Page 1

RSU-503

RSU-503

RSU-503RSU-503

Redundancy Switch Unit

Redundancy Switch Unit

Redundancy Switch UnitRedundancy Switch Unit

Installation and Operation Manual

Installation and Operation Manual

Installation and Operation ManualInstallation and Operation Manual

Part Number MN/RSU503.IOM

Revision 8

Page 2

Errata A

Comtech EFData Documentation Update

Subject:

Date:

Document:

Part Number:

Collating Instructions:

Changes to Chapter 3 (Communications Link Jum per Setting)

July 28, 1997

RSU-503 Redundancy Switch Unit Installation and Operation

Manual, Rev. 8, dated April 4, 1997

MN/RSU503.EA8

Attach this page to page 3-1

Comments:

The following changes provide the correct information for jumper placement when choosing

between RS-232 or -485. This inform at ion will be incorporat ed into the next revision.

Change Specifics:

3.4.1 Communications Link

The terminal functions can be remotely controlled and monitored via an RS-485 or RS-232

communications link.

• The RS-485 interface makes it possible to operate 255 terminals on a common communications

link.

• The RS-232 interface is used to communicate with a single terminal.

The M&C module must be hardware configured on the M&C board to one of the two interfaces. Refer to

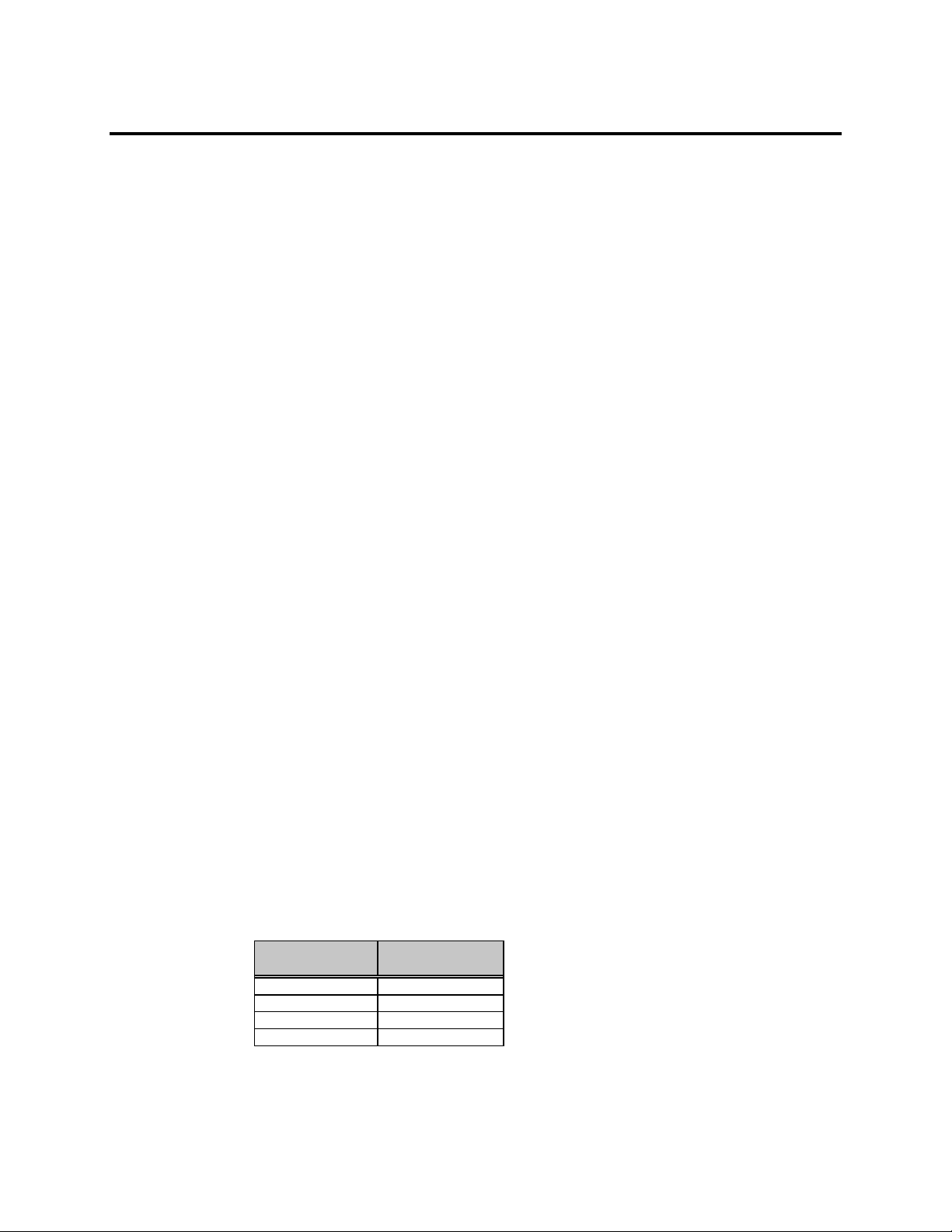

the following table for jumper placement at JP1:

RS-485

Configuration

1-2 9-10

3-4 11-12

5-6 13-14

7-8 15-16

Filename: T_ERRATA

RS-232

Configuration

1

Page 3

Comtech EFData is an ISO 9001 Registered Company

RSU-503

RSU-503

RSU-503RSU-503

Redundancy Switch Unit

Redundancy Switch Unit

Redundancy Switch UnitRedundancy Switch Unit

Installation and Operation Manual

Installation and Operation Manual

Installation and Operation ManualInstallation and Operation Manual

Part Number MN/RSU503.IOM

Revision 8

April 4, 1997

Special Instructions:

This is the ninth edition of the manual.

Change bars were not utilized. For an overview of changes made to Rev. 7, refer to the preface

(“Overview of Changes to Previous Edition”).

This revision supersedes part number MN/SDMRSU503 Rev. 7 dated January 22, 1996.

Copyright © Comtech EFData, 2000

All rights reserved.

Printed in the USA.

Comtech EFData, 2114 West 7th Street, Tempe, Arizona 85281 USA, (480) 333-2200, FAX: (480) 333-2161.

Page 4

Warranty Policy

This EFData Corporation product is warranted against defects in material and

workmanship for a period of one year from the date of shipment. Duri ng the warranty

period, EFData will, at its option, repair or replace produc t s that prove to be defective.

For equipment under warranty, the customer is responsible for f rei ght to EFData and

all related custom, taxes, tariffs, ins urance, etc. EFData is responsible for the freight

charges

return the equipment by the same method (i.e., A i r, Express, Surface) as the

equipment was sent to EFDat a.

for return of the equipment f rom the factory to the c ustomer. EFData will

only

Limitations of Warranty

The foregoing warranty shall not apply to defects resulting from improper installation

or maintenance, abuse, unaut horized modification, or operati on outside of

environmental specifi cations for the product, or, for damages that occur due t o

improper repackaging of equipment for return to EFData.

No other warranty is expressed or implied. EFData Corporation specifically

disclaims the implied warranties of merchantability and fitness for particular

purpose.

Exclusive Remedies

The remedies provided herein are the buyer's sole and exclusive remedies. EFData

Corporation shall not be liable for any direct, indirect, spec i al , incidental, or

consequential damages, whether bas ed on contact, tort, or any other l egal theory.

Disclaimer

EFData has reviewed this manual thoroughly in order that it will be an easy-to-use

guide to your equipment. All statements, technical information, and recommendations

in this manual and in any guides or rel ated documents are believed reliable, but the

accuracy and completeness thereof are not guaranteed or warranted, and they are

not intended to be, nor should they be unders t ood to be, representations or warranties

concerning the products described. Further, EFData reserves t he ri ght to make

changes in the specifications of the products described in this manual at any time

without notice and without obligation to not i fy any person of such changes.

If you have any questions regarding your equipment or the information in this manual,

please contact the EFData Customer Support Department. (For more informat i on,

refer to the preface.)

Page 5

About this Manual

This manual provides installation and operation information for the EFData RSU-503

redundancy switch unit, referred to in this manual as “the switch.” This is a technical

document intended for earth station engineers, technicians, and operators responsible for

the operation and maintenance of the RSU-503 redundancy switch unit.

Conventions and References Used in this Manual

Cautions and Warnings

CAUTION indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury. CAUTION may also be used to indicate other

CAUTION

unsafe practices or risks of property damage.

Preface

WARNING indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

WARNING

Rev. 8 i

Page 6

Preface RSU-503 Redundancy Switch Unit

Trademarks

Product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are hereby acknowledged.

Related Documents

The following documents are referenced in this manual:

• EFData Specification SP/3000

• EFData KP-10 External Keypad Installation and Operation Manual

Overview of Changes to Previous Edition

A summary of the changes made to Rev. 7 includes:

• Incorporated various cosmetic (non-technical) changes (e.g., formatting,

spelling)

• Addition of RFT-705 and KST-2000 to Section 1.1

• Corrected part numbers in Section 1.2

• Addition of RSU-503 dimensional drawing in Chapter 2

• Corrected installation parts kit in Chapter 2

• Addition of an external connection locations photos in Chapter 2 and Appendix

A

• Updated firmware information in Appendix B

Reporting Comments or Suggestions Concerning this Manual

Comments and suggestions regarding the content and design of this manual will be

appreciated. To submit comments, please contact the EFData Customer Support

Department according to the following information.

ii Rev. 8

Page 7

RSU-503 Redundancy Switch Unit Preface

Customer Support

Contact the EFData Customer Support Department for:

• Product support

• Information on returning a product

• Information on upgrading a product

• Product training

• Reporting comments or suggestions concerning manuals

An EFData Customer Support representative may be reached at:

EFData Corporation

Attention: Customer Support Department

2105 West 5th Place

Tempe, Arizona 85281 USA

(602) 968-0447 (Main EFData Number)

(602) 517-2444 (Customer Support Desk)

(602) 921-9012 FAX

or, E-Mail can be sent to the Customer Support Department at:

service@efdata.com

To return an EFData product (in-warranty and out-of-warranty) for repair or

replacement:

1. Request a Return Material Authorization (RMA) number from the EFData

Customer Support Department.

Be prepared to supply the Customer Support representative with the model

number, serial number, and a description of the problem.

2. To ensure that the product is not damaged during shipping, pack the product in

its original shipping carton/packaging.

3. Ship the product back to EFData. (Shipping charges should be prepaid.)

For more information regarding the warranty policies, refer to the disclaimer page

located behind the title page.

Rev. 8 iii

Page 8

Preface RSU-503 Redundancy Switch Unit

This page is intentionally left blank.

iv Rev. 8

Page 9

Table of Contents

CHAPTER 1. INTRODUCTION..................................................................................1–1

1.1 Overview....................................................................................................................................................... 1–2

1.2 Assemblies.................................................................................................................................................... 1–4

1.3 Specifications................................................................................................................................................ 1–4

CHAPTER 2. INSTALLATION...................................................................................2–1

2.1 Unpacking..................................................................................................................................................... 2–1

2.2 Inspecting the Equipment........................................................................................................................... 2–2

2.2.1 Included Parts......................................................................................................................................... 2–2

2.3 Switch Installation....................................................................................................................................... 2–4

2.3.1 Tools Required....................................................................................................................................... 2–6

2.3.2 Vertical Pole Installation........................................................................................................................ 2–6

2.3.2.1 Round Pole...................................................................................................................................... 2–6

2.3.2.2 Square Pole................................................................................................................................... 2–11

2.3.3 Spar Installation.................................................................................................................................... 2–12

2.4 External Connections................................................................................................................................ 2–14

2.4.1 TX/IF Output (J1, J5)........................................................................................................................... 2–16

2.4.2 RX/IF Input (J2, J6) ............................................................................................................................. 2–16

2.4.3 TX/RF Input (J3, J7)............................................................................................................................ 2–16

2.4.4 M&C (J4, J8)........................................................................................................................................ 2–17

2.4.5 TX/RF Output (J9)............................................................................................................................... 2–18

2.4.6 Waveguide Switch (J10)....................................................................................................................... 2–18

2.4.6.1 Waveguide Switch Pinout (J10)......................................................................................... ........... 2–18

2.4.6.2 LNA Plate to Waveguide Switch.................................................................................................. 2–19

2.4.7 TX/RF Output (J11)............................................................................................................................. 2–19

2.4.8 TX/IF Input (J12)................................................................................................................................. 2–19

2.4.9 RX/IF Output (J13).............................................................................................................................. 2–19

2.4.10 TX/IF Input (J14)............................................................................................................................... 2–19

2.4.11 RX/IF Output (J15)............................................................................................................................ 2–19

Rev. 8 v

Page 10

Table of Contents RSU-503 Redundancy Switch Unit

2.4.12 Monitor & Control (J16).................................................................................................................... 2–20

2.4.13 GND (ERDE)..................................................................................................................................... 2–21

2.5 External Cables.......................................................................................................................................... 2–22

2.6 Addressing.................................................................................................................................................. 2–24

CHAPTER 3. THEORY OF OPERATION..................................................................3–1

3.1 Power............................................................................................................................................................ 3–1

3.2 Waveguide and Coax Switch Drivers......................................................................................................... 3–2

3.3 LNA............................................................................................................................................................... 3–2

3.4 M&C Operational Control......................................................................................................................... 3–2

3.4.1 Communications Link............................................................................................................................ 3–2

3.4.2 Switch Indicators.................................................................................................................................... 3–3

3.4.3 Auto/Manual Modes............................................................................................................................... 3–4

CHAPTER 4. MAINTENANCE...................................................................................4–1

4.1 Internal Switches ......................................................................................................................................... 4–1

4.2 Internal Indicators....................................................................................................................................... 4–2

4.3 Servicing with Power On ............................................................................................................................ 4–3

4.4 Troubleshooting........................................................................................................................................... 4–4

4.5 Internal Connections................................................................................................................................... 4–5

4.5.1 Serial Interfaces (J19, J20, J21) ............................................................................................................. 4–6

4.5.2 M&C Switch CMD and Indicators (J18)................................................................................................ 4–7

4.5.3 M&C Input/Output Signals (J17)........................................................................................................... 4–8

APPENDIX A. RSU-503L OPTION........................................................................... A–1

A.1 Description...................................................................................................................................................A–2

A.2 Assemblies....................................................................................................................................................A–2

A.3 External Connections .................................................................................................................................A–3

A.3.1 LNA Waveguide Switch Pinout (J10)...................................................................................................A–5

A.4 External Cables...........................................................................................................................................A–6

A.5 Addressing...................................................................................................................................................A–7

APPENDIX B. REMOTE CONTROL OPERATION................................................... B–1

vi Rev. 8

Page 11

RSU-503 Redundancy Switch Unit Table of Contents

B.1 General.........................................................................................................................................................B–2

B.2 Message Structure.......................................................................................................................................B–2

B.2.1 Start Character.......................................................................................................................................B–3

B.2.2 Device Address......................................................................................................................................B–3

B.2.3 Command/Response ..............................................................................................................................B–4

B.2.4 End Character........................................................................................................................................B–4

B.3 Switch Redundancy Commands/Responses..............................................................................................B–5

B.3.1 RFT Commands/Responses...................................................................................................................B–5

B.3.2 Configuration Commands/Responses....................................................................................................B–5

B.3.3 Status Commands/Responses.................................................................................................................B–7

GLOSSARY ................................................................................................................g–1

INDEX ..........................................................................................................................i–1

Rev. 8 vii

Page 12

Table of Contents RSU-503 Redundancy Switch Unit

Figures

Figure 1-1. RSU-503....................................................................................................................................... 1–1

Figure 1-2. RSU-503 Interconnect Block Diagram ......................................................................................... 1–3

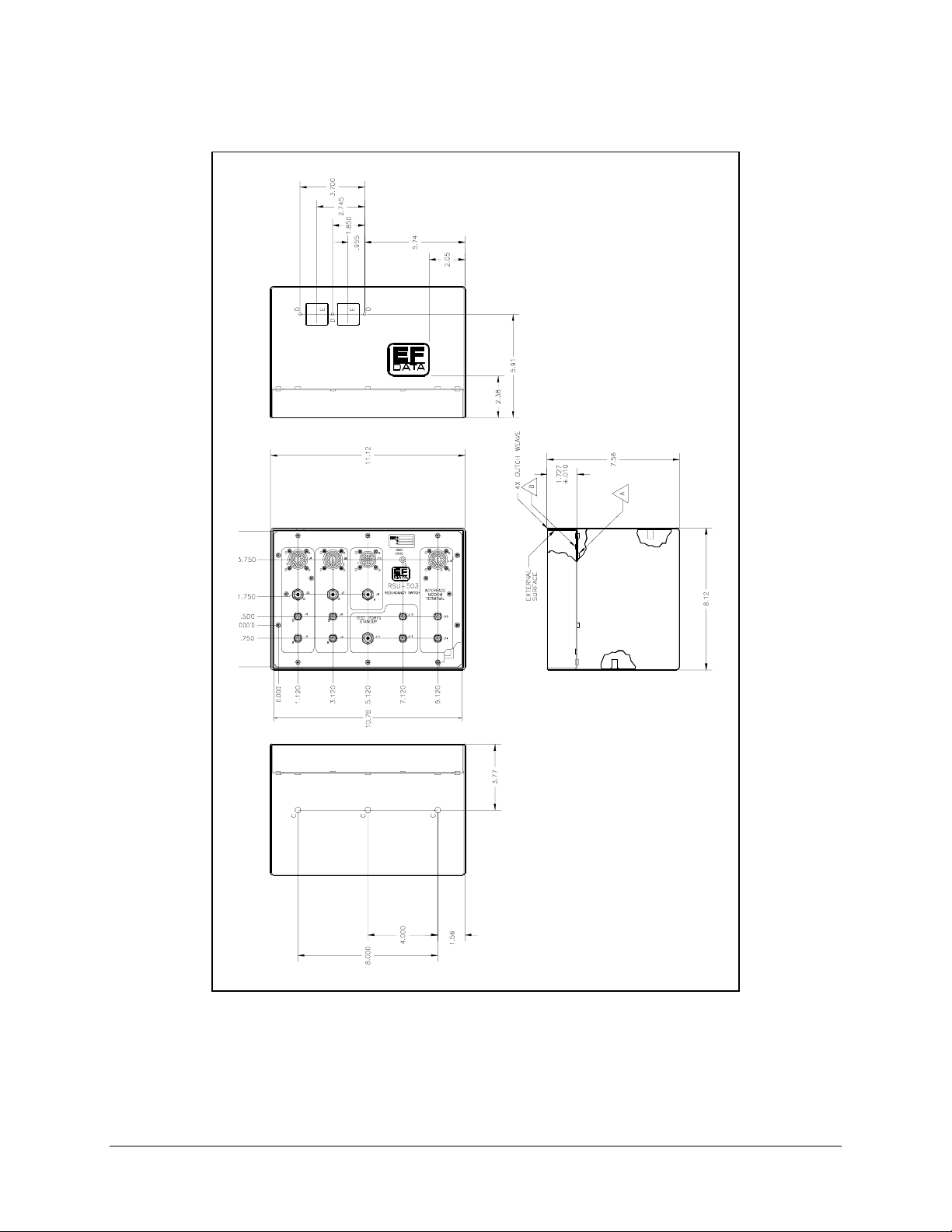

Figure 2-1. RSU-503 Dimensions................................................................................................................... 2–5

Figure 2-2. RSU-503 External Connections.................................................................................................. 2–15

Figure 2-3. Adapter Cables............................................................................................................................2–20

Figure 2-4. RSU-503 M&C, J4 and J8 (to RFT)........................................................................................... 2–22

Figure 2-5. RSU-503, J10 to Waveguide Switch Plate.................................................................................. 2–23

Figure 4-1. LED and Switch Locations........................................................................................................... 4–2

Figure 4-2. Access Panel................................................................................................................................. 4–3

Figure 4-3. Internal Connections..................................................................................................................... 4–5

Figure A-1. RSU-503L Front Panel.................................................................................................................A–1

Figure A-2. RSU-503L Low Loss Block Diagram..........................................................................................A–2

Figure A-3. RSU-503L External Connections.................................................................................................A–4

Figure A-4. RSU-503L, J10 to Waveguide Switches......................................................................................A–6

Tables

Table 1-1. RSU-503 Specifications................................................................................................................. 1–4

Table 2-1. External Connections................................................................................................................... 2–14

Table A-1. RSU-503L External Connections ..................................................................................................A–3

Table A-2. Waveguide Switch Cable Dimensions...........................................................................................A–7

viii Rev. 8

Page 13

Chapter 1.

INTRODUCTION

1

This chapter provides an overview, included assemblies, and specifications for the

RSU-503 (Figure 1-1).

Note:

Refer to Appendix A for information on the RSU-503L, a low-loss version of the

RSU-503.

Figure 1-1. RSU-503

Rev. 8 1–1

Page 14

Introduction RSU-503 Redundancy Switch Unit

1.1 Overview

The switch is a fully automated 1:1 protection switch designed to work with the

following EFData Radio Frequency Terminals (and their amplifiers):

• RFT-500

• RFT-505

• RFT-700

• RFT-705

• RFT-1200 (for RSU-503L information, refer to Appendix A)

• RFT-1225 (for RSU-503L information, refer to Appendix A)

• KST-2000 (for RSU-503L information, refer to Appendix A)

Note:

All references in this document to “RFT” apply to all the models listed above.

The switch has a weather resistant enclosure which houses the indicators and controls to:

• Switch RFTs and LNAs

• Command the waveguide switch to toggle

Specifically, the switch performs the following functions:

Controls waveguide/coaxial switch positions

•

Provides independent uplink and downlink paths

•

Routes the IF input to the online RFT

•

Routes the IF output from the online RFT

•

Initiates a switch-over in Auto mode by monitoring RFT faults

•

Supplies test ports for testing the standby channel

•

Receives RS-232/485 serial commands, routing them to the appropriate RFTs,

•

and returns their responses

Receives its own RS-232/485 command set for Auto/Manual mode, A/B online,

•

and address select

• Provides FORM-C relay contacts for Summary Fault status

Power is supplied by one or both RFTs.

1–2 Rev. 8

Page 15

RSU-503 Redundancy Switch Unit Introduction

Although there are no external indicators or switches (due to the nature of the

weatherproof housing), there is an access panel that can be removed, allowing use of

internal switches and indicators (refer to Chapter 4 for more information).

Note:

The internal indicators and switches are only used for factory testing and

troubleshooting.

The system, during setup and while running, is intended to be controlled remotely.

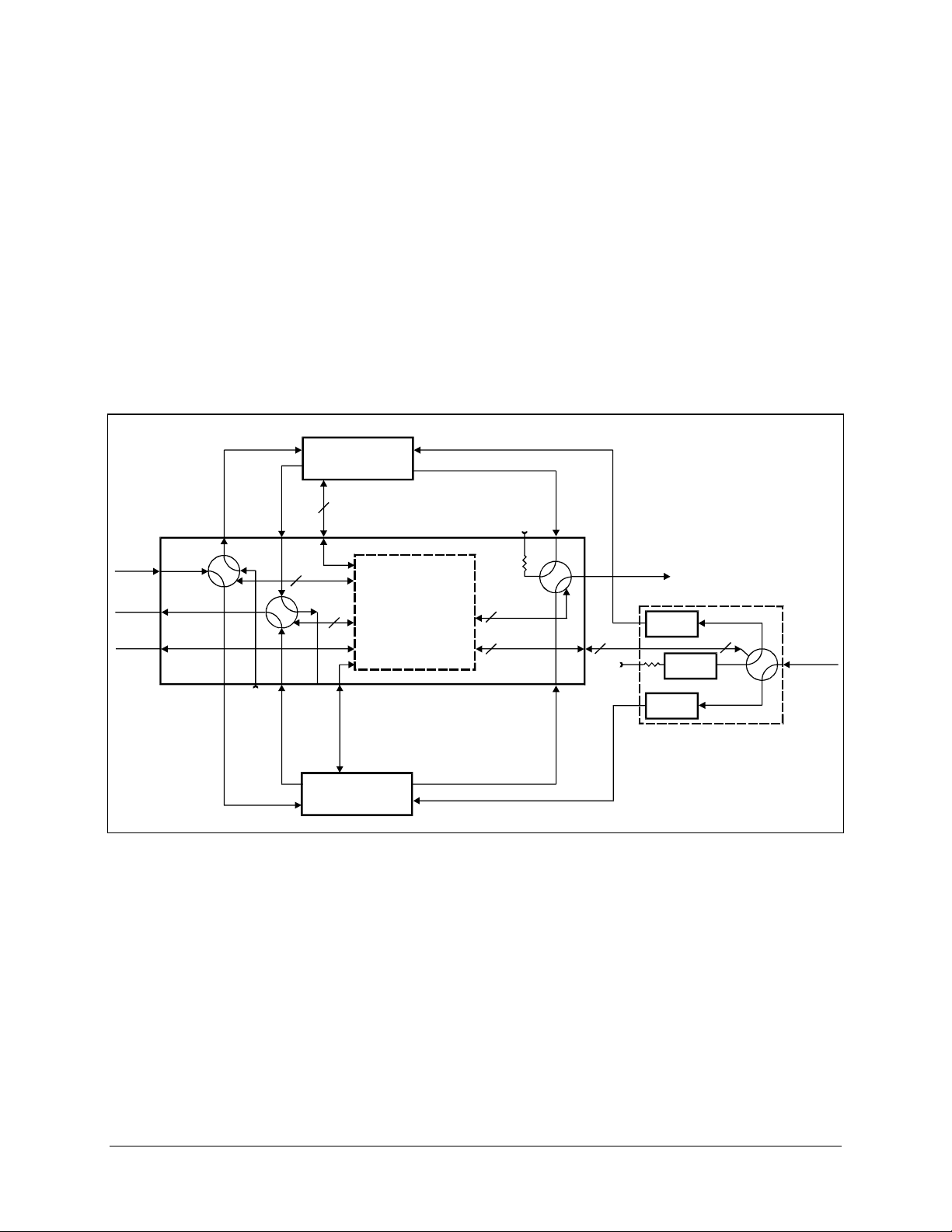

Refer to Figure 1-2 for an interconnection block diagram of the switch.

TX/IF

70 MHz

TX/IF

INPUT

70 MHz

RX/IF

OUTPUT

RS-232

REMOTE

CONTROL

CA/3005

S1

J14

TNC

J15

TNC

J16

1

3

4

TNC TNC TNC TNC

TX/IF

B

RX/IF

CA/3005

TX/IF

A

J1

TNC

2

S2

J5 J6J12 J13

STANDBY

TX/IF

TEST

INPUT

CA/3005

1

3

RF/IF

TX/IF

RX/IF

A

J2

6

2

4

RF/IF

B

STANDBY

RF/IF

TEST

OUTPUT

26

RFT-xxx

#A

CA/3003

M&C - RS-232

A

J4TNC

P19

IND

IND

6

P21

P20

J8

LOW LOSS REDUNDANCY SWITCH UNIT

CA/3003

M&C - RS-232

B

26

RFT-xxx

#B

SHOWN WITH "B" ONLINE

TX/RF

AS/3000

M&C

AS/3002

RSU-503

RX/RF

TX/RF

RX/RF

CA/1530

CA/3004

N

J11

IND

6

IND

6

CA/3004

TX/RF

N

J3

S3

4

3

2

1

J10

N

J7

CA/1530

J9

6

LNA

TEST

INPUT

TO

ANTENNA

LNA

N

#A

CA/3004

WG TO N

ADAPTER

WAVEGUIDE

LNA

N

#B

REDUNDANT SWITCH PLATE

6

LNA

SWITCH

FROM

ANTENNA

Figure 1-2. RSU-503 Interconnect Block Diagram

Rev. 8 1–3

Page 16

Introduction RSU-503 Redundancy Switch Unit

1.2 Assemblies

The switch consists of the following assemblies:

Assembly EFData Part #

Top Assembly PL/3000

RSU-503 Cable Harness PL/3001

Chassis Base FP/3802

Panel Divider FP/3139

M&C Assembly, RSU-503 PL/3002

M&C Firmware, RSU-503 FW/3080-1

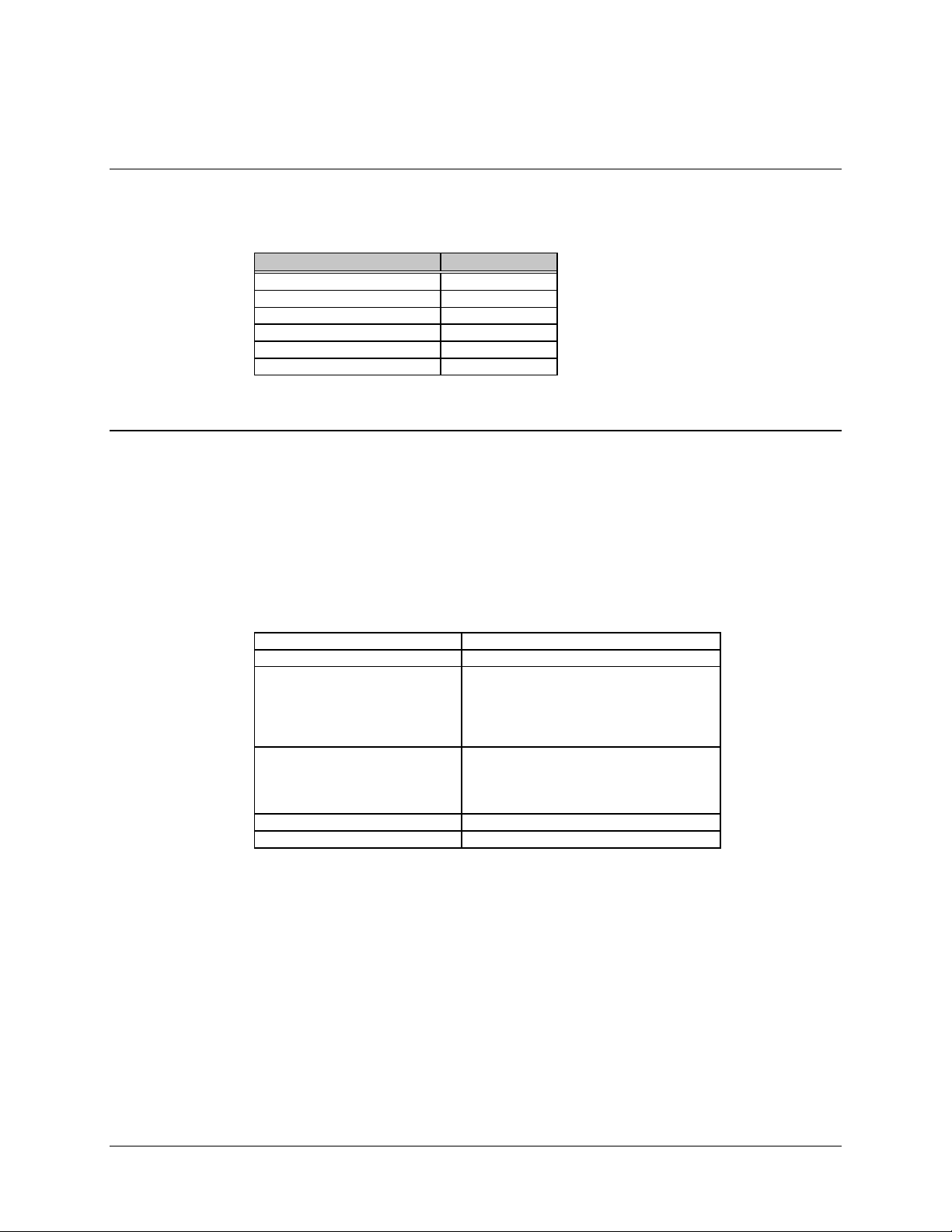

1.3 Specifications

Table 1-1 lists the operating specifications for the switch.

Note:

For more information pertaining to RSU-503 specifications, refer to EFData

Specification SP/3000.

Table 1-1. RSU-503 Specifications

Input power 10.8V, 1A (from either RFT)

Power consumption 5W

Physical:

Depth

Height

Width

Weight

Environmental:

Operating Temperature

Storage Temperature

Humidity

Front Panel Controls none

External Indicators none

7.5”

8”

11”

7.4 lbs.

-40 to +55°C

-40 to +100°C

5 to 85%, noncondensing

1–4 Rev. 8

Page 17

This chapter provides installation instructions and external connector information for the

switch.

2.1 Unpacking

Generally, the switch and manual are shipped as part of a redundant terminal system, and

are packaged in a wooden crate along with the redundant LNA plate and cables.

1. Remove the screws from the lid of the wooden crate, and remove the lid.

2. Remove the unit and manual from the cardboard and foam enclosure.

Chapter 2.

INSTALLATION

2

Save the packing material for reshipment.

Note:

If the switch and manual are shipped in a cardboard box:

1. Cut the tape at the top of the carton where it is indicated OPEN THIS END.

Do not use any cutting tool that will extend more than 1” into the

container and cause damage to the switch.

CAUTION

2. Lift the switch and manual out of the box, and remove the bubblepack and

plastic bag from the switch.

Save the packing material for reshipment.

Note:

Rev. 8 1

Page 18

Installation RSU-503 Redundancy Switch Unit

2.2 Inspecting the Equipment

1. Carefully check the equipment for damage incurred during shipment.

2. Carefully check the equipment against the packing list shipped with the

equipment to ensure that the shipment is complete. Refer to the following

paragraphs.

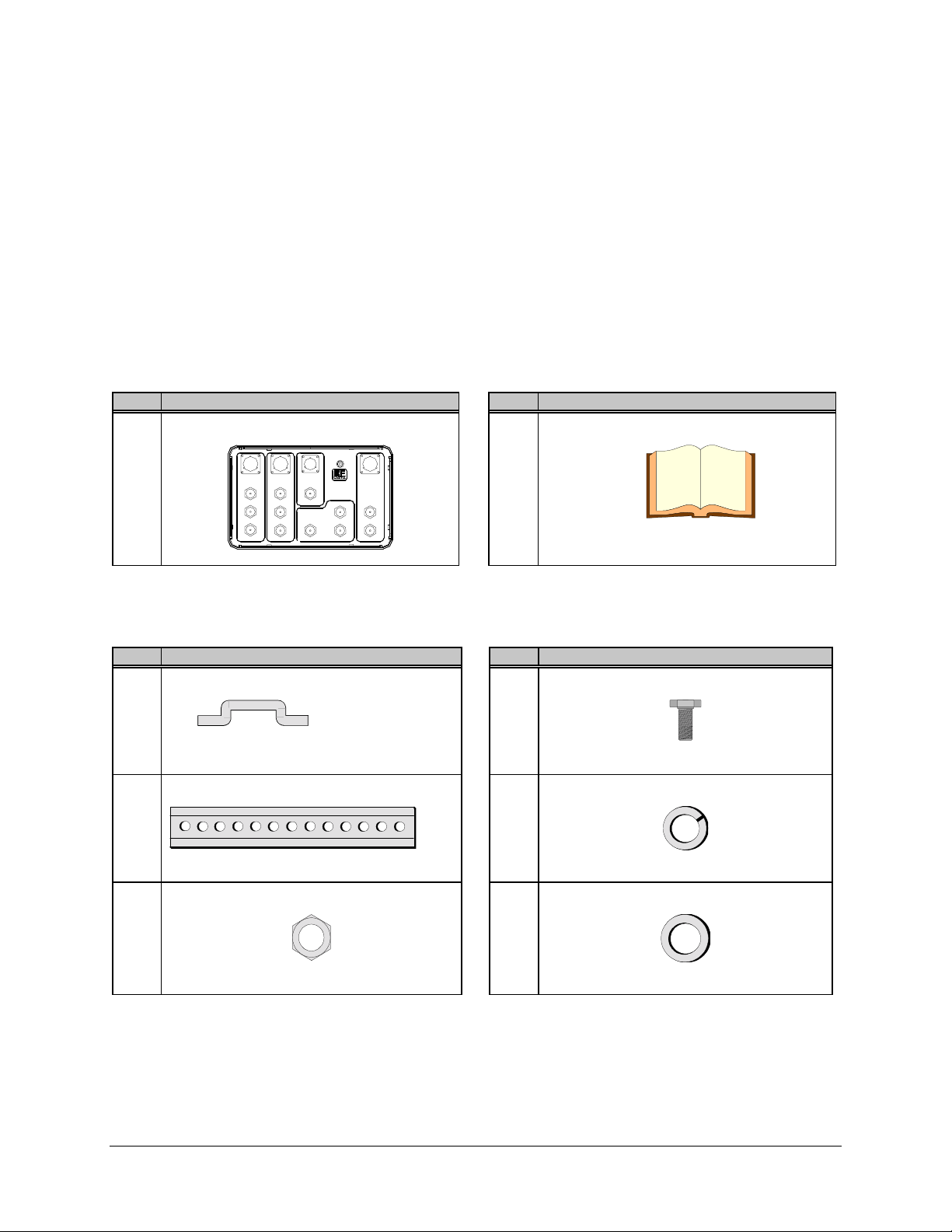

2.2.1 Included Parts

Parts are not drawn to scale.

Note:

Qty. Description Qty. Description

1 RSU-503. 1 Installation and operation manual.

The installation hardware listed below is included in the redundant system

Note:

installation parts kit KT/3577.

Qty. Description Qty . Description

1 Spar support bracket.

EFData Part # FP/3175.

Used for spar mount only.

2 Unistrut — 14” long.

EFData Part # FP/3595.

6 5/16-18 hex nut.

EFData Part # HW/5/16-18HEXNT.

4 5/16-18 x 1” bolt.

EFData Part # HW/5/16-18X1BLT.

10 5/16” split lockwasher.

EFData Part # HW/5/16-SPLIT.

10 5/16” flat washer.

EFData Part # HW/5/16-FLT.

2 Rev. 8

Page 19

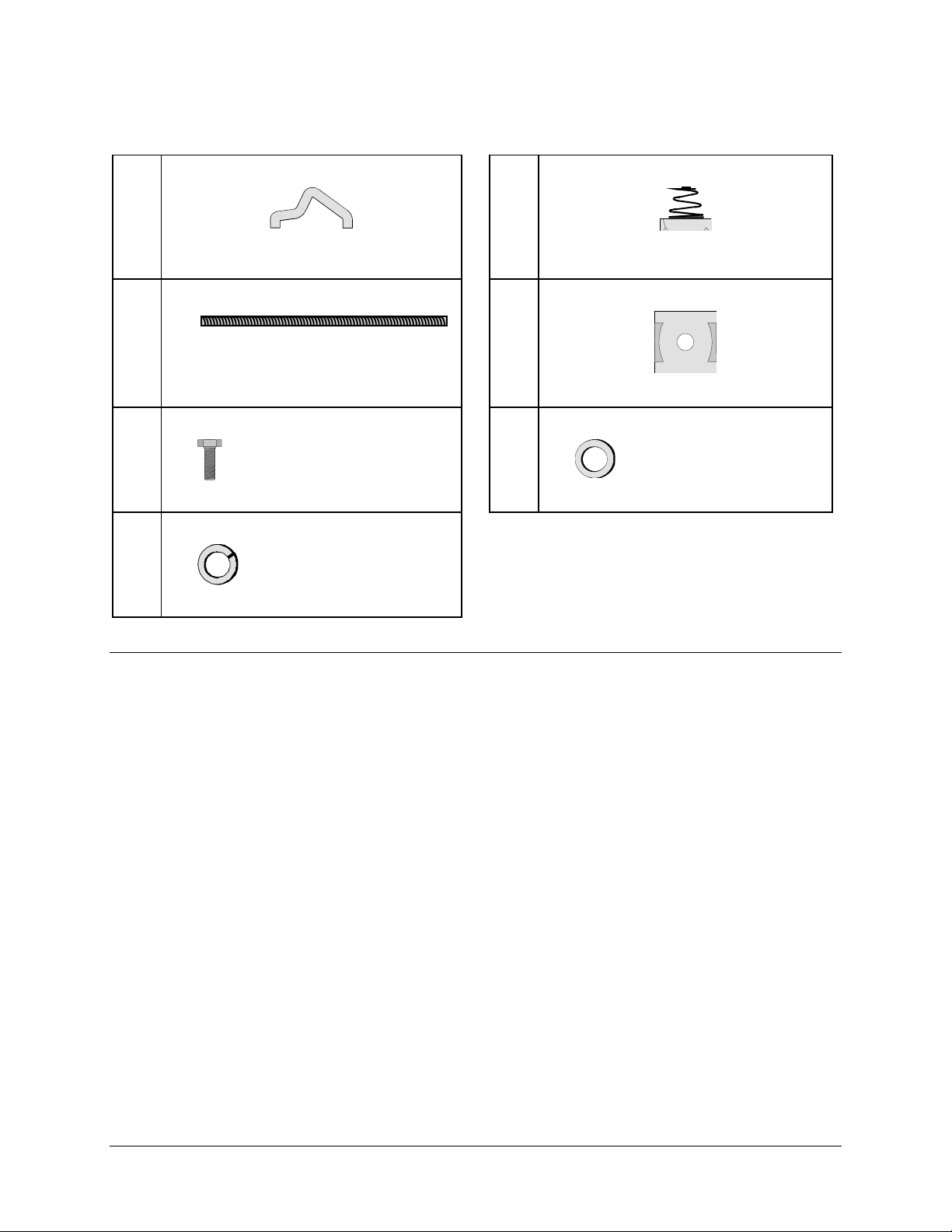

RSU-503 Redundancy Switch Unit Installation

4 Pipe block.

EFData Part # HW/BLK-PIPE2-8.

Used for round pole mount only.

2 Threaded rod, 5/16-18 x 14”.

EFData Part # HW/RD5/16-18X14.

Used for round and square pole mount only.

3 1/4-20 x 1” bolt.

EFData Part # 03P1079.

3 1/4” split lockwasher.

EFData Part # HW/1/4-SPLIT.

6 5/16-18 spring nut.

EFData Part # HW/5/16-18SPNUT.

4 Flat fitting plate, 5/16”.

EFData Part # HW/FIT-PLT-5/16.

3 1/4” flat washer.

EFData Part # O4P1022.

Rev. 8 3

Page 20

Installation RSU-503 Redundancy Switch Unit

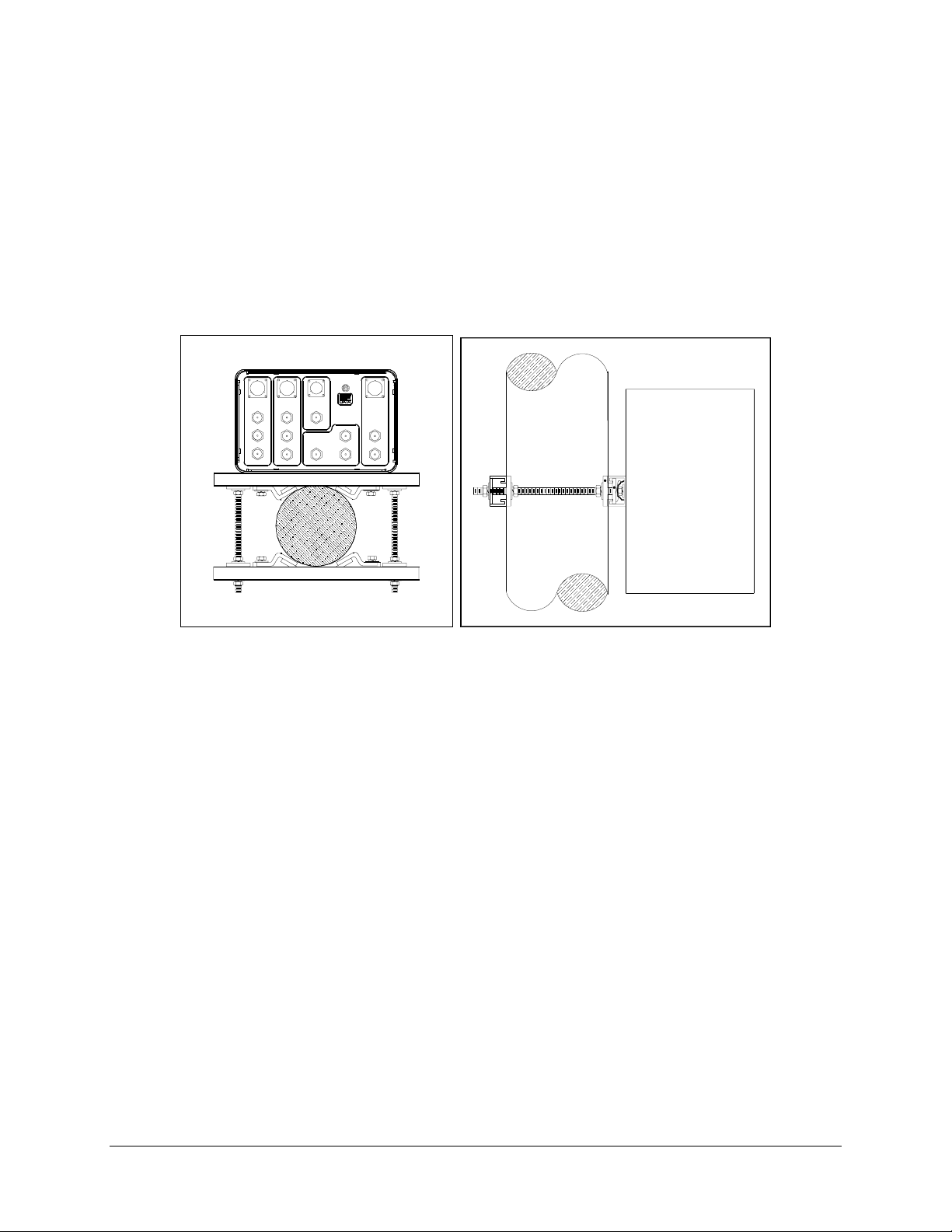

2.3 Switch Installation

At the customer’s discretion, the switch can be installed anywhere on or near the

antenna. The supplied hardware allows the installer a wide range of installation

alternatives, including:

Vertical pole (e.g., mast) (either square or round). This is the most typical

•

installation.

Within the hub of a large antenna.

•

Spar (i.e., rectangular bar) on the antenna structure.

•

The switch is designed to be mounted with the interface connections facing the ground.

For custom installations, refer to Figure 2-1 for dimensions of the RSU-503.

Note:

4 Rev. 8

Page 21

RSU-503 Redundancy Switch Unit Installation

Figure 2-1. RSU-503 Dimensions

All dimensions in inches.

Note:

Rev. 8 5

Page 22

Installation RSU-503 Redundancy Switch Unit

6 Rev. 8

Page 23

RSU-503 Redundancy Switch Unit Installation

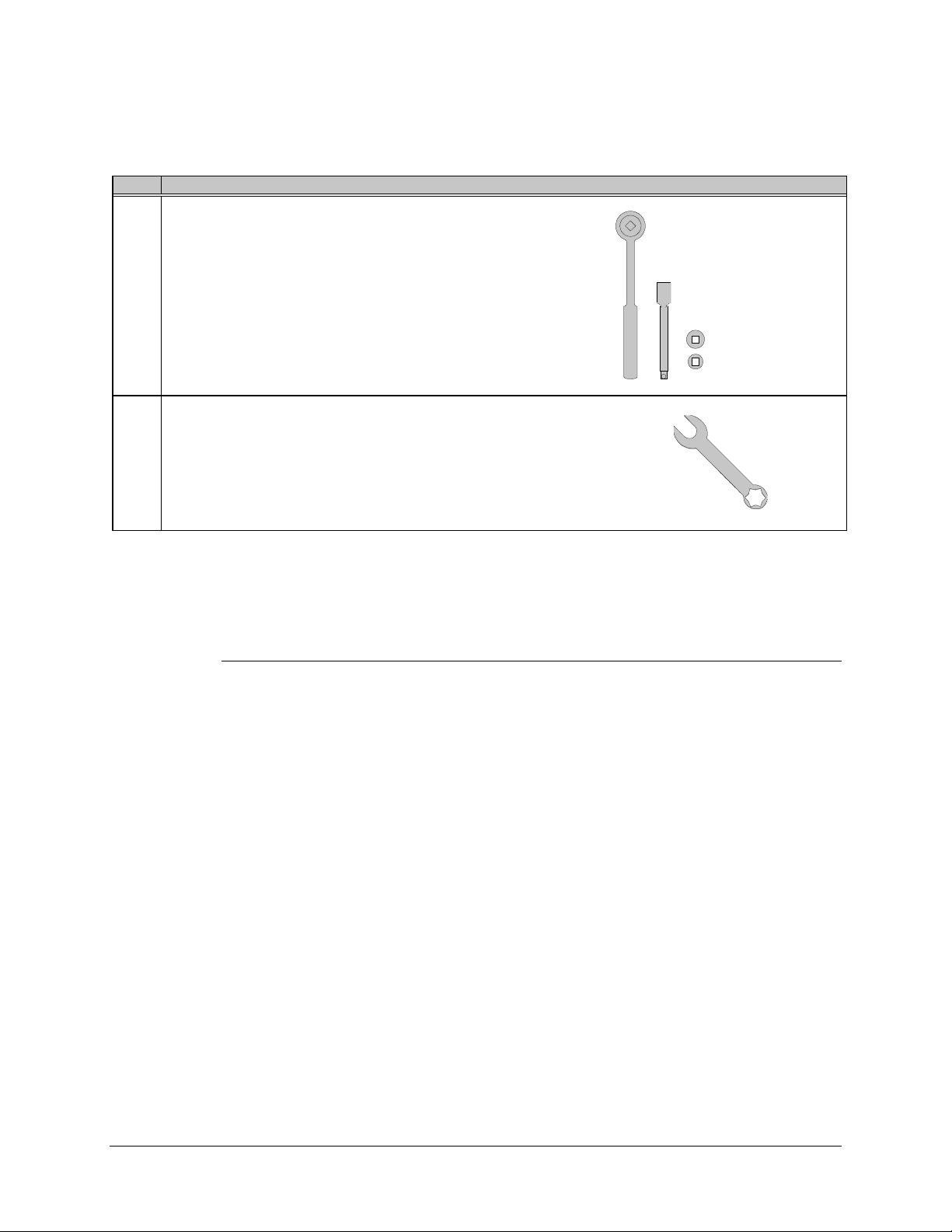

2.3.1 Tools Required

Qty. Description

1

3/8” drive ratchet.

1

3” x 3/8” drive extension.

1

7/16” x 3/8” drive socket. (Metric equivalent: 11mm , 6 pt.)

1

1/2” x 3/8” drive socket. (Metric equivalent: 12mm , 6 pt.)

1 1/2” combination wrench. (Metric equivalent: 12mm combination

wrench with a 6 pt. box end.)

2.3.2 Vertical Pole Installation

2.3.2.1 Round Pole

The process described is for a typical installation. Custom kits may be ordered and are

beyond the scope of this manual.

Rev. 8 7

Page 24

Installation RSU-503 Redundancy Switch Unit

To install the switch to a round vertical pole:

1. Set the switch on its side, with the mounting holes facing up.

2. Install the 14” unistrut as follows:

a. Position a 14” long

unistrut (with the open

side facing up) over

the mounting holes on

the unit.

b. Using three 1/4-20 x

5/8” bolts, 1/4” split

lockwashers, and 1/4”

flat washers, attach the

unistrut to the switch.

c. Tighten the bolts

firmly.

3. Install the pipe blocks as follows:

a. Install two spring nuts in the 14” long unistrut which is mounted on the unit,

and in a second 14” long unistrut.

Be sure to center the spring nuts in the unistruts wide enough apart so that

when the pipe blocks are installed, they will clear the pole when the unit is

lifted into place for installation.

b. Install each spring nut as follows:

(1) Place the spring

nut in the unistrut

channel, spring

side down, with

its wide side

parallel with the

unistrut channel.

8 Rev. 8

Page 25

RSU-503 Redundancy Switch Unit Installation

(2) Press down on

the spring nut to

compress the

spring, and rotate

the nut 90

°

(perpendicular to

the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

c. Using four 5/16-18 x

1” bolts, 5/16” split

lockwashers, and

5/16” flat washers,

loosely secure the pipe

blocks to the spring

nuts in each 14”

unistrut.

Ensure the pipe blocks

are installed with the

long angle facing

inward, toward the

pipe, as illustrated.

DO NOT tighten the

pipe block bolts until

after mounting the

switch on the vertical

pole (see Step 5.e.).

4. Install the threaded rods as follows:

a. Install two spring nuts in the 14” long unistruts mounted on the unit.

Ensure the spring nuts are positioned over the outer holes in the long

Note:

unistruts.

Rev. 8 9

Page 26

Installation RSU-503 Redundancy Switch Unit

b. To install each spring

nut:

(1) Place the spring

nut in the unistrut

channel, spring

side down, with

its wide side

parallel with the

unistrut channel.

(2) Press down on

the spring nut to

compress the

spring, and rotate

the nut 90

°

(perpendicular to

the unistrut).

(3) Release pressure on the spring nut.

(4) Repeat Steps 4.b.(1) through 4.b.(3) for each spring nut.

c. Thread a 5/16-18 nut approximately 1-1/2” onto each threaded rod. (This

will ensure that the threaded rods will extend beyond the spring nuts when

installed.)

d. Place a 5/16” split

lockwasher, 5/16” flat

washer, and flat fitting

plate over each

threaded rod.

e. One threaded rod at a

time, hold the washers

and plate in place on

the threaded rod and

screw it into a spring

nut, as illustrated.

10 Rev. 8

Page 27

RSU-503 Redundancy Switch Unit Installation

Notes:

1. Be sure to position the flanges of the fitting plates in the grooves of

the unistruts.

2. Before tightening the nuts on the threaded rods, ensure that the end

of each rod is screwed in until it is flush with the backside of the

unistrut. This ensures the rods are threaded completely through the

spring nuts.

Tighten each nut firmly.

f. Thread a 5/16-18 nut

about 2” onto the end

of each threaded rod.

g. Slip a 5/16” split

lockwasher, 5/16” flat

washer and flat fitting

plate (in that order)

onto each threaded

rod.

5. Mount the unit as follows:

a. Lift the unit into position on the vertical pole.

b Slip the 14” unistrut

over the threaded rods

(upper and lower).

Install the 14”

Note:

unistrut with its open

face toward the pole.

c. Install a 5/16” flat

washer, 5/16” split

lockwasher, and

5/16-18 nut on each

threaded rod.

d. Position the unit as desired, and tighten the 5/16-18 nuts installed in Step

5.c.

e. Slide the pipe blocks inward until they contact the vertical pole, then firmly

tighten the 5/16-18 bolts.

Rev. 8 11

Page 28

Installation RSU-503 Redundancy Switch Unit

2.3.2.2 Square Pole

For square vertical pole installation, follow the steps in Section 2.3.2.1, with the

following exceptions:

Do not perform Step 3.

•

Do not perform Step 5.e.

•

12 Rev. 8

Page 29

RSU-503 Redundancy Switch Unit Installation

2.3.3 Spar Installation

The process described is for a typical installation. Custom kits may be ordered and

Note:

are beyond the scope of this manual.

To install the switch to a spar:

1. Set the unit on its side, with the mounting holes facing up.

2. Install a 14” unistrut.

a. Position a 14” unistrut (with the open side facing up) over the mounting

holes on the switch.

b. Using three 1/4-20

bolts, 1/4” split

lockwashers, and 1/4”

flat washers, attach the

unistrut to the switch.

c. Tighten the bolts firmly.

3. Mount the switch as follows:

a. Install two spring nuts in the unistrut (centered on the unistrut, the width of

the spar bracket holes).

b. To install each spring nut:

(1) Place the spring

nut in the unistrut

channel, spring

side down, with

its wide side

parallel with the

unistrut channel.

(2) Press down on

the spring nut to

compress the

spring, and rotate

the nut 90° (i.e.,

perpendicular to

the unistrut).

Rev. 8 13

Page 30

Installation RSU-503 Redundancy Switch Unit

(3) Release pressure on the spring nut.

(4) Repeat Steps 3.b.(1) through 3.b.(3) for each spring nut.

c. Lift the switch into position.

d. Using two 5/16-18

bolts, 5/16” split

lockwashers, and

5/16” flat washers,

bolt the spar bracket in

place.

d. Tighten the bolts

firmly.

14 Rev. 8

Page 31

RSU-503 Redundancy Switch Unit Installation

2.4 External Connections

All connections between the switch and other equipment are made through front panel

connections, as shown in Table 2-1 (refer to Figure 2-2 for connector locations).

Failure to properly connect the units will result in loss of communications

between the switch and the RFTs.

CAUTION

Table 2-1. External Connections

Name Desig. Type Function

Switch to RFT #A (Primary)

TX/IF OUTPUT J1 TNC, 50

RX/IF INPUT J2 TNC, 50

TX/RF INPUT J3 N TX Uplink from Unit A

MONITOR &

CONTROL

TX/IF OUTPUT J5 TNC, 50

RX/IF INPUT J6 TNC, 50

TX/RF INPUT J7 N TX Uplink from Unit B

MONITOR &

CONTROL

TX/RF OUTPUT J9 N TX Uplink from online unit

WAVEGUIDE

SWITCH

TX/RF OUTPUT J11 N TX output test signal

TX/IF INPUT J12 TNC, 50

RX/IF OUTPUT J13 TNC, 50

TX/IF INPUT J14 TNC, 50

RX/IF OUTPUT J15 TNC, 50

MONITOR &

CONTROL

GND ERDE None #10-32 Stud Chassis Ground

J4 26-pin Circ. Monitor and control

Switch to RFT #B (Backup)

J8 26-pin Circ. Monitor and control

Switch to Antenna

J10 19-pin Circ. Waveguide switch control

Standby Unit Test Ports

Switch to Modem Terminal Interface

J16 26-pin Circ. Modem Terminal Interface (MTI)

IF Uplink to Unit A

Ω

IF Downlink from Unit A

Ω

See Section 2.4.4 for pinouts

IF Uplink to Unit B

Ω

IF Downlink from Unit B

Ω

See Section 2.4.4 for pinouts

See Section 2.4.6.1 for pinouts

IF input test signal

Ω

IF output test signal

Ω

IF Uplink

Ω

IF Downlink

Ω

See Section 2.4.12 for pinouts

Ground

(See note

(See note

)

)

Refer to Section 2.6 for addressing information.

Note:

Rev. 8 15

Page 32

Installation RSU-503 Redundancy Switch Unit

Figure 2-2. RSU-503 External Connections

16 Rev. 8

Page 33

RSU-503 Redundancy Switch Unit Installation

2.4.1 TX/IF Output (J1, J5)

The TX/IF Output connectors are TNC connectors, each with an impedance of 50Ω.

These

connectors carry the IF uplink signal to the online RFT (Unit A or B).

2.4.2 RX/IF Input (J2, J6)

The RX/IF Input connectors are TNC connectors, each with an impedance of 50Ω. These

connectors carry the IF downlink signal from the online RFT (Unit A or B).

2.4.3 TX/RF Input (J3, J7)

The TX/RF Input connectors are type N connectors, each with an impedance of 50Ω.

These connectors carry the transmit uplink signal from the online RFT (Unit A or B).

Rev. 8 17

Page 34

Installation RSU-503 Redundancy Switch Unit

2.4.4 M&C (J4, J8)

The M&C connectors are used to interface with Units A and B, respectively. Included on

these connectors are:

Nine RS-232/485 communication pins (A to J)

•

Switch power (L)

•

Fault reporting

•

The M&C connectors are 26-pin circular female connectors, with the following pinouts:

Pin # Name Function

RS-232 RS-485

AGND -RX/TX

B-RX/TX

C+RX/TX

D CTS +RX/TX Clear to Send

E TD/TX Transmit Data

F RTS Ready to Send

G RD/RX Receive Data

H DSR Data Set Ready

J GND Ground

K LNA POWER 10V to LNA

L EXT POWER Input Voltage, 11V, 1A max.

M EXT FLT IN Fault Input from TWT

N Reserved

PN/C

R GND Ground

S Chassis Ground Ground

T Reserved

U UL FLT NC Fault relay input, closes with Uplink fault

V UL FLT COM Fault relay input, COMMON

W UL FLT NO Fault relay input, opens with Uplink fault

X DL FLT NC Fault relay input, closes with Downlink fault

Y DL FLT COM Fault relay input, COMMON

Z DL FLT NO Fault relay input, opens with Downlink fault

a LNA RTN Ground return from LNA

b Reserved

c Reserved

Notes:

1. Clear to Send (CTS) is tied to Ready to Send (RTS) in RS-232 mode.

2. RD/RX and TD/TX are switched in the switch in order to communicate with

the RFTs.

18 Rev. 8

Page 35

RSU-503 Redundancy Switch Unit Installation

2.4.5 TX/RF Output (J9)

The TX/RF Output connector is a 50Ω type N connector that carries the transmit uplink

signal from the online RFT (Unit A or B) to the antenna.

2.4.6 Waveguide Switch (J10)

The Waveguide Switch connector connects the switch to the LNA plate using a 1:1

cable.

2.4.6.1 Waveguide Switch Pinout (J10)

The Waveguide Switch connector uses a 19-pin circular female connector with the

following pinouts:

Name Pin # Function

LNA Position 1 Command C +28V pulse for 500 milliseconds

LNA Command Common G Ground

LNA Position 2 Command D +28V pulse for 500 milliseconds

LNA Indicator, Position 1 H Connects to Common when in position 1

LNA Indicator, Common R Ground

LNA Indicator, Position 2 T Connects to Common when in position 2

RF Position 1 Command E +28V pulse for 500 milliseconds

RF Command Common L Ground

RF Position 2 Command F +28V pulse for 500 milliseconds

RF Indicator, Position 1 J Connects to Common when in position 1

RF Indicator, Common V Ground

RF Indicator, Position 2 K Connects to Common when in position 2

LNA PWR #A A

LNA RTN #A B

LNA PWR #B N

LNA RTN #B P

Rev. 8 19

Page 36

Installation RSU-503 Redundancy Switch Unit

2.4.6.2 LNA Plate to Waveguide Switch

The following table outlines the pinouts of the LNA plate to Waveguide Switch cable.

This cable is internal on the redundant LNA plate.

This pinout table may be helpful if an EFData Waveguide Switch is used.

Note:

Name Pin # Function

Command, Position 1 A +28V pulse for 500 milliseconds

Command Common B Ground

Command, Position 2 C +28V pulse for 500 milliseconds

Indicator, Position 1 D Connects to Common when in position 1

Indicator Common E Ground

Indicator, Position 2 F Connects to Common when in position 2

2.4.7 TX/RF Output (J11)

The TX/RF Output connector is a 50Ω type N connector used to monitor the transmit

output signal from the offline RFT. This connector is used to test the offline unit.

2.4.8 TX/IF Input (J12)

The TX/IF Input connector is a 50Ω TNC connector used to input the IF test signal to the

offline RFT. This connector is used to test the offline unit.

2.4.9 RX/IF Output (J13)

The RX/IF Output connector is a 50Ω TNC connector used to monitor the IF output

signal from the offline RFT. This connector is used to test the offline unit.

2.4.10 TX/IF Input (J14)

The TX/IF Input connector is a 50Ω TNC connector used to receive the IF uplink signal

from the modem. The switch routes the signal to the online RFT for transmission.

2.4.11 RX/IF Output (J15)

The RX/IF Output connector is a 50Ω TNC connector used to provide the IF downlink

signal to the modem (after the signal is picked up by the antenna and routed through the

online LNA and RFT).

20 Rev. 8

Page 37

RSU-503 Redundancy Switch Unit Installation

EFDAT

A:CN/STPG26M0

1

2.4.12 Monitor & Control (J16)

The Modem Terminal Interface (MTI) connector is the remote control interface

connector. Included on this connector are RS-232/485 communication lines and a

summary fault indication. For standard RS-232/485 applications, an adapter cable is

available to connect the 26-pin circular connector to a standard 9-pin D.

Refer to Figure 2-3 for an illustration of the adapter cable and its pinouts.

PT06E16-26P(SR)

P1

A

D

E

F

G

H

GND

CTS

RD/RX

RTS

TD/TX

DSR

5

9

4

8

3

7

2

6

1

26 PIN

EFDAT A: CN/STPG26M01

PT06E16-26P(SR)

A

B

C

D

J

26 PIN

-RX/TX

-RX/TX

+RX/TX

+RX/TX

GND

Figure 2-3. Adapter Cables

MALE

P1

5

9

4

8

3

7

2

6

1

MALE

Rev. 8 21

Page 38

Installation RSU-503 Redundancy Switch Unit

The MTI connector is a 26-pin circular female connector with the following pinouts:

Pin # Name Function

RS-232 RS-485

AGND -RX/TX

B-RX/TX

C+RX/TX

D CTS +RX/TX Clear to Send

E RD/RX Receive Data

F RTS Ready to Send

G TD/TX Transmit Data

H DSR Data Set Ready

J GND Ground

K Reserved

L EXT_PWR Output, 11V for KP-10

M

N EXT FLT1 #A TWT FLT input for primary channel

P EXT FLT1 #B TWT FLT input for secondary channel

RN/C

S Ground Chassis Ground

T Reserved

U Reserved

V Reserved

W Reserved

X FLT NC Summary fault relay, connects to COM with fault

Y FLT COM Summary fault relay, COMMON

Z FLT NO Summary fault relay, opens with fault

a Reserved

b Reserved

c Reserved

Clear to Send (CTS) is tied to Ready to Send (RTS) in RS-232 mode.

Note:

2.4.13 GND (ERDE)

GND is a #10-32 stud for the purpose of connecting all units to a common chassis

ground.

22 Rev. 8

Page 39

RSU-503 Redundancy Switch Unit Installation

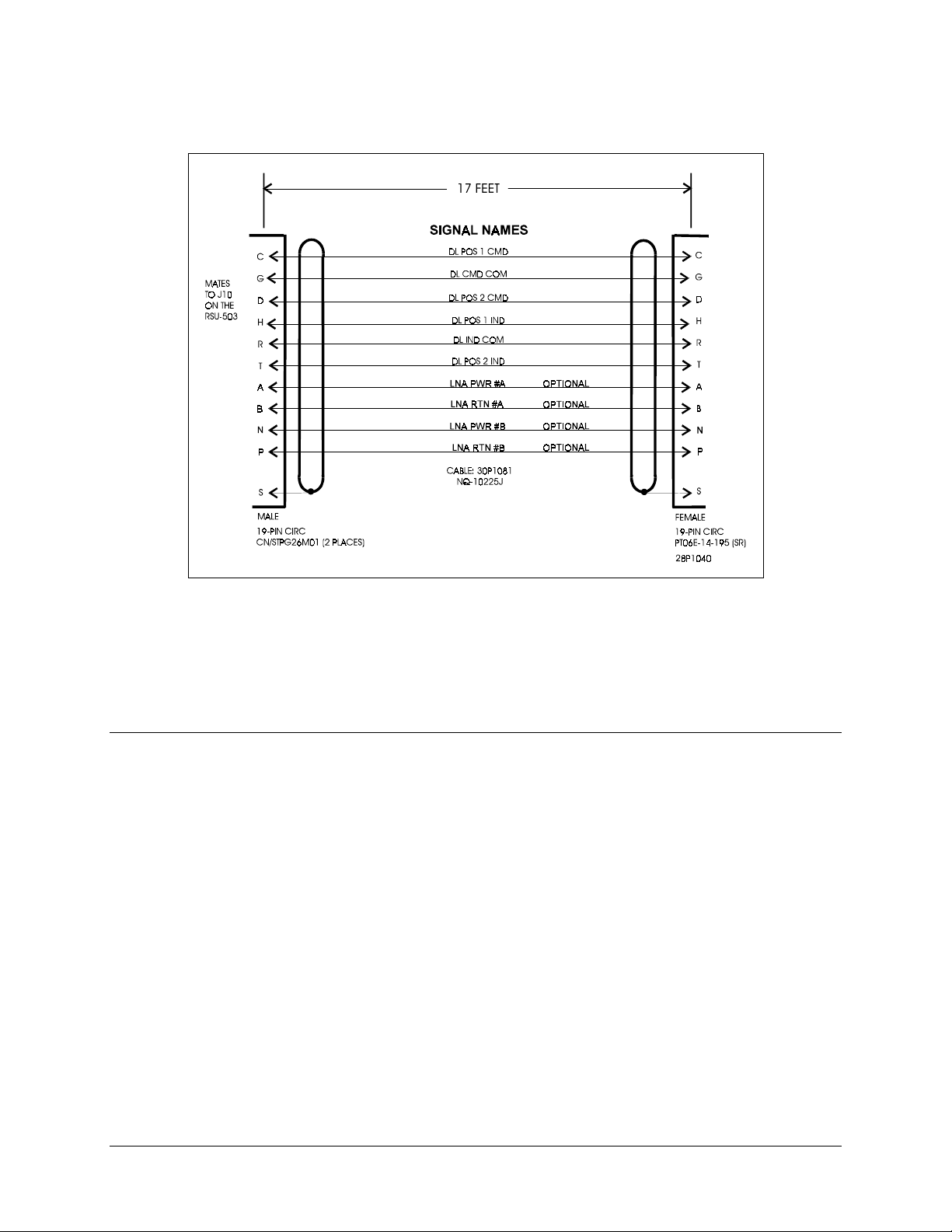

2.5 External Cables

Refer to Figures 2-4 and 2-5 for diagrams of the two different external multi-conductor

cables used with the switch in a redundant system.

Figure 2-4. RSU-503 M&C, J4 and J8 (to RFT)

Rev. 8 23

Page 40

Installation RSU-503 Redundancy Switch Unit

Figure 2-5. RSU-503, J10 to Waveguide Switch Plate

Be sure to connect the primary RFT (A) to J4, and the backup RFT (B) to J8.

Note:

24 Rev. 8

Page 41

RSU-503 Redundancy Switch Unit Installation

2.6 Addressing

The following are the factory default addresses:

Switch is set to address 1

•

RFT A is set to address 2

•

RFT B is set to address 3

•

The proper M&C cable hook-up is critical:

RFT A must be connected to the switch Port A

•

RFT B must be connected to the switch Port B

•

If these connections are reversed, no communications will take place.

Note:

Rev. 8 25

Page 42

3.1 Power

Chapter 3.

THEORY OF OPERATION

3

This chapter provides the basic theory for the following:

• Switch power

• Waveguide and coax switch drivers

• LNA

• M&C operational control

In a redundant system, the switch is powered from either of the two RFT terminals via

the M&C interconnect cable. External DC power (approximately 10.8V) enters the M&C

on pins 1 and 2 of connector J17 (25-pin D), and is “ORed” through diodes CR1 and

CR2.

The switch is monitored by the analog-to-digital (A/D) converter U16, and is made

available as a maintenance status through the serial terminal.

A 3-terminal regulator, U1, converts and regulates the +5V to all the logic, including the

microcontroller U18.

PS1 converts the 10V input voltage to 30V, where it is stored by capacitors C6 through

C10 to supply the 500 millisecond pulses to the transfer switches.

Rev. 8 3–1

Page 43

Theory of Operation RSU-503 Redundancy Switch Unit

3.2 Waveguide and Coax Switch Drivers

The microcontroller creates the 500 millisecond pulses to control the positions of all four

transfer switches. Photovoltaic opto-isolated switches U8, U9, U10, and U11 transform

the +5V logic into 30V pulses to drive the latching coils of the switches.

Each microwave transfer switch contributes 0.3 dB of insertion loss, with a minimum of

70 dB of isolation.

3.3 LNA

The LNAs are powered directly from their respective RFTs through the RF coax cable.

The RFT performs a current sense on its LNA, and informs the switch by declaring a

downlink fault, if one is detected.

3.4 M&C Operational Control

3.4.1 Communications Link

The terminal functions can be remotely controlled and monitored via an RS-485 or

RS-232 communications link.

• The RS-485 interface makes it possible to operate 255 terminals on a common

communications link.

• The RS-232 interface is used to communicate with a single terminal.

The M&C module must be hardware configured on the M&C board to one of the two

interfaces. Refer to the following table for jumper placement at JP3:

RS-485

Configuration

1-2 9-10

3-4 11-12

5-6 13-14

7-8 15-16

RS-232

Configuration

3–2 Rev. 8

Page 44

RSU-503 Redundancy Switch Unit Theory of Operation

Although the switch M&C is considered to be the slave unit on the MTI RS-232 bus, it

becomes the master when communicating to each of the two RFTs.

When not servicing MTI requests, the M&C monitors indicators, faults, and voltages.

When applicable, it generates switch-over pulses.

When polled from the MTI, the switch M&C will perform the following functions:

1. Return a response acknowledging receipt of the command.

2. Decode the address in the message, compare it to the stored addresses, and route

it to its intended destination.

3. Return a block of status information when requested.

3.4.2 Switch Indicators

Address 9000 reads in the eight indicator bits representing the four uplink and four

downlink indicator positions. The following tables show how the four bits are decoded to

indicate whether the unit A or B is currently online.

Uplink

B0 B1 B2 B3 WR8000, B0 WR8000, B4

IF_A RF_A IF_B RF_B 1 = A ON LINE

0 = B ON LINE

0000 1 0

0001 1 0

0010 1 0

0 0 1 1 1 1 - Valid state, A online

0100 0 0

0101 0 0

0110 0 0

0111 0 0

1000 1 0

1001 1 0

1010 1 0

1011 1 0

1 1 0 0 0 1 - Valid state, B online

1101 0 0

1110 0 0

1111 0 0

1 = OKAY

0 = AMBIGUITY FAULT

Rev. 8 3–3

Page 45

Theory of Operation RSU-503 Redundancy Switch Unit

Downlink

B4 B5 B6 B7 WR8000, B2 WR8000, B5

IF_A RF_A IF_B RF_B 1= A ON LINE

0 = B ON LINE

0000 1 0

0001 1 0

0010 1 0

0 0 1 1 1 1 - Valid state, A online

0100 0 0

0101 0 0

0110 0 0

0111 0 0

1000 1 0

1001 1 0

1010 1 0

1011 1 0

1 1 0 0 0 1 - Valid state, B online

1101 0 0

1110 0 0

1111 0 0

1 = OKAY

0 = AMBIGUITY FAULT

3.4.3 Auto/Manual Modes

In Auto mode, switch-over can only occur as a result of a fault, as listed in the following

table:

B0 B1

UL FLT A UL FLT B Fault Description

0 0 No faults.

0 1 Fault on B uplink, switch to uplink A, WR8001 B0.

1 0 Fault on A uplink, switch to uplink B, WR8001 B1.

1 1 Fault on both, do nothing. Monitor, and switch to the first

B2 B3

DL FLT A DL FLT B Fault Description

0 0 No faults.

0 1 Fault on B downlink, switch to downlink A, WR8001 B2.

1 0 Fault on A downlink, switch to downlink B, WR8001 B3.

1 1 Fault on both, do nothing. Monitor, and switch to the first

In Manual mode, the switch initiates the online pulses from only two sources:

• Request from the MTI

• Onboard push-button switches

RD9001

unit to remote the fault.

unit to remote the fault.

In normal service with the cover secured, switch-over can occur only from an MTI

request.

3–4 Rev. 8

Page 46

Chapter 4.

MAINTENANCE

4

This chapter provides information on the following:

• Internal switches, indicators, and connections

• How to service the switch with the power on

• Troubleshooting

Note:

Under normal conditions, this switch does not require periodic or preventive

maintenance. Most problems, if any, will arise during the initial installation. These

problems will most often be due to improper cabling, waveguide wiring, or indicator

positions.

4.1 Internal Switches

The switch does not have any external switches or controls. The internal switches

(shown in Figure 4-1) are not normally used by the operator. However, if the switch must

be opened, descriptions of the four push-button switches are provided in the following

table.

Switch Description

UL AUTO/MAN Depress to alternate between Uplink Auto and Manual.

UL A/B ONLINE Depress to alternate between A and B uplink online.

DL AUTO/MAN Depress to alternate between downlink Auto and Manual.

DL A/B ONLINE Depress to alternate between A and B downlink online.

Rev. 8 4–1

Page 47

Maintenance RSU-503 Redundancy Switch Unit

4.2 Internal Indicators

The switch does not have any external indicators. The internal indicators (shown in

Figure 4-1) are not normally used by the operator. However, if the switch must be

opened, descriptions of the indicators are provided in the following table.

Indicator LED Cause

System Status

PWR A Green Illuminates if RFT A power is available.

PWR B Green Illuminates if RFT B power is available.

32V Green Illuminates when power av ailable to switches.

SUM FLT Red Illuminates an ambiguity failure, RFT fault, or power supply

fault.

Uplink

FLT A Red Illuminates with failure of unit A uplink.

FLT B Red Illuminates with failure of unit B uplink.

FLT AMB Red Illuminates if uplink switch indicators do not agree.

B OL Yellow Illuminates when unit B uplink is online.

MAN Yellow Illuminates when uplink is in manual mode.

Downlink

FLT A Red Illuminates with failure of unit A downlink.

FLT B Red Illuminates with failure of unit B downlink.

FLT AMB Red Illuminates if downlink sw itch indicators do not agree.

B OL Yellow Illuminates when unit B downlink is online.

MAN Yellow Illuminates when downlink is in manual mode.

Figure 4-1. LED and Switch Locations

4–2 Rev. 8

Page 48

RSU-503 Redundancy Switch Unit Maintenance

4.3 Servicing with Power On

If maintenance must be performed on the unit while the link remains on the air, proceed

as follows:

1. Loosen the access panel screws on the side of the switch case (refer to

Figure 4-2) to expose the internal M&C Logic Control PCB.

Figure 4-2. Access Panel

2. Observe the LEDs on the M&C board, which will indicate the following:

a. Receipt of power from RFT A

b. Receipt of power from RFT B

c. Transfer switch power (32V) available

d. Summary fault indicator, if any fault in the system

e. Uplink RFT, Unit A fault

f. Uplink RFT, Unit B fault

g. Uplink Indicator Ambiguity fault

h. Uplink unit A or B currently online

i. Uplink mode in Auto or Manual

j. Downlink RFT, Unit A fault

k. Downlink RFT, Unit B fault

l. Downlink Indicator Ambiguity fault

m. Downlink unit A or B currently online

n. Downlink mode in Auto or Manual

3. Refer to Section 4.4 for troubleshooting assistance.

Rev. 8 4–3

Page 49

Maintenance RSU-503 Redundancy Switch Unit

4.4 Troubleshooting

The following paragraphs may be used to diagnose problems within the system. Locate

the malfunction in the left column that most closely matches the situation. Then, read

across to the possible problem.

All conditions except the first can be observed only when the cover of the switch is

removed.

Refer to Figure 4-1 for LED locations.

Condition Possible Problem

Cannot initiate switch-over from A

to B, or vice versa

PWR A LED not lit Cable not connected from RFT A.

PWR B LED not lit Cable not connected from RFT B.

32V LED not lit DC/ DC module PS1 bad on M&C board.

UL or DL Unit A fault LED lit RFT A has a fault in either the UL or DL. Cable from

UL or DL Unit B fault LED lit RFT B has a fault in either the UL or DL. Cable from

UL or DL Ambiguity Fault LED lit IF and RF transfer switches (input/output) are not in

Summary fault LED lit Request Fault Status from remote terminal to ascertain

System could be in AUTO mode, where sw itch-ov ers

are automatic.

RFT A not powered up.

RFT B not powered up.

Short on output of module PS1.

RFT A disconnected, or RFT A turned off.

RFT B disconnected, or RFT B turned off.

sync. Use remote terminal, or M&C push-buttons to

alternate between A and B online. This will synchronize

the pair.

the specific fault from fault list.

4–4 Rev. 8

Page 50

RSU-503 Redundancy Switch Unit Maintenance

4.5 Internal Connections

The internal connections are not normally seen by the user, since the switch is designed

to prevent the weather from damaging the internal circuitry. However, if the switch must

be opened, pinouts of the three internal connectors have been provided.

Refer to Figure 4-3 for location of the internal connections.

Figure 4-3. Internal Connections

Rev. 8 4–5

Page 51

Maintenance RSU-503 Redundancy Switch Unit

4.5.1 Serial Interfaces (J19, J20, J21)

The internal Serial Interface connectors are 9-pin D with the following pinouts:

Pin # Name Function

RS-232 RS-485

1GND

2 TD/TX Transmit Data

3 RD/RX Receive Data

4+RX/TX

5GND

6 DSR Data Set Ready (Tied high)

7 RTS -RX/TX Ready to Send

8 CTS Clear to Send

9-RX/TX

Notes:

1. J19 and J20 do not use DSR on pin 6.

2. Clear to Send (CTS) is tied to Ready to Send (RTS) in RS-232 mode.

(see Note 1)

(see Note 2)

(see Note 2)

4–6 Rev. 8

Page 52

RSU-503 Redundancy Switch Unit Maintenance

4.5.2 M&C Switch CMD and Indicators (J18)

This connector is a 37-pin female D connector with the following pinouts:

Pin # Name Function

1 Terminal Power Output, 10V power for the KP-10

20 Spare

2 UL IF IND COM T ied to signal ground

21 DL IF IND COM Tied to signal ground

3 UL RF IND COM Tied to signal ground

22 DL RF IND COM Tied to signal ground

4 Spare

23 UL IF A IND 0V = Indicates uplink IF connected to unit A

5 UL IF B IND 0V = Indicates uplink IF connected to unit B

24 Spare

6 UL RF A IND 0V = Indicates uplink RF connected to unit A

25 UL RF B IND 0V = Indicates uplink RF connected to unit B

7 Spare

26 DL IF A IND 0V = Indicates downlink IF connected to unit A

8 DL IF B IND 0V = Indicates downlink IF connected to unit B

27 Spare

9 DL RF A IND 0V = Indicates downlink RF connected to unit A

28 DL RF B IND 0V = Indicates downlink RF connected to unit B

10 Spare

29 Spare

11 Spare

30 UL IF A CMD +28V pulse, commands UL IF switch to unit A

12 UL RF A CMD +28V pulse, commands UL RF switch to unit A

31 Spare

13 UL IF B CMD +28V pulse, commands UL IF switch to unit B

32 UL RF B CMD +28V pulse, commands UL RF switch to unit B

14 Spare

33 DL IF A CMD +28V pulse, commands DL IF switch to A

15 DL RF A CMD +28V pulse, commands DL RF switch to unit A

34 Spare

16 DL IF B CMD +28V pulse, commands DL IF switch to unit B

35 DL RF B CMD +28V pulse, commands DL RF switch to unit B

17 Spare

36 UL IF CMD COM Tied to signal ground

18 UL RF CMD COM Tied to signal ground

37 DL IF CMD COM Tied to signal ground

19 DL RF CMD COM Tied to signal ground

Rev. 8 4–7

Page 53

Maintenance RSU-503 Redundancy Switch Unit

4.5.3 M&C Input/Output Signals (J17)

The M&C I/O connector is a 25-pin male D connector with the following pinouts:

Pin # Name Function

13 DC GND A T ied to signal ground

25 DC GND B T ied to signal ground

12 UL FLT COM A Tied to signal ground

24 UL FLT COM B Tied to signal ground

11 DL FLT COM A Tied to signal ground

23 DL FLT COM B Tied to signal ground

10 Spare

22 UL FLT NO A Input, connected to ground when normal

9 UL FLT NC A Input, connected to ground when faulted

21 UL FLT NO B Input, connected to ground when normal

8 UL FLT NC B Input, connected to ground when faulted

20 Spare

7 DL FLT NO A Input, connected to ground when normal

19 DL FLT NC A Input, connected to ground when faulted

6 DL FLT NO B Input, connected to ground when normal

18 DL FLT NC B Input, connected to ground when faulted

5 Spare

17 Spare

4 SUM FLT NO Output, connected to COM when normal

16 SUM FLT COM Output common

3 SUM FLT NC Output, connected to COM with any fault

15 Spare

2 XVA Input, DC power from unit A (approx. 11V)

14 Spare

1 XVB Input, DC power from unit B (approx. 11V)

4–8 Rev. 8

Page 54

Appendix A.

RSU-503L OPTION

A

This appendix describes the RSU-503L (Figure A-1), a low-loss version of the RSU-503.

Note:

The RSU-503 and RSU-503L are similar units. As a result, only the primary

differences of the RSU-503L are provided in this appendix.

Figure A-1. RSU-503L Front Panel

Rev. 8 A–1

Page 55

RSU-503L Option RSU-503 Redundancy Switch Unit

X

/

A

/

X

/

A

/

WAV

WAV

X

/

X

/

W

W

A

A

A.1 Description

Refer to Figure A-2 for an interconnection block diagram of the RSU-503L in a typical

earth station application.

Using WR229 (C-band) or WR75 (Ku-band) waveguide, the RSU-503L routes the RF

outputs from both RFTs directly to a waveguide switch on the antenna plate.

In addition to the RSU-503 functions, the RSU-503L provides command pulses for the

external uplink waveguide switch (28V).

A.2 Assemblies

The RSU-503L consists of the following assemblies:

Assembly EFData Part #

Top Assembly PL/3000-1

Cable Harness PL/3001-1

Chassis Base FP/3802

Panel Divider FP/3139

M&C Assembly, RSU-503L PL/3002

M&C Firmware, RSU-503L FW/3080-1

70 MHz

TX /IF

IN P U T

70 M Hz

RX/IF

OUTPUT

RS232

REM OTE

CONTROL

J14

TN C

J15

TNC

J16

C

S1

TX /IF

3005

CA/3005

A

TN C

J1

TN C

3

1

4

2

TN C TN C TN C

J5

STAND BY

B

TX /IF

TES T

IN P U T

C/A3005

T

RX/IF

S2

3

1

J12

RF/IF

TX /IF

IF

TNC

TN C

26

RX/IFTX /IF

A

J2

6

4

2

TN C

J6

RF/IF

B

STAND BY

RF/IF

TES T

OUTPUT

TNC

TNC

RFT-XXX

#A

AS/2578

CA/3003

M&C-RS232

A

J4

P19

6

P21

P20

J13

26

SHO

AS/3000-1

IND

IND

AS/3002

J8

RSU-503L

LOW LOSS REDUNDANCY SWITCH UNIT

CA/3003

M&C-RS232

B

RFT-XXX

#B

AS/2578

N

ITH " B "

M&C

RF

R

TX/RF

T

R

ON

12

WG

RF

RF

LIN E

J10

IND

EG UID E

1530

C

CA/1530

Figure A-2. RSU-503L Low Loss Block Diagram

19

LNA

TEST

IN P U T

WAVEGUIDE

CA/3951

N

REDUND ANT

LNA

N

#A

WG TO N

ADAPTER

LN A

#B

WAVEGUIDE

S3

4

2

3

1

6

6

LNA

EGUIDE

SW ITC H

SW ITC H P LA TE

UPLINK

SW ITCH

NTENN

TO

FROM ANTENNA

A–2 Rev. 8

Page 56

RSU-503 Redundancy Switch Unit RSU-503L Option

A.3 External Connections

Note:

The following connections, available on the RSU-503, are not available with the

RSU-503L:

• TX/RF Input (J3, J7)

• TX/RF Output (J9)

• TX/RF Output (J11) (test output only)

Failure to properly connect the units will result in loss of communications

between the switch and the RFTs.

CAUTION

All connections between the switch and other equipment are made through front panel

connections, as shown in Table A-1 (refer to Figure A-3 for connector locations).

Table A-1. RSU-503L External Connections

Name Desig. Type Function

Switch to RFT #A (Primary)

TX/IF OUTPUT J1 TNC, 50

RX/IF INPUT J2 TNC, 50

MONITOR &

CONTROL

TX/IF OUTPUT J5 TNC, 50

RX/IF INPUT J6 TNC, 50

MONITOR &

CONTROL

WAVEGUIDE

SWITCH

TX/IF INPUT J12 TNC, 50

RX/IF OUTPUT J13 TNC, 50

TX/IF INPUT J14 TNC, 50

RX/IF OUTPUT J15 TNC, 50

MONITOR &

CONTROL

GND ERDE None #10-32 Stud Chassis Ground

Note:

Refer to Section A.5 for addressing information.

J4 26-pin Circ. Monitor and control

Switch to RFT #B (Backup)

J8 26-pin Circ. Monitor and control

Switch to Antenna

J10 19-pin Circ. Waveguide switch control

Standby Unit Test Ports

Switch to Modem Terminal Interface

J16 26-pin Circ. Modem Terminal Interface (MTI)

IF Uplink to Unit A

Ω

IF Downlink from Unit A

Ω

See Section 2.4.4 for pinouts

IF Uplink to Unit B

Ω

IF Downlink from Unit B

Ω

See Section 2.4.4 for pinouts

See Section 2.4.6.1 for pinouts

IF input test signal

Ω

IF output test signal

Ω

IF Uplink

Ω

IF Downlink

Ω

See Section 2.4.12 for pinouts

Ground

(See note)

(See note)

Rev. 8 A–3

Page 57

RSU-503L Option RSU-503 Redundancy Switch Unit

Figure A-3. RSU-503L External Connections

A–4 Rev. 8

Page 58

RSU-503 Redundancy Switch Unit RSU-503L Option

A.3.1 LNA Waveguide Switch Pinout (J10)

Name Pin # Function

Command, LNA Position 1 C +28V pulse for 500 milliseconds

LNA Command Common G Ground

Command, LNA Position 2 D +28V pulse for 500 milliseconds

LNA Indicator, Position 1 H Connects to Common when in position 1

LNA Indicator, Common R Ground

LNA Indicator, Position 2 T Connects to Common when in position 2

Command, RF Position 1 E +28V pulse for 500 milliseconds

RF Command Common L Ground

Command, RF Position 2 F +28V pulse for 500 milliseconds

RF Indicator, Position 1 J Connects to Common when in position 1

RF Indicator, Common V Ground

RF Indicator, Position 2 K Connects to Common when in position 2

LNA PWR #A A 10V power for LNA 1

LNA RTN #A B Ground Return for LNA 1

LNA PWR #B N 10V power for LNA 2

LNA RTN #B P Ground Return for LNA 2

Chassis Ground S Ground for Shields

Rev. 8 A–5

Page 59

RSU-503L Option RSU-503 Redundancy Switch Unit

A.4 External Cables

Refer to Figure A-4 for a diagram of the waveguide switch cable and Table A-2 for cable

dimensions.

DIMENSION "A"

SEE TABLE

28P1038

PTO6E-14-19P (SR)

A

M

B

N

U

P

C

G

D

H

R

T

S

GRN

CABLE: 30P1034

NQ-1922SJ

BLK-WHT

WHT

BRN-WHT

BRN

BLU

RED

RED-WHT

GRN-WHT

ORN-WHT

VIO-WHT

ORN

YEL

LNA1 PWR

SPARE1

LNA RTN

LNA2 PWR

SPARE2

LNA2 RTN

DLPOS1CMD

DLCMD COM

DLPOS2CMD

DLPOS1IND

DLINDCOM

DLPOS2IND

28P1040

PTO6E-14-19S (SR)

GRN

A

M

B

N

U

MATES TO

ANTENNA BULKHEAD

P

CONN. 28P1041

PT00E-14-19P (SR)

C

G

D

H

R

T

S

E

L

F

J

V

K

ULPOS1 CMD

ULCMD COM

ULPOS2 CMD

ULPOS1 IND

ULIND CO M

ULPOS2 IND

CABLE:30P1054

BELDON 9260

DIMENSION "B"

SEE TABLE

A

B

U/L W G SW

C

D

(CONNECTOR SUPPLIED

WITH WG SWITCH)

E

CN/STPG06F02

F

Figure A-4. RSU-503L, J10 to Waveguide Switches

A–6 Rev. 8

Page 60

RSU-503 Redundancy Switch Unit RSU-503L Option

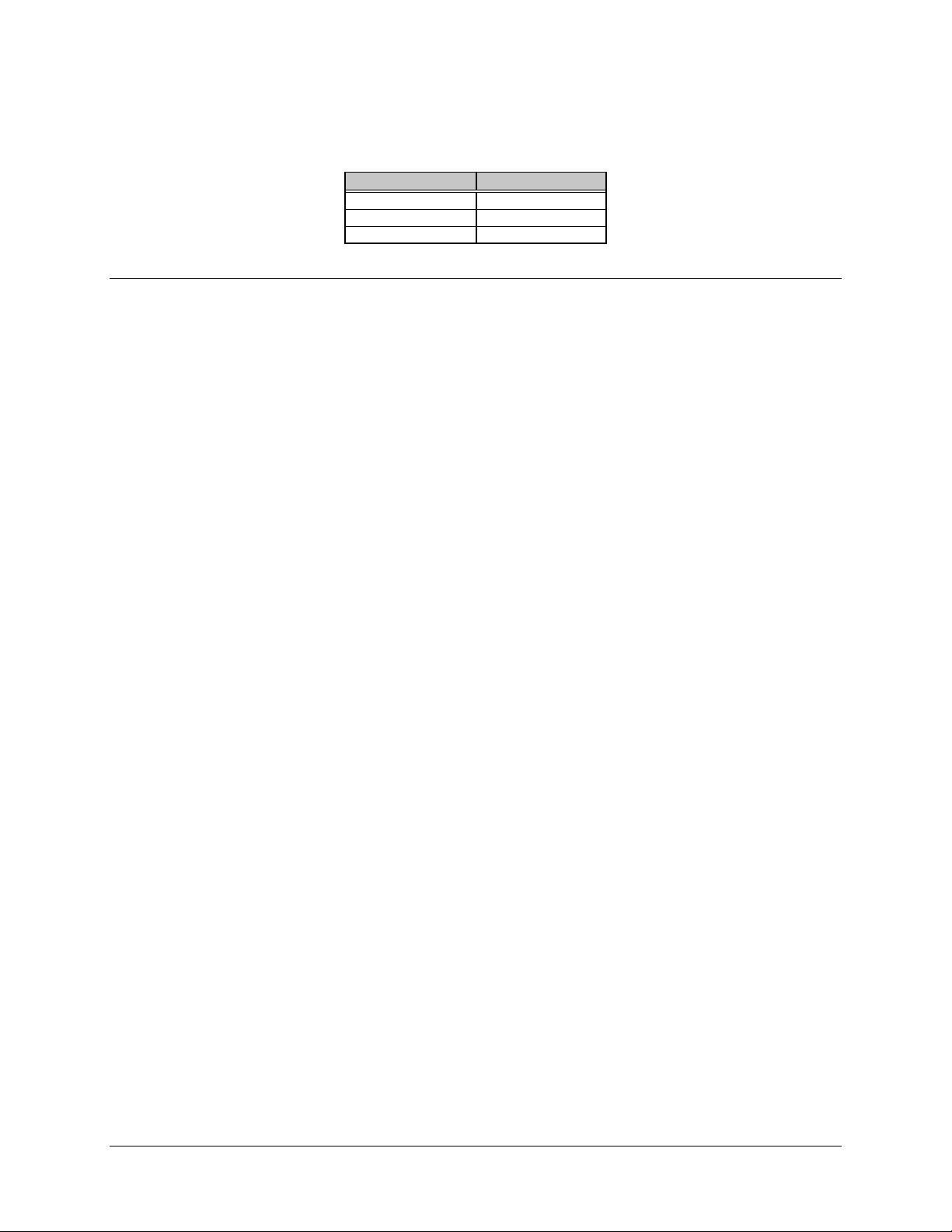

Table A-2. Waveguide Switch Cable Dimensions

Dimension “A” Dimension “B”

12 ft. 10 ft.

17 ft. 15 ft.

22 ft. 20 ft.

A.5 Addressing

The following are the factory default addresses:

• RSU-503 is set to address 1

• RFT A is set to address 2

• RFT B is set to address 3

The proper M&C cable hook-up is critical:

• RFT A must be connected to the RSU Port A

• RFT B must be connected to the RSU Port B

Note:

If these connections are reversed, no communications will take place

.

Rev. 8 A–7

Page 61

RSU-503L Option RSU-503 Redundancy Switch Unit

This page is intentionally left blank.

A–8 Rev. 8

Page 62

Appendix B.

REMOTE CONTROL OPERATION

B

This appendix describes the remote control operation of the RSU-503 and RSU-503L.

• Firmware number: FW/3080-1P

• Software version: 1.14

Notes:

1. Unless indicated otherwise, any references in this appendix to “the switch” apply

to both the RSU-503 and RSU-503L.

2. Before operating the system, ensure the installation is complete and the cable

connectors are tight, especially the connections from the waveguide switch

indicators. If not, no harm will come to the unit, but the online indicators might

read erroneously if the waveguide switch is not set to the same online position as

the coax switches in the switch.

Ambiguity between any of the RF switches can be corrected by commanding a

switchover from A to B, or B to A. This will then latch all switches on the same channel.

This natural ambiguity only occurs during installation, and would only reoccur if a

switch becomes faulty.

Note:

The firmware referenced in this manual may be an earlier version of the actual

firmware supplied with the unit.

Rev. 8 B–1

Page 63

Remote Control Operation RSU-503 Redundancy Switch Unit

B.1 General

Remote controls and status information are transferred via an RS- 485 (optional RS- 232)

serial communications link.

Commands and data are transferred on the remote control com munications link as

US ASCII-encoded character strings.

The remote communications link is operated in a half- duplex m ode.

Communications on the rem ote link are initiated by a rem o te controller or term inal. The

switch never transmits data on the link unless it is comm anded to do so.

Serial communications with either RFT through the switch remains the same as

communicating directly with the unit. Each individual RFT is assigned its own unique

address, and will respond when that address is polled. To the RFT, the interconnection is

transparent—it will not know whether the command came through the switch or directly

from the terminal.

The switch receives all commands from the interface, decodes the contained address,

compares it to its stored addresses, and routes the message to the intended destination.

When an RFT communication parameter (address, baud rate, and parity) is changed, the

switch will also store that information in its EEPROM.

Note:

All three units must have unique addresses.

B.2 Message Structure

The ASCII character form at used requires 11 bits/character:

• 1 start bit

• 7 information bits plus 1 parity bit

• 2 stop bits

or:

• 1 start bit

• 8 information bits with no parity bit

• 2 stop bits

Messages on the remote link fall into the categories of commands and responses.

Commands are m essag es w hich are transmitted to the switch, while responses are messages

returned by the switch in response to a command.

B–2 Rev. 8

Page 64

RSU-503 Redundancy Switch Unit Remote Control Operation

The general message structure is as follows:

• Start Character

• Device Address

• Command/Response

• End of Message Character

B.2.1 Start Character

A single character precedes all messages transmitted on the remote link. This character

flags the start of a message. This character is:

“<”

•

•

for commands

“>”

for responses

B.2.2 Device Address

The device address is the address of the switch which is designated to receive a transmitted

command, or which is responding to a command.

Valid device addresses are 1 to 3 characters long, and in the range of 1 to 255. Address 0 is

reserved as a global address which simultaneously addresses all dev ices on a g iv en

communications link. Devices do not acknowledge global commands.

Each switch and RFT connected to a common remote com munications link, must be

assigned its own unique address. Addresses are software selectable at the unit, and must be

in the range of 1 to 255.

Note:

Global address “*” is reserved for KP-10 (the external keypad) commands. Refer

to the KP-10 External Keypad Installation and Operation Manual.

Rev. 8 B–3

Page 65

Remote Control Operation RSU-503 Redundancy Switch Unit

B.2.3 Command/Response

The command/response portion of the messag e contains a v ariable-length character

sequence which conveys command and response data.

If the switch receives a messag e addressed to it w hich does not m atch the established

protocol or cannot be implemented, a negativ e acknowledg ment message is sent in

response. This message is:

>add/?ER1_parity error'cr''lf']

•

(Error message for received parity errors.)

>add/?ER2_invalid parameter'cr''lf ']

•

(Error message for a recognized command which cannot be implemented or has parameters

which are out of range.)

>add/?ER3_unrecognizable command'cr''lf ']

•

(Error message for unrecognizable command or bad command syntax.)

>add/?ER4_converter in lock mode'cr''lf']

•

>add/?ER5_not supported by hardware'cr''lf']

•

>add/?ER6_address in use'cr''lf']

•

>add/?ER7_RSU-503 in auto mode'cr''lf']

•

Note:

range between 1 and 255.

B.2.4 End Character

Each message is ended with a single character which sig n als the end of the m essag e:

“cr”

•

“]”

•

(Controller in Lock mode. Must go to Enable mode first.)

(Command is valid command, but it is not supported by the current hardware configuration.)

(Address specified in the ASA, ASB, or ASR command is alread y assigned.)

(Switch is in Auto mode. Must go to Manual mode first.)

“add” is used to indicate a valid 1 to 3 character device address in the

Carriage return character for commands

End bracket for responses