Page 1

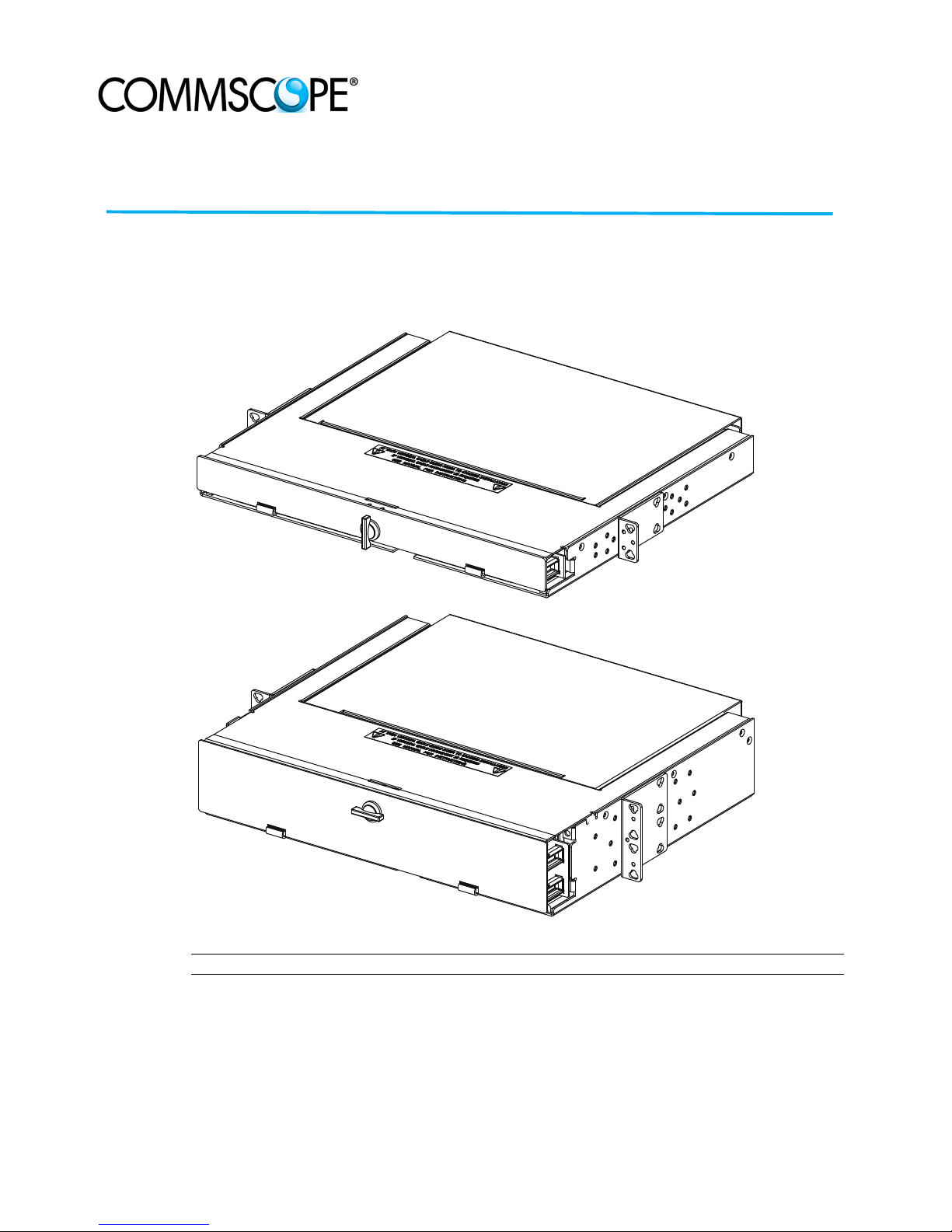

ADCP-92-098

1U PANEL

2U PANEL

23967-B

Rev. C, May 2018

commscope.com

User

Manual

FPX Series

1U & 2U Fiber Panel

Content Page

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Trademark Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Admonishments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

ADCP-92-098 Rev C Page 1

www.commscope.com © 2018 CommScope. All Rights Reserved.

(continued)

Page 2

ADCP-92-098 • Rev C • May 2018

Content (continued) Page

2.1 Selecting a Mounting Bracket Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installing the Panel on the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Installing Vertical Cable Guides (VCGs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Sliding the Drawer In and Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Panel Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Installing Adapter Packs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Installing MPO Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Termination Only Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 CABLE CLAMP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Installing a Cable Clamp for OSP Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Installing a Cable Clamp for MPO Trunk Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4 CABLE ROUTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1 Termination and Splice Panel Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Termination Only Panel Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3 MPO Termination Only Panel Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 CONTACT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.1 Routing Pigtails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.1.2 Routing OSP Cable, Right Side Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 Routing OSP Cable, Left Side Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1.4 Routing Pigtails and OSP Fibers in Splice Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2.1 Routing OSP Cable, Right Side Entry (Adapter Packs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2.2 Routing OSP Cable, Left Side Entry (Adapter Cassettes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.3 Routing OSP Cable, Left Side Entry (MPO Cassettes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2.4 Routing OSP Cable, Right Side Entry (MPO cassettes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.3.1 Routing MPO Trunk Cable, Right Side Entry (MPO Adapter Packs) . . . . . . . . . . . . . . . . . . . . . . . . 26

4.3.2 Routing MPO Trunk Cable, Left Side Entry (MPO Adapter Packs) . . . . . . . . . . . . . . . . . . . . . . . . . 27

INTRODUCTION

This manual contains descriptions and installation and cable routing instructions for the TE

Connectivity FPX 1U and 2U Fiber Panels.

Related Publications

Title/Description ADCP Number

FPX MPO Trunk Cable Clamp Kit Instructions 92-080

Trademark Information

CommScope (logo0 and CommScope are trademarks,

Page 2

© 2018 CommScope. All Rights Reserved.

Page 3

Admonishments

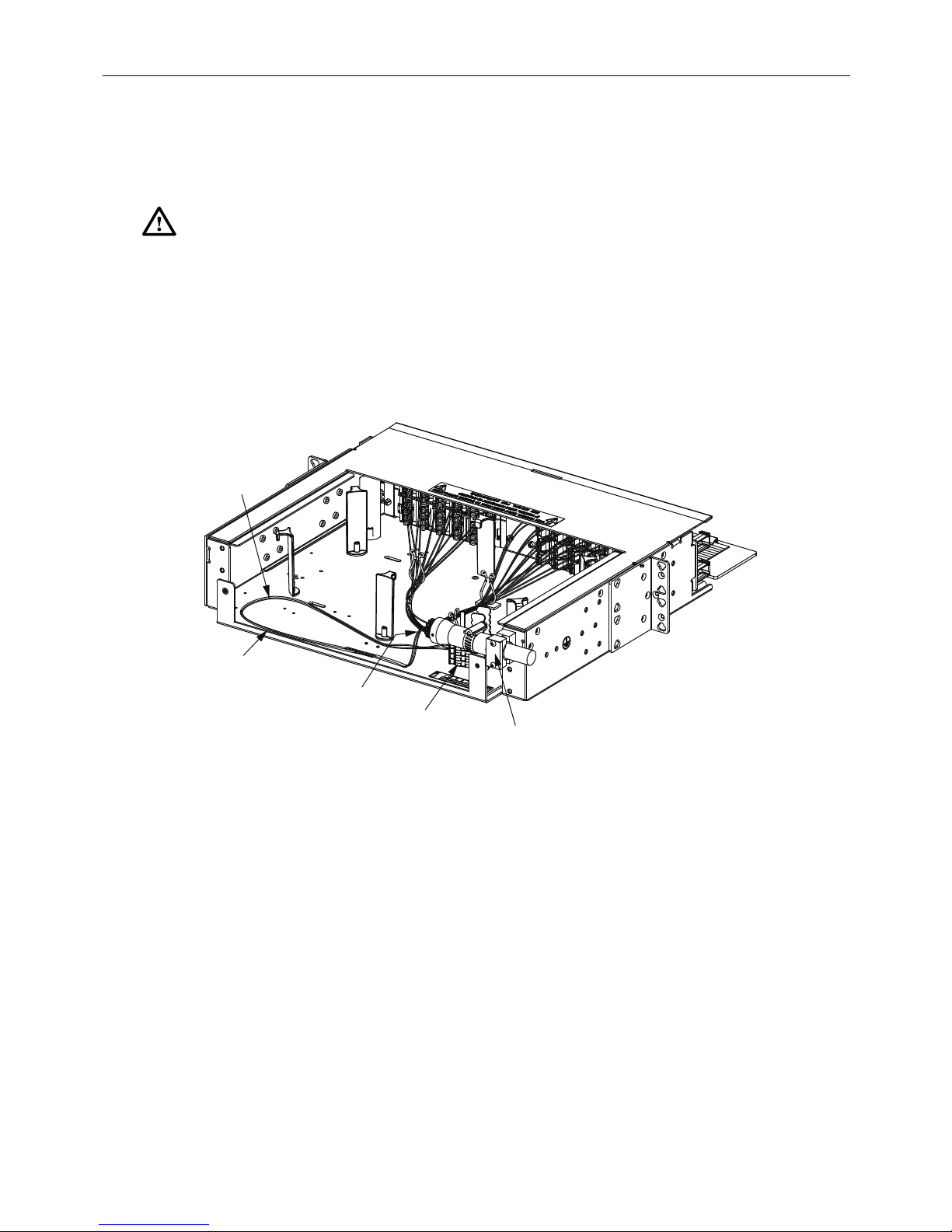

REMOVABLE REAR

COVER PROVIDES

EASY ACCESS FOR

CABLE ROUTING

AND MANAGEMENT

RADIUS LIMITERS FOR

CABLE MANAGEMENT (8)

CABLE CLIP

(1 PER SIDE)

HINGED

FRONT

COVER

DESIGNATION

LABEL (2)

COVER

LATCH

BULKHEAD

ACCOMMODATES

ADAPTER PACKS OR

MPO CASSETTES

OSP CABLE ENTRY

(EITHER SIDE)

SLIDING

TRAY

MOUNTING

BRACKET (2)

23970-A

SPLICE TRAY

LOCATION

TRAY RETAINING

CLIPS (2 PER SIDE)

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. These warnings are flagged by use of the triangular alert icon (seen

below) and are listed in descending order of severity of injury or damage and likelihood of

occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

1 DESCRIPTION

ADCP-92-098 • Rev C • May 2018

The FPX 1U and 2U Panels can accommodate up to 48 and 96 terminations, respectively. The

FPX 1U and 2U Panels can be configured for termination and splice or termination only

(without splice trays).

Note: The Fiber Panel Next Generation is designed to be installed in an environmentally

controlled network telecommunications facility such as a Central Office, Controlled

Environmental Vault, or Data Center.

Figure 1 shows the external features of a typical 1U panel.

Figure 1. FPX 1U Panel External Features

© 2018 CommScope. All Rights Reserved.

Page 3

Page 4

ADCP-92-098 • Rev C • May 2018

Typically, these panels ship empty (without adapter packs, MPO cassettes, splice trays, or

pigtails), but they may also be ordered with any of these components already installed.The panel

accommodates adapter packs and MPO cassettes.

Caution: Adapter packs and MPO cassettes should not be both used in the same panel.

The panel may be ordered loaded with adapter packs only, or loaded with both adapter packs

and pre-terminated, factory-installed cable. While not recommended, field-installed connectors

can be accommodated.

The panel may be used in either single mode or multimode applications, and with either

stranded or ribbon cable. Cables can be either Intrafacility Fiber (IFC) or Outside Plant (OSP).

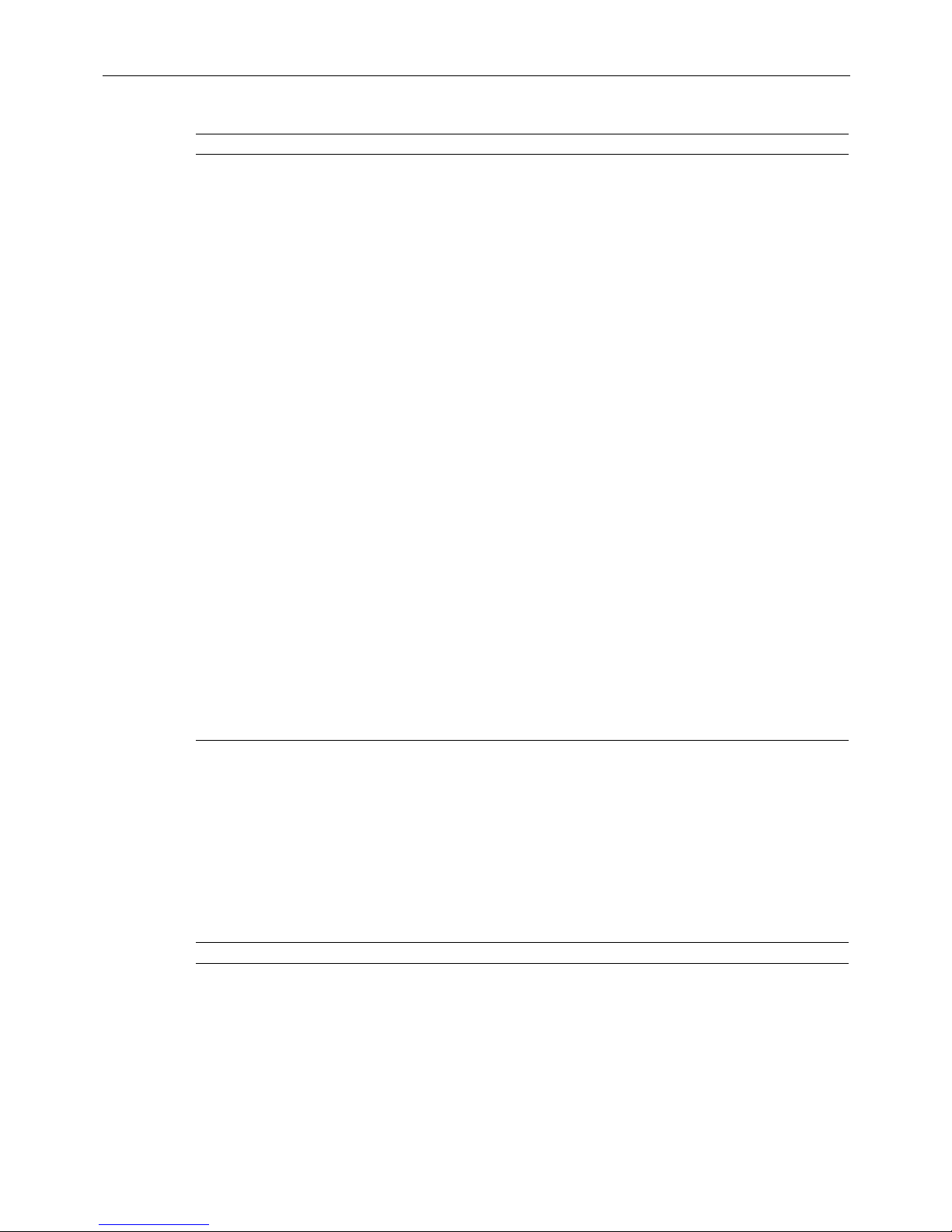

Figure 2 shows a 2U panel.

INDIVIDUAL

SUBUNIT

PROTECTIVE

TUBES

CABLE

BREAKOUT

FANOUT

CHIPS

CABLE

CLAMP

Figure 2. FPX 2U Panel with Termination Only (Rear View)

24620-A

Page 4

© 2018 CommScope. All Rights Reserved.

Page 5

ADCP-92-098 • Rev C • May 2018

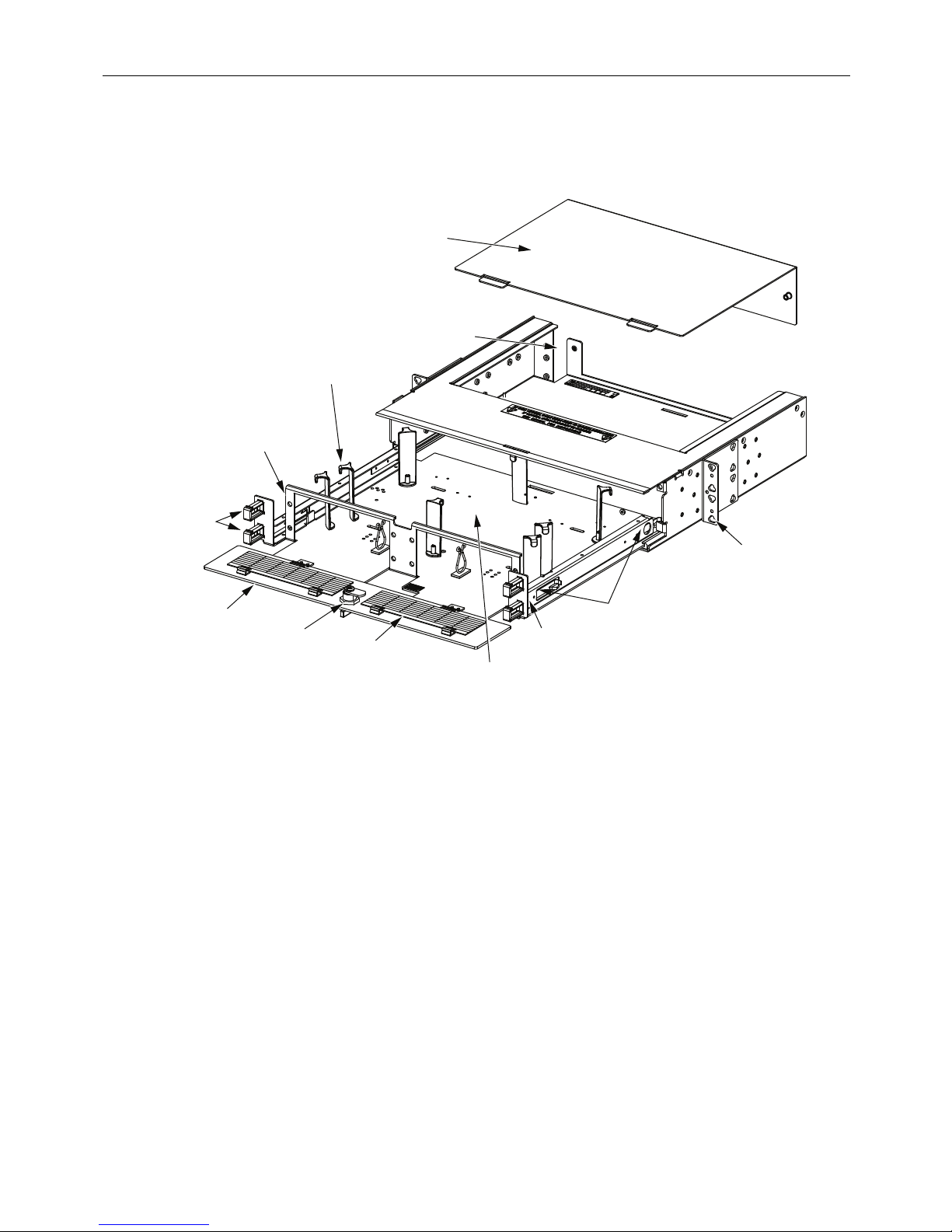

REMOVABLE REAR

COVER PROVIDES

EASY ACCESS FOR

CABLE ROUTING

AND MANAGEMENT

RADIUS LIMITERS FOR

CABLE MANAGEMENT (8)

HINGED

FRONT

COVER

DESIGNATION

LABEL (2)

COVER

LATCH

BULKHEAD

ACCOMMODATES

ADAPTER PACKS OR

MPO CASSETTES

OSP CABLE ENTRY

(EITHER SIDE)

MOUNTING

BRACKET (2)

24621-A

SPLICE

TRAY LOCATION

CABLE CLIP

(2 PER SIDE)

SLIDING

TRAY

TRAY RETAINING

CLIPS (2 PER SIDE)

The 1U termination and splice panel has one splice tray. The 2U termination and splice panel

has two splice trays.

Figure 3 shows the external features of a 2U panel.

2 INSTALLATION

Installation of a FPX panel involves the following tasks:

1. Selecting the mounting brackets (covered in Section 2.1 on Page 6);

2. Installing the panel on the rack (covered in Section 2.2 on Page 7);

3. (Optional) Installing vertical cable guides (covered in Section 2.3 on Page 8);

4. (Optional) Installing adapter packs (covered in Section 2.6 on Page 12);

5. (Optional) Installing MPO cassettes (covered in Section 2.7 on Page 13);

6. Termination Only Installation (covered in Section 2.8 on Page 14)

7. Installing a cable clamp (covered in Section 3 on Page 15);

8. Routing cables and pigtails (covered in Section 4 on Page 17).

Figure 3. FPX 2U Panel External Features

Page 5

© 2018 CommScope. All Rights Reserved.

Page 6

ADCP-92-098 • Rev C • May 2018

23968-B

1U FIBER PANEL

2U FIBER PANEL

5 INCH RACK RECESS

POSITION (AS SHIPPED)

5 INCH RACK RECESS

POSITION (AS SHIPPED)

ROTATE BRACKET

FOR 23-INCH

RACK MOUNTING

ROTATE BRACKET

FOR 23-INCH

RACK MOUNTING

Warning: Never install equipment in a wet location or during a lightning storm. When

installing or modifying communication lines, disconnect lines at the network interface before

working with uninsulated lines or terminals.

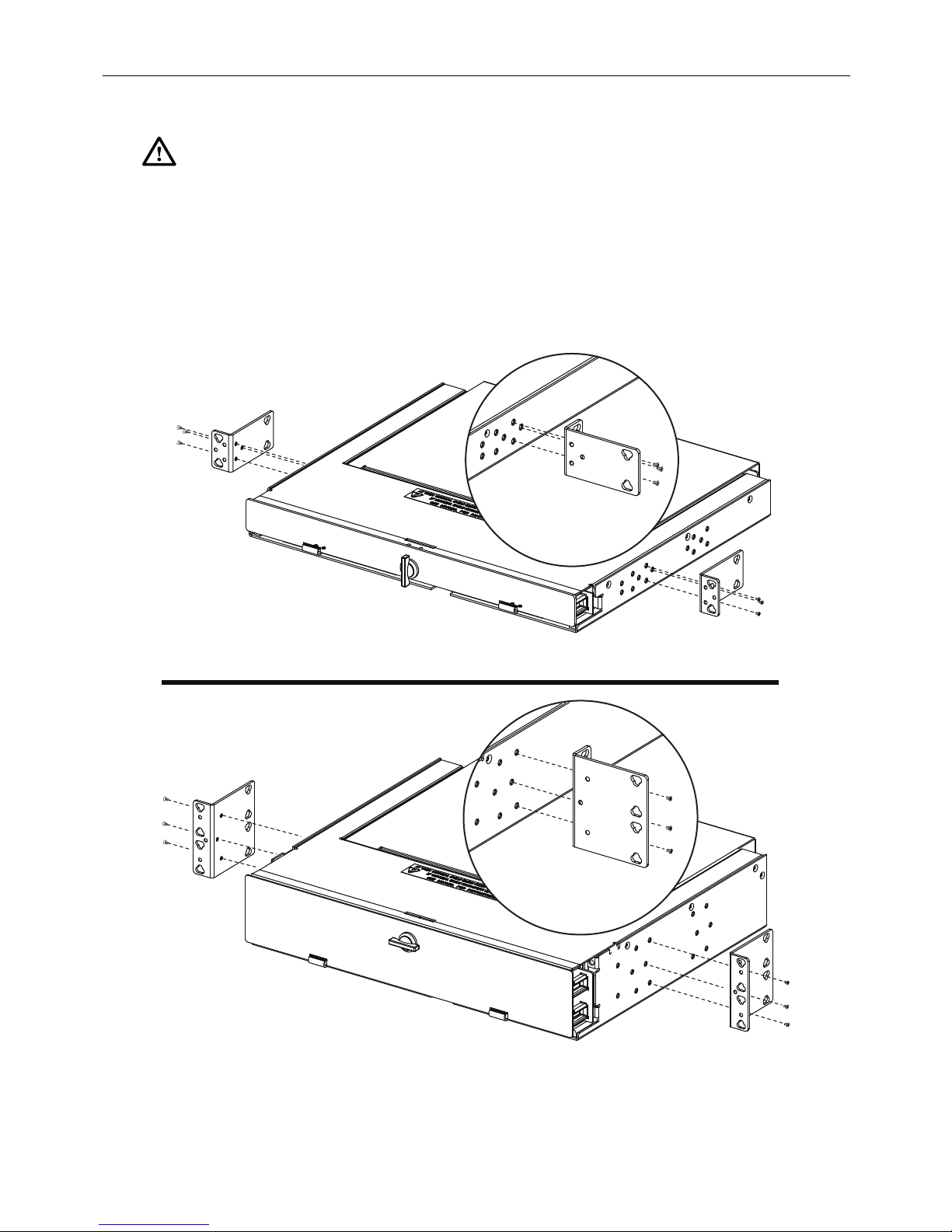

2.1 Selecting a Mounting Bracket Option

The 1U and 2U panels are shipped with mounting brackets configured for a 19-inch EIA/

WECO rack with a 5-inch recess. The mounting brackets can also be reconfigured for a 4-inch

rack recess.

Figure 4 shows the available mounting options for both panels.

Page 6

© 2018 CommScope. All Rights Reserved.

Figure 4. Selecting a Mounting Bracket Option

Page 7

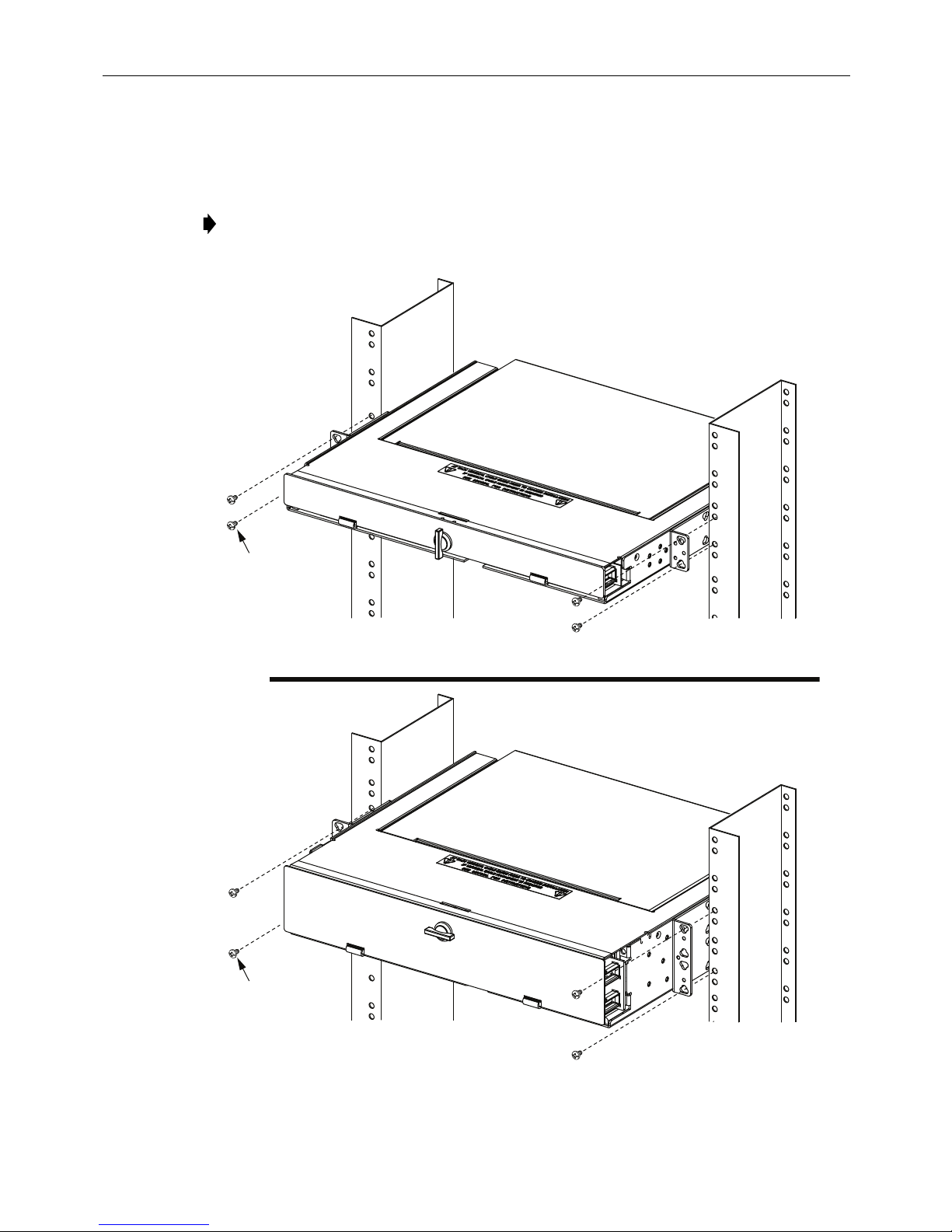

2.2 Installing the Panel on the Rack

12-24 SCREWS

(4 PLACES)

12-24 SCREWS

(4 PLACES)

23971-B

Using 12-24 screws, secure the panel on the rack as shown in Figure 5.

Note: Figure 5 shows the 1U and 2U fiber panels installed in a 19-inch rack with a 5-inch

recess.

ADCP-92-098 • Rev C • May 2018

Figure 5. Installing the Panel on the Rack

Page 7

© 2018 CommScope. All Rights Reserved.

Page 8

ADCP-92-098 • Rev C • May 2018

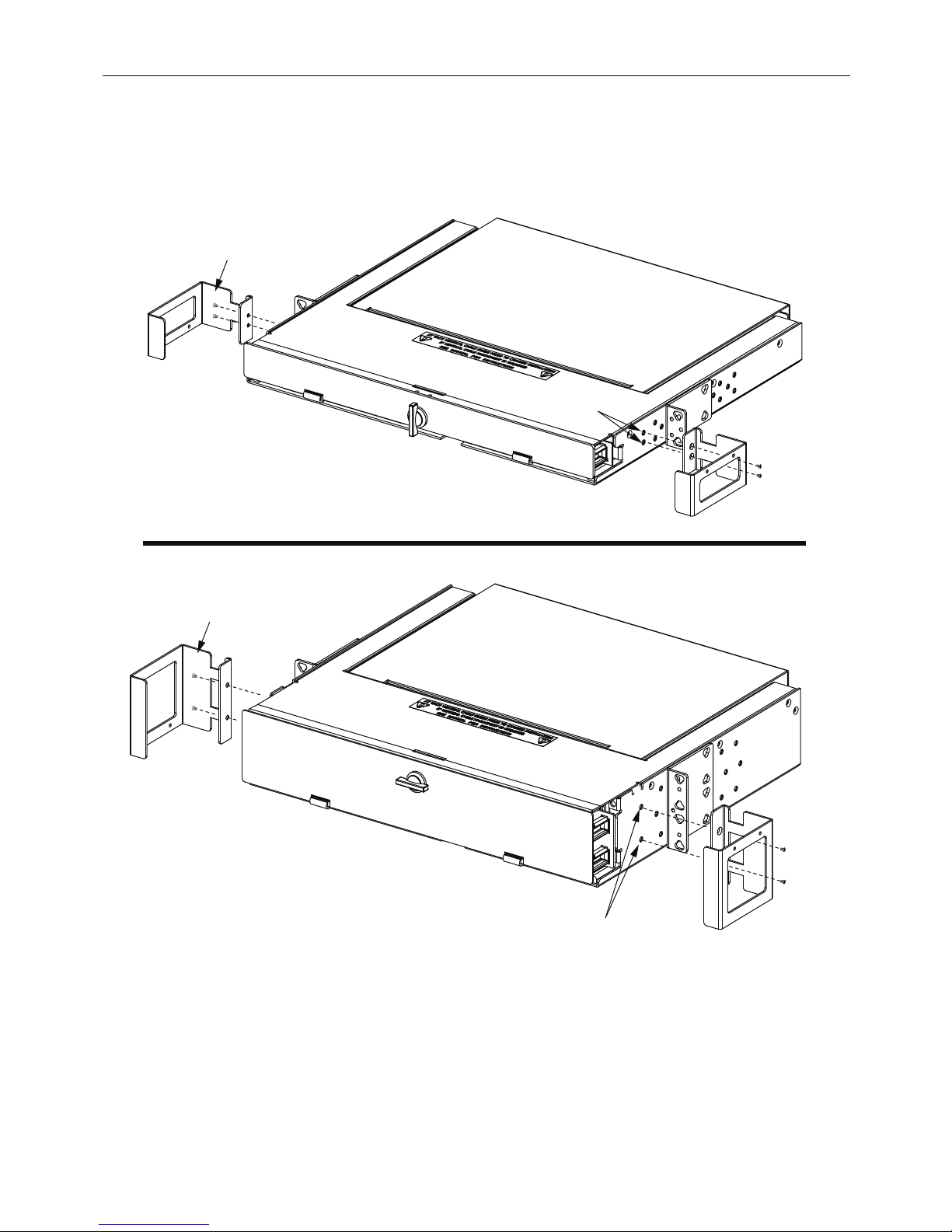

INSTALLATION

HOLES FOR VCG

6-32 SCREWS

(2 PER VCG)

(PROVIDED)

6-32 SCREWS

(2 PER VCG)

(PROVIDED)

1U FIBER PANEL

2U FIBER PANEL

VCG (2)

VCG (2)

INSTALLATION

HOLES FOR VCG

23972-B

2.3 Installing Vertical Cable Guides (VCGs)

Install the VCGs (one per side) as shown in Figure 6.

Page 8

© 2018 CommScope. All Rights Reserved.

Figure 6. Installing Vertical Cable Guides

Page 9

2.4 Sliding the Drawer In and Out

The panel has a tray release button and tray retainer clips designed to ensure that the drawer is

opened carefully and remains open until work in the drawer is competed. These items look the

same and operate the same on the 1U and 2U panels.

Use the following procedure to slide the drawer in and out (2U shown):

1. To release a closed drawer, press the release button down, as shown in Figure 7, and slide

the drawer out to the first detent.

ADCP-92-098 • Rev C • May 2018

PRESS BUTTON DOWN

TO PULL TRAY OUT

TO FIRST DETENT

Figure 7. Releasing Closed Drawer to Open It

23944-B

© 2018 CommScope. All Rights Reserved.

Page 9

Page 10

ADCP-92-098 • Rev C • May 2018

PRESS IN TRAY RETAINER

CLIPS (ONE ON EACH SIDE)

TO FULLY EXTEND TRAY

23945-B

PRESS IN TRAY RETAINER

CLIPS (ONE ON EACH SIDE)

TO SLIDE TRAY BACK

INTO PLACE

23946-B

2. To free the drawer to open it fully, press in the retainer clips (one on each side) located as

shown in

Figure 8. Slide the drawer out until it locks into place.

Figure 8. Freeing Drawer to Slide It Out Fully

3. To release an open drawer to close it, release the retainer clips (one on each side) located

as shown in

Figure 9. Slide the drawer in until it locks into the closed position.

Page 10

© 2018 CommScope. All Rights Reserved.

Figure 9. Releasing Open Drawer to Close It

Page 11

2.5 Panel Grounding

24016-A

2-HOLE LUG

TERMINAL

COPPER WIRE

STRIP BACK INSULATION

PER LUG MANUFACTURER'S

RECOMMENDATION

HOLE CENTER

SPACING:

0.625 INCHES

Each panel has a grounding location marked with the standard grounding symbol. This location

is on the right side of the panel (see

provided to attach a 2-hole lug terminal at the grounding location, as shown in Figure 11.

Follow local practice.

Note: Ground the unit to the local facility CBN (Common Bonding Network) or IBN

(Isolated Bonding Network) per local practice.

ADCP-92-098 • Rev C • May 2018

Figure 10). Use the two 10-32 screws and star washers

Figure 10. Grounding Location

(Rear View of Panel)

23947-B

GROUNDING

LOCATION

Figure 11. Ground Stud

Page 11

© 2018 CommScope. All Rights Reserved.

Page 12

ADCP-92-098 • Rev C • May 2018

INSTALL ADAPTER PACKS

IN ORIENTATION SHOWN

INSTALL RIGHT SIDE ADAPTER PACKS

WITH ADAPTERS ANGLED TOWARDTHE RIGHT

NYLATCH PLUNGER FASTENERS MUST BE

PULLED OUT BEFORE INSERTING THE

ADAPTER PACK INTO MOUNTING HOLES

IN PANEL

AFTER INSTALLING ADAPTER PACK,

PUSH NYLATCH PLUNGER FASTENERS

"IN" TO LOCK ADAPTER PACK INTO PANEL

"OUT"

POSITION

"IN"

POSITION

24622-A

INSTALL LEFT SIDE ADAPTER

PACKS WITH ADAPTERS ANGLED

TOWARD THE LEFT

2.6 Installing Adapter Packs

The 1U panel accommodates two adapter packs. The 2U accommodates four adapter packs.

Adapter packs are installed in the same manner for both 1U and 2U panels. Adapter packs

installed on left side of panel are angled left while adapter packs installed on right side are

angled right. Install the adapter packs as shown in

Figure 12 (2U shown).

Page 12

© 2018 CommScope. All Rights Reserved.

Figure 12. Installing Adapter Packs

Page 13

2.7 Installing MPO Cassettes

The 1U panel accommodates two MPO cassettes, the 2U accommodates four. The procedure for

the 1U and 2U is the same. To install or remove an MPO cassette, pull the Nylatch plunger

fastener out, orienting the MPO as shown in

Caution: Adapter packs and MPO cassettes should not be both used in the same panel.

INSTALL LEFT SIDE MPO

CASSETTES WITH ADAPTERS

ANGLED TOWARD THE LEFT

Figure 13.

INSTALL MPO CASSETTES

IN ORIENTATION SHOWN

ADCP-92-098 • Rev C • May 2018

"OUT"

POSITION

NYLATCH PLUNGER FASTENERS MUST BE

PULLED OUT BEFORE INSERTING THE

MPO CASSETTE INTO MOUNTING HOLES

IN PANEL

INSTALL RIGHT SIDE MPO

CASSETTES WITH ADAPTERS

ANGLED TOWARD THE RIGHT

AFTER INSTALLING MPO CASSETTE,

PUSH NYLATCH PLUNGER FASTENERS

"IN" TO LOCK CASSETTE INTO PANEL

"IN"

POSITION

23948-B

Figure 13. Installing MPO Cassettes

Page 13

© 2018 CommScope. All Rights Reserved.

Page 14

ADCP-92-098 • Rev C • May 2018

INDIVIDUAL

SUBUNIT

PROTECTIVE

TUBES

CABLE

BREAKOUT

FANOUT

CHIPS

RIGHT

ENTRY

LEFT

ENTRY

CABLE

CLAMP

24623-A

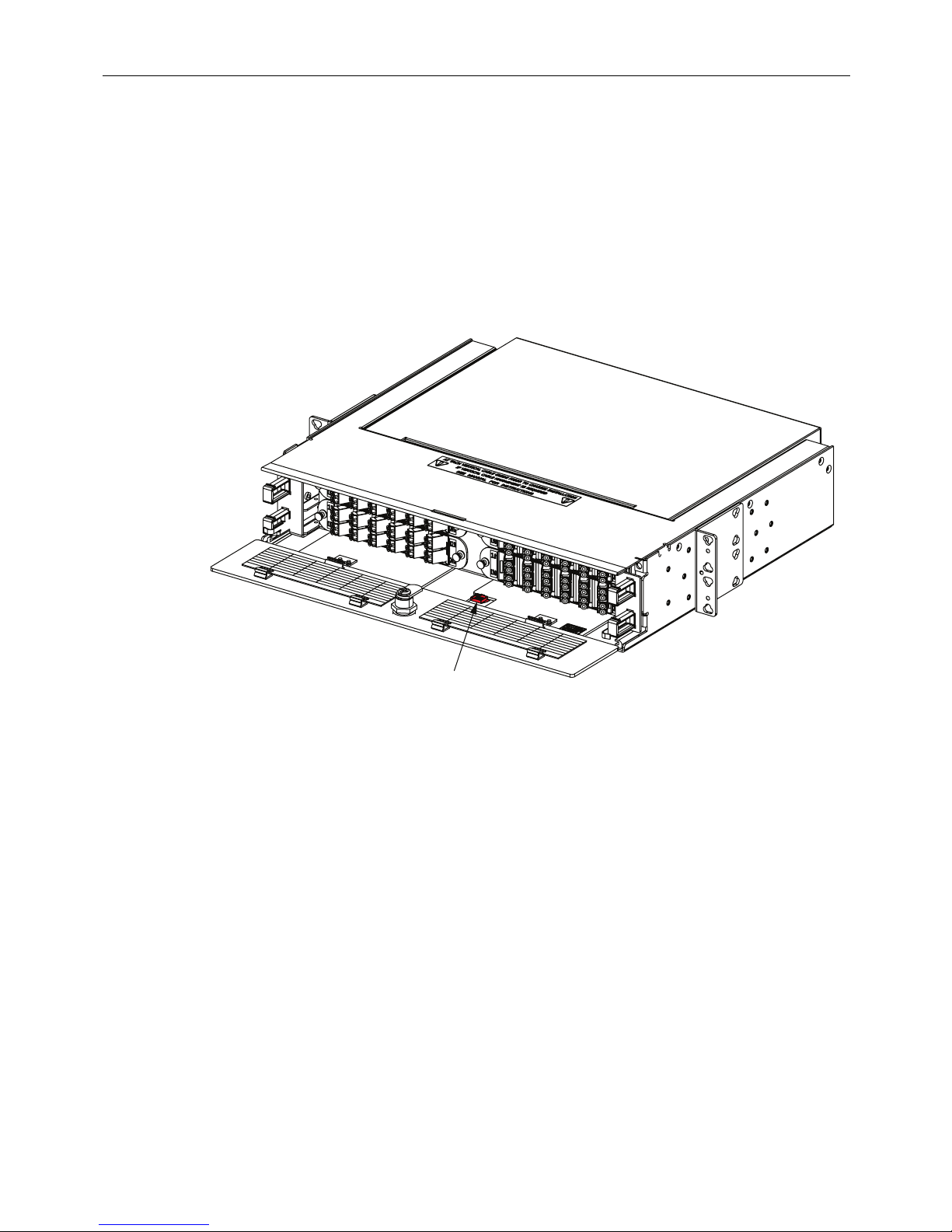

2.8 Termination Only Installation

Install cable after panel is mounted in the equipment rack, as described in

Section 2.2

. Installation

consists of routing cable to the panel, stripping back outside cable sheath exposing the optical

fibers, installing a cable clamp to secure cable to the panel, and routing fibers to the splice tray. If

cable has a metallic strength member it must be grounded following local practices.

Two clamps are provided since two cables may be installed on a single panel. Each clamp can

accommodate one cable with an outside diameter of 0.2 to 0.7 inches (0.51 to 1.78 cm). Refer to

Section 3.1 for clamp installation. Typically, only one cable is installed per panel. the cable

clamp may be installed on either side.

Allow a fiber service loop of at least 96-inches (2.5 meters) when stripping the cable sheath. This

provides sufficient length for routing the buffer tubes within the panel and for splicing. After

entry, the buffer tubes are routed to the splice tray. Splice tray mounts on the bottom of the panel.

Use the following procedure to secure the IFC/OSP cable at the fiber entry point and to route the

optical fibers into the panel:

1. Route the IFC/OSP cable to the selected entry opening at the side of the panel.

Note: Cables may enter the panel from either the left or right and may be clamped to

either the left or right side. For cable mounting locations see

Figure 14.

Figure 14. Typical FPX Configured with Termination Only (Rear View)

2. Strip back cable sheath approximately 96-inches (2.5 meters) to expose optical fibers.

Follow cable manufacturer's recommendations when stripping the sheath.

3. Determine the correct clamp and grommet combination required to secure the cable to the

panel. A rubber clamp and grommets of various sizes are provided. Select a grommet that

Page 14

© 2018 CommScope. All Rights Reserved.

Page 15

when placed around the cable, has a gap of nearly zero to 0.30 inches (0.76 cm). If the

LEFT SIDE

OSP CABLE

ENTRANCE

PLATE

SCREW (2)

YOKE (2)

GROMMET

(SIZE DETERMINED

BY DIAMETER OF

OSP CABLE)

RIGHT SIDE

OSP CABLE

ENTRANCE

REAR COVER

CAN BE REMOVED

TO AID IN OSP

CABLE ROUTING

CAPTIVE

SCREW (2)

24624-A

REAR

VIEW

cable diameter is greater than 0.70 inches (1.78 cm), only the rubber clamp is required.

4. Use the rubber clamp, clamp cover, grommet (if required), and two screws to secure the cable

end to the side of the panel, as shown in

5. If splicing is to be completed later coil the buffer tubes around the radius limiters on the

bottom of the panel and close rear cover. If splicing now follow local practices.

3 CABLE CLAMP INSTALLATION

3.1 Installing a Cable Clamp for OSP Cable

For both termination and splice panels and termination only panels, an OSP cable must be

installed and routed. The procedure is the same regardless of the type of panel being installed.

The OSP cable can enter the panel from the left or right side of the panel (as viewed from the

rear of the panel). Determine the direction of cable entrance and install the cable clamp as

shown in the example in

Figure 15.

Section 3.1

ADCP-92-098 • Rev C • May 2018

for a left or right entry cable.

Figure 15. Cable Clamp Assembly for OSP Cable

Page 15

© 2018 CommScope. All Rights Reserved.

Page 16

ADCP-92-098 • Rev C • May 2018

REAR COVER CAN BE

REMOVED TO AID IN

MPO TRUNK ROUTING

REAR

VIEW

LEFT SIDE

VERTICAL MPO

TRUNK CABLE

ENTRANCE

RIGHT SIDE

HORIZONTAL MPO

TRUNK CABLE

ENTRANCE

24625-A

CAPTIVE

SCREW (2)

3.2 Installing a Cable Clamp for MPO Trunk Cable

Note: This procedure requires use of the MPO trunk cable clamp kit, which can be

ordered from CommScope using catalog # TFP-ACC002. This kit is required for routing

MPO trunk cable in panels with MPO adapter packs. This kit may also be used for routing

MPO trunk cable in panels with MPO cassettes, but the kit is not required for MPO

cassette applications.

Note: When the MPO trunk cable clamp kit is used, there are limitations on the number of

panels that can be stacked up on the rack in certain configurations. For more information,

refer to the instructions (ADCP-92-080) provided with the kit.

For panels with MPO adapter packs, an MPO trunk cable must be installed and routed. The

procedure is the same regardless of the type of panel being installed.

The MPO trunk cable can enter the panel from the left or right side of the panel (as viewed from

the rear of the panel).

Determine the direction of cable entrance and install the cable clamp. Some orientation

examples are shown in

Figure 16.

Figure 16. Cable Clamp Assembly for MPO Trunk Cable

Page 16

© 2018 CommScope. All Rights Reserved.

Page 17

4 CABLE ROUTING PROCEDURES

24626-A

IF NECESSARY, PULL EACH 900 MICRON FIBER FROM

STUB END OF SUBUNIT, TO CORRECT LENGTH TO

ELIMINATE SLACK AT ADAPTER PACK.

CORRECT LENGTH AT ADAPTER PACK

STUB

END

SLACK LOOP AROUND OUTSIDE OF

SPLICE TRAY IS NOT REQUIRED

NOTE:

RECOMMENDED CABLE

LENGTH FROM STUB END

TO CONNECTOR IS 108 INCHES

4.1 Termination and Splice Panel Procedures

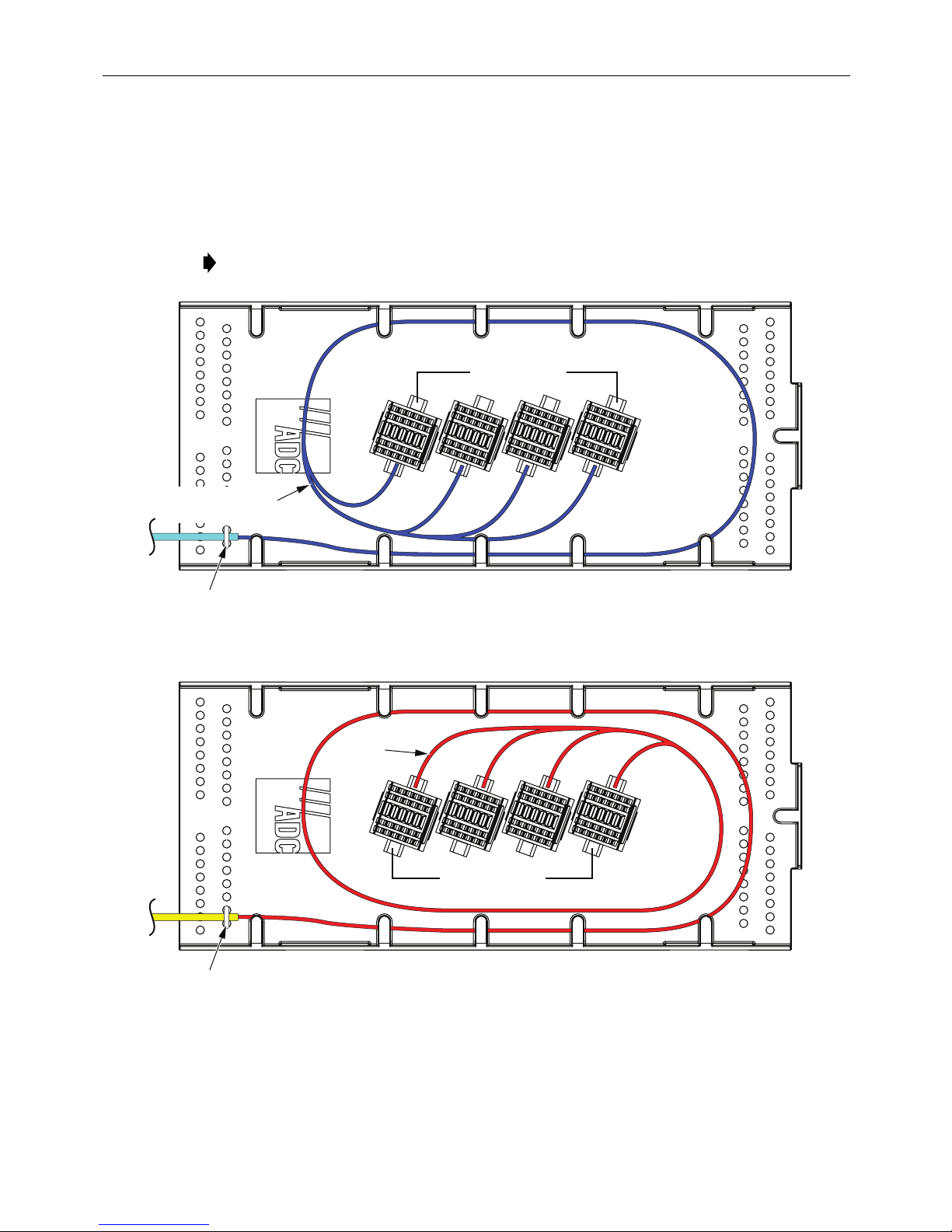

4.1.1 Routing Pigtails

Typically, the termination and splice panel is shipped without adapter packs or pigtails and will

therefore need to be configured as required. Alternatively, the panel may have been ordered with

adapter packs pre-cabled with pigtails or with MPO cassettes already installed. If pigtails need

to be routed in the panel being installed, route the pigtails corresponding to the example shown

in

Figure 17 for a right side adapter pack or Figure 18 for a left side adapter pack.

ADCP-92-098 • Rev C • May 2018

Figure 17. Routing Pigtails from Right Side (Top View)

© 2018 CommScope. All Rights Reserved.

Page 17

Page 18

ADCP-92-098 • Rev C • May 2018

24627-A

SLACK LOOP AROUND OUTSIDE OF

SPLICE TRAY IS NOT REQUIRED

NOTE:

STUB

END

CORRECT LENGTH AT ADAPTER PACK

IF NECESSARY, PULL EACH 900 MICRON FIBER FROM

STUB END OF SUBUNIT, TO CORRECT LENGTH TO

ELIMINATE SLACK AT ADAPTER PACK.

RECOMMENDED CABLE

LENGTH FROM STUB END

TO CONNECTOR IS 108 INCHES

Figure 18 shows routing from the left side.

Figure 18. Routing Pigtails from Left Side (Top View)

4.1.2 Routing OSP Cable, Right Side Entry

For right side cable entry, route the OSP cable from the cable clamp position to the splice tray as

shown in

Figure 19

. Note that “right” is defined here from the perspective of the front of the

panel.

Page 18

© 2018 CommScope. All Rights Reserved.

Page 19

NOTE:

SLACK LOOP AROUND

OUTSIDE OF SPLICE

TRAY IS NOT REQUIRED

CONVOLUTED

TUBING (1 FT)

(PROVIDED)

CABLE CLAMP

(RIGHT SIDE ENTRY)

24628-A

USE HOOK-AND-LOOP STRAP

(PROVIDED) TO SECURE

SPLICE TRAY TO PANEL

RECOMMENDED

BREAKOUT

LENGTH - 120 INCHES

ADCP-92-098 • Rev C • May 2018

Figure 19. Routing OSP Cable, Right Side Entry

© 2018 CommScope. All Rights Reserved.

Page 19

Page 20

ADCP-92-098 • Rev C • May 2018

USE HOOK-AND-LOOP STRAP

(PROVIDED) TO SECURE

SPLICE TRAY TO PANEL

24629-A

NOTE:

SLACK LOOP AROUND

OUTSIDE OF SPLICE

TRAY IS NOT REQUIRED

CONVOLUTED

TUBING (1 FT)

(PROVIDED)

CABLE CLAMP

(LEFT SIDE ENTRY)

RECOMMENDED

BREAKOUT

LENGTH - 120 INCHES

4.1.3 Routing OSP Cable, Left Side Entry

For left side cable entry, route the OSP cable from the cable clamp position to the splice tray as

shown in

Figure 20. “Left” is defined from the front of the panel.

Page 20

© 2018 CommScope. All Rights Reserved.

Figure 20. Routing OSP Cable, Left Side Entry

Page 21

4.1.4 Routing Pigtails and OSP Fibers in Splice Tray

Route the pigtail and OSP fibers in the splice tray as shown in the Figure 21.

Use hook-and-loop strap to secure the splice tray to the panel.

Note: For location of the hook-and-loop strap, refer to Figure 20 on the previous page.

OSP

WWW.ADC.COM WWW.ADC.COM

PIGTAIL FIBERS

FROM ADAPTERS

BREAKOUT

SIDE

ADCP-92-098 • Rev C • May 2018

USE LACING TO

SECURE SUBUNIT

USE LACING TO

SECURE SUBUNIT

PIGTAIL FIBER ROUTING

OSP

FIBERS

PIGTAIL

BREAKOUT

SIDE

OSP FIBER ROUTING

Figure 21. Routing Pigtails and OSP Fibers in Splice Tray

22066-A

© 2018 CommScope. All Rights Reserved.

Page 21

Page 22

ADCP-92-098 • Rev C • May 2018

4.2 Termination Only Panel Procedures

4.2.1 Routing OSP Cable, Right Side Entry (Adapter Packs)

For right side cable entry in a panel with adapter packs, route the OSP cable from the cable

clamp position to the splice tray as shown in

the perspective of the front of the panel.

CONVOLUTED

TUBING

(PROVIDED)

Figure 22. Note that “right” is defined here from

OSP CABLE

BREAKOUT LENGTH -

60 INCHES TOTAL WITH

APPROX. 9 INCHES OF

900 um FIBER EXPOSED

TIE-DOWN

POINT

- DRAWER IN CLOSED POSITION

NOTE:

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

TIE-DOWN

POINT

Figure 22. Routing OSP Cable, Right Side Entry (Adapter Packs)

24630-A

Page 22

© 2018 CommScope. All Rights Reserved.

Page 23

ADCP-92-098 • Rev C • May 2018

4.2.2 Routing OSP Cable, Left Side Entry (Adapter Cassettes)

For left side cable entry in a panel with adapter packs, route the OSP cable from the cable clamp

position to the splice tray as shown in

OSP CABLE

BREAKOUT LENGTH 60 INCHES TOTAL WITH

APPROX. 9 INCHES OF

900 um FIBER EXPOSED

Figure 23. “Left” is defined from the front of the panel.

CONVOLUTED

TUBING

(PROVIDED)

TIE-DOWN

POINT

NOTE:

- DRAWER IN CLOSED POSITION

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

TIE-DOWN

POINT

Figure 23. Routing OSP Cable, Left Side Entry (MPO Cassettes)

24631-A

© 2018 CommScope. All Rights Reserved.

Page 23

Page 24

ADCP-92-098 • Rev C • May 2018

CONVOLUTED

TUBING

(PROVIDED)

OSP CABLE

- DRAWER IN CLOSED POSITION

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

NOTE:

23955-A

CABLES SHOULD BE LONG

ENOUGH TO COMPLETELY

PULL OUT THE SLIDING TRAY

NOTE:

REMOVE THIS

RADIUS LIMITER

FOR LEFT SIDE

ENTRY

4.2.3 Routing OSP Cable, Left Side Entry (MPO Cassettes)

For left side cable entry in a panel with MPO cassettes, route the OSP cable from the cable

clamp position to the MPO casettes as shown in

the perspective of the front of the panel.

Figure 24. Note that “left” is defined here from

Figure 24. Routing OSP Cable, Left Side Entry (MPO Cassettes)

Page 24

© 2018 CommScope. All Rights Reserved.

Page 25

ADCP-92-098 • Rev C • May 2018

CONVOLUTED

TUBING

(PROVIDED)

OSP CABLE

- DRAWER IN CLOSED POSITION

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

NOTE:

23956-A

CABLES SHOULD BE LONG

ENOUGH TO COMPLETELY

PULL OUT THE SLIDING TRAY

NOTE:

REMOVE THIS

RADIUS LIMITER

FOR RIGHT SIDE

ENTRY

4.2.4 Routing OSP Cable, Right Side Entry (MPO cassettes)

For right side cable entry in a panel with MPO cassettes, route the OSP cable from the cable

clamp position to the MPO cassettes as shown in

Figure 25. “Right” is defined from the front of

the panel.

Figure 25. Routing OSP Cable, Right Side Entry (Adapter Packs)

© 2018 CommScope. All Rights Reserved.

Page 25

Page 26

ADCP-92-098 • Rev C • May 2018

4.3 MPO Termination Only Panel Procedures

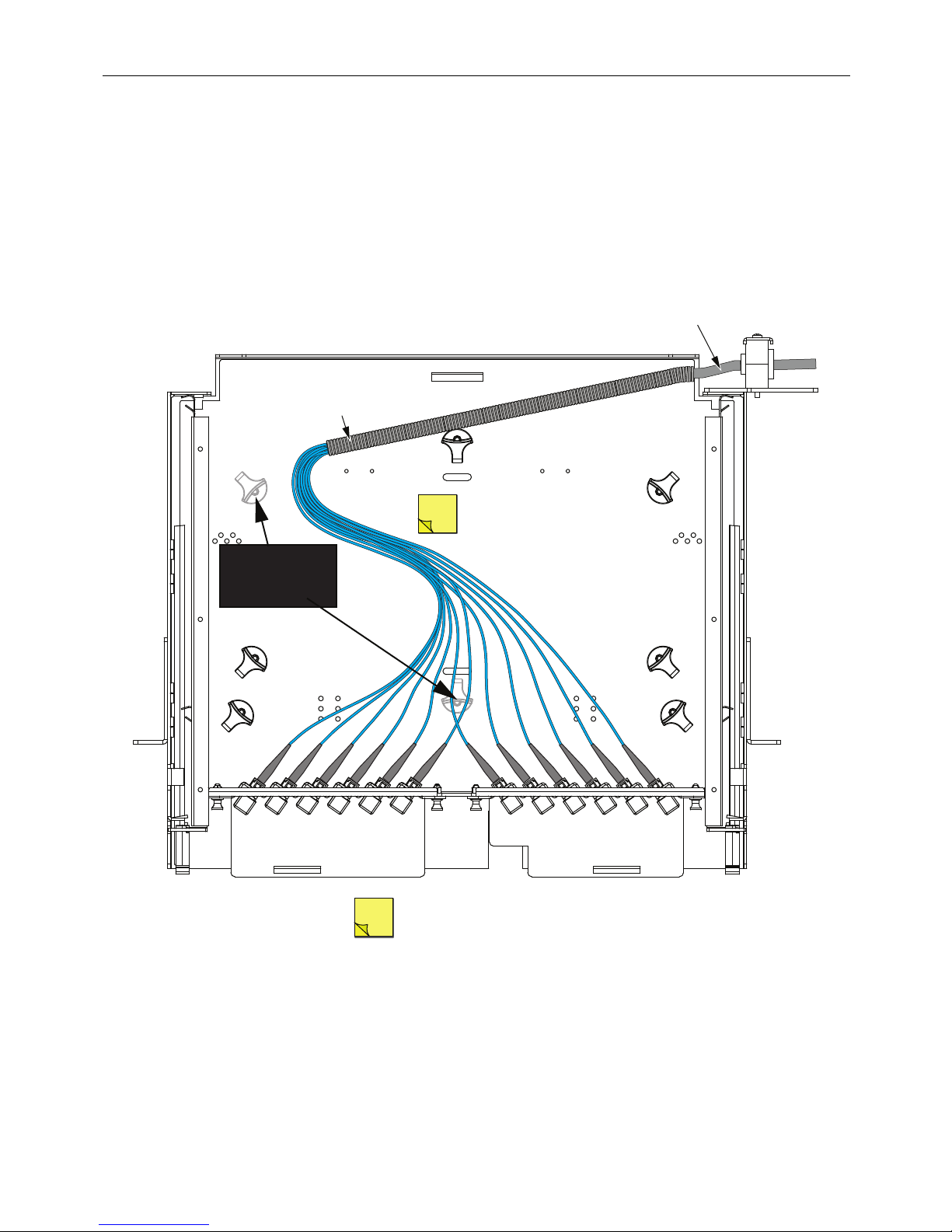

4.3.1 Routing MPO Trunk Cable, Right Side Entry (MPO Adapter Packs)

For right side cable entry in a panel with MPO adapter packs, route the MPO trunk cable from

the cable clamp position to the splice tray as shown in

here from the perspective of the front of the panel.

CONVOLUTED

TUBING

(PROVIDED)

NOTE:

Figure 26. Note that “right” is defined

MPO TRUNK

CABLE

CABLES SHOULD BE LONG

ENOUGH TO COMPLETELY

PULL OUT THE SLIDING TRAY

REMOVE THESE

RADIUS LIMITERS

FOR RIGHT SIDE

ENTRY

- DRAWER IN CLOSED POSITION

NOTE:

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

Figure 26. Routing MPO Trunk Cable, Right Side Entry (MPO Adapter Packs)

22180-A

Page 26

© 2018 CommScope. All Rights Reserved.

Page 27

ADCP-92-098 • Rev C • May 2018

CONVOLUTED

TUBING

(PROVIDED)

- DRAWER IN CLOSED POSITION

- TOP COVER NOT SHOWN, FOR CLARITY

- REAR COVER REMOVED

NOTE:

22181-A

MPO TRUNK

CABLE

CABLES SHOULD BE LONG

ENOUGH TO COMPLETELY

PULL OUT THE SLIDING TRAY

NOTE:

REMOVE THESE

RADIUS LIMITERS

FOR LEFT SIDE

ENTRY

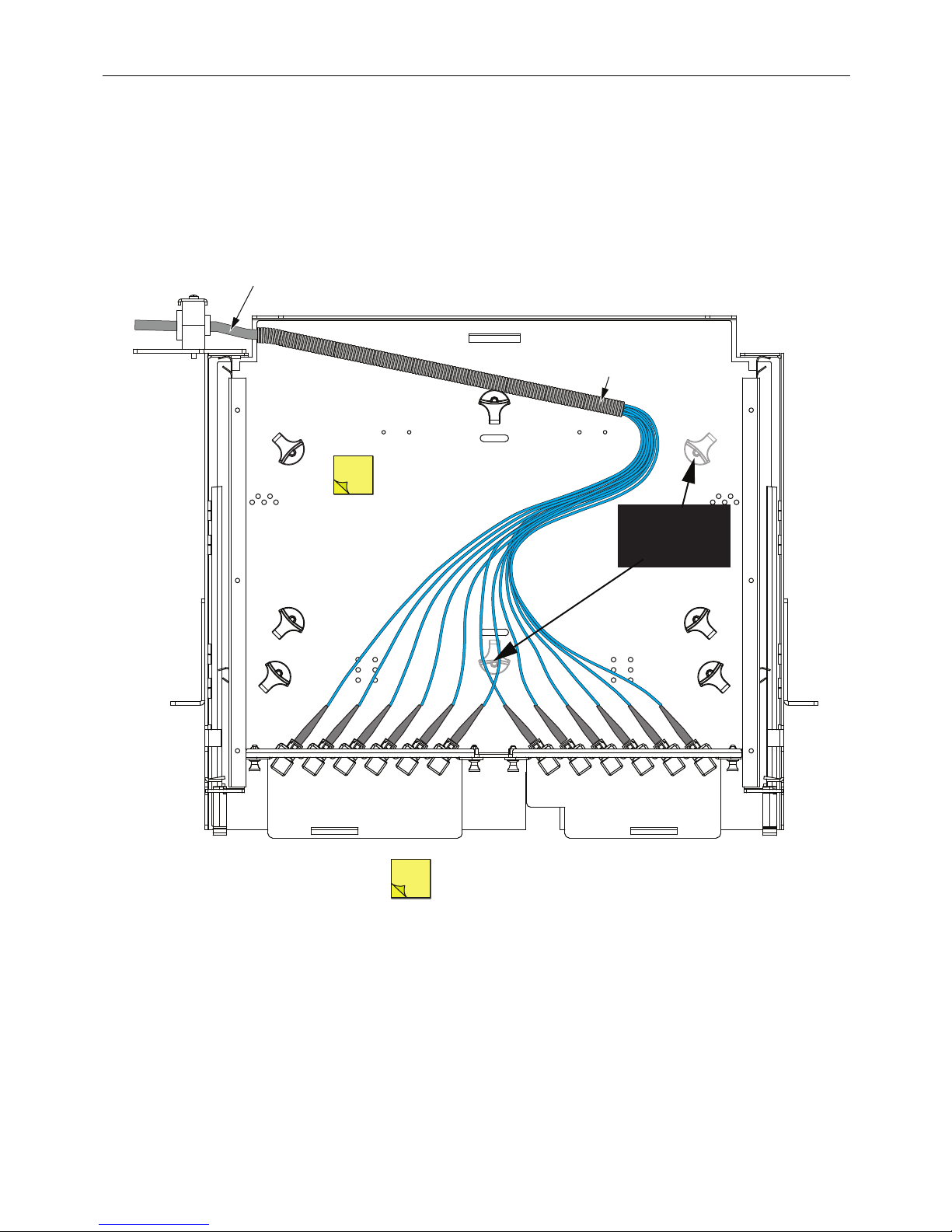

4.3.2 Routing MPO Trunk Cable, Left Side Entry (MPO Adapter Packs)

For left side cable entry in a panel with MPO adapter packs, route the MPO trunk cable from the

cable clamp position to the splice tray as shown in

Figure 27. “Left” is defined from the front of

the panel.

Figure 27. Routing MPO Trunk Cable, Left Side Entry (MPO Adapter Packs)

© 2018 CommScope. All Rights Reserved.

Page 27

Page 28

ADCP-92-098 • Rev C • May 2018

5 CONTACT INFORMATION

• To find out more about CommScope® products, visit us on the web at

www.commscope.com

• For technical assistance, customer service, or to report any missing/damaged parts, visit us at

http://www.commscope.com/SupportCenter

Page 28

Loading...

Loading...