Page 1

NetPerformer® SDM-9600 with SDM-9606 Blades

Hardware Installation Guide

Page 2

COPYRIGHTS AND DISCLAIMERS

Published Date: October 2013

Document # 1659 current revision tracker

This publication contains information proprietary and confidential to Memotec Inc. Any reproduction,

disclosure or unauthorized use of this publication is expressly prohibited except as Memotec Inc. may

otherwise authorize in writing.

Memotec Inc. reserves the right to make changes without notice in product or component design as warranted

by evolution in user needs or progress in engineering or manufacturing technology. Changes which affect the

operation of the unit will be documented in the next revision of the manual.

We have made every effort to ensure the accuracy of the information presented in our documentation.

However, Memotec assumes no responsibility for the accuracy of the information published. Product

documentation is subject to change without notice. Changes, if any, will be incorporated in new editions of

these documents. Memotec may make improvements or changes in the products or programs described within

the documents at any time without notice. Mention of products or services not manufactured or sold by

Memotec is for informational purposes only and constitutes neither an endorsement nor a recommendation for

such products or services.

Memotec Inc. is a wholly owned subsidiary of Comtech EF Data Corp., and its parent company Comtech

Telecommunications Corp (NASDAQ: CMTL).

AccessView, CXTool, CX-U Series, CX-UA Series, AbisXpress, NetPerformer, AccessGate, ACTView,

SDM-8400, and the SDM-9000 series of products are either registered trademarks or trademarks of Memotec

Inc.in Canada, the United States of America, and in other countries.

artf3363

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

Whatsup and WhatsupGold are registered trademarks of Ipswitch Inc. in the United States and other countries.

Any other trademarks are the property of their respective companies.

7755 Henri Bourassa Blvd. West

Montreal, Quebec

Canada H4S 1P7

Page 3

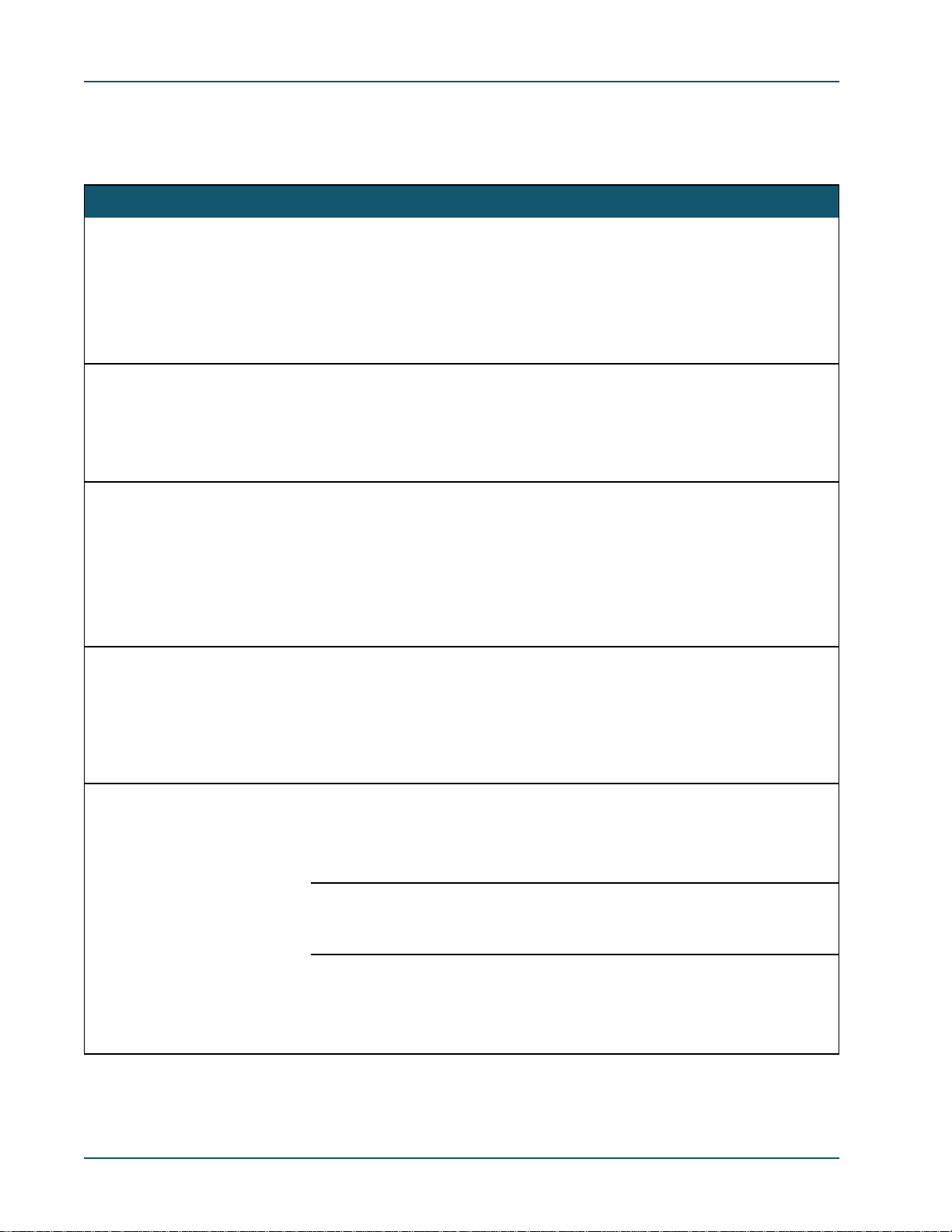

Contents

Chapter 1: Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1. 1 About this Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1. 2 Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.1 Instructions to the Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1. 3 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.1 SDM-9600 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.2 SDM-9606 Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.3 NetPerformer Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.4 Changes to Console Operations . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1. 4 Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.1 NetPerformer Document Set . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.2 Request for Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.4.3 Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1. 5 Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.5.1 Providing Product Numbers to Technical Support . . . . . . . . . . . 1-8

1.5.2 Product Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.5.3 Product Work Order Number . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.5.4 Checking the Contents of Your Product Package . . . . . . . . . . . 1-9

1.5.5 Returning an SDM-9600 Chassis or SDM-9606 Blade . . . . . . 1-10

1. 6 Sales Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Chapter 2: Compliance Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. 1 Regulatory – Compliance and Agency Approval. . . . . . . . . . . . . . . . . . . . 2-2

2. 2 Compliance and Regulatory Statements. . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.1 EU Directive 1999/5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2.2 Marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3 Intent of Use and Network Compatibility . . . . . . . . . . . . . . . . . . 2-6

2.2.4 EN55022 and CISPR22 Warning. . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.5 FERRITES (EMI Filters). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.6 FCC Part 15 Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.7 Industry Canada Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.2.8 Notice d'Industrie Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2. 3 Environmental Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.1 Waste Electrical and Electronic Equipment – WEEE. . . . . . . . . 2-8

2.3.2 Restriction of Hazardous Substances - RoHS . . . . . . . . . . . . . . 2-9

Memotec Inc.

Page 4

2.3.3 Compliance to China RoHS. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2. 4 Safety Warnings and Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2. 5 Making Changes or Modifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Chapter 3: Unpacking the SDM-9600 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3. 1 Selecting a Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.1 Rack Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.2 Distance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.1.3 Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3. 2 Preparing the Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.1 What You Will Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Chapter 4: Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4. 1 About the Hardware Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4. 2 Installing the SDM-9600 Chassis in a Rack . . . . . . . . . . . . . . . . . . . . . . . 4-3

4. 3 Installing or Upgrading the DSP Modules . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.1 Location of DSP Socket on the SDM-9606 Blade . . . . . . . . . . . 4-4

4.3.2 Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4. 4 Hardware Strapping for E1 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4.1 Strapping for E1-75 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4. 5 Installing a Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4. 6 Removing a Blade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

4. 7 Installing the Filler Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

4. 8 Powering Up the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

4.8.1 Connecting to the Power Source. . . . . . . . . . . . . . . . . . . . . . . 4-15

4.8.2 System Status on Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

4. 9 Connecting the Console Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

4.9.1 Important Console and Modem Settings for Startup . . . . . . . . 4-18

4.9.2 Activating the Console Connection . . . . . . . . . . . . . . . . . . . . . 4-19

4.9.3 Concerning HyperTerminal Connections. . . . . . . . . . . . . . . . . 4-20

4. 10 Installing the Licensed Software Options . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4.10.1 Software License Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

4. 11 Connecting the LAN Hub. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

4. 12 Cleaning the Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Chapter 5: Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Memotec Inc.

Page 5

5. 1 SDM-9600 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. 2 SDM-9606 Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. 3 Optional Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5. 4 Base Unit Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.4.1 Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.2 Chassis System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.3 Power Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.4.4 Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.4.5 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5. 5 Blades for SDM-9600 Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5.1 SDM-9606 Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

5.5.2 System Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5. 6 Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.1 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.2 LAN Port Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.3 LAN Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

5.6.4 RJ-45 Connector for Ethernet LAN Port. . . . . . . . . . . . . . . . . . 5-10

5. 7 DSP Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5.7.1 High-density DSP Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

5. 8 Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.8.1 Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.8.2 Console Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

5.8.3 RJ-45 Connector for Console Port. . . . . . . . . . . . . . . . . . . . . . 5-14

5. 9 E1/T1 Digital Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.9.1 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

5.9.2 E1/T1 Port Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

5.9.3 Supporting E1-75 on an E1/T1 Port. . . . . . . . . . . . . . . . . . . . . 5-16

5.9.4 Adaptor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

5.9.5 E1/T1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Chapter 6: Troubleshooting Tips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6. 1 Symptoms, Problems, and Solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Chapter 7: Networking Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7. 1 GSM A-bis/A-ter Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

7. 2 Voice Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7. 3 Network Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Memotec Inc.

Page 6

7. 4 Network Management and Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Memotec Inc.

Page 7

List of Figures

Location of Product Numbering on the SDM-9600 DC Nameplate . . . . . . . . . . . . . . . . . . . . . . . . 1-9

The SDM-9600 Chassis Equipped with SDM-9606 Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

DSP Socket on the SDM-9606 Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Inserting a DSP Module – Starting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Inserting a DSP Module – Final Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Installing an SDM-9606Blade in the SDM-9600 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Blade Handle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Rear View of the SDM-9600 Chassis with Filler Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Accessing the Air Filter Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Air Filter and Outer Grill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Front View of the SDM-9600 Chassis Equipped with SDM-9606 Blades . . . . . . . . . . . . . . . . . . . 5-3

Rear View of the SDM-9600 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Location of Fan Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Location of Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

The SDM-9606 Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Synchronous High-density DSP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

RJ-48 to E1-75 Dual BNC Adaptor Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Memotec Inc.

Page 8

Memotec Inc.

Page 9

List of Tables

Compatible Telecom Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

SDM-9606 Front Panel LED States During Normal Initialization Sequence . . . . . . . . . . . . . . . . 4-16

Feature items for the SDM-9600 chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Feature items for the SDM-9606 blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Feature items for optional hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

SDM-9606 ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

ST LED states. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

ALM LED states. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

RJ-45 pinout for Ethernet LAN port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

RJ-45 pinout for console port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Status LED indicators on SDM-9606 digital interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

RJ-48 pinout for E1/T1 ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Buffering scheme for packetization of DSP packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Memotec Inc.

Page 10

Memotec Inc.

Page 11

Preface

1

Memotec Inc. 1-1

Page 12

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1.1 About this Document

This document, NetPerformer® SDM-9600 Hardware Installation Guide, provides the

following information about the SDM-9600 chassis installed with SDM-9606 blades:

• Unpacking instructions (“Unpacking the SDM-9600” on page 3-1)

• Hardware installation instructions (“Hardware Installation” on page 4-1)

• Product description (“Product Description” on page 5-1)

• Troubleshooting procedures (“Troubleshooting Tips” on page 6-1)

• Networking features (“Networking Features” on page 7-1)

• Notice concerning HyperTerminal connection (“Notice Concerning HyperTermi-

nal Connections” on page 8-1).

For information on configuring the NetPerformer, consult the NetPerformer System

Reference. See the “NetPerformer Document Set” on page 1-6 for a list of other

references.

NOTE: All NetPerformer documents are available on the NetPerformer

Documentation CD, which is included with your product package.

CAUTION: All documents on the NetPerformer Documentation

CD, including this guide, must be opened with Adobe™

Acrobat Reader 6.0, which is provided on the CD. If you open a

NetPerformer document with an earlier version of Acrobat Reader,

some of the text will not appear in its intended format. This can

make the text difficult or impossible to read correctly, especially

from a printed copy.

1-2 Memotec Inc.

Page 13

1.2 Audience

This document is intended for use by NetPerformer system administrators as well as

technicians who are qualified to set up, configure and troubleshoot a NetPerformer

Enterprise Network.

Installation of NetPerformer hardware requires knowledge and proficiency in the

configuration, operation, maintenance and security of all enterprise network elements in

your application. You should also have a thorough understanding of telecommunications

and be familiar with the networking strategies and telephony solutions currently used by

your organization.

1.2.1 Instructions to the Reader

Instructions to the reader include notes, cautions and warnings, which are distinguished

from the rest of the text by distinctive formatting and icons. Here is an example of each:

NOTE: A note may contain a reference, tip or other information related to the subject

at hand. The content of a note is intended to be helpful or of interest to the

reader.

Preface

CAUTION: A caution contains an instruction that the reader must

follow in order to prevent damage to equipment, network failure or

loss of data. The content of a caution must be read carefully and

explicitly obeyed.

WARNING: A warning contains an instruction that the reader must

follow in order to prevent electrical shock, death or serious injury

to personnel. The content of a warning must be read carefully

and explicitly obeyed.

Memotec Inc. 1-3

Page 14

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1.3 Product Overview

1.3.1 SDM-9600 Chassis

The NetPerformer SDM-9600 is a high-end chassis based on a standardized platform

architecture for carrier-grade telecommunication applications. It is ideal for large-scale

network applications such as GSM using point-to-point E1/T1 circuits, transport through

IP (terrestrial or satellite) or satellite Single Channel Per Carrier (SCPC) connections, and

Voice over IP (VoIP). Voice/data over PowerCell applications can use IP or WAN

connections and are able to integrate SCPC on digital or serial interfaces.

• PICMG 3.0 standard rack solution

• 19" rack-mountable

• -48 VDC (dual feed)

• Maximum 5 blades, loaded from the front

NOTE: All slots on the SDM-9600 must be installed with the same type of blade, in

this case, the SDM-9606.

• Hot swappable components

• Removable fan control module and air filter.

The basic software set provides support of PowerCell Voice and Data (including legacy

user data) and IP routing over Ethernet, serial or digital ports using PPP or Frame Relay

RFC-1490. Optional software licenses can be procured for support of GSM A-bis/ter,

SkyPerformer satellite access and TCP Acceleration.

1.3.2 SDM-9606 Blade

• Loads into front slots (maximum 5)

• Each blade has 6 built-in T1/E1 universal digital ports in the front (NT hardwired)

• Can be loaded with 1 DSP module

• Each blade has a capacity of up to 120 digital telephony channels

• A fully loaded SDM-9600 supports 600 simultaneous voice calls

• 1 RJ-45 console port

• 2 10/100 Ethernet ports

• Hot swap capability and power management control

• GSM and ATM capable.

1-4 Memotec Inc.

Page 15

1.3.3 NetPerformer Software

The basic software set provides support of PowerCell voice and data (including legacy

user data) and IP routing over Ethernet, serial or digital ports using PowerCell WAN, PPP

or Frame Relay RFC-1490. The GSM A-bis/A-ter software license is sold separately.

Optional software licenses can be procured for support of SkyPerformer satellite access

and TCP Acceleration.

1.3.4 Changes to Console Operations

The following change to console operations was made in NetPerformer firmware version

V9.2.0 and higher. If you are familiar with earlier versions of the NetPerformer firmware,

this change should be taken into consideration before you configure or manage the

product.

• The way you access the NetPerformer console has changed to allow for multiple

user profiles:

CAUTION: The default LOGIN is now ADMIN instead of ACT.

Preface

NOTE: The default PASSWORD for this login remains SETUP.

For full instructions on setting up user profiles, refer to the Quick Configuration module of

the NetPerformer Reference Guides.

Memotec Inc. 1-5

Page 16

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1.4 Related Documents

NOTE: All of the documents listed here are available on the NetPerformer

Documentation CD, which is included with your product package (Part No.

520-0081-001).

1.4.1 NetPerformer Document Set

For complete information on the NetPerformer, consult the following:

• NetPerformer System Reference

Includes detailed information on NetPerformer features, menus, commands,

parameters and statistics displays for versions V10.2.1 R02 and higher. This System Reference, which is divided into fascicles for each application, also integrates all information from the Addenda to the NetPerformer System Reference

Manual for versions 9.0.0, 9.1.0, 9.2.0 and 10.1.X.

• NetPerformer Hardware Installation Guides

These documents describe the hardware specific to each NetPerformer product,

including installable options, complete installation instructions and firmware

download procedures.

• NetPerformer Release Bulletins

These documents summarize the system specifications, software fixes and

changes, and post-production documentation changes for a particular NetPerformer release. They also include firmware upgrade procedures.

• NetPerformer Network Design Guide

Offers valuable tips on how to design a NetPerformer application for maximum

efficiency, including an analysis of data and voice traffic throughput issues and

the impact of traffic flow. Provides examples of network setup and traffic measurement using various NetPerformer products.

1.4.2 Request for Comments

Our Technical Publications group welcomes your feedback. Please help us improve future

releases of this document by sending us your comments and suggestions. You can send

email to

docs@memotec.com.

1-6 Memotec Inc.

Page 17

1.4.3 Training

Preface

We offer a variety of classes to reduce your learning curve and make your employees

more productive. Students learn how to tailor NetPerformer products to meet their specific

business requirements. Each course is developed and delivered by certified instructors

who have in-depth expertise and extensive technical training experience.

To learn more about our training services, email our education facilities at

memotectraining@memotec.com.

Memotec Inc. 1-7

Page 18

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1.5 Technical Support

Memotec Technical Support is designed to meet your full range of support needs. From

basic service to mission-critical support, we are committed to ensuring your success with

NetPerformer products. We tailor different support plans to meet your evolving business

requirements. By employing state-of-the-art products and the latest technologies available,

we provide some of the fastest, most efficient service in the industry.

Our entire support organization is focused on complete customer satisfaction and

providing immediate solutions to your business needs.

You can contact Technical Support by calling or sending email to our helpdesk facilities:

Telephone: + (1) 514 738 4781 during regular business hours, EST (GMT-05:00)

Email:

Be prepared to provide the following information:

• Your name

• Company name

• Your location

• Telephone number

• Product serial numbers (see next section)

• Product work order number (see next section)

• Detailed problem description

• Remote access to the troubled unit via Telnet or dial-up modem.

MemotecSupport@memotec.com

1.5.1 Providing Product Numbers to Technical Support

You may be requested to provide the product serial number and work order number when

communicating with Technical Support.

1.5.2 Product Serial Number

The product serial number is provided on the nameplate on the underside of the SDM9606 blade (see

Figure 1-1).

1.5.3 Product Work Order Number

The product work order number provides the manufacturing year and month of your unit.

This may be required for RMA or inspection purposes. The work order number appears

1-8 Memotec Inc.

Page 19

only on the nameplate on the underside of the blade (see Figure 1-1).

Memotec Inc.

Preface

Model:

_

48V

This Class A digital equipment meets all requirements of the Canadian

Interference-Causing Equipment Regulations

Cet appareil numérique de la Classe A respecte toutes les exigences du

Règlement sur le Matériel Brouilleur du Canada.

SDM-9600 DC

3A max

Complies with the limits for Class A digital device, pursuant to

Part-15 of the FCC rules..

50

Sellable #

S/N:

Product Serial Number

Base Unit #

W/O

MEMP37000108-C

Work Order Number

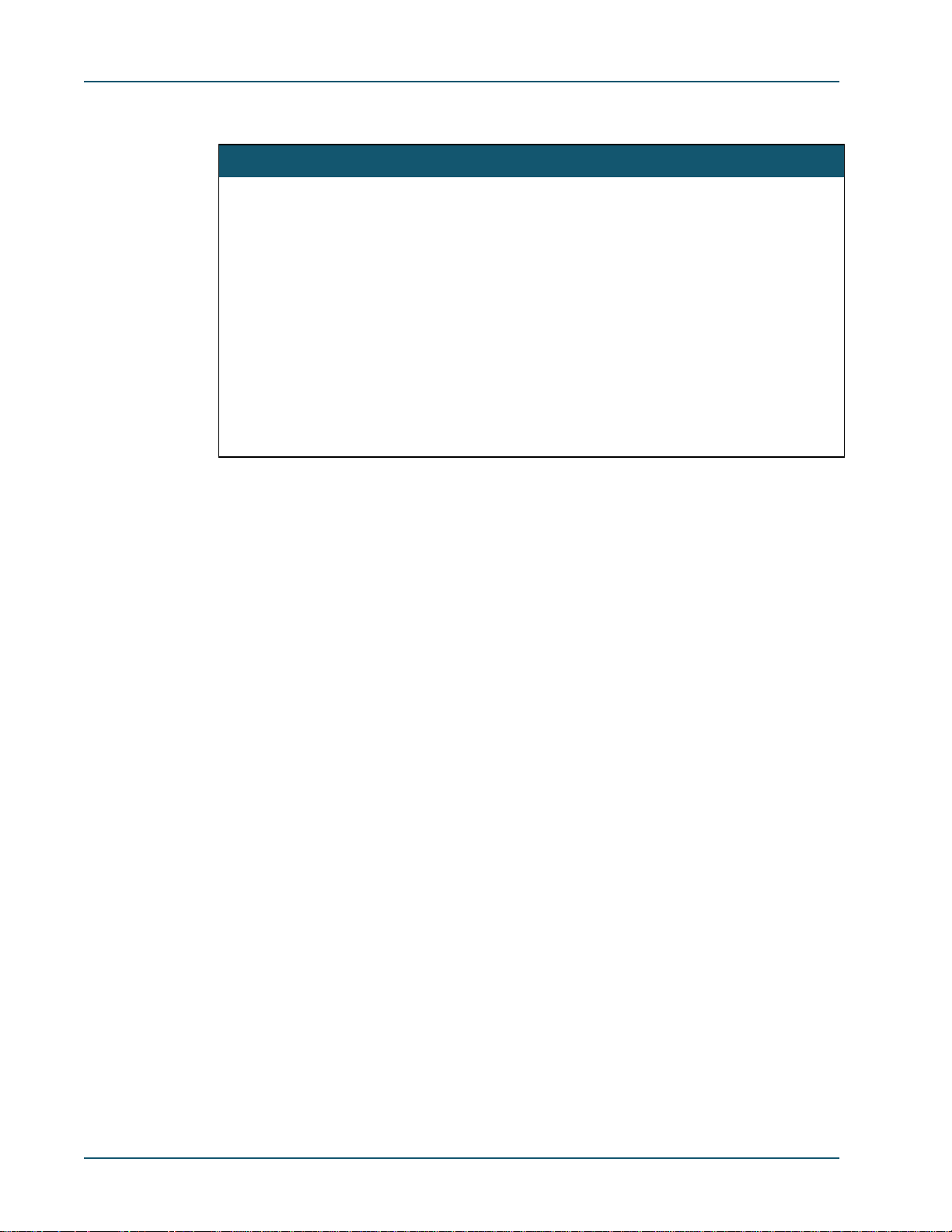

Figure 1-1: Location of Product Numbering on the SDM-9600 DC Nameplate

1.5.4 Checking the Contents of Your Product Package

CAUTION: As soon as you receive your SDM-9600 chassis and

components, check the carton and its contents for any sign of

damage during shipment. If there is any damage, contact the

shipping agent immediately.

Before you start SDM-9600 installation, verify the contents of the carton to ensure that

you have received all the units, blades, accessories, cables and optional hardware that you

ordered.

A summary of product items appears on “Product Description” on page 5-1.

If any items are missing, or if you have any questions concerning your shipment, contact

Technical Support.

Memotec Inc. 1-9

Page 20

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1.5.5 Returning an SDM-9600 Chassis or SDM-9606 Blade

If you need to return the SDM-9600 chassis or an SDM-9606 blade for any reason, you

must ship it in the original carton using adequate shock insulation material. Failure to

do so may void the equipment warranty. Consult the Warranty statements included with

the product package. Contact Technical Support for RMA requirements.

1-10 Memotec Inc.

Page 21

1.6 Sales Contacts

To order NetPerformer units, DSP modules, cables and optional parts, contact Memotec

Inc. or your NetPerformer distributor. To contact Memotec Inc.:

• Mail:

Memotec Inc.

7755 Henri Bourassa Blvd. West

Montreal, Quebec

Canada H4S 1P7

• Telephone: +1 (514) 738-4781 during regular business hours, EST (GMT-5:00)

• Fax: + (1) 514 738 4436

Preface

• Web:

http://www.memotec.com

Memotec Inc. 1-11

Page 22

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

1-12 Memotec Inc.

Page 23

Compliance Information

2

Memotec Inc. 2-1

Page 24

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

2.1 Regulatory – Compliance and Agency Approval

These products comply with or have obtained Regulatory Agency approval at least against

the following standards:

• EMC – Emission – Class A

• EMC – Immunity EN 55024:1998 + A1 + A2

• Safety EN 60950-1:2006 + A11

• Telecom – Digital

FCC Part 15

EN 55022:1998 + A1 + A2

TBR4

TBR 12 + TBR 13

2-2 Memotec Inc.

Page 25

Compliance Information

2.2 Compliance and Regulatory Statements

2.2.1 EU Directive 1999/5

DECLARATION OF CONFORMITY

We

declare under our sole responsibility that the NetPerformer product:

SDM-9600

Consisting of Model SDM-9600 DC

Equipped with the following blade:

- SDM 9606 blade (100-1210-501)

Equipped with the following cable

- RJ45 to Dual BNC (502-0459-001)

to which this declaration relates, is in conformity with all applicable essential

requirements following the provisions of the European Directive 1999/5/EC.

The conformity assessment procedure used for this declaration is the Annex II of the Directive.

Product compliance has been demonstrated against the following standards:

EN 55022 1998 + Amendments 1 and 2

EN 55024 1998 + Amendments 1 and 2

EN 60950-1 2006 + Amendment 11

The technical file is kept at:

Montreal, 11 March 2011

Stéphane Caron

Hardware Manager

Memotec Inc

7755 Blvd Henri Bourassa

Montreal, Quebec H4S 1P7

Canada

137-0026-001-B

Memotec Inc. 2-3

Page 26

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

• MEMOTEC vakuuttaa täten että NetPerformer tyyppinen laite on direktiivin

1999/5/EY oleellisten vaatimusten ja sitä koskevien direktiivin muiden ehtojen

mukainen.

• Hierbij verklaart MEMOTEC dat het toestel NetPerformer in overeenstemming

is met de essentiële eisen en de andere relevante bepalingen van richtlijn 1999/5/

EG.

• Par la présente MEMOTEC déclare que l'appareil NetPerformer est conforme

aux exigences essentielles et aux autres dispositions pertinentes de la directive

1999/5/CE.

• Härmed intygar MEMOTEC att denna NetPerformer står I överensstämmelse

med de väsentliga egenskapskrav och övriga relevanta bestämmelser som framgår av direktiv 1999/5/EG.

• Undertegnede MEMOTEC erklærer herved, at følgende udstyr NetPerformer

overholder de væsentlige krav og øvrige relevante krav i direktiv 1999/5/EF.

• Hiermit erklärt MEMOTEC, dass sich dieses NetPerformer in Übereinstimmung

mit den grundlegenden Anforderungen und den anderen relevanten Vorschriften

der Richtlinie 1999/5/EG befindet. (BMWi).

• ΜΕ ΤΗΝ ΠΑΡΟΥΣΑ MEMOTEC ΔΗΛΩΝΕΙ ΟΤΙ NetPerformer

ΣΥΜΜΟΡΦΩΝΕΤΑΙ ΠΡΟΣ ΤΙΣ ΟΥΣΙΩΔΕΙΣ ΑΠΑΙΤΗΣΕΙΣ ΚΑΙ ΤΙΣ

ΛΟΙΠΕΣ ΣΧΕΤΙΚΕΣ ΔΙΑΤΑΞΕΙΣ ΤΗΣ ΟΔΗΓΙΑΣ 1999/5/ΕΚ.

• Con la presente MEMOTEC dichiara che questo NetPerformer è conforme ai

requisiti essenziali ed alle altre disposizioni pertinenti stabilite dalla direttiva

1999/5/CE.

• Por medio de la presente MEMOTEC declara que el NetPerformer cumple con

los requisitos esenciales y cualesquiera otras disposiciones aplicables o exigibles

de la Directiva 1999/5/CE.

• MEMOTEC declara que este NetPerformer está conforme com os requisitos

essenciais e outras disposições da Directiva 1999/5/CE.

• Hawnhekk, MEMOTEC, jiddikjara li dan NetPerformer jikkonforma mal-htigijiet essenzjali u ma provvedimenti ohrajn relevanti li hemm fid-Dirrettiva 1999/

5/EC.

• Käesolevaga kinnitab MEMOTEC seadme NetPerformer vastavust direktiivi

1999/5/EÜ põhinõuetele ja nimetatud direktiivist tulenevatele teistele asjakohastele sätetele.

• Alulírott, MEMOTEC nyilatkozom, hogy a NetPerformer megfelel a vonatkozó

alapvetõ követelményeknek és az 1999/5/EC irányelv egyéb elõírásainak.

• MEMOTEC týmto vyhlasuje, že NetPerformer spĺňa základné požiadavky a

všetky príslušné ustanovenia Smernice 1999/5/ES.

• MEMOTEC tímto prohlašuje, že tento NetPerformer je ve shodě se základními

požadavky a dalšími příslušnými ustanoveními směrnice 1999/5/ES.

2-4 Memotec Inc.

Page 27

Compliance Information

• Šiuo MEMOTEC deklaruoja, kad šis NetPerformer atitinka esminius reikalavimus ir kitas 1999/5/EB Direktyvos nuostatas.

• Ar šo MEMOTEC deklarē, ka NetPerformer atbilst Direktīvas 1999/5/EK

būtiskajām prasībām un citiem ar to saistītajiem noteikumiem.

• MEMOTEC izjavlja, da je ta NetPerformer skladu z bistvenimi zahtevami in

ostalimi relevantnimi dolo㶜ili direktive 1999/5/ES.

• Hér með lýsir MEMOTEC yfir því að NetPerformer er í samræmi við grunnkröfur og aðrar kröfur, sem gerðar eru í tilskipun 1999/5/EC.

• Niniejszym MEMOTEC oświadcza, że NetPerformer jest zgodny z zasadniczymi

wymogami oraz pozostałymi stosownymi postanowieniami Dyrektywy 1999/5/

EC.

• MEMOTEC erklærer herved at utstyret NetPerformer er i samsvar med de

grunnleggende krav og øvrige relevante krav i direktiv 1999/5/EF.

• Noi MEMOTEC declarăm că aparatul NetPerformer este în conformitate cu

cerinţele esenţiale şi cu alte prevederi relevante ale Hotărârii Guvernuluinr.88/

2003 şi Directivei 1999/5/EC

• MEMOTEC декларирам на своя отговорност, че далекосъобщително

устройство NetPerformer съответства на съществените изисквания по 1999/

5/EC

2.2.2 Marking

This Telecom equipment bears the following CE mark:

Memotec Inc. 2-5

Page 28

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

2.2.3 Intent of Use and Network Compatibility

Item Compatible Telecom Services

With SDM-9606 blade

100-1210-501

This telecom Equipment is intended to be connected to the

following telecom services:

• ISDN Primary rate access at 2048 kbps in all the countries

• G.703 Leased circuits at 2048 kbps structured and

List of countries: Austria, Belgium, Bulgaria, Czech Republic,

Cyprus, Denmark, Estonia, Finland, France, Germany,

Greece, Hungary, Iceland, Republic of Ireland, Italy, Latvia,

Lithuania, Luxemburg, Malta, Netherlands, Norway, Poland,

Portugal, Romania, Slovakia, Slovenia, Spain, Sweden,

Switzerland, UK.

Table 2-1: Compatible Telecom Services

2.2.4 EN55022 and CISPR22 Warning

This is a Class A product that may cause radio interference. In this case, the user may be

required to take adequate measures.

2.2.5 FERRITES (EMI Filters)

listed below

unstructured, using 120 Ohm interface, in all the countries

listed below.

To ensure compliance in the European Union with the standard EN 55024:1998 + A1 +

A2, Ferrites are required on each RJ48 cable connected to an E1 port and on each cable

connected to an Ethernet port.

Simply clamp the ferrite onto the cable, approximately 1 inch away from the connector on

the chassis.

2-6 Memotec Inc.

Page 29

2.2.6 FCC Part 15 Statement

This digital equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference

when t he equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if n ot installed and used in accordanc e

with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference,

in which case the user will be required to correct the interference at his or her own

expense.

2.2.7 Industry Canada Statements

This digital equipment does not exceed Class A limits for radio noise emissions for digital

apparatus, set out in Radio Interference Regulation of the Industry Canada. Operation in a

residential area may cause unacceptable interference to radio and TV reception requiring

the owner or operator to take whatever steps necessary to correct the interference.

This product meets the applicable Industry Canada technical specifications.

Compliance Information

2.2.8 Notice d'Industrie Canada

Cet équipement ne dépasse pas les limites de Classe A d'émission de bruits

radioélectriques pour les appareils numériques, telles que prescrites par le Règlement sur

le brouillage radioélectrique établi par l’Industrie Canada. L'exploitation faite en milieu

résidentiel peut entraîner le brouillage des réceptions de radio et de télévision, ce qui

obligerait le propriétaire ou l'opérateur à prendre les dispositions nécessaires pour en

éliminer les causes.

Memotec Inc. 2-7

Page 30

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

2.3 Environmental Information

2.3.1 Waste Electrical and Electronic Equipment – WEEE

The WEEE (Waste Electrical and Electronic Equipment) legislation aims to raise the level

of recycling of electrical and electronic equipment and to encourage designers to create

products with recycling in mind.

The NetPerformer equipment that you bought has required the extraction and use of

natural resources for its production. It may contain hazardous substances that could impact

health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish

the pressure on the natural resources, we encourage you to use the appropriate take-back

systems. Those systems will reuse or recycle most of the materials of your end-of-life

equipment in a sound way.

The crossed-out wheeled bin symbol invites you not to dispose of WEEE as unsorted

municipal waste and to collect such WEEE separately.

If you need more information on the collection, reuse and recycling systems, please

contact your local or regional waste administration.

You can also contact us for more information on the environmental performances of our

products.

2-8 Memotec Inc.

Page 31

2.3.2 Restriction of Hazardous Substances - RoHS

RoHS - DECLARATION OF COMPLIANCE

We

declare that the NetPerformer product:

SDM-9600

Consisting of Model SDM-9600 DC

is in full compliance with the RoHS Directive 2002/95/EC of the European

Parliament and of the Council of 27 January 2003, on the restriction of the use of

the following substances in electrical and electronic equipment:

1- Mercury

2- Cadmium

3- Hexavalent chromium

4- Polybrominated biphenyls

5- Polybrominated diphenyl ethers

As permitted by item 7 of the Annex to the Directive 2002/95/EC, the SDM-9606

blades utilize the lead-in-solder exemption for Network Infrastructure

Equipment.

Compliance Information

The product bears the following label: RoHS-5/6

Montreal, 11 March 2011

Stéphane Caron

Hardware Manager

740-0504-001-C

Memotec Inc. 2-9

Page 32

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

䶵⚗₼⦌ 5R+6

䜘Ԧ〠

ᴹ∂ᴹᇣ⢙䍘ᡆݳ㍐

䫵

⊎

䭹

ޝԧ䬜

ཊⓤ㚄㤟

ཊⓤҼ㤟䟊

᧕

⭥㔶

ᔰޣ

ᵪ㇡

仾ᡷ

2.3.3 Compliance to China RoHS

䶵

(Compliance to China RoHS)

(Hazardous Substances)

(Parts)

(Interface Cards)

(Cables)

(Switch)

(Chassis)

(Fans)

(Pb)

X

OOOOOO

OOOOOO

OOOOOO

OOOOOO

(Hg)

OOOOO

(Cd)

(CrV)

(PBB)

(PBDE)

O㺘⽪䈕ᴹ∂ᴹᇣ⢙䍘൘䈕䜘Ԧᡰᴹ൷䍘ᶀᯉѝⲴ䟿൷൘ SJ/T11363-2006 ḷ߶㿴ᇊⲴ䲀䟿㾱≲ԕлDŽ

Indicates that the concentration of the hazardous substance in all homogeneous materials in the parts is

below the relevant threshold of the SJ/T11363-2006 standard.

X 㺘⽪䈕ᴹ∂ᴹᇣ⢙䍘㠣ቁ൘䈕䜘ԦⲴḀа൷䍘ᶀᯉѝⲴ䟿䎵ࠪSJ/T11363-2006 ḷ߶㿴ᇊⲴ䲀䟿㾱≲DŽ

Indicates that the concentration of the hazardous substance of at least one of all homogeneous materials in

the parts is above the relevant threshold of the SJ/T11363-2006 standard.

2-10 Memotec Inc.

Page 33

2.4 Safety Warnings and Precautions

WARNING:

Warnung

Avertissement

Compliance Information

Access to the interior of this

unit shall be made only by a

qualified technician.

Remove power plug from

the power socket before

performing any service on

the unit.

To ensure adequate cooling

of the equipment, a 2-inch

unobstructed space must

be provided around all sides

of the unit.

The Power Socket shall be

installed near the equipment and shall be easily

accessible.

To prevent the risk of shock

or fire hazard, replace fuse

with same type and rating.

Der Zugang ins Innere des

Gerätes ist nur einem

fachlich qualifizierten Techniker gestattet.

Vorm Ôffnen des Gerätes

muss der Netzstecker yom

Stromnetz getrennt werden!

Um die Kühlung des

Gerätes nicht zu beeinträchtigen, ist es notwendig,

an allen Seiten des Gerätes

ca 5 cm Raum zu lassen.

Stellen Sie das Gerät in der

Nähe eines geer- deten

Schutzkontaktsteckers so

auf, dass der Stecker leicht

erreichbar und zugänglich

ist.

Zür Vermeidung der Stromschlag-und Feuergefahr

beim Auswechseln Sicherungen des gleichen Typs

und der gleichen Nennleistung einsetzen.

Seul un spécialiste doit

avoir accès à l'appareil.

Débranchez l'appareil avant

de l'ouvrir.

Afin de ne pas nuire au processus de refroidissement,

il est nécessaire de laisser

un espace d'environ 5 cm

de chaque côté de l'appareil.

Placez l'appareil près d’une

prise de courant facilement

accessible.

Afin d’éviter tout risque

d’incendie ou d’électrocution, remplacez les fusibles

par des fusibles de même

type et de même ampérage.

2.5 Making Changes or Modifications

CAUTION:Any changes and modifications not expressly approved

by Memotec Inc.

approval, and will void the user’s authority to operate the

equipment.

Memotec Inc. 2-11

will void any compliance and regulatory

Page 34

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

2-12 Memotec Inc.

Page 35

Unpacking the SDM-9600

3

Memotec Inc. 3-1

Page 36

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

3.1 Selecting a Location

To ensure that the SDM-9600 functions properly, you should install the unit in an

appropriate location which satisfies certain criteria for size, connection distance and

ambient environment.

3.1.1 Rack Requirements

The SDM-9600 chassis is designed with rackmount ears for installation in a rack:

• Standard 19" rack

• Near an easily accessible -48 VDC power supply.

• To ensure proper ventilation of the SDM-9600 and its components, leave 5 cm (2

inches) of unobstructed space around the unit chassis.

CAUTION: Unit must be installed in a restricted access location.

3.1.2 Distance Requirements

The SDM-9600 unit should be no more than 2 meters (approx. 6 feet) away from:

• A power supply appropriate to the type of power module on the unit: -48 VDC, 3

Amps maximum.

• An independent Ground.

WARNING: Ensure that the unit is independently grounded with a

wire from Ground securely attached to the ground lug on the SDM9600 chassis. The ground lug is located below the

LED at the front of the chassis.

3.1.3 Environmental Requirements

For trouble-free operation of the SDM-9600 its location must satisfy the following

environmental criteria:

• Operating temperature: 0C to 45C (32F to 113F)*

• Storage temperature: -20C to 65C (-4F to 149F)

POWER ON

• Relative humidity: 10% to 95%, non-condensing

3-2 Memotec Inc.

Page 37

• Maximum operating altitude: 4572 meters (15 000 feet)*

* NOTE:Above 3048 meters (10 000 feet) altitude the maximum operating temperature

of the unit drops from 45°C to 35°C.

• Ventilation requirement: leave 5 cm (2 inches) of unobstructed space around the

unit. All unused slots must be closed with a filler panel.

3.2 Preparing the Site

3.2.1 What You Will Need

For trouble-free installation of the SDM-9600 hardware make sure you have the following

on hand:

• The SDM-9600 chassis, with all SDM-9606 blades, accessories, cables and

optional hardware you received in the product package. Refer to “Product

Description” on page 5-1.

Unpacking the SDM-9600

• At least one of the following configuration and management access devices:

- A console terminal (TTY terminal or a PC equipped with terminal emulation

software) for direct or dial-up connection to the console port on the front face

of the SDM-9606 blade

- A TELNET network device accessed through IP connectivity over LAN/

WA N

NOTE: When you first take an SDM-9606 blade out of the box, the only configura-

tion device you can use is the console terminal, since the unit does not yet

have an IP address. For details, see “Connecting the Console Terminal” on

page 4-18.

CAUTION: If you intend to use the HyperTerminal

communications program as your console terminal, read the

“Notice Concerning HyperTerminal Connections” on page 8-1.

• A sufficient number and length of cables for all digital ports:

These cables are not provided with the SDM-9600 product package.

- One RJ-48 to RJ-48 cable for each E1/T1 port (at least 26AWG, or 0.4mm)

Memotec Inc. 3-3

Page 38

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

- One crossover cable for each E1/T1 port that must provide a TE connection

(connecting to

NT equipment). All E1/T1 interfaces are strapped at the fac-

tory for NT mode

- Two BNC coaxial cables for each E1/T1 port that will be configured for E175 operations

An adaptor is also required for an E1-75 connection

on an E1/T1 port. The

following adaptors is available:

Adaptor cable: RJ-48 to E1-75 dual BNC (Part No. 161-0469-001). See

“Adaptor Cable” on page 5-17 for details.

- One straight through 10/100/1000BaseT LAN cable, RJ-45M to RJ-45M, for

each Ethernet port

• For all voice transmissions using PowerCell, an Internet connection or access to a

private IP network that supports the TCP and UDP/IP protocols.

PPP, Frame Relay (RFC1490) and WAN (PVCR) connections can be made without the requirement to support IP routing.

• All user equipment that will be directly connected to the digital ports.

3-4 Memotec Inc.

Page 39

Hardware Installation

4

Memotec Inc. 4-1

Page 40

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.1 About the Hardware Installation

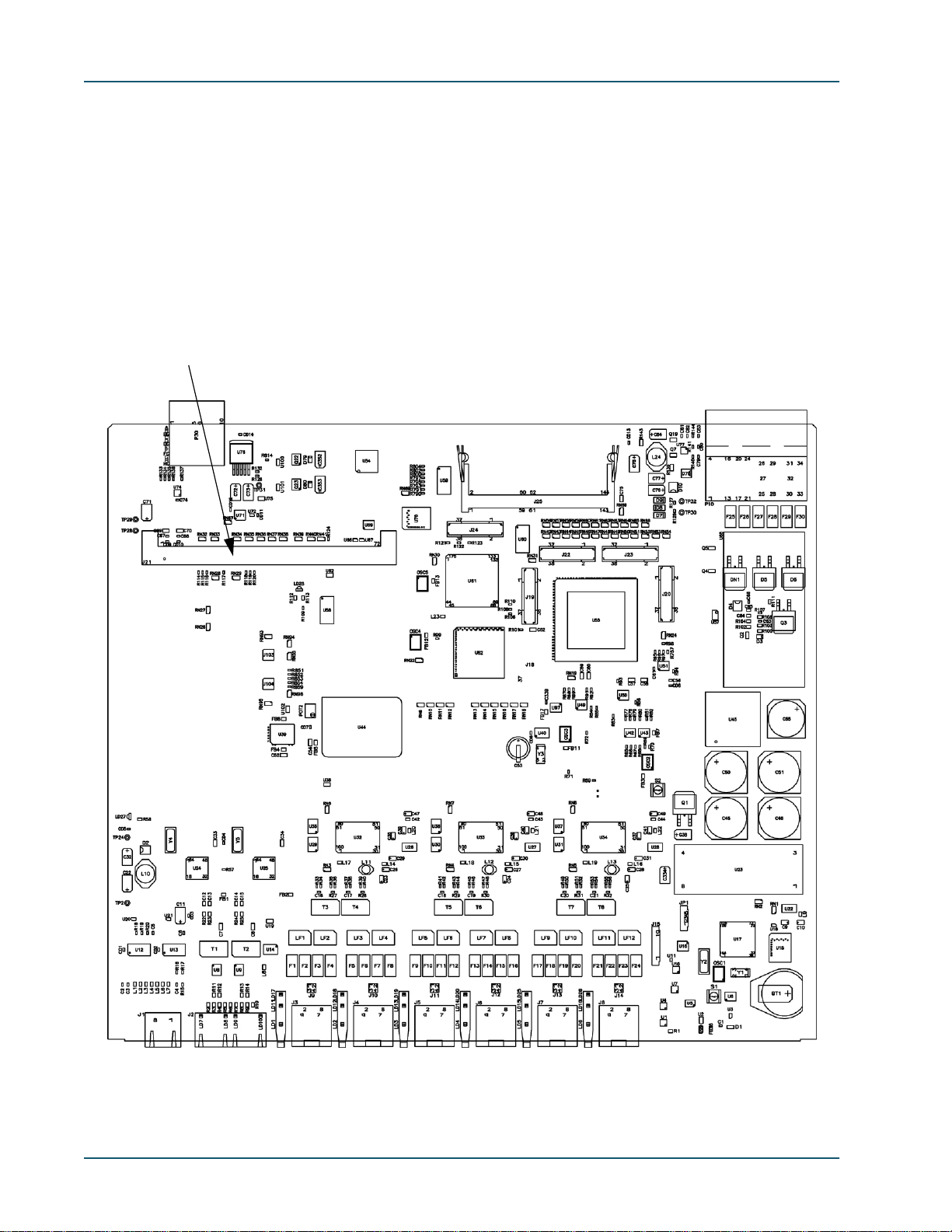

Figure 4-1: The SDM-9600 Chassis Equipped with SDM-9606 Blades

Hardware installation of the SDM-9600 involves the following steps:

• Installing the SDM-9600 chassis in a rack (“Installing the SDM-9600 Chassis in

a Rack” on page 4-3)

• Installing or upgrading a DSP module on the SDM-9606 blade (“Installing or

Upgrading the DSP Modules” on page 4-4)

• Hardware strapping on E1/T1 ports: Operation at 75 ohms (“Strapping for E1-75

Operation” on page 4-8)

• Installing a blade into the front of the SDM-9600 chassis (“Installing a Blade” on

page 4-9)

• Removing a blade (“Removing a Blade” on page 4-12)

• Installing the filler panels (“Installing the Filler Panels” on page 4-14)

• Powering up the unit (“Powering Up the Unit” on page 4-15)

• Connecting the console terminal (“Connecting the Console Terminal” on page 4-

18)

• Installing the licensed software options (“Installing the Licensed Software

Options” on page 4-21)

• (Optional) Connecting the unit to the LAN hub (“Connecting the LAN Hub” on

page 4-22)

In addition, the following maintenance procedure should be carried out on a regular basis:

• Cleaning the air filter in the SDM-9600 chassis (“Cleaning the Air Filter” on

page 4-23).

4-2 Memotec Inc.

Page 41

Hardware Installation

4.2 Installing the SDM-9600 Chassis in a Rack

The SDM-9600 chassis is designed with rackmount ears for installation in a standard 19"

rack (see Figure 4-1 on page 2). Rack requirements are discussed on page 2.

To install the SDM-9600 chassis in a rack:

1. Carefully insert the SDM-9600 chassis into the front of the rack

2. Secure each rackmount ear onto the rack using 2 mounting screws with washers.

Memotec Inc. 4-3

Page 42

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.3 Installing or Upgrading the DSP Modules

Follow the procedure in this section for both installation and upgrade of a DSP module on

the SDM-9606 blade.

You need to have a DSP module to support voice/fax channels and GSM TRXs. This DSP

module is ordered separately from the unit and must be installed when you set up the

hardware at your site. For ordering information, refer to “Sales Contacts” on page 1-11.

4.3.1 Location of DSP Socket on the SDM-9606 Blade

DSP Socket

Figure 4-2: DSP Socket on the SDM-9606 Blade

4-4 Memotec Inc.

Page 43

You can increase the number of voice channels supported by upgrading the DSP module.

Refer to “DSP Modules” on page 5-11 for a description of the different kinds of DSP

modules that can be installed.

CAUTION: These DSP modules are for the SDM-9210/9210GW, SDM-9220/

9220GW, SDM-9230/9230GW, SDM-9606 or SDM-9620 only. DO NOT use

a DSP module intended for the SDM-9360, SDM-9380 or SDM-9585.

NOTE: The SDM-9606 has one DSP socket for a single DSP module (see Figure 4-

2).

4.3.2 Installation Procedure

Hardware Installation

NOTE: To ensure proper digital voice operations and GSM traffic handling, install all

required DSP modules before you power up and configure the unit.

To install a DSP module:

1. Wear an ESD (Electrostatic Sensitive Devices) wrist strap, and attach it to one of the

ground lugs on the SDM-9600 chassis:

• Front ground lug, located beneath the

POWER ON LED. Refer to Figure 5-1.

• Rear ground lug, located to the right of the dual power input modules. Refer to

Figure 5-2.

CAUTION: Electrostatic charges can damage system components. Always use

an ESD wrist strap when accessing internal components of the unit.

In countries where a 2-pin non-grounded power cord must be used, ensure that the

SDM-9600 is independently grounded with a wire from Ground securely attached to

one of the ground lugs on the SDM-9600 chassis.

2. Locate the blade on which you want to install the DSP module. If this blade is already

installed in the SDM-9600 chassis, remove it as described in “Removing a Blade” on

page 4-12.

3. Place the blade on a hard, flat surface. Skip to step

6 if the DSP socket is empty.

4. If you are upgrading a DSP module that has already been installed:

Memotec Inc. 4-5

Page 44

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

a. Locate the small metal clips that hold the DSP module into place at each

side of the DSP socket

b. Push the clips apart with the tips of your fingers. The DSP module will

spring to an angle of about 45°.

5. Holding the DSP module by its edge, carefully lift it up and out of its socket.

Caution: Do not expose the DSP module or SDM-9606 blade to a mag-

netic field or electrostatic charge at any time. Damage to their components

could result.

6. Carefully remove the new DSP module from its protective packaging.

7. Hold the DSP module over the DSP socket at an angle of about 45° with its notched

edge down. Center the module over the socket.

45° angle

Figure 4-3: Inserting a DSP Module – Starting Position

8. Insert the DSP module into the DSP socket:

a. First push the bottom edge of the DSP module all the way into the socket.

Use enough pressure to ensure that the DSP module is properly aligned

and fully inserted.

4-6 Memotec Inc.

Page 45

Hardware Installation

b. Press the top edge down until the module snaps into place between the

two metal clips at each end of the DSP socket.

NOTE: When properly installed, the DSP module should lie flat in its socket, beneath

the two metal clips.

CAUTION: Do not force the DSP module into the DSP socket. If the DSP

module does not snap into place easily or sit properly in the socket, make

sure you have inserted it with the notched edge down.

DSP lies flat

Figure 4-4: Inserting a DSP Module – Final Position

9. Reinstall the SDM-9606 blade into the SDM-9600 chassis. Refer to the procedure on

“Installing a Blade” on page 4-9.

Memotec Inc. 4-7

Page 46

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.4 Hardware Strapping for E1 Ports

The E1/T1 interfaces on the SDM-9606 blade can be strapped for E1-75 operation

(see next section).

NOTE: No hardware strapping is required for NT/TE mode on these

interfaces. All E1/T1 interfaces ar e strapped at the factory as NT.

If you need a TE connection, attach a crossover cable to the interface.

For details about the E1/T1 ports, refer to “E1/T1 Digital Interfaces” on page 5-

15.

4.4.1 Strapping for E1-75 Operation

An E1-75 connection is accomplished by installing an adaptor on the E1/T1 port

(see “Supporting E1-75 on an E1/T1 Port” on page 5-16). The following adaptor

is available: RJ-48 to E1-75 dual BNC (Part No. AG2CA0001).

No other hardware strapping is required.

To set an E1/T1 port to E1-75, connect an adaptor for E1-75 operations onto the

digital port using an RJ-48 to E1-75 dual BNC adaptor cable (Part No.

AG2CA0001, see “Adaptor Cable” on page 5-17)

NOTE: Without an adaptor, the E1 port will not operate at 75 ohms.

CAUTION: The RJ-48 to E1-75 dual BNC adaptor cable and attached

BNC cables require strain relief to ensure that they do not loosen from

the digital port:

-If the unit is mounted in a rack, you must secure the cables to a side

rail using tie-wraps, or support the weight of the cables on a tray

-If the unit is on a table, you must support the weight of the cables on

the table.

The digital port can desynchronize and the unit reset if the full weight of the BNC

cables is unsupported.

4-8 Memotec Inc.

Page 47

4.5 Installing a Blade

The SDM-9606 blades are installed in slots at the front of the SDM-9600 chassis. Up to 5

blades can be installed. Refer to Figure 4-5.

NOTE: For easier installation and configuration, install all blades required for your

application before you power up and configure the unit. However, blades for

the SDM-9600 chassis are hot-swappable. The chassis does not need to be

powered down to insert another blade at a later time.

Hardware Installation

Figure 4-5: Installing an SDM-9606Blade in the SDM-9600 Chassis

To install a blade:

1. Wear an ESD (Electrostatic Sensitive Devices) wrist strap, and attach it to one of the

ground lugs on the SDM-9600 chassis:

• Front ground lug, located beneath the

POWER ON LED. Refer to Figure 5-1.

• Rear ground lug, located to the right of the dual power input modules. Refer to

Figure 5-2.

CAUTION: Electrostatic charges can damage system components. Always use

an ESD wrist strap when accessing internal components of the unit.

In countries where a two-pin non-grounded power cord must be used, ensure that the

SDM-9600 is independently grounded with a wire from Ground securely attached to

Memotec Inc. 4-9

Page 48

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

one of the ground lugs on the SDM-9600 chassis.

2. Select an available blade slot on the front of the SDM-9600 chassis. These are the

wide slots labelled from

1 to 5 down the left side.

There is no loading sequence; any slot can be chosen. You do not need to disconnect

any cables connected to the ports on other blades.

3. If a filler panel is installed in the blade slot, remove it as follows:

a. Unscrew the 2 knurled M3 retention screws that hold the filler panel into

place on both sides

These screws can be loosened, but not removed.

b. Slide the filler panel out of the chassis, and set it aside.

Important: Keep the filler panel for possible reuse at a later time. To limit

electromagnetic interference and ensure optimum ventilation, there should be

no large openings in the SDM-9600 chassis. If you decide to remove a blade at a

later time, you will need to replace the filler panel for that slot.

4. Carefully remove the SDM-9606 blade from its protective packaging.

CAUTION: Do not expose the blade to a magnetic field or electrostatic charge at

any time. Damage to its components could result. Use ESD procedure at all

times.

5. Hold the blade so that the printing on its front panel is right side up, and slide it into

the slot from the front of the chassis.

CAUTION: Do not force the blade into the slot. If the blade is properly

aligned, it should slide easily all the way in along the guide rails provided.

6. Press the blade firmly into place, so that the two alignment holes at the rear of the

blade connect with the pins at the rear of the chassis slot.

When the front face of the blade is flush with the front of the chassis, the card

handles will close toward the center.

CAUTION: Carefully insert each blade fully into the unit. If a blade is not

correctly installed, proper contact cannot be made with the power source.

7. To secure the blade in place, press the 2 retention screws in and tighten them

clockwise.

8. Ensure that both card handles are pressed flat against the blade:

• Push the small lever into its housing on the card handle, then

4-10 Memotec Inc.

Page 49

Hardware Installation

• Press the handle back toward the front face of the blade.

NOTE: The right card handle is equipped with a microswitch that senses whether the

blade is fully inserted. It is very important that the card handles be fully

closed.

Memotec Inc. 4-11

Page 50

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.6 Removing a Blade

Caution: Blades must be removed with care. Use ESD procedure at all times.

NOTE: Blades for the SDM-9600 chassis are hot-swappable, so the chassis does

not need to be powered down to remove a blade.

To remove a blade:

1. (Optional) Disconnect any cables that may be connected to the ports at the front of

the blade that you wish to remove.

2. Open both card handles slightly by pushing the lever in and opening the handle

toward you.

The blue H/S LED will blink, indicating that the blade is NOT READY to be

removed.

Caution: Do not remove the blade until the H/S LED has turned off.

3. When the

H/S LED has turned off, unscrew the two knurled M3 retention screws that

hold the blade into place on both sides.

These screws can be loosened, but not removed.

4. Pull the two card handles outward from the chassis, toward you.

The blade disengages from the pins at the rear.

Open outward

(toward you)

Left handle

Figure 4-6: Blade Handle Operation

4-12 Memotec Inc.

Page 51

Hardware Installation

5. Slide the blade the rest of the way out of the chassis.

Caution: Do not expose the blade to a magnetic field or electrostatic

charge at any time. Damage to its components could result.

6. Install a filler panel to cover the empty slot. Refer to the next section.

Memotec Inc. 4-13

Page 52

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.7 Installing the Filler Panels

To limit electromagnetic interference and ensure optimum ventilation inside the SDM9600 chassis, there should be no large openings in the chassis. Each unused slot on both

the front and rear of the chassis requires a filler panel (Part No. 161-1140-000) to control

the air flow.

Example:

An SDM-9600 installed with a single SDM-9606 blade requires 9 filler panels, 4 in the

empty front slots and 5 in the empty rear slots. See Figure 4-7.

To install a filler panel:

1. Slide the filler panel through the slot opening, along the guide rails provided.

2. To secure the filler panel in place, press the 2 knurled M3 retention screws into the

panel, and tighten them by turning clockwise.

Figure 4-7: Rear View of the SDM-9600 Chassis with Filler Panels

Filler

Panels

4-14 Memotec Inc.

Page 53

4.8 Powering Up the Unit

4.8.1 Connecting to the Power Source

NOTE: Information about the power input modules is provided on “Power Input

Modules” on page 5-4.

CAUTION: This procedure must be carried out by a qualified electrical

technician only.

WARNING: A 20A circuit breaker must be provided as part of the

building installation for the -48VDC power connection.

Hardware Installation

To connect the SDM-9600 chassis to the power source:

1. Turn off the circuit breakers to the -48 volt DC power supply.

WARNING: To avoid electrical shock and possible damage to the

unit, ensure that the -48 VDC power supply is shut OFF before

you connect the SDM-9600 DC unit.

2. Ensure that all blades and filler panels are fully inserted into their slots and secured

in place.

3. Ensure that all wires of the -48 VDC connection harness have an appropriate

connector for installation onto a DC inlet.

CAUTION: Select a harness with a wire gauge capable of supporting a maximum

of 20 Amps.

4. Remove the clear plastic protector from one of the DC inlets located at the rear of the

SDM-9600 chassis, either

INPUT A or INPUT B, by removing the screws from the

two spacers on either side of the inlet lugs. Refer to Figure 5-2.

5. Install the harness to the DC inlet, terminating the wire connectors on the lugs

labelled

Memotec Inc. 4-15

-48V and RTN.

Page 54

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

6. Connect the strip terminations of the harness wires to the -48 volt DC power supply.

7. Reinstall the clear plastic protector, ensuring that the harness wires come through the

hole in the bottom without obstruction. Tighten the two screws onto the spacers.

8. Turn on the circuit breakers to the -48 volt DC power supply.

9. Locate the power switch for the DC inlet you have selected, and turn the power switch

ON by pushing it to 1. The unit will begin power-up and system check immediately.

Warning: If at a later time you need to access internal components, turn OFF

the unit and the -48 VDC power supply, and disconnect the harness from the

DC inlet on the SDM-9600 DC chassis to avoid electrical shock and damage to

the unit.

4.8.2 System Status on Power-up

On power-up the SDM-9606 blades execute program decompression, Signaling Engine

software load and system test.

You can follow the system status from the console (see next section), or by watching the

LEDs on the front of the blades. Table 4-1 shows the various LED states that occur during

SDM-9606 initialization sequence (after a power-on or software reset).

NOTE: The entire startup sequence is executed within 30 seconds. Some of its stages

are brief, and may be difficult to distinguish from the rest..

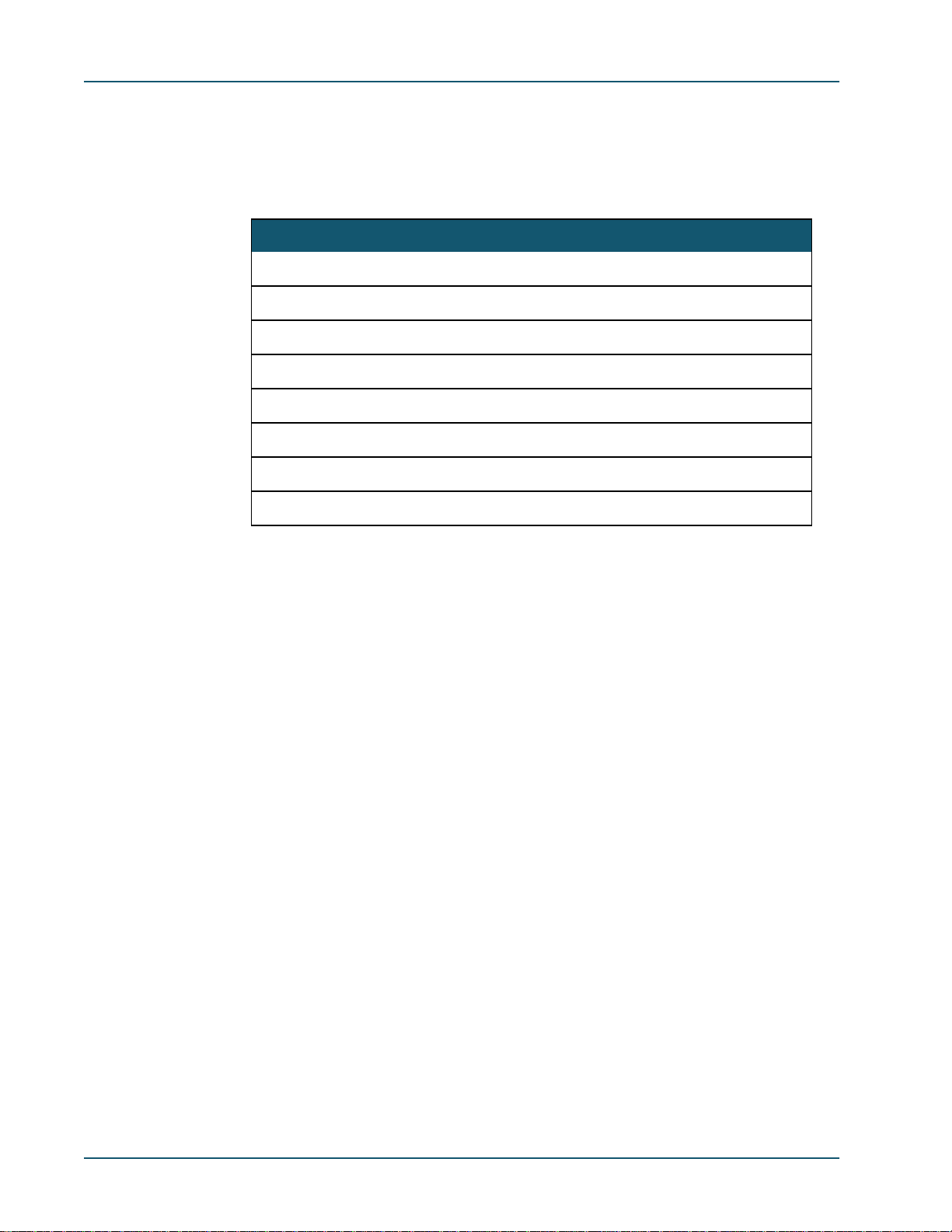

Stage OOS ST ALM H/S Current Status of the Unit

1 Amber Blink Blink Blink Quick hardware test by the boot-

strap; lamp test on all LEDs. Blinking and frequent color changes

occur during this stage

2 Green Red Green Off Hardware initialization by the boot-

strap

3 Green Red Off Off Bootstrap is running. Preparing to

start the boot sector

4 Green Amber Off Off Boot sector is running. Validating

the application

5 Green Amber Amber Off Boot sector is running. Decom-

pressing the application

Table 4-1: SDM-9606 Front Panel LED States During Normal Initialization Sequence

4-16 Memotec Inc.

Page 55

Hardware Installation

Stage OOS ST ALM H/S Current Status of the Unit

6 Green Off Off Off Application has started from a

power-on

Red Off Application has started from a soft-

ware reset

7 Green Green Off Off Application has started from a

power-on; at least one link is up

Red Off Application has started from a soft-

ware reset; at least one link is up

Table 4-1: SDM-9606 Front Panel LED States During Normal Initialization Sequence

NOTE: If the OOS LED on the SDM-9606 blade stays amber, the unit may be faulty.

Contact Technical Support for assistance ( “Technical Support” on page 1-8).

See also “Troubleshooting Tips” on page 6-1 for other critical error situations.

Memotec Inc. 4-17

Page 56

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.9 Connecting the Console Terminal

A console cable kit (Part no. 161-1066-001) is provided with the SDM-9606 product

package to connect your console terminal to the blade. This kit includes:

• A 14-ft. (4.25 m) console cable with RJ-45 male connectors at both ends, and

• A TIA-232 (V.24) terminal adaptor, RJ-45 female to DB-9 female.

NOTE: You can order an extra console cable kit from Memotec Inc. or your NetPer-

former distributor. Refer to “Sales Contacts” on page 1-11.

To connect the console terminal to the blade:

1. Install one end of the console cable onto the console port on the blade, labelled

Refer to Figure 5-5.

2. Connect the other end of the console cable to the RJ-45 female side of the terminal

adaptor.

3. Plug the DB-9 female side of the terminal adaptor into a COM port on the console

terminal or PC, or to a modem for dialup connection to a remote console.

4.9.1 Important Console and Modem Settings for Startup

The console port performs autobaud detection when in auto-sensing mode. The SDM9606 blade will set the speed of the console port as soon as it detects an active connection.

CAUTION: For trouble-free startup, you must set the console terminal and

modem as follows:

• Console terminal: The default console speed is 9600 bps during bootstrap ini-

tialization, boot sector validation and system initialization. Set your console ter-

minal emulator to 9600 bps to view all NetPerformer system status messages

on-screen during the startup sequence.

• Modem: Configure your modem with the following AT commands:

CSL.

-

at&d0 to ignore DTR. The SDM-9606 blade cannot supply DTR to the

modem when in auto-sensing mode (the default setting).

ats0=1 for Auto Answer mode

-

at&w0 to save the modem configuration.

-

Once system startup has completed successfully, the SDM-9606 blade enters auto-sensing

mode automatically. At that point, you can change your console speed, if desired.

4-18 Memotec Inc.

Page 57

• Available console speeds are 1200, 2400, 4800, 9600, 19200, 28800, 38400,

57600 and 115200 bps. The equipment you connect to the console port must

operate at one of these speeds.

4.9.2 Activating the Console Connection

To activate the console connection:

1. Ensure that all SDM-9606 blades have successfully powered up with no system status

errors (see “System Status on Power-up” on page 4-16).

2. Power the console terminal on or start your console terminal emulation program.

Take note of:

• “Important Console and Modem Settings for Startup” on page 4-18

• “Notice Concerning HyperTerminal Connections” on page 8-1.

Hardware Installation

3. When you see the prompt

T ype <ENTER> to connect, press the <Enter> key on the

console terminal keyboard several times, until the NetPerformer responds with a

prompt for the user login.

4. Enter the administrator login:

ADMIN.

This is the default login. Additional user logins can be defined. For details, refer to

the chapter

Configuration fascicle of the NetPerformer System Reference.

Controlling Access to the NetPerformer in the Quick

5. Enter the password for this login. The default password for the administrator login is

SETUP.

When the password is entered correctly, the SDM-9606 blade sends the product

banner to the console screen, as in this example:

LOGIN:ADMIN

PASSWORD:*****

ACCEPTED

SDM-9606 vx.x.x Memotec Technologies, Inc. (c) 2007

DSP QCxxx.BIZ code version: x.x.x

Console connected through TELNET

Voice transport method: PowerCell

Display commands, type HE

B3046082>

6. Enter the Display Alarms (DA) command at the NetPerformer console command line

to verify that your unit is problem free. In particular, look for any alarm messages that

indicate

Memotec Inc. 4-19

Call Technical Support.

Page 58

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.9.3 Concerning HyperTerminal Connections

The HyperTerminal communications program comes with Microsoft Windows

products, and can be used for very basic NetPerformer console functions if no terminal

emulation program is available.

Caution: HyperTerminal is not recommended for adjusting the

NetPerformer configuration or monitoring its operations. Known problems

include the following:

• The arrow keys cannot be used to view channel status on all slots

• The console speed cannot be changed once the console connection is up and running

• On some computers, the default Emulation setting of the HyperTerminal

com-

munications program can potentially cause problems for console operations.

must use HyperTerminal for your console connection, you should change the

If you

Emulation setting from

Auto detect to ANSI, as follows:

1. Access HyperTerminal using the Windows Start button and drop-down menus:

Start > Programs > Accessories > Communications > HyperTerminal

2. If you have already defined the connection to the NetPerformer console port, open

that connection:

File > Open > your_filename.ht

3. If you have not yet defined the connection to the NetPerformer console port, create a

new connection:

File > New Connection > your_filename

4. Open the Properties window for the connection:

File > Properties

5. Click on the Settings tab to view the current value of the Emulation parameter.

6. Select the value

7. Click

OK.

ANSI from the list box for the Emulation parameter.

NOTE: The above procedure does not resolve the problems with arrow key func-

tionality or console speed, and should be considered a temporary solution

only. You should procure a more robust terminal emulation software program

for configuration and monitoring purposes. Contact Technical Support if you

need further assistance.

4-20 Memotec Inc.

Page 59

Hardware Installation

4.10 Installing the Licensed Software Options

Execute the Product License Status (PLS) command at the NetPerformer console

command line to install all licensed software options you have purchased for your SDM9606 blade.

Each licensed option includes a Software Licensing Agreement, which can be found in the

product package. You must agree to the terms and conditions of this agreement before

loading the software. Each NetPerformer unit or blade participating in the software

application must be installed with a separate software license.

4.10.1 Software License Key

The Memotec Software License Key is a traceable number that is used to activate the

licensed software option.

• This number is printed on an adhesive label on the cover of the licensed software

option product package

• Enter this number during execution of the

PLS command to activate the software

license

• You must then execute Reset Unit (

For details concerning installation of licensed software options, refer to the

Installation and Licensing module of the NetPerformer System Reference, which

is included on the

NetPerformer Documentation CD in the product package.

RU) command to apply the new license.

Software

Memotec Inc. 4-21

Page 60

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

4.11 Connecting the LAN Hub

You must provide a standard straight through Ethernet 802.3 LAN cable (10/100/

1000BaseT, RJ-45M to RJ-45M) for connection to each LAN port.

NOTE: LAN cables are not provided with the SDM-9606 product package.

To connect the SDM-9606 blade to a LAN hub:

1. Connect one end of the LAN cable to one of the Ethernet LAN ports on the blade,

labelled

2. Connect the other end of the LAN cable to one of the 10/100/1000BaseT ports on

your local LAN hub.

ETH 1 and ETH 2. Refer to Figure 5-5.

3. The link is up when the

LAN connection:

- Amber: 100 Mbps

- Green: 10 Mbps.

LNK LED is on. The LED color indicates the speed of the

4-22 Memotec Inc.

Page 61

4.12 Cleaning the Air Filter

The air filter in the SDM-9600 chassis should be verified on a regular basis and cleaned

when required.

To clean the air filter:

1. Unscrew the M2.5 screw located near the center of the fan unit front panel. Refer to

Figure 4-8.

NOTE: This screw can be loosened, but not removed.

CAUTION: Do not unscrew the knurled M3 retention scr ew at the bottom of

the fan unit, which hold the fans in place.

2. Slide the air filter tray out of the SDM-9600 chassis.

Hardware Installation

Figure 4-8: Accessing the Air Filter Tray

Memotec Inc. 4-23

Page 62

SDM-9600 with SDM-9606 Blades Hardware Installation Guide

NOTE: If the air filter tray is difficult to remove, you can use the M3 retention screw

at the bottom of the fan unit as a gripping point.

3. The air filter is a black, washable fabric that adheres to the outer grill. Carefully peel

the air filter away from the outer grill.

Air filterOuter grill

Figure 4-9: Air Filter and Outer Grill

4. Wash the filter in a solution of warm water and mild detergent.

5. Rinse thoroughly in water and allow to dry completely before replacing the filter

in the fan unit.

WARNING: To prevent electrical shock and damage to the unit,

do not install a wet air filter into the SDM-9600 chassis.