Page 1

TECP-96-614 Issue 3 November 2016

FTTX Solutions Rapid Flexible Fiber Box

User Manual

24691-A

Rapid FFB With RapidReel and Sliding Adapter Packs

Content Page

INTRODUCTION .............................................................................2

Revision History ........................................................................2

Trademark Information ...................................................................2

Admonishments ........................................................................2

1 PRODUCT DESCRIPTION ..................................................................3

1.1 General Description................................................................3

1.2 Main Components .................................................................4

1.3 Bottom Plate Kit .................................................................. 6

1.4 Specifications and Dimensions ........................................................6

2 MOUNTING THE RAPID FFB ................................................................7

2.1 General Recommendations........................................................... 8

2.2 Wooden Utility Pole Mounting Procedure .................................................8

2.3 Metal Utility Pole Mounting Procedure ..................................................10

2.4 Wood-Framed Wall Mounting Procedure ................................................ 11

2.5 Masonry Wall Mounting Procedure .................................................... 14

3 GROUNDING THE RAPID FFB .............................................................. 16

4 OPENING AND CLOSING THE OUTER DOOR..................................................... 17

5 INSTALLING THE FEEDER CABLE............................................................ 18

6 INSTALLING A DROP CABLE ............................................................... 22

(continued)

TECP-96-614 Rev D Page 1

This product is covered by one or more U.S.patents or their foreign equivalents. © 2017 CommScope.

For patents, see http://www.commscope.com/ProductPatent/ProductPatent.aspx All Rights Reserved.

Page 2

TECP-96-614 • Issue 3 • November 2016

Content Page

7 CLEANING CONNECTORS AND ADAPTERS ..................................................... 23

8 ACCESSING ADAPTER PACKS .............................................................. 24

9 PERFORMING A SPLICE .................................................................. 24

10 PRODUCT SUPPORT .................................................................... 26

INTRODUCTION

This manual describes the Rapid Flexible Fiber Box (FFB) and provides all information needed

to install and operate this product. Select the procedures required for the product being installed.

Revision History

ISSUE DATE REASON FOR CHANGE

1 12/2011 Original.

2 3/2012 Details added for paying out feeder cable.

3 November 2016 Rebranded for CommScope.

Trademark Information

CommScope (logo) and CommScope are trademarks.

Admonishments

Important safety admonishments are used throughout this manual. The admonishments must be

followed at all times. These warnings are flagged by use of the triangular alert icon (seen below),

and are listed in descending order of severity of injury or damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that can cause minor personal

injury or property damage if the hazard is not avoided.

General Warning and Caution Statements

Danger: Avoid eye exposure to unmated connectors. Unmated connectors may emit invisible

laser radiation. Do not look directly into the end of a connector or adapter port. Do not inspect

with a magnifying device. To ensure safety, maintain caps on unmated connectors at all times.

Caution: Handle cables with care. Fiber optic cable stubs should be handled with care

throughout the installation procedure to avoid kinking and damage to cables.

Page 2

© 2017 CommScope. All Rights Reserved.

Page 3

1 PRODUCT DESCRIPTION

1.1 General Description

The Rapid Flexible Fiber Box (FFB), shown on the cover of this user manual, is a rugged,

weather-resistant demarcation and aggregation box equipped with an internal RapidReel

cable spool for easy storage, unreeling, and installation of a feeder cable spooled within the

product. The feeder cable may be either stub-ended or terminated with an MPO connector.

Cable length is either 100 feet for a 24-fiber cable or 200 feet for a 12-fiber cable.

The Rapid FFB is used in Fiber-to-the-Cell-Site (FTTCS) and Fiber-to-the-Antenna (FTTA)

applications. In a typical installation, the Rapid FFB is mounted on a utility pole or wall at a cell

site or tower, where it provides a splice or connection point between the backhaul network and

the cell site or tower.

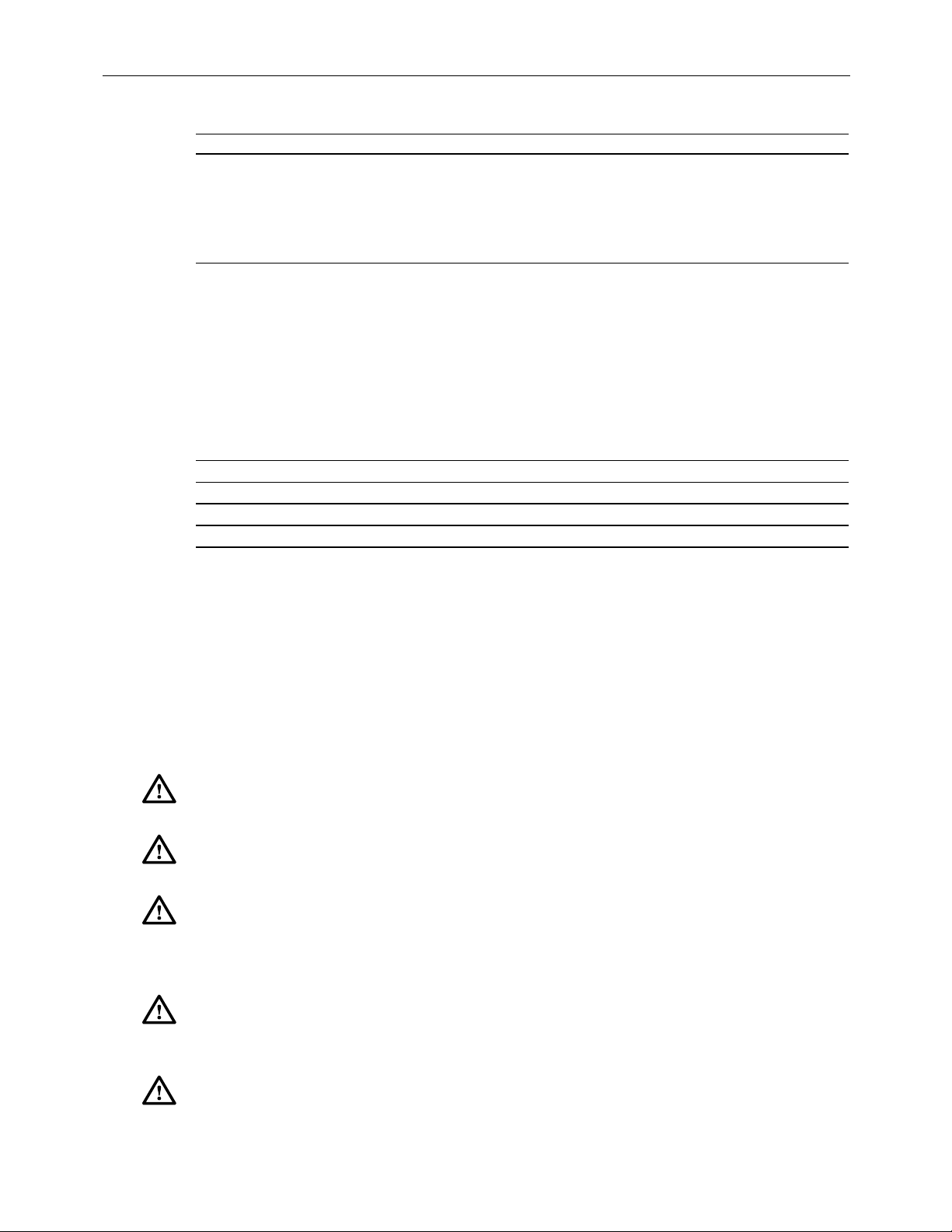

The Rapid FFB divides functionally into feeder cable components and drop cable components,

as shown in

• Feeder Cable Components—include the RapidReel, the feeder cable, and a compression

nut assembly for securing the feeder cable after it is unwound.

Figure 1.

TECP-96-614 • Issue 3 • November 2016

TM

fiber

• Drop Cable Components—consist of two compression nut assemblies for securing drop

cables and either sliding adapter packs or splice trays for terminating the drop cables

within the FFB.

24695-A

FEEDER

COMPONENTS

DROP

COMPONENTS

FROM

BACKHAUL

NETWORK

TO

CELL SITE OR

ANTENNA

Figure 1. Rapid FFB Functional Components

© 2017 CommScope. All Rights Reserved.

Page 3

Page 4

TECP-96-614 • Issue 3 • November 2016

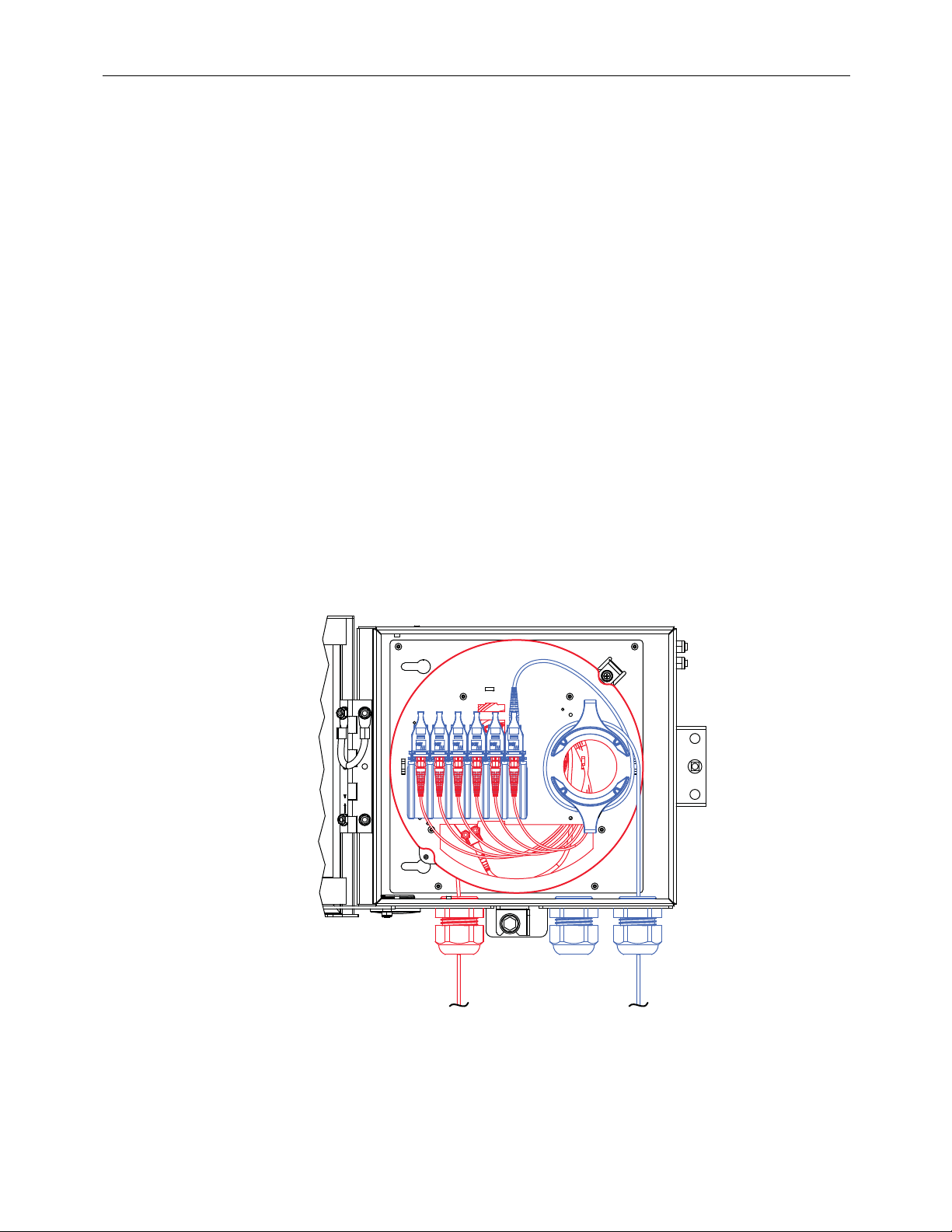

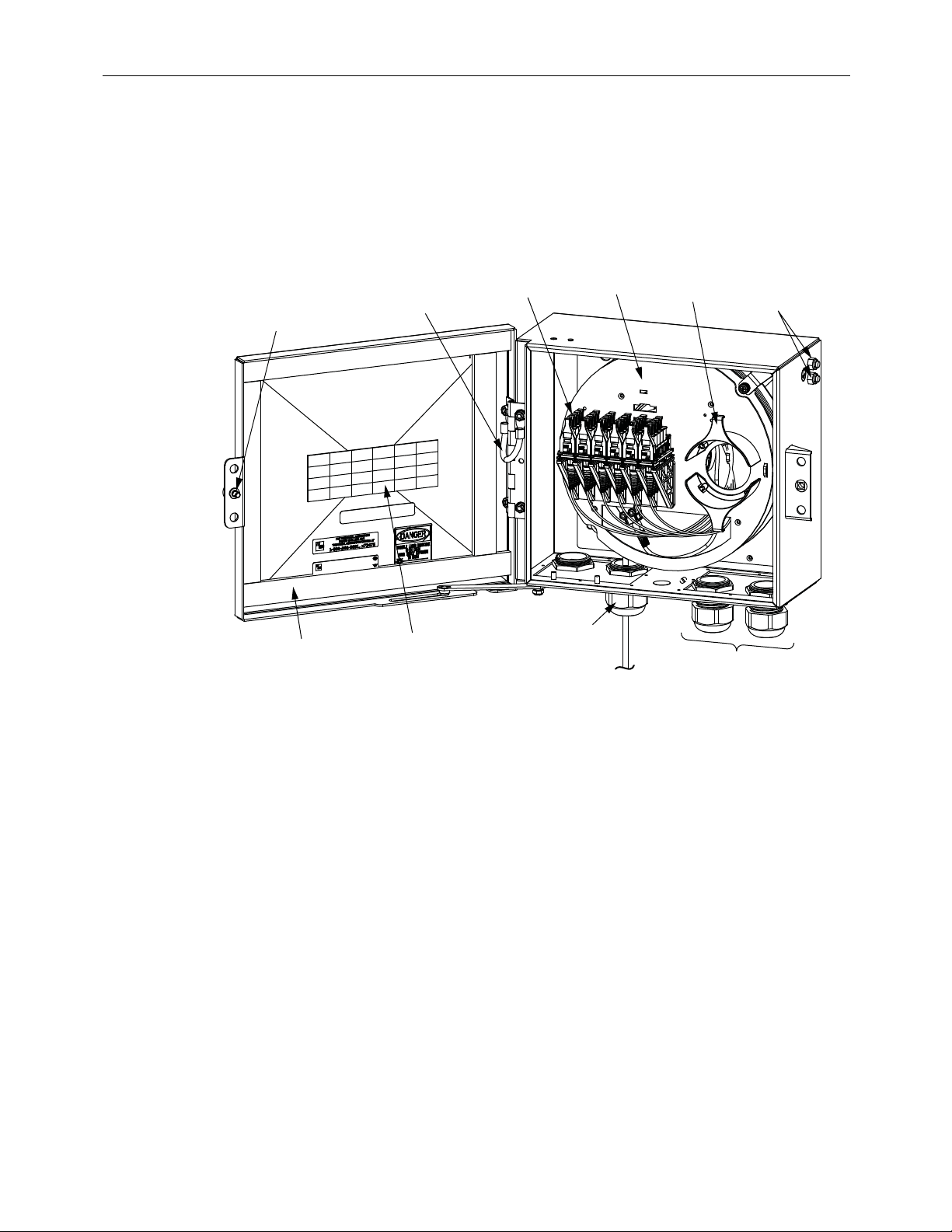

1.2 Main Components

Figure 2 provides a more detailed and comprehensive view of the main components of a Rapid

FFB with a feeder cable pre-wound onto the rapid wheel and with sliding adapter packs for

termination of drop cables.

OUTER

DOOR

LATCH

DOOR

DOOR

GROUNDING

WIRE

DESIGNATION

LABEL

SLIDING

ADAPTER

PACKS

FEEDER CABLE

PORTAL

RAPID

REEL

RADIUS

LIMITERS

DROP SIDE

CABLE PORTALS

GROUNDING

STUDS

24693-A

Figure 2. Main Components of Rapid FFB With Sliding Adapter Packs

The components called out are as follows:

• Outer Door—swings open to provide access to the interior of the box.

• Outer Door Latch—houses a door lock operated with a 216B key tool. It has a hole for an

optional padlock.

• Designation Label—provides an area to record the designation of drop cables.

• Door Grounding Wire—grounds the door to the main part of the box (which is in turn

grounded to the facility ground).

• Sliding Adapter Packs—transition between the feeder cable on the RapidReel and drop

cables. Depending on the fiber count of the feeder cable, the FFB may contain either 12 or

24 adapters.

• RapidReelTM— contains the spooled up feeder cable which is unspooled at the customer

site and routed to the connection point with the cable from the backhaul network. The

RapidReel is locked when shipped and must be unlocked before the cable can be

unwound.

Page 4

© 2017 CommScope. All Rights Reserved.

Page 5

TECP-96-614 • Issue 3 • November 2016

• Radius Limiters—are guides for wrapping around the drop cables when installed. They

prevent the drop cables from being damaged by being bent too sharply.

• Grounding Studs—are used to fasten a two-hole grounding lug and grounding wire.

• Feeder Side Cable Portal—holds the compression nut assembly that is used to secure the

feeder cable after it is unwound.

• Drop Side Cable Portals—holds the compression nut assemblies used to secure drop

cables after they are installed. Multiple cables may enter through the same portal.

Figure 3 shows the splice-specific components of a Rapid FFB with splice trays on the drop

side. This unit also has an internal RapidReel fiber cable spool and feeder cable.

• Radius Limiters—are guides for wrapping around the drop cables when installed. They

prevent the drop cables from being damaged by being bent too sharply.

• Hook-and-Loop Straps—secure the splice trays to the RapidReel and allow the splice

trays to be easily removed from the RapidReel and returned to it after completion of

splicing or other maintenance procedures.

• Splice Trays—are used to splice the feeder cable fibers to the drop cable fibers. The Rapid

FFB accommodates up to

two 12-fiber SC ribbon assemblies

RADIUS

LIMITERS

HOOK-AND-LOOP

STRAP

Figure 3. Main Components of Rapid FFB With Splice Trays

SPLICE

TRAYS

24694-B

© 2017 CommScope. All Rights Reserved.

Page 5

Page 6

TECP-96-614 • Issue 3 • November 2016

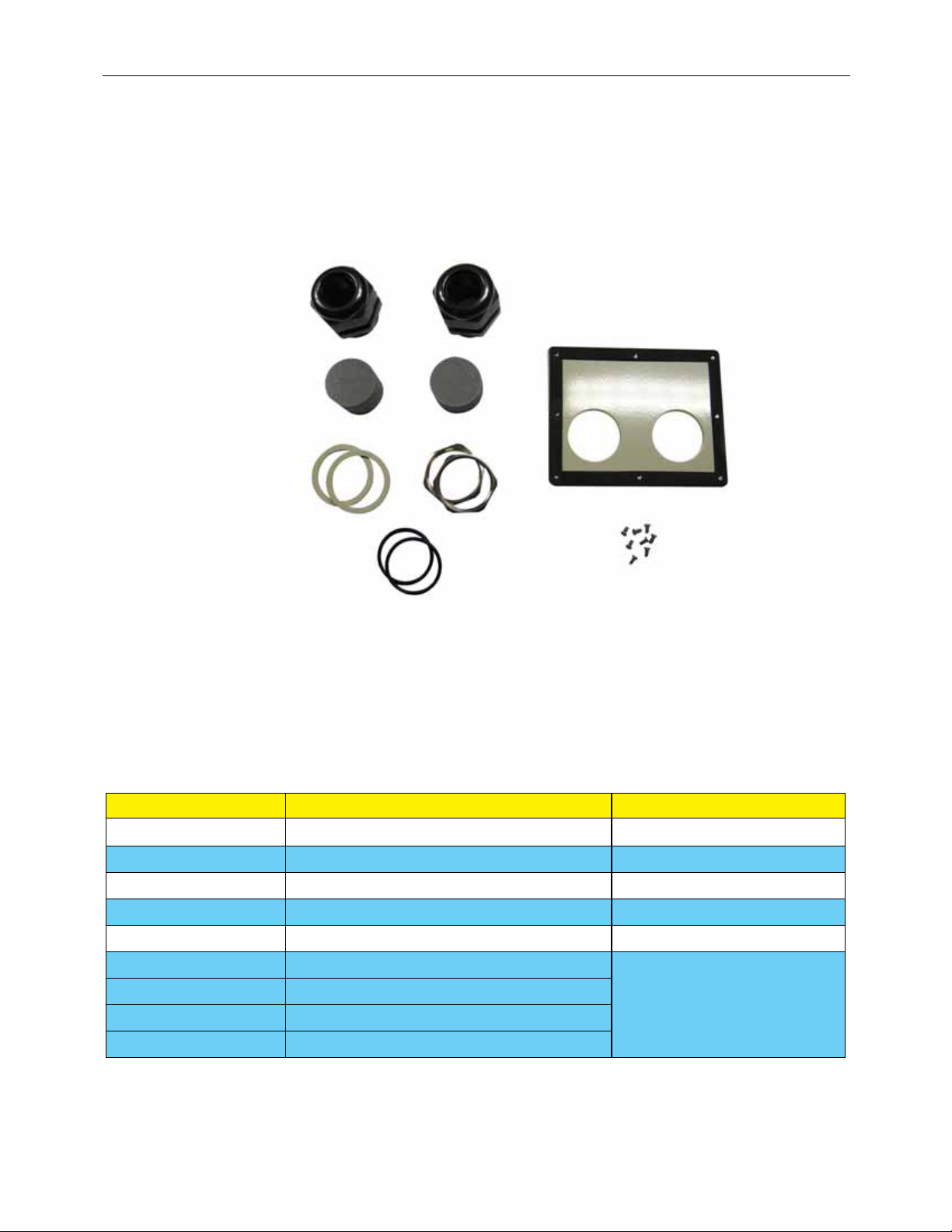

1.3 Bottom Plate Kit

A bottom plate kit (FFB-BTM-PLT-KIT) is available as a product accessory. The kit (shown in

Figure 4) contains one two-hole bottom plate, one gasket, two compression nut assemblies, and

eight mounting screws.

Figure 4. Bottom Plate Kit Components

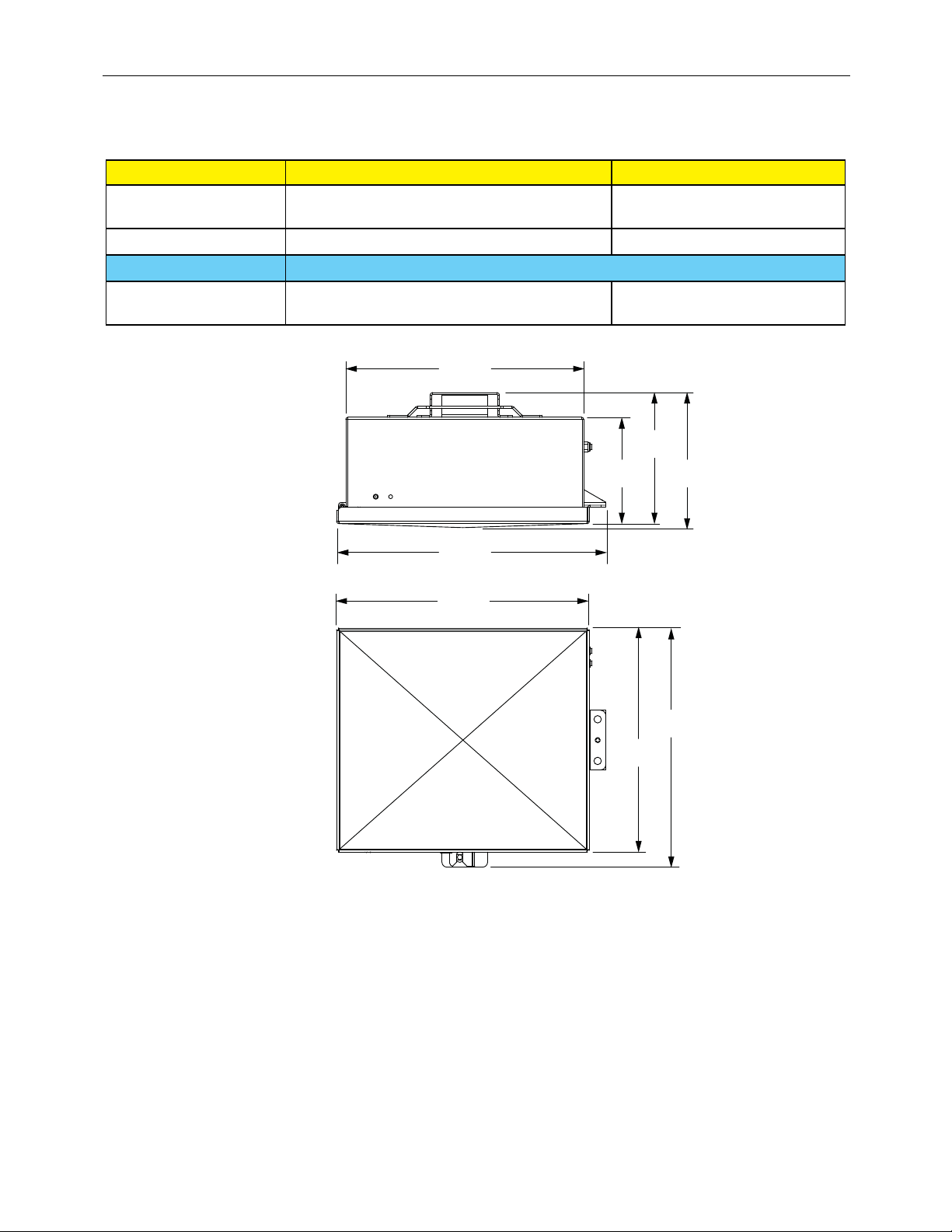

1.4 Specifications and Dimensions

Table 1 lists specifications, Figure 5 shows dimensions of the Rapid FFB.

Table 1. Specifications

ITEM SPECIFICATION COMMENTS

Dimensions (H x W x D) 11.30 x 12.74 x 5.36 in (38.70 x 32.36 x 13.61 cm)

Weight 11.50 lbs. (5.22 kg.)

Construction Aluminum 0.080 inch (.020 cm) thick

Color Putty white

Fiber count 12 or 24 fibers

Feeder cable types 100-foot, 24-fiber, MPO terminated Outside diameter:

200-foot, 12-fiber, MPO terminated

100-foot, 12-fiber, stub

200-foot, 24-fiber, stub

Basic box. See Figure 5

3.6 mm (single-mode)

3.8 mm (multimode)

Page 6

© 2017 CommScope. All Rights Reserved.

Page 7

TECP-96-614 • Issue 3 • November 2016

Table 1. Specifications, continued

ITEM SPECIFICATION COMMENTS

Drop cable termination Sliding adapter packs SC and LC; supports up to four

APL series modular adapter packs

Splice trays Up to two 12-fiber cables

Feeder cable portal Shipped with feeder cable already threaded through portal

Drop cable portals Two portals, can be used with up to 5 mm diame-

ter cables depending on configuration

12.00 IN.

(30.5 CM)

TOP VIEW

13.57 IN.

(34.5 CM)

12.74 IN.

(32.4 CM)

FRONT VIEW

Multiple cables may enter through

same portal

6.60 IN.

(16.8 CM)

5.36 IN.

(13.6 CM)

11.30 IN.

(28.7 CM)

6.80 IN.

(17.3 CM)

12.06 IN.

(30.6 CM)

2 MOUNTING THE RAPID FFB

The Rapid FFB can be mounted on a wooden utility pole, metal utility pole, wood-framed wall,

H-frame, or masonry wall. Use whichever procedure is appropriate for the application.

24653-A

Figure 5. Rapid FFB Dimensions

Page 7

© 2017 CommScope. All Rights Reserved.

Page 8

TECP-96-614 • Issue 3 • November 2016

2.1 General Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and provide

adequate parking for worker and vehicle safety. In addition, the installed FFB must not create a

visual or physical obstruction to vehicular or pedestrian traffic. Sufficient space must be

provided on all sides to facilitate FFB installation and maintenance.

Install a grounding system (not provided) that meets all local electrical codes. Check local codes

for grounding system installation, use of clamps, wire size, and any other grounding

requirements. Typically, a 2-hole grounding lug crimped to a #6 AWG solid copper wire is used

to connect the FFB to a approved earth ground source as specified by local code or practice.

2.2 Wooden Utility Pole Mounting Procedure

Use the following procedure to mount the FFB on a wooden utility pole.

1. Obtain the following fasteners and tools:

• 3/8-inch x 2 inch lag screw suitable for exterior application

• Drill

• 9/32-inch drill bit

• 1/2-inch drill bit (optional depending on pole condition)

• 9/16-inch wrench

• 216B key tool (accessory)

The following fasteners are optional depending on the condition of the pole:

• 1/2-inch threaded rod (1), 1/2-inch nut (1), 1/2-inch flat washer (2),

1/2-inch lock washer (2)

2. Using the mounting bracket as a guide, mark the location of the bracket mounting holes on

the pole as shown in

Figure 6.

3. Drill a 9/32-inch hole in the pole at each of the locations marked in step 2.

4. Secure the mounting bracket to the pole using the two 3/8-inch x 2-inch lag screws.

Tighten lag screws securely.

Page 8

© 2017 CommScope. All Rights Reserved.

Page 9

3/8-INCH X 2-INCH

LAG SCREW (2)

TECP-96-614 • Issue 3 • November 2016

FASTENERS USED TO

SECURE BRACKET TO

WOODEN UTILITY POLE

WOODEN

UTILITY POLE

MOUNTING

BRACKET

24219-A

Figure 6. Installing Mounting Bracket on a Wooden Utility Pole

Note: If the utility pole is in poor condition, install a 1/2-inch threaded rod or through-bolt

in addition to the lag screws to provide additional support in mounting the bracket to the

pole, as shown in

THREADED ROD

INSTALLATION

1/2-INCH LOCK

WASHER

1/2-INCH

NUT

Figure 7.

THREADED ROD

1/2-INCH FLAT

WASHER

1/2-INCH

1/2-INCH FLAT

WASHER

1/2-INCH FLAT

WASHER

24220-A

1/2-INCH LOCK

WASHER

1/2-INCH FLAT

WASHER

1/2-INCH

NUT

1/2-INCH

NUT

1/2-INCH

THROUGH-BOLT

THROUGH-BOLT

INSTALLATION

Figure 7. Threaded Rod or Through-Bolt Installation

© 2017 CommScope. All Rights Reserved.

Page 9

Page 10

TECP-96-614 • Issue 3 • November 2016

5. Using appropriate lifting equipment, hoist the FFB into position for attachment to the

mounting bracket.

Danger: Do not stand directly under the FFB as it is being hoisted into position for mounting. A

failure of the lifting equipment could result in serious personal injury.

6. Hang the FFB from the installed mounting bracket. The welded bracket on the back of the

FFB, shown in

partially installed cap screw at the bottom of the mounting bracket fits into the slotted tab

at the bottom of the FFB.

7. Tighten the partially installed cap screw at the bottom of the FFB using the 216B key tool.

Note: A cup washer is included with the cap screw to provide tamper resistance.

Figure 8, fits into the two slots at the top of the mounting bracket. The

WELDED

BRACKET

CAP SCREW

WITH CUP

WASHER

Figure 8. Installing FFB on Pole-Mounted Bracket

2.3 Metal Utility Pole Mounting Procedure

Use the following procedure to mount the FFB on a metal utility pole.

1. Obtain the following materials and tools:

Page 10

© 2017 CommScope. All Rights Reserved.

MOUNTING

BRACKET

24633-A

Page 11

TECP-96-614 • Issue 3 • November 2016

• 5/8-inch wide 304 AISI stainless steel banding

• Panduit BT1HT tool

2. Using a section of stainless steel banding, as shown in Figure 9, secure the pole mounting

bracket on the pole, and tighten the banding using Panduit tool #BT1HT. Adjust the tool

tension setting to #7.

Note: In operating the tool, follow the instructions provided by the tool manufacturer (see

MS Strapping Tool Operation Instructions PA24808A01).

3. Secure the bottom of the bracket to the pole by installing the cap screw with cup washer, as

shown in

Figure 9.

4. Locate the welded bracket on back of the FFB, and hang the FFB on the pole by hanging

the welded bracket on the pole mounting bracket, as shown in

Figure 9.

WELDED

BRACKET

POLE

MOUNTING

BRACKET

CAP SCREW

WITH CUP

WASHER

24730-A

Figure 9. Installing Mounting Bracket on a Metal Utility Pole

MOUNTING

SLOTS

STAINLESS

STEEL

BANDI NG

2.4 Wood-Framed Wall Mounting Procedure

Use the following procedure to mount the FFB on a wood-framed wall. If mounting the FFB on

an H-frame, follow the same basic steps except use the appropriately sized bolts with washers

and nuts in place of the wood screws in step 3.

© 2017 CommScope. All Rights Reserved.

Page 11

Page 12

TECP-96-614 • Issue 3 • November 2016

Warning: Use appropriate lifting equipment when moving or installing the FFB. Do not stand

under the FFB as it is being hoisted into position for installation. A failure of the lifting

equipment could result in serious personal injury.

1. Mount a plywood backer (not provided) on the wall in the location where the FFB will be

mounted as shown in

secure the backer to at least two (minimum) of the wall’s interior 2x4 studs.

FASTENERS USED TO

SECURE BRACKET TO

BACKER BOARD

#10 FLAT

WASHER (4)

#10 X 1-1/2 INCH

WOOD SCREW (4)

Figure 10. Use whatever tools and fasteners are required to firmly

3/4-INCH PLYWOOD

3/4-INCH PLYWOOD

BACKER BOARD

BACKER BOARD

(SECURE TO WALL STUDS)

(SECURE TO WALL STUDS)

MOUNTING

BRACKET

24216-A

Figure 10. Securing Backer Board to Wall and Installing Mounting Bracket on Backer Board

Note: It is recommended that pressure-treated plywood with a minimum thickness of

0.75-inch (19.0 cm) be used as a backer board. The backer must be firmly secured to the

interior framing of the wall to avoid a hazardous condition.

2. Obtain the following fasteners and tools:

• #10 x 1-1/2-inch wood screws (4) and # flat washers (4)

Note: If mounting on an H-frame, use appropriately-sized bolts with washers and nuts in

place of the woods screws listed above.

• Drill and 3/32-inch drill bit

• Screwdriver drill bit (for wood screws)

• 216B key tool (accessory)

3. Using the mounting bracket as a guide, mark the location of the bracket mounting holes on

the wall (or H-frame).

Page 12

© 2017 CommScope. All Rights Reserved.

Page 13

TECP-96-614 • Issue 3 • November 2016

4. Drill a 3/32-inch pilot hole in the backer board at each of the locations marked in step 3.

5. Secure the mounting bracket to the plywood backer using the four #10 x 1-1/2-inch wood

screws and four #10 flat washers. Thread the wood screws into the pilot holes and tighten

securely.

Note: If mounting on an H-frame, use the appropriately-sized bolts with washers and nuts

in place of the woods screws listed above.

6. Using appropriate lifting equipment, hoist the FFB into position for attachment to the

mounting bracket.

Danger: Do not stand directly under the FFB as it is being hoisted into position for mounting. A

failure of the lifting equipment could result in serious personal injury.

7. Hang the FFB from the installed mounting bracket. The welded bracket on the back of the

FFB, shown in

Figure 11, fits into the two slots at the top of the mounting bracket. The

partially installed cap screw at the bottom of the mounting bracket fits into the slotted tab

at the bottom of the FFB.

8. Securely tighten the partially installed cap screw at the bottom of the FFB using the 216B

key tool.

Note: A cup washer is included with the cap screw to provide tamper resistance.

WELDED

BRACKET

MOUNTING

BRACKET

CAP SCREW

WITH CUP

WASHER

24634-A

Figure 11. Installing FFB on Wall-Mounted Bracket

© 2017 CommScope. All Rights Reserved.

Page 13

Page 14

TECP-96-614 • Issue 3 • November 2016

2.5 Masonry Wall Mounting Procedure

Use the following procedure to mount the FFB on a masonry wall.

Warning: Use appropriate lifting equipment when moving or installing the FFB. Do not stand

under the FFB as it is being hoisted into position for installation. A failure of the lifting

equipment could result in serious personal injury.

1. Obtain the following fasteners and tools:

• 3/8-inch concrete anchor (2)

• 3/8-inch x 1-1/2 inch hex head capscrew (2)

• 3/8-inch flat washer (2) and 3/8-inch lock washer (2)

• Drill

• 5/8-inch masonry drill bit (check hole size with concrete anchor manufacturer)

• 9/16-inch wrench

• 216B key tool (accessory)

2. Using the mounting bracket as a guide, mark the location of the bracket mounting holes on

the masonry wall as shown in

Figure 12.

Note: Locate the mounting anchors as close as possible to the center of bricks or blocks.

3/8-INCH

CONCRETE

ANCHOR (2)

MASONRY

WALL

MOUNTING

BRACKET

3/8 x 1-1/2-INCH

CAP SCREW (2)

Page 14

© 2017 CommScope. All Rights Reserved.

3/8-INCH FLAT

3/8-INCH LOCK

WASHER (2)

WASHER (2)

24218-A

Figure 12. Installing Mounting Bracket on a Masonry Wall

Page 15

TECP-96-614 • Issue 3 • November 2016

3. Drill a 5/8-inch hole (check hole size with anchor manufacturer) in the wall at each of the

locations marked in step 2.

4. Secure the mounting bracket to the masonry wall using the two 3/8-inch x 1-1/2-inch cap

screws, two 3/8-inch lock washers, and two 3/8-inch flat washers. Tighten cap screws

securely.

5. Using appropriate lifting equipment, hoist the FFB into position for attachment to the

mounting bracket.

Warning: Do not stand directly under the FFB as it is being hoisted into position for cable

installation. A failure of the lifting equipment could result in serious personal injury.

6. Hang the FFB from the installed mounting bracket. The welded bracket on the back of the

FFB (see

Figure 13) fits into the two slots at the top of the mounting bracket. The partially

installed cap screw at the bottom of the mounting bracket fits into the slotted tab at the

bottom of the FFB.

WELDED

BRACKET

MOUNTING

BRACKET

CAP SCREW

WITH CUP

WASHER

24634-A

Figure 13. Installing FFB on Wall-Mounted Bracket

7. Tighten the partially installed cap screw at the bottom of the FFB using the 216B key tool.

Note: A cup washer is included with the cap screw to provide tamper resistance.

© 2017 CommScope. All Rights Reserved.

Page 15

Page 16

TECP-96-614 • Issue 3 • November 2016

3 GROUNDING THE RAPID FFB

Use the following procedure to connect the grounding wire to the FFB.

1. Locate the grounding studs shown in Figure 14.

2. Obtain a 2-hole compression-type grounding lug with 0.625-inch hole spacing (not

provided) and a length of #6 AWG solid copper wire.

3. Crimp the 2-hole grounding lug to the copper wire using the recommended crimping tool.

4. Secure the grounding lug and attached wire (see Figure 14) to the side of the FFB. Using a

torque wrench with a 7/16-inch socket, tighten the grounding stud nuts to 40 to 45 lbsforce inches (4.5 to 5.1 Nm) of torque.

Warning: Failure to properly tighten the grounding stud nuts could result in improper

grounding of the FFB and result in performance or safety issues.

5. Route the free end of the grounding wire to an approved earth ground source.

6. Cut the grounding wire to length and connect it to the earth ground source as specified by

local code or practice.

24661-A

Figure 14. Grounding Wire Connection To FFB

NUTS

GROUND

LUG

Page 16

© 2017 CommScope. All Rights Reserved.

Page 17

4 OPENING AND CLOSING THE OUTER DOOR

The outdoor door of the FFB is locked or unlocked with a 216B key tool. The outer door swings

out on a hinge. Use the following procedure to open or close the outer door. Refer to

To open the outer door, back out the cap screw using a 216B key tool. Swing out the door until

the wind jammer locks into place.

To close the door, lift the wind jammer to disengage it and swing the door closed. Lock the door

using the 216B key tool.

TECP-96-614 • Issue 3 • November 2016

Figure 15.

CAP

SCREW

WIND

JAMMER

Figure 15. Opening and Closing the Outer Door

24703-A

© 2017 CommScope. All Rights Reserved.

Page 17

Page 18

TECP-96-614 • Issue 3 • November 2016

5 INSTALLING THE FEEDER CABLE

The Rapid FFB is shipped with the feeder cable spooled around the internal RapidReel and with

the RapidReel locked to maintain tension.

Use the following procedure to install the feeder cable.

Caution: Keep tension on the cable when paying out it out. Otherwise, the cable may loosen on

the spool.

1. Locate the termination point to which the feeder cable will be routed.

2. Loosen the feeder cable compression nut and remove the grommet as shown in Figure 16.

3. Loosen the screw on the RapidReel and rotate the spool counterclockwise to pay out the

cable as shown in

Figure 16.

LOOSEN SCREW AND

ROTATE SPOOL TO

PAY-OUT CABLE

Note: Do not pull on the connector directly. Use either the pulling swivel as described here

or wrap the lead end of the cable around your hand as described in

4. Wrap several layers of vinyl tape around the pulling swivel and trailing connector (if any)

as shown in

5. Tie a pulling cord to the swivel and guide the pulling cord into the conduit or duct as

shown in

Page 18

© 2017 CommScope. All Rights Reserved.

Figure 18 and Figure 19.

LOOSEN

COMPRESSION

NUT AND REMOVE

GROMMET

GROMMET

Figure 16. Installing the Cable Compression Fitting

Figure 17.

24696-A

Figure 20 on Page 20.

Page 19

TECP-96-614 • Issue 3 • November 2016

Figure 17. Inserting Leading Connector Pulling Eye(s) into Pulling Swivel Mesh

B

Figure 18. Wrapping Vinyl Tape Around Pulling Swivel and Trailing Connector

FFB

MOUNTING

LOCATION

OPTIONAL

CONDUIT OR DUCT

TERMINATION

LOCATION

24857-A

Figure 19. Positioning External Spool at Mounting Location

6. At the conduit exit location, remove the tape, mesh, and pulling swivel from the leading

connector pulling eye(s).

© 2017 CommScope. All Rights Reserved.

Page 19

Page 20

TECP-96-614 • Issue 3 • November 2016

Caution: If the cable will be pulled to some further location, not within reach at the time being,

make sure to use the hand-wrap method shown in Figure 20 to pull the cable to the point where

the cable will be spliced or terminated.

7. At the termination location, when the entire cable is paid out, either splice or connect the

cable as follows:

a. If splicing, cut off the non-functional connector and splice the fibers following local

practice; or

b. If connecting to MPO adapters, remove the pulling eye(s) as directed in the instruction

sheet provided with the product (ADCP-90-389) and connect the connectors to the

MPO adapters.

8. Rotate the RapidReel clockwise (if possible) to wrap some cable back onto the spool

before tightening the screw as directed in the next step.

Page 20

© 2017 CommScope. All Rights Reserved.

Figure 20. Hand-Wrap Method

Page 21

TECP-96-614 • Issue 3 • November 2016

9. Within the FFB, rotate the spool to the notch and tighten the screw as shown in Figure 21.

10. Replace the grommet on the feeder cable, just below the compression nut, and stuff the

grommet into the compression nut as also shown in

Figure 21.

ROTATE SPOOL TO

NOTCH AND

TIGHTEN SCREW

INSERT GROMMET

AND TIGHTEN

COMPRESSION

NUT

GROMMET

24697-A

Figure 21. Securing the Feeder Cable

11. Tighten the compression nut to secure the cable in the compression nut assembly.

© 2017 CommScope. All Rights Reserved.

Page 21

Page 22

TECP-96-614 • Issue 3 • November 2016

6 INSTALLING A DROP CABLE

Use the following procedure to install a drop cable.

1. Locate the compression nut assemblies that were shipped with the FFB. They are in a

separate package.

2. Assemble the retaining nut, O-ring, compressing fitting base, metal spacer, grommet, and

compression nut on the FFB as shown in

Figure 22.

RETAINING

NUT

O-RING

COMPRESSION

FITTING BASE

METAL

SPACER

COMPRESSION

NUT

24791-A

Figure 22. Installing the Compression Nut Assembly

3. Thread the drop cable through the compression assembly into the FFB through the hole in

the compression nut assembly.

4. Route the drop cable to its destination.

5. Place the grommet on the cable just below the compression nut and stuff the grommet into

the compression nut as shown in

Figure 23. Tighten the nut.

6. Secure the drop cable inside the FFB using the mille-tie provided. Fasten the mille-tie to

the cable lance in the location shown in

Figure 23.

Page 22

© 2017 CommScope. All Rights Reserved.

Page 23

TECP-96-614 • Issue 3 • November 2016

MILLE-TIE

24698-A

7 CLEANING CONNECTORS AND ADAPTERS

Connectors and adapters should be carefully cleaned whenever connecting or disconnecting a

fiber optic cable or patch cord.

Refer to the Optical Fiber Systems Cleaning and Mating Instructions (ADCP-90-159) provided

with CommScope patch cords and optical cable assemblies for the connector and adapter

cleaning procedures.

INSERT GROMMET

AND TIGHTEN

COMPRESSION

NUT

GROMMET

© 2017 CommScope. All Rights Reserved.

Page 23

Page 24

TECP-96-614 • Issue 3 • November 2016

8 ACCESSING ADAPTER PACKS

1. Lift up the small tab on top of the adapter pack.

2. Lift up the adapter pack to the position shown in Figure 23.

TAB

9 PERFORMING A SPLICE

If installing a stub-ended drop cable, perform the following procedure to remove the splice trays

from the FFB and splice the drop fibers to the feeder fibers.

1. Follow the instructions in Topic 6 on Page 22 to install the drop cable until you get to the

step referring to this procedure for splicing.

2. Unstrap the hook-and-loop strap holding the splice trays and lift the splice tray out of the

box unto a flat surface as shown in

cable wound back into the FFB should be of approximately equal lengths.

3. Route the feeder pigtail fibers into the splice try as shown in Figure 25. Wind about 36

inches (91.4 cm) around within the tray, as indicated.

4. Complete the splicing procedures following local practice.

5. Return the splice tray to the box and secure the splice tray using the hook-and-loop strap.

ADAPTER

PAC K

24787-A

Figure 23. Accessing an Adapter Pack

Figure 24. Note that the lengths of feeder and drop

6. Complete the instructions in Topic 6 on Page 22 to replace the grommet on the cable and

secure the grommet and cable in the compression nut.

Page 24

© 2017 CommScope. All Rights Reserved.

Page 25

NOTE: FEEDER AND

DROP CABLE LENGTHS

WOUND INTO CABINET

SHOULD BE EQUAL.

TECP-96-614 • Issue 3 • November 2016

DROP

CABLE

FEEDER

CABLE

Figure 24. Positioning Splice Tray for Splicing

FOLD BACK

ARAMID YARN

FEEDER

CABLE

INTERNAL

PIGTAIL

CABLE

TIE-DOWN

POINTS

SPLICE

CHIP

Figure 25. Routing Feeder Fibers on Splice Tray

SPLICE

CHIP

24700-B

APPROX.

TOTAL WIND

36 IN.

(91.4 CM)

24671-A

© 2017 CommScope. All Rights Reserved.

Page 25

Page 26

TECP-96-614 • Issue 3 • November 2016

10 PRODUCT SUPPORT

http://www.commscope.com/SupportCenter

Page 26

Loading...

Loading...