Page 1

ProLiant ML370

Maintenance and Service Guide

Fourth Edition (June 2000)

Part Number 143091-004

Spare Part Number 158549-001

Compaq Computer Corporation

Page 2

Notice

The information in this publication is subject to change without notice.

COMPAQ COMPUTER CORPORATION SHALL NOT BE LIABLE FOR TECHNICAL OR

EDITORIAL ERRORS OR OMISSIONS CONTAINED HEREIN, NOR FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE, OR USE

OF THIS MATERIAL. THIS INFORMATION IS PROVIDED “AS IS” AND COMPAQ COMPUTER

CORPORATION DISCLAIMS ANY WARRANTIES, EXPRESS, IMPLIED OR STATUTORY AND

EXPRESSLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR

PARTICULAR PURPOSE, GOOD TITLE AND AGAINST INFRINGEMENT.

This publication contains information protected by copyright. No part of this publication may be

photocopied or reproduced in any form without prior written consent from Compaq Computer Corporation.

© 2000 Compaq Computer Corporation.

All rights reserved. Printed in the U.S.A.

The software described in this guide is furnished under a license agreement or nondisclosure agreement.

The software may be used or copied only in accordance with the terms of the agreement.

Compaq, Deskpro, Fastart, Compaq Insight Manager, Systempro, Systempro/LT, ProLiant, ROMPaq,

QVision, SmartStart, NetFlex, QuickFind, PaqFax, ProSignia, registered United States Patent and

Trademark Office.

Neoserver, Netelligent, Systempro/XL, SoftPaq, QuickBlank, QuickLock are trademarks and/or service

marks of Compaq Computer Corporation.

Microsoft, MS-DOS, Windows, and Windows NT are registered trademarks of Microsoft Corporation.

Pentium is a registered trademark and Xeon is a trademark of Intel Corporation.

Other product names mentioned herein may be trademarks and/or registered trademarks of their respective

companies.

Compaq ProLiant ML370 Maintenance and Service Guide

Maintenance and Service Guide

Fourth Edition (June 2000)

Part Number 143091-004

Spare Part Number 158549-001

Page 3

About This Guide

Symbols in Text.........................................................................................................vii

Compaq Technician Notes .......................................................................................viii

Where to Go for Additional Help.............................................................................viii

Integrated Management Display..........................................................................ix

Telephone Numbers ............................................................................................ix

Chapter 1

Illustrated Parts Catalog

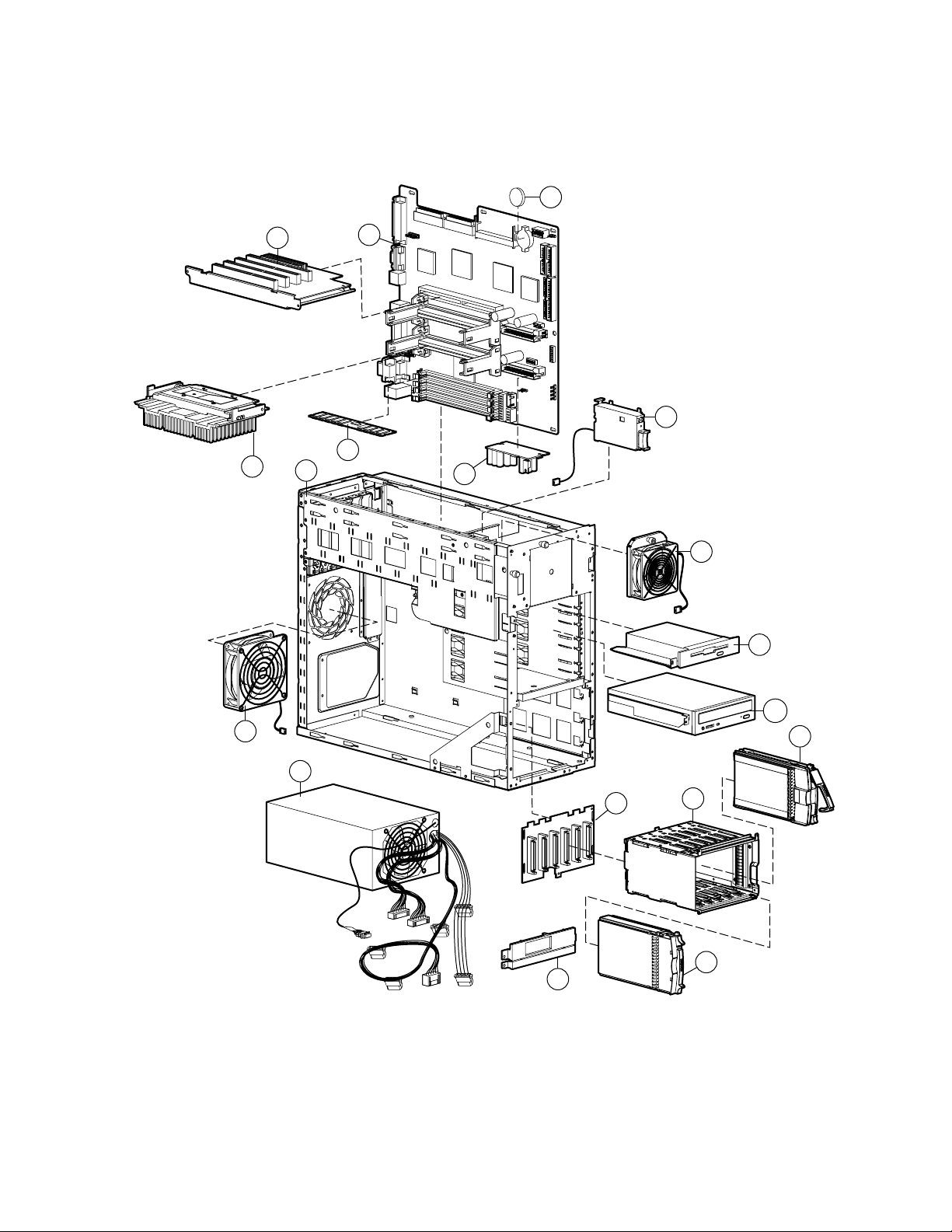

Mechanical Parts Exploded View.............................................................................1-2

Mechanical Spare Parts List ..................................................................................... 1-3

System Components Exploded View ....................................................................... 1-4

System Components Spare Parts..............................................................................1-5

Chapter 2

Removal and Replacement Procedures

Electrostatic Discharge Information.........................................................................2-2

Symbols in Equipment .............................................................................................2-2

Preparation Procedures.............................................................................................2-3

Powering Down the Server................................................................................2-3

Rack Warnings ......................................................................................................... 2-4

Server Warnings and Precautions.............................................................................2-5

Front Bezel ...............................................................................................................2-6

Rack Front Plate ....................................................................................................... 2-7

Feet...........................................................................................................................2-8

Large Access Panel...................................................................................................2-9

Small Access Panel.................................................................................................2-10

Right Side Panel .....................................................................................................2-11

Drives and Related Components ............................................................................2-12

Cable Routing Diagrams ........................................................................................2-13

IDE CD-ROM Drive Cable Diagram..............................................................2-13

Diskette Drive Cable Diagram ........................................................................2-13

SCSI Cable Diagram .......................................................................................2-14

Hot-Plug Drive Cage ..............................................................................................2-15

IDE CD-ROM Drive ..............................................................................................2-16

Diskette Drive.........................................................................................................2-17

Hard Drive Blank ...................................................................................................2-18

Hot-Plug SCSI Hard Drive.....................................................................................2-19

Removable Media Drive Bay Blank.......................................................................2-20

CPU Fan .................................................................................................................2-21

Contents

Page 4

iv Compaq ProLiant ML370 Maintenance and Service Guide

Removal and Replacement Procedures

continued

I/O Fan....................................................................................................................2-22

Power Switch with Cable and LED Indicators.......................................................2-23

Riser Board Expansion Slots..................................................................................2-25

I/O Expansion Slot Cover.......................................................................................2-26

I/O Expansion Board..............................................................................................2-27

Riser Board and Brace............................................................................................2-28

Processor ................................................................................................................2-29

Processor Power Module........................................................................................ 2-30

Memory .................................................................................................................. 2-31

Power Supply .........................................................................................................2-33

Hot-Plug SCSI Drive Backplane ............................................................................2-35

System Board .........................................................................................................2-36

Compaq Integrated Smart Array Controller Upgrade Module ...............................2-37

Internal Replacement Battery.................................................................................2-38

Chapter 3

Diagnostics and Troubleshooting

Diagnostic Tools Utility Overview...........................................................................3-2

Default Configuration...............................................................................................3-4

Default Configuration Messages.......................................................................3-4

Inspect Utility....................................................................................................3-4

Utilities Access.........................................................................................................3-5

Running Compaq Utilities.................................................................................3-5

Power-On Self-Test (POST).....................................................................................3-7

POST Error Messages ....................................................................................... 3-7

Diagnostics Software..............................................................................................3-26

Steps for Diagnostics.......................................................................................3-26

100-199, Primary Processor Test Error Codes ................................................3-27

200-299, Memory Test Error Codes................................................................3-28

300-399, Keyboard Test Error Codes..............................................................3-29

400-499, Parallel Printer Test Error Codes .....................................................3-29

500-599, Graphics Controller Unit Test Error Codes......................................3-30

600-699, Diskette Drive Test Error Codes......................................................3-31

1100-1199, Serial Test Error Codes................................................................3-31

1200-1299, Modem Communications Test Error Codes.................................3-32

6000-6099, Compaq NIC Boards Test Error Codes........................................3-32

6500-6599, SCSI Hard Drive Test Error Codes ..............................................3-33

6600-6699, SCSI/IDE CD-ROM Drive Test Error Codes ..............................3-33

6700-6799, SCSI Tape Drive Test Error Codes ..............................................3-34

8600-8699, Pointing Device Interface Test Error Codes.................................3-34

Array Diagnostic Utility (ADU)............................................................................. 3-35

Starting ADU...................................................................................................3-35

Integrated Management Log...................................................................................3-46

Multiple Ways of Viewing the Log.................................................................3-46

Event List ........................................................................................................3-48

Event Messages...............................................................................................3-48

Rapid Error Recovery.............................................................................................3-50

Automatic Server Recovery-2.........................................................................3-50

ASR-2 Integrated Management Log Messages...............................................3-60

Storage Fault Recovery Tracking.................................................................... 3-63

Storage Automatic Reconstruction..................................................................3-63

Network Interface Fault Recovery Tracking...................................................3-63

Memory Fault Recovery Tracking ..................................................................3-63

Page 5

Diagnostics and Troubleshooting

continued

Remote Service Features ........................................................................................ 3-64

ROMPaq Error Recovery Options..........................................................................3-64

ROMPaq Disaster Recovery ...........................................................................3-65

Compaq Insight Manager .......................................................................................3-67

Features of Compaq Insight Management.......................................................3-67

Compaq Insight Management Software Architecture .....................................3-68

Chapter 4

Connectors, Switches, and LED Indicators

Compaq ProLiant ML370 System Board Components ............................................4-2

Rear Panel Components ....................................................................................4-3

Switches ...................................................................................................................4-4

SW1 – System Identification Switch Settings...................................................4-5

SW2 – System Configuration Switch Settings..................................................4-5

LED Indicators .........................................................................................................4-6

Front Panel ........................................................................................................4-6

RJ-45 Connector................................................................................................4-7

System Board ....................................................................................................4-8

Riser Board........................................................................................................4-9

Contents v

Chapter 5

Physical and Operating Specifications

System Unit ..............................................................................................................5-2

Power Supply ...........................................................................................................5-3

Redundant Power Supply ......................................................................................... 5-4

Dual Inline Memory Modules (DIMM) ...................................................................5-5

1.44-MB Diskette Drive ...........................................................................................5-5

IDE CD-ROM Drive ................................................................................................5-6

Compaq Wide Ultra2 Hot-Plug SCSI Hard Drives ..................................................5-7

Integrated Dual Channel SCSI Controller................................................................5-8

Index

Page 6

Page 7

This maintenance and service guide is a troubleshooting guide that can be used for reference

when servicing Compaq ProLiant ML370 Servers.

IMPORTANT: The installation of options and servicing of this product shall be performed by individuals

who are knowledgeable of the procedures, precautions, and hazards associated with equipment

containing hazardous energy circuits.

Symbols in Text

These symbols may be found in the text of this guide. They have the following meanings.

About This Guide

WARNING: To reduce the risk of personal injury from electric shock and hazardous energy

levels, only authorized service technicians should attempt to repair this equipment. Improper

repairs could create conditions that are hazardous.

WARNING: Text set off in this manner indicates that failure to follow directions in the warning

could result in bodily harm or loss of life.

CAUTION: Text set off in this manner indicates that failure to follow directions could result in

damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents clarifying information or specific instructions.

NOTE: Text set off in this manner presents commentary, sidelights, or interesting points of information.

Page 8

viii Compaq ProLiant ML370 Maintenance and Service Guide

Compaq Technician Notes

WARNING: Only authorized technicians trained by Compaq should attempt to repair this

equipment. All troubleshooting and repair procedures are detailed to allow only

subassembly/module-level repair. Because of the complexity of the individual boards and

subassemblies, no one should attempt to make repairs at the component level or to make

modifications to any printed wiring board. Improper repairs can create a safety hazard.

WARNING: To reduce the risk of personal injury from electric shock and hazardous energy

levels, do not exceed the level of repair specified in these procedures. Because of the

complexity of the individual boards and subassemblies, do not attempt to make repairs at the

component level or to make modifications to any printed wiring board. Improper repairs could

create conditions that are hazardous.

WARNING: To reduce the risk of electric shock or damage to the equipment:

■ If the system has multiple power supplies, disconnect power from the system by

unplugging all power cords from the power supplies.

■ Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

■ Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at

all times.

CAUTION: To properly ventilate your system, you must provide at least 12 inches (30.5 cm) of

clearance at the front and back of the computer.

CAUTION: The computer is designed to be electrically grounded. To ensure proper operation,

plug the AC power cord into a properly grounded AC outlet only.

IMPORTANT: Any indications of component replacement or printed wiring board modifications may void

any warranty.

Where to Go for Additional Help

In addition to this guide, the following information sources are available:

■ User documentation

■ Online information at the Compaq website

http://www.compaq.com/support/servers/index.html

■ Compaq Service Quick Reference Guide

■ Service training guides

■ Compaq service advisories and bulletins

■ Compaq QuickFind

■ Compaq Insight Manager

■ Compaq download facility: Call 1-281-518-1418 using your modem.

Page 9

Integrated Management Display

Some Compaq server models include a Compaq Integrated Management Display (IMD), an

integrated, 16 × 4 character display mounted on the front of the server. This display provides

easy-to-use menu-driven access to server information, including model number, LCD firmware

revision, and POST operations.

Telephone Numbers

For the name of your nearest Compaq authorized reseller:

■ In the United States, call 1-800-345-1518.

■ In Canada, call 1-800-263-5868.

For Compaq technical support:

■ In the United States and Canada, call 1-800-386-2172.

■ For Compaq technical support phone numbers outside the United States and Canada, visit

the Compaq website at:

http://www.compaq.com

About This Guide ix

Page 10

Chapter

1

Illustrated Parts Catalog

This chapter provides the illustrated parts breakdown and a spare parts list for

Compaq ProLiant™ ML370 Servers. See Table 1-1 and Table 1-2 for the names of referenced

spare parts.

Page 11

1-2 Compaq ProLiant ML370 Maintenance and Service Guide

Mechanical Parts Exploded View

2

3

1

6

5

4

7

Figure 1- 1. Mechanical parts expl oded view

8

Page 12

Mechanical Spare Parts List

Item Description Spare Part Number

Chassis

1 Chassis 157986-001

2 Small access panel Part of kit 387762-001

3 Large access panel Part of kit 387762-001

4 Right side panel (tower model only) Part of kit 387762-001

5 Front bezel (tower model only) 217492-001

6 Rack front plate (rack-mountable model only) 163489-001

7 Feet (tower model only) 333575-001

8 Hot-plug drive cage, 6 x 1-inch 387089-001

9 1-Ghz processor spare 221536-001

Illustrated Parts Catalog 1-3

Table 1-1

Mechanical Spare Parts List

Page 13

1-4 Compaq ProLiant ML370 Maintenance and Service Guide

System Components Exploded View

12

14a

17

15

13

19

1

16

10

20

11

9

Figure 1-2. System components exploded view

27a

18

21a

22

8

26

Page 14

System Components Spare Parts

System Components Spare Parts List

Item Description Spare Part Number

System Components

9 Power supply, 325 W 402151-001

10 I/O fan, 92 mm 173907-001

11 CPU fan, 120 mm 326873-001

12 3V lithium battery 179322-001

13 Power switch with LED indicators and cable 157928-001

Boards

14 Processors

a) 6/600-MHz, with heat sink (heat sink may vary) 166146-001

b) 6/667-MHz, with heat sink (heat sink may vary)* 166109-001

c) 6/733-MHz, with heat sink * 166108-001

d) 6/800-MHz, with heat sink * 187781-001

e) 6/866-MHz, with heat sink * 187782-001

f) 6/933-MHz, with heat sink * 196628-001

Illustrated Parts Catalog 1-5

Table 1-2

15 System board 157824-001

16 Processor Power Module 157825-001

17 Riser board, with brace 157925-001

18 SCSI backplane board 163903-001

Memory

19 128-MB, 133-MHz, registered SDRAM dual inline memory module 159226-001

Mass Storage Devices

20 3-Mode, 1.44-MB diskette drive 179161-001

21 CD-ROM drives

a) 32x, IDE

b) 40x, IDE*

22 18-GB, 1-inch, 10K rpm, Wide Ultra2 hard drive 143920-001

Cables

23 Miscellaneous data cable kit * 386559-001

* Not shown

327659-001

179963-001

continued

Page 15

1-6 Compaq ProLiant ML370 Maintenance and Service Guide

Table 1-2

System Components Sp ar e Part s List

Item Description Spare Part Number

Cables

continued

24 Miscellaneous signal cable kit * 158530-001

a) Hard drive/CD-ROM drive data cable

b) Diskette drive cable assembly

c) 1-device SCSI cable assembly

d) 3-device SCSI cable assembly

25 Miscellaneous power cable kit * 158529-001

a) Diskette and CD-ROM drive power cable assembly

b) Power supply power cable assembly

c) Removable media bay power cable assembly

d) Signal power cable assembly

Miscellaneous

26 Hard drive blank 122759-001

continued

27 Miscellaneous plastics kit 140479-001

a) Removable media drive bay blank

28 Country kit * 158531-001

29 Maintenance and service guide * 158549-001

30 Illustrated parts map * 158550-001

31 Miscellaneous hardware kit * 281847-001

a) Slide rail, 22-inch, pair (rackmount model only)

32 Rack conversion kit * 163490-001

33 Keyboard * 386209-001

34 Baffle * 163364-001

Options

35 64-MB, 133-MHz, registered SDRAM dual inline memory module * 159225-001

36 256-MB, 133-MHz, registered SDRAM dual inline memory module * 159304-001

37 512-MB, 133-MHz, registered SDRAM dual inline memory module * 159227-001

38 1-GB, 133-MHz, registered SDRAM dual inline memory module * 163902-001

39 Integrated management display * 122223-001

40 18-GB, 1-inch, 7200 rpm, Wide Ultra2 hard drive * 104663-001

41 9.1-GB, 1-inch, 10K rpm Wide Ultra2 hard drive * 386536-001

* Not shown

continued

Page 16

Illustrated Parts Catalog 1-7

Table 1-2

System Components Spare Parts List

Item Description Spare Part Number

continued

Options

42 9.1-GB, 1-inch, 7200 rpm Wide Ultra2 hard drive * 104665-001

43 Compaq Integrated Smart Array Controller upgrade module * 158855-001

44 AC Power supply, 225-W, hot-plug redundant * 283623-001

45 DC Power supply, 225-W, hot-plug redundant * 333593-001

* Not shown

continued

Page 17

Chapter 2

Removal and Replacement Procedures

This chapter provides subassembly/module-level removal and replacement procedures for

Compaq ProLiant ML370 Servers. The ProLiant ML370 Server is available in tower and rack

models. The Compaq ProLiant ML370 Maintenance and Service Guide shows the tower model.

In most cases, the rack model removal and replacement procedures are slightly different from

the tower model procedures. After completing all necessary removal and replacement

procedures, run the diagnostics program to verify that all components operate properly.

To service Compaq ProLiant ML370 Servers, you might need the following:

■ Torx T-15 screwdriver

■ From the Compaq SmartStart and Support Software CD:

G System Configuration Utility

G Drive Array Advanced Diagnostics

G Diagnostics

Page 18

2-2 Compaq ProLiant ML370 Maintenance and Service Guide

Electrostatic Discharge Information

A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper

packaging and grounding techniques are necessary precautions to prevent damage. To prevent

electrostatic damage, observe the following precautions:

■ Transport products in static-safe containers such as conductive tubes, bags, or boxes.

■ Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

■ Cover work stations with approved static-dissipating material. Provide a wrist strap

connected to the work surface and properly grounded tools and equipment.

■ Keep work area free of nonconductive materials such as ordinary plastic assembly aids

and foam packing.

■ Make sure you are always properly grounded when touching a static-sensitive component

or assembly.

■ Avoid touching pins, leads, or circuitry.

■ Always place drives PCB assembly-side down.

■ Use conductive field service tools.

Symbols in Equipment

CLASS 1 LASER PRODUCT

WARNING: Any surface or area of the equipment marked with these symbols

indicates the presence of a hot surface or hot component. If this surface is

contacted, the potential for injury exists. To reduce the risk of injury from a hot

component, allow the surface to cool before touching it.

WARNING: Any surface or area of the equipment marked with these symbols

indicates the presence of electric shock hazards. The enclosed area contains no

operator serviceable parts. To reduce the risk of injury from electric shock

hazards, do not open this enclosure.

WARNING: Any RJ-45 receptacle marked with these symbols indicates a Network

Interface Connection. To reduce the risk of electric shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into this

receptacle.

WARNING: This label or equivalent is located on the surface of your CD-ROM

drive. This label indicates that the product is classified as a CLASS 1 LASER

PRODUCT.

Power supplies or systems marked with these symbols indicate the equipment is

supplied by multiple sources of power.

WARNING: To reduce the risk of injury from electric shock, remove all power

cords to completely disconnect power from the system.

Page 19

Weight in kg

Weight in lb

Preparation Procedures

Before beginning to remove any serviceable parts, determine whether the part is hot-pluggable

or non-hot-pluggable.

Hot-Pluggable Devices

Hot-pluggable devices in the ProLiant ML370 Servers include SCSI hard drives and power

supplies (with redundant power supply option kit).

IMPORTANT: It is not necessary to turn off the server to replace hot-plug devices when they are not in

active use.

Non-Hot-Pluggable Devices

Removal and Replacement Procedures 2-3

Any product or assembly marked with these symbols indicates that the

component exceeds the recommended weight for one individual to handle

safely.

If the part is non-hot-pluggable, the server must be powered down. Non-hot-pluggable parts

include the processors, all boards, DIMMs, fans, drive cages, and the standard power supply.

Powering Down the Server

System power in ProLiant ML370 Servers does not completely shut off with the front panel

Power On/Standby switch. The switch toggles between On and Standby, rather than On and Off.

The standby position removes power from most electronics and the drives, but portions of the

hot-plug power supply and some internal circuitry remain active. To completely remove all

power from the system, you must disconnect all power cords from the server.

WARNING: To reduce the risk of personal injury or damage to the equipment, ensure that only

one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARNING: Because the rack allows you to stack computer components on a vertical rather

than horizontal plane, you must take precautions to provide for rack stability and safety. It is

important that you follow these precautions to provide for rack stability and safety and to

protect both personnel and property. Heed all cautions and warnings throughout the installation

instructions that came with the server.

WARNING: To reduce the risk of injury from electric shock, remove all power

cords to completely disconnect power from the system.

Page 20

2-4 Compaq ProLiant ML370 Maintenance and Service Guide

WARNING: To reduce the risk of personal injury or damage to the equipment: If the server is

mounted in a rack, internal devices may not be accessible for removal and replacement. If the

server must be removed from the rack for device accessibility, remove the server from the rack

and place it on a sturdy table or workbench. Refer to the ProLiant ML370 Servers Setup and

Installation Guide for further information on working with racks.

CAUTION: The system power in the server does not completely shut off from the front Power

On/Standby switch. Moving the switch from On to Standby leaves some portions of the hot-plug

power supply and some internal circuitry active. Disconnect all power cords from the server to

remove all power from the system.

CAUTION: Electrostatic discharge can damage electronic components. Be sure you are

properly grounded before beginning any installation procedure. For more information, see the

section titled “Electrostatic Discharge Information” earlier in this chapter.

To power down the server:

1. Press the Power On/Standby switch to Standby. This places the server in standby mode,

thereby disabling the main power supply output and providing auxiliary power to the

server. Standby does not completely remove power from the system.

2. Verify that the system power LED indicator on the front panel, near the Power

On/Standby switch, is amber and that the fan noise stops.

3. Disconnect all AC power cords from the AC outlet, then from the server.

4. Disconnect all external peripheral devices from the server.

5. For stability and safety, properly positioning the server is critical. If the server is mounted

in a rack, remove the rack model server from the rack and place it on a sturdy table or

workbench. Refer to the ProLiant ML370 Servers Setup and Installation Guide for

instructions.

Rack Warnings

WARNING: To reduce the risk of personal injury, make sure that the rack is adequately

stabilized before extending a component outside the rack. A rack may become unstable if more

than one component is extended for any reason. Extend only one component at a time.

WARNING: To reduce the risk of personal injury or damage to the equipment, be sure that:

■ The leveling jacks are extended to the floor.

■ The full weight of the rack rests on the leveling jacks.

■ The stabilizers are attached to the rack if it is a single rack installation.

■ The racks are coupled together in multiple rack installations.

Page 21

Server Warnings and Precautions

WARNING: To reduce the risk of personal injury from hot surfaces, allow the internal system

components to cool before touching.

WARNING: To reduce the risk of electric shock or damage to the equipment:

■ Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

■ Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at

all times.

■ Install the power supply before connecting the power cord to the power supply.

■ Unplug the power cord before removing the power supply from the server.

■ Disconnect power from the server by unplugging the power cord from either the electrical

outlet or the server. If the system has multiple power supplies, disconnect power from the

system by unplugging all power cords from the power supplies.

CAUTION: Protect the server from power fluctuations and temporary interruptions with a

regulating uninterruptible power supply (UPS). This device protects the hardware from damage

caused by power surges and voltage spikes and keeps the system in operation during a power

failure.

Removal and Replacement Procedures 2-5

CAUTION: ProLiant ML370 Servers must always be operated with the system unit cover on.

Proper cooling will not be achieved if the system unit cover is removed.

Page 22

2-6 Compaq ProLiant ML370 Maintenance and Service Guide

Front Bezel

NOTE: This procedure applies to the ProLiant ML370 tower model only.

To open the front bezel:

1. Unlock the front bezel keylock.

2. Swing the front bezel out away from the server.

To remove the front bezel, continue with the following step.

3. Lift up the front bezel, then pull it away from the chassis.

Figure 2-1. Removing the front bezel

Reverse steps 1 through 3 to replace the front bezel.

Page 23

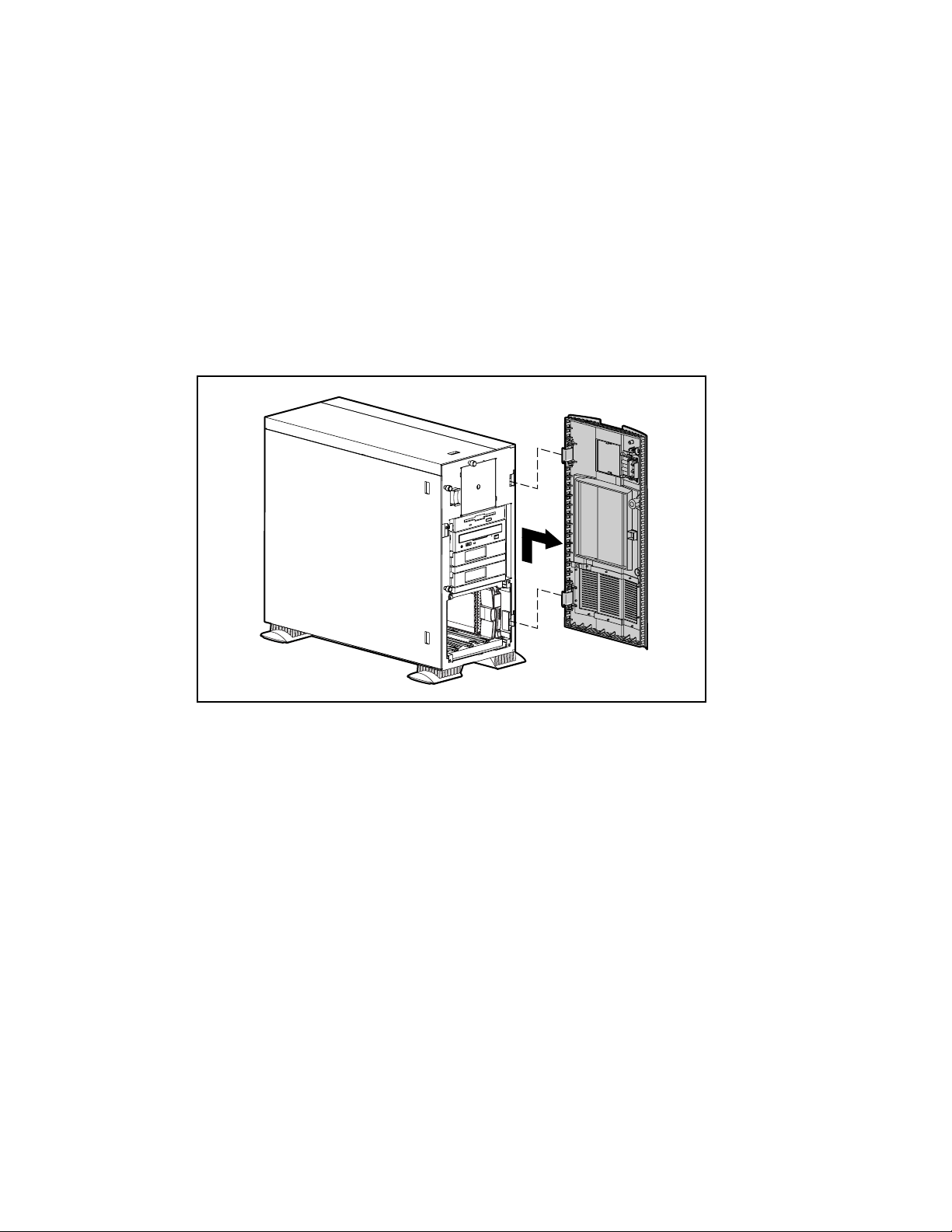

Rack Front Plate

NOTE: This procedure applies to the ProLiant ML370 rack-mountable model only.

To remove the rack front plate:

Removal and Replacement Procedures 2-7

1. Remove the ten T-15 screws from the rack front plate

2. Pull the rack front plate away from the server

2

Figure 2-2. Removing the rack front plate

Reverse steps 1 and 2 to replace the rack front plate.

.

.

1

Page 24

2-8 Compaq ProLiant ML370 Maintenance and Service Guide

Feet

NOTE: This procedure applies to the ProLiant ML370 tower model only.

To remove the feet from the chassis, one at a time:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Place the server on its right side (opposite from the large access panel).

3. Remove the T-15 screw from each foot ➊.

4. Pivot each foot down ➋; then pull it off the base of the chassis ➌.

2

3

1

Figure 2-3. Removing the feet from the chassis

Reverse steps 1 through 4 to replace the feet. Make sure each foot snaps securely into its holder.

Page 25

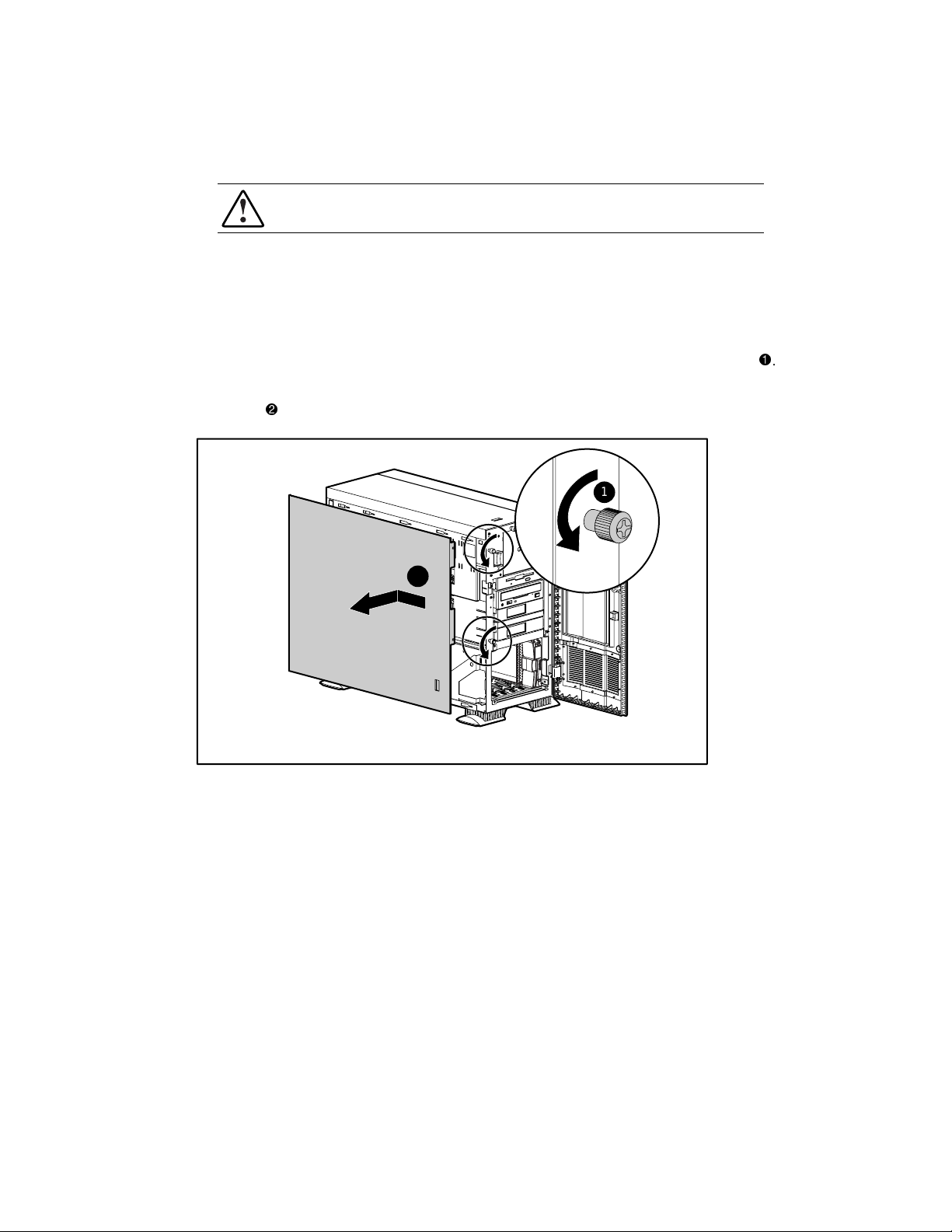

Large Access Panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow internal system

components to cool before touching them.

To remove the large access panel:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

Removal and Replacement Procedures 2-9

3. Loosen the two thumbscrews securing the large access panel to the front of the chassis

4. Slide the large access panel back about 1.5 cm (0.5 inches), then pull it away from the

chassis

Figure 2-4. Removing the large access panel

.

1

2

Reverse steps 1 through 4 to replace the large access panel.

.

Page 26

2-10 Compaq ProLiant ML370 Maintenance and Service Guide

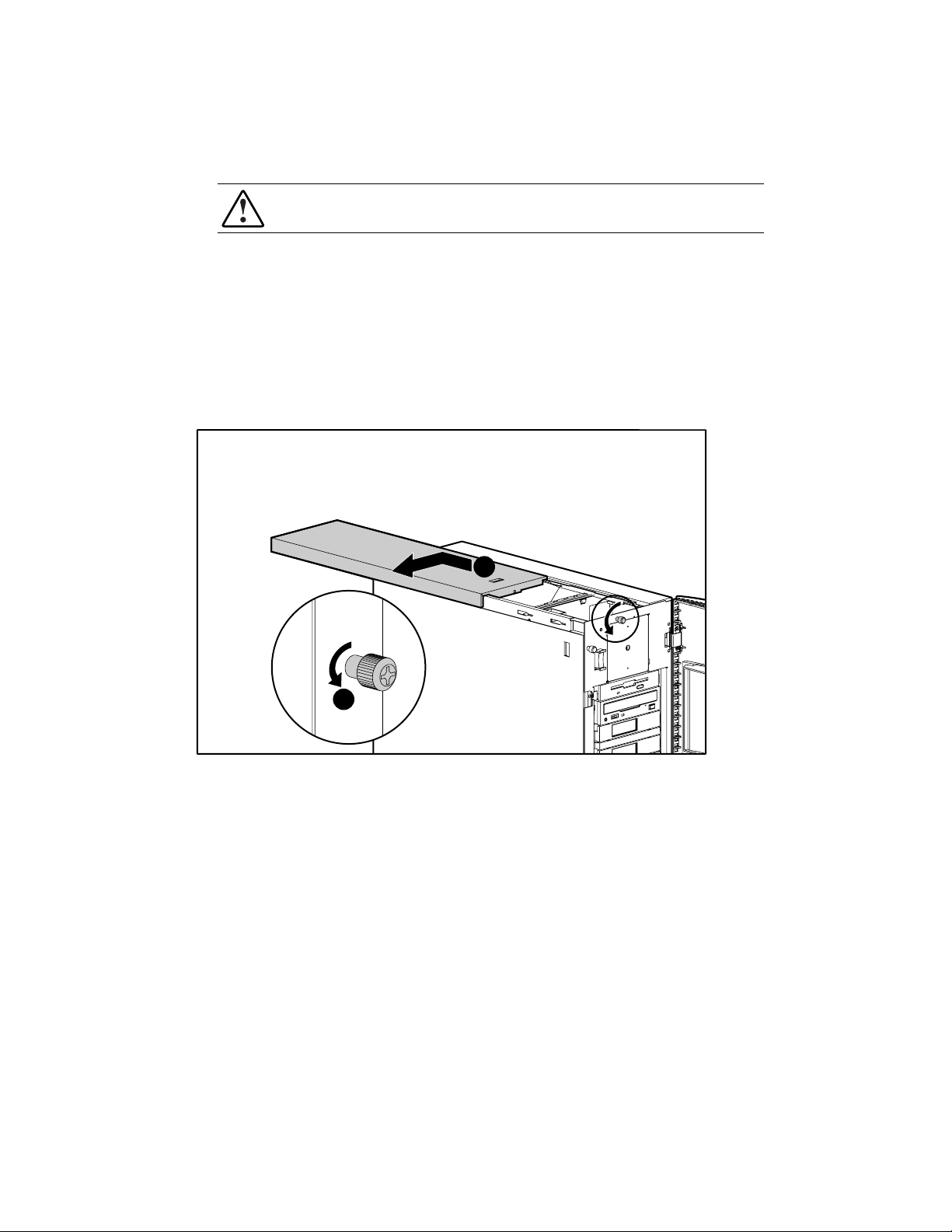

Small Access Panel

WARNING: To reduce the risk of personal injury from hot surfaces, allow internal system

components to cool before touching them.

To remove the small access panel:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Loosen the thumbscrew securing the small access panel to the chassis ➊.

4. Slide the small access panel toward the rear of the unit about 1.5 cm (0.5 inches), then off

to the side

➋.

2

1

Figure 2-5. Removing the small access panel

Reverse steps 1 through 4 to replace the small access panel.

Page 27

Right Side Panel

NOTE: This panel does not exist on the rack-mountable model. This procedure applies to the tower

model only.

To remove the right side panel from the chassis:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Remove the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the feet on the base of the right side panel. See “Feet” earlier in this chapter.

4. Remove the two Torx T-15 screws securing the right side panel to the front of the

chassis

Removal and Replacement Procedures 2-11

.

5. Pull the right side panel back, then away from the chassis

2

Figure 2-6. Removing the right side panel

Reverse steps 1 through 5 to replace the right side panel.

.

1

1

Page 28

2-12 Compaq ProLiant ML370 Maintenance and Service Guide

Drives and Related Components

Compaq ProLiant ML370 Servers ship standard with a hot-plug drive cage containing

six 1.0-inch hot-plug drive bays. Four removable media bays contain one third-height diskette

drive and one half-height IDE CD-ROM drive. Two bays can contain a second CD-ROM drive,

tape drives, hard drives, or any SCSI device.

Compaq ProLiant ML370 Servers support up to ten mass storage devices including the diskette

drive and IDE CD-ROM drive. Figure 2-7 and Table 2-1 describe the drive configurations.

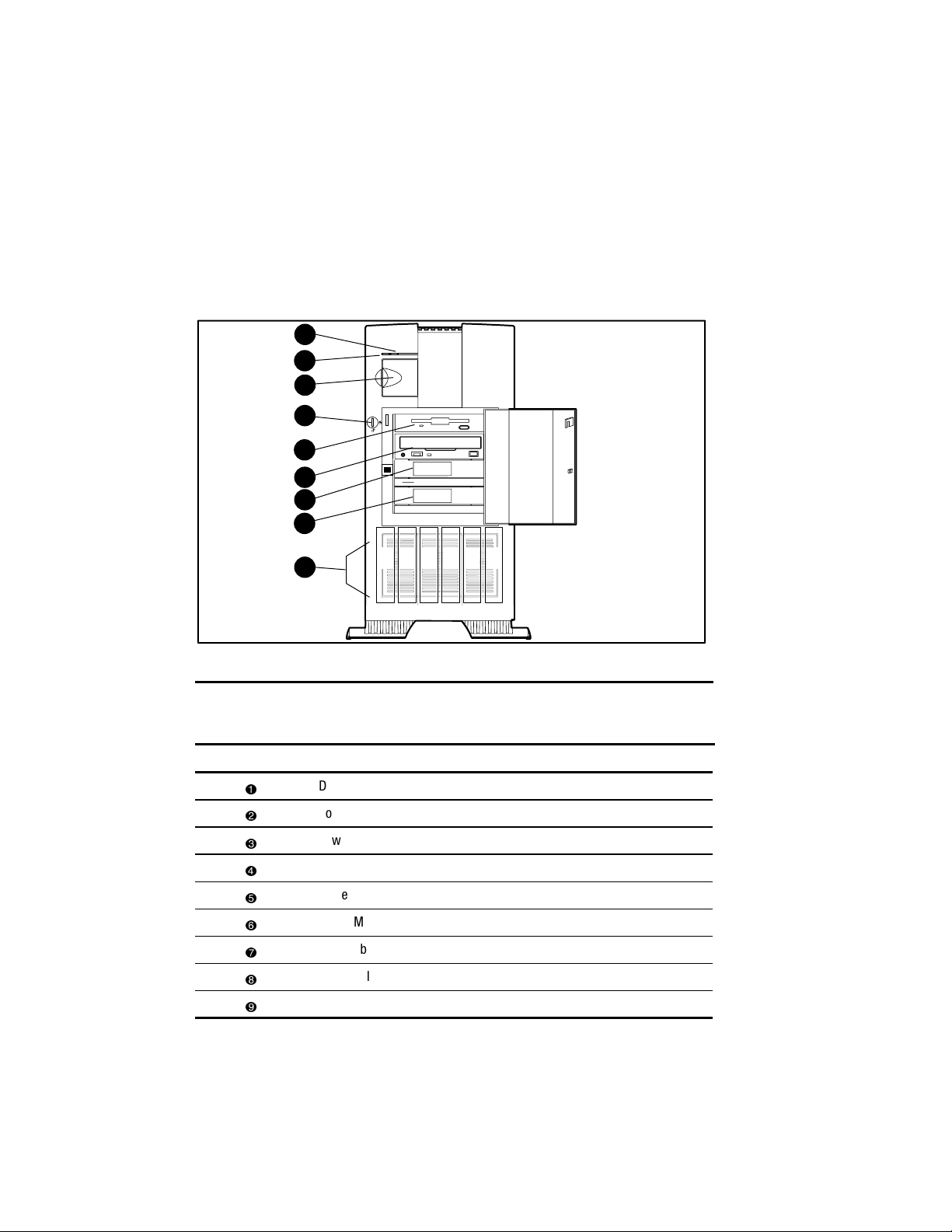

1

2

3

4

5

6

7

8

9

Figure 2-7. Drives and related components

5 4 3 2

Drives and Related Components

Item Description

Drive activity LED indicator

Power On/Standby status LED indicator

Power On/Standby switch

Key lock

Diskette drive

CD-ROM drive

Removable media slot

Removable media slot

Hot-plug drive bays 0-5

1 0

Table 2-1

Page 29

Cable Routing Diagrams

CAUTION: When routing cables, always ensure that the cables are not in a position where they

will be pinched or crimped.

IDE CD-ROM Drive Cable Diagram

1

Removal and Replacement Procedures 2-13

1

Figure 2-8. IDE CD-ROM drive cable

Diskette Drive Cable Diagram

1

Figure 2-9. Diskette drive cable

1

Page 30

2-14 Compaq ProLiant ML370 Maintenance and Service Guide

SCSI Cable Diagram

1

2

Figure 2-10. SCSI cable diagram: the three-device, terminated SCSI cable connected from

internal SCSI Port 1 to the vacant bays of the removable media area, and the point-to-point SCSI

cable connected from internal SCSI Port 2 to the backplane of the hot-plug drive cage

1

2

Page 31

Hot-Plug Drive Cage

To remove the hot-plug drive cage:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Remove the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Disconnect all cables from the hot-plug drive cage: one SCSI cable and two power

connectors.

Removal and Replacement Procedures 2-15

5. Remove the four T-15 screws securing the hot-plug drive cage to the chassis

6. Slide the hot-plug drive cage out the front of the chassis

2

Figure 2-11. Removing the hot-plug drive cage

.

1

1

Reverse steps 1 through 6 to replace the hot-plug drive cage.

.

1

1

CAUTION: Make sure that all power and signal cables to the hot-plug drive cage have been

reseated properly.

Page 32

2-16 Compaq ProLiant ML370 Maintenance and Service Guide

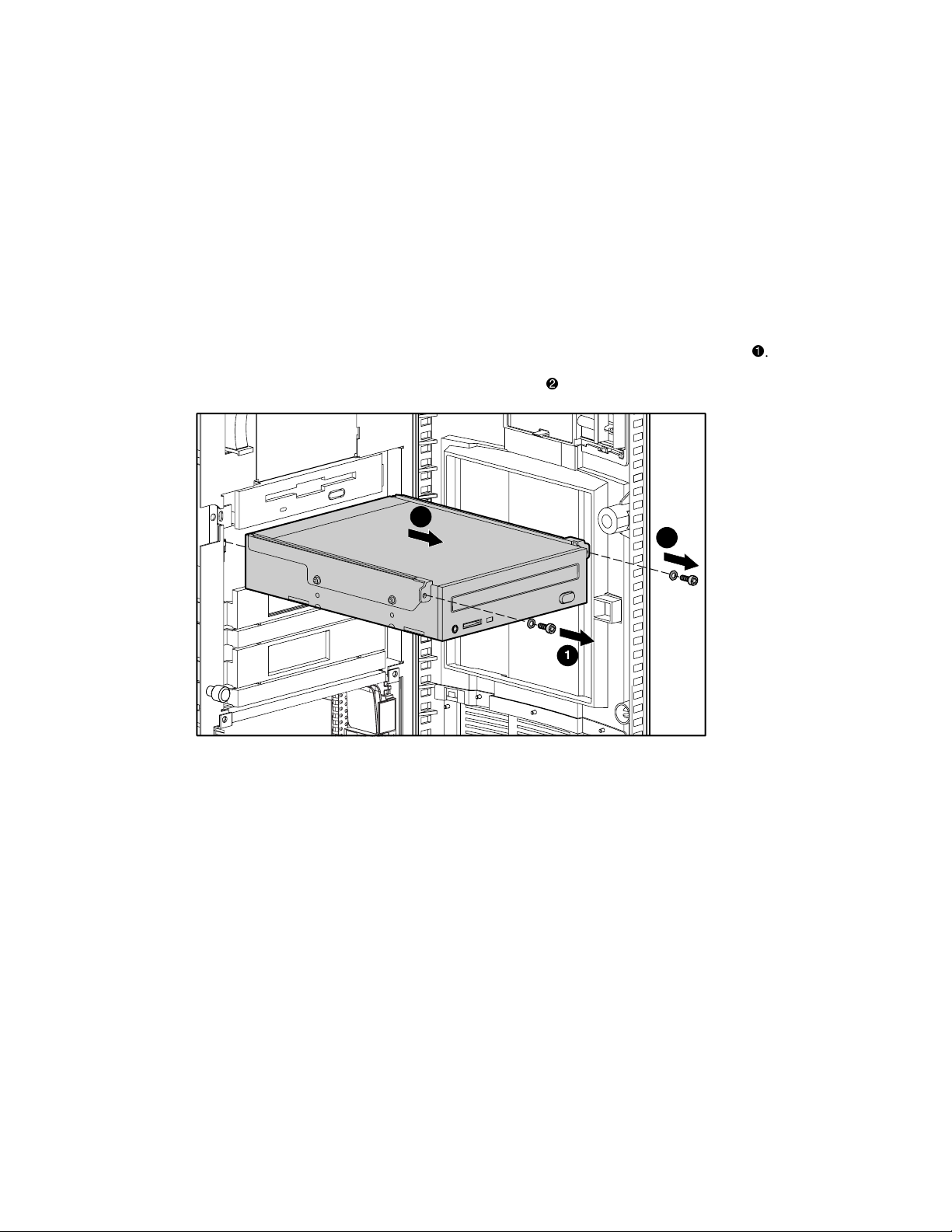

IDE CD-ROM Drive

To remove the CD-ROM drive:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Disconnect all cables from the CD-ROM drive.

5. Remove the two T-15 screws and washers securing the CD-ROM drive to the chassis

6. Slide the CD-ROM drive out the front of the chassis

2

Figure 2-12. Removing the CD-ROM drive

.

1

1

Reverse steps 1 through 6 to replace the CD-ROM drive.

.

Page 33

Diskette Drive

To remove the diskette drive:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Disconnect all cables from the diskette drive.

Removal and Replacement Procedures 2-17

5. Remove the two T-15 screws and washers securing the diskette drive to the chassis

6. Slide the diskette drive out the front of the chassis

2

Figure 2-13. Removing the diskette drive

.

1

1

Reverse steps 1 through 6 to replace the diskette drive.

.

Page 34

2-18 Compaq ProLiant ML370 Maintenance and Service Guide

Hard Drive Blank

IMPORTANT: A hard drive blank must be installed in an unused hard drive slot. Failure to install a hard

drive blank could result in system errors.

To remove a hard drive blank:

1. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

2. Squeeze the top and bottom tabs of the blank

3. Pull the blank out of the hard drive cage

1

1

Figure 2-14. Removing a hard drive blank

.

.

2

Reverse steps 1 through 3 to replace a hard drive blank.

Page 35

Hot-Plug SCSI Hard Drive

To remove a hot-plug SCSI hard drive:

1. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

Removal and Replacement Procedures 2-19

2. Press the release button

3. Pull the hot-plug SCSI hard drive out of the bay

Figure 2-15. Removing a hot-plug SCSI hard drive

and swing the lever outward from the bottom.

.

3

Reverse steps 1 through 3 to replace the hot-plug SCSI hard drive.

2

1

Page 36

2-20 Compaq ProLiant ML370 Maintenance and Service Guide

Removable Media Drive Bay Blank

To remove a removable media drive bay blank:

1. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

2. Remove the four Torx T-15 screws securing the removable media drive bay blank to the

chassis

.

3. Remove the removable media drive bay blank

2

.

1

Figure 2-16. Removing a removable media drive bay blank

Reverse steps 1 through 3 to replace a removable media drive bay blank.

1

Page 37

CPU Fan

Removal and Replacement Procedures 2-21

To remove the CPU fan:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the server large access panel. See “Large Access Panel” earlier in this chapter.

4. Unplug the CPU fan from the system board.

5. Remove the four screws

6. Remove the CPU fan

1

Figure 2-17. Removing the CPU fan

Reverse steps 1 through 6 to replace the CPU fan.

securing the fan assembly to the chassis.

.

2

Page 38

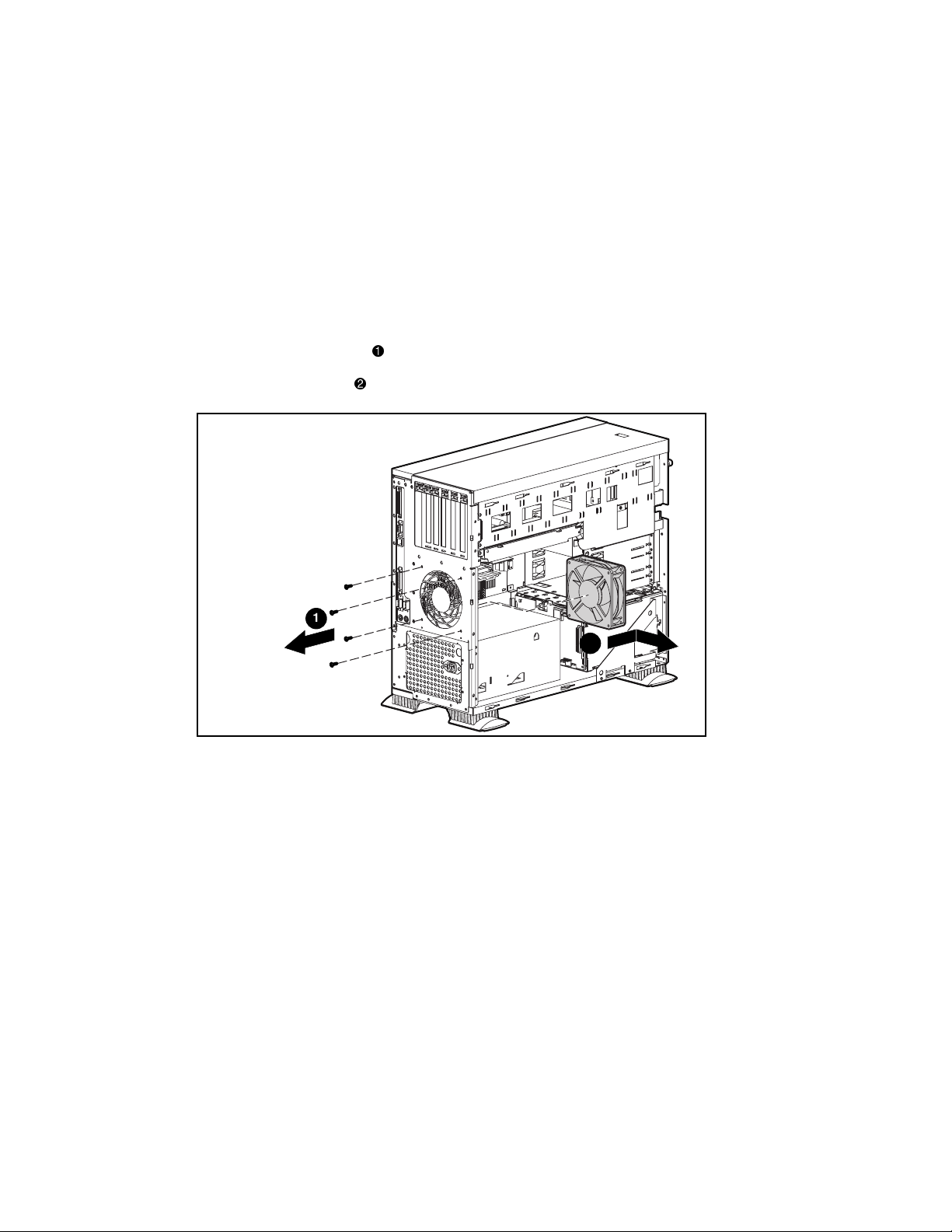

2-22 Compaq ProLiant ML370 Maintenance and Service Guide

I/O Fan

To remove the I/O fan:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large and small access panels. See “Large Access Panel” and “Small Access

Panel” earlier in this chapter.

4. Loosen the single thumbscrew securing the I/O fan to the chassis ➊.

5. Tilt the top of the I/O fan forward ➋.

6. Disconnect the I/O fan cable from the system board ➌.

7. Lift the I/O fan away from the chassis.

1

3

2

Figure 2-18. Removing the I/O fan

Reverse steps 1 through 7 to replace the I/O fan.

Page 39

Power Switch with Cable and LED Indicators

To remove the power switch and cable assembly:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Remove the single T-15 screw securing the power switch to the chassis ➊.

5. Slide the power switch housing back ➋, then lift it out of the chassis ➌.

2

Removal and Replacement Procedures 2-23

Figure 2-19. Removing the power switch with LED and cable

3

1

Page 40

2-24 Compaq ProLiant ML370 Maintenance and Service Guide

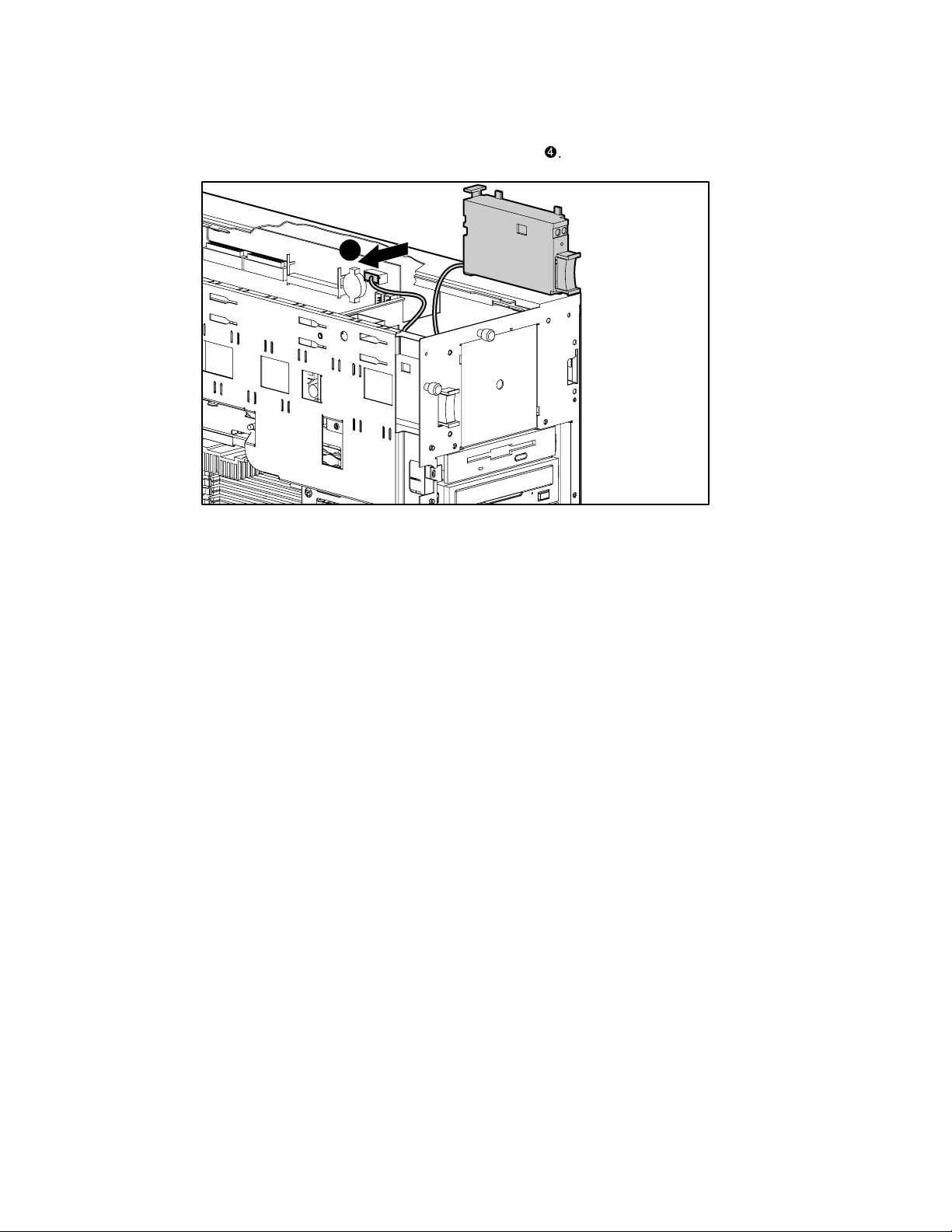

6. Disconnect the power switch from the system board

4

.

Figure 2-20. Unplugging the power switch from the system board

Reverse steps 1 through 6 to replace the power switch and cable assembly.

Page 41

Riser Board Expansion Slots

Figure 2-21. Riser board expansion slots

Removal and Replacement Procedures 2-25

6

2

5

3

4

4

3

5

2

6

1

Item Description

,

, , ,

Primary PCI bus slots 1 and 2 (32-bit)

Secondary PCI bus slots 3-6 (64-bit)

Table 2-2

Riser Board Expansion Slots

Page 42

2-26 Compaq ProLiant ML370 Maintenance and Service Guide

I/O Expansion Slot Cover

To remove an I/O expansion slot cover:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Press down on the release button at the top of the I/O expansion slot retention lever

5. Swing the I/O expansion slot retention lever upward

6. Lift the I/O expansion slot cover up and out of the server

3

Figure 2-22. Removing an I/O expansion slot cover

.

.

1

2

.

Reverse steps 1 through 6 to replace an I/O expansion slot cover.

Page 43

I/O Expansion Board

To remove an I/O expansion board:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Remove any peripheral devices attached to the I/O expansion board.

5. Release the I/O expansion board retention lever. See “I/O Expansion Slot Cover” earlier in

this chapter.

Removal and Replacement Procedures 2-27

6. Lift the I/O expansion board up and out of the server

1

Figure 2-23. Removing an I/O expansion board

Reverse steps 1 through 6 to replace an I/O expansion board.

IMPORTANT: If only removing the board, install an expansion slot cover.

.

Page 44

2-28 Compaq ProLiant ML370 Maintenance and Service Guide

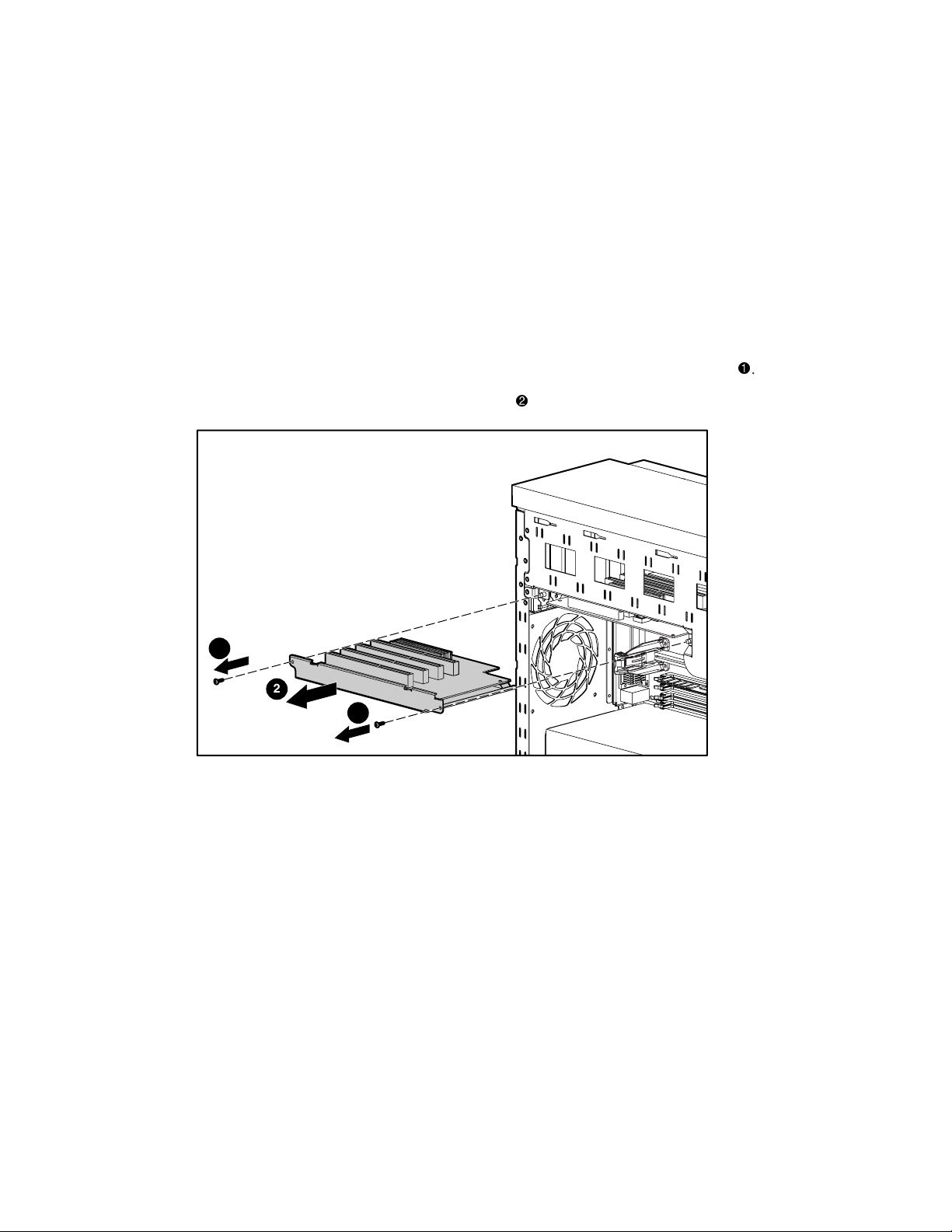

Riser Board and Brace

To remove the riser board and brace:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove any I/O expansion boards (if installed) from the riser board. See “I/O Expansion

Board” earlier in this chapter.

4. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

5. Remove the two Torx T-15 screws securing the riser board and brace to the chassis

6. Slide the riser board and brace out of the server

1

2

1

Figure 2-24. Removing the riser board and brace

.

Reverse steps 1 through 6 to replace the riser board and brace. Make sure that the board is

seated securely before the screws are tightened.

.

Page 45

Processor

To remove the processor:

Removal and Replacement Procedures 2-29

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Push in the tabs at each side of the processor until you hear two clicks

5. While holding the tabs in, pull out the processor ➋.

1

1

1

2

Figure 2-25. Removing the processor

Reverse steps 1 through 5 to replace the processor.

.

Use the System Configuration Utility to reconfigure the system if a faulty processor is replaced.

See Chapter 3, “Diagnostics and Troubleshooting,” for more information.

NOTE: Individual heat sinks may vary from the one(s) shown above.

Page 46

2-30 Compaq ProLiant ML370 Maintenance and Service Guide

Processor Power Module

To remove the Processor Power Module:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Press outward on the tabs at each end of the Processor Power Module ➊.

5. Pull the Processor Power Module out of the socket ➋.

1

2

Figure 2-26. Removing the Processor Power Module

Reverse steps 1 through 5 to replace a Processor Power Module. The clips on the Processor

Power Module will snap into a locked position automatically when the Processor Power Module

is fully seated in the socket. The module is keyed to ensure correct alignment.

Use System Configuration Utility to reconfigure the server. See Chapter 3, “Diagnostics and

Troubleshooting,” for more information.

Page 47

Memory

Removal and Replacement Procedures 2-31

Compaq ProLiant ML370 Servers ship standard with a 128-MB Synchronous DRAM

(SDRAM) dual inline memory module (DIMM) installed in DIMM slot 1. Memory is

expandable to 4 GB (when 1-GB DIMMs are available).

1

2

3

4

Figure 2-27. DIMM slots on the system board

Table 2-3

SDRAM DIMM Slot Locations

Item Description

CAUTION: Use only Compaq DIMMs. DIMMs from other sources may adversely affect data

integrity. Power-On Self-Test (POST) will warn of nonsupported DIMMs.

IMPORTANT: The following guidelines MUST be followed when installing or replacing memory:

■ Use 133-MHz, 64-, 128-, 256-, 512-MB or 1-GB registered SDRAM DIMMs, 3.3 volts, 72 bits wide,

with Error Correction Code (ECC).

■ Any combination of the above modules can be used.

■ Install SDRAM DIMM modules one at a time in sequential order, starting with DIMM slot 1.

■ Install DIMMs of the same speed. Do not install DIMM modules supporting different speeds.

■ Install DIMMs only in one direction. Ensure that the notch on the module matches the tab on the

DIMM slot and that the module is fully inserted and properly seated.

SDRAM DIMM slot 1 (populated with standard 128-MB DIMM)

SDRAM DIMM slot 2

SDRAM DIMM slot 3

SDRAM DIMM slot 4

Page 48

2-32 Compaq ProLiant ML370 Maintenance and Service Guide

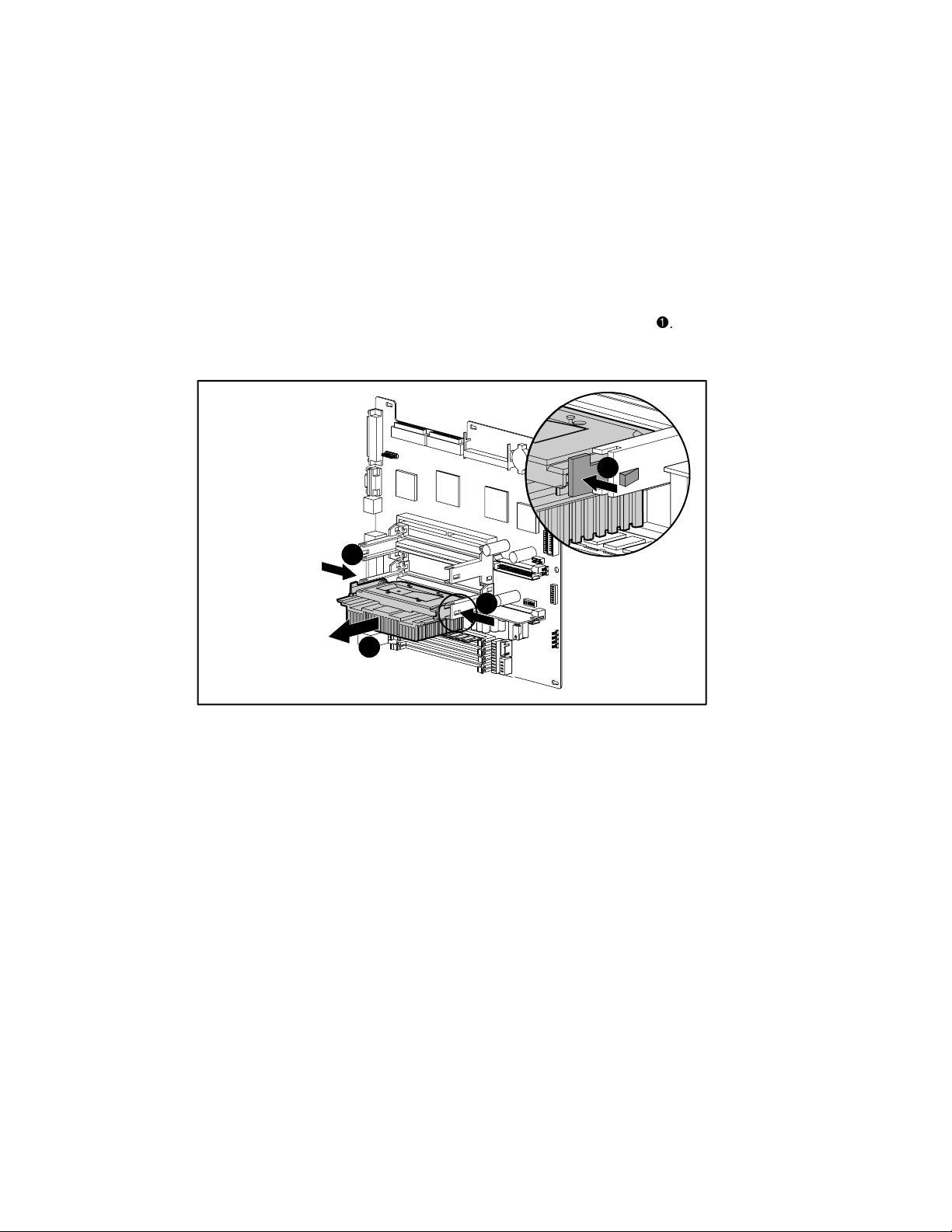

To remove an SDRAM DIMM:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Press both SDRAM DIMM slot release levers outward ➊.

5. Pull the DIMM module up from the board ➋.

2

1

1

Figure 2-28. Removing a DIMM module from the system board

Reverse steps 1 through 5 to replace the DIMM. The DIMM can be installed in only one way.

Match the notch on the DIMM module with the tab on the memory socket. Push the DIMM

module down into the socket, making sure that the module is fully inserted and properly seated.

Page 49

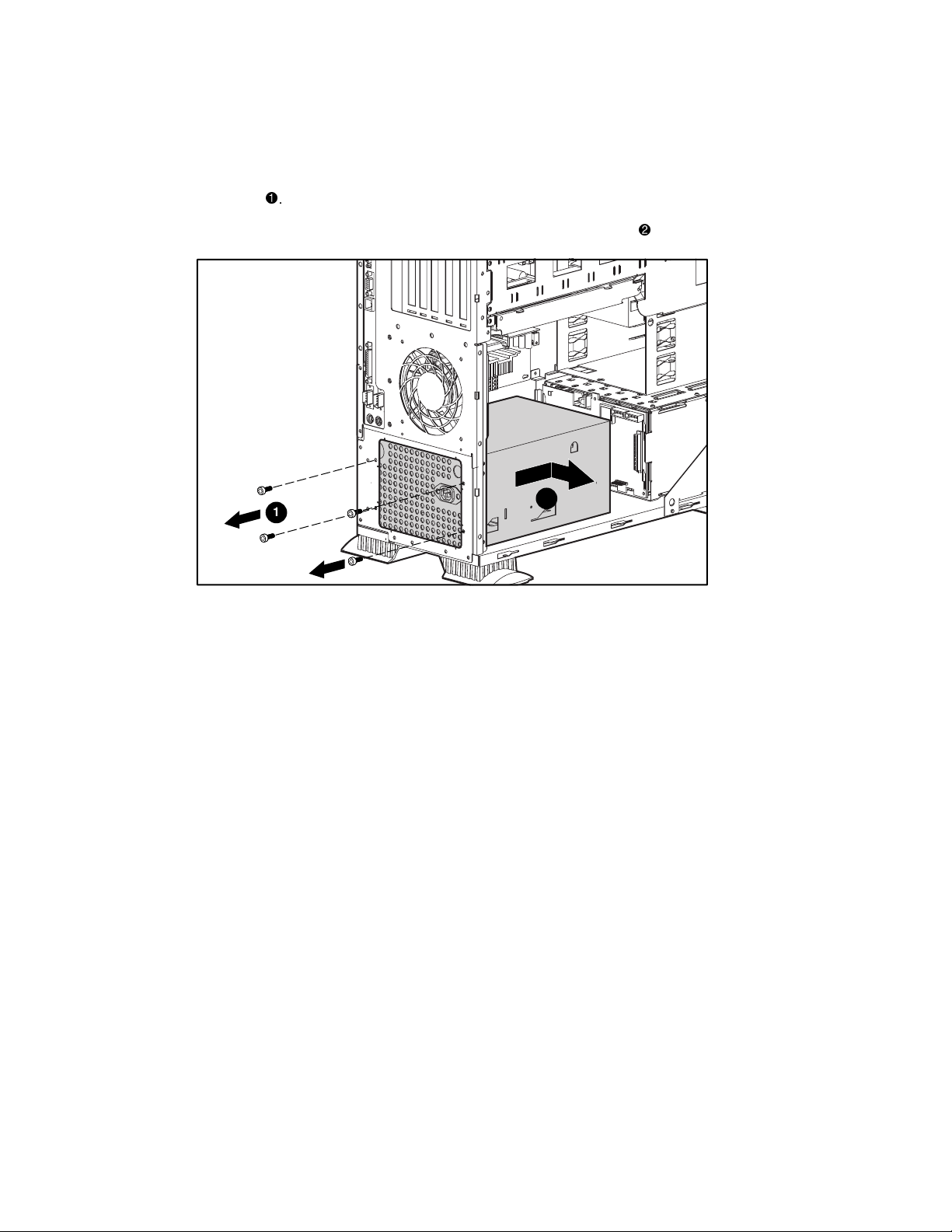

Power Supply

To remove the power supply:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Slide the hot-plug drive cage out slightly by loosening the screws attaching it to the

chassis. See “Hot-Plug Drive Cage” earlier in this chapter.

5. Disconnect the power supply cable from the system board.

Removal and Replacement Procedures 2-33

WARNING: To reduce the risk of electric shock, do not disassemble the power supply or

attempt to repair it. It should be replaced only with the specified Compaq spare part.

Figure 2-29. Disconnecting the power supply cable from the system board

Page 50

2-34 Compaq ProLiant ML370 Maintenance and Service Guide

6. Disconnect all other power supply cables.

7. Remove the four Torx T-15 screws securing the power supply to the back of the

chassis

.

8. Pull the power supply slightly back, then out the side of the chassis

2

1

Figure 2-30. Removing the power supply

Reverse steps 1 through 8 to replace the power supply.

.

Page 51

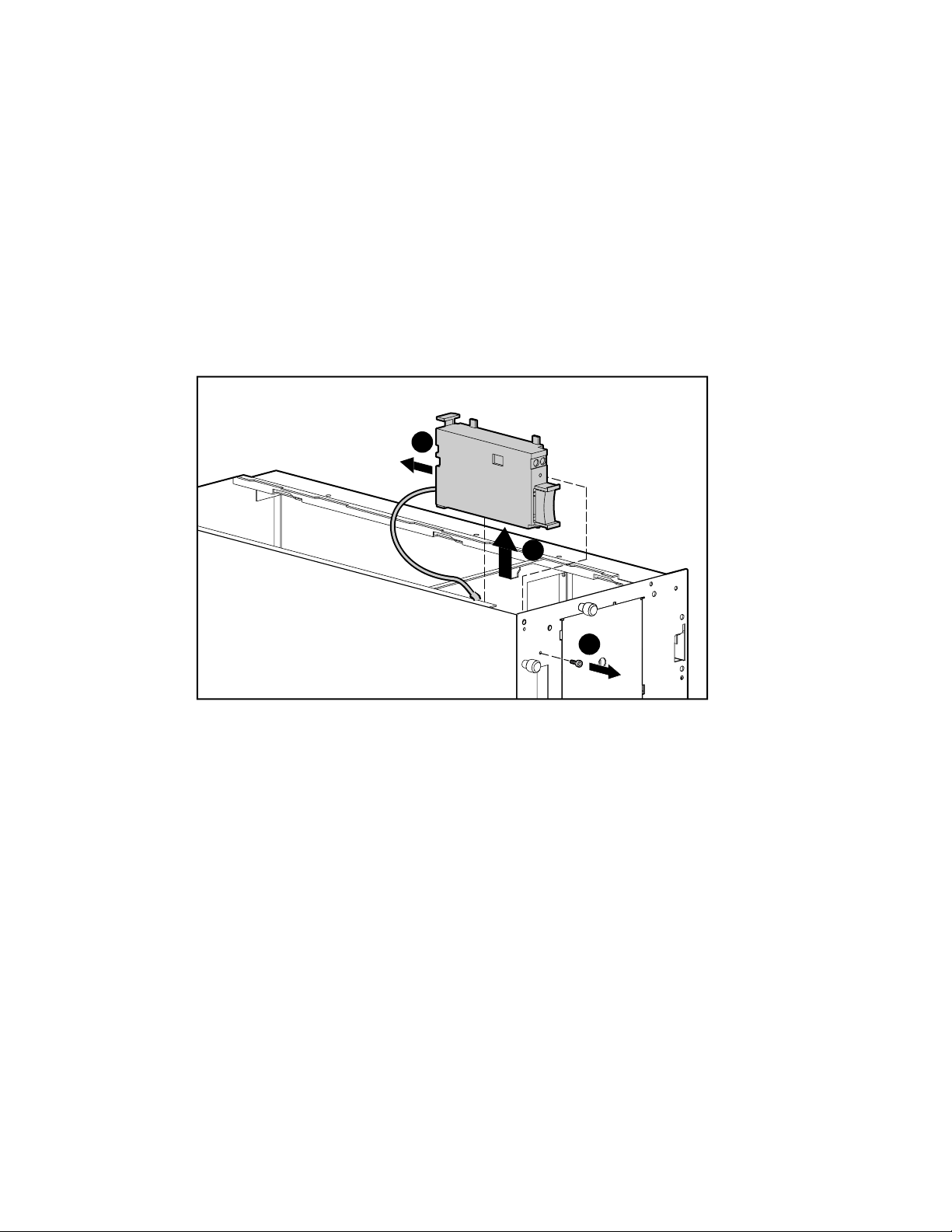

Hot-Plug SCSI Drive Backplane

To remove the hot-plug SCSI drive backplane:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

4. Remove all hard drive blanks and hot-plug hard drives. See “Hard Drive Blank” and

“Hot-Plug SCSI Hard Drive” earlier in this chapter.

5. Remove the hot-plug drive cage. See “Hot-Plug Drive Cage” earlier in this chapter.

6. Remove the three Torx T-15 screws securing the hot-plug SCSI drive backplane to the

hot-plug SCSI drive cage

7. Slide the hot-plug SCSI drive backplane down slightly. Then pull it from the mounting

posts

.

.

Removal and Replacement Procedures 2-35

1

2

1

1

Figure 2-31. Removing the hot-plug SCSI drive backplane

Reverse steps 1 through 7 to replace the hot-plug SCSI drive backplane.

Page 52

2-36 Compaq ProLiant ML370 Maintenance and Service Guide

System Board

To remove the system board:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Remove the large access panel. See “Large Access Panel” earlier in this chapter.

5. Remove all expansion boards. See “I/O Expansion Board” earlier in this chapter.

6. Remove the riser board and brace. See “Riser Board and Brace” earlier in this chapter.

7. Disconnect all internal and external cables

8. Loosen the thumbscrew securing the system board to the chassis

.

.

9. Slide the system board forward to release it from the six retaining guides, then pull the

system board out the top of the chassis

1

1

1

1

.

2

3

Figure 2-32. Removing the system board

Reverse steps 1 through 9 to replace the system board.

Page 53

Removal and Replacement Procedures 2-37

Compaq Integrated Smart Array Controller Upgrade

Module

NOTE: The Compaq Integrated Smart Array Controller upgrade module is an upgrade option in the

ProLiant ML370.

To remove the Compaq Integrated Smart Array Controller upgrade module:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Remove any I/O expansion boards. See “I/O Expansion Board” earlier in this chapter.

5. Push in the clips securing the Compaq Integrated Smart Array Controller module to the

system board

.

6. Pull the module away from the system board

1

2

Figure 2-33. Removing the Compaq Integrated Smart Array Controller upgrade module

Reverse steps 1 through 6 to replace the Compaq Integrated Smart Array Controller upgrade

module.

.

1

Page 54

2-38 Compaq ProLiant ML370 Maintenance and Service Guide

Internal Replacement Battery

WARNING: This server contains an internal lithium manganese dioxide battery. There is risk of

fire and burns if the battery pack is not handled properly. To reduce the risk of personal injury:

■ Do not attempt to recharge the battery.

■ Do not expose to temperatures higher than 60°C.

■ Do not disassemble, crush, puncture, short external contacts, or dispose of in fire or water.

■ Replace only with the Compaq spare designated for this product.

To install the internal replacement battery:

1. Perform the preparation procedures. See “Powering Down the Server” earlier in this

chapter.

2. Open the front bezel (tower model only). See “Front Bezel” earlier in this chapter.

3. Remove the small access panel. See “Small Access Panel” earlier in this chapter.

4. Remove the battery from the system board.

Figure 2-34. Removing the internal replacement battery

5. Install the replacement battery, then run the System Configuration utility to reconfigure

the server.

CAUTION: Loss of BIOS Settings will occur when the lithium battery is removed. BIOS settings

must be reconfigured whenever the battery is replaced.

CAUTION: Batteries, battery packs, and accumulators should not be disposed of

together with the general household waste. In order to forward them to recycling or

proper disposal, please use the public collection system or return them to Compaq,

your authorized Compaq Partners, or their agents.

Page 55

Chapter 3

Diagnostics and Troubleshooting

This chapter describes software and firmware diagnostic tools available for all Compaq server

products. The sections in this chapter are:

■ Diagnostic Tools Utility Overview

■ Default Configuration

■ Utilities Access

■ Power-On Self-Test (POST)

■ Diagnostics Software

■ Array Diagnostic Utility (ADU)

■ Integrated Management Log

■ Rapid Error Recovery

■ Remote Service Features

■ ROMPaq Error Recovery Options

■ Compaq Insight Manager

Page 56

3-2 Compaq ProLiant ML370 Maintenance and Service Guide

Diagnostic Tools Utility Overview

These utilities were developed to assist in diagnosing problems, testing the hardware, and

monitoring and managing Compaq server hardware.

Diagnostic Tools

Tool What it is How to run it

Table 3-1

Compaq Diagnostics

Program

Compaq Inspect

Utility

Compaq Insight

Manager

Compaq Survey

Utility

A utility to assist testing and/or verifying

operation of Compaq hardware. If

problems are found, Compaq

Diagnostics isolates failure(s) down to

replaceable part, whenever possible.

The Inspect Utility provides a report

detailing system information.

A client/server application used to

remotely manage Compaq hardware in

a network environment. Reports

hardware fault conditions (both failure

and prefailure) and collects data for

reporting and graphing.

An online information gathering agent

that runs on servers, gathering critical

hardware and software information

from various sources. A utility for

servers running Windows NT or

NetWare.

If a significant change occurs between

data gathering intervals, previous

information is marked, and the survey

text file is overwritten to reflect the

latest configuration and changes since

last configuration. This allows a

historical record of change events for

server hardware and software.

Diagnostics and Utilities are located on

Compaq system partition (if installed) or

your hard drive and must be accessed

when a system configuration error is

detected during Power-On Self-Test

(POST). Compaq Diagnostics software is

also available on Compaq SmartStart and

Support Software CD. A Diagnostics

diskette can be created from SmartStart

and Support Software CD, and

Diagnostics run from diskette.

The Inspect Utility can be run from either

the main menu of the System

Configuration Utility or the Compaq

Diagnostics program.

For more information, refer to the

Compaq Management CD and the

Compaq Insight Manager User Guide.

More information on viewing and printing

the event list can be found in the Compaq

Insight Manager section of this chapter.

Install Survey from SmartStart, Compaq

Integration Maintenance Utility, or from

Compaq Management CD.

continued

Page 57

Table 3-1

Diagnostic Tools

Tool What it is How to run it

continued

Diagnostics and Troubleshooting 3-3

Array Diagnostics

Utility (ADU)

Drive Array

Advanced

Diagnostics (DAAD)

Integrated

Management Log

A Windows-based tool designed to run

on all Compaq systems that support

Compaq array controllers. Two main

functions of ADU are to collect all

possible information about the array

controllers in the system and generate a

list of detected problems.

This tool is available for all Compaq

servers covered by this guide.

The predecessor to ADU, DAAD is a

DOS-based tool for Compaq servers

with Smart Array Controllers. DAAD

collects information about the array

controllers in the system and offers a

list of detected problems.

A log of system events, such as system

failures or nonfatal error conditions.

View events in the Integrated

Management Log:

■ On the Integrated Management

Display

■ From within Compaq Insight

Manager

■ From within Compaq Survey Utility

Use the information provided in Array

Diagnostics Utility (ADU) later in this

chapter.

For a list of Compaq servers still

supported by this tool, visit the Compaq

website:

www.compaq.com

The Integrated Management Log requires

Compaq Operating System-dependent

drivers. Refer to Compaq Support

Software CD for instructions on installing

the appropriate drivers.

System

Configuration Utility

Utility to easily configure the hardware

installed in or connected to the server.

Specifically, it can:

■ Resolve resource conflicts in areas

such as memory, port addresses,

and interrupts (IRQs)

■ Configure PCI boards automatically

■ Provide switch and jumper settings

■ Manage installation of memory,

processor upgrades, and mass

storage devices such as hard

drives, tape drives, and diskette

drives

■ Store configuration information in

nonvolatile memory

■ Assist in installation of an operating

system

■ Assist in running diagnostic tools

such as TEST and INSPECT

If the server has bootable CD-ROM drive,

run Compaq System Configuration Utility

directly from Support Software CD

supplied with Smart Controller Option Kit,

or SmartStart and Support Software CD

supplied with server. Use the CD supplied

for latest version supporting Smart

Controller.

If the server does not have a bootable

CD-ROM drive, create diskettes with

latest version of the System

Configuration Utility from Support

Software CD, or SmartStart and Support

Software CD.

Page 58

3-4 Compaq ProLiant ML370 Maintenance and Service Guide

Default Configuration

When the system is first powered up, the system ROM detects the unconfigured state of the

hardware and provides default configuration settings for most devices. By providing this

initialization, the system can run Diagnostics and other software applications before running the

normal SmartStart and System Configuration programs.

Default Configuration Messages

IMPORTANT: If you chose to format and partition the boot drive before running SmartStart and the

System Configuration programs, this may prohibit creating a Compaq System Partition and the off-line

remote management features that it provides.

If you insert a System Configuration, Diagnostics, or SmartStart and Support Software CD into

the CD-ROM drive prior to powering up the server, the system ROM boots to that utility. If the

system ROM does not detect one of those CDs, you will be prompted for the intended operating

system. The system reboots if any operating system-dependent configurations have changed

with the new operating system selection. If the selected operating system-dependent

configurations are the same as the current configurations, the system boots normally. If you

enter a wrong choice, on subsequent re-boots you may change the operating system.

Inspect Utility

The Inspect Utility provides configuration information such as the contents of the operating

system startup files, the current memory configuration, the ROM version, and Server Health

Log information. It operates with MS-DOS and in the MS-DOS emulation mode of OS/2.

Running the Inspect Utility

Printing the Inspect Listing

Select Print on the Inspect screen to print a copy of the Inspect listing. Keep a copy of the listing

with each server for later reference.

1. Turn the server off, and back on. Then press F10 when the cursor appears in the upper

right corner of the screen.

2. At the main menu, select Diagnostics and Utilities.

3. Press Enter.

4. Select Inspect Computer and press Enter.

5. Follow the instructions to view system information.

Page 59

Utilities Access

The Compaq SmartStart and Support Software CD contains the SmartStart program and many

of the Compaq utilities needed to maintain the system, including:

■ System Configuration Utility

■ Array Configuration Utility

■ Array Diagnostic Utility

■ ROMPaq Firmware Upgrade Utilities

■ Compaq Diagnostics

CAUTION: Do not select the Erase Utility when running the SmartStart and Support

Software CD. This will result in data loss to the entire system.

Running Compaq Utilities

Compaq utilities may be accessed from the Compaq System partition on the hard drive, from

diskette, or from the Compaq SmartStart and Support Software CD.

Running the Utilities on the Compaq System Partition

Diagnostics and Troubleshooting 3-5

If the system was installed using SmartStart, the Compaq utilities will automatically be

available on the Compaq system partition. The Compaq system partition could also have been

created during a manual system installation.

To run the utilities on the Compaq system partition, boot the system and press F10 when you

see: “Press F10 for Compaq system partition utilities.” Then select the utilities from the menu.

■ The System Configuration Utility is available under the System Configuration menu.

■ The Array Configuration Utility is available under the System Configuration menu.

■ Compaq Diagnostics (Test and Inspect) are available under the Diagnostics and Utilities

menu.

■ The ROMPaq Firmware Upgrade Utility is available under the Diagnostics and Utilities

menu.

Page 60

3-6 Compaq ProLiant ML370 Maintenance and Service Guide

Running the Utilities from Diskette

■ Run the utilities from their individual diskettes. If you have a utility diskette newer than

the version on the SmartStart and Support Software CD, use that diskette.

■ Create a diskette version of the utility from the SmartStart and Support Software CD.

To create diskette versions of the utilities from the CD:

1. Boot the Compaq SmartStart and Support Software CD.

2. From the Compaq System Utilities screen, select Create Support Software Disks then

Next.

3. Select the diskette you would like to create from the list, then follow the instructions on

the screen.

Running the Utilities from the Compaq SmartStart and Support

Software CD

IMPORTANT: Only the System Configuration Utility and the Array Configuration Utility and the Array

Diagnostic Utility can be executed from the Compaq SmartStart and Support Software CD. All other

utilities must be executed from the Compaq system partition or from diskette.

To run these utilities directly from the Compaq SmartStart and Support Software CD:

1. Boot the Compaq SmartStart and Support Software CD.

2. From the Compaq System Utilities screen, select the utility you wish to run, then select

Next.

G To execute the System Configuration Utility, select Run System Configuration Utility.

G To execute the Array Configuration Utility, select Run Array Configuration Utility.

G To execute the Array Diagnostic Utility, select Run Array Diagnostic Utility.

Page 61

Power-On Self-Test (POST)

POST is a series of diagnostic tests that run automatically on Compaq computers when the

system is turned on. POST checks the following assemblies to ensure that the computer system

is functioning properly:

■ System ROM

■ Keyboard

■ Power supply

■ System board

■ Memory

■ Controllers

■ Diskette drives

■ Hard drives

■ Processor Power Modules

■ Fans

Diagnostics and Troubleshooting 3-7

POST Error Messages

If POST finds an error in the system, an error condition is indicated by an audible and/or visual

message. If an error code displays on the screen during POST or after resetting the system, use

the instructions in the POST Error Messages table. The error messages and codes listed include

all codes generated by Compaq products. The system generates only those codes that are

applicable to the configuration and options.

NOTE: Many of the actions listed require you to run Diagnostics or the Compaq System Configuration

Utility. Steps for running these utilities are provided following the POST Error Messages tables.

In each case, the Recommended Action column lists the steps necessary to correct the problem.

After completing each step, run the Diagnostics program to verify whether the error condition

has been corrected. If the error code reappears, perform the next step, then run the Diagnostics

program again. Follow this procedure until Diagnostics no longer detects an error condition.

Page 62

3-8 Compaq ProLiant ML370 Maintenance and Service Guide

POST Error Messages

Error Code Audible Beeps Probable Source of Problem Recommended Action

A Critical Error

occurred prior to this

power-up

Unsupported

Processor Detected

System Halted

FATAL ROM ERROR:

The System ROM is

not properly

programmed

101 - ROM Error 1 long, 1 short System ROM checksum Run Diagnostics. Replace failed

101 - I/O ROM Error None Options ROM checksum Run Diagnostics. Replace failed

102 - System Board

Failure

104 - ASR-2 Timer

Failure

105 - Current System

ROM is corrupt—

now booting

redundant System

ROM

None A catastrophic system error,

1 long, 1 short Processor not supported by

1 long, 1 short ROM programmed in factory

None DMA, timers, and so on

None System board failure

2L Non-booted ROM image is

Table 3-2

which caused the server to

crash, has been logged.

current system ROM

incorrectly

corrupt

Run Diagnostics. Replace failed

assembly as indicated.

Check documentation for

supported processors, and if

supported, remove the

processor and update the

system to latest ROM.

Replace the physical ROM part.

assembly as indicated.

assembly as indicated.

Replace the system board. Run

the Compaq System

Configuration Utility.

Run Diagnostics. Replace failed

assembly as indicated.

Flash the ROM utilizing

ROMPaq.

162 - System

Options Not Set

163—Time & Date

Not Set

164 - Memory Size

Error

172 - Configuration

Nonvolatile Memory

Invalid

173 - Slot ID

Mismatch

174 - Configuration/

Slot Mismatch Device

Not Found

2S Configuration incorrect Run the System Configuration

Utility and correct.

2S Invalid time or date in

configuration memory

2S Configuration memory incorrect Run the System Configuration

None Nonvolatile configuration corrupt

or jumper installed

None Board replaced, configuration not

updated

None PCI board not found Run the System Configuration

Run the System Configuration

Utility and correct.

Utility and correct.

Run the System Configuration

Utility and correct.

Run the System Configuration

Utility and correct.

Utility and correct.

continued

Page 63

Diagnostics and Troubleshooting 3-9

Table 3-2

POST Error Messages

Error Code Audible Beeps Probable Source of Problem Recommended Action

continued

175 - Configuration/

Slot Mismatch Device

Found

177 - Configuration

Not Complete

178 - Processor

Configuration Invalid

180 - Log

Reinitialized

201 - Memory Error None RAM failure Run Diagnostics. Replace failed

203 - Memory

Address Error

207 - Invalid Memory

Configuration—

Check DIMM [SIMM]

Installation

208 - Invalid Memory

Speed—Check

DIMM [SIMM]

Installation

None PCI board added, configuration

not updated

None Incomplete system configuration Run the System Configuration

None Processor type or step does not

match configuration memory

None N/A N/A

None RAM failure Run Diagnostics. Replace failed

None Memory module installed

incorrectly

1 long, 1 short The speed of the memory is too

slow, where: xx00 = expansion

board SIMMs are too slow, or

00yy = system board SIMMs are

too slow. xx and yy have

corresponding bit set

Run the System Configuration

Utility and correct.

Utility and correct.

Run the System Configuration

Utility and correct.

assembly as indicated.

assembly as indicated.

Verify placement of memory

modules.

The speed of the memory

modules must be 60 ns. Verify

the speed of the memory

modules installed and replace.

209 - Memory

Detection Failure.

Check Memory

Installation

211 - Cache Switch

Set Incorrectly

212 - System

Processor Failed/

Mapped out

214 - DC-DC

Converter Failed

214 - Processor PPM

Failed Module X

1 long, 1 short Unable to size memory Check DIMM installation, and if

error persists, call Compaq

service provider.

None Switch not set properly during

installation or upgrade

1 short Processor in slot x failed Run Diagnostics and replace