Page 1

INSTALLATION AND OPERATION MANUAL

FDC80 Series

8-CHANNEL SUPERVISED CONTACT CLOSURE

This manual serves the following

ComNet Model Numbers:

FDC80TM1

FDC80RM1

FDC80NLRM1

FDC80TS1

FDC80RS1

FDC80NLRS1

FDC80T48 5

FDC80R485

FDC80NLR485

The FDC80 contact closure transmitter and receiver provide transmission of up

to eight independent supervised contact closures over either one optical fiber or

two wire RS-485 link. Microprocessor-based logic sends the contact information

in packets that are ordered and encoded, ensuring extremely robust transmission.

Packets that are garbled, packets out of sequence, and transmission bit errors will not

cause random changes of state on the contact relays. The receiver unit is offered in

both latching and non-latching relay configurations.

Multiple levels of supervision and receiver alarm control can be selected. See Figure

7 on Page 4 for switch settings.

Each module incorporates power and individual status indicating LED’s for monitoring

confirmation of contact closure of each of the eight channels. See Figure 8 on Page 4

for an explanation of the LED indicators.

These units are interchangeable between stand-alone or card mount configurations.

See Figure A on Page 7 for mounting instructions.

See Figures 1 – 11 for complete installation information, following the Application

Note on Page 6.

INS_FDC80_REV–

12/29/11

PAGE 1

Page 2

INSTALLATION AND OPERATION MANUAL FDC80

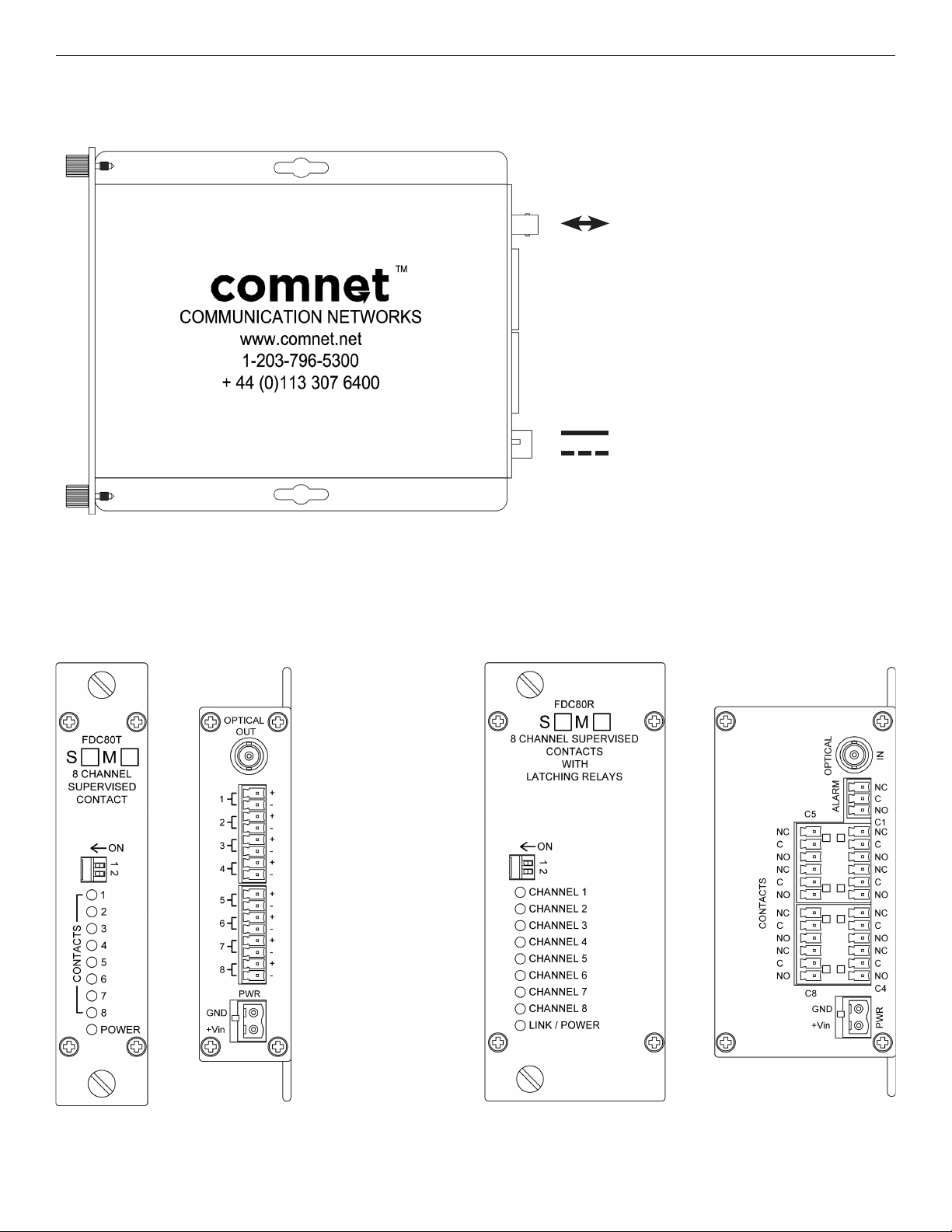

FIGURE 1 – FDC80 OPTICAL

MULTIMODE OR SINGLE MODE

OPTICAL FIBER (Depending on Model)

BLACK

BLACK WITH WHITE STRIPE

Power Supply:

Surface Mount: 8–15 VDC @ 150mA

Rack Mount: From Rack

NOTE: Remove Electrical Connector

for Rack Mount Units

FIGURE 2 – FDC80 TRANSMITTER FIGURE 3 – FDC80 RECEIVER

REAR PANEL REAR PANELFRONT PANEL FRONT PANEL

TECH SUPPORT: 1.888.678.9427

INS_FDC80_REV–

12/29/11

PAGE 2

Page 3

INSTALLATION AND OPERATION MANUAL FDC80

FIGURE 4 – FDC80 RS-485

RS485 2 Wire

BLACK

BLACK WITH WHITE STRIPE

Power Supply:

Surface Mount: 8–15 VDC @ 150mA

Rack Mount: From Rack

NOTE: Remove Electrical Connector

for Rack Mount Units

FIGURE 5 – FDC80 RS-485 TRANSMITTER FIGURE 6 – FDC80 RS-485 RECEIVER

REAR PANEL REAR PANELFRONT PANEL FRONT PANEL

TECH SUPPORT: 1.888.678.9427

INS_FDC80_REV–

12/29/11

PAGE 3

Page 4

INSTALLATION AND OPERATION MANUAL FDC80

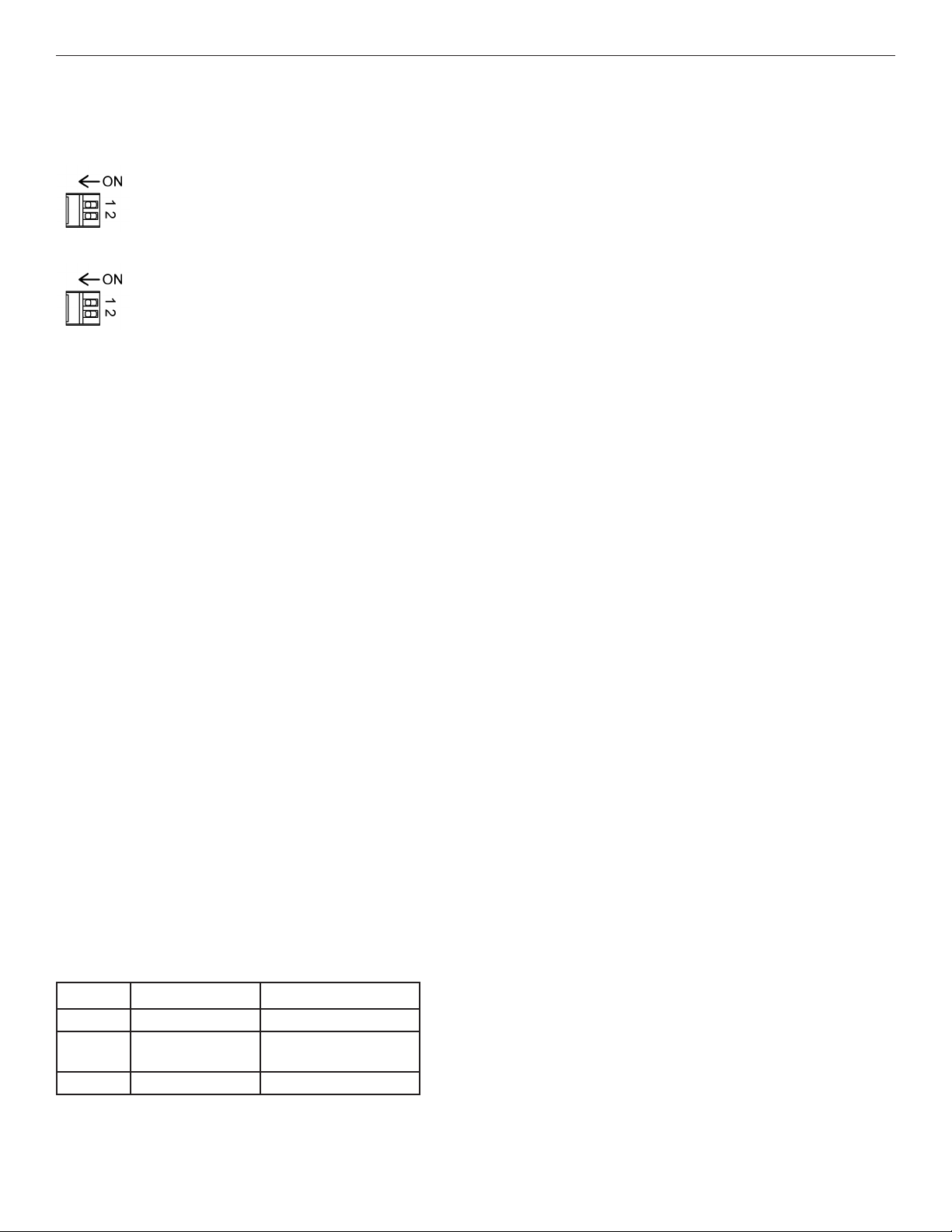

FIGURE 7 – SWITCH SETTINGS

The switch is located on the front panel of each unit.

Transmitter

1 - Series Supervision

2 - Parallel Supervision

Receiver

1 - Fiber Alarm

2 - Contact Fault Alarm

TX: The transmitter switch selects the supervision method, and this information is automatically transmitted to the receiver module.

There are four levels of supervision.

NONE: S1-OFF, S2-OFF. No supervision is active. The contact will show as closed when the inputs are shorted, and open when the

input are open. The associated LED will be either GREEN (closed) or OFF (open).

Series: S1-ON, S2-OFF. Series termination is when a 1K resistor is connected in series with the relay input. In this mode, shorts

across the contact inputs can be detected. When the relay is closed normally, the LED indicator will be GREEN, when open it will be

OFF, when shorted, the LED will flash RED slow.

Parallel: S1-OFF, S2-ON. Parallel termination is when a 1K resistor is connected in parallel, across the contact input. In this mode,

cut wires can be detected. When the relay is closed normally, the LED indicator will be GREEN, when open it will be OFF, and when

cut, it will flash RED fast.

Full Supervision: S1-ON, S2-ON. Full Supervision is when a 1K resistor is connected in series with the contact input, and a 1K

resistor is connected in parallel across the contact input. It can detect cuts (fast red flash), shorts (slow red flash) as well as normal

contact closures (GREEN) or opens (OFF).

RX: The switch on the Receiver module is used to add indications to the Alarm relay output. The Non-Latching ALARM output is

released when a power fault has occurred. Additionally, Fiber Loss and Contact Faults can induce the Alarm to trigger as follows:

S1-ON: Add Fiber Loss to the Alarm output

S2-ON: Add contact fault (any channel) to the alarm output (supervisory modes only)

If any contact is in fault (either Cut or Shorted) and S2 is ON, the Alarm will be triggered.

FIGURE 8 – LED INDICATORS

LINK/POWER CHANNEL (1 – 8)

GREEN Link Present Contact Closed

RED Link Loss Slow Flash: Shorted

Fast Flash: Cut

OFF Unit powered down Contact Open

INS_FDC80_REV–

TECH SUPPORT: 1.888.678.9427

12/29/11

PAGE 4

Page 5

INSTALLATION AND OPERATION MANUAL FDC80

FIGURE 9 – CONTACT INPUT CIRCUIT (Typ. 8)

INTERNAL

5V

1K Series*

1K

Parallel*

FIGURE 10 – RELAY OUTPUTS

1K

1K

* Optional external resistors

(provided) are required for

supervision. Place close to

the switch for optimal results.

FIGURE 11 – RS-485 CONTACTS

In RS-485 products (FDC80(T,R)485), the contacts can

be transmitted over a pair of wire instead of fiber. Since

communication is simplex only, just two wires are needed:

A and B. Connect as shown:

Input open

CONTACTSALARM

Input closed

Fault

No fault

TECH SUPPORT: 1.888.678.9427

100 m (300 ft)

Max

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

NO

INS_FDC80_REV–

12/29/11

PAGE 5

Page 6

INSTALLATION AND OPERATION MANUAL FDC80

APPLICATION NOTE

LATCHING RELAYS:

Latching relays are typically used when the application must insure that the contact outputs will not change state when either power

is lost or the fiber is broken. This is a common requirement at high security gate entrance locations, where the gates must not open

under any abnormal operating condition. In other words, they must open ONLY when commanded via the contact input state. Alarm

conditions detected by the wire supervision circuits will therefore leave the relays in their current state.

NON-LATCHING RELAYS:

Non-latching relays are utilized if the contact outputs must switch to a known state when the power is lost or the fiber is broken. This

is a common requirement in applications that require a known failsafe state during abnormal operating conditions. Alarm conditions

detected by the wire supervision circuits will therefore leave the relays in their default failsafe state.

TECH SUPPORT: 1.888.678.9427

INS_FDC80_REV–

12/29/11

PAGE 6

Page 7

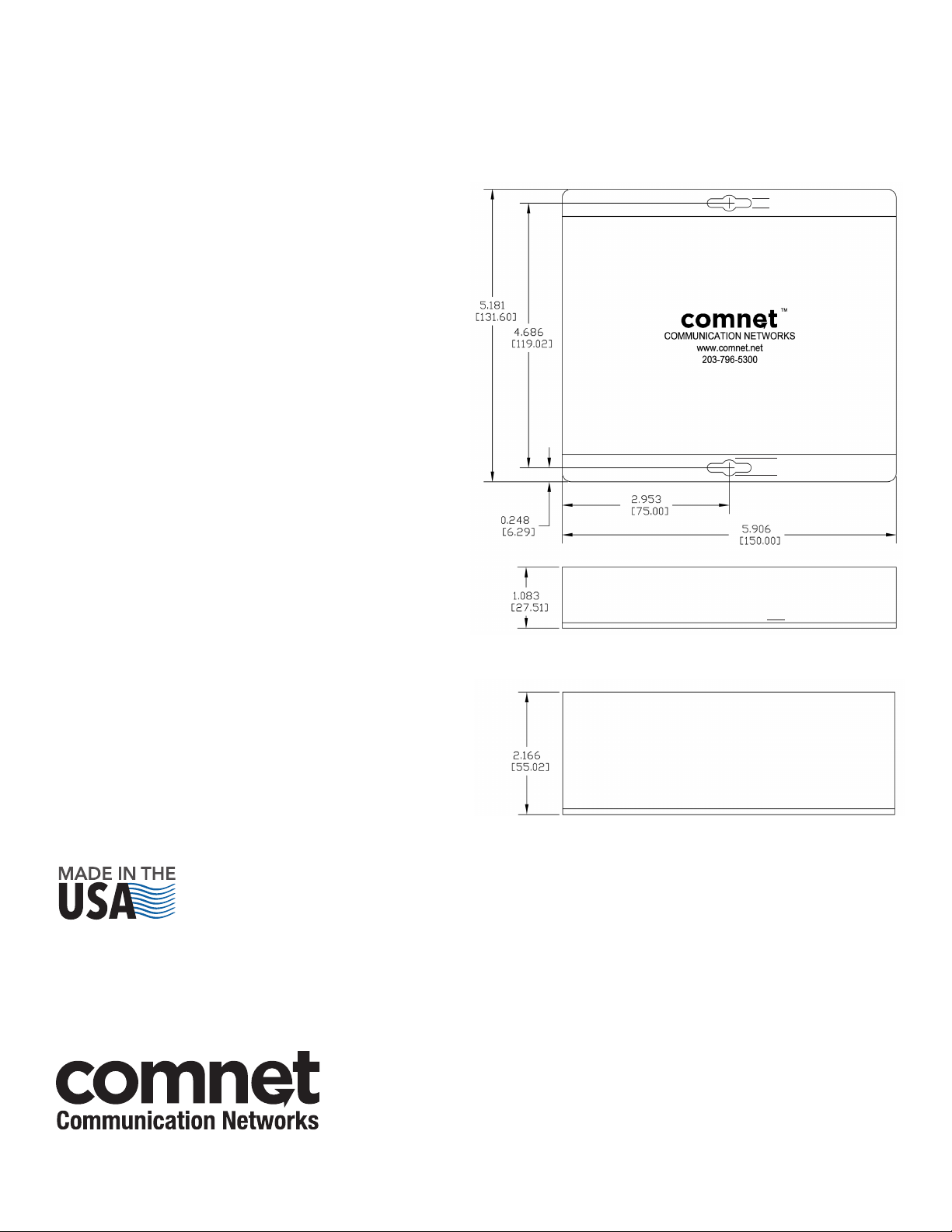

MECHANICAL INSTALLATION INSTRUCTIONS

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone/Rack module. Units

should be installed in dry locations protected from extremes of

temperature and humidity.

C1-US, C1-EU, C1-AU OR C1-CH CARD CAGE RACKS

CAUTION: Although the units are hot-swappable and may be installed

without turning power off to the rack, ComNet recommends that

the power supply be turned off and that the rack power supply is

disconnected from any power source.

1. Make sure that the card is oriented right side up, and slide it into the

card guides in the rack until the edge connector at the back of the

card seats in the corresponding slot in the rack’s connector panel.

Seating may require thumb pressure on the top and bottom of the

card’s front panel.

CAUTION: Take care not to press on any of the LEDs.

2. Tighten the two thumb screws on the card until the front panel of the

card is seated against the front of the rack.

WARNING: Unit is to be used with a Listed Class 2 power supply.

FIGURE A

Dimensions are for a standard ComNet™ module

.156 [3.96 mm]

.313 [7.95 mm]

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

One Slot Module

(Transmitter)

Two Slot Module

(Receiver)

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

INS_FDC80_REV–

12/29/11

PAGE 7© 2014 Communications Networks Corporation. All Right s Reserved. “ComNet ” and the “ComNet Logo” are regis tered trademarks of Communic ation Networks, LLC.

Loading...

Loading...