Page 1

Optical Remote Unit

ION™-M7P/85P/17P/19P

(ML-Cabinet)

User's Manual

MF0143AUA

Page 2

© Copyright 2011 CommScope, Inc.

All rights reserved.

User’s Manual for

ION™-M7P/85P/17P/19P (ML-cab)

Andrew Solutions is a trademark of CommScope, Inc.

All information contained in this manual has been revised thoroughly. Yet Andrew

Solutions accepts no liability for any omissions or faults.

Andrew Solutions reserves the right to change all hard- and software characteristics

without notice.

Names of products mentioned herein are used for identification purposes only and

may be trademarks and / or registered trademarks of their respective companies.

No parts of this publication may be reproduced, stored in a retrieval system,

transmitted in any form or by any means, electronical, mechanical photocopying,

recording or otherwise, without prior written permission of the publisher.

Andrew Wireless Systems GmbH, 24-November-2011

Page 2 MF0143AUA.doc

Page 3

TABLE OF CONTENTS

1. GENERAL 7

1.1. USED ABBREVIATIONS 7

1.2. HEALTH AND SAFETY WARNINGS 8

1.3. ABOUT ANDREW SOLUTIONS 10

1.4. INTERNATIONAL CONTACT ADDRESSES FOR CUSTOMER SUPPORT 12

2. INTRODUCTION 15

2.1. PURPOSE 15

2.2. THE ION™-M7P/85P/17P/19P (INTELLIGENT OPTICAL NETWORK; MMR) 15

3. COMMISSIONING 17

3.1. MECHANICAL INSTALLATION 17

3.1.1. General 17

3.1.2. Wall-Mounting Procedure 19

3.1.3. Pole-Mounting Procedure 20

3.2. ELECTRICAL INSTALLATION 21

3.2.1. General 21

3.2.2. Connections 23

3.2.3. Grounding 24

3.3. CONNECTION OF THE ANTENNA CABLES 24

3.4. POWER CONNECTION 25

3.5. OPTICAL-FIBER-CABLE CONNECTION - RULES 26

3.5.1. Protective Plug 29

3.5.2. Protective-Tube Kit 31

3.6. COMMISSIONING 33

4. ALARMS 37

4.1. BITE AND ALARMS 37

4.2. HANDLING OF ALARMS 37

4.3. ALARM STATUS 37

4.4. STATUS LED ALARMS 37

4.5. EXTERNAL ALARM INPUTS AND OUTPUTS 39

Page 3

Page 4

User’s Manual for

ION™-M7P/85P/17P/19P (ML-cab)

4.6. TROUBLESHOOTING 40

5. MAINTENANCE 41

5.1. GENERAL 41

5.2. REPLACING THE FAN UNIT 42

5.3. CLEANING THE HEAT SINK 43

6. APPENDIX 45

6.1. ILLUSTRATIONS 45

6.2. SPECIFICATIONS 46

6.2.1. Electrical Specifications 46

6.2.2. Mechanical Specifications 46

6.2.3. Environmental and Safety Specifications 46

6.3. SPARE PARTS 47

7. INDEX 49

Page 4 MF0143AUA.doc

Page 5

FIGURES AND TABLES

figure 3-1 Mounting bracket installation.................................................................... 19

figure 3-2 RU mounting ............................................................................................ 19

figure 3-3 Pole-mounting kit...................................................................................... 20

figure 3-4 Connector flange of ION-M7P/85P/17P/19P............................................ 23

figure 3-5 RS485 connector...................................................................................... 23

figure 3-6 Grounding bolt.......................................................................................... 24

figure 3-7 Grounding bolt, schematic view................................................................ 24

figure 3-8 AC power supply plug............................................................................... 25

figure 3-9 Protective-plug assembly ......................................................................... 29

figure 3-10 Tube-kit installation................................................................................. 32

figure 4-1 Flange connector, 5 poles........................................................................ 39

figure 4-2 Flange connector, 7 poles........................................................................ 39

figure 4-3 Alarm inputs and outputs, standard.......................................................... 40

figure 5-1 Fan unit and heat sink.............................................................................. 42

figure 6-1 Cabinet drawing........................................................................................ 45

table 1-1 List of international contact addresses....................................................... 13

table 3-1 Specified torques....................................................................................... 18

table 3-2 RS485 connector, pin assignment............................................................. 23

table 4-1 Status LED alarms..................................................................................... 38

Page 5

Page 6

For your notes:

User’s Manual for

ION™-M7P/85P/17P/19P (ML-cab)

Page 6 MF0143AUA.doc

Page 7

1 General

1. GENERAL

1.1. USED ABBREVIATIONS

3GPP 3rd Generation Partnership Project

AC/DC Alternating current / Direct Current

AIMOS Andrew Integrated Management and Operating System

ALC Automatic Level Control

BITE Built-In Test Equipment

BTS Base Transceiver Station

CE "Conformité Européenne" ("European Conformity")

CD Compact Disk

CPD Channel Power Detection

DL Downlink

DoC Declaration of Conformity

EDGE Enhanced Data Rates for GSM Evolution

EN European Norm

EP Extension Port

ESD Electrostatic Discharge

ETS European Telecommunication Standard

EU Extension Unit

GSM Global System for Mobile Communication

GND Ground

GUI Graphical User Interface

ICP3 Intercept Point 3

ID No Identification Number

ION Intelligent Optical Network

IP Ingress Protection

ISO International Organization for Standardization

LED Light Emitting Diode

LMT Local Maintenance Terminal

LTE Long Term Evolution

MIMO Multiple Input Multiple Output

MS Mobile Station

MU Main Unit

NF Noise Figure

OTRx Optical Transceiver = SRMU (Subrack Master Unit)

PDU Power Distribution Unit

PG Packing Gland

PIM Passive Intermodulation

R&TTE Radio & Telecommunications Terminal Equipment

Rev Revision

RF Radio Frequency

RU Remote Unit

RX Receiver

SNMP Simple Network Management Protocol

TS Technical Specification

TX Transmitter

UL Uplink

UMTS Universal Mobile Telecommunication System

UPS Uninterruptible Power Supply

VSWR Voltage Standing Wave Ratio

WCDMA Wideband Code Division Multiple Access

WDM Wavelength Division Multiplex

rd

order

Page 7

Page 8

User’s Manual for

1.2. HEALTH AND SAFETY WARNINGS

1. Only suitably qualified personnel is allowed to work on this unit and only after

becoming familiar with all safety notices, installation, operation and maintenance

procedures contained in this manual.

2. Read and obey all the warning labels attached to the unit. Make sure that the

warning labels are kept in a legible condition and replace any missing or

damaged labels.

3. Obey all general and regional installation and safety regulations relating to work

on high voltage installations, as well as regulations covering correct use of tools

and personal protective equipment.

4. Keep operating instructions within easy reach and make them available to all

users.

5. It is the responsibility of the network provider to implement prevention measures

to avoid health hazards which may be associated to radiation from the antenna(s)

connected to the unit.

ION™-M7P/85P/17P/19P (ML-Cab)

6. For US and Canadian installations: To comply with FCC RF exposure compliance

requirements, the following antenna installation and device operating

configurations must be satisfied: A separation distance of at least 4 m must be

maintained between the antenna of this device and all persons. RF exposure

compliance may need to be addressed at the time of licensing, as required by the

responsible FCC Bureau(s), including antenna co-location requirements of

1.1307(b)(3). Maximum permissible antenna gain is 17 dBi.

7. Please note for a Class A digital device or peripheral:

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in

which case the user will be required to correct the interference at his own

expense.

8. Make sure, access is restricted to qualified personnel.

9. Only licence holders for the respective frequency range are allowed to operate

this unit.

10. Corresponding local particularities and regulations must be observed. For national

deviations please refer to the respective documents included in the manual CD

delivered.

Page 8 MF0143AUA.doc

Page 9

1 General

11. Use this equipment only for the purpose specified by the manufacturer. Do not

carry out any modifications or fit any spare parts which are not sold or

recommended by the manufacturer. This could cause fires, electric shock or other

injuries.

12. Due to power dissipation, the repeater may reach a very high temperature. Do not

operate this equipment on or close to flammable materials.

13. Before opening the unit, disconnect power supply.

14. ESD precautions must be observed! Before commencing maintenance work, use

the available grounding system to connect ESD protection measures.

15. This unit complies with European standard EN60950.

16. Make sure the repeater settings are according to the intended use (see also

product information of manufacturer) and regulatory requirements are met.

17. Although the repeater is internally protected against overvoltage, it is strongly

recommended to earth the antenna cables close to the repeater’s antenna

connectors for protection against atmospheric discharge.

18. Laser radiation! Do not stare into the beam; do not view it directly or with optical

instruments.

Page 9

Page 10

User’s Manual for

1.3. ABOUT ANDREW SOLUTIONS

Andrew Wireless Systems GmbH based in Buchdorf/ Germany, is a leading

manufacturer of coverage equipment for mobile radio networks, specializing in high

performance, RF and optical repeaters. Our optical distributed networks and RF

repeater systems provide coverage for every application: outdoor use, indoor

installations, tunnels, subways and many more.

Andrew Wireless Systems GmbH has unparalleled experience in providing RF

coverage and capacity solution for wireless networks in both indoor and outdoor

environment and belongs to Andrew Solutions, a CommScope Company.

Andrew Solutions is the foremost supplier of one-stop, end-to-end radio frequency

(RF) solutions. Our products are complete solutions for wireless infrastructure from

top-of-the-tower base station antennas to cable systems and cabinets, RF site

solutions, signal distribution, and network optimization.

Andrew Solutions has global engineering and manufacturing facilities. In addition, it

maintains field engineering offices throughout the world.

We operate a quality management system in compliance with the requirements of

ISO 9001. All equipment is manufactured using highly reliable material. In order to

ensure constant first-rate quality of the products, comprehensive quality monitoring is

conducted at all fabrication stages. Finished products leave the factory only after a

thorough final acceptance test, accompanied by a test certificate guaranteeing

optimal operation.

) Note: Exceptions of and national deviations from this intended use may be

possible. To observe corresponding local particularities and

regulations, please refer to the respective documents (also in

national language) which are included in the manual CD delivered.

To make the most of this product, we recommend you carefully read the instructions

in this manual and commission the system only according to these instructions.

For technical assistance and support, please also contact the local office or Andrew

Solutions directly at one of the addresses listed in the following chapter.

ION™-M7P/85P/17P/19P (ML-Cab)

Page 10 MF0143AUA.doc

Page 11

1 General

Page 11

Page 12

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

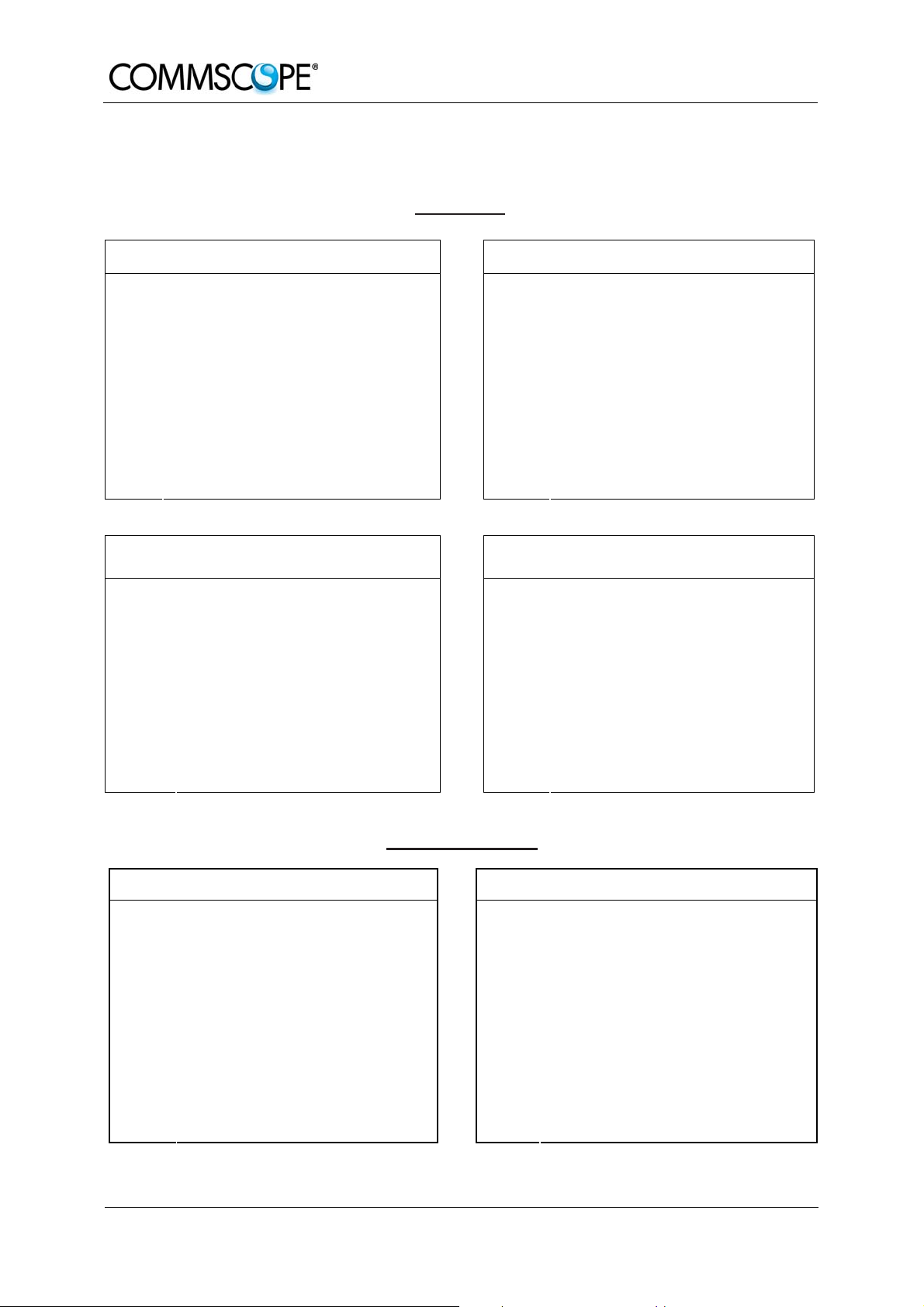

1.4. INTERNATIONAL CONTACT ADDRESSES FOR CUSTOMER SUPPORT

Americas:

Canada United States

Andrew Solutions Canada

620 North Greenfield Parkway

Mail

Phone

Fax +1-905-878-3297 Fax +1-919-329-8950

E-mail

Mail

Phone + 55-15-9104-7722 Phone

Fax + 55-15-2102-4001 Fax +52-55-1346-1901

E-mail WIsupport@commscope.com

Garner, NC 27529

U.S.A.

+1-905-878-3457 (Office)

+1-416-721-5058 (Mobile)

Peter.Masih@commscope.com,

WIsupport.us@commscope.com

Brazil & South America

CommScope Cabos do Brasil Ltda.

Av. Com. Camilo Julio 1256

Zonal Industrial CP 597

Sorocaba SP 18086-000

Brazil

Andrew LLC, A CommScope Company

Mail

Phone +1-888-297-6433

E-mail WIsupport.us@commscope.com

Mail

E-mail WIsupport@commscope.com

Andrew Solutions,

620 North Greenfield Parkway

Garner, NC 27529

U.S.A.

Mexico, Central America &

Caribbean region

Andrew Corporation Mexico,

SA DE CV

Av. Insurgentes Sur 688, Piso 6

Col. Del Valle, CP: 03100

Mexico City

Mexico

+52-55-1346-1900 (Office)

+52-1-55-5419-5260 (Mobile)

APAC Countries:

China, India and Rest of Asia Australia & New Zealand

Andrew International Corporation Andrew Corporation (Australia) Pty Ltd.

Room 915, 9/F

Chevalier Commercial Centre

Mail

Phone +852-3106-6100 Phone +613-9300-7969

Fax +852-2751-7800 Fax +613-9357-9110

E-mail WIsupport.China@commscope.com

8 Wang Hoi Rd

Kowloon Bay

Hong Kong

Mail

E-mail WIsupport.Australia@commscope.com

Unit 1

153 Barry Road

Campbellfield

VIC 3061

Australia

Page 12 MF0143AUA.doc

Page 13

1 General

Europe:

United Kingdom France

Andrew Solutions UK Ltd CommScope France

Unit 15, Ilex Building

Mulberry Business Park

Mail

Phone +44-1189-366-792 Phone

Fax +44-1189-366-773 Fax

E-mail WIsupport.uk@commscope.com

Mail

Phone +49-9099-69-0 Phone +420-464-6280-80

Fax +49-9099-69-930 Fax +420-464-6280-94

Fishponds Road

Wokingham Berkshire

RG41 2GY

England

Germany Czech Republic

Andrew Wireless Systems GmbH

Industriering 10

86675 Buchdorf

Germany

Mail

E-mail WIsupport@commscope.com

Mail

Immeuble Le Lavoisier

4, Place des Vosges

92052 Courbevoie

France

+33-1 82 97 04 00

+33-1 47 89 45 25

Andrew Solutions Czech Republic

C-Com, spol. s r.o

U Moruší 888

53006 Pardubice

Czech Republic

E-mail WIsupport@commscope.com

Austria Switzerland

Andrew Wireless Systems (Austria) GmbH Andrew Wireless Systems AG

Weglgasse 10

Mail

Phone +43-1706-39-99-10 Phone +41-62-386-1260

Fax +43-1706-39-99-9 Fax +41-62-386-1261

E-mail WIsupport.austria@commscope.com

Mail

Phone +39-0546-697111 Phone +34-91-745-20 40

Fax +39-0546-682768 Fax +34-91-661-87 02

E-mail WIsupport.italia@commscope.com

2320 Wien-Schwechat

Austria

Italy Spain and Portugal

Commscope Italy S.r.l., Faenza, Italy

Via Mengolina, 20

48018 Faenza (RA)

Italy

E-mail WIsupport@commscope.com

Tiergartenweg 1

Mail

E-mail WIsupport.ch@commscope.com

Mail

E-mail WIsupport.iberia@commscope.com

CH-4710 Balsthal

Switzerland

Andrew Solutions España S.A.

A Commscope Company

Avda. de Europa, 4 - 2ª pta.

Parque Empresarial La Moraleja

28108 Alcobendas (Madrid)

Spain

table 1-1 List of international contact addresses

Page 13

Page 14

For your notes:

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

Page 14 MF0143AUA.doc

Page 15

2 Introduction

2. INTRODUCTION

2.1. PURPOSE

Cellular telephone systems transmit signals in two directions between a base

transceiver station (BTS) and mobile stations (MS) within the signal coverage area.

If weak signal transmissions occur within the coverage area because of indoor

applications, topological conditions or distance from the transmitter, extension of the

transmission range can be achieved by means of an optical distribution system.

Such a system contains an optical Master Unit and several Remote Units. The

number of the Remote Units depends on the hardware and software configuration.

The Remote Units are connected to the Master Unit with optical links. The optical

loss must be less than 10 dB inclusive optical couplers or splitters.

The Master Unit is the connection to the base transceiver stations. The configuration

of a Master Unit depends on the number of the Remote Units and the frequency

range.

The optical transmission uses WDM-systems with a wavelength of 1550 nm in the

uplink and 1310 nm in the downlink.

2.2. THE ION™-M7P/85P/17P/19P (INTELLIGENT OPTICAL NETWORK; MMR)

The ION-M7P/85P/17P/19P transports signals on the RF layer in a way that multiple

operators and multiple technologies are moved simultaneously from a cluster of base

stations to a remote location over the same fiber.

The ION optical distribution system provides a coverage solution for dense urban

areas, tunnels, subway, airports, convention centers, high-rise buildings and other

locations where physical structures increase path loss. It has been specifically

designed to reduce zoning problems and to provide homogeneous coverage. The

compact, mechanical design is specifically architected to mount inside of poles or

along side structures in such a way that it has a minimal visual impact.

The ION-M7P/85P/17P/19P is available in single or multi-band configuration

supporting 700 MHz, 850 MHz, 1700 MHz/ 2100 MHz and 1900 MHz in parallel. It

has been specifically tested and optimized for LTE, iDEN, GSM, EDGE, CDMA2000,

EV-DO, WCDMA, HSPA+, and OFDMA. Furthermore, it is provisioned for future

improvements to the modulation and frequency bands. In addition it is backwards

compatible to legacy standards such as TDMA and Analog.

Page 15

Page 16

User’s Manual for

The ION is easily set-up and supervised via a graphical user interface (GUI). Remote

units can be commissioned through the use of built-in test equipment. An autoleveling function compensates for the optical link loss making installation easy and

quick. The entire system may be monitored remotely via an Andrew OMC. This

platform uses SNMP protocol and is compliant to X.733 standard.

Should a sophisticated interface not be required, the Master Unit can be directly

connected to the alarm interface of a base station via its contact relay.

Multi-channel, multi-operator support

Reduced visual impact form factor

Efficient, high power amplifier

Single fiber for multiple bands and multiple remotes

Comprehensive operations and management system for configuration and

alarming

ION™-M7P/85P/17P/19P (ML-Cab)

OMC with SNMP according to X.733 standard

Easy installation and commissioning

Page 16 MF0143AUA.doc

Page 17

3 Commissioning

3. COMMISSIONING

3.1. MECHANICAL INSTALLATION

3.1.1. General

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

1. Do not install the unit in a way or at a place where the specifications

outlined in the Environmental and Safety Specifications leaflet of the

supplier are not met.

2. It is recommended only to use the mounting hardware delivered by the

supplier. If different mounting hardware is used, the specifications for

stationary use of the Remote Unit must not be exceeded.

) Note: Exceeding the specified load limits may cause the loss of warranty!

3. The unit is considerably heavy. Make sure that a suitable mounting surface

is used. Ensure there is adequate manpower to handle the weight of the

system.

4. Due to power dissipation, the Remote Unit may reach a very high

temperature. Ensure sufficient airflow for ventilation as specified in the

individual mounting procedures.

5. When connecting and mounting the cables (RF, optical, power supply, ...)

ensure no water can penetrate into the unit through these cables.

6. Also observe all additional rules or restrictions regarding mounting that

depend on the type of Remote Unit. For details refer to chapter 7.2.2

Mechanical Specification. Install the unit vertically with the fan unit at the

top. A maximum tilt angle of 25° from a vertical position must be kept, as in

the following illustrations:

Page 17

Page 18

User’s Manual for

A spacing of 40 mm (1.58 inch) around the unit is required.

7. To ensure sufficient airflow when mounting the unit in enclosed spaces, two

lid openings (one for the air inlet and the other for the air outlet) have to be

provided. Do not block these air inlets and outlets when mounting the

Remote Unit. The size of each opening must equal at least 17 x 17 cm

(290 cm2). Make sure, too, there is no thermal short circuit between the air

inlet and air outlet.

If any different or additional mounting material is used, ensure that the mounting

remains as safe as the mounting designed by the manufacturer. Ensure that the

static and dynamic strengths are adequate for the environmental conditions of the

site. The mounting itself must not vibrate, swing or move in any way that might cause

damage to the Remote Unit.

Specified torques have to be observed for certain mounting procedures according to

the following table:

Type

Thread

Specified torques

Lens head

screws

M 4 M 8 M 4 M 8 PG 13.5 PG 29

3.3 Nm 27 Nm 2.3 Nm 27 Nm 3.75 Nm 10 Nm

Hex

nuts

ION™-M7P/85P/17P/19P (ML-Cab)

Spacing

bolts

PG

(plastic)

PG

(aluminium)

table 3-1 Specified torques

) Note: To avoid damage when mounting the unit, always make sure that

the M8 washers (DIN9021 or DIN125 depending on the mounting kit)

are placed behind and in front of the mounting drillings of the unit.

The mounting procedures for a stand-alone Remote Unit without optional

accessories are described and illustrated in the following sections. For further

information regarding special mounting procedures including mounting of accessory

equipment, please see separate manual.

Page 18 MF0143AUA.doc

Page 19

3 Commissioning

r

r

3.1.2. Wall-Mounting Procedure

Check the suitability of the wall-mounting kit and the wall.

Mark the position of the drilling holes (for measurements and a more detailed

description refer to the wall mounting plan that is part of the delivery).

Drill four holes at the marked positions and insert dowels*.

Screw the mounting brackets to the wall / dowels using the four dowel screws as

illustrated in figure 3-1 Mounting bracket installation.

For each bracket, first screw in the 2 washers, then the 2 spring washers, then

the 2 M8x80 screws (see also figure 3-1 Mounting bracket installation).

Hang the Remote Unit into the upper mounting bracket at a slight angle and let it

move smoothly towards the wall so that it engages firmly into the brackets (see

figure 3-2 RU mounting). Then, screw the Remote Unit to the lower mounting

bracket using 2 of the M8x25 screws that are part of the delivery (4 are provided).

Ensure that there is free access to the electrical connections as well as to the

cabinet. The approved bending radius of the connected cables must not be

exceeded.

Upper

mounting

bracket

Position of

dowels *

M8 screws

Spring washe

Lower

mounting

bracket

Washe

figure 3-1 Mounting bracket installation figure 3-2 RU mounting

* The dowels are not part of the delivery since the suitable type depends on the on-site conditions

(material of wall). Therefore, use dowels that are appropriate for the mounting surface.

Page 19

Page 20

User’s Manual for

3.1.3. Pole-Mounting Procedure

The standard mounting hardware also includes all parts required for pole mounting:

ION™-M7P/85P/17P/19P (ML-Cab)

figure 3-3 Pole-mounting kit

Use the screw bands to fasten the two mounting brackets to the pole.

) Note: When fastening the mounting brackets make sure that they are

installed congruently and not at an angle to each other. To

determine the distance between the beams, refer to the wall

mounting plan that is part of the delivery.

Hang the Remote Unit into the hooks of the upper mounting bracket and screw

the Remote Unit to the lower mounting bracket.

Ensure that there is free access to the electrical connections as well as to the

cabinet. The approved bending radius of the connected cables must not be

exceeded.

Page 20 MF0143AUA.doc

Page 21

3 Commissioning

3.2. ELECTRICAL INSTALLATION

3.2.1. General

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

1. This unit contains dangerous voltages. Loss of life, severe personal injury or

property damage can be the result if the instructions contained in this manual are

not followed.

2. Ground the unit before connecting power supply. A grounding bolt is provided on

the cabinet to connect the ground-bonding cable.

3. Although the Remote Unit is internally protected against over-voltage, it is

strongly recommended to earth the antenna cables close to the antenna

connectors of the Remote Unit for protection against atmospheric discharge. In

areas with strong lightning it is highly recommended to insert additional lightning

protection.

4. If the mains connector of the Remote Unit is not easily accessible, a disconnect

device in the mains circuit must be provided within easy reach.

5. Before connecting or disconnecting the mains connector at the Remote Unit,

ensure that mains supply is disconnected.

6. Make sure that an appropriate circuit breaker and an over-current limiting device

are connected between mains and Remote Unit.

7. A connection of mains supply to a power socket requires the power socket to be

nearby the Remote Unit.

8. Incorrectly wired connections can destroy electrical and electronic components.

9. To avoid corrosion at the connectors caused by electrochemical processes, the

material of the cable connectors must not cause a higher potential difference than

0.6 V (see electrochemical contact series).

10. Use an appropriate torque wrench for the coupling torque (25 N-m / 19 ft lb) of 716 DIN connectors with 1-1/4 in opening to tighten the 7/16-type antenna

connectors. For example, use torque wrench of item no. 244377 available from

the Andrew e-catalog. Do NOT use your hands or any other tool (e.g. a pair of

pliers)! This might cause damage to the connector and lead to a malfunction of

the Remote Unit.

11. Use a voltage limiting device for unstabilized electric networks that frequently

generate spikes.

12. The unit complies with the surge requirement according to EN 61000-4-5 (fine

protection); however, it is recommended to install an additional medium (via local

supply connection) and/or coarse protection (external surge protection),

depending on the individual application, in order to avoid damage caused by

overcurrent.

Page 21

Page 22

User’s Manual for

13. Observe the labels on the front panels before connecting or disconnecting any

cables.

ION™-M7P/85P/17P/19P (ML-Cab)

Page 22 MF0143AUA.doc

Page 23

3 Commissioning

3.2.2. Connections

Alarm output Status LED Optical-fiber

connector connector

Alarm input

connector

Antenna

connector

Power supply

connector

RS485 / 232

connector

Grounding

bolt

figure 3-4 Connector flange of ION-M7P/85P/17P/19P

Control Connector (RS485 / RS232)

This 8-pin male connector (type: Binder Series 712) primarily supports control of the

Extension Unit via RS485 bus.

PIN Assignment

1 not connected

2 RS232 Rx

3 RS232 Tx

4 not connected

5 GND (RS232)

6 RS485 R+/D+

7 RS485 GND

8 RS485 R-/D-

figure 3-5 RS485 connector table 3-2 RS485 connector, pin assignment

Page 23

Page 24

User’s Manual for

3.2.3. Grounding

Grounding must be carried out. Connect an earth-bonding cable to the grounding

connection provided at the outside of the Remote Unit (see chapter 3.2.2

Connections). Do not use the grounding connection to connect external devices.

ION™-M7P/85P/17P/19P (ML-Cab)

figure 3-6 Grounding bolt figure 3-7 Grounding bolt, schematic view

After loosening the hex nut, connect the earth-bonding cable between the two

washers as illustrated in the figures above. Then, fasten all parts again with the hex

nut.

3.3. CONNECTION OF THE ANTENNA CABLES

The Remote Unit has 7/16-type antenna connectors. Please refer to section 3.2.2

Connections for its location. Refer to the corresponding documentation of the

connector manufacturer for mounting the cable connectors.

The bending radius of the antenna cables must remain within the given

specifications.

Consider the type of cable best suited for the antenna. Remember that a cable with

higher loss is less expensive but impairs performance.

Use an appropriate torque wrench for the coupling torque (25 N-m / 19 ft

lb) of 7-16 DIN connectors with 1-1/4 in opening to tighten the 7/16-type

antenna connectors. For example, use torque wrench of item no. 244377

available from the Andrew e-catalog. Do NOT use your hands or any

other tool (e.g. a pair of pliers)! This might cause damage to the

connector and lead to a malfunction of the Remote Unit.

Page 24 MF0143AUA.doc

Page 25

3 Commissioning

To minimize passive inter-modulation (PIM) distortion, attention has to

be paid to the physical condition of the connector junctions. Do not use

connectors that show signs of corrosion on the metal surface. Prevent

the ingress of water into the connector. Attach and torque the

connectors properly.

3.4. POWER CONNECTION

Before connecting electrical power to the units, the system must be grounded as

described in the previous chapter.

Mains power must be connected at the power supply connector of the unit (see

chapter 3.2.2 Connections).

The power supply plug is part of the delivery. The correct wiring of the power supply

plug is as follows:

N

L

PE

figure 3-8 AC power supply plug

For the AC power supply connection, a minimum cross section of 1.5

2

mm

is required. Each wire must observe the applicable national

regulations regarding loop impedance, voltage drop, and methods of

installation. Make sure to connect the correct voltage to the unit.

n.c.

) Note: Do not connect or disconnect the power cord at the power supply

connector while power is on. Turn off mains power * before

connecting the power cord at the Remote Unit, then, engage mains

power again.

Page 25

Page 26

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

* Mains power must be interruptible with an external power supply breaker. For the power supply

breaker, observe the following recommendation:

120 Volt / 20 Amp max. or 240 Volt / 16 Amp, single-phase, 50 / 60 Hz AC service is needed, i.e.

the external AC breaker should be 20 Amps max. for 120-Volt service or 16 Amps for 240-Volt

service.

For the DC power supply, observe the local regulations of the DC service provider.

3.5. OPTICAL-FIBER-CABLE CONNECTION - RULES

Main optical system parameters:

Fiber:

Single mode fiber, type is E9/125 µm

Attenuation: <0.36 dB / km @ 1310 nm / <0.26 dB / km @ 1550 nm

Dispersion: <3.5 ps / nm km @ 1310 nm / <18.0 ps / nm km @ 1550 nm

Fibre-cable connectors E2000APC8°

ION-M system:

The specified bending radius ( < 4 cm) of the optical fibers must not be

exceeded.

The pigtails for the connection between Master Unit and Remote Unit must

have a sufficient length. A protection for the feeding into units must be given.

The system attenuation of the optical fibers, including the connectors, must

not exceed 10 dB.

System attenuation and attenuation of optical components must be determined. This

can be achieved by measuring attenuation and reflection with an appropriate

measuring instrument. For pigtails, a total value of < 0.4 dB (measured to a reference

plug) can be assumed due to the dead zone of the reflectometer. These

measurements must be made with a sufficient length of optical fiber, at the input and

output of the device which has to be measured.

Fiber-System Installation:

Fiber-cable connectors have to be of the same type (E2000APC8°) as the

connectors used for the unit. The fiber-optic cables are connected to the optical

transceiver.

Angled connectors are not compatible with straight optical connectors;

non-compatibility of connectors will result in permanent damage to

both connectors.

Page 26 MF0143AUA.doc

Page 27

3 Commissioning

Before connecting the fiber cables, follow the procedure below to ensure optimized

performance. It is important for these procedures to be carried out with care:

¾ Remove fiber-optic protective caps.

¾ Do not bend the fiber-optic cable in a tight radius (< 4 cm) as this may cause

cable damage and interrupt transmission.

¾ Using high-grade alcohol and lint-free cotton cleaning swabs, clean the end of

the fiber-optic cable that will be inserted in the optical connectors on the donor

interface box. Use a fiber end-face inspection tool to scan both, the class fiber

and its surrounding area.

¾ Check for dirt on the cladding, chips/pits, dirt on the ferrule, and scratches.

¾ Connect the fiber-optic cables by inserting the cable end into the laser

receptacle and aligning the key (on the cable end) with the keyed slot.

¾ Do not use any index-matching gels or fluids of any kind in these connectors.

Gels are intended for laboratory use and attract dirt in the field.

) Note: Care should be taken when connecting and disconnecting fiber-

optic cables - use the connector housing to plug or unplug a fiber.

Scratches and dust significantly affect system performance and

may permanently damage the connector. Always use protective

caps on fiber-optic connectors not in use.

Cleaning Procedure for Fiber-Optical Components:

Any contamination in the fiber connection results in additional optical transmission

loss which could cause whole system failure. It is thus recommended that every fiber

connector be inspected and cleaned prior to mating.

The goal is to eliminate any dust or contamination and to provide a clean

environment for the fiber-optic connection.

When you clean fiber components, always complete the following steps carefully:

1. Turn off the ION system (laser sources) before you inspect fiber connectors.

Never look into a fiber while the system lasers are on!

2. Check the connectors or adapters with a fiberscope before cleaning.

3. If the connector is dirty, clean it with a lint-free wipe (dry cleaning).

4. Inspect the connector.

Page 27

Page 28

User’s Manual for

5. If the connector is still dirty, repeat the dry cleaning technique.

6. Inspect the connector.

7. If the connector is still dirty, clean it with 99% isopropyl alcohol (wet cleaning)

followed immediately with a dry clean in order to ensure no residue is left on

the endface.

8. Repeat steps 5 through 7 until endface is clean.

Note: For a more detailed description please refer to:

http://www.cisco.com/en/US/tech/tk482/tk876/technologies_white_paper09186

a0080254eba.shtml

ION™-M7P/85P/17P/19P (ML-Cab)

Page 28 MF0143AUA.doc

Page 29

3 Commissioning

3.5.1. Protective Plug

Connection:

A protective plug is provided for the connection of the fiber-optic cables.

figure 3-9 Protective-plug assembly

) Note: Only high-quality connectors must be used for this type of plug.

Qualified brands are Diamond or Huber & Suhner.

Page 29

Page 30

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

For plug assembly, observe the following instruction:

1. Pass one or two contacts through the

backshell and the clamp ring.

2. Place the contact(s) on the lower insulation body by pushing the groove of the

contact into the cavity. If there is only one contact, cavity A must be used. *

3. Then, mount the upper insulation body on the lower insulation body. **

Upper insulation body

Cavity B

Cavity A

4. Bring the insulator into the plug. The narrow groove of the insulator must be fitted

into the stamp of the plug.

* To release the contact for disassembling, push the inner snap to the side and pull the contact out.

** To release upper and lower insulation bodies for disassembling, use a small screwdriver and

carefully open the snap-connections at the left and the right side of the insulator without

damaging them.

5. Fasten the insulator by screwing the

backshell tight onto it. Use a spanner

with opening 32 to screw the

backshell tight (no gap).

6. Place the appropriate seal parts (with

one groove for one contact or two

grooves for two contacts) over the

cable(s) and push them into the

backshell.

No gap

Seals with

one groove

Page 30 MF0143AUA.doc

Page 31

3 Commissioning

back to

ectio

7. Bring the plastic ring over the cable(s), push it into the backshell and compress

the seals and plastic ring by screwing the clamp ring tight (no gap) using a

spanner with opening 20. ***

Screw tight until gap is closed

8. Connect the plug to the optical-fiber

connector of the Remote Unit, again

9. To lock the connector, push the black

locking ring forward.****

by fitting a stamp on the plug into the

groove of the connector.

Groove

*** For disassembling, release the clamping ring and remove the seals and the plastic ring first.

**** Locking mechanism: The system of locking the plug is based on a “push-pull” mechanism. The

locking ring has to be pushed forward to lock the connector and pulled back to free the

connection.

Push forward to lock, pull

free conn

n

3.5.2. Protective-Tube Kit

As additional protection for the optical fibers, this connector type can be

supplemented by a special tube kit. To fasten the tube correctly, first unscrew the

clamp ring (if already installed) of the original plug kit.

Then, proceed according to the following instruction:

Page 31

Page 32

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

Protective plug

Fiber cable

Ring 3/4

Reducer

Screw the reducer to

the protective plug

backshell without any

gap!

Coupling

Place the appropriate seal

parts (with) one groove for

one contact or two grooves

for two contacts) over the

cable(s) and push them into

the backshell!

Push the fiber-optic cable carefully

through the tube until it comes out

at the other end.

Protective tube

G1055M0

figure 3-10 Tube-kit installation

Page 32 MF0143AUA.doc

Page 33

3 Commissioning

3.6. COMMISSIONING

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings as

well as the description carefully to avoid mistakes and proceed step by step as

described!

Do not operate the Remote Unit without terminating the antenna connectors.

The antenna connectors may be terminated by connecting them to their

respective antennas or to a dummy load.

Only qualified personnel should carry out the electrical, mechanical,

commissioning and maintenance activities that require the unit to be powered

on when open.

When opening the Remote Unit do not damage the warranty labels on the

internal devices. The warranty is void if the seals are broken.

Ensure that all connections have been performed according to chapter 3.2.1

General.

Page 33

Page 34

User’s Manual for

0

ION™-M7P/85P/17P/19P (ML-Cab)

Commissioning an ION-M Remote Unit

Manual for Remote

Unit

Philips

screwdriver

Mounting kit

Spanner, size

13 mm

Drilling

machine

Dowels

Screw driver

Screw driver

Spanner, size

13 mm

Grounding cable

Spanner 13 mm

Alarm kit

(M-cabinet)

Start

Preperation

Unpack RU, RU accessories and

mounting kit.

Mechanical installation

Fasten wall or pole mounting kit to wall or

Mount RU to mounting kit, ensure suffient

air flow and avoid thermal short circuits.

Connect grounding cable and

Connect external devices to the external

in or alarm out connectors, or to the

connecting board inside the RU.

pole.

Mechanical installation

Electrical connections

ground the RU.

External devices

E2000 APC8° connector

Spanner with opening 32

Mains cable

Connecting kit

Connect antenna cable to antenna port.

Mount the optical fibre with E2000 APC8°

connector into the connector. Plug the

Connect AC (DC) power to the power

cable. Ensure there is a circuit breaker

RF connection

Optical connections

connector into the RU.

Electrical connections

between mains and RU.

Mains

Switch mains power on.

G1055Z

G1055Z0

Page 34 MF0143AUA.doc

Page 35

3 Commissioning

Orange

LED on?

Yes

LED status

Green

No

Check power switch insi de RU

(RUs with door).

Check mains cabling.

Check mains power.

Red

.

LED statusYellow

Internal Error

Red

Change power supply (RUs with a

door)

Reduce environmental temperature.

Eliminate thermal short circuit.

Disconnect and connect mains. Fans

should run. If not, replace the fans at

RU.

MU: Change amplifier setting at MU

controller

Yes

Go to MU

Close the door (RUs wi th a door).

Check externally connected devices.

Check fibre loss of optical link.

Check optical connectors.

Clean optical connectors.

Check optical output power of corresponding

OTRx at master unit.

ALC alarm: Decrease DL input power of

affected band.

VSWR alarm: Check antenna and cable.

External error

Proceed to MU to set up the SW

Finished setting up

all RUs?

Yes

Output:

All RUs okay.

Green

Spare RU

available?

No

Contact customer

service

No

Page 35

Page 36

For your notes:

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

Page 36 MF0143AUA.doc

Page 37

4 Alarms

4. ALARMS

4.1. BITE AND ALARMS

The Built-In Test concept comprises the monitoring of the power supplies, the power

amplifiers and the optical interface.

All occurring alarms can be checked via software at the Master Unit.

4.2. HANDLING OF ALARMS

As soon as the software acknowledges a valid alarm, a message is transmitted to the

Master Unit.

If the reason for the alarm has been cleared or if the alarm should continue, a new

alarm message will not be repeated. If there was an interruption of at least five

seconds after acknowledgement, a new alarm message will be generated.

4.3. ALARM STATUS

For details refer to the corresponding software documentation of the Master Unit.

4.4. STATUS LED ALARMS

For local supervision, a status LED on the connector flange of the Remote Unit gives

an indication of possible reasons for alarms. This table shows possible on-site

measures that could be checked before referring to the Master Unit alarm list.

Status LED Indication Alarms Possible on-site measures

Green

Orange

No alarm Æ

Status ok

Door alarm Close the door (RUs with door).

Alarms not directly related to RU:

External alarms

Optical alarm Rx

ALC alarm

Check externally connected devices.

Check fiber loss of optical link.

Check optical connectors.

Clean optical connectors.

(MU: Check optical output power of

corresponding OTRx at Master Unit).

(MU: Decrease DL input power of

affected band).

Page 37

Page 38

A

Red

User’s Manual for

Alarms directly related to RU:

Power 28 V

Temperature

Fan

I²C Disconnect and connect power supply.

Optical alarm Tx Exchange RU.

Change power supply (RUs with door).

Replace the affected Remote Unit.

Reduce environmental temperature.

Eliminate thermal short circuit.

Disconnect and connect power supply.

Fans should run. If not, replace the fans

at RU.

ION™-M7P/85P/17P/19P (ML-Cab)

mplifier “Power

Down”

Status LED off Power supply

table 4-1 Status LED alarms

For the position of the status LED see chapter 3.2.2 Connections.

Explicit troubleshooting is available in the MU software, (software manual or WEB

Interface).

(MU: Change amplifier setting at MU

controller).

Check power switch inside of RU (RUs

with door).

Check power supply cabling.

Check power supply.

Page 38 MF0143AUA.doc

Page 39

4 Alarms

4.5. EXTERNAL ALARM INPUTS AND OUTPUTS

G1038Z0

G1038Z0

figure 4-1 Flange connector, 5 poles figure 4-2 Flange connector, 7 poles

The alarm outputs (open collector output 5 V / 1 mA) are normally low. In case of an

alarm they are high active (5 V). They can be used to monitor alarms with an external

alarm indicator.

The +28 V pin (for its location see figure 4-2 Flange connector, 7 poles) is protected

by a 500 mA thermoswitch. In case of exceeding this current between pin 7 and GND

and/or in case of a failure of the VSWR module, the thermoswitch turns into a highresistive status. In this case no fuse needs to be replaced. Just wait a few minutes

until the thermoswitch reaches the normal operating temperature again.

) Note: The manufacturer / supplier of this system accepts no liability for

damage caused by equipment connected to external outputs or by

effects from such equipment.

As accessory equipment the alarm kit is available to connect external devices to the

external alarm inputs and outputs. For the exact designation, please refer to chapter

6.3 Spare Parts.

Page 39

Page 40

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

With the external alarm inputs it is possible to monitor the status of connected

devices, e.g. a UPS, via software. All alarm inputs are normally high (5 V) without

connection. The polarity (high/ low) can be set via the software at the Master Unit (for

details please see according software manual).

The device to be monitored must be connected so that the alarm contacts will be

closed in case of an alarm (I max = 8 mA). The alarm inputs are potential-free with

common ground.

Subminiature circular connectors series 712 with five and seven contacts, which are

contained in the alarm kit, can be ordered directly from the Binder Connector Group,

the manufacturer, or indirectly from Andrew Solutions. For the designation of the

alarm kit see chapter 6.3 Spare Parts.

ION-M alarm outputs

ION-M alarm inputs

+5 V

4700R

Alarm output

Alarm GND

Alarm GND

+5 V

560R

Alarm GND

Alarm input

Alarm GND

V1651A1

figure 4-3 Alarm inputs and outputs, standard

4.6. TROUBLESHOOTING

The status of the Remote Unit can be checked via the Master Unit (for details please

refer to the software manual of the Master Controller). Locally, the status can be

checked at the LED, see chapter 4.4 Status LED Alarms.

Page 40 MF0143AUA.doc

Page 41

5 Maintenance

5. MAINTENANCE

5.1. GENERAL

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

) Note: The Remote Unit does not require preventative maintenance

measures.

) Note: To prevent malfunctions of the cooling system due to dirt or

pollution, it is recommended to clean the heat sink at regular

intervals. These cleaning intervals depend mainly on the location

of the Remote Unit and the corresponding degree of pollution.

Maintenance of the ION-M7P/85P/17P/19P should be performed by replacing only

components that are contained in this chapter. In order to maintain warranty, take

care not to damage unintentionally the seals on the modules.

The spare parts list, consequently, contains only units which can be replaced without

tuning or soldering work.

) Note: When sending back the unit, use an appropriate packaging, see

chapter 6.2.3 Environmental and Safety Specifications. We

strongly recommend using the original packaging!

) Note: Defect parts should only be replaced by original parts from the

supplier. All interventions inside the housing are at one’s own risk.

) Note: During maintenance ensure the Remote Unit has been

disconnected from power supply.

) Note: Before disconnecting any cables, label any unlabelled cables to

ensure correct connection.

For most maintenance procedures appropriate tools are required to ensure correct

handling. All these tools can be ordered from the supplier. For screwing procedures

observe that all our screws have a right-hand thread, i.e. for fastening the screws

turn the tool clockwise and for unscrewing them turn it counter-clockwise.

Due to the design of the Remote Unit the only component recommended to be

replaced is the fan unit. For replacing any other component, please contact the

supplier.

Page 41

Page 42

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

5.2. REPLACING THE FAN UNIT

Replacement of the fan unit is not required as a preventative measure. Only if an

alarm indicates a malfunctioning of a fan, must the unit be exchanged.

) Note: Please observe that the fan unit can only be replaced as a whole.

Do NOT remove the fans separately!

Read the health and safety warnings in chapter 1.2 as well as the instructions in

chapter 5.1 General before starting with the replacement.

1. Switch off the Remote Unit. Make sure the power supply connector is

disconnected for the following replacement procedure. Then, proceed as

follows:

2. Remove the fan guard by unscrewing (Torx 20) the four countersunk-head screws

(two at each side) by which it is fastened:1)

Fan unit connector

Heat sink Fan unit

3. Loosen the four fillister-head screws

M4x8 by which the fan unit is screwed

to the cabinet (circle-marked in the

figure to the right). 2)

4. Disconnect the fan-unit connector and

take out the fan unit.

5. To mount the new fan unit, re-connect

the fan unit connector and place the

fan unit back into its original position.

6. Screw the whole fan unit to the

cabinet with the four lens-head screws

M4x8. 2)

7. Finally mount the fan guard and fasten

it with the four countersunk screws. 1)

figure 5-1 Fan unit and heat sink

8. Then, mains power can be reconnected and the unit can be powered up.

1)

In order not to exceed the specified torque of 82 Ncm, use an appropriate tool!

2)

In order not to exceed the specified torque of 330 Ncm, use an appropriate tool!

Page 42 MF0143AUA.doc

Page 43

5 Maintenance

5.3. CLEANING THE HEAT SINK

To avoid a malfunctioning of the Remote Unit, the heat sink should be cleaned in

case of pollution. In order to prevent any damage, proceed as explained in the

following.

) Note: Read the health and safety warnings in chapter 1.2 Health and

Safety Warnings as well as the instructions in chapter 5.1 General

before starting with the replacement procedure. Then, proceed as

follows:

1. Switch off the Remote Unit. For the following procedure ensure that power supply

connector has been disconnected before and that the fans have stopped rotating!

2. Before any cleaning action, remove the fan guard and the fan unit from the

Remote Unit as described in the previous chapter 5.2 Replacing the Fan Unit.

3. Clean the ribs of the heat sink (see figure 5-1 Fan unit and heat sink) very

carefully with a soft brush (not metallic!). Take care that the material is not

scratched or damaged!

4. If necessary, use compressed air (max. 5 bar) to blow out the heat sink from front

to rear side.

) Note: NEVER blow out the fan unit with compressed air! This would

cause permanent damage to the unit.

5. In case the dirt cannot be blown out completely from the heat sink and parts of it,

still stick to the ribs, clean the parts concerned carefully from the front with the

soft brush. Take care that the material is not scratched or damaged.

6. After cleaning the heat sink, mount the fan unit and the fan guard again according

to chapter 5.2 Replacing the Fan Unit. Then, reconnect mains power and power

up the unit.

Page 43

Page 44

For your notes:

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

Page 44 MF0143AUA.doc

Page 45

6 Appendix

6. APPENDIX

6.1. ILLUSTRATIONS

G3219M0

figure 6-1 Cabinet drawing

Page 45

Page 46

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

6.2. SPECIFICATIONS

6.2.1. Electrical Specifications

ION-M7P/85P/17P/19P

Electrical

Power supply

Mains power 115 Vac or 230 Vac

Power consumption 1050 W

Optical

Connectors E2000/APC 8°

Optical return loss 45 dB min.

Fiber type Single mode E9/125 mm

Optical link budget 0 dB to 10 dB

All figures are typical values, unless otherwise stated

All data is subject to change without notice.

6.2.2. Mechanical Specifications

Height, width, depth * 817 x 245 x 218 mm (32.2 x 9.6 x 8.6 in)

Weight 34 kg (75 Ib)

* Spacing required 40 mm (1.58 in) around unit

All data is subject to change without notice.

6.2.3. Environmental and Safety Specifications

) Note: For detailed information, please refer to the Environmental and

Safety Specifications leaflet of the supplier, related to ETS 300 019

(European Telecommunication Standard).

Operating temperature range -33 °C to +50°C

Ingress protection

All data is subject to change without notice.

RF part IP67

Fan part IP55

Page 46 MF0143AUA.doc

Page 47

6 Appendix

6.3. SPARE PARTS

The following lists contain all parts available for the Remote Unit. The configuration of

the delivered unit meets the requirements of the customer and can differ depending

on the state of the delivery.

Maintenance of the ION-M7P/85P/17P/19P should be performed on an FRU (Field

Replaceable Unit) basis only. Do not damage the warranty labels on the

components, as this voids the warranty.

The following spare parts lists only contain units that can be replaced without tuning

or soldering work. To replace an FRU, use the appropriate tools. Replacement tools

may be ordered from the supplier. If any FRU not contained in the following list needs

to be replaced, please contact customer service for additional instructions.

Spare Parts List of the Remote Unit ION-M7P/85P/17P/19P

Designation: ID No: FRU

ION-M7P/85P/17P/19P

Protective Plug E2000 7160013 x

Protective Cap E 2000 7158914 x

Fan Unit ML-Cabinet 7632532-00 x

Manuals for ION-M7P/85P/17P/19P 7635253-00

Accessories

Wall Mounting Kit 7632566

Pole Mounting Kit 7636344

Alarm Kit 7157396

The manufacturer reserves the right to replace the spare parts listed above by

equivalent substitutes.

7629728

Page 47

Page 48

For your notes:

User’s Manual for

ION™-M7P/85P/17P/19P (ML-Cab)

Page 48 MF0143AUA.doc

Page 49

7 Index

7. INDEX

A

Abbreviations Used ................................................ 7

Address of Andrew Wireless Systems GmbH....... 13

Alarms

Alarm Status.................................................... 37

Bite and Alarms ............................................... 37

External Inputs........................................... 39, 40

Handling of Alarms .......................................... 37

List...................................................................40

Outputs......................................................39, 40

RU ................................................................... 40

Status LED....................................................... 37

Andrew Solutions.................................................. 10

C

Cleaning the Heat Sink......................................... 43

Commissioning

General............................................................ 33

Connection Rules

Optical-Fiber Cables........................................ 26

Connections

Antenna ........................................................... 24

Connector Flange............................................ 23

Power .............................................................. 25

Contact Addresses............................................... 12

Control Connector for EU..................................... 23

Customer Support Addresses............................... 12

E

Extension Unit

RS485/ RS232 Control Connector (8 pins)...... 23

External Inputs

Location...........................................................23

H

Health and Safety Warnings................................... 8

I

Illustrations........................................................... 45

Installation

Electrical.......................................................... 21

Mechanical ...................................................... 17

M

Maintenance......................................................... 41

Mounting

Pole (Outside).................................................. 20

Wall.................................................................. 19

O

Optical-Fibre Connection

Protective Plug ................................................ 29

Protective-Tube Kit.......................................... 31

Outputs

Location........................................................... 23

P

Pin Assignment

External Alarms............................................... 39

R

Replacement of Fan Unit...................................... 42

RS485/ RS232 EU Control Connector ................. 23

F

Fiber-Optical Components

Cleaning Procedure.........................................27

System Installation........................................... 26

Flange Connector

5 poles.............................................................39

7 poles.............................................................39

Spare Parts .......................................................... 47

Specifications

Electrical.......................................................... 46

Environmental and Safety................................ 46

Mechanical ...................................................... 46

S

T

G

Grounding............................................................. 24

Page 49

Troubleshooting.................................................... 40

Page 50

Loading...

Loading...