Conexant MFC2000 Datasheet

MFC2000

Multifunctional Peripheral Controller 2000

Hardware Description

Doc. No. 100723A

June 21, 2000

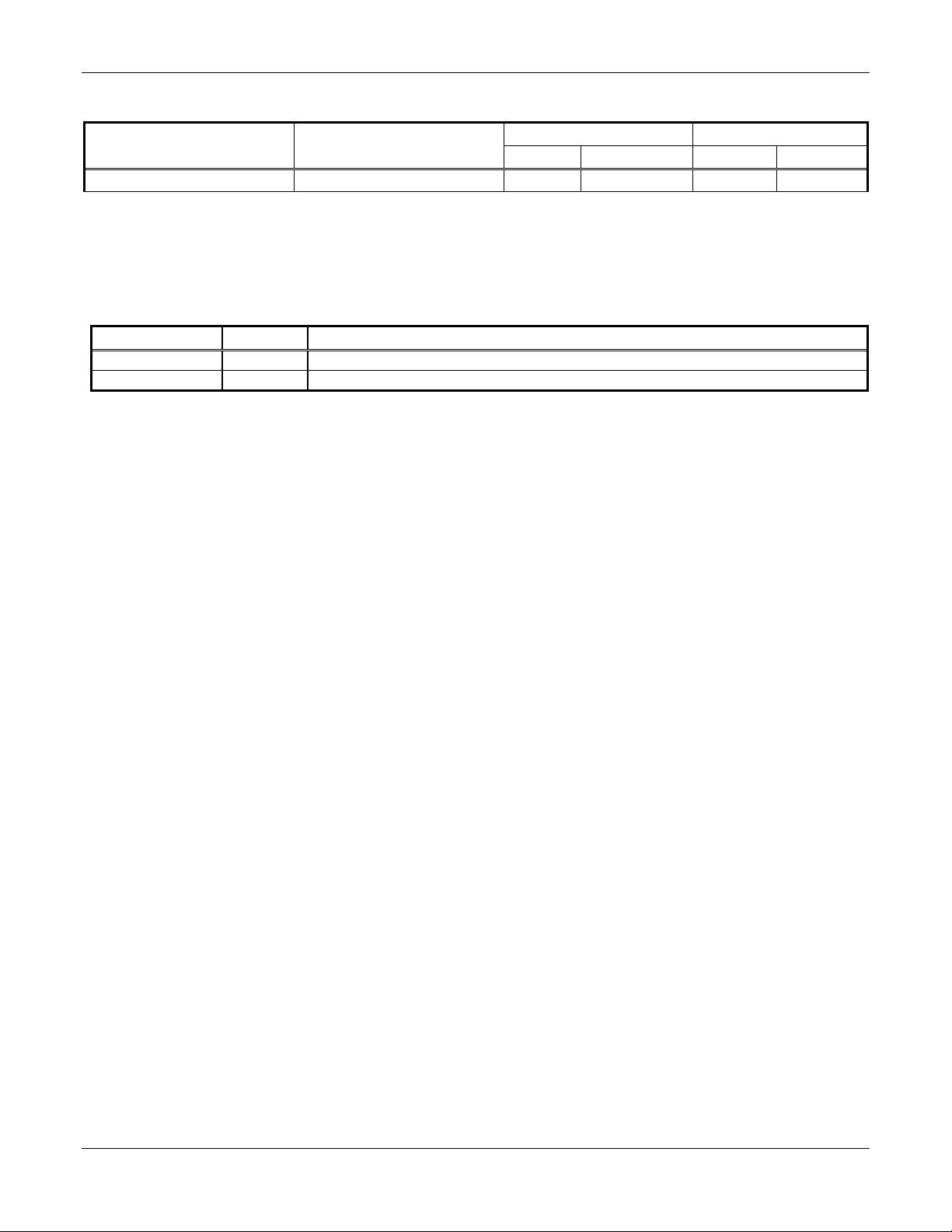

Ordering Information

Marketing Name Device Set Order No.

Part No. Package Part No. Package

MFC2000 xxx-xxx-xxx xxxxx

Revision History

Revision Date Comments

A 04/07/00 Initial, internal, preliminary release of document.

A 06/21/00 Second internal, preliminary release with revisions track ed.

© 2000, Conexant Systems, Inc. All Rights Reserved.

Information in this document is provided in connection with Conexant Systems, Inc. (" Conexant " ) products . These materials are p rovi ded by

Conexant as a service to its customers and may be used for informational purposes only. Conexant assumes no responsibili ty for errors or

omissions in these materials. Conexant may make changes to specifications and product descriptions at any time, without notice. Conexant

makes no commitment to update the information contained herein. Conexant shall have no responsibility whatsoev er for confl icts or

incompatibilities arising from future changes to its specificati ons and product descriptions.

No license, express or implied, by estoppel or otherwise, to any intellect ual property ri ghts is grant ed by this document. Except as provided in

Conexant’s Terms and Conditions of Sale for such products, Conexant assumes no liability whatsoever.

THESE MATERIALS AR E PR OVIDED "AS IS" WITHOUT W AR R AN TY OF ANY KIND, EITHER EX PR ESS OR IMPLIED, RELA TIN G TO

SALE AND/OR USE OF CONEXANT PRODUCTS INCLUDING LIABI LITY OR WARRANTIE S RE LAT ING TO FITNESS FOR A

PARTICULAR PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL

PROPERTY RIGHT. Conexant further does not warrant the accuracy or completeness of the information, text, graphics or other items

contained within these materials. Conexant shall not be liable for any special, indirect, i ncidental, or consequential damages, including without

limitation, lost revenues or lost profits, which may result from the use of these materials .

Conexant products are not intended for use in medical, life saving or life sustaining applicati ons. Conexant cust om ers usi ng or selling

Conexant products for use in such applications do so at their own risk and agree to fully indemnify Conexant for any damages resulting from

such improper use or sale.

The following are trademarks of Conexant Systems, Inc.: Conexant, the Conexant C symbol, “What’s Next in Communic ations Technologies”,

and SmartDAA. Product names or services listed in this publication are for identification purpos es only, and may be trademarks of third

parties. Third-party brands and names are the property of their respective owners.

Reader Response:

Conexant strives to produce quality documentation and welcomes your feedback. Please send comments

and suggestions to conexant.tech.pubs@conexant.com. For technical questions, contact your local Conexant sales office or

field applications engineer.

ii

Conexant

100723A

Contents

1. INTRODUCTION..............................................................................................................................................1-1

1.1 SCOPE ......................................................................................................................................................1-1

1.2 SYSTEM OVERVIEW................................................................................................................................1-1

1.3 REFERENCE DOCUMENTATION............................................................................................................ 1-5

2. MFC2000 SUMMARY ...................................................................................................................................... 2-1

2.1 MFC2000 DEVICE FAMILY....................................................................................................................... 2-1

2.2 MFC2000 SYSTEM BLOCK DIAGRAM .................................................................................................... 2-1

3. HARDWARE INTERFACE............................................................................................................................... 3-1

3.1 PIN DESCRIPTION ...................................................................................................................................3-1

3.2 MAXIMUM RATINGS.................................................................................................................................3-7

3.3 ELECTRICAL CHARACTERISTICS..........................................................................................................3-8

3.4 PIN LAYOUT............................................................................................................................................3-10

4. CPU AND BUS INTERFACE...........................................................................................................................4-1

4.1 MEMORY MAP AND CHIP SELECT DESCRIPTION...............................................................................4-1

4.2 CACHE MEMORY CONTROLLER..........................................................................................................4-19

4.3 SIU………. ...............................................................................................................................................4-24

4.4 INTERRUPT CONTROLLER................................................................................................................... 4-46

4.5 DRAM CONTROLLER (INCLUDING BATTERY DRAM)........................................................................4-54

4.6 FLASH MEMORY CONTROLLER...........................................................................................................4-72

4.7 DMA CONTROLLER ...............................................................................................................................4-76

5. RESET LOGIC/BATTERY BACKUP/WATCH DOG TIMER...........................................................................5-1

5.1 RESET LOGIC/BATTERY BACKUP ......................................................................................................... 5-1

5.2 WATCHDOG TIMER ...............................................................................................................................5-11

6. FAX TIMING CONTROL INTERFACE............................................................................................................6-1

6.1 PLL………….. ............................................................................................................................................6-1

6.2 FAX TIMING LOGIC ..................................................................................................................................6-2

6.3 MFC2000 TIMING CHAIN .........................................................................................................................6-3

6.4 SCAN CONTROL TIMING......................................................................................................................... 6-4

6.5 FAX TIMING REGISTERS.........................................................................................................................6-5

7. VIDEO/SCANNER CONTROLLER .................................................................................................................7-1

7.1 SCANNER CONTROLLER........................................................................................................................ 7-2

7.2 SERIAL PROGRAMMING INTERFACE..................................................................................................7-41

7.3 VIDEO CONTROLLER ............................................................................................................................7-50

8. ADC……...........................................................................................................................................................8-1

8.1 PADC AND SCAN ANALOG FRONT END ...............................................................................................8-1

8.2 TADC……………………. ........................................................................................................................... 8-5

100723A

Conexant

iii

9. BI-LEVEL RESOLUTION CONVERSION ....................................................................................................... 9-1

9.1 FUNCTIONAL DESCRIPTION .................................................................................................................. 9-1

9.2 REGISTER DESCRIPTION....................................................................................................................... 9-6

9.3 RESOLUTION CONVERSION PROGRAMMING EXAMPLES............................................................... 9-15

10. EXTERNAL PRINT ASIC INTERF ACE.........................................................................................................10-1

10.1 INTERFACE BETWEEN THE MFC2000 AND EXTERNAL PRINT ASIC..........................................10-1

11. BIT ROTATION LOGIC.................................................................................................................................. 11-1

11.1 FUNCTIONAL DESCRIPTION............................................................................................................11-1

11.2 BLOCK DIAGRAM...............................................................................................................................11-3

11.3 REGISTER DESCRIPTION.................................................................................................................11-6

11.4 FIRMWARE OPERATION................................................................................................................. 11-10

12. PRINTER AND SCANNER STEPPER MOTOR INTERFACE...................................................................... 12-1

12.1 VERTICAL PRINT STEPPER MOTOR INTERFACE .........................................................................12-1

12.2 SCANNER STEPPER MOTOR INTERFACE.....................................................................................12-5

13. GENERAL PURPOSE INPUTS/OUTPUTS (GPIO) ...................................................................................... 13-1

13.1 GPIO SIGNALS...................................................................................................................................13-1

13.2 GPO/GPI SIGNALS............................................................................................................................. 13-5

13.3 GPIO CONTROL AND DATA REGISTERS........................................................................................13-6

14. COMPRESSOR AND DECOMPRESSOR..................................................................................................... 14-1

14.1 FUNCTIONAL DESCRIPTION............................................................................................................14-1

14.2 REGISTER DESCRIPTION.................................................................................................................14-2

15. SYNCHRONOUS/ASYNCHRONOUS SERIAL INTERFACE (SASIF).........................................................15-1

15.1 FUNCTIONAL DESCRIPTION............................................................................................................15-1

15.2 REGISTER DESCRIPTION.................................................................................................................15-3

15.3 SASIF TIMING...................................................................................................................................15-12

15.4 FIRMWARE OPERATION.................................................................................................................15-16

16. USB INTERFACE .......................................................................................................................................... 16-1

16.1 FUNCTION DESCRIPTION ................................................................................................................ 16-1

16.2 REGISTER DESCRIPTION.................................................................................................................16-1

16.3 FIRMWARE OPERATION.................................................................................................................16-23

17. BI-DIRECTIONAL PARALLEL PERIPHERAL INTERFACE........................................................................ 17-1

17.1 OPERATIONAL MODES..................................................................................................................... 17-1

17.2 ADDITIONAL FEATURES................................................................................................................... 17-2

17.3 FUNCTIONAL DESCRIPTION............................................................................................................17-3

17.4 REGISTER DESCRIPTION.................................................................................................................17-4

17.5 TIMING..............................................................................................................................................17-16

17.6 FIRMWARE OPERATION.................................................................................................................17-22

iv

Conexant

100723A

18. REAL-TIME CLOCK ...................................................................................................................................... 18-1

18.1 DESCRIPTION....................................................................................................................................18-1

18.2 REAL-TIME CLOCK (RTC) REGISTERS ...........................................................................................18-2

18.3 RTC OPERATIONS.............................................................................................................................18-3

19. SYNCHRONOUS SERIAL INTERFACE (SSIF)............................................................................................19-1

19.1 INTRODUCTION AND FEATURES....................................................................................................19-1

19.2 REGISTER DESCRIPTION.................................................................................................................19-2

19.3 SSIF TIMING.......................................................................................................................................19-7

20. PROGRAMMABLE TONE GENERATORS ..................................................................................................20-1

20.1 INTRODUCTION.................................................................................................................................20-1

20.2 BELL/RINGER GENERATOR.............................................................................................................20-1

20.3 TONE GENERATOR........................................................................................................................... 20-6

21. PWM LOGIC .................................................................................................................................................. 21-1

21.1 FUNCTIONAL DESCRIPTION............................................................................................................21-1

21.2 REGISTER DESCRIPTION.................................................................................................................21-2

22. CALLING PARTY CONTROL (CPC) ............................................................................................................22-1

22.1 REGISTERS DESCRIPTION..............................................................................................................22-5

23. SSD_P80........................................................................................................................................................23-1

23.1 FUNCTION DESCRIPTION ................................................................................................................ 23-1

23.2 REGISTER DESCRIPTION.................................................................................................................23-3

23.3 FIRMWARE OPERATION...................................................................................................................23-6

24. COUNTACH IMAGING DSP BUS SUBSYSTEM ......................................................................................... 24-1

24.1 COUNTACH IMAGING DSP SUBSYSTEM........................................................................................ 24-3

24.2 COUNTACH IMAGING DSP BUS UNIT ............................................................................................. 24-4

24.3 ARM BUS INTERFACE.......................................................................................................................24-8

24.4 COUNTACH IMAGING DSP SUBSYSTEM INTERFACE ................................................................24-11

24.5 COUNTACH DMA CONTROLLER.................................................................................................... 24-12

24.6 VIDEO/SCANNER INTERFACE ....................................................................................................... 24-22

24.7 (S)DRAM CONTROLLER ((S)DRAMC)............................................................................................24-23

24.8 REGISTER DESCRIPTION...............................................................................................................24-28

25. CONFIGURATION ......................................................................................................................................... 25-1

25.1 HARDWARE VERSION ......................................................................................................................25-1

25.2 PRODUCT CODE ............................................................................................................................... 25-1

100723A

Conexant

v

Figures

Figure 1-1. MFP System Diagram Using MFC2000 .............................................................................................................. 1-1

Figure 1-2: MFC2000 Function Diagram............................................................................................................................... 1-4

Figure 2-1.

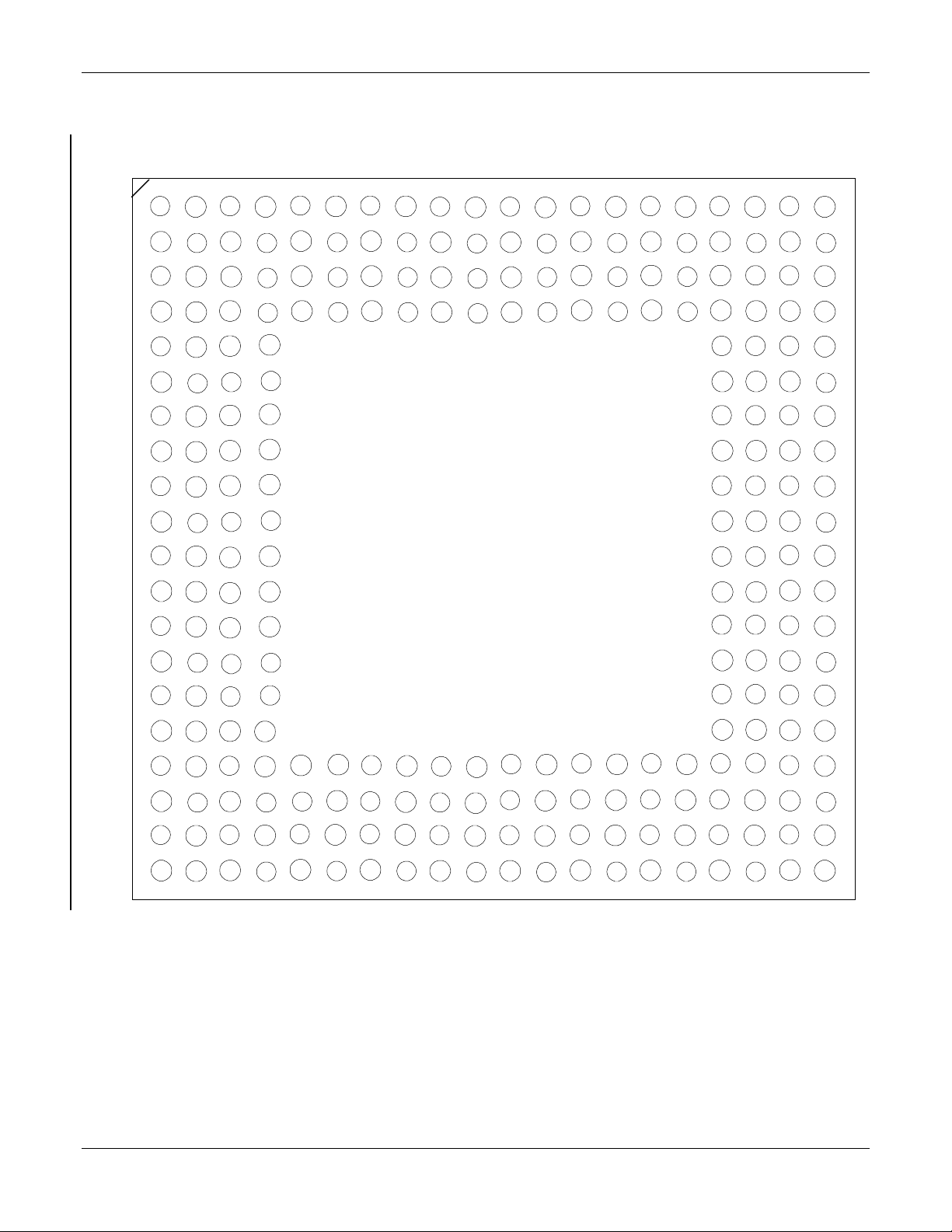

Figure 3-1. MFC2000 BGA Bottom View............................................................................................................................. 3-10

Figure 4-1. MFC2000 Memory Map....................................................................................................................................... 4-6

Figure 4-2. MFC2000 Internal Memory Map.......................................................................................................................... 4-7

Figure 4-3. MFC2000 Cache Organization.......................................................................................................................... 4-19

Figure 4-4. 2-Way Interleave ROM Connection................................................................................................................... 4-26

Figure 4-5. Zero Wait State, Single Access, Normal Read, Normal Write........................................................................... 4-36

Figure 4-6. One Wait State, Single Access, One Read, One Write..................................................................................... 4-37

Figure 4-7. Two Wait States, Single Access, Read On Delayed (CS1n), Write Early Off (CS2n)........................................ 4-38

Figure 4-8. Zero Wait State, Burst Access, Normal Read, Normal Write............................................................................. 4-39

Figure 4-9. Fast Page Mode ROM Access1,0,0 Read Access Followed by 1,1,1,1, Write Access.................................. 4-40

Figure 4-10. System Bus TimingRead/Write with Wait States ......................................................................................... 4-41

Figure 4-11. System Bus TimingZero-Wait-State Read/Write.......................................................................................... 4-42

Figure 4-12. System Bus Timing2-Way Interleave Read Timing (S = 1).......................................................................... 4-43

Figure 4-13. System Bus Timing2-Way Interleave Write Timing (S = 0 or 1)................................................................... 4-44

Figure 4-14. External Interrupt Request Timing................................................................................................................... 4-54

Figure 4-15. DRAM Bank/Address Map............................................................................................................................... 4-56

Figure 4-16. Simplified DRAM Controller Block Diagram .................................................................................................... 4-59

Figure 4-17. DRAM Interface Example................................................................................................................................ 4-60

Figure 4-18. 8-bit Memory Data Bus....................................................................................................................................4-65

Figure 4-19. 16-bit Memory Data Bus.................................................................................................................................. 4-65

Figure 4-20. CASn Non-Interleaved 8-bit DRAM Read........................................................................................................4-66

Figure 4-21. 2-Way Interleaved Memory with Halfword Bursts of Data............................................................................... 4-66

Figure 4-22. 2-Way Interleaved DRAM Read (3 words)...................................................................................................... 4-67

Figure 4-23. 2-Way Interleaved DRAM Write ...................................................................................................................... 4-67

Figure 4-24. Refresh Cycle.................................................................................................................................................. 4-68

Figure 4-25. DRAM TimingRead, Write and Wait States for Non-interleave Mode.......................................................... 4-68

Figure 4-26. DRAM Timing for 2-way Interleave Write........................................................................................................ 4-69

Figure 4-27. DRAM TimingRead for 2-way interleave mode............................................................................................ 4-69

Figure 4-28. DRAM Refresh Timing.................................................................................................................................... 4-70

Figure 4-29. DRAM Battery Refresh Timing........................................................................................................................ 4-70

Figure 4-30. Flash Control Block Diagram........................................................................................................................... 4-73

Figure 4-31. NAND-Type Flash Memory Access with Two Wait States .............................................................................. 4-75

Figure 4-32: External DMA Read Timing (Single Access, One Wait State) ....................................................................... .. 4-80

Figure 4-33. External DMA Write Timing (Single Access, One Wait State).........................................................................4-81

Figure 4-34. USB Logical Channels Block Diagram............................................................................................................ 4-82

Figure 5-1. Power Reset Block Diagram................................................................................................................................ 5-2

MFC2000 Organization

....................................................................................................................................... 2-2

vi

Conexant

100723A

Figure 5-2. Power-down Select Logic.................................................................................................................................... 5-3

Figure 5-3. Power Reset Timing Diagram.............................................................................................................................. 5-5

Figure 5-4. +5v Prime Power Signal and VGG...................................................................................................................... 5-6

Figure 5-5. Internal Power Detection................................................................................................................................... 5-10

Figure 5-6. Figure Caption Required................................................................................................................................... 5-10

Figure 5-7. Voltage Divider Circuit....................................................................................................................................... 5-11

Figure 5-8. Watchdog Timer Block Diagram........................................................................................................................ 5-12

Figure 5-9. Watchdog Time-Out Timing Diagram................................................................................................................ 5-13

Figure 6-1. Fax Timing Control Logic Block Diagram............................................................................................................6-2

Figure 6-2. MFC2000 Timing Chain...................................................................................................................................... 6-3

Figure 6-3. Scan Control Timing............................................................................................................................................ 6-4

Figure 7-1. Video/Scanner Controller Block Diagram............................................................................................................ 7-1

Figure 7-2. Untitled Timing Diagram.................................................................................................................................... 7-19

Figure 7-3. Untitled Timing Diagram.................................................................................................................................... 7-20

Figure 7-4. Untitled Timing Diagram.................................................................................................................................... 7-20

Figure 7-5. Untitled Timing Diagram.................................................................................................................................... 7-21

Figure 7-6. Untitled Timing Diagram.................................................................................................................................... 7-22

Figure 7-7. Untitled Timing Diagram.................................................................................................................................... 7-23

Figure 7-8. Untitled Timing Diagram.................................................................................................................................... 7-23

Figure 7-9. Untitled Timing Diagram.................................................................................................................................... 7-24

Figure 7-10. Untitled Timing Diagram.................................................................................................................................. 7-24

Figure 7-11. Untitled Timing Diagram.................................................................................................................................. 7-24

Figure 7-12. Untitled Timing Diagram.................................................................................................................................. 7-25

Figure 7-13. Untitled Timing Diagram.................................................................................................................................. 7-25

Figure 7-14. Untitled Timing Diagram.................................................................................................................................. 7-26

Figure 7-15. Untitled Timing Diagram.................................................................................................................................. 7-28

Figure 7-16. Untitled Timing Diagram.................................................................................................................................. 7-30

Figure 7-17. Untitled Timing Diagram.................................................................................................................................. 7-32

Figure 7-18. Untitled Timing Diagram.................................................................................................................................. 7-34

Figure 7-19. Untitled Timing Diagram.................................................................................................................................. 7-36

Figure 7-20. Untitled Timing Diagram.................................................................................................................................. 7-38

Figure 7-21. External circuit required for SONY–ILX516K interface.................................................................................... 7-40

Figure 7-22. LED timing for SONY–ILX516K....................................................................................................................... 7-40

Figure 7-23. Serial Programming Interface, Physical Connection.......................................................................................7-41

Figure 7-24. Bus Protocol.................................................................................................................................................... 7-42

Figure 7-25. Serial Programming Interface, Timing Diagram...............................................................................................7-42

Figure 7-26. Stretching the Low Period of the Clock ........................................................................................................... 7-44

Figure 7-27. Firmware OperationTransmission................................................................................................................ 7-48

Figure 7-28. Firmware OperationReception..................................................................................................................... 7-49

Figure 7-29. Connection to External Video Capture Device................................................................................................ 7-51

Figure 7-30. Untitled Timing Diagram.................................................................................................................................. 7-54

100723A

Conexant

vii

Figure 7-31. DMA Operation................................................................................................................................................7-55

Figure 8-1. Untitled Figure..................................................................................................................................................... 8-1

Figure 9-1: Bi-level Resolution Conversion Block Diagram...................................................................................................9-2

Figure 9-2. The Physical Nozzle Diagram for Typical Inkjet Heads....................................................................................... 9-5

Figure 9-3. Untitled Figure..................................................................................................................................................... 9-5

Figure 9-4: Resolution Conversion Programming................................................................................................................ 9-15

Figure 10-1. Print ASIC Interface.........................................................................................................................................10-2

Figure 11-1. Nozzle Diagram of a Typical Programmable Inkjet Head................................................................................11-1

Figure 11-2. Examples of Nozzle Head Configurations....................................................................................................... 11-2

Figure 11-3. Nozzle Configuration by Bit Rotation Block (Regardless of Physical Nozzle Configuration)........................... 11-2

Figure 11-4. MFC2000 Bit Rotation Block Diagram............................................................................................................. 11-3

Figure 11-5. Fetcher DMA Channel Fetch Order................................................................................................................. 11-4

Figure 11-6. CPU Background Print Data Preparation...................................................................................................... 11-12

Figure 11-7. MFC2000 Little-Endian Format ..................................................................................................................... 11-13

Figure 12-1. Vertical Printer Motor Control Block Diagram.................................................................................................. 12-1

Figure 12-2. Stepping Timing.............................................................................................................................................. 12-2

Figure 12-3. Scan Motor Control Diagram........................................................................................................................... 12-5

Figure 12-4. Stepping Timing.............................................................................................................................................. 12-7

Figure 12-5: Current Control Diagram................................................................................................................................. 12-9

Figure 14-1. Data Flow for Compression/Decompression................................................................................................... 14-1

Figure 14-2. Compressor/Decompressor FIFO Structure.................................................................................................... 14-2

Figure 15-1. SASIF Block Diagram......................................................................................................................................15-2

Figure 15-2. SASSCLK Timing Diagram............................................................................................................................15-12

Figure 15-3. Synchronous Mode Timing............................................................................................................................ 15-13

Figure 15-4. Asynchronous Transmitter Timing................................................................................................................. 15-14

Figure 17-1. Parallel Port Interface Controller Block Diagram............................................................................................. 17-3

Figure 17-2. Compatibility Mode Timing Diagram.............................................................................................................. 17-16

Figure 17-3. Nibble Mode Data Transfer Cycle ................................................................................................................. 17-17

Figure 17-4. BYTE Mode Data Transfer Cycle.................................................................................................................. 17-18

Figure 17-5. ECP Mode Timing Diagram........................................................................................................................... 17-19

Figure 17-6. Reverse ECP Transfer Timing....................................................................................................................... 17-20

Figure 17-7. Error Cycle Timing Diagram.......................................................................................................................... 17-21

Figure 18-1. RTC Block Diagram.........................................................................................................................................18-1

Figure 19-1. SSIF Block Diagram........................................................................................................................................ 19-1

Figure 19-2. SSCLK1 Diagram............................................................................................................................................ 19-3

Figure 19-3. SSCLK2 Diagram............................................................................................................................................ 19-6

Figure 19-4. Timing Diagram.................................................................................................... ........................................... 19-8

Figure 20-1. Bell/Ringer Timing........................................................................................................................................... 20-1

Figure 20-2. Bell/Ringer Block Diagram .............................................................................................................................. 20-2

Figure 20-3. Bell/Ringer Generator Waveform .................................................................................................................... 20-3

Figure 20-4. Tone Generator Frequency Change................................................................................................................ 20-6

viii

Conexant

100723A

Figure 22-1: CPC Signal...................................................................................................................................................... 22-1

Figure 22-2. CPC Operation Flowchart............................................................................................................................... 22-2

Figure 22-3: CPC Operation (with CPCThreshold = 4)........................................................................................................ 22-3

Figure 22-4: CPC Block Diagram........................................................................................................................................ 22-4

Figure 23-1. System Configuration One .............................................................................................................................. 23-1

Figure 23-2. System Configuration Two .............................................................................................................................. 23-2

Figure 23-3. System Configuration Three............................................................................................................................ 23-2

Figure 24-1. The ARM Bus System Block Diagram............................................................................................................. 24-2

Figure 24-2. SDRAM Setup and Hold Timing.................................................................................................................... 24-29

Figure 24-3. SDRAM Read or Write Timing.......................................................................................................................24-30

Figure 24-4. SDRAM Mode Timing....................................................................................................................................24-30

Figure 24-5. SDRAM Refresh Timing................................................................................................................................ 24-30

Figure 24-6. FPDRAM Timing (Read or Write).................................................................................................................. 24-31

Figure 24-7. FPDRAM Timing (Refresh)............................................................................................................................24-33

100723A

Conexant

ix

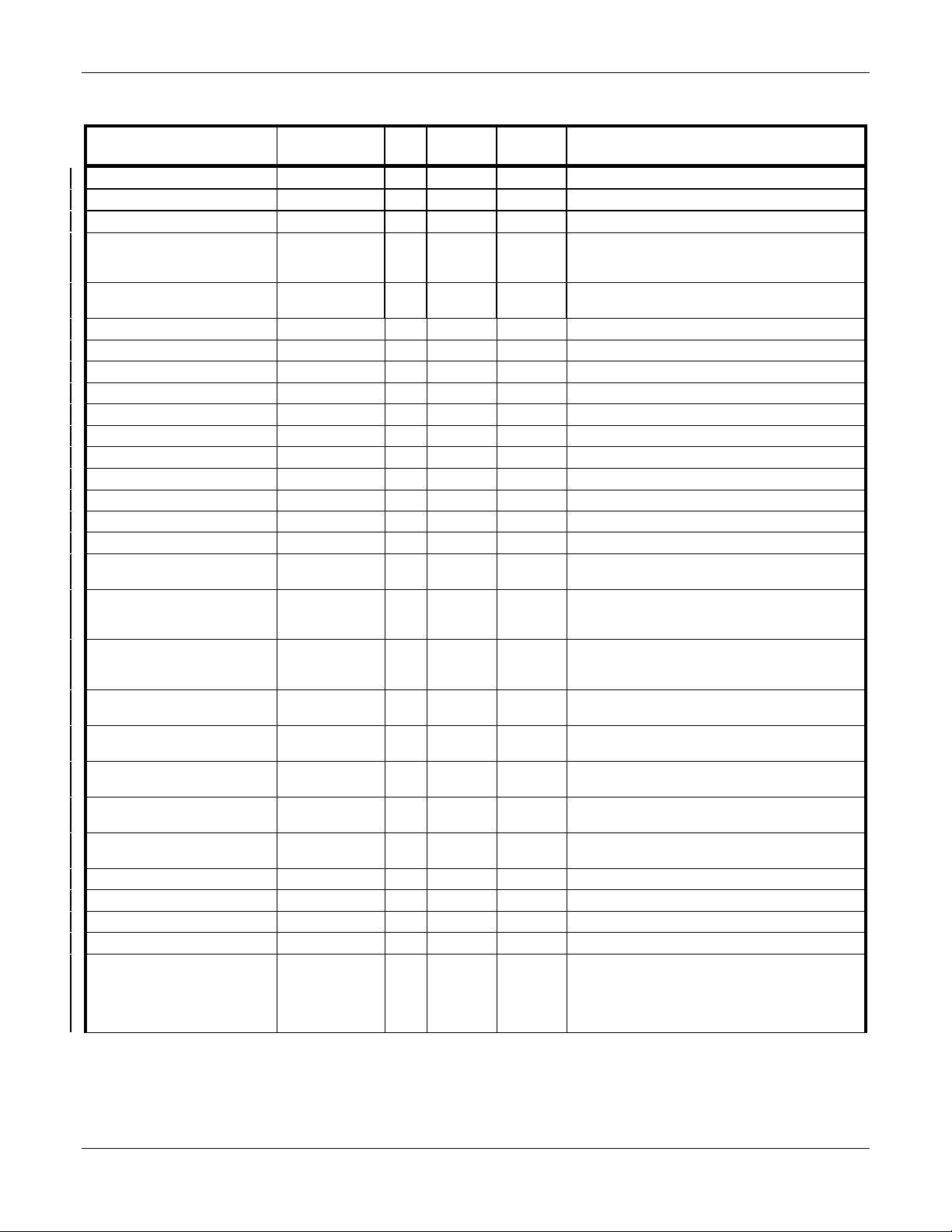

Tables

Table 1-1. Reference Documentation.................................................................................................................................... 1-5

Table 2-1. MFC2000 Device Family ...................................................................................................................................... 2-1

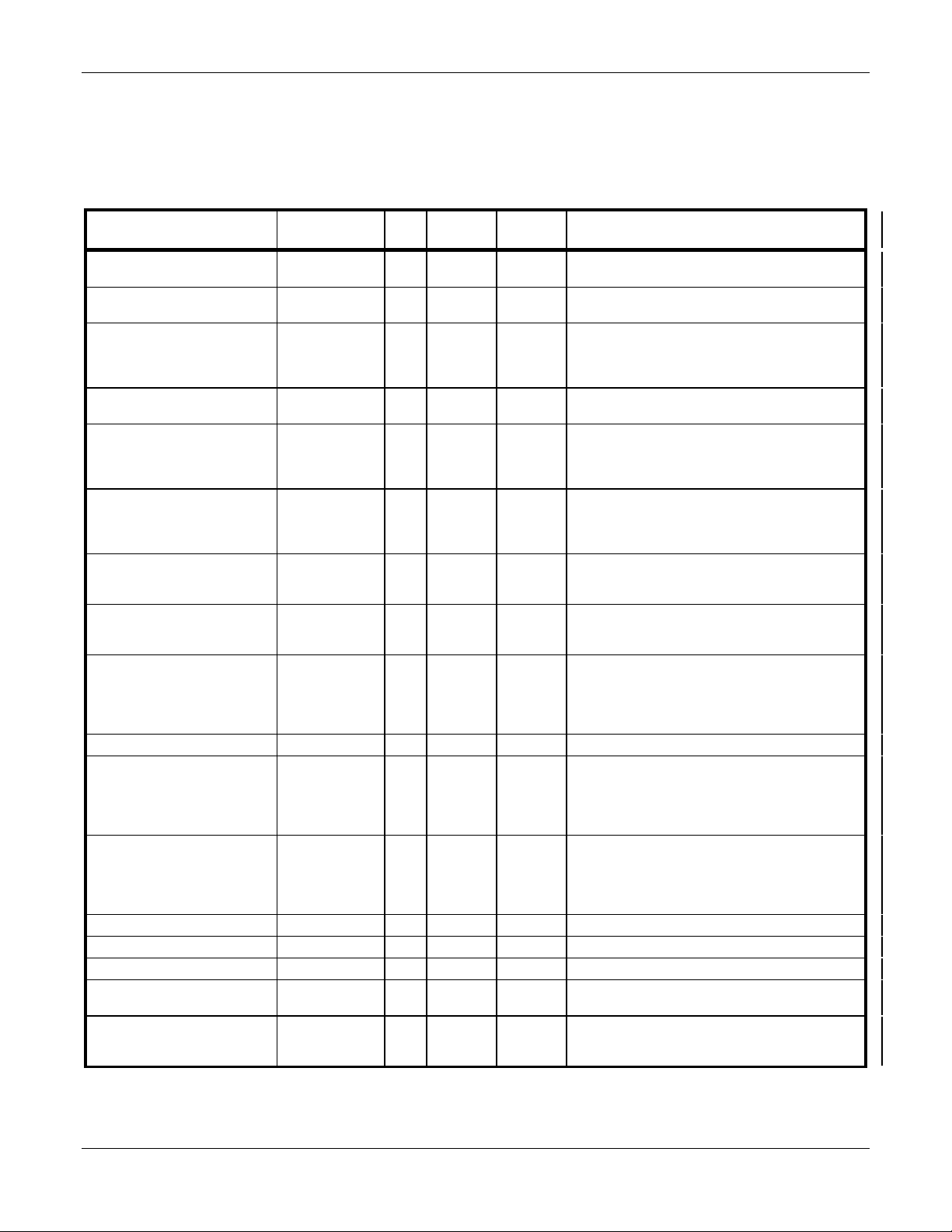

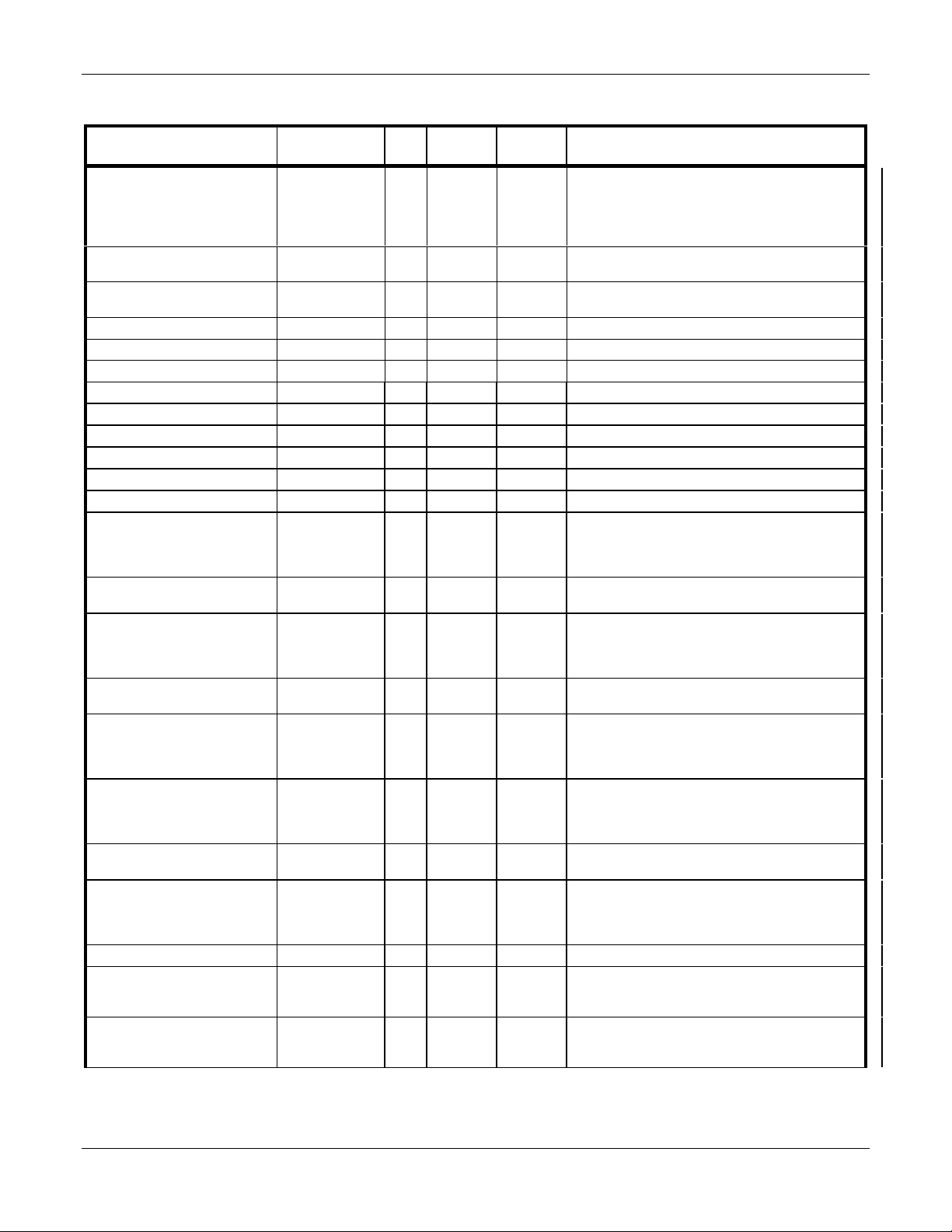

Table 3-1. Pin Description (1 of 6)......................................................................................................................................... 3-1

Table 3-2. Maximum Ratings................................................................................................................................................. 3-7

Table 3-3. Digital Input Characteristics.................................................................................................................................. 3-8

Table 3-4. Output Characteristics.......................................................................................................................................... 3-8

Table 3-5. Power Supply Requirements................................................................................................................................3-9

Table 3-6. Battery Power Supply Current Requirements........................................................................... ............................ 3-9

Table 4-1. Fixed-Location and Size Chip Selects.................................................................................................................. 4-4

Table 4-2. Operation Register Map (1 of 9)...........................................................................................................................4-8

Table 4-3. Setup Registers (1 of 2)...................................................................................................................................... 4-17

Table 4-4. Cache Tag Data Format (for Test Mode Read/Write Operation)........................................................................ 4-20

Table 4-5. Access Modes for Reading ROM ....................................................................................................................... 4-27

Table 4-6. Read Operation (Internal Peripheral Gets Data From Memory) ......................................................................... 4-29

Table 4-7. Write Operation (Internal Peripheral Puts Data Into Memory)............................................................................ 4-29

Table 4-8. Read/Write with Wait States Timing Parameters................................................................................................ 4-45

Table 4-9. MFC2000 Interrupt and Reset Signals ............................................................................................................... 4-46

Table 4-10. Programmable Resolution of Timer1 and Timer2............................................................................................. 4-53

Table 4-11. DRAM Wait State Configurations ..................................................................................................................... 4-55

Table 4-12. Address MultiplexingPart 1 ........................................................................................................................... 4-57

Table 4-13. Address MultiplexingPart 2 ........................................................................................................................... 4-57

Table 4-14. DRAM Row/Column Configuration................................................................................................................... 4-58

Table 4-15. DRAM Timing Parameters................................................................................................................................4-71

Table 4-16. Feature Matrix..................................................................................................................................................4-77

Table 4-17. DMA Channel Functions and Characteristics................................................................................................... 4-78

Table 4-18 DMA Channel 3 Control Bit Sssignment............................................................................................................ 4-79

Table 6-1. Operation Mode Frequencies............................................................................................................................... 6-1

Table 7-1. Register setup for Rohm–IA3008–ZE22............................................................................................................. 7-27

Table 7-2. Register setup for Dyna–DL507–07UAH............................................................................................................ 7-29

Table 7-3. Register setup for Mitsubishi-GT3R216..............................................................................................................7-31

Table 7-4. Register Setup for Toshiba–CIPS218MC300..................................................................................................... 7-33

Table 7-5. Register Setup for NEC – µPD3724...................................................................................................................7-35

Table 7-6. Register setup for NEC – µPD3794.................................................................................................................... 7-37

Table 7-7. Register Setup for SONY – ILX516K.................................................................................................................. 7-39

Table 8-1. Untitled Table.......................................................................................................................................................8-2

Table 8-2. Untitled Table.......................................................................................................................................................8-2

Table 8-3. Offset Adjustment on DAC ................................................................................................................................... 8-2

Table 8-4. Programmable Gain Amplifier (PGA).................................................................................................................... 8-3

Table 8-5. Pipelined ADC (PADC)......................................................................................................................................... 8-4

x

Conexant

100723A

Table 8-6. PADC Timing Diagram......................................................................................................................................... 8-4

Table 8-7. TADC Block Diagram........................................................................................................................................... 8-5

Table 9-1. Untitled Table.......................................................................................................................................................9-2

Table 9-2: Procedure to determine Pixels to remove........................................................................................................... 9-17

Table 9-3: Resolution Conversion Examples....................................................................................................................... 9-17

Table 12-1. Full Step/Single Phase Excitation..................................................................................................................... 12-3

Table 12-2. Full Step/Two Phase Excitation........................................................................................................................ 12-3

Table 12-3. Half-Step Excitation.......................................................................................................................................... 12-3

Table 12-4. Full Step/Single Phase Excitation..................................................................................................................... 12-7

Table 12-5. Full Step/Two Phase Excitation........................................................................................................................ 12-7

Table 12-6. Half-Step Excitation.......................................................................................................................................... 12-8

Table 18-1. RTC Crystal Specifications for 32.768 kHz....................................................................................................... 18-4

Table 20-1. Bell/Ringer Setting............................................................................................................................................ 20-2

Table 23-1. SSD Registers .................................................................................................................................................. 23-4

Table 23-2. P80 CORE Registers........................................................................................................................................23-5

Table 24-1. Needs a title....................................................................................................................................................24-11

Table 24-2. DMA Channels: Functionality and Priorities ................................................................................................... 24-12

Table 24-3. DMA Parameters Scratch Pad Addresses...................................................................................................... 24-13

Table 24-4: Supported FPDRAM Chip Characteristics...................................................................................................... 24-23

Table 24-5: Supported SDRAM Chip Characteristics........................................................................................................ 24-23

Table 24-6. Untitled table...................................................................................................................................................24-25

Table 24-7. Untitled table...................................................................................................................................................24-26

Table 24-8. Untitled table...................................................................................................................................................24-26

Table 24-9. SDRAM Setup and Hold Timing..................................................................................................................... 24-29

Table 24-10. Timing Parameters for 16-bit SDRAM Read and Write................................................................................ 24-31

Table 24-11. Timing Parameters for 8-bit SDRAM Read and Write.................................................................................. 24-31

Table 24-12. 60ns Timing.................................................................................................................................................. 24-32

Table 24-13. 50ns Timing.................................................................................................................................................. 24-32

Table 24-14. FPDRAM Timing (Refresh)...........................................................................................................................24-33

100723A

Conexant

xi

This page is intentionally blank

xii

Conexant

100723A

Hardware Description MFC 2000 Multifunctional Peripheral Controller 2000

1. Introduction

1.1 Scope

This document defines and describes all hardware functions of the MFC2000 chip. The MFC2000 design is based

on the MFC1000 design with many minor modifications/enhancements. It has several new key functions to

accomplish the following:

•

Support a full color MFP

•

Enhance connectivity to the PC

•

Provide an internal Fax Modem

•

Connect to external Conexant video chips

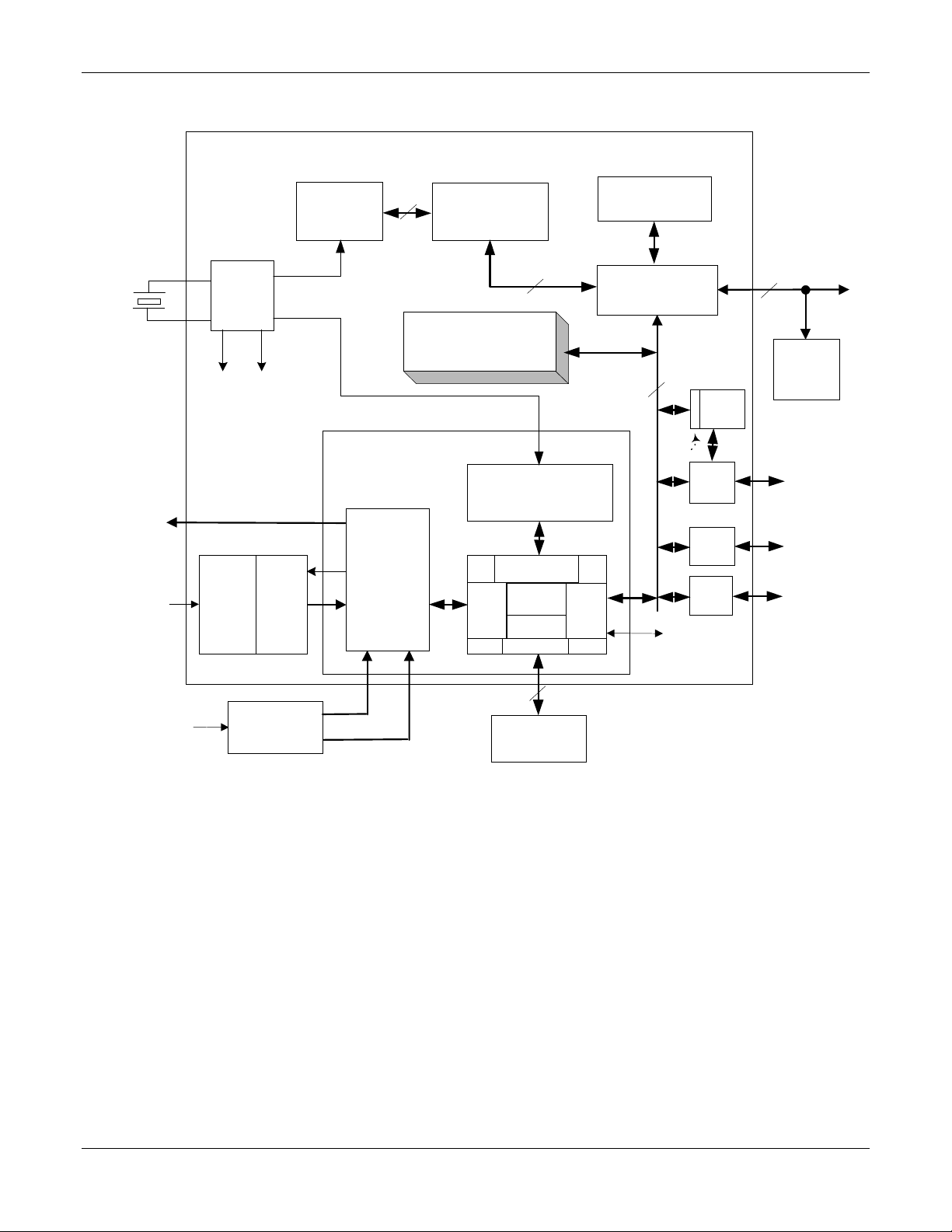

1.2 System Overview

The Conexant Multi-Functional Peripheral Controller 2000 (MFC2000) device set hardware, core code,

application code, and evaluation system comprise a full color Multi-Functional Peripheral (MFP) system−needing

only a power supply, scanner, printer mechanism, and paper path components to complete the machine. The

standard device set hardware includes Conexant’s MFC2000 chip, Conexant’s SmartDAA or IA chip, and a

Printer Interface chip. Optionally, a Conexant video chip with VIP interface can be used to support the video

capture function. If V.17 or V.34 faxing without voice is required, the internal V.17/V.34 Fax Modem in the

MFC2000 chip is used and the MFC2000 is connected to the external Conexant SmartDAA or IA chip. If the

voice/speech function is required, the external Voice Fax Modem device from Conexant will be needed. Any other

external interface device can be supported by using the external ARM for CPU and DMA accesses or by using

the internal serial interface. An MFP system-level block diagram using the MFC 2000 is illustrated in Figure 1-1.

Serial Interface (sync.)

USB Interface

or

PC

Color

Scanner

module

Data

DRAM/SRAM/Flash Memory

P1284 Interface

Scanner Interface

Program

ROM/Flash Memory

Operator

Panel

module

MFC2000

(Conexant)

External

ARM Bus

Prime power/

Battery power

hybrid and power

down circuit

SPI and VIP

Interface

Conexant

Proprietary

Interface

Printer IF

(Conexant)

Video Chip

(Conexant)

SmartDAA

(Conexant)

Video/Scan

SDRAM/DRAM

VDD

Battery

Color Inkjet

Printer

NTSC

/PAL

Video

Camera

Telephone

Line

(Color Faxing)

100723A

Figure 1-1. MFP System Diagram Using MFC2000

Conexant

1-1

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

1.2.1 Integrated Full Color MFP Controller (MFC2000)

The MFC2000 provides the majority of the electronics necessary to build a color scan and color inkjet printer

based MFP whose electronics are integrated into a one-chip solution including one CPU (ARM7TDMI) and two

DSPs (Countach Imaging DSP subsystem and P80 core).

Full printer and copier functionality is provided by the following:

•

1284 parallel port interface

•

USB serial port interface

•

Color scanner interface/controller

•

Countach Imaging DSP subsystem for video/scan/compression process

•

Flash memory controller

•

SDRAM/DRAM controllers

•

Resolution conversion logic

•

Inkjet data formatter

•

External inkjet printing

In addition, the MFC2000 performs facsimile control/monitoring, compression/decompression, and 33.6 Kbps Fax

Modem functions (P80 core). The MFC2000 interfaces with major MFP machine components like external

modems, SmartDAA, external Fax IA, motors, sensors, external video chip, and operator control panel. The

ARM7TDMI-embedded processor provides an external 48-MB direct memory access capability. An integrated

12-bit Pipeline ADC (PADC) and countach subsystem (DSP subsystem, combined with an advanced Conexant

proprietary color image processing algorithm, provides state of the art image processing performance on any type

of images, including text/half-tone and color images.

The full color MFP Engine provides the hardware and software necessary to develop a full-color Multifunctional

Peripheral including an architecture for color printing, color faxing, color scanning, video capturing, and color

copying. It also supports many of these operations concurrently.

1.2.1.1 Printing

The MFC2000 Controller supports color inkjet printing. Print speed throughput capabilities are inversely

proportional to resolution and also depend on the external printer interface. For host printing, the host sends the

image data with the print resolution; the MFC2000 performs no resolution conversion. If host printing and faxing

need to be performed for the same image, the printing image data must be sent to the MFP. The MFC2000

converts the printing image data to the faxing image data locally and then faxes it out. An external printer interface

chip is designed to support inkjet print mechanism/head subsystems. Different external printer interface chips can

be designed and used to support other inkjet mechanisms and heads according to customer requirements.

1.2.1.2 Faxing

Both host-based color faxing and standalone color faxing are supported in addition to monochrome faxing. Host-

based faxing can take place by using a Class One connection via the USB serial port or the P1284 parallel port.

For host faxing, the host sends the image data with the fax resolution; the MFC2000 performs no resolution

conversion. For standalone faxing, the resolution conversion is supported by the MFC2000. The standalone color

scan-to-fax function is supported using the advanced Conexant proprietary color image processing technology:

•

Shading correction

•

Gamma correction

•

Pixel-based dark-level correction

•

Color/monochrome image processing

•

Color conversion

•

JPEG

•

Multi-level resolution conversion.

1-2

Conexant

100723A

Hardware Description MFC 2000 Multifunctional Peripheral Controller 2000

1.2.1.3 Scanning

For the color scan-to-PC function, up to 8 bits of scan data per pixel can be sent to the host. JPEG compression

can be used to reduce the PC upload speed.

1.2.1.4 Copying

The MFC2000 and associated firmware supports several modes of copying including standard, fine, superfine,

and photo. Multiple copies of a single image can be made with a single pass. The standalone color/monochrome

copy function is supported by using MFC2000’s Inkjet print formatter, the external printer interface, and the

advanced Conexant proprietary color image processing system.

1.2.2 MFC2000 Evaluation System

The Conexant MFC2000 Evaluation System provides demonstration, prototype development, and evaluation

capabilities to full color MFP developers using the MFC2000 Engine device set. The MFC2000 Evaluation system

provides flexibility for visibility and access, i.e., plug-on board for the modem, sockets for programmable parts,

and connectors for an emulator (refer to Figure 1-2). Jumper options and test points are provided throughout the

MFC2000 evaluation Main Board. The MFC2000 Evaluation System is the most convenient environment for the

developer needing to experiment with the several interfaces encountered in the full color MFP, for example, color

printer functions.

1.2.3 New Function Highlights

•

PLL Clock Generation for several different clocks needed for ARM CPU, Countach Imaging DSP, Fax Modem

core, and USB Interface

•

4 KB 2-way Set Associative Inst ruction Cache

•

USB Interface (including USB Transceiver) to PC

•

Video/ Color Scan Controller (up to 600 dpi) (including programmable ADC sampling rate)

•

Countach Imaging DSP Subsystem for pixel-based dark level correction, shading correction, gamma

correction, video/color scan image processing, color science and JPEG

•

Countach Bus System which includes Countach Subsystem Interface, ARM Bus Interface, Video/Scan

Interface, Countach Bus Unit, Countach DMA Controller, and SDRAM Controller.

•

SmartDAA/IA Interface

•

P80 Core + ARM IPB interface logic (V.34 Fax Modem core)

•

Two Sync. Serial Interfaces

•

Color Scan IA which includes Color Scan analog Front End, 12-bit PA DC, Po wer -down Voltage Detection

Circuit, and TADC reference voltage.

•

SPI and VIP interface to the external Conexant video chip

100723A

Conexant

1-3

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

MFC2000

28.224

MHz

Mono and

Color CIS/

CCD

Control

Scanner In

PLL

48 MHz

for USB

Analog

Frontend

100 MHz or

28.224

MHz for

Modem

12-bit

PADC

ARM7TDMI

85.7 MHz

32

30 MHz,

37.5 MHz,

or 40 MHz

Cache Controller

and Memory (4KB)

All logic blocks on the

internal system bus from

MFC1000

Countach Bus System

Countach Subsystem

(for Video/Scan Image

Video/Scan

Controller

Video

/Scan

IF

32

Processing)

Countach

Subsystem IF

Countach

Bus Unit

CDMAC

SDRAMC

ARM

Bus

IF

DMA Controller

SIU

Internal

Peripheral

Bus

16

ARM

IPB IF

Smart

P1284

2 DMA channels

for the ARM Bus

System

P80

Core

DAA

IF

IF

USB

IF

External ARM

Bus

16

External

System

Memory

NTSC/

PAL

Signal

External

Conexant

Video Chip

SPI

VIP

Local (S)DRAM

16 or 8

External

Figure 1-2: MFC2000 Function Diagram

1-4

Conexant

100723A

Hardware Description MFC 2000 Multifunctional Peripheral Controller 2000

1.3 Reference Documentation

Table 1-1. Reference Documentation

Document

MFC2000 Data Sheet 100505

MFC2000 Firmware Architecture 100972

MFC2000 Hardware Description (this document) 100723

MFC2000 Programmer’s Reference Manual 100971

Number

100723A

Conexant

1-5

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

This page is intentionally blank

1-6

Conexant

100723A

Multifunctional Peripheral Controller 2000 MFC2000

2. MFC2000 Summary

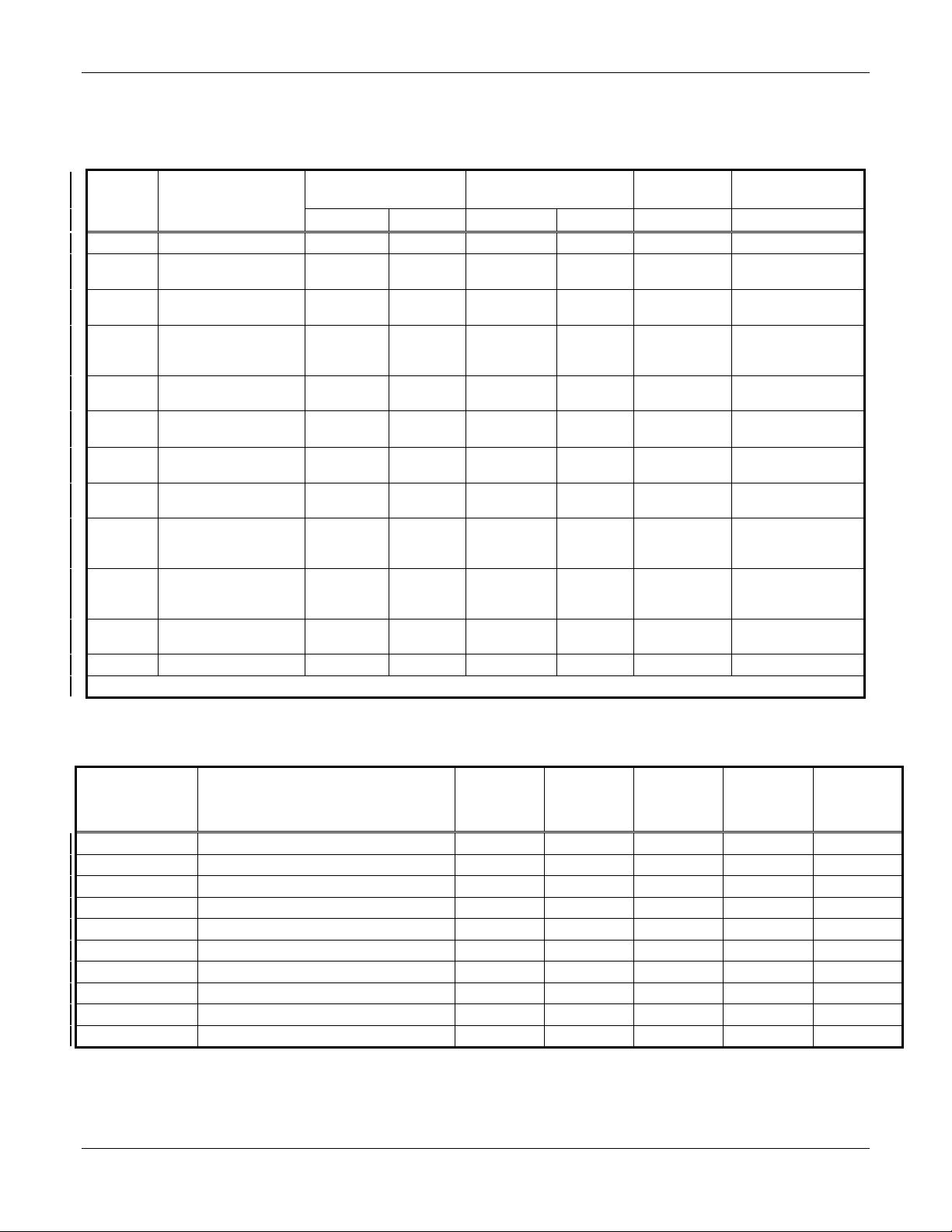

2.1 MFC2000 Device Family

The MFC2000 contains an internal 32-bit RISC Processor with 64-MB address space, the Countach Imaging DSP

(Conexant’s DSP) subsystem including embedded data and program memory, and dedicated circuitry optimized

for color scanning, color faxing, color copying, color printing, and multifunctional control and monitoring. The

device family with relevant features is described in Table 2-1.

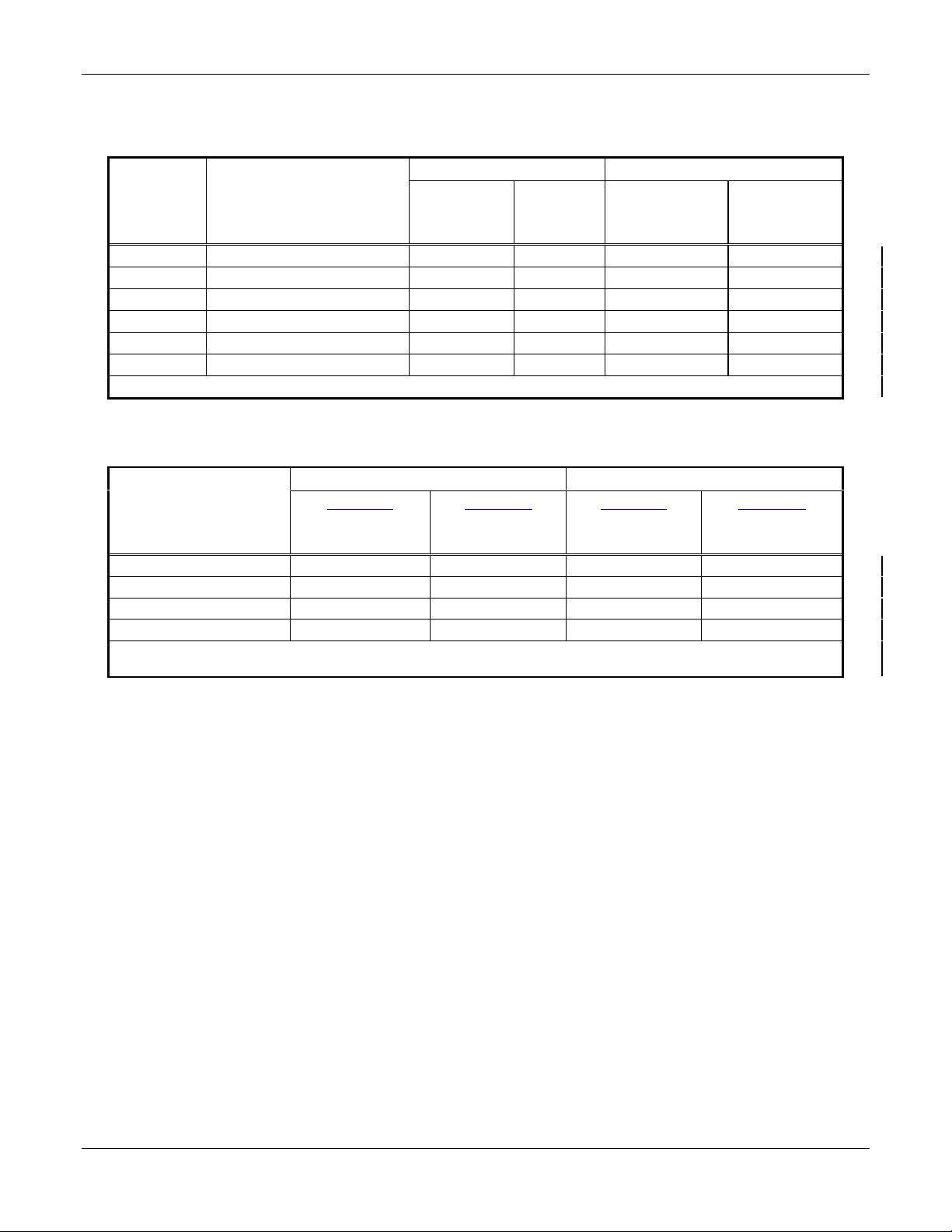

Table 2-1. MFC2000 Device Family

Device No. Product Code Data Modem

Function

CX0720X-11 BFH Yes Yes Yes

CX0720X-12 BDH Yes No Yes

CX0720X -13 BBH No Yes Yes

CX0720X -14 B9H No No Yes

CX0720X-15 B8H No No No

Voice Codec/Speaker

Phone Functions

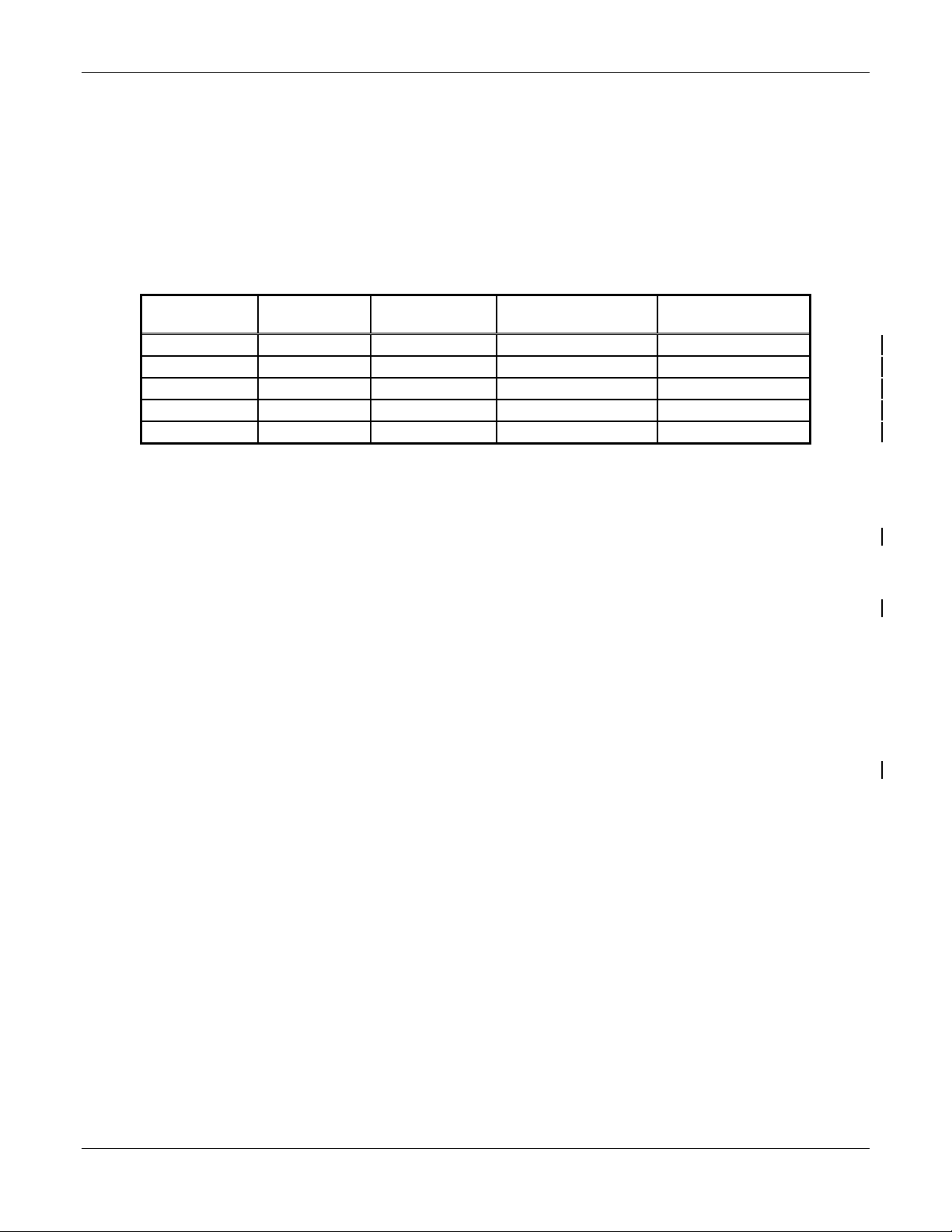

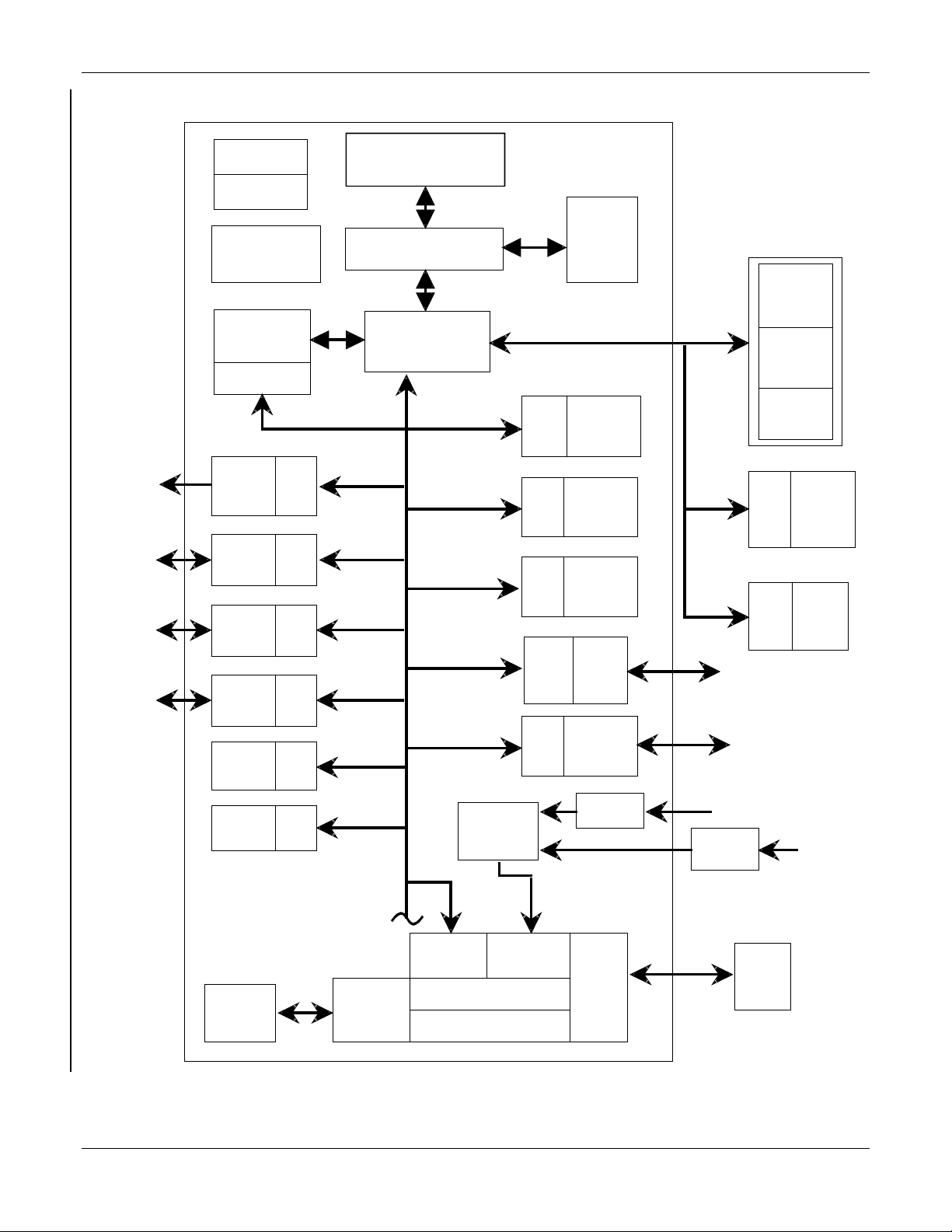

Smart DAA Support

2.2 MFC2000 System Block Diagram

The MFC2000 contains the ARM7TDMI RISC Processor (described separately in ARM7TDMI Manuals),

Countach Imaging DSP, Modem DSP, and specialized hardware needed for the Multifunctional machine control

and scanner and fax signal processing. The Countach Imaging DSP subsystem is on a separate data bus.

Therefore, the ARM system data bus can operate in parallel with the Countach Imaging DSP subsystem data bus

for most operations except the interaction time between two buses. The two-bus architecture is very important to

provide enough bandwidth for full color MFP products. Figure 2-1 shows the MFP2000’s two-bus architecture.

The ARM Bus System (ABS) has two mastersARM CPU and DMA Controller. They provide accesses to all

specialized hardware functions including the Countach Imaging DSP subsystem as a peripheral on the ARM Bus

System. ABS has several sections. The System Interface Unit (SIU) is the control center. The ARM CPU and

Cache Controller are on the Internal System Bus (ISB). The Cache Memory is on the Internal Cache Bus (ICB).

The DMA Controller is on the DMA Bus (DAB). All internal peripherals are on the Internal Peripheral Bus (IPB).

The SmartDAA/IA Interface and P80 core are on the IPB of the ARM Bus System. The ARM7TDMI runs at a

clock rate 40 MHz, 37.5 MHz, or 30 MHz. All external peripherals are on the ARM External Bus (AEB). There is a

separate bus system for the Countach Imaging DSP subsystem called Countach Bus System (CBS). There are

three sections, the Video/Scan Interface, the ARM Bus Interface, and the countach subsystem interface. The

external SDRAM/DRAM is on the Countac h Exter n al Bus (C EB).

100723A

Conexant

2-1

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

Motor

Drivers

PLL Clock

Generator

Timing

Control

Prime/Battery

Power and Reset

Control

DMA

Controller

IRQ/CPU

Access

Scan/Print

Motor

Controller

Sync/

Async

Serial Port

Sync

Serial

Panel IF

Serial

Operator

Panel IF

Watchdog

Timer

Countach

Subsystem

RTC

IRQ/

CPU

Access

IRQ/

CPU

Access

CPU

Access

CPU

Access

IRQ/

CPU

Access

CPU

Access

Cache Memory

Controller

16-bit

DAB

Bus IF

(including DRAM/

Flash Controller)

Countach

Subsystem

Interface

CPU Core

(ARM7TDMI)

32-bit

ISB

32-bit

ISB

16-bit

IPB

ARM Bus

Interface

Countach Bus Unit

Countach DMA Controller

Video/Scan

Controller

Video/Scan

Interface

ICB

CPU

Access

DMA/

CPU

Access

DMA/

CPU

Access

DMA/

IRQ/

CPU

Access

CPU

Access

1Kx32bit

(2Kx16bit)

Cache

Memory

Interrupt

Controller

Bit Rotation

Bi-level

Resolution

Conversion

P1284

or

USB

Host IF

GPIOs

and

PWM

Channels

Video/Color

Scan IA

DRAM/

SDRAM

Controller

16-bit

and/or

8-bit

AEB

Color Scanner

Conexant

Video Chip

16-bit

and/or

8-bit

CEB

Host

DRAM/

SDRAM

ROM/Flash

SRAM/Flash

DRAM/Flash

Inkjet

Engine

DMA/

(including

CPU

Inkjet

Access

Print ASIC)

IRQ/

CPU

Access

NTSC

/PAL Video

Fax

Modem

(Optional)

2-2

Figure 2-1.

MFC2000 Organization

Conexant

100723A

Multifunctional Peripheral Controller 2000 MFC2000

3. Hardware Interface

3.1 Pin Description

Table 3-1. Pin Description (1 of 6)

Pin Name Pin No. I/O

PRTIRQn U14 I HU5VT - (Hysteresis, Pull up) Interrupt from the external

AUXCLK K20 O - 2XT3V Auxiliary clock output for using as the master clock

A[11:0]/A[23:12] A20,B20,B19,B

ALE C16 O - 2XT5VT

AE[2]/GPO[14]/SSTXD2/

ROM_CONFIG[0]

AO[2]/GPO[15]/SSSTAT2/RO

M_CONFIG[1]

AE[3]/GPO[16]/

CLK_CONFIG[0]

AO[3]/GPO[17]/

CLK_CONFIG[1]

D[15:0]

RDn D12 O - 3XT5VT Read strobe (active low)

WREn/DOEEn B9 O - 4XT5VT Write strobe for the lower byte (active low) or

WROn/DOEOn C9 O - 4XT5VT Write strobe for the higher byte (active low) or

ROMCSn D10 O - 2XT5VT ROM chip select (active low)

CS[1]n A9 O - 2XT5VT I/O chip select (active low).

CS[0]n G18 O 3V 2XT3V SRAM chip select (active low) (VRTC powered)

RASn[1:0] F19,F18 O - 2XT3V DRAM row Address select for bank 0 and 1(active

CASOn[1:0] E17,F20 O - 2XT3V

18,B17,C20,C1

9,C18,C17,D20,

D19,D18

A19 I/O D5VT 2XT5VT (Pull down) Address bit for external ROM mux in

A18 I/O D5VT 2XT5VT (Pull down) Address bit for external ROM mux in

A17 I/O D5VT 2XT5VT (Pull down) Address bit for external ROM mux in

D16 I/O D5VT 2XT5VT (Pull down) Address bit for external ROM mux in

A12,B12,C12,A

13,B13,C13,D1

3,A14,B14,C14,

A15,B15,C15,D

15,A16,B16

I/O 5VT 3XT5VT Address bus (12-bit), A[23:12] and A[11:0] are

I/O 5VT 2XT5VT Data bus (16-bit)

Input

Type

Output

Type

printing ASIC (active low)

for external devices

muxed out through same pins.

Address Latch output signal for latching A[23:12]

externally

the ROM interleave access mode or GPO[14] or

TX data output for SSIF2 (ROM_CONFIG[0] input

during the reset period)

the ROM interleave access mode or GPO[15] or

Status input for SSIF2 (ROM_CONFIG[1] input

during the reset period)

the ROM interleave access mode or GPO[16]

(CLK_CONFIG[0] input during the reset period)

the ROM interleave access mode or GPO[17]

(CLK_CONFIG[1] input during the reset period)

DRAM output enables selects used for noninterleave mode and interleave modes. DOEEn is

used for reading the even address bank (active

low).

DRAM output enables selects used for noninterleave mode and interleave modes. DOEOn is

used for reading the odd address bank (active

low).

low) (VDRAM powered)

DRAM column odd address selects used for non-

interleave mode and interleave mode. (VDRAM

powered)

Pin Description

100723A

Conexant

3-1

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

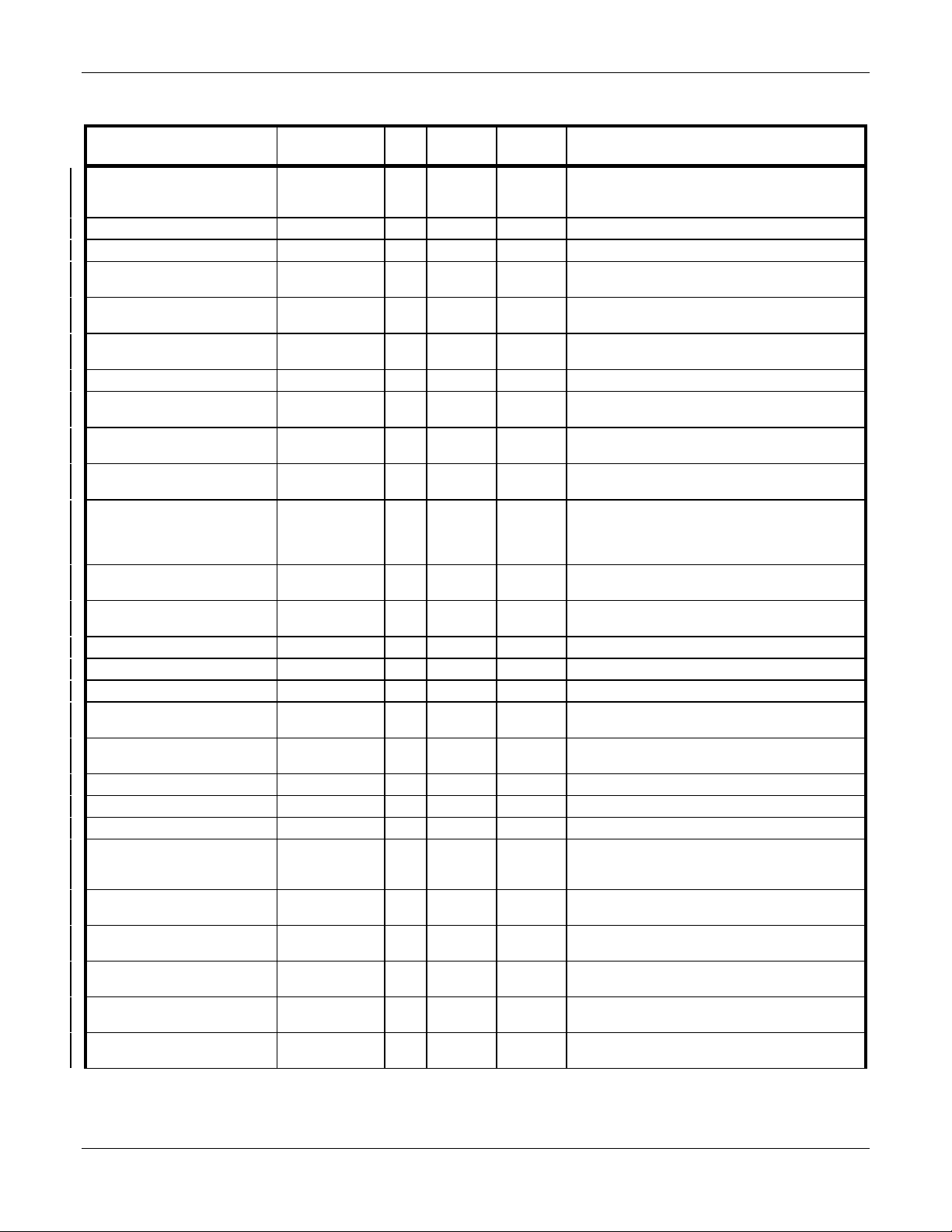

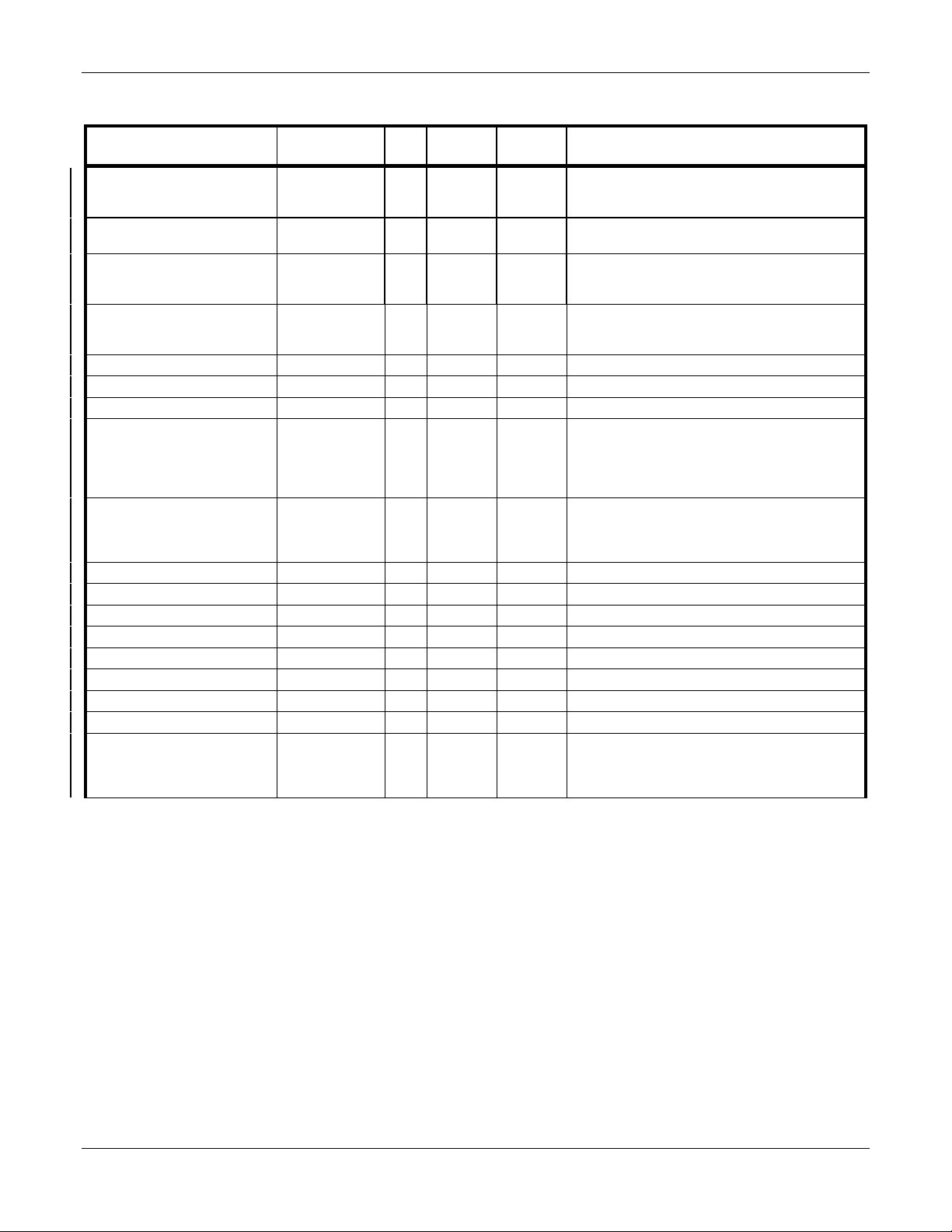

Table 3-1. Pin Description (2 of 6)

Pin Name Pin No. I/O

CASEn[1:0] E20,E19 O - 2XT3V DRAM column even address selects used for non-

DWRn D17 O - 2XT3V DRAM write. (VDRAM powered)

DMAACK2 K19 O - 1XT5VT External DMA acknowledge output (channel 2).

DMAREQ2 F4 I H5VT - (Hysteresis) External DMA request input (channel

FCS0n/PWM[1] D9 O - 2XT5VT Flash memory chip select 0 or PWM channel 1

FCS1n/PWM[2] A8 O - 2XT5VT Flash memory chip select 1 or PWM channel 2

RESETn K18 I/O HU5VT 2XT5VT (Hysteresis, Pull up) MFC2000 Reset input/output

XIN G20 I OSC - Crystal oscillator input pin for RTC. (VRTC

XOUT H20 O - OSC Crystal oscillator output pin for RTC. (VRTC

PWRDWNn H18 I H3V -

WPROTn H19 O - 1XT3V

BATRSTn G17 I H3V -

EXT_PWRDWN_SELn G19 I H3V - (Hysteresis) External power-down detector select

SC_START[0] V8 O - 1XT3V Scanner shift gate control 0

SC_CLK1/SC_CLK2A U9 O - 1XT3V Scanner clock.

SC_LEDCTRL[0] U7 O - 1XT3V Scanner LED control 0

SC_LEDCTRL[1]/

SC_START[1]

SC_LEDCTRL[2]/

SC_START[2]

SSTXD1 J19 O - 2XT3V TX data for SSIF1

SSRXD1 H17 I HU5VT - (Hysteresis, Pull up) RX data for SSIF1

SSCLK1 J20 I/O H5VT 2XT5VT (Hysteresis) Clock input or output f or SSIF 1

GPIO[0]/FWRn/CLAMP J4 I/O H5VT 2XT5VT (Hysteresis) GPIO[0] or flash write enable signal

GPIO[1]/FRDn M3 I/O H5VT 2XT5VT (Hysteresis) GPIO[1] or flash read enabl e signal for

GPIO[2]/DMAREQ1/ SSCLK2 V1 I/O H5VT 2XT5VT (Hysteresis) GPIO[2] or DMA channel 1 request

GPIO[3]/DMAAC K1/ SSRXD2 U4 I/O H5VT 2XT5VT (Hysteresis) GPIO[3] or DMA channel 1

GPIO[4]/CS[2]n U3 I/O H5VT 2XT5VT

GPIO[5]/CS[3]n/PWM[3] U2 I/O H5VT 2XT5VT (Hysteresis) G PIO[5]or I/O chip se le c t [3 ] (active

Y8 O - 1XT3V

W8 O - 1XT3V Scanner LED control 2 or Scanner shift gate

Input

Type

Output

Type

interleave mode and interleave mode. (VDRAM

powered)

2).

output

output signal.

powered)

powered)

(Hysteresis) Indicate the loss of prime power

(result in SYSIRQ). (VRTC powered)

Write Protect during loss of VDD power.

functional logic is powered by RTC battery power,

but the output drive is powered by DRAM battery

power. (VRTC powered)

(Hysteresis) Battery power reset input. (VRTC

powered)

input (active low)(VRTC powered)

Scanner LED control 1 or Scanner shift gate

control 1

control 2

for NAND-type flash memory or scanner clamp

control output

NAND-type flash memory.

input or clock input/output for SSIF2.

acknowledge or RX data for SSIF2

(Hysteresis) GPIO[4] or I/O chip select [2] (active

low)

low) or PWM channel 3 output

Pin Description

Note

: The

3-2

Conexant

100723A

Hardware Description MFC 2000 Multifunctional Peripheral Controller 2000

Table 3-1. Pin Description (3 of 6)

Pin Name Pin No. I/O

GPIO[6]/CS[4]n/ EADC_D[3] U1 I/O H5VT 2XT5VT (Hysteresis) GPIO[6] or I/O chip select [4] (active

GPIO[7]/CS[5]n/ T4 I/O H5VT 2XT5VT (Hysteresis) GPIO[7] or I/O chip select [5] (active

GPIO[8]/IRQ[11]/

SSSTAT1/SC_CLK1/2B

GPIO[9]/IRQ[13]/ EADC_D[2] T2 I/O H5VT 2XT5VT (Hysteresis) GPIO[9] or external interrupt [13] or

GPIO[10]/RING_DETECT/PW

M[4]

GPIO[11]/CPCIN/PWM[0]/ALT

TONE

GPIO[12]/SASCLK/

SMPWRCTRL

GPIO[13]/SASTXD/

PMPWRCTRL

GPIO[14]/SASRXD/ RINGER R1 I/O H5VT 2XT5VT

GPIO[15]/IRQ[16]/

SC_CLK1/2C

GPIO[16]/M_TXSIN P3 I/O H5VT 2XT5VT (Hysteresis) GPIO[16] or internal modem

GPIO[17]/M_CLKIN P2 I/O H5VT 2XT5VT (Hyst eresis) GPI O[17] or internal modem

GPIO[18]/M_RXOUT P1 I/O H5VT 2XT5VT (Hysteresis) GPIO[18] or internal modem

GPIO[19]/M_SCK/MIRQn N4 I/O H5VT 2XT5VT (Hys t eresis) GPI O[19] or internal modem or

GPIO[20]/M_STROBE/ MCSn N3 I/O H5VT 2XT5VT

GPIO[21]/M_CNTRL_SIN N2 I/O H5VT 2XT5VT (Hysteresis) GPIO[21] or internal modem

GPIO[22]/EADC_Sample N1 I/O H5VT 2XT5VT (Hysteresis) GPIO[22] or external ADC sample

SM[3:0]/

GPO[7:4]

PM[0]/SPI_SID/

EADC_D[0]/GPO[0]

PM[1]/SPI_SIC/

EADC_D[1]/GPO[1]

PM[2]/SMI0/GPO[2] Y9 O - 1XT3V Print motor control [2] output or GPO[2] output or

PM[3]/SMI1/GPO[3] Y12 O - 2XT3V Print motor control [3] output or GPO[3] output or

TONE V9 I/O H5VT 1XT5VT (Hysteresis) Tone output signal.

PIODIR C1 O - 2XT3V PIOD[7:0] is output when PIODIR is high and

STROBEn A2 I H5VT - (Hyst eresis ) I nput from PC (act iv e l ow)

AUTOFDn G3 I H5VT - (Hy steresis) Input from PC (active low)

SLCTINn G2 I H5VT - (Hysteresis) I nput from PC (activ e l ow)

INITn G1 I H5VT - (Hysteresis) I nput from PC (activ e l ow)

BUSY A1 O - 2XT3V PIO Returned status to PC

ACKn D3 O - 2XT3V PIO Returned status to PC (active low)

T3 I/O H5VT 2XT5VT

T1 I/O H5VT 2XT5VT (Hysteresis) GPIO[10] or ring detection input or

R4 I/O H5VT 2XT5VT

R3 I/O H5VT 2XT5VT (Hysteresis) GPIO[12] or clock input/output for

R2 I/O H5VT 2XT5VT (Hysteresis) GPIO[13] or TX data output for SASIF

P4 I/O H5VT 2XT5VT (Hysteresis) GPIO[15] or external interrupt [ 16] or

V7,W7,Y7,U6 O - 1XT3V Scan motor control [3:0] pins or GPO[7:4] pins.

U8 I/O 5VT 1XT5VT Print motor control [0] output or GPO[0] output or

W9 I/O 5VT 1XT5VT

Input

Type

Output

Type

low) or external ADC data [3] input

low).

(Hysteresis) GPIO[8] or external interrupt [11] or

status input for SSIF1 or scan clock output

external ADC data [2] input

PWM channel 4 output

(Hysteresis) GPIO[11] or calling party control input

or ALTTONE output

SASIF or Scan Motor Power Control output

or Print Motor Power Control output

(Hysteresis) GPIO[14] or RX data input for SASIF

or ringer output

scan clock output

external modem interrupt input

(Hysteresis) GPIO[20] or internal modem or

external modem chip select

signal output

data output for SPI or external ADC data [0] input

Print motor control [1] output or GPO[1] output or

clock output for SPI or external ADC data [1] input

scan motor current control 0.

scan motor current control 1.

PIOD[7:0] is input when PIODIR is low.

Pin Description

100723A

Conexant

3-3

MFC2000 Multifunctional Peripheral Controller 2000 Hardware Description

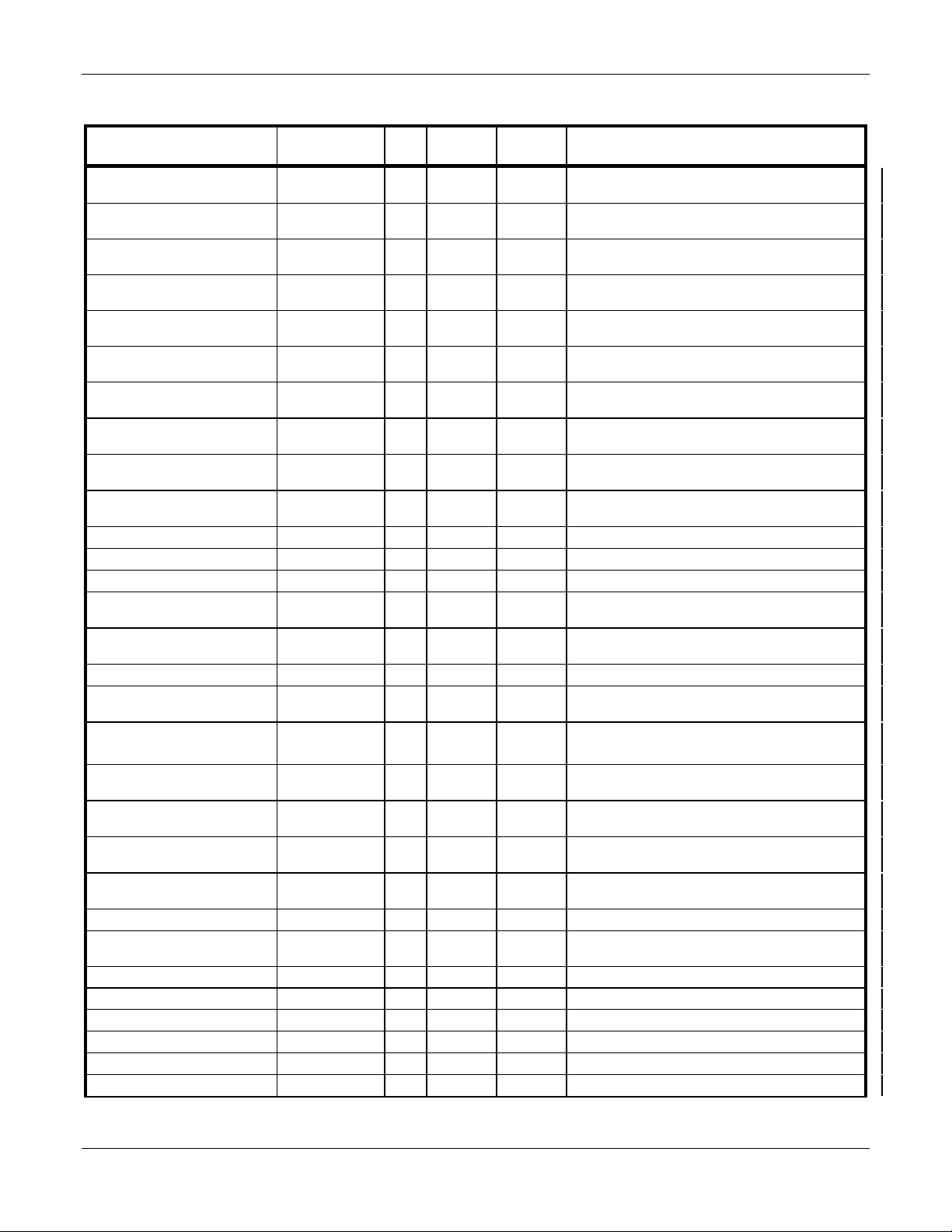

Table 3-1. Pin Description (4 of 6)

Pin Name Pin No. I/O

SLCTOUT C3 O - 2XT3V PIO Returned status to PC

PE B2 O - 2XT3V PIO Returned status to PC

FAULTn B1 O - 2XT3V PIO Returned status to PC (active low)

PIOD[7:0] D2,D1,C2,H4,H