Page 1

INSTALLATION AND OPERATION MANUAL

EXP100

EXPANSION MODULE FOR USE

WITH FDW1000 WIEGAND MODULE

When used with the FDW1000 series of fiber optic Wiegand extender modules,

the ComNet™ EXP100 Expansion Module enables additional Wiegand control

panels, readers, and associated door/gate hardware to be added to the network.

The 2-wire RS-485 data interface between the expansion modules provides a secure

and completely supervised connection, with excellent immunity to electrical noise

and interference. Up to 8 EXP100s can be used in a drop-and-repeat/daisy-chain

topology, and each EXP100 may be set to a unique address (1 thru 15) via DIP-switch

selection.

An auxiliary I/O (input/output) interface is available for ascertaining door, gate, and

control panel status and signaling, and a relay interface provides the door strike or

gate activation functions. See Figures 10 and 11 beginning on Page 5 for a guide

to the I/Os and Relay Controls.

The EXP100 is supplied as a remote unit for door or gate locations or a central unit

for control panel installation. See Figures 3 through 5 on Page 3 for Central and

Remote Dip Switch Settings.

These extenders are designed for long-term, reliable operation in harsh industrial

environments, and a fault-specific LED indicator is provided for rapidly ascertaining

the operating status of the extender and the link. See Figure 17 on Page 12 for an

explanation of LED indicators.

Packaged in a rugged aluminum housing, the EXP100 is designed for shelf or

surface mounting. See Figure A on Page 12 for mounting instructions.

See Figures 1 – 17 for complete installation details.

Rev. 04.18.13

INS_EXP100_REV– 12/04/12 PAGE 1

Page 2

INSTALLATION AND OPERATION MANUAL EXP100

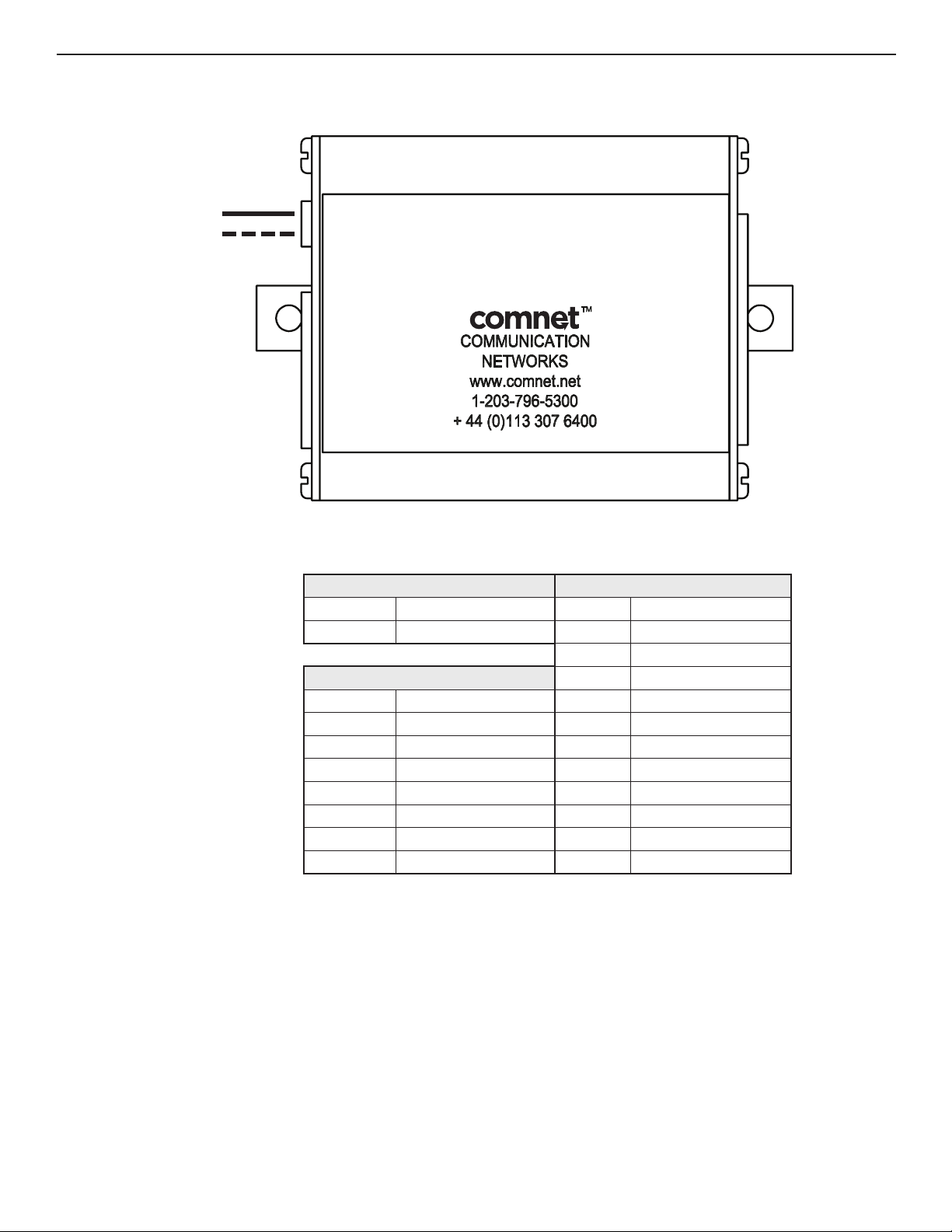

FIGURE 1 – EXP100/C CENTRAL DATA EXTENDER

BLACK

BLACK& WHITE/RED

Power Supply:

Input:

8–16 VDC @ 200mA Max

Output:

+5 VDC @ 100mA

18–16VDC

2GND

STATUS LED

EXP100/C

CENTRAL

EXPANSION

MODULE

1RS-485(+)

2RS-485(–)

3

4

5

6LED IN

7D1/DOUT

8D0/COUT

Power Connections Relay Connections

1 - 8 – 16VDC Power IN (+) 1 N.O. Contact

2 - GND Power IN (–) 2 Common

Data Connections 4 N.O. Contact

1 RS-485(+) RS-485 Input 5 Common

2 RS-485(–) RS-485 Input 6 N.C. Contact

3 +5 VDC OUT - 5V Power Out 7 RS232 Serial Data OUT

4 Analog Input #2 8 RS232 Serial Data IN

5 Analog Input #1 9 Wiegand/RS232 Ground

6 LED Signal Input/Output 10 Auxiliary Digital Output

7 D1/DOUT Wiegand Data 1 Output 11 Digital Input

8 D0/COUT Wiegand Data 0 Output RLY 1 IN 12 Digital Input

RLY 1IN12

3 N.C. Contact

1

2

3

4

5

6

7

8

9

10

11

INS_EXP100_REV– 12/04/12 PAGE 2TECH SUPPORT: 1.888.678.9427

Page 3

INSTALLATION AND OPERATION MANUAL EXP100

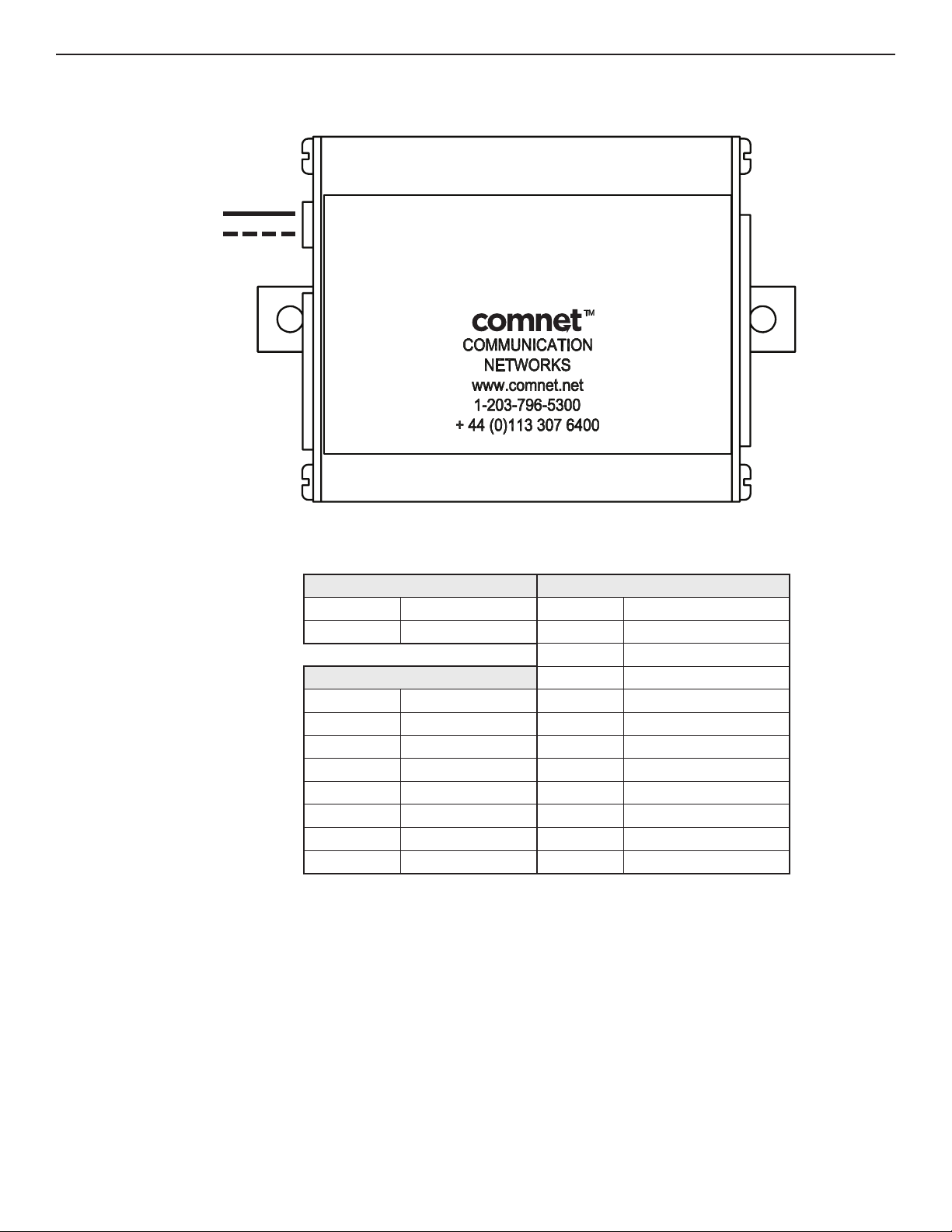

FIGURE 2 – EXP100/R REMOTE DATA EXTENDER

BLACK

BLACK& WHITE/RED

Power Supply:

Input:

8–16 VDC @ 200mA Max

Output:

+5 VDC @ 100mA

18–16VDC

2GND

STATUS LED

1RS-485(+)

2RS-485(–)

EXP100/R

REMOTE

EXPANSION

MODULE

RLY1N.O. 4

RLY1COM5

RLY1N.C. 6

3+5VDC OUT

4

5

6LED OUT

7D1/DIN

8D0/CIN

Power Connections Relay Connections

1 - 8 – 16VDC Power IN (+) 1 N.O. Contact

2 - GND Power IN (–) 2 Common

3 N.C. Contact

Data Connections RLY 1 N.O. 4 N.O. Contact

1 RS-485(+) RS-485 Input RLY 1 COM 5 Common

2 RS-485(–) RS-485 Input RLY 1 N.C. 6 N.C. Contact

3 +5 VDC OUT 5V Power Out 7 RS232 Serial Data OUT

4 Analog Input #4 8 RS232 Serial Data IN

5 Analog Input #3 9 Wiegand/RS232 Ground

6 LED OUT LED Signal Output 10 Auxiliary Digital Input

7 D1/DIN Wiegand Data 1 Input 11 Not Used

8 D0/CIN Wiegand Data 0 Input 12 Not Used

1

2

3

7

8

9

10

11

12

INS_EXP100_REV– 12/04/12 PAGE 3TECH SUPPORT: 1.888.678.9427

Page 4

INSTALLATION AND OPERATION MANUAL EXP100

1 2345678

FIGURE 3 – EXP-100/C DIP SWITCH ADDRESS SETTINGS

Dip Switch is located beneath the casing of each unit.

1. Initialize the EXP100 following these steps:

2. With the power off, set DIP switch #1 to ON, all other DIP switches to OFF.

3. Apply power to the EXP100. The STATUS LED should illuminate solid green.

4. Remove power and set all DIP switches to OFF.

5. Proceed with the following table to set DIP switches for address and Wiegand direction.

ON

Address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Switch

1 2 3 4 5 6 7 8

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

¡

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡

¡ ¡ ¡

¡ ¡ ¡

¡ ¡ ¡

¡ ¡

¡ ¡

¡ ¡

¡ ¡

¡ ¡

¡ ¡

¡ ¡

¡

¡

l

l

l

l

l l

l l

l l l

l l l l l

¡ ¡ ¡ ¡

l

l

l l

¡ ¡

l

¡

l

l l

l l l

¡ ¡ ¡

¡ ¡

¡

l

¡

l l

¡ ¡

¡

l

l

l

l

¡

¡

¡

¡

l = ON

¡ = OFF

Each EXP100 can be set to a unique address,

1 through 15.

When using the EXP100 units with a ComNet

gateway system, the addresses must be set

consecutively from 1 to the maximum address.

Most ComNet gateway systems will support a

maximum of eight (8) devices (refer to the ComNet

FDW100(M,S) Instruction Manual).

Example:

In a FDW1000 system set up with four (4) pairs of

EXP100 units, the addresses should be set: 1, 2, 3, 4

for the four pairs that will be used (not 2, 3, 4, 5 or 4,

6, 7, 8, etc.)

Note: To operate as a Wiegand Transmitter

(“Central”) unit, DIP switch #2 must be ON.

In a ComNet FDW1000 gateway system,

Dip switch #3 must be OFF.

INS_EXP100_REV– 12/04/12 PAGE 4TECH SUPPORT: 1.888.678.9427

Page 5

INSTALLATION AND OPERATION MANUAL EXP100

1 2345678

FIGURE 4 – EXP-100/R DIP SWITCH ADDRESS SETTINGS

Dip Switch is located beneath the casing of each unit.

1. Initialize the EXP100 following these steps:

2. With the power off, set DIP switch #1 to ON, all other DIP switches to OFF.

3. Apply power to the EXP100. The STATUS LED should illuminate solid green.

4. Remove power and set all DIP switches to OFF.

5. Proceed with the following table to set DIP switches for address and Wiegand direction.

ON

Address

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Switch

1 2 3 4 5 6 7 8

¡ ¡ ¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡ ¡

¡ ¡ ¡

¡ ¡ ¡

l

l

l

l

l l

l l

l l l

l l l l l

¡ ¡ ¡ ¡

l

l

l l

¡ ¡

l

¡

l

l l

l l l

¡ ¡ ¡

¡ ¡

¡

l

¡

l l

¡ ¡

¡

l

l

l

l

¡

¡

¡

¡

l = ON

¡ = OFF

Each EXP100 can be set to a unique address,

1 through 15.

When using the EXP100 units with a ComNet

gateway system, the addresses must be set

consecutively from 1 to the maximum address.

Most ComNet gateway systems will support a

maximum of eight (8) devices (refer to the ComNet

FDW100(M,S) Instruction Manual).

Example:

In a FDW1000 system set up with four (4) pairs of

EXP100 units, the addresses should be set: 1, 2, 3, 4

for the four pairs that will be used (not 2, 3, 4, 5 or 4,

6, 7, 8, etc.)

Note: To operate as a Wiegand Receiver (“Remote”)

unit, DIP switch #2 must be OFF.

In a ComNet FDW1000 gateway system,

Dip switch #3 must be OFF.

INS_EXP100_REV– 12/04/12 PAGE 5TECH SUPPORT: 1.888.678.9427

Page 6

INSTALLATION AND OPERATION MANUAL EXP100

80

FIGURE 5 – LED INDICATORS

EXP100/C EXP100/R

GRN FLASH

RED N/A

RED/GRN FLASH

OFF Unit Powered Down / Electrical Problem

Unit is operating correctly and there is a valid communication channel between the Central

and Remote units.

Remote unit is not receiving communication

from the Central unit.

Central unit is not receiving communication

from the Remote unit.

N/A

FIGURE 6 – TEMPERATURE RATING vs. VOLTAGE DERATING CURVE

55

Ambient

Temperature

(º C)

35

-40

8

The EXP100 should be operated with a filtered 12 VDC power supply. Any voltage between 8 and 16 Voltes can be utilized by

following this curve. Voltage should not exceed 16 VDC under normal operating conditions.

10 12

Supply Voltage

14 16

INS_EXP100_REV– 12/04/12 PAGE 6TECH SUPPORT: 1.888.678.9427

Page 7

INSTALLATION AND OPERATION MANUAL EXP100

RLY4N.O. 1

RLY4COM 2

RLY4N.C. 3

RLY3N.O. 4

RLY3COM 5

RLY3N.C. 6

GND7

AUXOUT8

RLY 2 IN 9

RLY 1 IN 10

1 EXP(+)

2EXP(–)

3 +5V OUT

4 PROG RES 2

5PROG RES 1

6LED IN

7 D1/DOUT

8D0/COUT

STATUS LED

18–16VDC

2GND

FDW1000S M/C

CENTRAL

DATA

EXTENDER

RXTX

1

2

3

4

5

6

7

8

9

10

11

RLY 1IN12

1RS-4 85(+)

2RS-485(–)

3

4

5

6LED IN

7D1/DOUT

8D0/COUT

STATUS LED

18–16VDC

2GND

EXP100/C

CENTRAL

EXPANSION

MODULE

1

2

3

4

5

6

7

8

9

10

11

RLY 1IN12

EXP100/C

CENTRAL

EXPANSION

MODULE

RXTX

RLY4N.O. 1

RLY4COM 2

RLY4N.C. 3

RLY3N.O. 4

RLY3COM 5

RLY3N.C. 6

GND7

AUXOUT8

RLY 2 IN 9

RLY 1 IN 10

FDW1000S M/C

CENTRAL

DATA

EXTENDER

RXTX

FIGURE 7 – TYPICAL APPLICATION IN CONJUNCTION WITH FDW1000 GATEWAY SYSTEM

CENTRAL REMOTE

FDW1000S1/C

FDW1000S1/R

Access

Control

System

EXP100/C

EXP100/R

EXP100/C

EXP100/R

EXP100/C

Access

EXP100/R

Control

System

EXP100/C

EXP100/R

FIGURE 8 – EXP100 CENTRAL INTERFACE

Card

Reader

Card

Reader

Card

Reader

Card

Reader

Card

Reader

Wiegand Data

Optic Fiber

RS485 Link – Muti-drop

DC

Power

Supply

Access

Control

Panel

Additional EXP100/C

Modules

18–16VDC

2GND

STATUS LED

1 EXP(+)

2EXP(–)

3 +5V OUT

4 PROG RES 2

5PROG RES 1

6LED IN

7 D1/DOUT

8D0/COUT

RLY4N.O. 1

RLY4COM 2

RLY4N.C. 3

RLY3N.O. 4

RLY3COM 5

RLY3N.C. 6

GND7

AUXOUT8

RLY 2 IN 9

RLY 1 IN 10

RXTX

R1 Input

Controls Strike

on Remote

FDW1000/C

18–16VDC

2GND

STATUS LED

1RS-4 85(+)

2RS-485(–)

3

4

5

6LED IN

7D1/DOUT

8D0/COUT

RLY 1IN12

1

2

3

4

5

6

7

8

9

10

11

EXP100/C

INS_EXP100_REV– 12/04/12 PAGE 7TECH SUPPORT: 1.888.678.9427

Page 8

INSTALLATION AND OPERATION MANUAL EXP100

STATUSLED

RLY2N.O. 1

RLY 2COM 2

RLY2N.C. 3

RLY1N.O. 4

RLY 1COM5

RLY 1N.C. 6

GND7

AUX IN8

9

10

1 EXP(+)

2EXP(–)

3+5V OUT

4RLY 4 IN

5RLY 3IN

6LED OUT

7D1/DIN

8D0/CIN

18–16VDC

2GND

FDW1000 SM/R

REMOTE

DATA

EXTENDER

RXTX

1

2

3

4

5

6

7

8

9

10

11

RLY 1IN12

1RS-4 85(+)

2RS-485(–)

3

4

5

6LED IN

7D1/DOUT

8D0/COUT

STATUS LED

18–16VDC

2GND

EXP100/C

CENTRAL

EXPANSION

MODULE

1

2

3

4

5

6

7

8

9

10

11

RLY 1IN12

EXP100/C

CENTRAL

EXPANSION

MODULE

RXTX

RLY2N.O. 1

RLY 2COM 2

RLY2N.C. 3

RLY1N.O. 4

RLY 1COM5

RLY 1N.C. 6

GND7

AUX IN8

9

10

FDW1000 SM/R

REMOTE

DATA

EXTENDER

RXTX

FIGURE 9 – FDW1000 TO EXP100 REMOTE INTERFACE

DC

Power

Supply

Card

Reader

Additional EXP100/R

Modules

18–16VDC

2GND

STATUS LED

1RS-4 85(+)

2RS-485(–)

3

4

5

6LED IN

7D1/DOUT

8D0/COUT

18–16VDC

2GND

STATUSLED

1 EXP(+)

2EXP(–)

3+5V OUT

4RLY 4 IN

5RLY 3IN

6LED OUT

7D1/DIN

8D0/CIN

RLY2N.O. 1

RLY 2COM 2

RLY2N.C. 3

RLY1N.O. 4

RLY 1COM5

RLY 1N.C. 6

GND7

AUX IN8

9

10

RLY 1IN12

RXTX

Door Strike

Output

FDW1000/R

1

2

3

4

5

6

7

8

9

10

11

EXP100/R

INS_EXP100_REV– 12/04/12 PAGE 8TECH SUPPORT: 1.888.678.9427

Page 9

Page 10

MECHANICAL INSTALLATION INSTRUCTIONS

INSTALLATION CONSIDERATIONS

This fiber-optic link is supplied as a Standalone module. Units should be

installed in dry locations protected from extremes of temperature and

humidity.

CAUTION: Take care not to press on the LED.

WARNING: Unit is to be used with a Listed Class 2 or LPS power supply.

IMPORTANT SAFEGUARDS:

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may

be greater than room ambient. Therefore, consideration should be given to

installing the equipment in an environment compatible with the maximum

ambient temperature (Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such

that the amount of air flow required for safe operation of the equipment is not

compromised.

FIGURE A

Dimensions are for a standard ComNet EXP100 module.

3.65"

[9.27 cm]

Unit Height

Ø0.15"

[0.38 cm]

0.75" [1.91 cm]

3.3"

[8.38 cm]

1.4" [3.56 cm]

2.8" [7.11 cm]

3 CORPORATE DRIVE | DANBURY, CT 06810 | USA

T: 203.796.5300 | F: 203.796.5303 | TECH SUPPORT: 1.888.678.9427 | INFO@COMNET.NET

8 TURNBERRY PARK ROAD | GILDERSOME | MORLEY | LEEDS, UK LS27 7LE

T: +44 (0)113 307 6400 | F: +44 (0)113 253 7462 | INFO-EUROPE@COMNET.NET

© 2013 Communications Ne tworks Cor poration. All Rights Re served. “ComNet” and the “ComNet Lo go” are registered trademark s of Communication Networks , LLC.

INS_EXP100_REV– 12/04/12 PAGE 10

Rev. 04.18.13

Loading...

Loading...