Page 1

SDM-300A

Satellite Modem

Installation and Operation Manual

Part Number MN/SDM300A.IOM Revision 6

Page 2

Page 3

Errata A

Comtech EF Data Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

Change paragraphs A. 1and A.2 are highlighted to read:

Change Specifics:

Appendix A. Remote Control Operation

June 21, 2005

SDM-300A Satellite Data Modem Installation and Operation

Manual, Rev. 4, dated June 15, 2000

MN/SDM300A.EA6

Attach this page to page A-1

A.1 General

Remote control and status information is transferred via a RS-485 or RS-232 serial

communications link. Commands and data are transferred on the remote control communications

link as US ASCII encoded character strings. The remote communications link is operated in a half

duplex mode. A remote controller or terminal initiates communications on the remote link. The

SDM300A never transmits data on the link unless it is commanded to do so.

A.2 Message Structure

The ASCII character format requires 11 bits/character: 1 start bit, 7 information bits with 1 parity bit

(odd/even) or 8 information bits with no parity bits, and 2 stop bits.

Messages on the remote link fall into the categories of commands and responses. Commands are

messages transmitted to a satellite modem, while responses are messages returned by a satellite

modem in response to a command.The general message structure is as follows:

• Start Character ‘<’

• Device Address 'add'

• Address De-limiter ‘/’

• Command/Response

• Qualifier ‘_’

• Optional Arguments ‘n, m, x, y, z’

• End of Message Character

Filename: T_ERRATA 1

Page 4

Comtech EF Data Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Comments:

Change paragraph 4.1.1 to read:

Change Specifics:

Correct RS reference in 4.1.1 Remote Connector and Pinouts (J6)

June 21, 2005

SDM-300A Satellite Data Modem Installation and Operation

Manual, Rev. 6, dated June 7, 2004

MN/SDM300A.EB6

Attach this page to page 4-4

Errata B

4.1.1 Remote Connector and Pinouts (J6)

The remote connector is a 9-pin subminiature female D connector (J6) located on the rear panel of

the modem. Screw locks are provided for mechanical security of the mating connector.

The remote connector interfaces the M&C functions to a remote location. The remote location can

be an M&C computer located away from the modem, but attached via cable to the remote

connector. This DCE interface is user selectable for either RS-232 or RS-485. Refer to Appendix A

for a description of the remote interface commands.

Filename: T_ERRATA 1

Page 5

Comtech EF Data is an ISO 9001

Registered Company.

SDM-300A

Satellite Modem

Installation and Operation Manual

Part Number MN/SDM300A.IOM

Revision 6

June 7, 2004

Copyright © Comtech EF Data, 2000, 2001, 2002. All rights reserved. Printed in the USA.

Comtech EF Data, 2114 West 7th Street, Tempe, Arizona 85281 USA, 480.333.2200, FAX: 480.333.2161.

Page 6

Customer Support

Contact the Comtech EF Data Customer Support Department for:

• Product support or training

• Information on upgrading or returning a product

• Reporting comments or suggestions concerning manuals

A Customer Support representative may be reached at:

Comtech EF Data

Attention: Customer Support Department

2114 West 7th Street

Tempe, Arizona 85281 USA

480.333.2200 (Main Comtech EF Data Number)

480.333.4357 (Customer Support Desk)

480.333.2161 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@comtechefdata.com

Contact us via the web at www.comtechefdata.com

To return a Comtech EF Data product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the Comtech EF

Data Customer Support Department.

Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

2. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

3. Ship the product back to Comtech EF Data. (Shipping charges should be

prepaid.)

For more information regarding the warranty policies, see Warranty Policy, p. xv.

.

ii

Page 7

Table of Contents

Chapter 1. INTRODUCTION...................................................................................................................................1–1

1.1 Overview......................................................................................................................................................1–3

1.1.1

Modem Features ..................................................................................................................................1–3

1.1.2 Standard Features ...............................................................................................................................1–3

1.1.3 Description of Interface Functions........................................................................................................1–4

1.1.4 Modes of Operation..............................................................................................................................1–4

1.2 Options ........................................................................................................................................................1–6

1.2.1 Factory-Installed Options .....................................................................................................................1–7

1.2.2 Factory- or user-Installed Options ........................................................................................................1–7

1.3

Description of FAST Options.....................................................................................................................1–8

1.4

Compatibility ...............................................................................................................................................1–9

1.5

Breakout Panels..........................................................................................................................................1–9

1.5.1 UB-300 Universal Breakout Panel........................................................................................................1–9

1.5.2 UB-530 Breakout Panel........................................................................................................................1–9

UB-54 Breakout Panel .......................................................................................................................1–10

1.5.3

1.6 Comtech EF Data Part Numbers..............................................................................................................1–10

1.7 New in this Release ..................................................................................................................................1–13

CHAPTER 2.

2.1 Description of Monitor and Control (M&C) ...............................................................................................2–1

2.1.1

2.1.2 Remote Baud Rate...............................................................................................................................2–4

2.1.3

FUNCTIONAL DESCRIPTION....................................................................................................2–1

Theory of Operation .............................................................................................................................2–1

Remote Address ..................................................................................................................................2–4

iii

Page 8

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

2.2 Decription of the Modulator .......................................................................................................................2–5

2.2.1

Theory of Operation .............................................................................................................................2–6

2.2.2 Theory of Modulation Types.................................................................................................................2–7

2.3 Description of the Demodulator ................................................................................................................2–8

2.4 Description of the Decoder ......................................................................................................................2–10

2.5 Description of the Interface .....................................................................................................................2–11

2.5.1

Available Interfaces............................................................................................................................2–13

2.5.2 Plesiochronous/Doppler/Buffer...........................................................................................................2–13

2.5.3 Closed Network..................................................................................................................................2–14

2.5.4 Open Network ....................................................................................................................................2–14

2.6 Backward Alarm Theory and Connections.............................................................................................2–15

CHAPTER 3.

3.1 Unpacking....................................................................................................................................................3–1

3.2 Installation...................................................................................................................................................3–2

3.3 Software and Hardware Installation/Upgrades.........................................................................................3–4

3.3.1 Overhead Interface PCB Installation ....................................................................................................3–4

3.3.2 Hardware Upgrades .............................................................................................................................3–6

3.4

Reed-Solomon PCB ....................................................................................................................................3–6

3.4.1 Unpacking ............................................................................................................................................3–6

3.4.2 Installation............................................................................................................................................3–6

3.5

Turbo Codec Installation............................................................................................................................3–8

3.5.1 Unpacking ............................................................................................................................................3–8

3.5.2 Installation............................................................................................................................................3–9

3.6

Duplex Reed-Solomon Codec Installation..............................................................................................3–13

3.7 Data I/O Interface Connector (J8) Removal/Installation ........................................................................3–17

3.7.1 Data I/O Connector (J8) Removal ......................................................................................................3–17

3.7.2 Data I/O Connector (J8) Installation ...................................................................................................3–18

INSTALLATION/UPGRADES.....................................................................................................3–1

3.8

Hardware Upgrades ..................................................................................................................................3–20

3.8.1 Main PCB Firmware Chips.................................................................................................................3–20

3.8.2 Overhead Interface PCB ....................................................................................................................3–22

iv

Page 9

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

CHAPTER 4. EXTERNAL CONNECTIONS......................................................................................................4–1

4.1 External Modem Connections....................................................................................................................4–1

4.1.1 Remote Connector and Pinouts (J6) ....................................................................................................4–4

4.1.2 Fault Connector and Pinouts (J7).........................................................................................................4–5

4.1.3 Data I/O Interface Connector (J8) ........................................................................................................4–6

4.1.4 G.703 ASYNC Interface .....................................................................................................................4–12

4.1.5 Auxiliary 1 Connector and Pinouts (J9) ..............................................................................................4–13

4.1.6 Alarms Connector and Pinouts (J10) .................................................................................................4–14

4.1.7 RF Output Connector (CP1)...............................................................................................................4–14

4.1.8 RF Input Connector (CP2)..................................................................................................................4–14

4.1.9 External Reference (CP3) ..................................................................................................................4–15

4.1.10 Power Entry........................................................................................................................................4–15

4.1.11 Ground Connector (GND) ..................................................................................................................4–15

CHAPTER 5. FRONT PANEL OPERATION.....................................................................................................5–1

5.1

Front Panel ..................................................................................................................................................5–1

5.1.1 LED Indicators......................................................................................................................................5–2

5.1.2 Front Panel Keypad .............................................................................................................................5–3

5.2 Menu System...............................................................................................................................................5–4

5.3

Revision Emulation Operation...................................................................................................................5–5

5.4 Opening Screen ..........................................................................................................................................5–7

5.4.1 Functional Select: Configuration ..........................................................................................................5–7

5.4.1.1 Functional Select: Configuration: Modulator................................................................................5–8

5.4.1.2 Functional Select: Configuration: Demodulator ........................................................................5–14

5.4.1.3 Functional Select: Configuration: Interface................................................................................5–22

5.4.1.4 Functional Select: Configuration: Local AUPC ..........................................................................5–42

5.4.1.5 Functional Select: Configuration: Mux ......................................................................................5–47

5.4.1.6 Functional Select: Configuration: Flex Mux ...............................................................................5–49

5.4.1.7 Functional Select: Configuration: Save .....................................................................................5–55

5.4.1.8 Functional Select: Configuration: Recall....................................................................................5–55

5.4.2

Functional Select: Monitor..................................................................................................................5–56

5.4.3 Functional Select: Faults/Alarms........................................................................................................5–60

5.4.4 Functional Select: Stored FLTS/ALMS...............................................................................................5–65

5.4.5 Functional Select: Remote AUPU (Conditional).................................................................................5–69

5.4.6

Functional Select: Utility.....................................................................................................................5–74

5.4.6.1 Functional Select: Utility: Fixed Modem Rate............................................................................5–74

5.4.6.2 Functional Select: Utility: Fixed Modem Rate: Code Rate/Data Rate .......................................5–74

5.4.6.3 Functional Select: Utility: Modulator ..........................................................................................5–75

5.4.6.4 Functional Select: Utility: Demodulator .....................................................................................5–80

5.4.6.5 Functional Select: Utility: Interface ............................................................................................5–84

5.4.6.6 Functional Select: Utility: System ..............................................................................................5–92

5.4.6.7 Functional Select: Utility: Modem Type ....................................................................................5–99

v

Page 10

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

5.4.6.8 Utility: Factory Set-Up..............................................................................................................5–109

5.5

Custom Modem Defaults........................................................................................................................5–110

CHAPTER 6. MODEM TYPES..........................................................................................................................6–1

6.1

Modem Types..............................................................................................................................................6–1

6.1.1 IDR Operation ......................................................................................................................................6–2

6.1.2 IBS Operation.......................................................................................................................................6–3

6.1.3 D&I Operation ......................................................................................................................................6–4

6.1.4

ASYNC/AUPC Operation .....................................................................................................................6–5

6.1.5 EFD Closed Network Configuration .....................................................................................................6–6

6.1.6 Custom Operation ................................................................................................................................6–7

6.1.7 SDM-100 Emulation Operation ............................................................................................................6–8

6.1.8 SDM-6000 Emulation Operation ..........................................................................................................6–9

6.2 Reed-Solomon Modes ..............................................................................................................................6–10

CHAPTER 7. CLOCKING OPTIONS ................................................................................................................7–1

7.1 Clocking Options ........................................................................................................................................7–1

7.1.1 EIA-232, EIA-422, or V.35 Master/Master............................................................................................7–1

7.1.2 EIA-232, EIA-422, or V.35 Master/Slave..............................................................................................7–1

7.1.3 IDR/IBS G.703 Master/Master..............................................................................................................7–2

7.1.4 IDR/IBS G.703 Master/Slave................................................................................................................7–2

7.1.5 D&I G.703 Master/Master.....................................................................................................................7–7

CHAPTER 8. BUFFERING................................................................................................................................8–1

8.1 Buffering ......................................................................................................................................................8–1

8.2

Buffer Size ...................................................................................................................................................8–4

8.3 Doppler ........................................................................................................................................................8–4

8.4

Plesiochronous...........................................................................................................................................8–5

8.5 Frame/Multiframe Length ...........................................................................................................................8–6

8.5.1

Multiples of the Frame Length..............................................................................................................8–6

8.5.2 Total Buffer Length...............................................................................................................................8–6

8.6 Converting Between Bits and Seconds ....................................................................................................8–6

8.6.1

Bits to Seconds..................................................................................................................................8–6

8.6.2 Seconds to Bits ....................................................................................................................................8–6

vi

Page 11

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

CHAPTER 9. FORWARD ERROR CORRECTION (OPTIONS) .......................................................................9–1

9.1 Introduction .................................................................................................................................................9–1

9.2

Viterbi...........................................................................................................................................................9–2

9.3 Sequential....................................................................................................................................................9–3

9.4

Reed-Solomon Outer Codec ......................................................................................................................9–4

9.4.1

Closed Network Modes ........................................................................................................................9–5

9.4.2 Open Network Modes ..........................................................................................................................9–5

9.5 Trellis Coding (FAST Option).....................................................................................................................9–6

9.6

Turbo Product Codec (Hardware Option).................................................................................................9–7

Introduction.........................................................................................................................................9–7

9.6.1

9.6.2 End-to-End Processing Delay ..............................................................................................................9–7

Comparison of all TPC Modes.........................................................................................................9–8

9.6.3

9.7 Uncoded Operation (No FEC) ....................................................................................................................9–9

CHAPTER 10. OPEN NETWORK OPERATIONS ............................................................................................10–1

10.1 Introduction...............................................................................................................................................10–1

10.2

Intelsat Business System (IBS) ...............................................................................................................10–1

10.2.1 IBS Specification ................................................................................................................................10–4

10.2.2 IBS Modem Defaults ..........................................................................................................................10–5

10.2.3 IBS Primary Data Interface.................................................................................................................10–6

10.2.4 IBS Clock and Dejitter ........................................................................................................................10–6

10.2.5 IBS Framing .......................................................................................................................................10–6

10.2.6 IBS Engineering Service Channel......................................................................................................10–6

10.2.7 IBS Scrambling ..................................................................................................................................10–6

10.3 Intermediate Data Rate (IDR)....................................................................................................................10–7

10.3.1 IDR Specification..............................................................................................................................10–10

10.3.2 IDR Modem Defaults........................................................................................................................10–11

10.3.3 IDR Primary Data Interface ..............................................................................................................10–12

10.3.4 IDR Framing.....................................................................................................................................10–12

10.3.5 IDR Engineering Service Channel....................................................................................................10–12

10.4 Drop and Insert (D&I)..............................................................................................................................10–13

10.4.1 D&I Specification..............................................................................................................................10–14

10.4.2 Theory of Operation .........................................................................................................................10–18

10.4.3 Data Interference .............................................................................................................................10–18

10.4.4 Transmitted MUX .............................................................................................................................10–18

10.4.5 Receive DEMUX ..............................................................................................................................10–19

10.4.6 Plesiochronous Buffer ......................................................................................................................10–19

10.4.7 Engineering Service Channel...........................................................................................................10–20

10.4.8 Backward Alarm ...............................................................................................................................10–20

vii

Page 12

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

10.4.9 D&I Framing Formats.......................................................................................................................10–20

10.4.10 D&I Modem Defaults ........................................................................................................................10–23

10.4.11 D&I Primary Data Interface ..............................................................................................................10–24

10.4.12 D&I Framing.....................................................................................................................................10–24

10.5

G.703........................................................................................................................................................10–25

CHAPTER 11. ASYNCHRONOUS INTERFACE/AUPC...................................................................................11–1

11.1

Asynchronous Interface/AUPC................................................................................................................11–1

11.2

AUPC..........................................................................................................................................................11–4

11.2.1

AUPC - Between Two Modems..........................................................................................................11–5

11.2.2 Self-Monitoring Local Modem AUPC Control .....................................................................................11–6

11.3 ASYNC .......................................................................................................................................................11–7

11.3.1 Terrestrial Data Interfaces..................................................................................................................11–7

11.3.2 ASYNC Data Interfaces......................................................................................................................11–7

11.3.3 Mux Operation....................................................................................................................................11–8

11.3.4 Demux Operation ...............................................................................................................................11–8

11.3.5 Buffer Operation.................................................................................................................................11–8

11.3.6 LoopTiming Operation........................................................................................................................11–9

11.3.7

Baseband Loopback Operation..........................................................................................................11–9

11.3.8 Non-ASYNC Operation ....................................................................................................................11–10

11.4

ASYNC Channel EIA-485 2- and 4-Wire operation ...............................................................................11–10

11.4.1 Valid ASYNC Baud Rates ................................................................................................................11–11

11.4.2 Front Panel Operation......................................................................................................................11–11

11.4.3 ASYNC Remote Operation...............................................................................................................11–12

11.4.4 ASYNC/AUPC Modem Defaults.......................................................................................................11–24

CHAPTER 12. ASYMMETRICAL LOOP TIMING .............................................................................................12–1

CHAPTER 13.

CHAPTER 14. 8-CHANNEL MULTIPLEXER ...................................................................................................14–1

14.1 Introduction...............................................................................................................................................14–1

14.2 Installation.................................................................................................................................................14–2

14.3 8-Channel Multiplexer Specifications .....................................................................................................14–4

14.4

8-Channel Multiplexer 100-pin Connector (J10).....................................................................................14–5

DUPLEX REED-SOLOMON CODEC .......................................................................................13–1

viii

Page 13

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

CHAPTER 15. FLEX MUX ................................................................................................................................15–1

15.1 Introduction...............................................................................................................................................15–1

15.2 Installation.................................................................................................................................................15–6

15.3 50-Pin Connector Assignments...............................................................................................................15–8

CHAPTER 16. FAST ACCESSIBLE OPTIONS ................................................................................................16–1

16.1 Introduction...............................................................................................................................................16–1

16.2 FAST Accessible Options ........................................................................................................................16–1

16.3 FAST System Theory................................................................................................................................16–3

16.4

Implementation .........................................................................................................................................16–3

16.5 Variable Data Rates ......................................................................................................................................16–6

CHAPTER 17.

CHAPTER 18. TROUBLESHOOTING ..............................................................................................................18–1

18.1 System Checkout......................................................................................................................................18–1

18.2

Interface Checkout....................................................................................................................................18–2

18.2.1

18.2.2 Demodulator Checkout ......................................................................................................................18–6

18.3 Fault Isolation............................................................................................................................................18–8

18.3.1 System Faults/Alarms ........................................................................................................................18–8

18.3.2 Faults/Alarms Display ......................................................................................................................18–12

18.3.3 Faults/Alarms Analysis.....................................................................................................................18–12

18.3.4

18.3.5 Remove and Replace the Fan Assembly .........................................................................................18–20

CHAPTER 19. SPECIFICATION.......................................................................................................................19–1

19.1 Specification Summary ............................................................................................................................19–1

Environmental and Physical Specifications...........................................................................................19–3

19.2

FLASH UPGRADING................................................................................................................17–1

Modulator Checkout ...........................................................................................................................18–3

Remove and Replace Power Supply................................................................................................18–19

19.3

Remote Control Specifications................................................................................................................19–4

19.4 Modulator Specifications .........................................................................................................................19–5

19.4.1

Digital Data Rate................................................................................................................................19–5

19.4.2 Modulation and Encoding Types ........................................................................................................19–7

19.4.3 Scrambling Types ..............................................................................................................................19–8

ix

Page 14

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

19.4.4 Differential Encoder............................................................................................................................19–8

19.4.5 BPSK BIT Ordering ............................................................................................................................19–8

19.4.6 Interleaver (Reed-Solomon Codec)....................................................................................................19–8

19.4.7 Transmit Frequency (IF).....................................................................................................................19–9

19.4.8 Frequency Reference.........................................................................................................................19–9

19.4.9

Transmit Frequency Change Time.....................................................................................................19–9

19.4.10 Phase Noise.......................................................................................................................................19–9

19.4.11 Transmit IF Output Switch................................................................................................................19–10

19.4.12 Transmit IF Power............................................................................................................................19–10

19.4.13 Modulator Power Offset ...................................................................................................................19–10

19.4.14

19.4.15 Spurious Emissions..........................................................................................................................19–10

19.4.16 Modulator Phase Error .....................................................................................................................19–10

19.4.17 Transmit IF Test Modes ...................................................................................................................19–11

19.4.18 Modulator Spectrum Rotation...........................................................................................................19–11

19.5

19.5.1

19.5.2 Demodulation and FEC Decoding Types .........................................................................................19–13

19.5.3 Descrambling Types ........................................................................................................................19–14

19.5.4

19.5.5 BPSK BIT Ordering ..........................................................................................................................19–14

19.5.6 Deinterleaver (Reed-Solomon Codec) .............................................................................................19–15

19.5.7 Demodulator Spectrum Rotation ......................................................................................................19–15

19.5.8 Frequency Reference.......................................................................................................................19–15

19.5.9

19.5.10 Phase Noise.....................................................................................................................................19–15

19.5.11 Transmit IF Output Switch................................................................................................................19–15

19.5.12

19.5.13 Channel Spacing/Adjacent Carrier Performance..............................................................................19–16

Modulated IF Output Shape .............................................................................................................19–10

Demodulator Specifications...................................................................................................................19–12

Digital Data Rate..............................................................................................................................19–12

Differential Encoder..........................................................................................................................19–14

Transmit Frequency Change Time...................................................................................................19–15

Demodulator IF Input Shape ............................................................................................................19–16

19.6 BER Performance Specifications ..........................................................................................................19–16

19.6.1

Performance with Noise, Viterbi Decoder, and Open Network Mode...............................................19–17

19.6.2 Performance with Noise, Viterbi Decoder, and Closed Network ......................................................19–17

19.6.3 Performance with Noise, Viterbi Decoder, and Reed-Solomon (Optional).......................................19–18

19.6.4

Performance with Noise, 56 kbps and Sequential Decoder (Optional) ............................................19–18

19.6.5 Performance with Noise, 1544 kbps and Sequential Decoder .........................................................19–19

19.6.6 Performance with Noise at 1544 kbps, Sequential Decoder, and Reed-Solomon ..........................19–19

19.6.7 8-PSK Performance with Noise and With/Without Reed-Solomon...................................................19–20

19.6.8 Performance with Noise, Viterbi Decoder, and Offset QPSK ...........................................................19–20

19.6.9

Performance with Noise, Uncoded (1/1) BPSK, QPSK, and Offset QPSK.......................................19–21

19.6.10 Performance with Noise Turbo Product Codec (Optional) ...............................................................19–21

19.6.11 BER Threshold.................................................................................................................................19–21

19.7

Acquisition Time.....................................................................................................................................19–22

19.7.1

Receive IF Carrier Acquisition Range ..............................................................................................19–22

19.7.2 Receive IF Carrier Reacquisition......................................................................................................19–22

19.7.3 AGC Output......................................................................................................................................19–24

x

Page 15

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

19.8 Interface Specifications..........................................................................................................................19–23

19.8.1

Transmit Clock Source.....................................................................................................................19–23

19.8.2 Send Clock Timing Source...............................................................................................................19–23

19.9 Terrestrial Interface Types.....................................................................................................................19–26

19.9.1

Universal ..........................................................................................................................................19–26

19.9.2 EIA-232 Specification.......................................................................................................................19–27

19.9.3 V.35 Specification V.10, V.11 Specification, Circuit Supported........................................................19–28

19.9.4

EIA-422/EIA-449 MIL-188-114A Specification .................................................................................19–29

19.9.5 G.703 (Optional with Overhead Card)..............................................................................................19–30

19.10 System Specifications............................................................................................................................19–31

19.10.1

19.10.2 Test Modes ......................................................................................................................................19–31

19.10.3 Remote Control ................................................................................................................................19–32

19.10.4

19.10.5 Monitored Signals ............................................................................................................................19–32

19.10.6

19.10.7 Inoperability Modes ..........................................................................................................................19–33

Loopback Modes..............................................................................................................................19–31

Modem Remote Address..................................................................................................................19–32

Modem Emulation Modes.................................................................................................................19–33

19.11

Dimensional Evelope..............................................................................................................................19–34

APPENDIX A.

GLOSSARY ................................................................................................................................................... g–1

INDEX .....................................................................................................................................................i–1

REMOTE CONTROL OPERATION ...........................................................................................A–1

xi

Page 16

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Figures

Figure 1-1. Block Diagram ....................................................................................................................................1–2

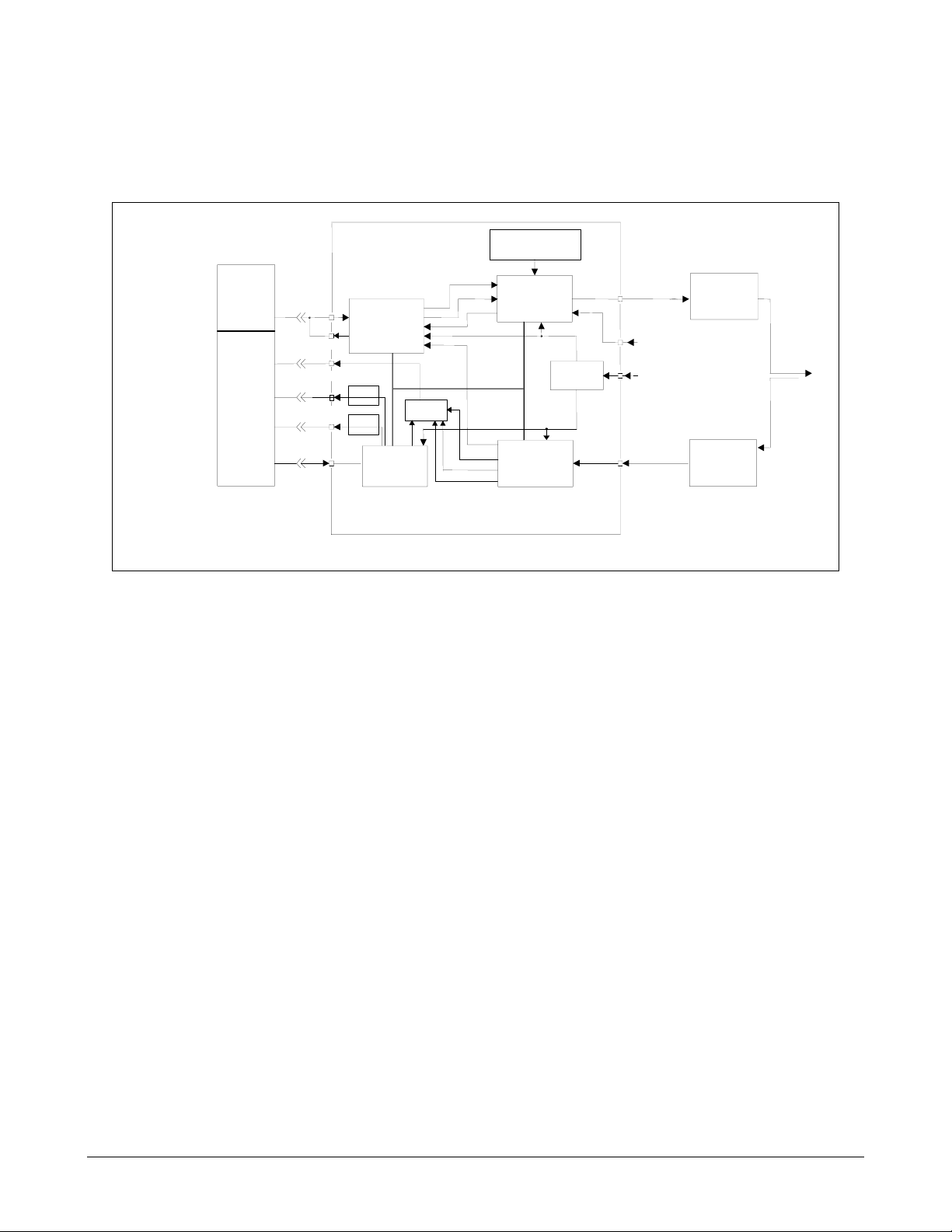

Figure 2-1. M&C Block Diagram ...........................................................................................................................2–2

Figure 2-2. Modulator Block Diagram ...................................................................................................................2–5

Figure 2-3. Demodulator Block Diagram...............................................................................................................2–8

Figure 2-4. Interface Block Diagram ...................................................................................................................2–12

Figure 3-1. Installation of the Mounting Bracket, KT/6228-1.................................................................................3–3

Figure 3-2. Overhead Interface PCB Installation ..................................................................................................3–5

Figure 3-3. Reed-Solomon Codec Installation...................................................................................................... 3–7

Figure 3-4. Turbo Codec Installation ..................................................................................................................3–10

Figure 3-5. Firmware Location............................................................................................................................3–11

Figure 3-6. PCB Location ...................................................................................................................................3–15

Figure 3-7. Installation of the Duplex Reed-Solomon Module ............................................................................3–16

Figure 3-8. Data I/O connector (J8) Removal/Installation...................................................................................3–19

Figure 3-9. Main Board Field-Changeable Chips................................................................................................3–21

Figure 3-10. Overhead Board Field-Changeable Chips...................................................................................... 3–22

Figure 4-1. Basic Modem, 25-Pin D Connector ....................................................................................................4–3

Figure 4-2. (V.35) 34-Pin Winchester Connector..................................................................................................4–3

Figure 4-3. EIA-422/449, 37-Pin D Connector ......................................................................................................4–3

Figure 4-4. Overhead Option, 50-Pin D Connector................................................................................................4–3

Figure 4-5. 8-Channel, 100-Pin MUX Connector ..................................................................................................4–3

Figure 5-1. Front Panel View ................................................................................................................................5–1

Figure 5-2. Keypad ...............................................................................................................................................5–3

Figure 5-3. Menu Tree.......................................................................................................................................... 5–6

Figure 5-4. RF Loopback.................................................................................................................................... 5–17

Figure 5-5. IF Loopback......................................................................................................................................5–18

Figure 5-6. Baseband Loopback......................................................................................................................... 5–27

Figure 5-7. Interface Loopback...........................................................................................................................5–28

Figure 7-1. EIA-422, EIA-232, or V.35 Master/Master Clocking Diagram.............................................................7–3

Figure 7-2. EIA-422, EIA-232, or Master/Slave Clocking Diagram .......................................................................7–4

Figure 7-3. IDR/IBS G.703 Master/Master Clocking Diagram...............................................................................7–5

Figure 7-4. IDR/IBS G.703 Master/Slave Clocking Diagram ................................................................................7–6

Figure 7-5. D&I G.703 Master/Master Clocking Diagram ..................................................................................... 7–8

Figure 8-1. Clock Slip ...........................................................................................................................................8–2

Figure 8-2. Doppler Shift.......................................................................................................................................8–3

Figure 9-1. Viterbi Decoder with Open Network BER Data ................................................................................9–11

Figure 9-2. Viterbi Decoder with Closed Netwrok BER Data ..............................................................................9–12

Figure 9-3. Viterbi Decoder with Reed-Solomon ................................................................................................9–13

Figure 9-4. Sequential BER Data (56 kbps)........................................................................................................ 9–14

Figure 9-5. Sequential Decoder, Reed-Solomon 1544 kbps ..............................................................................9–15

Figure 9-6. Sequential Decoder BER with Reed-Solomon 1544 kbps................................................................9–16

Figure 9-7 8-PSK with/without Reed-Solomon .................................................................................................9–17

Figure 9-8. Viterbi Decoder and Offset QPSK ....................................................................................................9–18

Figure 9-9. Uncoded 1/1 BPSK, QPSK, and Offset QPSK .................................................................................9–19

Figure 9-10. Turbo product Codec...................................................................................................................... 9–20

xii

Page 17

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Figure 10-1. IBS Interface Block Diagram ..........................................................................................................10–3

Figure 10-2. IDR Interface Block Diagram.......................................................................................................... 10–9

Figure 10-3. D&I with Asynchronous Overhead Block Diagram .......................................................................10–16

Figure 10-4. D&I with Asynchronous Overhead Data Flow ..............................................................................10–17

Figure 10-5. E1 Framing Formats..................................................................................................................... 10–21

Figure 10-6. T1 Framing Formats.....................................................................................................................10–22

Figure 11-1. ASYNC/AUPC Block Diagram........................................................................................................11–3

Figure 11-2. Remote ASYNC Connection Diagram for Y Cable....................................................................... 11–13

Figure 11-3. Remote ASYNC Connection Diagram for Breakout Panel ...........................................................11–13

Figure 12-1. Transmit Section of the Asymmetrical Loop Timing Block Diagram ...............................................12–3

Figure 12-2. Receive Section of the Asymmetrical Loop Timing Block Diagram ................................................12–4

Figure 14-1. 8-Channel Multiplexer PCB (AS/5985)........................................................................................... 14–2

Figure 14-2. 8-Channel Multiplexer Installation ..................................................................................................14–3

Figure 15-1. Flex MUX (AS/6450) ......................................................................................................................15–2

Figure 15-2. Flex Mux Multiplexer Installation ....................................................................................................15–7

Figure 18-1. Fault Isolation Test Setup............................................................................................................... 18–2

Figure 18-2. Typical Output Spectrum (with Noise) ............................................................................................18–5

Figure 18-3. Typical Output Spectrum (without Noise) .......................................................................................18–5

Figure 18-4. Typical Eye Constellations .............................................................................................................18–7

Figure 19-1. Dimensional Envelope Pre-1999.................................................................................................. 19–35

Figure 19-2. Dimensional Envelope Post-1999 ................................................................................................19–36

xiii

Page 18

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Tables

Table 1-1. Options ................................................................................................................................................1–6

Table 1-2. FAST Options and Required Configurations .......................................................................................1–8

Table 1-3. Comtech EF Data Part Numbers ....................................................................................................... 1–10

Table 1-4. Data Interface Connector (J8) Matrix.................................................................................................1–11

Table 1-5. SDM-300A Software Selection Table ................................................................................................1–11

Table 1-6. SDM-300A Spares/Accessories ........................................................................................................1–12

Table 3-1. Connector (J8) Matrix ........................................................................................................................3–17

Table 4-1. Modem Rear Panel Connection...........................................................................................................4–2

Table 4-2. Remote Connector and Pinouts (J6) ...................................................................................................4–4

Table 4-3. Fault Connector and Pinouts (J7)........................................................................................................ 4–5

Table 4-4. 25-Pin D Connector Pinouts ................................................................................................................4–7

Table 4-5. 34-Pin Winchester Connector Pinouts (V.35) ......................................................................................4–8

Table 4-6. 37-Pin Connector Pinouts (Optional) ...................................................................................................4–9

Table 4-7. 50-Pin Connector Pinouts.................................................................................................................. 4–10

Table 4-8. Flex Mux 50-Pin Connector Definition ...............................................................................................4–12

Table 4-9. AUX 1 Connector and Pinouts (J9)....................................................................................................4–13

Table 4-10. Alarms Connector and Pinouts (J10)...............................................................................................4–14

Table 5-1. LED Indicators .....................................................................................................................................5–2

Table 5-2. Revision Emulation Operation .............................................................................................................5–5

Table 5-3. Custom Modem Defaults .................................................................................................................5–110

Table 6-1. Modem Types......................................................................................................................................6–1

Table 6-2. IDR Parameter Settings....................................................................................................................... 6–2

Table 6-3. IBS Parameter Settings .......................................................................................................................6–3

Table 6-4. D&I Parameter Settings.......................................................................................................................6–4

Table 6-5. N x 64 Chart ........................................................................................................................................6–4

Table 6-6. Asynchronous Parameter Settings ......................................................................................................6–5

Table 6-7. Comtech EF Data Closed Network Parameter Settings ......................................................................6–7

Table 6-8. SDM-100 Emulation Parameter Settings.............................................................................................6–8

Table 6-9. SDM-6000 Emulation Parameter Settings...........................................................................................6–9

Table 6-10. Reed-Solomon Modes.....................................................................................................................6–10

Table 8-1. Minimum Doppler/Plesiochronous Buffer Capacity Requirements ......................................................8–7

Table 9-1. Turbo Product Coding Processing Delay Comparison ........................................................................9–8

Table 10-1. IBS Specifications............................................................................................................................10–4

Table 10-2. IBS Modem Defaults........................................................................................................................ 10–5

Table 10-3. IDR Specifications .........................................................................................................................10–10

Table 10-4. IDR Modem Defaults .....................................................................................................................10–11

Table 10-5. D&I Specifications .........................................................................................................................10–14

Table 10-6. D&I Modem Defaults ......................................................................................................................10–23

Table 10-7. G.703 Specifications....................................................................................................................... 10–25

Table 11-1. Setting AUPC Parameters................................................................................................................ 11–4

Table 11-2. ASYNC Remote Operation............................................................................................................. 11–12

Table 11-3. Local EIA-232 to Remote EIA-232.................................................................................................11–14

Table 11-4. Local EIA-232 to Remote EIA-485 (4-Wire)................................................................................... 11–15

Table 11-5. Local EIA-232 to Remote EIA-485 (2-Wire)................................................................................... 11–16

xiv

Page 19

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Table 11-6. Local EIA-485 (4-Wire) to Remote EIA-232...................................................................................11–17

Table 11-7. Local EIA-485 (4-Wire) to Remote EIA-485 (4-Wire).....................................................................11–18

Table 11-8. Local EIA-485 (4-Wire) to Remote EIA-485 (2-Wire).....................................................................11–19

Table 11-9. Local EIA-485 (2-Wire) to Remote EIA-232...................................................................................11–20

Table 11-10. Local EIA-485 (2-Wire) to Remote EIA-485 (4-Wire)...................................................................11–22

Table 11-11. ASYNC/AUPC Modem Defaults ..................................................................................................11–24

Table 15-1. System Specification .......................................................................................................................15–3

Table 15-2. Multiplexer Specification..................................................................................................................15–4

Table 15-3. Demultiplexer Specific Specifications.............................................................................................. 15–5

Table 15-4. 50-Pin Connector Assignments .......................................................................................................15–8

Table 16-1. FAST Option and Required Configurations .....................................................................................16–2

Table 18-1. Conversion to S/N and Eb/No Chart................................................................................................18–4

Table 18-2. SDM-300A Fault Tree...................................................................................................................... 18–9

Table 19-1. Specification Summary.................................................................................................................... 19–1

Table 19-2. Environmental and Physical Specifications .....................................................................................19–3

Table 19-3. Remote Control Specifications ........................................................................................................19–4

Table 19-4. Modulator Specifications .................................................................................................................19–5

Table 19-5. Modulator Digital Data Rate.............................................................................................................19–5

Table 19-6. Modulation and Encoding Types .....................................................................................................19–7

Table 19-7. Demodulator Digital Data Rate.......................................................................................................19–12

Table 19-8. Demodulation FEC Decoding .........................................................................................................19–14

Table 19-9. BER Performance Reference Tables .............................................................................................19–17

Table 19-10. Viterbi Decoder with Open Network BER Data............................................................................. 19–18

Table 19-11. Viterbi Decoder with Closed Network BER Data .........................................................................19–18

Table 19-12. Viterbi Decoder with Reed-Solomon............................................................................................19–19

Table 19-13. Sequential BER Data (56 kbps)................................................................................................... 19–19

Table 19-14. Sequential Decoder BER Data (1544 kbps) ................................................................................19–20

Table 19-15. Sequentail Decoder BER Data (Reed-Solomon)......................................................................... 19–20

Table 19-16. 8-PSK Specification.....................................................................................................................19–21

Table 19-17. Viterbi Decoder and Offset QPSK ...............................................................................................19–21

Table 19-18. Uncoded (1/1) BPSK, QPSK, and Offset QPSK.......................................................................... 19–22

Table 19-19. Turbo Product Code ....................................................................................................................19–22

Table 19-20. Acquisition Time ..........................................................................................................................19–23

Table 19-21. Test Modes..................................................................................................................................19–32

xv

Page 20

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

This page is intentionally left blank.

xvi

Page 21

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

About this Manual

This manual provides installation and operation information for the Comtech EF Data

SDM-300A Satellite Modem. This is a technical document intended for earth station

engineers, technicians, and operators responsible for the operation and maintenance of

the SDM-300A.

Related Documents

The following documents are referenced in this manual:

• Comtech EF Data UB-300 Universal Breakout Panel Installation and Operation

Manual

• Comtech EF Data UB-54 Universal Breakout Panel Installation and Operation

Manual

• Comtech EF Data SDR-54A Satellite Demodulator Installation and Operation

Manual

• Comtech EF Data Space Link Remote System User’s Guide

• INTELSAT Earth Station Standards 308, 309, 310, and 314

• International Telephone and Telegraph Consultative Committee V.35 and G.721

• UB-530 Universal Breakout Panel Installation and Operation Manual

Conventions and References

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

unsafe practices or risks of property damage.

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARN ING

IMPORTANT indicates a statement that is associated with the task

IMPORTANT

being performed. .

xvii

Page 22

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Examples of

Multi-Hazard

Formats

Metric Conversion

Metric conversion information is located on the inside back cover of this manual. This

information is provided to assist the operator in cross-referencing English to Metric

conversions.

Recommended Standard Designations

Recommended Standard (RS) Designations are interchangeable with the designation of

the Electronic Industries Association (EIA).

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the Comtech EF Data Technical

Publications department: tpubs@comtechefdata.com

xviii

Page 23

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

ELECTRICAL SAFETY

The SDM-300A Satellite Modem has been shown to comply with the following safety standard:

• EN 60950: Safety of Information Technology Equipment, including electrical business

machines.

The equipment is rated for operation over the range 85 to 264 volts AC. It has a maximum

power consumption of 60 watts.

FUSES

The SDM-300A Satellite Modem is fitted with two fuses, one each for line and neutral

connections. These are contained within the body of the IEC power connector, behind a small

plastic flap.

• For 230 volt AC operation, use T0.75A, 20mm fuses.

• For 115 volt AC operation, use T1.25A fuses, 20mm fuses.

IMPORTANT

Environmental

The SDM-300A shall not be operated in an environment where the unit is exposed to

extremes of temperature outside the ambient range 0 to 50°C (32 to 122°F), precipitation,

condensation, or humid atmospheres above 95% RH, altitudes (un-pressurised) greater

than 2000 metres, excessive dust or vibration, flammable gases, corrosive or explosive

atmospheres.

Operation in vehicles or other transportable installations that are equipped to provide a

stable environment is permitted. If such vehicles do not provide a stable environment,

safety of the equipment to EN60950 may not be guaranteed.

For continued operator safety, always replace the fuses with the

correct type and rating.

xix

Page 24

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

Installation

The installation and connection to the line supply must be made in compliance to local or

national wiring codes and regulations.

The SDM-300A is designed for connection to a power system that has separate ground,

line and neutral conductors. The equipment is not designed for connection to power

system that has no direct connection to ground.

The SDM-300A is shipped with a line inlet cable suitable for use in the country of

operation. If it is necessary to replace this cable, ensure the replacement has an equivalent

specification. Examples of acceptable ratings for the cable include HAR, BASEC and

HOXXX-X. Examples of acceptable connector ratings include VDE, NF-USE, UL, CSA,

OVE, CEBEC, NEMKO, DEMKO, BS1636A, BSI, SETI, IMQ, KEMA-KEUR and

SEV.

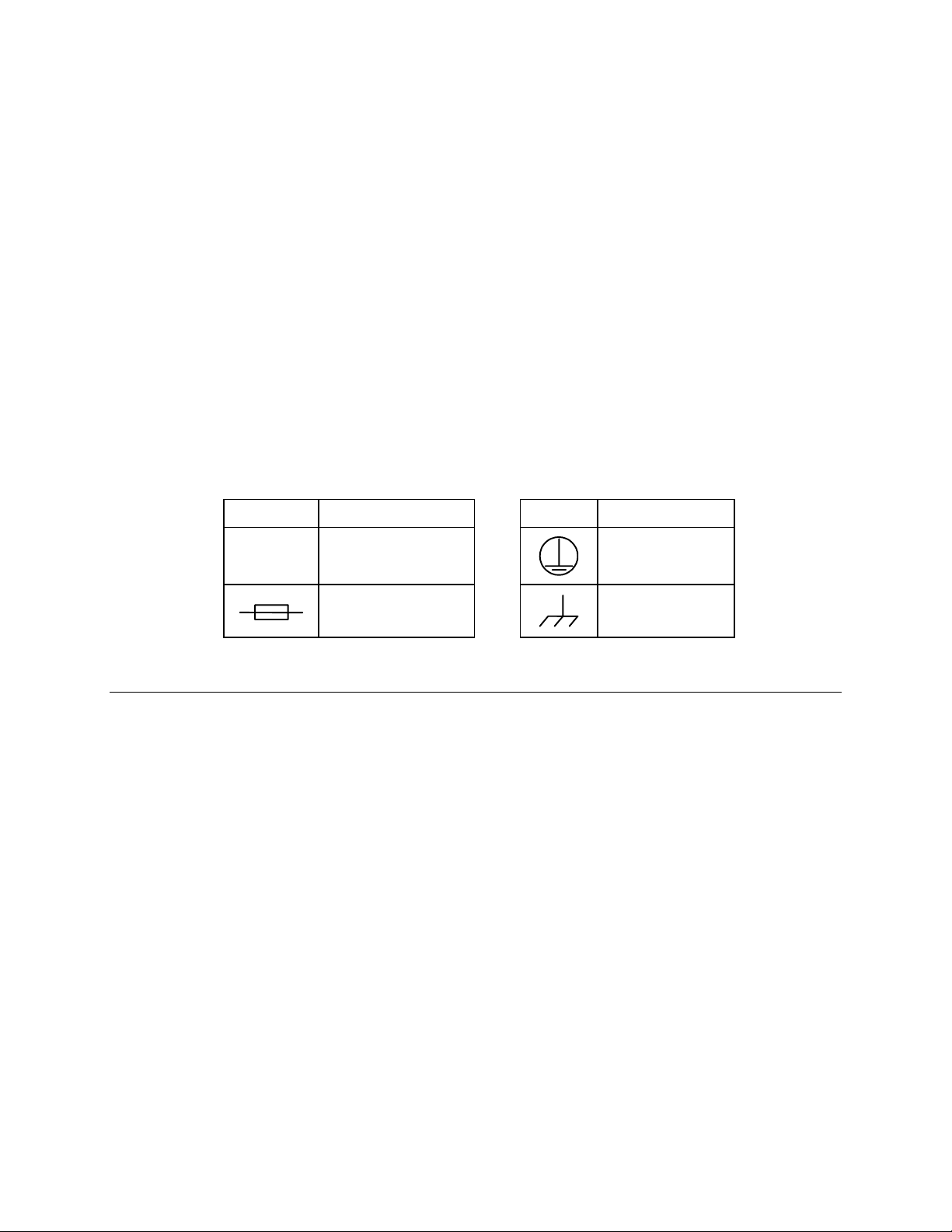

International Symbols:

Symbol Definition Symbol Definition

~

Alternating Current

Fuse

Telecommunications Terminal Equipment Directive

In accordance with the Telecommunications Terminal Equipment Directive 91/263/EEC,

this equipment should not be directly connected to the Public Telecommunications

Network.

Protective Earth

Chassis Ground

xx

Page 25

SDM-300A Satellite Modem Revision 6

Preface MN/SDM300A.IOM

EMC (Electromagnetic Compatibility)

In accordance with European Directive 89/336/EEC, the SDM-300A Satellite Modem

has been shown, by independent testing, to comply with the following standards:

Emissions: EN 55022 Class B - Limits and methods of measurement of radio interference

characteristics of Information Technology Equipment.

(Also tested to FCC Part 15 Class B)

Immunity: EN 50082 Part 1 - Generic immunity standard, Part 1: Domestic, commercial

and light industrial environment.

Additionally, the SDM-300A has been shown to comply with the following standards:

EN 61000-3-2 Harmonic Currents Emission

EN 61000-3-3 Voltage Fluctuations and Flicker

EN 61000-4-2 ESD Immunity