Page 1

QUICK START GUIDE

FDW1000 / EXP101

OPTICAL WIEGAND, MAGSTRIPE & F/2F DATA

EXTENDER AND EXPANSION MODULE

This guide serves the following

ComNet Model Numbers:

FDW1000M/C

FDW1000M/R

FDW1000S/C

FDW1000S/R

EXP101/C

EXP101/R

The ComNet FDW1000 Series and EXP101 Series of transceivers makes it possible to

install card readers farther from the access control panel by providing a long-range

fiber optic connection between the door or gate readers and most manufacturers’

access control panels. The series includes both a remote (door/gate) device and a

central (access control panel) device. The FDW1000 devices are compatible with the

EXP101 expansion modules that allow up to seven additional readers to share the

optical link created by the FDW1000/C (central) and FDW1000/R (remote) devices.

QSG_FDW1000_EXP101 01/06/2020

Page 2

QUICK START GUIDE FDW1000 / EXP101

Contents

General Information – FDW1000 and EXP101 Series 3

Device description 3

Items in this series 3

Specifications 4

Power 4

Inputs and outputs 4

Contact closure (relay) channels 4

Preparation 5

Tools 5

Before beginning 5

Configuration 6

Configuring an FDW1000 – current version – (rev .3xx range) 6

Configuring an EXP101 – current version – (rev .4xx range) 8

Wiring and Wiring Examples 9

Recommendations for new wire installation 9

Typical wiring diagrams 10

References 15

LED status 15

AutoCAD drawings 16

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 2

Page 3

QUICK START GUIDE FDW1000 / EXP101

General Information – FDW1000 and EXP101 Series

Device description

The ComNet FDW1000 Series and EXP101 Series of transceivers makes it possible to install

card readers farther from the access control panel by providing a long-range fiber optic connection between the door or gate readers and most manufacturers’ access control panels. The

series includes both a remote (door/gate) device and a central (access control panel) device. The

FDW1000 devices are compatible with the EXP101 expansion modules that allow up to seven

additional readers to share the optical link created by the FDW1000/C (central) and FDW1000/R

(remote) devices.

Items in this series

FDW1000M/C – Wiegand transceiver, central side, multimode

FDW1000M/R – Wiegand transceiver, remote side, multimode

FDW1000S/C – Wiegand transceiver, central side, singlemode

FDW1000S/R – Wiegand transceiver, remote side, singlemode

EXP101/C – expansion module, central side

EXP101/R – expansion module, remote side

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 3

Page 4

QUICK START GUIDE FDW1000 / EXP101

Specifications

The following specifications apply to all of the items in this series

Power

• operating voltage range = DC 8 to 12 V

• power consumption < 6 W each

• hardened power supply item number PS-AMR5-12 as needed

Inputs and outputs

Data

• Wiegand (max 248 bits pass through, filter the first eight bits unless Wiegand No Filter is active)

• strobed (clock and data)

• F/2F unsupervised

LED

• DC 0 to 30 V

Contact closure (relay) channels

Relay Channels 1 and 2

• FDW1000/C and EXP101/C central units will each accept up to two dry contact closures as

inputs – RELAY 1 IN and RELAY 2 IN – and pass the status of each contact to corresponding

FDW1000/R and EXP101/R remote units, each containing two single-pole, double-throw relays

– RELAY 2 OUT and RELAY 2 OUT.

Relay Channels 3 and 4

• FDW1000/R and EXP101/R remote unit will each accept up to two dry contact closures as

inputs – RELAY 3 IN and RELAY 4 IN – and pass the status of each contact to corresponding

FDW1000/C and EXP101/C central units, each containiing two single-pole, double-throw relays

– RELAY 3 OUT and RELAY 4 OUT.

Relay Contact Ratings

• DC 30 V, 1.0 A, resistive loads only, 1 × 105 operations at +room temperature (+20°C or+68°F)

• AC 125 V, 0.3 A, resistive loads only, 1 × 105 operations at +room temperature (+20°C or+68°F)

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 4

Page 5

QUICK START GUIDE FDW1000 / EXP101

Preparation

Tools

• #1 tip Phillips head screwdriver to remove metal covers

• small flat blade screwdriver to set the DIP switches

Before beginning

• determine the communications format for each reader;

• Wiegand with data words that are at least 8 bits (most readers), or;

• Wiegand with data words that are less than 8 bits (typical of reader / keypad combination units), or;

• unsupervised F/2F (Casi Rusco systems)

• determine the number of expansion module pairs – if any – that will be needed (this quantity

will be one less than the number of readers in the link);

• determine whether Relay 3 will be reserved to monitor the status of the optical link;

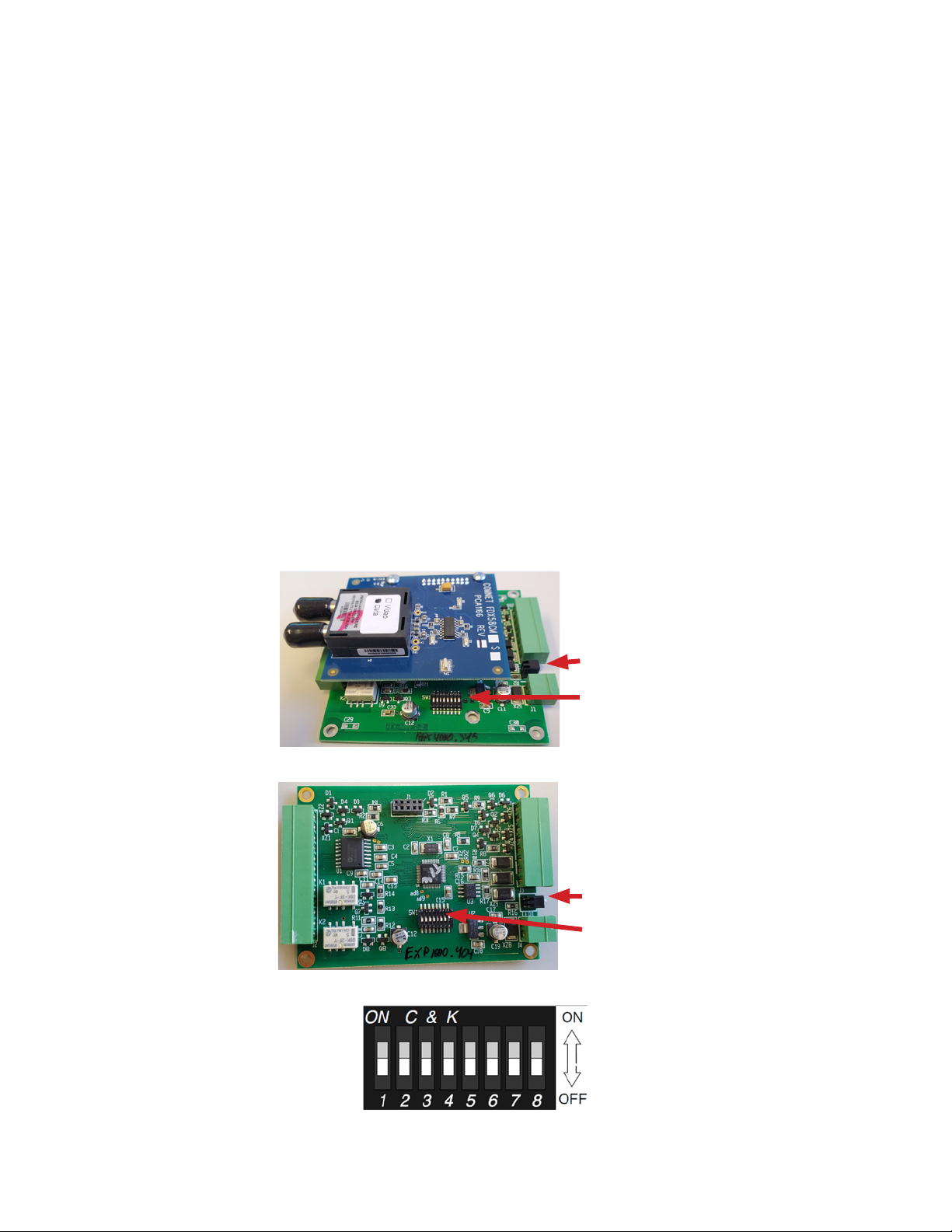

• locate the STATUS indicator LED (between the 2-pin power connector and the 8-pin terminal

strip – see Figures 1 and 2 below)

• with the cover removed, locate the eight DIP switches (OFF is toward the edge of the circuit

board and Switch 8 is closest to the power connector – see Figures 1, 2, and 3 below).

“S TAT US” LED

DIP switches

Figure 1 – FDW1000

“S TAT US” LED

DIP switches

Figure 3 – expanded view of DIP switches

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

Figure 2 – EXP101

QSG_FDW1000_EXP101 01/06/2020 PAGE 5

Page 6

QUICK START GUIDE FDW1000 / EXP101

Configuration

Configuring an FDW1000 – current version – (rev .3xx range)

Initialization

• Do not apply power to the FDW1000. Remove all fiber and signal connections. Remove the

metal housing to expose the DIP switches.

• Turn DIP Switches 1 and 4 ON, all others OFF.

• Using DIP Switches 6, 7, and 8, set the communications format using the following table:

Communications Format DIP Switch 6 DIP Switch 7 DIP Switch 8

not used during initialization OFF OFF OFF

Wiegand OFF OFF ON

Wiegand, no filter OFF ON OFF

strobed rising edge (MR-5) OFF ON ON

strobed rising edge (Dorado 644) ON OFF OFF

strobed rising edge (Mag-Tek) ON OFF ON

strobed falling edge ON ON OFF

unsupervised F/2F ON ON ON

• Apply power to the FDW1000.

• The STATUS indicator LED near the power connector should very quickly become solid green.

• If the STATUS indicator LED quickly becomes solid green, the unit is now initialized. Continue

to the Programming section below.

• If the STATUS indicator LED fails to quickly become solid green, repeat the steps above. If still

unsuccessful, consider the unit bad.

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 6

Page 7

QUICK START GUIDE FDW1000 / EXP101

Programming

• Remove power from the FDW1000.

• Turn all DIP switches OFF.

• Continue to set Central / Remote (Switch 3), Supervision Relay Mode (Switch 4), Pull-Up Resistor

Mode (Switch 5), and number of EXP101 pairs (Switches 6, 7, and 8) using the following table:

DIP Switch Number DIP Switch Setting

1 – not used during programming OFF

2 – not used during programming OFF

3 – Central / Remote

4 – Supervision Relay

5 – Pull-Up Resistor

6, 7, and 8 – Number of EXP101

Pairs

OFF = Remote unit

ON = Central unit

OFF = disables supervision relay – allows Relay Channel 3 to operate as an independent

dry contact closure channel

ON = enables supervision relay – allows Relay Channel 3 to be used to monitor the status

of the optical link

OFF = disables pull-up resistor

ON = enables pull-up resistor (for copper paths > 200 ft or when using F/2F Casi Rusco 941)

OFF OFF OFF = no expansion modules

OFF OFF ON = one pair of expansion modules

OFF ON OFF = two pairs of expansion modules

OFF ON ON = three pairs of expansion modules

ON OFF OFF = four pairs of expansion modules

ON OFF ON = five pairs of expansion modules

ON ON OFF = six pairs of expansion modules

ON ON ON = seven pairs of expansion modules

• Apply power to the FDW1000. The device is now ready to use.

A common ground connection is critical for proper operation. At each remote location, a common

ground must exist between the reader(s), the FDW1000/R, and any EXP101/Rs. At the central location, a common ground must exist between the panel, the FDW1000/C, and any EXP101/Cs.

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 7

Page 8

QUICK START GUIDE FDW1000 / EXP101

Configuring an EXP101 – current version – (rev .4xx range)

• Do not apply power to the EXP101. Remove all copper and signal connections. Remove the

metal housing to expose the DIP switches.

• Turn all DIP switches OFF.

• DIP Switch 1 on the EXP101 is used during factory testing but is not used during configuration

and should remain OFF.

• Using DIP Switch 2, set each unit as an EXP101/C (Central unit) or as an EXP101/R (Remote unit).

• Turn DIP Switch 2 ON to make the unit an EXP101/C (Central unit).

• Leave DIP Switch 2 OFF to make the unit an EXP101/R (Remote unit).

• Using DIP Switches 3, 4, and 5, set the communications format using the following table:

Communications Format DIP Switch 3 DIP Switch 4 DIP Switch 5

Not used OFF OFF OFF

Wiegand OFF OFF ON

Wiegand, no filter OFF ON OFF

strobed rising edge (MR-5) OFF ON ON

strobed rising edge (Dorado 644) ON OFF OFF

strobed rising edge (Mag-Tek) ON OFF ON

strobed falling edge ON ON OFF

unsupervised F/2F ON ON ON

• Using DIP Switches 6, 7, and 8, set the polling address of each pair of EXP101s using the table

below.

• If only one pair of EXP101s will be used, set the EXP101/C and the EXP101/R to polling address 1.

• If more than one pair of EXP101s will be used, set one pair of EXP101/C and EXP101/R to polling

address 1. Address the next pair using polling address 2 and continue sequentially as needed.

Number of EXP101 Pairs DIP Switch 6 DIP Switch 7 DIP Switch 8

Not used OFF OFF OFF

one pair of EXP101s – polling address 1 OFF OFF ON

two pairs of EXP101s – polling address 2 OFF ON OFF

three pairs of EXP101s – polling address 3 OFF ON ON

four pairs of EXP101s – polling address 4 ON OFF OFF

five pairs of EXP101s – polling address 5 ON OFF ON

six pairs of EXP101s – polling address 6 ON ON OFF

seven pairs of EXP101s – polling address 7 ON ON ON

• Apply power to the EXP101. The unit is now ready to use.

A common ground connection is critical for proper operation. At each remote location, a common

ground must exist between the reader(s), the FDW1000/R, and any EXP101/Rs. At the central location, a common ground must exist between the panel, the FDW1000/C, and any EXP101/Cs.

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 8

Page 9

QUICK START GUIDE FDW1000 / EXP101

Wiring and Wiring Examples

Recommendations for new wire installation

Power

PVC - Belden 8461 - 18 AWG 1 pair, 25 feet max.

Plenum - Belden 82740 - 18 AWG 1 pair, 25 feet max.

Wiegand / LED

PVC - Belden 9942 or 8777 - 22 AWG 3 pair shielded, 250 feet max.

Plenum - Belden 82777 - 22 AWG 3 pair shielded, 250 feet max.

PVC - Belden 9873 - 20 AWG 3 pair shielded, 500 feet max.

Plenum - Belden 83606 or 85164 - 20 AWG 3 pair shielded, 500 feet max.

Inputs and Outputs

PVC - Belden 8451 - 22 AWG 1 pair, 1,000 feet max.

Plenum - Belden 82761 - 22 AWG 1 pair, 1,000 feet max.

RS-485

PVC - Belden 9744 - 22 AWG 2 twisted pair, 4,000 feet max.

Plenum - Belden 82741 - 22 AWG 2 twisted pair, 4,000 feet max.

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 9

Page 10

QUICK START GUIDE FDW1000 / EXP101

Typical wiring diagrams

The following diagrams show some typical wiring examples. For simplicity, each diagram shows

only the connections that are relavent to the diagram’s purpose.

Wiring common grounds

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 10

Page 11

QUICK START GUIDE FDW1000 / EXP101

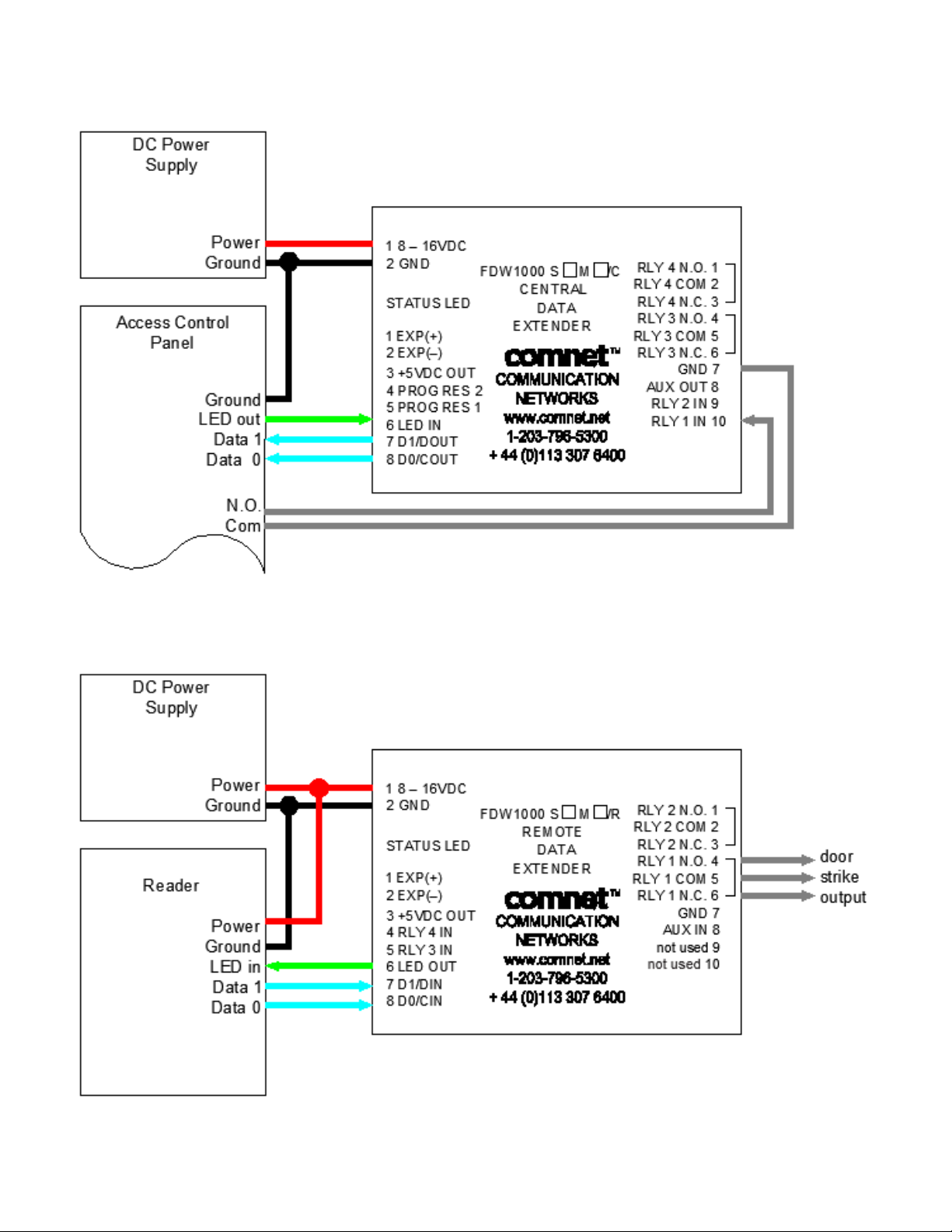

Door strike follows dry contact closure, one reader

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 11

Page 12

QUICK START GUIDE FDW1000 / EXP101

Door strike follows LED, one reader

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 12

Page 13

QUICK START GUIDE FDW1000 / EXP101

Door strike follows dry contact closure, two readers

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 13

Page 14

QUICK START GUIDE FDW1000 / EXP101

Door strike follows LED, two readers

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 14

Page 15

QUICK START GUIDE FDW1000 / EXP101

References

LED status

FDW1000s

• During initialization:

• A solid green STATUS LED on power up indicates that the unit has accepted the settings and

that it is ready to be programmed.

• After successful initialization and programming:

• An alternating green / red STATUS LED indicates that there is no optical link between the

FDW1000s.

• If using expansion modules, a solid green STATUS LED indicates a problem with at least one

expansion module connected to the FDW1000 at the opposite end.

• A rapidly flashing green STATUS LED indicates that there is communication between the Central

and the Remote units and – if using expansion modules – all expansions modules are operating

properly. The STATUS LED’s will flash green after each polling cycle. The frequency of the flashing

will depending on the number of expansion modules being used. With only one pair of FDW1000s

connected – no expansion modules – the STATUS LED should flash several times per second. With

seven sets of expansion modules, the STATUS LED could flash as slowly as one flash per second.

EXP101s

• Once a Central / Remote pair of FDW1000s and the pair(s) of EXP101s have been successfully

initialized and programmed:

• A STATUS LED-flashing green slowly indicates that there is no optical link between the FDW1000s.

• A solid red STATUS indicator LED indicates that the unit is properly powered but there is no

2-wire RS-485 link.

• A rapidly flashing green STATUS LED indicates that there is communication between the

Central and the Remote units and that there is a good 2-wire RS-485 link. The STATUS LED

will flash green after each polling cycle. The frequency of the flashing will depending on the

number of expansion modules being used. With only one pair of FDW1000s connected – no

expansion modules – the STATUS LED’s should flash several times per second. With seven sets

of expansion modules, the STATUS LED could flash as slowly as one flash per second.

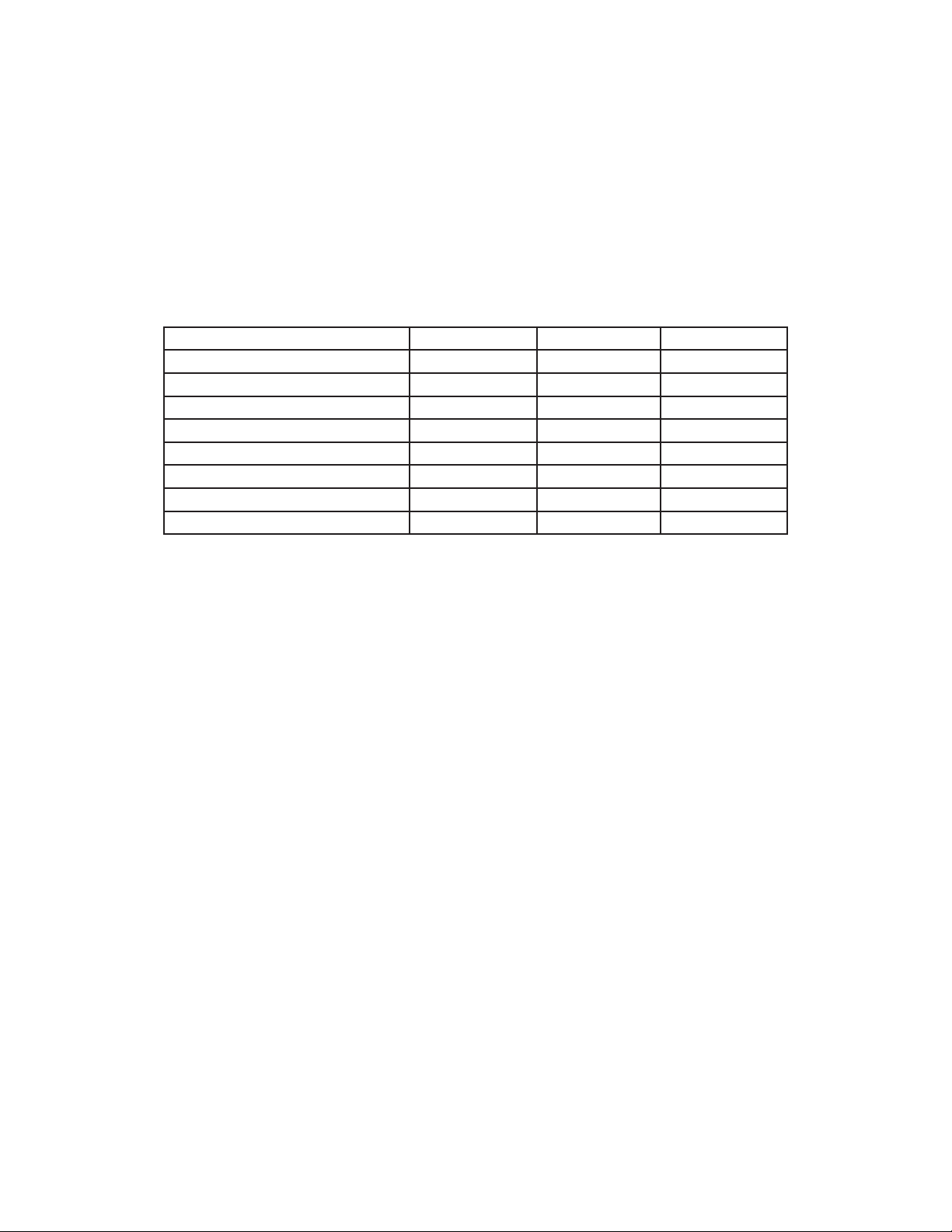

LED Status

STAT US LE D

Off not properly powered not properly powered not properly powered

Green, solid ready to be programmed opposite side expansion module failure not used

Green, flashing slowly not used not used optical link failure

Green, flashing rapidly not used good optical link

Red, solid not used not used no 2-wire RS-485 link

Red, flashing not used not used not used

Red / Green, alternating not used optical link failure not used

(during initialization)

FDW

(initialized and programmed)

FDW

EX P101

(programmed)

good optical link and

good 2-wire RS-485 link

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 15

Page 16

QUICK START GUIDE FDW1000 / EXP101

AutoCAD drawings

TECH SUPPORT: 1.888.678.9427 / +44 (0)203 630 1653

QSG_FDW1000_EXP101 01/06/2020 PAGE 16

Page 17

ComNet Customer Service

Customer Care is ComNet Technology’s global service center, where our

professional staff is ready to answer your questions at any time.

Email ComNet Global Service Center: customercare@comnet.net

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

SUITE 4 - 2 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)203 630 1652 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

© 2020 Communications Networks Corporation. All Rights Reserved. “ComNet ” and the “ComNet Logo” are registered trademarks of Communication Net works, LLC.

QSG_FDW1000_EXP101 01/06/2020

Loading...

Loading...