Page 1

23202-A

LGX-Compatible (LSX) 288-Position

Termination With Splicing Module

User Manual

ADCP-93-103 Issue 3 November 2016

ADCP-93-103 Rev B

Page 2

ADCP-93-103 • Issue 3 • November 2016 • Preface

COPYRIGHT

© 2016, CommScope Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 7/2014 Original.

2 Novemeber 2016 Updated to CommScope format.

TRADEMARK INFORMATION

CommScope and CommScope (logo), are trademarks.

Telcordia is a registered trademark of Telcordia Technologies, Inc.

GORE is a registered trademark of W. L. Gore & Associates, Inc.

PATENTS INFORMATION

This product is covered by one or more U.S.patents or their foreign equivalents. For patents, see

http://www.commscope.com/ProductPa

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. CommScope reserves the right to change the contents without prior notice.

In no event shall CommScope be liable for any damages resulting from loss of data, loss of use, or loss of profits and

CoommScope further disclaims any and all liability for indirect, incidental, special, consequential or other similar

damages.This disclaimer of liability applies to

This publication may be verified at any time by con

http://www.commscope.com/SupportCenter

tent/ProductPatent.aspx

all products, publications and services during and after the warranty period.

tacting CommScopes’s Support Center at

Page ii

Page 3

TABLE OF CONTENTS

Content Page

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Admonishments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

List of Acronyms and Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

1 DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Product Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 UNPACKING THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Mounting the Panel on the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Breaking Out a Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installing a Cable Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Cable Routing Within Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 PATCH CORD ROUTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Removing the Front Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Selecting Patch Cord Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Routing Patch Cords on Front of Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Cross-Connecting Within a Stand-Alone Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5 Cross-Connecting Between Two or More Bays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.6 Interconnect Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ADCP-93-103 • Issue 3 • November 2016 • Preface

© 2017 CommScope. All Rights Reserved.

Page iii

Page 4

ADCP-93-103 • Issue 3 • November 2016 • Preface

Page iv

Page 5

ABOUT THIS MANUAL

This manual describes and provides operating instructions for the LGX-Compatible (LSX) 288Position Termination With Splicing panel, for the sake of brevity also called the “LSX-288

termination with splicing panel.”

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below) and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

ADCP-93-103 • Issue 3 • November 2016

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

Danger: Use adequate lifting equipment when moving or installing the cabinet. Verify that the

maximum lift weight rating of the equipment is sufficient to handle the weight of the cabinet.

Danger: Do not stand under a cabin et as it is being hoisted into position for mounting. A failure

of the lifting equipment or apparatus could result in serious personal injury.

Warning: Before digging, check with all local utilities for the presence of buried cables or

pipes. Contact with underground cables or pipes, especially electric power cables and gas

service lines, could interrupt local utility service and cause serious personal injury and

extensive property damage.

© 2017 CommScope. All Rights Reserved.

Page v

Page 6

ADCP-93-103 • Issue 3 • November 2016

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AWG American Wire Gauge

C Centigrade

DI Distribution Intercept

DSL Digital Subscriber Line

DSLAM Digital Subscriber Line Access Multiplexer

F Fahrenheit

MON Monitor

POTS Plain Old Telephone Service

Page vi

© 2017 CommScope. All Rights Reserved.

Page 7

1 DESCRIPTION

This section describes the LSX 288-position termination with splicing panel. Topics include

general description, product function, main components, and dimension s and specifications

1.1 General Description

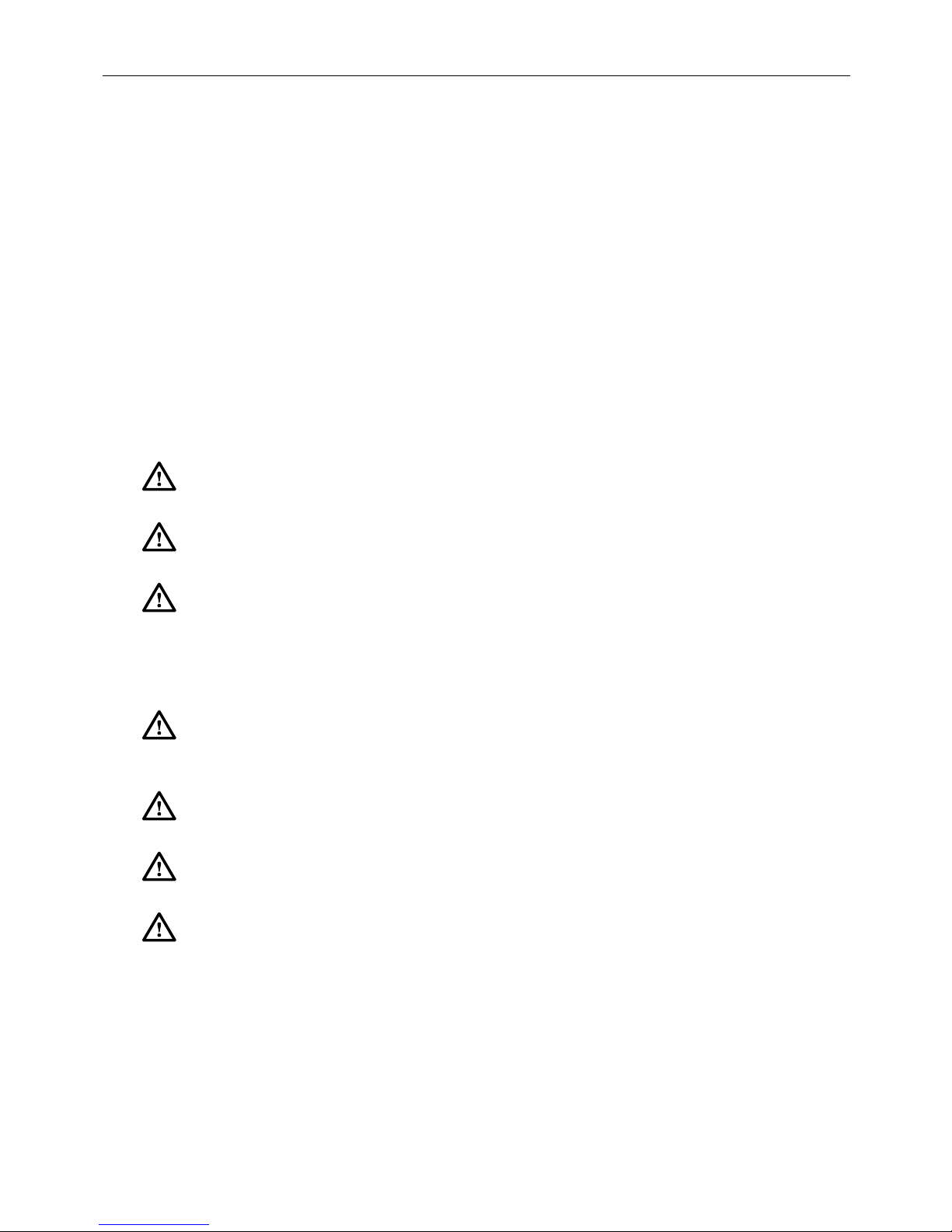

The LSX 288-position termination with splicing panel, shown in Figure 1, is a 23-inch rackmount, LGX-compatible panel that provides a splici

optic cables and a termination bulkhead for fiber optic patch cords.

ADCP-93-103 • Issue 3 • November 2016

ng transition between one or more fiber

This panel has a 15-inch depth permitting splice trays to be mounted in its back compartment.

The rear door swings down and locks in an open position to provide a horizontal working

surface for installing splices. The panel is designed to be mounted on an LSX 18-inch deep

high-density frame.

In a typical application, the pa

nel serves as a splicing and di stribution point to transition from

Outside Plant (OSP) or Intra Facility Cable (IFC) to inbuilding circuits connected to with patch

cords. The panel is shipped with pre-terminated, factory-installed pigtails, either of ribbon or

stranded construction. The panel may be used in either an interconnect or cross-connect

configuration, and in either single mode or multimode applications.

The panel is 11 inches (27.9 cm) high. Five panels fit on a standard 7 foot (2.1 m) frame.

Figure 1. LSX 288-Position Termination With Splicing Panel

23202-A

Page 1

© 2017 CommScope. All Rights Reserved.

Page 8

ADCP-93-103 • Issue 3 • November 2016

INTERNAL

PIGTAILS

SPLICE TRA Y

ACCESS DOOR

OSP OR IFC

CABLE

23203-A

MASS FUSION

SPLICE CHIP

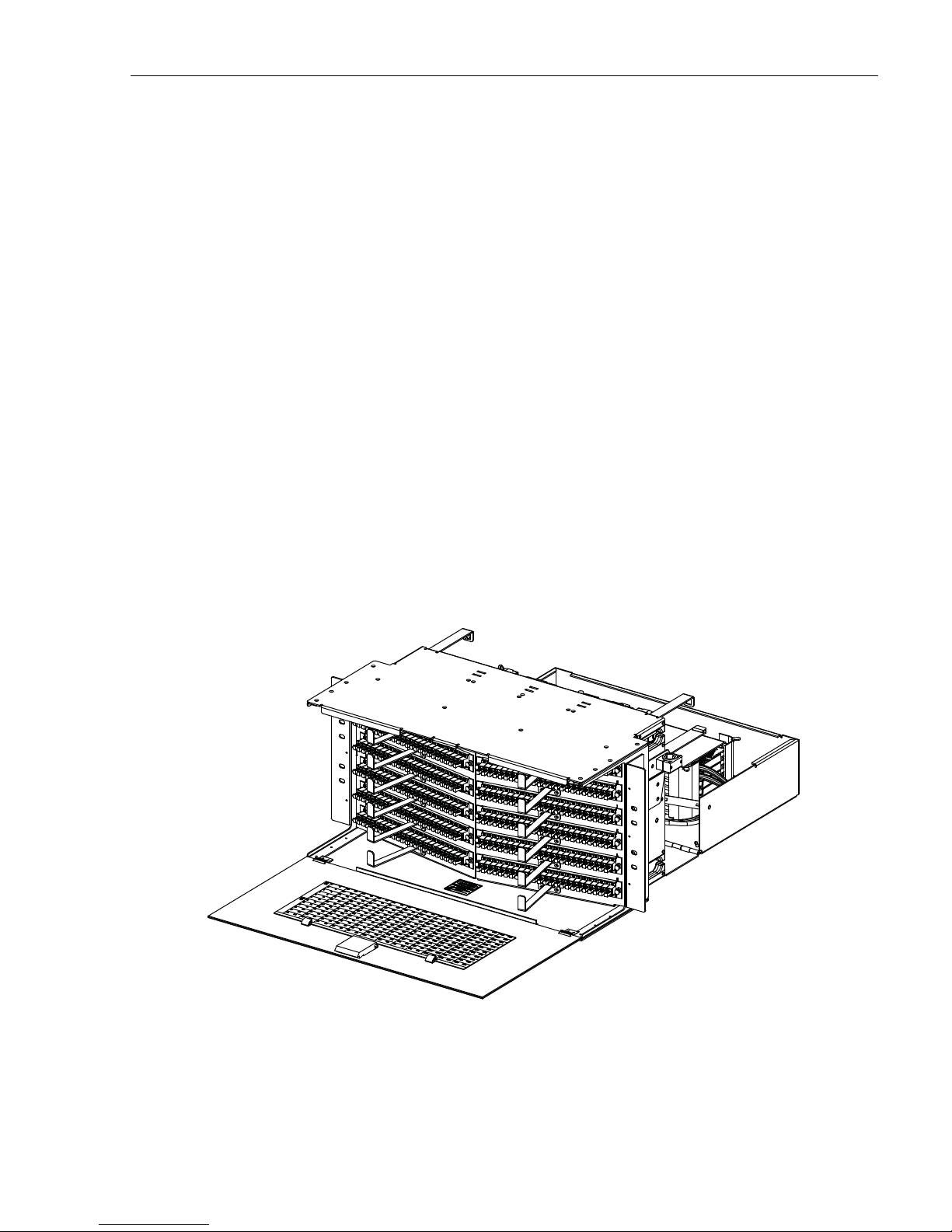

1.2 Product Function

Figure 2 summarizes the functional components of the LSX panel. As shown, an OSP or IFC

cable is routed through the panel to the splice area

spliced to internal ribbon pigtails. The internal pigtails transition to the bulkhead, located on the

front of the panel. Patch cords installed from the front side of the panel provide the connection

to fiber optic terminal equipment.

access door, where the component fibers are

Figure 2. Functional Components of LSX Termination

With Splicing Panel (Cut-Away Top View)

Page 2

© 2017 CommScope. All Rights Reserved.

Page 9

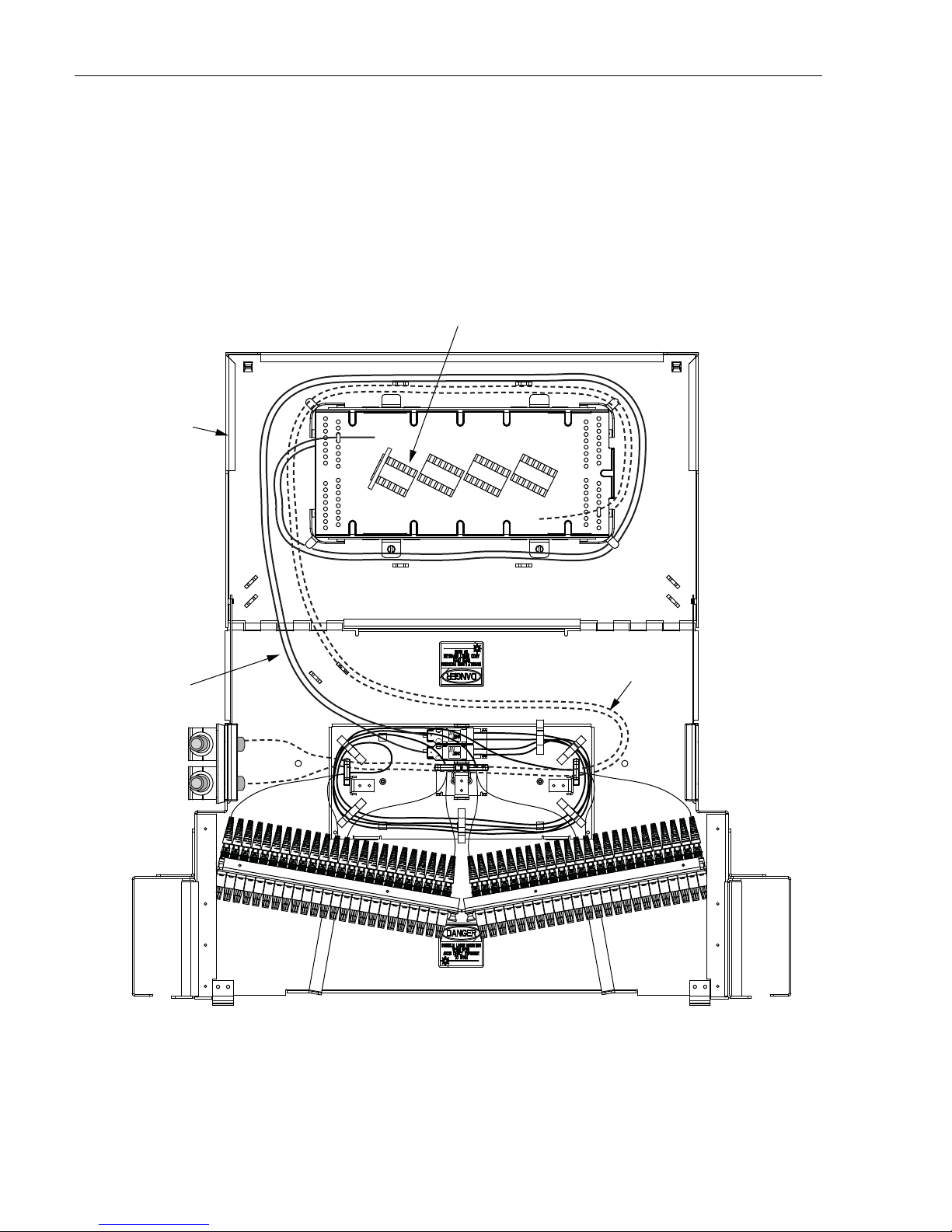

1.3 Main Components

23205-A

CONNECTOR

PACK

BULKHEAD

CHASSIS

PATCH CORD

GUIDE

REMOVABLE

FRONT COVER

PATCH CORD

DESIGNATION

CARD

MOUNTING

BRACKET

SPLICE TRA Y

ACCESS DOOR

Figure 3 shows the main external features of the LSX 288 Termination With Splicing Panel.

ADCP-93-103 • Issue 3 • November 2016

The features shown are as follows (going from top left counterclockwise in Figure 3):

• Chas

sis—is LGX compatible. It is of solid metal construction and painted white. Five

chassis may be installed on an LGX frame.

• Bulkhead—holds the pass-through adapters that provide the physical interface between

th

e connector ends of the LSX internal pigtails and patch cords installed on the front side

of the bulkhead. Its angled construction facilitates installation of patch cords.

• Con

nector Pack—mounts in the bulkhead providing one row of 24 adapters/connectors

for terminating patch cords. SC or LC connector types are available.

• Remo

vable Front Cover—provides unimpeded access for installation of patch cords.

• Patch Cord Des

• Patch Cord Guides—pro

• Mounting Bracket—is design

• Splic

e Tray Access Door—provides access to rear splice area.

Figure 3. Main External Features (Front View)

ignation Card—is used to record patch cord usage.

vide cable management in routing patch cords.

ed for 23-inch rack mount.

© 2017 CommScope. All Rights Reserved.

Page 3

Page 10

ADCP-93-103 • Issue 3 • November 2016

23207-A

OSP OR IFC

CABLE CLAMP

SPLICE

TRAYS

SPLICE TRA Y

ACCESS DOOR

CABLE RING

(TYPICAL)

RIBBON

FANOUT

BRACKET

Every panel has a rear splice area such as shown in Figure 4.

Figure 4. Main Internal Features (Rear View)

From top left counterclockwise, the main features in the rear splice area are as follows:

ble Ring—routes and secures stranded or ribbon cable on entry into splice area.

• Ca

• Splice Trays—secure and protec

• Splice Tray Access Door—folds down p

• Ribbon Fanou

• OSP or

IFC Cable Clamp—secures the cable to the panel.

t Bracket—holds one stack of four fanout chips.

Each panel is shipped with a cable clamp as well as vertical

t splices.

roviding a horizontal splice deck.

cable guides and cable shields (two

of each, not shown). Accessories available for the panel include patch cords, heatshrink- or

mass-fusion splice chips, and cable clamps (if additional clamps are needed).

Page 4

© 2017 CommScope. All Rights Reserved.

Page 11

1.4 Dimensions

18.60 IN.

(47.2 CM)

21.46 IN.

(54.5 CM)

4.78 IN.

(12.1 CM)

9.99 IN.

(25.4 CM)

10.92 IN.

(27.7 CM)

23209-A

TOP VIEW

FRONT VIEW

Figure 5 shows panel dimensions.

ADCP-93-103 • Issue 3 • November 2016

Figure 5. Panel Dimensions

Page 5

© 2017 CommScope. All Rights Reserved.

Page 12

ADCP-93-103 • Issue 3 • November 2016

1.5 Specifications

Table 1 lists specifications for the LSX combination panel.

ITEM DESCRIPTION

Dimensions (HxWxD) 15 x 23 x 15 in. (27.9 x 58.4 x 38.1cm)

Rack Mount Mounts in 23-inch rack

Weight (unloaded) 10 pounds (4.5 kg)

Terminations 288 terminations

Connector type SC or LC

Pre-installed pigtails Ribbon or straned IFC

Splice tray capacity Six splice trays

Splice chips Mass fusion or heatshrink fusion

Table 1. LSX Combination Termination/Splice panel Specifications

2 UNPACKING THE PRODUCT

Unpack and inspect the LSX combination panel as follows:

1. Inspect the exterior of the shipping contai ner for evidence of roug h handling that may have

d

amaged the contents of the container.

2. If damage is detected or if parts are missing, file a c

then notify ADC Customer Service. Save the damaged carton for inspection by the carrier.

Note: For information on how to contact ADC, if needed, see Section 5 on Page 18.

3. Save the shipping container for use in case the equi

date.

3 INSTALLATION

The main steps in installing an LSX panel are: mounting the panel on the frame, breaking out

the cable to be spliced within the panel, installing the cable on the outside of the panel using the

ADC-provided cable clamp, and routing the cable within the panel from the ca ble clamp to the

splice deck. For instructions, refer to the following subsections.

laim with the commercial carrier and

pment requires shipment at a future

3.1 Mounting the Panel on the Frame

Install the panel from the front side of the rack, using the following procedure. Refer to

Figure 6.

Page 6

© 2017 CommScope. All Rights Reserved.

Page 13

ADCP-93-103 • Issue 3 • November 2016

Note: Because of its extra depth due to its rear splice area, the LSX panel should be

installed on an LGX fiber distribution frame with a depth of at least 15 inches (38.1 cm).

CABLE

SHIELD

RACK FRONT

FLANGE

VERTICAL

CABLE GUIDE

(VCG)

1. Locate the two vertical cable guides (VCGs) and two cable shields among the separately

2. Install the VCGs and cable shields using the three small screws provided to secure them to

3. Determine the mounting location for the panel.

4. Secure the mounting brackets to the rack front flange using eight #12-24 mounting screws.

DESIGNATION

CARD

FRONT

DOOR

EDGE

PROTECTOR

MOUNTING

BRACKET

23210-A

Figure 6. Installing the Panel

packaged shipped items.

Note: The VCGs have a left or right orientation and only fit properly on the correct side of

the panel.

the three small holes in the mounting bracket.

© 2017 CommScope. All Rights Reserved.

Page 7

Page 14

ADCP-93-103 • Issue 3 • November 2016

3.2 Breaking Out a Cable

If preparing a cable for installation, break out and prepare the cable corresponding to Figure 7

for ribbon cable and Figure 8 for stranded cable. Kits are

END OF PROTECTIVE TUBE

available from ADC.

HOSE CLAMP

FLARE TUBE

INSTALL PROTECTIVE

TUBES ON RIBBON

IFC RIBBON CABLE

BREAKOUT LENGTH 94 IN. (238.76 CM)

EXPOSED RIBBON LENGTH

12 IN. (30.48 CM)

Figure 7. Recommended Breakout Dimensions for Ribbon Cable

IFC STRANDED CABLE

SUBUNIT

BREAKOUT LENGTH 94 IN. (238.76 CM)

23259-A

Figure 8. Recommended Breakout Dimensions for Ribbon Cable

Page 8

© 2017 CommScope. All Rights Reserved.

EXPOSED LENGTH

12 IN. (30.48 CM)

23258-A

Page 15

3.3 Installing a Cable Clamp

Every panel is shipped with two cable clamps. The clamps can be used to secure a cable to the

chassis. Route the cable in from above or below the panel and secure the cable in the cable

clamp at the cable breakout point. To install a cable clamp, use the following procedure. Refer

to Figure 9.

Note: Figure 9 shows the cable clamp bracket positioned for cable routing from above the

panel. For cable routing from below the panel, turn the cable clamp bracket upside down

compared to how it is shown in the figure an

figure as “for under floor cable entry.”

ADCP-93-103 • Issue 3 • November 2016

d use the mounting holes designated in the

CABLE

CLAMP

COVER

1. Install the cable clamp bracket on the clamp mou

nt plate using two #12-24 screws. Be sure

to position the cable clamp bracket corresponding to the note above.

STANDOFF

RUBBER

GROMMET

MOUNTING

HOLE (4)

YOKE (2)

STANDOFF (2)

CABLE CLAMP BRACKET

MOUNTING HOLES (2)

FOR OVERHEAD

CABLE ENTRY)

CLAMP

MOUNT

PLATE

STANDOFF

SCREW (2)

12-24X

SCREW (2)

CABLE

ENTRY HOLE

CABLE CLAMP BRACKET

(OVERHEAD CABLE POSITION)

Figure 9. Installing a Cable Clamp

CABLE CLAMP BRACKET

MOUNTING HOLES (2)

FOR UNDER FLOOR

CABLE ENTRY)

23248-A

Page 9

© 2017 CommScope. All Rights Reserved.

Page 16

ADCP-93-103 • Issue 3 • November 2016

CABLE GROMMET

GAP

0 - 0.30 IN.

(0 - 8 MM)

1440-A

2. Place the two standoffs in the standoff mounting holes in the cable clamp bracket.

Note: There are four standoff mounting holes. Either the two left holes or two right holes

can be used together, not the two in the middle. Do not mount two cables side by side.

3. Four rubber yokes and two grommets are provided with the cable clamp kit for securing

the cable to the panel. Select the grommet that, when fitted on the cable, as shown in

Figure 10, provides the gap width shown.

4. Open the splice area access door on the rear of the panel and direct the broken out sectio n

of the cable through the cable entry hole into the rear storage area of the panel. Allow the

cable to remain in that position for later routing within the rear storage area.

5. Working on the outside of the panel, where the ca

clamp components on the standoffs, as shown in Figure 9, with the cable secured within

the rubber grommet. Position the cable so

rubber grommet.

6. Secure the cable clamp components to the stando

Figure 9.

3.4 Cable Routing Within Panel

Use the following procedure to route the cable within the panel.

1. Route the cable from the entry hole horizontally across the top of the p

to the splice tray access door as shown in Figure 11 (top entry) and Figure 12 (bottom

entry). Secure the cable to the top of the p

shown in the figures.

2. Loop the cable clockwise around the spl

Figure 10. Grommet Selection

ble bracket was installed, stack the cable

that the breakout point occurs just beyond the

ffs using standoff screws, as shown in

anel and then down

anel using curleyloks at the tie-down points

ice tray as shown in Figure 13.

3. Tie down the cable at the point where the

protective tube per the breakout dimensions provided in Topic 3.2.

Page 10

© 2017 CommScope. All Rights Reserved.

exposed ribbon cable emerges from the

Page 17

23257-A

TIE-OFF

POINTS

ADCP-93-103 • Issue 3 • November 2016

Figure 11. Cable Entry From Top

TIE-OFF

POINTS

23255-A

Figure 12. Cable Entry From Bottom

Page 11

© 2017 CommScope. All Rights Reserved.

Page 18

ENTRY

HOLE

SPLICE TRA Y

ACCESS DOOR

CABLE

CLAMPS

24729-A

MASS FUSION

SPLICE CHIP

BREAKOUT

POINT

REAR VIEW

OSP OR IFC

CABLE

ADCP-93-103 • Issue 3 • November 2016

4 PATCH CORD ROUTING

4.1 Removing the Front Cover

The front cover of the chassis may be remove d to provide easie r access for installa tion of patc h

cords. To remove the cover, lift it straight out of the hinges. To replace a cover, position the

hinge edge of the cover on the hinges and press inward to push the edge into the hinges.

Page 12

© 2017 CommScope. All Rights Reserved.

Figure 13. Cable Routing

Page 19

4.2 Selecting Patch Cord Length

ADC recommends a maximum of four bays pe r lineup with five pan els per bay fo r a max imu m

of 5,670 terminations per lineup. For patch cord length, refer to Table 2.

ADCP-93-103 • Issue 3 • November 2016

Table 2. Recommended Patch Cord Length

NUMBER OF BAYS

APPROXIMATE

PATCH CORD LENGTH NUMBER OF BAYS

1 5 m (16.4 ft.) 3 6 m (19.7 ft.)

2 6 m (19.7 ft.) 4 7 m (23 ft.)

4.3 Routing Patch Cords on Front of Panel

Danger: Infrared radiation is invisible and can seriously damage the retina of the eye. Do not

look into the ends of any optical fiber. Do not look directly into the optical adapters of the

adapter packs. Exposure to invisible laser radiation may result. An optical power meter should

be used to verify active fibers. A protective cap MUST be immediately placed over any radiating

adapter or optical fiber connector to avoid the potential of dangerous amounts of radiation

exposure. This practice also prevents dirt particles from entering the adapter or connector.

Whenever patch cords are installed, route them down and to the side, as shown in Figure 14.

APPROXIMATE

PATCH CORD LENGTH

RADIUS

LIMITER

PATCH CORD

GUIDE

Figure 14. Correct Routing of Patch Cords

23247-A

CONNECTOR

PACK

Page 13

© 2017 CommScope. All Rights Reserved.

Page 20

ADCP-93-103 • Issue 3 • November 2016

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

23244-A

CONNECTING PORTS

ON THE SAME SIDE

OF A SINGLE BAY

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

23236-A

OPTIONAL

PROCEDURE

FOR PANELS

IN UPPER

HALF OF BAY

SINGLE BAY,

OPPOSITE SIDES

OF SAME BAY

4.4 Cross-Connecting Within a Stand-Alone Bay

Cross-connecting within a stand-alone bay may be required when facility and equipment

terminations are intermixed. Most cross-connection routing within a stand-alone bay should be

done with 5 meter (16.5 ft.) patch cords. Shorter 3 meter (9.9 ft.) patch cords can be used when

both ends are terminated in the top half of the bay.

Use the following procedure to route patch cords on a stand-alone bay.

1. Determine whether the ports to be connected are on the same side or opposite sides of the

ba

y, as shown in Figure 15.

2. Select from the routing paths shown a

nd route and connect the patch cord.

3. Loop up any cable slack around the appropriate spool on the vertical trough.

Figure 15. Routing Patch Cords on a Stand-Alone Bay

Page 14

© 2017 CommScope. All Rights Reserved.

Page 21

4.5 Cross-Connecting Between Two or More Bays

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

23237-A

SAME BAY WITHIN A MULTIBAY LINE-UP

Most cross-connection routing between adjacent racks should be done with 6 meter (19.8 ft.)

patch cords. Shorter 4 meter (13.2 ft.) patch cords can be used when both ends are terminated in

the top left of the frame. To route patch cords between adjacent bays, use the following

procedure.

1. Terminate one end of the patch cord on the originating LSX panel and bay, then route the

cord left or right to the nearest vertical trough.

patch

ADCP-93-103 • Issue 3 • November 2016

2. At the destination panel and bay,

terminate the opposite end of the patch cord, then route

the patch cord left or right to the nearest vertical trough.

3. Allow the patch cord to droop down

4. Based on the termination and ending points for the

into the lower raceway.

patch cord, select from the routing

paths shown in Figure 16 on this page or Figure 17 on the next page.

5. Arrange the patch cord using the lower ra

ceway and the indicated vertical trough to take

up the cable slack around the appropriate spool in the vertical trough.

Figure 16. Routing Patch Cords Between Adjacent Bays

Page 15

© 2017 CommScope. All Rights Reserved.

Page 22

23238-A

23242-A

23243-A

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

UPPER

RACEWAY

VERTICAL

TROUGH

ADCP-93-103 • Issue 3 • November 2016

Figure 17. Alternate Paths for Patch Cords Between Adjacent Bays

Page 16

© 2017 CommScope. All Rights Reserved.

Page 23

4.6 Interconnect Procedures

In an interconnect configuration, route the patch cord from the Fiber Optical Terminal (FOT)

equipment through an overhead or underfloor raceway as shown in Figure 18. Take up slack

using the vertical trough as sh

TO FOT

EQUIPMENT

OVERHEAD CABLING

ADCP-93-103 • Issue 3 • November 2016

own in the figure.

OVER RAISED

FLOOR CABLING

TO FOT

EQUIPMENT

Figure 18. Routing Patch Cords Between Adjacent Bays

© 2017 CommScope. All Rights Reserved.

23245-A

Page 17

Page 24

ADCP-93-103 • Issue 3 • November 2016

5 CUSTOMER INFORMATION AND ASSISTANCE

http://www.commscope.com/SupportCenter

Page 18

Loading...

Loading...