Page 1

9070

Uss

U

err

e

M

M

a

a

n

n

u

u

all

a

Rev. 002

Page 2

CCoommppuupprriinntt PPrroodduuccttss IInnffoorrmmaattiioonn

Thanks for choosing the Compuprint 9070 printer.

Your printer is a reliable working equipment that will be very useful in your daily job.

Our printers have been designed to be compact and respectful of the work environment. They offer

a wide range of features and multiple functions that confirm the high technological level reached

by the printers with Compuprint brand.

To maintain these printing performances unchanged in the long run, Sferal wwt has

developed specific Compuprint branded consumables for each printer type (for example: ribbon

cartridges for dot matrix printers, toner and OPC cartridges for laser printers, bubble ink jet

cartridges for inkjet printers) that assure an excellent operation with high printing quality level

reliability.

Sferal wwt recommends to use only its original Compuprint branded consumables with

original packaging (identified by its holographic label). In this way, a proper use of the printer at

quality level stated in the product characteristics can be assured. All typical usage problems

related to not certified consumables may be avoided, such as an overall quality print level

degradation and, often, the reduction of the product life due to the fact that the proper working

conditions for the print heads, OPC cartridge and other printer parts are not assured.

Moreover, Sferal does not only certify its consumables in terms of working conditions but also

carefully controls their compliance with the international standard rules concerning:

• no cancerous materials;

• no flammability of the plastic materials;

• other standards

Sferal advises the customers not to use products for which the compliance to this safety rules are

not warranted. Finally seek your dealer or contact a Sferal office and be sure that are provided you

the original Compuprint branded consumables.

Page 3

SSaaffeet

y

y

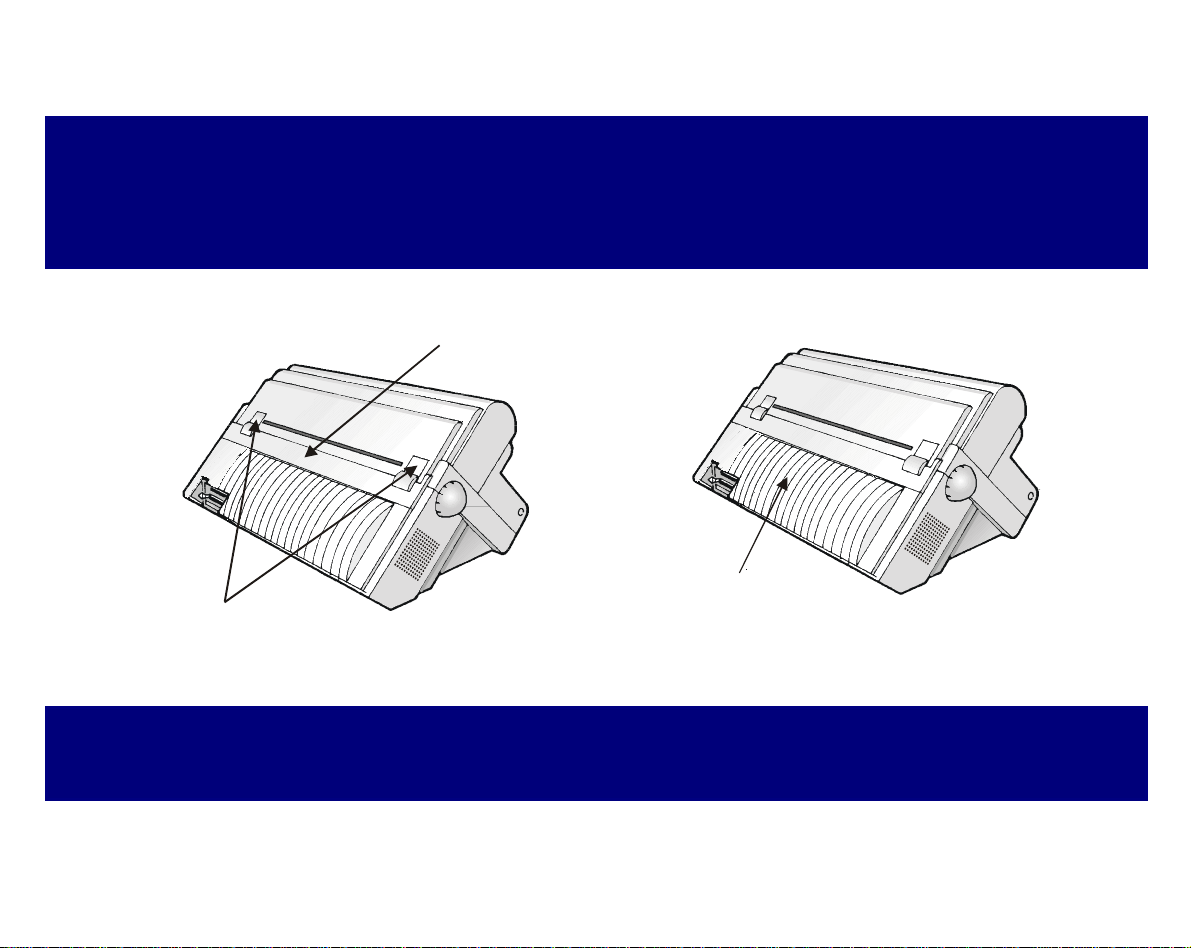

A. Never remove any printer cover except to install a printer accessory and as expressly

B. Please store the printer covers in a safe place. The covers must be reinstalled if you decide to

remove any printer accessory.

The following areas of the printer should be covered for safety reasons:

Rear Pull Tractor Cover

t

IInnffoorrmmaattiioonn

described in this manual.

ASF Area Cover

Rear Pull Tractor Attachment Area Covers

The above openings must always be protected with their cover when the corresponding option is

not installed. Do not touch inside and do not insert any object into these openings or into the

gears.

Page 4

g

g

g

g

FFFFCC NNootteess

This equipment has bee n tes ted an d found to com ply with the lim its fo r a Cl ass B digita l de vice, purs uant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause ha rmful interference to radio commun ications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encour ag ed t o tr y to c orr ec t t he int erf er ence by one o r more of

the following measures:

• Reorient or relocate the receivi ng antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help.

A shielded Centronics IEEE1284 compliant bi-directional parallel cable, maximum length 3 meters (10 feet), and a shielded RS-232

serial cable, maximum length 15 meters (50 feet), are necessary for this device to meet the requirements of a Class B digital dev ice

pursuant to part 15 of the FCC rules.

The above specified cables are readily available as Personal Computer or Peripheral accessories from multiple retail outlets.

Please consult your dealer for details concerning such cables and also for information about FCC rules for digital devices.

Changes or modifications to the device covered by this manual, which are not expressly approved by the party responsible for

compliance, could void the user’s authority under the FCC rules to operate the equipment.

CCaannaaddiiaann DD..OO..CC.. RRaaddiioo IInntteerrffeerreennccee RRe

This digital apparatus complies with the Canadian ICES-003 Class B limits for radio frequency emissions.

Cet appareil numérique est conforme aux limites de Classe B de la norme N MB-003 du Canada.

EEEECC RRe

This equipment conforms to the EEC Directive 89/392 (the sound pressure, measure d according to ISO 7779, does no t exceed 70

dBA).

e

uullaattiioonnss

e

uullaattiioonn

Page 5

TTaabbllee ooff CCoonntteennttss

Compuprint Products Information ...................... ii

Safety Information................................................. iii

FCC Notes .............................................................. iv

Canadian D.O.C. Radio Interference Regulation iv

EEC Regulations ................................................... iv

Table of Contents................................................... v

Getting to Know Your Printer ............................... 1

Printer Features (PRT9070 Model)..................................... 1

Printer Features (PRT9071 Model)..................................... 2

Unpacking Your Printer........................................................ 3

Printer Parts .......................................................................... 4

Front View ........................................................................4

Rear View......................................................................... 6

Setting Up Your Printer ......................................... 7

Choosing a Suitable Location.............................................. 7

Printer Assembly .................................................................. 8

Removal of the Shipment Locks ..................................... 8

Ribbon Cartridge Installation ........................................... 9

Host Computer Connection ...............................................14

Software Driver Selection................................................... 15

Power Connection.............................................................. 16

Selecting the Display Language......................... 18

Configuring the Printer........................................ 19

Operator Panel Presentation .............................................19

Display Messages.......................................................... 20

Indicators ........................................................................ 25

Function Keys ................................................................26

Printer Setups ..................................................................... 31

Entering the Printer Setups ...........................................31

Moving within the Printer Setups................................... 31

Leaving the Printer Setups ............................................32

Power-On Configuration..................................................... 33

Entering the Power-On Configuration........................... 33

Program Setup ...................................................................76

Entering the Program Setup.......................................... 76

How to Select the Paper Path.......................................... 103

How to Use the Tear-Off Function................................... 104

Selection of the Paper Size .........................................104

Adjusting the Tear-Off Position ................................... 105

Selection of the Tear-Off Mode................................... 106

How to Lock/Unlock the Printer Setups .......................... 107

How to Handle the Paper Parking................................... 108

Paper Handling................................................... 113

Paper Paths...................................................................... 113

Paper Specifications ........................................................ 114

Fanfold Paper (PRT9070 and PRT9071 models)...... 114

Envelopes (PRT9070 model only).............................. 114

Cut Sheets (PRT9070 model only)............................. 115

Cut Sheets........................................................................ 116

Cut Sheets Loading Modes......................................... 116

Loading Cut Sheets ..................................................... 116

Fanfold Paper Loading..................................................... 119

Loading Paper Using the Front1 Push Tractor .......... 119

Printer Maintenance and Troubleshooting...... 127

Cleaning the Printer.......................................................... 127

Replacing the Ribbon Cartridge ...................................... 128

Printing the Self Test........................................................ 130

Error Handling .................................................................. 131

Options ............................................................... 134

The Front2 Push Tractor.................................................. 134

Installing the Front2 Push Tractor............................... 134

Removing the Front2 Push Tractor............................. 137

Loading Paper Using Front2 Push Tractor (option)... 138

Loading Paper Using F1 Push & F2 Push Tractor

(Option) is Installed...................................................... 144

The Rear Pull Tractor....................................................... 146

Installing the Rear Pull Tractor.................................... 146

Removing the Rear Pull Tractor.................................. 149

Loading Paper Using F1 Push & Rear Pull Tractor .. 151

The Cutter......................................................................... 154

The LAN Interface Board ................................................. 154

The Automatic Sheet Feeder (ASF)................................ 155

The Color Kit..................................................................... 156

The Printer Pedestals....................................................... 157

Printer Specifications ........................................ 158

Page 6

GGeettttiinngg ttoo KKnnooww YYoouurr PPrriinntteerr

PPrriinntteerr FFeeaattuurreess ((PPRRTT99007700 MMooddeell))

• 24 Needle Print Head

• 136 columns @10 cpi

• Draft printing at 700 cps, LQ printing at 133 cps

• IBM Proprinter XL24/XL24 AGM, Per sonal Printer 2391+ and E PSON LQ Series emulations

• Base paper handling configuration: Front1 push path (fanfold) + Manual paper path (cut sheets)

• Multiple copies (1 original and 7 copies)

• Automatic paper path selection

• Automatic Sheet Feeder option which handles cut sheets, multicopy and envelopes, accepts up to

two additional paper bins and includes paper stacker

• Easy operability via operator panel setup and S/W commands

• Usage of all specific features by means of the Specific Software Driver which is applicable to the

most popular S/W Packages

• Plug & Play capability for Windows 95/98/2000/XP/NT4.0/Millennium ®

• Bi-directional IEEE 1284 parallel interface and standard serial RS-232/C and RS-422/A interface

• Ethernet 10/100 Base-T interface option that coexists with the parallel interface

• Optional 6 pin 1° Front Push Tractor

• Optional 4 pin Rear Pull Tractor

• Color Kit option

• Paper Cutter option

• Two optional printer pedestals

1

Page 7

PPrriinntteerr FFeeaattuurreess ((PPRRTT99007711 MMooddeell))

• 24 Needle Print Head

• 136 columns @10 cpi

• Draft printing at 700 cps, LQ printing at 133 cps

• IBM Proprinter XL24/XL24 AGM, Per sonal Printer 2391+ and E PSON LQ Series emulations

• Base paper handling configuration: : Front1 push path (1st fanfold)

• Multiple copies (1 original and 7 copies)

• Automatic paper path selection

• Automatic Sheet Feeder option which handles cut sheets, multicopy and envelopes, accepts up to

two additional paper bins and includes paper stacker

• Easy operability via operator panel setup and S/W commands

• Usage of all specific features by means of the Specific Software Driver which is applicable to the

most popular S/W Packages

• Plug & Play capability for Windows 95/98/2000/XP/NT4.0/Millennium ®

• Bi-directional IEEE 1284 parallel interface and standard serial RS-232/C and RS-422/A interface

• Ethernet 10/100 Base-T interface option that coexists with the parallel interface

• Optional 6 pin 1° Front Push Tractor

• Optional 4 pin 2° Front Push Tractor (2nd fanfold)

• Optional 6 pin 2° Front Push Tractor (2nd fanfold)

• Optional 4 pin Rear Pull Tractor

• Color Kit option

• Paper Cutter option

• Two optional printer pedestals

2

Page 8

r

()

g

UUnnppaacckkiinngg YYoouurr PPrriinntteer

The following items are included in the box:

Installation G uide

Notify any damage to your supplier.

CD -Rom

with Use r Manual include d

Power Cable

Ribbon Cartrid

e

3

Page 9

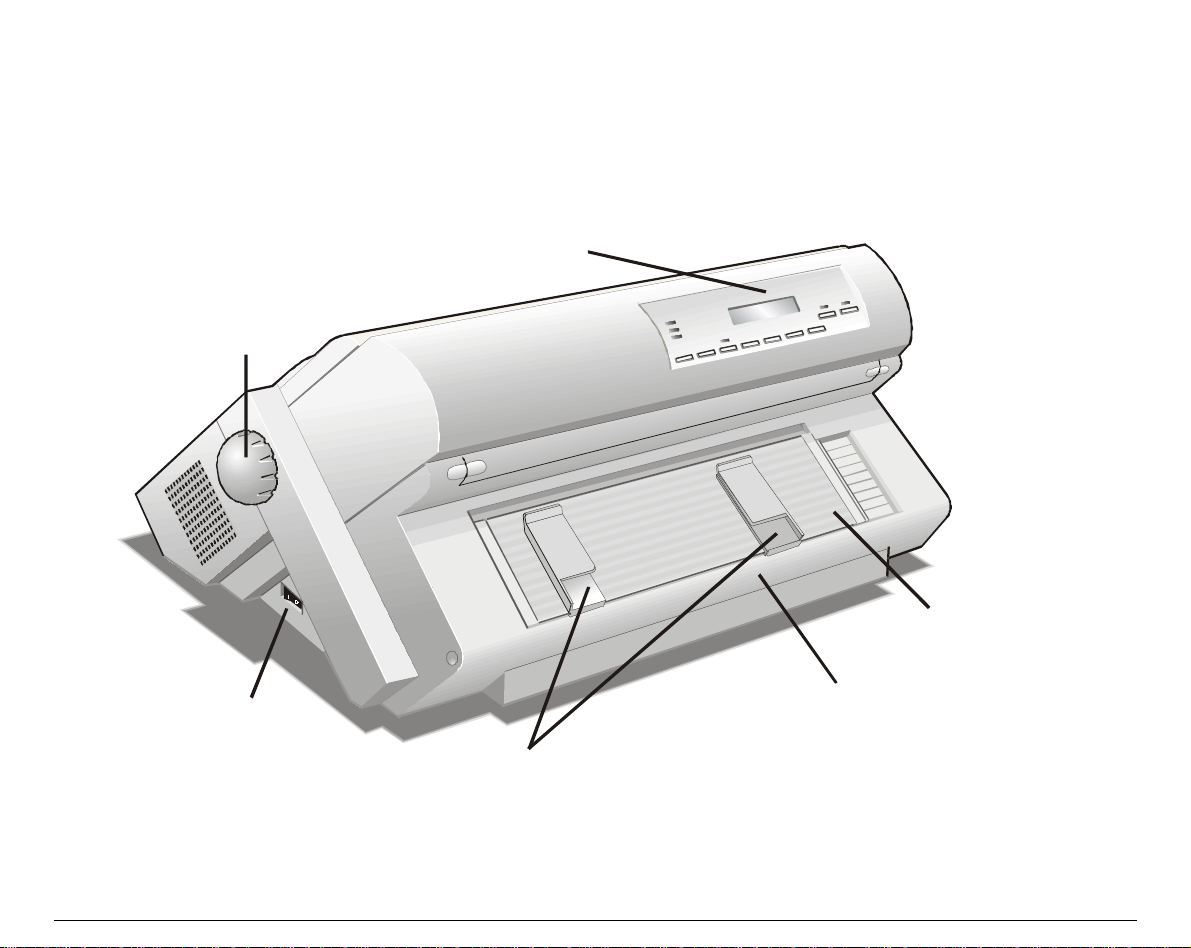

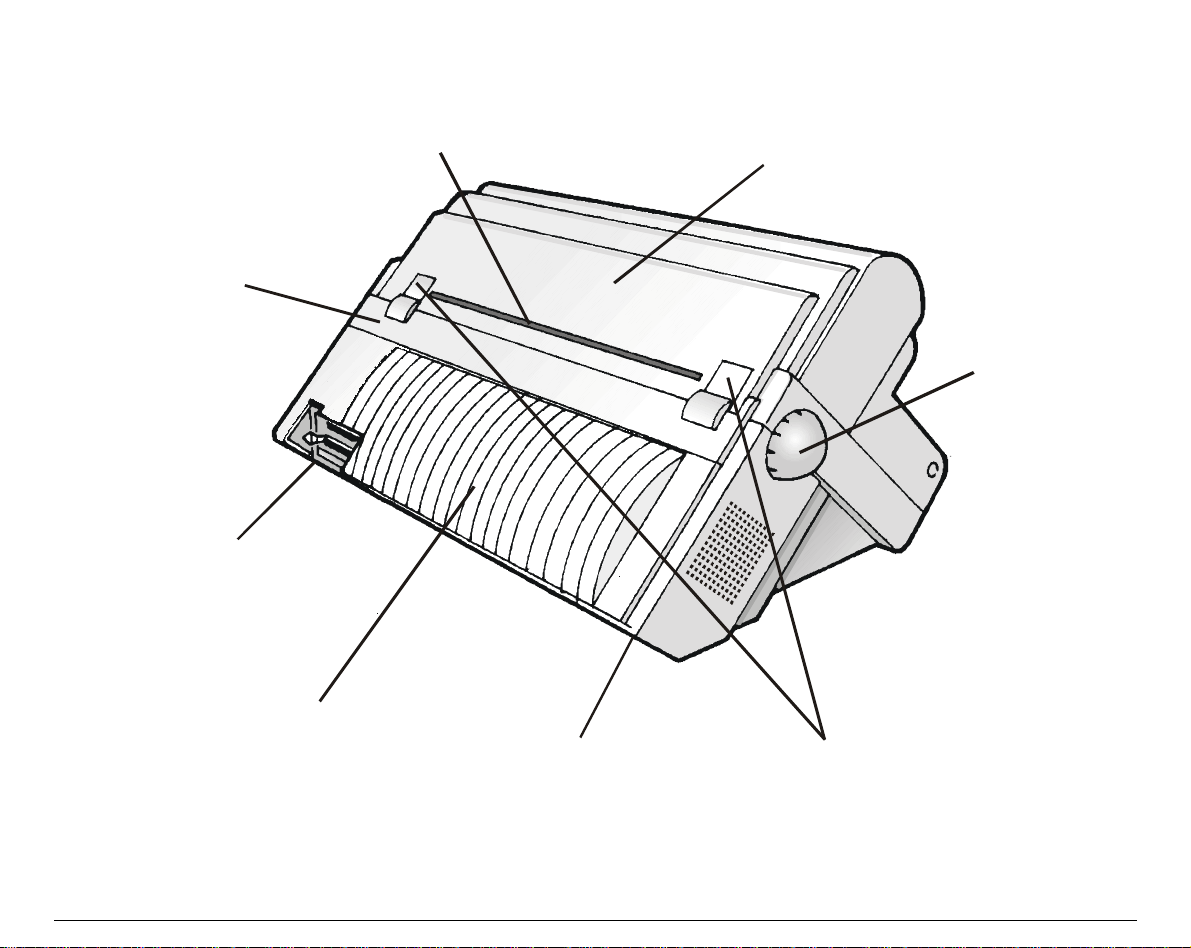

PPrriinntteerr PPaarrttss

FFrroonntt VViieeww

PRT9070 Model

Paper Knob

Operator Panel

Cut Sheet Support

Power Switch

Paper Guides

4

Push Tractors Cover

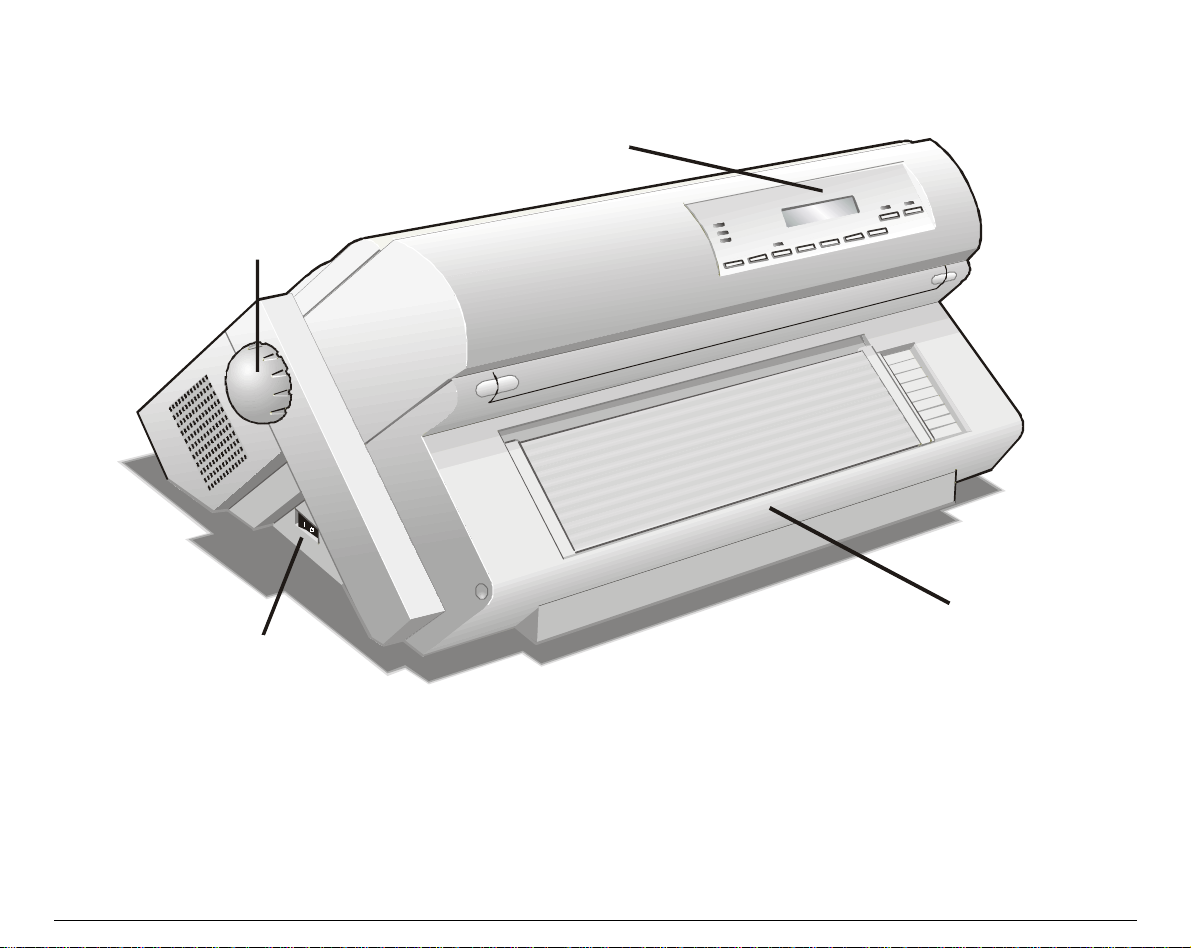

Page 10

PRT9071 Model

Paper Knob

Power Switch

Operator Panel

Push Tractors Cover

5

Page 11

RReeaarr VViieeww

Rear Pull Tractor Cover

Interface Connectors

Rear Paper Slot

Top C ov er

Paper Knob

ASF Area Cover

Pow er C able C onnector Rear P ull Tracto r Attachm ent

Area Covers

6

Page 12

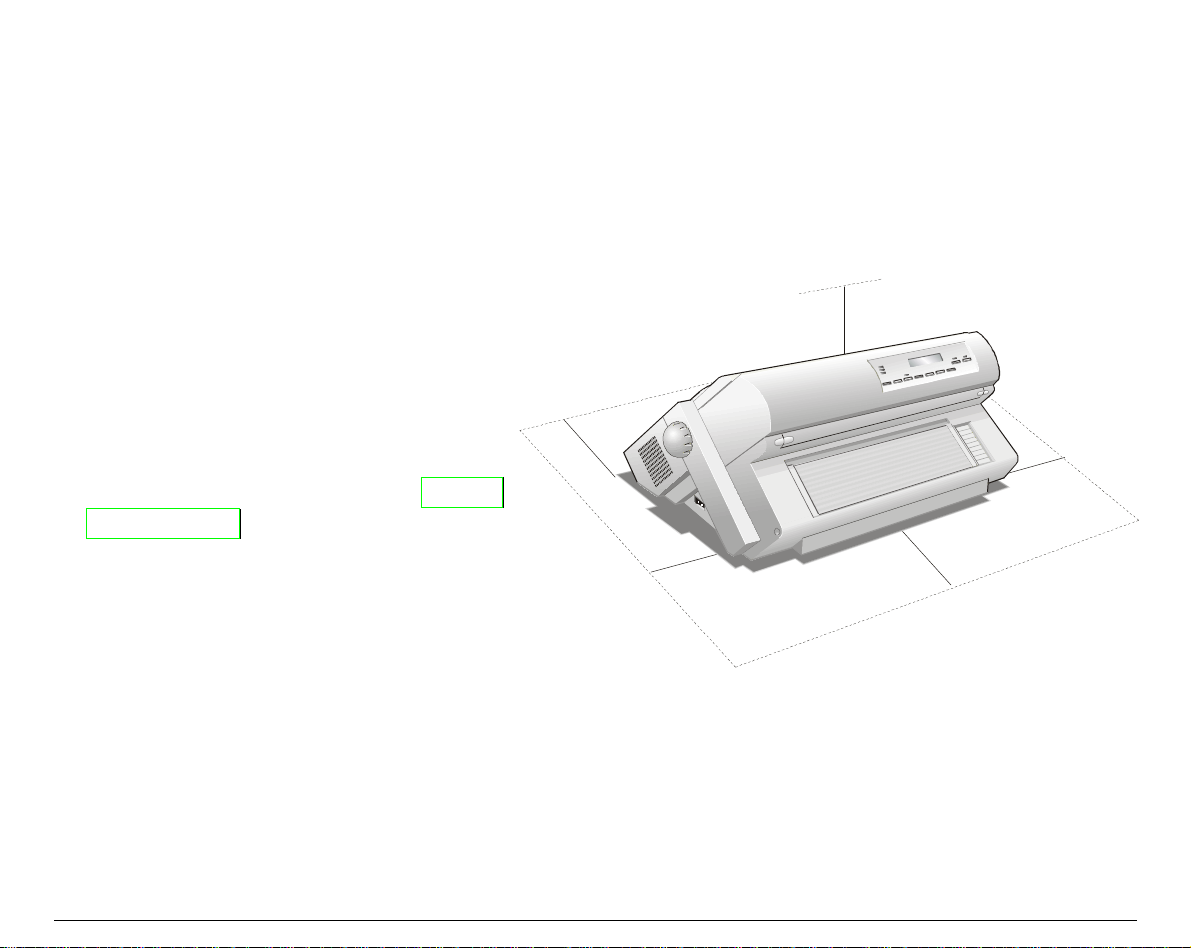

SSeettttiinngg UUpp YYoouurr PPrriinntteerr

CChhoooossiinngg aa SSuuiittaabbllee LLooccaattiioonn

Consider the following points when you

choose the location for your printer:

• The distance between the printer and

the host computer must not exceed the

length of the interface cable;

• The location must be sturdy,

horizontal and stable;

• Your printer must not be exposed to

direct sunlight, extreme heat, cold,

dust or humidity (see "Printer

Specifications" later);

• The power outlet must be compatible

with the plug of the printer's power

cord.

There must be sufficient clearances on

all sides for easy operation. The

required space is shown in the figure:

80 cm

31.5 in.

1

0

0

3

9

c

.

m

4

i

n

m

c

0

2

n

i

9

.

7

1

0

3

0

9

c

.

4

m

i

m

c

0

2

n

i

9

.

7

n

7

Page 13

PPrriinntteerr AAsssseemmbbllyy

RReemmoovvaall ooff tthhee SShhiippmmeenntt LLoocckks

Open all the printer covers and make sure that you remove all the shipment locks from the

printer.

s

8

Page 14

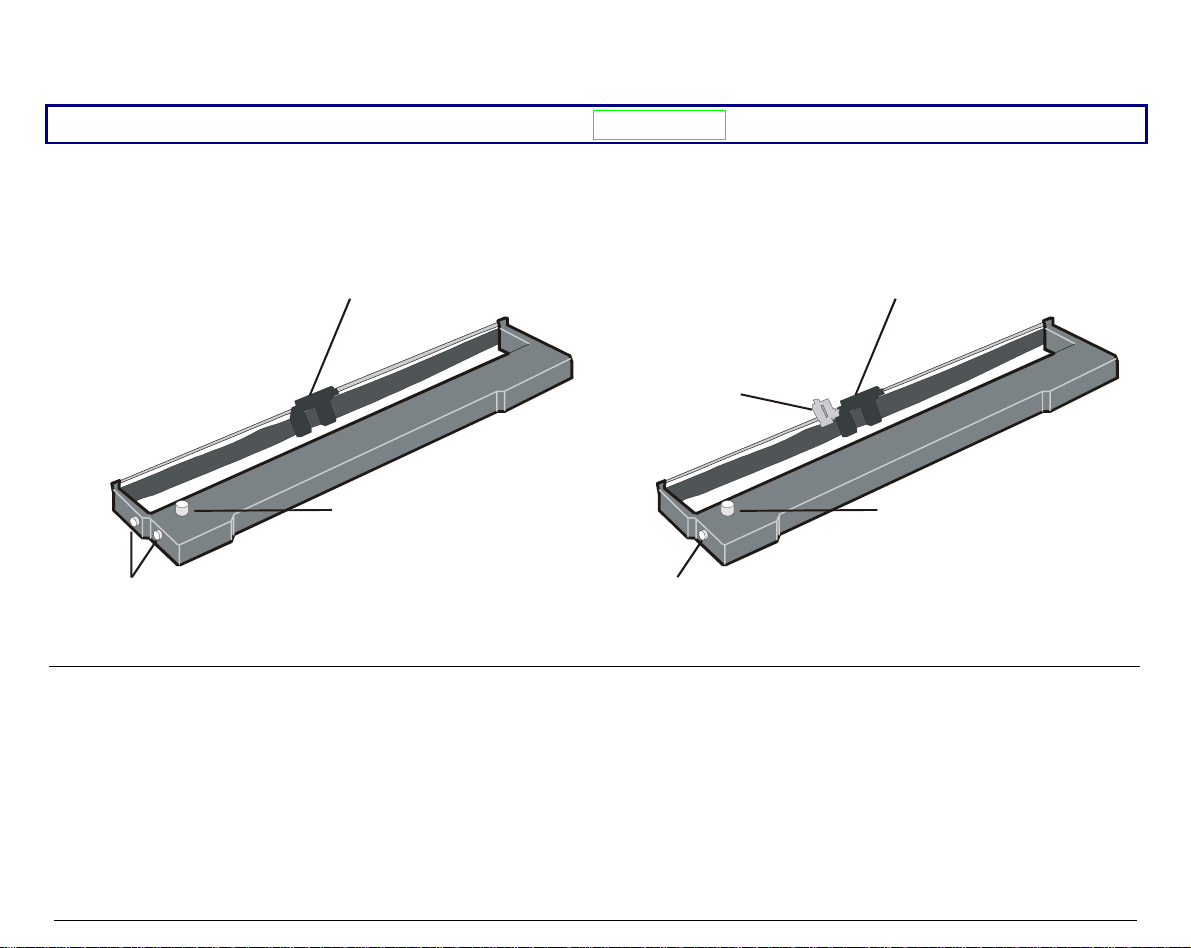

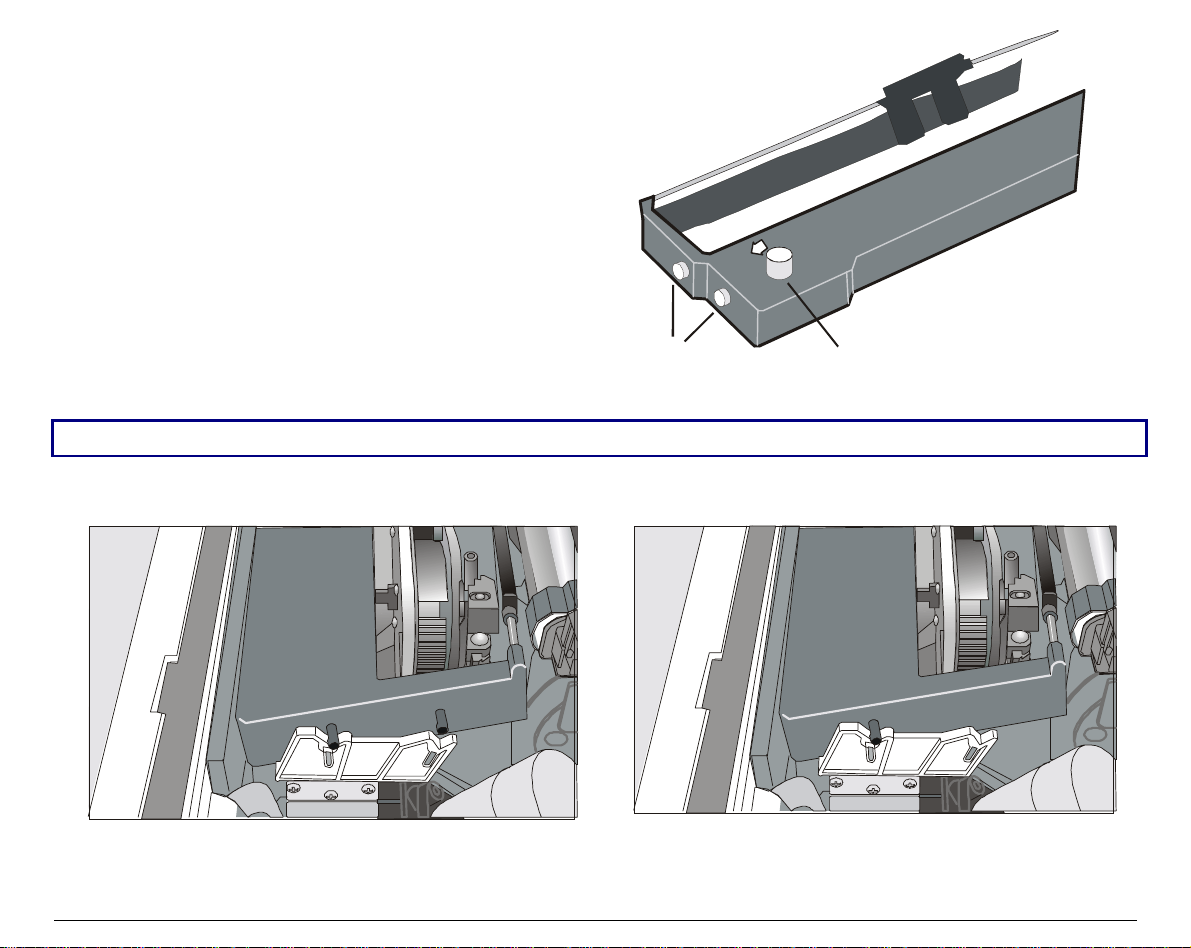

RRiibbbboonn CCaarrttrriiddggee IInnssttaallllaattiioonn

g

g

g

g

Make sure that you are using only Compuprint original consumables.

1. Make sure that the pri nter is turned off.

2. Find the ribbon cartridge a m ong the accessories

Ribbon Guide

Knob

Ca rtrid

Ribbon Windin

e Pins

To be used when the color kit option is not

installed

Ribbon Guide

Colo r S h ifter H older

Ribbon Windin

e Pin

Ca rtrid

Knob

To be used when the color kit option is

installed

9

Page 15

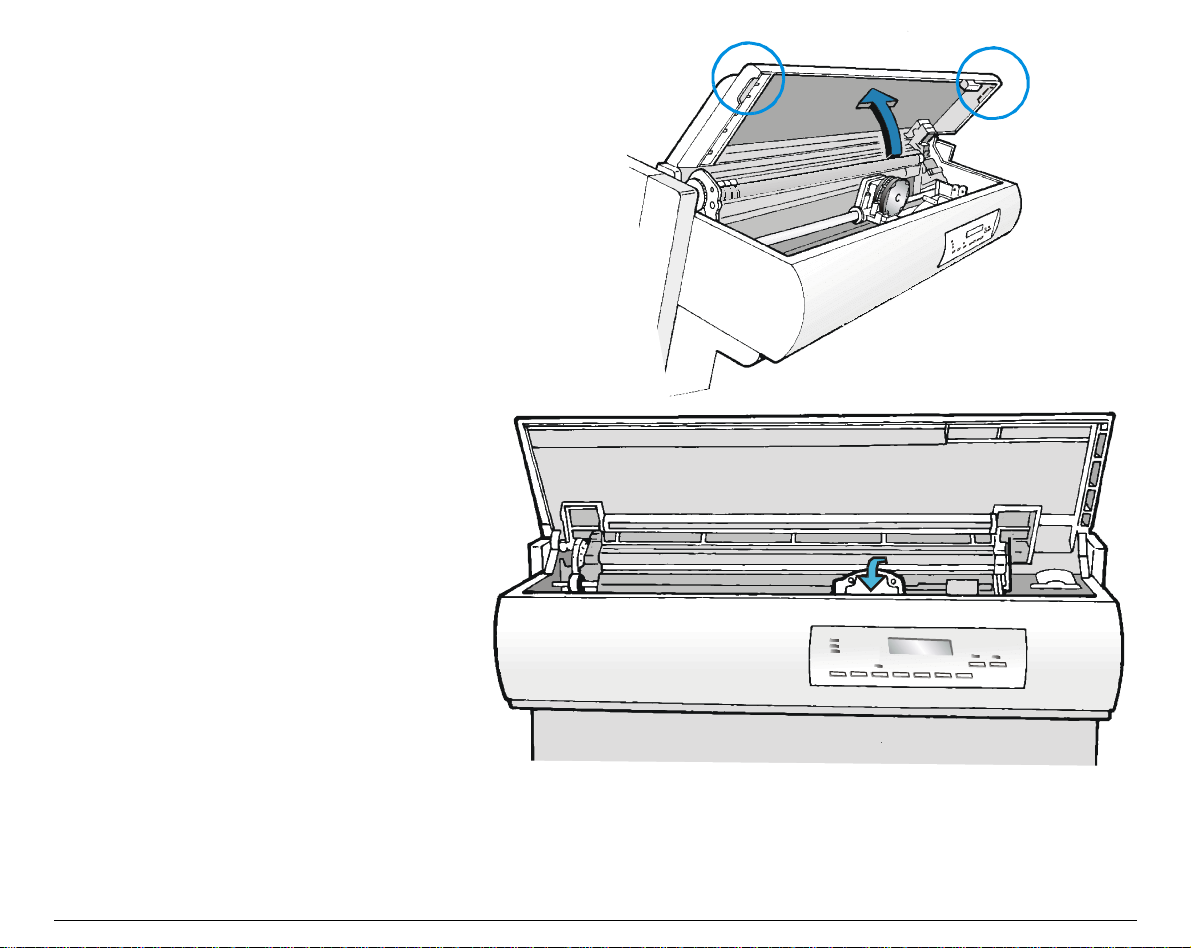

3. Open the top cover using the small

handles on either side of the top

cover.

4. Turn the printer on. The print

carriage prepares for ribbon

cartridge installation.

10

Page 16

5. Before installing the ribbon cartridge

g

turn the ribbon-winding knob in the

arrow direction (loca ted on the cartridge)

to take up slack in the ribbon.

Cartrid

e Pins

Ribbon Winding Knob

To avoid damage to the ribbon, do not turn the winding knob in the wrong direction.

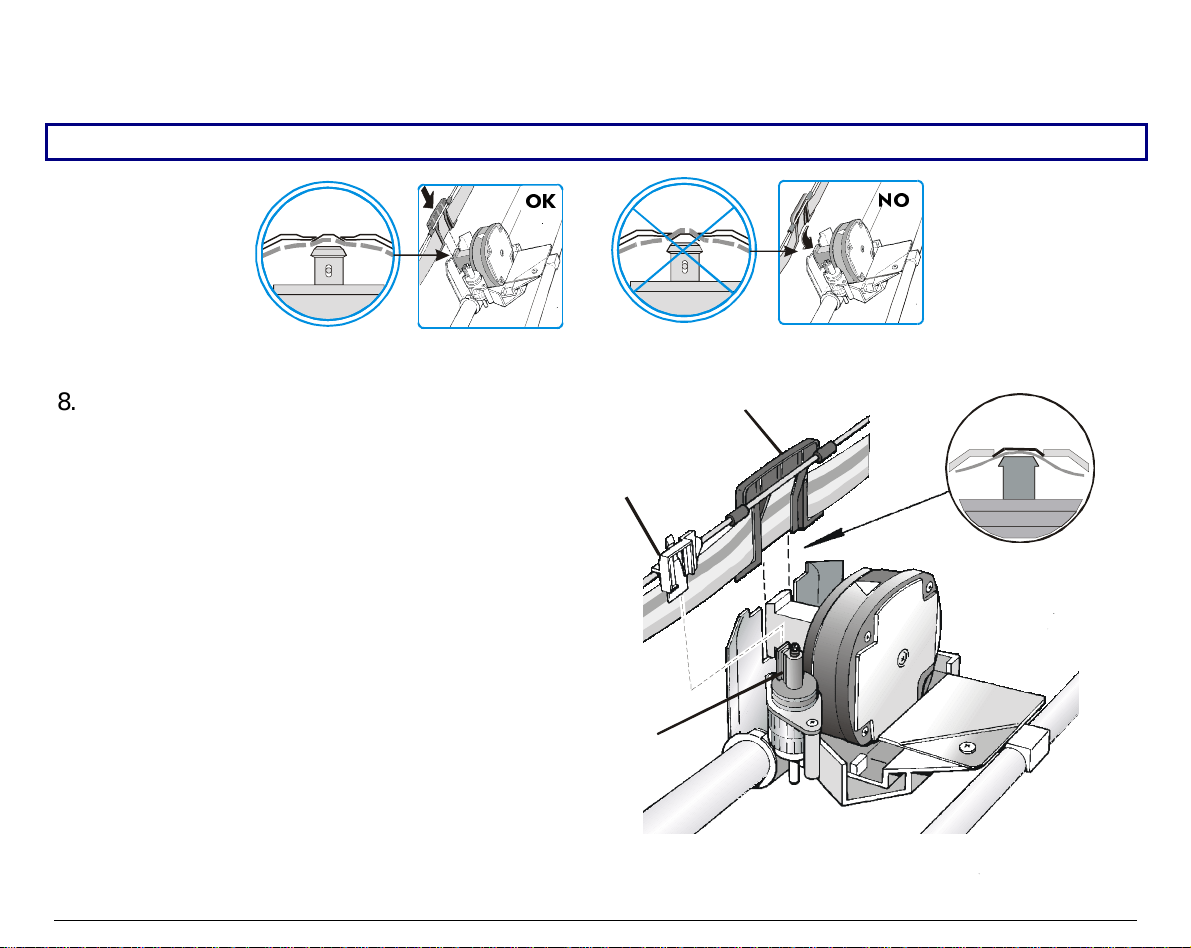

6. Align the right and left cartridge pins with the printer locking points.

Black cartridge when the c olor kit option is not

installed

Black “Long Life” or Color cartridge when

the color kit option is installed

11

Page 17

7. Slide and insert the ribbon guide between the print head and the ribbon guide mask holding it

perpendicular to the print head.

Make sure that the ribbon is inserted correctly between the print head and the print head mask.

8. If the color kit option is installed on

your printer, insert the shifter holder

onto the color shifter as shown in

this figure.

2.

Shifter Holder

Co lor Sh ifter

12

Ribbon Guide

12

Page 18

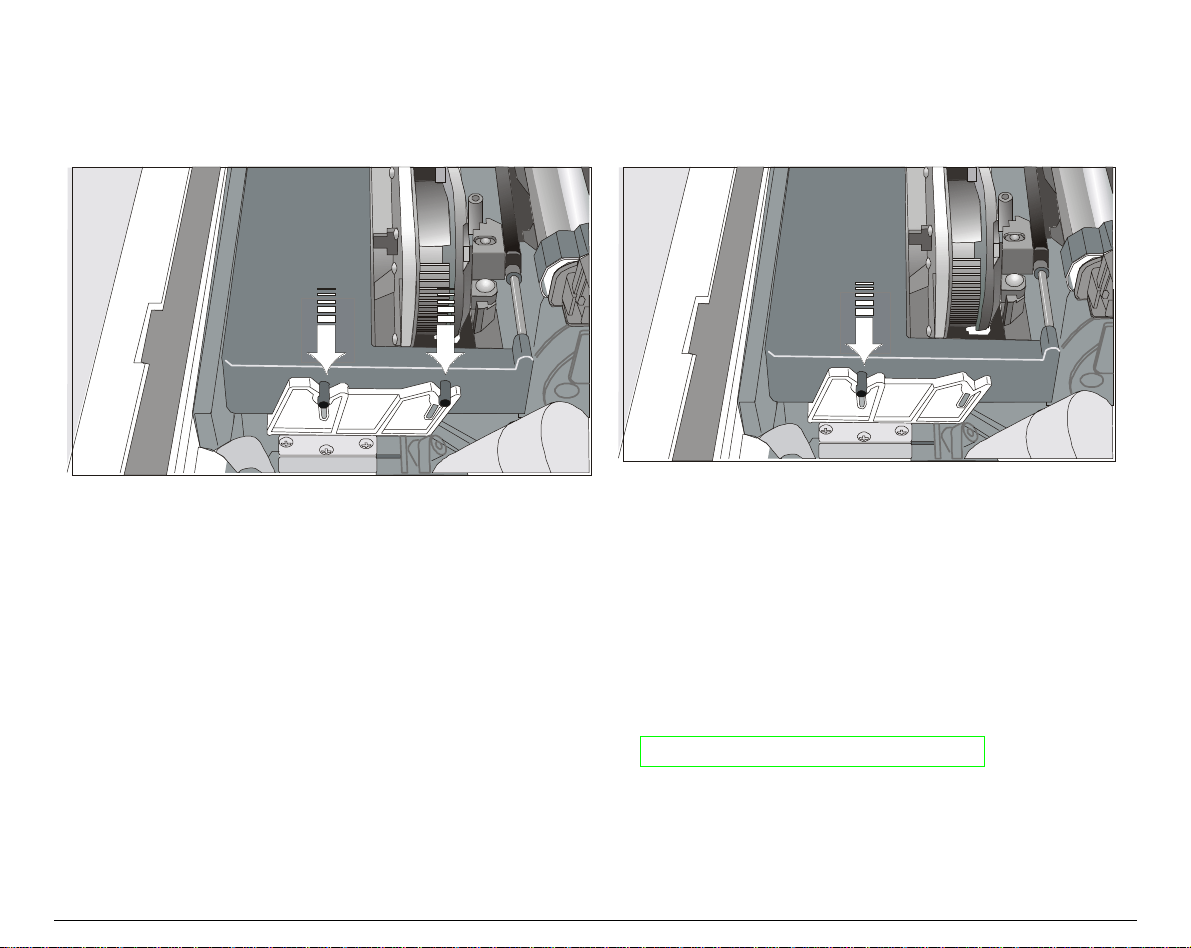

9. Turn the ribbon-winding knob in the arrow direction (located on the cartridge) to take up

slack in the ribbon.

10. Push the cartridge down gently until it c lips in to place at loc king po ints.

Black cartridge when the c olor kit option is not

installed

Black “Long Life” or Color cartridge when

the color kit option is installed

11. Turn the ribbon-winding knob again in the direction of the arrow to take up s lack in the ribbon.

12. To ensure that the ribbon guide runs freely along the ribbon, manually move the print carriage

horizontally.

If the used ribbon cartridge needs to be replaced, see " Replacing The Ribbo n Cartridge ", later in this

manual.

13

Page 19

n

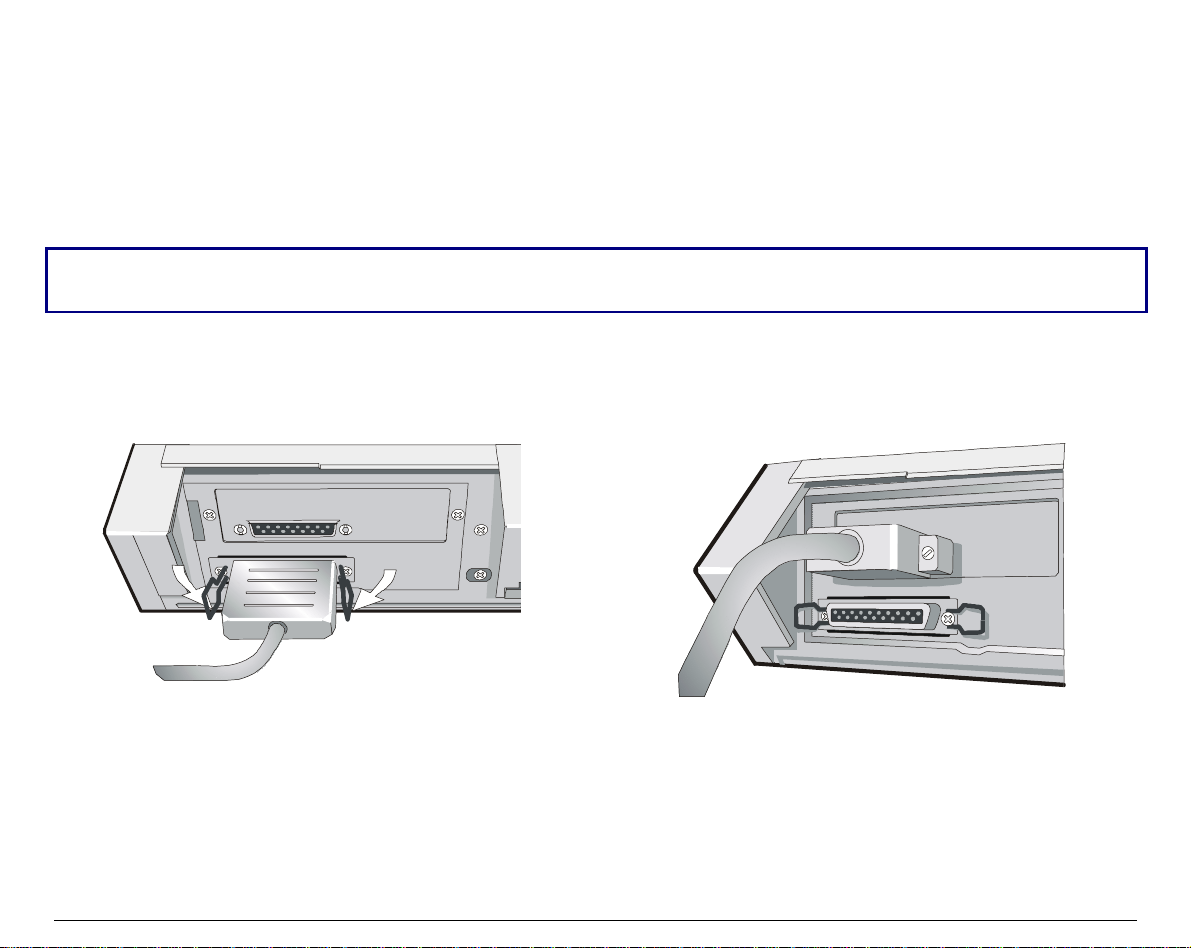

HHoosstt CCoommppuutteerr CCoonnnneeccttiioon

This printer can be connected to your host computer via two available interfaces. The interface

connectors are located on the rear of the printer.

• A bidirectional IEEE1284 parallel interface

• A RS-232C/422A serial interface

Before connecting the interface cable, make sure that the printer and the host computer are

Insert the parallel interface cable into the parallel connec tor and fasten it by mean s of the c lips.

Insert the serial interface cable into the serial connector and fasten it by means of the two screws (use

the screwdriver).

turned OFF .

Parallel Interface

14

Serial Interface

Page 20

SSooffttwwaarree DDrriivveerr SSeelleeccttiioonn

At this point it is necessary to configure your printer for your application package. The installation

procedures depend upon the host environment.

Follow the instructions in the readme file you find on the CD-ROM .

In a WINDOWS 95/98/2000/XP/NT4.0/Millennium® environment the printer supports the Plug &

Play feature.

The printer drivers of all Compuprint printers can be found at the Internet Address

http://www.compuprint.net/

15

Page 21

PPoowweerr CCoonnnneeccttiioonn

The power outlet must be compatible with the plug of the printer’s power cable.

1. Make sure the power outlet is near the printer location and easily accessible.

2. Make sure that the power switch is in 0

position (OFF).

Always use a grounded outlet.

16

Page 22

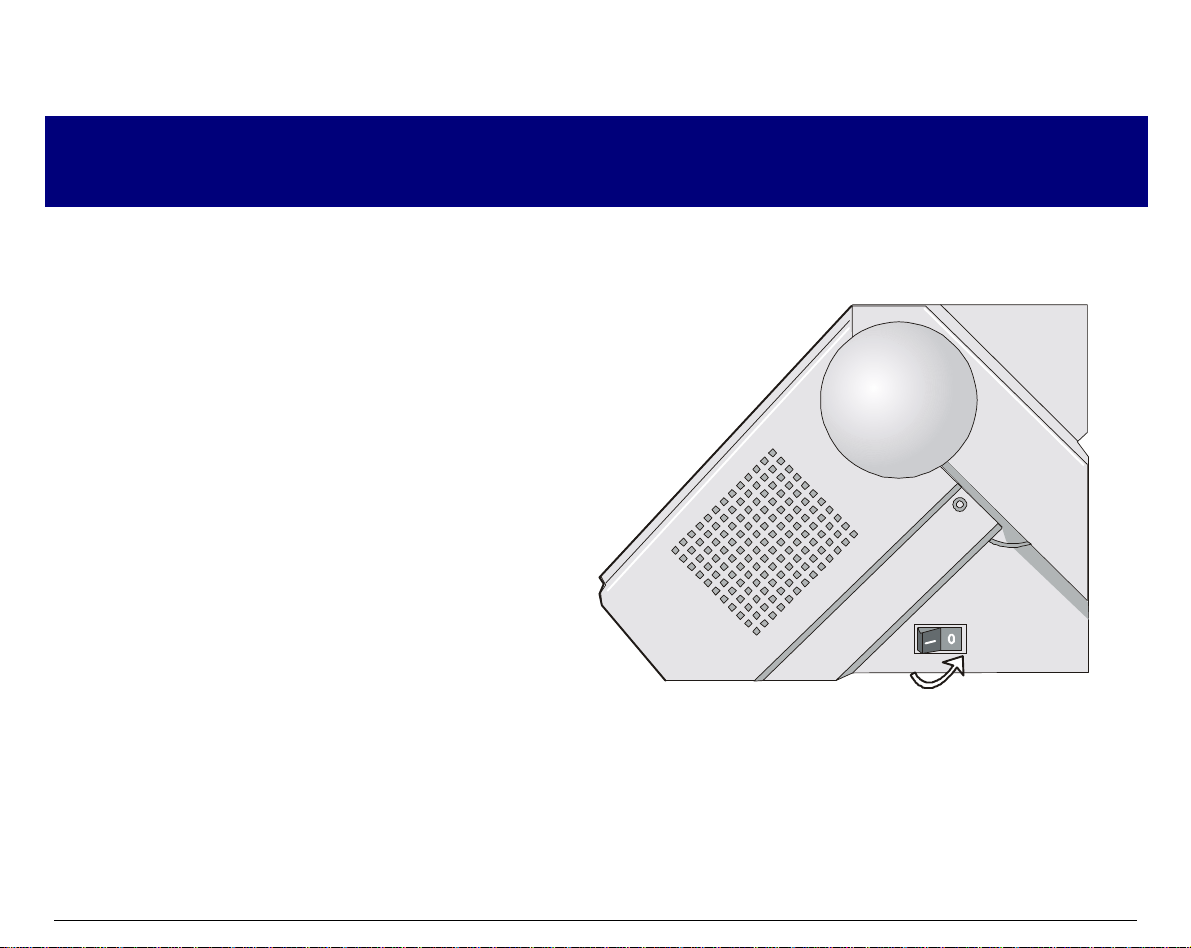

3. Insert the power cable plug into the printer connector and the other power ca ble end into a

convenient outlet (the figure shows the European version).

12

4. If you need to turn the printer on, press the

power switch in the I position (ON).

17

Page 23

SSeelleeccttiinngg tthhee DDiissppllaayy LLaanngguuaaggee

The display messages for this pri nter can be di splayed i n five different lang uages: Engli sh (Default),

French, German, Italian and Spanish. To select the language, that you prefer, pr oceed as follows:

1. Press the

message will be displayed:

2. When you release the

then,

3. Press the ↓ key to enter the setup. The first setup item is displayed:

4. Press the ↓ key until the langu age first level f unc tion is dis played:

5. Press the → key to pass to the second level functions:

6. Press the ↓ key until the s etup lan guage is dis played:

7. Press the → key to scroll the setup la nguages. When the desi red language i s displayed, press the

PROGRAM

in the selected language.

PROGRAM

key to select it. The printer exits the setup. From now on the displa y messa ges appear

key and keep i t pressed while powering on the printer until the following

RELEASE KEY

key, the following messages will be displayed :

PROGRAM

9070

PRINT OUT? NO

EMUL. OPTIONS

FUNCTIONS

BUZZER YES

MENU ENGLISH

18

Page 24

CCoonnffiigguurriinngg tthhee PPrriinntteerr

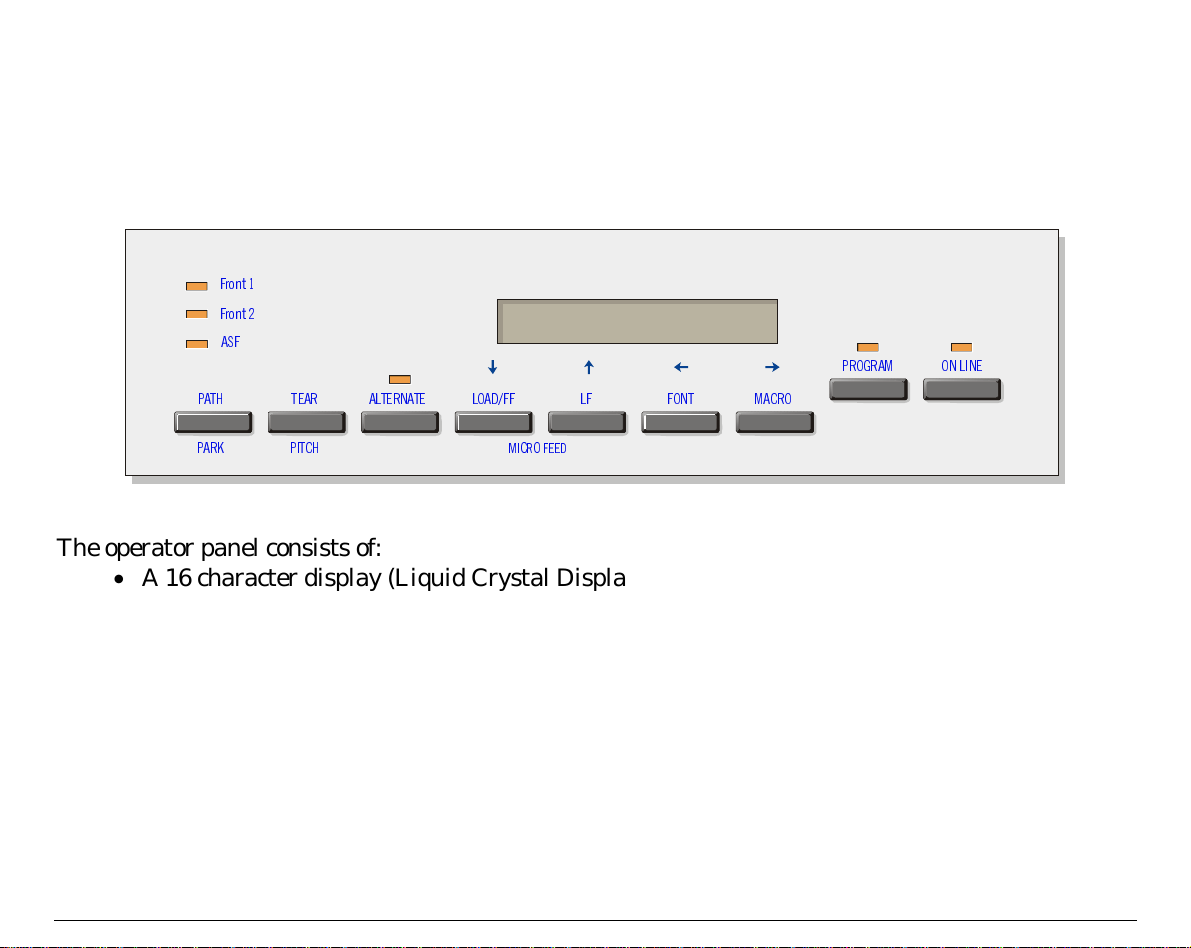

OOppeerraattoorr PPaanneell PPrreesseennttaattiioonn

The operator panel enables you to perform many of the printer functions including paper path

selections, font selection and the printer setup.

)URQW

)URQW

$6)

352*5$0 21 /,1(

3$7+

3$5.

7($5

3,7&+

$/7(51$7( /2$')) /) )217 0$&52

0,&52 )(('

The operator panel consists of:

• A 16 character display (Liquid Crystal Display)

• Six led indicators

• Nine function keys

19

Page 25

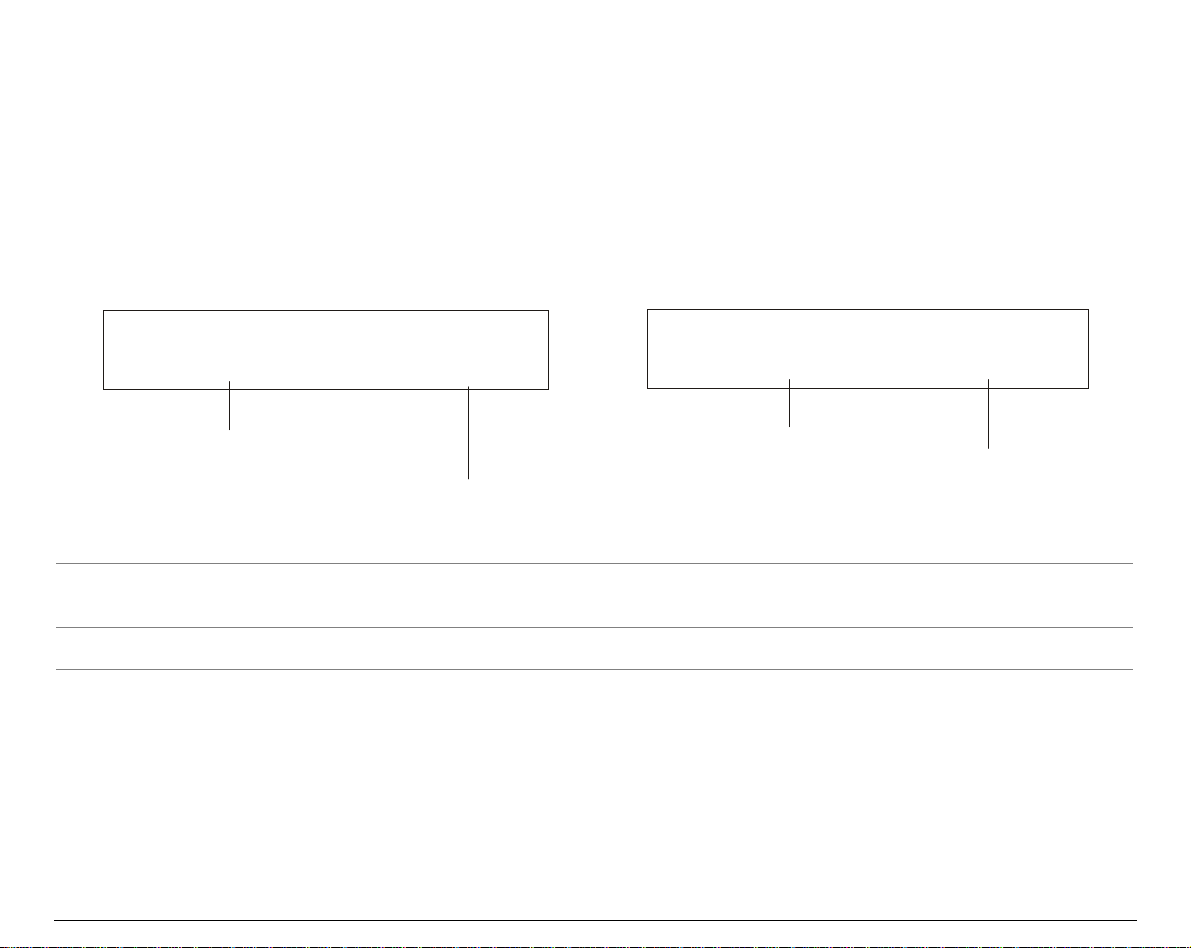

DDiissppllaayy MMeessssaaggeess

The printer display is used to indicate the printer status or to request an user intervention.

When the printer is in Ready state, the display gives the following information:

• when paper is already loaded and the

printer is off line (

ON LINE

indicator unlit):

OFF LINE M1

Printer Status

where:

OFF LINE

ON LINE

M1, M2, M3, M4

Current Macro

Indicates the printer status.

Indicate which of the four User Macros is currently used.

• when paper is already loaded and the

printer is on line (

ON LINE

indicator lit):

ON LINE M1

Printer Status

Current Macro

20

Page 26

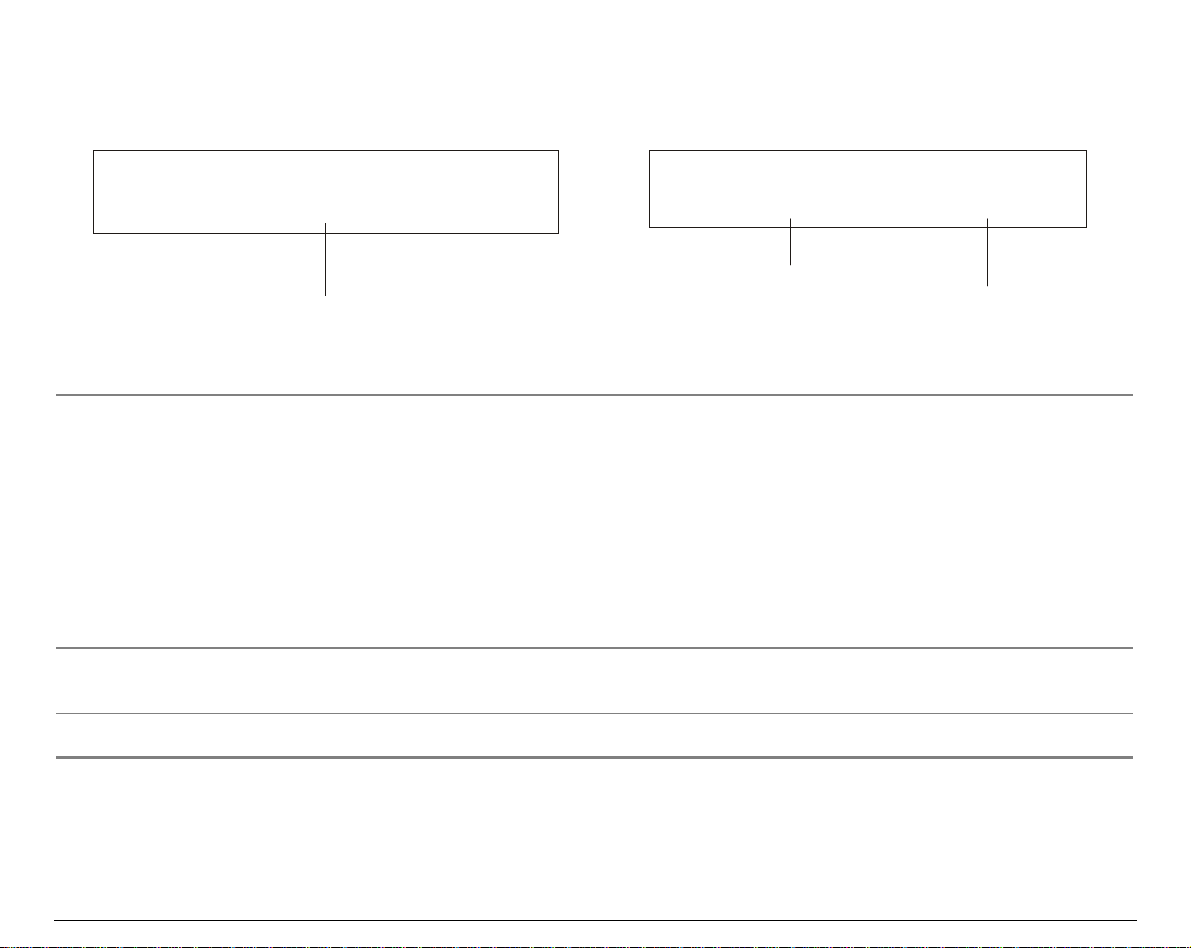

• when there is no paper loaded and the

printer is off line (

ON LINE

indicator unlit):

• when there is no paper loaded and the

printer is on line (

ON LINE

indicator lit):

Load Front1

Current Paper Path

where:

LOAD FRONT1

LOAD FRONT2

LOAD PUSH-PULL

LOAD FR1 PUSH&MF

LOAD MANUAL FORM

LOAD PSH-PLL&MF

LOAD ASF1

LOAD ASF2

LOAD ASF3

OFF LINE

ON LINE

M1, M2, M3, M4

ON LINE M1

Printer Status

Indicates that the currently selected paper path is out of paper.

The messages are displayed onl y for the available paper paths,

according to the installed devices.

LOAD FRONT2

LOAD FR1 PUSH&MF

LOAD MANUAL FORM

LOAD PSH-PLL&MF

Indicates the printer status.

Indicate which of the four User Macros is currently used.

(only PRT9071 model)

(only PRT9070 model)

(only PRT9070 model)

(only PRT9070 model)

Current Macro

21

Page 27

The following messages appear to i ndicate other printer conditions or user intervention requests.

The list is in alphabetical order.

Message Description

ALTERNATE

BUSY M1

COVER OPEN

CLOSE COVER

EJECTING

INITIALIZING LAN

LOAD FRONT1

LOAD FRONT2

LOAD PUSH-PULL

LOAD FR1 PUSH&MF

LOAD MANUAL FORM

LOAD PSH-PLL&MF

LOAD ASF1

LOAD ASF2

LOAD ASF3

This message appears to indicate that the Alternate functions of the operator

panel keys have been selected pressing the

This message appears to indicate that the printer is printing. It is busy.

When the printer cover is not closed correctly, the buzzer sounds and the

display shows alternately these two messages. Close the printer cover.

The printer is ejecting the paper out of the printer.

This message is displayed when the LAN is reset (only if the LAN interface

board is installed).

These messages are displayed when the corresponding paper path is out of paper.

The printer displays only the messages related to the installed devices.

FR1 PUSH&MF

PSH-PLL&MF

= Front1 push and manual paper path.

= Push-Pull and manual paper path.

ALTERNATE

key.

LOCKED MENU

MACRO CHANGING

When the access to the Printer Setups has been locked at the power on, the

printer displays this message.

The macro has been changed and the printer is updating the settings.

22

Page 28

Message Description

MICRO FEED DOWN

MICRO FEED UP

OPT. I/F CHANGED

PRESS ON LINE

OPER. INTERRUPTED

PARKING

PATH CHANGING

PRESS A KEY

NVM CHANGED

RELEASE KEY

REMOTE CONTROL

The paper is fed in microsteps downwards when pressing the ↓ arrow key .

The paper is fed in microsteps forwards when pressing the ↑ arrow key.

These messages are displayed at power on when the I/F board option has been

changed previously in the printer. Press the

This message is displayed if the

park procedure.

The printer is parking the fanfold paper.

The path has been changed and the printer is updating the settings.

The NVM has been changed. Press any key to set the printer.

This message is displayed when you can release the

test selection or in the Power-on Configuration procedure.

This message is displayed when the printer operates from remote control (only

if the LAN interface board is installed).

ALTERNATE

ON LINE

key has been pressed to interrupt a

key to confirm.

PROGRAM

key in the Self-

RESET & BREAK

SELF TEST

TEAR IF NECESS.

EJECT PAPER

TEAR IF NECESS.

The printer received a reset and break command via interface.

Printing the self-test page.

These messages are displayed when the printer receives a paper parking

command and the

the fanfold then press the

These messages are displayed when the printer receives a paper parking

TEAR NO

23

item is selected for the tear-off function. Tear off

key to eject the paper.

PARK

Page 29

Message Description

PARK PAPER

TEAR OFF PAPER

EJECT PAPER

TEAR OFF PAPER

PARK PAPER

UNLOCKED MENU

For the error messages see "Error Handling” later in this manual.

command. Tear off the fanfold paper if necessary and then press the

to park the paper.

These messages are displayed when the printer receives a paper ejecting

command (

not able to execute it, because the paper to be ejected is longer than 18 inch.

Tear off the fanfold paper and then press the

These messages are displayed when the printer has received a paper parking

command but was not able to execute it, because the paper to be parked is

longer than 18 inch. Tear off the fanfold paper and then press the

park the paper.

When the access to the Printer Setups has been unlocked at the power on, the

printer displays this message.

TEAR NO

item has been selected for the tear-off function) but was

key to eject the paper.

PARK

PARK

PARK

key to

key

24

Page 30

IInnddiiccaattoorrss

Lit when the printer can receive and print data (printer online).

21/,1(

352*5$0

$/7(51$7(

7439

7439

$

Blinks when there is data in the buffer and the printer is offline.

Unlit when the printer is disabled and the buffer does not contain any data, or

during the initialization, setup or tests.

Blinks when one of the printer setup procedures has been selected:

Configuration

Lit when the alternate function of the keys has been enabled pressing the

ALTERNATE

Lit when the Front1 paper path or the Push-pull paper path is selected.

Unlit when neither the Front1 paper path nor Push-pull paper path are selected.

Lit when the Front2 paper path (PRT9071 model) or the Manual paper path

(PRT9070 model) is selected.

Unlit when the Front2 paper path (PRT9071 model) or the Manual paper path

(PRT9070 model) is not selected.

Lit when the Automatic Sheet Feeder (ASF) paper path is selected.

or

Power-On Configuration

key.

.

Program

Unlit when the Automatic Sheet Feeder (ASF) paper path is not selected.

25

Page 31

FFuunnccttiioonn KKeeyyss

g

Pressing the function keys it is possible to activate the functions indicated by the word or symbol

signed near the key. Each key may have different functions, according to the selected function

modes: Normal, Alternate or Program.

Pro

Normal function

3$7+

7($5

ram Function

$/7(51$7( /2$')) /) )217 0$&52

352*5$0 21 /,1(

Normal Function

Alternate Function

Program Function

3$5.

The

normal

3,7&+

Alternate function

0,&52 )(('

function of the keys is written above the keys and does not require any

previous action to select it.

alternate

The

pressing the

When the alternate function of the keys is selected, the

the display shows

program

The

•

If you press the key while powering the printer on, the

function of the keys is written below the keys and is selected

ALTERNATE

ALTERNATE

function of the keys is selected pressing the

key.

.

ALTERNATE

PROGRAM

indicator is lit and

key, where:

Power-On Configuration

is selected.

•

If you press the key when the printer is enabled without printing or disabled

(

ON LINE

indicator unlit), the

In the Program Setup mode only the four arrow keys and the

enabled and the

PROGRAM

indicator is lit.

Program Setup

is selected.

PROGRAM

key are

26

Page 32

ON LINE Key

ON LINE

Normal

Function

Program

Function

PROGRAM Key

PROGRAM

Normal

Function

Program

Function

Enables or disables the printer.

If this key is pressed while powering the printer on, the self test is printed;

•

the printout is stopped pressing this key again.

In an error condition, once the error cause has been removed, press this

•

key to enable the printer

Pressing this key, the input buffer is cleared an a break (250 msec.) on a serial

interface is sent. The message RESET & BREAK is displayed.

Enables the printer setups as follows:

Pressing this key while powering on the printer, the

•

Configuration

Pressing this key when the printer is enabled without printing or disabled

•

the

Program Setup

Exits the printer setups.

is selected.

is enabled (

PROGRAM

indicator lit).

Power-On

MACRO Key

MACRO

→

Normal

Function

Program

Function

Selects one of the user macros (Macro 1, Macro 2, Macro 3 or Macro 4). If you

want to select the displayed macro, wait for 2 seconds without pressing any

key and the parameters of this macro will be set .

Scrolls the parameters of the functions or macros forwards.

27

Page 33

FONT Key

FONT

Normal

Function

←

Program

Function

LF Key

LF

MICRO FEED

↑

Normal

Function

Alternate

Function

Program

Function

LOAD/FF Key

LOAD/FF

MICRO FEED

Normal

Function

Alternate

Function

Selects the font to be used with the currently selected pitch. The selected font

is valid until the printer is turned off or a new font is selected using this key.

Scrolls the parameters of the functions or macros backwards.

Performs a line feed according to the current line spacing settings.

Moves the paper forward in microsteps. Keeping the key pressed the paper is

moved continuously at increasing speed.

Scrolls the setup and macro functions backwards.

Executes a Form Feed (FF): when paper is loaded into the printer, it advances

to the following page; if no paper is loaded, it is positioned for printing.

Moves the paper backward in microsteps. Keeping the key pressed the paper

is moved continuously at increasing speed.

↓

Program

Scrolls the setup and macro functions forwards.

Function

28

Page 34

ALTERNATE Key

ALTERNATE

Normal

Function

Alternate

Function

TEAR/PITCH Key

TEAR

PITCH

Normal

Function

Alternate

Function

Enables the alternative key functions.

If the printer is receiving print data, press the

ALTERNATE

key.

ON LINE

If no printing data are in the print buffer, pressing the

key before pressing the

ALTERNATE

key, the printer

goes offline.

The display then shows

of the keys is enabled (

ALTERNATE

ALTERNATE

May be used to abort paper parking procedure. See also “

Paper Parking

”, later in this manual.

to indicate that the Alternate Function

indicator lit).

How to Handle the

When the printer is in Program Setup Mode, this key is disabled.

Disables the alternative key functions.

Moves the paper to the tear-off position (

in the

Program Setup

).

TEAR NORMAL

function must be selected

Selects the pitch to be used with the currently selected font. The selected pitch is

valid until the printer is turned off.

29

Page 35

PATH/PARK Key

PATH

PARK

Normal

Function

Alternate

Function

Selects one of the paper paths in offline status. The parameters of the displayed

path are set after 2 seconds without pressing any key.

Parks the paper in the currently selected paper path.

Key Combinations

ONLINE + MACRO + ALTERNATE

Normal

Function

Lock or unlock the access to the printer setups. See later

“How to Lock/Unlock the Printer Setups” section.

30

Page 36

PPrriinntteerr SSeettuuppss

The main printer setup parameters can be sel e cted via the operator panel. The setup parameters are

divided into two printer setups, the Power-O n Configuration, that allows a complete configuration at

installation time according to the hardware and the emulation types, and the Program Setup, that

allows you to set the functions that are the most useful in your daily job. These settings can be

selected when the printer is online without printing or offline (

the NVM.

ON LINE

indicator unlit) and stored i n

EEnntteerriinngg tthhee PPrriinntteerr SSeettuuppss

• Press the

message is displayed to select the Power-On Configuration.

• Press the

indicator unlit) to select the Program Setup.

PROGRAM

PROGRAM

key and keep it pressed at the printer power on unti l the RELEASE KEY

key when the printer is online without printing or offline (

MMoovviinngg wwiitthhiinn tthhee PPrriinntteerr SSeettuuppss

The arrow keys ↑, ↓, ← , → are used to move within the different functions inside the Printer Setups.

See the following description of the setup items.

ON LINE

31

Page 37

LLeeaavviinngg tthhee PPrriinntteerr SSeettuuppss

• Pressing the

PROGRAM

in the Power-On Configuration key the printer exits from the setup and

the new settings will be automatically saved.

• Pressing the

PROGRAM

key in the Program Setup, the following choice is offered for the storage of

the values set:

STORE? QUIT

STORE? SAVE

The new settings are not activated and the old settings remain valid.

The new settings are stored permanently in the NVM (Non Volatile

Memory).

STORE? CURRENT

The new settings remain valid until the p rinter is tur ned off .

Press the → or ← keys to scan these selections forwa rd and backwards. When the desired setting is

displayed, press the

PROGRAM

key to exit from the Setup.

32

Page 38

PPoowweerr--OOnn CCoonnffiigguurraattiioonn

The default values of the various functions are indicated in bold.

EEnntteerriinngg tthhee PPoowweerr--OOnn CCoonnffiigguurraattiioonn

1. Make sure that the printer is turned off.

2. Press a nd hold the

message is displayed. As soon as the

displayed:

then,

PROGRAM

key pressed while powering on the printer until the RELEASE KEY

PROGRAM

PRINT OUT? NO

9070

key gets released, the following message will be

33

Page 39

Main Structure

This figure shows the structure of the Power-On Configuration and how to move inside the Setup.

Print out? N O

Emul. Options

Parall Interface

Serial Interface

Fu nctions

Back to M FG ? N O

Print out? Y ES

LA N Interface

34

Page 40

The setup item Functions groups the following printer functions:

• Buzzer setting,

• Paper loading sequence,

• Paper overlay (only PRT9070 model),

• Quick cut sheet loading (only PRT9070 model),

• Ribbon type,

• Bar code density,

• Text printing direction,

• Graphics printing direction,

• Bar code printing direction,

• Graphics printing speed,

• Paper path at power on,

• Language of the display messages,

• Paper tractor jam sensors (if the optional 6 pin Front 1/Front2 Push tractors are installed),

• Tear-off position adjustment

• Cut position adjustment (if the optional cutter is installed)

Printout of the Printer Settings

PRINT OUT? NO

↓

EMUL. OPTIONS

→

or ←

PRINT OUT? YES

PRINT OUT? NO

PRINT OUT? YES

The Setup is not printed.

The printer setup is printed showing the currently selected values. The

printout starts as soon as you select this value.

35

Page 41

Emulation Options

This setup defines the available options according to the selected emulation and is structured as

follows:

Options

Emul. Options

Parall. Inte rfa c e

Emul EPSON LQ

Char. Set ...

Nation ...

Auto CR ...

Auto LF …

Em ul IBM...

Char. Set ...

Nation ...

Auto CR …

Auto LF ...

20 CPI IBM ...

36

Page 42

Setting the Emulation Options

Printer Emulation

PRINT OUT? NO EMUL. OPTIONS

↑

EMUL. OPTIONS

↓

PARALL INTERFACE

EMUL. IBM 2391

CHAR. SET CS2

→

↑

EMUL. EPSON LQ

EMUL. IBM XL24

EMUL. IBM XL24AGM

↓

EMUL EPSON LQ

EMUL IBM XL24

EMUL IBM XL24AGM

EMUL. IBM 2391

The printer uses the EPSON LQ Series emulation.

The printer uses the IBM Proprinter XL24 emulation.

The printer uses the IBM Proprinter XL24 AGM emulation.

The printer uses the IBM Personal 2391+ emulation.

→

→

→

→

or ←

←

or

←

or

or ←

37

Page 43

EPSON Character Sets

EMUL. EPSON LQ

↑

CHAR. SET CS1

CHAR. SET CS2

CHAR. SET ITALIC

↓

NATION CP437

→ or ←

→ or ←

→ or ←

These items select the character set to be used in EPSON emulation.

IBM Character sets

EMUL. IBM xxx

↑

CHAR. SET CS1

CHAR. SET CS2

↓

NATION CP437

→ or ←

→ or ←

These items select the character set to be used in IBM Proprinter emulation.

38

Page 44

EPSON National Character sets

CHAR. SET CS2

↑

NATION CP437

NATION …

NATION LATIN A1

↓

AUTO CR YES

→ or ←

→ or ←

→ or ←

The following national character sets ar e available:

CP 437

CP 857 CP 858 CP 860 CP 862 CP 863 CP 864 CP 865 CP 866

CP 867 CP 876 CP 877 CP 1250 CP 1251 CP 1252 CP 1253 CP 1254

CP 1255 CP 1256 CP 1257 GOST TASS MAZOWIA ISO 8859/1 ISO 8859/2

ISO 8859/3 ISO 8859/4 ISO 8859/5 ISO 8859/6 ISO 8859/7 ISO 8859/8 ISO 8859/9 ISO 8859/15

CP 437SL CP 1098 UKRAIN KOI8-U USA FRANCE GERMANY ENGLAND

DENMARK1 SWEDEN ITALY SPAIN1 JAPAN NORWAY DENMARK2 SPAIN2

CP437 G 96GREEK CP850 CP851 CP 852 CP 853 CP 855

LATIN A1

The CP 858 and ISO 8859/15 character sets contain the Euro character.

39

Page 45

IBM National Character Sets

CHAR. SET CS2

↑

NATION CP437

NATION …

NATION KOI8-U

↓

AUTO CR NO

→ or ←

→ or ←

→ or ←

The following national character sets can be se lected:

CP 437

CP 857 CP 858 CP 860 CP 862 CP 863 CP 864 CP 865 CP 866

CP 867 CP 876 CP 877 CP 1250 CP 1251 CP 1252 CP 1253 CP 1254

CP 1255 CP 1256 CP 1257 GOST TASS MAZOWIA ISO 8859/1 ISO 8859/2

ISO 8859/3 ISO 8859/4 ISO 8859/5 ISO 8859/6 ISO 8859/7 ISO 8859/8 ISO 8859/9 ISO 8859/15

CP 437SL CP 1098 UKRAIN KOI8-U

CP437 G 96GREEK CP850 CP851 CP 852 CP 853 CP 855

TThhee CCPP 885588 aanndd IISSOO 88885599//1155 cchhaarraacctteerr sseettss ccoonnttaaiinn tthhee EEuurroo cchhaarraacctteerr..

40

Page 46

CR Code Behavior

NATION xxx

↑

AUTO CR NO

AUTO CR YES

↓

AUTO LF NO

AUTO CR NO

AUTO CR YES

→ or ←

→ or ←

No automatic carriage return is performed after a LF, VT or ESCJ code.

Default value in IBM emulation.

The printer performs an automatic carriage return after a LF, VT or ESCJ code.

Default value in EPSON emulation.

41

Page 47

LF Code Behavior

AUTO CR xx

↑

AUTO LF NO

AUTO LF YES

AUTO LF HOST

↓

20 CPI IBM NO

or

EMUL. OPTIONS

→ or ←

→ or ←

→ or ←

AUTO LF NO

AUTO LF YES

AUTO LF HOST

No Automatic LF after CR.

Automatic LF after CR.

Only in EPSON emulation. The printer checks the AUTOFEEDXT signal coming

from the host and executes an automatic LF after CR, if the signal is low.

42

Page 48

IBM Compressed Printing

These items are displayed only if the IBM emulation is selected.

AUTO LF NO

↑

20 CPI IBM NO

20 CPI IBM YES

↓

EMUL. OPTIONS

20 CPI IBM NO

20 CPI IBM YES

→ or ←

→ or ←

The compressed printing is performed at 17.1 cpi.

The compressed printing is performed at 20 cpi.

43

Page 49

Parallel Interface

This setup defines the use of the parallel interface and is structured according to the interface

specific parameters.

Parallel Interface Parameters

Parall Interface

Serial Interface

RU

LAN Interface

1284 Bidir. I/F

Select-In Host

Data Bits 8

Input Buffer 2K

CX. Parallel I/F

Select-In On

Data Bits 7

Input Buffer …

44

Page 50

Setting the Parallel Interface Parameters

Interface Type

EMUL. OPTIONS PARALL INTERFACE

↑

PARALL INTERFACE

↓

SERIAL INTERFACE

or

LAN INTERFACE

1284 BIDIR. I/F

CX. PARALLEL I/F

→

CX. PARALLEL I/F

SELECT-IN HOST

↑

1284 BIDIR. I/F

↓

Bidirectional IEEE 1284 parallel interface.

Centronics type parallel interface (monodirectional).

→

→

or ←

or ←

Setting the Select-In Signal

1284 BIDIR . I/F

↑

SELECT-IN HOST

SELECT-IN ON

↓

DATA BITS 8

→ or ←

→ or ←

SELECT-IN HOST

SELECT-IN ON

The printer checks the SELECT-IN signal coming from the host.

The SELECT-IN signal of the parallel interface is ignored and treated always

as ON.

45

Page 51

Number of Data Bits

SELECT-IN HOST

→

→

or ←

or ←

↑

DATA BITS 8

DATA BITS 7

↓

INP. BUFFER 2K

Selection of the number of data bits: 7 or 8

Input Buffer Size

DATA BITS 8

→

→

→

→

→

→

or ←

or ←

or ←

or ←

or ←

or ←

↑

INP. BUFFER 256

INP. BUFFER 2K

INP. BUFFER 12K

INP. BUFFER 32K

INP. BUFFER 64K

INP. BUFFER 128K

↓

PARALL. INTERFACE

Selects the input buffer size.

46

Page 52

Serial Interface

y

y

The following Serial interface functions will display only if the Serial I/F board is installed in the

printer.

This setup defines the use of the serial interface and is structured according to the interface

specific parameters.

Serial Interface Parameters

Serial Interface

Functions

Serial I/F No

Baud 9600

Data Bits 8

Parit

None

Handshake DTR

Connection Local

Input Buffer 2K

Serial I/F ...

Baud ...

Data Bits 7

Parit

...

Handshake Xon/Xof

Connect. R em ote

Input Buffer ...

47

Page 53

Setting the Serial Interface Parameters

Interface Type

PARALL INTERFACE

↑

SERIAL INTERFACE

↓

FUNCTIONS

BAUD 9600

→

SERIAL I/F 232

SERIAL I/F 422

SERIAL INTERFACE

↑

SERIAL I/F NO

↓

SERIAL I/F NO

SERIAL I/F 232

SERIAL I/F 422

The serial interface is disabled.

Defines the usage of the serial interface RS-232/C.

Defines the usage of the serial interface RS-422/A.

→ or ←

→ or ←

→ or ←

48

Page 54

Baud Rate

SERIAL I/F NO

↑

BAUD 300

BAUD 600

BAUD 1200

BAUD 2400

BAUD 4800

BAUD 9600

BAUD 19200

BAUD 38400

↓

DATA BITS 8

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

The baud rate is selected in bits per second. The above values can be selected.

Number of Data Bits

BAUD 9600

↑

DATA BITS 8

DATA BITS 7

↓

PARITY NONE

→ or ←

→ or ←

Selection of the number of data bits: 7 or 8.

49

Page 55

Parity Check

DATA BITS 8

↑

PARITY NONE

PARITY ODD

PARITY EVEN

PARITY MARK

PARITY SPACE

↓

HANDSHAKE DTR

PARITY NONE

PARITY ODD

PARITY EVEN

PARITY MARK

PARITY SPACE

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

Data does not have a parity bit, i.e. 8 bit data are transferred and the parity

check is disabled.

Parity check is enabled for odd parity.

Parity check is enabled for even parity.

Parity check is disabled and the transmitted parity bit is always a Mark.

Parity check is disabled and the tr ansmitted p arity bit is always a Sp ace.

50

Page 56

Handshake Protocol

PARITY NONE

↑

HANDSHAKE DTR

HANDSHAKE XONXOF

↓

CONNECTION LOCAL

→ or ←

→ or ←

HANDSHAKE DTR

HANDSHAKE XONXOF

Connection Type

HANDSHAKE DTR

↑

CONNECTION LOCAL

CONNECT. REMOTE

↓

INP. BUFFER 2K

The Handshake is performed using the DTR Protocol.

The Handshake is performed using the XON-XOFF Protocol.

→ or ←

→ or ←

Selects the connection type: local or remote.

51

Page 57

Input Buffer Size

CONNECTION LOCAL

→

→

→

→

→

→

or ←

or ←

or ←

or ←

←

or

or ←

↑

INP. BUFFER256

INP. BUFFER 2K

INP. BUFFER12K

INP. BUFFER32K

INP. BUFFER64K

INP. BUFFER128K

↓

SERIAL INTERFACE

Selects the input buffer size.

52

Page 58

LAN Interface

The following LAN interface functions will display only if the Ethernet 10/100 Mbit interface board

option is installed in the printer.

This setup defines the use of the LAN interface and is structured according to the interface specific

parameters.

LAN Interface Parameters

LAN Interface

Functions

IP Assign Fixed

Init IP A dd re ss …

SMTP Enabl. No

No v ell E n. N o

IP A s sig n …

Init IP A dd re ss …

SMTP Enabl.Yes

No v ell E n. Yes

53

Page 59

IP Assignment

PARALL INTERFACE

↑

LAN INTERFACE

↓

FUNCTIONS

INIT IP ADDRESS 127.000.000.000

→

LAN INTERFACE

↑

IP ASSIGN FIXED

IP ASSIGN DHCP

IP ASSIGN ARP

↓

IP ASSIGN FIXED

IP ASSIGN DHCP

IP ASSIGN ARP

Init IP Address

IP ASSIGN FIXED

INIT IP ADDRESS 000.000.000.000

INIT IP ADDRESS …

INIT IP ADDRESS 255.255.255.255

Assigns the static or fixed IP address.

Assigns the dynamic IP address (DHCP protocol).

Assigns the user’ s defined IP address (ARP protocol).

→ or ←

→

or ←

→ or ←

→ or ←

→ or ←

→ or ←

↓

INIT NET MASK 255.255.254.000

These values set the INIT IP address. The IP address is represented by a decimal notation where the

decimal values are divided by points in four fields. Each field ranges between 0 and 255. Use the ←

or → keys to increase or decrease the values in one field and the

(p to move to the right and n to move to the left). The default value is

54

p or n keys to move to the next field

127.000.000.000

.

Page 60

Init Net Mask

INIT IP ADDRESS 127. 000.000.000

↑

INIT NET MASK 000.000.000.000

INIT NET MASK …

INIT NET MASK 255.255.255.255

→ or ←

→

or ←

→ or ←

↓

DEF. GATEWAY ID 000.000.000.000

These values set the INIT net mask number. This number is represented by a decimal notation

where the decimal values are div ided by points in four fields. Each field ranges betw een 0 and

255. Use the ← or → keys to increase or decrease the values in one field and the p or nkeys to move

to the next field (p to move to the right and n to move to the left). The default value is

255.255.254.000

.

ID Default Gateway

INIT NET MASK 255.255.254.000

↑

DEF. GATEWAY ID

DEF. GATEWAY ID …

DEF. GATEWAY ID 255.255.255.255

↓

INIT HOST NAME CPG_xxxxxx

000.000.000.000

→ or ←

→

or ←

→ or ←

These values set the ID default gateway number. This number is represented b y a decimal notation

where the decimal values are divided by points in four fields. Each field ranges between 0 and 255.

Use the ← or → keys to increase or decrease the values in one field and the p or nkeys to move to

the next field (p to move to the right and n to move to the left).

55

Page 61

Init Host Name

DEF. GATEWAY ID 000.000.000.000

↑

INIT HOST NAME ……………

PROGRAM

↓

INIT WORKGROUP CPG_GROUP

key

→ or ←

The host is identified by a name. This function allows to create the name of the init host using a 15character string. Use the ← or → keys to increase or decrease the values in one field and the p or

keys to move to the next field (p to move to the right and n to move to the left). Press the

n

PROGRAM

key to save the selected init host name. The default name is

Init Workgroup Name

INIT HOST NAME CPG_xxxxxx

↑

INIT WORKGROUP ……………

PROGRAM

↓

key

CPG_xxxxxx

→ or ←

.

SMTP ENABL. NO

The workgroup is identified by a name. This function allows to create the name of the workgroup

using a 15-character string. Use the ← or → keys to increase or decrease the values in one field and

the p or nkeys to move to the next field (p to move to the right and n to move to the left). Press the

PROGRAM

key to save the selected init workgroup name. The default name is

CPG_GROUP

.

56

Page 62

Enable/Disable the SMTP Service

INIT WORKGROUP CPG_GROUP

↑

SMTP ENABL. NO

↓

NOVELL EN. NO MAIL SERV.ADDRES 000.000.000.000

→ or ←

SMTP ENABL. YES

↓

SMTP ENABL. NO

Disables the SMTP (Simple Mail Transfer Protocol) service, that is disables

the reception/transfer/error service of the e-mail.

SMTP ENABL. YES

Enables the SMTP (Simple Mail Transfer Protocol) service, that is enables

the reception/transfer/error service of the e-mail.

Mail Server Address

This item is displayed only if the

SMTP ENABL. YES

↑

MAIL SERV.ADDRES

MAIL SERV.ADDRES …

MAIL SERV.ADDRES 255.255.255.255

000.000.000.000

→ or ←

→

or ←

→ or ←

SMTP ENABL

function is selected in

.

YES.

↓

EMAIL ADDRESS 000.000.000.000

These values set the mail server address. This number is represented by a decimal notation where the

decimal values are divided by points in fo ur fields. Eac h field ranges between 0 and 255. Us e the ← or

keys to increase or decrease the values in one field and the p or nkeys to move to the next field (p to

→

move to the right and n to move to the left).

57

Page 63

E-mail Address

This item is displayed only if the

MAIL SERV.ADDRES 000.000.000.000

↑

EMAIL ADDRESS xxxxxxxxxxx

↓

SENDER ADDRESS xxxxxxxxxxx

→

or ←

SMTP ENABL

function is selected

.

YES.

This function allows to write the e-mail address where you can notify the failures. Use the ← or →

keys to increase or decrease the values in one field and the p or nkeys to move to the next field (p to

move to the right and n to move to the left). Press the

Sender Address

This item is displayed only if the

EMAIL ADDRESS xxxxxxxxxxx

↑

SENDER ADDRESS xxxxxxxxxxx

↓

→

or ←

SMTP ENABL

PROGRAM

key to save the e-mail address.

function is selected

.

YES.

SMTP ENABL. YES

This function identifies the address of the sender’s e-mail using a string of characters. Use the ← or

keys to increase or decrease the values in one field and the p or nkeys to move to the next field (p

→

to move to the right and n to move to the left). Press the

PROGRAM

key to save the sender’s e-mail

address.

58

Page 64

Enable/Disable the Novell Service

SMTP ENABL. NO

↑

NOVELL EN. NO

↓

IP ASSIGN FIXED

→ or ←

NOVELL EN. NO

NOVELL EN. YES

Print Server Name in Novell Network

Disables the service to see the printer via NOVELL network.

Enables the service to see the printer via NOVELL network.

This item is displayed only if the

NOVELL EN. YES

↑

NOV. SERVER NAME ………..

↓

NOV. PRINTER NAME xxxxxxxxxxx

→

o ←

NOVELL EN. YES

↓

NOV. SERVER NAME xxxxxxxxxxx

NOVELL EN.

function is selected

YES.

This function allows to create the print server name in Novell network. Use the ← or → keys to

increase or decrease the values in one field and the p or nkeys to move to the next field (p to move

to the right and n to move to the left). Press the

default print server name is

NW_COMPUPRINT

.

PROGRAM

key to save the print server name. The

59

Page 65

Printer Name in Novell Network

This item is displayed only if the

NOV. SERVER NAME xxxxxxxxxxx

↑

NOV. PRINTER NAME ……………

↓

NOV. QUEUE NAME xxxxxxxxxxx

→ or ←

NOVELL EN.

function is selected

YES.

This function allows to create the printer name in Novell network. Use the ← or → keys to increase

or decrease the values in one field and the p or nkeys to move to the next field (p to move to the

right and n to move to the left). Press the

printer name is

Queue Name in Novell Network

PS1.

This item is displayed only if the

NOV. PRINTER NAME xxxxxxxxxxx

↑

NOV. QUEUE NAME …………..

→ or ←

PROGRAM

NOVELL EN.

key to save the printer name. The default

function is selected

YES.

↓

NOV.FRAME TYPE xxxxxxxxxxx

This function allows to create the print queue name in Novell network. Use the ← or → keys to

increase or decrease the values in one field and the p or nkeys to move to the next field (p to move

to the right and n to move to the left). Press the

default printer name is

Q1.

PROGRAM

60

key to save the print queue name. The

Page 66

Frame Type in Novell Network

This item is displayed only if the

NOV. QUEUE NAME xxxxxxxxxxx

↑

NOV.FRAME TYPE 0

NOV. FRAME TYPE …

NOV. FRAME TYPE 30

↓

NOVELL EN YES

→

→

→

or ←

or ←

or ←

NOVELL EN.

function is selected

YES.

These values select the frame type number in Novell network. This number ranges between 0 and

30. The default frame type number is

0.

61

Page 67

Functions

(*)

(*)

(**)

(**)

This item groups various printer functions, with which you can configure the printer.

PRT9070 Model

Functions

Buzzer Yes

Sequence None

Paper Overly No

Quick Yes

Ribbon Black

Bar Code 60

Text Direct Bi

Graph Direct Bi

Barcodes Dir. Uni

Graph H.S No

P.O n P a t h M a c ro

Menu English

F1 Jam Sens. Y

Tear Adjust 0

Buzzer No

Sequence …

Paper Overly Yes

Quick No

Ribbon Color

Bar Code 90

Text Direct Uni

Graph Direct Uni

Barcodes Dir. Bi

Graph H.S Yes

P.O n P a t h La s t

Menu …

F1 Jam Sens. N

Tear Adjust …

Cut Adjust 0

This item is displayed only if the 6 pin Front1 push tractor option is installed.

Th is item is displa y ed o nly if the c utter op tion is in sta lled .

62

Cut Adjust …

Page 68

PRT9071 Model

q

q

j

j

j

j

(*)

(*)

(**)

(**)

(

)

(

)

Functions

Buzzer Yes

Se

uence None

Ribbon Black

Bar Code 60

Text Direct Bi

Graph Direct Bi

Barcodes Dir. Uni

Graph H.S No

P. O n P at h M a cr o

Menu ENGLISH

F1 Jam Se ns. Y

F2 Jam Se ns. Y F2 Jam Se n s. N

Buzzer No

Se

uence …

Ribbon Color

Bar Code 90

Text Direct Uni

Graph Direct Uni

Barcodes Dir. Bi

Graph H.S Yes

P.On Path Last

Menu …

F1 Jam Sens. N

ust ....

Tear A d

ust 0

Cut Ad

ust 0

This item is displayed only if the 6 pin Front1 push tractor option is installed.

This item is displayed only if the 6 pin Front2 push tractor option is installed.

***

This item is displayed only if the C utter option is installed.

Tear A d

Cut Ad

ust …

***

63

Page 69

Setting the Functions Group Items

Enable/Disable the Buzzer

SERIAL INTERFACE

or

LAN INTERFACE FUNCTIONS

↑

FUNCTIONS

↓

RETURN TO MFG: NO

SEQUENCE NONE

→

BUZZER NO

↑

BUZZER YES

↓

→

→

Enable or disables the buzzer.

or ←

or ←

64

Page 70

Paper Loading Sequence

BUZZER YES

→ or ←

→ or ←

→

or ←

→ or ←

PRT9071

↑

SEQUENCE NONE

SEQ. F1+F2 PUSH

SEQUENCE ASF 1+2

SEQUENCE ASF 123

↓

PAPER OVERLY NO PRT9070

or

RIBBON BLACK

(PRT9071 model)

TThheessee iitteemmss aarree ddiissppllaayyeedd oonnllyy iiff tthhee aacccceessssoorriieess ttoo wwhhiicchh tthheeyy rreeffeerr aarree iinnssttaalllleedd..

SEQUENCE NONE

SEQ. F1+F2 PUSH

The paper is fed only through the path selected by operator panel.

The paper is fed firstly with the Front1 push tractor and successively

through the Front2 push tractor option (PRT9071 model only).

SEQUENCE ASF 1+2

The paper is fed from the first bin of the ASF option until this bin is out

of paper. Then the paper is fed from the second bin

SEQUENCE ASF123

The paper is fed from the first bin of the ASF option until this bin is out

of paper. Then the paper i s fed from the second bin and finally from the

third bin.

65

Page 71

Paper Overlapping (only PRT9070 model)

SEQUENCE NONE

↑

PAPER OVERLY NO

PAPER OVERLY YES

↓

QUICK NO

(PRT9070 only)

PAPER OVERLY NO

→ or ←

→ or ←

When feeding a cut sheet through the manual entry slot, the fanfold

paper must be parked.

PAPER OVERLY YES

A cut sheet can be fed simultaneously with fanfold.

If the printer is using the Push Pull paper feed mode, the Overlay Function cannot be selected.

Only the

Quick Manual Loading through the Manual Slot (only PRT9070 model)

PAPER OVERLY NO

↑

QUICK NO

QUICK YES

(PRT9070 only)

→ or ←

→ or ←

Paper Overly No

item appears.

↓

RIBBON BLACK

QUICK NO

QUICK YES

The cut sheet in the manual path is loaded by the operator. The printer is

then disabled.

The cut sheet in the manual path is loaded automatically. The printer

is then enabled.

66

Page 72

Ribbon Type Selection

QUICK YES

or

SEQUENCE NONE

↑

RIBBON BLACK

RIBBON COLOR

↓

BAR CODE 60DPI

(PRT9070 model)

(PRT9071 model)

→ or ←

→ or ←

Selects the ribbon type to be used with the printer: black or color.

Bar Code Density

RIBBON BLACK

↑

BAR CODE 60DPI

BAR CODE 90DPI

↓

→ or ←

→ or ←

TEXT DIRECT BI

Selects the bar code print density: 60 or 90 dpi.

67

Page 73

Text Print Direction

BAR CODE 60DPI

↑

TEXT DIRECT BI

TEXT DIRECT UNI

↓

GRAPH DIRECT BI

→ or ←

→ or ←

Selects the print direction for text: bidirectional or unidirectional.

Graphics Print Direction

→ or ←

→ or ←

TEXT DIRECT BI

↑

GRAPH DIRECT BI

GRAPH DIRECT UNI

↓

BARCODES DIR.UNI

Selects the print direction for graphics: bidirectional or unidirectional.

68

Page 74

Bar Codes Print Direction

GRAPH DIRECT BI

↑

BARCODES DIR. BI

BARCODES DIR. UNI

↓

GRAPH H.S. YES

→ or ←

→ or ←

Selects the print direction for bar codes: bi directional or unidireccional.

Graphics Printing Speed Selection

BARCODES DIR. UNI

↑

GRAPH H.S. NO

GRAPH H.S. YES

↓

P. ON PATH MACRO

→ or ←

→ or ←

GRAPH H.S NO

GRAPH H.S YES

Selects graphics printing (bit image data) at normal speed.

Selects graphics printing (bit image data) at high speed.

69

Page 75

Paper Path at Power-On

GRAPH H.S. YES

↑

P. ON PATH MACRO

P. ON PATH LAST

↓

MENU ENGLISH

P. ON PATH MACRO

P. ON PATH LAST

→ or ←

→ or ←

The paper path at power-on is the one from the default Macro.

The paper path at power-on is the last one that was selected before the printer

was powered off.

Selection of the Language of the Display Messages

P. ON PATH MACRO

↑

MENU ENGLISH

MENU ITALIANO

MENU FRANCAIS

→ or ←

→ or ←

→ or ←

MENU ESPANOL

MENUE DEUTSCH

↓

F1 JAM SENS. Y

→ or ←

→ or ←

These items are self explaining.

See also “Selecting the Display Language” before in this manual.

70

Page 76

Enable/Disable Front1 Tractor Jam Sensor

This item is displayed only if the 6 pin Front1 Push Tractor option is installed.

MENU ENGLISH

↑

F1 JAM SENS. Y

F1 JAM SENS. N

↓

F2 JAM SENS. Y (PRT9071 model)

or

TEAR ADJUST:xxx

→

or ←

→ or ←

F1 JAM SENS. Y

F1 JAM SENS. N

Enables the paper jam sensor located in the 6 pin Front1 push tractor option.

Disables the paper jam sensor located in the 6 pin Front1 push tractor option.

When the cutter option is used, the jam sensor should be enabled for higher cut precision.

71

Page 77

Enable/Disable Front2 Tractor Jam Sensor (only PRT9071 model)

This item is displayed only if the 6 pin Front2 push tractor option is installed.

F1 JAM SENS. Y

↑

F2 JAM SENS. Y

F2 JAM SENS. N

↓

TEAR ADJUST:xxx

→

or ←

→ or ←

F2 JAM SENS. Y

F2 JAM SENS. N

Enables the paper jam sensor located in the 6 pin Front2 push tractor option.

Disables the paper jam sensor located in the 6 pin Front2 push tractor option.

When the cutter option is used, the jam sensor should be enabled for higher cut precision.

72

Page 78

Adjusting the Tear-Off Position

F2 JAM SENS. Y

or

(PRT9071 model)

F1 JAM SENS. Y (if 6 pin Front1 Push Tractor is installed)

or

MENU ENGLISH

↑

TEAR ADJUST: - 30

TEAR ADJUST: ...

TEAR ADJUST: +360

↓

CUT ADJUST (if the cutter option is installed)

→ or ←

→ or ←

→ or ←

or

BUZZER YES

TEAR ADJUST: xxxx

These values adjust the distance between the Tear-Off Perforation and

the Tear-Off Bar. The values corresp ond to 1/180 inch units, i.e. the

tuning ranges between -1/6 and 2 inch. 0 is the default value.

See also “How to Use the Tear-Off Function”, later in this Chapter.

73

Page 79

Adjusting the Cut Position

This item is displayed only if Cutter option is installed.

TEAR ADJUST: xxx

↑

CUT ADJUST: - 30

CUT ADJUST: ...

CUT ADJUST: +360

↓

BUZZER YES

CUT ADJUST: xxxx

→ or ←

→ or ←

→ or ←

These values adjust the position in which the paper is cut. The values

correspond to 1/180 inch units, i.e. the tuning ranges between -1/6 and 2 inch.

is the default value.

0

74

Page 80

Resetting to Factory Default Values

With the BACK TO MFG function it is possible to reset all items in the Power On Configuration Setup

and in the Program Setup to their factory default values. This may be useful if you do not remember

the values you set in the setups, or because you simply changed you mind about the settings you

have just done. The default values for the setup items are indicated in bold.

FUNCTIONS

↑

BACK TO MFG: NO

↓

or

PROG

PRINT OUT ?

→

or

BACK TO MFG: YES

←

If you want to select BACK TO MFG:YES, you have to exit from this item using the ↑ or the ↓ key, in

order to confirm the selec tion of this value.

At this point, the Power On Configuration Setup procedure i s fini shed. If y ou exi t pressi ng the ↓ and

PROGRAM

the

key, the new settings will be saved.

Do not power off the printer before all data have been written into the NVM and the printer has

returned online.

75

Page 81

PPrrooggrraamm SSeettuupp

The default values of the various functions are indicated in bold.

EEnntteerriinngg tthhee PPrrooggrraamm SSeettuupp

Press the

following message will be displayed:

The figure in the following page shows the structure and how to move inside the Program Setup.

PROGRAM

key when the printer is turned on and is offline or online without printing. The

PRINT OUT? NO

76

Page 82

Main Structure

g

g

Print out? No

User Macro

. Me nu No

Confi

Hex Dump No

Print out? Yes

Macro # 1

Line sp. 6 lpi

...

MACRO PARAMETER BLOCK

Next Macro? No

Confi

. Me nu Yes

Hex Dump Yes

Line sp. ...

Next Macro? Yes

…

Macro # 4

Parall. Interface

Serial Interface or LAN Interface

CONFIGURATION MENU BLOCK

The items define the following parameters:

• Four user macros

• The direct access to the Power-On Configuration

• Hexadecimal printout

77

Page 83

Printout of the Printer Settings

PRINT OUT? NO

USER MACRO

→

or ←

↓

PRINT OUT? YES

PRINT OUT? NO

PRINT OUT? YES

The setup is not printed.

The printer setup is printed. The printout starts as soon as you select this value.

NOTE: The Program setup printout indicates:

• the currently selected values,

• the current selected macro is marked with the #x# symbols (USER MACRO #x#),

• the current firmware release.

78

Page 84

User Macro

The USER MACRO item allows to prepare four printing environments (

MACRO#3

and

MACRO#4

). Each macro is composed of a group of parameters which define a

MACRO#1, MACRO#2

configuration that can then be recalled to easily set the printer for four printing environments.

Selection of the User Macro

PRINT OUT? NO USER MACRO

↓

USER MACRO

↓

CONFIG MENU NO MACRO#3

MACRO#4

→

MACRO#2

↑

MACRO#1

↓

LINE SP. 6 LPI

→

→

→

→

or

or

or

or

←

←

←

←

Selection of the macro for which you intend to set the parameters.

WWhheenn aa nneeww mmaaccrroo iiss sseelleecctteedd aanndd tthhee ffaannffoolldd ppaappeerr iiss pprreesseenntt iinn tthhee ppaappeerr ppaatthh sseett iinn tthhee

pprreevviioouuss mmaaccrroo,, iitt wwiillll bbee aauuttoommaattiiccaallllyy ppaarrkkeedd (

TTeeaarr ooffff tthhiiss ffaannffoolldd ppaappeerr aanndd pprreessss PPAARRKK kkeeyy..

(

TTEEAARR IIFF NNEECCEESSSS//PPAARRKK PPAAPPEER

R

iiss ddiissppllaayyeedd))..

,

79

Page 85

User Macro Parameters

g

y

g

g

g

g

User macro

M acro #1 M a cro # 2

Line sp. 6 lpi

Line Sp. Lock No

Len

th 66 Lines

Top of Form 0

Ign o re F.F. N o

Skipover 0

Draft Mode Norm

Qualit

LQ

Font Draft

Pitch 10 cpi

Macro #3 Macro #4

Lin e sp. ...

Line Sp. Lock Yes

th ...

Len

Top of Form …

nore F.F. Yes

I

Skipover …

Draft Mode Best

Quality NLQ

Font …

Pitch …

15&24 cpi Micro 15&24 cpi Normal

Pitch Lock No

Left Mar

in 0

Pitch Lock Yes

Left Mar

in …

80

Page 86

g

g

g

g

y

g

g

g

g

Right Margin 136 Right Margin …

Slash Zero No

Path Front 1

Tear Normal

Tear Dela

Stron

Perfor. Safe N o

Quiet P rint Off

Auto

Tunin

Tunin

Macro-> MFG No

1

Impact

ap 0

: Horiz 0

: Vert 0

Slash Zero Yes

h

Pat …

Tear …

Tear Delay …

Soft Impact

Perfor. Safe Yes

Quiet P rint On

Auto

ap ...

Tunin

: Horiz ...

: Vert ...

Tunin

Macro-> MFG Yes

Enable Cutter

VT:FF + Cut

Confi

Next Macro? No

. Menu No

Next Macro? Yes

81

Page 87

Line Spacing

MACRO#1

MACRO#1

→

LINE SP. 8 LPI

LINE SP. 12 LPI

↑

LINE SP. 6 LPI

LINE SP. 3L/30MM

LINE SP. 4L/30MM

LINE SP. 6L/30MM

LINE SP. 8L/30MM

LINE SP.12L/30MM

↓

LINE SP. LOCK NO

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

These values define the line spacing in lines/inch (6, 8, 12) or in lines per 30 mm (3, 4, 6, 8, 12).

Line Spacing Lock

LINE SP. 6 LPI

↑

LINE SP. LOCK NO

LINE SP. LOCK YES

↓

LENGTH xxx

→

←

or

→

←

or

LINE SP. LOCK NO

LINE SP. LOCK YES

Setting this item, the value set for vertical spacing can be changed by software

or operator panel

Setting this item, the value set for vertical spacing cannot be changed by

software but only by operator panel.

82

Page 88

Page Length

LINE SP. LOCK NO

↑

LENGTH 1 LINE

LENGTH ... LINES

LENGTH 244 LINES

LENGTH A5

LENGTH A4

LENGTH A3

LENGTH A2

LENGTH LEGAL

LENGTH LETTER

↓

TOP OF FORM 0

→ or ←

→

or ←

→

or ←

→

or ←

→

or ←

→

or ←

→

or ←

→

or ←

→ or ←

These items set the page length for fanfold paper in number of lines depending on the current

vertical spacing. For the cut sheets the page format can be specified in number of lines or the

standard formats LETTER, LEGAL, A2, A3, A4, A5. Default value is

66 lines

.

83

Page 89

Top of Form

LENGTH xx

↑

TOP OF FORM 0

TOP OF FORM …

TOP OF FORM xxx

↓

IGNORE F.F. NO

→ or ←

→ or ←

→ or ←

These items set the top of form. The values range between 0 and the page length - 1.

Form Feed (FF) Command

TOP OF FORM 0

↑

IGNORE F.F. NO

IGNORE F.F. YES

↓

SKIPOVER 0

→ or ←

→ or ←

IGNORE F.F. NO

IGNORE F.F. YES

The Form Feed (FF) command is always executed.

The Form Feed (FF) command is ignored when the paper is in the top of form

(TOF) position. A

Form Feed can be performed if the

LOAD/FF

key is pressed.

84

Page 90

Skip Over Perforation

IGNORE F.F. NO

↑

SKIPOVER 0

SKIPOVER …

SKIPOVER xxx

↓

DRAFT MODE NORM

→ or ←

→ or ←

→ or ←

These items set the skipover perforation. The values range between 0 and the page length - 1.

Draft Print Mode Selection

SKIPOVER 0

↑

DRAFT MODE NORM

DRAFT MODE BEST

↓

QUALITY LQ

→ or ←

→ or ←

DRAFT MODE NORM

DRAFT MODE BEST

The printer performs the draft printing at normal speed.

The printer performs the draft printing at low speed to obtain better quality

printing.

85

Page 91

Quality Print Mode Selection

DRAFT MODE NORM

↑

QUALITY LQ

QUALITY NLQ

↓

FONT Draft

QUALITY LQ

QUALITY NLQ

Font Selection

QUALITY LQ

↑

FONT Draft

FONT Courier

FONT OCR-B

FONT Gothic

FONT Prestige

→ or ←

→ or ←

The printer performs the Letter Quality printing.

The printer performs the Near Letter Quality printing.

→ or ←

→ or ←

→ or ←

→ or ←

→ or ←

FONT Present

FONT OCR-A

FONT Script

↓

PITCH 10 CPI

→ or ←

→ or ←

→ or ←