Page 1

EF

Installation Guide

M’Ax

*

*

**

Compact, high-performance, single-axis servo

amplifier for brushless AC servo motors

Part Number: 0453-0016-06

Issue Number: 6

www.controltechniques.com

Page 2

General information

The manufacturer accepts no liability for any consequences resulting from inappropriate , negligent

or incorrect installation or adjustment of the optional operating parameters of t he equipment or from

mismatching the drive with t he motor.

The conten ts of this Installation Guide are believed t o be correct at the time of printing. In the

interests ofacommitment to apolicy of continuousdevelopment and improv ement, the manufacturer

reserves the right tochange the specification of the product or itsperformance, or the contents of the

Installation Guide, without not ice.

All rights reserved. No p arts of this Installation Guide may be reproduced or transmitted in any f orm

or by any means, electrical or mechanical including photocopying, record ing or by any informationstorage or retrieval system, without permission in writing from t he publisher.

Important...

Servo-amplifier software version

This product issupplied with the latest vers ion of user-interface and machine-control software. If this

product isto be used w ith other Control Techniques servoampli fiers in anexisting system, there may

be some differences between theirsoftware and the software in this product. These differences may

cause a difference in functions. This may also apply to servo amplifiers returned from a Control

Techniques S erv ice Centre.

If there i s any doubt, contact a Control Techniques Drive Centre.

Copyright © January 2003 Control Techni ques Drives Ltd

Issue: 6

Page 3

Contents

*

1 Safety Information .................................1

1.1 Warnings, Cautions and Notes .............................1

1.2 Electrical safety - general warning ........................1

1.3 System design ......................................................1

1.4 Environmental limits ..............................................1

1.5 Compliance with regulati ons .................................1

1.6 Safety of personnel ...............................................1

1.7 Risk analysis .........................................................1

1.8 Motor .....................................................................1

1.9 Adjustment of parameters .....................................1

2 Installing the drive ................................2

2.1 Installation considerations .....................................2

2.2 Model sizes and versions .. ....................................2

2.3 AC supply protection .............................................2

2.4 AC supply disturbances - use of line reactors .......3

2.5 Power cables ........................................................3

2.6 Signal cables and connectors ...............................5

2.7 RJ45 connectors and cables .................................6

2.8 SLM connector ......................................................7

2.9 D-type connectors .................................................7

2.10 Method of mounting ..............................................7

2.11 Output current, Ambient temperat ure, Heat

dissipation, De-rating ............................................7

2.12 Thermal protection ................................................8

2.13 When to use a braking resistor .............................8

2.14 Braking resistor data .............................................8

2.15 Braking resistor precautions .................................9

2.16 Thermal protection of the braking resistor .. ..........9

2.17 Braking-resistor example calculations ..................9

2.18 Minimum permissible deceleration time ..............10

2.19 Power rating of the braking resistor ....................10

2.20 Value of the braking resistor ...............................11

2.21 Disabling protection of the internal braking

resistor ................................................................11

2.22 Current setting for a thermal overload protection

relay ....................................................................11

2.23 Enclosure layout .................................................11

2.24 Clearances for the signal cables .........................12

2.25 Enclosure calculations for heat removal .............13

2.26 Mounting the drive ..............................................15

2.27 Attaching the drive to the back-plate ...................16

2.28 Precautions for making p ower connections ........17

2.29 Terminal sizes and tightening torques ................17

2.30 Method of connecting the power cables .............18

2.31 Circuit diagrams f or the powe r connections ........19

2.32 EMC emission standards - compliance

information ..........................................................21

2.33 EMC emission standards - instructions ...............21

2.34 Clearances from the RFI filter and AC supply

cables ..................................................................22

2.35 Additional ground connections f or the signal

cables ..................................................................22

2.36 Bonding the cable shield to the motor frame ......24

Appendix A UL Listing Information ...........25

A.1 AC supply specification .......................................25

A.2 Maximum continuous output current ...................25

Appendix B Data ..........................................26

B.1 M’Ax Data ...........................................................26

B.2 Optional RFI filter dat a ........................................28

Index ..............................................................29

M’Ax InstallationGuide

Issue Number: 6 www.controltechniques.com

Page 4

Declaration of Conformity

Control Techniques

The Gro

Newtown

Powys

UK

SY16 3BE

MAX403SL MAX406SL MAX409SL MAX412SL

MAX403AN MAX406AN MAX409AN MAX412AN

The servo drive product M'Ax, modelnumbersas listedabove,hasbeen designedand manufactured in accordance with the

following European harmonised, national and international standards:

EN60249 Base materials for printed circuits

IEC326-1 Printed boards: general information for the specification writer

IEC326-5

IEC326-6 Printed boards: specification for multilayer printed boards

IEC664-1

EN60529 Degrees of protection provided by enclosures (IP code)

UL94 Flammability rating of plastic materials

UL508C Standard for power conversionequipment

Printed boards: specification for single- and double-sided printed boards with

plated-through holes

Insulation co-ordination for equipment within low-voltage systems: principles,

requirements and tests

These productscomply with the Low VoltageDirective 73/23/EECand the CE Marking Directive

93/68/EEC.

W. Drury

Executive VP Technology

Newtown

Date: 27 March 2001.

This electronic Drive product is intended to be used with an appropriate motor, controller,

electrical protection components and other equipment to form a complete en d product o r

system. It must only be installed by a professional assembler who is familiar with

requirements for safety and electromagnetic compatibility ("EMC"). The assembler is

responsible for ensuring that the end product or system complies with all th e relevant laws in

the country where it is to be used. Refer to the product m anual or EMC data sheet for furth er

information on EMC standards complied with by the product, and guidelines for installation.

Page 5

1 Safety Informati on

1.1 Warnings, Cautions and Notes

A Warning contains information which is essential for

avoiding a safety hazard.

WARNING

A Caution contains information which is necessary for

avoiding a risk of damage to the product or other equipment.

CAUTION

NOTE

1.2 Electrical safety - general warning

The voltages used in the drive cancausesevere electrical shock and/or

burns, and could be lethal.

Extreme care is necessary at all times when working with or adjacent to

the drive.

Specific warnings are given at the relevant places in this Installation

Guide,and the accompanying User Guide.

The installation must comply with all relevant safety legislation in the

countryof use.

1.3 System design

The drive is intended as a component for professional incorporation into

complete equipment or a system. If installed incorrectly,the drive may

present a safety hazard.

The drive uses highvoltage and currents, carries a high levelof stored

electrical energy, and is used to control equipment which can cause

injury.

Close attention is required to the electrical installation and the system

designt o avoidhazards,either in normaloperation or in the event of

equipment malfunction. System design, installation, commissioning and

maintenance must be carried out by personnelwho have the necessary

training and experience. They mustread this safety information and this

Installation Guide carefully.

To ensure mechanicalsafety,additional safetydevicessuch as electromechanical interlocksmay be required. The drivemust not be used in a

safety critical application without additional high integrity protection

against hazards arising from a malfunction.

1.4 Environmental limits

Instructionsin this User Guideregarding transport,storage, installation

and use of the drive must be complied with, including the specified

environmental limits. The drive must not be subjected to excessive

physical force.

A Note containsinformation which helps to ensurecorrect

operation of the product.

*

1.6 Safety of personnel

The STOP function of the drive does not removedangerous voltages

from the output of the drive or from any external option unit.

The STOP and START controls or electrical inputs of the drive must

not be relied upon to ensure safety of personnel. If a safety hazard

could exist from unexpected starting of the drive, an interlock that

electrically isolates the drive from the AC supply must be installed

to prevent the motor being inadvertently started.

Carefulconsideration must be given to the functions of the drivewhich

might resultin a hazard,eitherthrough their intended functions or

through incorrect operation due to a fault (e.g. stop/start, forward/

reverse, maximum speed).

Under certain conditions, the drive can suddenly discontinue control of

the motor.If the load on the motor could cause the motor speed to be

increased (e.g. in hoists and cranes), a separate method of braking and

stopping the motor must be used (e.g. a mechanical brake).

Before connecting the AC supply to the drive, it is important that you

understandthe operatingcontrolsand their operation. If in doubt,do not

adjust the drive. Damage may occur, or lives be put at sisk. Carefully

follow the instructions in this Installation Guide.

Beforemaking adjustments to the drive, ensure all personnelin thearea

are warned. Make notes of all adjustmentsthat are made.

1.7 Risk analysis

In any application where a malfunction of the drive could lead to

damage, loss or injury, a riskanalysis must be carriedout, and where

necessary, further measures taken to reduce the risk. This would

normally be an appropriate form of independent safety back-up system

usingsimpleelectro-mechanical components.

1.8 Motor

Ensure the motor is installed in accordance with the manufacturer’s

recommendations.

Servomotorsare designed to operate at elevated temperatures which

may reach 100

contact should be taken.

1.9 Adjustment of parameters

Some parameters have a profound effect on the operation of the drive.

These parameters must not be adjusted without careful consideration of

theimpactthat wouldbemadeon the controlled system.Measuresmust

be taken to prevent unwanted changesfrom being made, e.g. due to

error or tampering.

o

C. Where necessary, precautionsto preventhuman

1.5 Compliance with regulations

The installer is responsible for complying with all relevant regulations,

such as national wiring regulations, accident prevention regulations and

electromagnetic compatibility (EMC) regulations. Particular attention

must be givento the cross-sectionalareasof conductors, the selection

of fuses or otherprotection, and protective earth(ground) connections.

This Installation Guide contains instruction for achieving compliance with

specific EMC standards.

Withinthe European Union, all machinery in which thisproductis used

must comply with thefollowing directives:

• 97/37/EC: Safety of machinery.

• 89/336/EEC: Electromagnetic Compatibility.

M’Ax Installation Guide 1

Issue Number: 6 www.controltechniques.com

Page 6

*

2 Installing the drive

2.1 Installation considerations

Adhere to the instructions

The mechanical and electrical installation instructions

WARNING

WARNING

must be adhered to. Any questions or doubt should be

referred to the supplierof the equipment.It is the

responsibility of the owner or user to ensure that the

installation of thedrive and any external option unit, and

the way in which they are operated and maintained,

comply with the requirements of the Health and Safety at

Work Act in the United Kingdom or applicable legislation

and regulations and codes of practice in the country in

whichthe equipmentis used.

Motor voltage

The motor must be suitable for use with a M’Ax drive and

its required supply voltage.

CAUTION

Competence of the installer

The drive must be installed only by professional

assemblers who are familiar with the requirements for

safety and EMC. The assembler is responsible for

ensuring that the end-product or system complies with

all the relevant laws in the country where it is to be used.

Flash/insulation testing

The driveand RFI filter have internal electrical

components connected between the AC-supply phases

CAUTION

and ground. In order to avoid damaging these

components when flash or insulation testing the ACsupply circuit and/or motor circuit, first disconnect the

drive completely from the circuit to be tested.

Electromagnetic compatibility

The drive contains powerful electronic circuits which can cause

electromagnetic interference. The information and instructions in this

chapterinclude routine EMC precautionsthat will minimise the risk of

disturbanceto typical industrialcontrol equipment.These include

installing the drive in a metal enclosure as well as careful attention to the

layoutof the connectingcables.

Additional precautions must be taken if any of the following apply:

• Strict compliance with emission standardsis required

• It is known thatelectromagnetically sensitive equipment, such as

radio receivers, is located nearby

• Thedriveistobeoperatedinaresidentialenvironment

The information and instructions relating to theseadditionalprecautions

are contained in the EMC emission standardssections later in this

chapter. These precautions include installing an RFI filter in the AC

supplyto each drive andadditional attention paid to cables and

grounding.

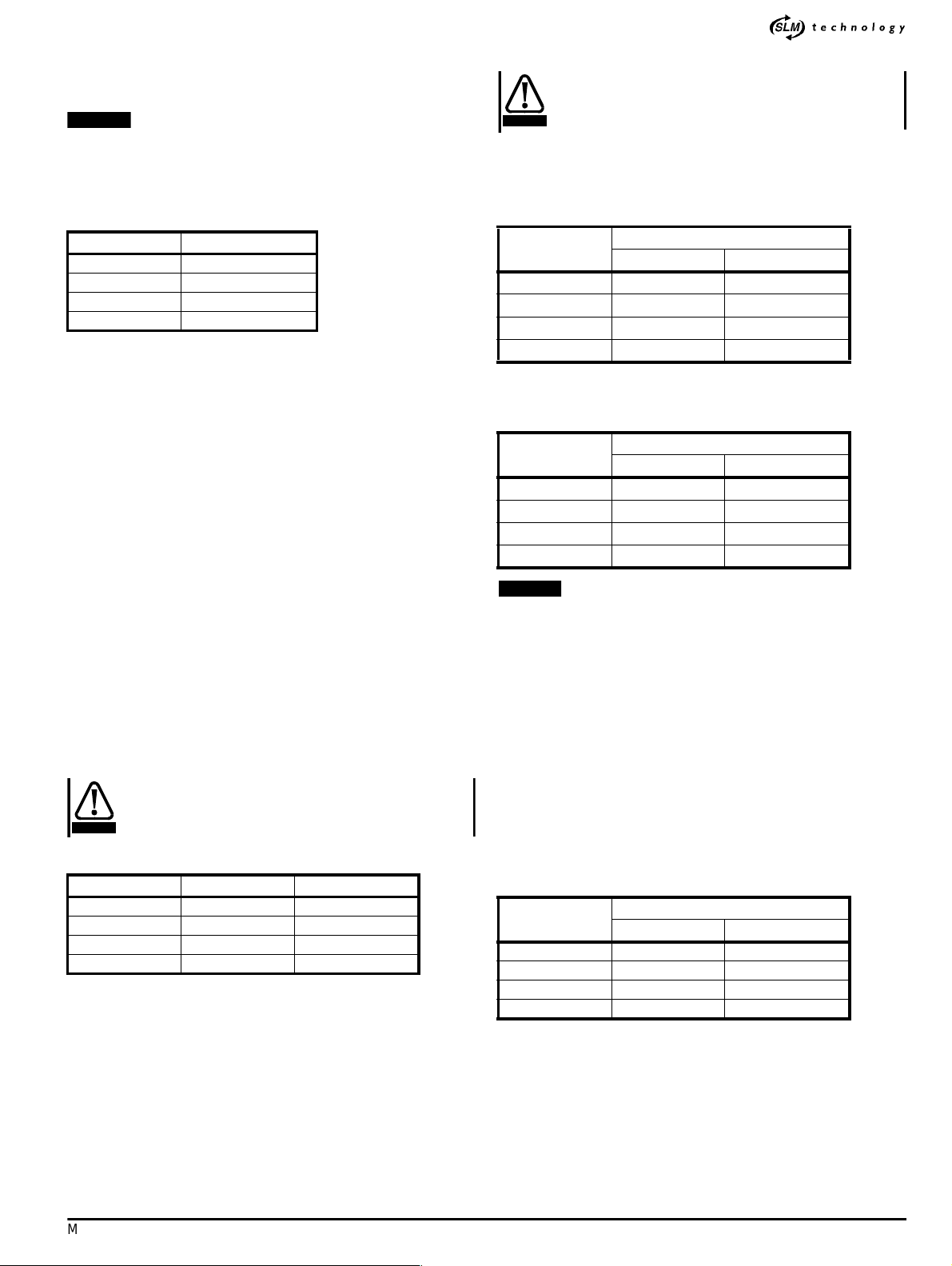

2.2 Model sizes and versions

Table 2-1 Model sizes, model numbers and current ratings

Output c urre nt

Model size Model

M’Ax403

M’Ax406

M’Ax409

M’Ax412

Maximum

continuous

3.5 A

6.5 A

9.5 A

12.5 A

Maximum

overload

(2s max.)

7.0 A

13.0 A

19 A

25 A

All imperialmeasurements (in feetand inches) are an

approximation of their metric translations.

CAUTION

Authorised access

Only authorised, trained service personnel should be allowed access to

the drive.

Installation in an enclosure

The drive must be protected against water, condensation and electrically

conductive contamination.

The drive has ingress protection ratedat IP20 (in accordance with

IEC60529).

UL listing is valid when the drive is installed in a type 1 enclosure as

defined in UL50.

Fire enclosure

The drive case is not classified as a fire enclosure.When this protection

is required, the drive should be installed in a fire enclosure.

Hazardous areas

The drive not be located in a classified hazardousarea unless it is

installed in an approvedenclosure and the installation is certified.

Environmental

See Appendix A for UL-listing information.

See Appendix B Data for environmental requirements.

If condensation is likely to occur when the drive is not in use, an anticondensation heater must be installed. This heater must be switched off

when the drive isin use; automatic switching is recommended.

If the drive is to be mounted directly above any heat-generating

equipment (such as another drive), the maximum temperature of the air

immediately below the drive should be taken as the ambient temperature

for the drive.

Table 2-2 Versions

Suffix Functionality

_SL

(eg. M’Ax 403_SL)

_AN

(eg. M’Ax 403_AN)

Standard-precision analog input

No display and keypad

High-precision analog input

Displayand keypad

AC supply requirements

380V to 480V ±10%

3-phase

47.5 to 63Hz

Maximum supplyimbalance: 2% negative phase sequence (equivalent

to 3% voltage imbalance between phases)

2.3 AC supply protection

g

The AC supply to the drive must be fitted with suitable

protection against overload and short-circuits. Table 2-3

WARNING

WARNING

Include a fuse of the specified rating in each phase of the AC supply.

The use of the following types of fuse is recommended:

• Europe: TypegG HRC industrial fuses to IEC 60269 (BS88)

•USA:CC600VAC

shows recommended fuse ratings. Failure to observe

this recommendation will cause a risk of fire.

The AC supply to the drive must have a sufficiently low

impedance path to ground so that a ground fault would

cause the AC supply protection to operate.

2 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 7

An MCB or MCCB having thecorrectthermal and magnetic trip ratings

may be used in place of fuses, on condition the fault-current clearing

capacity is sufficient for the installation.

NOTE

UL listing is dependent on the use of the correct type of UL-listed

fuse, and applies when the symmetricalshort-circuit current does

not exceed 5kA. Refer to Appendix A UL Listing Information.

Table 2-3 Fuse ratings

Model Fuse rating

M’Ax 403 10A

M’Ax 406 15A

M’Ax 409 20A

M’Ax 412 20A

2.4 AC supply disturbances - use of line reactors

When a driveis connected to an AC supplywhich is subject to severe

disturbances - for example, if any of the following conditions apply...

• Capacity exceeds 200kVA

• Faultcurrent exceeds 5kA

• Power-factor correction equipment is connected close to the drive

• Large DC drives having no or ineffective line reactors are connected

to the supply

• Direct-on-line started motor(s) are connected to the supply and,

whenany of these motors are started,a dip is producedin excessof

20% of the actual supplyvoltage

... excessive peak current may flow in the input power circuit of the drive.

This may cause nuisance tripping or, in extreme cases, failure of the

drive.

A line reactor should then be connected in each phase of the supply to

eachdrive. Line reactor(s)add the required impedanceto the ACsupply

in order to reduce current transients to a level that can be tolerated by

the drive.

Threeindividual reactors,or a singlethree-phase reactorshould be

used. Each drive must have its own reactor(s).

RFI filters (for EMC purposes) do not give adequate

protection against these conditions.

CAUTION

Table 2-4 Typicalline-reactorvalues

Model Value Part no

M’Ax 403 2mH 4402-0227

M’Ax 406 2mH 4402-0227

M’Ax 409 1mH 4402-0228

M’Ax 412 1mH 4402-0228

Current ratings

Continuous rms: Not lesst han the continuous input current rating of

the drive

Repetitive max rms:Not less than 4 x continuous input current rating of

the drive (to avoid magnetic saturation)

*

2.5 Power cables

Wiring must be in accordance with local regulations and

codes of practice. The table below shows typical PVC

WARNING

The cable sizes recommendedin Table 2-5 are in accordancewith

EN60204-1; installation method:B2 - one loaded cable in conduitor

trunking attached to a wall.

Table 2-5 Power cable sizes, metric

The cable sizes recommendedin Table 2-6 are in accordancewith

UL508C; installation method: one loaded three phase cable in conduit

Table 2-6 Power cable sizes, imperial

NOTE

This assumes the motor maximum current matches that of the

drive. Where a motor of reduced rating is used, the cable rating

may be chosen to match that of the motor. To ensure that the motor

and cable are protected againstover-load, the drive must be

programmed with the correct motor rated current.

Ground conductors

A ground conductor can be includedin the motor and brakingresistor

cables, or a separate wire external to thesecablescan be used.

Motor cable

Most cables have an insulating jacket between the cores and the armour

or shield; these cables have a low capacitance.When using a cableof

this type, observe the recommended maximum lengthsstatedin

Table 2-7 .

Table 2-7 Maximum cable lengths

* Cable lengths in excess of the specified values may be used only when

special techniquesare adopted; refer to the supplierof the drive.

Cable capacitance

High-capacitance cablestend not to have an insulating jacketbetween

the cores and the shield or armour. If a cable of this type is used, the

maximum cable length is half the figure quoted in Table 2-7 .

For identification, see Figure 2-1.

cable sizes for power input and output wiring. In the

event of a conflict, local regulations prevail.

Model

M’Ax403

M’Ax406

M’Ax409

M’Ax412

Model

M’Ax403

M’Ax406

M’Ax409

M’Ax412

Model

Input cable Output cable

1.5mm

2.5mm

4.0mm

4.0mm

Input cable Output cable

16 AWG

14 AWG

12 AWG

12 AWG

Cable size

2

2

2

2

1.0mm

1.0mm

1.5mm

2.5mm

2

2

2

2

Cable size

18 AWG

16 AWG

14 AWG

14 AWG

Maximum cable length *

mft

M’Ax 403 50 165

M’Ax 406 50 165

M’Ax 409 50 165

M’Ax 412 50 165

M’Ax Installation Guide 3

Issue Number: 6 www.controltechniques.com

Page 8

*

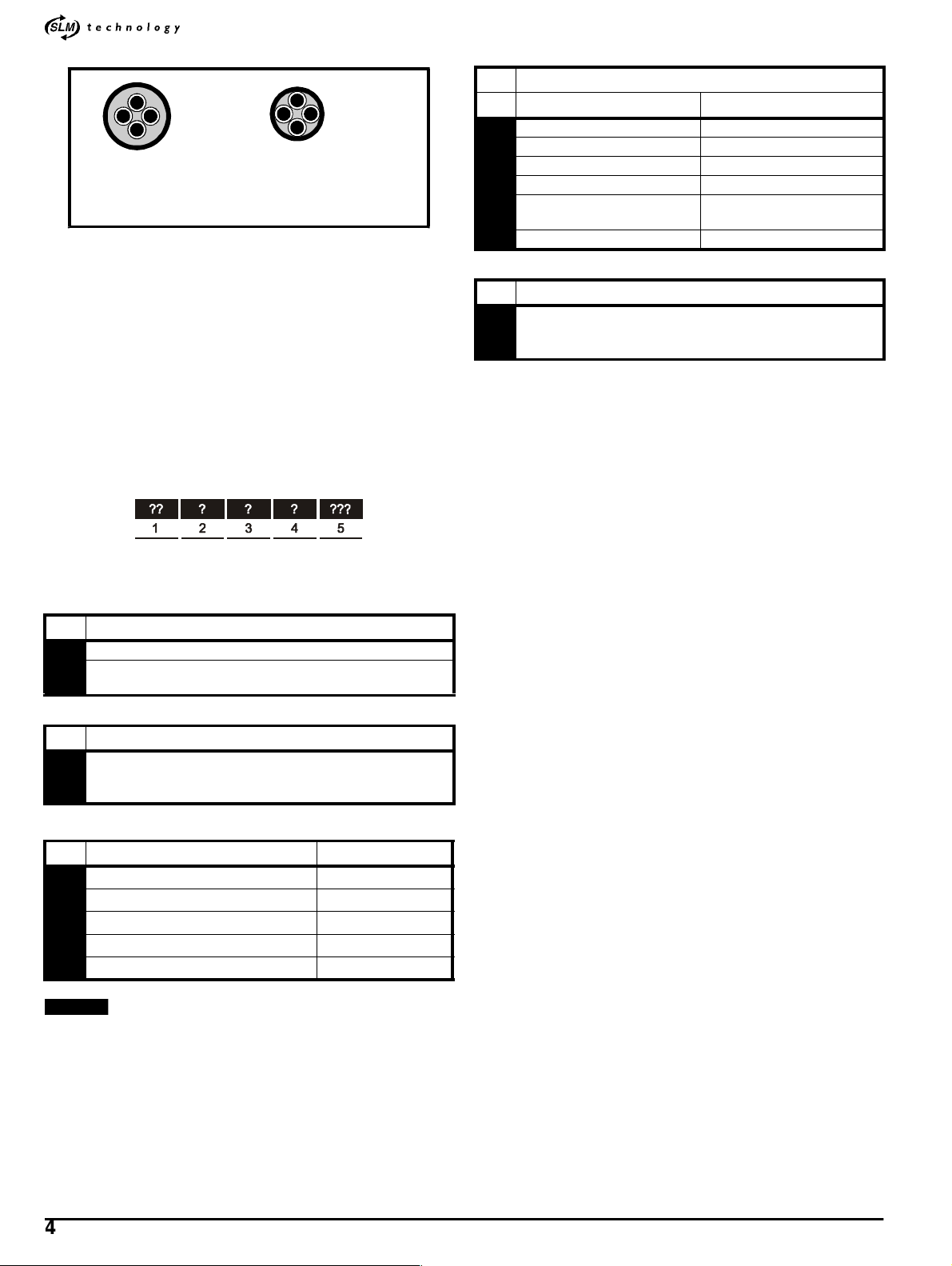

Figure 2-1 Cable construction influencing the capacitance

Normal capacitance

Shield or armour

separated from the cores

Parallel connection of DC buses

When a number of drives are used in a system, it is possible to connect

their DC buses in parallel in order to allow energy sharing, especially

when one or more motors are being braked. Operation in this manner is

not coveredby this Installation Guide; cable sizes and otherinformation

can be obtaine from the supplier of the drive.

High capacitance

Shield or armour close

to the cores

4 Cable terminations

For connection to the drive For connection to the motor

A Termination ferrules 6-way size-1 plug

C Termination ferrules Termination ferrules

K Termination ferrules 6-way s ize-1.5 plug

L Cut ends 6-waysize-1.5 plug

T ermination ferrules / Ring for

M

M’Ax

6-way size-1 plug

X Cutends Cut ends

5 Cable length

Specify length in metres

Minimum: 002 (2 metres)

Maximum: 050 (50 metres)

Ordering motor cables

Cablesof the required lengths and type of sheath,and fittedwith

appropriate terminations to suit the drive and CT-Dynamics SL motors,

are supplied by Control TechniquesD ynamics Ltd. For ordering, create

the required ordercode (see below)and contact the supplierof the drive.

The order code is constructed as follows:

See opposite for the details of the code.

1 Number of conductors

PS 3-phase + ground

3-phase + ground

PB

+ motor-brake control

2 Type of sheath

PUR

B

Use for dynamic applications (motor mounted on a moving

structure) – increased oil resistance

Example

PSBAM010

10m Unimotorconnection to ferrules power cable for a dynamic

application

3 Conductor size (phases and ground) Current rating

G

A

B

C

D

NOTE

The values stated are for 40

2

1.5mm

2

2.5mm

2

4.0mm

2

6.0mm

2

10.0mm

o

C ambient free air applications.

16A

22A

30A

39A

58A

Information should only be used for reference.

4 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 9

2.6 Signal cables and connectors

5

2

1

43543216785

432

167854321678678543210

H

D

c

0

2

H

D

0

2

2

E

2

H

D

c

c

5

c

c

1

2

4

3

H

B

M

M

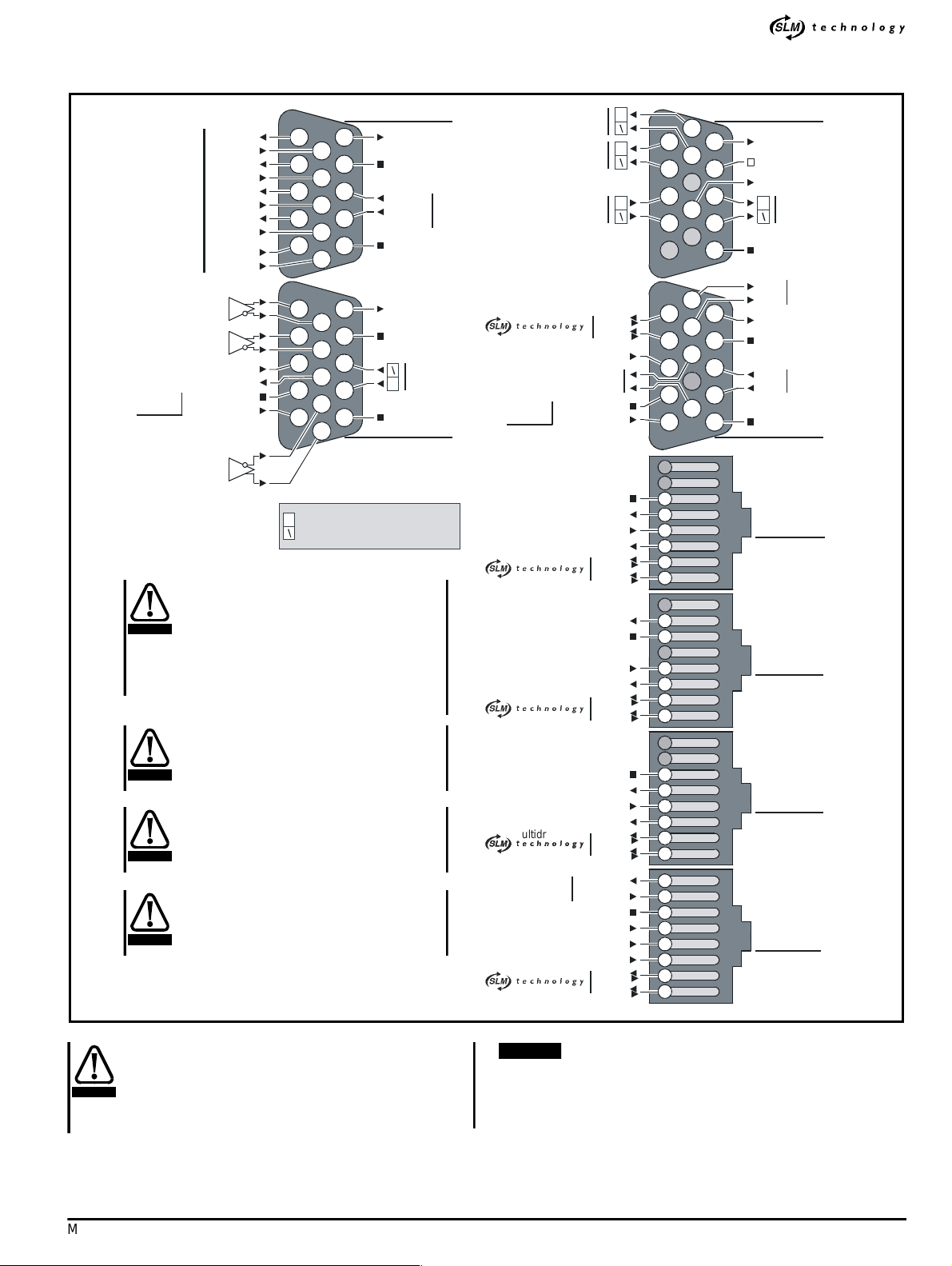

Figure 2-2 Plan view of top of drive: Locations of the terminals and their connector

*

Digital I/O

Frequency input

Quad. A input

Direction input

Quad. B input

Hardware enable

Digital output 4

0V COMMON

SLM-and-user

back-up supply

Touch-trigger

Output 1

Input 1

Output 2

Input 2

Output 3

Input 3

Output 4

Input 4

Input 5

Input 6

+24V

input

5

10

4

9

3

8

2

7

1

6

5

10

4

9

3

8

2

7

1

6

Non-inverting input/output

Inverting input/output

Terminate pulse reference inpu t

connections (frequency / direction or

quadrature inputs) at the drive by

CAUTION

connecting across the related input

terminals a resistor whose value equals the

characteristic impedance of the cable that

is being used. When more than one drive is

connected a resistor is required only at the

last drive.

0V and 0V common must be used only in

conjunction with their related signal

connections, and must not be used in place

CAUTION

of each other.

Any cable connecting to the SIM ENC

connector should have its cable shield

connected to Pin 15. Failure to d o so can

CAUTION

result in damage to the drive.

Wait30 secondsafter removing power to

the drive before inserting or removing

control cables as ‘hot plugging’ cables can

CAUTION

result in damage to the drive or SLM.

DIGITAL I/O SIM ENC

15

14

13

12

11

15

14

13

12

11

24V user supply

0V COMMON

Input 7

Input 8

0V COMMON

24V user supply

0V COMMON

0V COMMON

STANDALONE MC/EIA485

Digital I/O

High-precision

analog input

Standard-precision

*

SLM-and-user

back-up supply

*

*

ultidrop

**

ultidrop

*

output

A output

analog input

om\

om\

Hardware enable

Status-relay

contact

0V COMMON

+24V

V COMMON

24V SLM supply

ardware enable

Drive-status supply

com\

com\

24V user supply

0V COMMON

ardware enable

rive-status supply

om\

com\

V COMMON

4V loopsupply

ardware enable

rive-status output

IA232

ardware enable

rive-status input

om\

com\

32 TXD

32 RXD

V COMMON

4V loop input

om\

com\

6

11

7

12

8

13

9

14

10

15

6

11

7

12

8

13

9

14

10

15

Analog output 1

0V

Analog output 2

Z output

Cable shields

TX

EIA 485

TX\

24V user supply

0V COMMON

RX

EIA 485

RX\

0V COMMON

SLM

MC

MULTIDROP

OUT

MULTIDROP

IN/PC

WARNING

Isolation

The signal connections are isolated from the power

circuits by basic insulation only. Ensure that all external

control circuits connected to this connector are

separated from human contact by at least one layer of

insulation rated for use at the AC supply voltage.

NOTE

0V connections

Do not connect 0V COMMON to 0V, or use these in place of each

other; doing so may cause instability in use. See Functions of the

signal terminals in Chapter 2 of the M’Ax User Guide.

M’Ax Installation Guide 5

Issue Number: 6 www.controltechniques.com

Page 10

*

2.7 RJ45 connectors and cables

RJ45 connectors

For connection to the following connectors on the drive...

•SLM

•MC

• MULTIDROP OUT

• MULTIDROP IN/PC

... use the following:

Cables

Up to four twisted-pairs having an overall shield (unused wires must not

be connected to pins at the other end)

Maximum length: 50m (165ft)

Maximumdiameter:6.6mm (

Static installations:for example, use BICC type S-FTP patch,four

twisted pairs, 5.33mm diameter

1

/4in)

Ordering signal cables

Cablesof the required lengths and fitted with RJ45 connectors as

required are supplied by Control Techniques Dynamics Ltd. For

ordering, create the required order code (see below) and contact the

supplier of the drive.

The order code is constructed as follows:

Details of the code are as follows:

1Typeofcable

SL Two twisted pairs in overall shield

Dynamic installations: for example, use Intercond type 3MBM 26P 02P,

2 twisted pairs, 5.5mm diameter

Connectors

Shielded 8-way RJ45 plugs

18

1

2

3

4

5

6

7

8

Connectthe pinsin pairs as shown.

Comb out the braided shield, fold the strands back and trap them under

the cable clamp to ensuregood electrical contact with the clamp.

2Typeofsheath

PUR

B

Use for dynamic applications (motor mounted on a moving

structure) – increased oil resistance

3 Options

A Standard

4 Cable terminations

F RJ45 plug 5-way Din connector Drive to SLM

G RJ45 plug Cut end

K RJ45 plug RJ45 plug Drive to drive

X Cut end Cut end

5 Cable length

Specify length in metres

Minimum: 002 (2 metres)

Maximum: 050 (50 metres)

Wait 30 seconds after removing power to the drive before

inserting or removing control cables as ‘hot plugging’

CAUTION

cablescan result in damage to the drive or SLM.

Do not use unshielded plugs.

Use RS Component part no 290-4780 for shielded

WARNING

connector 5.7mm, or

Use RS Component part no 342-2087 for shielded

connector 6.6mm

6 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 11

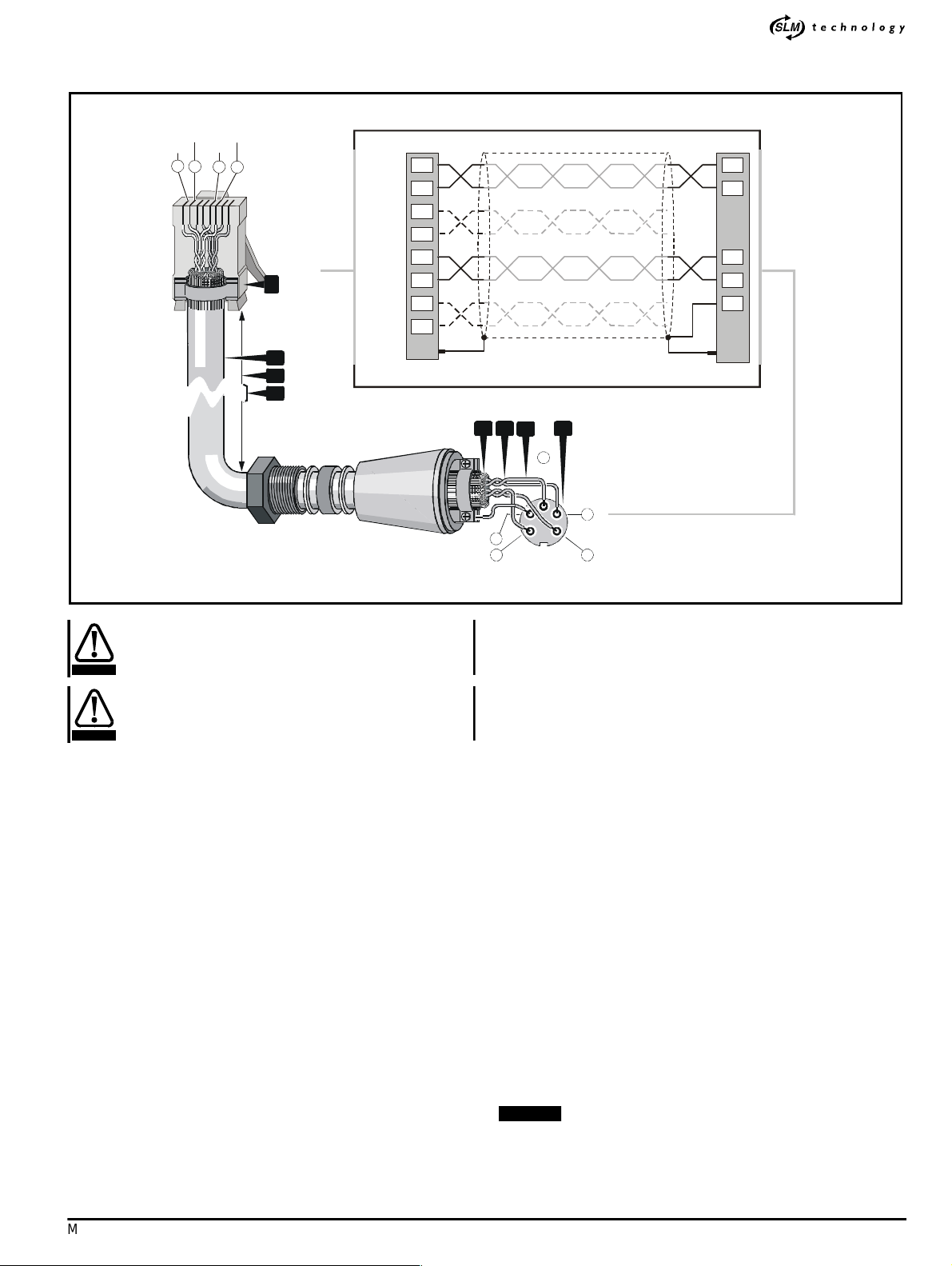

2.8 SLM connector

2

3

10V+

c

7

SLM(

Figure 2-3 Connecting the SLM cable to the connectors (only the relevant parts of the connectors are shown)

com\

com

1

0V

+24V

1

2

6

5

Drive

(RJ45)

8

com

com/

+24V

0V

2

3

4

5

6

7

8

*

5

1

3

2

4

1

2

3

Drive

Incorrect wiring of this cable could result in failure of the

WARNING

M’Ax or SLM.

Wait 30 seconds after removing power to the drive before

inserting or removing control cables as ‘hot plugging’

CAUTION

cablescan result in damage to the drive or SLM.

1. 8-way shielded cable having an overall diameter not greater than

1

6.6mm(

/4in)

2. Maximum length: 50m (165ft)

3. Route the cable by the shortest convenient path and so that it is no

closerthan 300mm (1ft) from any powercable.

4. Overall shield of tinned copper braid. Comb out the braid at both

ends, fold the strands back and trap them under thecable clamp to

ensuregood electrical contactwith the connector shell.

5. The required twisted pairs connected to the DIN connector, the

unwanted twisted pairs should be cut at each end and insulated to

prevent inadvertent contact.

6. Make the wire ends as short as possible (this affects performance).

7. AmphenolC091 31D005 100 2 5-way screw-locking DIN connector

meetingIP67.

8. Shielded RJ45 8-way plug

2.9 D-type connectors

For connection to the following connectors on the drive...

•SIMENC

• MC/EIA485

• DIGITAL I/O

• STANDALONE

... use the following:

SLM

54

6

24V

0V

4

5

com

om/

DIN)

Cables

Manyof the signalsare EIA485 comms.and thesemust use twisted

pairsof the correct characteristicimpedancecables having tinnedcopperstranded conductors, overallbraidedshield

Maximum overall diameter:dependson the D-typeconnector being

used

Connectors

SIM ENC

MC/EIA485

15-wayhigh-density male D-type having a metalshell (improved

EMC type)

DIGITAL I/O

STANDALONE

15-wayhigh-density female D-typehaving a metal shell (improved

EMC type)

2.10 Method of mounting

The two mounting brackets fittedto the driveare intended for mounting

the drive on the back-plate of the enclosure. Exhaust heat from the drive

is emitted in front of the back-plate. (Mounting instructions are given

laterin this chapter.)

Alternativelythe drivecan be mounted through an aperture in the backplate to allow the exhaust heat t o be emitted behind the back-plate.I n

this case, the two mounting brackets fitted to the drive must be removed,

modified and re-fitted; the ground bracket supplied with the drive must

also be modified.For instructions, refer to the supplier of the drive.

2.11 Output current,Ambient temperature, Heat dissipation, De-rating

NOTE

Theambienttemperature shouldbe taken as the temperature of the

air immediately under the drive. This is especially important when

the drive is to be installed above heat-generating equipment.

M’Ax Installation Guide 7

Issue Number: 6 www.controltechniques.com

Page 12

*

The drive can supply the rated maximum continuous output current

(FLC) as follows...

ModelsM’Ax 403 and M’Ax 406: Up to an ambient temperature of

55°C (131°F)

ModelsM’Ax 409 and M’Ax 412: Up to an ambient temperature of

45°C (113°F); from 45°C to 55°C (131°F), the maximum permissible

continuous output currentis reducedto 8.5A and 10.5A respectively.

2.13 When to use a braking resistor

When an AC motor is decelerated,or the drive is preventing the motor

from gaining speed due to mechanical influences, energy is returned to

the drive from the motor. When this energy is too great for the drive to

absorb, the DC-bus voltage is raised, which increases the possibility of

the drive trippingdue to excessive DC-bus voltage.

If the driveis to be used at an altitude in excess of 2000m (6600ft), deratingfor altitude must be appliedto the output current; see Altitude on

page 26.

Make a note of the following values for the model to be used; you will

need to know theselater:

• Maximum intended ambient temperature (T

max) (required for

AMB

calculating the enclosure size later in thischapter)

• Maximum continuous output current(if this needs to be a de-rated

value)

• Maximum heat dissipated into the enclosure

Current de-rating

If this precaution is not taken, the output current of the

drivecan exceedthe maximum permissible value. This

CAUTION

may result in loss of motor control due to excessive

heatsink temperature causing the drive to trip.

2.12 Thermal protection

The power output stage (IGBT bridge) of thedrive is protectedas

follows:

• When the heatsink temperature reaches an alarm level the drive

continues operating;the lower line of thedisplayindicates hot as a

pre-warning

• Ifthe load is not reducedand the heatsinktemperaturecontinues to

rise the drive will trip; the lower line of the display indicates O.ht2

Depending on the braking requirements, an internal braking resistor

fitted in the drive, or an external braking resistor, can be used for

absorbingthe returned energy. Thebraking resistoris t hen switchedinto

circuitby an internaltransistor when theDC-busvoltagereaches 780V.

The required value for the braking resistor is determined by the

maximum required braking torque, while the required power rating is

determined by the amount of energy to be dissipated, the duty cycle and

repetition time, as well as the cooling available for the resistor. When the

valueand power rating havebeencalculated,a decisioncan be made to

use the internal resistoror an external resistor.

It is important that the brakingresistor is adequately

ratedo therwise the drive could trip due to excessive DCbus voltage; braking will then cease, allowing the motor

CAUTION

to coast uncontrolled.

2.14 Braking resistor data

Table 2-9 Internal braking resistor

Value 75Ω

Operating voltage (V

)

R

Peak current rating 10.9A

Peak power rating 8.9kW

Maximumcontinuous braking power 125W

780V at switch-on

760V at switch-off

Table 2-8 Maximum currents and heat dissipated into the

enclosure (these do not show de-ratingfor altitude)

Maximumheat

Output current

dissipated into

enclosure

Model

T

AMB

max.

Maximum

continuous

Maximum

overload

(2 secs.

max.)

Using

internal

braking

resistor

enclosure

o

55

M’Ax403

M’Ax406 55

M’Ax409

M’Ax412

(131

(131

45

(113

55

(131

45

(113

55

(131

C

o

o

C

o

o

C

o

o

C

o

o

C

o

o

C

o

3.5A 7.0A 250W 100W

F)

6.5A 13.0A 290W 140W

F)

9.5A 19A

F)

8.5A 17.0A

F)

12.5A 25A

F)

10.5A 21A

F)

330W 180W

350W 200W

Using

external

braking

resistor

mounted

outside

the

Table 2-10 External braking resistor

Absoluteminimum permissible

value

Operating voltage (V

)

R

Maximum possible braking current

(through 40Ω)(Ib

MAX

)

40Ω

780V at switch-on

760V at switch-off

20.5A

Peak power rating for 40Ω 16.8kW

Continuous power rating

(See Braking-resistor example

calculations later in this chapter)

The instantaneouspowerratingrefers to the power dissipated during the

conducting periods (milliseconds) of the braking transistor (this operates

undera form of pulse width modulation during braking).Higher

resistance values require proportionately lower instantaneous power

ratings.

The required averagepower rating of (and heat dissipated by) the

braking resistor depends on the duty cycle of the application (see 2.17

Braking-resistor example calculations on page 9).

8 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 13

2.15 Braking resistor precautions

Electric shock risk

The voltages present on the braking resistor, its

WARNING

WARNING

associated components and terminals on the driveare

capable of inflicting a severe electric shock and may be

lethal.

Thermal overload protection

When an external braking resistor is used, it is essential

that a thermal overload protection device is incorporated

in the braking-resistor circuit in order to minimise the

risk of fire in the event of unexpectedly high current, or

loss of control of the braking circuit. A typical protection

circuit is shown in the following section, Thermal

protection of the braking resistor.

2.16 Thermal protection of the braking resistor

High temperatures

Braking resistors can attain high temperatures and

WARNING

When a braking resistor is to be used, ensure the following:

• Include a lock-out circuit that will prevent the AC supply from being

• An external braking resistor should be capable of tolerating thermal

• It is essential that the instantaneous and average power ratings of

• Whenan external braking resistoris mounted insidethe enclosure,

• Always use shielded or steel wire armoured cable for connecting an

When an external braking resistoris used, a thermal-protectioncircuit

must be added. This must disconnectthe AC supplyfromthe drive if the

brakingresistorbecomes overloaded. For guidance,Figure2-4 showsa

typical circuit arrangement (complete circuit diagrams for the power

connections appear later in this chapter).

When the internal braking resistor is used, a thermal-protection circuit is

not requiredsince thermal-modelling in the drivecauses the drive to trip

if the r esistor becomesoverloaded (trip code: It.br); also, the braking

resistor itself is fail-safe.

should be segregated from temperature-sensitive

equipment and personnel.

re-connected to the driveuntilthe cause of a trip has been fully

investigated.

shock; pulserated resistors are recommended.

the braking resistor are sufficientfor the most extreme braking duty

that is likely to be encountered. If the internalbraking resistoris

overloaded, the drive will trip (trip code: It.br).

or the i nternal braking resistoris used, the heat dissipated by the

resistor will increase the ambient temperature inside the enclosure.

(The value of heatdissipationis used forcalculating the enclosure

size or ventilation which are described later in this chapter.)

external braking resistor.

*

Figure2-4 Typical protection circuit for an external braking

1. START/RESET switch (momentary)

2. STOP switch (latching)

3. Control-circuit supply

4. Contactor coil

5. Thermal overload protectionrelay

6. External braking resistor

7. 380 ~ 480V AC supply to the drive

8. Drive power connectors.

2.17 Braking-resistor example calculations

Conditions

Model:M’Ax409

Maximum peak output current (Ipk) from the drive (for 2 seconds

maximum): 1 9A

Full-load speed (n)ofmotor:4000RPM

Continuous stall torque (T

Motor K

Motorinertia(J

Loadinertia(JL): 10.29 x 10-3kg m

Total inertia (JT= JM+ JL): 13.7 x 10-3kg m

Required deceleration time (td) from full to zero speed: 0.5 second

Repeat cycle time for deceleration (t

Minimump ermissiblebraking-resistorvalue: 40Ω

Operating voltage(V

=1.6Nm/A

T

M

): 3.43 x 10-3kg m

) at switch on: 780V

R

resistor

)ofmotor:12.2Nm

CS

2

2

): 7 seconds

r

2

M’Ax Installation Guide 9

Issue Number: 6 www.controltechniques.com

Page 14

*

R

2.18 Minimum permissible deceleration time

The minimum permissible decelerationtime is limited by thefollowing:

• The peak current of the drive (Ipk)

•Theintermittent torque limit of the motor (the value of torque that the

motor can deliver for a specified time - see the motor manufacturer’s

data)

1. Calculate the maximum torque that the motor would produce when

the drive is delivering peak current (19A), as follows:

M

bDRIVEIpkKT

Thedrivewouldcausethisvalueoftorquetobeproducedforupto2

seconds.

2. Refer to the the motor manufacturer’s data to obtain the permissible

overload (continuous stall torque) for 2 seconds.

Then use this figure to calculate the intermittenttorque limit for the

motorfor a 2-second duration.For this example,3 times thenominal

torquerating is assumed,as follows:

M

bINTTCS

3. For calculating the minimum permissible deceleration time (t

use the lower of the two calculated values, as follows:

M

bMAX

4. The followingequation is usedas thebasisfor the calculations:

M

b

Usethefollowingderivativeof the equationto calculatethe minimum

permissible deceleration time (t

load speed:

=

t

bMIN

× 19 1.6× 30.4Nm===

3× 12.2 3× 36.6Nm===

30.4Nm=

JTn

π

------ ----

----- -

30

b

JTπn

------ ----------- -------- -

30M

bMAX

Nm()×=

t

) for stopping the motor fromfull-

bMIN

bMIN

),

2.19 Power rating of the braking resistor

1. Calculate the kinetic energy (EK) that will be dissipated in the

braking resistor, as follows:

2

n π×

æö

E

0.5 J×

K

0.5 13.7× 10

E

K

E

1.2kJ=

K

2. Calculate the average power over deceleration time (td):

E

------ -

=

P

PK

td

1.2kJ

---------------

P

PK

3. Calculate the average power (P

whole cycle:

E

------ -

P

=

av

tr

1200

------ ------ -

P

av

When the value ofPavis less than 125W, the internal braking

resistor can be used. For this example (which shows marginal

conditions), an external braking resistor must be used in order to

reduce the risk of the drive tripping under braking; tripping would

remove control from the motor, allowing it to coast.

4. Since brakingis planned to occurintermittently, an external resistor

can be ratedfor intermittent rather than continuouspower

dissipationso that the overload factor of the resistor can be used.

This factor can beobtained fromcooling curves for theresistor, as

shown in Figure 2-5.

Figure 2-5 Example cooling curves for power resistors (in

practice, refer to the cooling curves for the resistor to be used)

×=

K

0.5

K

7

Overload

factor

------ ------ -

èø

30

3– 4000 π×

æö

××=

èø

2.4kW==

171W==

------ ----------- -----

2

30

) that will be dissipated over the

av

epeat cycle times

10

9

8

7

6

5

4

3

2

1

7s 1min5min

30s 30min

13.7 103–×π× 4000×

t

----- ----------- ----------- ----------- ----------- ---------- -

bMIN

Check that t

30 30.4×

is less than td;ifnot,systemdesignmustbe

bMIN

0.19 ondsec==

reconsidered.

Resulting torque

Calculatethe torquethat resultsfromtherequired decelerationtime,

as follows:

JTn

π

M

b

M

b

----------

------ ----

× Nm()=

30

t

d

13.7 103–×π× 4000×

------ ----------- ----------- ----------- ----------- -------- -

0.5 30×

11.5Nm==

0.1 0.2 0.5 1 2 5 10 20 50

Deceleration time

5. The coolingcurves indicatethat for a brakingtime of 0.5 second and

repeatcycletimeof7seconds,theoverloadfactor(F)is3.5.

10 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 15

6. Calculate the minimum required power rating of the resistor, as

follows:

P

RMIN

P

----------

PK

F

×

2.4 10

------- ----------- ----- -

3.5

3

0.7kW== =

If the braki ng resistor is tobe mounted inside the enclosure,make a

note of this value;you will need it whencalculating the enclosure

size.

In practice,use a resistor having a powerrating higher than the

calculated value. For thisexample: P

=750Wor0.75kW

R

*

2. Select a model of thermal overload relay that can be set at 1.9A

3. Calculate the maximum current that could flow througha resistor

(e.g. due to the braking resistor becoming short circuit), as follows:

V

780

R

------ -

------- -- -

I

Rpk

R

4. Calculate the overload factor for this condition, as follows:

I

Rpk

---------------

F

===

S\C

I

SET

5. Use the tripping curves to findthe time that thethermaloverload

relay will take to trip (e.g. 30 seconds approximately).

200

3.9

------- - 2

1.9

3.9A== =

2.20 Value of the braking resistor

1. Calculate the maximum suitable value for the braking resistor, as

follows:

2

V

()

R

MAX

------ -------- -

P

PK

R

2

780

------ ------------ ----- -

2.4 10

×

3

250Ω== =

2. Inpractice,usearesistorhavingapreferredvalueclosetoand

lowerthan the calculated value.This is becausethecalculatedvalue

would cause the braking transistor to be switched on almost

continuouslyduringbraking.In this case, the drive will nothave full

controlof the DC-bus voltage.A lower value of braking resistor will

causethe brakingtransistorto act as a chopper whichwillthen allow

the drive to control the DC-bus voltage m ore accurately.

The reduction in value does not increase the power dissipation since

the average voltage across the resistor is reduced by the braking

transistor operatingas a chopper.

For this example: R=200Ω

2.21 Disabling protection of the internal

braking resistor

The internalbrakingresistor is protected against I2toverloadby

calculationsperformed in the drive software. When an externalbraking

resistorbeingused,thiscalculationmustbedisabledinordertoremove

the possibility of it causingthe drive to trip unnecessarily.

Balancedoperation 3-phase,

from cold state

Balancedoperation 2-phase,

from cold state

Balancedoperation 3-phase,

Time (s)

aftera long period of set current

flow (hot state)

100

50

20

10

5

2

1

0.5 1 2 5 10 17

X current setting

(F)

2.23 Enclosure layout

Refer to Figure 2-6 for minimumclearances above and belowthedrive.

The bookcase format allows drives to be mountedin rows withno need

for horizontal spacing.

Figure 2-6 Minimum clearances above and below the drive

Todisable the I

2

t protection for the internalbraking resistor,make a note

to set parameter 10.55at 1 whenfollowingChapter6 Setting Up the

drive for Basic Applications in the UserGuide.

Do not disable the I

2

t protection when the internal

braking resistor is to be used.

CAUTION

2.22 Currentsetting for a thermal overload

protection relay

1. Calculate the maximum permissible continuous current through

the brakingresistor that is to be used, as follows:

P

750

R

------- -- - 1.9A== =

I

Rmax

------ -

200

R

where:

P

is the continuouspower rating of the resistor to be used ( not

R

the minimum requiredpower rating)

R is the actual value of the braking resistor (not the calculated

value)

M’Ax Installation Guide 11

Issue Number: 6 www.controltechniques.com

Refer to Figure 2-7 for the arrangement of the associated equipment and

wiring in the enclosure. This diagram shows two drives, one having an

external brakingresistor connected. When EMC emission standards are

to be met, an RFI filter will need to be included for each drive; see the

sections on EMC emission standards later in this chapter.

Page 16

*

Figure 2-7 Arrangement of the drive and associated equipment in

the enclosure

EMC compliance

When compliance with EMC emission standards is required, additional

precautions must be taken; see the EMC emission standards sections

laterin this chapter.

2.24 Clearances for the signal cables

Recommendedclearances areshown on this page;theyarerequiredfor

routine EMC precautions as well as for compliance with EMC emission

standards.

Clearance from the drive

Do not locate sensitive

signalcircuits or pass

signalcableswithin

300mm(12 in) of the drive.

1. Enclosure. For high ingress protection, this must be sealed and the

drive mounted on the back-plate.

2. Enclosure back-plate.

3. When an external braking resistor is to be used, mount the resistor

either above or inside the enclosure, as follows...

Inside Locate theresistor on or near the top panel.

Outside Mount the resistor in an adequately ventilatedmetal

housing that will prevent inadvertent contact with the resistor.A

separate external braking resistor must be used for each drive

(unless their DC-buses are connected in parallel).

4. Thermal overload protection relay required for each external braking

resistor. Locate as required.

5. System controller. Locate as required.

6. Signal cables and circuits. See the next section in this chapter for

clearances.

7. Drivemountedverticallyon the enclosure back-plate (see 1. above).

8. Power cables.P osition as required.

9. Isolator, contactor, and fuses or MCBs. Locate as required.

10. Alternative locationso f fuses or MCBs. Locate asrequired.

11. Power cables entering the enclosure. Position as required.

Clearance from power

cables

Do not pass signal cables

within300mm (12 in) of:

• Motor cables

• Braking resistor

cables

• AC supply cables

12 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 17

Crossing angle

When power and

signalcables

cross,the

crossing angle

must be 90°.

*

Total heat dissipation

1. Add the dissipation figures from step 6 (in Planning the installation)

for each drive thatis to be installedin the enclosure. Make a note of

the total value.

2. IfanRFIfilteristobeusedwitheachdrive,addthedissipation

figures from step 29 (in EMC emissionstandards – instructionslater

in this chapter) for each RFI filter that is to be installed in the

enclosure. Make a note of the total value.

3. If the braking resistoris to be mounted inside the enclosure,add the

average power dissipation from step 12 (in Planning the installation)

foreachbraking resistorthat is to be installedin the enclosure.Make

a note of the total value.

4. Make a note of the total heat dissipation(in Watts) of any other

equipment to be installed in the enclosure.

5. Add the heat dissipation figures obtained (as appropriate) from lines

1, 2, 3 and 4 above. This gives a figure in Watts for the total heat that

will be dissipatedinside the enclosure. Make a note of thisfigure.

Calculating the size of a sealed enclosure

The enclosuretransfers internally generatedheat into the surrounding

air by natural convection(or external forced air flow);the greaterthe

surface area of the enclosure walls, the better is the dissipation

capability. Only the surfaces of the enclosure that are unobstructed (not

in contact with a wall or floor) can dissipate heat.

Calculate the minimum required unobstructed surface area A

enclosure from:

P

------ ----------- ----------- -----

=

A

e

kT

–()

iTamb

Where:

Unobstructed surface area in m2(1m2= 10.8ft2)

A

e

T

Maximum expected ambient temperature in °C outside the

amb

enclosure

T

Maximumintended ambient temperaturein °C insidethe

i

enclosure

P Power in Watts dissipated by all heat sources in the

enclosure

k Heat transmission coefficientof the enclosure material

in W/m

2

/°C

for the

e

2.25 Enclosure calculations for heat removal

Decidewhether the enclosure is to be sealed or ventilated, asfollows:

Sealed enclosure

Asealedenclosurecangiveahighingress-protectionrating,butwith

reduced heat removal capabilities. If possible, locate heat-generating

equipment (other than braking resistors) in the lower part of the

enclosure to encourage internalconvection. If necessary, a taller

enclosure, and/or air-circulation fans inside the enclosure, can be used.

For calculating the minimum size of sealed enclosure that will

adequately cool the drive(andother drives),see Enclosure calculations

later in this chapter.

Ventilated enclosure

If a high ingress-protection rating is not required, a ventilated enclosure

canbeusedwithafantosupplyforcedaircooling;thiscangivealower

ambient temperature than asealed enclosure. For calculating the

minimum requiredvolume of coolingair, see Calculating the air-flow in a

ventilated enclosure on page 14.

NOTE

Take care when performing these calculations in order to ensure

the ambient temperature inside the enclosure does not exceed

55°C (131°F)or 45°C (113°F), as appropriate (see step 6 in Planning

the installation).

Example

Tocalculate the size of an enclosure for the following:

• Three M’Ax409

• Each driveis to have an externalbrakingresistormountedinside the

enclosure

• AnRFI filter (model 3258-16-45) to be used witheach drive

• Maximum ambient temperature inside the enclosure: 55°C

• Maximum ambienttemperature outsidethe enclosure:30°C

Dissipation of the drive:180W (from section 2.11Output current,

Ambient temperature, Heat dissipation, De-rating on page 7)

Average dissipation from the braking resistor: 171W (fromsection

2.18 Minimumpermissible deceleration time on page 10)

Dissipation of each RFI filter: 6W (max) (from Installing an RFI filter on

page 21

T otal dissipation: 3 x (180 + 171 + 6) = 1071W

The enclosure is to be made from painted 2mm (0.0787in) sheet steel

havinga heat transmissioncoefficientk of 5.5W/m

front, and two sides of the enclosure are to be free to dissipate heat.

2

/°C. Only the top,

M’Ax Installation Guide 13

Issue Number: 6 www.controltechniques.com

Page 18

*

Figure 2-8 Enclosurehaving front,sides and top panels free to

dissipate heat

P

0

k

Ratio of

p

----- -

P

1

Where:

is the air pressureat sea level

P

0

P

is the air pressureat the installation

1

Typicallyuse a factor k

drops in dirty air-filters.

of1.2to1.3,toallowalsoforpressure-

a

H

D

W

Insertthe following values:

T

55°C

i

T

30°C

amb

k 5.5

P 1071W

The minimum required heat conducting area is then:

(1m

A

e

2

=10.8ft2)

1071

------- ----------- ----------- --- -

5.5 55 30–()

7.8

2

84ft2()==

Estimate two of the enclosuredimensions- the height(H)and depth(D),

for instance. Calculate the width (W) from:

A

2HD–

e

------ ----------- -------- -

=

W

HD+

Inserting H = 2mand D = 0.6m, obtain the minimum width:

7.8 2 2× 0.6×()–

----- ----------- ----------- ----------- --------

W

20.6+

2.08m 6ft10in()==

If the enclosure is too large for the spaceavailable, it can be made

smaller only by attendingto one or all of the following:

• Reducing the ambient temperature outside the enclosure, and/or

applying forced-air cooling to the outside of the enclosure

• Removingotherheat-generating equipment, eg. braking resistors

• Reducingthe number of drives in the enclosure

• Aircirculating fan insideenclosure (see section 2.25 Enclosure

calculations for heat removal on page 13)

Example

T ocalculate the required air flow in an enclosure for the following:

• ThreeM’Ax409

• Eachdrive is to have an external brakingresistor mounted outside

the enclosure

• Maximum ambient temperature inside the enclosure: 55°C

• Maximum ambient temperature outside the enclosure: 30°C

•Atsealevel(k

=1forthisexample)

p

Dissipation of each drive: 180W (from section 2.11 Output current,

Ambient temperature, Heat dissipation, De-rating on page 7)

T otal dissipation: 3 x 180 = 540W

Insert the following values:

T

55°C

i

T

30°C

amb

k

1.3

a

P 540W

Then:

31.3× 540×

------ ----------- ----------- ----- -

V

55 30–

84m

3

hr 493min()==

Calculating the air-flow in a ventilated enclosure

The dimensions of the enclosure are required only for accommodating

the equipment. The equipment is cooled by the forced air flow.

Calculate the minimum requiredvolumeof ventilating air from:

3kP

------ ----------- ------- -

V

=

T

–

iTamb

Where:

3

V Air-flow in m

T

Maximum ambientt emperaturein °C outsidethe enclosure

amb

per hour

Ti Maximum ambient temperaturein °C inside the enclosure

P Power in Watts dissipated by allheat sourcesin the

enclosure

14 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 19

2.26 Mounting the drive

Parts supplied

Quantity Part Purpose

1 M5 nut

Ground stud1 M5 plain washer

1 M5springwasher

1 Groundbracket Safetygroundconnections

3 Hose clip (11 to 16mm[0.433to 0.630 in] dia.) Clamppower cables to the ground bracket

2 Keyed plug-in 4-way connector

1 Keyed plug-in5-way connector andbraking link

1 Upper mountingbracket

1 Lower mountingbracket

4 M4 x 8mm T20Torx-head Taptite screws

Fitting the mou nting brackets to the drive

Figure 2-9 Locations of the mounting brackets

Power connections

Mounting the drive

*

1. Locatethe tabsof the upper mountingbracket (not fittedwith a stud)

in the slots near the top of the rear panel of thedrive.

2. Retain the bracket with two of the M4 T20 Torx-head screws

supplied.

3. Locate the tabs of the lower mounting bracket (fitted with stud S)in

the slots near the bottom of the rear panel of the drive.

4. Retain the bracket with two of the M4 T20 Torx-head screws

supplied.

M’Ax Installation Guide 15

Issue Number: 6 www.controltechniques.com

Page 20

*

(

(

(

2.27 Attaching the drive to the back-plate

Figure 2-10 Mounting details for the drive

M5

9.724in)

11mm (0.433in)

14.173in)

(0.590in)

(1.986in)

M5

12.992in)

(10.748in)

(0.787in)

(0.905in)

(2.440in)

1. Back-plate with mounting holes A.

2. Upper mounting bracket fitted to the rear of the drive.

3. Lower mounting bracket with M5 stud S fitted to the rear of the drive.

The stud must be used for ground termination (see section

2.30 Method of connecting the power cables on page 18).

4. If compliance with EMC emission standardsis required, both

mountingbracketsmust make direct electricalcontact with the backplate;the screw holes should be threaded.

5. Area occupied by thedrive.

6. Looselyfit screws (B), locate the slotted holes in the mounting

brackets over the screws, then tighten the screws.

16 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 21

2.28 Precautions for making power connections

Electric shock risk

The voltages present in the following locations can

WARNING

WARNING

WARNING

WARNING

causesevereelectricshockandmaybelethal:

• AC supply cables and connections

• Output cables and connections

• Many internal parts of the drive

• An auxiliary back-up supply when connected in

addition to the AC supply.

Isolation device

The AC supply must be disconnected from the drive

using an approved isolation device before any coveris

removed from the drive or before any servicing work is

performed.

Stored charge

The drive contains capacitors that remain charged to a

potentiallylethal voltage after the AC supply has been

disconnected. If the drive has b een energised, the AC

supply must be isolated at least five minutes before work

may continue.

AC supply by plug and socket

Special attentionmust be givenif the driveis installed in

equipment which is connected to the AC supply by a

plugand socket.TheAC supplyterminalsof the driveare

connected to the internal capacitors through rectifier

diodes which do not giveisolation. If the plug terminals

can be touched when the plug is d isconnectedfrom the

socket, a means of automatically isolating the plug from

the drive must be used (eg. a latching relay).

*

2.29 Terminal sizes and tightening torques

To avoid a fire hazard and maintain validity of the UL

listing, adhere to the specified tightening torques for the

WARNING

RFI filter

power and ground terminals. Refer to the following

tables.

Power terminals Ground terminal

Unit

Drive

Size

Type

Plug-in

terminal

block

Screw

terminals

Torque Size

Type

0.5N.m

4.4lb.in

0.7N.m

6.2lb.in

M5 stud

Screw

terminals

Torque tolerance ±10%

Torque

2N.m

17.7lb.in

0.7N.m

6.2lb.in

WARNING

WARNING

STOP function

The STOP function does not remove dangerous voltages

from the drive.

Safety ground connection

The ground loop impedance must conform to the

requirements of local safety regulations.

The electrical safety of the installation depends on the

correct fitting and use of the ground bracket supplied

with the drive. All ground connections to the drive must

be made to this ground bracket.

The ground bracket must be grounded by a connection

capable of carrying the prospective fault current until the

protective device (fuse, etc) disconnects the AC supply.

The ground connections must be inspected and tested at

appropriate intervals.

M’Ax Installation Guide 17

Issue Number: 6 www.controltechniques.com

Page 22

*

0

W

L

W

2.30 Method of connecting the power cables

Figure 2-11 Locations of the power connections and correct fitting of the ground bracket

ARNING

V

ive circuit dedicated

isolated supply is

required.

20mm (0.787in)

5

The and 0V terminals are not connected together

inside the drive. It is essential that the ground

WARNING

For electrical safety, thegroundbracketmust be fitted as shown.S ee

alsosection2.31 Circuitdiagramsfor the power connections on page 19

and section 2.29 Terminalsizes and tighteningtorqueson page 17.

Perform all of the following:

1. Fit a plug-in multi-wayconnector into eachof the threesockets on

2. Loosenthe screwfor each of the ground terminals of the 4-way

3. Fit the two tongues of the ground bracket in the ground terminals of

4. Fit onto the groundstud the M5 plain washer,spring washer and nut

connections from the AC supply and to the motor are

made to the ground bracket as shown.

the undersideof the drive. These connectors are keyed to ensure

correct fitting.

connectors.

the 4-way connectors and pass the hole in the upright section (as

viewed in the diagram) of the ground bracket over the ground stud in

the lower mounting bracket.

supplied with thedrive.While tightening the nutt o the specified

torque, ensure the tongues on the ground bracket remain fully

inserted in the terminals.

12mm (0.472in)

Ground bracket must

be fitted due to risk

ARNING

5. Tighten the screwsin the two groundterminals to thespecified

torque.

6. Strip back the insulating sheath on the shielded cablesto expose at

least 12mm (0.472in)of shield and 30mm (1.181in) of inner

conductors.

7. Fit a hose clip over each cable shield to clamp it to the ground

bracket; for reliable contact, it may be necessary to wrap copper foil

aroundthe shield.

8. Connect the ground wire of the motor cable to the ground bracket

usingthe related hole at thepositionshown. This applies whether

thegroundwireisinsideoroutsidethecable.

When an external braking resistor is used,use the same

arrangement for the brakingresistor cable.

9. UseacabletietosecuretheACsupplywiringtothegroundbracket.

10. If an auxiliary back-up supply is to be connected, ensure its output is

isolated and it is connected only to terminals H and

back-upsupplies in Chapter 2 Connecting the drive in the User

Guide.

of electric shock

−;seeTypes of

18 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 23

*

0

2.31 Circuit diagrams for the power connections

Figure 2-12 Power connections to be made when an external braking resistor is used, including a typical protection circuit for the

braking resistor

Key to Figure

1. START/RESET switch

2. STOP switch

3. Control supply

4. Contactor coil

5. Thermal overload protection relay

6. Brakingresistor

7. AC supply to the drive

8. AC supply Isolator

V

M’Ax Installation Guide 19

Issue Number: 6 www.controltechniques.com

Page 24

*

0

Figure 2-13 Power connectionsto be made when the internal braking resistor is used

Key to Figure

1. START/RESET switch

2. STOP switch

3. Control supply

4. Contactor coil

5. AC supply to the drive

6. AC supply isolator

7. Link to connect the internal braking resistor

V

20 M’AxInstallationGuide

www.controltechniques.com Issue Number: 6

Page 25

2.32 EMC emission standards compliance information

NOTE

*

EN 50081-2, use an RFI filter for each drive,as shown in Table 2-11 .

(Standards that aremet are specif ied in AppendixB Data on page 26.)

Table 2-11 RFI filter details

Conditions for EMC compliance

The installer of the drive is responsible for ensuring compliance

with the EMC regulations that apply where the drive is to be used.

The drive will comply with thestandards for emission, such as

EN50081-2, only when the instruct ions given in this section are

adhered to closely.

Special note for EN61800-3 (EMC Power Drive Systems)

For installation in the‘secondenvironment’, i.e. where the low

voltage supply network does not supply domestic premises, and

wheretheratedinput current of the drive system exceeds100A, no

filter is required in order to meet IEC61800-3 (EN61800-3).

Operating the drive in this environment without an EMC filter may

cause interference to nearby electronic equipment whose

sensitivity has not beenappreciated.The user must take remedial

measures if this situation arises.

If the consequencesof unexpected disturbances are severe, it is

recommended that the emission limits of EN50081-2 be adhered to.

In any other case, adhere to the precautions described in this

section.

When the drive is used in the ‘first environment’, i.e. where the low

voltage supply network also supplies domestic premises, the following

warning applies:

Thisis a productof restricted distribution class

according to IEC61800-3. In a domestic environment this

WARNING

product may cause radio interference in which case the

user may be required to take adequate measures.

RFI filter

Model

M’Ax 403 4200-1645 4200-0081 6W IP20

M’Ax 406 4200-1645 4200-0081 6W IP20

M’Ax 409 4200-1645 4200-0081 6W IP20

M’Ax 412 4200-1645 4200-0081 6W IP20

MakeanoteofthefollowingforeachRFIfiltertobeused:

• Part number

• Maximum power dissipation figure

•IPrating

Dimensions of the bookcase RFI filter

LWH J B CG T

250 45 70 220 25 235 5.4 1.0 mm M5

9.842 1.772 2.776 8.661

Dimensions of the footprint RFI filter

LWHJBCGT X

360 54.5 40 273 N/A 330 5.5 1.0 mm M5

14.173 2.156 1.575 10.748 N/A 12.992 0.216 0.039 in

Bookcase

filter part

number

Footprint

filter part

number

9.252

0.984

Maximum

power

dissipation

0.039

0.2

Ingress

protection

in

X

3

/

16

3

/

16

2.33 EMC emission standards instructions

Follow these instructions in addition to those given earlier in this chapter.

Enclosure

The enclosure must be made of metal but does not require specialEMC

features.

Back-plate

Ensure the enclosure back-plate is unpainted, but it may be zinc plated.

Mounting brackets electrically connected to the back-plate

Ensurethe mounting brackets for the driveand RFI filter make direct

electrical connection with the back-plate.

Grounding

For compliance with EMC emission standards, employ the grounding

arrangements shownin thissection.These arrangementsare in addition

to (not instead of) the safety requirements.

The fittingof an additional safety ground will not reduce the EMC

performance.

External braking resistor

When an external braking resistor is to be mounted outside the

enclosure, ensure the following:

• The resistorhousing will giveelectromagnetic shielding(without

compromising ventilation)

• The braking-resistor wiring must be shielded/armoured

WARNING

The filter has a high leakage current to ground. A

permanent fixed ground connection must be provided.

Installing an RFI filter

For compliance with emission standards such as EN 50081-1 or

M’Ax Installation Guide 21

Issue Number: 6 www.controltechniques.com

Page 26

*

2.34 Clearances from the RFI filter and AC supply cables

1. Mount the RFI filter as close as

possible to thedrive. No

clearance is required either

side of the RFI filter or the

drive.

2. Make the wires connecting the

RFI filter to the drive as short

as possible.

3. Allow at least 100mm (4 in)

clearance (C) between the AC

supplycableand the following:

• Signalcables

•Drive

• Braking resistors and cables

• Motorsand cables