces the possibility of electrocution or unwanted motion.

Installation Manual

Installation

Enclosure

The controller is intended to be mounted in an enclosure which prevents access except by

trained and authorized personnel, and which prevents the ingress of contamination.

The controller was designed for use in an environment classified as pollution degree 2 in

accordance with IEC 664-1, meaning that only dry, non-conducting contamination is

acceptable.

Selecting an Enclosure

The AXIMA 2000/4000 multi-axis controller is designed for most industrial environments.

However, no sophisticated electronic system can tolerate atmospheric contaminants such as

moisture, oils, conductive dust, chemical contaminants and metallic particles. If the AXIMA

2000/4000 controller is going to be subject to this type of environment, it must be mounted

in a metal enclosure with a minimum rating of NEMA 12.

The temperature inside the enclosure should not exceed 40° C (104° F).

If the ambient temperature exceeds 40° C (104° F) active cooling must be installed.

Setting Up, Commissioning and Maintenance

It is essential that changes to the controller settings are given careful consideration.

Depending on the application, a change could have an impact on safety. Appropriate

precautions must be taken against inadvertent changes or tampering.

5

Page 18

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Restoring default parameters set in certain applications may cause unpredictable or hazardous

operation.

Safety of Machinery

Within the European Union all machinery in which this product is used must comply with

Directive 89/392/EEC, Safety of Machinery.

The AXIMA 2000/4000 hardware and PowerTools software are designed and tested to a high

standard, and failures are very unlikely. However the level of integrity offered by an AXIMA

2000/4000 control function – for example stop/start, forward/reverse and maximum speed –

is not sufficient for use in safety-critical applications without additional independent channels

of protection. All applications where malfunction could cause injury or loss of life must be

subject to a risk assessment, and further protection provided where needed.

Electromagnetic Compatibility (EMC)

The AXIMA 2000/4000 controllers are designed to the high standards of EMC. Under

extreme conditions an AXIMA 2000/4000 controller might cause or suffer from disturbances

due to electromagnetic interaction with other equipment. It is the responsibility of the installer

to ensure that the equipment or system into which the drive is incorporated complies with the

relevant EMC legislation in the country of use.

The following instructions provide you with installation guidance designed to help you meet

the requirements of the EMC Directive 89/336/EEC.

Although Control Techniques cannot guarantee your system will meet tested emission or

immunity requirements, adhering to the following guidelines will greatly improve the

electromagnetic compatibility of your system.

• Choose an enclosure made of a conductive material, such as carbon steel, aluminum or

stainless steel.

• Devices mounted to the enclosure mounting plate, which depend on their mounting

surfaces for grounding, must have the paint removed from their mounting surfaces and the

mating area on the mounting plate to ensure a good ground. The AXIMA 2000/4000

controller does not require removal of paint.

• If grounding is required for cable grommets, connectors and/or conduit fittings at

locations where cables are mounted through the enclosure wall, paint must be removed

from the enclosure surface at the contact points.

• AC line filter input and output wires and cables should be shielded, and all shields must

be grounded to the enclosure.

Although final responsibility for EMC compliance rests with the machine builder, we are

including the following installation suggestions. They describe the components that were

used and how they were installed during the EMC compliance testing.

6

Page 19

Installation

Achieving Low Impedance Connections

Immunity can be improved and emissions reduced by maintaining the components of the

installation at the same ground potential. Establishing zero potential difference between

components requires a low impedance connection between the components.

This can be achieved by bringing the conductive surfaces of the components into direct

contact. Over the short term this can be very effective. Over an extended period of time,

degradation of the connection may occur due to corrosion. Corrosion can occur when a

material reacts with the atmosphere or when two dissimilar materials react with each other.

Therefore component materials should be conductive, compatible and exhibit good

atmospheric corrosion resistance.

Bringing components into direct contact cannot always be achieved. In these situations a

conductor must be relied upon to provide a low impedance path between components. The

impedance of the conductor is dependent on conductivity and frequency. Conductors that

provide a low impedance path at low frequencies may not provide a low impedance path at

higher frequencies.

A good rule to follow when specifying conductors for high frequency applications is to use a

metal strap with a length to width ratio that is less than 3:1.

A low impedance connection should exist between the following components, but not limited

to:

• Enclosure and mounting plate

• Servo amplifier chassis and mounting plate

• EMI/RFI AC line filter chassis and mounting plate

• Other interface equipment chassis and mounting plate

• Other interface equipment chassis and electrical connectors

• Enclosure and conduit fittings or electrical connectors

• Enclosure mounting plate and earth ground

• Motor chassis and conduit fittings or electrical connectors

• Encoder chassis and electrical connector

• Cable shields when and where they should be grounded

Note

It is critical that you keep the filter inputs routed away from any electrical noise sources

to prevent noise from being induced into them and carried out of the enclosure.

7

Page 20

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Environmental Concerns

If your AXIMA 2000/4000 controller will be subjected to atmospheric contaminants such as

moisture, oils, conductive dust, chemical contaminants and metallic particles, you must

mount it vertically in a metal NEMA type 12 enclosure.

If the ambient temperature inside the enclosure will exceed 40° C (104° F), you must consider

forced air cooling. The amount of cooling depends on the size of the enclosure, the thermal

transfer of the enclosure to the ambient air and the amount of power being dissipated inside

the enclosure.

Basic Installation Notes

You are required to follow all safety precautions during start-up, such as providing proper

equipment grounding, correctly fused power and an effective Emergency Stop circuit which

can immediately remove power in the case of a malfunction.

• To avoid problems associated with Electromagnetic Interference (EMI), you should route

high power lines (AC input power and motor power) away from low power lines (encoder

feedback, serial communications, etc.).

• You should consider future troubleshooting and repair when installing all wiring. All

wiring should be either color coded and/or tagged with industrial wire tabs.

• As a general rule, the minimum cable bend radius is ten times the cable outer diameter.

• All wiring and cables, stationary and moving, must be protected from abrasion.

• Ground wires should not be shared with other equipment. Also ensure that metal to metal

contact is made between the enclosure ground lug and the metal enclosure.

• All inductive coils must be suppressed with appropriate devices, such as diodes or

resistor/capacitor (RC) networks.

General Warning

Failure to follow safe installation guidelines can cause death or serious injury. The

voltages used in the unit can cause severe electric shock and/or burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to it. The installation

must comply with all relevant safety legislation in the country of use.

AC supply Isolation device

The AC supply must be removed from the controller using an approved isolation device

or disconnect before any servicing work is performed, other than adjustments to the

settings or parameters specified in the manual.

Grounding (Earthing, equipotential bonding)

The controller must be grounded by a conductor sufficient to carry the prospective fault

8

Page 21

current in the event of a fault. The ground connections shown in the manual must be

adhered to.

Fuses

Fuses or over-current protection must be provided at the input in accordance with the

instructions in the manual. Failure to observe the instructions closely may cause a fire

hazard.

Isolation of control circuits

The control circuits are isolated from the power circuits in the controller by basic

insulation only. The installer must ensure that the external control circuits are isolated

from human contact by at least one layer of insulation rated for use at the applied AC

supply voltage.

Mounting Requirements

The AXIMA 2000/4000 controller should be back mounted vertically in a metal NEMA

enclosure. A minimum spacing of four inches must be maintained above and below the

controller for ventilation. The following diagram shows the dimensions of the AXIMA 2000/

4000 controller.

Installation

9

Page 22

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

11.70

(297.18)

0.9

(22.86)

3.0

(76.20)

1.25

(31.75)

5.5

(139.70)

3.68

(98.30)

3.0

(76.20)

7.1

(183.00)

0.25

(6.35)

11.19

(284.23)

0.20 (5.08) typ. 4 places

Dimensions in ( ) are in millimeters.

Figure 3: Mounting Dimensions

System Grounding Requirements

AXIMA 2000/4000 Controller Grounding

The PE terminal of the AXIMA 2000/4000 controller is internally bonded to the chassis. The

enclosure PE and the AXIMA 2000/4000 controller PE should have a common signal point

that ultimately is a continuous path to earth ground. These ground wires of the AXIMA 2000/

4000 controller should not be shared with other equipment in the enclosure.

The TE terminal is connected to the internal digital ground of the AXIMA. The TE

connection should be tied to the PE connection in the enclosure. Do not jumper the connection

to the PE terminal on the AC input connector.

10

Page 23

Installation

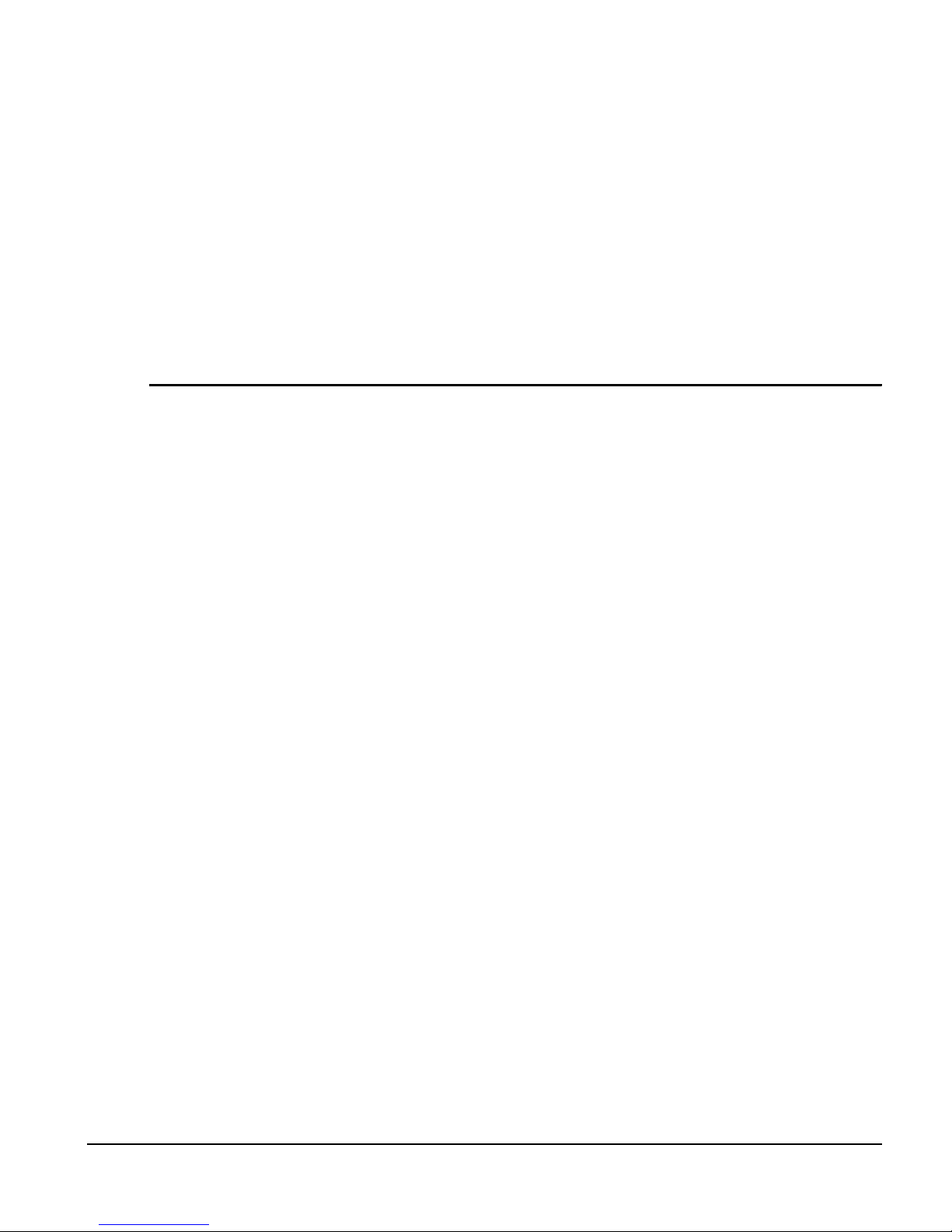

Figure 4: AXIMA 2000/4000 Controller Grounding Point

The AXIMA 2000/4000 controller PE terminal must be connected to the equipment

grounding conductor of the AXIMA’s AC supply circuit and bonded to the enclosure. This

should be accomplished with a short wire from the PE terminal to a grounding block in the

enclosure. All other equipment in the enclosure must use its own connection to this grounding

block.

11

Page 24

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

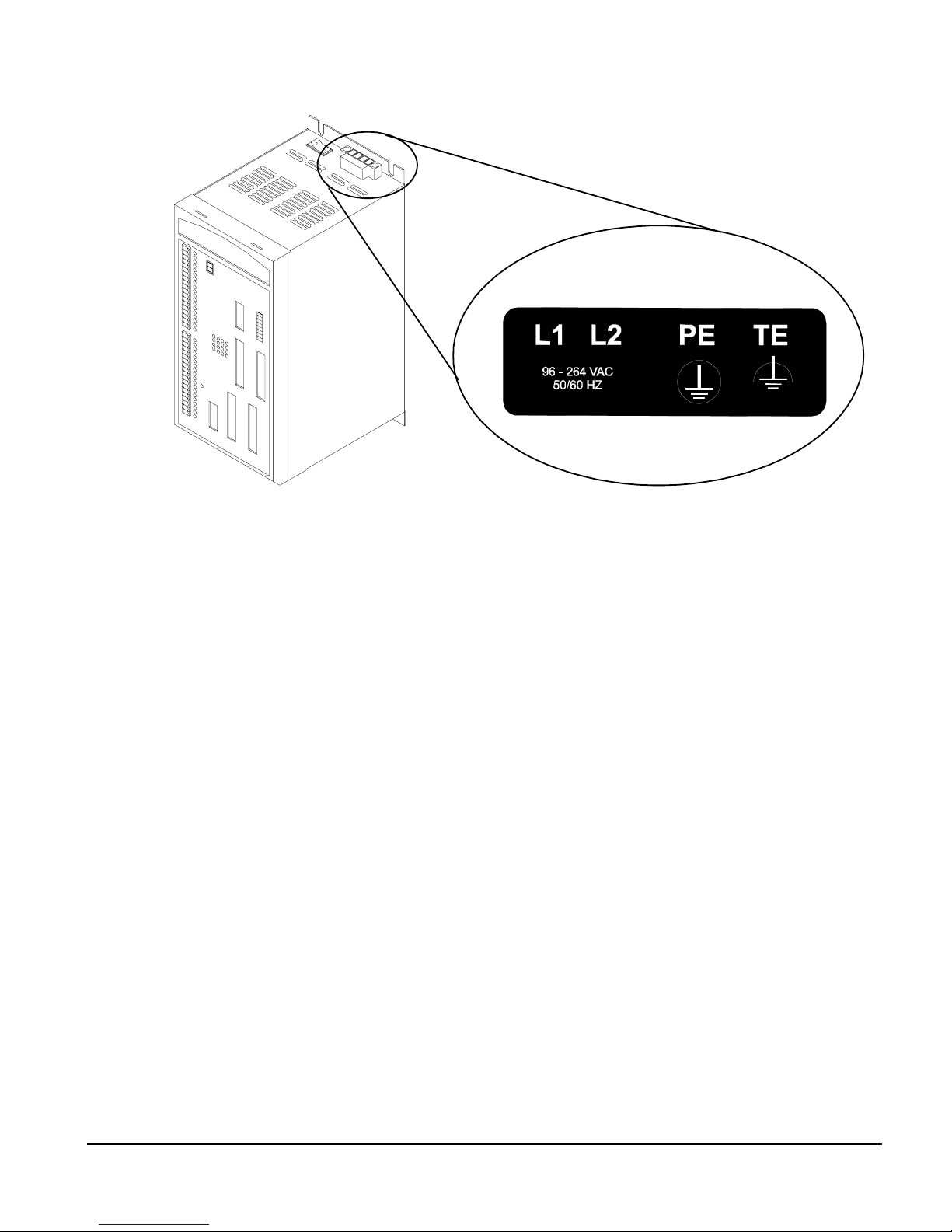

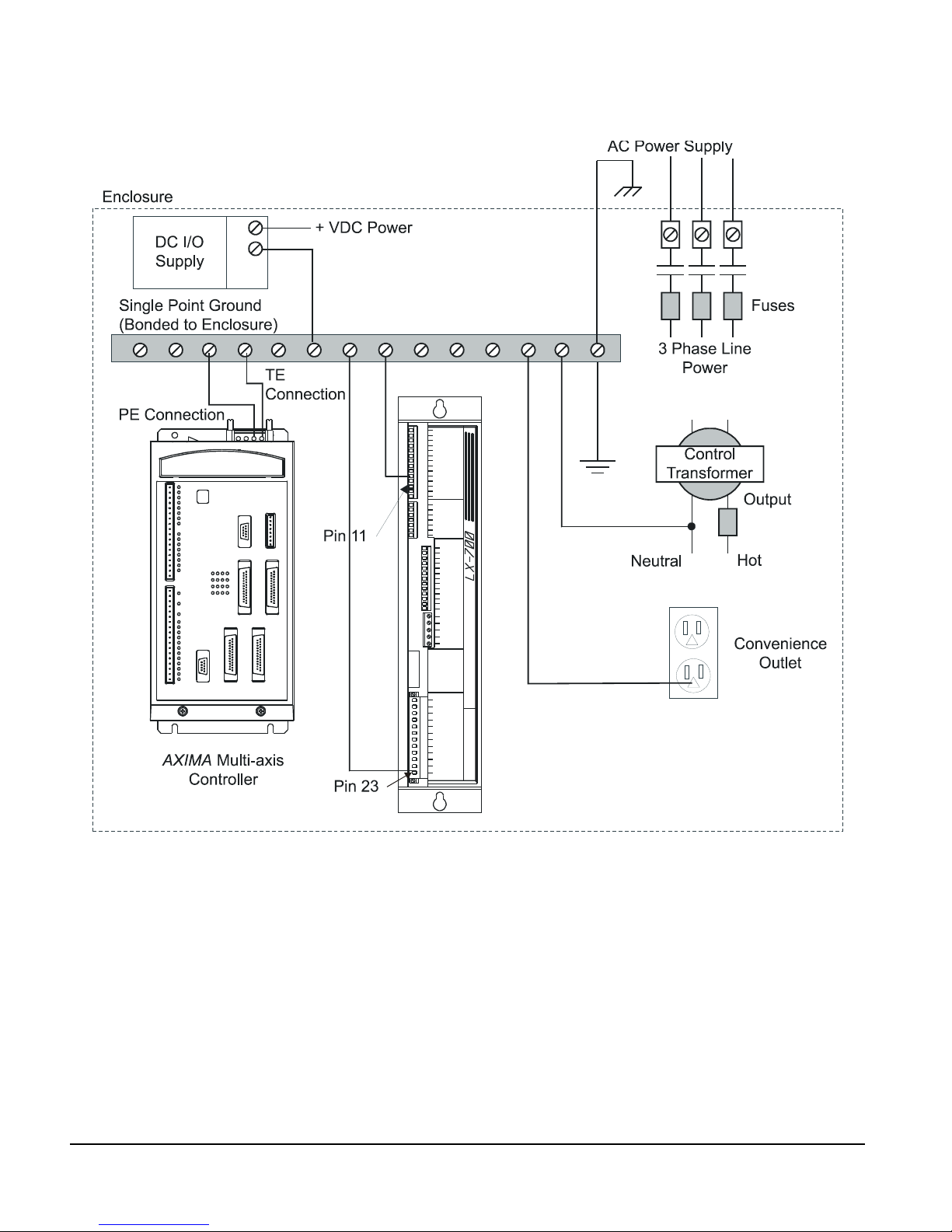

AXIMA/E Series Drives Grounding Example

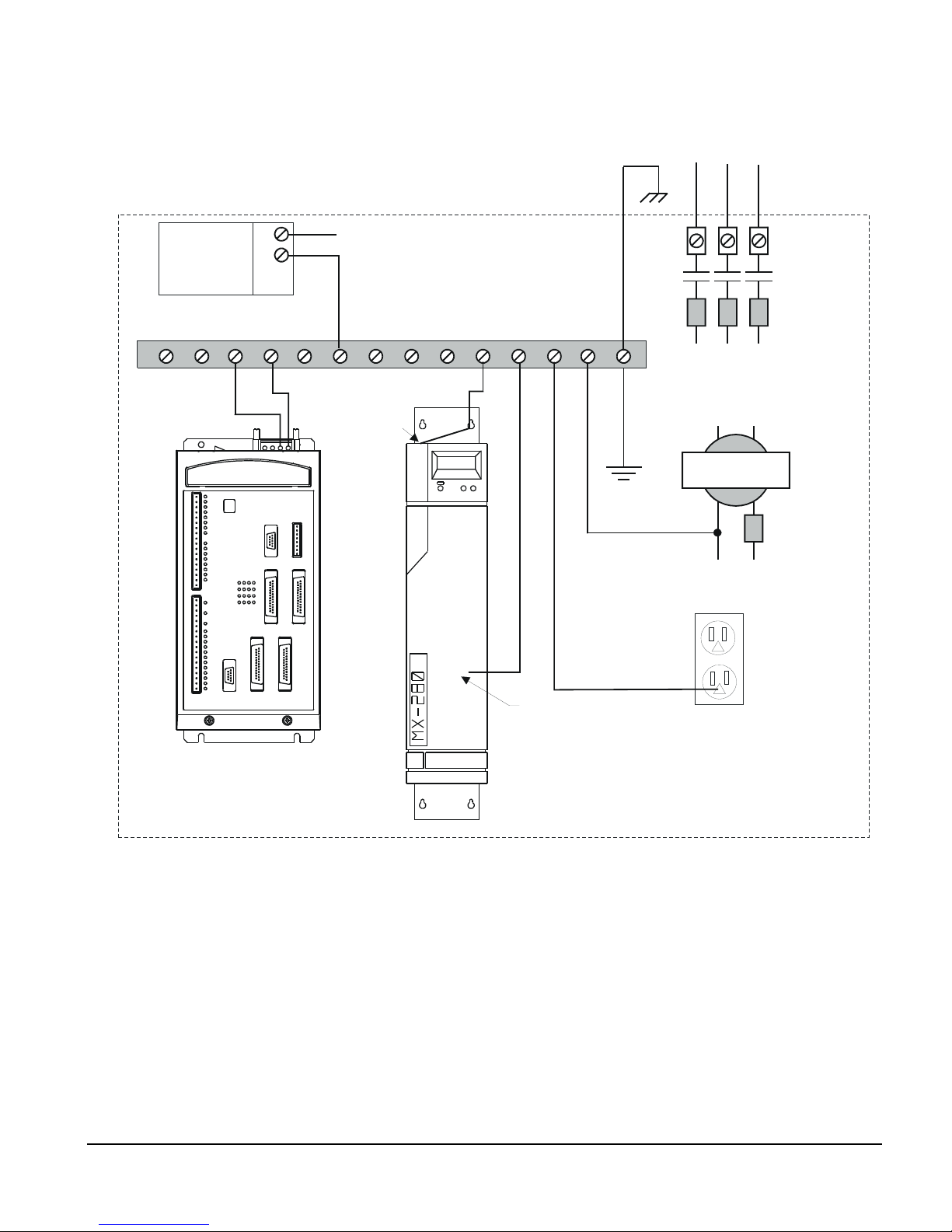

Figure 5: E Series Drive and AXIMA System Grounding Diagram

12

Page 25

AXIMA/MX Drives Grounding Example

Enclosure

Installation

AC Power Supply

DC I/O

Supply

Single Point Ground

(Bonded to Enclosure)

TE Connection

PE Connection

+ VDC Power

Jumper from

AMP GND to

"Y" Terminal

3 Phase Line

Power

Transformer

Neutral

Fuses

Control

Output

Hot

Convenience

Outlet

Pin 11

AXIMA Multi-axis

Controller

MX Digital

Servo Drive

Figure 6: MX Drive and AXIMA System Grounding Diagram

13

Page 26

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

AXIMA/LX Drives Grounding Example

Figure 7: LX Drive and AXIMA System Grounding Diagram

Power Requirements

Rated AC power input is 120 VAC at 1 A or 240 VAC at 0.5 A, single phase, 50 or 60 Hz.

AC power must be between 96 and 204 VAC.

The AC power connects to a removable connector on the top of the AXIMA 2000/4000

chassis. The AC power input must be between 96 and 264 VAC, single phase, and 50 to 60

Hertz. At 115 VAC, 1.0 Amps RMS is required, or at 230 VAC, 0.5 Amps RMS is required.

However, at power-up the unit has an inrush current that is typically 20 Amps at 115 VAC

14

Page 27

Installation

and 40 Amps at 230 VAC for 2 milliseconds. This inrush current must be considered when

choosing AC power fusing.

Note

The AC Power removable connector terminals are to be torqued 6 to 7 inch pounds at

installation of wiring.

Figure 8: AC Power Connector

AC Supply

Volt age

115 VAC 1 Amp 20 Amps FLM-2 or equivalent

230 VAC 0.5 Amp 40 Amps 2 Amp Slo-Blo

Current

Inrush Current

(2 ms)

External Fusing Requirement

The AC power supply must be fused with a 2 amp fuse in each ungrounded line. A grounded

line (neutral) must not be fused. Littelfuse

can be used.

®

’s FLM-2 SLO-BLO type fuse, or an equivalent,

Fusing Frequency (Hz) AC Supply Limit

50/60 96 to 264 VAC

15

Page 28

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Grounded Supply Requirement

A significant AC power problem occurs when the secondary of the AC distribution

transformer is not electrically referenced to earth ground (i.e., left floating). In this case, the

voltages that develop between the AC power lines and earth ground can continuously exceed

the voltage limit of 264 VAC. When this happens the protection circuit in the AXIMA 2000/

4000 controller will try to suppress this excess voltage. If the condition is prolonged, the

AXIMA 2000/4000 controller protection circuits will fail.

The voltage limit of 264 VAC applies from L1 to PE and L2 to PE as well as from L1 to L2.

Use a ground referenced AC supply.

16

Page 29

AXIMA® 2000/4000 Multi-Axis Controller

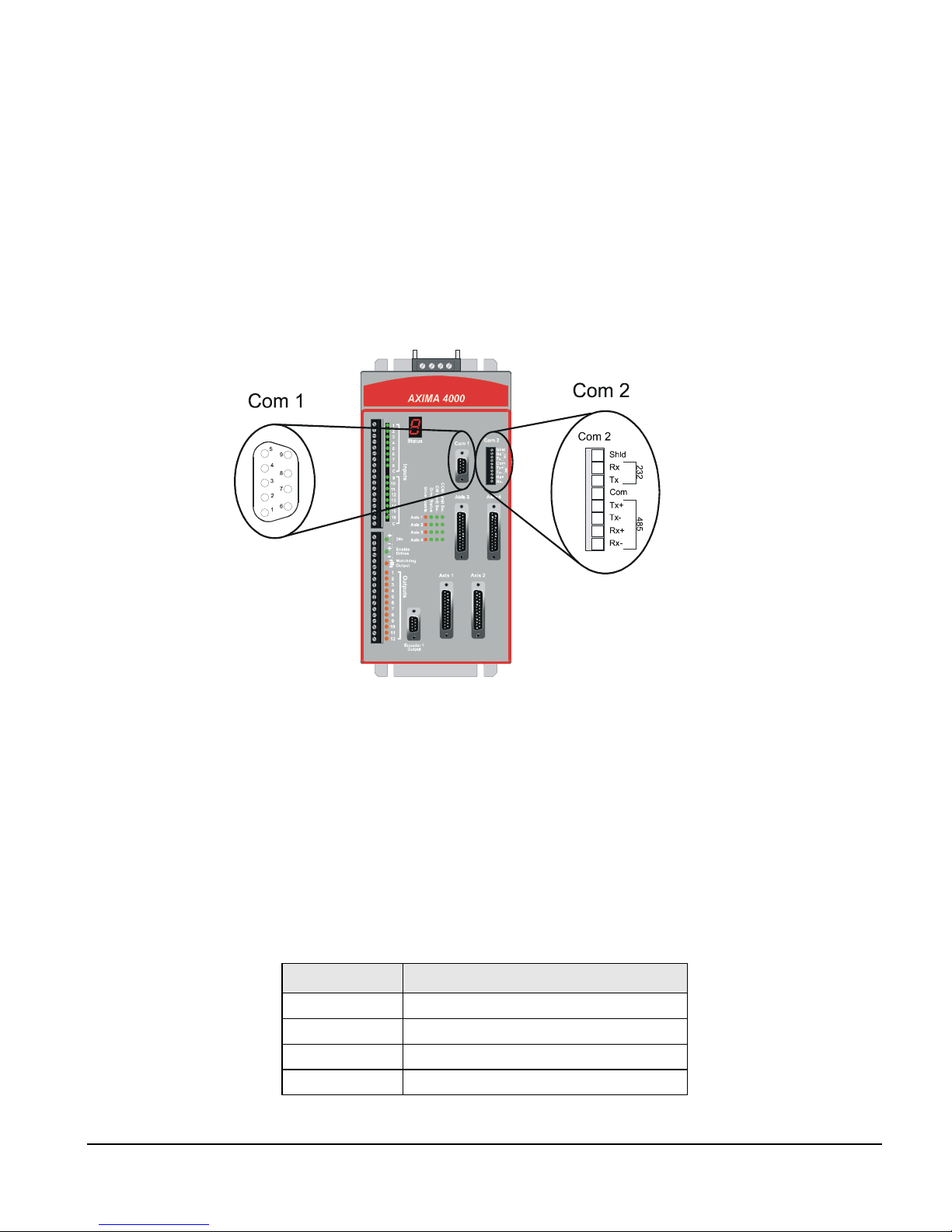

Serial Communications

The AXIMA® 2000/4000 controller has two optically isolated serial ports (COM 1 and COM

2). COM 1 is a RS232 port. COM 2 can be configured for RS232, RS422 or RS485 using DIP

switches located behind the removable access panel on the top front of the AXIMA 2000/

4000 controller.

Installation Manual

Connections and Cabling

Figure 9: AXIMA 2000/4000 Controller Communication Ports, Com 1 and Com 2

COM Port 1

The AXIMA 2000/4000 controller COM 1 connection is a RS232 serial communication port.

The COM 1 port is activated and will automatically detect the baud rate by receiving one

carriage return after power up. Both serial ports, COM 1 and COM 2, can be open

simultaneously and attached to different programs. For example, one port could be used as a

programming and diagnostics port while the second port is communicating with an operator

interface panel such as the Control Techniques T-60 panel.

Pin Number Description

1 Shield

2Rx

3Tx

4 Not connected

17

Page 30

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Pin Number Description

5 Common

6 Not connected

7 Not connected

8 Not connected

9 Not connected

Note

The COM 1 port is supplied through a DC-to-DC convertor which is isolated from the

main board’s 5 VDC supply. All communications signals are isolated using optoisolators.

Serial Port and Cable Specifications

It is recommended that all communication lines be twisted pair shielded cable. Cables should

be routed away from motor power and other high voltage or noisy wiring.

Serial Communication Setup

Max baud rate 38.4 K

Stop bit 1

Data bits 8

Parity none

The RS232 serial communication cables should be no longer than 50 feet to comply with

RS232 specifications. However, longer cables may be used at slower baud rates (less than

9600). The wiring diagrams on the next page show the TIX and TIA serial cables which are

available from Control Techniques in 10, 25 and 50 foot lengths. Non-standard lengths can

be special ordered.

18

Page 31

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

25 PIN

"D" CONNECTOR

FEMALE

COMPUTER

Tx

2

Rx

3

GND

7

PIN

NUMBER

TIX-XXX CABLE

TIA-XXX CABLE

COM 1

Rx

Tx

GND

SHLD

Connections and Cabling

2

3

5

1

PIN

NUMBER

5

9

4

8

3

7

2

6

1

9 PIN

"D" CONNECTOR

MALE

5

9

4

8

3

7

2

6

1

9 PIN

"D" CONNECTOR

FEMALE

Figure 10: RS232C Serial Communication Cables Wiring Diagram

COM Port 2

To communicate with more than one AXIMA 2000/4000 controller, and using the AXIMA

Software or other host controller, you must use COM 2 configured as an RS485. The COM 2

serial communication port is shipped as a RS232 as default.

DIP Switch Settings

COM 2 can be configured for RS232, RS422 or RS485 using switches located behind the

removable access panel on the top front of the AXIMA 2000/4000 controller.

COMPUTER

Tx

3

Rx

2

GND

5

PIN

NUMBER

COM 1

Rx

Tx

GND

SHLD

2

3

5

1

PIN

NUMBER

5

9

4

8

3

7

2

6

1

9 PIN

"D" CONNECTOR

MALE

19

Page 32

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Figure 11: AXIMA 2000/4000 Controller DIP Switches Location

RS232 DOWN

RS422 UP DOWN DOWN DOWN

RS485 (2 wire/SD) UP UP UP UP

RS485 (4 wire/SD) UP DOWN UP UP

RS485 (4 wire/RTS) UP DOWN DOWN UP

20

DIP Switch Settings

1 2 3 4

Page 33

Mode Selection

RS232C Mode (Default Mode)

The AXIMA 2000/4000 controller is shipped with COM 2 in RS232 mode.

RS232C

DEVICE

Figure 12: COM 2, RS232 Configuration

Tx

Rx

GND

Com 2

1

2

3

4

5

6

7

8

Connections and Cabling

Shld

Rx

Tx

Com

Tx+

Tx-

Rx+

Rx-

232 485

Note

The COM 2 port is supplied through a DC-to-DC convertor which is isolated from the

main board’s 5 VDC supply. All communications signals are isolated using optoisolators.

RS422 Mode

With COM 2 in RS422 mode, the transmitter is not put into a tri-state mode. The Tx

(Transmit) lines of multiple AXIMA 2000/4000 controllers CAN NOT be wired together.

The receive line of the last AXIMA should be terminated with a 100 ohm ½ watt resistor. See

Figure 13.

RS485 Mode

RS422 and RS485 modes are similar because they both use differential drivers and receivers.

RS485 mode adds the ability to enable and disable the receivers and transmitters as required

for multidrop installations. See Figure 14 and 15.

The enable and disable operations of the AXIMA 2000/4000 controller serial port can be

selected to operate in two different transmission methods. These methods are selectable with

a DIP switch behind the access panel on the top front of the controller. It is labeled, SD (Send

Data) or RTS (Ready to Send). See Figure 11.

SD (Send Data) Method:

This is the simplest mode. Whenever the AXIMA 2000/4000 controller serial port senses that

data is present the transmitter is enabled. The transmitter stays enabled long enough to assure

the last bit has been sent then it disables or tri-states the transmission. It does this for baud

21

Page 34

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

rates down to 9600 baud. The transmitter is in tri-state mode or disabled when data is not

being sent so it can receive data.

RTS (Ready to Send) Method:

This method enables the transmitter under two conditions.

1. When a particular AXIMA 2000/4000 controller has been chosen by the host to be

online, the command, CTRL A - “Axis ID #” - Enter, is issued. The transmitter stays

enabled until a “CTRL B” command is received.

2. When the AXIMA Software Application executes an Open Com Instruction, the

transmitter is enabled. The transmitter goes back to tri-state mode when a Close Com

Instruction is issued. See the AXIMA Software User’s Guide (P/N 400263-00) for more

information.

The Echo On/Off DIP switch controls the enable/disable function of the AXIMA receiver.

With the switch “On”, the receiver is always enabled. This switch should be “On” for RS422

and RS485 four wire operation. With the switch “Off”, the receiver is disabled whenever the

transmitter is enabled. This is needed for two wire mode. This is to prevent the AXIMA 2000/

4000 controller from receiving the same characters it just transmitted.

The figure below shows a wiring diagram for serial communications of a RS422

configuration.

22

Page 35

Connections and Cabling

GND

NC

NC

NC

100

Ω

½ WATT

TYPICALLY

UP TO 10

SLAVES

SEE NOTE

BELOW

NC

15

E

Figure 13: RS422 Two Wire Muli-Drop Wiring Diagram

Note

A standard RS-422 host transmitter can drive up to 10 slaves. However, the AXIMA

transmitter can drive up to 15 slaves in RS-422 mode.

The figure below shows a wiring diagram for serial communications in an RS485 four wire

multi-drop configuration.

23

Page 36

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

GND

UP TO 15

SLAVES

24

15

E

Figure 14: RS485 Four Wire Multi-Drop Wiring Diagram

The figure below shows a wiring diagram for serial communications of a RS485 two wire

termination connection.

Page 37

GND

Connections and Cabling

UP TO 15

SLAVES

15

E

Figure 15: RS485 Two Wire Termination Connection Wiring Diagram

RS485 termination

Two 120 ohm, ½ watt resistors must be installed on an RS-485 network, one at the node (RS485 port) physically at the beginning of the cable and one on the node at the end.

25

Page 38

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Com 2

Shld

1

Rx

2

Tx

3

Isolated Com *

4

Tx+

5

Tx-

6

Rx+

7

Rx-

8

* Isolated from the rest of the

AXIMA Controller through a

DC-to-DC convertor.

RS485

or

RS422

Device

GND

Rx +

Rx -

Tx +

Tx -

Figure 16: COM 2, RS485 Configuration

Serial Port Grounding

The AXIMA 2000/4000 controller provides an isolated logic supply for its communication

circuitry. COM is the circuit common for both COM port circuits. COM 1 and COM 2

devices, such as PC serial ports, typically have signal ground connected to earth ground

internally in the PC.

If your COM devices do not have signal grounds that are common with respect to each

other (such as both connected to earth ground) then you must connect them together.

Failure to connect device grounds together could cause damage to the device or the

AXIMA 2000/4000 controller.

26

Page 39

INTERNALLY

CONNECTED

COM 1

5

9

4

8

3

7

2

6

1

9 PIN

"D" CONECTOR

COM 2

Shld

1

Rx

2

Tx

3

Com

4

Tx+

5

Tx-

6

Rx+

7

Rx-

8

232 485

COM 1 DEVICE

(RS232C)

SIGNAL

COMMON

COM 2 DEVICE

(RS422 OR RS485)

SIGNAL

COMMON

Connections and Cabling

GROUND

GROUND

Figure 17: Serial Communications Grounding Diagram

Serial Port and Cable Specifications

It is recommended that all communication lines be twisted pair shielded cable. Low

capacitance shielded twisted pair cable will deliver optimum performance especially with

long cable lengths and high baud rates. Cables should be routed away from motor power and

other high voltage or noisy wiring.

Serial Communication Setup

Max baud rate 38.4 K

Stop bit 1

Data bits 8

Parity none

Note

As baud rates increase or cable lengths get longer your susceptibility to noise increases.

Therefore, if you are experiencing communication problems, it is recommended that you

install a ½ watt terminating resistor, 100 ohm for RS422 and 120 ohm for RS485.

27

Page 40

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Controller ID Number/Address

The following table shows how the Address DIP switch positions relate to the AXIMA 2000/

4000 controller axis ID number. The DIP switches are located behind the top front access

panel of the AXIMA 2000/4000 controller.

Figure 18: AXIMA 2000/4000 Controller Address DIP Switch Location

AXIMA ID Address DIP Switch Settings

1 2 3 4

0 OFF OFF OFF OFF

1 OFF OFF OFF ON

2OFFOFFONOFF

28

Page 41

Connections and Cabling

AXIMA ID Address DIP Switch Settings

3OFFOFFONON

4 OFF ON OFF OFF

5 OFF ON OFF ON

6 OFF ON ON OFF

7 OFF ON ON ON

8 ON OFF OFF OFF

9ONOFFOFFON

A ON OFF ON OFF

B ON OFF ON ON

CONONOFFOFF

DONONOFFON

EONONONOFF

Reserved ON ON ON ON

Note

The following procedure is needed if a corrupted program is run on power-up or in making

communications.

The reserved address setting is used for bypassing the flash memory and ignoring the run on

power-up command for programs in the Application. This is needed if the flash memory

becomes corrupted. Corrupted flash can lock-up communications and load the corrupted

program into RAM on power-up. This requires revision A7 or later firmware. The

instructions for using this function are as follows:

1. Turn the AXIMA 2000/4000 controller power “Off”.

2. Set the DIP switches to the reserved positions. (All switches in the “On” position).

3. Turn the AXIMA 2000/4000 controller power “On”.

4. Set the DIP switches back to the address being used.

5. Download the AX-WIN Application.

Multi-Drop Installations

If your application uses more than one AXIMA 2000/4000 controller (up to 15 can be linked

serially), each must have a different ID number. This allows each AXIMA 2000/4000

controller to be addressed individually over the same multi-drop serial cable in the RS422 and

RS485 modes.

29

Page 42

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Axis Connections

The front panel of the AXIMA 2000/4000 controller has four, 25 pin female “D-sub”

connectors. The AXIMA 2000 has two axes and two auxiliary encoder connections, while the

AXIMA 4000 has four axes connections.

Figure 19: AXIMA 2000/4000 Controller Connectors (4 Axes)

30

Page 43

Connections and Cabling

These axis connectors are used to connect the AXIMA 2000/4000 controller to the individual

amplifiers (E Series, MX, LX, etc.). The following table shows the pinout of the 25-pin

female “D-sub” connectors.

Pin Number Signal Name Pair Number

13 A Encoder Input Signal

25 A/ Encoder Input Signal

12 B Encoder Input Signal

24 B/ Encoder Input Signal

11 Z Encoder Input Signal

23 Z/ Encoder Input Signal

10 +5 VDC for Encoder Feedback

22 VDC Common (0 VDC Common for Encoder Feedback

- Pulse Output

5 Pulse/ Output

17 Direction Output

- Direction/ Output

8 Analog Command Output -

20 Analog Command Output +

9 Enable Contact

21 Enable Contact

14 Ø VDC I/O Supply Common

2 +24 VDC I/O Supply

3 Discrete Input (CCW Travel Limit)

16 Discrete Input (CW Travel Limit)

15 Discrete Input (Drive Status)

18 Low Current Mode Output

7 Analog Input 1

19 Analog Input 2

6 Analog Common 13

4 Overall Shield

1

2

3

4

5

6

7

8

9

10

11

12

* Grayed-out Pin Numbers are NOT available in the AXIMA 2000’s Encoder Connection 3 and 4.

31

Page 44

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Analog Inputs

Note

These are only active if the factory Analog Input option is installed.

Pin 7 Pin 19

Axis 1 Analog Input 1 Analog Input 2

Axis 2 Analog Input 3 Analog Input 4

Axis 3 Analog Input 5 Analog Input 6

Axis 4 Analog Input 7 Analog Input 8

Encoder Inputs

Encoder signals are low voltage, high frequency signals susceptible to noise if not properly

shielded. For reliable operation it is important that encoder cables be shielded and routed

away from motor power or other high voltage signals. Shields should be connected at the

controller end.

Specifications

Input Signal Quadrature square wave

Maximum Rate 8 MHz

Type Differential Receiver, DS26LS32

Voltage 5 VDC maximum, 2 VDC minimum

Supply 5 VDC, 250 mA maximum per axis

The encoder signals may come from an encoder or from the encoder simulation output of a

brushless servo drive (see wiring diagrams below).

32

Page 45

Connections and Cabling

ENCODER

SIMULATION

FROM

SERVO DRIVE

A

A/

B

B/

Z

Z/

Figure 20: Encoder Simulation Wiring Diagram

AXIS

CONNECTION

A

13

A/

25

B

12

B/

24

Z

11

Z/

SHLD

23

4

PIN

NUMBER

"D" CONNECTOR

25 PIN

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

AXIS 1 (FOR 4000)

ENCODER 3 (FOR 2000)

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

SHIELD

LOGIC

COMMON

EARTH

GROUND

A

A/

B

B/

Z

Z/

N/C

N/C

13

25

12

24

11

23

4

PIN

NUMBER

ENCODER 1 OUTPUT (FOR 4000)

ENCODER 3 OUTPUT (FOR 2000)

RED/WHT

YEL/WHT

BLU/WHT

BLK/WHT

YEL

BLU

BLK

RED

5

9

4

8

3

7

N/C

N/C

6

PIN

NUMBER

A/

B

B/

Z

Z/

A

9 PIN

"D" CONNECTOR

EARTH

GROUND

5

4

3

2

1

9

8

7

6

LOGIC

COMMON

Figure 21: AX4-ED Encoder Cable Wiring Diagram

33

Page 46

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Shown below is the wiring diagram for the AX4-ENC-XXX cable which is available from

Control Techniques in 15, 25 and 50 foot lengths for connection to Control Techniques’

SCSLD encoders.

AXIMA 2000/4000

CONTROLLER

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

LOGIC

COMMON

EARTH

GROUND

ENC COM 0V

ENC SUP +5V

SHIELD

A

A/

B

B/

Z

Z/

13

25

12

24

11

23

22

10

4

PIN

NUMBER

RED/WHT

YEL/WHT

BLU/WHT

BLK/WHT

YEL

BLU

BLK

RED

ENCODER

A

A

H

A/

B

B

I

B/

C

Z

J

Z/

F

ØV

D

5V

10 PIN

"MS" CONNECTOR

HBA

IG

FJ

DE

C

Figure 22: AX4-ENC Encoder Cable Wiring Diagram

Encoder Power Supply

The AXIMA 2000/4000 controller can be used to provide the 5 Volt power source for external

encoders. Connections are provided on each axis I/O connector. The current on the 5 Volts

must be limited to 250 milliAmps per axis and the maximum current for 4 encoders must be

limited to 1 Amp.

Each 5 volt Encoder Supply has a PTC switch in line thus excessive currents will open the

switch. The switch will close if it is allowed to cool down. Removing the load for a few

seconds will reset the fuse.

Analog Outputs

The AXIMA 2000/4000 controller’s analog command output to the servo amplifier is a

precision 16 bit output. These signals are susceptible to noise if not properly shielded. For

reliable operation it is important that command cables be shielded and routed away from

motor power or other high voltage signals. Shields should be connected at the AXIMA 2000/

4000 controller end. The input stage of the amplifier should be a differential circuit. The

output voltage is ±10 VDC, output current is 5 milliAmps maximum.

34

Page 47

Figure 23: Analog Command Output

Drive Enable (Enable Contact)

Each axis has an Enable Relay Contact. The contact has a rating of 30 VDC and is capable of

switching 0.5 Amps for a resistive load. All Enable relays are interlocked with the Watchdog

relay as well as the Enable Drives input. Each relay is also individually controlled by the predefined Drive Enable output.

Connections and Cabling

20

8

9

ENABLE

CONTACT

21

Figure 24: Drive Enable (Enable Contact) Circuit

Note

It is recommended that the Enable Contact be used. If these contacts are not used,

physically connecting a drive (E Series, MX, LX or other) to the controller while that

drive is enabled may cause unwanted motion.

In the event the Enable Contact is not used, the following power sequence must be followed:

1. Apply power to the AXIMA 2000/4000 controller

2. Apply power to the drives

3. Enable the drives

4. Normal machine operation

5. Disable or power down the drives

6. Power down the AXIMA 2000/4000 controller

35

Page 48

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Drive Status and Overtravel

Drive Status or Overtravel inputs do not perform any pre-defined action in the controller.

They are available as pre-defined bits and may be used in the AXIMA Software’s PLC,

Motion or Auxiliary Programs to perform desired logic.

LED

INPUT

0 VDC I/O Supply

2.21K

1.2K

2.21K

Figure 25: Drive Status and Overtravel Input Circuit

Example Axis Connections

If desired, the AXIMA 2000/4000 controller can be used to generate a torque or current

command instead of a speed command. When the drives are used in torque mode, the drive

velocity loop gain adjustments no longer need to be considered. This can simplify the tuning

procedure for some applications.

E Series Drives

All command and I/O signals are accessed using the 44 pin command connector located on

the front of the E Series drive.

The wiring diagram below shows the typical command connections between the AXIMA

2000/4000 controller and an E Series drive using the AX4-CEN-XXX cable.

+ 5

AXIMA INPUT

COM

36

Page 49

Connections and Cabling

AXIMA 2000/4000

CONTROLLER

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

ANALOG CMD OUT -

20

7

19

ANALOG CMD OUT +

6

18

5

17

DRV ENABLE

4

16

3

15

2

14

1

DIRECTION CMD OUT

I/O COM -

I/O SUPPLY +

CCW LIMIT

CW LIMIT

DRIVE STATUS

ANALOG IN 1

ANALOG IN 2

ANALOG COM

LOGIC COMMON

PULSE/ CMD OUT

E SERIES DRIVE

13

A

25

A/

12

B

24

B/

11

Z

23

Z/

14

2

8

20

9

21

3

16

15

N/C

7

19

6

N/C

5

17

PRP/BLU

BLU/PRP

PRP/ORG

ORG/PRP

PRP/BRN

BRN/PRP

BRN/YEL

YEL/BRN

WHT/BLU

BLU/WHT

BLK/GRN

GRN/BLK

BRN/BLK

BLK/BRN

YEL/GRY

GRY/YEL

WHT/GRN

GRN/WHT

WHT/RED

RED/WHT

GRN/PRP

PRP/GRN

8

A

9

A/

23

B

24

B/

37

Z

38

Z/

31

I/O COM -

33

I/O SUPPLY +

14

ANALOG CMD IN -

15

ANALOG CMD IN +

16

DRV ENABLE IN

34

I/O SUPPLY +

17

OUTPUT #3

18

OUTPUT #2

19

OUTPUT #1

N/C

43

ANALOG OUT 1

44

ANALOG OUT 2

29

ANALOG COM

N/C

20

OPEN COLLECTOR PULSE/

36

OPEN COLLECTOR DIRECTION

"D" CONNECTOR

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

44 PIN

30

44

29

43

28

42

27

41

26

40

25

39

24

38

23

37

22

36

21

35

20

34

19

33

18

32

17

31

16

4

PIN

NUMBER

PIN

NUMBER

10

Ω

PE

LOGIC

COMMON

EARTH

GROUND

SHIELD

Figure 26: AX4-CEN Cable

Note

See Figure 5 , E Series Drive and AXIMA System Grounding Diagram.

MX Drives

To operate an MX drive in torque mode, set the command selector bit bØ6 in the MX drive,

to 1. Refer to the MX Drives Setup and Programming Operator’s Manual (P/N 400268-00)

for detailed information on setting and saving this bit status.

AXIMA 2000/4000 Controller to MX Drive Connections (Torque Mode)

The wiring diagram below shows the typical command connections between the AXIMA

2000/4000 controller and an MX amplifier.

37

Page 50

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

A

AXIMA 2000/4000

CONTROLLER

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

ANALOG CMD OUT -

20

7

19

ANALOG CMD OUT +

6

18

5

DRV ENABLE

17

4

16

3

15

2

14

1

LOGIC

COMMON

GROUND

ENC COM ØV

CCW LIMIT

CW LIMIT

DRIVE STATUS

ANALOG IN 1

ANALOG IN 2

ANALOG COM

LOGIC

COMMON

EARTH

13

A

25

A/

12

B

24

B/

11

Z

23

Z/

22

N/C N/C

8

20

9

21

3

16

15

PRP/BLU

BLU/PRP

PRP/ORG

ORG/PRP

PRP/BRN

BRN/PRP

BLU/RED

RED/BLU

WHT/BLU

BLU/WHT

BLK/GRN

GRN/BLK

BRN/BLK

BLK/BRN

YEL/GRY

GRY/YEL

WHT/GRN

GRN/WHT

WHT/RED

RED/WHT

SHIELD

N/C

NUMBER

7

19

6

4

PIN

TO PANEL

GROUND

MX

MPLIFIER

1

A

2

A/

3

B

4

B/

5

Z

6

Z/

RESERVED

"B" CONNECTOR STRIP

9

CMD -

10

CMD +

14

ENABLE

13

+10V

4

PROG INPUT (CCW)

5

PROG INPUT (CW)

15

DR OK

N/CN/C

17

TACH OUT

16

ANALOG OUT

RESERVED

N/C

11

PIN

NUMBER

9 PIN

"D" CONNECTOR

5

9

4

8

3

7

2

6

1

Figure 27: AXIMA 2000/4000 Controller to MX Amplifier Connections Using The

AX4-MX cable (Torque Mode)

Note

Make sure AXIMA Logic Common is connected to the same point in the cabinet as the

MX Logic Common. See Figure 5 , E Series Drive and AXIMA System Grounding

Diagram.

LX Drives

AXIMA 2000/4000 Controller to LX Drive Connections (Torque Mode)

To operate an LX drive in torque mode, connect the AXIMA 2000/4000 controller command

wires to the Current CMD and Common inputs on the LX drive (terminal pins 2 and 3) as

shown in the wiring diagram below.

38

Page 51

Connections and Cabling

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

LOGIC

COMMON

AXIMA 2000/4000

CONTROLLER

ENC COM ØV

ENC SUP +5V

ANALOG CMD OUT -

ANALOG CMD OUT +

DRV ENABLE

CCW LIMIT

CW LIMIT

DRIVE STATUS

(STEPPER) LOW CURR MODE

ANALOG IN 1

ANALOG IN 2

ANALOG COM

LOGIC COMMON

DIRECTION CMD OUT

PULSE/ CMD OUT

I/O COM -

I/O SUPPLY +

SHIELD

EARTH

GROUND

A

A/

B

B/

Z

Z/

N/C

N/C

N/C

13

25

12

24

11

23

22

10

8

20

9

21

3

16

15

18

7

19

6

17

5

14

2

4

PIN

NUMBER

PRP/BLU

BLU/PRP

PRP/ORG

ORG/PRP

PRP/BRN

BRN/PRP

BLU/RED

RED/BLU

WHT/BLU

BLU/WHT

BLK/GRN

GRN/BLK

BRN/BLK

BLK/BRN

YEL/GRY

GRY/YEL

WHT/GRN

GRN/WHT

WHT/RED

RED/WHT

GRY/PRP

PRP/GRY

GRN/PRP

PRP/GRN

BRN/YEL

YEL/BRN

LX AMPLIFIER

38

A

37

A/

40

B

39

B/

42

Z

41

Z/

3

COMMON

2

CUR CMD

4

ENABLE

5

+10V

12

HIGH IRMS

10

DRIVE OK

9

DRIVE OK

Figure 28: AXIMA 2000/4000 Controller to LX Amplifier Connections Using The AX4-

GP Cable (Torque Mode)

Note

Make sure AXIMA Logic Common is connected to the same point in the cabinet as the

LX Logic Common. See Figure 5 , E Series Drive and AXIMA System Grounding

Diagram.

The current command input of the LX amplifier is a single ended input not a differential input.

Refer to the LX Drives Setup and Programming Operator’s Manual (P/N 400272-00) for

more detailed information.

39

Page 52

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

If the CMD output of the AXIMA 2000/4000 controller is mistakenly connected to the

common input of the LX drive, this could damage the AXIMA 2000/4000 controller

analog output signal.

Because the input is single ended, it will be more susceptible to noise. Be sure the LX

common pin number 11 is connected to a single point ground as shown in the system

grounding illustration.

When the LX amplifier is used in current mode, the LX I

2

t (high RMS) circuitry is bypassed

and does not fold back the current to the motor.

To prevent damage to the amplifier or motor, the high RMS output of the LX must be

connected to an AXIMA 2000/4000 controller input. This input would then be programmed

to limit the AXIMA 2000/4000 controller command voltage using the command limit

instruction to decrease or shut off the analog command. This input could also be used to turn

off the drive enable output.

When using the LX drive in current mode the LX limit switch inputs are inactive.

AXIMA 2000/4000 Controller to LX Drive Connections (Velocity Mode)

The wiring diagram below shows the typical command connections between the AXIMA

2000/4000 controller and an LX amplifier operating in velocity mode.

40

Page 53

Connections and Cabling

25 PIN

"D" CONNECTOR

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

LOGIC

COMMON

AXIMA 2000/4000

CONTROLLER

ENC COM ØV

ENC SUP +5V

ANALOG CMD OUT -

ANALOG CMD OUT +

DRV ENABLE

CCW LIMIT

CW LIMIT

DRIVE STATUS

(STEPPER) LOW CURR MODE

ANALOG IN 1

ANALOG IN 2

ANALOG COM

LOGIC COMMON

DIRECTION CMD OUT

PULSE/ CMD OUT

I/O COM -

I/O SUPPLY +

SHIELD

EARTH

GROUND

A

A/

B

B/

Z

Z/

N/C

N/C

N/C

13

25

12

24

11

23

22

10

8

20

9

21

3

16

15

18

7

19

6

17

5

14

2

4

PIN

NUMBER

PRP/BLU

BLU/PRP

PRP/ORG

ORG/PRP

PRP/BRN

BRN/PRP

BLU/RED

RED/BLU

WHT/BLU

BLU/WHT

BLK/GRN

GRN/BLK

BRN/BLK

BLK/BRN

YEL/GRY

GRY/YEL

WHT/GRN

GRN/WHT

WHT/RED

RED/WHT

GRY/PRP

PRP/GRY

GRN/PRP

PRP/GRN

BRN/YEL

YEL/BRN

LX AMPLIFIER

38

A

37

A/

40

B

39

B/

42

Z

41

Z/

8

SPEED CMD -

7

SPEED CMD +

4

ENABLE

5

+10V

43

CCW LIMIT

45

CW LIMIT

10

DRIVE OK

9

DRIVE OK

Figure 29: AXIMA 2000/4000 Controller to LX Amplifier Connections using the AX4-

GP Cable (Velocity Mode)

Note

Make sure AXIMA Logic Common is connected to the same point in the cabinet as the

LX Logic Common. See Figure 5 , E Series Drive and AXIMA System Grounding

Diagram.

Encoder 1 or 3 Output Connection

An encoder output port is provided to allow easy cable connections between multiple

AXIMA 2000/4000 controllers for line shafting type applications using the AX4-ED-XXX

cable.

41

Page 54

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

AXIS 1 (for 4000)

OR

ENCODER 3 (for 2000)

13

25

12

24

11

23

10

22

9

21

8

20

7

19

6

18

5

17

4

16

3

15

2

14

1

25 PIN

"D" CONNECTOR

13

A/

25

12

B/

24

11

Z/

23

PIN

NUMBER

AXIMA INTERNAL CONNECTIONS

A

B

Z

ENCODER 1 OUTPUT (for 4000)

OR

ENCODER 3 OUTPUT (for 2000)

A

5

A/

B

B/

Z

Z/

NUMBER

9

4

8

3

7

PIN

5

9

4

8

3

7

2

6

1

9 PIN

"D" CONNECTOR

Figure 30: Internal Encoder Connections for AXIMA 2000/4000 Controller

AXIMA 4000

AXIMA 2000

ENCODER

1 OUTPUT

AXIS 1

ENCODER 1 OUTPUT

ENCODER

3 OUTPUT

ENCODER 3 OUTPUT

TO

AXIS 1 CONNECTION

ENCODER 3 CONNECTION

Figure 31: Front Panels of AXIMA 2000/4000 Controllers

ENCODER 3

TO

42

Page 55

Input/Output Connections

Dedicated I/O

Connections and Cabling

Figure 32: Enable Drives and Watchdog Output Locations on the Front Panel of the

AXIMA 2000/4000 Controller

Enable Drives Input

The Enable Drives input provides the +24 VDC supply to one side of all the drive enable

relays. The + Enable Drives input is connected to the +24 V terminal.

Watchdog Output

This relay contact is closed and the LED is ON under normal conditions. The contact is rated

for +30 VDC and .5 Amps maximum.

43

Page 56

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

FUSE F103 (Located Under the Access Panel)

Littlefuse 451002

EMERSON P/N 212132-02

24 V

SUPPLY

Enable Drives

Customer

Contact or PLC

Output

Watchdog

Output

+

2 A

24 V

LED

-

+

Enable

Drives

LED

-

+ 5 V

Pre-defined AXIMA Output

(See Software Manual)

+ 5 V

WD

Enable

Drive

LED

Drive Enable

Relay

Watchdog Output

Relay

WD

+ 24 VDC

0 VDC I/O Supply

EN

WD

Predefined AXIMA Input

Typical Drive Enable CKT

2 for AXIMA 2000

4 for AXIMA 4000

Enable Contacts on

Axis Connector

Watchdog LED

Pin 2

Pin 14

+ 24 V

Controller Watchdog

Output

Figure 33: Watchdog, Drive Enable Circuit

+ 24 Common

Diagnostic

Status LED

Decimal

Point

44

Page 57

User Defined I/O

Inputs

Connections and Cabling

Figure 34: Inputs Location on the Front Panel of the AXIMA 2000/4000 Controller

The inputs can be wired for either sink or source mode in groups of eight. The inputs are rated

at 24VDC and the input voltage operating limit is +10 to 30 VDC. Each input line requires a

minimum of 5 milliAmps at 10 VDC to be recognized as a valid input.

+ 5 V

2K

+ 5 V

+ 5 V

+ 5 V

0 VDC

I/O SUPPLY

1.33K

2K

1.33K

2K

1.33K

2K

1.33K

+ 24 VDC

Figure 35: Sinking Mode Input Diagram

45

Page 58

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

+ 5 V

+ 24 VDC

0 VDC

I/O SUPPLY

2K

1.33K

2K

1.33K

2K

1.33K

2K

1.33K

+ 5 V

+ 5 V

+ 5 V

Figure 36: Sourcing Mode Input Diagram

Special Purpose Inputs

Inputs 13 through 16 can be assigned to trigger the high speed hardware encoder position

capture function. These inputs and the Z encoder channels have direct connection to the

encoder DSP gate arrays. If your application requires accurate positioning or measurements

based on inputs from sensors or switches, inputs 13 through 16 should be used. See position

capture input table below. See the Encoder Capture Instruction Registration Move in the

AXIMA Software Reference Manual (P/N 400262-00) for more information.

Encoder Input Number Position Capture Input #

Since these inputs go through filtering and optoisolation, there is up to10 microsecond delay

from the time the input is turned on until the position is captured. The capture can be

programmed to trigger on rising or falling edge of the input. Due to the switching

characteristics of the opto-isolators, faster triggering speeds can be obtained by using the

rising edge rather than the falling edge. The encoder Z channel time delay is significantly less

at 0.1 microsecond.

46

1 13 or 14

2 13 or 14

3 15 or 16

4 15 or 16

Page 59

Connections and Cabling

Outputs

Figure 37: Outputs Location on the Front Panel of the AXIMA 2000/4000 Controller

Outputs can be operated in source mode only. Maximum allowable output voltage is 18 to 30

VDC, maximum current is 150 milliAmps per output continuously.

Note

It is your responsibility to limit the current to 150 milliAmps or less.

AXIMA

OUTPUT

LED

+ 5 V

CONTROLLER

OUTPUT

SIGNAL

TO ALL

OUTPUT

CIRCUITS

Figure 38: Output Circuit Diagram

+ 24

1 - 12

MACHINE

0 VDC I/O

SUPPLY

DIODE REQUIRED

FOR ALL INDUCTIVE

LOADS

47

Page 60

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

I/O Power Supply

The AXIMA requires a customer supplied I/O power supply, usually +24 VDC. This power

supply must be connected to the 24V ± terminals. The +24 VDC are protected against reverse

polarity. If the polarity is reversed the +24 VDC fuse blows. The fuse is located under the

front access panel. This supply is the "machine side" of the inputs and outputs and also

provides power for the Enable Drive relay coils. The system is designed to operate from a 24

VDC power supply but will function between 18 and 30 VDC.

Figure 39: I/O Power Supply Location on the Front Panel of the AXIMA 2000/4000

Controller

Note

For situations where all 16 inputs, 12 outputs at full load and 4 relays are being used

simultaneously, your power supply must supply at least 2.5 Amps @ 24 Volts.

Each input requires 12 mA @ 24 VDC (5 mA @ 10 VDC).

Each output can source up to 150 mA to drive a load.

Your power supply must be capable of supplying enough current for the dedicated load

requirements. (Enable Drive, Drive Status, Overtravel L.S.) as well as the input and output

load requirements.

Each Input: (# of inputs) * (12 mA)

Each Output: (# of outputs) * (Load Current)

Dedicated Circuits:

Inputs:

CW Limits SW 5 mA

48

Page 61

Connections and Cabling

CCW Limit SW 5 mA

Status 5 mA

Output:

Enable Drives 8 mA

For example, suppose you had four axes of dedicated I/O, four inputs (# 1 through 4), and

four outputs (# 1 through 4) with a 150 mA load, and your power supply was 24 VDC, in the

worst case scenario (all inputs and outputs are being used simultaneously) the current load on

the power supply would be 0.74 Amps. This value was found using the following formula:

(12 mA * 4 IN) + (150 mA * 4 OT) + (8 mA * 4 R) + 4 axis (5 mA * 3 D) = 0.74 Amps

Where:

IN = inputs

OT = outputs

R = relays for Enable Drives

D = dedicated inputs

Diagnostics Status Display

The Diagnostic Status display on the top front of the AXIMA 2000/4000 controller is

controlled by the programmer and can be used to display machine status or fault codes.

During the download of an AXIMA Software Application an asterisk (*) is displayed.

The decimal point is lit when the controller Watchdog is “On”.

Note

The very first time power is applied to the AXIMA controller the diagnostic status will

display a random character.

49

Page 62

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

50

Page 63

AXIMA® 2000/4000 Multi-Axis Controller

Installation Manual

Analog Input Option

An Analog Input feature is available as a factory option only. It allows the AXIMA® 2000/

4000 controller to accept single-ended and differential inputs with 12 bit resolution. You can

configure these inputs with up to eight single-ended inputs, four differential inputs or

combinations of single and differential inputs.

Quantity 8

Resolution 12 bits

Configuration Single-ended or differential

Input Voltage Range ±10 VDC

Note

If you wish to add the Analog Input option to an existing AXIMA 2000/4000 controller,

it must be returned to the factory.

The source of each analog input can be selected to be either from the analog input connector

on the left side of the unit or the axis connector on the front of the unit. This is done by setting

a DIP switch located behind the left side panel, of the AXIMA 2000/4000 controller. This

selection is provided to allow easy interface to the analog signals from an E Series drive.

NOTE:

DIP SWITCHES ARE MOUNTED BEHIND

THE LEFT PANEL OF THE AXIMA CONTROLLER

S3

4

12

12341234

AXIS INPUTS (Up Position)

EXTERNAL INPUTS

3

S4

12

4

3

Figure 40: Analog DIP Switch Location Behind the Left-Side Panel of the AXIMA

2000/4000 Controller

51

Page 64

AXIMA® 2000/4000 Multi-Axis Controller Installation Manual

Switch Analog Input

S3-1 Analog Input 1

S3-2 Analog Input 2

S3-3 Analog Input 3

S3-4 Analog Input 4

S4-1 Analog Input 5

S4-2 Analog Input 6

S4-3 Analog Input 7

S4-4 Analog Input 8

The AXIMA 2000/4000 controller takes raw voltage (±10 Volts) from the analog input

terminal and, with the AXIMA Software, converts it to user units. Each analog input channel

can be assigned to a Pre-defined Variable, within the AXIMA Software, which can be used

in a Motion or an Auxiliary Program.

11.70

(297.18)

0.9

(22.86)

3.0

(76.20)

1.25

(31.75)

5.5

(139.70)

3.68

(98.30)

3.0