Page 1

ci0039

issue 9, 2015-09-04

Sentinel 300P series

Automatic switch mode battery chargers

Installation, Operation & Maintenance

This manual refers to the following models

All models are UL recognised or listed

Open frame

models

SNTL300P

SNTL300PC

Base open-frame (protective cover) model.

As above, plus CAN J1939 communication.

Enclosed

models

ESNTL300PM

ESNTL300PCL

ESNTL300PCLM

Enclosed model, analogue meters.

Enclosed model, CAN J1939 communications

and LCD display

Enclosed model, CAN J1939 communications,

LCD display and analogue meters.

For safe and correct use of these chargers, read and save the safety

information that precedes the installation and operation instructions.

This guide contains 12 pages (including this one). If any pages are

missing, contact the battery charger supplier or manufacturer for

replacement documentation.

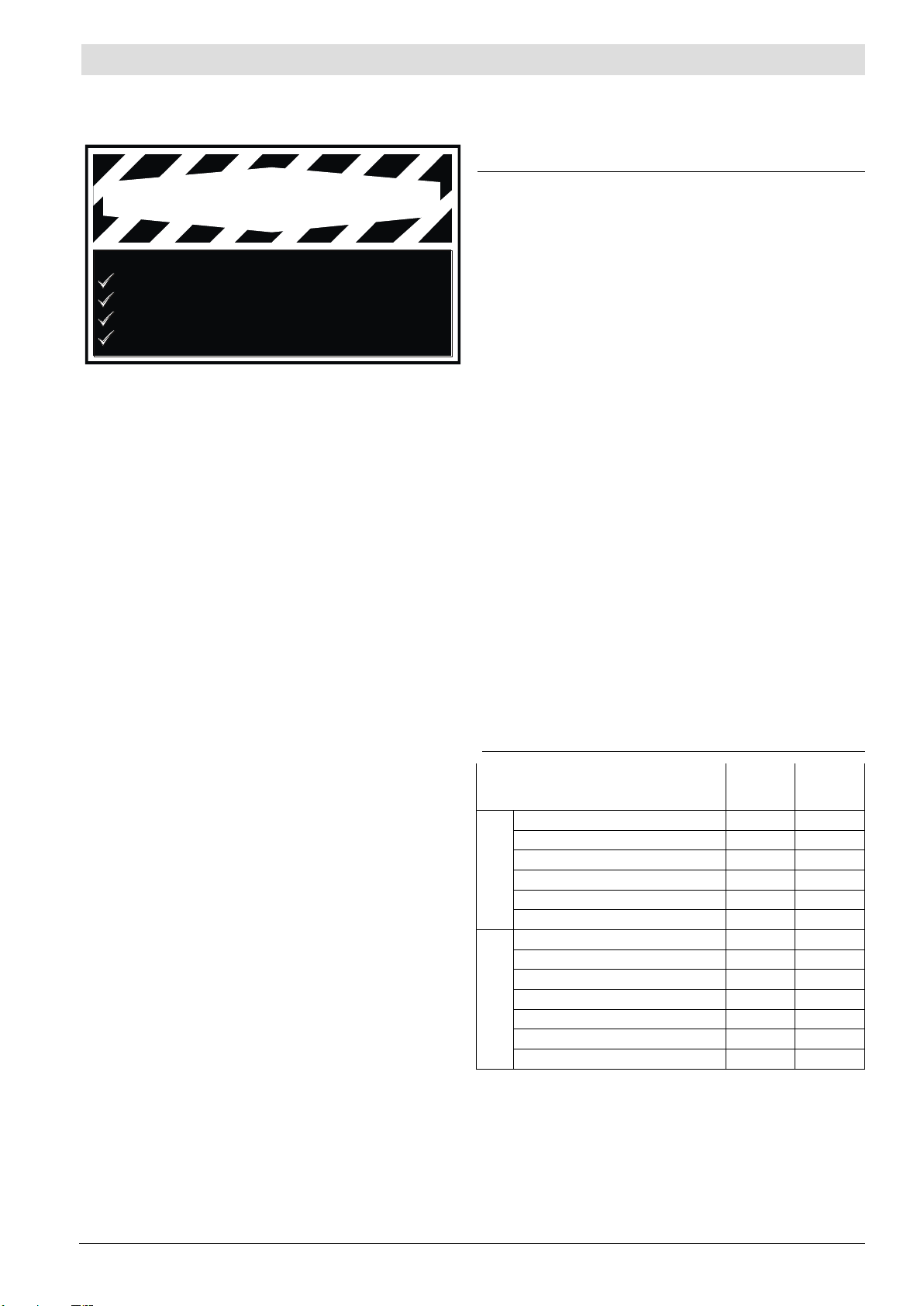

Sentinel 300P (open-frame, with protective cover)

SNTL300P model shown

Enclosed Sentinel 300P

ESNTL300PCLM model shown

For sales & support, contact:

ENOVATION CONTROLS LTD.

Church Road, Laverstock,

Salisbury, SP1 1QZ, United Kingdom

Phone: +44 1722 410055

Fax: +44 1722 410088

E-mail: sales@enovationcontrols.eu

Web: www.computroniccontrols.com

www.fwmurphy.eu/computronic

ENOVATION CONTROLS

5311 S 122nd East Avenue,

Tulsa, OK 74146, USA

Phone: +1 918 317 4100

Fax: +1 918 317 4266

E-mail: sales@enovationcontrols.com

sales@fwmurphy.com

Web: www.fwmurphy.com

Page 2

Sentinel 300P installation, operation & maintenance

ci0039 p2/12 issue 9 2015-09-04

Important Safety Information – Read and Save These Instructions

This manual contains important safety and operating instructions for all SNTL300P and ESNTL300P models.

Do not expose the battery charger to rain, snow or wet environments.

The use of any attachment not recommended or sold by the battery charger manufacturer may result in risk of fire,

electric shock, injury to persons or damage to property.

Do not operate the charger if it has received a sharp blow, been dropped, or otherwise damaged in any way: return to

supplier.

Do not disassemble the charger: return to supplier when service or repair is required. Incorrect re-assembly may result

in a risk of electric shock, fire or faulty operation.

WARNING – RISK OF EXPLOSIVE GASES

WORKING IN THE VICINITY OF A HIGH POWER BATTERY IS DANGEROUS. BATTERIES MAY GENERATE

EXPLOSIVE GASES DURING NORMAL OPERATION AND CHARGING.

To reduce the risk of battery explosion, follow these instructions and those published by battery manufacturers and the

manufacturer of any equipment you intend to use in the vicinity of the battery. Review cautionary marking on these

products and any attached equipment.

PERSONAL PRECAUTIONS.

(i) Someone should be within range of your voice or close enough to come to your aid when you work near a lead acid

or high power battery.

(ii) Have plenty of fresh water and soap nearby in case battery acid contacts skin, eyes or clothing.

(iii) Wear complete eye protection and clothing protection. Avoid touching eyes whilst working near batteries.

(iv) If battery acid or chemicals contact skin or clothing, wash immediately with soap and water. If acid or chemicals

enter the eyes, immediately flood eyes with running cold water for at least 10 minutes and get immediate medical

attention.

(v) NEVER smoke or allow a spark or flame in vicinity of battery.

(vi) Be extra cautious to reduce risk of dropping a metal tool on to the battery. It may spark or short-circuit the battery or

other electrical part that may cause explosion.

(vii) Remove personal metal items such as rings, bracelets, necklaces and watches when working with batteries.

High power batteries can produce a short-circuit current high enough to weld a ring or the like to metal, causing severe

burns.

(viii) Use the charger only for charging battery types as stated on the charger. Do not use the charger for charging dry-

cell batteries that are commonly used with home appliances. These batteries may burst and cause injury to persons and

damage to property.

(ix) NEVER CHARGE A FROZEN BATTERY

PRIOR TO INSTALLATION /COMMISSIONING

Clean battery terminals. Be careful to keep corrosion from coming into contact with eyes.

For lead acid batteries, add distilled water in each cell until the battery acid reaches a level specified by the battery

manufacturer. This helps purge excessive gas from the cell. Do not overfill. For a battery without cell caps, carefully

follow manufacturer’s recharging instructions.

Study all battery manufacturer’s specific precautions, such as removing or not removing cell caps while charging and

recommended rates of charge.

Determine the battery voltage by referring to the engine manual and ensure this matches the charger’s output voltage.

CHARGER LOCATION AND CONNECTION

Never place the charger directly above the battery being charged: battery gases will corrode and damage the charger.

When reading specific gravity or filling batteries, never allow battery acid or chemicals to drip on to the charger.

Do not operate the charger in a closed-in area or restrict ventilation in any way.

The battery charger should be connected to a grounded, metal, permanent wiring system; or an equipment–grounding

conductor should be run with circuit conductors not connected to equipment-grounding terminal on the battery charger.

Connections to the battery charger should comply with all local codes and ordinances.

Open frame SNTL models – these chargers should be installed so that they are not likely to be contacted by people.

Wiring for the AC supply input, DC charge output and DC control (e.g. alarm output) circuits must be physically

separate, e.g. using separate wire harnesses and cable gland access. For AC supply and ground connections, use

1mm²/17 AWG or larger wire conductors rated to 90°C/194°F. For DC (charger to battery) leads, use 4mm²/11 AWG or

larger wire.

For safe and correct use of the charger, follow steps below. Should you have any problems or the unit does not function as

expected, consult our troubleshooting guide at the end of these instructions.

Visually inspect unit for any signs of damage, caused by transport or storage.

Mount the charger as outlined above, paying attention to ventilation and ambient temperature.

Ensure the mains AC supply is isolated, and ensure the correct rated input voltage before connection.

Ensure the charger is earthed at the marked earth terminal/stud.

Check batteries in accordance with the manufacturer’s guidelines.

Check that the charger is correct for battery type, number of cells and voltage.

Connect the charger to the batteries, observing correct polarity and ensuring a secure and tight connection.

Switch on the charger at the mains AC power supply.

Page 3

Sentinel 300P installation, operation & maintenance

ci0039 p3/12 issue 9 2015-09-04

BEFORE BEGINNING INSTALLATION OF THIS PRODUCT

Disconnect all electrical power to the charger

Make sure the charger cannot operate during installation

Follow all safety warnings of the battery manufacturer

Read and follow all installation instructions

W A R NING

Specifications

Power supply

Operating voltage: 95 – 250 V AC

Operating frequency: 47 – 63 Hz.

DC Charge Output

Nominal voltage: programmable 12 or 24 V DC

Float/boost voltage: programmable, see ‘DC output calibration’ table

Maximum current limit: 10 A

Voltage ripple: <1%

Line regulation: <2%

Load regulation: <2%

Outputs x3 (optional x4 on non-CAN models):

All models:

1 x SPDT (RL1), 1 x SPNC (RL2), 1 x SPNO (RL3),

dry/volt-free contacts (common feed for RL1, RL2 & RL3)

Standard models (non-CAN configurations):

1 x SPNC (RL4), dry/volt-free contacts

standard model output functions are compliant with NFPA 110

Rating (all relays): 1A max @ 30 VDC (resistive load), UL class 2

Inputs x2

Closed to negative DC to activate

Physical

Operating temperature: –40 to +60°C / –40 to +140°F

Display viewability (LCD models only): 0 to 50°C / 32 to 122°F

Humidity: 20% to 90% RH

Dimensions: see Dimensions and Assembly section

Weights: see Dimensions and Assembly section

Electrical safety: 2006/95/EC

Electromagnetic compatibility:

2004/108/EC, EN 55022 class B

(EN 61000-6-1, EN 61000-6-3)

UL approvals

All (E)SNTL300P models:

BBGQ: UL1236, CSA 22.2 no. 107.2

BBHH: UL1236 SE

DC output calibration

Battery type:

float volts

(V DC)

boost volts

(V DC)

12V

Wet (vented) lead acid, 6 cells

13.5

14.1

Calcium-Calcium, 6 cells

13.8

15.6

Lead acid hybrid Sb-Ca, 6 cells

13.5

14.7

VRLA, AGM, 6 cells

13.5

14.4

VRLA, Gel, 6 cells

13.5

13.8

NiCd, 10 cells

14.1

14.5

24V

Wet (vented) Lead acid, 12 cells

27.0

28.2

Calcium-Calcium, 12 cells

27.6

31.2

Lead acid hybrid Sb-Ca, 12 cells

27.0

29.4

VRLA, AGM, 12 cells

27.0

28.8

VRLA, Gel, 12 cells

27.0

27.6

NiCd, 18 cells

25.6

26.1

NiCd, 20 cells

28.2

29.0

Note: Calibration figures at 20 deg C. Output voltage will vary if

temperature compensation is enabled – see Electrical Connection &

Configuration section.

General Information

Please read the following before installing. A visual inspection of this product for damage during shipping is

recommended before installation. It is your responsibility to ensure that qualified mechanical and electrical

technicians install this product. If in doubt, please contact your local Computronic representative.

Sentinel 300P battery chargers provide new levels of DC

power control, monitoring and protection for standby battery

and engine starting applications.

Computronic advanced charger features included as

standard:

Switch mode charging technology: high power efficiency

and low heat dissipation, plus wide supply voltage

tolerance, in a compact and lightweight package.

Multistage charging: float, bulk, absorption and AutoBoost

stages ensure no compromise between rapid charge

recovery and long term battery capacity and life.

Low output ripple: <1% ripple, beneficial for vented lead

acid & NiCd cells, essential for VRLA, and configurable for

use as a stand-alone DC power supply.

AutoBoost: triggered automatically on low charge levels,

or manually by remote switch, AutoBoost temporarily

increases the charge voltage before returning to float mode.

AutoBoost equalises battery cell charge, maximising battery

capacity and life, without overcharge and gassing.

Temperature compensation: ensures batteries are

charged at the optimal voltage, which varies significantly

with ambient temperature. Sentinel can measure

temperature with a battery mounted sensor and adjust

output voltage to prevent under or over charging.

In addition, the Sentinel 300P also provides:

Flexible configuration: microprocessor programmability

for automatic or manual configuration of output voltages

(12 or 24V nominal), cell types/numbers and charging

applications – all in one standard model. Programming is

by circuit board links and/or PC software configuration and

monitoring tool.

Inputs & outputs: for remote charger control, and

signalling of charge fail, high/low battery volts and

mains fail faults. Standard model outputs comply with

the NFPA 110 standard. Non-standard input/output

functions available to special order.

Display, instrumentation and communication: options

are available for LCD readout, analogue amp/volt metering

and CAN SAE J1939 communication. All models include

RS485 communication for configuration and control.

The Sentinel 300P is available either as an open-frame

(UL-recognized) module for mounting in existing control

panels, or as a wall-mounted (UL-listed) stainless steel

enclosure with LCD and analogue metering options.

Electrical connection is by circuit board mounted screw

terminal blocks. On enclosed models, wiring harness

access is by knock-out cable gland holes in the case side.

Page 4

Sentinel 300P installation, operation & maintenance

ci0039 p4/12 issue 9 2015-09-04

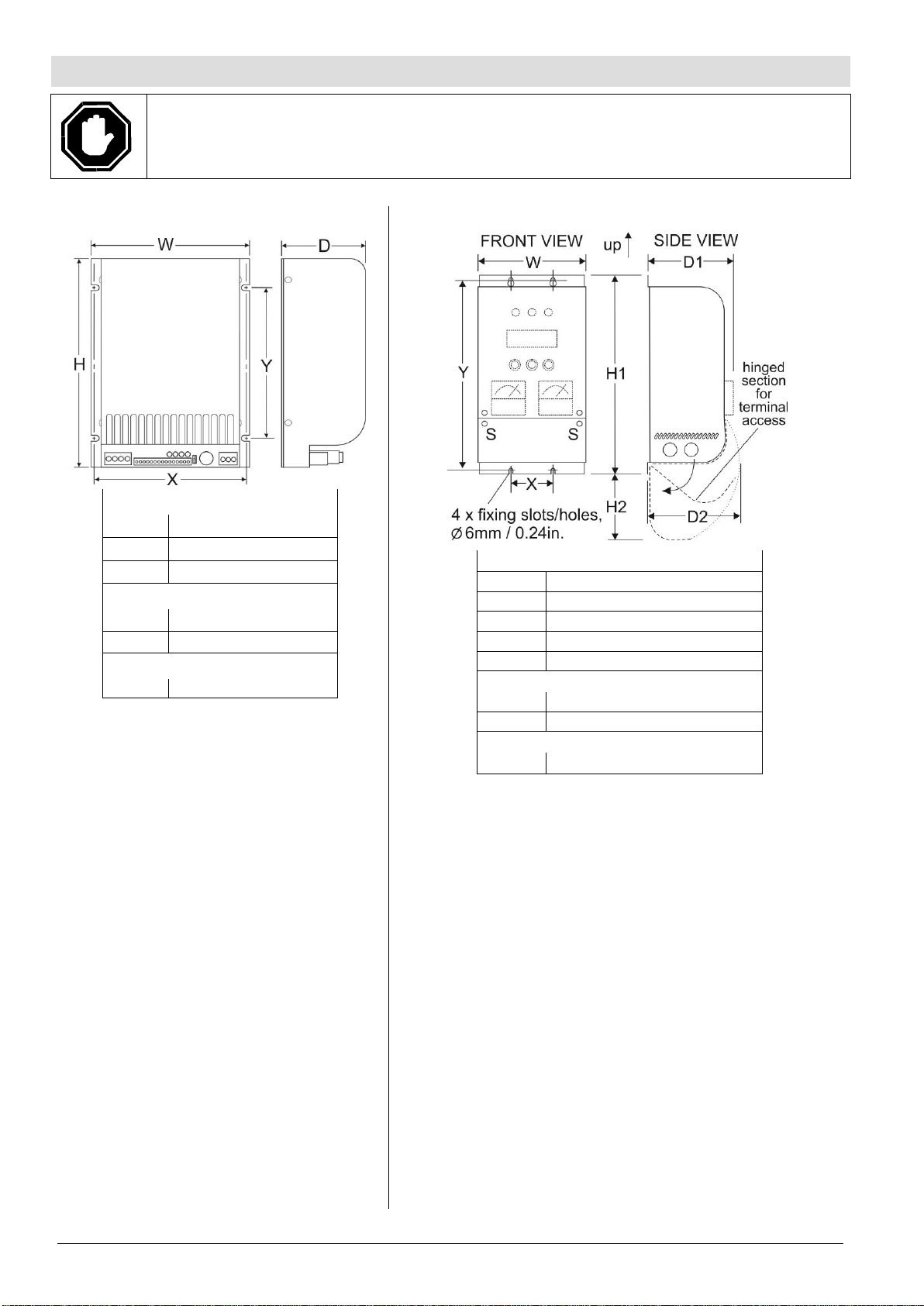

Dimensions and Assembly

CAUTION: Sentinel 300P chargers should be handled by the circuit board cover (SNTL models) or steel

enclosure (ESNTL models). Care should be taken not to handle static sensitive components through exposed

circuit boards and terminals.

SNTL300P models

Overall:

W

158 mm / 6.22 in.

H

208 mm / 8.19 in.

D

84 mm / 3.31 in.

Fixing holes:

X

150 mm / 5.91 in.

Y

150 mm / 5.91 in.

Weight:

1.1 kg / 2.5 lb

These chargers are designed for mounting in a

vertical plane inside an enclosed control panel

or housing. Mounting orientation should be as

shown above, with electrical connection

terminals lowermost.

For safe heat dissipation, mount Sentinel in

the orientation shown, with a minimum air-gap

clearance of 40mm/1.5 in. above/below and

25mm/1 in. at the sides. Consideration must be

given to ventilation for proper heat dissipation.

For surface mounting, use the 2 centre slots (Ø

6mm/0.24in.) or 4 corner slots (Ø 6mm/0.24in.).

Ensure that the mounting studs/bolts/nuts/

screws adequately support the charger, and are

tightened sufficiently to not to become loose

during normal use, e.g. due to engine/equipment

vibration.

Optional clip for DIN rail mounting (2 required for

each charger), part number 045-0001.

ESNTL300P models

Overall:

W

165mm / 6.50 in.

H1

300 mm / 11.81 in.

H2

80 mm / 3.15 in.

D1

125 mm / 4.92 in.

D2

130 mm / 5.12 in.

Fixing holes:

X

63.5 mm / 2.50 in.

Y

285.5 mm / 11.25 in.

Weight:

2.0 – 2.1 kg / 4.4 – 4.6 lb

These chargers are designed for wall or frame mounting in the

orientation shown above, with enclosure air vents uppermost.

For safe heat dissipation, allow a minimum air-gap clearance

of 40mm/ 1.5 in. above/below and 25mm/1 in. at the sides.

Consideration must be given to ventilation for proper heat

dissipation.

Mounting is via the enclosure back-plate, using 4 holes/slots

(Ø 6mm/0.24in.) on the upper and lower edges. Ensure that the

mounting studs/bolts/nuts/ screws adequately support the charger

weight, and are tightened sufficiently to not to become loose during

normal use, e.g. due to engine/equipment vibration.

Access to the electrical connection terminals is via a hinged lower

front plate. Remove the 2 x securing screws (marked S above),

and then rotate the hinged section through 90 degrees.

Electrical cable harness entry is via knock-out ports on either side of

the enclosure, which must be carefully removed from the enclosure

sides. A suitable cable-gland (20mm/0.8in. diam.) must be used to

prevent damage to cables and stop unwanted entry into the inner

part of charger. Wiring for DC charge output (connector CN1),

DC control (CN2) and AC supply input (CN3) must be physically

separate, e.g. using separate wire harnesses and case access ports:

see page 5 section Wire Harness Separation.

Connect the charger wiring as detailed in the following Electrical

Connection section. When wiring is complete, and before using the

charger, re-secure the hinged front section using the 2 fixing screws.

Page 5

Sentinel 300P installation, operation & maintenance

ci0039 p5/12 issue 9 2015-09-04

Connection - General

Before DC connection or disconnection:

Ensure AC supply input is isolated.

Disconnecting the batteries while the

AC supply is live can result in sparking at

the battery terminals, ignition of battery

gasses and serious personal injury.

Check that the charger has been configured

for compatibility with the battery type &

voltage (see Configuration section below).

Incompatibility may result in damage to

the charger, batteries and serious

personal injury.

CN1

pin

Function

1, 2

+ DC charge output

3, 4

– DC charge output

Electrical Connection

DANGER !

HIGH VOLTS

WARNING: DANGER OF INJURY OR DEATH. During normal operation, Sentinel is

connected to high voltage AC circuits. Before connection, disconnection or handling of

these chargers, ensure isolation of all AC power supplies. Connection or disconnection

with live wiring can also cause hazardous sparking and component damage.

SNTL300P open-frame (protective cover) models:

Open frame models use 3 circuit board mounted screw

terminal blocks:

All models – wire harness separation

For all models, wire connections for the DC charge output

(connector block CN1), DC control signals (CN2) and AC

input supply (CN3) must be physically separated, e.g.

using separate wiring harnesses to each connector block,

separately routed through the case/panel. For enclosed

ESNTL models, use separate cable gland access:

CN1: a 4-way block for connection of the DC Charge

Output. Use a 5 mm/0.2 in. flat-head screwdriver

Battery DC Charge Output

to tighten/loosen the terminals. For the DC Output

(10 Amp max), use 4.0mm²/13 AWG or larger

connecting wire. For details of fusing, see the Battery

DC Charge Output section following.

CN2: a 15-way block for connection of DC control

signals: DC voltage sensing, temperature compensation

remote sensor, control inputs and outputs. Use a

2.5mm/ 0.1 in. flat-head screwdriver to tighten/ loosen

the terminals. Use 1mm²/17 AWG or larger wire for

these connections. This connector block also includes

terminals for RS485 and optional CAN (SAE J1939)

communications: use wiring in accordance with the

appropriate data communication standard (typically a

twisted pair, with shield grounded at one end only).

CN3: a 3-way block for connection of the mains AC live

and neutral power supply. Use a 5mm/0.2in flat-head

Connect the Sentinel output to the battery terminals,

observing the warnings above and the correct DC polarity:

screwdriver to tighten/loosen the terminals. The AC

supply ground/earth must be connected to a separate

M4 stud marked FG (Frame Ground) on the charger

chassis. For all AC supply/ground wiring, use 1mm²/

17 AWG or larger wire conductors rated for 90°C/194°F.

An AC fuse holder is located next to CN3: for fuse

details, see the AC Input (power supply) section

following.

4 LEDs (coloured green, blue, yellow, red) above the

terminal blocks provide indication of configuration and

operating status. Circuit board jumper J2 is for the

configuration of automatic temperature compensation.

For full details of LED and J2 operation, see Configuration

and Operation section.

ESNTL300P (enclosed) models

Enclosed ESNTL models have the same circuit board

terminal numbering as SNTL models.

Access to the screw terminals, and access for the wiring

harness (via cable glands), is detailed in the Dimensions

and Assembly section.

All (E)SNTL300P models include self-resetting electronic

protection against reverse polarity, overload and shortcircuit faults. In the event of such faults, the DC output

switches off, protecting the charger. After a 4 second delay,

Sentinel checks the DC output connection: if the fault has

cleared, the output automatically re-activates; if the fault is

still present, the output deactivates again, and the

delay/check cycle repeats.

If the DC output fails to re-activate after a fault has cleared,

contact your charger supplier for further advice.

Float & AutoBoost output voltages

The DC charge output can be configured to give one of

several 12 or 24V ‘charge profiles’, each with Float and

AutoBoost voltages that are optimised for the battery type

and number of cells.

Charge profile configuration is either via circuit board DIP

switches, or (on LCD models) using display menus and

control keys: see Configuration section below. Charge

profile can also be set using the Computronic SNTL300PPCSUITE PC software tool and RS485 communication link.

For full details, see separate software manual ref. ci0042.

Page 6

Sentinel 300P installation, operation & maintenance

ci0039 p6/12 issue 9 2015-09-04

Battery DC voltage sense

CN2

pin

Function

1

+ DC voltage sense

2

– DC voltage sense

CN2

pin

Function

3

TC (temperature compensation) sensor

4

Ground (for RTC sensor)

J2 jumper

position /

mode

Description

External /

disabled

(Factory default setting). Temperature

compensation is enabled automatically when a

remote RTC sensor is connected. For each

1°C change in ambient temperature above or

below 20°C (within the range -10 to +50°C),

output voltage automatically varies by 3mV

per cell. Increasing ambient temperatures

cause decreasing output voltages; decreasing

ambient temperatures cause increasing output

voltages.

If no RTC sensor is connected, temperature

compensation is automatically disabled and

the output voltage does not vary with ambient

temperature.

Sensor connection and operating status is

indicated by a blue LED – see Operation

section for details.

Internal

Not for customer use. Temperature

measurement by internal sensor, for factory

calibration only.

Electrical Connection (cont.)

Typical Connection:

Notes:

1. AC input fusing (F1): replaceable, circuit board mounted fuse, rating as shown on the product label.

2. DC output fusing: all models include a self-resetting electronic output fuse.

3. DC output is isolated from chassis.

4. connection shown for standard configurations with output RL4. (RL4 is not available on units configured for CAN communication.)

These terminals are used to accurately measure battery

voltage, independently of the voltage drop that can occur

between the battery and DC charge output (particularly at

higher charge currents, and with longer cables).

Accurate measurement of battery voltage allows Sentinel

to automatically compensate for volt drops in the charging

circuit, by increasing charge voltage.

Connect the battery DC Sense terminals to battery

positive and negative using 1mm²/17 AWG or larger wire.

TC Temperature Compensation Sensor

These terminals allow optional connection of a Computronic

RTC temperature sensor. With the sensor connected, and

the sensor head positioned to give the most accurate/

representative measurement of battery temperature,

Sentinel automatically varies DC output voltage for optimal

charging. Circuit board jumper J2, located between terminal

blocks CN2 and CN3, must also be in the correct position:

CN2 terminals 3 and 4 are designed for connection to a

Computronic RTC sensor only. DO NOT connect other

types of temperature sensor, such as thermocouples,

thermistors or resistance probes.

The standard RTC sensor (part code 42.70.3619) includes

a 3 metre lead assembly. Non-standard lead lengths are

available to special order.

Page 7

Sentinel 300P installation, operation & maintenance

ci0039 p7/12 issue 9 2015-09-04

Inputs (control)

CN2

pin

Function

5

Input 1: AutoBoost initiate. Allows the operator to

manually initiate one AutoBoost cycle, regardless

of battery voltage. Activation is by momentary

connection to battery negative DC, e.g. using a

push-to-make panel button.

6

Input 2: reduce output to nominal 12 or 24V.

Connect input 1 to battery negative (e.g. via a switch

or relay contact) for as long as the output needs to

be reduced, e.g. for remotely controlled battery test

equipment. In this mode, Sentinel continues to

support any DC load up to the 10 Amp current limit.

CN2

pin

Function

7

Common power feed for RL1 – 3. Connect to the

positive or negative DC supply as required.

8 9 RL1 normally open (N/O) contact.

RL1 normally closed (N/C) contact

Standard function: charge fail. Relay RL1:

energises (pin 8 closes to pin 7, pin 9 opens from

pin 7) during normal charging conditions.

de-energises (pin 8 opens from pin 7, pin 9 closes

to pin 7) if a charge fail fault occurs for longer

than 2 minutes.

10

RL2 normally closed (N/C) contact.

Standard function: low battery volts. Relay RL2:

energises (pin 10 opens from pin 7) during normal

charging conditions.

de-energises (pin 10 closes to pin 7) if a low battery

voltage fault occurs for longer than 2 minutes.

11

RL3 normally open (N/O) contact.

Standard function: high battery volts. Relay RL3:

de-energises (pin 11 opens from pin 7) during

normal charging conditions

energises (pin 11 closes to pin 7) if a high battery

voltage fault occurs for longer than 2 minutes.

CN2

pin

Function

12

13

RL4 common (COM) contact, volt-free/dry

RL4 normally closed (NC) contact, volt free/dry

Standard function: Mains fail. Relay RL4:

energises (pin 13 opens from pin 12) when the

mains AC supply is healthy.

de-energises (pin 13 closes to pin 12) when the

mains AC supply is off or failed.

CN2

pin

Function

12

13

CAN Hi

CAN Lo

CN2

pin

Function

14

15

RS485 A

RS485 B

DANGER !

HIGH VOLTS

Before AC connection, disconnection or fuse

replacement:

Isolate the AC supply

Ensure a good ground/earth connection to

the ground/earth stud (marked FG) on the

charger’s metal chassis.

Ensure the AC supply voltage is

compatible with the charger’s supply

rating. Exceeding the rated voltage may

result in damage to the charger and

connected equipment, and cause

serious personal injury.

Fit only the fuse types/ratings shown on

each product’s label.

CN3

pin

Function

1 2 AC supply live, 95 to 250 VAC, 47 to 63 Hz

AC supply neutral

Electrical Connection (cont.)

All (E)SNTL300P models include two switch inputs for

control purposes. On standard models:

Non-standard control input functions are available to

special order.

Outputs (alarm)

All (E)SNTL300P models include at least three relay

outputs, RL1 – 3. An additional output RL4 is available on

standard (non-CAN) models/configurations. All output

contacts are dry/volt-free (RL1, RL2 and RL3 have a

common power feed), rated 1A @ 30VDC max.

The standard, NFPA 110 compliant output functions are

shown below, but non-standard functions are available to

special order:

CAN (Control Area Network) communications

SNTL300PC, ESNTL300PCL and ESNTL300PCLM

models may be configured with a CAN 2.0B port for data

exchange and control with other CAN devices. The CAN

connection supports the SAE J1939 protocol commonly

found in many industrial engine applications, or custom

CAN protocols to OEM requirements. Connection:

These terminals include an internal 120 Ohm terminating

resistor, designed for connection at the end of the CAN

network. Connection wiring must be in accordance with

the CAN 2.0B standard, typically a twisted pair and shield

cable of maximum network length 40 metres (132 feet),

with the shield grounded at one end only.

RS485 communication

All 300P models include an RS485 MODBUS data port:

These terminals include an internal 120 Ohm terminating

resistor, for connection at the end of an RS485 network.

Connection wiring must be in accordance with the RS485

standard, typically a twisted pair and shield cable with the

shield grounded at one end only.

The RS485 port allows remote communication,

configuration and monitoring with a PC running

Computronic SNTL300P-PCSUITE software. The port can

also be used to transmit RS485 Modbus data about battery

and charger parameters, e.g. to a remote PLC, SCADA or

other control/monitoring system. For further details, please

see separate SNTL300P-PCSUITE document ci0042.

AC Input (power supply)

Models not configured for CAN J1939 communication

include access to relay RL4:

Connect these terminals to the AC power supply. The AC

supply ground/earth must be connected to the M4 stud

marked FG (Frame Ground), located inside the charger

case near connector CN3.

For AC input and ground connections, use 1mm²/

17 AWG or larger wire conductors rated for temperature

90°C/194°F. All models include a replaceable anti-surge

fuse (20mm, type T, 3.15A) in a circuit board mounted

holder, located next to connector CN3.

Page 8

Sentinel 300P installation, operation & maintenance

ci0039 p8/12 issue 9 2015-09-04

After the POST sequence, the LEDs revert to indication of

Measured

voltage

Operation

< 1 V

No output: battery missing fault signalled.

1 to 16.0 V

Charge output: 12V vented lead acid.

16.1 to 32 V

Charge output: 24V vented lead acid.

Configuration and Operation

Operation

Power-up and POST sequence

At power up, Sentinel goes through a POST (Power On Self Test) sequence, including status indication using 4 LEDs

(located on the main circuit board above connector CN2). The sequence is:

POST LED display

1) LED test: all lit for 2 sec, all off for 2 sec:

2) Indication confirming standard 300P calibrations, 2 sec:

Flashing sequence:

3) Indication confirming selected charge profile, 2 sec:

Nominal

voltage

Battery type

Profile name

DIP switch settings

(0 = off/down, 1 = on/up)

1 2 3

4 5 6

Auto /

local

12 or 24 wet (vented) lead acid

AUTO DETECT

(Local)

0 0 0 0 0 0 Flashing:

Auto /

remote

AUTO DETECT

(Remote)

0 0 0 0 1 0 Flashing sequence:

12V

Wet (vented) lead acid, 6 cells

12V WET LA

0 0 0 1 0

0

Calcium Calcium, 6 cells

12V CA/CA

0 0 1 0 0

0

Lead acid hybrid Sb-Ca, 6 cells

12V LA HYBRID

0 0 1 1 0

0

VRLA, AGM, 6 cells

12V VRLA – AGM

0 1 0 0 0

0

VRLA, Gel, 6 cells

12V VRLA – GEL

0 1 0 1 0

0

NiCd, 10 cells

10 CELL NiCd

0 1 1 0 0

0

12V power supply

12V POWER SUPPLY

0 1 1 1 0

0

24V

NiCd, 18 cells

18 CELL NiCd

1 0 0 0 0

0 NiCd, 20 cells

20 CELL NiCd

1 0 0 1 0

0

Wet (vented) lead acid, 12 cells

24V WET LA

1 0 1 0 0

0

Calcium Calcium, 12 cells

24V CA/CA

1 0 1 1 0

0 Lead acid hybrid Sb-Ca, 12 cells

24V LA HYBRID

1 1 0 0 0

0

VRLA, AGM, 12 cells

24V VRLA - AGM

1 1 0 1 0

0

VRLA, Gel, 12 cells

24V VRLA - GEL

1 1 1 0 0

0 24V power supply

24V POWER SUPPLY

1 1 1 1 0

0

operating status. See LED Indication section below.

Auto mode battery detection

Immediately after power-up, if an ‘Auto’ charge profile has

been selected, the Sentinel 300P measures the connected

battery voltage and operates as follows:

registers a battery missing fault, it checks for reconnection

once every minute (non-adjustable).

Sentinel does not check for ‘battery missing’ during

AutoBoost operation, to ensure maximum charge rate is

maintained.

AutoBoost

If measured battery voltage falls below the Boost Initiate

threshold (below 12.5 V for 12V nominal batteries, or

below 25.0 V for 24V nominal batteries), Sentinel adopts

AutoBoost mode (indicated by a slow-flashing yellow LED)

and charge output increases to the higher Boost voltage

Float mode

If measured battery voltage is within normal limits (above

12.5 V for 12V nominal batteries, and above 25.0 V for

24V nominal batteries), Sentinel adopts float mode

charging, indicated by a constantly lit yellow LED. Sentinel

maintains the battery at the float voltage (appropriate for

the selected battery type), and supplies any additional DC

load current (up to the maximum rated 10 Amps).

Battery check

When in float charge mode, Sentinel periodically checks

for a ‘battery missing’ fault. During this check, output

current reduces to nominal (12 or 24V) for approx. 30

seconds and the yellow LED goes off.

The default period for checking ‘battery missing’ is every

30 minutes, but this time can be adjusted using the

SNTL300P-PCSUITE configuration tool. Once Sentinel

level.

Once measured battery voltage has increased to the

Boost level, Sentinel enters a Boost Extension period (360

mins on standard units), during which time Boost voltage

is maintained and the yellow LED flashes rapidly.

At the end of the Boost extension period, output voltage

and current reduces, but the yellow LED continues to flash

rapidly. In this Boost Decay phase, battery voltage

naturally decreases back towards float level. Sentinel then

reverts to float mode charging, indicated by a continually lit

yellow LED.

AutoBoost can also be initiated manually by an operator,

regardless of battery voltage. This is achieved on standard

units through input 2: after input activation, e.g. by a

momentary push-to-make panel switch, Sentinel goes

through a single AutoBoost cycle.

Page 9

Sentinel 300P installation, operation & maintenance

ci0039 p9/12 issue 9 2015-09-04

Configuration and Operation (cont.)

DIP switch configuration

WARNING: AC and DC connections must be isolated during DIP switch configuration. The correct battery type

and cell number must be configured correctly before charger power-up and battery connection. Incorrect

configuration may result in under or over charge of batteries, which may cause failure or damage to the batteries,

charger and connected equipment, and result in serious personal injury.

All Sentinel models include a 6 way DIP switch for configuration of battery type and cell number. The DIP switch is accessible

through a cut-out in the case rear:

Open frame SNTL models Enclosed ESNTL models

DIP switch functions:

1 – 4

Sets the charge profile (battery type and cell number) when ‘local’ mode is selected – see switch 6 below.

5

Sets whether the Sentinel charge profile is set in local or remote mode:

Local mode: charge profile set by DIP switches 1 to 4. The default setting is ‘Local, Auto’, where Sentinel automatically selects 12 or 24V operation based on the battery voltage measured at power up – see ‘operation’ below.

Remote mode: charge profile set by remote RS485 communication (e.g. SNTL300P-PCSUITE software), or (on

LCD models only) using display menu options. When remote mode is selected, the default charge profile is ‘Auto’.

6

Reserved use. Do not adjust from default (0/off/down) setting.

Nominal

voltage

Battery type

Profile name

DIP switch setting

(0 = off/down,

1 = on/up)

voltage/time settings

1 2 3 4 5 6 float

(VDC)

boost

(VDC)

boost

initiate

(VDC)

boost

time

(min)

low

alarm

(VDC)

high

alarm

(VDC)

DIP switches 1 – 4, local mode settings

12/24V

Auto

(12V or 24V wet lead acid)

AUTO DETECT

0 0 0 0 0 0 13.5/

27.0

14.1/

28.2

12.5/

25.0

360

12.0/

24.0

16.0/

32.0

12V

Wet (vented) lead acid, 6 cells

12V WET LA

0 0 0 1 0 0 13.5

14.1

12.5

360

12.0

16.0

Calcium Calcium, 6 cells

12V CA/CA

0 0 1 0 0 0 13.8

15.6

12.5

360

12.0

16.0

Lead acid hybrid Sb-Ca, 6 cells

12V LA HYBRID

0 0 1 1 0 0 13.5

14.7

12.5

360

12.0

16.0

VRLA, AGM, 6 cells

12V VRLA – AGM

0 1 0 0 0 0 13.5

14.4

12.5

360

12.0

16.0

VRLA, Gel, 6 cells

12V VRLA – GEL

0 1 0 1 0 0 13.5

13.8

12.5

360

12.0

16.0

NiCd, 10 cells

10 CELL NiCd

0 1 1 0 0 0 14.1

14.5

12.5

360

12.0

16.0

12V power supply

12V POWER SUPPLY

0 1 1 1 0 0 12.0

n/a

n/a

n/a

n/a

n/a

24V

NiCd, 18 cells

18 CELL NiCd

1 0 0 0 0 0 25.6

26.1

25.0

360

24.0

32.0

NiCd, 20 cells

20 CELL NiCd

1 0 0 1 0 0 28.2

29.0

25.0

360

24.0

32.0

Wet (vented) lead acid, 12 cells

24V WET LA

1 0 1 0 0 0 27.0

28.2

25.0

360

24.0

32.0

Calcium Calcium, 12 cells

24V CA/CA

1 0 1 1 0 0 27.6

31.2

25.0

360

24.0

32.0

Lead acid hybrid Sb-Ca, 12 cells

24V LA HYBRID

1 1 0 0 0 0 27.0

29.4

25.0

360

24.0

32.0

VRLA, AGM, 12 cells

24V VRLA - AGM

1 1 0 1 0 0 27.0

28.8

25.0

360

24.0

32.0

VRLA, Gel, 12 cells

24V VRLA - GEL

1 1 1 0 0 0 27.0

27.6

25.0

360

24.0

32.0

24V power supply

24V POWER SUPPLY

1 1 1 1 0 0 24.0

n/a

n/a

n/a

n/a

n/a

DIP switch 5: local / remote mode:

Local

x x x x 0 0

Local mode, profile set by switches 1-4

Remote

Auto Remote

x x x x 1 0 Remote mode, profile set by LCD or PC

software. Default charge profile: ‘Auto’.

DIP switch 6: reserved

x x x x x 0

Default setting, do not adjust.

Page 10

Sentinel 300P installation, operation & maintenance

ci0039 p10/12 issue 9 2015-09-04

LED indication

LED operation

Status

Red

on

Fault condition (except AC supply &

battery connection errors).

flashing,

slow

AC supply not available

(DC connected).

flashing,

fast

Battery connection error.

off

No fault conditions.

Yellow

on

In Float mode.

flashing,

slow

In AutoBoost mode.

flashing,

fast

In AutoBoost extension mode / boost

decay.

off

Output off / output to nominal.

Blue

on

Temperature compensation active,

sensor connected.

flashing,

slow

Temperature compensation auto

disabled due to external fault.

flashing,

fast

Temperature compensation at absolute

limit, i.e. <–10ºC or >+50ºC.

off

Temperature compensation disabled.

Green

on

AC supply available, charge output on.

flashing,

slow

AC supply available, charge output off.

flashing,

fast

Boost decay or battery missing

(if red LED is also on).

off

AC supply not available.

At power-up, Sentinel

displays an initial message

that includes the unit

firmware version, followed

*******************

* SENTINEL 300P *

* V 3.0 *

*******************

by...

The default operating

screen, showing date, time,

battery volts, charge

current and charge mode.

20/05/10 10:23

VDC: 13.2 ADC: 8.5

FLOAT CHARGE

When Sentinel is in AutoBoost mode, the 4th line changes

to show the current boost stage, displaying (in sequence)

‘ramping to boost’, ‘boost extension’ and ‘boost decay’.

When a fault condition

occurs, an appropriate

message is shown on the

display 3rd line.

20/05/10 10:23

VDC: 13.2 ADC: 8.5

CHARGE FAIL

FLOAT CHARGE

Fault messages automatically clear from the display when

the fault condition clears. In the event of multiple faults,

the 3rd line displays the highest priority message, ranked

in the following order (highest priority first):

AC mains failure

DC connection error

Sensed connection error

Battery missing (detected during battery check routine)

Incorrect battery type (when configured with a 12V

charge profile, but the connected battery voltage is

above 16.1 V).

No battery detected (when configured with an ‘auto’

charge profile, but the connected battery, or lack of

connection, is below 1.0V).

High battery voltage

Charge fail

Low battery voltage

Volt sense level fault

To access the Settings

menu, press and hold the

Up and Down keys. The first

screen displayed is:

SETTINGS

FLOAT: XX.XVDC

BOOST: XX.XVDC

BOOST EXT: XXX MINS

Press Up or Down keys to

view more settings:

SETTINGS

LOW ALARM: XX.XVDC

HIGH ALARM: XX.XVDC

ALARM DELAY: XXX SEC

Press Up or Down keys to

view more settings:

SETTINGS

MODEL: XXXXXXXXX

SERIAL NO: XXXXXX FIRMWARE:

XXXXXXX

Configuration and Operation (cont.)

In normal operation, the four circuit board LEDs indicate

operating status: fault conditions, charge mode,

temperature compensation and AC supply:

Normal charging: float and AutoBoost modes

Fault messages

LCD Models

Enclosed models ESNTL300PCL and ESNTL300PCLM

include a backlit graphic LCD, three push-button controls

(Up, Down, Enter) and three additional indicating LEDs:

Green: CAN network status (CAN-enabled models only).

Lights continuously in normal CAN operation.

Yellow: charging mode, operation as yellow circuit board

LED.

Red: fault conditions, operation as red circuit board LED.

In normal charging mode, the LCD displays Sentinel and

battery status, e.g. operating mode, charge voltages and

currents, date/time, faults, etc.

In configuration menu modes, the LCD and push-buttons

can be used by the operator to view/edit operating

parameters and options (date/time, charge profiles, etc).

Configuration mode

The LCD and control keys can be used to view or change

configuration settings. The Sentinel 300P has three

configuration menus, named ‘Settings’, ‘System’ and

‘CAN’. While the operator is viewing or editing these menu

settings, Sentinel continues normal charge operation, but

current charging status or fault information is not displayed

on the LCD.

Settings menu

This sequence of screens allows viewing (but not editing)

of several operating and device parameters.

Press Up and Down to review the parameters again, or

press Enter to exit the Settings menu.

Page 11

Sentinel 300P installation, operation & maintenance

ci0039 p11/12 issue 9 2015-09-04

System Menu

4 digit passkey entry.

Use the Up or Down keys to

change the first digit, press

enter, then repeat for 2nd,

DD:MM:YY HH:MM

SYSTEM MENU

ENTER PASSKEY? X

UP & DOWN:CHANGE ENTER:OK

3rd and 4th digits.

Correct passkey entry (the factory default is 1234) allows

viewing and editing of the following functions:

Date and time

Press Enter to edit date and

time (5 separate screens for

setting day, month, year,

hours, minutes), or press

DD:MM:YY HH:MM

SYSTEM MENU

EDIT DATE & TIME?

ENTER – YES DOWN - SKIP

Down to skip (bypass) this

section and move on to...

Reset AC on hours

Sentinel stores data on the

number of hours it has been

powered. Press Enter to

reset this to zero, or press

DD:MM:YY HH:MM

SYSTEM MENU

RESET AC ON HOURS?

ENTER – YES DOWN - SKIP

Down to keep the existing

value and move on to...

Reset Charging hours

Sentinel stores data on the

number of hours it has been

charging the battery. Press

Enter to reset this to zero,

DD:MM:YY HH:MM

SYSTEM MENU

RESET CHARGING HOURS?

ENTER – YES DOWN - SKIP

or press Down to keep the

existing value and move on

to...

Change Passkey

Allows custom setting of the

4 digit System Menu

passkey. Press Enter to

change (a series of four

DD:MM:YY HH:MM

SYSTEM MENU

CHANGE PASSKEY?

ENTER – YES DOWN - SKIP

screens, one for each

passkey digit), or press

Down to skip this and move

on to...

Select Charging Profile

Allows the charge profile to

be changed (but only if DIP

switch 6 is set to 1/on/up: an

error message results if

DD:MM:YY HH:MM

SYSTEM MENU

SELECT CHARGE PROFILE?

ENTER – YES DOWN - SKIP

switch 6 is set to 0/off/down.)

Press Enter to change the

charge profile, which is

selected on a following

screen; or press Down to

skip this and move on to...

Confirm changes

Press Enter to confirm any

System Menu changes and

exit. Press Down to discard

the changes and exit.

DD:MM:YY HH:MM

SYSTEM MENU

CONFIRM CHANGES?

ENTER – YES DOWN – CANCEL

Configuration and Operation (cont.) Configuration and Operation (cont.)

Maintenance, Fault Finding and Warranty

Maintenance and Warranty

Sentinel chargers are supplied with a 2 year warranty on

parts and workmanship.

Maintenance is limited to keeping the charger free from

ingress of dust, dirt or moisture, and ensuring clear air-flow

for ventilation.

In the event of an operating query or suspected fault, please

consult the sections in this manual on LED/LCD indication,

and the flowchart on page 12, or contact your supplier for

further advice before returning the charger.

WARNING: Except for AC fuse replacement,

Sentinel 300P battery chargers are not userserviceable.

In the event of a failure, the charger should be

returned to the supplier. No attempt should be

made to repair the charger. Any attempt to do

so may invalidate warranties, cause damage to

the charger and connected equipment, and

result in serious personal injury.

This passkey-protected menu allows the clearing of the

system log, the resetting of date/time and AC/charging

hours run, and (if DIP switch 6 is set to ‘remote’) the

selection of a charge profile.

To access the System menu, press and hold the Up and

Enter keys.

CAN Menu

On CAN-enabled units, this menu is reserved for

viewing/editing of the CAN network settings.

To access this menu, press and hold Down and Enter

keys. The settings in this menu settings will vary according

to part number specification: please contact Computronic

for separate details or documentation.

Page 12

Sentinel 300P installation, operation & maintenance

ci0039 p12/12 issue 9 2015-09-04

Maintenance, Fault Finding and Warranty (cont.)

Troubleshooting Flowchart:

Loading...

Loading...